This two-element, tri-band quad operates on 10, 15,

ground and hoist it

position as sho

and 20 meters. The choice to two band settings:

phone and CW, presents low VSWR across each

segment with broadband characteristics.

Heavy swaged aluminum tubing speraders offer

strength and durability, and are free of pattern

distortion effects. The spreaders are broken at

strategic electrical points with high impact-cycolac

insulators and are completely free of "RF" an d pattern

The Driven Element is at DC ground to eliminate

static noise and to provide lightning protection .

Separate pretuned gamma matches offer isolation.

The closed loop feature decreases static build-up.

Taper swaged tubing and vertix-feed combine to

provide mechanical stability. Th e cast alu minum tilthead boom gives strength and offers a choice of mast

diameters.

The preset speader arms are drilled for easy

assembly. You only need to measure the element

One transmission line feeds all thre e bands. RG-8/au

offers minimum cable loss and full legal power

capabilities. If your cable run is less than 60 feet and

power doesn't exceed 200 watts use RG-58/au.

Decide the best height for your installation . Heigh t

above the ground determines the angle of radiation

(the lower the angle, the greater the range).

For best results, install the Hy-Qu ad at least 45 feet

above the ground and 8 to 10 feet above your tower

or rotator.

The site should be clear of any objects of a large,

conductive mass which tend to sh ift an tenna

resonance, affect the VSWR, and distort the radiation.

NOTE: To prolong the life of this product in or aroun d

coastal areas, it is recommended that all hardw are be

encapsulated with a silicone rubber compoun d such

as Dow-Corning silastic rubber or GE silicon e sea l to

prevent atmospheric deterioration.

Electrical

Input impedance (nominal)…………………52 ohms

Forward gain… 10 meters -8.7 dB; 15 meters -8.5 dB;

20 meters -8.3 dB

Front-to-back ratio …………………… 25 to 35 dB

depending on electrical height

Maximum power input ……………….. 1 kw AM, 4 kw

P.E.P VSWR at resonance ................ 1.5:1 or better

Lightning protection .................... DC ground

Study the manual and familiarize yourself with the

NOTE: When unpacking

of all

inside

smaller

articles are sometimes put

tubing

tubing

etc.). To conserve space, these smaller

your antenna,

check the

for parts (clamps, insulators,

the larger pieces.

inside

NOTE: All tubing supplied with the Hy-Quad is

designed to telescope together. It is held in place with

two #10 x

3

self-tapping screws. All tubing lengths

/8"

are predrilled for your convenience. For optimu m

operation, all element-to-wire dimension s should be

followed by ±

1/8"

.

The size of this antenna requires consideration as to

how you are going to get it to the top of your tower.

