Page 1

OPERATING INSTRUCTIONS AND PARTS LIST

INSTRUCCIONES DE OPERACIÓN Y LISTA DE PIEZAS

MODELS: MC1809R (9 HP ROBIN)

MC1809H (9 HP HONDA)

MC1813R (13.5 HP ROBIN)

MC1813H (13 HP HONDA)

MC1805G (5 HP GAST)

MC1805B (5 HP BALDOR)

Model:

Serial Number:

Engine Serial No.:

Purchase Date:

0A7859

Copyright © July 11, 2002 DBInc.

Printed in U.S.A.

MC18

Concrete Saw

17400 West 119th Street

Olathe, Kansas 66061

Customer Service ..... 800-288-5040

Corp. Office ............... 913-928-1000

Cust. Service FAX .... 800-825-0028

Corp. Office FAX ....... 913-438-7951

Int’l. FAX ....................913-438-7938

Internet www.targetblue.com

1

Page 2

EVERY MACHINE IS THOROUGHLY TESTED BEFORE LEAVING THE FACTORY. EACH MACHINE IS SUPPLIED

WITH A COPY OF THIS MANUAL. OPERATORS OF THIS EQUIPMENT MUST READ AND BE FAMILIAR WITH THE

SAFETY WARNINGS. FAILURE TO OBEY WARNINGS MAY RESULT IN INJURY OR DEATH. FOLLOW

INSTRUCTIONS STRICTLY TO ENSURE LONG SERVICE IN NORMAL OPERATION.

CONTENTS

Symbol Definitions .................................................................................................................................4 - 6

Decal Descriptions and Locations ......................................................................................................... 7

Saw Configurations and Models / Power Source / Dimensions............................................................9

Safety Warnings - DO's & DO NOT's ....................................................................................................10 - 11

Reference Figures .................................................................................................................................12

Pre-Operation Checklist / Maintenance Schedule ................................................................................13

Instructions:

1. Features .................................................................................................................................14

2. Assembly ................................................................................................................................14

3. General Instructions ............................................................................................................... 14

4. Check Before Starting ............................................................................................................15

5. Fitting the Blade......................................................................................................................15

6. Starting the Power Source......................................................................................................15

7. Maneuver the Saw.................................................................................................................. 16

8. To Start Sawing.......................................................................................................................16

9. Stopping the Saw....................................................................................................................16

10. Maintenance Instructions .......................................................................................................17

11. Optional And Accessory (Field Installed) ................................................................................17

12. Governor Speed .....................................................................................................................18

13. Repairs ...................................................................................................................................18

14. Service Parts ..........................................................................................................................18

Parts List Diagrams:

Diagram 1 - Frame & Axle .....................................................................................................................20, 21

Diagram 2 - Depth Control (Screw Feed)..............................................................................................22, 23

Diagram 3 - Depth Control (Lock Bar)................................................................................................... 24, 25

Diagram 4 - Pointer & Belt Guard..........................................................................................................26, 27

Diagram 5 - Guards & Water Distribution .............................................................................................28, 29

Diagram 6 - Blade Guard....................................................................................................................... 30, 31

Diagram 7 - Engine & Bladeshaft .......................................................................................................... 32, 33

Diagram 8 - Electric Motor .....................................................................................................................34, 35

Diagram 9 - Air Motor ............................................................................................................................36, 37

Diagram 10 - Kit, Water Tank (174957).................................................................................................38

2

Page 3

NOTE:

NOTA:

