Page 1

IBM SAN Fibre Channel Switch

2109 Model S16 Installation and Service

Guide

The IBM License Agreement for Machine Code is included

in this book. Carefully read the agreement. By using this

product you agree to abide by the terms of this agreement

and applicable Copyright Laws.

SC26-7352-01

Page 2

Page 3

IBMSANFibreChannelSwitch

IBM

2109 Model S16 Installation and Service

Guide

SC26-7352-01

Page 4

Note:

Before using this information and the product it supports, read the information in “Safety and environmental notices” on

page xi and “Notices” on page 131.

Second Edition (December 2000)

This edition replaces SC26-7352-00.

Publications are not stocked at the address given below. If you want additional IBM publications, ask your IBM

representative or write to the IBM branch office serving your locality.

A form for your comments is provided at the back of this publication. If the form has been removed, address your

comments to:

International Business Machines Corporation

RCF Processing Department

Dept. G26/Bldg. 050-3

5600 Cottle Road

San Jose, CA 95193-0001

U.S.A.

FAX: 1-800-426-6209

You can also send your comments electronically to: starpubs@us.ibm.com

When you send information to IBM, you grant IBM a nonexclusive right to use or distribute the information in any

way it believes appropriate without incurring any obligation to you.

© Copyright International Business Machines Corporation 1999, 2000. All rights reserved.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 5

Contents

Figures ...........................vii

Tables ............................ix

Safety and environmental notices .................xi

Translated safety notices .....................xi

Disposing of products.......................xi

About this book ........................xiii

Who should use this book.....................xiii

Where to start ........................xiii

Limited vocabulary ......................xiii

Ordering publications ......................xiii

Product library ........................xiii

Related publications ......................xiv

Web sites..........................xiv

Chapter 1. Introduction......................1

Switch features .........................1

Performance .........................2

Manageability .........................2

System components .......................2

GBICs ...........................2

Power supply .........................3

Fibre-channel cable connections ..................4

Front panel..........................5

Diagnostics overview .......................7

Verifying a power-on self-test (POST) ................7

Running diagnostics ......................7

Loop (FL) connections .....................8

||

Chapter 2. Customer planning ...................9

Chapter 3. Installing the switch ..................19

Pre-installation checklist .....................19

Installing the switch .......................20

Tabletop installation ......................20

Rack-mount installation .....................20

Installing the optional power supply .................24

Installing GBICs ........................25

Setting the IP address ......................26

Setting the IP address using the Ethernet port ............27

Setting the IP address from the front panel .............28

Switch installation verification ..................31

Code upgrade procedure .....................31

Upgrade procedure .......................31

Downloading firmware from a UNIX

Downloading firmware using a Microsoft

®

host ..............31

®

Windows NT operating system 32

Chapter 4. Maintenance action plans ................33

Problem determination start map ..................33

System reported error .....................33

Service reference table ......................35

© Copyright IBM Corp. 1999, 2000 iii

Page 6

Action codes and recommended actions ..............35

Chapter 5. Replacing FRUs....................45

Parts catalog .........................45

Replacing the power supply ....................45

Tools that are required .....................46

Removing a power supply....................46

Installing a power supply ....................47

Replacing a GBIC module.....................47

Tools that are required .....................47

Removing a GBIC module....................47

Installing a GBIC module ....................47

Replacing a fan assembly .....................48

Tools that are required .....................48

Removing a fan assembly....................48

Installing a fan assembly ....................49

Replacing the system board assembly ................49

Tools that are required .....................49

Removing the system board ...................49

Installing the system board ...................50

Replacing the chassis with touchpad .................50

Tools that are required .....................50

Removing the old chassis ....................51

Installing the new chassis ....................51

Verifying switch repair ......................51

Verifying a repair that did not require turning the switch off........52

Verifying a repair that required turning the switch off ..........52

||

||

||

||

||

||

||

||

||

||

||

||

||

||

||

||

||

||

||

||

||

||

Chapter 6. Optional features ...................53

Fabric Watch .........................53

Threshold behavior models ...................54

Installing Fabric Watch .....................55

Installing Fabric Watch through Telnet ...............55

Installing Fabric Watch through the IBM StorWatch Specialist.......56

Fabric Watch overview .....................56

Telnet commands overview ...................57

Telnet commands .......................58

Remote Switch .........................62

Introducing the Remote Switch ..................62

Installing the Remote Switch ...................62

Installing through Telnet.....................63

Installing through the IBM StorWatch Specialist ............63

Extended Fabrics ........................64

Introducing Extended Fabrics ..................64

Installing Extended Fabrics ...................64

Installing through Telnet.....................64

Installing through the IBM StorWatch Specialist ............65

Using Extended Fabrics ....................65

Configuring Extended Fabrics ..................65

Accessing through the Telnet interface ...............66

Chapter 7. Management tools ...................69

||

||

||

||

Switch management methods ...................69

Hardware setup for switch management ...............70

Setting switch IP address using the front panel ............71

Setting the IP address using the Ethernet port ............71

iv IBM SAN Fibre Channel Switch: 2109 Model S16 Installation and Service Guide

Page 7

||

||

||

||

Setting the IP address .....................73

Managing with Telnet ......................73

Default user name ......................73

Changing passwords......................74

Managing with SNMP ......................74

SNMP transports .......................76

||

||

Managing using the management server ...............78

Using the management server ..................79

syslog daemon .........................79

Introduction .........................79

syslogd support .......................80

Error message format .....................80

Message classification .....................81

Power-on self-test (POST).....................82

Chapter 8. Zoning overview ...................85

Appendix A. Specifications....................87

General specifications ......................87

Fabric management specifications..................87

Optical port specifications .....................88

Environmental specifications ....................88

Power supply specifications ....................89

Appendix B. Diagnostics.....................91

Diagnostic overview .......................91

Isolating a system fault .....................91

Removing power .......................91

Service action for error messages .................91

POST tests .........................91

Diagnostic tests ........................92

Test menu .........................92

Running diagnostics from the front panel ..............92

Front panel switch menus ....................94

Running diagnostics using Telnet.................101

||

||

||

||

||

||

||

Appendix C. Error messages ..................117

System error message formats ..................117

Diagnostic error message formats .................118

Error message numbers .....................119

Repair action code meanings for diagnostic error messages........121

Diagnostic error messages ....................122

System error messages .....................125

Notices ...........................131

Trademarks..........................131

Electronic emission statements ..................132

Federal Communications Commission (FCC) statement ........132

Industry Canada compliance statement ..............132

European Community compliance statement ............132

Germany compliance statement .................133

Japanese Voluntary Control Council for Interference (VCCI) class 1

statement ........................134

Korean Government Ministry of Communication (MOC) statement ....134

Taiwan class A compliance statement ...............134

IBM license agreement for Machine Code ..............134

Contents v

Page 8

Statement of limited warranty ...................135

Production status ......................135

IBM warranty for Machines ...................135

Warranty service.......................136

Extent of warranty ......................136

Limitation of liability......................137

||

Glossary ..........................139

Index ............................145

vi IBM SAN Fibre Channel Switch: 2109 Model S16 Installation and Service Guide

Page 9

Figures

1. Front panel of the 2109 Model S16 Switch ......................1

2. Short wavelength (SWL) laser fiber-optic GBIC module (P/N and labeling vary) ........3

3. Long wavelength (LWL) laser fiber-optic GBIC module (P/N and labeling vary) ........3

4. Power supplies ................................4

5. Dual SC fiber-optic plug connector .........................5

6. Front panel functionality.............................5

7. Moving slide ................................22

8. Mounting the moving portion of slide and locking ears to the switch ............22

9. Mounting the fixed portion of the rail and the locking ears to the rack ...........23

10. Inserting slides into the rack rails .........................24

11. 2109 model S16 with two power supplies ......................25

12. GBIC ...................................26

13. GBIC swing handle ..............................26

14. Ethernet port connector ............................27

15. Front panel - operator display and control buttons...................28

16. Front panel of the 2109 Model S16 Switch .....................33

17. Generated Telnet messages when a power supply is turned off and removed ........46

18. Power supply handle .............................47

19. IBM GBIC module ..............................47

20. Fan assembly ................................48

21. System board assembly ............................49

22. Chassis with touchpad.............................51

||

23. Example of range threshold: temperature (Celsius) ..................54

||

24. Example of rising and falling threshold: Error rate ...................55

||

25. Methods for managing the switch .........................70

||

26. Front panel — operator display and control buttons ..................71

||

27. Front panel of the 2109 Model S16 Switch .....................72

||

28. MIB tree ..................................75

29. Example of a no memory error generated by the shell .................81

30. syslogd support ...............................82

31. Example syslog configuration file entry .......................82

32. Example syslog configuration file entry .......................82

33. A fabric with three zones ............................86

34. Front panel functionality ............................93

35. Select menu ................................93

36. Menu hierarchy ...............................94

37. Switch setup to run crossPortTest.........................98

38. System memory test .............................98

39. ramTest ..................................99

40. portLoopbackTest command example .......................99

41. portRegTest command example .........................99

42. Push button command example .........................100

43. spinSilk command example ..........................100

44. Switch offline command example ........................101

45. Switch online command example ........................101

46. camTest command example ..........................102

47. centralMemoryTest command example ......................103

48. cmemRetentionTest command example ......................103

49. cmiTest command example ..........................103

50. crossPortTest command example ........................106

51. diagClearError command example ........................106

52. diagDisablePost command example .......................107

53. diagEnablePost command example .......................107

© Copyright IBM Corp. 1999, 2000 vii

Page 10

54. diagShow command example..........................108

55. portLoopbackTest command example .......................109

56. portRegTest command example .........................110

57. ramTest command example ..........................110

58. setGbicMode 1 command example ........................111

59. setGbicMode 0 command example ........................111

60. sramRetentionTest command example ......................114

61. supportShow command example ........................115

||

62. errShow command example ..........................118

viii IBM SAN Fibre Channel Switch: 2109 Model S16 Installation and Service Guide

Page 11

Tables

1. Cabling connections ..............................4

2. Control buttons ................................5

3. Front panel LED status indicators .........................6

4. Offline and Online tests .............................7

5. Offline and online test .............................8

6. Example of a planning worksheet for a 2109 switch ..................9

||

7. Blank of a planning worksheet for a 2109 switch ...................11

||

8. Example of a configuration worksheet for a 2109 switch ................12

||

9. Blank of a port configuration worksheet for a 2109 switch ................13

||

10. Example of a zone definitions worksheet ......................14

||

11. Blank of a zone definitions worksheet .......................15

||

12. Zone configuration worksheet example.......................16

||

13. Blank of a zone configuration worksheet ......................17

||

14. Pre-installation checklist ............................19

15. Control buttons ...............................28

16. Service reference table ............................35

17. Action code and recommended actions ......................35

18. Field replaceable units (FRUs) list ........................45

19. Fabric Watch Telnet commands .........................57

||

20. Comparison of management access methods ....................69

||

21. Default user name ..............................73

||

syslogd

22.

