ORDER NO. 380S

p

Model 2BDQ-S

Trap Dipole Antenna

INSTRUCTION MANUAL

General Description

The Hy-Gain Model 2BDQ-S is a 1/2

wavelength, dipole antenna for 40 and 80

meters. Band switching is accomplished

automatically through the use of two matched

Hy-Gain 40-m eter Hy-Q t raps. The maximum

overall length is 100' 10 1/2". If the antenna

is mounted in an inverted "V" configuration,

the overall length will be shorte ned.

The balun will improve the performance and

efficiency of the 2BDQ-S. The Hv-Gain

Model BN-86 is a broadband balun designed

specifically for dipole-type antennas. The

balun balances the input impedance to the

antenna and prevents transmission line

radiation.

Theory of Operation

Matched Hy-Gain Hy-Q traps give true 1/2wave resonance. They are tuned at the factory

and no adjustments are necessary. They

operate as a high impedance circuit on 40

meters and add to the overall length of the

antenna as center loading for the 80/75 meter

resonance.

Construction

The Hy-Q traps will withstand h ard wear and

severe weather conditions. All hardware is

passivated stainless steel. The center of the

dipole is supported with a yoke-type center

insulator to which the transmission line

attaches. The ends of th e dipole are suppo rted

by two end insulators constructed of high

impact ABS plastic. The antenna wire is

Alumoweld© #12, which resists rust and has

a breaking strength of 1200 pounds.

SWR and Feedline

The 2BDQ-S antenna is designed for use with

single 50 ohm coaxial feedline. The SWR at

resonance is 1.5:1 or less on both bands.