3

Page 4

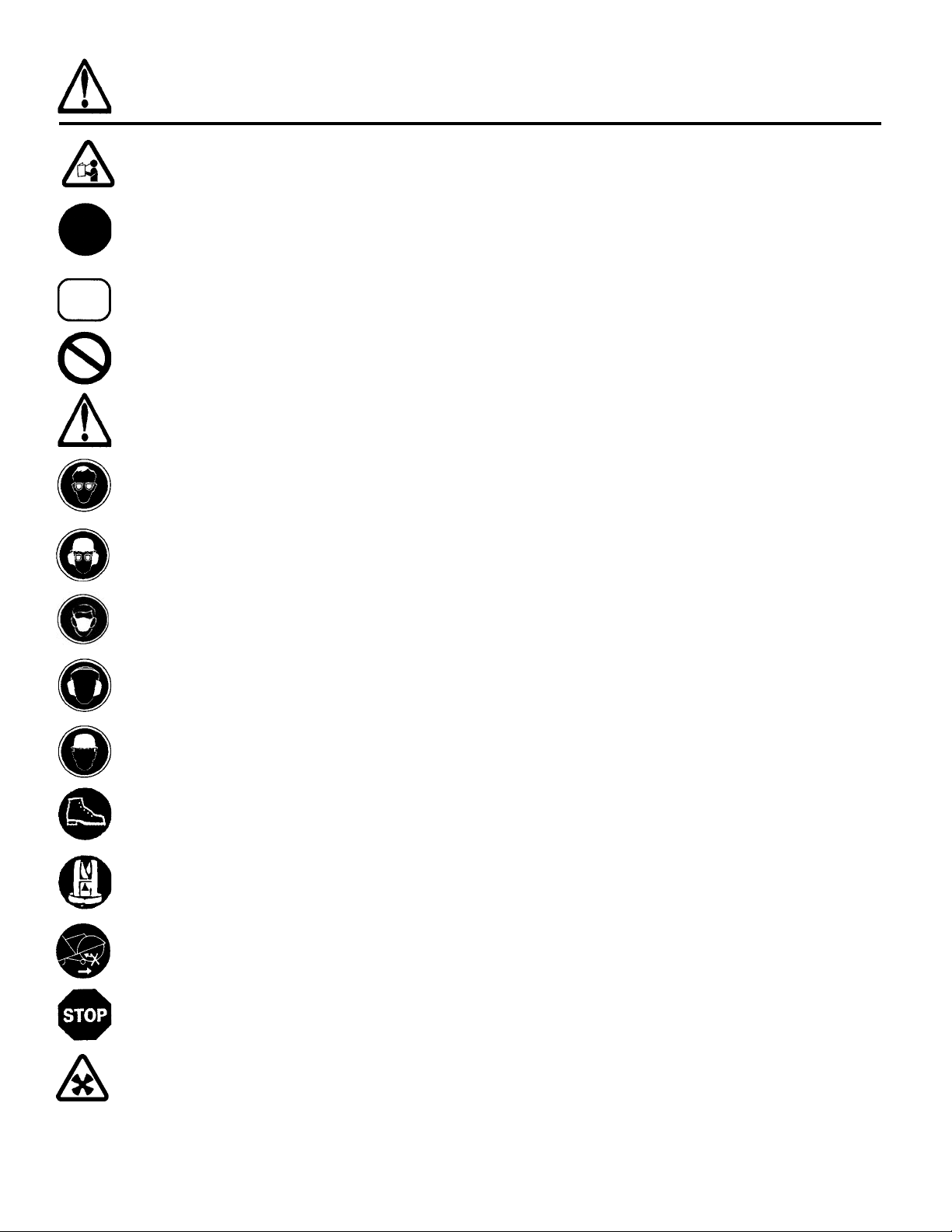

Symbol Definitions

Definición De Simbolos

• Please Read The Instructions For Use Prior To Operating The Machine For The First Time.

• Antes De La Puesta En Marcha, Lea Detenidamente Las Instrucciones Y Familiaricese Con La Máquina.

• Mandatory

• Obligatorio

• Indication

• Indicación

• Prohibition

• Prohibición

• Warning Triangle

• Triángwulo De Advertencia

• Wear Eye Protection

• Usar Gafas De Protección

• Wear Head Protection

• Usar Casco De Protección

• Wear Breathing Protection

• Usar Máscara De Protección

• The Use Of Ear Protection Is Mandatory

• Es Obligatorio El Uso De Protección Auditiva

• Wear a Hard Hat

• Usar Casco Duro

• Wear Safety Shoes

• Usar Zapatos De Seguridad

• Wear Appropriate Clothing

• Usar Ropa Adecuada

• Remove The Blade Prior To Hoisting, Loading, Unloading And Transporting The Machine On Jobsite

• Desmontar El Disco Antes De Desplazar, Cargar, Descargar O Transportar La Máquina En La Obra

• Motor Off

• Parar El Motor

• Use In Well Ventilated Area

• Usar En Una Área Bien Ventilada

4

Page 5

• Do Not Use In Flammable Areas

• No Usar In Áreas Inflamables

• Machinery Hazard, Keep Hands And Feet Clear

• Máquina Peligrosa - Mantenga Manos Y Pies Alejados De La Máquina

• Danger, Poison Exhaust Gas

• Peligro, Gas De Escape Venenoso

• No Non-working Personnel In Area

• Prohibido Para Personas Ajenas A La Obra

• No Smoking

• No Fumar

• Do Not Operate Without All Guards In Place

• No Operar Sin Todas Las Protecciones In Su Sitio

• Always Keep the Blade Guards In Place

• Mantenga Siempre Las Protecciones De La Hoja En Su Sitio

• Water Supply On

• Suministro De Agua Desconectado

• Water Supply Off

• Suministro De Agua Des Conectado

• Keep Work Area Clean/Well Lit, Remove All Safety Hazards

• Mantenga Limpio El Sitio De Trabajo/Bien Iluminado, Elimine Todos Los Riesgos De Seguridad