23. Switch specifications .............................87

24. Fabric management specifications ........................87

25. Environmental specifications ..........................88

26. Power supply requirements ...........................89

27. POST tests .................................91

28. Control buttons ...............................93

29. Offline and online diagnostic tests ........................94

30. centralMemoryTest example...........................95

||

31. cmemRetention test example ..........................96

||

32. cmiTest example ...............................96

||

33. Offline and online diagnostic tests ........................102

34. diagShow command field descriptions ......................108

35. portLoopbackTest command field descriptions....................109

36. spinSilk command example 1..........................112

37. spinsilk command example 2 ..........................113

38. Probable failure actions ............................118

||

39. Error message code defined ..........................119

||

40. Action codes and recommended actions......................121

||

41. Diagnostic error messages...........................122

||

42. System error messages ............................125

||

message classifications .........................81

© Copyright IBM Corp. 1999, 2000 ix

Page 12

x IBM SAN Fibre Channel Switch: 2109 Model S16 Installation and Service Guide

Page 13

Safety and environmental notices

Safety notices are printed throughout this manual. Danger notices warn you of

conditions or procedures that can result in death or severe personal injury. Caution

notices warn you of conditions or procedures that can cause personal injury that is

neither lethal nor extremely hazardous. Attention notices warn you of conditions or

procedures that can cause damage to machines, equipment, or programs.

Translated safety notices

The translation of the safety notices in this manual are contained in a separate

manual. See the

translation of any danger and caution notices.

Disposing of products

This unit may contain batteries. Remove and discard these batteries, or recycle

them, according to local regulations.

IBM External Devices Safety Information Manual

, SA26-7003, for a

© Copyright IBM Corp. 1999, 2000 xi

Page 14

xii IBM SAN Fibre Channel Switch: 2109 Model S16 Installation and Service Guide

Page 15

About this book

This book describes how to install and maintain the IBM SAN Fibre Channel Switch

2109 Model S16.

Who should use this book

This book is intended for trained service representatives and service providers who

act as the primary level of field hardware service support to help solve and

diagnose hardware problems on the IBM SAN Fibre Channel Switch 2109 Model

S16.

This book also assists the customer in planning the installation of the 2109 Model

S16 switch.

|

|

“Chapter 2. Customer planning” on page 9 contains the customer planning

worksheets that are required to be filled out before installing the 2109 switches.

Before using this book, you must know how to service the switch hardware, and

how to analyze, isolate, report, and resolve problems. You must also know how to

safely work with electrical components. Throughout this book, the term “switch”

applies to any IBM 2109 switch, unless the reference is to a specific model.

Where to start

When performing any service action on the switch, follow the directions given in

“Chapter 4. Maintenance action plans” on page 33. This ensures that you use the

correct remove, replace, or repair procedures for this machine, including the correct

procedures to turn the power on and off. Failure to follow these instructions can

cause damage to the machine.

Limited vocabulary

This book uses a specific range of words so that the text can be understood by IBM

service support representatives in countries where English is not the primary

language.

Ordering publications

All of the publications listed in the switch product library are shipped as appropriate

with their respective switches. You can also order additional copies of each

publication.

Product library

The IBM 2109 Model S16 is an IBM SAN Fibre Channel Switch product. See the

following publications for more information about the switch:

v

IBM SAN Fibre Channel Switch 2109 Model S16 User’s Guide

This book introduces the IBM 2109 Model S16 Switch, and its features. It also

provides information about using the IBM StorWatch

Specialist, setting up zoning, and methods for managing the IBM 2109 Model

S16 Switch remotely.

IBM SAN Fibre Channel Switch 2109 Model S16 Installation and Service Guide

v

SC26-7352.

© Copyright IBM Corp. 1999, 2000 xiii

, SC26-7351

™

SAN Fibre Channel Switch

,

Page 16

This book introduces the product and lists the features you can order. It also

provides procedures for installing, configuring, and servicing the IBM 2109 Model

S16 Switch.

IBM External Devices Safety Information

v

This book provides translations of the Danger and Caution notices used in IBM

2109 switch publications.

Related publications

v

Electrical Safety for IBM Customer Engineers

v

Fibre Channel Standards

Web sites

For additional information about storage products, see our Web site at:

www.ibm.com/storage/fcswitch

For detailed information about the fibre-channel standards, see the fibre-channel

association Web site at:

www.fibrechannel.com

, SA26-7003.

, S229-8124

xiv IBM SAN Fibre Channel Switch: 2109 Model S16 Installation and Service Guide

Page 17

Chapter 1. Introduction

The IBM SAN Fibre Channel Switch 2109 Model S16 is a 16-port, fibre-channel,

switch. The IBM 2109 Model S16 Switch consists of a system board with

connectors for supporting up to 16 ports, and a fabric operating system for creating

and managing a fabric. A

scheme for a fibre channel.