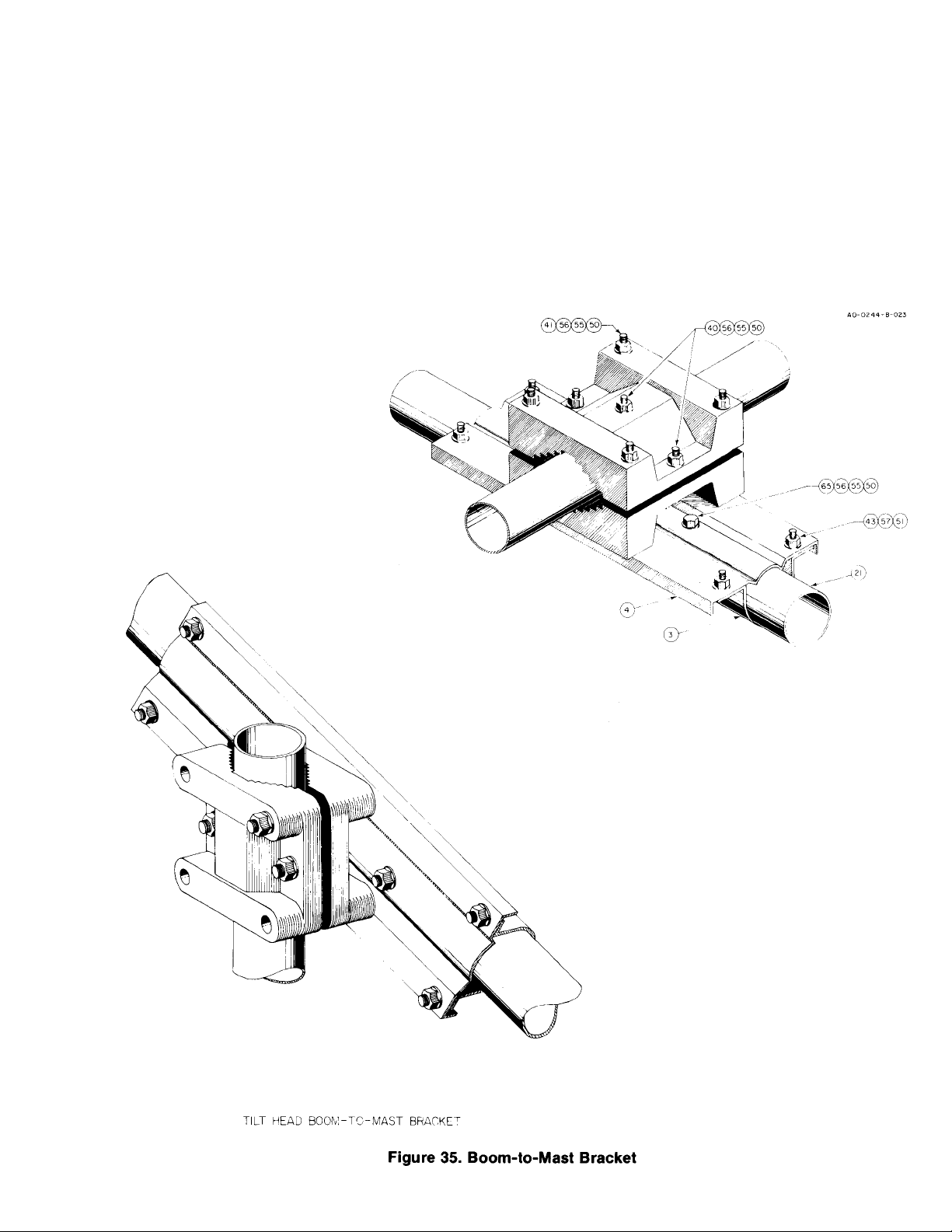

The tilt-head boom-to-mast bracket (see Figure 35)

facilitates assembly of the an tenna in halv es. Th ere

are two installation methods :

Method 1 - Completely assemble the antenn a on the

into

wn in Figure 1.

Method 2 - Assemble the antenna on the groun d in

halves, then hoist each half up the tower and attach

to the boom-to-mast bracket on th e tower.

The best method is to assemble the antenna in halv es

on the ground. When this is done the reflector and

driven element spreaders must be in the same plane.

Attach the boom to the boom-to-mast br acket an d

assemble the sperader arm to boom bracket on the

boom. MAKE SURE THE DRIVEN ELEMENT AND

REFLECTOR BRAC K ETS A RE IN THE SA ME PLAN E. Now

separate the antenna in halves and complete th e

e. Driven Element Spreader Arm Assembly Horizontal

1

5

y

p

g

f. Assembly of Spreader Arms to Boom Sections

g. Compression Clamp

Assembly h. Element Ass embly

i. Phone By-Pass

Wires j. Element

Tension

k. Gamma Match

Assembly I. Boom

Horizontal

( ) Both ends of the horizontal spreader arms are

assembled in exactl y the same way. For s im plicit y, the

assembly procedures for only one end will be

( ) Insert the 1

tube. Align the hol es and secure the tubes using #10

3

x

self tapping screws.

/8"

x 48" tube into the

/8"

1'/4"

x 14'

/6"

( ) Select the spreader arm insulators and attach them

loosel

on the end of the

( ) Select the tube measuring 1

into the s

reader arm insulator.

