Page 1

Hustler FasTrak

36" & 42" Decks

Parts Manual

•••••••

Hustler Turf Equipment

•••••

P.O. Box 7000

•••

Hesston, Kansas

•

67062-2097

Page 2

IMPORTANT: This engine is not equipped with a spark arr ester muffler. It is a violation of California Public Resource Code

Section 4442 to use o r operate this eng i ne on any fo rest-co vered, brush-cover ed, or grass-co ver ed unimproved land . Other

states or federal areas may have similar laws.

This spark ign i tion sy stem c ompli es with Can adian ICES -002.

The Eng ine Owne r’s Ma nual provide s info rma tion regarding the U.S. E nvironmenta l Protection Agency (EP A) a nd the

California Emission Control Regulation of emission systems, maintenance and warranty.

Keep E ng ine Owner’s Manual with your unit. Sho uld the E ngine Owner’s Manual become damaged or illeg ible, replace i mmediately. Re pl acements may be o rd ered per the information found in th e Produc t In f ormation section of th e

owner’s manual.

The engine exhaust from this product

contains chemicals known to the State

of Calif orn ia to cau se c an cer, birt h

defects or other reproductive harm.

WARNING:

cl-2 333559 9/08

Page 3

333559 9/08 cl-3

Page 4

cl-4 333559 9/08

Page 5

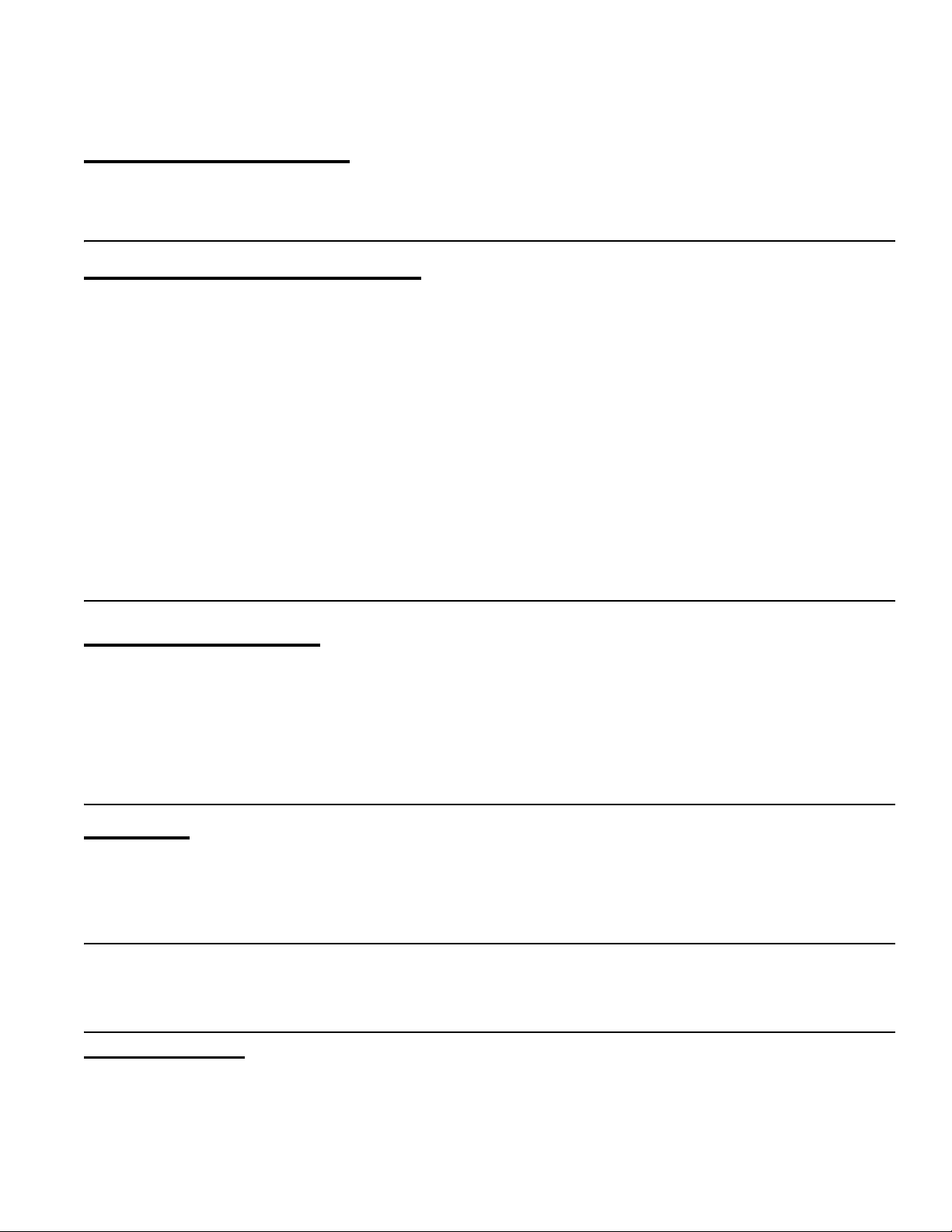

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Table of Contents

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Tractor Frame Rivet Nut Installation . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Engine Guard and Anti-rollover Bracket Assemblies . . . . . . . . . . . 2-3

Footrest Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Battery Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Deck Lift Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Hydro Transmission Installation S/N Prior To 07091558 . . . . . . . . 3-4

Hydro Transmission Installation S/N Higher Than 07091558. . . . . 3-6

Steering and Brake Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

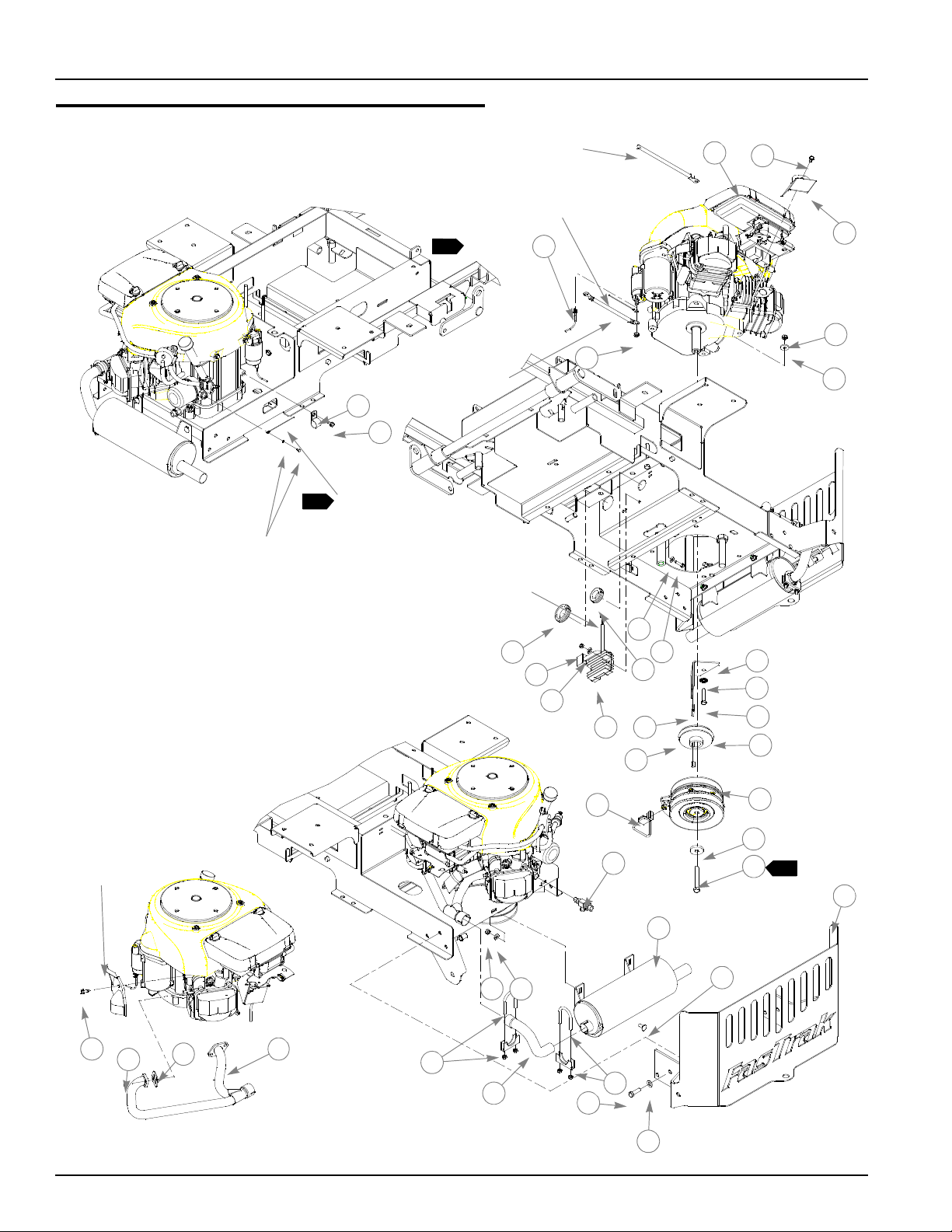

Honda 16 HP Engine Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

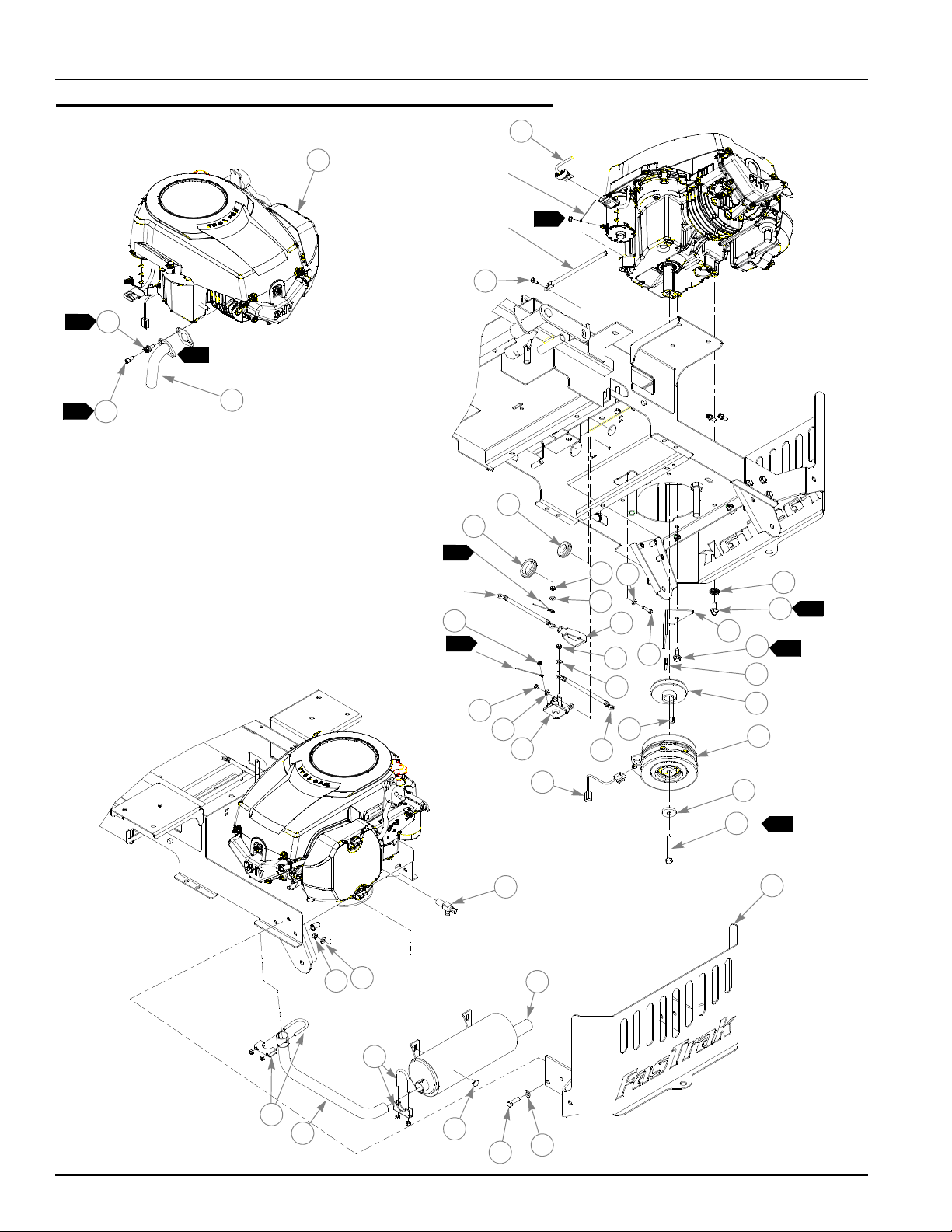

Kohler 15 & 17 HP Engine Installation . . . . . . . . . . . . . . . . . . . . . . 4-6

Fuel System Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Instrument Panel Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Honda 16HP Electrical Schematic (793083). . . . . . . . . . . . . . . . . . 4-14

Kohler 15 & 17 HP Electrical Schematic (601127& 793117) . . . . . 4-16

Chapter 5

Front Wheel Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Front Wheel Breakdown -768044 . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Drive Wheel Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Chapter 6

Deck Assembly 36". . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Deck Pulley Assembly 36" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Deck Assembly 42". . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Deck Pulley Assembly 42" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Blade Spindle Assembly Breakdown . . . . . . . . . . . . . . . . . . . . . . . 6-14

Chapter 7

Deck Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Belt Routing and Tensioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Seat Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Chapter 8

Tractor Decals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

42" Deck Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

36" Deck Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Chapter 9

Maintenance & Adjustment Safety . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-20

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i-1

333559 09/08 c-1

Page 6

c-2 333559 09/08

Page 7

Chapter 1

General Information

This Manual covers “Mini” FasTrak 15/36 model 927343, “Mini” FasTrak 17/42 model 927350,

“Mini” FasTrak 16/42 model 927368, & “Mini” FasTrak 16/36 model 927376,

Frequently Ordered Parts

PART NO. DESCRIPTION

793836 Pump Drive Belt

793828 Deck Belt 36"

793893 Deck Belt 42"

068478 Fuel Filter Kohler

785626 Fuel Filter Honda

794370 Air Filter, Kohler

787226 Air Filter, Honda

747303 Engine Oil Filter, Kohler

787234 Engine Oil Filter, Honda

793794 20.50" 42D X 0.631 CW Blade

793802 13.75" 42D X 0.631 CW Blade

Service Literature

PART NO. DESCRIPTION

601156 Owners Manual

794313 Kohler Engine Manual

787242 Honda 16 HP Engine Manual

Options

PART NO. DESCRIPTION

793331 Armrest Kit

338442 Mulch Kit, 36/42"

Note: When ordering parts, yo u must use the part number as shown for each part, not the index number . Always give

the model and serial number to your parts and service represen tative.

Note: Items sold in bulk such as seals and hoses are sold by the foot.

Using this manual

Illustrations used were current at the time of printing, but subsequent production changes may cause your machine to

vary slightly in detail. Excel Industries, Inc. reserves the right to redesign and change the machine as deemed nece ssary, without notification. If a change has been made to your machine which is not reflected in this parts manual, see

your Hustler dealer for current information and parts.

333559 09/08 1-1

Page 8

Hardware Description Codes & Abbreviations

The following codes are used throughout this parts manual. Refer to this list when ordering parts.