Alumoweld® is a registered trademark of Copperweld

Bimetallic Grou

Assembly Procedure

g up

d

p

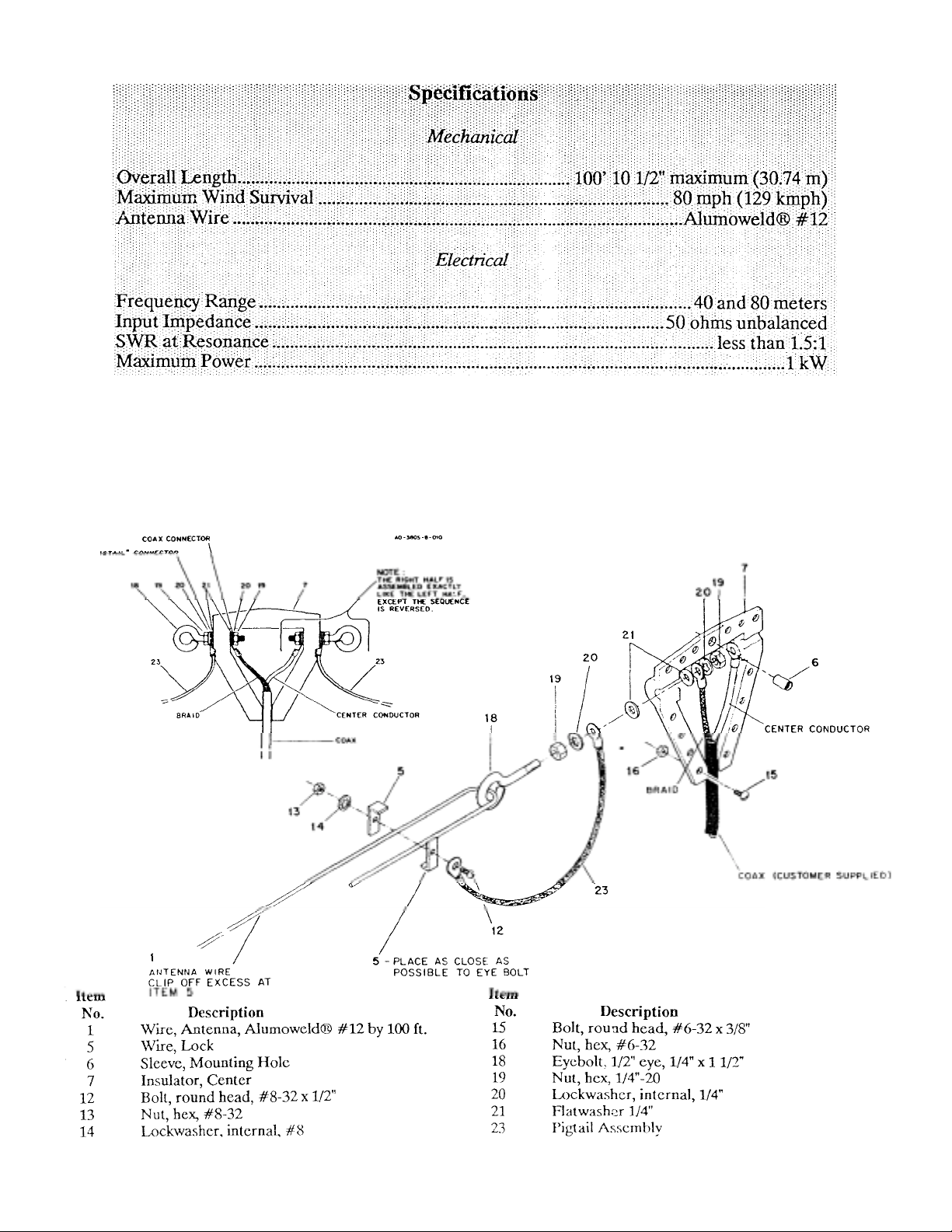

Referring to Figure 1, place one half of the

center insulator (Item No.7) on a flat surface

with the inside facin

.

Assemble the hardware on the eyebolts an

lace in the insulator.

Figure 1 Ass embl y of Antenn a Wi re to Cent er

Insula tor

Strip the coax and s eparate the center condu ctor from the braid. Solder the braid to one

solder lug (Item No. 22) and the center

conductor to the other solder lug. For a

smaller coax , a reducing sleeve is provided.

Apply silicone gr ease or V aselin e®, etc . (not

supplied) to the matin g halves.

Place the halves together and secure them

using the #6-32 x 3/8" bolts and nuts (Item

Nos. 15 & 16).

Hold the eyebolt to keep it from turning and

tighten the 1/4" nuts on the outside, first one

NOTE: Both sides of the antenna are exactly

the same. Each of the following steps must be

done first for one side then repeated for the

other side.

