Page 1

2220 Nways BroadBand Switch

Models 300, 500, and 501

IBM

Service Guide

SY33-2121-01

Page 2

Page 3

2220 Nways BroadBand Switch

Models 300, 500, and 501

Service Guide

IBM

SY33-2121-01

Page 4

Note|

Before using this information and the product it supports, be sure to read the general information under “Notices” on page xi.

Second Edition (March 1999)

The information contained in this manual is subject to change from time to time. Any such changes will reported in subsequent

revisions.

Order publications through your IBM representative or the IBM branch office serving your locality. Publications are not stocked at the

address given below.

A form for readers' comments appears at the back of this publication. If the form has been removed, address your comments to:

IBM France

Centre d'Etudes et Recherches

Service 0798 - BP 79

06610 La Gaude

France

FAX: 33 4 93 24 77 97

IBM Internal Use: LGERCF at IBMFR

Internet: lgercf@fr.ibm.com

When you send information to IBM, you grant IBM a non-exclusive right to use or distribute the information in any way it believes

appropriate without incurring any obligation to you.

Copyright International Business Machines Corporation 1998, 1999. All rights reserved.

Note to U.S. Government Users — Documentation related to restricted rights — Use, duplication or disclosure is subject to

restrictions set forth in GSA ADP Schedule Contract with IBM Corp.

Page 5

Contents

Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

European Union (EU) Statement ........................... xii

Year 2000 Statement ................................. xii

Electronic Emission Notices .............................. xii

Safety Notices for United Kingdom ........................ xiii

Safety Notice for Australia ............................. xiv

Telecommunication Connectivity Notices ...................... xiv

Notice to Users of Machines Installed in the U.S. ............... xiv

Notice to Users of Machines Installed in Canada ................ xv

Trademarks and Service Marks ........................... xvi

General and Product Safety ............................ xvii

Service Inspection Safety Procedures ........................ xvii

Safety and Disposal Instructions for Batteries ................... xvii

Service Inspection Safety Procedures ....................... xviii

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

Sicherheitsüberprüfungen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxv

Einführung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxv

Safety Label Locations .................................. xl

Safety Label Identifications .............................. xliv

About this Manual .................................. xlix

Aim of this Manual ................................... xlix

Who Should Read this Manual ............................ xlix

How this Manual is Organized ............................ xlix

Chapter 1. START - Finding a Service Procedure ............... 1-1

Service Operation via Nways Switch Administration Station ........... 1-2

Chapter 2. Introduction / Overview ........................ 2-1

Typical Broadband Network Based on 2220 .................... 2-1

2220 Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2220 Control Panel Functions ............................ 2-3

Chapter 3. Nways Switch Administration Station Functions ........ 3-1

How to Start on the Local 2220 ........................... 3-1

How to Logon to the Remote 2220 ......................... 3-1

Nways Switch Administration Station Windows Overview ............. 3-5

How to Display the CMIP Status ........................... 3-8

How to Display the Alarm Desk .......................... 3-11

How to Display the Nways Switch Configuration ................. 3-13

How to Display the Test Event Desk ........................ 3-18

How to Find a TCP/IP Address ........................... 3-20

How to Display the Nways Switch Control Program Inventory and Level ... 3-22

How to Remove a Line or Trunk Cable ...................... 3-24

How to Perform the Emergency Trunk Unlock .................. 3-26

Copyright IBM Corp. 1998, 1999 iii

Page 6

Chapter 4. 2220 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

2220 Diagnostics Available from the NAS ..................... 4-1

All Switch to Line Interface Tests .......................... 4-2

Switch to Line Interface Test ............................. 4-2

Line Interface Test ................................... 4-4

Line Wrap Plug Test .................................. 4-5

Line Loopback Test .................................. 4-6

2220 Trunk Loopback Test .............................. 4-6

Loop Line and Loop Trunk .............................. 4-7

How to Run the All Switch to Line Interface Test ................. 4-8

How to Run the Switch to Line Interface Test .................. 4-10

How to Run the Line Interface Test ........................ 4-12

How to Run the Line Loopback Test ........................ 4-15

How to Test an ACDC Power and Battery .................... 4-25

Chapter 5. 2220 Problem Determination ..................... 5-1

MAP 0500: 2220 Basic Verification ....................... 5-2

Chapter 6. 2220 FRU Exchange .......................... 6-1

MAP: Before Exchanging an FRU ........................ 6-1

Opening The Doors And Covers of 2220 Installed in 37 U Rack ........ 6-6

Opening The Doors And Covers of 2220 Installed in 29 U Rack ........ 6-7

2220 Component Locations ............................. 6-9

Locating System Components in the 2220 .................... 6-9

Format of Location Identifier ............................ 6-9

Module Connector Positions ........................... 6-10

2220 Model 300/500/501 in 37 U Rack Example ............... 6-11

2220 Model 300/500/501 in 29 U Rack Example ............... 6-12

2220 Model 300/500 Unit Identification Examples ................ 6-13

2220 Front View in 37 U Rack ......................... 6-15

2220 Rear View in 37 U Rack .......................... 6-16

2220 Front View in 29 U Rack ......................... 6-17

2220 Rear View in 29 U Rack .......................... 6-18

Identify the ACDC Power Type ......................... 6-19

Identify the DC48 Power Type .......................... 6-20

Identify the APC Type .............................. 6-21

Exchange an ACDC ............................... 6-22

Exchange an APC ................................. 6-27

Exchange an ARC ................................ 6-29

Exchange a Battery ................................ 6-30

Exchange a Board ................................ 6-34

MAP: Prerequisite to Exchange a Clock ................... 6-39

Exchange a Clock ................................. 6-43

MAP: Prerequisites for Exchanging a Clock Redrive ............ 6-45

Exchange a Clock Redrive ............................ 6-50

Exchange a DC48 Power Input ......................... 6-51

Exchange a DCD1 or DCD2 ........................... 6-53

Exchange a Fan Box ............................... 6-55

Exchange an LCEE ................................ 6-56

Exchange an LCEB ................................ 6-58

Exchange an LCPB ................................ 6-60

Exchange an LCPE ................................ 6-62

Exchange a LIC .................................. 6-64

Exchange a Control Panel ............................ 6-66

iv 2220 Models 300, 500, and 501: Service Guide

Page 7

MAP: Prerequisite to Exchange a Switch or Switch Redrive ........ 6-67

Exchange a Switch or Switch Redrive ..................... 6-69

After Exchanging a Switch or Switch Redrive ................. 6-71

Exchange a TPA ................................. 6-72

Exchange a Voice Server Adapter ....................... 6-73

Exchange a Voice Server Extension ...................... 6-74

Ending the Exchange Procedure .......................... 6-75

Leaving Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-75

Appendix A. Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Power and Control Cables (With APC Type A) .................. A-2

Power 48 V DC Distribution (With APC Type A) ................. A-3

Power Control (With APC Type A) ......................... A-4

Control Panel and FAN Control (With APC Type A) ............... A-5

Power and Control Cables (With APC Type B) .................. A-6

Power 48 V DC Distribution (With APC Type B) ................. A-7

Power Control (With APC Type B) ......................... A-8

Control Panel and FAN Control (With APC Type B) ............... A-9

Clock Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

Appendix B. Maintenance Aids . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Clock Module LED Segment Reference ...................... B-1