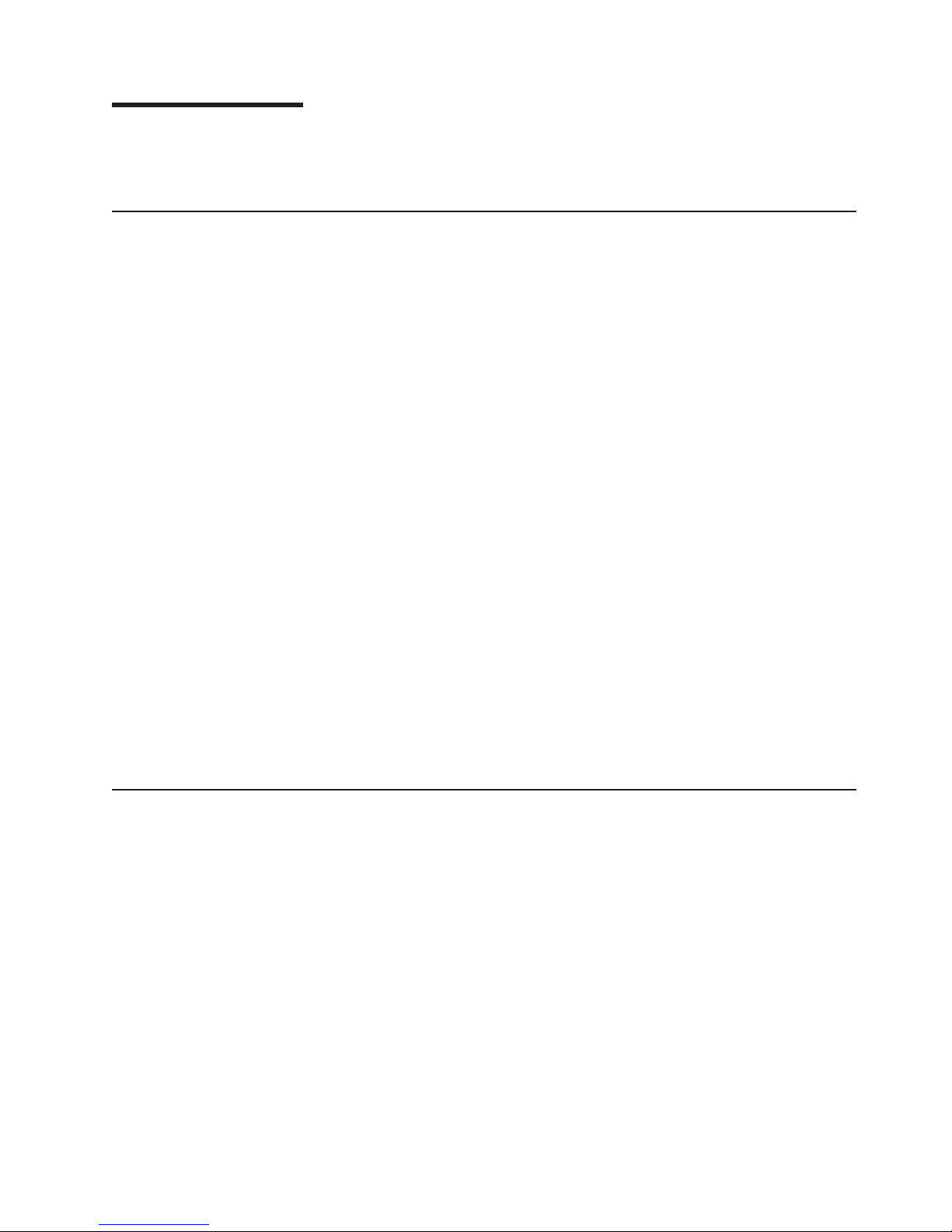

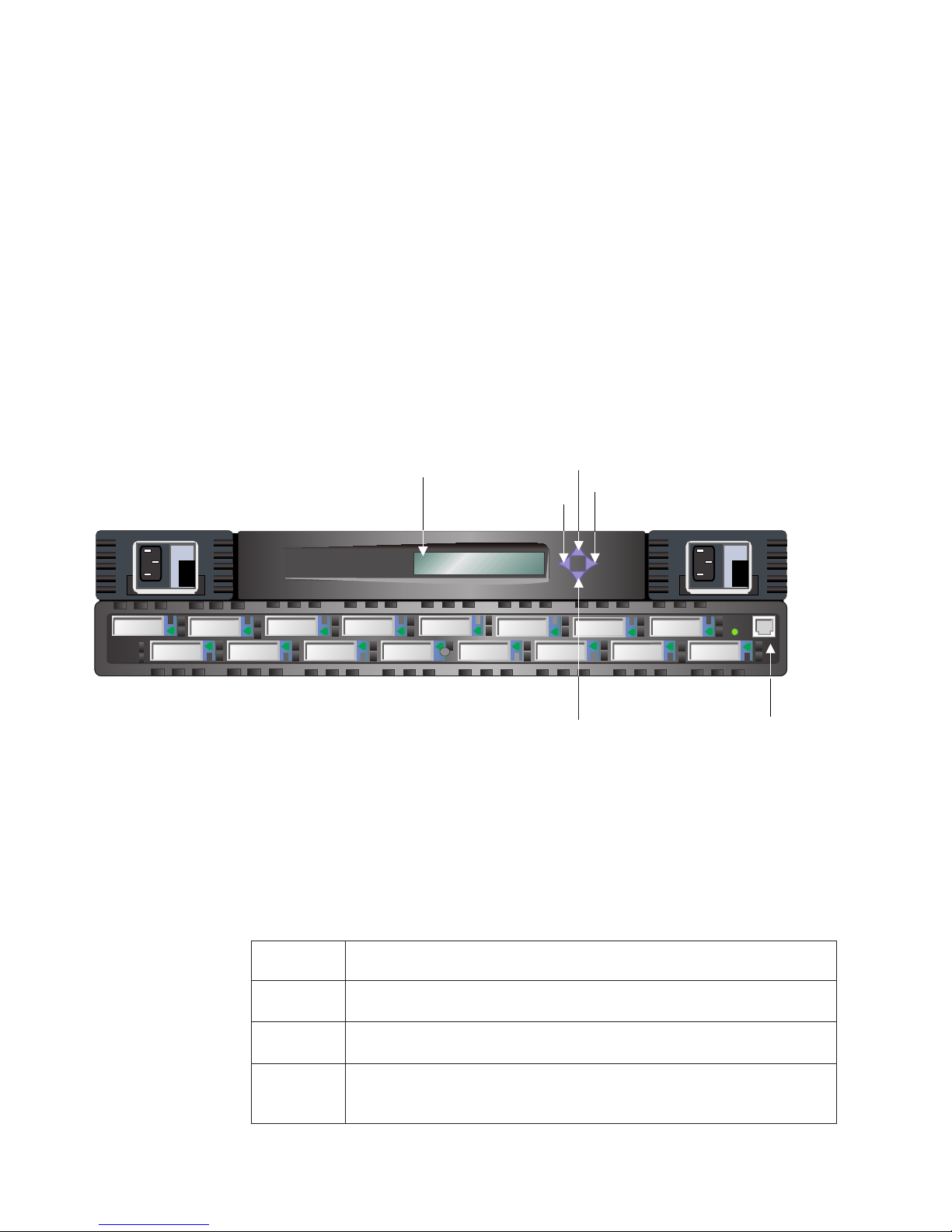

Figure 1 shows the front view of the 2109 Model S16 Switch. Ports are numbered

sequentially starting with zero for the left-most port. The switch faceplate includes a

silk screen imprint of the port numbers. Up to two power supplies are supported;

these are shown to the left and right of the switch ports in Figure 1.

fabric

is an active, intelligent, nonshared interconnection

Power supply 2

Port 0

Figure 1. Front panel of the 2109 Model S16 Switch

Switch features

The switch is a high-performance, fibre-channel, switch with the following features:

Simple

Easy setup and configuration. After the power-on self-test (POST), you

need only to add the internet protocol (IP) address to the switch. The

remainder of the switch setup is automated.

Power supply 1

Fiber Channel Switch 2109 S16

Port 15

Ready LED

Ethernet port

SJ000040

Intelligent

Flexible

Reliable

© Copyright IBM Corp. 1999, 2000 1

The fabric operating system of the switch allows discovery of all connected

devices and determines optimum data paths without intervention. It

supports up to 32 interconnected switches.

Modular design with multiple GBIC (Gigabit interface converter) modules

that support fiber transmission media. The modular construction of the

switch gives the switch a range of flexibility in creating, upgrading,

maintaining, and configuring a fabric.

Highly integrated, reliable, multifunction ASIC (application specific integrated

circuit) devices are used throughout the switch.

Page 18

Performance

Manageability

|

|

|

High performance

Low-latency, high-performance design resulting in a worst-case

data-transfer latency of less than 2µs from any port at peak fibre-channel

performance of 100 MBps. The latency can differ when the destination or

device is a loop.

Cascading

Switches can be cascaded for large fabric support.

Universal

The switch ports are designed to support F, FL, and E-port modes of

operation with the software selecting the optimum mode of operation.

A minimum aggregate routing capacity of 4 000 000 frames per second is specified

for class 2, class 3, and class F frames. Non-blocking throughput of up to 800

MBps (0.8 GBps) is provided.

A maximum switch latency of less than 2 µs is specified for class 2, class 3, and

class F frames when the output port is free.

The unit is managed using the 10BASE-T Ethernet port for Telnet or Web-based

management using the IBM StorWatch Specialist. The switch also provides a front

operator panel for simple switch configuration and diagnostics.

System components

The system board is enclosed in an air-cooled chassis that is either mounted in a

standard rack or used as a stand-alone unit. The chassis includes one or two power

supplies, a fan tray, and an RJ-45 Ethernet connection for switch setup and

management.

GBICs

The switch holds up to 16 GBIC modules. All interfaces have status lights that are

visible from the front panel that let you see the status and activity of the GBICs.

The GBIC modules supported are the short wavelength (SWL) and long wavelength

(LWL) fiber-optic versions.

If your installation requires installing less than 16 GBIC modules, the unused port

positions are protected by a metal, spring-loaded door.

SWL fiber-optic GBIC module

The SWL fiber-optic GBIC module, with an SC connector color-coded black, is

based on short wavelength 850 nm lasers supporting 1.0625 GBps link speeds.

This GBIC module supports 50-µm, multimode fiber-optic cables up to 500 m (1640

ft) in length. Figure 2 on page 3 shows an SWL GBIC module.

2 IBM SAN Fibre Channel Switch: 2109 Model S16 Installation and Service Guide

Page 19

Switch connector end SC connector end

SJ000041

Figure 2. Short wavelength (SWL) laser fiber-optic GBIC module (P/N and labeling vary)

Note: The SWL GBIC module uses a class 1 laser, which complies with the 21

CFR, subpart (J) as of the date of manufacture.

LWL fiber-optic GBIC module

The LWL fiber-optic GBIC module, with the SC connector color-coded blue, is

based on long wavelength 1300-nm lasers supporting 1.0625-GBps link speeds.

This GBIC module supports 9-µm single-mode fiber-optic cables up to 10 km (32

808 ft) in length with a maximum of five splices. Figure 3 shows an LWL GBIC

module.

Switch connector end

Figure 3. Long wavelength (LWL) laser fiber-optic GBIC module (P/N and labeling vary)

Power supply

The 2109 Model S16 Switch has one or two power supplies. See Figure 4 on

page 4. Only one power supply must be operational for normal switch function. If

two power supplies are present, they operate as load-sharing power supplies. If the

optional second power supply is ordered, it is installed during the installation

procedure. The switch is shipped with one power supply installed and has the

following requirements:

v Properly wired, earth-grounded outlet

v Input voltage: 85 - 265 V ac

v Total power: Up to 110 watts (depending on configuration)

SC connector end

SJ000042

Chapter 1. Introduction 3

Page 20

v Input line frequency: Nominally 47 - 63 Hz

The switch has an autoranging power supply that automatically accepts voltages

and line frequencies within its ranges.

Fiber Channel Switch 2109 S16

Figure 4. Power supplies

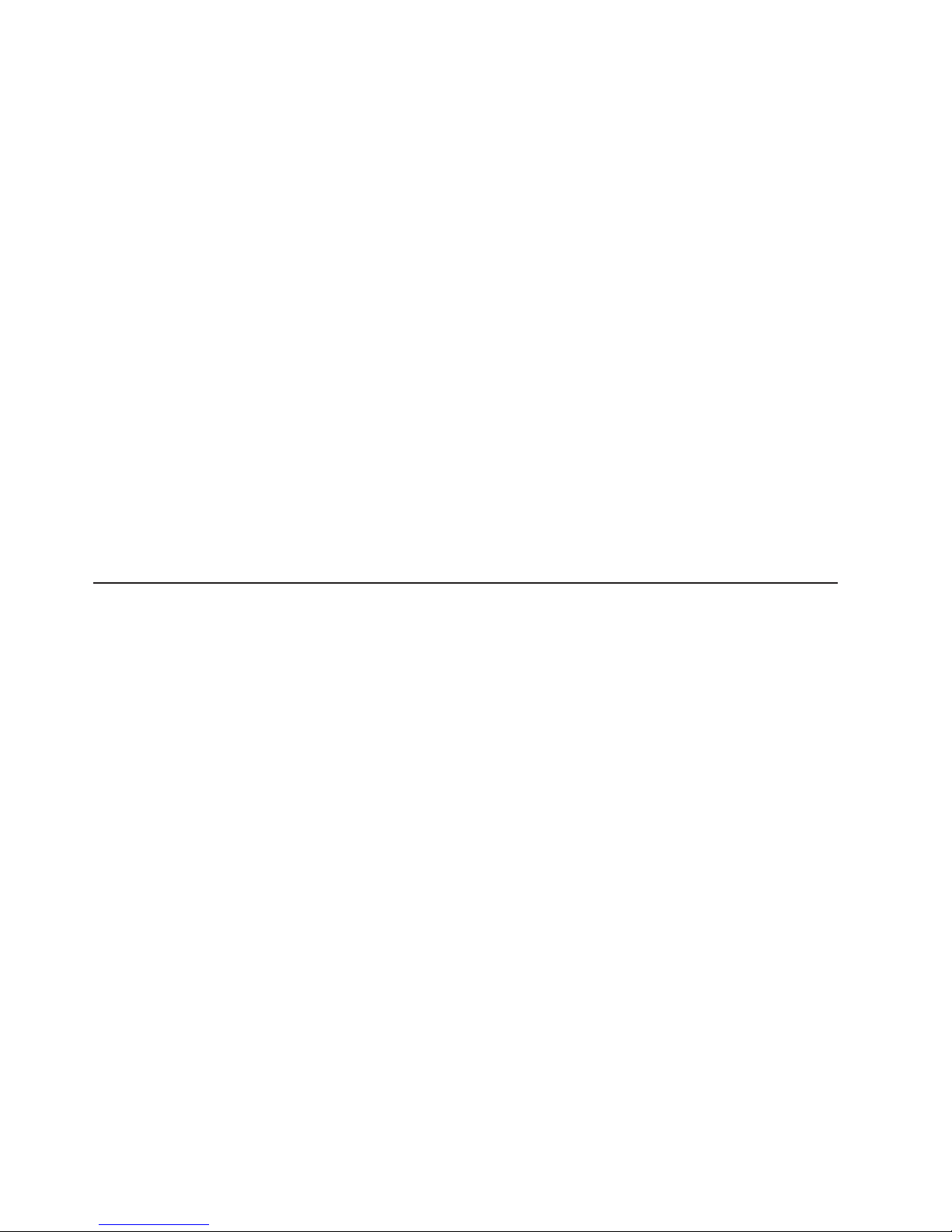

Fibre-channel cable connections

All network cable connections are at the front panel of the switch. All recommended

cabling supports the 1.0625-GBps transfer rate of the switch, as shown in Table 1.

Table 1. Cabling connections

Cable type Cable specification Maximum run length GBIC module

Power supply 1Power supply 2

SJ000043

Optical wavelength

SWL

fiber-optic

LWL

fiber-optic

v Duplex standard

connection (SC) plug

connectors

v Multimode fiber

v 50 µm core diameter

v 125 µm cladding

diameter duplex

cable

v Duplex SC plug

connectors

v Single mode fiber

v 9 µm core diameter

v 125 µm cladding

diameter duplex

cable

500 m (1641 ft) 780 - 860 µm without open

fiber control (non-OFC)

10 Km (32808 ft) 1270 - 1350 µm without

open fiber control

(non-OFC)

Fiber cables connect to the front panel of the switch using standard dual SC plug

connectors as shown in Figure 5 on page 5.

