Page 1

HP StorageWorks

SAN Switch installation guide

Part number: AA-RWF3A-TE

fth edition: May 2007

Fi

Page 2

Legal and notice information

© Copyright 2004-2007 Hewlett-Packard Development Company, L.P.

© Copyright 2004-2007 Brocade Communications Systems, Incorporated

Hewlett-Packard Company makes no warranty of any kind with regard to this material, including, but not

limited to, the implied warranties of merchantability and fitness for a particular purpose. Hewlett-Packard shall

not be liable for errors contained herein or for incidental or consequential damages in connection with

the furnishing, performance, or use of this material.

This document contains proprietary information, which is protected by copyright. No part of this document

may be photocopied, reproduced, or translated into another language without the prior written consent of

Hewlett-Packard. The information is provided “as is” without warranty of any kind and is subject to change

without notice. The only warranties for HP products and services are set forth in the express warranty statements

accompanying such products and services. Nothing herein should be construed as constituting an additional

warranty. HP shall not be liable for technical or editorial errors or omissions contained herein.

Compaq Computer Corporation is a wholly-owned subsidiary of Hewlett-Packard Company.

Microsoft® and Microsoft Windows® are U.S. registered trademarks of Microsoft Corporation.

UNIX® is a registered trademark of The Open Group.

Page 3

Contents

Aboutthisguide .................... 11

Intendedaudience.............................. 11

Relateddocumentation............................ 11

Documentconventionsandsymbols ...................... 12

Rackstability .............................. 13

HPtechnicalsupport............................. 13

HPauthorizedreseller .......................... 14

Helpfulwebsites ............................ 14

1Overview ...................... 15

4/8and4/16SANSwitchmodels ...................... 15

4/8and4/16SANSwitchfeatures .................... 16

4/8and4/16SANSwitchchassis .................... 17

4/8and4/16SANSwitchportside.................. 17

4/8and4/16SANSwitchnonportside ................ 17

Activating additional 4/8 and 4/16 SAN Switch ports . . . . . . . . . . . . 17

EnablingE_Portsonthe4/8SANSwitch .................... 18

SANSwitchlicensing........................... 19

4/32SANSwitchmodels........................... 20

4/32SANSwitchfeatures ........................ 20

4/32SANSwitchchassis......................... 20

4/32SANSwitchportside...................... 21

4/32SANSwitchnonportside .................... 31

Activating additional 4/32 and 4/32B SAN Switch ports . . . . . . . . . . . 22

4/64SANSwitchmodels........................... 24

4/64SANSwitchfeatures ........................ 24

4/64SANSwitchchassis......................... 25

4/64SANSwitchportside...................... 25

4/64SANSwitchportnumbering................... 27

4/64SANSwitchnonportside .................... 27

Activating additional 4/64 SAN Switch ports . . . . . . . . . . . . . . 28

4/32BSANSwitchmodels.......................... 29

4/32BSANSwitchfeatures........................ 29

4/32BSANSwitchchassis ........................ 29

4/32BSANSwitchportside ..................... 30

Locating4/32BSANSwitchFCports.................. 31

Activating additional 4/32B SAN Switch ports . . . . . . . . . . . . . . . . 31

SAN Switch installation guide

3

Page 4

SANSwitchISLTrunkinggroups........................ 31

OptionalSANSwitchfeatures......................... 32

SANSwitchoptionalportlicensesandhardware................. 33

2InstallingandconfiguringSANSwitches ......... 35

Shippingcartoncontents ........................... 35

Installationandsafetyconsiderations...................... 38

Electricalconsiderations ......................... 38

Environmentalconsiderations ....................... 38

Rackspecifications............................ 39

Coolingconsiderations.......................... 39

Installingtheswitchasastand-alonedevice................... 40

InstallingtheswitchusingtheSANSwitchRackMountKit ............. 41

InstallingthePlenum(ifrequired)...................... 49

Securingtheswitchtotheouterrails .................... 50

CablingandconfiguringtheSANSwitch .................... 52

Recommendationsforcablemanagement.................. 52

ConnectingtheSANSwitchtothefabric .................... 53

Obtainrequireditems .......................... 53

Makeaserialconnection......................... 53

Applypowertotheswitchandlogin.................... 56

SettheIPaddress ............................ 57

CreateanEthernetconnection....................... 58

ModifytheFCdomainID(optional) .................... 58

InstalltheSFPtransceivers......................... 59

Connectthecables............................ 60

Verifytheconfiguration.......................... 60

Backuptheconfiguration......................... 60

Settheswitchdateandtime........................ 61

Synchronizethelocaltimewithanexternalsource .............. 61

Setthetimezone ............................ 62

3ManagingSANSwitches................ 65

Poweringonandoff............................. 66

4/8and4/16SANSwitchmodels .................... 66

4/32,4/32Band4/64SANSwitchmodels ................ 66

SANSwitchmanagementfeatures ....................... 67

Managing SAN Switches from a single management station . . . . . . . . . . . . 67

InterpretingLEDactivity............................ 69

4/8and4/16SANSwitchLEDs ....................... 69

4/8and4/16SANSwitchLEDpatterns .................... 70

PowerStatusLEDpatterns......................... 70

4/8and4/16SANSwitchsystemStatusLEDpatterns ............ 71

4/8and4/16SANSwitchportLEDpatterns ................ 72

4/8and4/16SANSwitchEthernetLEDpatterns .............. 74

4/32SANSwitchportsideLEDs........................ 74

4

Page 5

4/32SANSwitchnonportsideLEDs...................... 78

4/64SANSwitchportsideLEDs........................ 79

4/64SANSwitchnonportsideLEDs...................... 82

4/32BSANSwitchLEDs ........................... 85

POSTandbootspecifications ......................... 88

POST ................................. 88

Boot.................................. 88

InterpretingPOSTresults ........................... 89

Diagnostictests ............................... 89

4Installingfield-replaceableunits............. 91

Replacingthe4/32SANSwitchpowersupply.................. 91

Itemsrequired.............................. 93

Procedure ............................... 94

Replacingthe4/32SANSwitchfanassembly.................. 96

Itemsrequired.............................. 97

Procedure ............................... 97

Replacingthe4/64SANSwitchpowersupply.................. 99

Itemsrequired............................. 100

Procedure .............................. 101

Replacingthe4/64SANSwitchfanassembly.................. 103

Itemsrequired............................. 104

Procedure .............................. 104

Replacing the 4/32B SAN Switch Power Supply/Fan Assembly Unit . . . . . . . . 106