1 1/8"

x 48" tube.

x 10" and insert it

1/8"

The assembly sequence will be described in the

following order:

a. Reflector Spreader Arm Assembly Horizontal

b. Reflector Spreader Arm Assembly Vertical

c. Driven Element Spreader Arm Assembly Top

Vertical d. Driven Element Spreader Arm Assembly

Bottom Vertical

CAUTION

The 10" piece

that allows a 2" space bet ween it and the

depth

48"

length of 1

of 1

1

1

tube must be inserted to a

/8"

tube. Once this 2"spacing

/8"

dimension is assured, securely

insulator sections to

ether using the 1/4" x 3/4"

tighten

the

This concludes the assembly of half the horizontal

pping

reflector spreader arm. The other half is assembled in

exactly the same way.

Vertical

( ) Select a 1'/4" x 14'

5

/6' tube and a

x 48" tube.

1'/8"

Do not interc hange the ends. The ho le diameters are

different and the small holes must be inside the large

tubes. Align the holes and secure the tubes using #10

( ) Select the 1 " x 36

the smaller drilled holes into the

the holes an d secur e usin g #10 x

( ) Select the

%e"

end into the 1 " x 36

secure with #10 x

() Select the

end into the

%8"

using the #10 x

5

tubes and slip the end with

/8"

x 48" tubes. Align

1'/8"

self tapping

3/8"

x 24" tubes and slip the unswaged

5

tubes. Align the holes and

/8"

self tapping screws.

3/8"

5

x 41'5/2' tubes and slip the drilled

/8"

x 24" tubes. Align the holes and secure

3

self tapping screws.

/8"

Driven Elemen t

Top Vertical Spre ader Arm

Refer to Figure 4. Select a 1'/4" x 14'

x 48" tube. Slip the

/8"

x 48" tube into the end of

1'/8"

5

tube and a 1'

/,6"

the 1'/4" tube. Align the holes and secure using the

( ) Select a 1 " x 32

3

tube and s lip t he en d w ith the

/4"

smaller drilled holes into the 10" piece of 1

Align the holes and secure using the #10 x

ta

( ) Select the

smaller holes into the 1 " x 32

and secure using #10 x

( ) Select the

into the

using the #10 x

screws.

x24" tu be an d sl ip t he en d w ith

%e"

5

/8"

x 24" tube. Align the holes and secure

%e"

3

x 32

/8"

self tapping screws.

3/8"

3

tube. Align the holes

/4"

self tapping sc rews.

3/6"

tube and slip the drilled end

-

1/8"

3

/8"

tube.

self

( ) Next, select the 1 " x 36

5

tube, which is drilled for

/8"

attachment of a tombstone insulator, and insert into

the

#10 x

() Select the

36

( ) Next, select the

x 48" tube. Align the holes an d secure us ing

1'/8"

self tapping scr ews.

3/8"

x 24" tube and insert into the 1 " x

5

tube. Align the holes and secure using #10 x

/8"

%e"

5

/8"

x 35

3

tube, which is also

/4"

drilled for attachment of the tombstone insulator, and

insert into the

holes line up. The hole for the tombstone insulator in

5

this

tube must line up with the tombstone insulator

/8"

hole in the 1 " x 36

x 24" tu be . Tur n th e tu be so the

%8"

5

tube.

/8"

( ) This completes assembly instructions on the top

driven element assembly. This should now be marked

"Top DE" and set aside for future use.

Bottom Vertical Spreader Arm

( ) First, select the

1'/4"

tube, Insert the drilled end of

the drilled end of the 1'/4

( ) Select the 1 " x 36

end into the 1

1

5

tube. Align the holes and fasten

/8"

secur e ly , using t h e # 1 0 x

5

x 14'

tube and insert the drilled

/8"

3/e"

tube and a

/,6"

diameter tube into

1'/8"

"

diameter tube. Align the

self tappin g scr ews.

1'/8"

x 48"

Align the holes and fasten securely.

3

/8"

( ) Select the 78" x 24" tube and insert it into the 1 " x

g

"

5

y

y

p

g

p

g

g

3

g

g

/

5

g

y

y

(

g

y

5/8"

36

tube. Align the holes and secure using #10 x

( ) Finally, select the 5/8" x 353/4" tube and insert in the

"

78

tube. Again, ali gn th e ho le s and faste n secu rely

usin

the same type hardware as before.

