Page 1

8265 Nways ATM Switch IBM

Installation Guide

SA33-0441-02

Page 2

Page 3

8265 Nways ATM Switch IBM

Installation Guide

SA33-0441-02

Page 4

Note|

Before using this information and the product it supports, be sure to read the general information under Appendix C, “Notices”

on page 69.

Third Edition (September 1998)

The information contained in this manual is subject to change from time to time. Any such changes will be reported in subsequent

revisions.

Order publications through your IBM representative or the IBM branch office serving your locality. Publications are not stocked at the

address given below.

A form for readers' comments appears at the back of this publication. If the form has been removed, address your comments to:

IBM France

Centre d'Etudes et Recherches

Service 0798 - BP 79

06610 La Gaude

France

FAX: 33 4 93 24 77 97

IBM Internal Use: LGERCF at IBMFR

Internet: lgercf@fr.ibm.com

When you send information to IBM, you grant IBM a non-exclusive right to use or distribute the information in any way it believes

appropriate without incurring any obligation to you.

Copyright International Business Machines Corporation 1994, 1998. All rights reserved.

Note to U.S. Government Users — Documentation related to restricted rights — Use, duplication or disclosure is subject to

restrictions set forth in GSA ADP Schedule Contract with IBM Corp.

Page 5

Contents

Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

General Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Safety Notice for United Kingdom ........................................ ix

About this Book .................................................. xi

Who Should Use this Book ............................................ xi

How to Use This Book ............................................... xi

Prerequisite Knowledge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Where to Find More Information ......................................... xi

Chapter 1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Before You Begin .................................................. 1

Installation Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Chapter 2. Unpacking the 8265 ........................................ 3

8265 Shipping Group Contents .......................................... 3

Removing the Switch From the Shipping Box ................................. 4

Unpacking the 8265 Switch .......................................... 4

Additional Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Unpacking Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter 3. Installing the Chassis ....................................... 7

Installing the Cable Management Tray in a Rack ............................... 8

Pre-installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installing the Tray ................................................ 10

Installing the 8265 in a Rack ........................................... 11

Pre-installation Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Pre-installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installing the Switch in a Telco Rack ..................................... 15

Installing the Switch in a Metric Rack .................................... 16

Installing the Switch on a Table or Shelf .................................... 17

Chapter 4. Installing Power Supplies .................................... 19

Installing an AC Power Supply .......................................... 20

Installing a DC Power Supply ........................................... 21

Before You Begin ................................................ 21

Preparing and Installing the DC Input Power Cords ............................ 23

Installing the DC Power Supply Unit ..................................... 25

Installing the Power Supply Bay Grille ...................................... 26

Chapter 5. Installing Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Before You Start .................................................. 27

Unpacking Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Installing the Control Point and Switch Module ................................. 29

Before You Begin ................................................ 29

Installing the PCMCIA Card .......................................... 30

Installing the Memory Upgrade ........................................ 31

Installing the Module .............................................. 32

Copyright IBM Corp. 1994, 1998 iii

Page 6

Installing the Controller Module .......................................... 33

Considerations When Installing Two Controller Modules .......................... 33

Installing the Module .............................................. 33

Guidelines for Installing 8265 Media Modules ................................. 35

Cautionary Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Guidelines for Installing 8260 ATM Media Modules ............................ 37

Chapter 6. Attaching a Configuration Console ............................... 39

Configuring the Modem .............................................. 40

Example Parameter Settings ........................................... 41

ASCII Terminal Cabling .............................................. 43

VT100 Emulation on PS/2 ............................................. 44

Chapter 7. Completing the Installation ................................... 45

Checking Your Installation ............................................. 45

Powering on the 8265 ............................................... 46

DC Power Source ................................................ 46

AC Power Source ................................................ 46

Verifying Your Installation ............................................. 47

Verifying Power Supply Operation ...................................... 48

Verifying Fan Operation ............................................ 49

Verifying Controller Module Operation .................................... 50

Verifying Control Point and Switch Module Installation ........................... 51

Verifying Configuration Console Installation ................................. 53

Appendix A. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Troubleshooting Fault Conditions ........................................ 55

Specific CPSW2 Module Problems ...................................... 57

Problems After Power-On .......................................... 57

Problems When Hot-Plugging ....................................... 58

Appendix B. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Replacing a Defective Power Supply ...................................... 61

Replacing an AC Power Supply ........................................ 62

Replacing a -48 Volt DC Power Supply ................................... 64

Replacing a -48 Volt DC Power Supply Cable ............................... 65

Replacing a Defective Fan Unit .......................................... 66

Replacing a Defective Controller Module .................................... 68

Appendix C. Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Product Page/Warranties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Statement of Limited Warranty .......................................... 70

Production Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

The IBM Warranty ................................................ 70

Warranty Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Extent of Warranty ............................................... 71

Limitation of Liability .............................................. 72

Warranty and Maintenance Service ...................................... 73

Industry Standards Reflected in This Product ................................. 75

European Union (EU) Statement ......................................... 76

Year 2000 Statement ............................................... 76

Electronic Emission Notices ............................................ 77

iv IBM 8265: Installation Guide

Page 7

Radio Frequency Interference (RFI) Compliance ................................ 79

NEBS Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Trademarks and Service Marks ......................................... 82

Bibliography . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

8265 Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

ATM Forum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Contents v

Page 8

vi IBM 8265: Installation Guide

Page 9

Figures

1. Unpacking the Switch Shipping Box .................................... 4

2. Cable Management Tray Rack Mount Positions ............................. 9

3. Installing a Clip Nut in the Rack ...................................... 10

4. Installing the Cable Management Tray in a Rack ............................ 10

5. Telco and Metric Rack Screw Locations ................................. 13

6. Attaching a Rubber Foot to the 8265 Switch ............................... 17

7. 8265 Power Supply Locations ....................................... 19

8. Installing an AC Power Supply ....................................... 20

9. -48 Volt DC Power Supply ......................................... 22

10. -48 Volt DC Input Power Cord ....................................... 23

11. Connecting the Red/Black Wires ..................................... 24

12. Connecting the Cable Ground Wire .................................... 24

13. -48 Volt DC Power Supply Keyed-Connector .............................. 25

14. Installing the Power Supply Bay Grille .................................. 26

15. 8265 Control Point and Switch Module .................................. 29

16. Installing a Controller Module ....................................... 34

17. Modem Cable Attachment (Part Number 59G0278) ........................... 41

18. ASCII Terminal Cabling ........................................... 43

19. PC or PS/2 Cabling ............................................. 44

20. 8265 Controller Module LEDs ....................................... 50

21. 8265 CPSW2 Module LEDs ........................................ 52

22. Replacing a Defective Power Supply ................................... 62

23. Replacing a Defective Fan Unit ...................................... 66

Copyright IBM Corp. 1994, 1998 vii

Page 10

viii IBM 8265: Installation Guide

Page 11

Safety Information

General Safety

The IBM 8265 Nways ATM Switch complies with the following industry safety standards or their updated

versions:

Safety of Information Technology Equipment:

Number Date Description

IEC 950 1991 International Standard

C22.2 No. 950 1989 (Canadian Standard)

UL 1950 1991 (U.S.A. Standard)

EN 60 950 1992 (European CENELEC Standard)

AS/NZS 3260 1993 (New Zealand Standard)

Safety of Laser Products:

Number Date Description

IEC 825-1 1993 Equipment Classification, Requirements, and User's

Guide

IEC 825-2 1993 Safety of Optical Fiber Communications Systems

EN 60825-1 1993 (European CENELEC IEC 825-1 Standard)

EN 60825-2 1993 (European CENELEC IEC 825-2 Standard)

Safety Notice for United Kingdom

The network adapter interfaces housed within the IBM 8265 Nways ATM Switches are approved

separately, each one having its own independent approval number. These interface adapters, supplied by

IBM, do not use or contain excessive voltages. An excessive voltage is one that exceeds 42.4 V peak ac

or 60 Vdc. They interface with the IBM 8265 Nways ATM Switch using Safety Extra Low Voltages (SELV)

only. In order to maintain the separate (independent) approval of the IBM adapters, it is essential that

other optional cards, not supplied by IBM, do not use mains voltages or any other excessive voltages.

Seek advice from a competent engineer before installing other adapters not supplied by IBM.

Copyright IBM Corp. 1994, 1998 ix

Page 12

x IBM 8265: Installation Guide

Page 13

About this Book

This book gives a description of the activities required to unpack, prepare, and install the IBM 8265

Nways ATM Switch and accessories.

Who Should Use this Book

This book is intended for the following people at your site:

Hardware installer.

How to Use This Book

This book is divided into the following chapters and appendixes. It essentially covers all the activities

necessary to install your 8265.

Chapter 1 provides a summary of the installation steps required to install the 8265.

Chapter 2 describes the basic and optional components, and how to unpack them.

Chapter 3 describes how to install the 8265 chassis in a rack or on a table or shelf.

Chapter 4 describes how to install the power supplies (AC or DC).

Chapter 5 details how to install the Control Point and Switch, Controller, and media modules.

Chapter 6 explains how to attach a configuration console to the 8265.

Chapter 7 describes how to complete the installation of the 8265, by checking that the required

components are installed, powering on the 8265, and verifying that the installed components

are working properly.

Appendix A provides troubleshooting information.

Appendix B details maintenance and service procedures.

Appendix C contains various notices related to this product.

Prerequisite Knowledge

This book assumes that you are familiar with the IBM 8265 Nways ATM Switch, as described in the

8265 Nways ATM Switch Product Description

, GA33–0449.

Where to Find More Information

IBM

Refer to the “Bibliography” on page 83 for a list of IBM manuals that contain related information and

publications for the 8265 switch.

World Wide Web ;You can access the latest news and information about IBM network products, customer

service and support, and microcode upgrades via the Internet, at the URL:

http://www.networking.ibm.com

Copyright IBM Corp. 1994, 1998 xi

Page 14

xii IBM 8265: Installation Guide

Page 15

Chapter 1. Introduction

This chapter describes the steps required to install your IBM 8265 Nways ATM Switch.

These steps are explained in detail in later chapters of this book.