PowerSupply/FanAssemblyoverview .................. 106

HowtodeterminetoreplacethePowerSupply/FanAssemblyUnit ...... 108

Itemsrequired............................. 109

Procedure .............................. 109

ReplacinganSFP ............................. 110

ARegulatorycomplianceandsafety............ 113

Regulatorycompliance........................... 113

Federal Communications Commission notice for Class A equipment . . . . . . 113

Declaration of conformity for products marked with the FCC logo, United States

only............................... 113

Modifications........................... 114

Cables.............................. 114

Regulatorycomplianceidentificationnumbers ............... 114

Laserdevice ............................. 114

Lasersafetywarning........................ 114

Certificationandclassificationinformation............... 115

Laserproductlabel......................... 115

Internationalnoticesandstatements ..................... 115

Canadiannotice(avisCanadien) .................... 115

ClassAequipment......................... 115

EuropeanUnionnotice......................... 116

SAN Switch installation guide

5

Page 6

BSMInotice.............................. 116

Japanesenotice............................ 117

Koreannotices ............................ 117

Safety .................................. 118

Batteryreplacementnotice ....................... 118

Taiwanbatteryrecyclingnotice ..................... 119

Powercords.............................. 119

Japanesepowercordstatement ..................... 119

WasteElectricalandElectronicEquipmentdirective............... 120

Englishnotice............................. 120

Dutchnotice ............................. 120

Czechoslovakiannotice......................... 121

Estoniannotice ............................ 121

Finnishnotice.............................. 122

Frenchnotice .............................. 122

Germannotice ............................. 123

Greeknotice .............................. 123

Hungariannotice ............................ 124

Italiannotice .............................. 124

Latviannotice.............................. 125

Lithuaniannotice ............................ 125

Polishnotice .............................. 126

Portuguesenotice ............................ 126

Slovakiannotice............................. 127

Sloveniannotice............................. 127

Spanishnotice ............................. 128

Swedishnotice ............................. 128

BElectrostaticdischarge................. 129

Howtopreventelectrostaticdischarge ..................... 129

Groundingmethods ............................. 129

CSANSwitchtechnicalspecifications ........... 131

Generalspecifications ............................ 132

Weightandphysicaldimensions........................ 134

Facilityrequirements............................. 134

Environmentalrequirements .......................... 136

Datatransmissionranges........................... 137

FCportspecifications ........................... 140

4/8and4/16SANSwitchFCportspecifications ............. 140

4/32and4/64SANSwitchFCportspecifications............. 140

4/32BSANSwitchFCportspecifications................. 141

Serialportspecifications .......................... 141

Powersupplyspecifications .......................... 143

Memory ................................. 144

SupportedSFPs .............................. 144

6

Page 7

SupportedHBAs............................... 145

Glossary........................ 147

Index ......................... 157

SAN Switch installation guide

7

Page 8

Figures

14/8and4/16SANSwitchportside .................. 17

24/32SANSwitchportside ...................... 21

34/32SANSwitchnonportside..................... 22

44/64SANSwitchportside ...................... 26

54/64SANSwitchportnumbering.................... 27

64/64SANSwitchnonportside..................... 28

74/32BSANSwitchportside...................... 30

84/32BSANSwitchFCports...................... 31

9SANSwitchshippingcartoncontents .................. 35

10 Installing the rear mounting brackets (HP 10000 series racks) . . . . . . . 43

11Installingtherearmountingbrackets(HPSystem/eRack) ......... 43

12Installingtheouterrails(HP10000seriesracks) ............. 44

13Assemblingtheouterrails(HP10000seriesracks)............ 45

14Assemblingtheouterrails(HPSystem/eRack).............. 46

15Attachingtheinnerrailstothe4/8or4/16SANSwitch ......... 48

16Attachingtheinnerrailstothe4/32or4/64SANSwitch......... 48

17AttachingthePlenumtothe4/8or4/16SANSwitch .......... 50

18 Securing the switch (in HP 9000 Series or HP 10000 Series Racks) . . . . . 51

19Securingtheswitch(inanHPSystem/erack) .............. 51

20Connectingtheserialcable...................... 54

21Connectingthepowercord...................... 56

22ConnectingtheEthernetcable..................... 58

234/8and4/16SANSwitchLEDlocations................ 69

244/32SANSwitchportsideLEDs.................... 75

254/32SANSwitchnonportsideLEDs.................. 78

264/64SANSwitchportsideLEDs.................... 80

274/64SANSwitchnonportsideLEDs.................. 83

284/32BSANSwitchportsideLEDs................... 85

294/32SANSwitchpowersuppliesonthenonportside .......... 92

30Installingthepowersupplyina4/32SANSwitch ............ 94

314/32SANSwitchfanassembliesonthenonportside........... 96

32Installingthefanassemblyina4/32SANSwitch ............ 98

334/64SANSwitchpowersuppliesonthenonportside .......... 99

34Installingthepowersupplyinthe4/64SANSwitch ........... 102

354/64SANSwitchfanassembliesonthenonportside........... 103

36Insertingthefanassemblyina4/64SANSwitch ........... 105

374/32BSANSwitchPowerSupply/FanAssemblyUnit.......... 106

38 Inserting the Power Supply/Fan Assembly Unit in the 4/32B SAN Switch . . 110

39InstallingtheSFP ......................... 112

40Class1laserproductlabel ..................... 115

8

Page 9

Tables

1Documentconventions......................... 12

2Optionalportlicensesandhardwarekits................. 33

3SANSwitchshippingcartonchecklist .................. 36

4SANSwitchRackMountKithardware .................. 42

5Numberofscrewsrequiredtoassembletheinnerrails ........... 46

6Timezonecommandvalues ...................... 63

7Managementtools .......................... 67

8Exampleofasetofgatewayaddresses ................. 68

94/8and4/16SANSwitchLEDpatterns................. 70

10SystemstatusLEDpatternsduringnormaloperation............ 71

11PortLEDpatternsduringnormaloperation................ 72

12EthernetLEDpatterns......................... 74

134/32SANSwitchportsideLEDpatterns ................ 76

144/32SANSwitchnonportsideLEDpatterns............... 79

154/64SANSwitchportsideLEDpatterns ................ 81

16 4/64 SAN Switch nonport side LED patterns during normal operation . . . . 84

174/32BSANSwitchLEDpatternsduringnormaloperation......... 85

184/32SANSwitchPowerSupplyStatusLEDs............... 93

194/32SANSwitchFanStatusLEDbehavior ............... 97

20FanStatusLEDs.......................... 104

21 4/32B SAN Switch power supply/fan assembly unit status LED . . . . . . . 107

22Generalspecifications ........................ 132

23SANSwitchphysicaldimensions.................... 134

24Facilityrequirements......................... 134

25Environmentalrequirements...................... 136

26 Laser data transmission ranges for the 4/8 and 4/16 SAN Switches . . . . 137

27Laserdatatransmissionrangesforthe4/32SANSwitch ......... 138

28Laserdatatransmissionrangesforthe4/64SANSwitch ........ 140

29Laserdatatransmissionrangesforthe4/32BSANSwitch........ 140

30Cablingpinouts........................... 142

31Powersupplyspecifications ...................... 143

324/8and4/16SANSwitchmemoryspecifications........... 144

334/32and4/64SANSwitchmemoryspecifications .......... 144

344/32BSANSwitchmemoryspecifications............... 144

SAN Switch installation guide

9

Page 10

10

Page 11

About this guide

This installation guide provides information to help you set up and configure the

following HP switches:

• HP StorageWorks 4/8 SAN Switch

• HP StorageWorks 4/16 SAN Switch

• HP StorageWorks SAN Switch 4/32

• HP StorageWorks 4/64 SAN Switch

• HP StorageWorks 4/32B SAN Switch

“About t his Gu ide” t opics in clu de :

• Intended audience, page 11

• Related documentation, page 11

• Document conventions and symbols, page 12

•

HP technical support, page 13

Intended audience

This guide i

experience

• Configuration aspects of customer Storage Area Network (SAN) f abric

• Acustomerhostenvironment,suchasMicrosoftWindowsorIBMAIX

• The built

the switches through a supported web browser

s intended for use by system administrators and technicians who are

d with the following:

-in Graphical User Interface (GUI) , Advanced Web Tools, for configuring

Related documentation

Access documents, including white papers and best practices documents from the

B-Series switches section of the following web page:

ttp://www.hp.com/go/san

h

IMPORTANT:

For late breaking, supplemental i nformation, access the latest version of the

StorageWorks Fabric OS 5.2.x release notes

HP

.

SAN Switch installation guide

11

Page 12

Document conventions and symbols

This document follows the conventions in Table 1.

Table 1 Document conventions

Convention

Medium blue text: Figure 1

Medium blue underlined text (http://

www.hp.com)

Bold font

Italics font

Monospace font

Monospace, italic font

RNING!

WA

xt set off in this manner indicates that failure to follow directions in the warning could

Te

Cross-refere

Web site addresses

• Key names

• Text typed

into a box

• GUI eleme

such as me

check bo

Text emphasis

• File and directory names

• System output

• Code

• Text typed a t the command-line

de variables

• Co

mmand-line variables

• Co

Element

nce links and e-mail addresses

into a GUI element, such as

nts that are clicked or selected,

nuandlistitems,buttons,and

xes

result in bodily harm or death.

12

CAUTION:

Text set off in this manner indicates that failure to follow directions could result in

damage to equipment or data.

NOTE:

Text set off in this manner presents commentary, sidelights, or interesting points of

information.

About this guide

Page 13

Rack stability

Rack stability pr

WARNING!

To reduce the risk of personal injury or damage to the equipment, be sure that:

• Thelevelingjacksareextendedtothefloor.

• The full weight o

• In single rack installations, the stabilizing feet are attached to the rack.

• In multiple rack installations, the racks are coupled.

• Only one rack co

more than one rack component is extended for any reason.

otects personnel and equipment.

f the rack rests on the leveling jacks.

mponent is extended at any time. A rack may become unstable if

HP technical support

Telephone numbers for worldwide technical support are listed on the HP support web

ttp://www.hp.com/support/.

site:h

Collect the following information before calling:

• Technical support registration number (if applicable)

• Product serial numbers

• Product model names and numbers

• Applicable error messages

• Operating system type and revision level

• Detailed, specific questions

For continuous quality improvement, calls may be recorded or monitored.

HP strongly recommends that customers sign up online using the Subscriber’s choice web

site: h

ttp://www.hp.com/go/e-updates.

• Subscribing to this service provides you with e-mail updates on the latest product

enhancements, newest versions of drivers, and firmware documentation updates

as well as instant access to numerous other product resources.

• After signing up, you can quickly locate your products by selecting Business

support and then Storage under Product Category.

If you still have a question after reading this guide, contact an HP authorized service

provider or access our Web site: h

ttp://www.hp.com.

SAN Switch installation guide

13

Page 14

HP authorized reseller

For the name of your n

• In the United States, call 1-800-345-1518.

• Elsewhere, visit the HP web site: h

find locations and

Helpful web sites

For third-party product information, see the following HP web sites:

ttp://www.hp.com

•h

•http://www.hp.com/go/storage

•http://www.hp.com/support/

•http://www.docs.hp.com

earest HP-authorized reseller:

ttp://www.hp.com.ThenclickContactHPto

telephone numbers.

14

About this guide

Page 15

1Overview

This chapter describes the following topics:

• 4/8 and 4/16 SAN Switch models,page15

•

Enabling E_Ports on the 4/8 SAN Switch ,page18

•

4/32 SAN Switch models,page20

•4/64SANSwitchmodels, page 24

•

4/32B SAN Switch models,page29

•

SAN Switch ISL Trunking groups, page 31

•

Optional SAN Switch features,page32

•

SAN Swtich optional kits, page 33

4/8 and 4/16 S

The HP Stora

• HP StorageWorks 4/8 SAN Switch Base ships with eight ports activated and

no E_Por t license. It includes Advanced Web Tools and Zoning as standard

software components.

• HP Storag

includes a Full Fabric license, Advanced Web Tools, and Zoning as standard

software components.

• HP StorageWorks 4/16 SAN Switch ships with 16 ports activated and includes

aFullFabriclicense,AdvancedWebTools,andZoningasstandardsoftware

compon

• HP StorageWorks 4/16 SAN Switch Power Pack s h ips with 16 ports activated

and includes a Full Fabric license, Advanced Web Tools, and Zoning as standard

software components. It also includes integrated licenses for all optional

management tools (including Advanced Performance Monitoring, ISL Trunking,

Exte

geWorks 4/8 SAN Switch and 4/16 SAN Switch models include:

eWorks 4/8 SAN Switch Full ships with eight por ts activated and

ents.

nded Fabric and Fabric Watch).

AN Switch models

SAN Switch installation guide

15

Page 16

4/8 and 4/16 SAN Switch features

The 4/8 and 4/16 SAN Switches support link speeds of 1, 2, and 4 G b/s. The switch

operates in a fa

The 4/8 and 4/16 SAN Switches provide the following features:

• Air-cooled 1U chassis. The switch can be installed as a stand-alone unit or

mounted in one

•HPSystem/eRack

• HP 10000 G2 Series Rack, HP 9000 Series Rack and HP 10000 Series Rack

• Eight or sixt

• Automatic negotiation to the highest common speed of all devices connected

to the port

•Portinterf

pluggable (SFP) transceivers

• Universal and self-configuring ports capable of becoming an F_Por t (fabric

enabled), FL_Port (fabric loop enabled), or E_Port (expansion port)

• Ports act

licensed ports via HP StorageWorks 4-Port Upgrade Licenses.

• One RS-232 serial p ort with a DB-9 connector, see Serial port

specifi

• One 10/100 Mb/s Ethernet port with an RJ-45 connector.

• One built-in, fixed power supply, not available as a field-replaceable unit (FRU).

• Three b

• A real-time clock (RTC) with a 10-year battery.

bric that contains multiple switches or as the only switch in a fabric.

of the following HP custom racks:

een Fibre Channel (FC) ports with the following characteristics:

aces compatible with short wave a nd long wave small form factor

ivated via licenses. The 4/8 SAN Switch can be upgraded to 12 or 16

cations,page141.

uilt-in fans (not available as FRUs) .

16 Overview

Page 17

4/8 and 4/16 SAN Switch chassis

This section describes the chassis front (port side) and rear (nonport side).

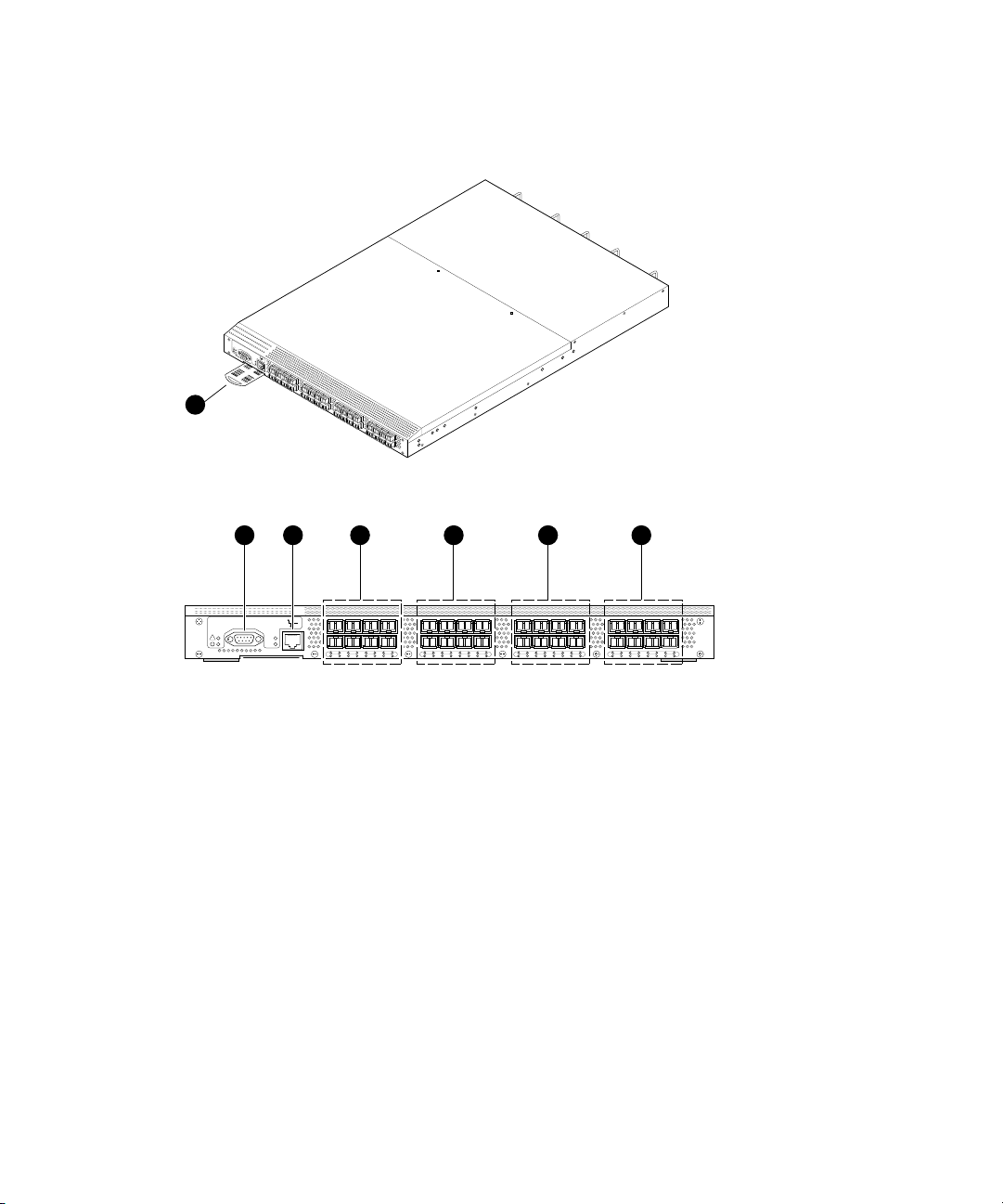

4/8 and 4/16 SAN Switch port side

All L EDs reside on the port side of the switch (see Figure 1). The 4/8 and 4/16 SAN

Switch enclosure uses forced-air cooling, with the fans pushing the air from the nonport

side of the chassis through the enclosure and exhausting at the port side.

