Page 1

SureMark 4610 Printers

User’s Guide for

Models TI1, TI2, TI3, TI4, TI8, TI9 , TG3,

TG4, TG8, TG9, TF6, and TM6

GA27-4151-07Updated April 2, 2009

Page 2

Page 3

SureMark 4610 Printers

User’s Guide for

Models TI1, TI2, TI3, TI4, TI8, TI9 , TG3,

TG4, TG8, TG9, TF6, and TM6

GA27-4151-07Updated April 2, 2009

Page 4

Updated April 2, 2009

Note

Before using this information and the product it supports, be sure to read Appendix H, “Safety information,” on page 197 and

the general information under Appendix I, “Notices,” on page 203.

April 2009

This edition applies to IBM SureMark Printer Models TI1, TI2, TI3, TI4, TI8, TI9, TG3, TG4, TG8, TG9, TF6 and TM6.

Current versions of Retail Store Solutions documentation are available on the IBM Retail Store Solutions Web site at

http://www.ibm.com/solutions/retail/store/support/. Click Publications.

A form for reader’s comments is also provided at the back of this publication. If the form has been removed, address

your comments to:

IBM Corporation

Retail Store Solutions Information Development

Department ZBDA

PO Box 12195

Research Triangle Park, North Carolina 27709 USA

When you send information to IBM, you grant IBM a nonexclusive right to use or distribute whatever information you

supply in any way it believes appropriate without incurring any obligation to you.

© Copyright International Business Machines Corporation 1997, 2006.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 5