Shipping Group Tools ................................ B-2

Appendix C. 2220 Power Consumption .................... C-1

2220 Power Limits .................................. C-1

2220 Base Machine and Modules Power Consumption ............. C-1

Appendix D. Parts Catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

How to Use This Parts Catalog ........................... D-2

Part Listing Glossary ................................. D-3

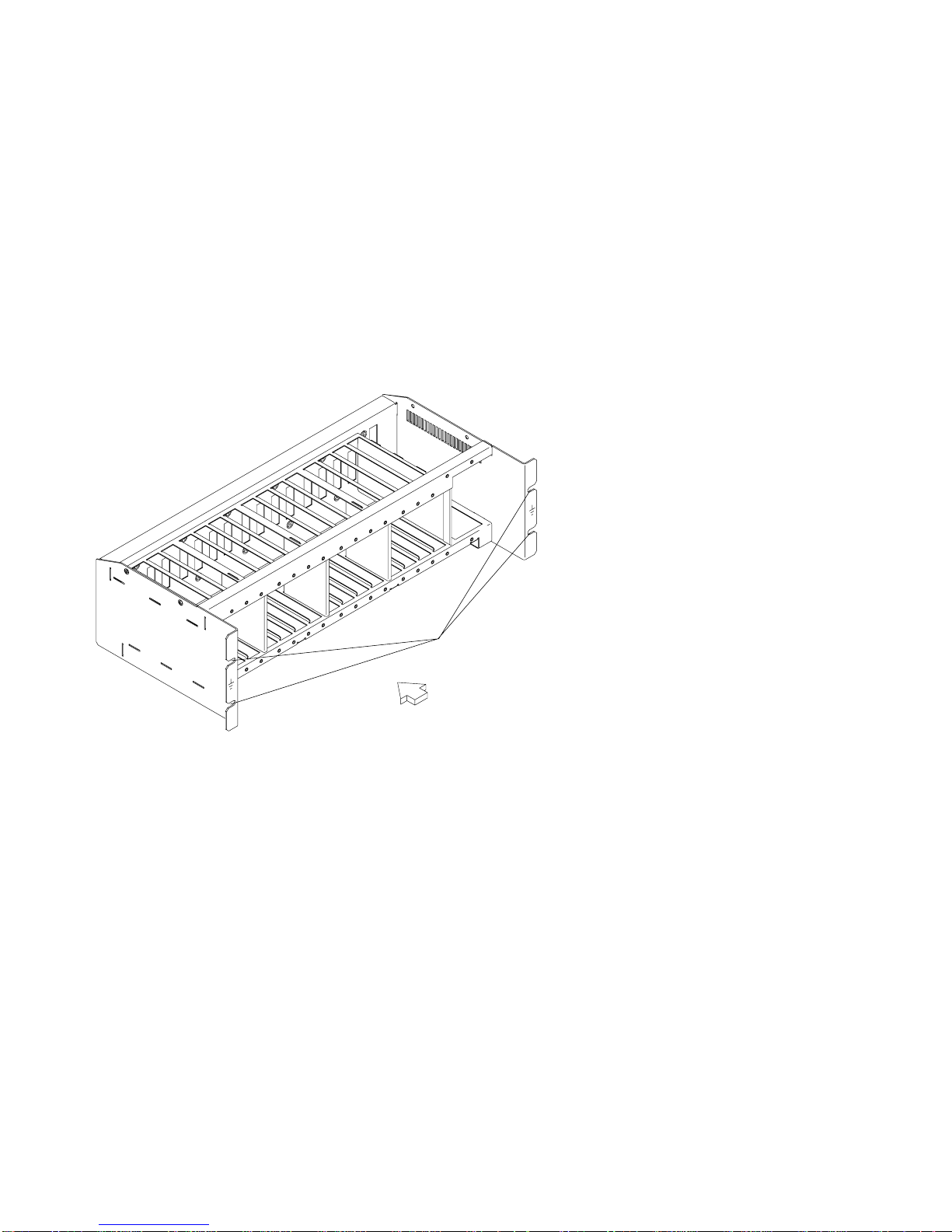

2220 Visual Index .................................. D-4

37 U Rack Visual Index ............................... D-5

29 U Rack Visual Index ............................... D-6

Catalog Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-7

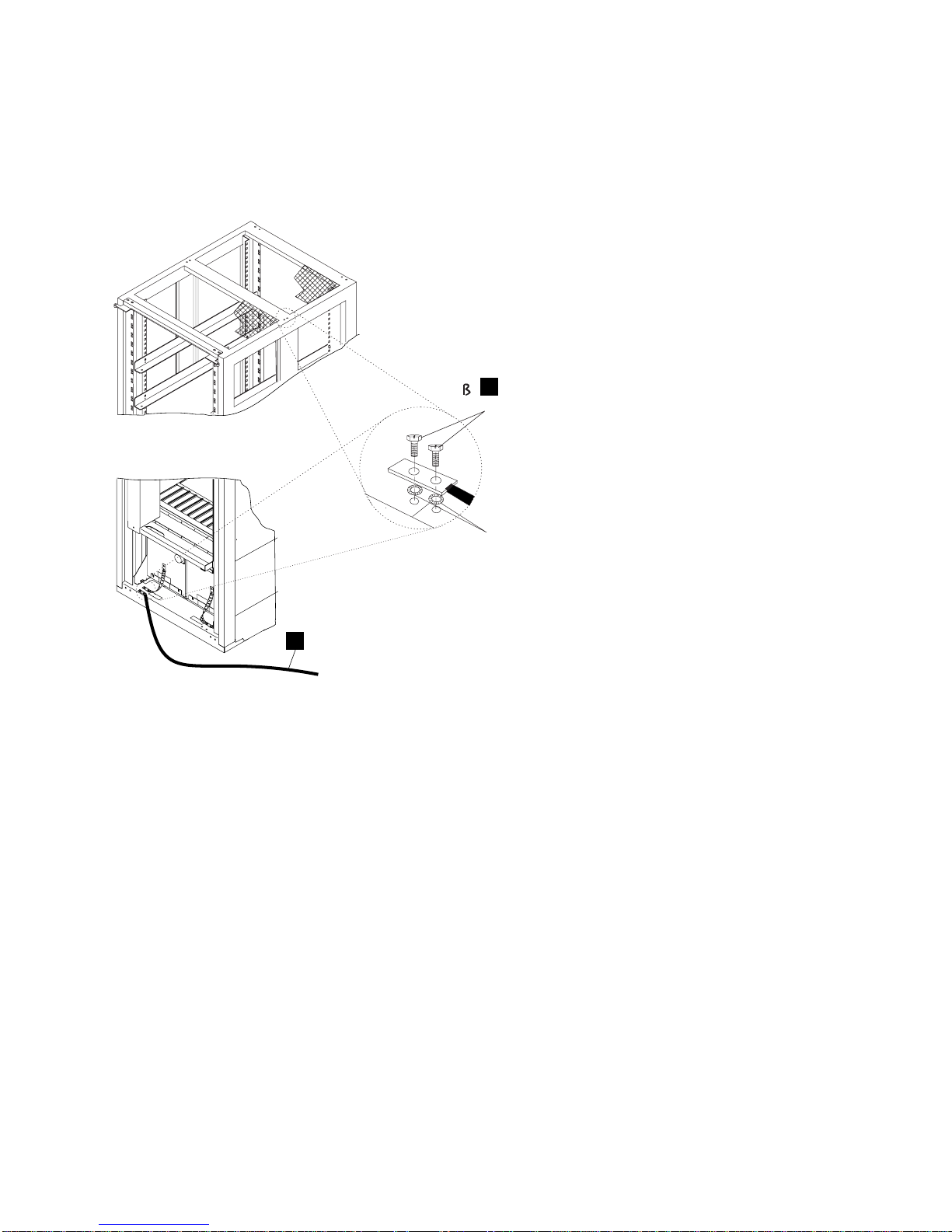

Assembly 1: 2220 Enclosure Assembly, Models 300, 500, and 501 ... D-8

Assembly 2: 2220 Control Panel and FAN Box Assembly ......... D-10

Assembly 3: 2220 AC/DC and DC Power Supply Assembly ........ D-12

Assembly 4: 2220 Board Assembly ...................... D-14

Assembly 5: 2220 Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . D-16

Assembly 6: LCBB and LCBE Assembly ................... D-18

Assembly 7: Internal Cables Assembly .................... D-20

Assembly 8: 37 U RACK Assembly ...................... D-22

Assembly 9: 29 U RACK Assembly Side Covers .............. D-24

Assembly 10: 29 U RACK Assembly Top, Rear, and Front Covers .... D-26

Assembly 11: 29 U RACK Assembly Details ................. D-28

Assembly 12: 29 U RACK Assembly Rear Side ............... D-30

Assembly 13: Power Attachment Cord Assembly .............. D-32

Appendix E. Part Number Index ......................... E-1

Bibliography . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X-1

Nways Switch Publications ............................. X-1

Nways 2220 Switch Manager Publications .................... X-1

Contents v

Page 8

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X-1

World Wide Web ................................... X-1

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X-3

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X-13

vi 2220 Models 300, 500, and 501: Service Guide

Page 9

Figures

0-1. 2220 Ground Wire A ............................ xix

0-2. 2220 Ground Wire B Between 2220-500and 2220-501 ......... xx

0-3. 2220 Ground Pin on Mainline ac/dc Power Cable ............ xxi

0-4. 2220 Ground Straps (Former Machine) .................. xxi

0-5. 2220 Ground Straps ............................. xxi

0-6. LCB Grounding via Screws ......................... xxii

0-7. LCB Grounding via Ground Wire .................... xxiii

0-8. Standard Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

0-9. Bellcore Specification Connection .................... xxiii

0-10. Schutzleiter A am 2220 .......................... xxvii

0-11. 2220 Schutzleiter B zwischen 2220-500 und 2220-501 ........ xxviii

0-12. Schutzleiterkontakt am Hauptnetzkabel des 2220 ........... xxix

0-13. Schutzleiter am 2220 (vorheriges Modell) ............... xxix

0-14. 2220 Schutzleiter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxix

0-15. Erdung des Verteilerkastens über Schrauben .............. xxx

0-16. Erdung des Verteilerkastens über Schutzleiter .............. xxx

0-17. Standardanschluß . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxxi

0-18. Anschluß nach Bellcore-Norm ...................... xxxi

0-19. Safety Labels on Internal Front Cover ................... xl

0-20. Safety Labels on Internal Rear Board Cover ................ xl

0-21. Safety Labels on Internal Front Board Cover .............. xli

0-22. Safety Labels on Rear of the 2220 Rack ................. xli

0-23. Safety Label on LCB ............................ xlii

0-24. Safety Labels on Battery .......................... xliii

0-25. Power Label (PN 57G7919 and PN 57G7976) ............. xliv

0-26. Board Labels (PN 57G7920) ........................ xliv

0-27. Other Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xlv

0-28. Labels Used for Europe, Taiwan, and Brazil (PN 57G7959) ...... xlv

0-29. Labels Used for Other Countries (PN 57G7958) ............ xlvi

0-30. Power Rating Label for DC48 ....................... xlvi

0-31. Power Rating Label for ACDC ....................... xlvi

0-32. Label for 2220 Rack (PN 80G3929) ................... xlvii

0-33. Label for LCB (PN 80G3928) ...................... xlvii

3-1. Nways Switch Desktop Display ...................... 3-1

3-2. Example of Expanded Tree ......................... 3-4

3-3. Example of Expanded Tree ......................... 3-6

3-4. Example of Options Available for a Selected Resource ........ 3-7

3-5. Example of Options Available for a Switch ................ 3-7

3-6. Example of Expanded Tree ......................... 3-9

3-7. Search Options in the Alarm Desk Window .............. 3-12

3-8. Nways Switch Desktop Window ..................... 3-20

3-9. Nways Swith Installation Window .................... 3-20

3-10. Installation Program Main Menu ..................... 3-20

3-11. Example of TCP/IP address ....................... 3-21

3-12. Example of Nways Switch Control Program Software Inventory ... 3-23

4-1. Area Tested by Switch to Line Interface Test .............. 4-2

4-2. Area Tested by Switch to Line Interface Test on LIC511 ........ 4-2

4-3. Area tested by Switch to Line Interface Test with a Wrap Plug .... 4-3

4-4. Area tested by Switch to Line Interface Test with a Wrap Plug on

LIC511 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Copyright IBM Corp. 1998, 1999 vii

Page 10

4-5. Area Test by the Line Interface Test ................... 4-4

4-6. Area Tested by the Line Interface Test on LIC511 ........... 4-4

4-7. Area Tested by the Line Wrap Plug Test ................. 4-5

4-8. Area Tested by the Line Wrap Plug Test on LIC511 .......... 4-5

4-9. Area Tested by the Line Loopback Test ................. 4-6

4-10. Area Tested by the 2220 Trunk Loopback Test ............. 4-6

4-11. Loop Trunk and Loop Line on Remote 2220 ............... 4-7

4-12. Example of Test Selection ........................ 4-19

6-1. 2220 CPx Powering ............................. 6-2

6-2. 2220 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6-3. Module Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6-4. Front, Rear Door And Side Cover Latches for 37 U Rack ....... 6-6

6-5. Front, and Rear Door Opening for 29 U rack .............. 6-7

6-6. Side Cover Removing for 29 U rack ................... 6-8

6-7. 2220 Component Location in 37 U Rack ............... 6-11

6-8. 2220 Component Location in 29 U Rack ............... 6-12

6-9. 2220 Identification in 37 U Rack .................... 6-13

6-10. 2220 Identification in 29 U Rack .................... 6-14

6-11. 2220 Front View Location with NAS Type 7585 Installed in 37 U

Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

6-12. 2220 Rear View Location in 37 U Rack with NAS Type 7585

Installed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

6-13. 2220 Front View Location in 29 U Rack with NAS Type 6275

Installed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

6-14. 2220 Rear View Location in 29 U Rack with NAS type 6275

Installed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

6-15. APC Type Identification .......................... 6-21

6-16. 2220 Front View .............................. 6-39

6-17. 2220 Front View .............................. 6-45

6-18. 2220 Rear View .............................. 6-67

6-19. Display Power ON/OFF Switch ..................... 6-75

B-1. Clock Module LED Segment Reference ................ B-1

viii 2220 Models 300, 500, and 501: Service Guide

Page 11

Tables

4-1. Resources and Available Diagnostics ................... 4-1

6-1. FRU Exchange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6-2. Examples of Location for the 2220 Models 300, 500, and 501 ... 6-14

C-1. Maximum total consumption allowed. .................. C-1

C-2. Base Machine and Module Power Consumption ........... C-1

Copyright IBM Corp. 1998, 1999 ix

Page 12

x 2220 Models 300, 500, and 501: Service Guide

Page 13

Notices

References in this publication to IBM products, programs, or services do not imply

that IBM intends to make these available in all countries in which IBM operates.

Any reference to an IBM product, program, or service is not intended to state or

imply that only IBM's product, program, or service may be used. Any functionally

equivalent product, program, or service that does not infringe any of IBM's

intellectual property rights may be used instead of the IBM product, program, or

service. Evaluation and verification of operation in conjunction with other products,

except those expressly designated by IBM, is the user's responsibility.

IBM may have patents or pending patent applications covering subject matter in

this document. The furnishing of this document does not give you any license to

these patents. You can send license inquiries, in writing, to the IBM Director of

Licensing, IBM Corporation, 500 Colombus Avenue, Thornwood, New York 10594,

U.S.A. Commercial Relations, IBM Corporation, Purchase, NY 10577, U.S.A.

Copyright IBM Corp. 1998, 1999 xi

Page 14

European Union (EU) Statement

This product is in conformity with the protection requirements of EU Council

Directive 89/336/EEC on the approximation of the laws of the Member States

relating to electromagnetic compatibility. IBM can not accept responsibility for any

failure to satisfy the protection requirements resulting from a non-recommended

modification of the product, including the fitting of non-IBM option cards.

Year 2000 Statement

This product is Year 2000 ready. When used in accordance with its associated

documentation, it is capable of correctly processing, providing, and/or receiving

date data within and between the 20th and 21st centuries, provided all other

products (for example, software, hardware, and firmware) used with the product

properly exchange accurate date data with it.

For more information, refer to:

http://www.ibm.com/year2000

Electronic Emission Notices

Federal Communications Commission (FCC) Statement

Note: This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to the Part 15 of FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause

harmful interference, in which case the user will be required to correct the

interference at his own expense.

Properly shielded and grounded cables and connectors must be used in order to

meet FCC emission limits. IBM is not responsible for any radio or television

interference caused by using other than recommended cables and connectors or by

unauthorized changes or modifications to this equipment. Unauthorized changes or

modifications could void the user's authority to operate this equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference, and (2)

this device must accept any interference received, including interference that may

cause undesired operation.

Industry Canada Compliance Statement

This Class A digital apparatus complies with Canadian ICES-003.