See Interpreting LED activity on page 69 for a complete description of switch LEDs.

1

2 3

IOIOI

4

scale: 5/16" = 1"

!

0

4

152

3

8

11

7

6

91310

12

15

14

MRO25019a

1. AC power receptacle 3. Serial port

2. Ethernet port

4. FC port

s(16)

Figure 1 4/8 and 4/16 SAN Switch port side

4/8 and

4/16 SAN Switch nonport side

The non

port side is used solely for airflow and serial number labels. There are two labels

on the rear of the chassis: one is the HP serial number, the other is the switch supplier’s

serial number. The left label also contains the 4/8 SAN Switch or 4/16 SAN Switch

MAC ad

dress and world wide name (WWN).

Activating additional 4/8 and 4/16 SAN Switch ports

The 4/16 SAN Switch models offer 8, 12, or 16 licensed ports. To enable ports

8 through 11, you must purchase and install one or more HP StorageWorks 4-Port

Upgrade Licenses. To enable ports 12 through 15, you must purchase and install a

second HP StorageWorks 4-Port Upgrade License.

To activate additional ports:

1. Use the portshow command to verify the number of p orts licensed on your switch.

The port status output indicates Started and Licensed for enabled ports. See

the Fabric OS command reference manual for specific information on this command.

2. Use the switchshow command to obtain your SAN Switch WWN, which your HP

representative requires to assign a license key.

SAN Switch installation guide

17

Page 18

3. Contact your HP representative to purchase th e HP StorageWorks 4-Port Upgrade

License, part number T4260A.

4. Upon receipt of the HP StorageWorks 4-Port Upgrade License, install the license:

a. Log in to the 4/16 Switch as admin.

b. Issue the licenseadd command, followed by the license key enclosed in

quotation marks. (The license key consists of approximately 16 uppercase

and lowercase letters and numerals.)

NOTE:

Enter the license key exactly as issued. If you enter the key incorrectly,

the license will not function properly.

c. Issue the licenseshow command to verify that the license is valid. If a

licensed product is not displayed, the license is invalid.

NOTE:

It is not necessary to reboot the system. The product is available

immediately after you enter the license key.

5. Configure th

commandloadstheportcode,unliketheportenable command, which enables

the port laser. For example:

portstart 1

6. Issue the portenable command to enable the ports. For example:

portenable 16–31

7. Op tional:

are started.

einactiveports.Issuetheportstart command to start the ports. This

6–31

Issue the portshow command to verify that the newly activated ports

Enabling E_Ports on the 4/8 SAN Switch

The 4/8 SAN Switch requires that you purchase the Full Fabric Upgrade License, part

number T4261A, to enable E_Ports (the 4/16 SAN Switch ships with the Full Fabric

license installed). The switch, by default, cannot be connected to another switch until this

license is installed. Without the license, the switch can still be directly connected to hosts

and storage devices. To install the Full Fabric Upgrade License,usethelicenseadd

command. After it has been installed, the license appears under the licenseshow

command as Full Fabric License and indicates that E_Ports are now automatically

enabled when interswitch links (ISLs) are connected.

18 Overview

Page 19

SAN Switch lice

nsing

SAN Switches o

domain licens

perate differently in the network, depending on which HP StorageWorks

es are installed. The 4/8 Base SAN Switch has no E_Port, unless you

purchase and install the HP StorageWorks 4/8 Full Fabric Upgrade License.

• Full Fabric license— Allows one or more switches to operate within a domain.

All SAN Switc

h Power Pack models ship with this license installed.

To determine the type of license installed on your SAN Switch, issue the licenseshow

command at the command line interface (CLI) prompt. The Full Fabric license is listed as

Fabric lice

nse. A list of all licenses currently installed on the switch is displayed,

as shown in Example 1.

Example 1:

switch:admin> licenseshow

AbbbcDefcQxdezdr:

Web license

Zoning license

Fabric license

Remote switch license

Extended fabric license

Fabric Watch license

Performance Monitor license

Trunking license

Security license

switch:admin>

NOTE:

If the licen

sed feature is displayed, the feature is installed and immediately available.

SAN Switch installation guide

19

Page 20

4/32 SAN Switch models

TheHPStorageWorks4/32SANSwitchmodelsinclude:

• HP StorageWorks 4/32 SAN Switch Base ships with 16 ports activated and

includes Zoning and Advanced Web Tools as standard software components.

• HP StorageW

includes Zo

• HP StorageWorks 4/32 SAN Switch Power Pack ships with 32 ports activated

and includes a Full Fabric license, Advanced Web Tools, and Zoning as standard

software components. It also includes integrated licenses for all optional

management tools (including Advanced Performance Monitoring, ISL Trunking,

Extende

NOTE:

To add ports, see Activating additional 4/32 SAN Switch ports on page 31.

4/32 SAN Switch features

The HP StorageWorks 4/32 SAN Switch provides the following features:

• Air-cooled 1U chassis

• Thirty-two fixed autosensing 1, 2, or 4-Gb/s FC ports with the following

characteristics:

• Automatic negotiation to the highest common speed of all devices connected

to the port

• Port interfaces compatible with SFP transceivers, both SWL and LWL

• Universal and self-configuring ports capable of becoming an F_Port (fabric

enabled), FL_Port (fabric loop enabled), or E_Port (expansion port)

• One RS-232 serial port designed to connect to a DTE port

• One 10/100 Mb/s Ethernet port with an RJ-45 connector

• Two redundant, hot-pluggable, universal AC power supplies

• Three redundant, hot-pluggable fans

orks 4/32 SAN Switch Full ships with 32 ports activated and

ning and Advanced Web Tools as standard software components.

d Fabric and Fabric Watch).

4/32 SAN Switch chassis

This section provides an illustration of the front (port side) and rear (nonport side) panels

of the SAN Switch chassis and identifies the components of each side.

20 Overview

Page 21

4/32 SAN Switch port side

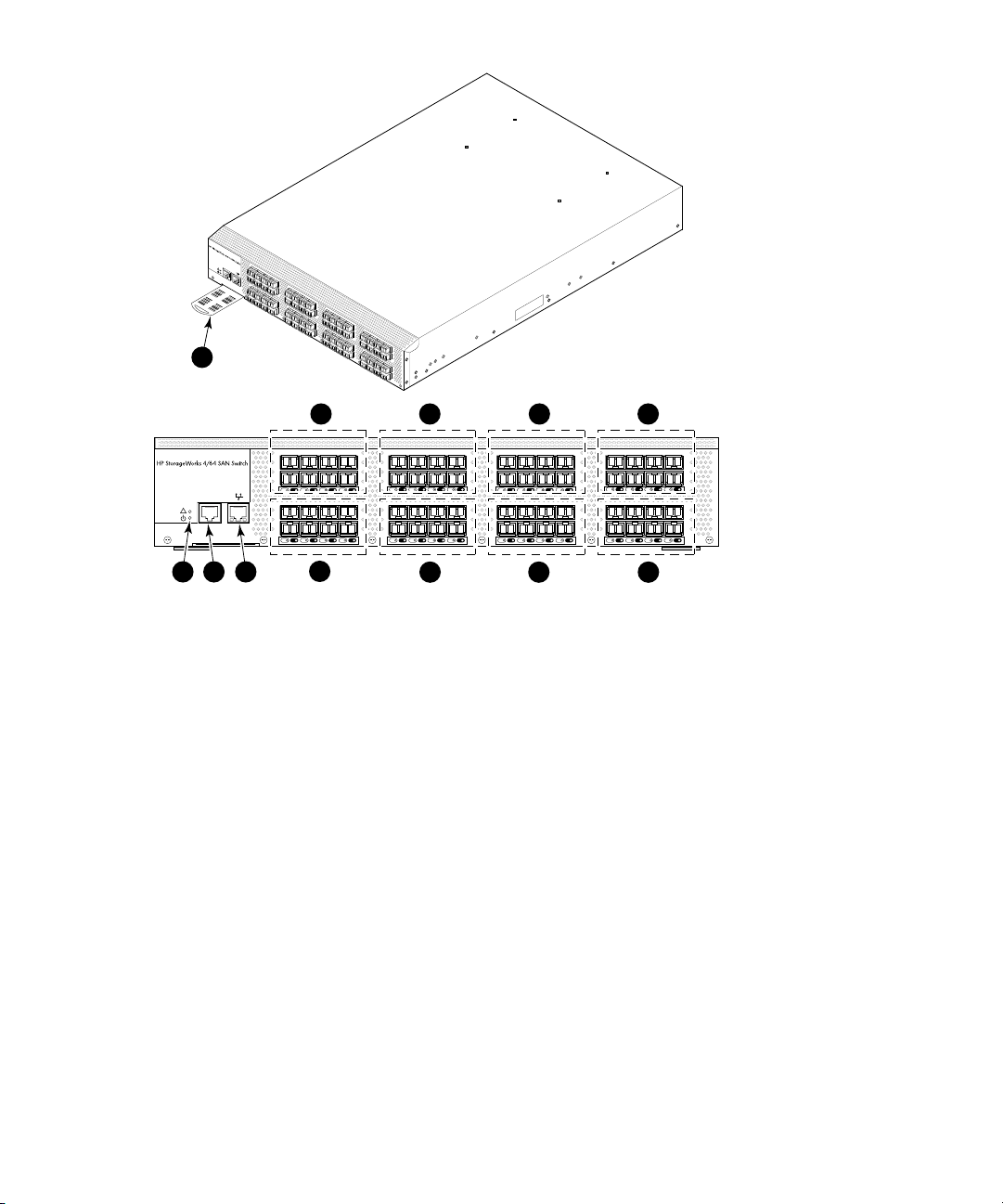

Figure 2 shows the port side of the 4/32 SAN Switch and identifies the components.

!

IO

IO

I

LNK

SP

D

1

scale: 1/8" = 1"

4 5 6 732

IOIOI

!

