Hyundai DHY6000SELR2 User Manual

DIESEL GENERATOR

Model DHY6000SELR2

User Manual

CONTENTS

Section Description

Page No/N

o’s

1. SAFETY

3 – 7

2. MACHINE LAYOUT

8 – 9

3. PREPARATION for STARTING

10 – 13

4. OPERATING THE GENERATOR

14 – 15

5. LOAD

15 – 16

6. STOPPING THE MACHINE

16

7. PERIODIC MAINTENANCE

16 – 17

8. LONG TERM STORAGE

18

9. TROUBLE SHOOTING 19

10. SPECIFICATIONS

20

11. WIRING DIAGRAM

21

12. SERVICE RECORD SHEET

22

13. GENPOWER CONTACT DETAILS

23

14. DECLARATIONS OF CONFORMITY

24

Page 2

1.

1.1.2. The machine should never be left it in a condition which would allow

an untrained or unauthorised person/s to operate this machine.

1.1.3. All due care and diligence should be taken by the operator for the safety of and

with regard to those around whilst using the machine

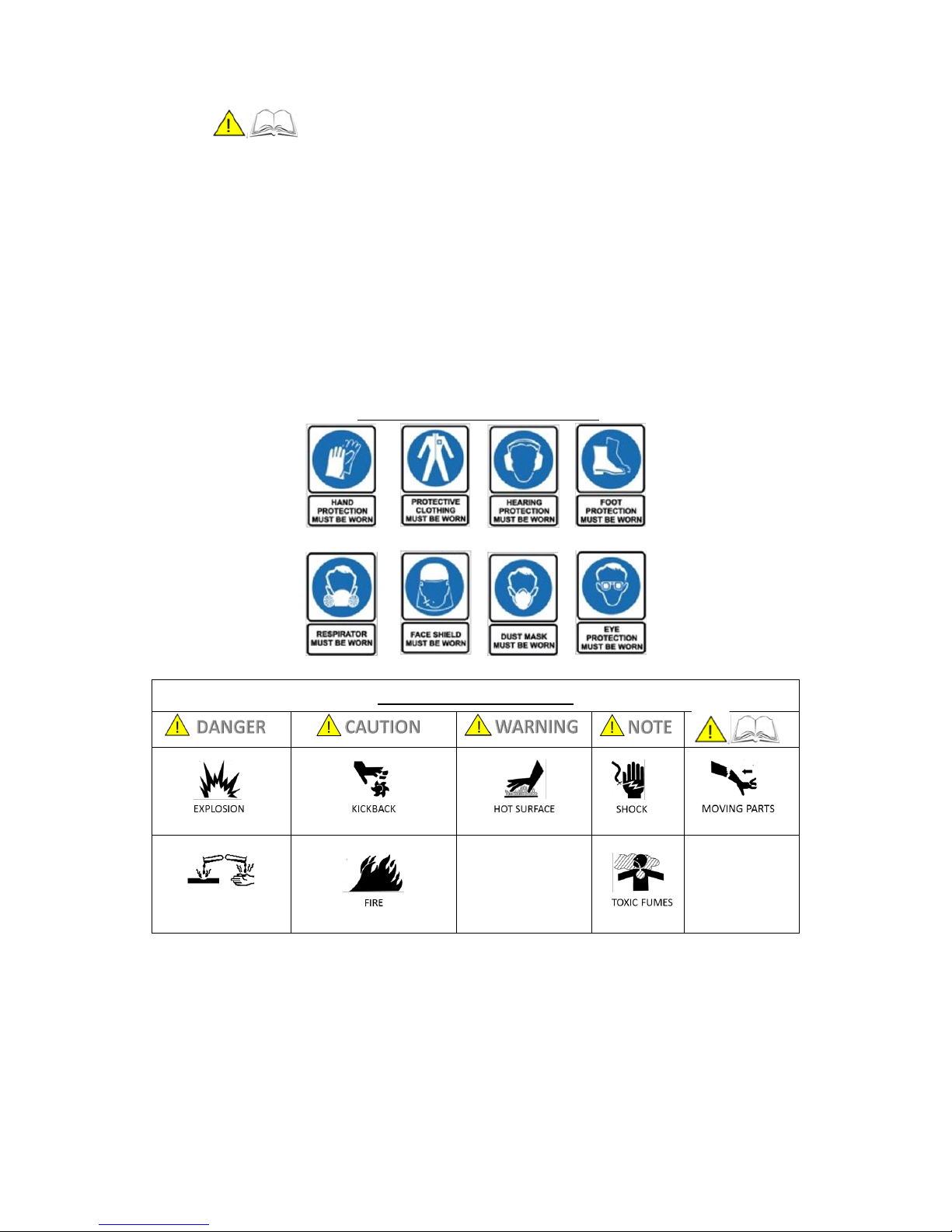

1.2. Some or all of the following PPE, Warning Signs and symbols may appear throughout this

manual and you must adhere to their warning/s. Failure to do so may result in personal

injury.

Warning Signs and Symbols

Personal Protective clothing (PPE)

Page 3

SAFETY.

1.1. The operator of the machine is responsible for and has a duty of care in making sure that

the machine is operated safely and in accordance with the instructions in this user manual.

Please note the following safety points

CORROSIVE

1.4. General fuel safety.

1.4.1. Fuel Safety additional information can be obtained from the Health and Safety

Executive (HSE) document SR16.

1.4.2. All fuels are Flammable.

1.4.3. Keep away from all ignition sources i.e. Heaters, Lamps, sparks created from

grinding or welding.

1.4.4. Hot work on tanks that have contained fuel is extremely dangerous and should not

be carried out.

1.4.5. Keep work area clean and tidy.

1.4.6. Clean up all spills promptly using correct methods i.e. absorbent granules and a