ABBREVIATION DESCRIPTION

CB Carriage Bolt

CE Clevis Pin

CP Cotter Pin

CS Cap Screw

CW Cup Washer

FDRW Fender Washer

FW Flat Washer

HX Hex Head

LW Lock Washer

MB Machine Bushing

MS Machine Screw

NT Nut

SC Self Tapping Cap Screw

SH Socket Head

SB Shoulder Bolt

SS Set Screw

OD Outside Diameter

ID Inside Diameter

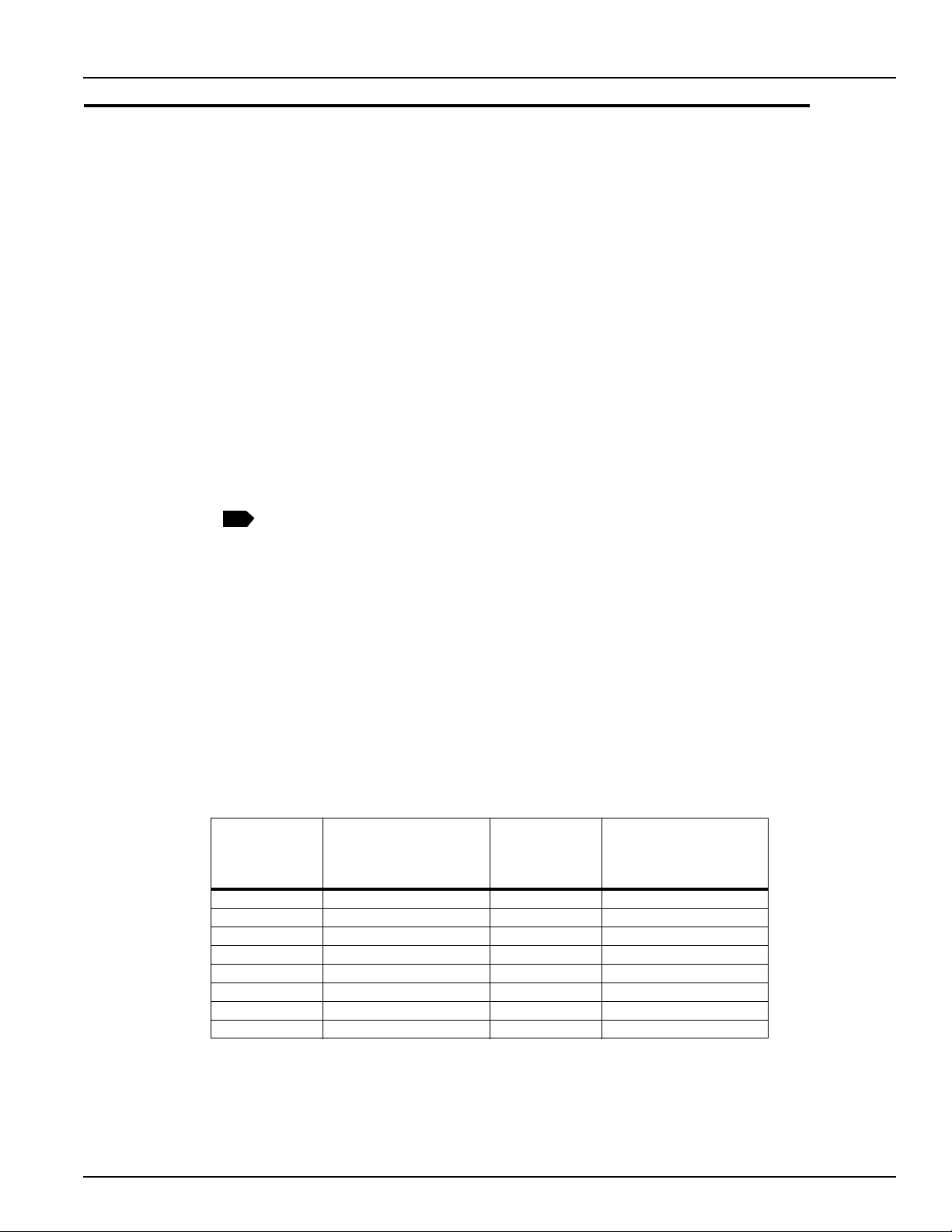

Standard Torques

The following chart lists the standard torque va lues for the threaded fasteners found in this manual. Torque all cap

screws, nuts and set screws to these values unless a different torq ue is shown in the Notes section n ext to the fastener

SIZE FT-LBS NM SIZE FT-LBS NM

.250 8.2 11.1 M3 1 1.3

.312 17 23 M4 2.2 3

.375 30 40 M5 4.5 6.1

.438 48 65 M6 7.7 10.4

.500 73 99 M8 18.5 25

.562 105 143 M10 37 50

.625 145 200 M12 64 87

.750 260 350 M16 160 215

.875 420 565 M20 320 435

1.00 625 850 M24 555 750

NOTE:

Loctite 592 to be used on all pipe threads.

Lubricate all grease zerks.

1-2 333559 09/08

Page 9

Chapter 2 Contents

Tractor Frame Rivet Nut Installation . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Engine Guard and Anti-rollover Bracket Assemblies. . . . . . . . . . . . . 2-3

Footrest Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

333559 09/08 2-1

Page 10

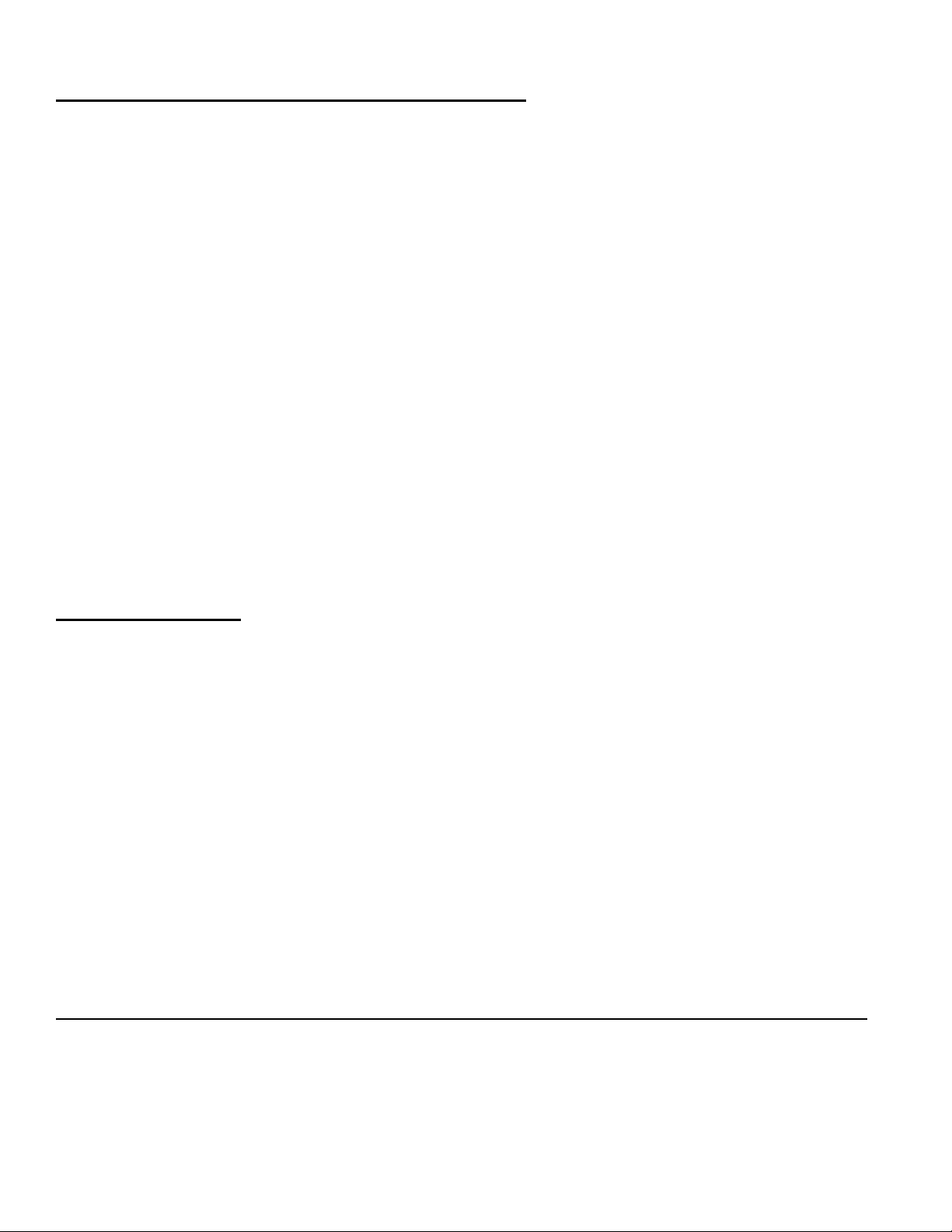

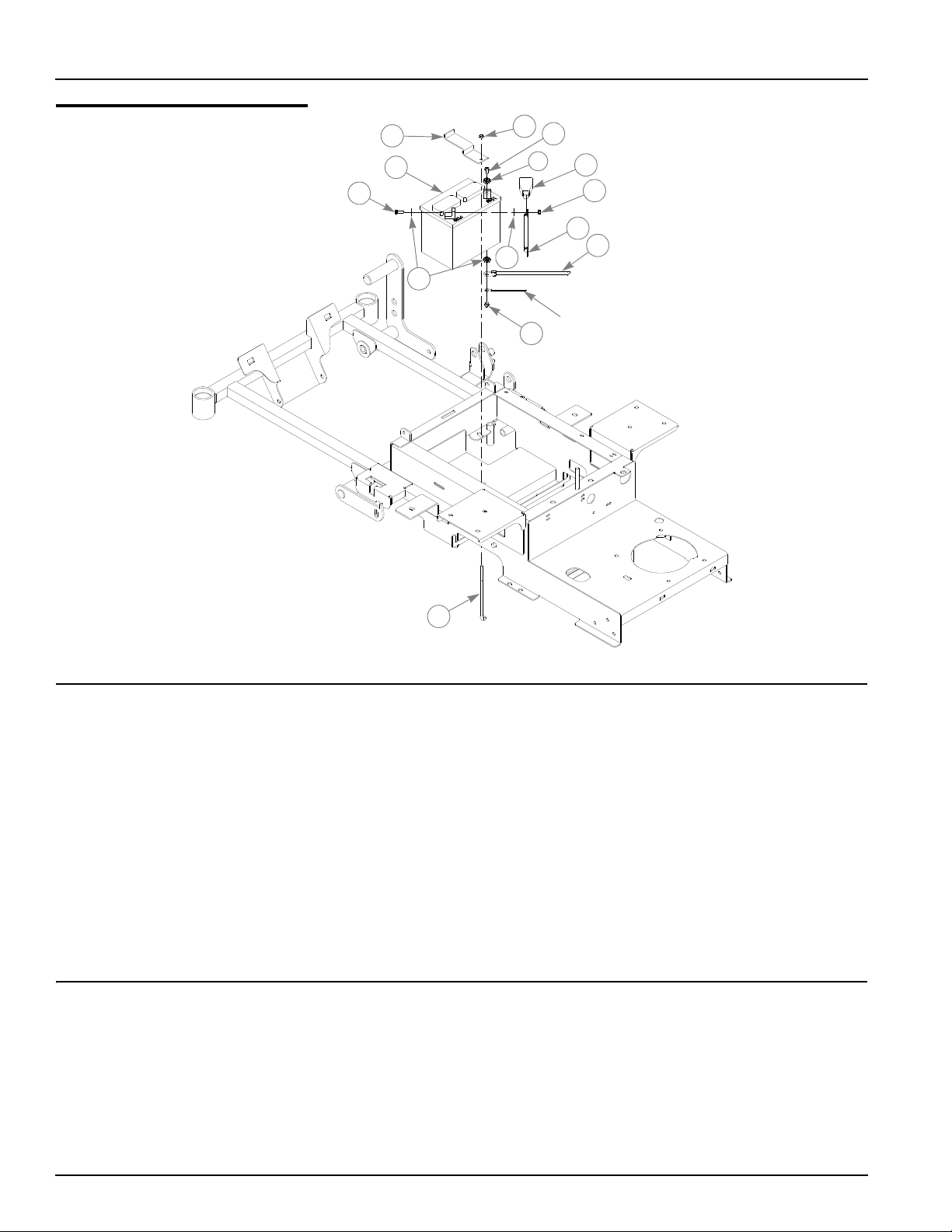

Tractor Frame Rivet Nut Installation

2

1

3

INDEX

NO.

SERVICE

PART NO.

1 546911 315440 1 FASTRAK 36 FRAME

546895 320242 1 FASTRAK 42 FRAME

2 808493 808493 2 3/8-16 THREAD RIVET NUT

3 793869 793869 2 1.5 SQ TUBE PLUG

MFG. PART

NO.

QTY. DESCRIPTION

NOTES:

2-2 333559 09/08

Page 11

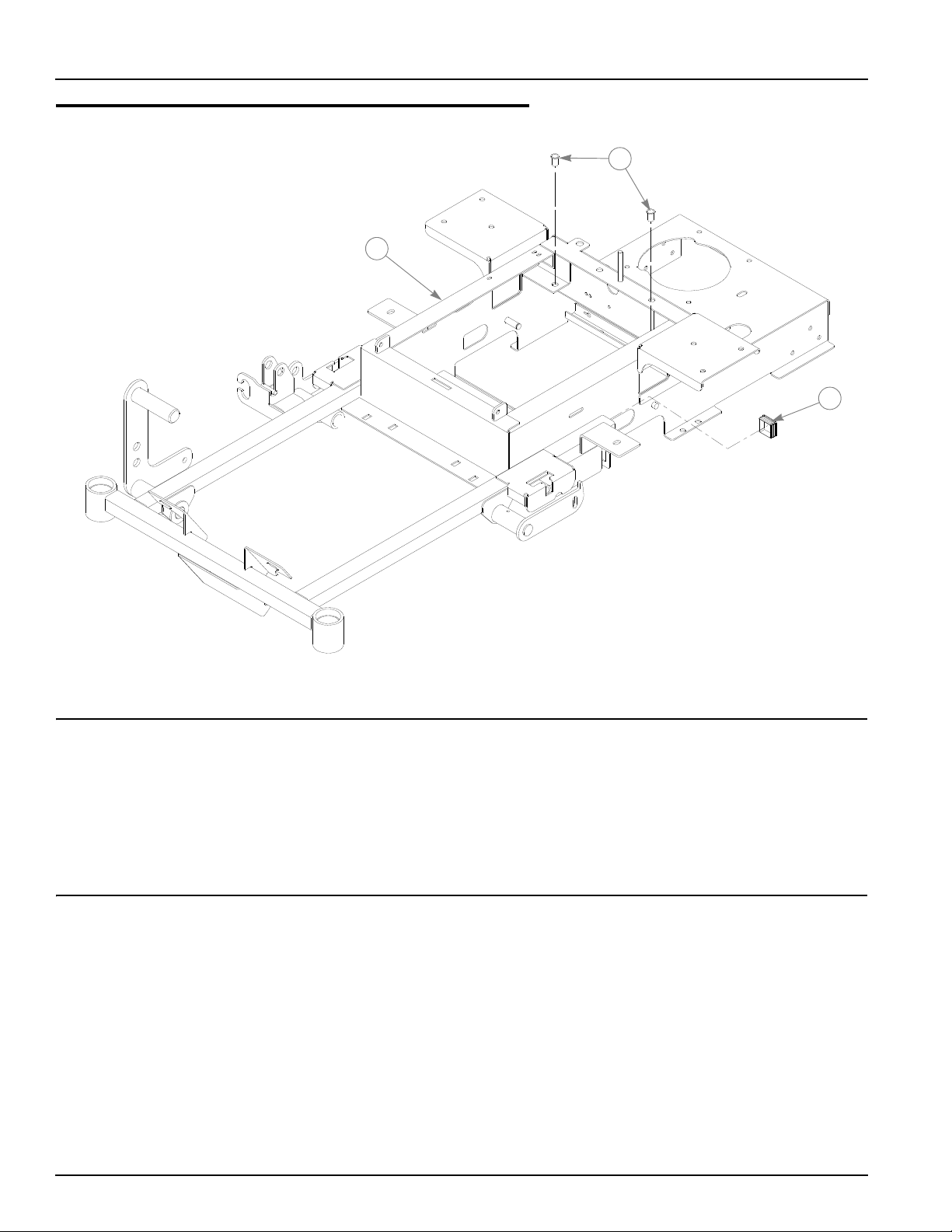

Engine Guard and Anti-rollover Bracket Assemblies

1

3

3

2

3

4

5

7

8

9

6

1

INDEX

NO.