LNK

SPD

0

37152

8

11

4

6

91310

12

14

16

19

15

172118

20

22

24

23

252926

28

scale: 5/16" = 1"

1. Switch

ID pull-out tab

3. Ethernet port

2. Serial

4. FC ports 0–7

port

5. FC ports 8–15 6. FC ports 16–23

7. FC por

ts 24–31

Figure24/32SANSwitchportside

27

31

30

MRO25009a

SAN Switch installation guide

21

Page 22

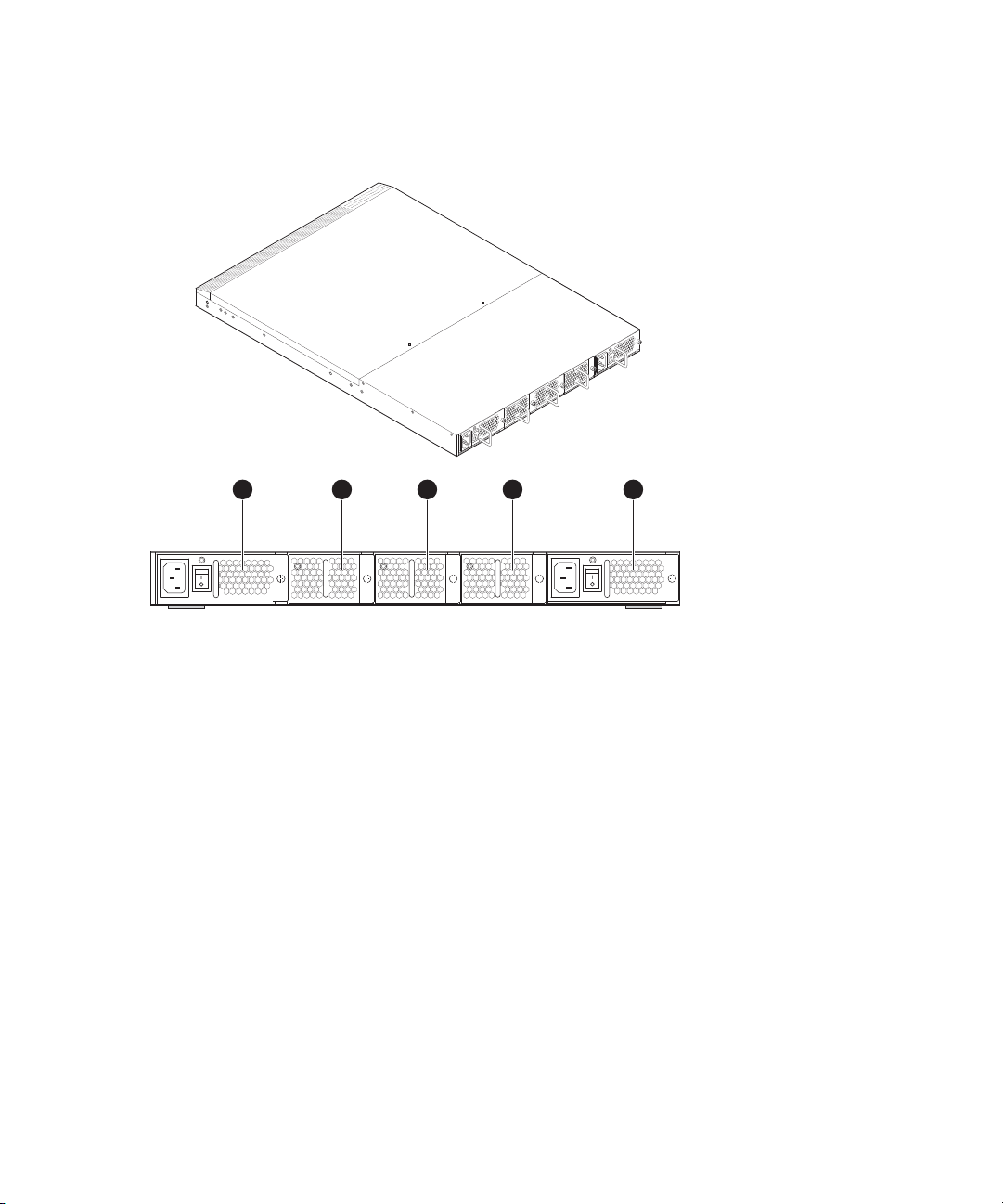

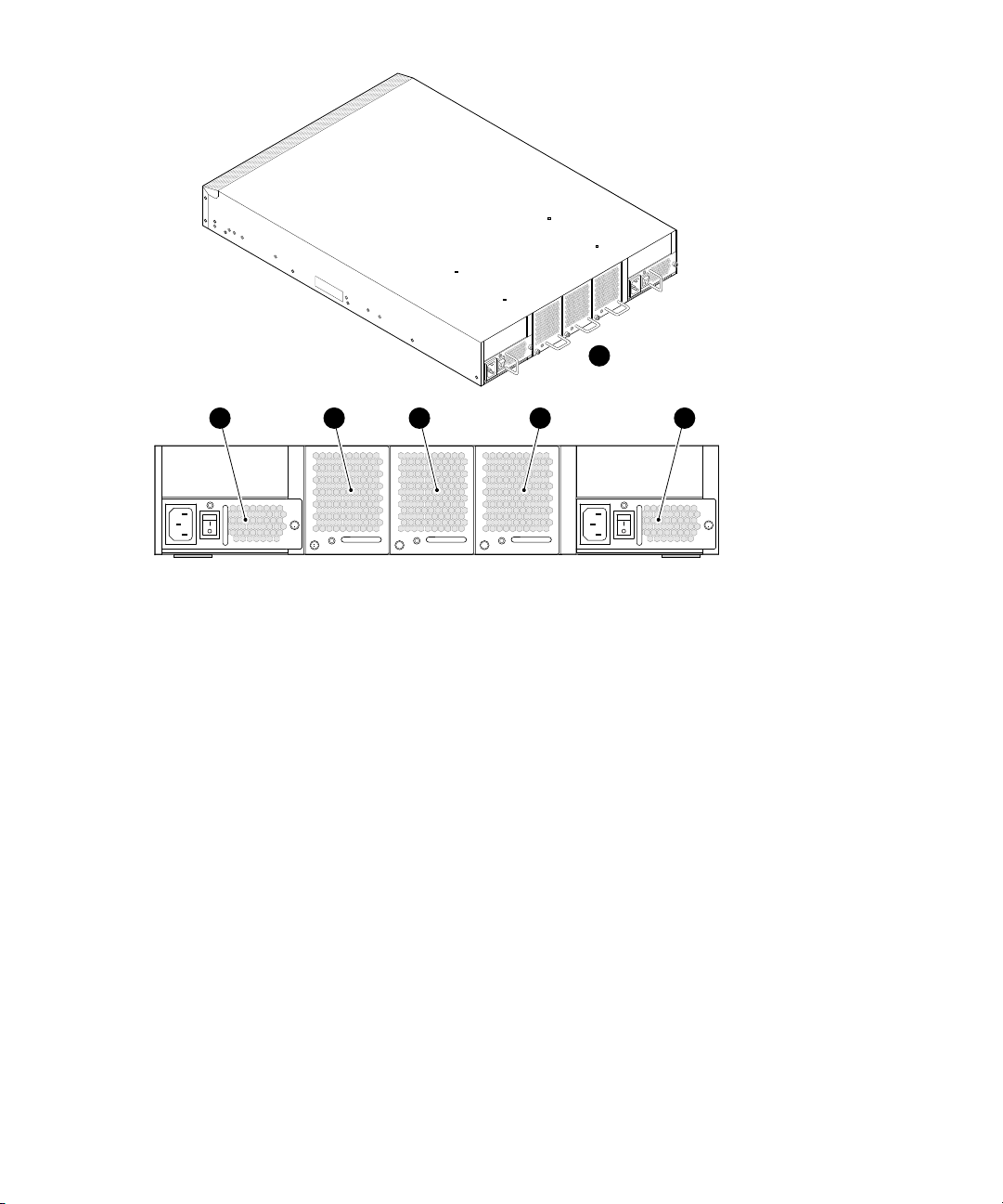

4/32 SAN Switch nonport side

Figure 3 shows the nonport side of the 4/32 SAN Switch, which contains the power

supplies (including the AC power inlet and AC power switch) and fans.

Scale: 1/8" = 1"

3 4 521

MRO25010a

1. Power supply 2

3. Fan 2

5. Power supply 1

2. Fan 3

4. Fan 1

Figure34/32SANSwitchnonportside

Activating additional 4/32 and 4/32B SAN Switch ports

The SAN Switch 4/32 and 4/32B SAN Switches are available with either 16 ports

hrough 1 5) activated for the Base model or 32 ports (0 through 31) activated for

(0 t

the Full model.

To activate additional ports, contact your HP representative to purchase the HP

rageWorks 8-Port Upgrade License, part number T3677A. If your 4/32 SAN Switch

Sto

shipped with 16 active ports, purchase one 8-Port Upgrade License to activate ports 16

through 23; purchase a second 8-Port Upgrade License to activate ports 24 through 31 .

22 Overview

Page 23

NOTE:

Check the port status to determine whether the license is preinstalled. Use the

portshow command for ports 16 through 31. If the port status output indicates

Started and Licensed, all 32 ports are activated.

1. If ports 16 through 31 show no license, you can purchase the HP StorageWorks

8-Port Upgrade License, part number T3677A, from an authorized HP representative.

Your HP representative requires the 4/32 SAN Switch’s WWN in order to assign a

license key. Enter the switchshow command to obtain the WWN of your 4/32

SAN Switch.

2. Install the HP StorageWorks 8-Port Upgrade License. The license key consists of

approximately 16 uppercase and lowercase letters and numerals.

a. Log in to the 4/32 SAN Switch as admin.

b. Enter the licenseadd command, followed by the license key enclosed in

quotation marks.

NOTE:

Enter the license key exactly as issued. If you enter it incorrectly, the

license will not function properly.

c. After entering the license key, use the licenseshow command to verify that

the license is valid. If a licensed product is not displayed, the license is invalid.

NOTE:

After entering a license key, the licensed product is available

immediat

ely.Thesystemdoesnotrequireareboot.

3. Configure the inactive ports. Issue the portstart command to start the ports. This

command loads the port code, unlike the portenable command, which enables

the port laser. For example:

portstart 16–31

4. Issue the portenable command to enable the ports. For example:

portenable 16–31

5. Optional: Issue the portshow command to verify that the newly activated ports

are started.

SAN Switch installation guide

23

Page 24

4/64 SAN Switch models

TheHPStorageWorks4/64SANSwitchmodelsinclude:

• HP StorageWorks 4/64 SAN Switch Base ships with 32 ports activated and

includes Zoning and Advanced Web Tools as standard software components.

• HP StorageWorks

includes Zonin

• HP StorageWorks 4/64 SAN Switch Power Pack ships with 32 ports a ctivated

and includes a Full Fabric license, Advanced Web Tools, and Zoning as standard

software components. It also includes integrated licenses for all optional

management tools (including Advanced Performance Monitoring, ISL Trunking,

Extended Fab

NOTE:

To add ports, see Activating additional 4/64 SAN Switch ports on page 28.

4/64 SAN Switch features

The HP StorageWorks 4/64 SAN Switch provides the following features:

• Air-cooled 2U chassis.

• 64 autosensing 1, 2, or 4-Gb/s Fibre Channel ports with the following

characteristics:

• Automatic negotiation to the highest common speed of all devices connected

to the port

• Port interfaces compatible with SFP transceivers, both SWL and LWL

• Universal and self-configuring ports capable of becoming an F_Port (fabric

enabled), FL_Port (fabric loop enabled), or E_Port (expansion port)

• Three redundant, hot-pluggable fan FRUs.

• Two redundant, hot-pluggable, universal AC power supplies. The unit can run on

one power supply, but HP recommends using both for redundancy.

• Two AC power supply cables

• One RS-232 serial port, designed to connect to a DTE port.