lidded bin.

Page 4

1.3. Carbon Monoxide

1.3.1. Carbon monoxide is a colourless and odourless. Breathing in this gas can cause

death as well as serious long term health problems such as brain damage.

1.3.2. The symptoms of Carbon monoxide poisoning can include the following;

1.3.2.1. Headaches, Dizziness, Nausea, Breathlessness, Collapsing or Loss of

consciousness.

1.3.2.2. Carbon monoxide symptoms are similar to flu, food poisoning, viral infections

and simply tiredness. That’s why it’s quite common for people to mistake this

very dangerous poisoning for something else.

1.3.3. To avoid Carbon monoxide poisoning KEKd Use Petrol/Diesel powered

equipment in an enclosed area or a moving vehicle.

1.3.4. If you think you or someone around you has been affected by carbon

monoxide poisoning you must take the following action;

1.3.4.1. Get fresh air immediately.

1.3.4.2. If you have used indoors open doors and windows, turn off machine

and leave the affected area.

1.3.4.3. See your doctor immediately or go to hospital - let them know that you

suspect carbon monoxide poisoning.

1.4.7. Dispose of waste fuels correctly.

1.4.8. Diesel safety.

1.4.8.1. Always fuel and defuel in well-ventilated area.

1.4.8.2. Always wear correct, suitable and fit for purpose Personal Protective

Equipment (PPE), suggested items are as follows, but are not limited too.

1.4.8.3. Hand protection.

1.4.8.4. Protective clothing.

1.4.8.5. Respiratory protective equipment should be used when in an

unventilated area.

1.4.8.6. When defueling always use a propriety fuel retriever.

1.4.8.7. Always carry fuel in the correct and clearly marked container.

1.4.9. Petrol safety.

1.4.9.1. Always fuel and defuel in well-ventilated area.

1.4.9.2. Always wear correct, suitable and fit for purpose Personal Protective

Equipment (PPE), suggested items are as follows, but are not limited too.