10 788166 788166 2 ANTI SCALP WHEEL ASSEMBLY

SERVICE

PART NO.

1 316836 316836 1 ENGINE GUARD

2 320580 320580 2 ANTI ROLLOVER BRACKET

3 808493 808493 8 3/8-16 THREAD RIVET NUT

4 781567 781567 2 NT .50-13 HX LK NY ZNYC

5 344267 344267 4 FW .510 X 2.15 X .187SPL ZNYC

6 053199 N/A 2 NT .500-13 HX JAM ZNYC

7 767962 N/A 4 FW .531 X 1.063 X .090 SAE HD ZN

8 031997 N/A 2 ANTI-SCALP WHEEL

9 781708 N/A 2 CS .500-13 X 4.25 HX G5 ZNYC

1. Includes items 6 through 9.

MFG. PART

NO.

QTY. DESCRIPTION

NOTES:

333559 09/08 2-3

Page 12

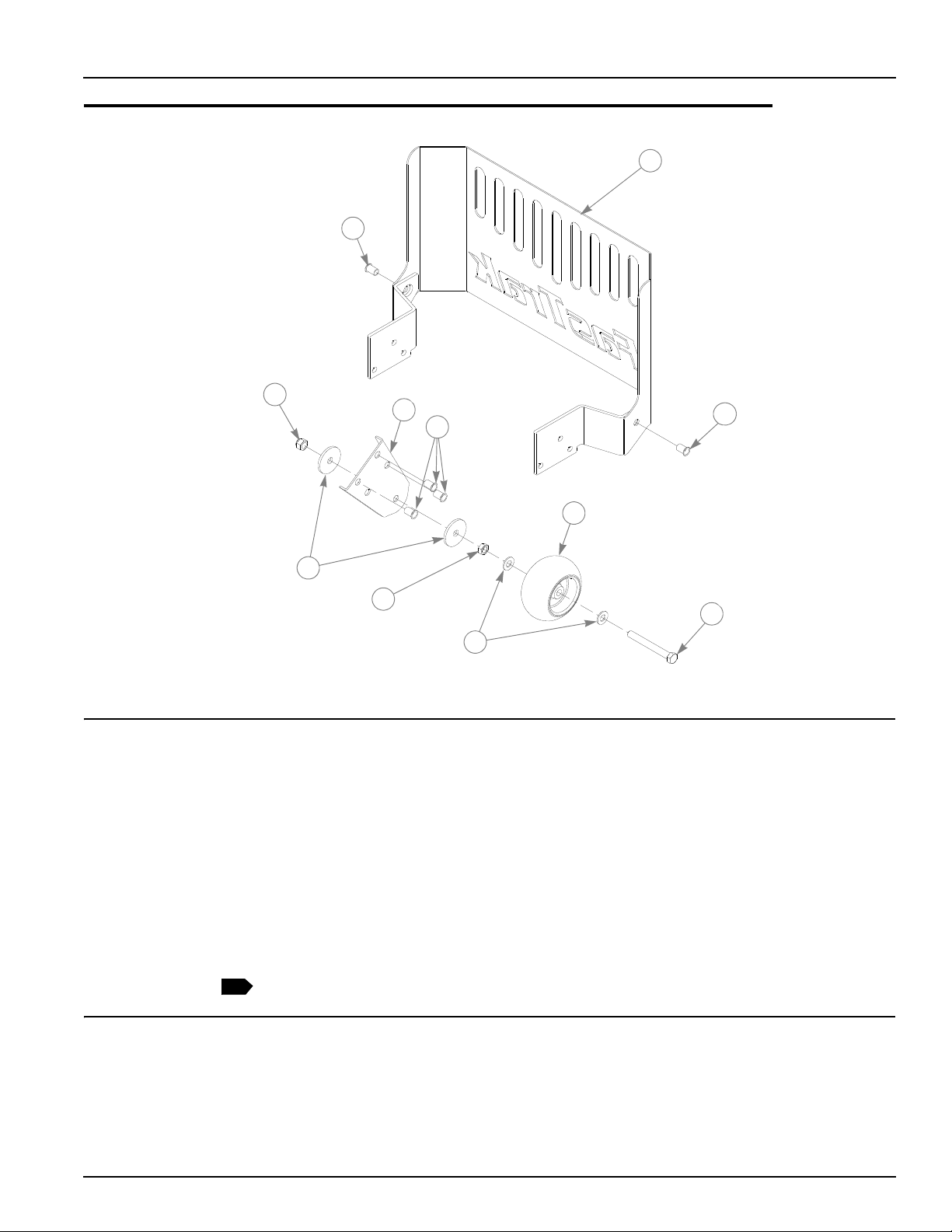

Footrest Assembly

1

2

3

4

1

7

6

5

7

6

INDEX

NO.

SERVICE

PART NO.

1 011320 011320 4 CB .375-16 X .75 STD ZN

2 785485 785485 2 UPPER STEP TREAD

3 793844 793844 2 LOWER STEP TREAD

4 320267 320267 1 FLOOR PLATE 36" MOWERS

316844 316844 1 FLOOR PLATE 42" MOWERS

5 767954 767954 2 FW .406 X .812 X .060 SAE HD ZN

6 076422 076422 2 FW.406X 1.000X.06 ZNYC

7 054502 054502 4 NT .375-16 HX GRD 5 ZNYC

MFG. PART

NO.

QTY. DESCRIPTION

NOTES:

2-4 333559 09/08

Page 13

Chapter 3 Contents

Battery Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Deck Lift Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Hydro Transmission Installation S/N Prior To 07091558. . . . . . . . . . 3-4

Hydro Transmission Installation S/N Higher Than 07091558 . . . . . . 3-6

Steering and Brake Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

333559 09/08 3-1

Page 14

Battery Installation

1

2

2

2

3

3

4

4

6

5

7

8

9

PART OF WIRE

HARNESS (BLK)

4

INDEX

NO.

SERVICE

PART NO.

1 314989 314989 1 BATTERY CLAMP STRAP

2 024927 024927 3 NT .250-20 HX GR.5 ZNYC

3 055939 055939 2 CS .250-20 X .75 HX G5 ZNYC

4 029868 029868 4 LW .250 INT-EXT TOOTH ZNYC

5 740696 740696 1 BATTERY VU1LH-8

6 771428 771428 1 RED BATTERY CABLE BOOT

7 785063 785063 1 POSITIVE BATTERY CABLE (KOHLER)

786632 786632 1 POSITIVE BATTERY CABLE (HONDA)

8 786640 786640 1 NEGATIVE BATTERY CABLE

9 793489 793489 1 BATTERY CLAMP ROD

MFG. PART

NO.

QTY. DESCRIPTION

NOTES:

3-2 333559 09/08

Page 15

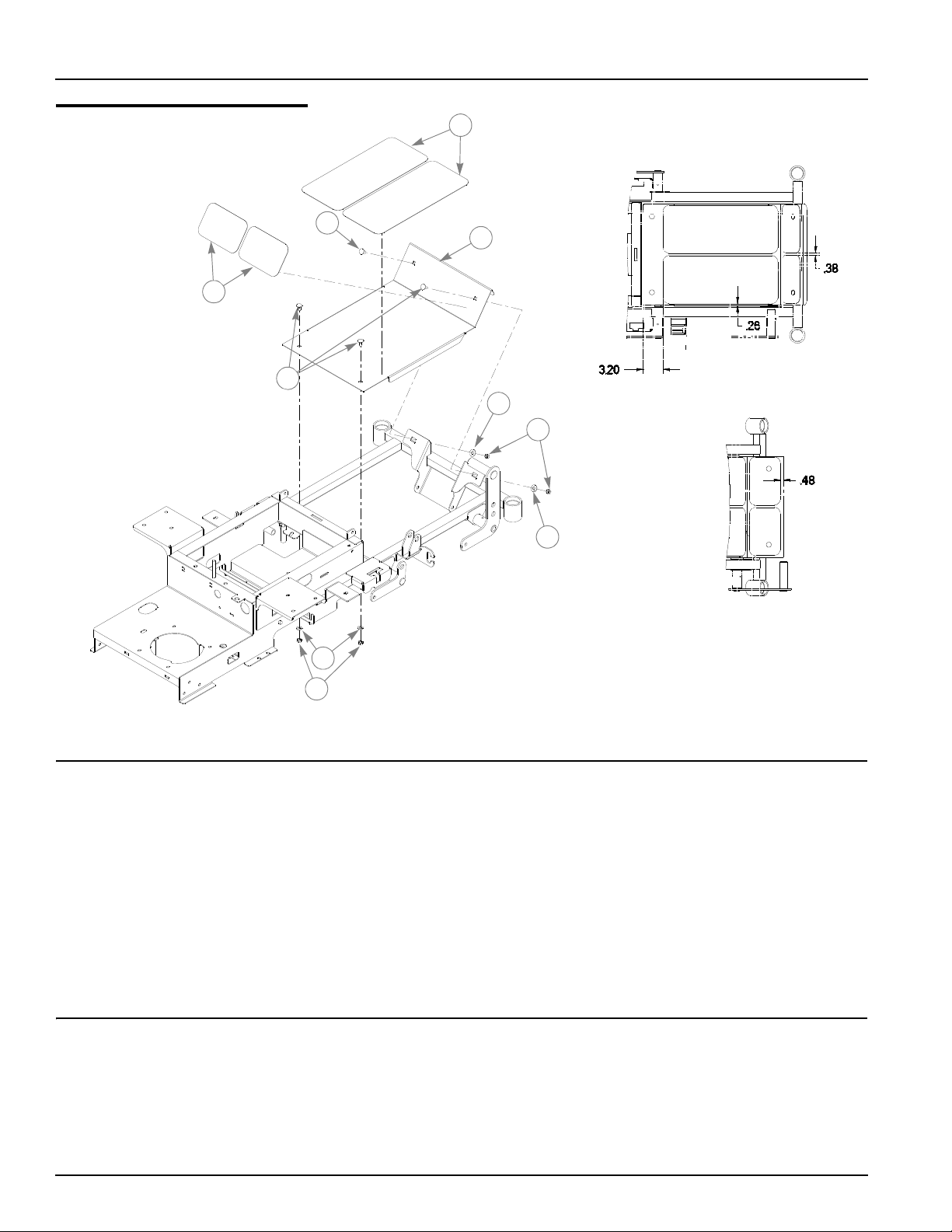

Deck Lift Assembly

1

1

2

3

4

5

6

7

7

7

7

8

8

9

9

9

9

9

10

8

11

12

13

16

16

15

5

14

17

1

11

7

INDEX

NO.

10 781229 781229 1 CE .750 X 2.25 X 1.75 HEADLESS

11 015495 015495 3 STRAIGHT GREASE FITTING

12 756270 756270 1 CS .312-18 X 1.50 FLTHR GR5 ZNYC

13 034272 034272 1 NT .312-18 HX G5 ZNYC

14 348458 348458 1 DECK LEVELER YOKE

15 781831 781831 1 CS .437-14 X 1.75 FULTH G5 ZNYC

16 360131 018846 2 DECK LIFTCHAIN

17 767962 767962 2 FW .531 X 1.063 X .090 SAE HD ZN

1. Apply grease to zerks (see owners manual).

SERVICE

PART NO.

1 348318 348318 1 STOP HANDLE

2 348284 348284 1 HEIGHT ADJUSTMENT STOP

3 793505 793505 1 DECK HEIGHT INDICATOR

4 782995 782995 1 DECK LIFT SPRING

5 055749 055749 2 CS .437-14 X 1.75 HX G5 ZNYC

6 334045 334045 1 DECK LIFT LINK

7 704643 704643 6 NT .437-14 HX FLG ZN

8 025296 025296 4 FW .760 X 1.625 X .08 ZNYC

9 781294 781294 5 E CLIP 1.00 X.625X .050

MFG. PART

NO.