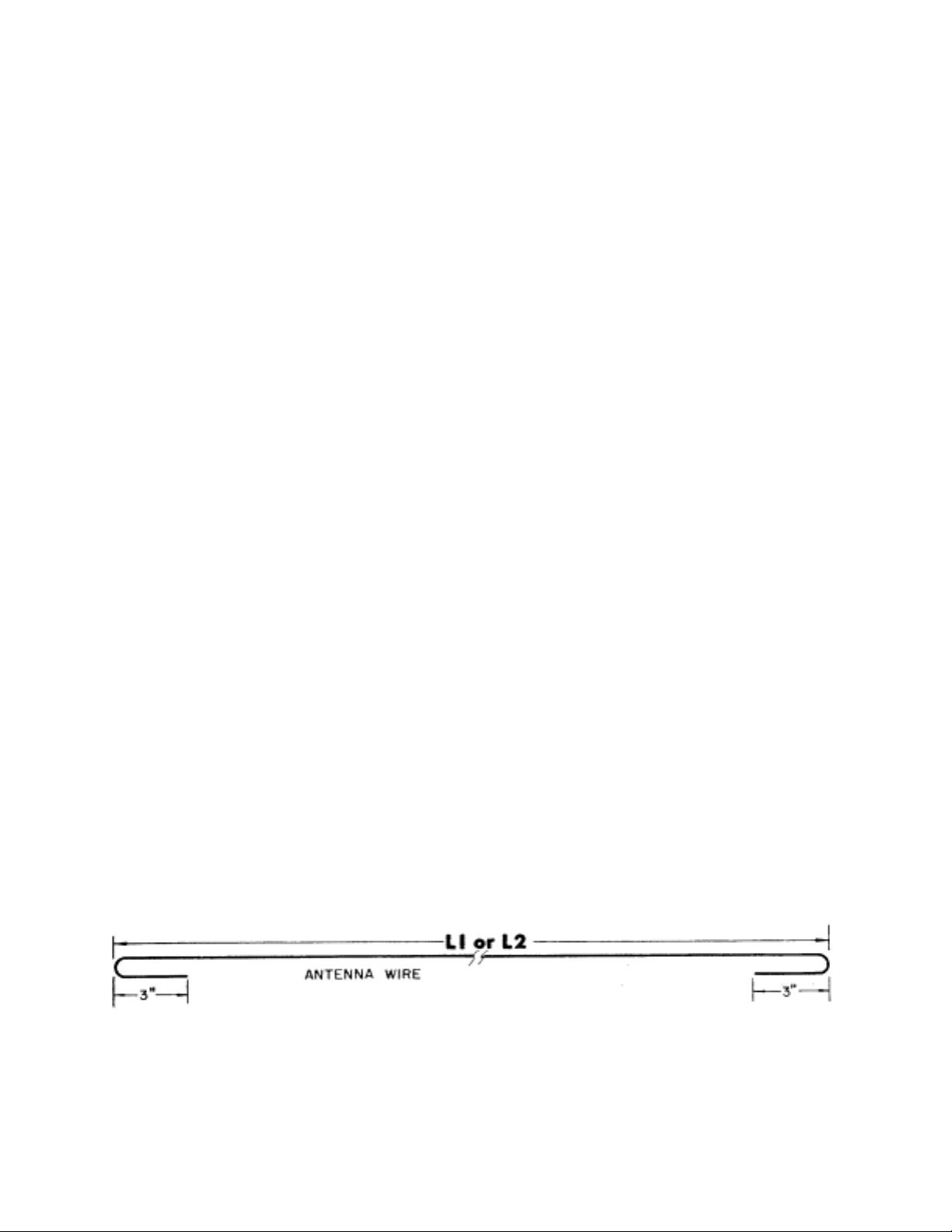

Cut the 40-mete r wire (LI) to eithe r Phone or

Continuous Wave (CW) dimensions as shown

in Figures 2 and 3. Add an extra thr ee inches

on each end for attaching to the center

insulator and 40-meter trap. Example: Ll

length for CW operation is 19' 8 1/4". Add

six inches, three inches each end, which

makes a total length of 20' 2 1/4". Each

insulator or trap requires three inches for

proper attachm ent.

NOTE: When you have selected your mode of

transmission (Phone o r CW), you must us e the

same mode for all dimensions .

Attach one end of the wire (just cut) to the

center insulator (Item No.7) using the wire

locks as shown in Figure 1. Do not forget to

connect th e pigtail to the wire lock.

Clip off all excess wire extendin g past the

wire lock.

Select the 40-meter trap and the trap

connector clamps. Assemble the clamps on

both ends of the trap using the #10-24 x 1

1/2" bolts, lockwashers, and nuts (Item Nos.

9, 11, and 10), as shown in Figure 4.

Carefully remeasure the antenna wire connected to the center insulator and bend the

wire for attachment to the 40-meter trap as

shown in Figures 2 and 3.

Connect the wire to the trap using the wire

locks (Item No. 5) and shown in Figure 4.

Clip off all excess wire extending past the

wire lock.

Figure 2 Antenna Wire

is a registered trademark of Chesebrough -Ponds,

Measurements

NOTE: The end of the trap which has a small bolt must be

m

N

N

p

N

N

N

ps

pointed in the direction of the center insulator as shown in

Figures 3 and 4. This is very important for proper operation

of the antenna.