Avis de conformité aux normes d'Industrie Canada

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du

Canada.

xii 2220 Models 300, 500, and 501: Service Guide

Page 15

Japanese Voluntary Control Council for Interference (VCCI) Statement

This product is a Class A Information Technology Equipment and conforms to the

standards set by the Voluntary Control Council for Interference by Information

Technology Equipment (VCCI). In a domestic environment this product may cause

radio interference in which case the user may be required to take adequate

measures.

Harmonics Compliance (JEIDA)

This product conforms to the Harmonics Guideline (JEIDA). The input current of

this product is less than or equal to 20 A per phase.

Korean Communications Statement

Please note that this device has been certified for business use with regard to

electromagnetic interference. If you find this is not suitable for your use, you may

exchange it for one of residential use.

Taiwanese Class A Warning Statement

This is a Class A product. In a domestic environment this product may cause radio

interference in which case the user will be required to take adequate measures.

Safety Notices for United Kingdom

1. The IBM 2220 Nways BroadBand Switch is manufactured according to the

International Safety Standard EN 60950 and as such is approved in the UK

under the General Approval Number NS/G/1234/J/100003 for indirect

connection to the public telecommunication network.

2. The network adapter interfaces housed within the IBM 2220 Nways BroadBand

Switch are approved separately, each one having its own independent approval

number. These interface adapters, supplied by IBM, do not use or contain

excessive voltages. An excessive voltage is one that exceeds 42.4 V peak ac

or 60 V dc. They interface with the IBM 2220 Nways BroadBand Switch using

Safety Extra Low Voltages (SELV) only. In order to maintain the separate

(independent) approval of the IBM adapters, it is essential that other optional

cards, not supplied by IBM, do not use mains voltages or any other excessive

Notices xiii

Page 16

voltages. Seek advice from a competent engineer before installing other

adapters not supplied by IBM.

Safety Notice for Australia

In Australia, the LIC545 and LIC546 must be connected only to Safety Extra Low

Voltage (SELV) networks.

If an attachment to a Telephone Network Voltage (TNV) network is required, you

must use a LIC515 instead of a LIC545, and a LIC516 instead of a LIC546.

Telecommunication Connectivity Notices

Notice to Users of Machines Installed in the U.S.

This equipment complies with Part 68 of the FCC rules. On the LIC module of this

equipment is a label that contain, among other information, the FCC registration

number. If requested, this information must be provided to the telephone company.

If this equipment causes harm to the telephone network, the telephone company

will notify you in advance that temporary discontinuance of the service may be

required. If advance notice is not practical, the telephone company will notify you as

soon as possible. Also, you will be advised of your right to file a complaint with the

FCC if you feel it is necessary.

The telephone company may make changes in its facilities, equipment, operations,

or procedures, that could affect the operation of the equipment. If this happens, the

telephone company will provide advance notice in order for you to make the

necessary modifications to maintain uninterrupted service.

If you experience trouble with this equipment, please contact (800) IBM-SERV for

repair and warranty information. If the trouble is causing harm to the telephone

network, the telephone company may request you to remove the equipment from

the network until the problem is resolved.

No repair can be done by you, customer. Please contact (800) IBM-SERV.

This equipment cannot be used on telephone company-provided coin service.

Connection to Party Line Service is subject to state tariffs.

Equipment Ordering Information for U.S. Machines

This section provides information about Facility Interface Codes and Service Order

Codes that are needed to order the corresponding services to the carrier company.

Please refer to “Notice to Users of Machines Installed in the U.S.” for the legal

information related to the connection of this equipment to the telephone network.

LIC514

Facility Interface Code Service Order Code Module type

04DU9-BN 6.0F LIC514

04DU9-DN 6.0F LIC514

04DU9-1KN 6.0F LIC514

04DU9-1SN 6.0F LIC514

xiv 2220 Models 300, 500, and 501: Service Guide

Page 17

The standard connecting arrangement code for this equipment is:

Connector type 8-position miniature

Connector model RJ48C

Cable length 30 m (98 ft) maximum

R.E.N Not applicable.

LIC544

Facility Interface Code Service Order Code Module type

04DU9-BN 6.0P LIC544

04DU9-DN 6.0P LIC544

04DU9-1KN 6.0P LIC544

04DU9-1SN 6.0P LIC544

The standard connecting arrangement code for this equipment are:

Connector type 8-position miniature

Connector model Not Applicable

Cable length 30 m (98 ft) maximum

R.E.N Not applicable

or,

Connector type 15-position

Connector model DB15F

Cable length 30 m (98 ft) maximum

R.E.N Not applicable

Notice to Users of Machines Installed in Canada

The Industry Canada label identifies certified equipment. This certification means

that the equipment meets certain telecommunications network protective,

operational and safety requirements as prescribed in the appropriate Terminal

Equipment Technical Requirements document(s). The Department does not

guarantee the equipement will operate to the user's satisfaction.

Before installing this equipment, users should ensure that it is permissible to be

connected to the facilities of the local telecommunications company. The equipment

must also be installed using an acceptable method of connection. The customer

should be aware that compliance with the above conditions may not prevent

degradation of service in some situations.

Repairs to certified equipment should be coordinated by a representative

designated by the supplier. Any repairs or alterations made by the user to this

equipment, or equipment malfunctions, may give the telecommunications company

cause to request the user to disconnect the equipment.

Users should ensure for their own protection that the electrical ground connections

of the power utility, telephone lines and internal metallic water pipe system, if

present, are connected together. This precaution may be particularly important in

rural areas.

Notices xv

Page 18

Caution: Users should not attempt to make such connections themselves, but

should contact the appropriate electric inspection authority, or electrician, as

appropriate.

Equipment Ordering Information for Canadian Machines

LIC514:

Connector type 15-position or 8-position miniature

Connector model CA81A or CA48C

Cable length 30 m (98 ft) maximum

Load number Not applicable

Please refer to “Notice to Users of Machines Installed in Canada” on page xv for

the legal information related to the connection of this equipment to the telephone

network.

The standard connecting arrangement code for this equipment is:

LIC544:

Connector type 15-position or 8-position miniature

Connector model CA81A or CA48C

Cable length 30 m (98 ft) maximum

Load number Not applicable

Please refer to “Notice to Users of Machines Installed in Canada” on page xv for

the legal information related to the connection of this equipment to the telephone

network.

The standard connecting arrangement code for this equipment is:

Trademarks and Service Marks

The following terms, denoted by an asterisk (*), used in this publication, are

trademarks or service marks of IBM Corporation in the United States or other

countries:

IBM Nways OS/2

AT XGA NetView

RETAIN Presentation Manager

The following terms, denoted by a double asterisk (**), used in this publication, are

trademarks of other companies:

Hayes Hayes Microcomputer Products, inc.

xvi 2220 Models 300, 500, and 501: Service Guide

Page 19

General and Product Safety

This product meets the safety standards. For more information, see the

Nways BroadBand Switch Models 300, 500, and 501; Safety Information

GA33-0401 (P/N 80G4908), manual.

Service Inspection Safety Procedures

Service Inspection Safety Procedures - English

Sicherheitsüberprüfungen - Deutsch

Safety and Disposal Instructions for Batteries

When disposing of the batteries, follow procedures in accordance with your national

or local regulations for recycling the materials. If no regulation of this kind exists,

return the batteries to your equipment seller or to IBM.

2220

,

xviii

xxv

xxiv

Copyright IBM Corp. 1998, 1999 xvii

Page 20

Service Inspection Safety Procedures

Introduction

A safety inspection procedure for the 2220 should be performed:

When it is inspected for an IBM agreement

When IBM service is requested and no service has recently been performed by IBM

When an alterations and attachments review is performed

When changes have been made to the equipment that might affect its safety.

If the inspection indicates unacceptable safety conditions, the conditions must be corrected before IBM

services the equipment.

Note: The correction of any unsafe condition is the responsibility of the owner of the equipment.

The 2220 areas and functions checked through these procedures are:

1. External covers

2. Safety labels

3. Grounding (earthing)

4. Circuit breaker and circuit protector rating

5. Input power voltage

6. Power ON indicators

7. Emergency power OFF of the board

8. Cooling

Steps 1 through 8 must be performed Power OFF, as follows:

Main CBs switched OFF on the 2220.

All the equipment installed in the 2220 rack or connected to it is OFF.

Power supplies at customer premises are switched OFF.

On the 2220 do not remove the power cords and ground wire .A/ in order to maintain the ground

protection (see Figure 0-1 on page xix).

1.External Covers

Check that:

All external covers are present on the 2220.

Appropriate service clearances and accesses are provided around the racks with external covers

opened.

Leave all external covers opened to allow further inspection steps.

2.Safety Labels

Check that:

All the safety labels are at the places indicated by letters in “Safety Label Locations” on page xl.

Each label corresponds to the correct model as indicated by the letter as shown in “Safety Label

Identifications” on page xliv.

xviii 2220 Models 300, 500, and 501: Service Guide

Page 21

To check the labels on the ACDC and/or DC48 power input and on the battery (if present) you must

remove these FRUs. Refer to Chapter 6, “2220 FRU Exchange” on page 6-1 for detailed instructions.

3. Grounding (Earthing)

Note

In this book "ground", means that the equipment must be connected to the earth.

a. Grounding of the 2220, NAS, display, and modem to the Premises Grounding System

Electrical continuity is assured between their frame ground and premises grounding system,

through their power cords.

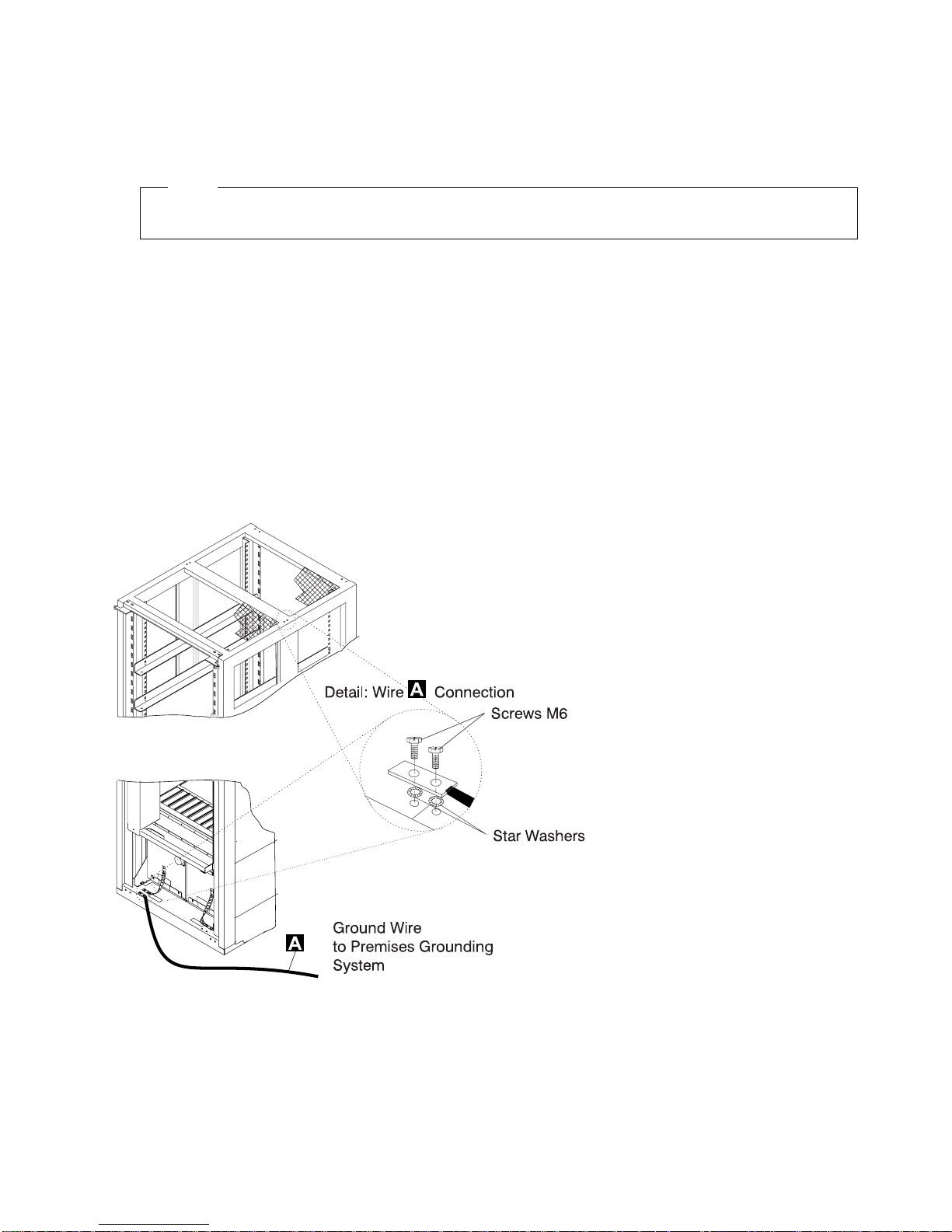

For the 2220-300 and the 2220-500, an additional ground wire .A/ is also used.