3

/8"

( ) Mark this spreader arm assembly "Lower DE" and

Horizontal Spreader Arm Assembly

The last spreader arm ass embly is the hor izontal arm s

of the driven element. These to o will be assem bled in

halves. Both halves are identical, therefore, assembly

( ) Select the 1'/4

Insert the end of the 11/8" x 48"tube into the drilled end

1'/4"

of the

securel

using the #10 x 3/8" self tapping screw.

x 14'

5

/,6"

/,6"

x 14'

tube and 1'/8" x 48" tu be .

tube. Align the holes and fasten

( ) Select the spreader arm insulators and attach

loosel

on the end of the 11/8" x 48" tube.

( ) Select the tube measuring 11/8" x 14" and insert into

the s

reader arm insulator.

Fi

ure 5. Spreader Arms Grouped and Labeled

NOTE: To aid in this part of the assembly, a 3" dia. x 3'

length of pipe can be driven in the ground about 1 foot.

This will hold each boom section in a near vertical

osition while the spreader arms are assembled.

( ) Select the eight spreader element brackets and

loosely assemble using '/4-20 x

3/4"

bolts, nuts, and

lockwashers, '/4"-20 x V anchor bolts and square nuts,

as shown in Fi

ure 6.

CAUTION

The 14" piece of 1

depth leaving a 2" space between it an d the 48"

length of 1

dimension is assured, securely tighten the

insulator sections together, using the

( ) Select the 1" x 28

1

/8" tube m ust be inserted to a

1

/8" tube. Once this 2" spacing

1

/4" x 3/4"

/4" tube and slip the en d wi th th e

smaller holes into the 14" piece of 1'/8" tube. Align the

holes and secure usin

( ) Select the 78" x 24" tube and slip the end with the

smaller drilled holes into the 1 " x 28

holes and secure usin

( ) Select the

into the 78

usin

#10 x

/8" x 283/8" tube and slip the drilled end

"

x 24" tube. Align th e ho les and se cure

3/a"

self tapping screws.

#10 x 3/8" self tapping screws.

3

/4" tube. Align the

3

#10 x

8"

self tapping screws.

( )This complete s the a ssembly of half the horiz ont al

driven element spreader arm. The other half is

assembled in exactl

the same way.

( ) Select a 2" x 4778" of tubing and stick the end with

5

the

/16" dia. hole into the piece of 3" pipe driven in the

round previously. This is one half of the boom.

ure 6. Boom-to-spreader Arm Assembl

Fi

Assembl

of Spreader Arms To Boom Sections:

( ) Place two pair of loosely assembled spreader

( ) At this point, 8 spreader arms should be properly

labeled and grouped together as to Reflector or Driven

Element

four in each group) as shown in Figure 5.

element brackets in position on the end of the boom as

shown in Figure 7. Place the 2" caplugs on the ends of

( ) Select the remaining 2" x

pip

p

y

e end of each bracket, as sho

above

g

p

( )

3

(

)

p

1

insert the drilled end into the

47%8"

boom section and

e as done before.

( ) Select the last 2 pair of loosely assembled boomtospreader arm brackets and assemble them on the

7.

opposite and of the boom, as shown in Figure

Leave

just enough room for the 2" caplug to be inserted on

the end of the boom tube as shown.

( ) Insert the four remaining spreader arm insulators

into the ends of each

air of brackets.

( ) From the group of driven element spreader arms,

select the one marked Driven Element Top and the

Figure 7. Boom-to-spreader Arm Bracket Assembl

( ) Select 4 spreader arm insulators and insert one into

th

wn

.

( ) From the group of reflector spreader arms

assembled earlier, take the two marked horizontal

and slip them into the two spreader arm insulators in

the brackets farthest from the end of the boom See

( ) From the same group, take the two spreader arms

marked top and bottom reflector and insert them into

the other pair of brackets assembled closest to the

( ) Insert these into each end of the spreader arm

insulators on the bracket farthest from the top end of

( ) Turn the driven element top spreader arm so that

when the boom section is standing vertical the extra

holes in the 1 " and

5/8"

tubes of this spreader arm

assembly are pointing straight up.