1.4.9.3. Hand protection.

1.4.9.4. Protective clothing.

1.4.9.5. Respiratory protective equipment should be used when in an

unventilated area.

1.4.9.6. When defueling always use a propriety fuel retriever.

1.4.9.7. Always carry fuel in the correct and clearly marked container.

1.4.10. Electrical Safety.

1.4.10.1. Electricity can kill - never work on LIVE/ENERGISED equipment.

1.4.10.2. Identify electrical isolation method and always isolate all electrical supplies,

prior to carrying out any maintenance work.

1.4.10.3. Prior to use and with all electrical supplies isolated check all electrical cables,

plugs and connections for the following.

1.4.10.3.1. That they are intact and have no signs of damage, to include but not limited

to bare wires, chaffing, cuts and loose wiring. If there are any signs of

damage, the damaged item should be taken out of service until the damage

has been repaired by an electrically competent person.

1.4.10.4. All trailing cables should be routed so as not to cause any kind of trip hazard.

Page 5

1.4.10.5. Never work on or near electricity with wet hands, wet clothing, or wet

gloves.

1.4.10.6. Batteries present a risk if they are damaged there maybe the

possible risk of leaking electrolyte. This electrolyte is an acid and can cause

serious injuries. Care should be taken when working on or near batteries.

1.4.10.6.1. Should you come into contact with acid you should;

1.4.10.6.1.1. Remove all clothing contaminated with acid.

1.4.10.6.1.2. Get medical assistance as soon as possible.

1.4.10.6.1.3. Use fresh running water to wash off excess acid, continue this

until medical assistance arrives.

1.4.10.6.1.4. If the acid comes into contact with a persons or eyes the

acid needs to be immediately washed away. Make sure that you do

not wash the acid to another part of the face or body.

1.4.10.6.1.5. Gasses from charging batteries are highly flammable and great

care should be taken to charge in well ventilated areas.

1.5. Additional Safety guidelines’

1.5.1. Exhaust and Engine

1.5.1.1. The engine and exhaust will become very hot during use. DO NOT touch.

1.5.1.2. These items remain hot for some time after use.

1.5.1.3. Place the machine in an area where pedestrians or children are not likely to

touch the machine.

1.5.1.4. Avoid placing any flammable materials near the exhaust outlet during

operation.

1.5.1.5. Keep the machine at least 1 metre from buildings or other equipment, or the

machine may overheat.

1.5.1.6. Avoid operating the engine with a dust cover.

1.5.2. Control Functions

1.5.2.1. Oil Warning System

1.5.2.1.1. When the pressure switch senses low oil pressure engine will stop

automatically.