4 IBM SAN Fibre Channel Switch: 2109 Model S16 Installation and Service Guide

Page 21

Front panel

SJ000044

Figure 5. Dual SC fiber-optic plug connector

The connectors are keyed and must be correctly aligned before they are inserted

into the GBIC-module connector. In most cases, one of the two connector plugs is a

different color to aid in proper connector alignment.

Note: Remove the protective plug from the GBIC. Do not force the fiber-optic plug

into the GBIC module as you may damage the connector, the GBIC module,

or both. Make certain that the fiber surface is clean and free of dust or debris

before inserting the connector into a GBIC module.

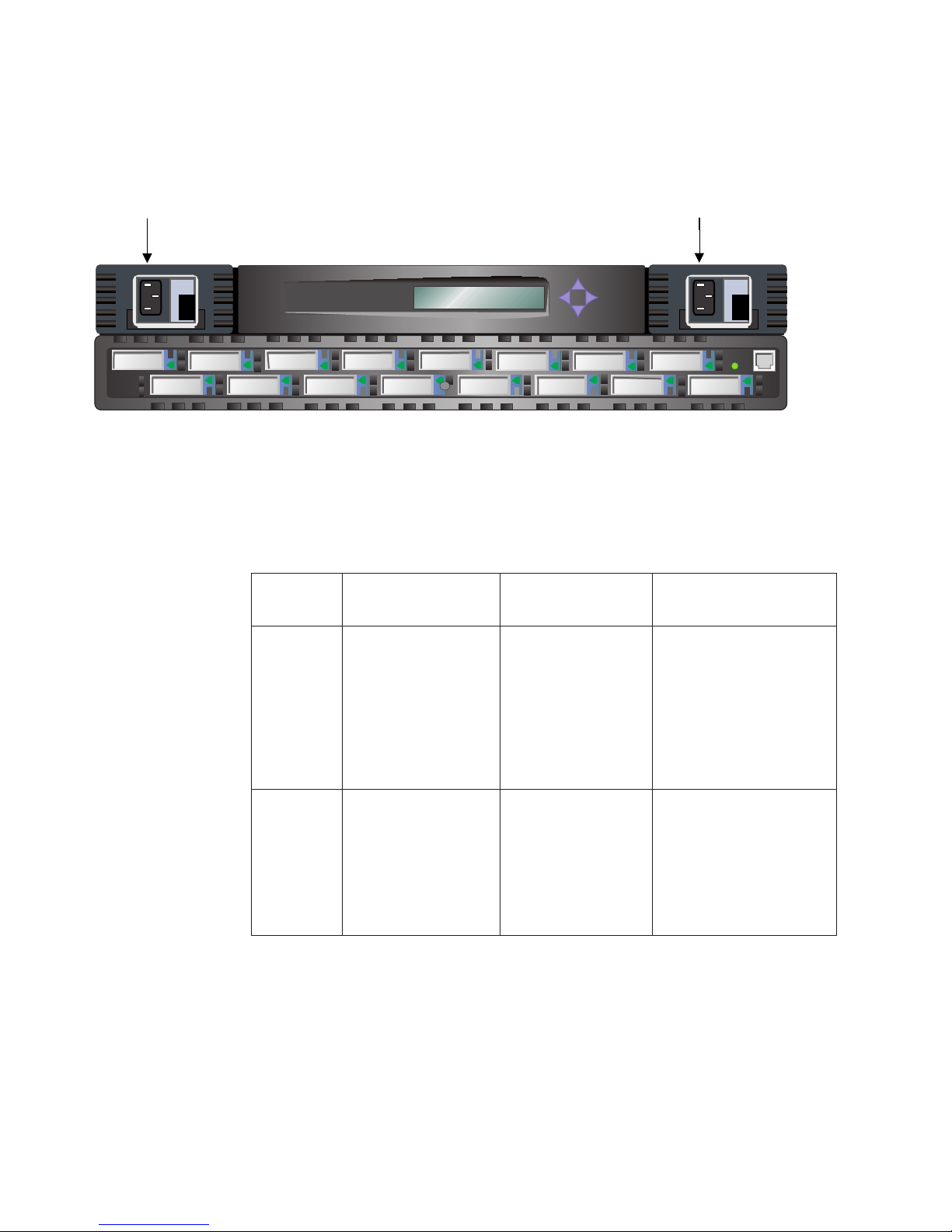

Figure 6 shows the front panel buttons.

Figure 6. Front panel functionality

Control buttons

Table 2 on page 6 lists the primary control button functions. The function of the

button changes depending on the menu level. Buttons either control navigating

through the menus or they increment and decrement numeric values.

Display

Fiber Channel Switch 2109 S16

Up button

Tab/Esc button

Down button

Enter button

RJ-45 10 BASE-T

connection

SJ000045

Chapter 1. Introduction 5

Page 22

Table 2. Control buttons

Control

buttons

Down The Down button scrolls down the command list; or, if the user is changing

Up The Up button scrolls up the command list; or, if the user is changing a

Tab/Esc The Tab/Esc button tabs through multiple options. When displaying a menu

Enter The Enter button accepts the input and executes the selected function.

Description

a numeric display, it decrements the numeric value.

numeric display, it increments the numeric value.

item, pressing the Tab/Esc button reverses through previous commands. If

pressed repeatedly, it turns off the front panel display.

When entering a number, the Up and Down buttons start in the slow mode and

change to the fast mode if either button is held down. Most numbers go to a

maximum of 255; for large numbers, it may be faster to use the Down button.

Ethernet connection

Connecting an existing Ethernet 10BASE-T or 100BASE-T LAN to the switch

through the front panel RJ-45 connector gives you access to the internal SNMP

agent of the switch and also allows Telnet and Web access for remote monitoring

and testing. The IP address is changed using the Ethernet port.

Note: The connection is only for Telnet, SNMP agent, and the Web-based server

access. This connection uses no fabric connection.

Front panel LED port indicators

Each switch port has an LED indicator. A properly functioning port with no GBIC

installed has no LED light. A yellow port indicator depicts faults and problems.

The LED color and flash speed of each port, as described in Table 3, indicates the

status of each individual port.

Table 3. Front panel LED status indicators

Front panel LEDs Definition

No light showing No light or signal carrier (no module, no cable) for media interface

LEDs.

Steady yellow Receiving light or signal carrier, but not yet online.

Slow yellow Disabled (as a result of diagnostics or a portDisable command).

Flashes every 2 seconds.

Fast yellow Error, fault with a port. Flashes every one-half second.

Steady green Online (connected with a device over a cable).

Slow green Online, but segmented (loopback cable or incompatible switch).

Flashes every 2 seconds.

Fast green Internal loopback (diagnostic). Flashes every one-half second.

Flickering green Online and frames flowing through port.

When a GBIC is installed and a cable is connected to a properly functioning

fibre-channel device, the LED indicator is a steady green. If a slow green flash is

observed, it indicates that the port is seeing light, but cannot make a proper fabric

connection. This could indicate that a loop back cable is installed, the fabric is

6 IBM SAN Fibre Channel Switch: 2109 Model S16 Installation and Service Guide

Page 23

segmented (an E-port connection to another switch cannot be completed and the

switches cannot form a fabric), or the 2109 Model S16 Switch has been connected

to an incompatible switch.

When frame traffic is being transferred on a port, the LED flickers fast green,

showing that the port is active and is transferring data.

Switch power on and ready indicator

After the power-on self-test (POST) diagnostics have completed, this LED indicates

a successful completion of the system board diagnostics.

Diagnostics overview

The switch is designed for maintenance-free operation. When there is a suspected

failure, the switch has self-diagnostic capabilities to aid in isolating any equipment

or fabric failures.

The switch supports POSTs and diagnostic tests. The diagnostic tests determine

the status of the switch and isolate problems. The diagnostic tests are run using

Telnet commands. For more information about diagnostic testing commands and

procedures, see “Appendix B. Diagnostics” on page 91.

Verifying a power-on self-test (POST)

Table 4 lists the diagnostic tests that are automatically run during a POST.

Table 4. Offline and Online tests

Test Description

CAM test Checks the CAM

Central memory test Checks the system-board SRAMs

CMI conn test Checks the CMI bus between ASICs

Memory test Checks CPU RAM memory

Port loopback test Checks all of the switch hardware. Frames are transmitted,

Port register test Checks the ASIC registers and SRAMs

After the switch completes the POST, the GBIC module returns to a steady state

from the flashing states shown during the tests.

A yellow GBIC module light indicates that the module failed one of the POSTs.

Telnet can display error conditions after the switch completes the POST.

The ready LED verifies a successful POST approximately 2 minutes after power is

turned on.

Running diagnostics

For detailed information about running diagnostics, see “Appendix B. Diagnostics”

on page 91.

looped back and received.

The following diagnostic tests can be run from the Telnet connection of the switch:

v CAM test (camTest)

v Central memory test (centralMemoryTest)

Chapter 1. Introduction 7

Page 24

v CMem data retention test (cmemRetentionTest)

v CMI conn test (cmiTest)

v Cross port test (crossPortTest)

v Memory test (ramTest)

v Port loopback test (portLoopbackTest)

v Port register test (portRegTest)

v Spin silk test (spinSilk)

v SRAM data retention test (sramRetentionTest)

v Switch offline (switchDisable)

v Switch online (switchEnable)

Table 5 shows the available offline and online tests.

Attention: Offline tests are disruptive to switch operations. Do not run these tests

unless you are sure that switch operation can be disrupted.

Table 5. Offline and online test

Offline tests Offline and online tests

camTest crossPortTest

centralMemoryTest ramTest

cmemRetentionTest

cmiTest

portLoopbackTest

portRegTest

spinSilk

sramRetentionTest

Loop (FL) connections

The system-board module is structured to accommodate a single channel FL_port

interface module in the same slot used by the dual G_port interface module. Mixing

|

8 IBM SAN Fibre Channel Switch: 2109 Model S16 Installation and Service Guide

of FL_port and G_port interface modules in different slots is permitted.

Page 25

|

Chapter 2. Customer planning

|

|

|

|

|

|

|

|

|

|

||

||

|

|

|

|

|

|

|

|

||

||

||

||

||

||

||

||

||

||

||

||

||

The following information will be needed to properly configure the 2109 in an

operational environment.

Table 6 shows an example of a completed worksheet for an installed switch.