NOTE: To avoid problems later in the assembly, be

sure that all the tubes bottom out a

ainst the insulator.

( ) Select the two remaining spreader arms marked

( ) Insert these into the spreader arm insulators

located in the

Tighten the

air of brackets closest to the end cap.

'/4"

/4"

x

bolts securely.

( ) Adjust the spreader arms to 90° apart by slowly

turning the boom-to-spreader arm brackets, then

tightening the

'/4" x 3/8"

anchor screws located on each

Figure 8. Boom-to-spreader Arm Bracket

NOTE: The spreader arm bracket containing the

horizontal spreader arms should be parallel with the

5

/,5"

diameter hole in the opposite end of the 2" boom

( ) Remove this assembly from the pipe and prepare

to assemble the driven element spreader arms on the

other 2" x

-8

47%8"

boom section.

( ) This completes the driven element half of the

NOTE: Make sure the horizontal spreaders are

parallel with the

5

/s"

diameter hole in the opposite end

"

Compression Clamp Assembly

See Figures 10, 11, and 12

Driven Element

NOTE: Com

( ) Slip the two 1

over the ends of the horizonal element spreader tubes

and assemble them in their proper position on the 1

ression clamps should only be hand

/8"

compression clamps, item 28,

1

/8"

( ) Install the six 1" compression clamps, item 29. Slip

,

g

g

5

p

g

p

g

p

g

p

y

three of them over the bottom vertical driven element

spreader arm as shown in Figure 9. Slip one over the

top end of the vertical spreader arm as shown and

slip one over each end of the driven element

horizontal spreader arm as shown in Figure 9.

( ) For proper assembly of the middle 1 " compression

clamp on the middle of the bottom driven element

tube

refer to Figure 24, Gamma Match Detail.

( ) Select two %a" compression clamps, item 30, and

slip one on the end of each vertical driven element

spreader arm and loosely attach them on the %a"

tubin

at the dimensions called for in Figure 9.

( ) Next, select five of the "/16" compression clamps

and place them on each spreader arm at the locations

shown'in Fi

ure 9.

NOTE: The

/8" tube of the bottom vertical driven

element spreader arm takes two "/16" compression

clam

s as shown.

( ) This completes the basic assembly of the

compression clamps on the driven element half of the

antenna. Remove this half from the pipe and lay it to

( ) Insert the reflector half of the antenna in the pipe

and prepare to assemble the compression clamps as

shown in Fi

ure 13.

( ) Select seven 1 " compression clamps and

hardware. Slip two clamps on each end of the

horizontal reflector spreader arms, two clamps on the

bottom vertical reflector spreader arms and one clamp

on the to

vertical reflector spreader arm.

( ) Loosely assemble these clamps at the location

iven in Figure 13.

( ) Select three 7/8 " compression clamps and

hardware. Slip two clamps over the bottom vertical

reflector spreader arms and one clamp over the top

vertical reflector s

reader arm.

( ) Move them to the proper dimensions shown in

Fi

ure 13 and fasten loosely.

( ) Select five' /,

compression cl amps and hardware

s"

and slip two clamps on the e nd of the bottom vertical

reflector s

reader arm as shown in Figure 13.

( ) Slip one clamp on each of the other reflector

spreader arms. Fasten all five compression clamps

loosel

at the locations shown in Figure 13.

1. Measurements are made from the center of

pping

y

pping

g

g

y

g

g

g

compression clamps and the center of hole in

insulators. Tolerances are not specific: antenna

performance depends on assembly.

2. Add 2112' to this dimension for overall length of the

wire to allow for wra

and bypass loops.

ure 14. Measurements For Antenna Stringin

Fi

3. Length of the loop must be maintained at 9". All

other bypass wire dimensions are found in det ai led

assembl

4. Add 1 1/2' to this dimension for overall length of wire

to allow for wra

illustrations. Keep all dimensions accurate.

and bypass loop.

IMPORTANT

The

most difficult part of

the

antenna assembly

is the stringing of the element wire. Take extra

time to plan the remaining steps. Figure 14

NOTE: Dimensions of jumper wires are critical. All

The element wire shrinks in cold weather, DO NOT

hten it during assembly.

overti

gives the lengths and spacings of the elements.