Updated April 2, 2009

Contents

%%

Figures ............................xi

Tables............................xiii

Preface ...........................xv

Who should read this manual....................xv

How this manual is organized ...................xv

Related publications and diskettes..................xvi

Where to find more information ...................xvi

Tell us what you think ......................xvi

Summary of changes .....................xvii

GA27-4151-07 (April, 2009) ....................xvii

GA27-4151-07 (February/March, 2007 update) .............xvii

GA27-4151-07 (May, 2006) ....................xvii

Web-only update GA27-4151-06 (December, 2005) ...........xvii

GA27-4151-06 (August, 2005) ...................xvii

Web-only update for corrections to GA27-4151-05 (August, 2004) ......xvii

Web-only update for corrections to GA27-4151-05 (August, 2003) ......xvii

Web-only update for Model TI8, GA27-4151-05 (April, 2003) .......xviii

Web-only update for GA27-4151-04 (March, 2002) ...........xviii

Web update for GA27-4151-04 (June, 2001) .............xviii

GA27-4151-04 ........................xviii

GA27-4151-03 .........................xix

GA27-4151-02 .........................xx

Part 1. General information ..........................1

Chapter 1. Introduction ......................3

Printer overview .........................3

Description of models .......................4

Features used with the SureMark printers ..............6

Comparison of the SureMark models ................7

Planning information .......................9

Your responsibilities ......................9

Limitations ..........................9

Communication interfaces ....................10

Temperature and humidity limits .................10

Physical dimensions ......................10

Power requirements ......................12

Hardware requirements .....................13

Software requirements .....................13

Resident code pages .....................15

Bar codes ..........................15

Chapter 2. Installation instructions.................17

Unpacking the printer ......................18

Installing a SureMark printer ....................18

Installing for EIA-232/RS-485 communication .............18

Installing SureMark for USB communication .............21

Using the wall mounting feature...................23

Installing the fillers .......................24

Installing fillers for EIA-232/RS-485 printers .............24

© Copyright IBM Corp. 1997, 2006 iii

Page 6

Updated April 2, 2009

Installing fillers for USB printers..................26

EIA-232 communication mode selections (all models except TI8, TI9, TG8, TG9) 28

Baud rate selection ......................28

EIA-232 communications protocol selection .............28

EIA-232 communication mode selections (Models TI8, TI9, TG8, TG9) ....30

Baud rate selection ......................30

EIA-232 communications protocol selection .............30

USB communication mode ....................31

USB selection .........................31

Chapter 3. SureMark installation, service, and utility software ......33

Software adjustments (Models TI1, TI2, TI3, TI4, TI8, TI9, TG3, TG4, TG8, and

TG9) ............................34

Offline configurations for Models TI8, TI9, TG8, TG9 ..........34

Using the IBM Diagnostics for the POS Systems and Peripherals (all models

except Models TI1 and TI2) ..................34

Using the reference/service diskettes (Models TI1 and TI2) .......35

4610 fonts and logos utilities ....................37

Utility diskette ........................37

IBM Diagnostics for POS Systems and Peripherals package (all models

except TI1 and TI2) .....................37

Proportional font conversion utility ..................37

Firmware update ........................37

Using a firmware update diskette (Models TI1 and TI2 only) .......38

Using POSS for Windows to update SureMark printer firmware (RS-485 and

USB only) .........................39

Using JavaPOS for Windows to update SureMark printer firmware (EIA-232,

RS-485, and USB)......................39

Updating SureMark firmware using temporary EIA-232 attachment .....40

Limitation on updating firmware ..................41

Emulating the IBM Model 3 or Model 4 printers .............41

Limitations for emulation ....................41

Printing saved data ......................41

Emulating an Epson single-station printer (single-station only) .......43

Enabling Epson emulation....................43

Limitations for Epson emulation ..................43

MICR data parser sample code (Models TI2, TI4, TI8, TI9, TG4, TG8, and TG9

only) ............................44

Resources on the Internet .....................44

Part 2. Models TI1, TI2, TI3, TI4, TI8, TI9, TG3, TG4, TG8, TG9 .........45

Chapter 4. Operation ......................47

Operating controls and indicators ..................47

Ribbon loading .........................51

Paper loading .........................53

Clearing jams in the check flipper area ................55

%%

iv SureMark Printers User’s Guide

MICR reader read head cleaning ..................56

Thermal print head cleaning ....................57

Document scanner cleaning (Model TI8, TI9, TG8, TG9) .........59

Document scanner calibration (Models TI8, TI9, TG8, TG9) ........60

Chapter 5. Testing and problem analysis ..............61

Testing the printer ........................61

Offline tests ..........................62

Customer receipt test .....................62

Page 7

Updated April 2, 2009

Document insert test ......................63

MICR reader and check flipper test (Models TI2, TI4, TI8, TI9, TG4, TG8, and

TG9 only) .........................65

EIA-232 hex dump ......................66

Resetting the printer - offline ...................66

Electronic journal dump.....................66

Problem determination ......................67

Part 3. Models TF6 and TM6 .........................69

Chapter 6. Operation (Models TF6 and TM6) .............71

Operating controls and indicators ..................71

Paper loading .........................71

Thermal print head cleaning ....................73

Chapter 7. Testing and problem analysis (Models TF6 and TM6) .....75

Testing the printer ........................75

Offline test ..........................76

EIA-232 hex dump .......................77

Resetting the printer - offline ....................78

Problem determination ......................78

Part 4. Appendixes..............................79

Appendix A. Consumable supplies.................81

Paper specifications .......................81

Thermal paper ........................81

Document insert forms (Models TI1, TI2, TI3, TI4, TI8, TI9, TG3, TG4, TG8,

and TG9 only) .......................82

Print ribbons (Models TI1, TI2, TI3, TI4, TI8, TI9, TG3, TG4, TG8, and TG9

only) ............................83

%%

%%

Expendable supplies .......................83

Appendix B. Printer maintenance procedures ............85

Product care procedures .....................85

Service provider system maintenance procedures ............85

Models TI1, TI2, TI3, TI4, TI8, TI9, TG3, TG4, TG8, and TG9 .......85

Models TF6 and TM6 .....................85

Appendix C. Technical information .................87

General description .......................87

Specifications .........................87

Memory units .........................89

Immediate commands ......................89

Voltage conversion circuitry ....................89

RS-485 serial I/O parameters ...................90

Cash drawer connector pin assignments ...............90

EIA-232 connector pin assignments .................91

EIA-232 parameters .......................91

USB connector pin assignments ..................92

Code page definitions ......................92

Generic code page ......................93

Code page 437........................94

Code page 858........................95

Code page 860........................96

Contents v

Page 8

Updated April 2, 2009

Code page 863........................97

Code page 865........................98

Character fonts .........................98

Thermal printing font ......................98

Impact printing fonts (Models TI1, TI2, TI3, TI4, TI8, TI9, TG3, TG4, TG8, and

TG9) ...........................99

Appendix D. EIA-232 programming information ...........101

EIA-232 commands summary by function...............104

Alphabetized EIA-232 commands summary ..............108

System commands .......................111

Exercise program ......................111

Verify previous commands completed ...............111

Status request........................112

Extended address command-request printer ID ...........112

Preset or Onetime-Set commands .................114

All models .........................114

Models TI8 and TI9 only ....................114

Download graphics (logo) commands ...............115

Predefine messages .....................117

Download user-defined characters ................118

Thermal code page ......................119

Proportional font .......................120

Impact code page ......................122

Flash storage write ......................123

Erase flash EPROM sector ...................123

Send checksum of flash EPROM sector ..............124

Microcode tolerance (MCT) information - loading ...........124

Microcode tolerance (MCT) information - request ...........125

Setup commands .......................129

Set print mode .......................129

Set or cancel double-wide mode .................130

Set or cancel double-high mode .................131

Set or cancel underline mode ..................131

Set or cancel overline mode ..................131

Set or cancel invert mode ...................131

Set or cancel emphasized printing ................132

Select maximum print speed ..................132

Set or cancel unidirectional printing ................133

Request document length for landscape print ............133

Set document length for landscape print ..............133

Set print station .......................134

Select user-defined or resident character sets ............134

Set code page .......................135

Set intercharacter spacing ...................135

Set or cancel rotated characters .................135

Set print station parameters...................136

Select 1/8-inch line spacing ...................136

Select 1/6-inch line spacing ...................136

Select color printing......................137

Set line spacing using minimum units ...............137

Set sheet eject length .....................138

Set horizontal tab positions ...................138

Set left margin position ....................138

Set relative position......................139

Align positions........................139

vi SureMark Printers User’s Guide

Page 9

Updated April 2, 2009

Set error recovery function ...................140

Define document wait time ...................141

Status sent to system .....................141

Select character for reprinted lines ................142

Re-initialize the printer.....................142

Enable or disable the feed buttons ................143

Enable or disable the beeper (Models TF6 and TM6 only) .......143

Enable or disable upside-down printing ..............144

Select character size for scalable fonts ..............145

Fix font matrix........................146

Print logo inline .......................146

Select thermal paper .....................147

Bar code commands ......................147

Print bar code........................147

Select horizontal size of bar code ................152

Select bar code height ....................152

Select printing position of human readable information (HRI) ......152

Select font for HRI ......................153

Print PDF417 bar code ....................153

Print PDF417 bar code using binary mode .............154

Select PDF417 ECC (error correction codewords) level ........154

Select aspect ratio PDF417 bar code ...............155

Enable PDF417 truncation ...................155

Print character commands ....................156

Print and line feed ......................156

Print and line feed ......................156

Print, form feed, and cut the paper (FF) ..............156

Print and feed paper n lines...................156

Print and feed paper using minimum units .............156

Print and feed paper in reverse using minimum units .........157

Print graphic messages .....................157

Select and print a graphics (logo) command.............157

Print predefined graphics (logo) command .............159

Print predefined messages ...................159

Miscellaneous commands ....................160

Tab to next tab stop .....................160

Return home (select print head location) ..............160

Paper cut/DI eject ......................161

Generate drive pulse for cash drawer ...............161

Retrieve the flash storage ...................161

Retrieve size of user flash storage ................162

Retrieve printer usage statistics .................162

Check processing commands (Models TI2, TI4, TI8, TI9, TG4, TG8, and TG9

only) ...........................164

Models TI8 and TI9 MICR read commands .............164

MICR read .........................165

Flip check .........................166

Document scanner commands...................166

Start scan .........................166

Print scanned image .....................168

Store scanned image and/or select partial image for retrieval ......169

Retrieve scanned image ....................172

Scanner calibration ......................173

Retrieve next image location ..................174

Retrieve first unread image location ................174

Select compression format and scanned image threshold ........174

Contents vii

Page 10

Updated April 2, 2009

Asynchronous (real-time) commands ................175

Real-time requests ......................175

Data buffer management and batch printing ..............176

Reset line count .......................176

Disable line count ......................176

Hold printing until buffer is released ................177

Page mode printing commands ..................177

Select page mode ......................177

Select standard mode .....................177

Select printable area .....................178

Select printing direction/position .................178

Set vertical position......................178

Set relative vertical position ...................179

Set left margin position (standard mode), set absolute print position (page

mode) ..........................179

Set relative horizontal position ..................180

Set printing position......................180

Print and form feed and cut the paper ...............181

Print page in page mode ....................181

Clear print data in page mode ..................181

Document handling .......................181

Portrait mode ........................181

Landscape mode ......................182

Status summary .......................184

Message from the printer....................184

Status byte 1 ........................184

Status byte 2 ........................185

Status byte 3 ........................185

Status byte 4 ........................185

Status byte 5 ........................186

Status byte 6 ........................186

Status byte 7 ........................186

Status byte 8 ........................186

Appendix E. Uploading electronic journal data ...........187

Enable the upload of EJ data ...................187

Disable the upload of EJ data ...................187

Upload the EJ data .......................188

Request the size of the EJ space .................188

Erase the EJ data in the printer ..................188

Appendix F. Proportional fonts ..................189

Preparing the fonts .......................189

Implementing proportional fonts ..................189

Layout using align commands ..................190

Layout using set tab position ..................191

Appendix G. Emulation support for Epson single-station printer.....193

Commands supported in emulation mode...............193

Commands with limited support in emulation mode ...........195

Commands not supported in emulation mode .............196

Connectivity differences .....................196