333559 09/08 3-3

QTY. DESCRIPTION

NOTES:

Page 16

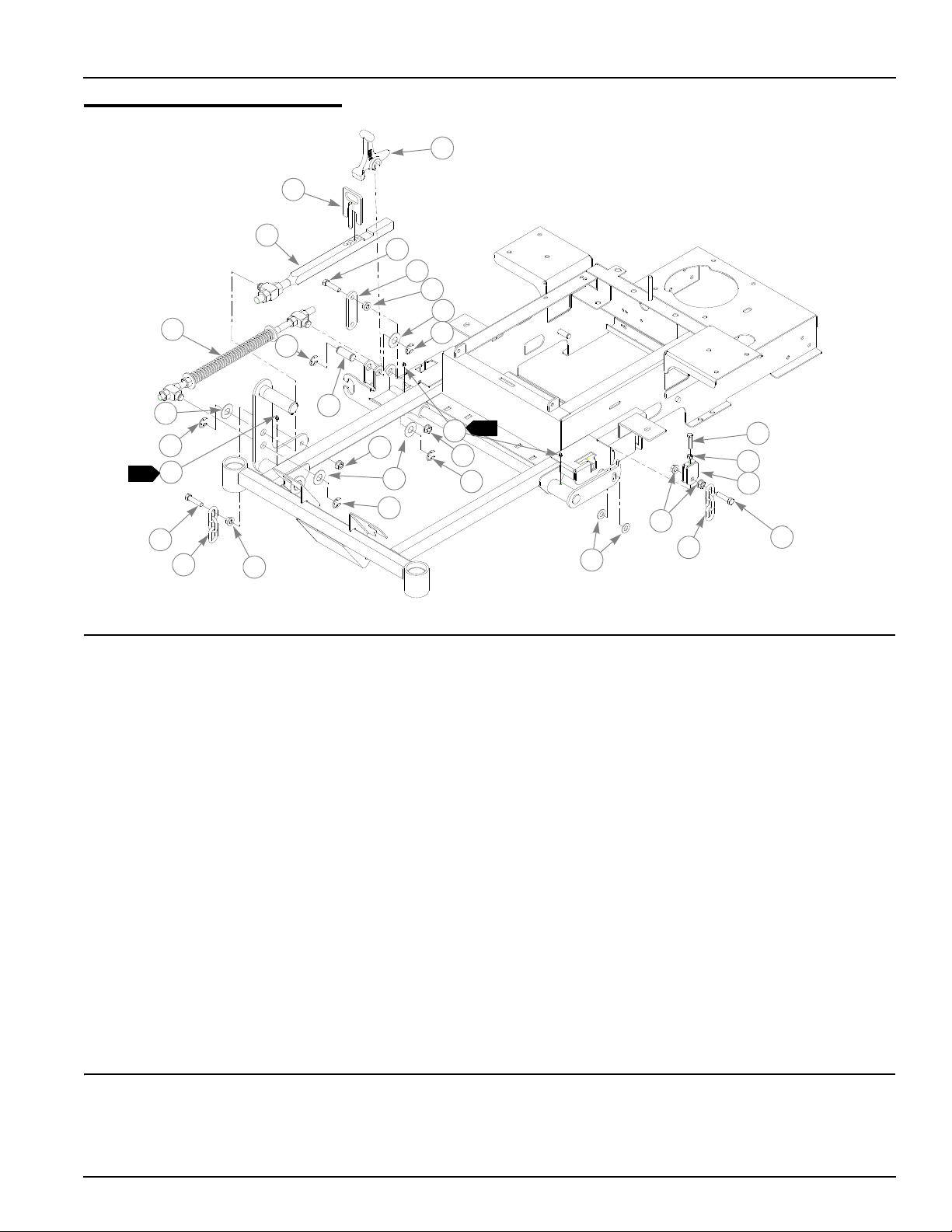

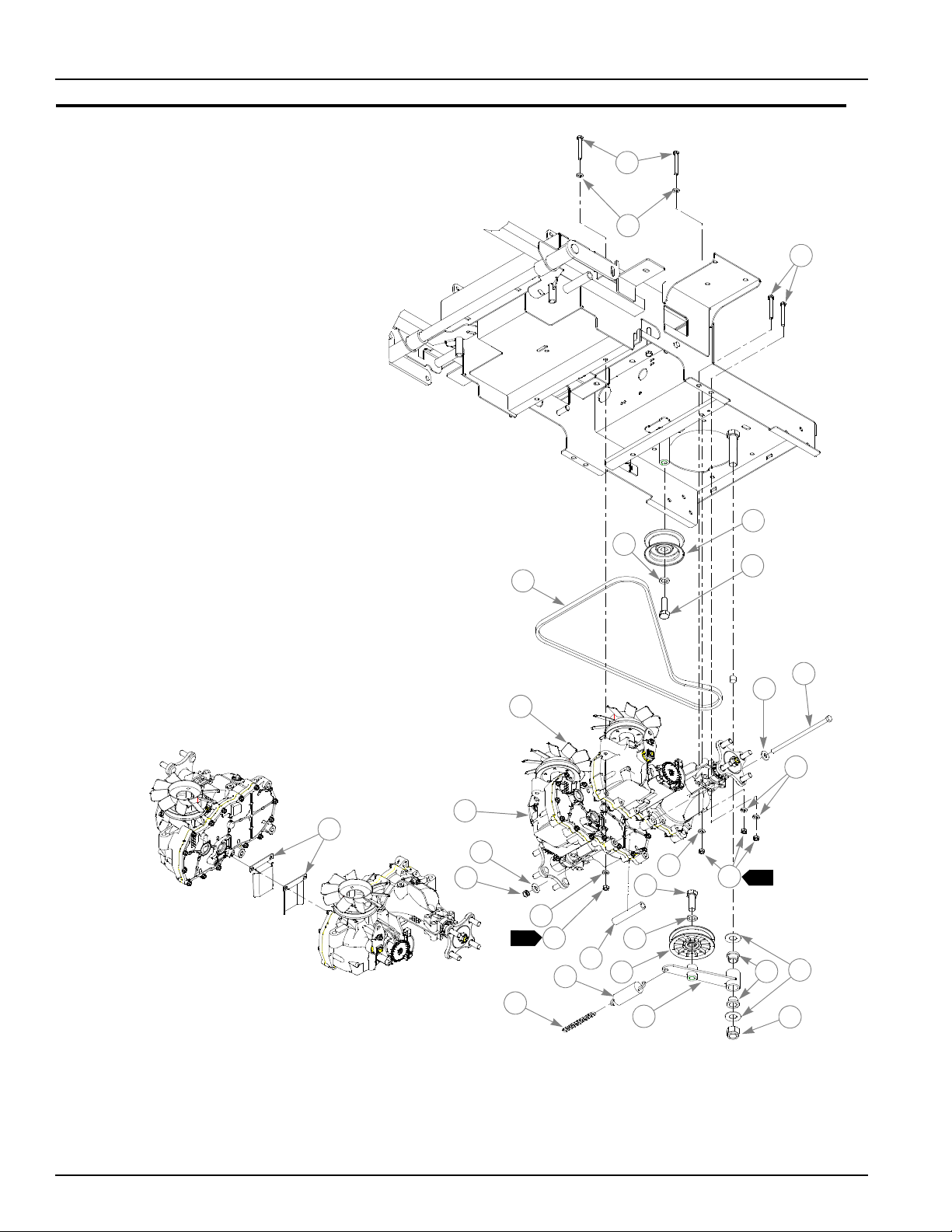

Hydro Transmission Installation S/N Prior To 07091558

3

4

5

7

6

1

1

12

12

13

13

4

2

14

12

15

16

18

19

20

17

12

11

8

10

21

1

1

2

9

3-4 333559 09/08

Page 17

Hydro Transmission Installation S/N Prior To 07091558

INDEX

NO.

10 794552 794552 1 NT .375-16 HXZY NL

11 335695 335695 1 SPACER TUBE-EZT MINI FST

12 768523 768523 12 FW .343 X .687 X .051/.080 HD ZNYC

13 034272 034272 8 NT .312-18 HX G5 ZNYC

14 784827 784827 1 4.00"OD, 5/8"ID IDLER PULLEY

15 781153 781153 2 UHMW BUSHING

16 025296 025296 2 FW .760 X 1.625 X .08 ZNYC

17 324046 324046 1 PUMP BELT IDLER ARM

3

18 061101 061101 1 NT .750-10 HX NL ZN

19 036384 036384 1 IDLER SPRING

20 364315 059931 1 SPRING CHAIN

21 335893 335893 2 BELT DEFLECTOR

SERVICE

PART NO.

1 710087 710087 8 CS .312-18 X 2.50 HX G5 ZNYC

2 028118 028118 2 FW .62 X 1.00 X .134 ZNYC

3 794404 794404 1 PULLEY

4 025007 025007 2 CS .625-11 X 1.75 HX G5 ZNYC

5 793836 793836 1 A-SECTION PUMP BELT

6 792911 792911 1 EZT LEFT PUMP/MOTOR COMBO

7 792895 792895 1 EZT RIGHT PUMP/MOTOR COMBO

8 718288 718288 1 FW .516 X .875 X .09 ZNYC

9 035238 035238 1 LW .437 MED SPRING ZYNC

MFG. PART

NO.

QTY. DESCRIPTION

NOTES:

1. Torque to 17 ft.-lbs.

2. Install using existing hardware on EZT.

3. Do not torque, item 17 (Pump Belt Idler Arm) must pivot freely .

4. Hydro transmission service parts:

PART NUMBER

PRIOR TO

SERIAL NUMBER

06081543

792013 AXLE NUT 788877 AXLE NUT

794982 FAN, EZT 794974 EZT PULLEY KIT

795005 RIGHT EZ CAP-VENT ASSY 795039 LEFT EZ VENT TUBE ASSY

795013 EZT NUT, SPECIAL 791723f FW .530 X 1.63 X .06 SLO

795021 HUB ASSEMBLY 788232 HUB ASSEMBLY

795047 PARKING PAWL KIT, EZT 798363 PARKING BRAKE GEAR

795054 90 DEG VENT FITTING 795062 RIGJHT EZT VENT HOSE

798371 RETAINING RING 792929 PULLEY/FAN COMBO 36/42

DESCRIPTION

PART NUMBER

SERIAL NUMBER

06081543

DESCRIPTION

333559 09/08 3-5

Page 18

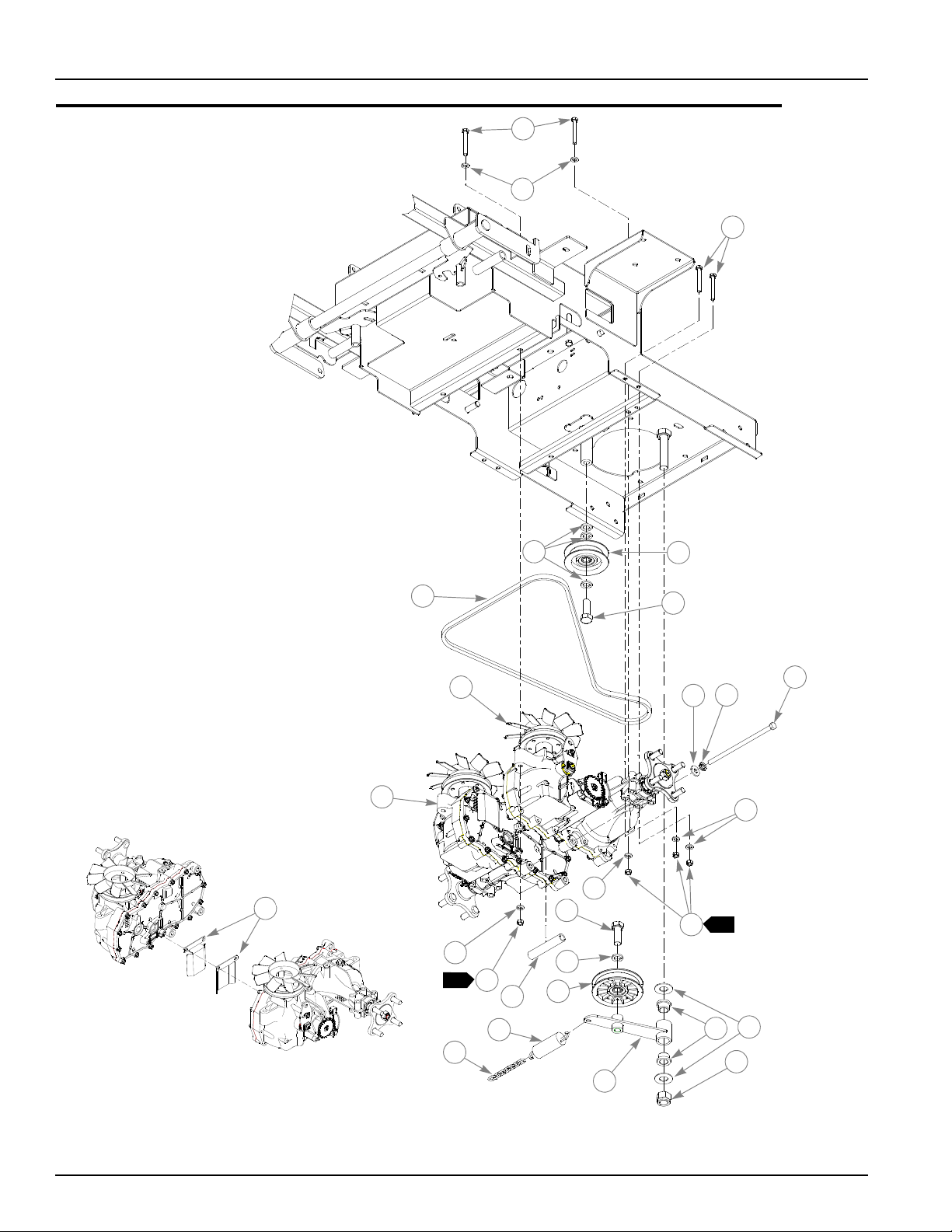

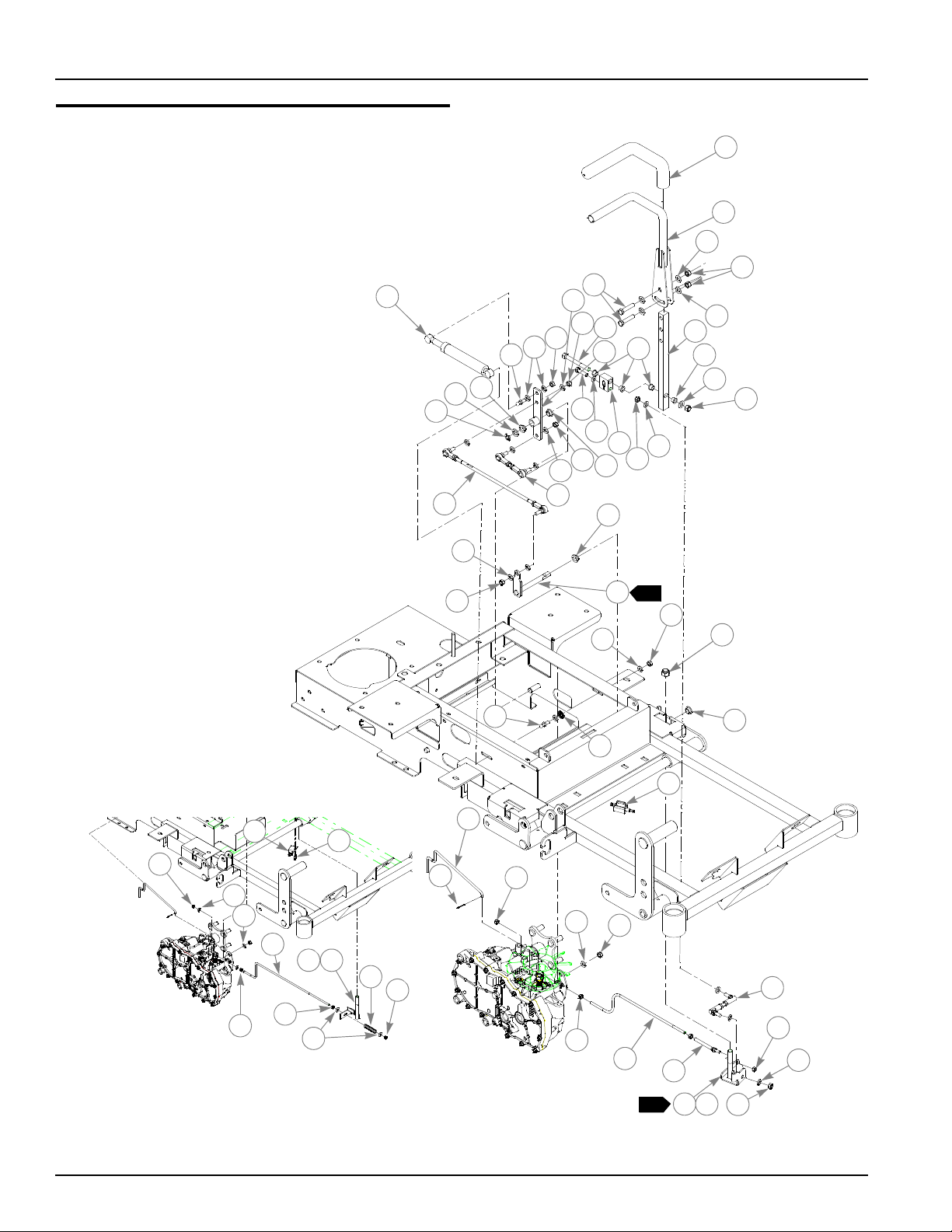

Hydro Transmission Installation S/N Higher Than 07091558

3

4

5

7

6

1

1

11

11

12

12

4

2

13

11

14

15

17

18

19

16

11

10

8

9

20

1

1

2

8

21

3-6 333559 09/08

Page 19

Hydro Transmission Installation S/N Higher Than 07091558

INDEX

NO.