Before You Begin

The 8265 ATM Switch is designed for easy access, maintenance, installation, and upgrade by service

personnel. When installing the switch, be sure to comply with the environmental and power guidelines

given in the

Ambient (room) Temperature: 10 to 40° Celsius (50 to 104° Fahrenheit)

Relative humidity: 8–85%, non-condensing

Power source (AC or DC) within 6 feet (approximately 2.7 meters)

Safety regulations stipulate that the table, shelf or rack on which the 8265 rests should be able to

support at least three times the weight of a fully loaded 8265. A fully loaded 8265 weighs

approximately 120 lbs., or 54 kg, so the table, shelf, or rack must be able to support 360 lbs. or 163

kg.

IBM 8265 Nways ATM Switch Planning and Site Preparation Guide

, SA33-0460. In particular:

That the surface on which the 8265 is to be installed is level.

Copyright IBM Corp. 1994, 1998 1

Page 16

Installation Summary

Table 1 describes the installation steps and the order in which you perform them.

Table 1. Installation Steps

Step Description See

1 Unpack the 8265 and components. page 3

2 Check that you have all the required components. pages 3 to 6

3 Install the cable management tray in the rack if you plan to install the

8265 in a rack (optional).

4 Install the 8265 chassis in a rack or on a table or shelf page 11 or 17

5 Install the power supplies (AC or DC). page 20 or 21

6 Install the power supply bay grille. page 26

7 Install the Control Point and Switch module(s). page 29

8 Install the Controller module(s). Optional when CPSW2 Control Point

and Switch modules used.

9 Determine the number, types, and slot locations of media modules

you plan to install in the 8265 before installing your first module.

10 Connect a configuration console to the Control Point and Switch

module.

11 Check that you have installed all the required components. page 45

12 Power on the 8265. page 46

13 Verify that all components are operating correctly. page 47

page 8

page 33

page 36

page 39

2 IBM 8265: Installation Guide

Page 17

Chapter 2. Unpacking the 8265

This chapter describes how to unpack the 8265 chassis and additional components.

8265 Shipping Group Contents

An 8265 ATM Switch is automatically shipped with the following components:

17-slot chassis, with the following components already installed:

– Backplane

– Three fan units

– Fourteen blank single-slot faceplates

– Two blank Control Point and Switch module slot faceplates

– Two blank Controller Module slot faceplates

– Two rack mount flanges

A power supply bay grille to manage power supply cords

Cables and connectors for connecting a configuration console:

– Adaptor DTE/DCE Cable DB9/DB25

– Interposer "Null modem"

– Gender Changer

8265 installation hardware (includes screws and clip nuts needed to assemble the 8265)

Rubber feet kit for table or shelf installations (consists of 4 rubber feet and 4 screws).

Copyright IBM Corp. 1994, 1998 3

Page 18

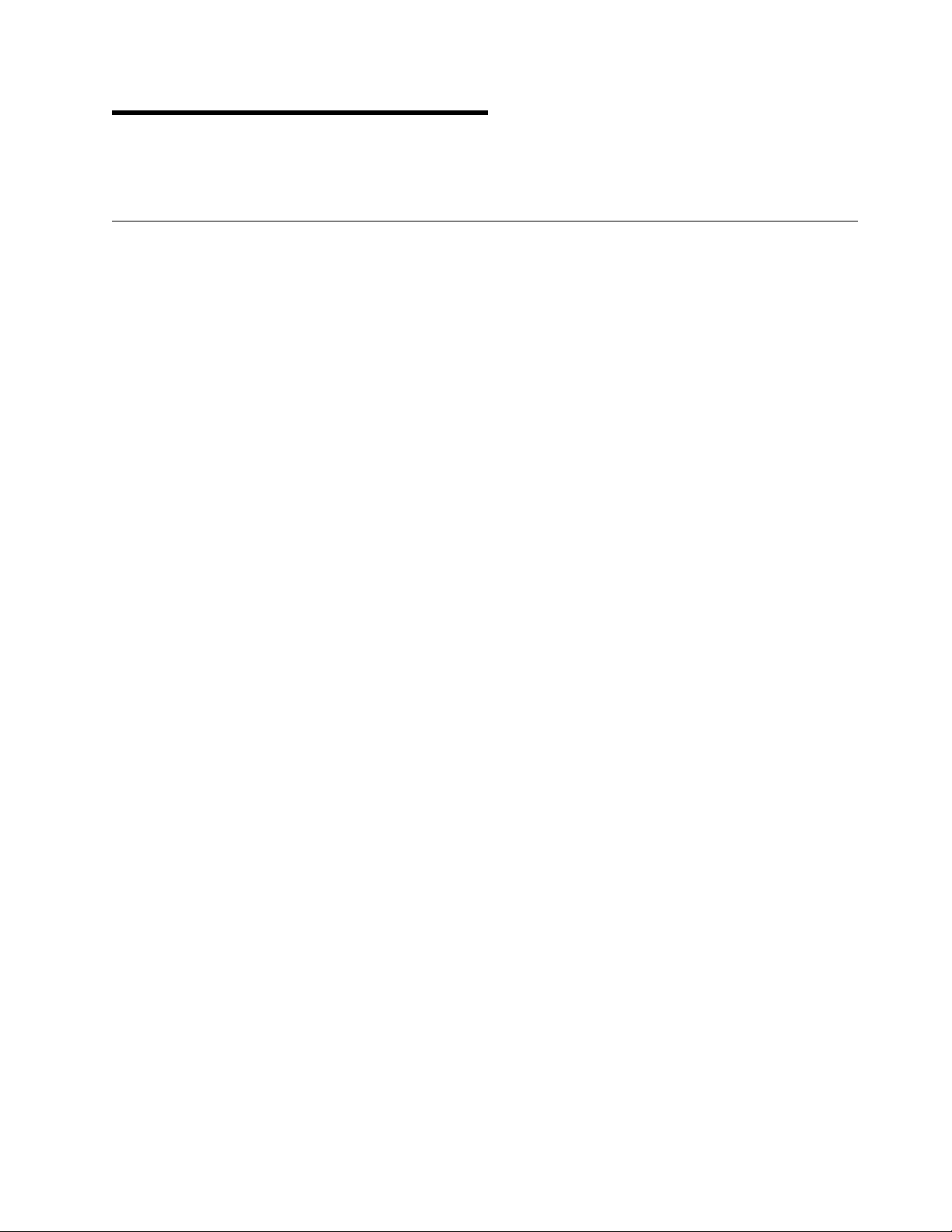

Removing the Switch From the Shipping Box

This section explains how to unpack your switch. Refer to the section earlier in this chapter for a list of

shipped items.

Note: All shipping boxes are reusable. After removing all contents, replace the packing materials and

store the shipping box for future use.

Unpacking the 8265 Switch

To remove a switch from the shipping box:

1. Place the switch shipping box on the floor or on a table.

CAUTION:

UL safety requirements stipulate that a table used to support the switch and shipping box prior

to table top switch installation should be capable of supporting approximately three times the

weight of the switch as shipped.

Switch weight as shipped averages about 49 lbs. (22 kg), so a table used to support the hub

must support 147 lbs. (66 kg).

2. Cut the tape that covers the seam on the top of the box and remove the foam packing material. To

remove the foam packing material, pull it straight up.

3. Squeeze and remove the locking inserts at the bottom of the box.

Foam packing

material

Corrugated

sleeve

To remove the locking

inserts, press the inner

latch mechanism together

to release them and then

pull them out.

Figure 1. Unpacking the Switch Shipping Box

4. Remove the corrugated sleeve by pulling it straight up.

5. Pull off the tape from the top of the bag that covers the switch.

6. Remove the bag by pulling it straight up.

7. Remove the power supply grille from the switch shipping box.

4 IBM 8265: Installation Guide

Page 19

8. Place the switch next to the rack or on the table on which it will be installed. Be sure to stand the

switch on its bottom (do not lay the switch down on its top or back).

9. Place all packing materials in the switch shipping box and store the box for future use.

Note: Do not remove blank faceplates from the switch until after the switch has been installed in its

desired location. If modules do not slide easily into the switch, it may be because the switch has

been lifted after some or all blank faceplates have been removed.

Chapter 2. Unpacking the 8265 5

Page 20

Additional Components

The following components are required to operate the 8265 (these components are ordered separately

from the 8265 chassis):

Power supplies (at least two are required), either:

– 415 W AC (Feature Code 8027), or

– 295 W DC –48 V (Feature Code 8026 or 8028)

You cannot mix AC and DC power supplies.

Control Point and Switch (CPSW) module(s), either:

– Feature Code 6501 (standard model), or

– Feature Code 6502 (enhanced model, also referred to as CPSW2), with integrated power control.

One Control Point and Switch module is required for normal operation. A second module made be

installed for redundancy purposes, provided both modules are of the same type.

Controller module(s) (Feature Code 8000)

Only required when the standard CPSW module (Feature Code 6501) is used. May be installed in

conjuction with CPSW2 module (Feature Code 6502) if you prefer power control to be handled by a

Controller module instead of the CPSW2 module.

One Controller module is required for normal operation. A second module made be installed for

redundancy purposes.

A PCMCIA card containing the Control Point and Switch microcode. This card must be inserted in the

Control Point and Switch module before the module is inserted in the 8265. The following cards are

available:

– Base microcode with UNI and IISP functions (Feature Code 6545)

– Enhanced microcode with UNI, IISP, and PNNI functions (Feature Code 6546)

Media modules (at least one is required).

Check that these components are available before commencing the installation of the 8265.

The following components are optional (and are ordered separately from the 8265 chassis):

Rack Mount Kit, Part Number 25H1834.

Cable Management Tray, Part Number 13J8751.

16 MB Memory upgrade (Feature Code 6516) for the standard Control Point and Switch modules

(Feature Code 6501).

Note: This memory upgrade is required when running the enhanced version of microcode.

Documentation CD-ROM (automatically included when PCMCIA card ordered), Feature Code 6508.

Unpacking Components

Unpack components only when you are ready to install them. Instructions and guidelines for unpacking

components are given in each section later in the book.

6 IBM 8265: Installation Guide

Page 21

Chapter 3. Installing the Chassis

This chapter describes step by step instructions to install the chassis in a rack, or on a table or shelf.

Note: The information and procedures in this chapter should be used only by service personnel

CAUTION:

To reduce the possibility of personal injury or serious damage to the switch, install the switch with

the help of a partner.

This is especially important for rack installations because you must hold the switch in place while

securing the switch to the rack.