1.5.2.1.2. Unless you refill with oil the engine will not start again.

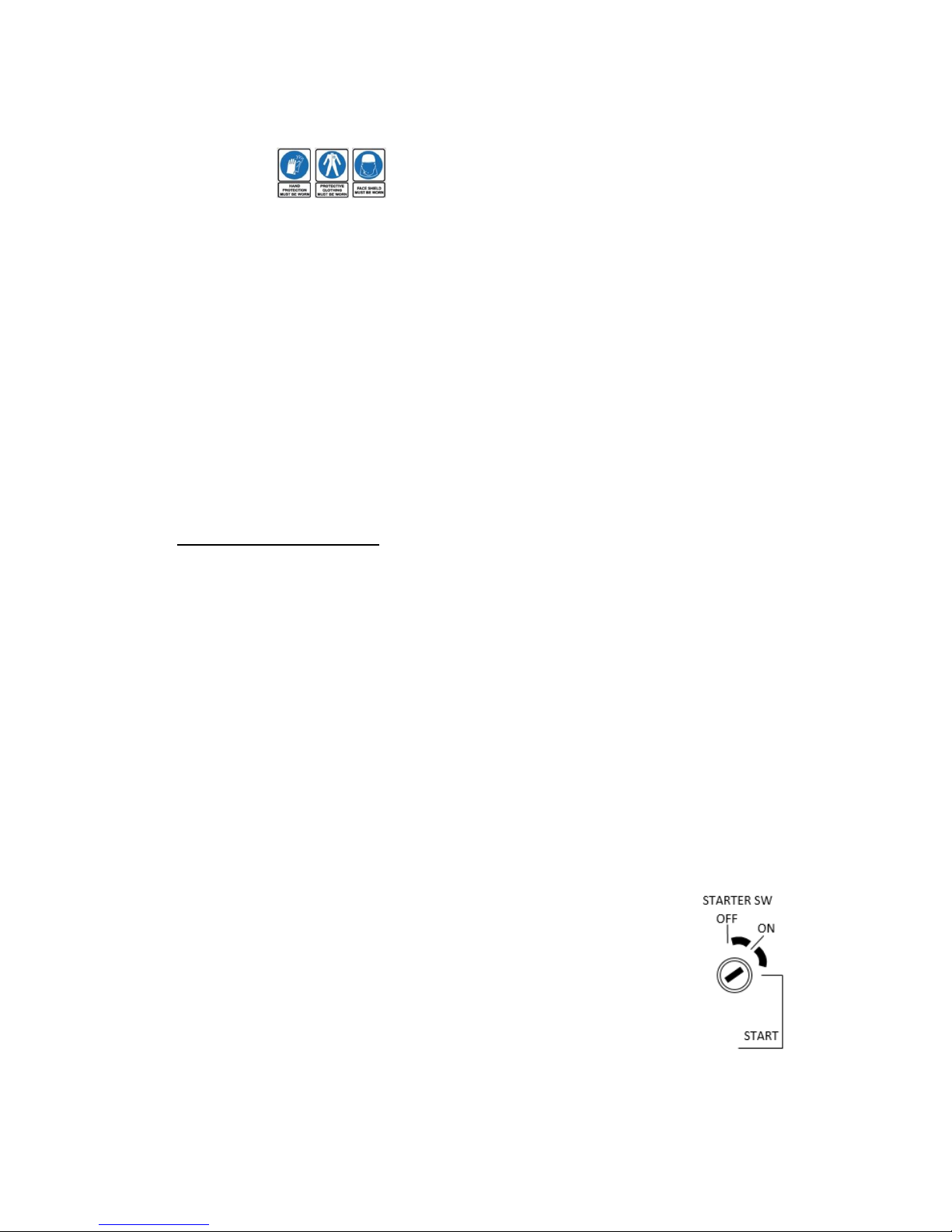

1.5.3. Starter Switch (SW)

1.5.3.1. The engine starter switch controls the ignition.

1.5.3.2. In the ‘OFF’ Position the ignition circuit is switched

off and the engine will not run

1.5.3.3. In the ‘ON’ position the engine is ready for starting

1.5.3.4. In the ‘START’ position (pushed against spring

tension) the starter motor is engaged and the machine

will start.

Page 6

1.4.10.6.1.6. Make sure the charging location is not near where hot working such as

welding grinding or drill is taking place.

1.5.4. AC Switch (Breaker)

1.5.4.1. The AC Switch (Breaker) will turn ‘OFF’ automatically

when the load connected exceeds the generator output.

1.5.4.2. If AC switch turns ‘OFF’ then before resetting remove all

of the load connected to the machine. Make sure you keep the

load required below the rated output of the machine.

1.5.4.3. Then turn on the equipment making sure not to overload

the machine.

1.5.5. DO NOT Connect the generator to Mains AC

sockets in your building – commonly known as ‘back feeding’ it is

extremely dangerous and illegal.