Functional differences ......................196

Appendix H. Safety information .................197

viii SureMark Printers User’s Guide

Page 11

Updated April 2, 2009

Appendix I. Notices ......................203

Electronic emission notices ....................205

Federal Communications Commission (FCC) statement ........205

European Union EMC Directive conformance statement ........205

Industry Canada Class A Emission Compliance statement .......206

Avis de conformité aux normes d’Industrie Canada ..........206

Germany .........................206

Australia and New Zealand ...................206

Chinese Class A warning statement................207

Japanese power line harmonics compliance statement.........207

Japanese Voluntary Control Council for Interference (VCCI) statement 207

Korean communications statement ................207

Taiwanese Class A warning statement ...............208

Taiwan contact information ....................208

Cable ferrite requirement.....................208

Electrostatic Discharge (ESD) ...................208

Product Recycling and disposal ..................209

Battery return program .....................210

For Taiwan:.........................210

For the European Union: ....................211

For California: ........................211

Flat panel displays .......................212

Monitors and workstations ....................212

Trademarks..........................212

Index ............................213

Contents ix

Page 12

Updated April 2, 2009

x SureMark Printers User’s Guide

Page 13

Updated April 2, 2009

Figures

1. IBM SureMark printers .............................3

2. SureMark printer dimensions (Models TI1, TI2, TI3, TI4, TG3, and TG4) ..........11

3. SureMark printer dimensions (Models TI8, TI9, TG8, TG9) ...............11

4. SureMark printer dimensions (Models TF6 and TM6) .................12

5. Cable connectors and EIA-232 settings switch for thermal/impact SureMark printers ......18

6. Cable connectors for single-station SureMark printers .................19

7. EIA-232 mode switches for single-station SureMark printers ...............19

8. EIA-232 and RS-485 cable routing for single-station SureMark printers ...........20

9. USB Ports for thermal/impact SureMark printers ...................21

10. USB ports for single-station SureMark printers ....................22

11. USB cable routing for single-station SureMark printers .................22

12. Mounting a single-station SureMark on a wall ....................24

13. Installing the fillers for EIA-232/RS-485 systems ...................25

14. Installing the fillers for USB systems........................27

15. SurePOS 500 integration ............................28

16. Adjustment and alignment printouts ........................36

17. Switch for Epson emulation ...........................43

18. SureMark printer indicators, controls, and printing stations (Models TI1, TI2, TI3, TI4, TI8, TI9,

TG3, TG4, TG8, and TG9) ...........................47

19. Inserting checks for all models except TF6 and TM6 ..................48

20. Inserting checks or documents in a Model TI2, TI4, TI8, TI9, TG4, TG8, or TG9 printer .....48

21. Inserting checks or documents in a Model TI2 or TI4 printer ...............49

22. Side insertion of documents in a Model TI8 printer ..................49

23. Printable area of an inserted document (portrait) ...................50

24. Printable area of an inserted document (landscape) ..................50

25. Opening the ribbon cover............................51

26. Ribbon cartridge loading ............................51

27. Ribbon path around the print head ........................52

28. Paper cover (Models TI1, TI2, TI3, TI4, TI8, TI9, TG3, TG4, TG8, and TG9) .........53

29. Paper loading path (Models TI1, TI2, TI3,TI4, TI8, TI9, TG3, TG4, TG8, and TG9) .......54

30. Removing the lower document insert cover .....................55

31. Removing the check flipper cartridge (except Models TI8, TI9) ..............56

%%

32. MICR reader read head ............................57

33. Print head and print line area (Models TI1, TI2, TI3, TI4, TI8, TI9, TG3, TG4, TG8, and TG9) 58

34. Scanner and print head location (Model TI8, TI9, TG8, TG9) ...............59

35. Printer buttons ................................62

36. Offline printer test pattern from the customer receipt station (Models TI1, TI2, TI3, TI4, TI8, TI9,

TG3, TG4, TG8, TG9) .............................64

37. MICR reader test results (Models TI2, TI4, and TG4): Good noise level ...........65

38. MICR reader test results (Models TI8, TI9, TG8, TG9): Good noise level ..........65

39. MICR reader test results: Noise level needs adjusting .................66

40. SureMark printer indicator, control, and printing station (Models TF6 and TM6) ........71

41. Paper loading path (Models TF6 and TM6) .....................72

42. Print head and print line area (Models TF6 and TM6) .................73

43. Offline printer test pattern (Models TF6 and TM6) ...................77

44. Printer’s resident character set - generic code page ..................93

45. Code Page 437 ...............................94

46. Code Page 858 ...............................95

47. Code Page 860 ...............................96

48. Code Page 863 ...............................97

49. Code Page 865 ...............................98

50. Proportional font example ...........................122

51. Scanned image layout ............................169

© Copyright IBM Corp. 1997, 2006 xi

Page 14

Updated April 2, 2009

52. Scanned image organization ..........................170

xii SureMark Printers User’s Guide

Page 15

Updated April 2, 2009

Tables

1. Warranty information ..............................5

2. J2 connector pin assignments ..........................12

3. Troubleshooting (Models TI1, TI2, TI3, TI4, TI8, TI9, TG3, TG4, TG8, and TG9)........67

4. Troubleshooting (Models TF6 and TM6) ......................78

5. Station characteristics .............................88

6. Sound characteristics .............................88

7. Cash drawer connector pin assignments ......................90

8. EIA-232 connector pin functions .........................91

9. 9-pin to 9-pin EIA-232 connector layout ......................91

10. 25-pin to 25-pin EIA-232 connector layout .....................91

11. Standard USB connector pin assignments .....................92

12. Powered USB connector pin assignments .....................92

13. Driver documentation by operating system .....................103

14. EIA-232 commands organized by function .....................104

15. EIA-232 commands in alphabetical order .....................108

16. Memory allocation for Models TI8 and TI9 functions .................115

17. MCT command definitions ...........................125

18. Fonts for Models TI3, TI4, TG3, TG4, TG8, TG9, TI8, TI9, TF6, and TM6 .........129

19. Fonts for Models TI1 and TI2 ..........................130

20. Width and height for scalable fonts........................145

21. Code 128 character set ............................149

22. Print bar code examples ...........................152

23. Buffer sizes ................................158

24. Retrievable usage data ............................162

25. Data table .................................172

26. Average size for a personal check with little background data ..............174

27. Print direction ...............................178

28. Commands supported in Epson emulation mode...................193

29. Commands with limited support in Epson emulation mode ...............195

30. Commands not supported in Epson emulation mode .................196

© Copyright IBM Corp. 1997, 2006 xiii

Page 16

Updated April 2, 2009

xiv SureMark Printers User’s Guide

Page 17

Updated April 2, 2009

Preface

This manual assists you with installation, testing, and problem determination of

®

SureMark™printers.

IBM

Who should read this manual

This manual is intended for use by persons who are installing, testing, or

programming an IBM SureMark printer. The manual should also be used for

problem determination on the printer.

How this manual is organized

Part 1, “General information,” on page 1 contains information that applies to

SureMark printers in general:

v Chapter 1, “Introduction” provides an overview of the features and options of the

SureMark printers.

v Chapter 2, “Installation instructions” provides information on installing the

SureMark printers.

v Chapter 3, “SureMark installation, service, and utility software” provides

information about using SureMark utilities to setup or modify your system

configuration.

Part 2, “Models TI1, TI2, TI3, TI4, TI8, TI9, TG3, TG4, TG8, TG9,” on page 45

contains information that is specific to the thermal/impact SureMark printers:

v Chapter 4, “Operation” provides information about the controls and indicators.

Ribbon loading and paper loading instructions are also included.

v Chapter 5, “Testing and problem analysis” provides information on testing and on

problem determination.

Part 3, “Models TF6 and TM6,” on page 69 contains information that is specific to

the single-station SureMark printers:

v Chapter 6, “Operation (Models TF6 and TM6)” provides information on the

controls and indicators. Paper loading instructions are also included.

v Chapter 7, “Testing and problem analysis (Models TF6 and TM6)” provides

information on testing and on problem determination.

The appendixes contain the following information:

v Appendix A, “Consumable supplies” provides information about consumable

supplies.

v Appendix C, “Technical information” provides information about technical

specifications.

v Appendix D, “EIA-232 programming information” provides information about

EIA-232 programming commands.

v Appendix E, “Uploading electronic journal data” provides information about

uploading electronic journal data while the SureMark is in Model 4 emulation

mode.

v Appendix F, “Proportional fonts” provides information about creating and using

proportional fonts.

v Appendix G, “Emulation support for Epson single-station printer” provides

expanded information about Epson emulation mode.

© Copyright IBM Corp. 1997, 2006 xv

Page 18

v Appendix H, “Safety information” provides important safety warnings in several

languages.

v Appendix I, “Notices” provides information about trademarks and electronic

emission notices.

v For California: provides information about perchlorate material.

Related publications and diskettes

v IBM SureMark Printers: Hardware Service Manual, GY27-0355

v IBM SureMark Printers: Fonts and Logos Utility Diskette

v IBM SureMark Printers: Firmware Update Diskettes

v IBM 4693 Point-of-Sale Terminals Reference Diskette

v IBM 4694/4695 Point-of-Sale Terminals Service Diskette

v IBM Safety Information—Read This First, GA27-4004.

v IBM SurePOS 700 Series: System Reference, SA27-4220.

v IBM SurePOS 500 Series: System Reference, SA27-4255.

v POSS Programming Reference and User’s Guide, SC30-3560

Diskettes are available by download from the Internet. See “Resources on the

Internet” on page 44 for more information.

Updated April 2, 2009

For information about ordering IBM publications not shipped with the SureMark

printers, contact your IBM representative or your place of purchase.

Where to find more information

A CD-ROM is available that contains books that are part of the IBM Retail Store

Solutions Library Collection, SK2T-0331.

Current versions of Retail Store Solutions documentation and downloadable

diskettes are available on our Web site. See “Resources on the Internet” on page

44 for information about accessing the site.

Tell us what you think

Your feedback is important in helping to provide the most accurate and high-quality

information. Please take a few moments to tell us what you think about this book.

The only way for us to know if you are satisfied with our books, or how we might

improve their quality, is through feedback from customers like you. If you have any

comments about this book, there is a comment form at the back of this book. You

can also get a copy of the form from the PDF version of the book on the Web.

To access a PDF version of this book, visit the Retail Store Solutions Web site at

http://www.ibm.com/solutions/retail/store/support/. From there, select Publications.

After you have filled out the form, return it by mail, by fax, or by giving it to an IBM

representative. If applicable, include a reference to the specific location of the text

on which you are commenting. For instance, include the page or table number.

Between major revisions of this manual we may make minor technical updates. The

latest softcopy version of this manual is available under Publications on the IBM

Retail Store Solutions Web site.

xvi SureMark Printers User’s Guide

Page 19

Updated April 2, 2009

Summary of changes

This section summarizes the changes included in the latest editions of this manual.

GA27-4151-07 (April, 2009)

%

%

%

%

%

This update provides changes to the MICR reader read head cleaning procedures,

expandable supplies, and product care procedures.

Changes or additions to the text are indicated by a change bar (%) to the left of the

text.

GA27-4151-07 (February/March, 2007 update)

v Model 3 and Model 4 emulation support notes

v Various clarifications and corrections

v Updated notices Appendix I, “Notices,” on page 203

GA27-4151-07 (May, 2006)

This update provides new part numbers for existing products that are manufactured

using updated methods or materials required in certain jurisdictions, such as the

European Union. It also includes other edits based on user feedback.

Web-only update GA27-4151-06 (December, 2005)

This update provides new and updated commands and programming information,

and more references to Models TI8/TG8 and TI9/TG9.

GA27-4151-06 (August, 2005)

This Web-only update adds Model TI9 and TG9, as well as references to Model

TI8.

Web-only update for corrections to GA27-4151-05 (August, 2004)

Corrections and clarifications for:

v “Paper specifications” on page 81

v “Microcode tolerance (MCT) information - request” on page 125

v “Re-initialize the printer” on page 142

v “Start scan” on page 166

v “Select standard mode” on page 177

v Minor changes to formatting

Web-only update for corrections to GA27-4151-05 (August, 2003)

Corrections and clarifications for:

v “Document scanner calibration (Models TI8, TI9, TG8, TG9)” on page 60

v Minor changes to formatting

© Copyright IBM Corp. 1997, 2006 xvii

Page 20

Web-only update for Model TI8, GA27-4151-05 (April, 2003)

This update adds the new Model TI8 to this User’s Guide. This model provides

document-scanning capability and a powered flipper.

Web-only update for GA27-4151-04 (March, 2002)

This update contains changes to the paper loading procedure for Models TF6 and

TM6.

Web update for GA27-4151-04 (June, 2001)

This update contains the following changes and additions:

v The location of the Euro character for code page 858 has been corrected. See

“Code page 858” on page 95.

v Information on the new Models TG3 and TG4.

v Command format details about bar codes 128a and 128b.

v Flash memory usage message. See the remarks in Flash storage write on page

123.

v New table for Code 128 character set. See Table 21 on page 149.

v The commands in Appendix D, “EIA-232 programming information,” on page 101

are to be used for EIA-232 connections only. Additional information about where

to find commands when using RS-485 or USB communications has been added

to the beginning of that appendix.

Updated April 2, 2009

GA27-4151-04

This edition adds information about the new single-station SureMark printers, which

are Models TF6 and TM6, and also about updates for Models TI3 and TI4.

Changes for this edition include:

v Because there are important differences between Models TF6 and TM6, which

are single-station SureMark printers, and the thermal/impact SureMark printers,

the book has been reorganized into three parts.

– Part 1 contains information that is similar for all SureMark models. Information

about the new single-station printers has been added throughout this part.

– Part 2 contains information that is specific to the thermal/impact SureMark

printer Models TI1, TI2, TI3, TI4, TG3, and TG4.