The 2220-501 is connected to the 2220-500 via a ground wire .B/ (see Figure 0-2 on

page xx).

1) 2220 Model 300 and 500 Ground Wire

Check the presence of ground wire .A/ on the 2220 (see Figure 0-1).

The ground wire .A/ can also be installed on the top of the 2220 Model 300/500 frame if

necessary.

Figure 0-1. 2220 Ground Wire A

General and Product Safety xix

Page 22

Notes:

a) .A/ Wire (PN 80G3815)

b) Screws (PN 43G3084)

c) Star washers (PN 1622348)

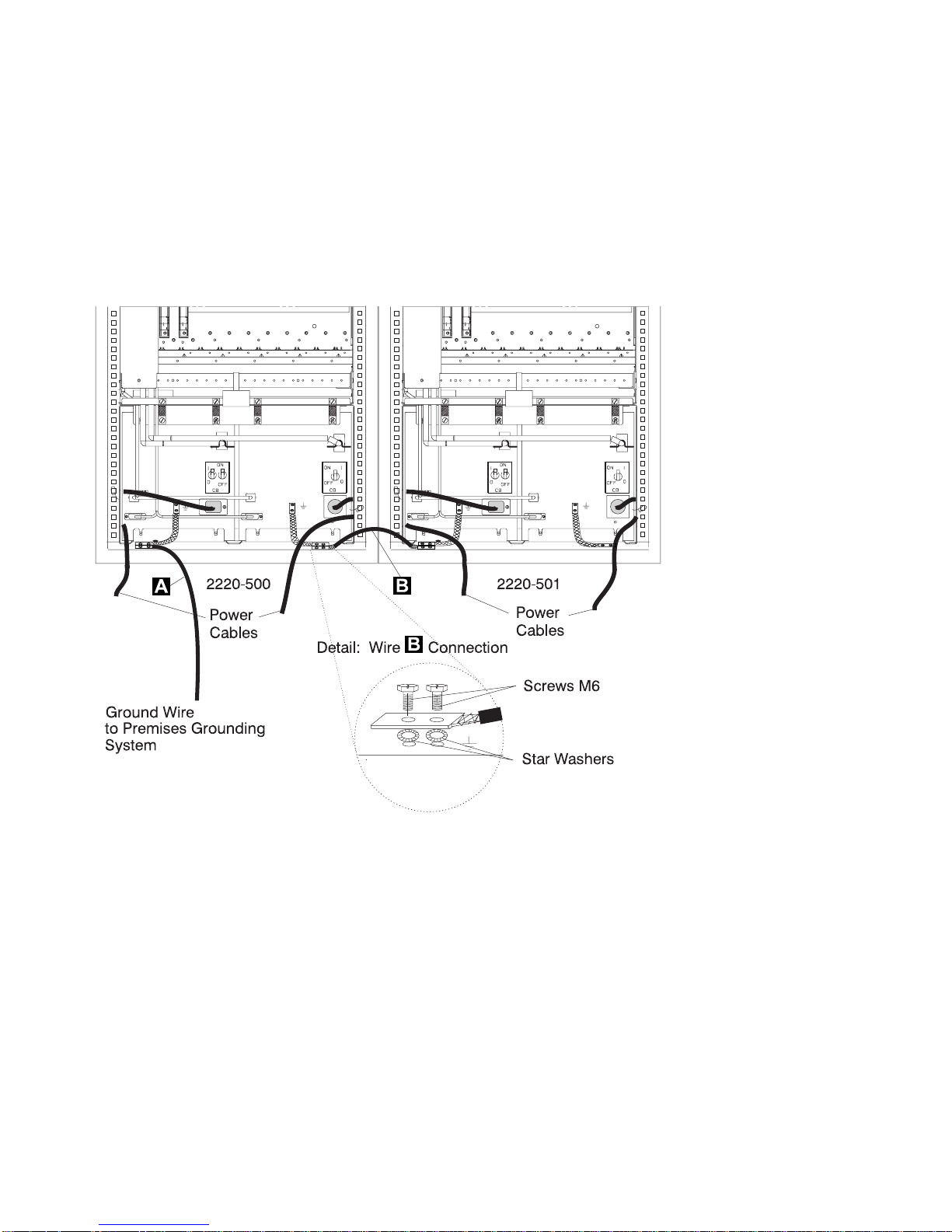

2) 2220 Model 501 Ground Wire

When a 2220-501 is installed, check the presence of ground wire .B/ between the

2220-500and the 2220-501 (see Figure 0-2).

Figure 0-2. 2220 Ground Wire B Between 2220-500and 2220-501

Notes:

a) .B/ Wire (PN 80G3715)

b) Screws (PN 43G3084)

c) Star washers (PN 1622348)

3) ac/dc Power Cable Ground Wire

Check the mainline ac/dc power cable for damaged or burned pins and broken insulation

on all units.

Measure the resistance of the disconnected mainline ac/dc power cable from ground pin

on one end to the ground pin on the other end.

The reading should be 0.1 ohm or less.

xx 2220 Models 300, 500, and 501: Service Guide

Page 23

Ground Pin

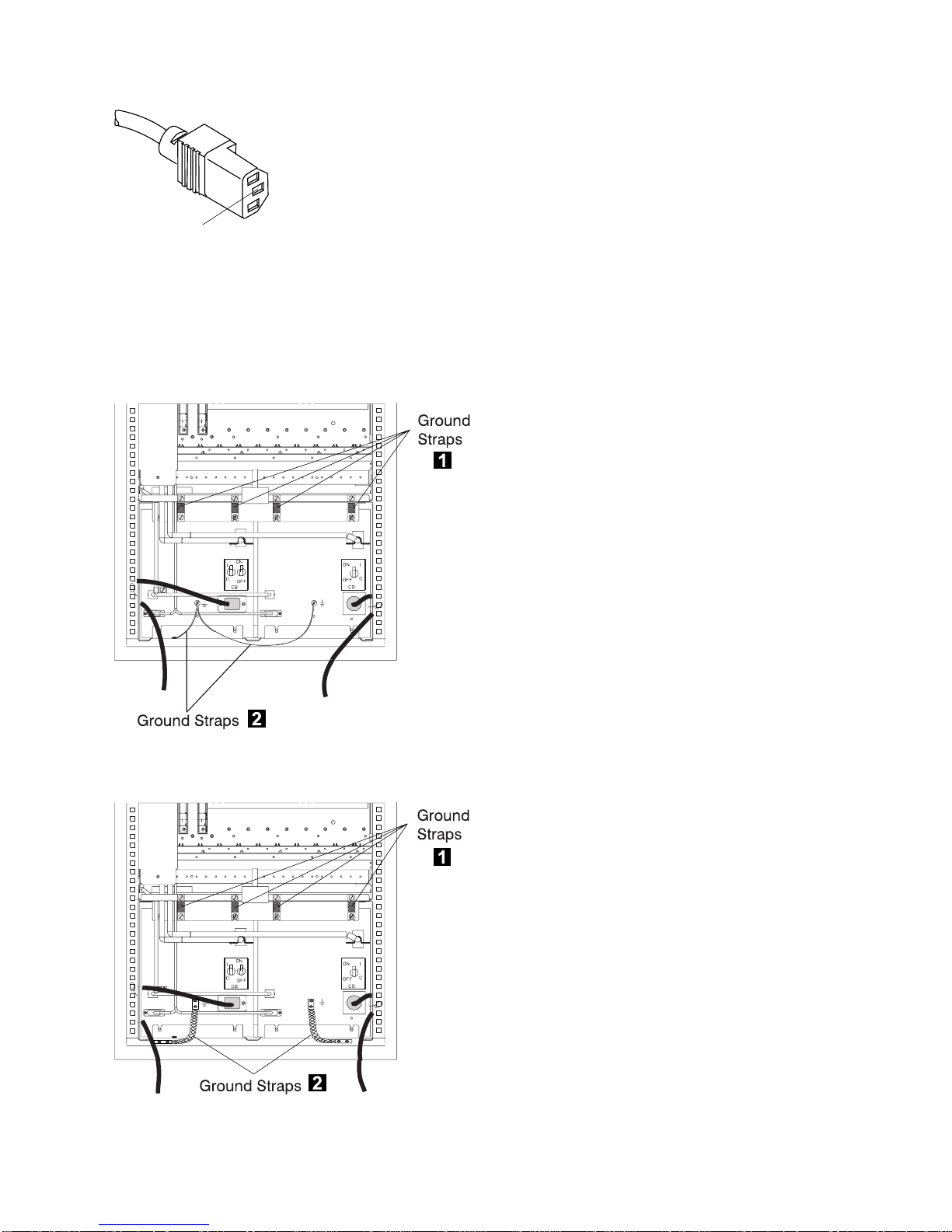

Figure 0-3. 2220 Ground Pin on Mainline ac/dc Power Cable

b. Internal Grounding in the 2220

Check that:

Electrical continuity is assured within each rack, between the rack ground and the installed

power supplies via ground straps .1/.

Figure 0-4. 2220 Ground Straps (Former Machine)

Figure 0-5. 2220 Ground Straps

General and Product Safety xxi

Page 24

Electrical continuity is assured, between the rack ground and the power supply receptacle via

ground straps .2/.

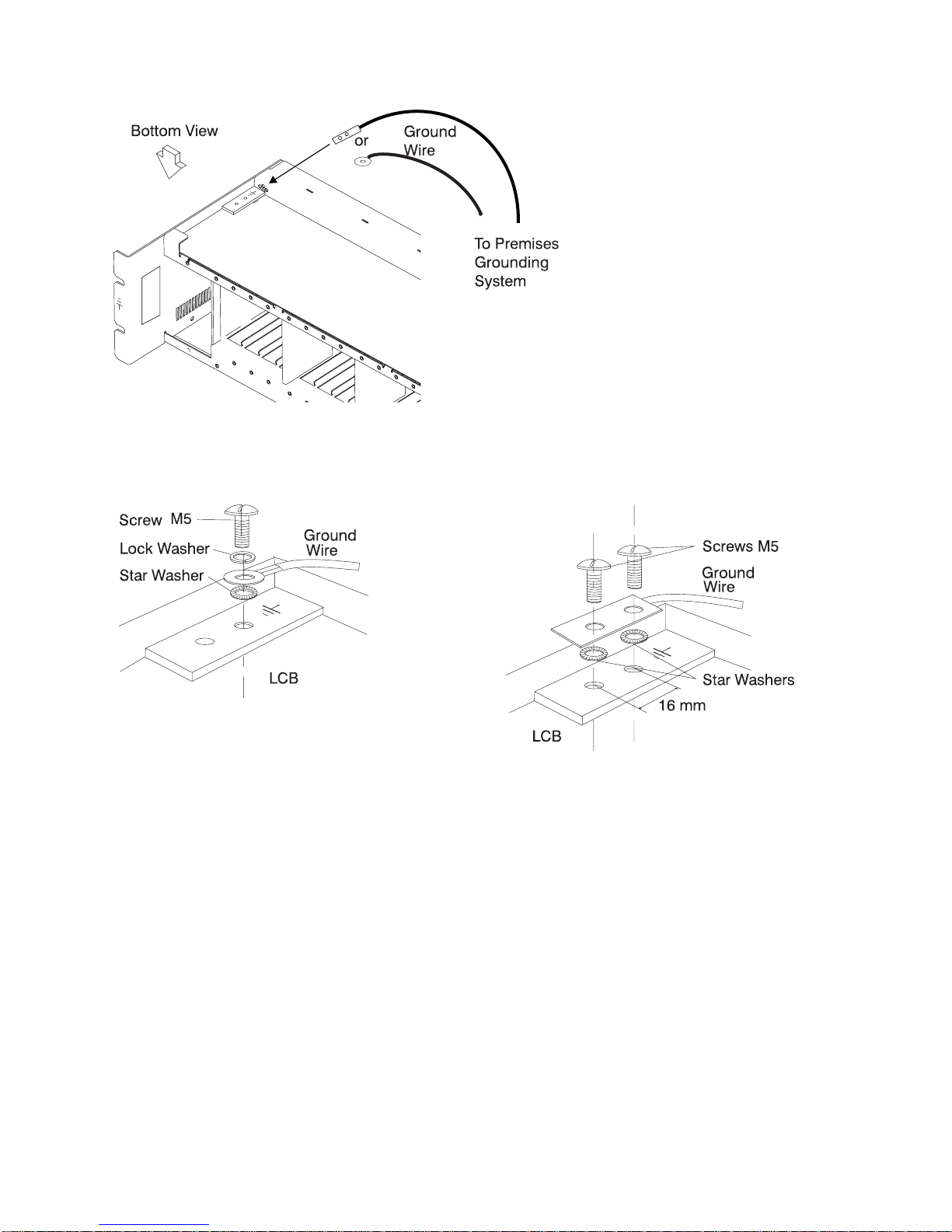

Electrical continuity is assured, between the rack ground and the Line Connection Box (LCB),

if LCBs are present. This operation must be performed before any network connection (see