• One 10/100 Mb/s Ethernet port with an RJ-45 connector.

• Three internal temperature sensors.

4/64 SAN Switch Full ships with 64 ports activated and

g and Advanced Web Tools as standard software components.

ric and Fabric Watch).

24

Overview

Page 25

4/64 SAN Switch chassis

This section provides an illustration of the front (port side) and rear (nonport side) of

the SAN Switch c

4/64 SAN Switch port side

Figure 4 shows the port side and identifies the components.

hassis.

SAN Switch installation guide

25

Page 26

Scale: 1/8" = 1"

I

O

!

IO

I

0

47

1

5

2

6

3

8

3

2

1

2

3

6

9

3

3

1

3

3

73

1

0

3

4

1

4

8

1

1

3

5

1

5

3

9

1

6

0

4

0

2

0

4

4

1

7

1

1

2

1

4

5

1

8

2

4

2

2

2

4

6

1

9

3

4

34

2

3

4

7

2

4

0

4

8

2

8

5

2

2

5

1

4

9

2

9

5

3

2

6

2

5

0

3

0

5

4

2

7

3

5

1

3

1

5

1

5

0

5

6

6

0

1

5

7

6

1

2

5

8

6

2

3

5

9

6

3

k

c

a

.

r

n

r

i

:

fo

4

N

6

h

/

t

3

g

1

IO

n

r

e

T

l

o

w

N

m

e

r

E

m

c

5

T

s

e

T

m

b

A

u

o

t

m

i

g

x

a

in

t

M

n

u

o

m

5

Scale:

!

2

5/16" = 1"

IOIOI

3

4

0 4 1 5 2 6 3 7

32 36 33 37 34 38 35 39

9

1. Switch ID pull-out tab

6 7

8 12 9 13 10 14 11 15

40 44 41 45 42 46 43 47

16 20 17 21 18 22 19 23

48 52 49 53 50 54 51 55

10 11 12

2. System Status LED (top) & Power LED

(bottom)

3. Serial port 4. Ethernet port

5. FC por

ts 0–7

7. F C p o rt s 1 6 – 23

9. FC po rts 32– 39

11. FC p

orts 48–55

6. FC por

8. FC ports 24–31

10. FC ports 40–47

12. FC ports 56–63

ts 8–15

Figure 4 4/64 SAN Switch port side

8

24 28 25 29 26 30 27 31

56 60 57 61 58 62 59 63

25180a

26 Overview

Page 27

4/64 SAN Switch port numbering

Figure 5 identifies port numbering for the 4/64 SAN Switch.

0123

4567

0 4 1 5 2 6 3 7

32 33 34 35

36 37 38 39

32 36 33 37 34 38 35 39

!

Scale:

5/16" = 1"

IOIOI

Figure 5 4/64 SAN Switch port numbering

4/64 SAN Switch nonport side

Figure 6 shows the nonport side of the 4/64 SAN Switch, which contains the power

supplies (including the AC power inlet and AC power switch) an d fans.

8 91011

12 13 14 15

8 12 9 13 10 14 11 15

40 41 42 43

44 45 46 47

40 44 41 45 42 46 43 47

16 17 18 19

20 21 22 23

16 20 17 21 18 22 19 23

48 49 50 51

52 53 54 55

48 52 49 53 50 54 51 55

24 25 26 27

28 29 30 31

24 28 25 29 26 30 27 31

56 57 58 59

60 61 62 63

56 60 57 61 58 62 59 63

25181a

SAN Switch installation guide

27

Page 28

Scale: 1/8" = 1"

A

T

T

E

M

N

a

x

T

i

m

m

IO

u

o

m

u

N

n

s

t

:

in

c

r

g

e

w

t

o

l

b

e

e

n

g

5

t

m

h

m

f

o

r

o

r

r

a

1

c

k

3

/

6

4

i

n

.

1

2 3 4

1. Nonport side of switch

3. Fanassembly3 4. Fanassembly2

5. Fan assembly 1 6. Power supply 1

Figure 6 4/64 SAN Switch nonport side

Activating additional 4/64 SAN Switch ports

The 4/64 SAN Switch contains 64 ports, with ports 0 through 31 enabled. To enable

additional ports, you must purchase and install the HP StorageWorks 16-Port Upgrade

e, part number T4411A. The license enables ports in 16-port increments.

Licens

Forexample,toenableports32through47,youmustpurchaseandinstalloneHP

StorageWorks 16-Port Upgrade License. To enable ports 48 through 63, you must install

an addi

For det

guide.

tional 16-Port Upg rade License. Enabling ports on the switch is nondis ruptive.

ailed information on these optional licenses, see the Fabric OS administrator’s

5 6

2. P ower s

upply 2

Scale:

5/16" = 1"

25182a

28 Overview

Page 29

4/32B SAN Switch mod

els

The HP StorageWor

• HP StorageWorks 4/32B SAN Switch ships with 16 ports activated, and includes

a Full Fabric license, Zoning and Advanced Web Tools as standard software

components.

• HP StorageWorks

Fabric and incl

components.

• HP StorageWorks 4/32B SAN Switch Power Pack ships with 32 ports activated,

includes a Ful

software com

management

Extended Fabric and Fabric Watch).

NOTE:

To add ports, see Activating additional 4/32 and 4/32B SAN Switch ports.

ks 4/32B SAN Switch models include:

4/32B Full SAN Switch ships with 32 ports activated, Full

udes Zoning and Advanced Web Tools as standard software

l Fabric license, Advanced Web Tools, an d Zoning as standard

ponents. It also includes integrated licenses for all optional

tools (including Advanced Performance Monitoring, ISL Trunking,

4/32B SAN Switch features

The HP StorageWorks 4/32B SAN Switch provides the following features:

• Air-cooled 1U chassis

• Thirty-two fixed autosensing 1, 2, or 4Gbps FC ports with the following

characteristics:

• Automatic negotiation to the highest common speed of all devices connected

to the port

• Port interfaces compatible with SFP transceivers, both SWL a nd LWL

• Universal and self-configuring ports capable of becoming an F_Port (fabric

enabled), FL_Port (fabric loop enabled), or E_Port (expansion port)

• One RS-232 serial p ort designed to connect to a DTE port, see Serial port

specifications, page 141

• One 10/100 Mb/s Ethernet port with an RJ-45 connector

• Two hot-swappable, redundant power supply/fan assembly units. They are

identical and interchangeable.

4/32B S AN Switch chassis

This section provides an illustration of the front (port side) chassis and identifies the

components.

SAN Switch installation guide

29

Page 30

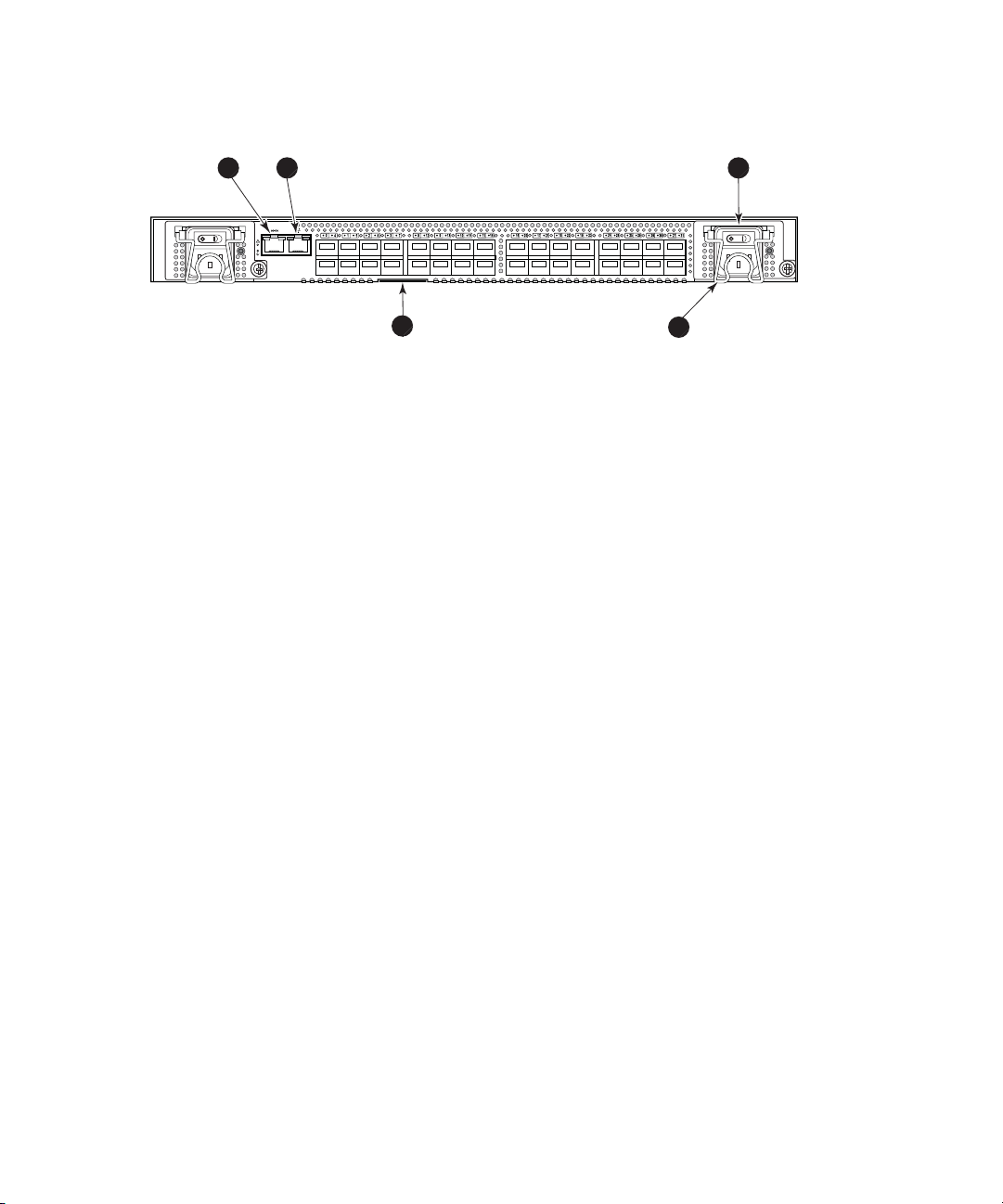

4/32B SAN Switch port side

Figure 7 shows the port side of the 4/32B SAN Switch and identifies components.

1 2 3

5

1. Serial port 4. Power cord retainer

2. Ethernet or c

onsole port

5. Switch ID pul

louttab

3. Power supply/fan assembly

Figure 7 4/32B SAN Switch port side

4

25271a

30 Overview

Page 31

Locating 4/32B SAN Switch FC ports

FC ports are numbered from left to right, in eight-port groups, and are also numbered

on the faceplate, see Figure 8.

25273a

Figure 8 4/3

2B SAN Switch FC ports

Activating additional 4/32B SAN Switch ports

The 4/32B SAN Switch is available with either 16 ports (0 through 15) activated for the

standard model or 32 ports (0 through 31) activated for the Full or Power Pack models.

To activate ad ditional ports, contact your HP representative to purchase the HP

StorageWorks 8-Port Upgrade License, part number T3677A. If your 4/32B SAN Switch

shippedwith16activeports,purchaseone8-Port Upgrade License to activate ports 16

through 23; purchase a second 8-Port Upgrade License to activate ports 24 through 31.

NOTE:

Check the port status to determine whether the license is preinstalled. Use the

portshow command for ports 16 through 31. If the port status output indicates

Started and Licensed, all 32 ports are activated.

See Activating additional 4/32 and 4/32B SAN Switch por ts ,page22forstepson

installing the license and activating ports.