Use only one bolt on the side of the clamp opposite the

drain holes. An off-center wire attachment is used to keep

the drain holes downward. Remove the twists and kinks

from the wire prior to the installation to insure that the traps

do not rotate in the final mounting position.

Ite Ite

o. Description

4Clam

5 Wire Lock 14 Lockwasher, internal, #8

9 Bolt, hex head, #10-24 x 1 1/2" 17 Bolt, hex head, 1/4"-20 x

10

11 Lockwasher, internal, #10 20 Lockwasher, internal 1/4"

12 Bolt, ro und he a d, #8 -32 x 112"

, Trap Connector 13

ut, hex, #10-24 19

o. Description

ut, hex, #8-32

ut, hex, 1/4" -20

Figure 4 Assembly of the Antenna Wire

to the Tra

Cut the 80-meter antenna wire (L2) to the

length shown for your mode of transmission

(Phone or CW). Do not forget to allow an

extra three i nches on each end for attachm ent

to the 40-meter tr ap and end insul ator.

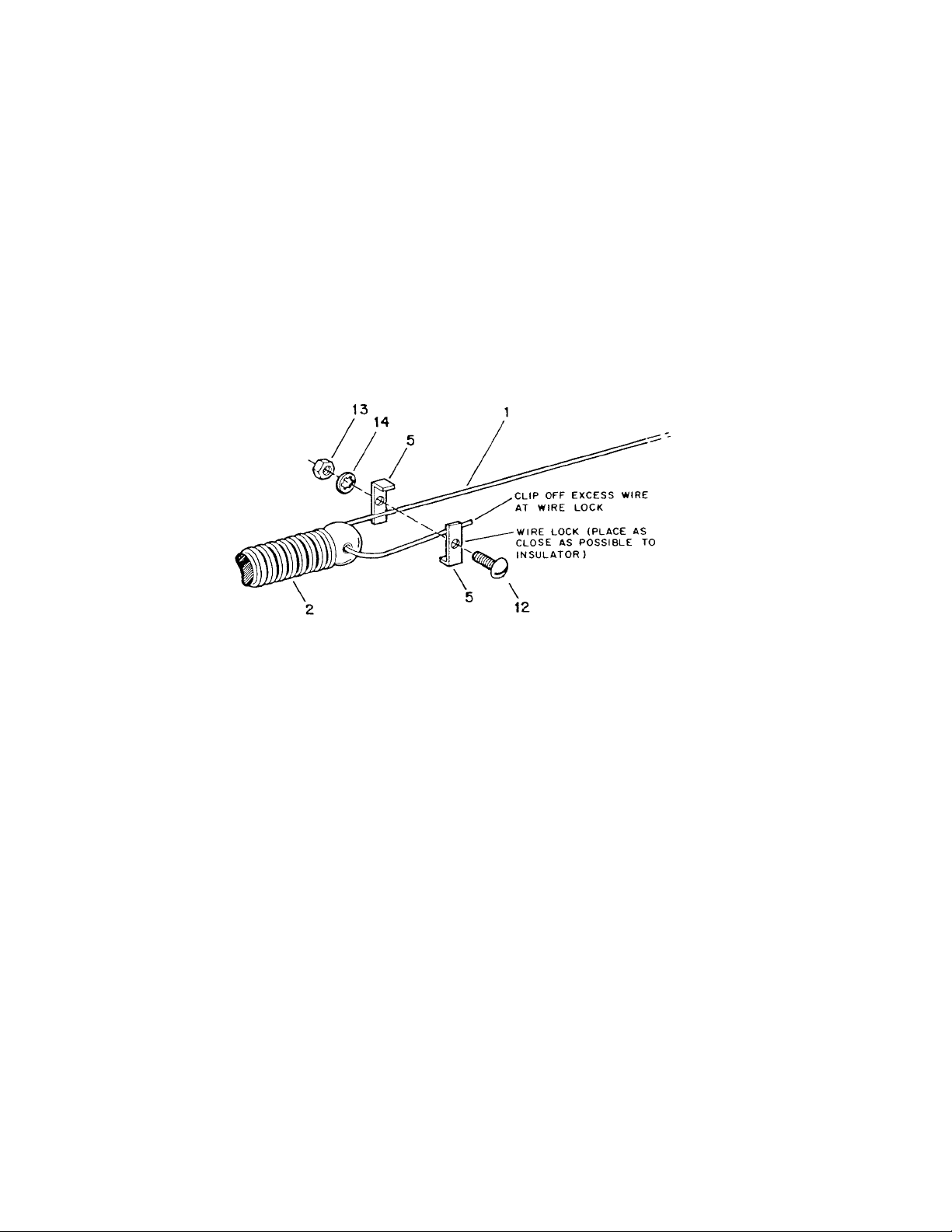

Bend one end of the wire and attach to the

40meter trap as shown in Figures 2 and 4. Do

not forget to clip off the excess wire

Carefully remeas ure wire and bend for att achment to the end insulator.

Attach the wire to the end insulator as shown

in Figure 5. Clip off all excess wire extending

past the wire lo ck.

Item

No. Description

1 Wire, Antenna, Alumoweld #12 by 100 ft.

2 Insulat o r, End

5 Wire Lock

12 Bolt, round head, #8-32 x 1/2"

Assembly of the Antenna Wire to th e End Insul ator

Mounting

The antenna is now ready to be mounted in

either the horizontal or inverted "V"

configuration. Refer to Figures 6 and 7 for

proper dimensions. When suspending the end

insulators, non-metallic line is preferred. If

you do use «ire, it must be broken up every

six feet with strain insulators to prevent

harmful effects to your radiatio n pattern.

Figure 5

Suspend the antenna by attaching the end insulators to a stable structure. The center insulator may be supported by the antenna itself

or suspended from a support. When