• Dangerously High Noise Level

• Nivel De Ruido Elevadamente Peligroso

• Pay Extreme Attention To The Care And Protection Of The Machine Before Starting Up

• Ponga Extrema Atención Al Cuidado Y Preparación De La Máquina Antes De Ponerla En Marcha

• Remove Tools From Area And Machine

• Elimine Las Herramientas Del Área Y De La Máquina

• Oil Required

• Necesita Aceita

• Dipstick, Maintain Proper Oil Level

• Varilla De Control, Mantenga El Nivel De Aceite Correcto

• Lubrication Point

• Punto De Lubrication

• Unleaded Fuel Only

• Combustible Sin Piomo Solamente

5

Page 6

• Repairs Are To Be Done By An Authorized Dealer Only

• Las Reparaciones Deben Ser Efectuadas Únicamente Por Un Distribuidor Autorizado

• Diamond Blade

• Sierra Diamantada

• Blade Diameter

• Diámetro De La Hoja

• Pulley Diameter

• Diámetro De La Correa

• Number of Revolutions Per Minute, Rotational Speed

• N° De Revoluciones Por Minuto, Velocidad De Rotación

• Blade Flange Diameter

• Diámetro De La Brida De La Hoja

• Machine Mass (lbs)

• Masa De La Máquina (lbs)

• Electric Motor

• Motor eléctrico

• Engine

• Motor

• Engine Speed Revolutions/Minute

• Velocidad Del Motor En Revoluciones Por Minuto (RPM)

• Engine Start

• Arranque Del Motor

WARNING

HEARING HAZARD

DURING NORMAL USE OF THIS MACHINE, OPERATOR MAY BE EXPOSED TO A NOISE

LEVEL EQUAL OR SUPERIOR TO 85 dB (A)

ATENCION

RIESGO DE DAÑO AUDITIVO

EN CONDICIONES NORMALES DE UTILIZACIÓN, EL OPERADOR DE ESTA MÁQUINA PUEDE

ESTAR EXPUESTO A UN NIVEL DE RUIDO IGUAL O SUPERIOR A 85 dB (A)

6

Page 7

DECAL DESCRIPTIONS AND LOCATIONS

DECRIPCIÓN DE CALCAMONIAS Y UBICACIONES

P/N 189732

Location: Front of Frame (All Models)

Quantity: 1

P/N 174993

Location: Belt Guard (All Models)

Quantity: 1

Location: Blade Guard (All Models)

Location: Frame (All Models)

P/N 189731

Quantity: 1

P/N 187691

Quantity: 1

P/N 174998

Location: Top of Screw Feed Bracket

(Screw Feed Model Only)

Quantity: 1

P/N 139633

Location: Front of Handle Support (E-Z Tilt Model Only)

Quantity: 1

P/N 177588

Location: Top of Belt Guard (All Models)

Quantity: 1

P/N 169065

Location: Engine Fuel Tank (All Models)

Quantity 1

P/N 040563

Location: Front of Frame (All Models)

Quantity: 1

7

Page 8

NOTE:

NOTA:

8

Page 9

MC 18 Specifications

Power Source Pneumatic Electric

MC 18 Model MC 18 9R MC 18 9H MC 18 13.5R MC 18 13H MC 18 5A MC 18 5E

Horsepower 9 HP 9 HP 13.5 HP 13 HP 5 HP 5 HP (230 V)

Standard Model C00094 C00084 C00098 C00086 C00088 C00090

Screw Feed Model

C00095

C00085 C00099 C00087 C00089 C00091

ALL SAWS FEATURE:

Max. Blade Cap. in. (mm) 18 (450) 18 (450) 18 (450) 18 (450) 18 (450) 18 (450)

Max. Depth of Cut

4-5/8"-6-5/8" (117.5-168.3mm)

Blade Shaft RPM 2,600 2,600 2,600 2,600 2,500 1,800

Weight Crated - lb. (Kg) 199 (90) 209 (95) 222 (101) 222 (101) 203 (92) 268 (120)