SAN Switch ISL Trunking groups

ISL Trunking is optional HP StorageWorks software that allows you to create trunking

groups of ISLs between adjacent switches. For more information about trunking, see the

Fabric OS administrator’s guide.

If your SAN Switch is licensed for ISL Trunking (for example, Power Pack models ship

with this license), use the trunking groups available on the switch.

SAN Switch installation guide

31

Page 32

NOTE:

The maximum number of ports per trunk for the 4/8 and 4/16 SAN Switches is four.

The FC ports are numbered from left to right in groups of four. This arrangement

indicates the groups of ports that can be used in the same ISL trunking group. The

trunking groups are the t wo or four sets of ports at the top or bottom of the group, as

shown in Figure 5 on page 27.

Optional SAN Switch features

SAN Switches support the following optional software, activated with the p urchase of

alicensekey:

NOTE:

All SAN Switch Power Pack models ship with these licensed options enabled.

• ISL Trunking

• Secure Fabric OS

• Fabric Watch

• Advanced Performance Monitoring

• Extended Fabrics

For detailed information on these features, see the Fabric OS administrator’s guide

for the firmware version you are running.

32 Overview

Page 33

SAN Switch optional port licenses and hardware

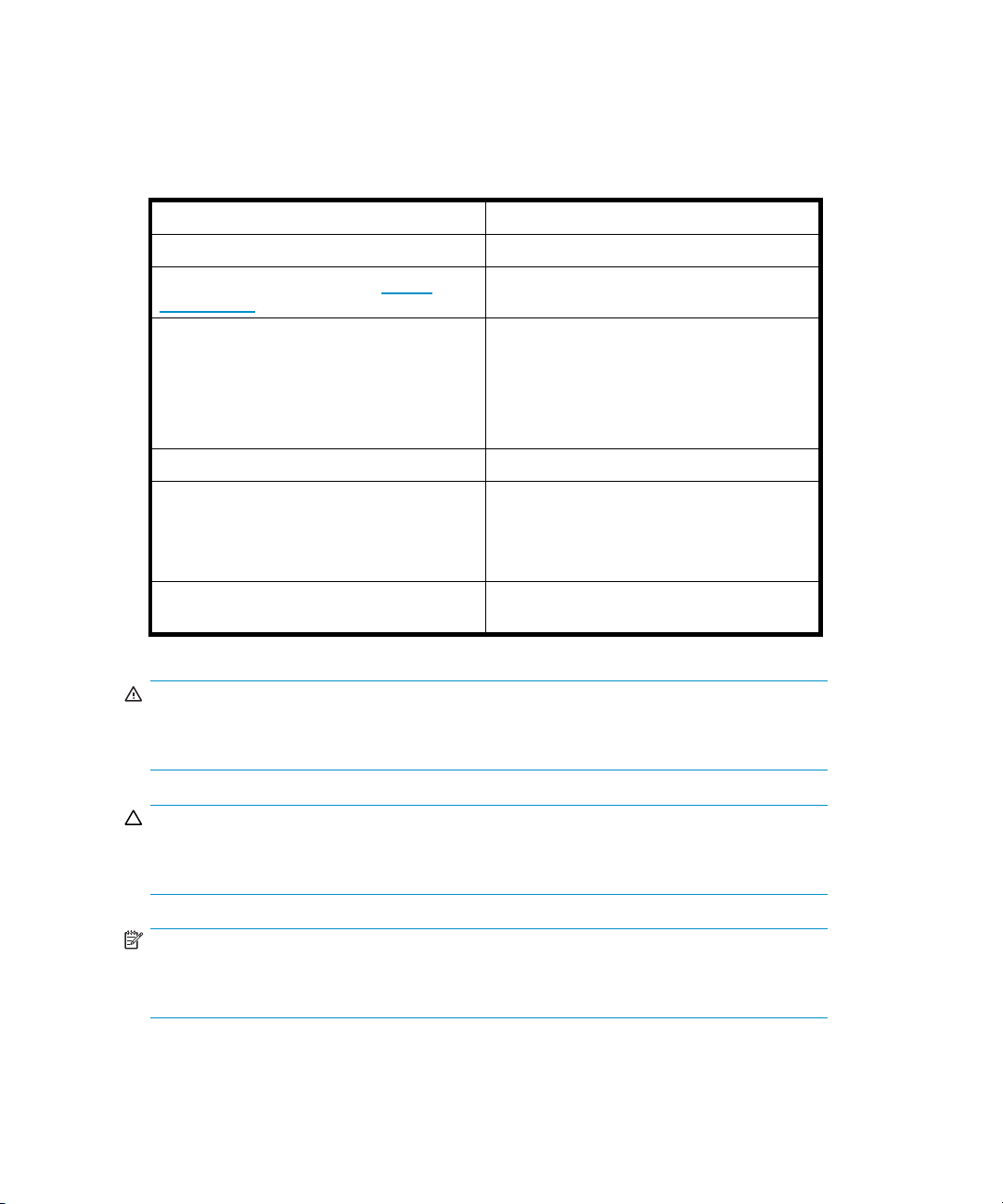

Table 2 lists the optional port licenses and hardware kits available for SAN Switches.

Table 2 Optional port licenses and h ardware kits

Option

HP StorageWor

SAN Switch on

HP StorageWorks 8-Port Upgrade License (for 4/32

SAN Switch and 4/32B SAN Switch only)

HP StorageWorks 16-Port Upgrade License (for 4/64

SAN Switch only)

HP Storage

License (for 4/64 SAN Switch only)

HP StorageWorks 4 Gb SW SnglePK SFP Transceiver

Long wavelength 4 Gb SFP, 10 km

Short wa

Long wavelength 2 Gb SFP, 10 km

Long wavelength 2 Gb SFP, 35 km

2 m LC-to-LC multi-mode FC cable

5 m LC-to-LC multi-mode FC cable

15 m LC-to-LC multi-mode FC cable

30 m LC

50 m LC-to-LC multi-mode FC cable

2 m LC-to-SC multi-mode FC cable

5 m LC-to-SC multi-mode FC cable

15mLC-to-SCmulti-modeFCcable

30 m LC-to-SC multi-mode FC cable

LC-to-SC multi-mode FC cable

50 m

*

Pre-merger Compaq part number

ks 4-Port Upgrade License (for 4/8

ly)

Works 64-Port Power Pack Upgrade

velength 2 Gb SFP

-to-LC multi-mode FC cable

Part number

T4260A

T3677A

T4411A

T4412A

A7446B

AE493A

A6515A

A6516A

300836–B21

221692–B21

221692–B22

221692–B23

2–B26

22169

221692–B27

221691–B21

221691–B21

221691–B23

221691–B26

691–B27

221

*

*

*

*

*

*

*

*

*

*

*

SAN Switch installation guide

33

Page 34

NOTE:

To obtain the latest i nformation on hardware and software components, go to the B-Series section of the following web page:

ttp://www.hp.com/go/san.

h

34

Overview

Page 35

2 Installing an d configuring

SAN Switches

This chapter describes the following topics:

•

Shipping carton contents, page 35

•

Installation and safety considerations, page 38

•

Installing the switch as a stand-alone device, page 40

• Installing the switch using the SAN Switch Rack Mount Kit, page 41

•

Cabling and configuring the SAN Switch, page 52

•

Connecting the SAN Switch to the fabric, page 53

Shipping carton contents

Figure 9 and Table 3 identify shipping carton contents for a typical SAN Switch.

1

3

IOIOI

!

k

c

.

ra

:

in

or

h f

/64

t

ION

eng

r 13

l

o

ENT

w

m

cre

m

ATT

m s

be 5

imu

ax

M

nting to

u

mo

2

MRO25011b

Figure 9 SAN Switch shippin g carton contents

SAN Switch installation guide

35

Page 36

Table 3 identifies the carton contents included with your SAN Switch.

Table 3 SAN Switch shipping carton checklist

Number

1

2

3

Description

One SAN Switch Acc

• One 3.0 m (10 ft) RS

removing the ada

• Plenum (not show

the switch to draw cooler air into the switch from outside the rack, rather than

drawing in heated air from within the rack. SAN Switches that require a

plenum include:

—SANSwitch2/16V

— SAN Switch 2/16

—4/8SANSwitch

—4/16SANSwitch

—4/32BSANSwitch

• SAN Switch Rack Mount Kit hardware contained in plastic pouches:

• 14 #8-32 x 3/16-inch Phillips pan-head screws with thread lock for the

SAN Switch 2/32 (requires twelve screws, six per rail)

• 14 #8-32 x 5/16-inch pan-head SEMS screws for use with the 4/8,

4/16, 4/32, 4/32B and 4/64 SAN Switches (All require ten screws

except for the 4/32B SAN Switch which requires six screws)

• Ten #10-32 x 1/2-inch Phillips pan-head screws with captive star

lock-washers

• Eight #10 alignment washers

• Eight #10 adapter washers

• Two 1/4-20 hex nuts with captive star lock-washers

• Two 1/4-inch flat washers

• Four rubber feet for mounting on a flat surface (a lab bench, for example)

• EZSwitchSetup CD

• One set of HP StorageWorks product documentation including Safety Guides,

User License, Read Me First, and Warranty

• For the 4/8 and 4/16 SAN Switches, one country-specific AC power cord

and one PDU power cord (not shown); for the 4/32, 4/32B and 4/64 SAN

Switches, two country-specific AC power cords and two PDU power cords

(not shown)

SAN Switch Rack Mount Kit rail assemblies:

• Two rear mounting brackets

• A right inner rail and a right outer rail

• A left inner rail and a left outer rail

One of the following:

• One HP StorageWorks 4/8 SAN Switch

essories Box containing:

-232 serial cable; convertible to an RJ-45 connector by

pter on the end of the cable

n) — An air duct that attaches to the switch rails, enabling

36

Installing and configuring SAN Switches

Page 37

Number

Description

• One HP StorageWork

• One HP StorageWor

• One HP StorageWo

• One HP StorageWo

s4/16SANSwitch

ks 4/32 SAN Switch

rks 4/32B SAN Switch

rks 4/64 SAN Switch

SAN Switch installation guide

37

Page 38

Installation and safety considerations

Install the switch using one of the following methods:

• As a stand-alone unit on a flat surface. See Installing the switch as a stand-alone

device on pag

• HP highly recommends mounting the switch in one of the following HP customized

racks:

•HPSystem/e

• HP 10000 G2 Series Rack, HP 9000 Series Rack and HP 10000 Series Rack

See Installing the switch using the SAN Switch Rack Mount Kit on page 41 for detailed

instructio

ns.

Electrical considerations

For successful installation and operation of the switch, ensure that the following electrical

requirements are met. For power supply information, see SAN Switch technical

specifications on page 131.

• PrimaryACinput100–240VAC,2.0A,47–63Hz(switchautosensesinput

voltage)

• A correctly wired primary outlet, with a circuit protected by a circuit breaker and

grounded in accordance with local electrical codes

• Adequate supply circuit, line fusing, and wire size, as specified by the electrical

rating on the switch nam e plate

e40.

Rack

Environmental considerations

Before

• To ensu re adequate cooling, install the switch with the nonport side (which

• Verify that a minimum of 24 cubic ft/minute of airflow is available to the air

• Verify that the ambient air temperature does not exceed 40 ºC (104 ºF) while

38

installing the switch:

contains the air intake vents) facing the cool-air aisle.

ke vents on the nonport side of the switch.

inta

the switch is o perating.

Installing and configuring SAN Switches

Page 39

IMPORTANT:

The40ºCvalueappliestotheambientairtemperatureattheairintakeventsonthe

nonport side of the switch. The temperature inside the switch can be up to 80 ºC (176

ºF) during switch operation. If the internal temperature range exceeds the operating

ranges of the components, the LEDs, error messages, and Fabric Watch alerts indicate

a problem. Enter the tempshow or Fabric Watch command to view temperature

status.