10 335695 335695 1 SPACER TUBE-EZT MINI FST

11 768523 768523 12 FW .343 X .687 X .051/.080 HD ZNYC

12 034272 034272 8 NT .312-18 HX G5 ZNYC

13 784827 784827 1 4.00"OD, 5/8"ID IDLER PULLEY

14 781153 781153 2 UHMW BUSHING

15 025296 025296 2 FW .760 X 1.625 X .08 ZNYC

16 324046 324046 1 PUMP BELT IDLER ARM

17 061101 061101 1 NT .750-10 HX NL ZN

18 036384 036384 1 IDLER SPRING

19 364315 059931 1 SPRING CHAIN

20 335893 335893 2 BELT DEFLECTOR

21 086660 086660 1 NT .375-16 HXZY NL

SERVICE

PART NO.

1 710087 710087 8 CS .312-18 X 2.50 HX G5 ZNYC

2 028118 028118 2 FW .62 X 1.00 X .134 ZNYC

3 601162 601162 1 PULLEY

4 025007 025007 2 CS .625-11 X 1.75 HX G5 ZNYC

5 793836 793836 1 A-SECTION PUMP BELT

6 792911 792911 1 EZT LEFT PUMP/MOTOR COMBO

7 792895 792895 1 EZT RIGHT PUMP/MOTOR COMBO

8 712919 712919 2 FW .516 X .875 X .09 ZNYC

9 721134 721134 1 CS .375-16X8.0 HX.GR5 Z

MFG. PART

NO.

QTY. DESCRIPTION

1. Torque to 17 ft.-lbs.

2. Hydro transmission service parts:

PART NUMBER

PRIOR TO

SERIAL NUMBER

06081543

792013 AXLE NUT 788877 AXLE NUT

794982 FAN, EZT 794974 EZT PULLEY KIT

795005 RIGHT EZ CAP-VENT ASSY 795039 LEFT EZ VENT TUBE ASSY

795013 EZT NUT, SPECIAL 791723f FW .530 X 1.63 X .06 SLO

795021 HUB ASSEMBLY 788232 HUB ASSEMBLY

795047 PARKI NG PAWL KIT, EZT 798363 PARKING BRAKE GEAR

795054 90 DEG VENT FITTING 795062 RIGJHT EZT VENT HOSE

798371 RETAINING RING 792929 PULLEY/FAN COMBO 36/42

DESCRIPTION

NOTES:

PART NUMBER

SERIAL NUMBER

06081543

DESCRIPTION

333559 09/08 3-7

Page 20

Steering and Brake Assembly

2

1

3

4

4

5

6

7

8

9

9

11

11

8

8

13

13

14

15

16

8

11

17

18

19

20

21

8

5

7

22

23

23

24

25

26

28

8

11

12

28

13

29

30

311132

33

8

4

11

10

10

8

27

2

3

13

41

28

21

8

39

36

37

38

27

27

20

40

See Note 4

35

35

3-8 333559 09/08

Page 21

Steering and Brake Assembly

4

5

3

3

333

3

3

INDEX

NO.

10 797779 797779 8 IGUS® BUSHING

11 023655 023655 12 NT .312-24 HX ZNYC

12 325464 325464 2 STEERING CONTROL ARM

13 768259 768259 8 IGUS® BUSHING

14 718288 718288 2 FW .516 X .875 X .09 ZNYC

15 793059 793059 2 E CLIP .80X.396X.042

16 793646 793646 2 PUMP ROD ADJUSTER ASSEMBLY

17 794396 794396 2 STEERING LINK ROD

18 793612 793612 2 STEERING DRIVE ARM

19 797753 797753 2 STEERING ARM

20 005108 005108 2 CS .375-16 X 3.50 HX G5

21 079186 079186 2 CS .312-18 X 1.25 HX G5 ZNYC

22 797761 797761 2 STEERING BLOCK

23 781567 781567 2 NT .50-13 HX LK NY ZNYC

24 795625 795625 2 SNAP MOUNT PLUNGER SWITCH

25 796615 796615 2 BALL JOINT LINK

26 793174 793174 2 TOWLINK ROD

27 048553 048553 2 CP .062D X 1.00 LG HML ZN

28 068551 068551 4 NT .250-20 HX NL ZNYC

29 797050 797050 2 BRAKE ACTUATOR ROD

30 795229 795229 2 INLINE BALL JOINT

31 352112 352112 1 L. H. BRAKE PIVOT (SHOWN)

32 352054 352054 1 R. H. BRAKE PIVOT (NOT SHOWN)

33 024927 024927 2 NT .250-20 HX GR.5 ZNYC

34 781211 781211 2 PUSH BUTTON SWITCH, (DELTA)

35 060731 060731 4 CS 10-24 X .500 HXFLK ZNYC

36 315382 N/A 1 LEFT BRAKE PIVOT ARM (SHOWN)

37 315101 N/A 1 RIGHT BRAKE PIVOT ARM (NOT SHOWN)

38 794883 794883 2 COMPRESSION SPRING

39 793182 793182 2 BRAKE ACTUATOR ROD

40 089789 089789 4 FW .266 X .750 X .06 ZNYC

41 029876 029876 2 LW .312 INT-EXT TOOTH Z

SERVICE

PART NO.

1 781260 N/A 2 STEERING BAR GRIP

2 360487 360487 2 STEERING BAR

3 600221 600221 2 CENTERING DAMPER

783696 783696 2 CENTERING DAMPER

4 767954 767954 10 FW .406 X .812 X .060 SAE HD ZN

5 086660 086660 6 NT .375-16 HX LK NY

6 705178 705178 4 CS .375-16 X 1.75 HX G5 ZNYC

7 034272 034272 4 NT .312-18 HX G5 ZNYC

8 768523 768523 22 FW .343 X .687 X .051/.080 HD ZNYC

9 781922 781922 4 DAMPER BALL STUD

MFG. PART

NO.

QTY. DESCRIPTION

NOTES:

1. To adjust park brake safety switch: with Steering Bars in park position,

adjust item 24 (795625 Snap Mount Plunger Switch) outboard until

333559 09/08 3-9

Page 22

switch is activated by items 31/32 (352112/352054 Brake Pivots).

2. Order these parts for mowers with serial number prior to 05040000.

3. Includes Item 1 (781260 Steering Bar Grip).

4. Use on mowers with serial numbers prior to 060171975.

3-10 333559 09/08

Page 23

Chapter 4 Contents

Honda 16 HP Engine Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Kohler 15 & 17 HP Engine Installation. . . . . . . . . . . . . . . . . . . . . . . . 4-6

Fuel System Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Instrument Panel Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Honda 16HP Electrical Schematic (793083) . . . . . . . . . . . . . . . . . . 4-14

Kohler 15 & 17 HP Electrical Schematic (601127& 793117). . . . . . 4-16

333559 09/08 4-1

Page 24

Honda 16 HP Engine Installation

1

3

4

5

7

NEGATIVE

BATTERY

CABLE

POSITIVE

BATTERY

CABLE

1

1

RED/BLK

YEL

6

8

TO ENGINE

(4 WIRES)

10

12

8

9

13

14

15

17

19

21

22

16

20

18

4

25

32

26

27

29

28

36

34

35

23

PART OF

ENGINE

FROM

RECTIFIER

37

31

33

11

2

2

24

2

PART OF

ENGINE

30

4

4-2 333559 09/08

Page 25

Honda 16 HP Engine Installation

INDEX

NO.

10 787267 N/A 1 HONDA 16 AMP RECTIFIER

11 794644 794644 1 GM 1.50 X 2.12 X 1.75 X .12

12 706531 706531 1 GM 1.12 X 1.75 X 1.37 X .12

13 330274 330274 1 CLUTCH ANCHOR

14 029876 029876 4 LW .312 INT-EXT TOOTH ZNYC

15 050161 050161 4 CS .312-18 X 1.75 HX G5 ZNYC

16 784918 784918 1 RUBBER BUMPER

17 793760 793760 1 ENGINE-HYDRO DRIVE PULLEY

18 712372 712372 1 KEY 1/4 SQ. X 0.66 LONG

19 601325 601325 1 WARNER CLUTCH

20 791251 N/A 1 CLUTCH WIRE HARNESS PIGTAIL

21 763417 763417 1 FW .454 X 1.50 X.250

22 785048 785048 1 CS .437-20 X 3.00 HX G5 ZNYC

23 043570 043570 1 SINGLE HOSE CLIP

24 791608 791608 1 OIL DRAIN VALVE, M16 X 1.5

25 768523 768523 2 FW .343 X .687 X .051/.080 HD ZNYC

26 793125 793125 1 MUFFLER 15,17 KOHLER & 16 HONDA

27 016253 016253 2 CB .312-18 X .750 FUL ZN

28 316836 316836 1 ENGINE GUARD

29 767954 767954 6 FW .406 X .812 X .060 SAE HD ZN

30 052860 052860 6 CS .375-16 X 1.25 HX G5 ZNYC

31 794180 794180 1 1.125" EXHAUST CLAMP

32 793166 793166 1 16 HONDA MID EXHAUST PIPE

33 794172 794172 1 1.25" EXHAUST CLAMP

34 793141 793141 1 16 HONDA MANIFOLD

35 005231 005231 4 NT M6-1.0-10 HX FLG ZN

36 785543 N/A 2 HONDA MUFFLER GASKET

37 793083 793083 1 HONDA WIRE HARNESS

38 104786 104786 1 OIL DRAIN HOSE (NOT SHOWN)

SERVICE

PART NO.

1 785394 785394 1 HONDA 16HP ENGINE (USED ON 927368 &

2 739144 792796 3

3 378273 378273 1 16HP EXHAUST HEAT SHIELD

4 034272 034272 6 NT .312-18 HX G5 ZNYC

5 712927 712927 4 FW .344 X 1.00 X .12 HRD ZNYC

6 782664 782664 1 NT M8-1.25 HX STAINLESS STEEL

7 024927 024927 2 NT .250-20 HX GR.5 ZNYC

8 768515 768515 4 FW .281 X .625 X .051/.080 HD ZNYC

9 056077 056077 2 CS .250-20 X 1.00 HX G5 ZNYC

MFG.

PART NO.

QTY. DESCRIPTION

927376)

333559 09/08 4-3

Page 26

NOTES:

1. Part of item (793083 Honda Wire Harness).

2. Engine oil capacity:See engine owner’s manual.

3. Engine speed; 3550±50 RPM.

4. Torque to 45-48 ft-lb.

4-4 333559 09/08

Page 27

.This page intentionally left blank.

333559 09/08 4-5

Page 28

Kohler 15 & 17 HP Engine Installation

1

1

2

1

5

1

TTO

TO STARTER

SOLENOID

6

7

6

7

6

7

11

12

13

7

14

15

16

17

18

19

20

21

22

23

24

25

30

29

28

32

27

26

34

RED/BLK

FROM NEGATIVE

BATTERY TEMINAL

33

33

35

2

2

RED

PUR

8

31

17

TO BATTERY

10

5

5

9

4

1

3

8

4-6 333559 09/08

Page 29

Kohler 15 & 17 HP Engine Installation

7

INDEX

NO.

10 771428 771428 1 RED BATTERY CABLE BOOT

11 044255 044255 1 NT #10-32 HX ZN

12 030817 030817 1 STARTER SOLENOID

13 792762 792762 1 BATTERY CABLE

14 056077 056077 2 CS .250-20 X 1.00 HX G5 ZNYC

15 330274 330274 1 CLUTCH ANCHOR

16 793885 793885 1 LW .375 INT-EXT TOOTH

17 036244 792788 4 CS .375-16X1.000 HX G5

18 784918 784918 1 RUBBER BUMPER

19 793760 793760 1 ENGINE-HYDRO DRIVE PULLEY

20 712372 712372 1 KEY 1/4 SQ. X 0.66 LONG

21 601325 601325 1 WARNER CLUTCH

22 791251 N/A 1 CLUTCH WIRE HARNESS PIGTAIL

23 763417 763417 1 FW .454 X 1.50 X.250

24 785048 785048 1 CS .437-20 X 3.00 HX G5 ZNYC

25 316836 N/A 1 ENGINE GUARD

26 767954 767954 6 FW .406 X .812 X .060 SAE HD ZN

27 052860 052860 6 CS .375-16 X 1.25 HX G5 ZNYC

28 768523 768523 2 FW .343 X .687 X .051/.080 HD ZNYC

29 016253 016253 2 CB .312-18 X .750 FUL ZN

30 793125 793125 1 MUFFLER 15,17 KOHLER & 16 HONDA

31 796516 796516 1 3/8-18 OIL DRAIN VALVE

32 034272 034272 2 NT .312-18 HX G5 ZNYC

33 794180 794180 2 1.125" EXHAUST CLAMP

34 793158 793158 1 KOHLER 15 & 17 HP MID EXHAUST PIPE

35 793117 793117 1 KOHLER WIRE HARNESS

SERVICE

PART NO.

1 792945 792945 1 KOHLER 15 HP ENGINE SV470S

792952 792952 1 KOHLER 17 HP ENGINE SV530S

2 793133 793133 1 KOHLER 15 & 17 HP EXHAUST MANIFOLD

3 017004 N/A 2 LW .312 MED SPRING ZNYC

4 704478 N/A 2 CS .312-18 X .75 SKTHD BO

5 739144 792796 1 CS M 6-1.0 X 12 10.9 HX

6 024927 024927 4 NT .250-20 HX GR 5 ZNYC

7 768515 768515 6 FW .281 X .625 X .051/.080 HD ZNYC

8 706531 706531 1 GM 1.12 X 1.75 X 1.37 X .12

9 794644 794644 1 GM 1.50 X 2.12 X 1.75 X .12

601127 601127 1 KOHLER WIRE HARNESS

MFG.

PART NO.

QTY. DESCRIPTION

NOTES:

333559 09/08 4-7

Page 30

1. Supplied with engine.

2. Part of Kohler Wire Harness item 35 (601127-For S/N higher than

07011902; 793117-For S/N prior to 07011902).

3. Engine oil capacity: See engine owner’s manual.

4. Engine speed; 3600±50 RPM.

5. Torque to 33-37 ft.-lbs. Do not reuse factory installed screw when

performing service to mower requiring removal of engine, replace with

3/8-16 X 1.0 long grade 5 cap screw.

6. Used on mowers with serial numbers prior to 7020776.

7. Used on mowers with serial numbers after 7020776.

8. Torque to 45-48 ft-lb.

4-8 333559 09/08

Page 31

This page intentionally left blank.

333559 09/08 4-9

Page 32

Fuel System Installation

1

1

1

2

3

4

4

4

4

4

5

5

6

6

7

7

8

1

9

10

11

12

8

12

4-10 333559 09/08

Page 33

Fuel System Installation

5

6

INDEX

NO.