– Part 3 contains information that is specific to the new single-station SureMark

printer Models TF6 and TM6.

v A new thermal font has been added. See “Set print mode” on page 129 and

“Thermal printing font” on page 98.

v Support for emulation of an Epson single-station printer has been added. See

“Emulating an Epson single-station printer (single-station only)” on page 43 for

information about how to enable emulation and an overview of the limitations to

using emulation mode. See Appendix G, “Emulation support for Epson

single-station printer,” on page 193 for detailed information about what Epson

commands are supported in emulation mode.

v A font conversion utility has been added as part of the support for proportional

fonts. See “Proportional font conversion utility” on page 37.

xviii SureMark Printers User’s Guide

Page 21

Updated April 2, 2009

v Information about uploading electronic journal data while the printer is emulating

a Model 4 printer has been added. See Appendix E, “Uploading electronic journal

data,” on page 187.

v The following commands have been added:

Note: These commands are not supported for Models TI1 and TI2. Currently

installed Model TI3, TG3, TI4, and TG4 printers support these commands

after you download the latest firmware.

– “Proportional font” on page 120

– “Select color printing” on page 137

– n=09 (Align Column Right) for “Align positions” on page 139

– “Enable or disable upside-down printing” on page 144

– “Select character size for scalable fonts” on page 145

– “Fix font matrix” on page 146

– “Print logo inline” on page 146

– “Select thermal paper” on page 147

– n=09 (Code 128A, 128B, and 128C) for “Print bar code” on page 147

v The following command, which is supported only on Models TF6 and TM6, has

been added:

– “Enable or disable the beeper (Models TF6 and TM6 only)” on page 143

GA27-4151-03

This edition includes information for the support of a USB logic card.

Information that was added includes:

v “USB connector pin assignments” on page 92.

v USB information has been added to “Voltage conversion circuitry” on page 89.

v The part number for the available USB cables has been added to “Features used

with the SureMark printers” on page 6.

v Information about your responsibilities when using USB communications has

been added to “Planning information” on page 9.

v The data rate for USB communications has been added to “Communication

interfaces” on page 10.

v USB information has been added to “Hardware requirements” on page 13.

v Information about installing the SureMark printer for use with USB

communications has been added to “Installing SureMark for USB communication”

on page 21.

v Information about installing fillers for the SureMark printer when the USB feature

is used has been added to “Installing fillers for USB printers” on page 26.

v Communication mode information for USB has been added to “USB

communication mode” on page 31.

v Relevant information for performing problem determination with USB has been

added to Table 3 on page 67.

Summary of changes xix

Page 22

GA27-4151-02

Updated April 2, 2009

This edition includes information about two new models of the SureMark printer:

Model TI3 and Model TI4. Because Model TI3 is a new version of Model TI1, and

Model TI4 is a new version of Model TI2, in some cases only the new model

number was added to the existing text.

Information that was added includes:

v “Comparison of the SureMark models” on page 7, which describes the

microcode, hardware, and operating system differences.

v “Firmware update” on page 37, which describes the methods that you can use to

update the SureMark firmware.

v “Enable or disable the feed buttons” on page 143 and “Select maximum print

speed” on page 132, which describe new EIA-232 commands.

Information that was changed includes:

v “Software requirements” on page 13, which includes operating system and driver

requirements, and application requirements.

v “Code page definitions” on page 92. Code page 850, which is resident in Model

TI1 and TI2, has been replaced in this document by code page 858, which is

resident in Models TI3 and TI4. Code page 858 is the same as code page 850

plus the euro character symbol.

v Zero (0) is no longer valid for the EIA-232 command “Microcode tolerance (MCT)

information - request” on page 125.

v The Remarks under “Define document wait time” on page 141 have been

corrected and expanded.

Because documentation, drivers, and diskettes are now available on the Web,

“Resources on the Internet” on page 44 was added to describe how to locate the

applicable Web site.

Along with these changes and additions, the manual was also reorganized. The

information that was in Appendixes B and E, along with some additional information,

is now in Chapter 3, “SureMark installation, service, and utility software,” on page

33.

xx SureMark Printers User’s Guide

Page 23

Updated April 2, 2009

Part 1. General information

This part contains descriptions of the SureMark printers and information about

installing the printers.

© Copyright IBM Corp. 1997, 2006 1

Page 24

Updated April 2, 2009

2 SureMark Printers User’s Guide

Page 25

Updated April 2, 2009

Chapter 1. Introduction

Printer overview .........................3

Description of models .......................4

Features used with the SureMark printers ..............6

Comparison of the SureMark models ................7

Differences among SureMark models ...............7

Differences between Models TI3, TI4, TI8, TI9, TG3, TG4, TG8, TG9, and

Models TF6, TM6 .....................8

Planning information .......................9

Your responsibilities ......................9

Limitations ..........................9

Communication interfaces ....................10

Temperature and humidity limits .................10

Physical dimensions ......................10

Models TI1, TI2, TI3, TI4, TG3, and TG4 .............10

Models TI8, TI9, TG8, TG9 ..................11

Models TF6 and TM6 ....................12

Power requirements ......................12

Hardware requirements .....................13

Software requirements .....................13

Operating system requirements .................13

Application requirements ...................14

Resident code pages .....................15

Bar codes ..........................15

Printer overview

Figure 1. IBM SureMark printers

The IBM SureMark printers are high-performance, high-function printers. The

SureMark is available in several models:

v Models TI3, TI4, TG3, and TG4 feature a thermal customer receipt station and an

impact document insert station. The dual print heads enable quiet, fast printing at

the customer receipt station while providing the capability to print and frank

© Copyright IBM Corp. 1997, 2006 3

Page 26

Updated April 2, 2009

checks and to print multipart forms through the document insert station. (Models

TI1 and TI2 are older versions of Models TI3 and TI4, respectively. Production of

the older models has ceased.)

v Models TI8, TI9, TG8, and TG9 provide a document scanner and a powered

flipper, in addition to all the features of Model TI4.

v Models TF6 and TM6 are single-station thermal printers. They contain no

document insert station. These models cost less, weigh less, and have a smaller

footprint than the thermal/impact SureMark printers. Models TF6 and TM6 have

been designed for wall mounting, if desired by the retailer.

All SureMark printers provide:

v Fast, quiet receipt printing

v Easy paper loading

v 256-KB flash memory for storing messages, logos, code pages, and electronic

journal data

v Models TI8, TI9, TG8 and TG9 have 1 MB of flash memory for scanned image

storage

v Bar code generation

v Downloadable fonts and code pages

v Downloadable microcode

v Small footprint

v Support for EIA-232 (RS-232) and RS-485 (EIA-485) interfaces

Note: RS-232 and EIA-232 are synonymous; EIA-232 is used throughout this

v Support for Universal Serial Bus (USB) interface

The single-station SureMark printers, the SureMark Model TI8, TI9, TG8 and TG9,

and SureMark Models TI3, TI4, TG3, and TG4 that have been updated with the

latest firmware, support the following in the thermal station:

v Proportional fonts

v Scalable fonts

v Color printing: black plus one accent on two-color thermal paper (thermal station

only)

v Upside-down printing

Additional features of some SureMark models include:

v Single-pass handling of checks (Models TI2, TI4, TI8, TI9, TG4, TG8, TG9)

v Easy-to-load ribbon cartridge (Models TI1, TI2, TI3, TI4, TI8, TI9, TG3, TG4,

TG8, TG9)

v Epson emulation (Models TF6, TM6)

v Document scanning (Models TI8, TG8, TI9, TG9)

v Check 21 compliance (Models TI9, TG9)

Description of models

document. RS-485 and EIA-485 are synonymous; RS-485 is used

throughout this document.

Note: All TGx models are functionally equivalent to the corresponding TIx models.

The SureMark printers are available in the following models:

4 SureMark Printers User’s Guide

TGx models have iron gray covers, while TIx models have pearl white

covers.

Page 27

Updated April 2, 2009

Models TI1 and TI3

Standard models that support receipt and document printing. (Model TI1

can no longer be ordered.)

Models T12 and TI4

High-function models that feature improved check handling. Check handling

uses the magnetic character ink recognition (MICR) reader and check

flipper that are included in these models. (Model TI2 can no longer be

ordered.)

With one insertion of a check into a Model TI2, TI4, TI8, or TI9 printer, the

printer uses its MICR reader to read the magnetic-ink-character line on the

check, franks the check, and prints the face of the check. While the printer

is processing the check, the operator is free to attend to the customer’s

needs, which shortens the total transaction time.

Model TI8

In addition to the features of the Model TI4, these models have a document

scanner feature. Scanned documents can be stored and retrieved in TIFF,

JPEG, and BMP formats. The Model TI8 has increased flipper speed due to

a powered flipper. (Model TI8 can no longer be ordered.)

Model TI9

In addition to the features of the Model TI8, the TI9 is compliant with Check

21 legislation, which means that it enables single-insertion check handling

and scanning of both sides of the full length of the document.

Models TF6 and TM6

Smaller models that contain only a thermal customer receipt station.

Because there is no document insert station, these models do not support

document printing.

Models TF6 and TM6 have an audible alarm, a spill-resistant design, and

an optional wall mount.

For Food Service customers, Model TF6 covers match the IBM SurePOS

™

500 Series systems. For Retail customers, Model TM6 covers match the

IBM 4694 systems if the EIA-232/RS-485 interface is ordered, and the

covers match the IBM SurePOS 700 Series systems if the USB interface is

ordered.

Note: Model TG3 is functionally equivalent to TI3, TG4 is functionally equivalent to

TI4, and so on.

Table 1 shows the warranty information for each printer model.