NOTE:

For a complete list of environmental considerations, see Table 25 on page 136.

Rack specifications

If you are installing the switch in a rack:

• Plan a rack space that is one rack unit (4.45 cm or 1.75 in) high, 48.3 cm (19

in) wide, and at least 76.2 cm (30 in) deep.

• Verify that the rack is mechanically secured to ensure stability in the event of an

earthquake or other natural disaster.

• Ground all equipment in the rack through a reliable branch circuit connection;

maintainthegroundatalltimes. Donotrelyonasecondaryconnectiontoa

branch circuit, such as a power strip.

• Ensure that airflow and temperature requirements are met on an ongoing basis,

especially if the switch is installed in a closed or multi-rack assembly .

• Verify that the additional weight of the switch does not exceed the rack’s weight

limits or unbalance the rack in any way.

Cooling co

Cooling ai

chassis.

recomme

the rack

Follow

• Install the switch with the nonport side (which contains the air intake vents) facing

• Ensure

• Ensure that a minimum of 24 cu ft/min of airflow is available to the air intake

nsiderations

r is drawn into the switch chassis by the fans mounted on the rear of the

The air is expelled through vents in the front (port side) of the chassis. HP

nds installing the switch so that air intake and exhaust for all comp onents in

are flowing in the same front-to-back direction.

these guidelines to ensure proper airflow and to prevent component overheating:

the cool-air aisle.

that all equipment in the rack forces air in the same direction to avoid

taking in exhaust air.

on the nonport side of the switch.

vents

SAN Switch installation guide

39

Page 40

• Ensure that the ambient air temperature does not exceed 40 ºC (104 ºF) while

the switch is o perating.

NOTE:

Do not block air vents. The switch uses ambient air for cooling.

Installing the switch as a stand-alone device

To install the switch as a stand-alone unit:

1. Unpack the switch and verify tha t all items listed in Shipping carton

contents on page 35 are present.

2. Locate the four rubber feet in the accessory box.

3. Apply the adhesive rubber feet to the switch. The rubber feet help prevent the switch

from sliding off the supporting surface:

a. Clean the indentations at each corner of the bottom of the switch to ensure that

they are free of dust or other debris that might lessen the adhesion of the feet.

b. Withtheadhesivesideagainstthechassis,placeonerubberfootineach

indentation and press into place.

4. Place the switch on a flat, sturdy surface.

5.

Apply power to the switch as described in Powering on and off on page 66.

40

CAUTION:

Do not connect the switch to the network until the IP address is set. For instructions on

setting the IP address, see Cabling and configuring the SAN Switch on page 52.

Installing and configuring SAN Switches

Page 41

Installing the switch using the SAN Switch Rack

Mount Kit

This section provides instructions for installing the SAN Switch in the following HP

custom racks:

• HP System/e Rack

• HP 10000 G2 Series rack, HP 9000 and HP 10000 Series racks

For optimal c

Mount Kit to

rack. In this installation, the port side of the switch is set 12.7 cm (5 in) back from the

edge of the rack, allowing a more gradual bend in the fiber optic cables.

NOTE:

The SAN Swi

Obtain the following items:

• SAN Switch

• Power cables

• #2 Phillips screwdriver

• 7/16-inch wrench or socket

• Plenum (if required, see Table 3) to determine if you need to install a plenum

prior to rack mounting your switch).

• SAN Switch Rack Mount Kit hardware, shown in Table 4 on page 42, which

identifies rails and rail mounting hardware

able management, HP recommends that you install the SAN Switch Rack

allowthenonportsideoftheswitchtoslideoutofthecool-airsideofthe

tch Rack Mount Kit installation requires one technician.

SAN Switch installation guide

41

Page 42

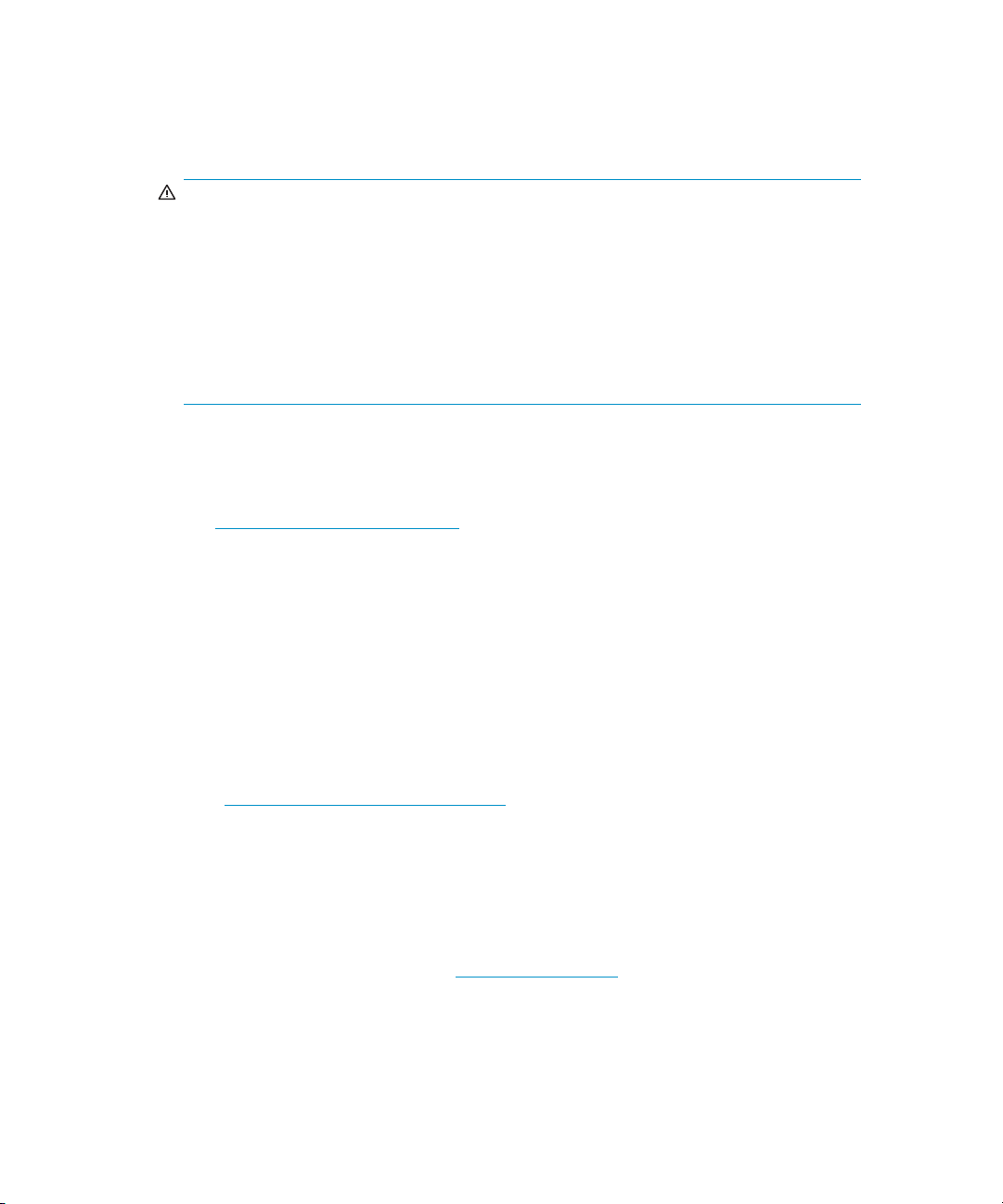

Table 4 SAN Switch Rack Mount Kit hardware

Item

Description

Two rear mounting

A right inner rail and a right outer rail

A left inner rail and a left outer rail

14 #8-32 x 3/16-inch Phillips pan-head screws with

thread lock for use with the SAN Switch 2/32 only.

14 #8-32 x 5/ 16-inch Phillips pan-head SEMS screws

for use with the 4/8, 4/1 6, 4/32, 4/64 and 4/32B

SAN Switches (All require ten screws, except for the

4/32B SAN Switch which requires six screws)

Ten #10-32 x 1/2-inch Phillips pan-head screws with

captive star lock-washers

Eight #10 al

brackets

ignment washers

42

Eight #10 ad

Two 1/4-20 hex nuts with captive star lock-washers

Two 1/4-inch flat washers

Installing and configuring SAN Switches

apter washers

Page 43

CAUTION:

Forproperairflow,theSFPmediasideoftheSANSwitchmustfacetherearoftherack.

To install the switch in a rack:

1.

Verify that the required parts and hardware are available. See Table 3 on page 36.

2. Choose a mounting location for the switch in the rack.

3. Attach the rear mounting brackets to the rear rack uprights:

• For H P 10000 series racks, assemble each of the two brackets with two

#10-32 x 1/2-inch Phillips pan-head screws with captive star lock-washers

and two #10 adapter washers, as shown in Figure 10 on page 43.

• For an HP System/e Rack, install the two rear mounting brackets with

two #10-32 x 1/2-inch Phillips pan-head screws and two #10 alignment

washers, as shown in Figure 11 on page 43.

Figure 10 Installing the rear mounting brackets (HP 10000 seri es

racks)

Figure 11 Installing the rear mounting brackets (HP System/e Rack)

NOTE:

Your SAN Switch Rack Mount Kit contains both left rails and right rails.

SAN Switch installation guide

43

Page 44

4. Assemble the outer rails by completing option a or option b:

a. Attach the left outer rail and the right outer rail to the rear mounting brackets

using two 1/4-20 hex nuts with captive star lock-washers attached loosely,

as shown in Figure 12. Do not tighten the nuts until completing the steps in

Securing the switch to the outer rails, page 50.

Figure 12 In

stalling the outer rails (HP 10000 s eries racks)

44

Installing and configuring SAN Switches

Page 45

b. D e pending on the rack you a re using, complete one of the following tasks:

• For HP 10000 series racks, install two #10-32 x 1/2-inch Phillips

pan-head screws with captive star lock-washers and two #10 adapter

washers in the upper and lower hole locations of the right rail. Then

install two #10-32 x 1/2-inch Phillips pan-head screws with captive star

lock-washers and t wo #10 adapter washers in the upper and lower

hole locations of the l eft rail. See Figure 13.

Figure 13 Assembling t he oute r rails (HP 10000 series racks)

•ForanHPS

ystem/e Rack, install two #10-32 x 1/2-inch Phillips

pan-head screws with captive star lock-washers and two #10 alignment

washers in upper and lower hole locations of the right rail. Then, install

two #10-32 x 1/2-inch Phillips pan-head screws with captive star

lock-washers and two #10 alignment washers in the upper and lower

hole locations of the left rail. See Figure 14 on page 46.

SAN Switch installation guide

45

Page 46

Figure 14 Assembling the o uter rails (HP System/e Rack)

5. D epending on the device model, the SAN Switch Rack Mount Kit requires different

screw types for securing the inner rails. Use Table 5 to determine the number and

screw type for your specific switch.

CAUTION:

Do not use any screws other than those provided. Using longer screws

than those provided can cause damage to internal components.

Table 5 Number of screws required to assemble the inner rails

46

SAN Switch

2/32 N/A

4/8, 4/16

4/32

4/64

4/32B

Installing and configuring SAN Switches

#8-32 x 5/16-inch screws #8-32 x 3/16-inch screws

Ten (Five per rail)

Ten (Five per rail)

Ten (Five per rail)

Six (Three per rail)

12 (Six per rail)

N/A

N/A

N/A

N/A

Page 47

6. Identif y the screw holes to be used on the inner rails designed for the switch:

• To attach the inner rails to the SAN Switch 2/32 use the screw holes

marked 32.