suspending the center insulator from a

support, be sure to keep the insulator from

contacting any of the supporting structure. For

proper operation of this antenna, the center

insulator should be about 46 feet above the

ground. The higher the a ntenna, the better the

operation.

Figure 6 Horizontal

g

g

p

Mountin

Figure 7 Inverted "V "

Mounting

it is extremely important that the antenna be

mounted in the clear. Detrimental effects of

surrounding objects is often underestimated

in the average antenna installation. In

particular, power lines and other metal

objects of considerable length or mass will

deteriorate the performance of any antenna.

When installing the antenna, keep the two

halves balanced with respect to ground and

surrounding objects. Do not attempt to

remove all the sag or tremendous strain will

develop which could cause mechanical

failure. A few feet of sag in the antenna wire

will not harm the performance of the 2BDQ-S

either me chanic ally or electrically.

A Model 2BDQ-S may be mounted in the inverted "V" configuration as shown by the

drawings in this manual. Care must be taken

to insure that the ends of the antenna are at

least 16 feet above the ground. Keep the

antenna balanced. Anything you do to one

end must also be done to the other end or

serious deterioration in performance will

result. One advantage of the inverted "V" is

that you can more nearly match the antenna

impedance to the transmission line impedance. A directional pattern, in the

direction of the slant, will result if angle "A"

(as shown in Fi gure 7) ex ceeds 35 de grees.

VSWR Charts

Figure 8 shows typical SWR curves for this

antenna mounted appr oximately 50 feet above

round.

The optimum heights for this antenna on 40

meters would be between 20 and 30 feet or

greater than 70 feet. The optimum heights for

this antenna on 80 meters would be between

30 and 70 feet. Heights other than these will

roduce SWR in exc ess of 1.5: 1.