Uncrated - lb. (Kg) 172 (78) 182 (83) 195 (88) 195 (88) 176 (80) 241 (109)

Arbor Size

Blade Flange

Blade Drive

Blade Control

Blade Coolant

Axle Front

Wheels Front

Rear

Chassis

1" (25.4mm)

4-1/2" dia. with drive pin

2 V-belts (5-8 HP); 3 V-belts (13 HP engine)

Spring assisted raise/lower system with single lock down knob or spring assisted screw feed

Removable dual water spray tubes; water supply connector located on left side of saw; control

3/4" (19 mm) diameter; raises and lowers cutting head

5" x 1-1/2" x 3/4" (102 x 38 x 19mm); solid rubber tires, cast iron hub, roller bearings, lube

8" x 2" x 5/8" (203 x 51 x 15.9mm); ball bearings; semi-pneumatic tires

One piece reinforced box base

POWER SOURCE:

Engine/Motor Robin

Gas Engine

Specifications EX27 GX270 EH41 GX390 120CFM

Max. Horsepower 9 HP 9 HP 13.5 HP 13 HP 5 HP 5 HP

Displacement cu. in. (cc) 16.7 (265) 16.5 (270) 24.7 (404) 23.7 (389)

Bore - in. (mm) 2.95 (75) 3.0 (76) 3.5 (88) 3.5 (88) 21.5/20 - Full Load

Stroke - in. (mm) 2.36 (60) 2.3 (58) 2.6 (65) 2.5 (64)

Cylinders/Stroke 1/4 1/4 1/4 1/4

Fuel Capacity - gal. (l) 1.6 (6) 1.59 (6.0) 1.85 (7.0) 1.72 (6.5)

Oil Capacity - pt.(l) 2.2 (1.1) 2.3 (1.1) 2.5 (1.2) 2.3 (1.1)

Air Filter Dry type

dual element

w/pre cleaner

Starter Rec oil Rec oil Recoil Recoi l Valve Switc h

Engine Coolant Air Air Air Air Air Air

Oil Sentry

Standard

Honda

Gas Engine

Dry type

dual element

w/pre cleaner

Standard Standard Standard N/A N/A

Gas

Robin

Gas Engi ne

Dry type

dual element

w/pre cleaner

Honda

Gas Engine

Dry type

dual element

w/pre

Gast

Pneumatic

Motor

Baldor

Electric

Motor, 1 ph

208/230V

@90 PSI

60 cy/AC

Amp Rating

Accessories Item No.

Tie Down Kit 167189

Outer Flange

Replacement Blade Wrench 163988

Water Tank Kit

(1/2" cutting width)

(Standard s aw)