Copyright IBM Corp. 1994, 1998 7

Page 22

Installing the Cable Management Tray in a Rack

The Cable Management Tray manages module cables at the front of the 8265 by feeding them under the

8265 and out the back. Use is optional. The Cable Management Tray kit includes:

Two rack-mount flanges (used to secure the tray to the rack)

Installation rack-mount hardware (screws and clip nuts)

Cable Management Tray.

This section describes:

Pre-installation guidelines

Installing the Cable Management Tray.

8 IBM 8265: Installation Guide

Page 23

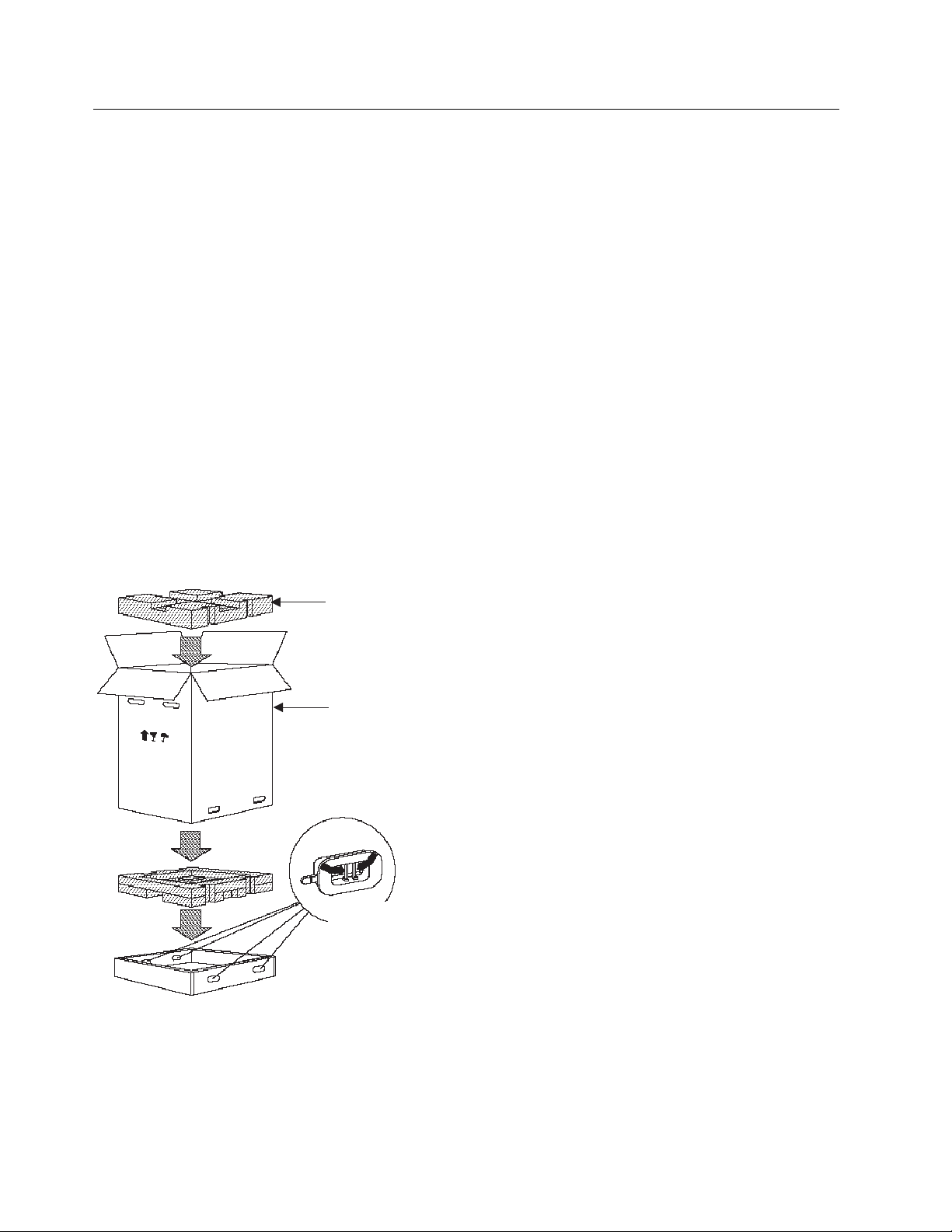

Pre-installation Guidelines

Before installing the cable management tray in a rack, determine which cable management tray rack

mount position is best for you by examining the following:

Location in the rack where the switch will be installed (refer to “Pre-installation Guidelines” on

page 13).

Depth of the rack in to which the switch will be installed.

Space required for ventilation. A minimum of 15 cm (6 in.) is required between the rear of the 8265

and the nearest wall or vertical surface.

Room required for module cables to bend.

Proximity of other devices in the rack and their installation or environmental requirements.

Figure 2 shows cable management tray rack mount positions.

Flush Mount

5/8" (1.6 cm) Recess

2 1/8" (5.4 cm) Recess

2 3/4" (7.0 cm) Recess

Figure 2. Cable Management Tray Rack Mount Positions

Table 2 provides cable management tray rack settings.

Table 2. Rack Mount Settings for Cable Management Tray

Setting Description

Flush mount Mounts the tray flush with the front of the rack.

5/8-inch (1.6 cm) recess Recesses the tray 5/8-inch (1.6 cm) from the front of the rack.

2 1/8-inch (5.4 cm) recess Recesses the tray 2 1/8-inch (5.4 cm) from the front of the rack.

2 3/4-inch (7.0 cm) recess Recesses the tray 2 3/4-inch (7.0 cm) from the front of the rack.

Select any rack position that is at least 28 inches (approximately 71 cm) from the top of the rack or the

next higher unit in the rack.

Be sure to select a rack position that leaves you enough room to install the cable management tray below

the installed switch.

Chapter 3. Installing the Chassis 9

Page 24

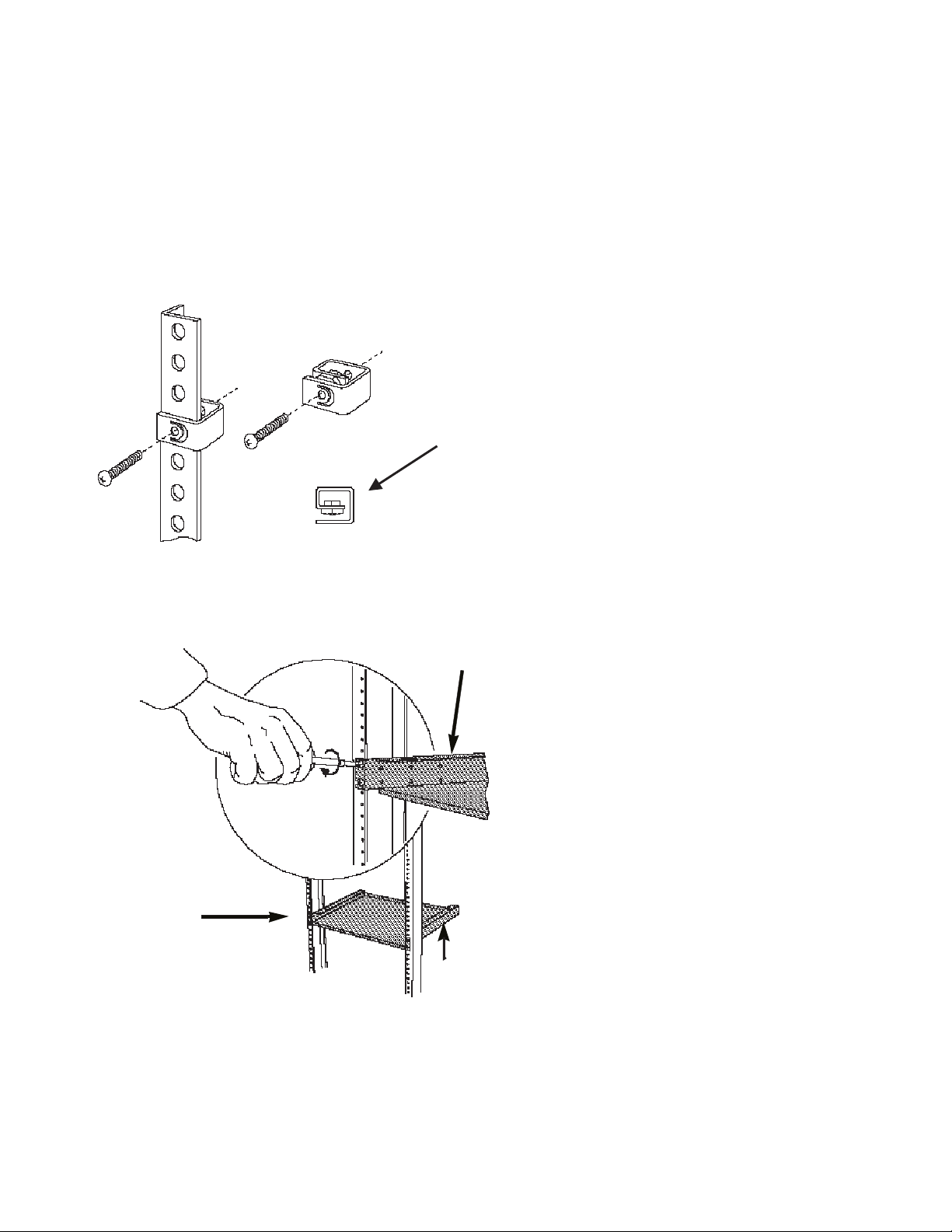

Installing the Tray

To install the Cable Management Tray in the selected rack:

1. Attach the two rack mount flanges (supplied) to the Cable Management Tray using the flathead screws

provided (eight, 8-32 x 1/4-inch screws, four per side). Install the screws using a Phillips- head

screwdriver. Installed Cable Management Tray rack mount flanges are shown in Figure 4.

2. Install the clip nuts provided (four) onto the front of the rack at the position where the Cable

Management Tray will be attached. Figure 3 shows the clip nut installation.

Be sure to thread the screw

through this nut to securely

attach each clip nut to the rack.

Figure 3. Installing a Clip Nut in the Rack

Figure 4 shows the Cable Management Tray in the rack.

Installed rack

mount flange

Installed cable

management

tray

Installed rack

mount flange

Figure 4. Installing the Cable Management Tray in a Rack

3. Place the Cable Management Tray in the rack and attach the tray to the front of the rack using the

screws provided (four, 10-32 x 1/2-inch screws). Install the screws with a Phillips head screwdriver.