Figure 0-6).

c. Grounding of Line Connection Boxes (LCBs) not Installed in 2220

Check that electrical continuity is assured between the LCB housing and the premises grounding

system.

There are two ways to insure a proper grounding of the LCB, according to where it is installed:

1) Grounding is insured by the four screws (which secure the LCB on the rack) if the frame of the

rack is connected to the premises ground system.

Figure 0-6. LCB Grounding via Screws

2) Grounding is insured by a wire connected from the LCB to the premises ground system, when

the LCB is installed in a rack with frame not connected to the premises ground system.

Screws for

Grounding

Front View

xxii 2220 Models 300, 500, and 501: Service Guide

Page 25

Figure 0-7. LCB Grounding via Ground Wire

Ground Wire Connection on LCB

There are two ways to secure the ground wire on the LCB.

Figure 0-8. Standard Connection

Figure 0-9. Bellcore Specification Connection

This operation must be performed before any network connection.

Note: All the previous checking should indicate 0.1 ohm or less.

d.Building Grounding

Check there is less than 1 V ac between the metal housings of plugs, connectors,

receptacles, and so on, and any grounded point in the building. This can be any grounded

metal structure, such as the stanchions of a raised floor (if they are electrically connected

to building ground), a metal water pipe, building steel, and so on.

Notes:

1) When probing a painted metal part, be sure that the meter probe tip penetrates the paint.

2) Also check the plugs metal housing of incoming cables.

4. Circuit Breaker and Circuit Protector Rating

Each power box has one circuit breaker (CB) and six circuit protectors (CPs).

General and Product Safety xxiii

Page 26

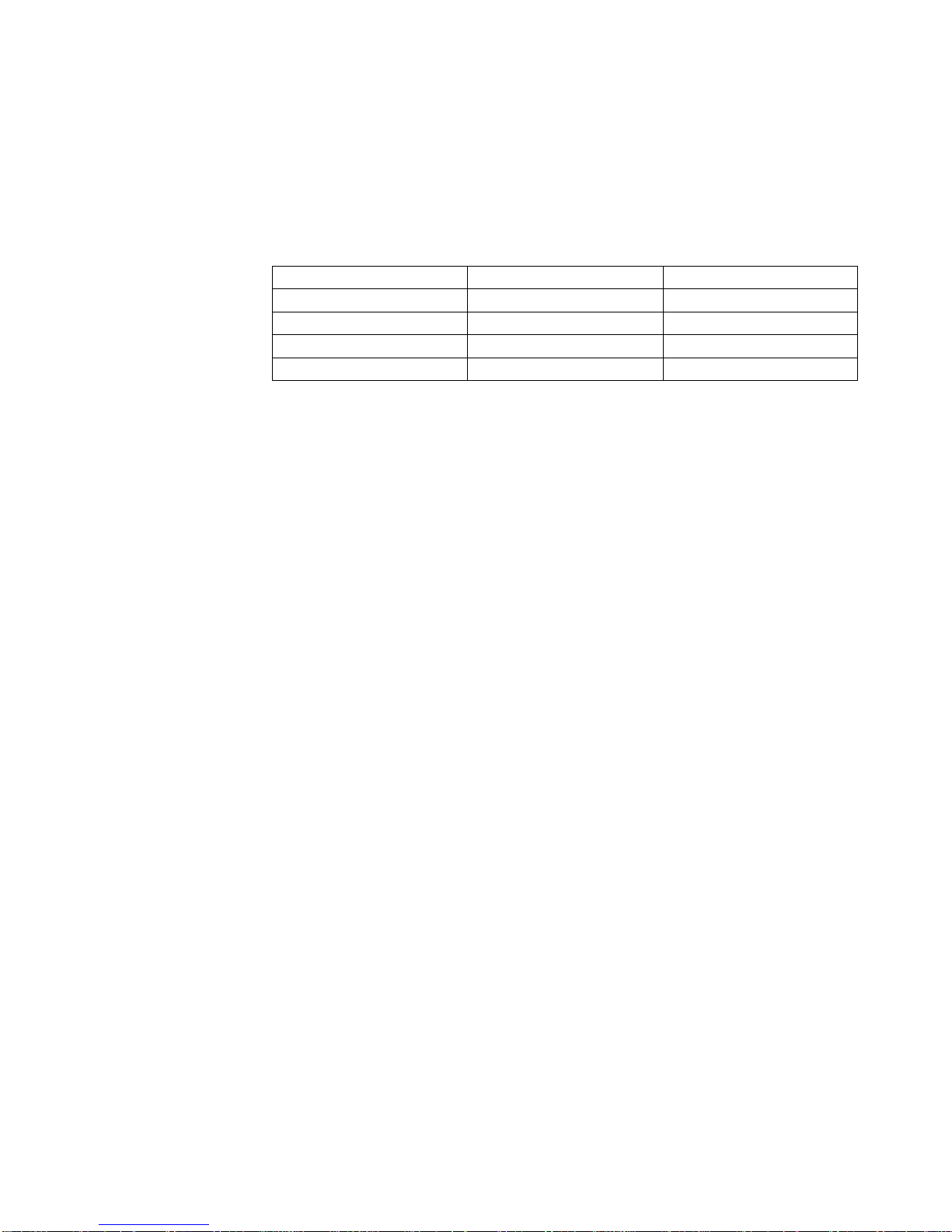

Power Box CB/CP Rating

ACDC / DC48 CP1 to CP5 CP6 8A dc 4A dc

ACDC CB 12A ac

DC48 CB 40A dc

The CB and all CPs are in the sealed ACDC or DC48 power box.

Check the PN on the input power box, refer to the parts catalog. In the case of a discrepancy, contact

your support structure.

5. Input Power Voltage

Two types of power boxes can be installed on 2220 family machines:

ACDC Power: The input power voltage is from an ac voltage (200-240 V and 50 or 60 Hz).

DC48 Power: The input power voltage is from a dc source (39-60 V).

In the 2220 family, the ACDC and DC48 power boxes can be mixed on each machine model.

6. Power ON Indicators

Ask the customer to:

a. Connect the power cords to the customer's energy supplies

b. Put the CBs ON

c. Turn the power ON/STANDBY switch to ON (position on the control panel).

Once the 2220 is powered ON, using the following table, check the status of each element.

Element Status

Control Panel The green LED(s) POWER SUPPLY 1 and 2 on the 2220control panel are ON (if you

have two power boxes installed in the 2220).

The APC green LED blinks during power on self test (POST), and then comes ON.

The yellow LEDs FAN BOX and ALARM are OFF.

ACDC Power The green LEDs AC GOOD and DC/HW GOOD are ON.

The yellow LED BATTERY EXCHANGE REQUIRED is OFF.

DC48 Power (if

installed on

your machine)

On top of

Modules

installed in

your 2220

The green LED (DC/HW GOOD) is ON.

Green LEDs are ON.

7. Emergency Power OFF of the Board

Turn the power ON/STANDBY switch to STANDBY (position on the control panel) and check that:.

The POWER SUPPLY 1 and 2 LEDs on the control panel are OFF.

The fans are stopped.

8.Cooling

Be sure that all the modules and dummy modules are properly installed to ensure proper cooling.

xxiv 2220 Models 300, 500, and 501: Service Guide

Page 27

Sicherheitsüberprüfungen

Einführung

Die Sicherheit des 2220sollte in folgenden Fällen überprüft werden:

Bei einer Prüfung nach Absprache mit IBM

Wenn eine IBM Wartung angefordert wird, und in der letzten Zeit keine Wartung durch IBM

durchgeführt worden war.

Wenn Änderungen am Gerät oder Anschlüsse überprüft werden.

Wenn Änderungen am Gerät vorgenommen worden sind, die möglicherweise die Sicherheit

beeinträchtigen.

Wenn bei der Überprüfung ein unzureichender Sicherheitszustand festgestellt wird, müssen die Mängel

behoben werden, bevor IBM das Gerät wartet.

Anmerkung: Für die Behebung von Sicherheitsmängeln ist der Besitzer des Geräts verantwortlich.

Folgende Bereiche und Funktionen des 2220 werden im folgenden geprüft:

1. Äußere Abdeckungen

2. Sicherheitsaufkleber

3. Erdung

4. Sicherungsautomat und Überstromschutzschalter

5. Netzeingangsspannung

6. Betriebsanzeigen

7. Notausschalter der Platine

8. Kühlung

Vor der Prüfung der oben genannten Punkte muß die Stromzufuhr folgendermaßen unterbrochen

werden:

Am 2220 die Hauptsicherungsautomaten öffnen.

Alle im Einschub des 2220 installierten Geräte oder damit verbundenen Geräte ausschalten.

Stromversorgung beim Kunden ausschalten.

Netzkabel und Schutzleiter .A/ am 2220 nicht entfernen, damit die Erdung gewährleitet ist (siehe

Figure 0-10 on page xxvii).

General and Product Safety xxv

Page 28

1.Äußere Abdeckungen

Prüfen, ob

alle äußeren Abdeckungen am 2220 angebracht sind.

die Einschübe genügend Raum und Zugänge für Wartungsarbeiten haben, wenn die äußeren

Abdeckungen geöffnet sind.

Alle äußeren Abdeckungen für weitere Überprüfungen offen lassen.

2.Sicherheitsaufkleber

Prüfen, ob

sich alle Sicherheitsaufkleber an den mit Buchstaben gekennzeichneten Stellen befinden, wie

unter “Safety Label Locations” on page xl beschrieben.

jeder Aufkleber dem richtigen Modell entspricht, wie anhand der Buchstaben unter “Safety Label

Identifications” on page xliv angegeben ist.

Für die Prüfung der Aufkleber am ACDC-Eingang (Gleichstrom-Wechselstrom) und/oder

DC48-Eingang (48Volt Gleichstrom) und an der Batterie (sofern vorhanden) müssen Sie diese

Funktionseinheiten entfernen. Unter Chapter 6, “2220 FRU Exchange” on page 6-1 sind ausführliche

Anweisungen zu finden.

3.Erdung

a. Schutzleiterverbindung von 2220, NAS, Bildschirm und Modem an das Erdungssystem des

Gebäudes

Der elektrische Durchgang zwischen Gehäuseerdung und dem Erdungssystem des Gebäudes

wird über die Netzkabel sichergestellt.

Beim 2220-300 und 2220-500 wird zusätzlich ein Schutzleiter .A/ verwendet.