Table 1. Warranty information

Machine type Description Warranty

service

4610-TI3 EIA-232, RS-485, USB (Pearl white covers) IOR 24x7 none

4610-TI4 EIA-232, RS-485, USB (Pearl white covers) IOR 24x7 none

4610-TI5 (DBCS,

AP only)

4610-TI8 EIA-232, RS-485, USB (Pearl white covers) IOR 24x7 none

4610-TI9 EIA-232, RS-485, USB (Pearl white covers) IOR 24x7 none

4610-TM6 EIA-232, RS-485, USB (Pearl white covers) IOR 24x7 none

EIA-232, RS-485, USB (Pearl white covers) IOR 24x7 none

Warranty

upgrade

Chapter 1. Introduction 5

Page 28

Updated April 2, 2009

Table 1. Warranty information (continued)

Machine type Description Warranty

service

4610-TM7

(DBCS, AP only)

4610-TF6 TM6 with iron gray covers Depot

4610-TF7 TM7 with iron gray covers Depot

4610-IF6 Functionally equivalent to TF6 with iron gray

4610-TG3 Functionally equivalent to Model TI3 with iron

4610-TG4 Functionally equivalent to Model TI4 with iron

4610-TG5

(DBCS, AP only)

4610-TG8 Functionally equivalent to Model TI8 with iron

4610-TG9 Functionally equivalent to Model TI9 with iron

4610-DG3 Functionally equivalent to Model TG3 but

4610-DG4 Functionally equivalent to Model TG4 but

4610-DI3 Functionally equivalent to Model TI3 but with

4610-DI4 Functionally equivalent to Model TI4 but with

4610-DI8 Functionally equivalent to Model TI8 but with

4610-DI9 Functionally equivalent to Model TI9 but with

4610-DM6 Functionally equivalent to Model TM6 but

4610-DG8 Functionally equivalent to Model TG8 but

4610-DG9 Functionally equivalent to Model TG9 but

EIA-232, RS-485, USB (Pearl white covers) IOR 24x7 none

repair

repair

IOR 24x7 none

covers but with IOR warranty

IOR 24x7 none

gray covers

IOR 24x7 none

gray covers

Functionally equivalent to Model TI5 with iron

gray covers

gray covers

gray covers

with Depot warranty

with Depot warranty

Depot warranty

Depot warranty

Depot warranty

Depot warranty

with Depot warranty

with Depot warranty

with Depot warranty

IOR 24x7 none

IOR 24x7 none

IOR 24x7 none

Depot

repair

Depot

repair

Depot

repair

Depot

repair

Depot

repair

Depot

repair

Depot

repair

Depot

repair

Depot

repair

Warranty

upgrade

IOR 24x7,

9x5

IOR 24x7,

9x5

IOR 24x7,

9x5

IOR 24x7,

9x5

IOR 24x7,

9x5

IOR 24x7,

9x5

IOR 24x7,

9x5

IOR 24x7,

9x5

IOR 24x7,

9x5

IOR 24x7,

9x5

IOR 24x7,

9x5

Note: IOR 24x7 is IBM on-site repair 24 hours times seven days per week. 9x5 is

nine hours per day for five days per week.

Features used with the SureMark printers

All models support the following features:

v Integration Panel

v 40-Character VFD or LCD Post Extension

v Distributed Printer Cable (RS-485)

v Integrated Cable (RS-485)

6 SureMark Printers User’s Guide

Page 29

Updated April 2, 2009

v Short EIA-232 Communications Cable, 2 m (about 6.6 ft), P/N 40N4780

v Long EIA-232 Communications Cable, 4 m (about 13.1 ft), P/N 40N4781

v Power Supply (EIA-232 and USB), P/N 40N5051

v Power Cords (country-specific)

v EIA-232/RS-485 Interface Card

Models TI3, TI4, TI8, TI9, TG3, TG4, TG8, TG9, TM6 and TF6 support the following

features:

v USB Cable, Powered, 0.5 m (about 1.6 ft), P/N 40N4715

v USB Cable, Powered, 3.8 m (about 12.5 ft), P/N 40N4716

v USB Cable, Standard, 5.0 m (about 16.4 ft), P/N 40N4767

v USB Interface Card

Because a cash drawer can attach directly to the SureMark, all models also support

the following features:

v Compact Cash Drawer, Vertical Till

v Compact Cash Drawer, Horizontal Till

v Full-size Cash Drawer, Adjustable Till

v Full-size Cash Drawer, Fixed Till Insert

v Short Cash Drawer Cable, P/N 40N4778

v Long Cash Drawer Cable, P/N 40N4779

Comparison of the SureMark models

The SureMark models can be divided into three groups:

v Models TI1 and TI2 can no longer be ordered. Because these are not currently

being manufactured, they do not support some functions that are on the current

models.

v Models TI3, TI4, TI8, TI9, TG3, TG4, TG8, and TG9 have a thermal print station

for customer receipts and an impact print station for document processing. These

models are currently being manufactured.

– Models TI8 and TG8 additionally have document scanning.

– Models TI9 and TG9 additionally have document scanning compliant with

Check 21.

v Models TF6 and TM6 have only a thermal print station for customer receipts.

Differences among SureMark models

v Different microcode is required to operate each of the following groups of

printers:

– Models TI1 and TI2

– Models TI3, TI4, TG3, TG4, TM6, TF6

– Models TI3, TI4, TG3, TG4, TF6, TM6 with the 2 MB card option

– Models TI3, TI4, TG3, and TG4 with the 8 MB card option

– Models TI8, TI9, TG8, and TG9

v Total amount of data space available for the download of graphic messages is

65 376 bytes for Models TI1 and TI2, but only 65 136 bytes for Models TI3, TI4,

TG3, and TG4. Models TI8, TI9, TG8, and TG9 have from 0 KB to 1 MB, user

allocatable.

Chapter 1. Introduction 7

Page 30

Updated April 2, 2009

v Memory allocated to store incoming commands and data is 16 KB for Models

TI3, TI4, TI8, TI9, TG3, TG4, TG8, and TG9, but only 4 KB for Models TI1 and

TI2.

v Models TI3, TI4, TI8, TI9, TG3, TG4, TG8, and TG9 operate at higher speeds

than Models TI1 and TI2.

v Code page 858, which contains the euro character symbol, is resident in Models

TI3, TI4, TI8, TI9, TG3, and TG4. Code page 850, which contains all character

symbols from code page 858 excluding the euro character symbol, is resident in

Models TI1 and TI2.

v The second byte of the device ID specifies what model of SureMark is being

used. The 4690 OS uses the printer model to determine the name of the

microcode update file:

– ADXPJPUF.DAT for Models TI1 and TI2

– ADXPJPFF.DAT for Models TI3, TI4, TG3, TG4, TM6, TF6

– ADXPJP2F.DAT for Models TI3, TI4, TG3, and TG4 with the 2 MB card option

– For microcode update information for Models TI8, TI9, TG8, and TG9, see the

IBM Retail Store Solutions Web site at http://www.ibm.com/solutions/retail/

store/support/.

Differences between Models TI3, TI4, TI8, TI9, TG3, TG4, TG8, TG9, and Models TF6, TM6

Models TF6 and TM6 are single-station thermal printers. These models do not

include an impact station. Therefore they can not be used for any of the check

handling that thermal/impact SureMark Models TI3, TI4, TI8, TI9, TG3, TG4, TG8,

and TG9 support.

The single-station SureMark printers have a lower weight, lower cost, and smaller

footprint than the thermal/impact printers. The single-station SureMark printers are

designed to provide a cost-effective printer in environments that do not require

document printing and check processing.

The single-station SureMark printers are spill-resistant, which makes them a good

choice for food service customers. In the single-station printers, the logic card and

interface card are mounted vertically, which minimizes the possibility of damage

from spills. (In the thermal/impact printers, although the logic card is mounted

vertically, the interface card is mounted horizontally.) For particularly hazardous

locations, an optional spill cover is available for Models TF6 and TM6.

Models TI3, TI4, TI8, TI9, TG3, TG4, TG8, and TG9 have a trap-door design that

allows you to easily change to a new interface, for example when upgrading from

EIA-232 to USB. To change the interface on a single-station SureMark, you must

remove the bottom cover, then remove both the logic card and the interface card

(they are joined by a connector).

The single-station SureMark printers support a 90 mm diameter paper roll, instead

of the 80 mm paper roll that is used with the thermal/impact printers. The

single-station printers also support an external larger paper roll via RPQ. When the

external paper roll is used, the paper feeds into the printer through a slot in the

bottom cover of the printer.

A power switch is located inside the top cover of the single-station SureMark

printers. Power to the thermal/impact SureMark printers is controlled by the system

or by an external power supply.

8 SureMark Printers User’s Guide

Page 31

Updated April 2, 2009

Because of their smaller size and lighter weight, the single-station SureMark

printers are designed for wall mounting. Like the other SureMark printers, they can

also be mounted on a system unit or a countertop.

Planning information

This section contains information that helps you plan your environment, supply

requirements, and power requirements.

Your responsibilities

You are responsible for replenishing consumable supplies, including roll paper for

the thermal (customer receipt station) printer, and, depending on your model, forms,

ribbon cartridges for the impact (document insert) station, and MICR read head

cleaning cards for the MICR reader. (See Appendix A, “Consumable supplies,” on

page 81.)

It is your responsibility to update printer firmware as needed prior to installing

printers, and as desired during the printer’s life.

If you plan to use EIA-232 communications, you are responsible for ordering a 24 V

dc power supply with a power cord. You are also responsible for ordering the

EIA-232 cable.