10 IBM 8265: Installation Guide

Page 25

Installing the 8265 in a Rack

This section describes:

Pre-installation Precautions

Pre-installation Guidelines

Installing the Switch in a Telco Rack

Installing the Switch in a Metric Rack.

Use the following rack mount installation precautions guidelines to ensure safety and optimal performance.

These precautions and guidelines apply to all versions of the switch. Review all guidelines prior to

installation.

All rack mount illustrations provided in this chapter show the switch installed in a Telco rack.

Chapter 3. Installing the Chassis 11

Page 26

Pre-installation Precautions

Before installing the 8265 in an equipment rack, observe the following precautions:

Because the equipment rack environment can cause increased ambient temperatures and reduced air

flow, review the switch specifications and site requirements contained in

Planning and Site Preparation Guide

To ensure mechanical stability and to avoid circuit overloading and improper grounding, follow the rack

manufacturer's instructions for rack installation. If the instructions are unclear, consult a qualified

electrician.

For proper ventilation, install the switch in a rack that has an open back.

With a full complement of modules and load-sharing power supplies, the 8265 Switch weighs

approximately 120 lbs. (54 kg). Therefore, install your switch before you install modules and power

supplies.

, SA33-0460.

IBM 8265 Nways ATM Switch

12 IBM 8265: Installation Guide

Page 27

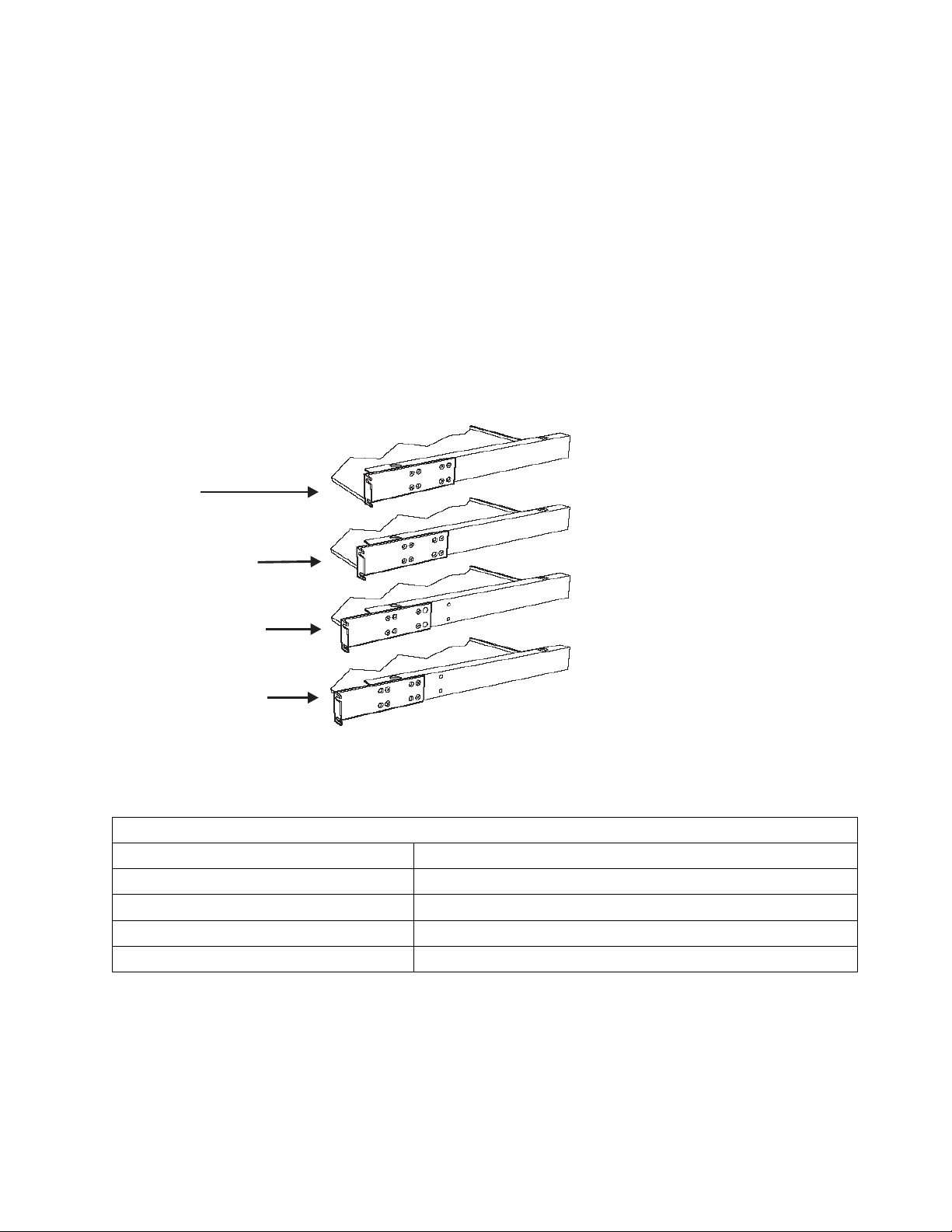

Pre-installation Guidelines

Before mounting the 8265 in a rack:

1. First make sure the selected rack can support at least three times the weight of a fully- loaded switch.

2. Bolt the rack to the floor.

3. Brace the top of the rack to the wall.

4. Ensure that there is sufficient vertical space in your rack for each 8265 you wish to install.

5. Install patch panels in the rack for easier cable management.

6. Rack mount flanges are set to flush mount at the factory. If desired, change the rack mount flange

position by removing the screws that attach each flange to the switch. When re-installing the rack

mount flanges on the switch, make sure both flanges are set to the same position before you re-install

the screws. Also, make certain that all removed screws are re-installed correctly.

7. When installing the switch, continue to support the weight of the switch until after you have installed

four of the eight screws (two screws per rack mount flange). Install the four remaining screws to fully

secure both rack mount flanges to the rack.

Telco rack and Metric rack screw locations are shown in Figure 5

Screw position (Telco rack)

Screw position (Metric rack)

Screw position (Telco rack)

Screw position (Metric rack)

Screw position (Metric rack)

Screw position (Telco rack)

Screw position (Metric rack)

Screw position (Telco rack)

Figure 5. Telco and Metric Rack Screw Locations

8. Install the Cable Management Tray beneath the switch. The tray is designed to manage the cables

attached to the front of the switch by feeding them under and through the back of the unit. Use of the

cable tray is optional. You can mount the cable tray onto the rack in one of four positions. Mount the

switch using the same rack mount position settings as those used to mount the cable tray.

Chapter 3. Installing the Chassis 13

Page 28

CAUTION:

You can install the switch in the rack either before or after you install the Cable Management

Tray, but the tray must be installed below the switch. Never allow an installed cable tray to

support the weight of the switch. The weight of a switch resting on a rack mounted cable tray

may cause the tray to buckle or separate from the rack. Personal injury may result.

14 IBM 8265: Installation Guide

Page 29

Installing the Switch in a Telco Rack

To install the switch in a Telco rack:

1. Install each of the 8 clip nuts provided onto each side of the front of the rack (4 clip nuts per rack

mount flange). Install each clip nut behind a hole into which you plan to install a trusshead screw.

(See Figure 5 on page 13.)

2. Slide the switch into the rack until both rack mount flanges are flush with the front of the rack.

CAUTION:

Continue to support the weight of the switch until after you have installed four of the eight

screws (2 screws per rack-mount flange).

If you attempt to place the weight of the rack-mounted 8265 switch on fewer than four fully

installed screws, the switch may drop off of the rack. Personal injury or serious damage to the

switch may result.

3. Match the uppermost open slot on each rack mount flange with the corresponding hole on the rack.

Hold the switch in place until you complete step 4. The remaining three open slots on each rack

mount flange automatically line up when each uppermost open slot is matched to a hole on the rack.

4. Secure the switch to the rack with the screws provided (eight, 10-32 x 1/2-inch screws):

a. Install one screw in the uppermost open slot on

b. Install an additional screw in each rack mount flange, and tighten all screws completely before you

allow the weight of the switch to rest (unaided) on the rack. A fully installed screw is flush with the

surface of each rack mount flange.

c. Install the remaining screws in open slots on each rack mount flange (for a total of four screws per

rack mount flange). Install each screw so it is (approximately) equidistant from the screw installed

directly above it and the screw installed directly below it. Tighten the screws completely.

each

of the rack mount flanges.

Chapter 3. Installing the Chassis 15

Page 30

Installing the Switch in a Metric Rack

Note: When installing the switch in a metric rack, install the screws in the

To install the switch in a Metric Rack:

1. Install each of the eight clip nuts provided onto the front of the rack (install four clip nuts per rack

mount flange). Install each clip nut behind a hole into which you plan to install a trusshead screw.

(See Figure 5 on page 13.)

2. Slide the switch into the rack until the switch is flush with the front of the rack.

CAUTION:

Continue to support the weight of the switch until after you have installed four of the eight

screws (2 screws per rack-mount flange).

If you attempt to place the weight of the rack-mounted 8265 switch on fewer than four fully

installed screws, the switch may drop off of the rack. Personal injury or serious damage to the

switch may result.

3. Match the uppermost closed slot on each rack mount flange to the uppermost hole on the rack where

you previously installed a clip nut. Do not attempt to install screws in open slots on either rack mount

flange. Hold the switch in place until you complete step 4

4. Secure the switch to the rack with the screws provided (eight, 10-32 x 1/2-inch screws).

a. Install one screw in the uppermost closed slot on each rack mount flange.

b. Install an additional screw in each rack mount flange, and tighten all screws completely before you

allow the weight of the switch to rest (unaided) on the rack. A fully installed screw is flush with the

surface of each rack mount flange.

closed

slots.

c. Install the remaining screws in closed slots on each rack mount flange (for a total of four screws

per rack mount flange). Install each screw so it is (approximately) equidistant from the screw

installed directly above it and the screw installed directly below it. Tighten all screws completely.

16 IBM 8265: Installation Guide

Page 31

Installing the Switch on a Table or Shelf

Though it is recommended that you install the 8265 switch in a rack, you can also install the switch on a

table or shelf.

CAUTION:

Do not use the Cable Management Tray when installing the switch on a table top or shelf.

If you choose to install the rubber feet, be advised that the switch could tip over under certain

conditions. Hardware damage or personal injury may result.