Der 2220-501 wird über ein Schutzleiter .B/ an den 2220-500 angeschlossen (siehe

Figure 0-11 on page xxviii).

xxvi 2220 Models 300, 500, and 501: Service Guide

Page 29

1) Schutzleiter des 2220 Modell 300 und 500

Prüfen, ob am 2220 ein Schutzleiter .A/ vorhanden ist (siehe Figure 0-10).

Der Schutzleiter .A/ kann gegebenenfalls auch oben am Rahmen des 2220 Modell 300/500

installiert sein.

Detail: Kabelanschu

Schutzleiter an

A

Erdungssystem

des Gebäudes

Figure 0-10. Schutzleiter A am 2220

Notes:

a) Kabel .A/: (Teilenummer 80G3815)

b) Schrauben: (Teilenummer 43G3084)

c) Zahnscheiben: (Teilenummer 1622348)

A

Schrauben M6

Zahnscheiben

General and Product Safety xxvii

Page 30

2) Schutzleiter am 2220 Modell 501

Wenn ein 2220-501 installiert ist, prüfen, ob sich ein Schutzleiter .B/ zwischen 2220-500und

2220-501 befindet. (siehe Figure 0-11).

A

Schutzleiter an Erdungssystem

des Gebäudes

Figure 0-11. 2220 Schutzleiter B zwischen 2220-500 und 2220-501

3) Schutzleiter des Netzkabels

2220-500 2220-501

Netzkabel

Detail: Kabelanschu

Notes:

a) Kabel .B/ (Teilenummer 80G3715)

b) Schrauben (Teilenummer 43G3084)

c) Zahnscheiben (Teilenummer 1622348)

Hauptnetzkabel aller Geräte auf beschädigte oder verbrannte Kontakte und beschädigte

Isolierung prüfen.

B

Netzkabel

B

2

Schrauben M6

Zahnscheiben

Den Widerstand des nicht angeschlossenen Hauptnetzkabels zwischen dem

Schutzleiterkontakt am einen und dem Schutzleiterkontakt am anderen Ende messen.

Der Widerstand darf maximal 0,1 Ohm betragen.

xxviii 2220 Models 300, 500, and 501: Service Guide

Page 31

Schutzleiterkontakt

Figure 0-12. Schutzleiterkontakt am Hauptnetzkabel des 2220

b. Interne Erdung im 2220

Prüfen, ob

der elektrische Durchgang innerhalb eines jeden Gehäuses über Schutzleiter .1/ zwischen

dem Gehäuseschutzleiteranschluß und den installierten Netzteilen gewährleistet ist.

Schutzleiterverbindungen

1

Schutzleiterverbindungen

1

Schutzleiterverbindungen

Figure 0-13. Schutzleiter am 2220 (vorheriges Modell)

der elektrische Durchgang über Schutzleiter .2/ zwischen dem Gehäuseschutzleiteranschluß

und dem Schutzleiterkontakt gewährleistet ist.

der elektrische Durchgang zwischen dem Gehäuseschutzleiteranschluß und dem

Verteilerkasten, sofern vorhanden, gewährleistet ist. Dieser Schritt muß vor dem Anschluß von

Signalkabeln erfolgen (siehe Figure 0-15 on page xxx).

c. Erdung der nicht im 2220 installierten Verteilerkästen

Prüfen, ob der elektrische Durchgang zwischen dem Gehäuse des Verteilerkasten und dem

Erdungssystem des Gebäudes gewährleistet ist.

Je nach Installationsort kann der Verteilerkasten auf zweierlei Arten geerdet werden:

1) Erdung über die vier Schrauben (mit denen der Verteilerkasten am Gehäuse befestigt ist), falls

der Gehäuserahmen mit dem Erdungssystem des Gebäudes verbunden ist (siehe Figure 0-15

on page xxx).

2

Schutzleiterverbindungen

Figure 0-14. 2220 Schutzleiter

2

General and Product Safety xxix

Page 32

Schrauben

für Erdung

Vorderansicht

Figure 0-15. Erdung des Verteilerkastens über Schrauben

2) Erdung über ein Kabel, das den Verteilerkastens mit dem Erdungssystem des Gebäudes

verbindet, wenn der Verteilerkasten in einem Gehäuse installiert ist, dessen Rahmen nicht mit

dem Erdungssystem des Gebäudes verbunden ist.

Unteransicht

oder

Schutzleiter

an Erdungssystem

des Gebäudes

Figure 0-16. Erdung des Verteilerkastens über Schutzleiter

xxx 2220 Models 300, 500, and 501: Service Guide

Page 33

Schutzleiteranschluß am Verteilerkasten

Der Schutzleiter kann auf zweierlei Arten am Verteilerkasten angeschlossen werden.

Schraube

M5

Sicherungsscheibe

Zahnscheibe

Verteilerkasten

Figure 0-17. Standardanschluß

Dieser Schritt muß vor dem Anschluß jeglicher Signalkabel erfolgen.

Anmerkung: Bei allen vorherigen Prüfungen sollten maximal 0,1 Ohm gemessen werden.

d. Erdung des Gebäudes

Sicherstellen, daß zwischen den Metallgehäusen von Steckern, Buchsen usw. und jeder

geerdeten Stelle im Gebäude eine Wechselspannung von weniger als 1 V anliegt. Dies kann

jedes geerdete Metallteil sein, wie z. B. die Stützen eines Doppelbodens (wenn sie mit dem

Gebäudeerder verbunden sind), ein metallisches Wasserrohr, Baustahl usw.

Anmerkung:

Schutzleiter

Schrauben M5

Schutzleiter

Zahnscheiben

16 mm

Verteilerkasten

Figure 0-18. Anschluß nach Bellcore-Norm

1) Beim Prüfen an einem lackierten Metallteil sicherstellen, daß die Prüfspitze die Farbe

durchbohrt.

2) Auch Metallgehäuse der anzuschließenden Kabel überprüfen.

4. Sicherungsautomat und Überstromschutzschalter

Jeder Energieversorgungsblock verfügt über eine Sicherung und sechs Sicherungsschalter.

Sicherungsautomat

Energieversorgungsblock

ACDC, DC48 Überstromschutzschalter 1 bis 5

ACDC Sicherungsautomat 12 A-Wechselstrom

DC48 Sicherungsautomat 40 A-Gleichstrom

Überstromschutzschalter Nennstrom

8 A Gleichstrom 4 A Gleichstrom

Überstromschutzschalter 6

Der Sicherungsautomat und die Überstromschutzschalter befinden sich in dem versiegelten

Energieversorgungsblock (ACDC bzw. DC48).

Die Teilenummer des Eingangsenergieversorgungsblocks prüfen, siehe Teilekatalog. Falls

Unstimmigkeiten auftreten, an das KD-Unterstützungspersonal wenden.

5.Eingangsspannung

In die Geräten der 2220-Familie können zweierlei Energieversorgungsblöcke installiert werden.

ACDC: Bei der Eingangsspannung handelt es sich um Wechselspannung (200-240 V, 50 oder 60

Hz).

General and Product Safety xxxi

Page 34

DC48: Bei der Eingangsspannung handelt es sich um Gleichspannung (39-60 V).

Bei der 2220-Familie können gleichzeitig der ACDC- und der DC48-Energieversorgungsblock in

jedem Modell installiert sein.

6.Betriebsanzeigen

Den Kunden um folgendes bitten:

a. Netzkabel an das Netz des Kunden anschließen.

b. Sicherungen EINSCHALTEN.

c. Den Betriebsschalter des Geräts auf EIN stellen. (Position am Bedienungsfeld).

Sobald der 2220 eingeschaltet ist, anhand der folgenden Tabelle den Status eines jeden Elements

prüfen.

Element Status

Bedienungs-

feld

ACDC Die grünen LEDs (AC GOOD und DC/HW GOOD) LEUCHTEN.

DC48 (sofern

installiert)

Oben auf den

im 2220

installierten

Modulen

Die grünen LEDs (STROMVERSORGUNG 1 und 2) am Bedienungsfeld des

2220LEUCHTEN (wenn im 2220 zwei Energieversorgungsblöcke installiert sind).

Die grüne LED APC blinkt während des Selbsttests beim Einschalten und LEUCHTET

dann dauerhaft.

Die gelben LEDs (VENTILATOR und ALARM) LEUCHTEN NICHT.

Die gelbe LED (BATTERY EXCHANGE REQUIRED) LEUCHTET NICHT.

Die grüne LED (DC/HW GOOD) LEUCHTET.

Grüne LEDs LEUCHTEN.

7. Notausschalter der Platine

Den Betriebsschalter auf BEREITSCHAFT stellen. (Position am Bedienungsfeld) und sicherstellen,

daß:

die LEDs STROMVERSORGUNG 1 und 2 am Bedienungsfeld NICHT LEUCHTEN.

die Lüfter nicht laufen.

8.Kühlung

Prüfen, ob alle Module und Dummy-Module richtig installiert sind, damit eine ausreichende Kühlung

gewährleistet ist.

xxxii 2220 Models 300, 500, and 501: Service Guide

Page 35

General and Product Safety xxxiii

Page 36

xxxiv 2220 Models 300, 500, and 501: Service Guide

Page 37

General and Product Safety xxxv

Page 38

xxxvi 2220 Models 300, 500, and 501: Service Guide

Page 39

General and Product Safety xxxvii

Page 40

xxxviii 2220 Models 300, 500, and 501: Service Guide

Page 41

General and Product Safety xxxix

Page 42

Safety Label Locations

In the following figures, labels are designated by letters. A particular wording

corresponds to each letter (see “Safety Label Identifications” on page xliv).

A

Figure 0-19. Safety Labels on Internal Front Cover

B

C

Figure 0-20. Safety Labels on Internal Rear Board Cover

xl 2220 Models 300, 500, and 501: Service Guide

Page 43

D

Figure 0-21. Safety Labels on Internal Front Board Cover

R

Figure 0-22. Safety Labels on Rear of the 2220 Rack

General and Product Safety xli

Page 44

Figure 0-23. Safety Label on LCB

S

G

J2

J2

J3

J4

J5

J4

J3

J5

J N

J

Safety Labels on DC48 Power (Old Model)

Safety Labels on DC48 Power (New Model)

xlii 2220 Models 300, 500, and 501: Service Guide

Page 45

G

H

H

K

J3

J4

J5

P

Safety Labels on ACDC Power (Old Model)

K

J2

M1

MOV

J5

M2

J3

J4

Safety Labels on ACDC Power (New Model)

Figure 0-24. Safety Labels on Battery

General and Product Safety xliii

E

L

Page 46

Safety Label Identifications

LABEL A

ATTENTION

POUR COUPER COMPLETEMENT

LE COURANT DANS LE RACK,

METTRE LES CBs EN POSITION OFF,

ET DECONNECTER TOUS LES CORDONS

D’ALIMENTATION A L’ARRIERE

CAUTION

TO REMOVE POWER COMPLETELY

IN THE RACK TURN ALL CBs OFF,

THEN DISCONNECT ALL

POWER CORDS AT THE REAR

I

ON

1

O

OFF

2

Figure 0-25. Power Label (PN 57G7919 and PN 57G7976)

Note: Depending on the machine configuration you may have one or two power

supplies installed. Based on that, one or two power cords may be present.

Only a part of this label is shown. This label installed on the machine is

translated into 14 languages.