1 779306 779306 2 3.5" FUEL CAP

2 792978 792978 1 36/42 LEFT SIDE FUEL TANK

3 792960 792960 1 36/42 RIGHT SIDE FUEL TANK

4 000323 000323 6 CLIP

5 745059 745059 1 3-WAY FUEL VALVE

6 767954 767954 10 FW .406 X .812 X .060 SAE HD ZN

7 055822 055822 8 CS .375-16 X .75 HX G5 ZNYC

8 000331 000331 2 SMALL, SHORT WIRE TIE

9 015818 015818 1 FUEL LINE, 21.00" LONG

10 015818 015818 1 FUEL LINE, 16.25" LONG (HONDA)

11 015818 015818 1 FUEL LINE, 8.5" LONG

12 781880 781880 2 BUMPER, .500X 1.00X .312 X.188

SERVICE

PART NO.

015818 015818 1 FUEL LINE, 12.00" LONG

015818 015818 1 FUEL LINE, 14.00" LONG

MFG.

PART NO.

QTY. DESCRIPTION

(KOHLER)

(KOHLER)

NOTES:

1. Torque to 20 ft.-lbs.

2. Service parts (not shown) for fuel system:

799221 SUCTION HOSE ASSY

794081 FUEL FILTER SCREEN

785295 FUEL GROMMET

792986 SITE-LINE TANKS FUEL FITTING

3. Used on mowers with serial numbers higher than 07110561.

4. Used on mowers with serial numbers prior to 07110561.

333559 09/08 4-11

Page 34

Instrument Panel Installation

1

2

3

4

5

8

6

7

5

1

7

8

9

11

10

12

13

12

13

FUSE SIZE

AND LOCATION

20a

10a

1

1

4-12 333559 09/08

Page 35

Instrument Panel Installation

2

INDEX

NO.

10 026237 N/A 2 RELAY

11 793810 793810 1 THROTTLE CABLE (HONDA)

12 055947 055947 3 CS .250-20X .500 HX G5 ZNYC

13 768515 768515 3 FW .281 X .625 X .051/.080 HD ZNYC

SERVICE

PART NO.

1 786657 786657 1 CHOKE CABLE (KOHLER)

785030 785030 1 CHOKE CABLE (HONDA)

2 776476 776476 1 PTO SWITCH

3 712257 712257 1 RED INDICATOR LIGHT

4 785808 785808 1 KEY ASSEMBLY

5 045898 045898 1 KEY SWITCH

6 714998 714998 2 MS #10-24 X .625 HX ZN

7 704932 704932 4 FW .219 X .500 X .048 ZNYC

8 059832 059832 4 NT #10-24 HX NL ZN

9 321059 321059 1 INSTRUMENT PANEL

778365 778365 1 THROTTLE CABLE (KOHLER)

MFG.

PART NO.

QTY. DESCRIPTION

NOTES

1. Part of 601127, 793117 or 793083 (Tractor Wire Harness).

2. Includes one (1) key and one (1) 083022 metal key.

333559 09/08 4-13

Page 36

Honda 16HP Electrical Schematic (793083)

4-14 333559 09/08

Page 37

Honda 16HP Electrical Schematic (793083)

333559 09/08 4-15

Page 38

Kohler 15 & 17 HP Electrical Schematic (601127& 793117)

4-16 333559 09/08

Page 39

Kohler 15 & 17 HP Electrical Schematic (601127&793117)

333559 09/08 4-17

Page 40

This page intentionally left blank.

4-18 333559 09/08

Page 41

Chapter 5 Contents

Front Wheel Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Front Wheel Breakdown -768044 . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Drive Wheel Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

333559 08/08 5-1

Page 42

Front Wheel Assembly

1

1

1

2

2

3

4

4

5

6

7

8

8

10

10

9

9

8

6

4

5

3

4

11

2

3

3

3

3

2

INDEX

NO.

10 306969 306969 2 GAGE WHEEL SPACER

11 768044 768044 2 TIRE/WHL 11X4-5 RIBBED

1. Apply grease to zerks, see owners manual.

SERVICE

PART NO.

1 705954 705954 2 CS .500-13 X 1.25 HX G5 ZNYC

2 344267 344267 2 FW .510 X 2.15 X .187 SPL ZNYC

3 712976 712976 2 FW .531 X 1.375 X .125 ZNYC

4 784223 784223 4 BEARING

5 784603 784603 2 SPACER

6 339689 339689 2 CASTER FORK

7 781567 781567 2 NT .50-13 HX LK NY ZNYC

8 767962 767962 4 FW .531 X 1.063 X .090 SAE HD ZN

9 042630 042630 2 CS .500-13 X 6.50 HX G5 ZNYC

MFG. PART

NO.

QTY. DESCRIPTION

NOTES:

2. Torque to 75 ft.-lbs.

3. Assemble with extended inner race down.

5-2 333559

Page 43

Front Wheel Breakdown -768044

768044

1

2

2

INDEX

NO.

1 772814 N/A 1 3/4" ROLLER BEARING

2 772806 N/A 2 BEARING CAP

SERVICE

PART NO.

MFG.

PART NO.

QTY DESCRIPTION

NOTES:

1. Inflate tire to 8-12 psi.

333559 08/08 5-3

Page 44

Drive Wheel Assembly

2

1

2

3

4

5

6

3

INDEX

NO.

1 783134 783134 2 WHEEL/TIRE ASSEMBLY 18 X 8.50 (PER 36" MOWER)

2 783142 N/A 1 TIRE 18 X 8.5-8

3 783159 N/A 1 WHEEL ASSY 8.00 X 7.00

4 019521 N/A 1 TIRE VALVE

5 061077 061077 8 WHEEL NUT (PER MOWER)

6 793406 793406 8 SPACER, .375TH X .53 ID X 1.0 0D ZN (PER MOWER)

1 784264 784264 2 WHEEL/TIRE ASSY 18 X 9.50 (PER 42” MOWER)

2 784272 N/A 1 TIRE 18 X 9.5-8

3 784280 N/A 1 WHEEL ASSY 8.00 X 6.32

4 019521 N/A 1 TIRE VALVE

5 061077 061077 8 WHEEL NUT (PER MOWER)

SERVICE

PART NO.

MFG.

PART NO.

QTY DESCRIPTION

NOTES:

1. Inflate tire to 8-12 psi.

2. Torque to 65-75 ft.-lb.

3. Used on 36" mowers only (927343(CE) & 927376(CE))

5-4 333559

Page 45

Chapter 6 Contents

Deck Assembly 36" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Deck Pulley Assembly 36". . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Deck Assembly 42" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Deck Pulley Assembly 42". . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Blade Spindle Assembly Breakdown. . . . . . . . . . . . . . . . . . . . . . . . 6-14

333559 08/08 6-1

Page 46

Deck Assembly 36"

2

1

2

3

5

6

7

8

8

9

9

9

9

10

10

11

12

12

12

13

13

14

15

16

17

17

18

19

4

6-2 333559 09/08

Page 47

Deck Assembly 36"

1

INDEX

NO.

10 034280 034280 2 CS .312-18 X .75 HX G5 ZNYC

11 546937 315572 1 36" FASTRAK DECK

12 808485 808485 3 5/16-18 THREAD RIVET NUT

13 034272 034272 2 NT .312-18 HX G5 ZNYC

14 330225 330225 2 PULLBAR

15 781567 781567 1 NT .50-13 HX LK NY

16 053199 N/A 1 NT .500-13 HX JAM ZNYC

17 767962 N/A 2 FW .531 X 1.063 X .090 SAE HD ZN

18 031997 N/A 1 ANTI-SCALP WHEEL

19 781708 N/A 1 CS .500-13 X 4.25 HX G5 ZNYC

SERVICE

PART NO.

1 330399 330399 1 DISCHARGE CHUTE

2 086660 086660 2 NT .375-16 HX LK NY

3 036244 036244 2 CS .375-16 X 1.00 HX G5 ZNYC

4 781880 781880 1 BUMPER, .500X 1.00X .312 X.188

5 054502 054502 2 NT .375-16 HX GRD 5 ZNYC

6 767954 767954 2 FW .406 X .812 X .060 SAE HD ZN

7 352500 352500 1 DISCHARGE CHUTE BASE

8 322974 322974 2 PULLBAR PIN

9 768523 768523 4 FW .343 X .687 X .051/.080 HD ZNYC

788166 788166 1 ANTI SCALP WHEEL ASSY

MFG. PART

NO.

QTY. DESCRIPTION

NOTES:

1. Includes items 16 through 19.

2. Do not torque, Item 1 (330399 Discharge Chute) must pivot freely.

333559 08/08 6-3

Page 48

Deck Pulley Assembly 36"

1

2

2

4

4

5

5

6

8

10

9

11

12

1

13

13

14

14

14

14

16

15

17

17

18

18

18

18

19

20

19

20

20

21

22

22

23

23

25

24

1

13

1

3

3

7

6-4 333559 09/08

Page 49

Deck Pulley Assembly 36"

333

3

3

INDEX

NO.

10 781302 781302 1 IDLER SPRING

11 321398 321398 1 RIGHT PULLEY COVER

12 330324 330324 1 LEFT PULLEY COVER

13 781872 781872 4 CS .625-11 X 1.25 HX G5 ZNYC

14 782474 782474 4 CW .631 2.250 X .187 PNT

15 793786 793786 1 DECK PULLEY (FASTRAK 36")

16 793778 793778 1 DECK PULLEY (FASTRAK 36"/42")

17 054502 054502 8 NT .375-16 HX GRD 5 ZNYC

18 767954 767954 16 FW .406 X .812 X .060 SAE HD ZN

19 064006 064006 4 CS .312-18 X .625 HX G5 ZNYC

20 768523 768523 10 FW .343 X .687 X .051/.080 HD ZNYC

21 058776 058776 6 NT .312-18 HX NL ZNYC

22 783506 783506 2 BLADE SPINDLE ASSEMBLY

23 005116 005116 8 CS .375-16 X 1.375 HX G5 ZNYC

24 793794 793794 1 20.50" 42D X 0.631 CW BLADE

25 793802 793802 1 13.75" 42D X 0.631 CW BLADE

28 079186 N/A 6 CS .312-18 X 1.25 HX G5

29 712927 N/A 6 FW .344 X 1.00 X .12 HRD ZN

30 785832 N/A 2 DECK IDLER UHMW CLAMP

31 787069 N/A 2 DECK IDLER UHMW RISER

32 017129 N/A 6 FW .440 X 1.000 X .083 ZNYC

SERVICE

PART NO.

1 793828 793828 1 A-SECTION BELT (FASTRAK 36")

2 025007 025007 2 CS .625-11 X 1.75 HX G5 ZNYC

3 046821 046821 2 FW .656 X 2.00 X .078 ZNYC

4 797449 797449 2 FW .650 X 1.00 X .180 ZNYC G5

5 784504 784504 2 IDLER PULLEY, 5.00"OD, 5/8"ID

6 784199 784199 6 CS .312-18 X 1.25 FLT SH

7 601434 601434 2 UHMW IDLER SLIDE

8 321877 321877 1 DECK IDLER

9 364315 059931 1 SPRING CHAIN

MFG. PART

NO.

QTY. DESCRIPTION

NOTES:

1. Torque to 118 ft. lbs.

2. See “Belt Routing and Tensioning” on page 7-3 for belt tensioning

3. Deck belt tensioning idler for mowers with serial numbers prior to

06010082 (see FIG 6-1).

333559 08/08 6-5

Page 50

FIG. 6-1

2

3

4

5

30

9

31

12

28

29

11

32

13

15

6-6 333559 09/08

Page 51

This page intentionally left blank.

333559 08/08 6-7

Page 52

Deck Assembly 42"

1

2

2

3

5

6

7

8

9

9

9

9

10

10

11

12

12

12

13

13

14

15

16

17

18

19

8

4

17

6-8 333559 09/08

Page 53

Deck Assembly 42"

1

INDEX

NO.

10 034280 034280 2 CS .312-18 X .75 HX G5 ZNYC

11 546929 316919 1 42" FASTRAK DECK

12 808485 808485 3 5/16-18 THREAD RIVET NUT

13 034272 034272 2 NT .312-18 HX G5 ZNYC

14 330225 330225 2 PULLBAR

15 781567 781567 1 NT .50-13 HX LK NY

16 053199 N/A 1 NT .500-13 HX JAM ZNYC

17 767962 N/A 2 FW .531 X 1.063 X .090 SAE HD ZN

18 031997 N/A 1 ANTI-SCALP WHEEL

19 781708 N/A 1 CS .500-13 X 4.25 HX G5 ZNYC

SERVICE

PART NO.

1 330399 330399 1 DISCHARGE CHUTE

2 086660 086660 2 NT .375-16 HX LK NY

3 036244 036244 2 CS .375-16 X 1.00 HX G5 ZNYC

4 781880 781880 1 BUMPER, .500X 1.00X .312 X.188

5 054502 054502 2 NT .375-16 HX GRD 5 ZNYC

6 767954 767954 2 FW .406 X .812 X .060 SAE HD ZN

7 352500 352500 1 DISCHARGE CHUTE BASE

8 322974 322974 2 PULLBAR PIN

9 768523 768523 4 FW .343 X .687 X .051/.080 HD ZNYC

788166 788166 1 ANTI SCALP WHEEL ASSY

MFG. PART

NO.

QTY. DESCRIPTION

NOTES:

1. Includes items 16 through 19.

2. Do not torque, Item 1 (330399 Discharge Chute) must pivot freely.

333559 08/08 6-9

Page 54

Deck Pulley Assembly 42"

1

2

1

3

3

5

2

5

6

8

10

9

11

12

13

14

15

16

17

19

19

19

18

20

18

21

17

22

23

14

24

1

4

4

7

6-10 333559 09/08

Page 55

Deck Pulley Assembly 42"

INDEX

NO.

10 781302 781302 1 IDLER SPRING

11 321398 321398 1 RIGHT PULLEY COVER

12 321042 321042 1 LEFT PULLEY COVER

13 781872 781872 2 CS .625-11 X 1.25 HX G5 ZNYC

14 782474 782474 4 CW .631 2.250 X .187 PNT

15 793778 793778 2 DECK PULLEY (FASTRAK 36"/42")

16 054502 054502 8 NT .375-16 HX GRD 5 ZNYC

17 767954 767954 16 FW .406 X .812 X .060 SAE HD ZN

18 064006 064006 4 CS .312-18 X .625 HX G5 ZNYC

19 768523 768523 10 FW .343 X .687 X .051/.080 HD ZNYC

20 058776 058776 6 NT .312-18 HX NL ZNYC

21 783506 783506 2 BLADE SPINDLE ASSEMBLY

22 005116 005116 8 CS .375-16 X 1.375 HX G5 ZNYC

23 793794 793794 2 20.50" 42D X 0.631 CW BLADE

24 781872 781872 2 CS .625-11 X 1.25 HX G5 ZNYC

27 712927 N/A 6 FW .344 X 1.00 X .12 HRD ZN

28 785832 N/A 2 DECK IDLER UHMW CLAMP

29 787069 N/A 2 DECK IDLER UHMW RISER

30 017129 N/A 6 FW .440 X 1.000 X .083 ZNYC

31

SERVICE

PAR T N O.

1 793893 793893 1 A-SECTION BELT (FASTRAK 42")

2 025007 025007 2 CS .625-11 X 1.75 HX G5 ZNYC

3 046821 046821 2 FW .656 X 2.00 X .078 ZNYC

4 797449 797449 2 FW .650 X 1.00 X .180 ZNYC G5

5 784504 784504 2 IDLER PULLEY, 5.00"OD, 5/8"ID

6 784199 784199 6 CS .312-18 X 1.25 FLT SH ZY

7 601434 601434 2 UHMW IDLER SLIDE

8 321877 321877 1 DECK IDLER

9 259812 059931 1 SPRING CHAIN

MFG. PART

NO.