167963

174957

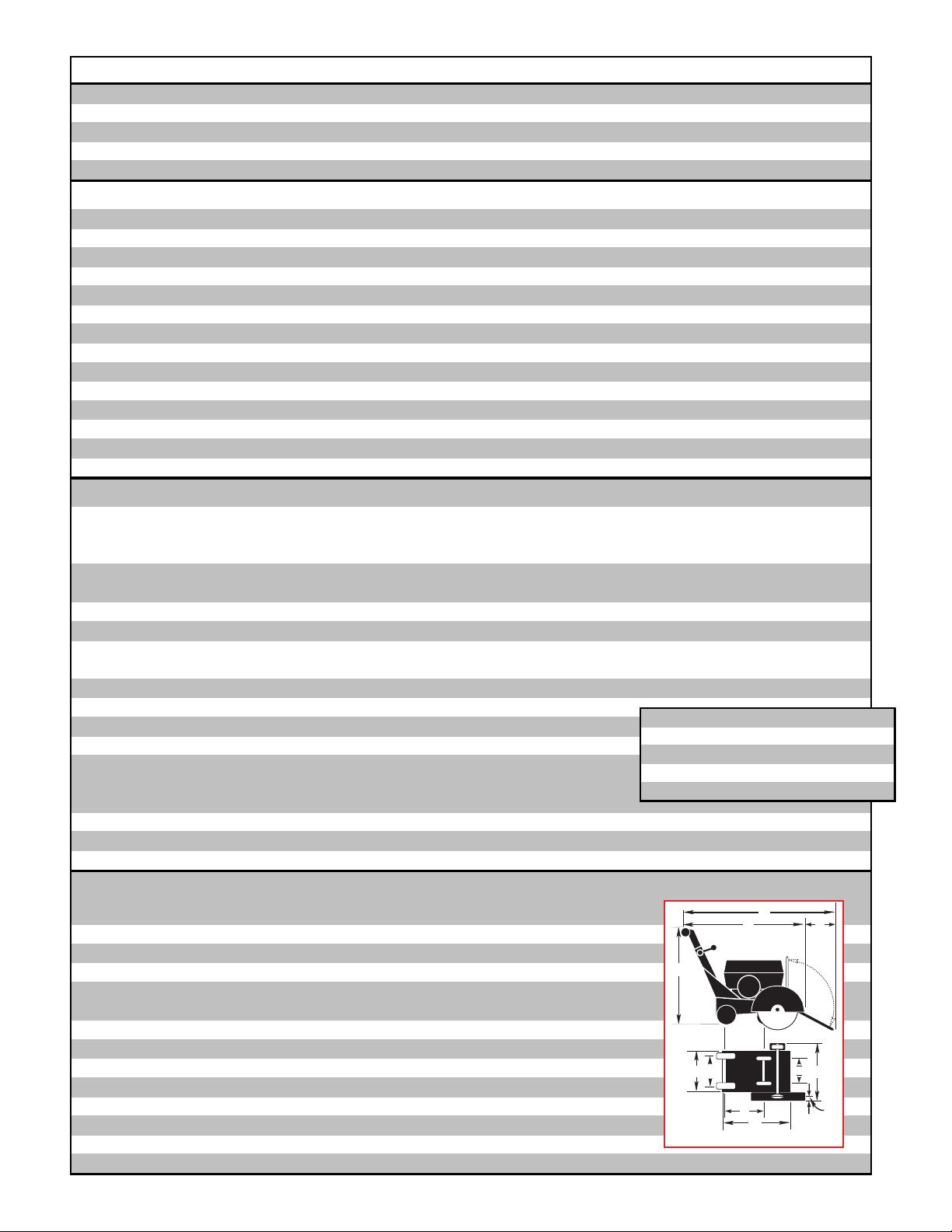

SAW DIMENSIONS: Inches (mm)

Crated Dimensions: L-35" x H-30-1/2" x W-22" (889 x 775 x 559mm)

Inches

A - Height (Max.) - In. (mm) 47-1/2 (1207)

B - Saw Length, Pointer Up 45-1/2 (1156)

C - Max. Saw Length,

Pointer 64-1/4 (1632)

E - Pointer Extension 18-3/4 (476)

F - Frame Width 16 (406)

G - Frame Length 22-1/2 (572)

H - Saw Width 22 (559)

I - Front Axle Length 10-1/4 (260)

J - Rear Wheel Track 19-1/2 (495)

K - Blade to Wall 2-3/8 (61)

L - Wheel Base Length

15

Specifications are subject to change without notice.

Metric (mm)

(381)

C

B

A

J

F

L

G

E

I

H

K

9

Page 10

SAFETY FIRST!

WARNINGS

DO’s and DO NOT’s

WARNING: FAILURE TO COMPLY WITH THESE WARNINGS AND OPERATING

INSTRUCTIONS COULD RESULT IN DEATH OR SERIOUS BODILY INJURY.

DO

DO read this entire operator’s manual before operating this machine. Understand all warnings, instructions, and controls.

DO keep all guards in place and in good condition.

DO wear safety approved hearing, eye, head and respiratory protection.

DO read and understand all warnings and instructions on the machine.

DO read and understand the symbol definitions contained in this manual.

DO keep all parts of your body away from the blade and all other moving parts.

DO know how to stop the machine quickly in case of emergency.

DO turn the “ON/OFF” switch to the “OFF” position prior to connecting the electric powered model to the power source.

DO inspect the blade, flanges and shafts for damage before installing the blade.

DO use the blade flange size shown for each blade size.

DO use only steel center diamond blades manufactured for use on concrete saws.

DO use only reinforced abrasive blades or steel center diamond blades manufactured for use on concrete saws.

DO use only the blade flanges supplied with the saw. Never use damaged or worn blade flanges.

DO use only blades marked with a maximum operating speed greater than the blade shaft speed. Verify speed by checking blade

shaft rpm and pulley diameters.

DO verify saw drive configuration by checking blade shaft RPM, pulley diameters, and blade flange diameter.

DO read all safety materials and instructions that accompany any blade used with this machine.

DO inspect each blade carefully before using it. If there are any signs of damage or unusual wear, DO NOT USE THE BLADE.

DO mount the blade solidly and firmly. Wrench tighten the arbor nut.