LABEL B

<

60 V dc

240 V A

>

LABEL C

<

>

LABEL D

60 V dc

<

>

240 V A

Figure 0-26. Board Labels (PN 57G7920)

xliv 2220 Models 300, 500, and 501: Service Guide

60 V dc

240 V A

<

>

<

>

60 V dc

240 V A

60 V dc

240 V A

<

>

60 V dc

240 V A

<

>

60 V dc

240 V A

<

>

60 V dc

240 V A

<

>

60 V dc

240 V A

<

>

60 V dc

240 V A

60 V dc

<

>

240 V A

Page 47

LABEL E

< 60 V dc

> 240 V

A

LABEL G

DO NOT OPEN

NE PAS OUVRIR

NICHT ÖFFNEN

NIET OPENEN

NON APRIRE

NO ABRIR

~

NAO ABRIR

LABEL P

-

200

-

8

/

50

Figure 0-27. Other Labels

LABEL H

LABEL J

240 V

6.3A

60 Hz

>18Kg

SAFETY EXTRA LOW VOLTAGE INPUT ONLY

ALIMENTATION TRES BASSE TENSION DE

SECURITE SEULEMENT

NUR AN SICHERHEITS-KLEINSPANNUNG ANSCHLIESSEN

LABEL L

SEALED LEAD

ACID BATTERY

BATTERY MUST

BE RECYCLED

Figure 0-28. Labels Used for Europe, Taiwan, and Brazil (PN 57G7959)

General and Product Safety xlv

+

Pb

LABEL K

CONTAINS

SEALED LEAD

ACID BATTERY

BATTERY MUST

BE RECYCLED

+

Pb

Page 48

LABEL L

Pb

SEALED LEAD

ACID BATTERY

BATTERY MUST

BE RECYCLED

LABEL K

Figure 0-29. Labels Used for Other Countries (PN 57G7958)

LABEL N

R

NRTL/C LEVEL 5

CODE: 3557-99-100

INPUT: -48V(60V...-39V) - - -

OUTPUT:

CP1-CP5: -48V - - - 12A (-60V. . . -36V - - -)

TOTAL OUTPUT POWER:

1550W MAXIMUM

LR 56325

MagneTek S.p.A.

MADE IN ITALY

43A MAXIMUM

CP6: -48V - - - 6A (-60V . . . -36V - - -)

Pb

CONTAINS

SEALED LEAD

ACID BATTERY

BATTERY MUST

BE RECYCLED

Figure 0-30. Power Rating Label for DC48

LABEL M1 and M2

R

NRTL/C LEVEL 5

LR 56325

MagneTek S.p.A.

MADE IN ITALY

CODE: 3547-99-100

OPERATIONFROM MAINS

INPUT:200-240 V 50-60Hz 9.1 A

OUTPUT:

CP1-CP5: -48V ---10A

CP6: -48V - - - 6A

TOTAL OUTPUT POWER: 1350W MAXIMUM

OPERATIONFROM BATTERY BACK-UP UNIT

OUTPUT:-59V . . . -36V - - -

TOTAL OUTPUT POWER: 675 W MAXIMUM

Figure 0-31. Power Rating Label for ACDC

10

OK

OK

HP2600 Vdc

M1

M2

xlvi 2220 Models 300, 500, and 501: Service Guide

Page 49

LABEL R

HIGH LEAKAGE CURRENT

Permanent ground connection

is mandatory

before connecting power supplies

and making network connections.

Figure 0-32. Label for 2220 Rack (PN 80G3929)

LABEL S

HIGH LEAKAGE CURRENT

Permanent ground connection

is mandatory

before network connections.

Figure 0-33. Label for LCB (PN 80G3928)

General and Product Safety xlvii

Page 50

xlviii 2220 Models 300, 500, and 501: Service Guide

Page 51

About this Manual

Aim of this Manual

The service guide gives the service representative the information needed to:

Exchange all the FRUs of the 2220

Run diagnostics on the 2220.

It is expected that the 2220 problem determination has been done by the remote

support center (RSC).

Who Should Read this Manual

The person using this manual should be:

Trained to service the 2220.

Familiar with the configuration and operation of the 2220.

Familiar with the configuration and operation of the Nways Switch

administration station.

The intended audience for this manual is Product-Trained Customer Engineers

(PT-CE). The Product-Support Customer Engineer (PST-CE) is also expected to

refer to the manual when required to perform the same tasks as the PT CE.

How this Manual is Organized

This manual is organized as follows:

Safety information is at the beginning of this book.

Chapter 1 Gives page number references for starting various service and

troubleshooting procedures.

Chapter 2 Gives an introduction and an overview of the 2220.

Chapter 3 Gives an overview of the functions available on Nways Switch

administration station, and how to invoke some of them.

Chapter 4 Gives the diagnostics available for 2220, and how to invoke

these diagnostics.

Chapter 5 Gives the MAPs to be used for problem determination on the

2220.

Chapter 6 Gives the procedure to exchange the FRU on 2220.

Appendixes A to E Give:

Copyright IBM Corp. 1998, 1999 xlix

Schematics

Maintenance aids

2220 Power Consumption

Parts catalog

Page 52

Part number index

Appendix X Gives:

Bibliography

Glossary

Index.

l 2220 Models 300, 500, and 501: Service Guide

Page 53

Chapter 1. START - Finding a Service Procedure

Note: The 2220 models 300, 500, and 501 are installed in a 37 U1 rack or 29 U rack. In this manual

the 2220 models are shown installed in a 37 U rack. The 29 U rack is shown only when the

procedures are different from the 37 U rack.

Select the first entry point that fits your situation.

If You Have Description Go to

GENERAL

SYMPTOM

MAINTENANCE

ACTION

MISCELLANEOUS

INFORMATION

2220 power symptom “MAP 0500: 2220 Basic Verification” on page 5-2.

2220 control panel symptom “MAP 0500: 2220 Basic Verification” on page 5-2.

Nways Switch administration

station symptom

2220 Basic verification “MAP 0500: 2220 Basic Verification” on page 5-2.

2220 FRU to exchange Chapter 6, “2220 FRU Exchange” on page 6-1.

Nways Switch administration

station FRU to exchange

Run diagnostics on the 2220 or “Service Operation via Nways Switch

2220 Service operation via the

Nways Switch administration

station

Run diagnostics on the Nways

Switch administration station

Test the Nways Switch

administration station links

2220 In broadband network “Typical Broadband Network Based on 2220” on

2220 model overview “2220 Models” on page 2-2.

Nways Switch administration

station windows overview

2220 control panel functions “Nways Switch Administration Station Windows

2220 schematics Appendix A, “Schematics” on page A-1.

2220 parts catalog Appendix D, “Parts Catalog” on page D-1.

Refer to the Nways Switch administration service

guide.

Refer to the Nways Switch administration service

guide.

Administration Station” on page 1-2.

“Service Operation via Nways Switch

Administration Station” on page 1-2.

Refer to the Nways Switch administration service

guide.

Refer to the Nways Switch administration service

guide.

page 2-1.

“Nways Switch Administration Station Windows

Overview” on page 3-5.

Overview” on page 3-5.

1

U means EIA Units (U-units)

Copyright IBM Corp. 1998, 1999

1-1

Page 54

Service Operation via Nways Switch Administration Station

Service Action Go to

Logon to the 2220 (Local) “How to Start on the Local 2220” on page 3-1

Logon to the 2220 (Remote) “How to Logon to the Remote 2220” on page 3-1

Display the Nways Switch

configuration

Display the TCP/IP addresses “How to Find a TCP/IP Address” on page 3-20

Display the Nways Switch Control

Program Inventory

Display the test event desk “How to Display the Test Event Desk” on page 3-18

Display CMIP Status “How to Display the CMIP Status” on page 3-8

Display the Alarm Desk “How to Display the Alarm Desk” on page 3-11

Run diagnostics on the 2220 Chapter 4, “2220 Diagnostics” on page 4-1.

Run diagnostics on the Nways Switch

administration station

Test the link between the Nways

Switch administration station and the

NSC

Test the Nways Switch administration

station links

Find machine and module power

consumption

Emergency trunck unlock “How to Perform the Emergency Trunk Unlock” on page 3-26.

Removing a line or trunk cable on

operational 2220

“How to Display the Nways Switch Configuration” on page 3-13

“How to Display the Nways Switch Control Program Inventory and

Level” on page 3-22

Refer to the Nways Switch administration service guide.

Refer to the Nways Switch administration service guide.

Refer to the Nways Switch administration service guide.

Appendix C, “2220 Power Consumption” on page C-1.

“How to Remove a Line or Trunk Cable” on page 3-24.

1-2 2220 Models 300, 500, and 501: Service Guide

Page 55

Chapter 2. Introduction / Overview

Typical Broadband Network Based on 2220

To IBM Network

Support Center

(Via Modem)

User

Premises

User

Premises

2220

Centralized

Configuration

Database

OS/2 Workstation

with Nways Switch

Configuration Tool

Ethernet LAN

Entry

point

2220

Via

2220

Network Management Station

and

Change Control Server

NetView for AIX with

Nways Enterprise Manager

and

NetView DM for AIX

Broadband

Network

2220

User

Premises

Copyright IBM Corp. 1998, 1999 2-1

2220

Nways Switch

Adminstration

Station

User

Premises

Customer

Remote Console

(via Modem or

Ethernet LAN)

Page 56

2220 Models

This manual covers the following 2220 models:

2220 Model 300 (low-end unit)

2220 Model 500 (base unit)

2220 Model 501 (expansion to 2220 Model 500)

2-2 2220 Models 300, 500, and 501: Service Guide

Page 57

2220 Control Panel Functions

FAN BOX

1

2

APC RESET

ALARM

A P C

POWER SUPPLY

1

2

The front panel contains:

The power ON/STANDBY switch, which is used to power ON (position on the

control panel) or STANDBY (position on the control panel) the 2220 (see

note).

The APC RESET button, which resets the APC (but does not disturb the data

traffic).

Six LEDs that indicate different status:

POWER SUPPLY 1 and 2 Each of these two green LEDs reflects the status

of one power supply (1 or 2). Each LED is ON

when the associated power supply is ON.

APC This green LED is ON when the alarm and power

control (APC) module inside the 2220is running

error free. It is blinking during the power on self

test (POST), or when an adapter has been

disabled.

ALARM This yellow LED is ON when an error has been

detected in the 2220.

FAN BOX 1 and 2 Each of these two yellow LEDs reflects the status

of one FAN box. They are ON as soon a FAN

problem has been detected.

Note: When the power ON/STANDBY switch is on the STANDBY position on

the control panel), the 2220 board is powered OFF while the power-supplies

are still in Stand-by mode (energized).

Chapter 2. Introduction / Overview 2-3

Page 58

2-4 2220 Models 300, 500, and 501: Service Guide

Page 59

Chapter 3. Nways Switch Administration Station Functions

How to Start on the Local 2220

To log on:

1. Be sure that the 2220 and the Nways Switch administration station are

powered ON.

2. In the Nways Switch Desktop window, select the desired icon by clicking on

the left button of the mouse (left button is used to select an icon or resource,

and the right button displays the associated menu).

Figure 3-1. Nways Switch Desktop Display

3. For detail refer to the “Nways Switch Administration Station Windows Overview”

on page 3-5.

How to Logon to the Remote 2220

When the Nways Switch administration station is powered ON and initialized the

Nways Switch Desktop window is displayed:

1. Double click on the Nways Switch Services icon.

2. In the Nways Switch Services window, double click on the Nways Switch

Resource Control (Remote) icon.

Copyright IBM Corp. 1998, 1999 3-1

Page 60

The Logon Remote NAS window is displayed.

3. Enter the requested information then click on Logon.

4. The following windows are displayed. Click on OK on each of them.

3-2 2220 Models 300, 500, and 501: Service Guide

Page 61

The Nways Switch Resource Control window of the remote NAS is displayed.

5. In the Nways Switch Resource Control window, click on View then on View,

Expanded Tree View.

6. Wait until all icons are displayed.

Chapter 3. Nways Switch Administration Station Functions 3-3

Page 62

Figure 3-2. Example of Expanded Tree

7. Perform the desired action on the window.

3-4 2220 Models 300, 500, and 501: Service Guide

Page 63

Nways Switch Administration Station Windows Overview

When the Nways Switch administration station is powered ON and initialized the

Nways Switch Desktop window is displayed.

1. Double click on the Nways Switch Services icon.

2. In the Nways Switch Services window, double click on the Nways Switch

Resource Control (Local) icon.

3. Click on OK in the Product Information window.

4. In the Nways Switch Resource Control window, click on View, Expanded

Tree View.

5. Wait until all icons are displayed.

Chapter 3. Nways Switch Administration Station Functions 3-5

Page 64

Figure 3-3. Example of Expanded Tree

6. In the Node Resources window, using the right key on the mouse, click on the

icon of the resource that you want to select, then using the left button on the

mouse, click again on the resource to display a popup window with all options

available for the resource.