QTY. DESCRIPTION

NOTES:

1. Torque to 118 ft. lbs.

2. See “Belt Routing and Tensioning” on page 7-3 for belt tensioning

3. Deck belt tensioning idler for mowers with serial numbers prior to

06010082 (see FIG 6-2).

4. Item 7 (601434) replaces idler slide components 600171, 600189 and

786335 found on mowers with serial numbers prior to 08010000.

333559 08/08 6-11

Page 56

FIG. 6-2

2

3

4

5

29

9

12

27

28

11

31

3

15

30

6-12 333559 09/08

Page 57

This page intentionally left blank.

333559 08/08 6-13

Page 58

Blade Spindle Assembly Breakdown

1

2

2

3

4

5

c

INDEX

NO.

SERVICE

PART NO.

1 783548 N/A 1 BLADE SPINDLE RETAINING RING

2 783555 N/A 2 BLADE SPINDLE BEARING

3 783530 N/A 1 BLADE SPINDLE SPACER

4 783514 N/A 1 BLADE SPINDLE HOUSING

5 783522 N/A 1 BLADE SPINDLE SHAFT

MFG. PART

NO.

QTY. DESCRIPTION

6-14 333559 09/08

Page 59

NOTES:

333559 08/08 6-15

Page 60

This page intentionally left blank.

6-16 333559 09/08

Page 61

Chapter 7 Contents

Deck Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Belt Routing and Tensioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Seat Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

333559 08/08 7-1

Page 62

Deck Installation

1

2

3

4

4

4

5

5

5

2

INDEX

NO.

SERVICE

PART NO.

1 781567 781567 2 NT .500-13 HX GR 8 ZY NL

2 767962 767962 4 FW .531 X 1.063 X .090 SAE HD ZN

3 017616 017616 2 CS .500-13 X 1.75 HX G5 ZNYC

4 704643 704643 5 NT .437-14 HX FLG ZN

5 055749 055749 3 CS .437-14 X 1.75 HX G5 ZNYC

MFG. PART

NO.

QTY. DESCRIPTION

NOTES:

7-2 333559

Page 63

Belt Routing and Tensioning

NOTES:

1. Spring length after tensioning belt–measured from outside of hook to out side

of hook.

2. Route belt as shown.

333559 08/08 7-3

Page 64

Seat Installation

1

3

2

3

5

6

4

7

8

9

1

2

INDEX

NO.

SERVICE

PART NO.

1 793679 793679 1 STANDARD MICHIGAN SEAT

2 086660 086660 3 NT .375-16 HX LK NY

3 767954 767954 3 FW .406 X .812 X .060 SAE HD ZN

4 320275 320275 1 SEAT PAN

5 052860 052860 2 CS .375-16 X 1.25 HX G5 ZNYC

6 793851 793851 2 COMPRESSION SPRING, 1.25X4.00X.188

7 768523 768523 4 FW .343 X .687 X .051/.080 HD ZNYC

8 034280 034280 4 CS .312-18 X .750 HX G5 ZNYC

9 036244 036244 2 CS .375-16 X 1.00 HX G5 ZNYC

MFG. PART

NO.

QTY. DESCRIPTION

NOTES:

1. Do not torque, Item 4 (320275 Seat Pan) must pivot on these fasteners.

2. Available service parts and options for Michigan Seat:

797456 ARMREST KIT (ROUND STYLE)

793315 SEAT SWITCH KIT

7-4 333559

Page 65

Chapter 8 Contents

Tractor Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

42" Deck Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

36" Deck Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

333559 08/08 8-1

Page 66

Tractor Decals

2

4

5

3

6

7

9

8

12

10

13

15

14

11

1

16

17

8-2 333559

Page 67

Tractor Decals

INDEX

NO.

10 793703 793703 1 INSTRUMENT PANEL DECAL

11 793554 793554 1 FASTRAK 36/42 FUEL VALVE DECAL

12 771436 771436 1 STABILIZER DECAL

13 727016 727016 1 BATTERY DECAL

14 788968 788968 1 ENGINE COMPARTMENT DECAL

15 785147 785147 1 SERVICE DECAL

16 600899 600899 1 PUMP BELT WARNING DECAL

17 600941 600941 1 PATENT DECAL

SERVICE

PART NO.

1 794545 794545 1 DEFLECTOR SHIELD DECAL

2 N/A 083279 1 TURF PROD SERIAL NO PLATE

3 784710 784710 1 FASTRAK DECAL

4 782573 782573 1 FIRST ZERO TURN DECAL

5 793547 793547 1 FASTRAK OPERATION DECAL

6 793588 793588 1 HUSTLER NAME PLATE

7 794305 794305 1 DECK HEIGHT DECAL

8 785139 785139 1 FASTRAK LEFT SIDE STEERING DECAL

9 785220 785220 1 FASTRAK RIGHT SIDE STEERING DECAL

MFG. PART

NO.

QTY. DESCRIPTION

NOTES:

333559 08/08 8-3

Page 68

42" Deck Decals

1

2

3

4

6

5

x

INDEX

NO.

SERVICE

PART NO.

1 793521 793521 1 42" DECK ID DECAL

2 793687 793687 1 BELT ROUTING DECAL

3 794503 794503 1 STEP TREAD

4 793570 793570 1 DECK WARNING DECAL

5 727172 727172 1 “MADE IN U.S.A.” DECAL

6 794297 794297 1 DISCHARGE CHUTE DECAL

MFG. PART

NO.

QTY. DESCRIPTION

NOTES:

8-4 333559

Page 69

36" Deck Decals

2

1

4

5

6

3

x

INDEX

NO.

SERVICE

PART NO.

1 793513 793513 1 36" DECK ID DECAL

2 793687 793687 1 BELT ROUTING DECAL

3 794503 794503 1 STEP TREAD

4 727172 727172 1 “MADE IN U.S.A.” DECAL

5 793570 793570 1 DECK WARNING DECAL

6 794297 794297 1 DISCHARGE CHUTE DECAL

MFG. PART

NO.

QTY. DESCRIPTION

NOTES:

333559 08/08 8-5

Page 70

8-6 333559

Page 71

Chapter 9 Contents

Maintenance & Adjustment Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-20

333559 09/08 9-1

Page 72

Maintenance & Adjustment Safety

This safety alert symbol is used to call attention to a message intended to provide a reasonable degree of

PERSONAL SAFETY for operators and other persons during the normal operation and servicing of this equipment.

DANGER – denotes immediate hazards which WILL result in severe personal injury or death.

WARNING - denotes a hazard or unsafe practice which COULD result in severe personal injury or death.

This manual uses two other words to highlight information. IMPORTANT calls attention to special mechanical information and NOTE: emphasizes general information worthy of special attention.

All operators and mechanics should read this manual, and be instructed about safe operating and maintenance procedures. If the operators or mechanics cannot read and understand English, it is the owner’s

responsibility to explain this material to them.

Improper use or maintenance by the operator, mechanic, or owner can result in injury. T o reduce the potential for injury,

comply with these safety instructions and always pay attention to the safety alert symbol, which means DANGER or

WARNING - “personal safety instructions.” Failure to comply with the instructions may result in personal injury or death.

Incorrect usage of this machine may result in severe injury. Personnel operating and maintaining it should be trained in

the proper use and should read the manuals completely and thorou ghly before attempting to set-up, operate, adjust, or

service this machine.

The Quick Reference Decals are designed to give the operator brief information needed in the daily operation and service of the machine. These decals are not intended to be used in place of this manual but instead

is to be used as an extension of this manual. These decals should not be removed or obliterated. Replace

these decals if they become unreadable.

It is the owner’s responsibility to make certain that the operators and mechanics read and understand this

manual and all decals before operating this machine. It is also the owner ’s responsibility to make certain that

the operators and mechanics area qualified and physically able individuals, properly trained in the operation

of this equipment. All operators and mechanics must become familiar with the safe operation of the equipment, operator controls and safety signs before operating the equipment.

Never let children or untrained people operate or service the equipment. Local regulation may restrict the

age of the operator.

The owner should also ensure that the operators and mechanics know that they are responsible for their

own safety as well as the safety of ot her person s within t he vic inity. Remember, the operator is responsible for

accidents or hazards occurring to other people or their property.

Safe Maintenance & Adjustment Practices

This product is capable of amputating hands and feet and throwing objects. Always follow all safety

instructions to avoid serious injury or death.

Unless specifically required, DO NOT have engine running when servicing or making adjustments to tractor. Park

the machine on level ground. Place control levers in the park brake position, disengage deck clutch, lower deck,

remove ignition switch key and disconnect the negative battery cable before doing any maintenance. Wait for all

movement to stop before adjusting, cleaning or repairing. Repairs or maintenance requiring engine power should

be performed by trained personnel only. To prevent carbon monoxide poisoning, be sure proper ventilation is

available when engine must be operated in an enclosed area. Read and observe safety warnings in front of

manual.

Follow daily and weekly checklists, making sure hoses are tightly secured and bolts are tightened.

Keep your machine clean and remove any deposits of trash and clippings, which can cause engine fires and

hydraulic overheating as well as excessive belt wear. Clean up oil or spillage. Allow machine to cool before

storing.

Clean flammable material from machine. Prevent fires by keeping the top of the deck, engine

compartment, exhaust area, battery, hydraulic lines, fuel line, fuel tank and operator’s station clean of

accumulated trash, grass clippings, and other debris. Always clean up spilled fuel and oil.

9-2 333559 09/08

Page 73

Always wear adequate ear protection, such as earplugs, when operating this equipment as prolonged exposure to

uncomfortable or loud noises can cause impairment or loss of hearing. Do not wear radios or music headphones

while operating the machinery. Safe operation requires your full attention.

Never put hands or feet under any part of the machine while it is running.

Except when changing or checking belt, always keep belt covers on mower for safety as well as cleanliness.

Stop the engine before removing the grass catcher or unclogging the discharge chute. Never clear the discharge

chute with the engine running. Turn off the engine and be sure the blades have stopped before cleaning. Use a

stick to clear a plugged discharge area. Never use your hand!

Exercise caution when loading or unloading the machine onto a trailer or truck.

Always wear safety goggles or safety glasses with side shields when operating the mower.

Always wear adequate eye protection when servicing the battery, hydraulic system or when grinding mower blades

and removing accumulated debris.

Use extra caution when handling gasoline and other fuels. They are flammable and vapors are explosive.

Never remove fuel cap or refuel tractor while engine is running; never refuel near an open flame or near devices

which can create a spark. Refuel outdoors. Never refuel or drain the fuel from the machine indoors.

Never attempt to start engine when there is a strong odor of gasoline fumes present. Locate and correct cause.

Never run the engine in an enclosed area unless exhaust is vented to the outside. Exhaust gases contain carbon

monoxide which is odorless and deadly poison.

Never attempt to make any adjustment s o r repairs to the tractor dr ive system, mower deck or an y atta chment while

the tractor engine is running or deck clutch is engaged. Repairs or maintenance requiring engine power should

be performed by trained personnel only.

Never work under the machine or attachment unless it is safely supported with jack stands. Make certain machine

is secure when it is raised and placed on the jack stands. The jack stands should not allow the machine to move

when the engine is running and the drive wheels are rotating. Use only certified jack stands. Use only

appropriate jack stands, with a minimum weight rating of 2000 pounds to block the unit up. Use in pairs only.

Follow the instructions supplied with the vehicle stands.

Before working on or under the deck, make certain engine cannot be accidentally started. Shut engine off and

remove ignition switch key for maximum safety. Repairs or maintenance requiring engine power should be

performed by trained personnel only.

Use a stick or similar instrument to clean under the mower making sure that no part of the body, especially arms

and hands are under mower.

Exercise caution when working under the deck as the mower blades are extremely sharp. Wrap the blade(s) or

wear gloves and use extra caution when servicing them.

Do not touch hot parts of machine.

Keep nuts and bolts tight, especially the blade attachment bolts. Keep equipment in good working condition.

Never tamper with safety devices. Check their proper operation regularly.

Grass collection system components are subject to wear, damage and deterioration, which could expose moving

parts or allow objects to be thrown. Frequently check components and replace with manufacturer’s

recommended parts, when necessary.

Use only genuine Hustler replacement parts to ensure that original standards are maintained.

Using a ramp

Use extreme caution when loading and unloading a unit onto a truck or trailer with a ramp.

Use only a single, full width ramp; do not use individual ramps for each side of the unit. Having a full width ramp

provides a surface for the tractor frame to contact if the unit starts to tip backwards. It also reduces the risk of a

wheel going off and the machine tipping over.

Do not exceed a 15 degree angle between the ramp and the ground or between the ramp and the trailer or truck.

When on a ramp avoid sudden acceleration.

333559 09/08 9-3

Page 74

Children

Tragic accidents can occur if the operator is not alert to the presence of children. Children are often

attracted to the machine and the mowing activity. Never assume that children will remain where you last saw

them.

Never leave machine unattended with ignition key in switch, especially with children present.

Children or bystanders may be injured if they move or attempt to operate the tractor while it is unattended. Always

disengage deck clutch, place steering control levers in park brake position, stop tractor engine, and remove

ignition key when leaving operator’s seat.

Keep children out of the mowing area and under the watchful care of a responsible adult other the operator.

Be alert and turn the machine off if children enter the area.

Before and while backing, look behind and down for small children.

Never carry children, even with the blades off. They may fall off and be seriously injured or interfere with safe

machine operating. Children who have been given rides in the past may suddenly appear in the mowing area for

another ride and be run over or backed over the machine.

Never allow children to operate the machine.

Use care when approaching blind corners, shrubs, trees, the end of a fence or other objects that may obscure

vision.

Never allow children of others in or on towed equipment.

9-4 333559 09/08

Page 75

Safety and Instruction Decals

Part Number

727016

Part Number

793547

Part Number

600899

Part Number

793570

Specific safety warning decals are located on the equipment near the immediate areas of potential hazards. These

decals should not be removed or obliterated. Replace them if they become non-readable.

The following illustrations show the various

tion is shown to help the operator understand the meanings of these decals.

Read Owner’s Manual and Quick Reference Decal before attempting to operate this machine.

Avoid skin contact with battery acid. Always wear eye protection when checking the battery, acid can cause

serious injury to skin and eyes. If contact occurs, flush area with clean water and call physician immediately.

Acid will also damage clothing.

Do not allow open flame near the battery when charging.

Hydrogen gas forms inside the battery. This gas is both toxic and flammable and may cause an explosion if

exposed to flame. Always remove the negative ground first and replace it last.

Do not overfill battery. Electrolyte may overflow and damage paint, wiring or structure. When cleaning the

battery, use soap and water. Be careful not to get soap and water into the battery. Use soda mixed in water to

clean corrosion off the terminals.

safety decals that are located on the machine. A brief explana-

Do not remove or modify stabilizer wheels or rear engine guard or

injury can result. When operating on a slope of 15° or more, be aware

of any condition that may cause the tractor drive tires to lose traction

resulting in a possible loss of control of the machine.

steering control levers in the park brake position immediately. Inspect the machine and involve

If you loose steering control while operating the machine, place the

your Hustler dealer to resolve the problem before continuing to operate.

If pump belt fails, steering control will be lost. Refer to owner’s manual for inspection and

replacement intervals and refer to above paragraph for emergency procedures.