Limitations

Note: If a 3-wire EIA-232 cable is to be used, the printer must be set to

XON/XOFF mode. (See “EIA-232 communications protocol selection” on

page 28.)

If you plan to use RS-485 communications, you are responsible for ordering the

RS-485 cable.

If you plan to use USB communications, you are responsible for ordering one of the

following:

v A powered USB cable. The 3.8-m USB cable for a distributed configuration is

P/N 40N4716 and the 0.5-m USB cable for an integrated configuration is P/N

40N4715.

v A standard USB cable, P/N 40N4767, with a Type B connector for the printer,

and a power brick.

With SureMark printer models you can use an electronic journaling

application. Electronic journaling eliminates the need to store paper journal tapes

and the time-consuming task of searching papers should the need arise.

SureMark printers have a safety feature which slows printing if excessive duty

cycles are used. This feature protects the printer hardware from potential damage

and should not be noticeable during normal operation.

For Model TI2, TI4, TI8, and TI9, sources of electromagnetic noise (for example,

displays, security towers, and other sources) can interfere with the MICR read

head. The printer is equipped to filter noise from many of these devices. If the

MICR reader does not function properly, rearranging the printer relative to the

device may improve MICR reading. The noise source should be as far away as

possible from the right side of the printer. For additional information on

troubleshooting MICR reader problems, see “Offline tests” on page 62.

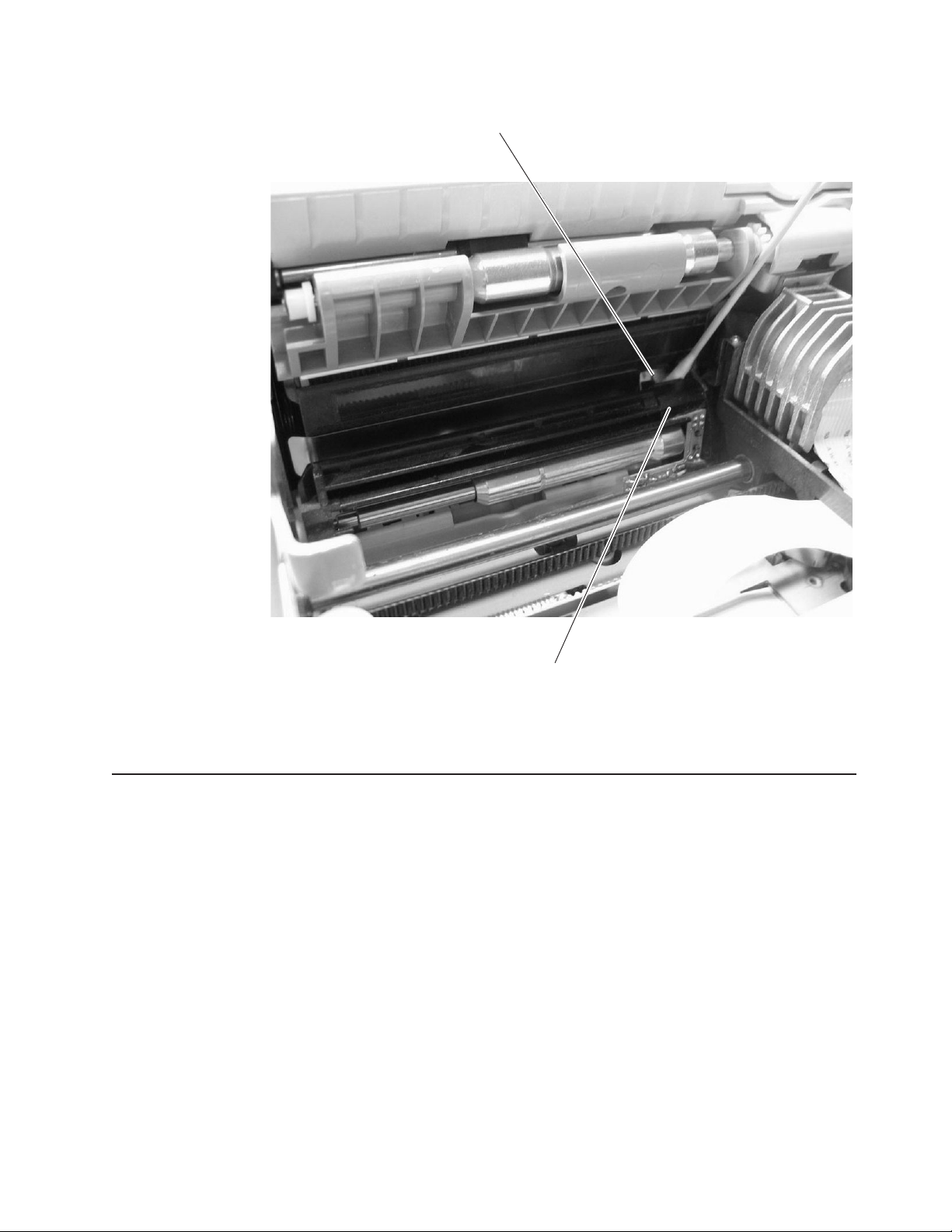

Chapter 1. Introduction 9

Page 32

The single-insert check handling feature of SureMark Models TI2, TI4, TI8, TI9,

TG4, TG8, and TG9 is provided as an added convenience when customer service

is a priority. Checks in good condition will feed reliably; damaged checks may not.

Communication interfaces

All SureMark printers can support the EIA-232 and RS-485 interfaces. Models TI3,

TI4, TI8, TI9, TG3, TG4, TG8, TG9, TM6, and TF6 can also support the USB

interface. For SureMark models that can support the USB interface, you can

upgrade installed printers from EIA-232/RS-485 to USB by ordering a USB interface

card.

EIA-232 supports 9600 and 19 200 bps baud rates and, in the Models TI8, TG8,

TI9, and TG9 only, 115 200 bps.

RS-485 operates at a 187.5 Kbps baud rate.

USB supports data rates up to 12 Mbps.

Temperature and humidity limits

Shipping -40° to 60° C (-40° to 140° F) with 5% to 100% relative humidity

including condensation, but excluding rain

Updated April 2, 2009

Storage 0° to 60° C (32° to 140° F)

Operating 0° to 40° C (32° to 104° F) with 8% to 80% relative humidity

To allow convection cooling, ventilation holes in the covers must not be blocked.

Physical dimensions

Models TI1, TI2, TI3, TI4, TG3, and TG4 all have the same dimensions. Models TI8,

TI9, TG8, are TG9 are taller, whereas Models TF6 and TM6 have a smaller

footprint.

Models TI1, TI2, TI3, TI4, TG3, and TG4

Width 190.5 mm (7.5 in.)

Depth 255 mm (10 in.)

Height Front: 140 mm (5.5 in.), Rear: 190 mm (7.5 in.)

Weight 4.4 kg (9.6 lb) without paper

10 SureMark Printers User’s Guide

Page 33

Updated April 2, 2009

190.5 mm

(7.5 in.)

140 mm

(5.5 in.)

255 mm

(10 in.)

Figure 2. SureMark printer dimensions (Models TI1, TI2, TI3, TI4, TG3, and TG4)

200.5 mm

(7.9 in.)

190.5 mm

(7.5 in.)

Models TI8, TI9, TG8, TG9

Width 190.5 mm (7.5 in.)

Depth 255 mm (10 in.)

Height Front: 153.4 mm (6.0 in.), Rear: 199.5 mm (7.9 in.)

Weight 4.9 kg (10.8 lb) without paper

199.5 mm

(7.9 in.)

153.4 mm

(6.0 in.)

255 mm

(10 in.)

200.5 mm

(7.9 in.)

190.5 mm

(7.5 in.)

Figure 3. SureMark printer dimensions (Models TI8, TI9, TG8, TG9)

Chapter 1. Introduction 11

Page 34

Models TF6 and TM6

Width 145 mm (5.7 in.)

Depth 177 mm (7.0 in.)

Height Front: 95 mm (3.7 in.), Rear: 121 mm (4.8 in.)

Weight 1.4 kg (3.0 lb) without paper

121 mm

(4.8 in.)

Updated April 2, 2009

95 mm

(3.7 in.)

Figure 4. SureMark printer dimensions (Models TF6 and TM6)

Power requirements

SureMark printers do not contain a power supply. When the printer is operating in

EIA-232 mode, an external power supply must be attached to connector J2 of the

interface card of the printer. This connector is located under the printer and is

accessible without removing the printer covers. (See Figure 5 on page 18 for

thermal/impact SureMark printers, and Figure 6 on page 19 for single-station

SureMark printers.) Connector J2 has the following pin functions:

Table 2. J2 connector pin assignments

Pin Signal

1 +24Vdc

2 Not Connected

3 Ground

177 mm

(7.0 in.)

145 mm

(5.7 in.)

When the SureMark is operating in RS-485 mode, power is supplied to the printer

from the IBM POS system. The system supplies 38V dc and 5V dc to the printer.

When the SureMark has the USB feature installed and is using the powered USB

cable with a SurePOS 700 Series system, 24 V is supplied from the system unit.

12 SureMark Printers User’s Guide

Page 35

Updated April 2, 2009

When the SureMark has the USB feature installed and is using a 4-wire cable with

a Type B connector, an external power brick (+24 V dc) must be used.