3-6 2220 Models 300, 500, and 501: Service Guide

Page 65

Figure 3-4. Example of Options Available for a Selected Resource

Figure 3-5. Example of Options Available for a Switch

Chapter 3. Nways Switch Administration Station Functions 3-7

Page 66

How to Display the CMIP Status

When the Nways Switch administration station is powered ON and initialized the

Nways Switch Desktop window is displayed.

1. Double click on the Nways Switch Services icon.

2. In the Nways Switch Services window, double click on the Nways Switch

Resource Control (Local) icon.

3. In the Nways Switch Resource Control window, click on View, Expanded

Tree View.

4. Wait until all icons are displayed.

3-8 2220 Models 300, 500, and 501: Service Guide

Page 67

Figure 3-6. Example of Expanded Tree

5. In the Node Resources window, using the right key on the mouse, click on the

icon of the resource that you want to select. A popup window with all options

available for the resource is displayed.

Chapter 3. Nways Switch Administration Station Functions 3-9

Page 68

6. Click on the Open the on the Status option.

The Display CMIP Status window is displayed with the current status

highlighted.

3-10 2220 Models 300, 500, and 501: Service Guide

Page 69

How to Display the Alarm Desk

When the Nways Switch administration station is powered ON and initialized the

Nways Switch Desktop window is displayed.

1. Double click on the Nways Switch Services icon.

2. In the Nways Switch Services window, double click on the Nways Switch

Alarm Desk icon.

The Alarm Desk window is displayed.

3. By clicking on the Search option in the menu bar you have all the facilities for

selecting a specific alarm.

Chapter 3. Nways Switch Administration Station Functions 3-11

Page 70

Figure 3-7. Search Options in the Alarm Desk Window

3-12 2220 Models 300, 500, and 501: Service Guide

Page 71

How to Display the Nways Switch Configuration

When the Nways Switch administration station is powered ON and initialized the

Nways Switch Desktop window is displayed.

1. In the Nways Switch Desktop window, double click on the Nways Switch

Configuration icon.

2. Double click on the Nways Switch Configuration Tool icon.

3. A Nways Switch Configuration Tools window is displayed.

4. Double click on the rack icon that you want to know the configuration.

Chapter 3. Nways Switch Administration Station Functions 3-13

Page 72

5. Different icons are displayed. Double click on the selected icon. According to

the icon selected you have different window displayed. For example if you click

on the Rack A the following window is displayed.

6. If you double click on the LIC511 the following window is displayed.

3-14 2220 Models 300, 500, and 501: Service Guide

Page 73

7. Double click on the LCB 1 Expansion icon the following window is displayed.

8. Double click on the 29 line icon. The following window is displayed showing the

line configuration

Chapter 3. Nways Switch Administration Station Functions 3-15

Page 74

9. From the rack configuration window you also can select an adapter.

3-16 2220 Models 300, 500, and 501: Service Guide

Page 75

10. Double click on a adapter icon the following window is displayed showing the

adapter configuration.

Chapter 3. Nways Switch Administration Station Functions 3-17

Page 76

How to Display the Test Event Desk

When the Nways Switch administration station is powered ON and initialized the

Nways Switch Desktop window is displayed.

1. Click on the Nways Switch Services icon.

2. In the Nways Switch Services window, click on the Nways Switch Resource

Control (Local) icon.

3. In the Nways Switch Resource Control window, click on View and then on

the Test Event Desk option.

The following window is displayed.

3-18 2220 Models 300, 500, and 501: Service Guide

Page 77

Chapter 3. Nways Switch Administration Station Functions 3-19

Page 78

How to Find a TCP/IP Address

The Nways Switch Installation Program is used to customize the IP parameters

from the data imported with the configuration file.

1. Double click on the Nways Switch Installation icon.

Figure 3-8. Nways Switch Desktop Window

2. Double click on the Nways Switch Installation Program icon.

Figure 3-9. Nways Swith Installation Window

3. Select option 5 and press Enter.

Figure 3-10. Installation Program Main Menu

4. In the window displayed search for the required TCP/IP address. See

Figure 3-11 on page 3-21.

3-20 2220 Models 300, 500, and 501: Service Guide

Page 79

Figure 3-11. Example of TCP/IP address

Chapter 3. Nways Switch Administration Station Functions 3-21

Page 80

How to Display the Nways Switch Control Program Inventory and

Level

When the Nways Switch administration station is powered ON and initialization is

completed the following window is displayed:

1. Double click on the Nways Switch Services icon.

2. In the Nways Switch Services window, double click on the Nways Switch

Control Program Inventory icon.

3. A Nways Switch Control Program Software Inventory window is displayed

with the file name and the date of changes.

3-22 2220 Models 300, 500, and 501: Service Guide

Page 81

Figure 3-12. Example of Nways Switch Control Program Software Inventory

Chapter 3. Nways Switch Administration Station Functions 3-23

Page 82

How to Remove a Line or Trunk Cable

Important

Before removing a line or trunk cable attached to an active LIC, lock the

corresponding line or trunk using the following procedure.

The following procedure is an example of how to Lock a Line. The window

contents may be different on your screen.

When the Nways Switch administration station is powered ON and initialized the

Nways Switch Desktop window is displayed.

1. Click on the Nways Switch Services icon.

2. In the Nways Switch Services window, click on the Nways Switch Resource

Control (Local) icon.

3. In the Nways Switch Resource Control window, using the left or bottom

button on the mouse, click on the

right or top button on the mouse, click again on the resource.

Line

that you want to lock. Then using the

4. The following window is displayed. Click on the Lock option.

3-24 2220 Models 300, 500, and 501: Service Guide

Page 83

5. A warning Disruptive action window is displayed with the following message.

6. Click on Yes

7. A new window is displayed. Click on OK.

Remove the cable.

If you re-install a new cable, using the same procedure, do not forget to unlock the

line .

Chapter 3. Nways Switch Administration Station Functions 3-25

Page 84

How to Perform the Emergency Trunk Unlock

Important

The emergency trunck unlock must be performed when the trunck as been

locked inadvertently from the NSM.

The following procedure is an example of how to Unlock a Trunk. The window

contents may be different on your screen.

When the Nways Switch administration station is powered ON and initialized the

Nways Switch Desktop window is displayed.

1. Click on the Nways Switch Services icon.

2. In the Nways Switch Resource Control window, using the left or bottom

button on the mouse, click on the

the right or top button on the mouse, click again on the resource.

3. The following window is displayed. Click on the Emergency Trunk Unlock

option.

trunk

that you want to unlock. Then using

3-26 2220 Models 300, 500, and 501: Service Guide

Page 85

Chapter 4. 2220 Diagnostics

2220 Diagnostics Available from the NAS

Several diagnostics are available from the Nways Switch administration station.

These diagnostics are automatically displayed as soon as the resource has been

selected and diagnostics invoked

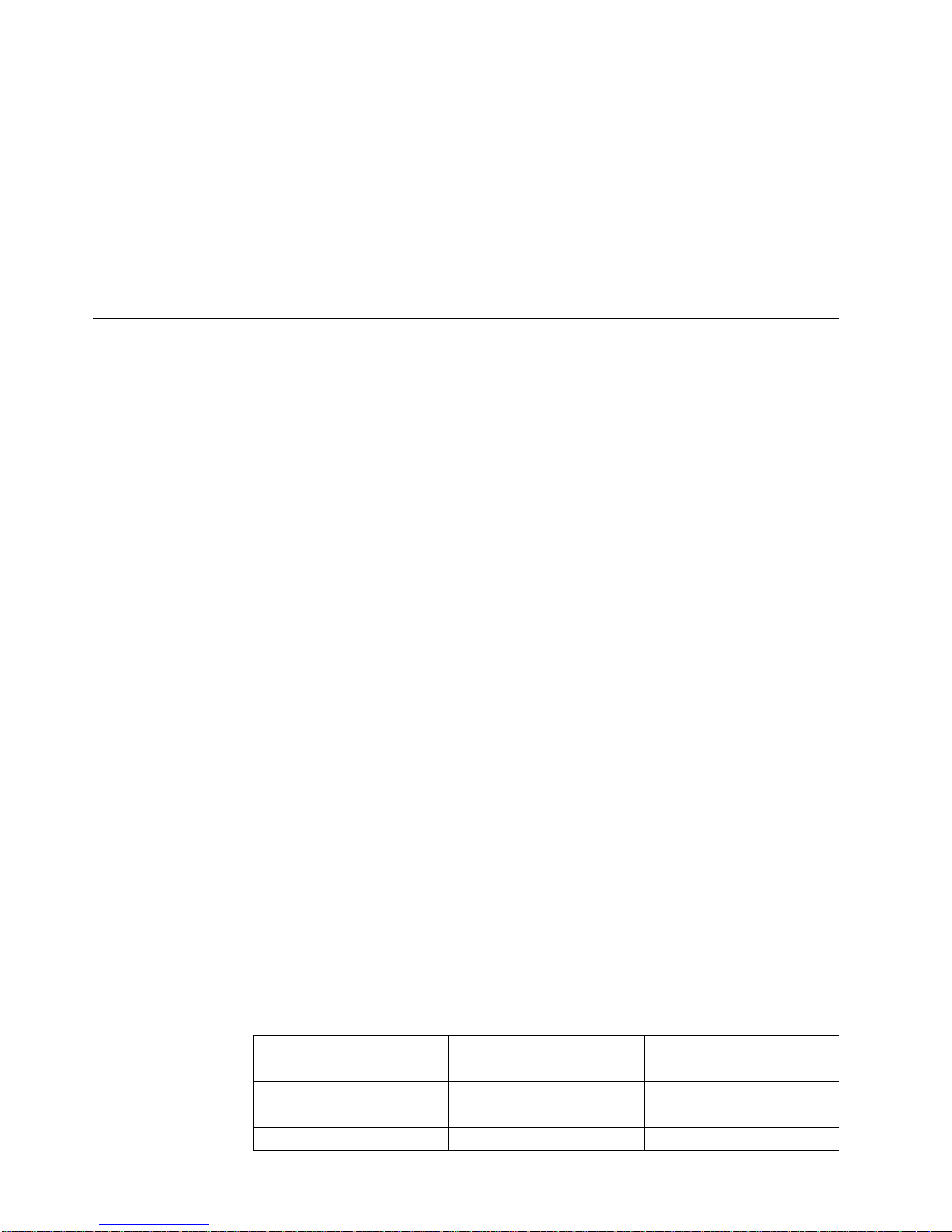

The following table gives the resources that have associated diagnostics

Table 4-1. Resources and Available Diagnostics.

Resource

Name

Rack All Switch to Line

Adapter Switch to Line Interface See “Switch to Line Interface

Line or Trunk

Power Battery test Test the loading of the battery

Name of Diagnostics

Available

Interface

Line Interface Test See “Line Interface Test” on

Line wrap plug test See “Line Wrap Plug Test” on

Line loopback test See “Line Loopback Test” on

2220 trunk loopback

test

Line loop See “Loop Line and Loop

Trunk loop See “Loop Line and Loop

Diagnostics Description How to Run Diagnostics

See “All Switch to Line

Interface Tests” on page 4-2

Test” on page 4-2

page 4-4.

page 4-5.

page 4-6.

See “2220 Trunk Loopback

Test” on page 4-6

Trunk” on page 4-7.

Trunk” on page 4-7.

on 24 hours.

Go to “How to Run the All

Switch to Line Interface Test”

on page 4-8.

Go to “How to Run the Switch

to Line Interface Test” on

page 4-10.

Go to “How to Run the Line

Interface Test” on page 4-12.

Go to “Line Loopback Test” on

page 4-6.

Not yet available.

The line loop must be done on

the remote site before starting

a line loopback test. See “Line

Loopback Test” on page 4-6.

The trunk loop must be done

on the remote side before

starting a 2220 trunk loopback

test.

Go to “How to Test an ACDC

Power and Battery” on

page 4-25.

Copyright IBM Corp. 1998, 1999 4-1

Page 86

All Switch to Line Interface Tests

This diagnostic performs a power on self test (POST) and loopback on all adapters

of the rack (see “Switch to Line Interface Test”) equivalent test for one adapter.

Attention:

During an All Switch to Line Interface Test the Nways Switch traffic is stopped.

Switch to Line Interface Test