Do not fill tank with engine running, or while the engine is hot.

Allow engine to cool before storing machine inside a building.

Store away from open flame or spark if there is fuel in tank.

Clean up any gasoline spills.

Do not smoke while refueling.

Do not refuel while in enclosed trailer or other enclosed areas.

Never operate the mower deck with side deflector damaged, altered, removed or in

raised position, except when the entire grass catcher attachment or mulching system

is being used. Stay clear of mower blades as long as engine is running.Keep a safe

distance from machine. Keep shields or covers in place while machine is in

operation. Keep hands away from rotation pulleys and belts.

333559 09/08 9-5

Page 76

Whirling blades! Keep hands and feet away. Beware of thrown object s. Neve r oper ate the mower

Part Number

794297

Part Number

727453

deck with side deflector damaged, altered, removed or in raised position, except when the entire grass catcher attachment or mulching system is being used.

long as engine is running. Beware of thrown object.

Keep shields or covers in place while machine is in operation. Keep hands away from rotating pulleys and belts.

Stay clear of mower blades as

9-6 333559 09/08

Page 77

1

7

7

16

2

3a

3b

4

5

6

6

8

9

9

10

10

11

11

12

14

13

MAINTENANCE LOCATOR

CHART

Viewed from top of unit

1. Engine Oil Fill & Dipstick (Honda & Kohler)

2. Fuel Filter

3a. Engine Air Cleaner (Honda)

3b. Engine Air Cleaner (Kohler)

4. Engine Oil Drain Plug)

5. Battery

6. Fuel Tanks

7. Wheel Bearing Zerks (2)

8. Engine Oil Filter

9. Deck Lift Pivot Zerks (4)

10. Park Brake Switch (2)

11. Drive Tire

12. Deck Belt

13. Pump Belt

14. Blades

15. Engine Air Intake Screen

16. Front Tires

15

Maintenance

333559 09/08 9-7

FIG. 1

Page 78

SERVICE AT INTERVALS INDICATED

Verify safety start interlock system

V isually inspect unit for loose hardware and/or damaged

parts

Visually inspect tires

Check oil level, engine (1)

Clean air intake screen (4)

Clean Foam element (4)

Check fuel level

Blades–sharpen & securely fastened

Discharge chute–securely in place & in lowest position

Grease deck height pivots

Grease front wheel bearings

Change engine oil & filter (1) (3)

Clean cylinder and head fins (a)

Check battery connections

Check tire pressure with a gauge

Clean engine exterior (a)

Replace air cleaner paper element (4)

Clean and re-gap spark plugs (a)

Check pump and deck belt tension & condition (5)

Check fuel lines (6)

Tighten lug nuts on wheels (2)

Change fuel filter

Replace spark plugs

Check engine valve clearance (a)

Service starter (8)(a)

Replace EZT pump belt

WEEKLY OR 50

HOURS

Prior to each use

Prior to each use

Prior to each use

Prior to each use or ever 4 hrs.

Prior to each use or ever 4 hrs.

Prior to each use or ever 4 hrs.

Prior to each use

Prior to each use

Prior to each use

X

X

X

X

X

X

X

X

Every 200 hours or 2 years

Every 200 hours or 2 years

Every 200 hours or 2 years

ANNUALLY OF

100 HOURS

X

X

X

X

X

X

NOTES:

1. Initial oil change is after 5 hours of operation. Thereafter, change oil after ever 40 ho urs. operating. Change

more often under dusty or dirty conditions and during hot weather periods.

2. Torque initially and after first 2 hours of operation .

3. Change engine oil filter per the engine manufacturer’s recommendations. Refer to Engine Owner’s Manual

for recommendations and other maintenance items.

4. Service more often under dusty or dirty conditions.

5. Pump drive belt only–Inspect every 6 months or 100 hours and r eplace of wor n or cracking is noticed.

Otherwise, replace ever 200 hours or 2 years, whichever comes first.

6. Check fuel line hoses, fuel valve and grommet for any cracks or leaks

7. Honda engine only.

8. Kohler engine only.

References:

a Refer to Engine Owner’s Manual

NOTE: After completing Maintenance cycle (100 hours), repeat cycle.

Introduction

Regular maintenance is the best prevention for costly downtime or expensive, premature repair. The fol-

9-8 333559 09/08

Page 79

lowing pages contain suggested maintenance information and schedules which the operator should follow on

a routine basis.

Remain alert for unusual noises, they could be signaling a problem. visually inspect the machine for any

abnormal wear or damage. A good time to detect potential problems is while performing scheduled maintenance service. Correcting the problem as quickly as possible is the best insurance.

Clear away heavy build-up of grease, oil and dirt, especially in the engine and under the seat platform

areas; minute dust particles are abrasive to close-tolerance engine and hydraulic assemblies.

Daily inspect mower for grass clippings and wire and string tangles. The underside of the mower deck will

collect a build-up of grass clippings and dirt, especially when grass is wet or has high moisture content. This

build-up will harden, restricting blade and air movement and will probably show a poorer quality of cutting.

Therefore, it should be removed routinely.

To do this, it will be necessary to raise and block the deck, using jack stands or blocks, in the full up position and scrape the build-up from underneath.

Some repairs require the assistance of a trained service mechanic and should not be attempted by

unskilled personnel. Consult your Hustler service center when assistance is needed.

Torque values

WARNING: Particular attention must be given to tightening the drive wheel lug nuts and blade

spindle bolts. Failure to correctly torque these items may result in the loss of a wheel or blade,

which can cause serious damage or personal injury.

Torque values given below:

Ft.-lbs. Nm

Wheel (lug) nuts 65-75 88.14-101.7

Blade spindle top bolt 118 160

Blade spindle bottom bolt 118 160

It is recommended that these be checked after the first 2 hours of operation, initially and every 50 hours

following removal for repair or replacement.

For all other torques refer to the torque call out chart located elsewhere in this manual.

For engine torque values, see engine owner’s manual.

Tires

It is important for level mowing that the tires have the same amount of air pressure. The recommended

pressures are:

PSI

Drive Tires 8-12

Front Wheels 8-12

Solid fill tires are not recommended for Hustler turf equipment. On any machine , with solid filled ti res, the warranty claim wi ll be

denied.

WARNING: Explosive separation of a tire and rim can cause serious injury or death. Do not

attempt to mount a tire without the proper equipment and experience to perform the task. Always

maintain the correct tire pressure and never over inflate. Never weld or heat a wheel and tire

assembly as an explosion may occur. Welding can weaken or deform a wheel. When inflating tires

stand to one side and not in front of or over the tire assembly. Check tires for low pressure,

blemishes, damaged rims, or missing lug bolts and nuts.

Lubrication

1. Grease the front wheel bearings per the Maintenance Schedule. Use SAE multi-purpose grease.

2. Grease the four deck lif t pivots, located to the side of the operator’s footrest per the Maintenance

Schedule. Use SAE multi-purpose grease.

Electrical system

333559 09/08 9-9

Page 80

The electrical system is a 12 volt, negative ground. Recommended battery size is a garden tractor BCI

BATTERY

group UIR with 225 or better cranking AMP rating . A maint enance-free battery is recommended. Othe rwise, follow battery manufacturer’s maintenance, safety, storing, and charging specification.

The Battery is located under the seat platform (FIG. 2).

WARNING:

chemicals known to the State of California to cause cancer and reproductive harm. Wash hands

after handling.

Battery post, terminals, and related accessories contain lead and lead compounds–

WARNING: Change batteries in an open well ventilated area, away from spark and flames.

Unplug charger before connecting or disconnecting from the battery. Wear protective clothing and

use insulated tools.

WARNING: Avoid skin and clothing contact with ba ttery acid. Always wear eye protection when

checking the battery, acid can cause serious injury to skin and eyes. If contact occurs, flush area

with clean water and call physician immediately. Acid will also damage clothing. Do not drink the

battery electrolyte. Do not allow open flame near the battery when charging. Hydro gen gas forms

inside the battery. This gas is both toxic and flammable and may cause an explosion if exposed to

flame. Always remove the negative ground first and replace it last. Do not overfill battery.

Electrolyte may overflow and damage paint, wiring or structure. W hen cleaning the battery, use

soap and water. be careful not to get soap and water into the battery. Clean the battery terminals

with a solution of four parts water and one part baking soda when they become corroded.

FIG. 2

WARNING: Shorts caused by battery terminals or metal tools touching metal tractor

components can cause sparks. Sparks can cause a battery gas explosion which will result in

personal injury. Prevent the battery terminals from touching any metal tractor parts when removing

or installing the battery. Do not allow metal tools to short between the battery terminals and metal

tractor parts.

WARNING: Incorrect battery cable routing could cause damage to the tractor and battery

cables. This can cause sparks which can cause a battery gas explosion which will result in

personal injury. Always disconnect the negative (black) battery cable before disconnecting the

positive (red) cable.

Common circuit failures are usually caused by shorting, corroded or dirty terminals, loose connection,

defective wire insulation or broken wires. Switches, solenoids and ignition components may also fail, causing

a shorted or open circuit.

The electrical system is protected by fuses located on the right fuel tank instrument panel FIG. 3). The

fuses are as follows:

Main 20 amp, blade type

Clutch/Aux 10 amp, blade type

Before attempting any failure diagnosis of the electrical system, use a test light or voltmeter to check the

9-10 333559 09/08

Page 81

battery voltage. If the battery voltage is satisfactory, check the cleanliness and tigh tness of the terminal s and

FUSES

LOCK NUT

FLAT WASHER

ground connections. A general underst a nding of ele ctric al servic ing a nd use o f bas ic tes t equipment is nec es-

sary for troubleshooting and repair.

FIG. 3

Major overhaul or repair of the starting motor or charging system should be performed by trained techni-

cians only.

Access to integrated pump/motor units

The integrated pump/motor units are accessed by lifting the seat platform. The seat platform is hinged at

the front. The seat platform is hinged at the front. To raise it, remove the lock nut and flat washer and tilt seat

platform up and forward (FIG. 4).

brake position and pivot the arm rests upward before placing the seat platform in the full forward position to

prevent damage to the arm rests.

Hydraulic system

333559 09/08 9-11

FIG. 4

If the seat is equipped with the optional arm rest kit, make certain to place the control arms in the park

Page 82

The Hustler FasTrak is equipped with two Hydro-Gear EZT integrated pump/motor transmissions (FIG. 5).

EZT INTEGRATED

PUMP/MOTOR

FIG. 5

The EZT integrated pump/motor transmission are sealed for life and do not require any scheduled service.

The EZT integrated pump/motor transmissions are filled with 20 W50 en gine oil. If they ev er become low on

oil, fill to the level shown in FIG. 6.

Fuel system

FIG. 6

DANGER: Observe usual fuel handling precautio ns :

Do not smoke while refueling. Extinguish all cigarettes, cigars, pipes and other sources of ignition.

Do not remove fuel cap or fill tank with engine running or while engine is hot. Clean up any gasoline

spills.

Allow engine to cool before storing machine inside a building.

Keep fuel away from open flame or spar k and stor e ma chine away fr om ope n flame or spark or pilot light

such as on a water heater or other appliances.

Use extreme care when handling gasoline and other fuels. They are extremely flammable and vapors

are explosive. A fire or from gasoline can burn you and others and can damage property.

Never refuel or drain the fuel from the machine indoors.

Never attempt to start engine when there is a strong odor of gasoline fumes present. Locate and correct

cause.

Store gasoline in an approved container and keep it out of the reach of children. Never buy more than a

30 day supply of gasoline.

Always place gasoline containers on the ground away from your vehicle before filling.

Do not fill gasoline containers inside a vehicle or on a truck or trailer bed with interior carpets or plastic

bed liners.

Always place gasoline containers on the ground away from your vehicle before filling.

When practical, remove gas-powered equipment from the truck or trailer and refuel the equipment with

its wheels on the ground. If this is not possible, then refuel the equipment on the truck or trailer using a

portable container an not a gasoline dispenser nozzle. If a gasoline dispenser nozzle must be used,

keep the nozzle in contact with the rim of the fuel tank or container opening at all times until fueling is

complete. Do not use a nozzle lock-open device.

9-12 333559 09/08

Page 83

WARNING: Gasoline is harmful or fatal if swallow ed. Long-term exposure to vapors can cause

FUEL TANK

serious injury and illness. Avoid prolonged breathing of vapors. Keep face away from nozzl e and

gas tank or fuel container opening. Keep gasoline away from eyes and skin. If fuel is spilled on

clothing, change clothing immediately.

The fuel tanks are located in the t rac tor’ s fe nder s (FIG. 7). Total capacity for the fuel tanks is 6 U. S. gallons

(22.71 L.).

FIG. 7

IMPORTANT: Do not overfill the fuel tanks.The fuel tanks should be filled no higher than 2” below the

tank’s fill neck.When filling the fuel tanks disengage deck clutch, place control levers in park brake

position, and stop tractor engine. Clean around the fuel tank cap and remove the cap and begin filling.

When finished, screw the cap on securely and wipe up any spilled gasoline.

When filling the fuel tanks disengage deck clutch, place control levers in park brake position, and stop

tractor engine. Clean around the fuel tank cap and remove the cap and begin filling. When finished, screw the

cap on securely and wipe up any spilled gasoline.

Use regular unleaded gasoline with an octane rating of 87 or higher.

IMPORTANT: Never use methanol, gasoline containing methanol, or gasohol containing more than

10% ethanol because the fuel system could be damaged. Do not mix oil with gasoline.

Using a fuel stabilizer/conditioner in the tractor can provide benefits such as:

1. Keep s gasoline fresh during storage of 90 days or less. For longer storage, drain the fuel tanks

2. Cleans the engine during operation.

3. Eliminates gum-like varnish buildup in the fu el system.

IMPORTANT: Do not use fuel additives containing methanol or ethanol.

Add the correct amount of gas stabilizer/conditioner to the gas. Follow the gas stabilizer/conditioner manufacturer’s directions for best results.

The fuel filter (FIG. 8, & FIG. 9) is installed in the fuel line between fuel tank s and en gine fuel pump. Re place

filter annually or after every 100hours of operation, whichever occurs first. For fuel filter removal refer to the

engine owner’s manual.

When replacing the fuel filter, check the fuel line hoses and fuel tank fitting grommets for any cracks or

leaks. Replace as needed. A fuel shut-off valve is located to the right rear of the seat (FIG. 10). Close this valve

(center position) to prevent fuel flow to the engine. Close this valve when transporting the unit on a trailer or

truck.

333559 09/08 9-13

Page 84

FIG. 8 HONDA FIG. 9 KOHLER

FUEL FILTER

INLET HOSE

FUEL FILTER

INLET HOSE

FUEL SHUT-OFF

VALVE

RIGHT FUEL

TANK POSITION

LEFT FUEL

TANK POSITION

CLOSED POSITION

SHOWN

FIG. 10

DRAINING THE FUEL TANKS

FasTraks have a fuel shut-off valve (Hustler p/n 7480159) located behind the seat to the right side of the

operator (FIG. 10). Close this valve (center position) to prevent fuel flow to the engine. The valve’s two other

positions are front and rear. To drain a fuel tank equipped with this fuel shut -off valve kit, use the following

method:

1. Park the unit on a flat surface. Stop the engine and remove the ignition key. Make sure deck clutch switch

2. Close fuel shut-off valve (center position) (FIG. 10.