Hardware requirements

SureMark printers work with the following systems:

v IBM 4614 SureOne

v IBM 4683 systems (RS-485 connection only)

v IBM 4693 systems

v IBM 4694 systems

v IBM 4695 systems (EIA-232 connection only and with power supply)

v 7497 POS Attachment Adapter (RPQ 8Q1238 in US, RS-485 only)

v PC or other store controller with an EIA-232 or USB port

v SurePOS 700 Series systems

v SurePOS 500 Series systems

v SurePOS 300 Series systems

v IBM Self Checkout solution

Software requirements

Operating system requirements

POSS drivers can be downloaded from the Retail Store Solutions Web site. See

“Resources on the Internet” on page 44 for more information.

®

POS terminal (EIA-232 connection only)

If you use the RS-485 interface, you must use POSS or 4690 OS drivers. If you use

the EIA-232 interface, use the commands described in Appendix D, “EIA-232

programming information,” on page 101.

EIA-232 interface: When using the EIA-232 interface, attach thermal/impact

SureMark printers to systems that are running one of these operating systems:

v Windows

®

XP Professional

v Novell Linux®Point of Service (NLPOS)

v IBM Retail Environment for SUSE Linux

v Windows 2000 Professional with OPOS and JavaPOS support from POS Suite

V1.2 or later

v Windows 98 Second Edition or Windows NT

®

4.0 with OPOS and JavaPOS

support from POS Suite V1.0 or later

When using the EIA-232 interface, attach single-station SureMark printers to

systems that are running Windows 2000 Professional, Windows 98 Second Edition,

or Windows NT 4.0 with OPOS and JavaPOS support from POS Suite V1.3.1 or

later.

RS-485 interface: When using the RS-485 interface, attach thermal/impact

SureMark printers to systems that are running one of these operating systems:

v 4690 Operating System Version 1 at maintenance level 9910, 4690 OS V2 or

4690 OS V2R3

v IBM Retail Environment for SUSE Linux

v Novell Linux Point of Service

v IBM PC DOS 2000 or later with POSS for DOS V1.60(b) plus delta package

160(D), or later

v Windows XP Professional

v Windows 2000 Professional with:

– POSS for Windows from POS Suite V1.1 or later

– OPOS and JavaPOS support from POS Suite V1.2 or later

Chapter 1. Introduction 13

Page 36

Updated April 2, 2009

v Windows 98 Second Edition or Windows NT 4.0 with POSS for Windows, OPOS

and JavaPOS support from POS Suite V1.0 or later

When using the RS-485 interface, attach single-station SureMark printers to

systems that are running one of these operating systems:

v IBM PC DOS 2000 with POSS for DOS V2.10 or later (Model TM6 only)

v Windows XP Professional, Windows 2000 Professional, Windows 98 Second

Edition, or Windows NT 4.0 with:

– POSS for Windows from POS Suite V1.3.0 or later

– IBM Retail Environment for SUSE Linux

– OPOS and JavaPOS support from POS Suite V1.3.1 or later

USB interface: When using the USB interface, attach thermal/impact SureMark

printers to systems that are running one of these operating systems:

v 4690 OS V2R3, which includes JavaPOS 1.4

v Windows XP Professional

v IBM Retail Environment for SUSE Linux

v Novell Linux Point of Service

v Windows 2000 Professional with:

– POSS for Windows from POS Suite V1.1 or later

– OPOS and JavaPOS support from POS Suite V1.2 or later

v Windows 98 Second Edition or Windows NT 4.0 with POSS for Windows, OPOS

and JavaPOS support from POS Suite V1.0 or later

When using the USB interface, attach single-station SureMark printers to systems

that are running one of these operating systems:

v Windows XP Professional, Windows 2000 Professional, Windows 98 Second

Edition, or Windows NT 4.0 with:

– POSS for Windows from POS Suite V1.3.0 or later

– OPOS and JavaPOS support from POS Suite V1.3.1 or later

Application requirements

Customers must be at these application levels (or higher) when running the 4690

OS:

Application Name Product

Number

IBM SUREPOS Application Client/Server

Environment for 4690 OS

IBM Chain Drug Sales Application 5669-212 9701 with PRPQ 5799-QYP

IBM 4680/4690 General Sales Application 5696-546 9701 with APAR IR33229 and

IBM 4680/4690 Supermarket Application 5696-536 9701 with APAR IR33228 plus

™

StoreFlow

Notes:

1. Where available, supports Models TI3, TI4, TG3, and TG4 at the point of sale.

2. 4690 Terminal Services for Windows NT is required when you use Windows NT 4.0 or

Windows 2000 as the primary operating system with these 4690 applications.

(see note 1) Release 1.4

5745-C44 N/A

Maintenance Level

PRPQ 5799-QYN

PRPQ 5799-QYL

14 SureMark Printers User’s Guide

Page 37

Updated April 2, 2009

Resident code pages

These code pages are resident in the printer:

v Generic

v 437 (US)

v 850 (International) – only Models TI1 and TI2

v 858 (International) – only Models TI3, TI4, TI8, TG3, TG4, TF6 and TM6

v 860 (Portuguese)

v 863 (Canadian French)

v 865 (Norwegian)

Additional code pages (four thermal and two impact) can be downloaded, if desired,

using diskettes that are available on the Web. See “Resources on the Internet” on

page 44 for more information about downloading diskettes.

Bar codes

SureMark printers can generate these bar codes:

v UPC-A

v UPC-E

v JAN13 (EAN-13)

v JAN8 (EAN-8)

v Code 39

v ITF

v Codabar

v Code 128C

v Codes 128A, 128B, and 128C (only Models TI3, TI4, TI8, TI9, TG3, TG4, TG8,

TG9, TF6 and TM6)

v Code 93

v PDF417

Chapter 1. Introduction 15

Page 38

Updated April 2, 2009

16 SureMark Printers User’s Guide

Page 39

Updated April 2, 2009

Chapter 2. Installation instructions

Unpacking the printer ......................18

Installing a SureMark printer ....................18

Installing for EIA-232/RS-485 communication .............18

Installing SureMark for USB communication .............21

Using the wall mounting feature...................23

Installing the fillers .......................24

Installing fillers for EIA-232/RS-485 printers .............24

Installing fillers for USB printers..................26

EIA-232 communication mode selections (all models except TI8, TI9, TG8, TG9) 28

Baud rate selection ......................28

EIA-232 communications protocol selection .............28

DTR/DSR control ......................29

XON/XOFF control .....................29

EIA-232 communication mode selections (Models TI8, TI9, TG8, TG9) ....30

Baud rate selection ......................30

EIA-232 communications protocol selection .............30

DTR/DSR control ......................30

XON/XOFF control .....................30

USB communication mode ....................31

USB selection .........................31

Before installing an IBM SureMark printer, be sure to read “Electronic emission

notices” on page 205.

DANGER

To avoid a shock hazard, do not connect or disconnect any cables

or perform installation, maintenance, or reconfiguration of this

product during an electrical storm.

DANGER

To avoid shock hazard:

The power cord must be connected to a properly wired and

earthed receptacle.

Any equipment to which this product will be attached must also

be connected to properly wired receptacles.

Note: For translations of these safety notices, see IBM Safety Information—Read

This First, GA27-4004.

© Copyright IBM Corp. 1997, 2006 17

Page 40

Unpacking the printer

Note: Save all packing material and shipping containers.

1. Remove the SureMark printer from the shipping container and place it on a flat

surface.

2. Open any shipping containers of additional options and accessories to install

with the SureMark printer.

3. Carefully remove any remaining packing material and packing tape.

Installing a SureMark printer

This section describes SureMark printer installation.

Installing for EIA-232/RS-485 communication

1. Power the system off and disconnect the EIA-232 power supply.

2. Locate the rear cable connectors.

3. If you are using the EIA-232 communication port:

a. For all models except TI8, TG8, TI9, TG9, check the settings on the

EIA-232 mode switch, which is near the rear cable connections. See

Figure 5 for thermal/impact printers. See Figure 6 on page 19 and Figure 7

on page 19 for single-station printers.

Updated April 2, 2009

Notes:

1) If the EIA-232 communication cable has only 3 wires or if the system

output is 3 pins (2 signals and a ground), you must use XON/XOFF

mode.

2) Models TI8, TG8, TI9, TG9 do not have a mode switch for EIA-232

settings. See “EIA-232 communication mode selections (Models TI8,

TI9, TG8, TG9)” on page 30.

b. Connect the power supply to the printer.