Safety regulations state that the selected table or shelf must be able to support at least three times

the weight of a fully loaded switch.

To install the 8265 switch on a table or shelf:

1. If you wish to install the rubber feet to the switch, lay the switch on its side on the table or shelf so the

bottom of the switch is accessible.

2. Optionally, remove the rubber feet (4) and the screws supplied (4) from the plastic bag in which they

were shipped and fasten the rubber feet to the bottom of the switch with the screws.

Figure 6 shows how to attach the rubber feet to the bottom of the switch.

Figure 6. Attaching a Rubber Foot to the 8265 Switch

3. Reposition the switch on the table or shelf so it rests squarely on the table or shelf. Ensure module

and power supply slots are unobstructed and easy to reach.

Chapter 3. Installing the Chassis 17

Page 32

18 IBM 8265: Installation Guide

Page 33

Chapter 4. Installing Power Supplies

This chapter describes how to install power supplies in an 8265.

For information on the power requirements for AC and DC power supplies, refer to the

ATM Switch Planning and Site Preparation Guide

, SA33-0460.

IBM 8265 Nways

Figure 7 shows the installation locations for the four power supplies, marked PS1, PS2, PS3, and PS4.

POWER

POWER

SUPPLY

SUPPLY

21

21

4

4

3

3

F

F

A

AN

N

1

1

2

2

3

3

ACT

A

S

STB

CT

T

B

Y

Y

T

T

E

E

M

M

P

P

L

L

E

ED

D

TE

T

E

ST

S

T

P

P

O

O

W

W

R

R

E

ER

E

E

R

S

S

ET

E

T

PS1 PS2 PS3 PS4

Figure 7. 8265 Power Supply Locations

Copyright IBM Corp. 1994, 1998 19

Page 34

Installing an AC Power Supply

You can install power supplies in any of the power supply slots. A factory label located directly below the

power supply slots identifies the slot number associated with each power supply.

To install a power supply:

1. Remove the blank faceplate covering each slot in which you will install a power supply. Keep this

blank faceplate for later use.

2. Set the ON/OFF (I/O ) switch on the front of the power supply you are installing to the OFF (O)

position before inserting the power supply into the switch.

3. Slide the power supply into the selected power supply slot. Push the power supply unit into the switch

until the front panel of the power supply is flush with the front of the switch. The rear power supply

connectors should now be firmly seated into the 8265 power supply connectors.

O

I

Figure 8. Installing an AC Power Supply

4. Fasten the power supply to the 8265 by tightening the two screws on the power supply faceplate.

Ensure that both screws are securely fastened (finger-tight).

5. Plug the power cord into the power supply unit socket.

6. Set the power supply's ON/OFF (I/O) switch to the ON (I) position.

7. Repeat steps 1 through 6 for subsequent power supplies.

20 IBM 8265: Installation Guide

Page 35

Installing a DC Power Supply

This section describes how to prepare and install the -48 Volt DC power supply and power cord in your

8265.

CAUTION:

Only trained electrical service personnel must make connections and disconnections to the -48

Volt DC power source.

A circuit breaker (short-circuit protection) must be set up in the main power source. This circuit

must be grounded to a safety ground. For each power supply use one 20-A protection device to

protect the cabling of the -48 Volt DC power supply against short-circuits.

To comply with UL requirements, the -48 Volt DC Power Supply must only be installed in a

rack-mounted 8265 installed in an enclosed cabinet.

The -48 Volt Power Supply switch only shuts off the output side of the power supply.

Before You Begin

This section describes what you should know before you begin installing the -48 Volt DC Power Supply in

your 8265:

1. Verify that the power source is compatible with the voltage and tolerances specified on the input rating

plate located on the power supply unit. The nominal value is -48 Volt DC, 11 Amps.

2. Remove the following items from the shipping box:

Power supply unit

Power input cable

Bags containing the terminal rings.

The -48 Volt DC power supply ships with 3 bags of terminal rings:

– Part Number AMP 320563, contains 1 terminal ring for only the green/yellow ground wire.

– Part Number AMP 31890, contains 4 terminal rings for the red and black wires.

– Part Number AMP 31880, contains 4 terminal rings for the red and black wires.

The -48 Volt DC power supply ships with different size terminal rings. One terminal ring is for only the

green/yellow ground wire. The remaining terminal rings are used with the red and black wires. Choose

the correct the terminal rings to support your installation.

The AMP part number for the terminal crimping tool is AMP # 58433-2 (this includes the correct

crimping die set). The AMP Die Set part number is 58423-1 (for people that already have the crimping

tool with other dies).

Chapter 4. Installing Power Supplies 21

Page 36

3. Set the power supply ON/STANDBY switch to the Standby position.

Figure 9 shows the front panel of the -48 Volt DC power supply with the ON/STANDBY switch.

Serial Number

Input Rating Label

Warnings Label

STANDBY Position

ON/STANDBY Switch

ON Position

Figure 9. -48 Volt DC Power Supply

Keyed-Connector

22 IBM 8265: Installation Guide

Page 37

Preparing and Installing the DC Input Power Cords

Note: The following terminal ring installation shows how you install terminal rings to the power cord. The

installer should adapt the building DC input and make the power cord connection using the

terminal rings shipped with the power supply or whatever method is necessary to meet system

installation requirements. For compatibility with the building power source, the installer chooses

which size terminals rings are to be crimped on the power cord wires.

To prepare and install the -48 Volt DC input power cords:

1. Obtain the power supply cables that you removed from the shipping boxes. The input power cables

have 3 groups of wires. Each wire is labeled with the corresponding voltage. The 2 red wires are

labeled 48VDC and the 2 black wires are labeled 0VDC.

Figure 10 shows the -48V DC input power cord.

Terminal Ring

2 Black Wires

(0 Volt Return)

Figure 10. -48 Volt DC Input Power Cord

2 Red Wires (-48 Volt DC)

1 Green/Yellow Ground Wire

Safety Label

Keyed-Connector

Note: To comply with UL requirements, the power cords must be routed through a rack or cabinet

raceway to the rack or cabinet distribution panel delivering the -48 Volt DC input power. The

cables may be routed to the back using the cable tray option of the 8265.

2. Fit the terminal rings to each wire of the power cords and tighten them with a crimping tool according

to the AMP rings size. Each wire has a terminal ring at the end.

3. Connect the cable ground wire (green/yellow) to the premises ground system.

CAUTION:

You must install the green/yellow ground wire before installing any of the red or black wires.

4. Take the 2 black wires and connect them to the positive (+) symbol on the power source (zero Volt

return).

Chapter 4. Installing Power Supplies 23

Page 38

5. Take the 2 red wires and connect them to the minus (-) symbol of the power source (-48 Volt).

Figure 11 shows how to connect the red and black wires.

For 0 Volt return

and -48 Volt

Red/Black Wire

Figure 11. Connecting the Red/Black Wires

Terminal Ring

Flat Washer

Screw

6. (Optional). Additional rack grounding can be achieved by connecting a ground cable from the 8265

chassis to the rack.

Figure 12 shows how to connect the additional ground cable, for standard and 'Bellcore' installations.

For Ground Terminal For Ground Terminal

Terminal Ring

Star Washer

Green/Yellow Ground Wire

Figure 12. Connecting the Cable Ground Wire

Screw

Star Washers

Green/Yellow Ground braid

"Bellcore" Installation"Standard" Installation

Tinned braid

or equivalent

Screws

Note: The power source should be labeled with minus (-) and positive (+) symbols.

24 IBM 8265: Installation Guide

Page 39

Installing the DC Power Supply Unit

To install the -48 Volt DC power supply unit:

1. Make certain that the ON/STANDBY switch on the unit is in the STANDBY (O) position.

2. After removing a blank faceplate that covers a power supply slot, carefully slide the power supply into

the selected slot of the 8265 chassis.

3. Fasten the power supply to the 8265 by tightening the two spring-loaded screws on the power supply

faceplate. Ensure that both screws are securely fastened (tighten the screws to 3 to 5 inch pounds).

4. Plug the keyed-connector into the power supply socket.

Figure 13 shows the power supply keyed-connector with strain relief.

Keyed-Connector

Strain Relief

Figure 13. -48 Volt DC Power Supply Keyed-Connector

5. Set the ON/STANDBY switch to the ON (I) position.

6. Repeat steps 1 through 5 for each subsequent power supply.

Chapter 4. Installing Power Supplies 25

Page 40

Installing the Power Supply Bay Grille

This section describes how to install the power supply bay grille for the 8265 switch.

Note: If your installation applies standard GR-63-CORE (Issue 1, October 1995), you should not install

this grille.

To install the power supply bay grille:

1. Remove the power supply bay grille from the switch shipping box.

2. Grasp both ends of the grille and place the two bottom tabs into the notches at the base of the power

supply bay.

3. Flex the grille so the tab on each end of the grille can be fitted into the corresponding notches on the

power supply bay.

4. Still flexing the grille, insert the tabs into each respective notch.

Figure 14. Installing the Power Supply Bay Grille

5. Once the tabs have been inserted in each notch, release the grille to complete the installation.

26 IBM 8265: Installation Guide

Page 41

Chapter 5. Installing Modules

This chapter describes the following:

How to install the 8265 Control Point and Switch module(s)

How to install the 8265 Controller module(s)

Guidelines for installing 8265 media modules

Guidelines for installing 8260 media modules.

Before You Start

Take the following precautions before unpacking any modules:

Do not remove components from their anti-static bags until you are ready to install the modules in the

8265. This avoids the possibility of having electrostatic discharge damage static-sensitive devices on

the components.

Always use a floor strap and grounded mat, or wear a grounded static discharge wrist strap whenever

you inspect or install a module. Alternatively, touch a grounded rack or another source of ground

before handling the module.

Verify that the module (and daughter cards if required) are correct by matching the part number listed

on the side of the shipping carton to the part number you ordered.

Copyright IBM Corp. 1994, 1998 27

Page 42

Unpacking Modules

When unpacking modules, follow these steps:

1. Remove the anti-static bag containing the module from the shipping carton.

2. Remove the module from the anti-static bag and inspect it for damage. Always handle modules by

their faceplates, being careful not to touch the internal components.

If the module appears damaged, put it back in the anti-static bag, and put the bag back into the

shipping carton. Then contact your local IBM dealer or IBM representative.