Following Table 6 is an explanation of each item in Table 6. Table 7 on page 11 is a

blank worksheet for your use. Make as many copies of Table 7 on page 11 as you

need to plan the installation of each of your switches. Provide the system

administrator with copies of the completed worksheets

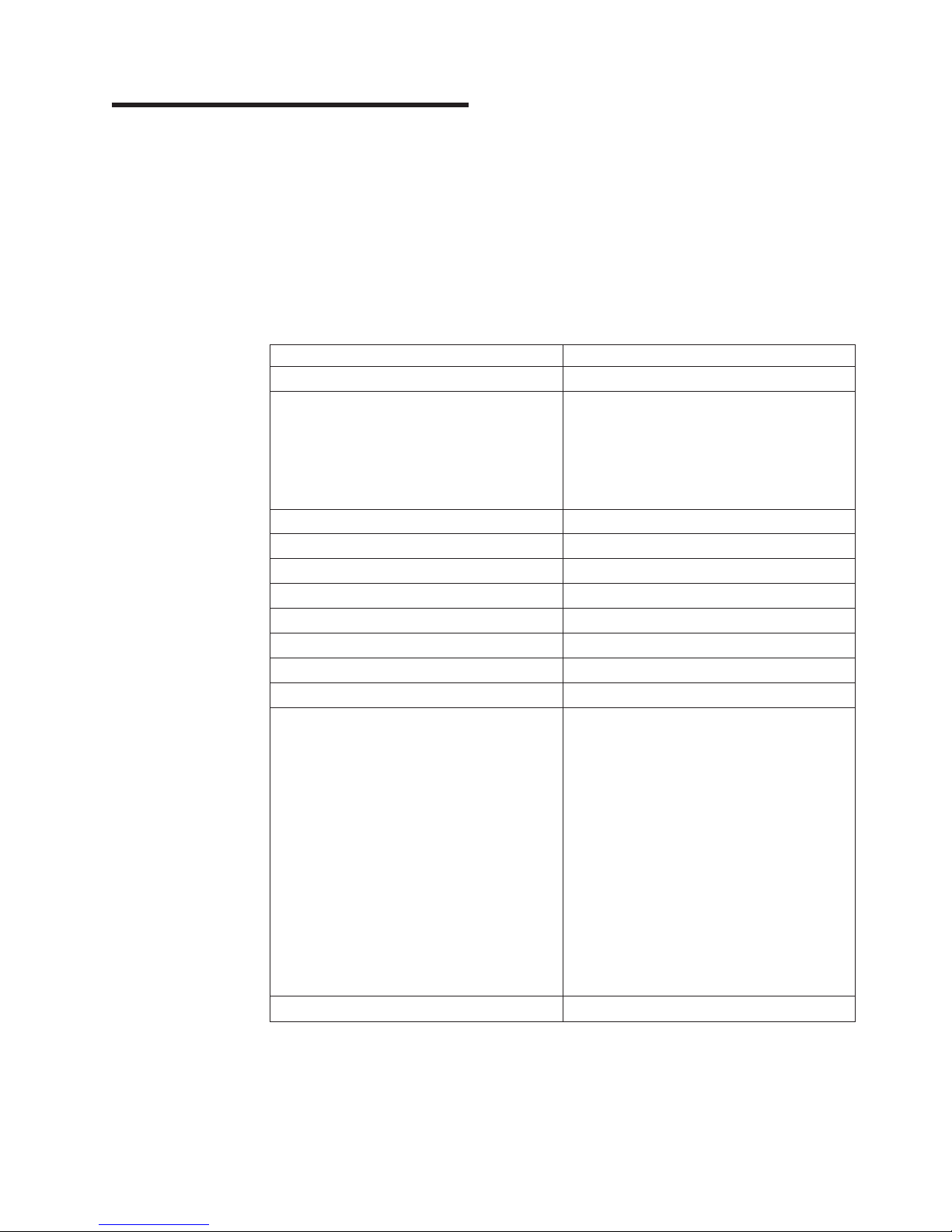

Table 6. Example of a planning worksheet for a 2109 switch

Item Description

Firmware level V 2.1.7

Firmware location:

Server name

Username

Directory

Switch name 2109-1

Domain ID 1

FCnetID (Fibre-channel IP address)

FC netmask

WWN To be supplied when box is turned on

Role Principal switch

Syslog daemon IP address 192.20.236.4

Users defined - access level admin - admin, petuser - none

SNMP information:

System description TestSANlet1_2109-1

System contacts (Contact name)

System location B/003-3 Col C-4

Event trap level0-5 5

C02STOR01

sanman

G:\sanman\2109\firmware\v2.1

|

|

|

||

||

||

||

||

Enable authentication traps No

RW community string dingo

RO community string pet

Trap recipients IP Address 192.20.236.3

License keys Required for optional features.

|

|

|

The following is a description of the items in Table 6.

Firmware levels

|

|

© Copyright IBM Corp. 1999, 2000 9

Refer to the

2109 Model S16 User’s guide

information.

IBM SAN Fibre Channel Switch

for additional

The firmware levels for the 2109 and the required code that the service

representative is to install on an NT StorWatch Specialist workstation.

Page 26

|

|

Server name

The network name of the server where the StorWatch Specialist is run.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

||

|

Username

The username on the StorWatch Specialist server that owns the firmware

for the 2109. IBM recommends that this not be a username with

administrative or security privileges on the server.

Directory

The location where the firmware files are located.

Firmware location

The directory location on the StorWatch Server that has the firmware for the

2109. IBM recommends that a different directory be used for each level of

firmware that is loaded.

Switch name

The name of this particular fibre channel switch.

Domain ID

The domain ID that identifies this switch in the SAN configuration.

FCnetID

The fibre channel IP address for this switch.

FC netmask

The netmask for the fibre channel IP network.

WWN The World-wide name assigned by the manufacturer.

Role The role this switch will be assigned (principal switch, subordinate switch, or

disabled switch).

|

|

|

|

|

|

|

|

|

Syslog daemon IP address

The IP address of the host that the syslog daemon messages will be

forwarded to.

Users defined - access level

A list of users in SAN administration network and their roles.

License keys

The required license keys for optional features.

Use Table 7 on page 11 to plan your switch installation. Make a copy of Table 7 on

page 11 for each switch you plan to install.

10 IBM SAN Fibre Channel Switch: 2109 Model S16 Installation and Service Guide

Page 27

|

|

||

||

|

|

Table 7. Blank of a planning worksheet for a 2109 switch

Item Description

Firmware level

Firmware location:

|

|

|

||

||

||

||

||

||

||

||

||

||

||

||

||

|

||

||

||

||

||

Server name

Username

Directory

Switch name

Domain ID

FCnetID (fibre-channel IP address)

FC netmask

WWN

Role

Syslog daemon IP address

Users defined - access level

SNMP information:

System description

System contacts

System location

Event trap level0-5 See

Enable authentication traps

RW community string

RO community string

Trap recipients IP address

License keys

IBM SAN Fibre Channel Switch 2109

Model S16 User’s Guide

|

Chapter 2. Customer planning 11

Page 28

|

|

|

|

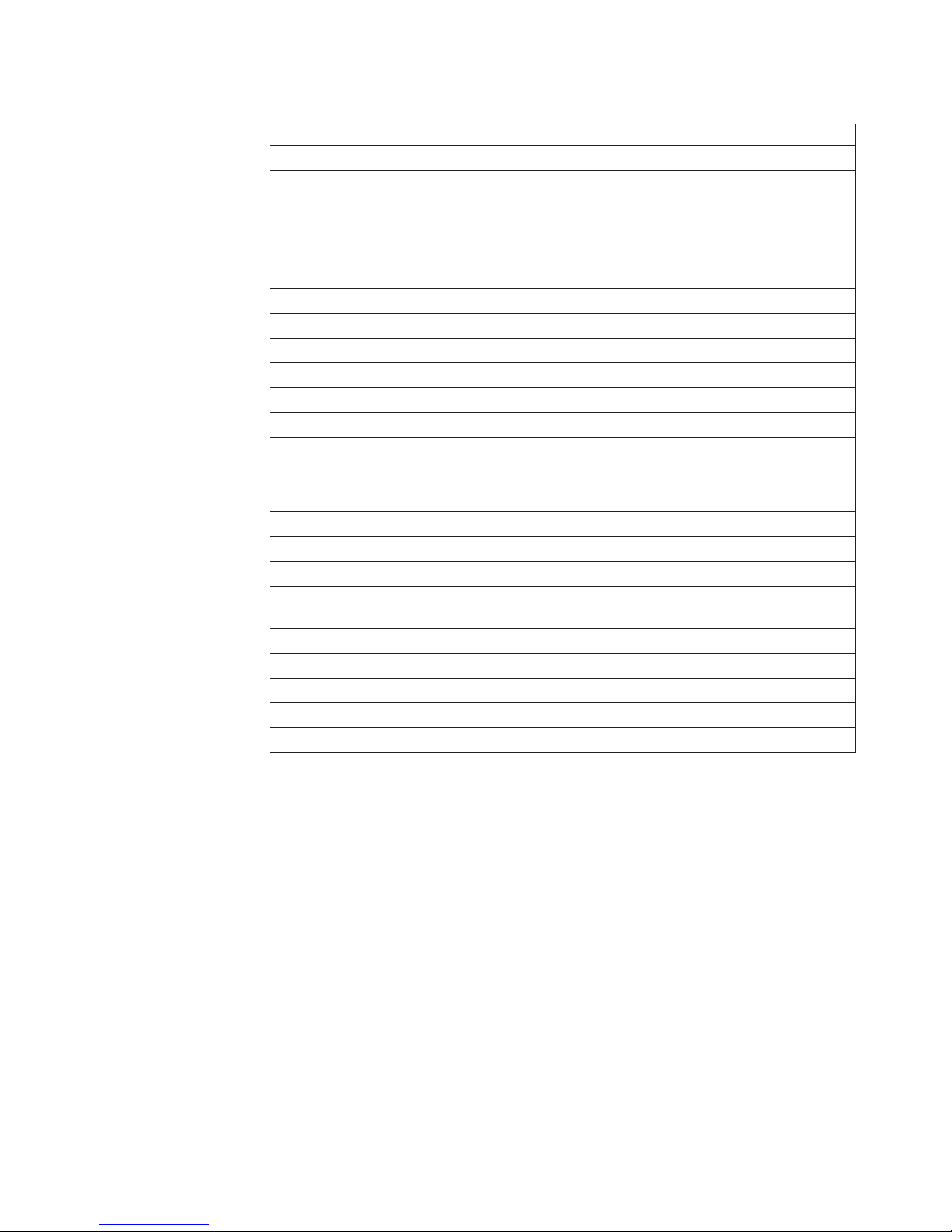

Table 8 shows an example of a completed worksheet for port configuration. Table 9

on page 13 is a blank worksheet for your use in planning your port configuration.