NOTE: To prevent tangling, do not cut all wires ties

holding the large roll of wire. Improvise a spool or

General Assembly Outline

The general outline of steps is listed below. Follow the

detailed instructions for assembl

1. Attach all insulators to the compression clamp

2. Strin

3. Attach all jumper wires, i.e. phone bypass, driven

element bypass etc. as shown in the detailed

drawings, Figure 16 through Figure 34.

the element wires.

.

some other means of containment and pull off only as

much wire as needed for each piece. Do not use pliers

to pull or wrap the wire. Any nicks weaken the wire.

Detailed Assem b ly Instructions

( ) Mount the element insulator hangers, item 68, on

the element tubes. The locations for the driven

element spreader arms are noted in Figure 15. Their

typical mounting is shown in Figures 16, 17, 21, 22,

and 23. Refer to Fi

ure 34 for more detail.

( ) Squeeze the hanger ends together so the

p

g

'

( ) Assemble the ten and fifteen meter driven element

upper insulators as shown in Figure 18, 19 and 20,

and attach to the to

( ) Fasten the compression clamps securely at the

dimensions shown in Fi

driven element spreader arm.

ure 13.

NOTE: These figures are only to be used for proper

bottom d

eader a

ging

assembly of the hangers and insulators on the

various compression clamps and should not be used

at this time for attaching element wire. This phase of

assembly will be explained later.

( ) Refer to Figure 24 for attaching hardware to the

riven element spr

Strin

( ) Cut two lengths of wire to the dimen sions giv en in

Figure 14. String them individually from the left

spreader arm through the insula tors on the top

spreader arm, and down to the right spreader arm.

NOTE: Cut the wires 2'-6" longer th an specified to

allow for loops and wrapping at each end but mark

the specified lengths with tape.

( ) All remaining wires on the driven element can be

strung in halves. This is don e by adding the

dimensions together, cuttin g th e wire and then

stringing. Example: Driven Element, 10 Meter.

Combining the two dimensions shown in Figure 14

(left spreader-to-top spreader and right spreader-totop spreader) you have 16' 3". Add 2'6" to this

dimension for excess to be used for the loops and

Element

rm.

( ) Use the same procedure on the bottom half of the

10 Meter driven element wire and splice the two

halves together with a Western Union Splice (Figure

21), making sure the splicing loop length is 9". Clip

off all excess wire when the antenna is completely

strung. Use this procedure at all the remaining points

within the antenna.

( ) Connect the fifteen meter wire on the driven

element spreader arms as shown in Figures 18, 22

and 24. The jumper wire in Figure 18 presents wire

slippage, tie it as short as possible.

( ) Connect the ten meter wire on the driven element

spreader arms as shown in Figure 19, 23 and 24.

Refer to these figures and Figure 14 for aid in this

part of the assembly. The jumper wire in Figure 19

presents wire slippage - tie it as short as possible.

( ) Beginning with the 20 meter wire on the left

spreader insulator, Figure 21, wrap and tie the wire

through the insulator leav ing enough wir e for

splicing. The loop length with splice mus t be 9". Run

the wire through the insulator on the top sprea der

arm, Figure 16, and connect it to the insula tor on th e

right spreader arm as shown in Figure 21, only

reversed. Your lengths must correspond to the

NOTES

1. Same general arrangement as in Detail "A". 2. Use a

flat washer on each side of wire. 3. Center conductor of

coax connects to 10 meter gamma match, braid

connects to compression clamp screws.

( ) Cut the wire as was done with the driven element.

gth,

g

g

p

p

y

g

pp

p

Use Figure 14 as a guide. Double the dimension and

add 2'6". Cut the wire. When stringing and attaching

the 20 meter element wire, refer to Figures 26, 28, and

33. Note that Figure 26 shows the left horizontal

spreader arm attachment. The right horizontal

spreader arm attaches to the element wire the same

as the left. Therefore, Figure 26 will be used as a

guide for both horizontal connections of the 20 meter

( ) The 15 meter wire should be cut by referring to

Figure 14 for the dimensions, then doubling the

len

add 2' 6" for loops and splices, and cut.