Page 7

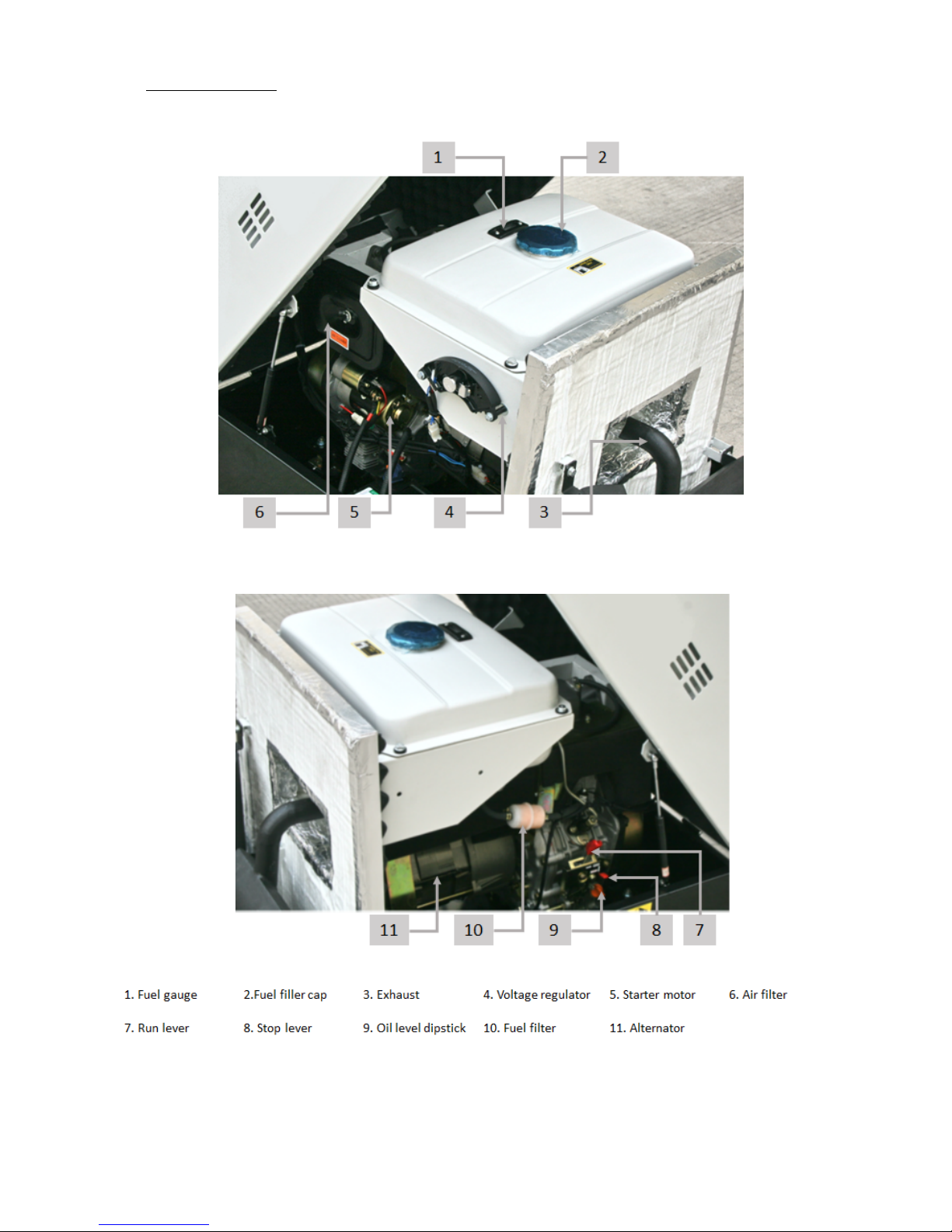

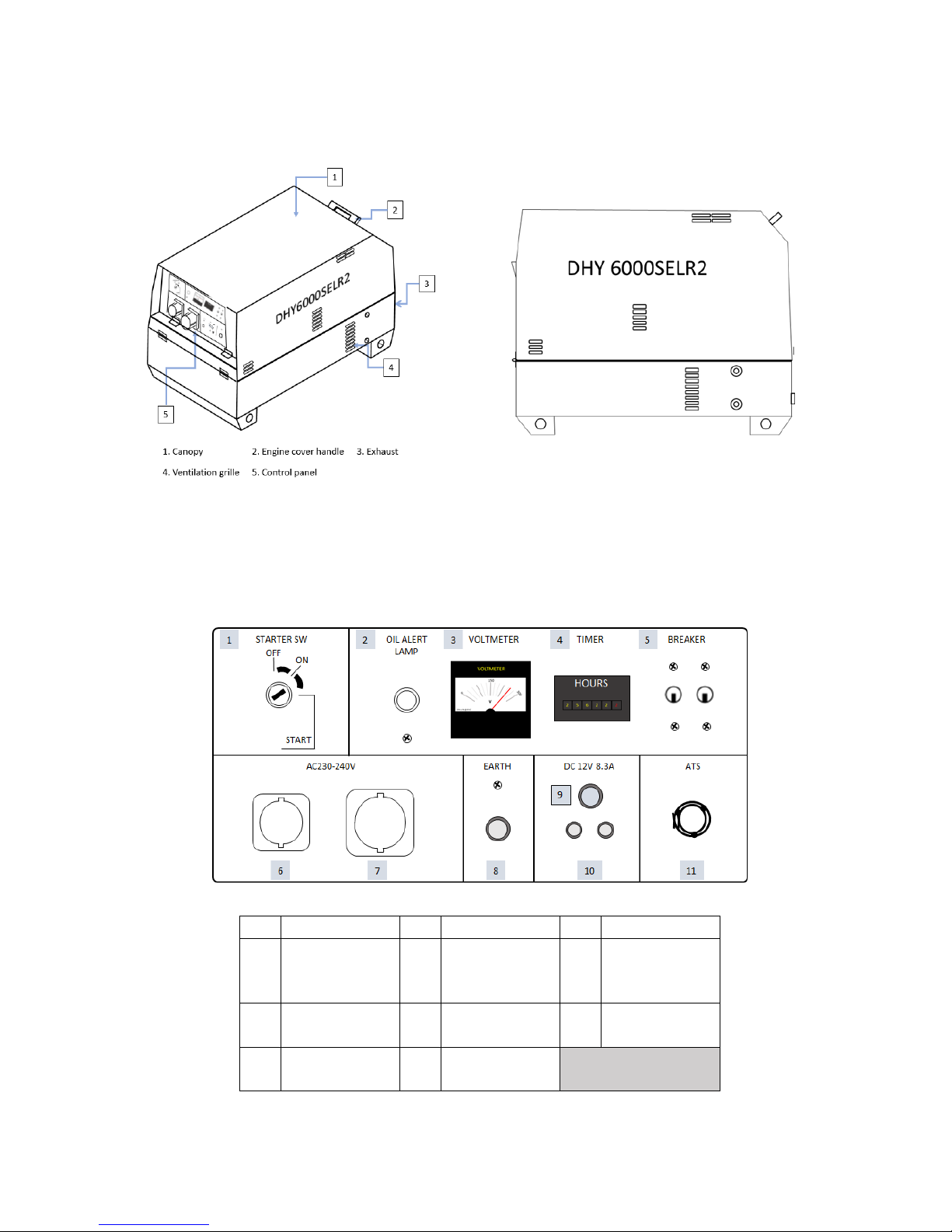

2. MACHINE LAYOUT

Page 8

1 Starter Switch 5 Breaker 9 DC Fuse

2

Oil Warning

Lamp

6

16 Amp – 230

Volt AC Outlet

10

DC

Connection

Points

3 Voltmeter 7

32 Amp – 230

Volt AC Outlet

11

ATS

Connection

4 Hours Run 8

Ground/Earth

point

Page 9

Control panel

Loading...

Loading...