Make as many copies of Table 9 on page 13 as you need to plan the installation of

each of your ports.

|

|

||||||||||

|

||||||||

||||||||

||||||||

||||||||

||||||||

|||||||

|||||||

|||||||

|||||||

|||||||

|||||||

|||||||

|||||||

Table 8. Example of a configuration worksheet for a 2109 switch

Port

number

0 2108-1 PMC1-1 2m (6 ft) SW Connects to

1 2108-1 PMC2-2 2m (6 ft) SW Connects to

2 2108-1 PMC3-3 2m (6 ft) SW Connects to

3 2108-2 PMC1-1 2m (6 ft) SW Connects to

4 2108-2 PMC2-2 2m (6 ft) SW Connects to

5 2108-2 PMC3-3 2m (6 ft) SW 205

6 s1411201e0 P2-I3 25m (82 ft) SW 206

7 s1411203e0 P2-I3 25m (82 ft) SW 207

8 s1411205e0 P2-I2 25m (82 ft) SW 208

9 2109-15 Port 8 2m (6 ft) SW 209

10 2109-15 Port 13 2m (6 ft) SW 213

11 Open SW

12 K38 node 1 25m (82 ft) SW 214

Device

name

Device port Cable

length

Port type Notes Cable

number

200

2105-1

201

2105-1

202

2105-1

203

2105-1

204

2105-1

|

12 IBM SAN Fibre Channel Switch: 2109 Model S16 Installation and Service Guide

Page 29

|

|

|||||||||||

|

|||||||

|||||||

|||||||

|||||||

|||||||

|||||||

|||||||

|||||||

|||||||

|||||||

|||||||

|||||||

|||||||

|||||||

|||||||

|||||||

Table 9. Blank of a port configuration worksheet for a 2109 switch

Port

number

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Device

name

Device port Cable

length

Port

type

Notes Cable

number

|

Chapter 2. Customer planning 13

Page 30

|

|

|

|

Table 10 shows an example of a completed worksheet for an installed switch.

Table 11 on page 15 is a blank worksheet for your use in planning your switch

installation. Make as many copies of Table 11 on page 15 as you need to plan the

installation of each of your switches.

|

|

||||||

||||

||||

||||

||||

||||

||||

Table 10. Example of a zone definitions worksheet

Zone member type

(switch, port, WWN)

Port (ID,P) 1, 15 Test_Zone_Config_1 K38 node 1

Port (ID,P) 1, 0 Same 2108-1 PMC1-1

Port (ID,P) 15, 3 Same 2108-2 PMC1-4

Port (ID,P) 15, 14 Same K38 node 2

Port (ID,P) 1, 10 Same EMC-1 dir 5 port 0

Port (ID,P) 15, 10 Same EMC–1 dir 5 port 0

Zone member Zone configuration

name

Comments

|

14 IBM SAN Fibre Channel Switch: 2109 Model S16 Installation and Service Guide

Page 31

|

|

||||||

||||

||||

||||

||||

||||

||||

Table 11. Blank of a zone definitions worksheet

Zone member type

(switch, port, WWN)

Port (ID,P)

Port (ID,P)

Port (ID,P)

Port (ID,P)

Port (ID,P)

Port (ID,P)

Zone member Zone configuration

name

Comments

|

Chapter 2. Customer planning 15

Page 32

|

|

|

|

Table 12 shows an example of a completed worksheet for an installed switch.

Table 13 on page 17 is a blank worksheet for your use in planning your switch

installation. Make as many copies of Table 13 on page 17 as you need to plan the

installation of each of your switches.

|

|

|||||||

||||

||||

||||

||||

||||

||||

||||

||||

||||

||||

||||

||||

||||

||||

||||

||||

||||

||||

||||

||||

||||

||||

||||

Table 12. Zone configuration worksheet example

Zone member type

(switch, port, WWN)

Port (ID, P) 1, 1 Test_Zone_Config_1 2108-1 PMC2–2

Port (ID, P) 1, 2 Same 2108-1 PMC3–3

Port (ID, P) 1, 3 Same 2108-1 PMC1–1

Port (ID, P) 1, 4 Same 2108-2 PMC2–2

Port (ID, P) 1, 5 Same 2108-2 PMC3–3

Port (ID, P) 1, 6 Same s1411201e0 P2–I3

Port (ID, P) 1, 7 Same s1411203e0 P2–I3

Port (ID, P) 1, 8 Same s1411205e0 P2–I3

Port (ID, P) 1, 9 Same 2108-15 port 8

Port (ID, P) 1, 11 Same EMC-1 dir 16 port 0

Port (ID, P) 1, 12 Same 2102-3 BDI

Port (ID, P) 1, 13 Same 2109-15 port 13

Port (ID, P) 15, 1 Same 2108-1 PMC2-5

Port (ID, P) 15, 2 Same 2108-1 PMC3-6

Port (ID, P) 15, 0 Same 2108-1 PMC1-4

Port (ID, P) 15, 4 Same 2108-2 PMC2-5

Port (ID, P) 15, 5 Same 2108-2 PMC3-6

Port (ID, P) 15, 6 Same s1411201e0 P3-I3

Port (ID, P) 15, 7 Same s1411203e0 P3-I3

Port (ID, P) 15, 8 Same 2109-1 port 9

Port (ID, P) 15, 9 Same s1411206e0 P2–I2

Port (ID, P) 15, 11 Same EMC-1 dir 16 port 2

Port (ID, P) 15, 13 Same 2109-1 port 13

Zone

member

Zone configuration

name

Connects to

|

16 IBM SAN Fibre Channel Switch: 2109 Model S16 Installation and Service Guide

Page 33

|

|

|||||||

||||

||||

||||

||||

||||

||||

||||

||||

||||

||||

||||

||||

||||

||||

||||

||||

||||

||||

||||

||||

||||

||||

||||

Table 13. Blank of a zone configuration worksheet

Zone member type

(switch, port, WWN)

Port (ID, P)

Port (ID, P)

Port (ID, P)

Port (ID, P)

Port (ID, P)

Port (ID, P)

Port (ID, P)

Port (ID, P)

Port (ID, P)

Port (ID, P)

Port (ID, P)

Port (ID, P)

Port (ID, P)

Port (ID, P)

Port (ID, P)

Port (ID, P)

Port (ID, P)

Port (ID, P)

Port (ID, P)

Port (ID, P)

Port (ID, P)

Port (ID, P)

Port (ID, P)

Zone

member

Zone configuration

name

Connects to

|

Chapter 2. Customer planning 17

Page 34

18 IBM SAN Fibre Channel Switch: 2109 Model S16 Installation and Service Guide

Page 35

|

Chapter 3. Installing the switch

This chapter discusses the installation of the SAN Fibre Channel 2109 Model S16

Switch.

Pre-installation checklist

Verify the items in the pre-installation checklist, shown in Table 14 before you begin

the installation of the 2109 Model S16 Switch. This ensures a successful installation

of the product. Some of the steps may vary depending on which host platform you

attach to the switch. The customer should have the internet protocol (IP) adapter for

the switch and should have arranged for other installation activities.

Table 14. Pre-installation checklist

Step Customer action or decision Comments and references

1

|

|

2 Ensure that the required host platform

v Desktop install

v Rack-mount install

v Location

OS service pack is installed. For

example: Microsoft

service pack 5 (or later) and any

required hot fixes.

®

Windows NT 4.0,

Determine whether the 2109 Model S16

Switch is to be installed on a desktop or if

it is to be rack mounted.

For a current list of supported platforms,

required host platform code updates, and

information about how to obtain them, see

our Web site at:

www.ibm.com/storage/fcswitch

3 Ensure that the required fibre-channel

host bus adapter (HBA) BIOS, and

device driver are available.

4 Ensure that all host fiber-channel

cables have been ordered with the

product or have been pre-installed and

checked

Ensure that all cables have been

marked with:

v Host system identifier

v Switch identifier

5 Ensure that the disk or tape system

installation has been completed.

For tape attachment, ensure that the

tape device driver was installed or

updated.

or contact IBM technical support.

For a list of supported HBAs and the

required basic input/output system (BIOS)

and device driver, see our Web site at:

www.ibm.com/storage/fcswitch

or contact IBM technical support.

Refer to the HBA specification provided

with your HBA.

Usually performed by a service

representative during target device

installation.

© Copyright IBM Corp. 1999, 2000 19

Page 36

Table 14. Pre-installation checklist (continued)

Step Customer action or decision Comments and references

6 Decide on the switch network

parameters.

Obtain the switch network parameters

from your network administrator.

|

|

|

|

|

|

|

Installing the switch

The 2109 Model S16 Switch is installed either in a rack-mount configuration or a

tabletop configuration.

Ethernet port configuration decisions:

v Static IP address _____________

v Netmask (if required)__________

If the switch, the SNMP manager, or

the Syslog server are on different

TCP/IP subnets (see note), assign the

default network gateway address and

route table entries.

Attention: Save this configuration

for future reference.

7 Install the Ethernet cable from the

server (see note) to the network hub.

8 Install the Ethernet cable from the

network hub where the switch will be

installed.

Note: The term server used here refers to the computer used for the IBM StorWatch

Specialist.

Attention: Use of incorrect network

parameters can cause problems on the

Ethernet network.

None

None

Note: Before installing GBICs, power cords, and the optional second power supply,

install either the rubber tabletop mounting feet or install the switch in the

rack.

Tabletop installation

The switch is shipped in its tabletop configuration. Adhesive rubber feet are

supplied. These must be applied to the bottom of the switch in the four depressions

provided.

1. Turn the switch upside down and lay it on its top.

2. Clean the four depressions by wiping them free of dust.

3. Remove the rubber feet from the sheet that is provided with the shipping kit,

and place one rubber foot in each depression.

4. Firmly press the rubber feet in place.

5. Return the switch to its normal upright position, and place it in its intended

service location.

6. Go to “Installing the optional power supply” on page 24 (even if you do not have

an optional power supply).

Rack-mount installation

Read the following statements before starting the rack-mount installation:

20 IBM SAN Fibre Channel Switch: 2109 Model S16 Installation and Service Guide

Page 37

Attention: Do not install this switch in a rack where the internal rack-ambient

temperature will exceed 40°C.

v Do not install this unit in a rack where the airflow is compromised. The airflow is

from the back of the unit to the front; therefore, do not block the front or the back

of the rack.

v Take care that a hazardous condition is not created due to uneven mechanical

loading when installing this unit in a rack. If the rack this equipment is being

installed in has a stabilizer, it must be firmly attached before installing or

removing this unit.

|

|

|

v This unit requires 2 A of power with an input of 110 - 127 V ac or 1 A with an

input of 200 - 240 V ac. Ensure that you do not overload the circuits you are

connecting this equipment to.