( ) Refer to Figures 27 and 29 for connecting the top

( ) Refer to Figures 27 and 32 for connecting the

bottom half of the 15 meter wire. Again, the left and

right horizontal connecti ons are ident ic al as sho wn in

Figure 27, and referred to the Figure 25. The loop

len

th with splice must be 9", as shown in Figure 34.

( ) Connect the wires using a Western Union splice, as

done before. The lengths must correspond to the

dimensions shown in Fi

ure 14.

NOTE: When stringing the wires, do not wrap the wire

around the compression clamp screws. Pass the

wires by the screws and wrap around the hanger.

Remember the wire wra

( ) Refer to Figure 25 for a general diagram of how

wire should look on the reflector half of the antenna. 14

ed on the hanger is shorted

( ) Refer to Figures 27 and 30 for connecting the top

half of the 10 meter wire to the reflector s

( ) Figure 27 and 31 give detailed instructions as to

the proper connection of the bottom half of the

( ) Connect the ends with the Western Union splice.

Kee

the 9" loop dimension accurate. Referto Figure

Phone B

For operation on the phone frequencies, the phone

bypass wires should be installed exactly as shown in

Fi

ures 16 and 19 and in Figures 31, 32 and 33.

( ) Driven Element: Tension the driven element by

loosening the compression clamps on the top, right

and left spreader arms and moving the clamps out

( ) Tension and remove the kinks from the wires, but

do not over tension them. There should be some slack

in the wire to

( ) Reflector: Tension the reflector by loosening the

compression clamp screws on the top and bottom

spreader arms and moving the clamps out toward the

ends of the arms. The wire should not be wrapped

around these screws. Pull the wires taut, move the

clamps out, secure the clamp and tighten the nuts.

revent the spreader arms from bowing.

-Pass Wires

reader

( ) Moving the compression clamps out on the

y

g

spreader arms will create an error when compared to

the dimensions in Figures 9 and 13. These are

approximate positioning dimensions and may not

meet at the end of the antenna assembly. The critical

dimensions are the lengths of the element loops, as

shown in Figure 14.

( ) Upon completion of the assembly, each leg of the

antenna loop should be accurate to within

±1/4"

(Figure

14) and '/z of the element loop should be within +/1/2". Example: 10 Meter, Driven Elem ent. Each

dimensions of 8' 1 1/2" to within

±1/4"

and 16' 3" to

NOTE: If you want best performance for the phone

sections of the amateur bands, the element by-pass

wires should be installed now. See the detailed

illustrations.

Gamma Match Assembl

( ) Select the gamma match clamps and hardware

and install them on the

amma matches. See Figure

( ) Attach the gamma matches to the element wires.

When you have the correct spacings on the gamma

spacing clamps, crimp the clips to the element wires to

insure a good electrical connection. The wire clips

should be snug but not too tight or the element wires

may be cut.

( ) Select the two gamma rods (9, 10) and install on

the gamma match insulators.

Assembly of the Boom

y

( ) Select the cast aluminum brackets, boom-tobracket clamp, and the casting-to-boom bracket and

assemble loosel

.

( ) Select the two boom sections and slip the drilled

end into the boom-to-mast bracket. Line up the holes.

Attach the boom sections to the brackets using the

5

two

/,5'"-18 x 2 1/2" bolts, nuts and lockwasher

provided. Do not tighten them now. The bracket must

be loose to facilitate mounting the antenna on the

-

-

Final

5

( ) There are two styles of

/8"

caplugs. Insert these

caplugs on the end of each stringer element now. The

caplugs with the holes in the end must be placed on

the stringer element that points down when the

antenna is in its erected position. Th is insur es proper

drainage of any moisture that may accumulate in

these tubes. The two inch caplugs can now be

inserted on the ends of the boom.

( ) Run the coax feedline up the mast, across the

boom, down the driven element spreader arm and

attach to the 10 meter (top connection) gamma

match as shown in Figure 24.

( ) Recheck all mechanical connections for tightness.

Seal the coax connections with Dow Corning silicone

rubber (Silastic), GE RTV compound, or some similar

substance.

Loading...

Loading...