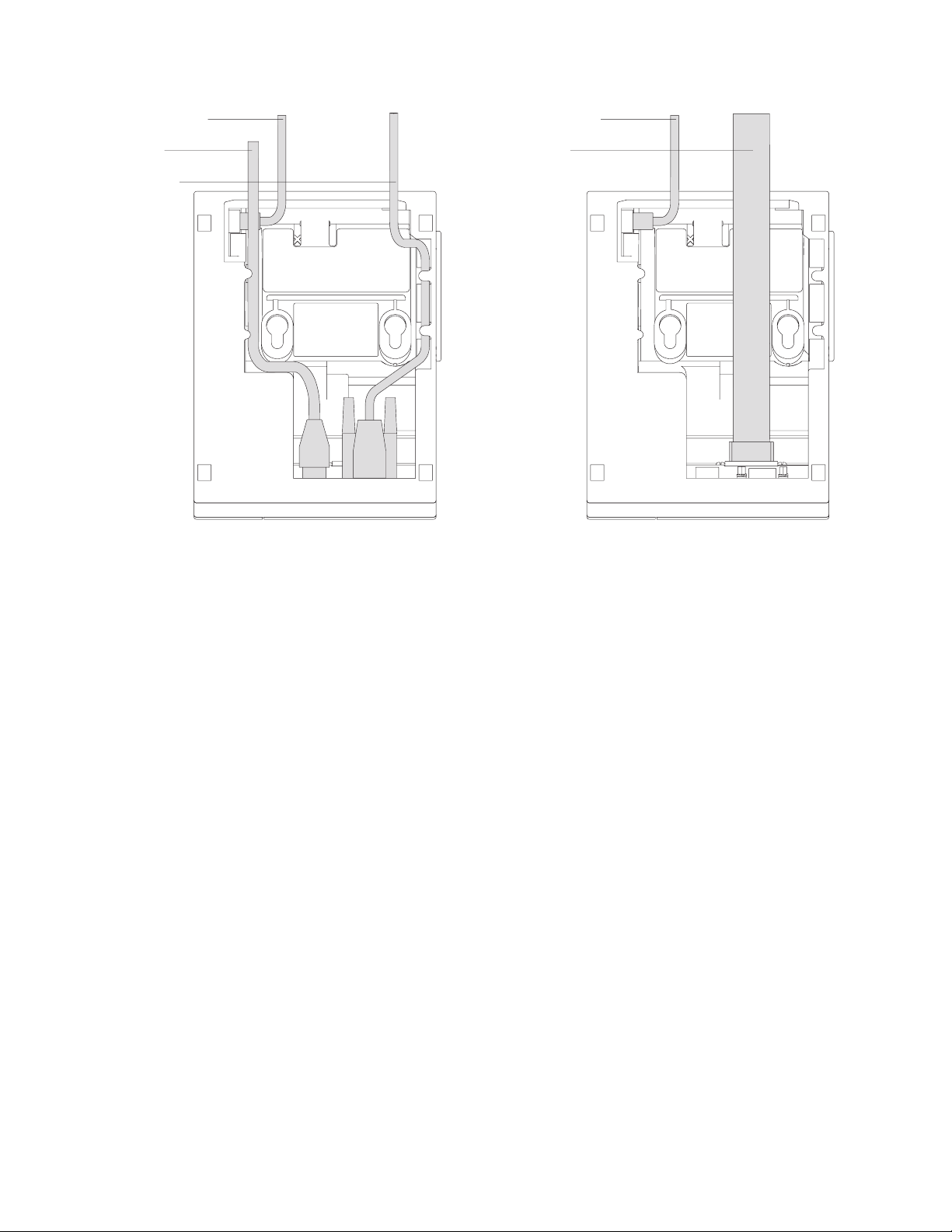

1

OFF

2

EIA-232

Mode

Switch

(some

models)

Cash

Drawer

Por t

Power Supply

Port (EIA-232

Only)

EIA 232

Por t

RS-485 Port

Figure 5. Cable connectors and EIA-232 settings switch for thermal/impact SureMark printers.

(View is from the bottom rear of the printer)

18 SureMark Printers User’s Guide

Page 41

Updated April 2, 2009

Power supply port (EIA-232 only)

EIA-232 port

RS-485 port

Cash drawer connector

Figure 6. Cable connectors for single-station SureMark printers. (View is from the bottom rear

of the printer)

OFF

4

3

2

1

EIA-232 mode switches

Cash drawer connector

Figure 7. EIA-232 mode switches for single-station SureMark printers. (View is from the

bottom rear of the printer)

4. Connect the RS-485 or EIA-232 communication cable to the correct port.

5. For single-station printers, route any power cord and cables as shown in

Figure 8 on page 20.

Chapter 2. Installation instructions 19

Page 42

Updated April 2, 2009

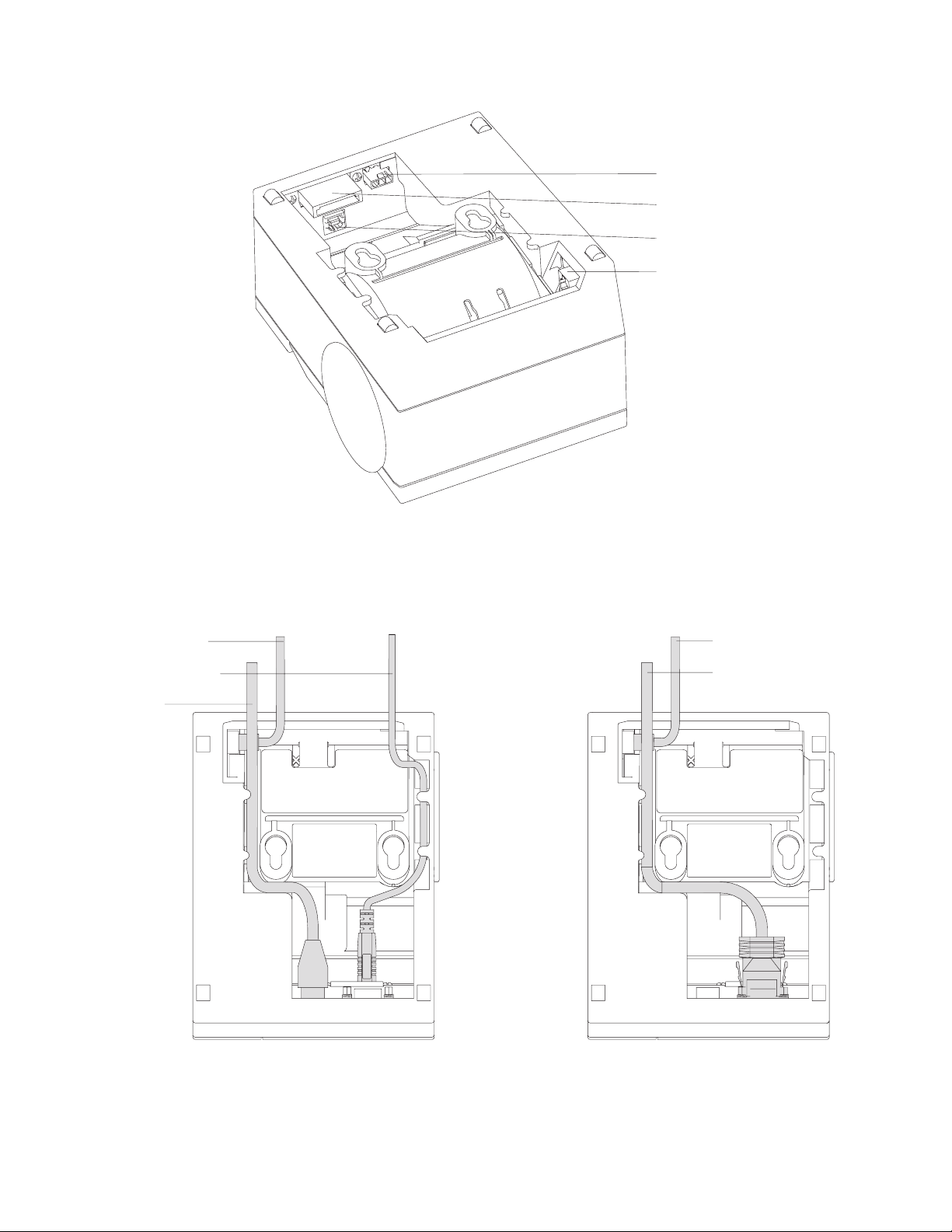

Cash drawer cable

Power cord

EIA-232 cable

Figure 8. EIA-232 and RS-485 cable routing for single-station SureMark printers

Cash drawer cable

RS-485 cable

6. Connect any other signal cables for I/O devices to the correct ports.

7. Check that all signal cables are installed and seated in the correct ports.

8. If you are installing the printer on an integrated unit:

a. Pull out the locking lever at the left side of the system unit. (wide systems

only)

b. For single-station printers, place the printer in the square-shaped filler

panel.

c. Route the keyboard cable to the side of the tab as shown in Figure 13 on

page 25.

d. Route all cables attached to the printer through the center opening of the

system unit and place the printer (with its filler panel, if it is a single-station

printer) on the system unit.

e. If you have additional fillers to install, go to “Installing the fillers” on page

24.

f. Lift the system unit rear cover and attach any cables from the printer to the

system unit. (If this is a EIA-232-attached printer, reattach the brick power

cord if you had to detach it to route it through the center opening.)

9. Power on the printer by either:

v Connecting the brick power supply cable to a properly wired and grounded

power source and powering it on.

v Powering on the POS system unit for an RS-485-attached printer.

Attention: Never connect both voltage sources to the printer at the same

time, even if one of the sources is powered off. Potential system damage

could occur under these conditions.

10. For single-station SureMark printers, turn on the power on/off switch on the

printer.

20 SureMark Printers User’s Guide

Page 43

Updated April 2, 2009

11. For thermal/impact SureMark printers, locate the ribbon cartridge and install it

in the printer. (See “Ribbon loading” on page 51.) Be sure that the ribbon is

routed through the print head correctly.

12. Load the paper roll into the printer. See “Paper loading” on page 53 for

thermal/impact SureMark printers or “Paper loading” on page 71 for

single-station SureMark printers.

13. Installation is now complete. Go to Chapter 5, “Testing and problem analysis,”

on page 61 for thermal/impact printers or Chapter 7, “Testing and problem