DANGER

An electrical outlet that is not correctly wired could place a hazardous

voltage on the metal parts of the system or the products that attach to the

system. It is the customer’s responsibility to ensure that the outlet is

correctly wired and grounded to prevent an electrical shock (72XXD201).

Before starting the switch rack-mount installation process, locate the rack-mount

slides and the mounting bracket package provided in the shipping container.

Overview

The rack-mount installation process is performed in four steps:

1. Mounting the moving slide and locking the ears to the switch.

2. Mounting the fixed portion of the slide in the rack.

3. Inserting the switch and moving a portion of the slide into the fixed portion on

the rack.

4. Locking the switch in the rack using the mounting ears installed in step 1.

Follow the detailed instructions for each step as identified in the following sections.

Chapter 3. Installing the switch 21

Page 38

Step 1. Mounting the moving slide and locking ears to the switch

1. Locate and disassemble the slides by fully extending the slide, pressing the

release as shown in Figure 7, and pulling the slide apart.

SJ000046

Figure 7. Moving slide

2. Mount the moving portion of the slide and the locking ears to the switch as

shown in Figure 8. Use the screws provided with the locking ears. Mount the

slide portion first, and then the locking ears.

Figure 8. Mounting the moving portion of slide and locking ears to the switch

Step 2. Mounting the fixed portion of the slide in the rack

1. Open the rack-mounting brackets kit and mount the brackets to the wider fixed

portion of the four slides. One bracket mounts to each end of the fixed portion

of the slides as shown in Figure 9 on page 23.

22 IBM SAN Fibre Channel Switch: 2109 Model S16 Installation and Service Guide

Front

SJ000047

Page 39

Leave the mounting screws on the rear bracket finger tight. You will tighten

these after the switch is installed. The brackets on the front should be tightened,

leaving approximately 15 mm (5/8 in.) of the bracket in front of the end of the

outer fixed slide member. This is to allow installation space for the locking ears.

SJ000048

Figure 9. Mounting the fixed portion of the rail and the locking ears to the rack

2. Using the rack-mount clips and the screws provided, mount the fixed portion of

the slides with the mounting brackets to the vertical mounting bars in the rack.

3. Install three rack clips at the front and at the back of the rack. The middle rack

clip in the front is for the locking ears.

Step 3. Inserting the switch and the moving portion of the slide

into the fixed portion on the rack

1. Lift the switch and match the portion of the rail mounted on the switch with the

receiving rail members mounted in the rack, as shown in Figure 10 on page 24.

Push the switch all the way back until it is fully in the rack.

Chapter 3. Installing the switch 23

Page 40

Figure 10. Inserting slides into the rack rails

2. Slide the switch back and forth on the rack several times to ensure that it

moves freely. Move the switch partially forward and tighten the mounting screws

on the rear brackets that were left finger tight.

Step 4. Locking the switch in the rack using the mounting ears

installed in step 1

1. Slide the switch fully back in the rack.

2. Using the remaining screws provided with the locking ears, lock the switch in

the rack.

This completes the rack mounting of the switch.

To install GBICs, see “Installing GBICs” on page 25. To install the optional power

supply, see “Installing the optional power supply”.

Installing the optional power supply

Before installing the optional power supply, read the following danger notices.

DANGER

To prevent a possible electrical shock during an electrical storm, do not

connect or disconnect cables or station protectors for communications

lines, display stations, printers, or telephones. (72XXD003)

SJ000049

DANGER

Do not attempt to open the covers of the power supply. Power supplies are

not serviceable and are replaced as a unit. (72XXD300)

DANGER

An electrical outlet that is not correctly wired could place hazardous

voltage on metal parts of the system or the products that attach to the

system. It is the customer’s responsibility to ensure that the outlet is

correctly wired and grounded to prevent an electrical shock. (72XXD201)

24 IBM SAN Fibre Channel Switch: 2109 Model S16 Installation and Service Guide

Page 41

DANGER

To prevent a possible electrical shock when installing the device, ensure

that the power cord for that device is unplugged before installing signal

cables. (72XXD204)

If you do not have the optional second power supply, locate the power cord for the

single power supply that is already installed in the machine frame. Insert the power

cord into the power receptacle on the front of the machine. Go to “Installing GBICs”.

If you do have an optional second power supply, remove it from its shipping

container.

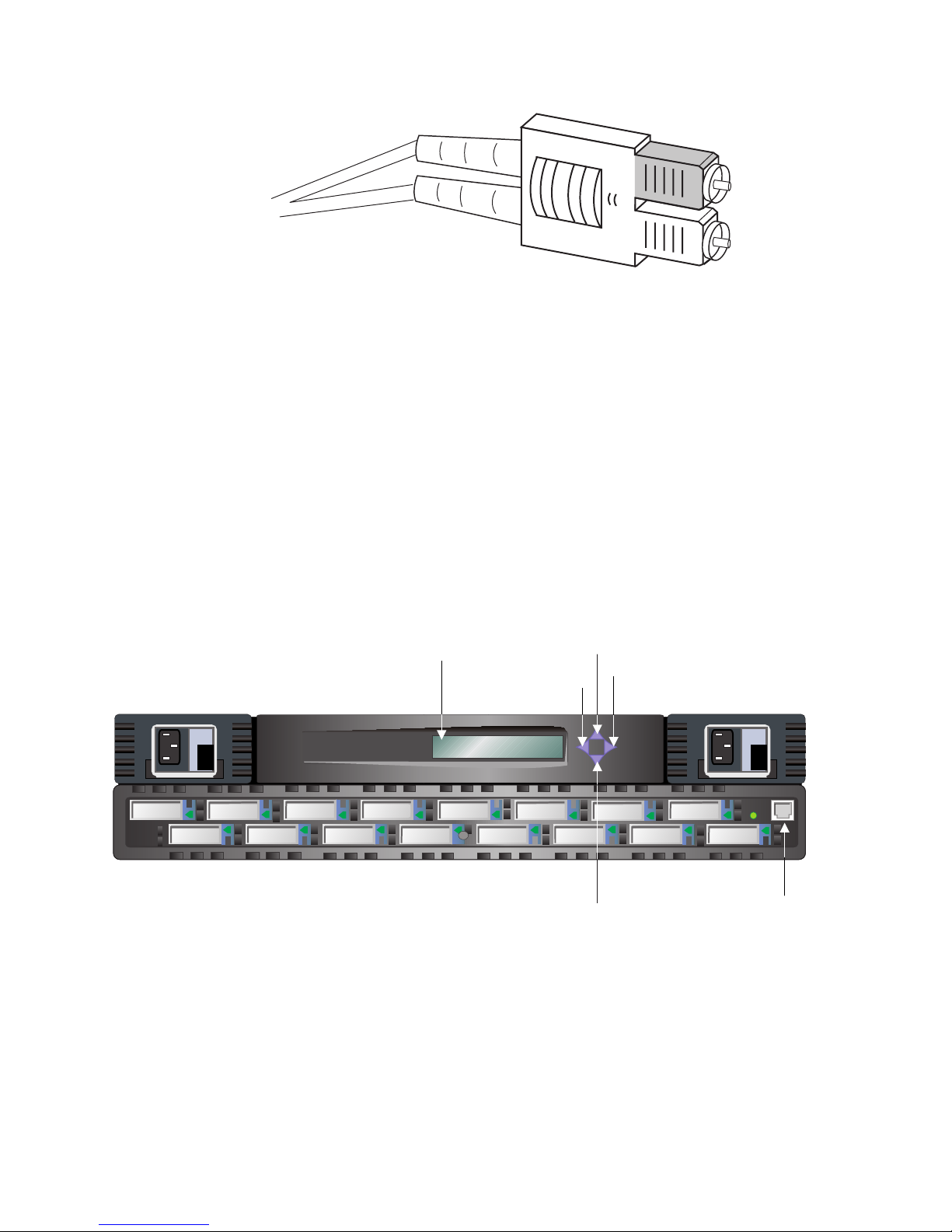

Look at Figure 11. On your machine, the left power supply location is filled with a

temporary cover. Grasp the cover and pull it forward while holding the machine

firmly. Remove and discard the cover.

Power supply 1Power supply 2

Fiber Channel Switch 2109 S16

Figure 11. 2109 model S16 with two power supplies

To install the optional second power supply, perform the following steps:

1. Look at the back of the power supply; the power supply is installed with the

connector in the down position.

2. Pull out the handle on the front of the power supply by grasping the handle at

the top and pulling out and down.

3. Slide the second power supply unit into its slot until it connects into the back

panel.

4. Lock the handle into the power supply by pushing the handle back into the

upright and locked position.

5. Locate the power cords and insert them into the power receptacles on the front

of the machine. Go to “Installing GBICs”.

Installing GBICs

The 2109 Model S16 Switch comes standard with four GBICs as shown in

Figure 12 on page 26. Up to 12 additional GBICs are available. GBICs can be

inserted in any port in the switch in any order, including skipping ports.

SJ000050

Chapter 3. Installing the switch 25

Page 42

Dust protection

rubber plug

SJ000051

Figure 12. GBIC

Figure 13 shows the front of the GBIC. The dust protection rubber plug must remain

in the GBIC until a fibre-channel cable is inserted. The other end of the GBIC is

inserted in the switch.

The GBICs are keyed and only seat if inserted correctly. The GBICs in the top row

of ports are inserted with the swing handle down as shown in Figure 13. The GBICs

in the bottom row of ports are rotated 180° so that the swing handle is on top.

Swing handle

Figure 13. GBIC swing handle

Setting the IP address

The switch ships from the factory with the default IP address (10.77.77.77)

pre-installed on the switch. This IP address is noted on a label on the top front edge

of the switch. This address is for the external Ethernet connection.

Use this default address to attach to the customer’s local area network (LAN) and

to establish a network connection to the switch. You can change this IP address by

using a Telnet command issued from any server having access to the same LAN.

This is the easiest way to set the IP address. Ask the customer’s LAN administrator

if the default address can be used. If this is not possible, set the IP address using

the front panel. See “Setting the IP address from the front panel” on page 28.

Instructions are provided for setting the IP address using either the front panel or

the Ethernet port. The locations of these ports are shown in Figure 14 on page 27.

Set the IP address by using the pre-installation checklist you obtained from the

customer LAN Administrator.

SJ000058

26 IBM SAN Fibre Channel Switch: 2109 Model S16 Installation and Service Guide

Page 43

|

Power supply 2

Fiber Channel Switch 2109 S16

|

|

Figure 14. Ethernet port connector

|

Setting the IP address using the Ethernet port

If you cannot use this method, go to “Setting the IP address from the front panel” on

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

page 28.