Figure S Typical SWR Curves for

this Antenna Installed 50 feet

Above Ground

Hints on Handling Alumoweld© Wire

To meet the numerous re quests for a n on-cor-

rosive, super strength wire, Hy-Gain is now

using Alumoweld© wire in many wire-type

antennas and mounting kits.

Alumoweld© wire meets Military

Specifications for virtually all environmental

conditions. The wire is designed for arcs of

high humidity and salt exposures as well as

other less durable forms of wire but the lasting

properties are far superior. Conducting

properties closely approach that of pure

aluminum making it ideal electrically for RF

use.

There may be some difficulty encountered in

working with the wire due to its tendency to

kink. Kinks may be removed by a pole or

similar stationary curved object and working

the wire b ack an d forth a s shown in Figure 9.

Figure 9 Removing Kinks from

Alumoweld Wire

PARTS LIST

p

,

No. Part No. Description Qt

y

1 691067 Wire, Antenna, Alumowel #12 by 100 ft. .........................1

2 861021 Insulator, End......... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...2

3 877234 Trap Assembly, 40-Meter..........................................................2

877233-1 Parts Pack 380 S, Stai nles s S teel .. .... .... .... .... .... .... .... .... .... .... .... .. 1

4 167236 Clam

, Trap Connector... ...... ...... ...... ...... ...... ..... ....... ...... ...... 8

5 1672 38 Wire Lock... ...... ...... ..... ....... ...... ...... ...... ...... ..... ...... .... ...... ...... 16

6 171586 Sleeve

Mounting Hole...... .... .... .... .... .... .... .... .... .... ... 1

7 465460 Insulator, C ent er. .... .... .... ... ..... .... .... .... .... .... .... ... ..... .... .... .... .... 2

8 465570 Plug, Center Insulator Adaptor............................................ 1

9 500159 Bolt, hex head, #10-24 x 11/2 "... ...... ...... ...... .... ....... ...... .......8

10 55 4071 Nut, hex, # 10-24 ………….. ...... ...... ...... ...... ...... ...... ...... ...... ..... 8

11 565697 Lock-washer, internal, #10 .................................................,.. 8

12 50 0185 Bolt, rou nd h ead , #8 -32 x 1/ 2".. .... .... .... .... .... .... .... ..., .... .„. .... 8

13 550063 Nut, hex, #8-32...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... .....8

14 560035 Lockwasher, internal, #8.......... ...... ...... ...... ...... ...... ...... ....,..„ 8

15 501118 Bolt, round head, #6-32 x 3 /8".. .... .... .... .... .... .... .... .... .... ...,..14

16 55 5888 Nut, hex, #6 -32.. .... .... ... ..... .... .... .... .... .... .... .... .... .... .... .... .... ...1 4

17 50 5266 Bolt, hex head , 1/4" -20 x 3/4 "...... ...... ...... ...... ....., ...,.. ...... ,.„„. 4

18 540066 Eyebolt, 1/2" eye, 1/4" x 11/2 ". ...... ...... ...... ...... ...... ...... ...... ....2

19 554099 Nut, hex, 1/4"-20..... ..... ....... ...... .... ...... ...... ...... ...... ..... ...... ...... 14

20 56 2961 Lockwasher, inter nal, 1 /4" .... ...... ...... ...... ...... ...... ...... .,.,.. ..„„ . 8

21 566344 Flatwasher, 1/4".......................................................................4

22 67 7555 Lug, Solder……… ……….. ....... ...... ...... ...... ...... ........ ...... ...... ... 2

23 878466 Pigtail Assembly ..................................................................... 2

Converting American

to Metric

Use this scale to identify lengths of bolts,

diameters of tubes, etc.. The American inch

(1") and foot (1') can be converted to

centimeters in this way.

1 inch (1 ") = 2. 54 c m

1 foot (1') = 30.48 cm

Example

42" x 2.54 = 106.7 cm

Loading...

Loading...