• To attach the inner rails to the 4/8, /16 and 4/32B SAN Switches, use five

screw holes marked 8, and the plenum requires one screw hole m arked 8

and one screw hole marked 16,asshowninFigure 15 on page 48.

• To attach the inner rails to the 4/32 or 4/64 SAN Switch, use the screw

holes marked 16,asshowninFigure 16 on page 48.

7. Assemblethetwoinnerrailstothedeviceusingtheappropriatenumberofscrews

(see Table 5):

• For the 4/8 and 4/16 SAN Switches, secure each inner rail (one on each

side) to the switch using seven #8-32 x 5/16-inch Phillips p an-head SEMS

screws, as shown in Figure 15 on page 48.

• For the 4/32 SAN Switch, secure each inner rail (one on each side) to the

switch using five #8-32 x 5/16-inch Phillips pa n-head screws with thread

lock, as shown in Figure 16 on page 48.

• Forthe4/64SANSwitch,secureeachinnerrail(oneoneachside)to

the switch using five #8-32 x 5/16-inch Phillips pan-head SEMS screws,

as shown in Figure 16 on page 48.

• For the 4/32B SAN Switch, secure each inner rail (one on each side)

to the switch using six #8-32 x 5/16-inch Phillips pan-head screws with

thread lock.

NOTE:

For integration in a cabinet, tighten the #8-32 x 5/16-inch Phillips

pan-head SEMS screws and torque between 6 and 8 inch-pounds.

SAN Switch installation guide

47

Page 48

8. If you are installing the 4/8, 4/16 or 4/32B SAN Switch, verify that a plenum (an

air duct that attaches to the switch rails, enabling the switch to draw cooler air into

the switch from outside the rack, rather than drawing in heated air from within the

rack.) is preinstalled, as shown in Figure 15.

If not installed, see Installing the Plenum (if required), page 49 to install a plenum

on the 4/8, 4/16 or 4/32B SAN Switch.

If not installing one of the devices listed in step 8, go to Securing the switch to the

outer rails, page 50 to complete the rack mount procedure.

1

2

3

A

T

T

E

M

N

a

T

xi

I

m

m

O

o

u

N

u

m

n

s

:

tin

cre

g t

w

o

le

b

e

ng

5

th

m

fo

m

r ra

or

1

c

3/

k

6

4 in

.

IO

I

O

I

!

25052a

Figure 15 At

taching the inner rails to the 4/8 or 4/16 SAN Switch

1. Plenum 2. SAN Switch

3. Two screws for attaching the plenum

to the rails

!

IOIOI

LNK

SPD

MRO25018b

48

Figure 16 Attac h ing t he inner rails to t he 4/32 or 4/64 SAN Switch

Installing and configuring SAN Switches

Page 49

Installing the Plenum (if required)

If installing one of the following SAN switches only, you must install the plenum that

ships in the accessory kit with the rack mount hardware:

• 4/8 SAN Switch

• 4/16 SAN Switch

• 4/32B SAN Switch

To install th

1. Place the device (with inner rails attached) on a flat surface, see Figure 17.

2. Obtain the plenum and four 8-32 x .312 Phillips Pan-head SEMs screws from the

3. For each in

CAUTION:

Verify that the open end of the plenum faces the rear of the switch. For example, when

installe

panel of the switch on the other.

eplenum:

accessory kit.

ner rail (Left and Right)useonescrewholemarked8 and one screw

hole marked 16 to attach the plenum.

d properly you should see the plenum’s air vent holes on one side, and the front

SAN Switch installation guide

49

Page 50

NOTE:

Figure 17 illustrates how to attach the plenum to the 4/8 or 4/16 SAN Switch

specifically. If installing the plenum on the 4/32B SAN Switch, the procedure and

figure also applies.

1

2

3

A

T

T

E

M

N

a

T

x

im

I

m

O

o

u

N

u

m

nt

s

:

in

cr

g

e

t

w

o

le

be

ng

5

th

m

fo

m

o

r

r

r

a

1

c

3

k

/

6

4 in

.

I

O

I

O

I

Figure 17 At taching the Plenum to the 4/8 or 4/16 SAN Switch

1. Plenum 2. SAN Switch

3.Twoscrewsforattachingplenumtorails

Securing the switch to the outer rails

To secure the switch to the outer rails:

1. Insert the switch with the attached inner rails into the outer rails.

NOTE:

This step applies to installing a switch in HP 9000 Series, HP 10000

Series or HP System/e racks.

2. Insert the device into the rack and install (2) #10-32 x 1/2-inch Phillips pan-head

screws with captive star lock washers with one on each side. See Figure 18 and

Figure 19.

!

25052a

50

Installing and configuring SAN Switches

Page 51

Figure 18 Securing the switch (in HP 9000 Series or HP 10000 S eries

Racks)

Figure 19 Securing the switch ( in an HP System/e rack)

3. Tighten the hex nuts installed earlier. See step 4a, page 44.

NOTE:

To uninstall a switch, remove the middle #10-32 x 1/2-inch Phillips pan-head screw

with captive star lock-washer from either side of the rack uprights.

This completes the rack mount procedure.

SAN Switch installation guide

51

Page 52

Cabling and configuring the SAN Switch

The SAN Switch must be configured to ensure correct o peration with a network and

fabric. For instructions on configuring the switch to operate in a fabric containing

switches from other vendors, see the Fabric OS administrator’s guide.

For more information about the commands used in this procedure, see the Fabric OS

command referenc

NOTE:

All supp orting Fabric OS documentation is accessible from the B-Series switches link

on the following web site: h

Recommendations for cable management

Before installing the switch, plan the rack space required for cable management based

on the following HP recommendations:

• Leave enough space to allow for the fact that the minimum bend radius for a

50-micron cable is 2 inches under full tensile load and 1.2 inches with no

tensile load.

• Leave at least 1 m (3.28 ft) of slack for each port cable. This provides room to

remove and replace the switch, allows for inadvertent movement of the rack, and

helps prevent the cables from being bent to less than the minimum bend radius.

• If you are using ISL Trunking, consider grouping cables by trunking groups. The

cables used in trunking groups must meet specific requirements, as described in

the Fabric OS administrator’s guide.

• For easier maintenance, label the fiber optic cables and record the devices

to which they are connected.

• Keep LEDs visible by routing port cables and other cables away from the LEDs.

• Do not use tie wraps on fiber optic cables; tie wraps are easily overtightened

and can damage the optic fibers. HP recommends using velcro straps to secure

and organize fiber optic cables.

emanualfor the Fabric OS version running on your switch.

ttp://www.hp.com/go/san.

52

Installing and configuring SAN Switches

Page 53

Connecting the SAN Switch to the fabric

Connecting the SAN Switch to the fabric involves the following steps:

1.

Obtain requir

2.

Make a serial connection on page 53

3.

Apply power to the switch and log in on page 56

4. Set the IP address on page 57

5.

Create an Ethernet connection on page 58

6.

Modify the

7.

Install the SFP transceivers on page 59

8.

Connect the cables on pa ge 60

9.

Verify t

10.

Back up the configuration on page 60

11.

Set the switch date and time on page 61

12.

13.

ronize the local time with an external source on page 61

Synch

Set the time zone on page 62

Obtain required items

ed items on page 53

FC domain ID (optional) on page 58

he configuration on page 60

To configure the SAN Switch for use in a network, ensure that you have the following:

• SAN Switch installed and connected to a power source

• Workstation with an installed terminal emulator, such as HyperTerminal

• Access to an FTP server to back up the switch configuration

• Unused IP address and corresponding subnet mask and gateway address

• Serial cable (supplied with switch)

• Ethernet cable

• SFP transceivers and compatible cables, as required

Make a serial connection

o make a serial connection through the SAN Switch serial port:

T

1. Insert the serial cable into the serial port on the switch.

2. Connect the serial cable to an RS-232 serial port on the workstation, as shown

in Figure 20.

SAN Switch installation guide

53

Page 54

NOTE:

IftheserialportontheworkstationusesanRJ-45connectorinsteadof

an RS-232 connector, remove the adapter on the end of the serial cable

and insert the exposed RJ-45 connector into the RJ-45 serial port on

the workstation.

IO

I

O

!

I

.

:

rack

in

N

for

th

IO

T

r 13/64

N

TTE

screw leng

A

m

u

be 5mm o

im

ng to

Max

nti

mou

0014b

Figure 20 Connecting t he serial cabl e

54

Installing and configuring SAN Switches

Page 55

NOTE:

Figure 20 shows the 4/ 16 SAN Switch; however, this procedure is similar

for all SAN Switches.

3. Close any serial communication programs running on the workstation.

4. Open a terminal emulator application (such as HyperTerminal on a PC or TERM in

a UNIX environment) and configure the application as follows:

• In a Windows 95, 98, 2000, or NT environment:

•9600bitspersecond

• 8 data bits

• No parity

•1stopbit

• No flow control

• In a UNIX environment, enter the following at the prompt:

tip/dev/ttyb –9600

SAN Switch installation guide

55

Page 56

Apply power to t

Once a serial connection is established, apply power to the switch:

1. Connect the power cord to a power inlet on the switch and a power source, as

shown in Figur

NOTE:

The 4/32, 4/32

The 4/8 and 4/16 SAN Switches use one power cord.

Figure 21 Connecting the power cord

he switch and log in

e21.

B and 4/64 SAN Switch models use two power cords.

IO

I

O

!

I

ck

:

ra

in.

N

for

/64

IO

T

ength

or 13

EN

m

TT

5m

A

m screw l

be

imu

to

ax

M

nting

mou

0015b

56

NOTE:

To protect against AC failure on the 4/32, 4/32B and 4/64 SAN Switch

models, connect each power cord to outlets on separate circuits. Verify

that the cords have a minimum service loop of 6-inches to avoid stress.

2. To power on, set the two AC switches to the ON position (I).

IMPORTANT:

The 4/8 and 4/16 SAN Switches utilize one power switch. The 4/32,

4/32B and 4/64 SAN Switches utilize two power switches.

The power supply LED lights green and the switch runs the power-on self test (POST).

The switch requires at least three minutes to boot and complete POST.

3. After POST and the boot process are completed, verify that the System Status and

System Power LEDs light green.

Installing and configuring SAN Switches

Page 57

4. When the terminal emulator application, which uses a serial connection, stops

reporting information, press Enter to display the login prompt.

5. Log in using the administrative account; the logon is admin and the default

password is password. Create up to two simultaneous admin sessions and four

user sessions.

For more details, see the Fabric OS administrator’s guide and the Fabric OS

command reference manual for the Fabric OS running on your switch.

Set the IP address

By default, the

information w

1. Enter ipaddrset at the terminal emulator application prompt.

2. Enter the IP addressing information, as prompted.

3. O ptional: Verify that the address is correct by issuing the ipaddrshow command

at the promp

4. Record the IP address on the label located on the port side of the chassis.

For the 4/32, 4/32B and 4/64 SAN Switches, record the IP address on the

pull-out t

locate the pu ll-out tabs.

5. If the serial port is no longer required, log out of the serial console, remove the serial

cable, and replace the safety plug in the serial port.

IP address is set to 10.77.77.77. To replace the default IP addressing

ith the information provided by your network administrator:

t.

ab on the port side of the switch. See Figure 2, Figure 7 or Figure 4)to

SAN Switch installation guide

57

Page 58

Create an Ether

To create an Ethernet connection:

1. Connect an Ethernet cable to the Ethernet port and to the workstation, or to an

Ethernet netw

NOTE:

Figure 22 show

for all SAN Sw

Figure 22 C o nnecting the Ethernet cable