1. Attach the customer’s LAN to the front panel of the switch by plugging an

existing Ethernet 10BASE-T or 100BASE-T LAN cable to the RJ-45 connector

on the front of the switch.

2. Turn on the switch. If two power supplies are present, turn on both. After

waiting two minutes for the diagnostics to complete, continue with step 3.

3. From a LAN attached server, type: Telnet IP address (for example: Telnet

10.77.77.77). If this is the first installation, the IP address will be as written on

the label on the top left corner of the switch. If the switch was previously

installed and the label has been maintained, the current address should be

used from the label. If the label was not maintained, you must get the address

from the customer.

The switch displays as shown; in each case enter the requested information.

After each entry, press Enter.

4. Login: admin

The switch is shipped with the phrase “admin” set as the default administrator

name.

5. Password: password

The switch is shipped with the word “password” set as the default password.

You do not see the password as you type.

6. Ipaddress:admin>ipAddrSet

The Ipaddress is the command to set the IP address.

7. Ethernet IP address [the current address is shown]: new IP address.

This is the new address from the customer.

8. Ethernet Subnetmask [Enter the current subnet mask or the word “None”]: new

Subnetmask.

Operator panel

Power supply 1

RJ-45 Ethernet

connector

SJ000054

|

Note: Enter the new Subnetmask the customer has provided; or, if none is

|

required, press Enter.

Chapter 3. Installing the switch 27

Page 44

|

|

|

9. Fibre-channel IP Address [If none]: press Enter.

10. Fibre-channel Subnetmask [If none]: press Enter.

11. Gateway address [The current or new Gateway address or “None”]:

|

|

|

|

Note: Enter the Gateway address the customer has provided; or, if none is

required, press Enter.

12. Ipaddress:admin>logout

The logout command ends the Telnet session.

You have completed the installation of the 2109 Model S16 Switch. To do a quick

check of the fibre-channel ports on the switch before returning the machine to the

customer, see “Switch installation verification” on page 31.

Setting the IP address from the front panel

See Figure 15 for the location and function of each button on the front panel of the

2109 Model S16 Switch.

Display

Tab/Esc button

Fiber Channel Switch 2109 S16

Up button

Enter button

Down button

Figure 15. Front panel - operator display and control buttons

Control buttons

Table 15 lists the primary control button functions. The function of the button

changes depending on the menu level. Buttons either control navigating through the

menus or increment or decrement numeric values.

Table 15. Control buttons

Control

button

Down The Down button scrolls down the command list, or, if the user is changing a

Up The Up button scrolls up the command list, or, if the user is changing a

Tab/Esc The Tab/Esc buttons tab through multiple options. When displaying a menu

28 IBM SAN Fibre Channel Switch: 2109 Model S16 Installation and Service Guide

Description

numeric display, it decrements the displayed value.

numeric display, it increments the displayed value.

item, pressing the Tab/Esc button reverses through previous commands and,

if pressed repeatedly, turns off the front panel display.

RJ-45 10BASE-T

connection

SJ000055

Page 45

Table 15. Control buttons (continued)

Control

button

Enter The Enter button accepts the input and executes the selected function.

Description

When entering a number, the Up and Down buttons start in the slow mode and

change to the fast mode if either button is held down. Most numbers go to a

maximum of 255; for large numbers, it may be faster to use the Down button.

Setting the IP address from the front panel:

1. Turn on the switch.

Wait two minutes while the diagnostics complete. The display panel goes blank

after the diagnostics have completed.

2. Press the Up button. The switch displays:

Configuration menu

3. Press the Enter button. The switch displays:

Ethernet IP address

4. Press the Enter button. The switch displays the current Ethernet IP address in

the form xxx xxx xxx xxx

5. Change the current address to the preferred address.

Notes:

a. Press the Tab/Esc button to move the cursor (the entry point) from one

field to the next. If you go past a field, continue pressing the Tab/Esc

button until the cursor wraps around and returns to the desired spot.

b. Press the Up button to increment the current field. Press the Down button

to decrement the current field. Hold either button down to make these

actions happen rapidly. The numbers in the field wrap from 0 to 255 or

from 255 to 0, depending on whether you are incrementing or

decrementing. This helps you get to the desired value quickly.

When you have all fields set to the desired value continue with the next step:

6. Press the Enter button . The switch displays:

Accept ? Y N

Press the Tab/Esc button to indicate Yes. Press the Enter button to indicate No.

a. If you respond No, the switch again displays the Ethernet IP address. You

can now restart the process.

b. If you respond Yes, the switch displays: updating the Config.

This response causes the new address to be stored.

After the switch has made the change, it again displays the Ethernet

address.

c. If no other address is to be changed (gateway or Subnet), stop here by

pressing the Tab/Esc button. You are done setting up the switch.

d. If you need to set other switch addresses (gateway or subnetmask), press

the Up button. The switch displays: Ethernet Subnetmask.

7. Press the Enter button. The switch displays the current Ethernet Subnetmask in

the form xxx xxx xxx xxx.

8. Change the current Subnetmask to the preferred address.

When you have all fields set to the desired value, continue with the next step.

Chapter 3. Installing the switch 29

Page 46

9. Press the Enter button. The switch displays:

Accept ? Y N

Press the Tab/Esc button to indicate Yes. Press the Enter button to indicate No.

a. If you respond No, the switch again displays: Ethernet Subnetmask, and you

can restart the process.

b. If you respond Yes, the switch displays: Updating the Config.

This response causes the new address to be stored.

After the switch has made the change, it again displays Ethernet

Subnetmask.

c. If no other address is to be changed (gateway or subnet), press the Tab/Esc

button. You are done setting up the switch.

d. If you need to set other switch addresses (gateway or domain), press the

Up button. The switch displays: Fibre Channel IP address (not required at

this time).

10. Press the Up button. The switch displays: Fibre Channel Subnetmask (not

required at this time).

11. Press the Up button. The switch displays: Gateway Address.

12. Press the Enter button. The switch displays the current Gateway address in

the form xxx xxx xxx xxx.

13. Change the current gateway address to the preferred address.

Press the Up button to increment the current field. Press the Down button to

decrement the current field. Hold the button down to make this happen rapidly.

The numbers in the field wrap from 0 to 255 or from 255 to 0, depending on if

you are incrementing or decrementing. This helps you get to the desired value

quickly.

When you have all fields set to the desired value, continue with the next step.

14. Press the Enter button. The switch displays: Accept ? Y N.

Press the Tab/Esc button to indicate Yes. Press the Enter button to indicate No.

a. If you press No, the switch again displays: Gateway Address, and you can

restart the process.

b. If you press Yes, the switch displays: Updating the config.

This causes the new address to be stored.

After the switch has made the change, it again displays: Gateway Address.

c. If no other address is to be changed (gateway or subnet), press the

Tab/Esc button. You have completed setting up the switch.

d. If you need to set other switch addresses such as domain, press the Up

button. The switch displays: Domain.

15. Press the Enter button. The switch responds by displaying the current domain

in the form: xxx xxx xxx xxx.

16. Change the current domain to the preferred address.

When you have all fields set to the desired value continue with the next step.

17. Press the Enter button. The switch displays: Accept ? Y N.

Press the Tab/Esc button to indicate Yes. Press the Enter button to indicate No.

a. If you press No, the switch displays: Domain, and you can restart the

process.

b. If you press Yes, the switch displays: Updating config.

This causes the new address to be stored.

After the switch has made the change, it again displays: Domain.

30 IBM SAN Fibre Channel Switch: 2109 Model S16 Installation and Service Guide

Page 47

18. Press the Tab/Esc button.

You have completed the installation of the 2109 Model S16 Switch. To do a

quick check of the fibre-channel ports on the switch before returning the

machine to the customer, see “Switch installation verification”.

Switch installation verification

Perform this procedure to verify that all GBICs are installed and working correctly.

1. Turn off the switch.

2. Turn on the switch (if this is a dual power switch, turn on both power supplies).

3. Verify that the associated power supply LEDs are on.

4. Wait two minutes while the POST diagnostics run.

5. Verify that the switch-ready LED is on.

6. Plug the appropriate wrap connector (black for shortwave and grey for

longwave) into each GBIC. Verify that each associated port LED shows a slow

green that flashes every two seconds.

7. If any of the previous checks fail, see “Chapter 4. Maintenance action plans” on

page 33. If not, return the machine to the customer.

Code upgrade procedure

The 2109 Model S16 Switch is shipped with the latest level of code. When new

code is released, it can be easily downloaded to the switch. This task requires

saving the data and executable software to the customer’s server.

The latest code can be obtained from the SAN Fibre Channel Switch Web site at:

www.ibm.com/storage/fcswitch

This Web site provides instructions for downloading the code and loading it on the

switch. Loading new code to the switch can be done without disrupting the switch.

To make the new code functional, the switch must be turned off and then turned on.

Upgrade procedure

You can download firmware to the switch from either a UNIX host or a Windows NT

host. For a UNIX host, no special software is needed. For a Windows NT host, you

need a daemon to support a remote shell (RSH) with the firmware on the Web site.

This daemon is available from the Web site. Firmware download is by way of a

remote procedure call (RPC) command running on top of transmission control

protocol (TCP) between the switch and the host.

Downloading firmware from a UNIX®host

Perform this procedure to download new firmware.

1. Download the firmware from the Web site at:

www.ibm.com/storage/fcswitch

Remember the directory name where you save the code.

Code can only be loaded to the switch over the Ethernet LAN port.

2. Start a Telnet session to the switch from a LAN-attached server that has

connectivity to the switch.

The command format is:

Chapter 3. Installing the switch 31

Page 48

telnet [switch IP address]

3. Login using the admin userid. For example:

login: admin

4. Enter the password at the prompt. For example:

Password: password

Respond to the password prompt with the current switch password. The switch

ships with a default password of “password”.

5. Type the following command:

firmwareDownload [“host name/IP address”], [“user name”], [“filename”]

For example: firmwareDownload “192.111.2.1”, “timm”,

“/tmp/os/v2.0.1a_0621”

Note: The host name is the host name or the host IP address. The username

is a valid host username. The file name is a path to the new firmware

file.

The RSH server validates the username and delivers the file to the switch

where it is stored in flash memory.

6. Restart the switch to initiate the new firmware.

Downloading firmware using a Microsoft®Windows NT operating

system

Perform this procedure to download firmware using Windows NT.

1. Download the firmware from the Web site at:

www.ibm.com/storage/fcswitch

Remember the directory name where you save the code.

Download the two utilities (rshd.exe and cat.exe) from the Web site. Download

these into the same directory as the firmware.

2. In a DOS window, enter:

rshd [to execute the RSH daemon].

®

3. Go to “Downloading firmware from a UNIX