It is recommended that you retain the shipping carton and anti-static bag in case you later want to

repackage the module for storage or shipment.

28 IBM 8265: Installation Guide

Page 43

Installing the Control Point and Switch Module

Before You Begin

Before installing a Control Point and Switch module:

Make sure that you also have the PCMCIA card containing the Control Point and Switch microcode.

There are two versions, a basic version containing IISP and UNI protocols, and an enhanced version

with additional PNNI protocol. One of these MUST be installed on the module before the module is

installed in the 8265.

If you are installing the memory upgrade for the standard Control Point and Switch module, make sure

that it is to hand.

The memory module must be installed on the Control Point and Switch module before its insertion in

the 8265.

(CPSW2 module only) — Check that the Power Control jumper setting is in the correct position. To

use the integrated power control functions, the FORCE RCTL jumper must be in the OFF (down)

position. If you are using Controller modules for power management, the jumper must be in the ON

(up) position.

Important!: If you are installing two CPSW2 modules, the jumper setting must be the same on both

modules.

Attention: You must not install an 8260 CPSW module into the 8265.

Figure 15 illustrates the PCMCIA card slot, memory bank location, and the location of the Power Control

(FORCE RCTL) jumper (CPSW2 modules only).

PCMCIA Card

DRAM Memory

Banks

FORCE RCTL

Jumper

Figure 15. 8265 Control Point and Switch Module

Chapter 5. Installing Modules 29

Page 44

Installing the PCMCIA Card

To install a PCMCIA card:

1. Remove the card from its packaging.

2. Position the card so that it is just above the slot on the CPSW module, making sure that the edge with

the connectors is inserted first.

3. Slide the card into the slot.

4. Push gently downward until the card clicks into place. If the card does not seat properly, turn the card

over and try again. The card will not click into place when inserted back-to-front.

To remove a PCMCIA card, simply press down on the small lever on the left of the slot.

30 IBM 8265: Installation Guide

Page 45

Installing the Memory Upgrade

To install the memory upgrade:

1. Remove the memory module from its packaging.

2. Locate the end of the module that has a small notch.

3. Position the module above the vacant socket on the CPSW module, making sure that the end with the

notch is facing to the rear of the module.

4. Gently insert the module into the socket at 45 degrees.

5. Push gently downwards on the module until it clips into place.

To remove a memory module, release the clips at either end of the module, then slide the module

upwards gently and lift out.

Chapter 5. Installing Modules 31

Page 46

Installing the Module

To install a CPSW module:

1. Insert the CPSW module into slots 9 and 10, or 11 and 12 of the switch by matching the top and

bottom board guides as you slide the module cleanly into place (by pressing evenly on the top and

bottom of the faceplate).

2. Check that the module is plugged into the connectors on the ATM backplane.

3. Fasten the spring-loaded screws on the top and bottom of the front panel of the module to the chassis

using your finger. Do not over-tighten.

4. If the switch is already powered on, press the LED Test button to ensure that all LEDs are functional

(optional).

5. Repeat the above steps for the second module if you are installing two.

32 IBM 8265: Installation Guide

Page 47

Installing the Controller Module

Controller modules are only required when the standard CPSW module is to be used (Controller module

functionality is in-built in the enhanced CPSW2 module). Controller modules may be installed in

conjunction with a CPSW2 module if you prefer power management to be handled by the Controller

module instead of the CPSW2 module. When using Controller modules with CPSW2 module(s), the

FORCE RCTL jumper on the CPSW2 module(s) must be set to the ON position (see ,Figure 15 on

page 29 for the jumper location).

The 8265 Controller modules must be installed in the Controller module slots. These slots are located at

the lower right front corner of the switch, slot 18 (left) and slot 19 (right). Controller modules are not

designed for installation in any other slot.

The 8265 Controller module bay accommodates up to two Controller modules. Install at least one

Controller module for normal 8265 operation. Install a second Controller module to achieve Controller

module fault-tolerance.

Note: The second Controller module can only act as a backup for another Controller module. It cannot

act as a backup for a CPSW2 module using integrated power control.

Considerations When Installing Two Controller Modules

When two controller modules are to be installed, which module becomes the active depends on whether

the 8265 is powered on or not.

If the 8265 is not powered on, the controller module installed in slot 18 will become the active one

(and the module in slot 19 will become the standby module) when the 8265 is powered on, regardless

of the order in which they are installed.

If the 8265 is already powered on, the first controller module to be installed will become the active

one, irrespective of the slot used. It will also remain the active one when the second module is

installed later.

Installing the Module

To install a Controller module:

1. Remove the Controller module from the shipping carton.

2. Remove the Controller module from the anti-static bag and inspect it for damage. If the module

appears to be damaged, put it back in the anti-static bag, place it in the shipping carton, and contact

your local supplier.

3. Record the serial number and software version of your Controller Module. (Once the switch is

operational, you can view this information by entering the SHOW INVENTORY command at the

terminal prompt.)

4. If the controller slot is covered by a blank faceplate, remove the faceplate by turning the two

spring-loaded screws that hold the faceplate in place, counterclockwise. The Controller bay is located

at the lower right front corner of the switch.

Note: Each 8265 Controller module is equipped with an ejector that helps you to remove the

Controller module. This ejector can be in any position when you install the Controller module.

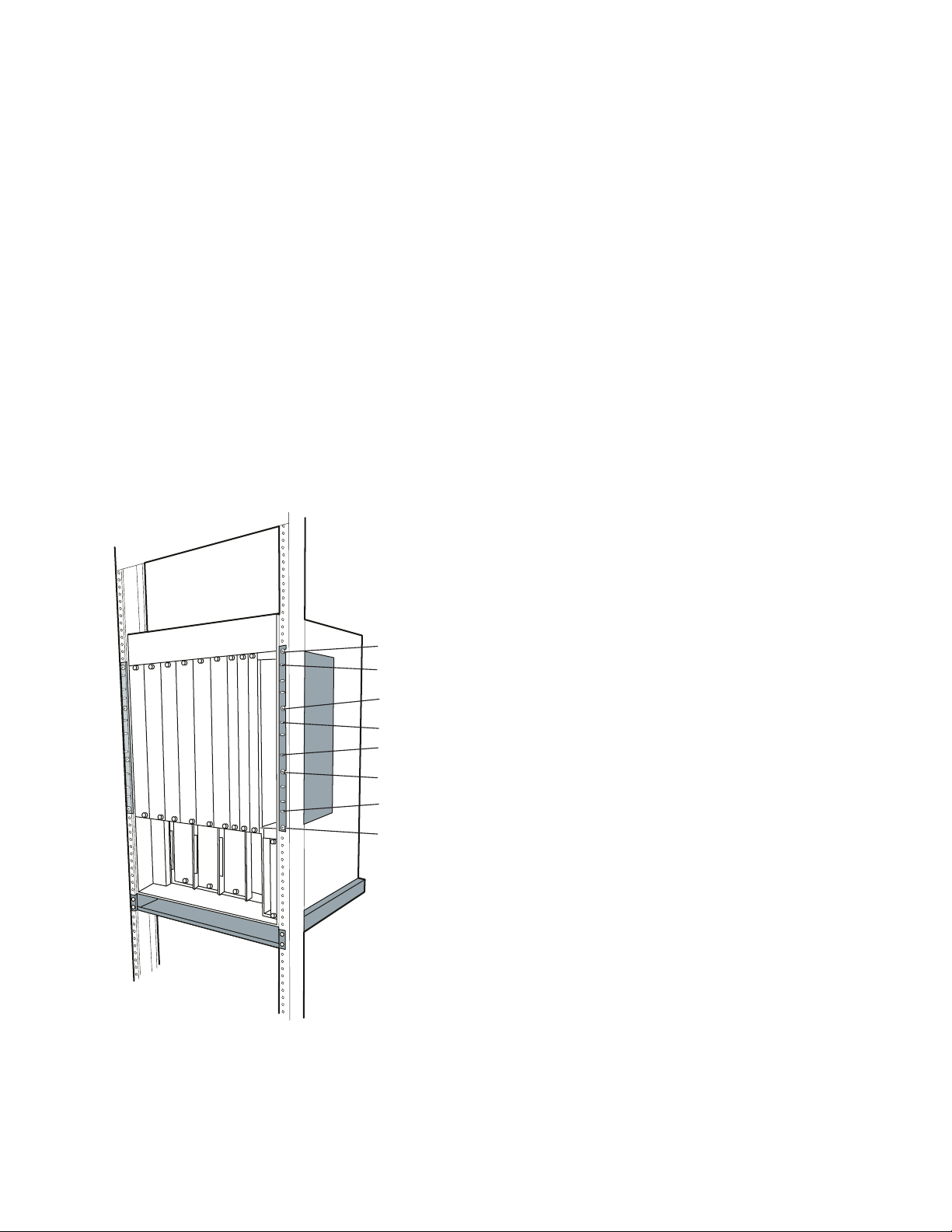

Figure 16 on page 34 shows how to insert a Controller module.

Chapter 5. Installing Modules 33

Page 48

Slide the Controller

Module into the

selected slots as

shown here.

Figure 16. Installing a Controller Module

5. Lock the ejector into place by applying pressure to the Controller module faceplate with one hand as

you pull up on the end of the ejector. Ensure that the Controller module remains fully seated in the

backplane connector as you close the Controller module ejector.

6. Lift the end of the ejector until the ejector locks into place.

7. Complete the installation by hand-turning each of the spring-loaded screws at the top and bottom of

the module in a clockwise direction. Do not overtighten the screws.

8. If you are using the Controller module(s) in conjunction with the CPSW2 module(s), make sure that

the FORCE RCTL jumper on the CPSW2 module is set to the ON position (on both CPSW2 modules

if two are installed).

Attention: To ensure adequate cooling airflow, install blank slot cover plates over

all

empty slots.

34 IBM 8265: Installation Guide

Page 49

Guidelines for Installing 8265 Media Modules

Before installing a media module, refer to the module-specific installation instructions that accompany your

module (See the Media Module Reference Guide). Some media modules require the installation of

daughter cards before the module is installed in the switch).

Note: It is not necessary to power down the switch when installing or removing media modules. You can

install or remove all media modules without disrupting switch operation.

This section describes guidelines for installing media modules. This section contains the following topics:

Cautionary guidelines

Installation guidelines

Guidelines for installing 8260 ATM media modules

Observe these guidelines when handling, installing, or removing an ATM module.

Cautionary Guidelines

Before you begin to install a module, review the following guidelines when handling a module:

Electrostatic discharge (ESD) can damage static-sensitive devices on circuit boards:

– Do not remove the module from its anti-static shielding bag until you are ready to install it.

– To ensure that static charge is removed, touch any installed module's fastener screw before

installing the module. This dissipates charge energy through the chassis to the grounded power

cord.

– Handle the module by the faceplate only.

Do not twist or otherwise force modules into the switch.

Chapter 5. Installing Modules 35

Page 50

Installation Guidelines

This section describes guidelines to follow when installing media modules.

1. 8265 media modules can be installed in slots 1–8 and 12–17. Slots 9, 10, and 11, are reserved for

Control Point and Switch modules.

Note: Slot 12 can be only be used in the following circumstances:

a. No CPSW module is installed in slot 11.

b. If the CPSW2 module is installed, the 8265 must be equipped with the backplane Part

Number 26L0112. Release 4 versions of the 8265 are equipped with this backplane. Older

versions of the 8265 are equipped with backplane Part Number 13J8689 and do not

support media modules in slot 12. The backplane part number can be displayed by

entering the the SHOW INVENTORY VERBOSE command. Alternatively, look for "Release

4" on the label to the left-hand side of the power supplies.

Table 3 lists the 8265 media modules that can be installed.

Table 3. Media Module Slot Availability

Module Feature Code

4-port 155 Mbps (MMF) 6540

4-port 155 Mbps (Flex) 6543

1-port 622 Mbps (MMF) 6511

1-port 622 Mbps (SMF) 6512

WAN 2.5 6561

MSS Server 2.5 5401

2. When deciding which available slot to use, consider the following:

If you intend to also install 8260 ATM modules, note that they can only be installed in slots 1, 3, 5,

and 7. See Table 4 on page 37 for the slot widths of the 8260 modules. Make sure that adjacent

slots are also available if you are installing a 2– or 3–slot module.

Note: 8260 modules can only operate in the 8265 when the standard CPSW module is installed.

They will not operate when the enhanced CPSW2 module is installed.

The media module slots are divided into three heat management areas:

– Slots 1 through 8

– Slots 6 through 13

– Slots 10 through 17.

If an overheat condition is detected (due to a fan failure, for example), then modules within that

area are selectively powered down, according to their power class settings, until the temperature

falls below the overheat threshold (how to set power class settings for modules is described in the

8265 Nways ATM Switch User's Guide

).

You should therefore install your most important modules in different management areas.

3. When installing a media module on which daughter cards are installed, take special care to insert the

host module straight into the slot. This ensures that daughter cards attached to the host module are

not damaged during host module installation.

36 IBM 8265: Installation Guide

Page 51

4. To assure proper installation, match the top and bottom board guides as you slide the module cleanly

into place. Do not attempt to push the module all the way into the switch until you verify that module

ejectors are open.

Note: If the 8265 is powered on, the Error LED on the 4-port 155 Mbps and 1-port 622 Mbps modules

will illuminate when the module is installed. This is because the module detects that there is no

signal present, as there is no cable connection to the module's port(s) at this time. The LED will

extinguish once a connection is made.

Guidelines for Installing 8260 ATM Media Modules

1. 8260 media modules can only operate in the 8265 when the standard CPSW module (Feature Code

6501) is installed. They will not operate with the enhanced version of the CPSW module (Feature

Code 6502).

2. 8260 media modules must only be installed in slots 1, 3, 5, and 7.

Slots 7 can only be used for a 3–slot module when there is no CPSW module installed in slot 9.

3. Some 8260 media modules must have a minimum FPGA level in order to operate in the 8265. The

modules must have this FPGA level, or higher, before being installed in the 8265.

If your 8260 module does not have the specified FPGA level (or higher), upgrade the module before

removing it from the 8260, using MES 5099. For information on how to upgrade FPGA code, refer to

IBM 8260 Nways Multiprotocol Switching Hub, ATM Control Point and Switch Module Installation and

User's Guide

, SA33-0326.

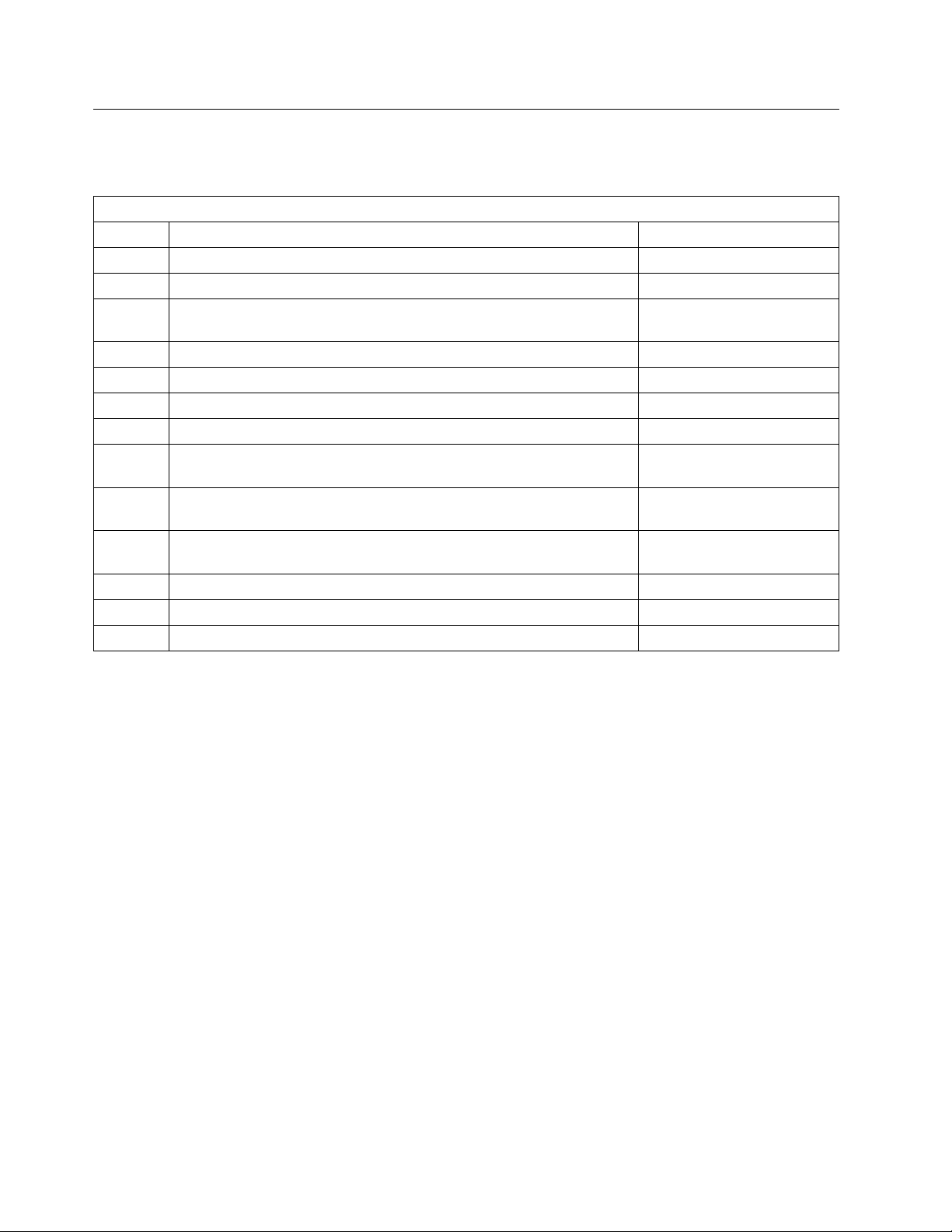

Table 4 lists the modules and the minimum FPGA levels required (if any).

Table 4. Minimum FPGA Levels Required for 8260 ATM Modules

Module Faceplate

Marking

4-port 100 Mbps A4-SC100 1 B50

12-port 25 Mbps A12-TP25 1 C30

2-port 155 Mbps A2-MB155 1 B50

3-port 155 Mbps A3-MB155 1 C31

ATM WAN A2-WAN 1 B50

ATM WAN 2 A8-WAN 1 C32

ATM Carrier A-CMU1 1 B50

ATM Carrier A-CMU2 2 B50

MSS Server A-MSS 2 B50

8271 ATM/Ethernet A-E12LS2 2 none

8271 ATM/Ethernet A-E12LS4 3 none

8272 ATM/Token-Ring A-TR8LS2 2 none

8272 ATM/Token-Ring A-TR8LS4 3 none

8281 ATM LAN Bridge A04MB-BRG 2 B50

Video Distribution A8-MPEG 2 none

Slot Width Required

FPGA Level

Chapter 5. Installing Modules 37

Page 52

38 IBM 8265: Installation Guide

Page 53

Chapter 6. Attaching a Configuration Console

You must attach an ASCII-type terminal to the RS-232 console port on the active CPSW module in order

to perform the initial configuration of the 8265. The connection can either be local or via modem.

If you use the modem cable delivered with the 8265 (Part Number 59G0278), you must also use the

supplied null modem adapter (Part Number 58F2861).

When the EIA-232 terminal attachment has a male connector, the gender changer (Part Number

58G4422) must be used.

1. Verify that the console and modem (if used) meet the factory defaults of the CPSW module. If they are

not compatible, you will not be able to communicate with the module. The default settings are:

9600 baud rate

8 data bits

No parity

1 stop bit.

2. Attach one end of an RS-232 cable to the 9-pin RS-232 console port on the front panel of the CPSW

module). Loop the cable through the Cable Management Tray (if installed) and attach the other end

(9-pin or 25-pin) into the appropriate port on the device.

3. After attaching a console to the CPSW RS-232 console port, make sure that the console is set up for

asynchronous serial communication.

How to set up the configuration console and enter command is described in the

Switch User's Guide

4. After connecting a modem to the console port, configure the modem by following the steps given in

the next section.

, SA33-0456.

IBM 8265 Nways ATM

Copyright IBM Corp. 1994, 1998 39

Page 54

Configuring the Modem

The CPSW module supports the use of dial-in modems with the following requirements:

The modem must be 100% Hayes-compatible

Any valid baud rate (300, 1200, 2400, 9600, 19200) may be used. 9600 is recommended.

The modem must be set to Dumb/Auto Answer mode.

To configure a modem, enter the following commands from the console to which the modem is attached:

1. Type at&F and press Enter (to restore the factory default settings).

2. Type at&dð and press Enter (to ignore changes in DTR status) If you have enabled automatic modem

hangup with the SET TERMINAL HANGUP ENABLE command and want to keep this setting, enter

at&d2and press Enter. This sets the DTR parameter so that hangup remains enabled when DTR

switches from ON to OFF.

3. Type atsð=1 and press Enter (to auto-answer on the first ring).

4. Type atsð? and press Enter (to verify the auto-answer if 001 is returned).

5. Type atq1 and press Enter (to ignore the result codes).

6. Type at&W and press Enter (to save the configuration changes).

7. Type at&Y and press Enter (to define the configuration as the new default).

8. Set the modem to Dumb mode (with command recognition disabled) by following the instructions in

the modem's user guide.

40 IBM 8265: Installation Guide

Page 55

Example Parameter Settings

Table 5 and Table 6 on page 42 show examples of EIA-232 xMM parameter settings for certain emulated

ASCII terminals.

Table 5. Entries for the IBM 3163, 3164, and 3101

Field Name 3163 3164 3101

Operating Mode ECHO ECHO ECHO

Interface RS-232C RS-232C RS-232C

Line Control IPRTS IPRTS IPRTS

Speed (bps) 9600 9600 9600

Parity No No No

Return Character CR CR CR

Stop Bit 1 1 1

Word Length (bits) 8 8 —

Response Time (ms) 100 100 —

Interruption Signal (ms) 500 500 —

A modem can also be used at lower speeds by using the appropriate xMM commands.

8265

Modem

Figure 17. Modem Cable Attachment (Part Number 59G0278)

Chapter 6. Attaching a Configuration Console 41

Page 56

Table 6. Entries for the IBM 3151

Menu Field Name Field Input

1. General Machine Mode 3151

Screen NORMAL

Row and Column 24 x 80

Scroll JUMP

Auto LF OFF

CRT Saver OFF

Line Wrap OFF

Forcing Insert OFF

Tab FIELD

2. Communication Operating Mode NOECHO

Line Speed (bps) 9600

Word Length (bits) 8

Parity NO

Stop Bit 1

Turnaround Character CR

Line Control IPRTS

Break Signal (ms) 170

Send Null Suppress OFF

3. Keyboard Enter RETURN

Return NEW LINE

New Line CR/LF

Send LINE

Insert Character MODE

42 IBM 8265: Installation Guide

Page 57

ASCII Terminal Cabling

8265

Figure 18. ASCII Terminal Cabling

Asynchronous

Terminal

Null Modem

Interposer

P/N 58F2861

Chapter 6. Attaching a Configuration Console 43

Page 58

VT100 Emulation on PS/2

Use emulation VT100 of communication manager to emulate an ASCII terminal.

8265

PS/2

Gender Changer

Interposer

P/N 58G4422

Null Modem

Interposer

P/N 58F2861

Figure 19. PC or PS/2 Cabling

Terminal

44 IBM 8265: Installation Guide

Page 59

Chapter 7. Completing the Installation

This chapter describes the following:

Checking that you have installed all required components.

Powering on the 8265.

Verifying that components are operating correctly.

Checking Your Installation

Use the following table to check that you have installed all the required components. Refer to the relevant

page if you have omitted a component.

Table 7 lists the items to have been installed.

Table 7. Installation Steps

Item Required/Optional See

Cable Management Tray optional page 8

DC power supply power cord preparation required if DC power used page 23

AC or DC power supplies 2 minimum required page 20 or 21

Power supply bay grille optional page 26

Control Point and Switch module(s). 1 minimum required page 29

PCMCIA card for CPSW module required page 30

Memory upgrade for CPSW module optional page 31

Controller module(s) 1 minimum required only when

standard CPSW used

Configuration console required page 39

page 33

Note: You should also have switched each power supply unit to ON.

Copyright IBM Corp. 1994, 1998 45

Page 60

Powering on the 8265

CAUTION:

When one or more power supplies are active, module and power supply slots carry electric

current. To avoid possible electric shock and damage to switch components, do not place hands,

tools, or other objects (other than properly installed modules and power supplies) into exposed

module or power supply slots. Do not allow liquids of any kind to contact exposed slots.

DC Power Source

CAUTION:

Connect the -48 Volt DC power supply to Safety Extra Low Voltage (SELV) only. Carefully read the

safety label attached to the power supply cord you received.

Make certain that the building power source is turned OFF (circuit breaker is in the OFF position).

1. Ensure that the -48 Volt building power source is turned OFF.

2. Plug the power cord for each power supply unit into the wall outlets.

3. Turn on the -48 Volt building power source.

The power supplies should now be fully operational.

AC Power Source

1. Plug the power cord for each power supply unit into the wall outlets.

The power supplies should now be fully operational.

46 IBM 8265: Installation Guide

Page 61

Verifying Your Installation

This section explains how to check that each component of the 8265 is correctly installed:

Power supply units

Fan units

Controller module

Control Point and Switch module

Configuration console.

Refer to the Media Module Reference Guide for information on media modules.

Chapter 7. Completing the Installation 47

Page 62

Verifying Power Supply Operation

To verify normal operation of an installed power supply or supplies, confirm that a power supply fault is not

indicated by checking the Power Supply LEDs.

There are four Power Supply LEDs, one for each power supply. These LEDs are located on the front

panel of the Controller modules and CPSW2 modules. Depending on your installation you should check

the LEDs on:

On the Controller module if you are using the standard CPSW module or the CPSW2 module with

integrated power control disabled (FORCE RCTL jumper set to ON on the CPSW2 module). If you

have two Controller modules installed, you should check the LEDs on the active module.

On the CPSW2 module if you are using the integrated power management functions (FORCE RCTL

jumper set to OFF on the CPSW module). If you have two CPSW2 modules installed, you should

check the LEDs on the active module. If you have CPSW2 modules installed, but have disabled power

management, you must check the LEDs on the active Controller module.

The LEDs are numbered 1 through 4, with 1 indicating the left-most power supply bay, and 4 indicating

the right-most power supply bay.

The LED for each unit installed should be lit. If any of the LEDs blinks or does not light for each installed

power supply when the 8265 is powered up, refer to Appendix A, “Troubleshooting” on page 55.

48 IBM 8265: Installation Guide

Page 63

Verifying Fan Operation

To verify that all fan units are operating normally:

Visually inspect all fans, making sure that each is turning without interruption.

Check that a fan fault is not indicated by checking the FAN LEDs. There are three FAN LEDs, one for

each fan unit. These LEDs are located on the front panel of the Controller modules and CPSW2

modules. Depending on your installation you should check the LEDs:

– On the Controller module if you are using the standard CPSW module or the CPSW2 module with

integrated power control disabled (FORCE RCTL jumper set to ON on the CPSW2 module). If you

have two Controller modules installed, you should check the LEDs on the active module.

– On the CPSW2 module if you are using the integrated power management functions (FORCE

RCTL jumper set to OFF on the CPSW2 module). If you have two CPSW2 modules installed, you

should check the LEDs on the active module. If you have CPSW2 modules installed, but have

disabled power management, you must check the LEDs on the active Controller module.

Each FAN LED should be on. If the LED is off or blinking, refer to Appendix A, “Troubleshooting” on

page 55.

Check that the Temp LED (on the active Controller module or the active Advantage CPSW module,

depending on which is being used for power management) is off, indicating normal 8265 internal

operating temperature.

If the LED is blinking or on, it indicates excessive internal operating temperature. This may mean that:

– One or more fans are not functioning normally

– Ventilation holes are blocked

– Fan exhaust temperature (internal 8265 operating temperature) is above 60 °C, (140 °F).

Fan exhaust temperature

each exhaust fan. Heat produced by circuit boards and power supplies accounts for most of this

warm air. Fan exhaust temperature is measured by a temperature sensor located at the rear of

each fan unit

is the temperature of air inside the 8265 as it passes out the back of

Chapter 7. Completing the Installation 49

Page 64

Verifying Controller Module Operation

To verify Controller module operation:

1. Press the LED test button and check that all LEDs illuminate. Then release the LED test button.

Repeat for the second Controller module if two are installed.

2. Check the STBY (Standby) and Active LEDs.

If one Controller module is installed, check:

a. that the STBY LED is off

b. that the Active LED is on

c. that the Power Supply LED is on for each power supply unit installed

d. that the FAN LEDs are on

e. that the Temperature LED is off.

If two Controller modules are installed, check:

– that the Active LED on the active Controller module is on.

– that the STBY LED on the active Controller module is off.

– that the Active LED on the standby Controller module is off.

– that the STBY LED on the standby Controller module is on.

If any of the LEDs fail the above checks, refer to Table 8 on page 55.

Figure 20 shows the location of the LEDs on the Controller module front panel.

POWER

Power Supply LEDs

SUPPLY

112

3

FAN

4

Power Supply LEDs

Fan1LED

Standby LED

LED Test Button

Reset Button

2

3

STBY

ACTIVE

8000-RCTL

TEMP

LED

TEST

HUB

RESET

Fan2LED

Fan3LED

Active LED

Temperature LED

Figure 20. 8265 Controller Module LEDs

For troubleshooting information, refer to page 55.

50 IBM 8265: Installation Guide

Page 65

Verifying Control Point and Switch Module Installation

You can verify that the Control Point and Switch module is correctly installed by checking the front panel:

The CPU Stop LED should be off.

When the 8265 is powered on (or reset), the Control Point and Switch module is initialized and the

System Status LCD displays the various steps of the initialization

1. INIT - initialization process is running.

2. If diagnostics are enabled, the following steps are shown while testing the first bank of DRAM

memory

– SET1, RFW1, RBW1, BRST.

3. CLR1 - first DRAM memory bank is being cleared.

4. If diagnostics are enabled, the following steps are shown while testing the second bank of DRAM

memory (if installed):

– SET2, RFW2, RBW2, BRST.

5. CLR2 - second DRAM memory bank is being cleared (if installed).

6. LOAD - operational code is being copied from the PCMCIA card into the DRAM.

Once the initialization has completed successfully, the System Status LCD will show either ACTV (on

the active CPSW module) or STBY (on the standby Control Point and Switch module when two are