DO make sure the blade and flanges are clean and free of dirt and debris before mounting the blade on the saw.

DO use the correct blade for the type of work being done. Check with blade manufacturer if you do not know if blade is correct.

DO use caution and follow the instructions when loading and unloading the machine.

DO operate this machine only in well ventilated areas.

DO instruct bystanders on where to stand while the machine is in operation.

DO establish a training program for all operators of this machine.

DO clear the work area of unnecessary people. Never allow anyone to stand in front of or behind the blade while the engine is

running.

DO make sure the blade is not contacting anything before starting the engine.

DO use caution when lifting and transporting this machine.

DO always tie down the machine when transporting.

DO use caution and follow instructions when setting up or transporting the machine.

DO have all service performed by competent service personnel.

DO make sure electric powered machines are plugged into a properly grounded circuit.

DO make sure power cords are the proper size and in good condition.

DO verify the blade arbor hole matches the machine spindle before mounting the blade

DO always check for buried electrical cables before sawing. If unsure, contact the local utilities.

DO clean the machine after each day’s use.

DO follow all electrical codes in your area.

DO consider work area environment. Don’t expose power tools to rain. Don’t use power tools in wet locations.

DO use caution to guard against electric shock. Prevent body contact with grounded surfaces (i.e., pipes, radiators, ranges,

refrigerators).

DO use correct voltage and proper extension cords. Never carry tool by cord or yank it to disconnect it from receptacle. Keep cord

away from heat, oil and sharp edges.

DO always transport the machine with the motor stopped.

DO keep the handles dry, clean and free of oil and dirt.

DO disconnect tools from power source when not in use, before servicing and when changing accessories.

DO carefully maintain and clean for better and safer performance. Follow instructions for changing accessories. Inspect tool cords

periodically and, if damaged, have repaired by authorized service facility.

DO always give a copy of this manual to the equipment user. If you need extra copies, call TOLL FREE 1-800-288-5040.

10

Page 11

SAFETY FIRST!

WARNINGS

DO’s and DO NOT’s

WARNING: FAILURE TO COMPLY WITH THESE WARNINGS AND OPERATING

INSTRUCTIONS COULD RESULT IN DEATH OR SERIOUS BODILY INJURY.

DO NOT

DO NOT operate this machine unless you have read and understood this operator’s manual.

DO NOT operate this machine without the blade guard, or other protective guards in place.

DO NOT stand behind or in front of the blade path while the engine/motor is running.

DO NOT leave this machine unattended while the engine/motor is running.

DO NOT work on this machine while the engine/motor is running.

DO NOT operate this machine when you are tired or fatigued.

DO NOT use a wet blade without adequate water supply to the blade.

DO NOT exceed maximum blade speed shown for each blade size. Excessive speed could result in blade breakage.

DO NOT operate the machine if you are uncertain of how to run the machine.

DO NOT use damaged equipment or blades.

DO NOT touch or try to stop a moving blade with your hand.

DO NOT cock, jam, wedge or twist the blade in a cut.

DO NOT transport a cutting machine with the blade mounted on the machine.

DO NOT use a blade that has been dropped or damaged.

DO NOT use carbide tipped blades.

DO NOT touch a dry cutting diamond blade immediately after use. These blades require several minutes to cool after each cut.

DO NOT use damaged or worn blade flanges.

DO NOT allow other persons to be near the machine when starting, refueling, or when the machine is in operation.

DO NOT operate this machine in an enclosed area unless it is properly vented.

DO NOT operate this machine in the vicinity of anything that is flammable. Sparks could cause a fire or an explosion.

DO NOT allow blade exposure from the guard to be more than 180 degrees.

DO NOT operate this machine with the belt guard or blade guard removed.

DO NOT operate this machine unless you are specifically trained to do so.

DO NOT use a blade that has been over heated. (Core has a bluish color.)

DO NOT jam material into the blade.

DO NOT grind on the side of the blade.

DO NOT lay power cords in or near the water.

DO NOT tow this machine behind a vehicle.

DO NOT replace the motor with any motor that does not have a special grounding connection.

DO NOT operate this machine while under the influence of drugs or alcohol.

*****************

This saw was designed for certain applications only. DO NOT modify this saw or use for any application other than for

which it was designed. If you have any questions relative to its application, DO NOT use the saw until you have written

Diamant Boart, Inc. and we have advised you.

Diamant Boart, Inc.

17400 West 119th Street

Olathe, Kansas 66061

USA

11

Page 12

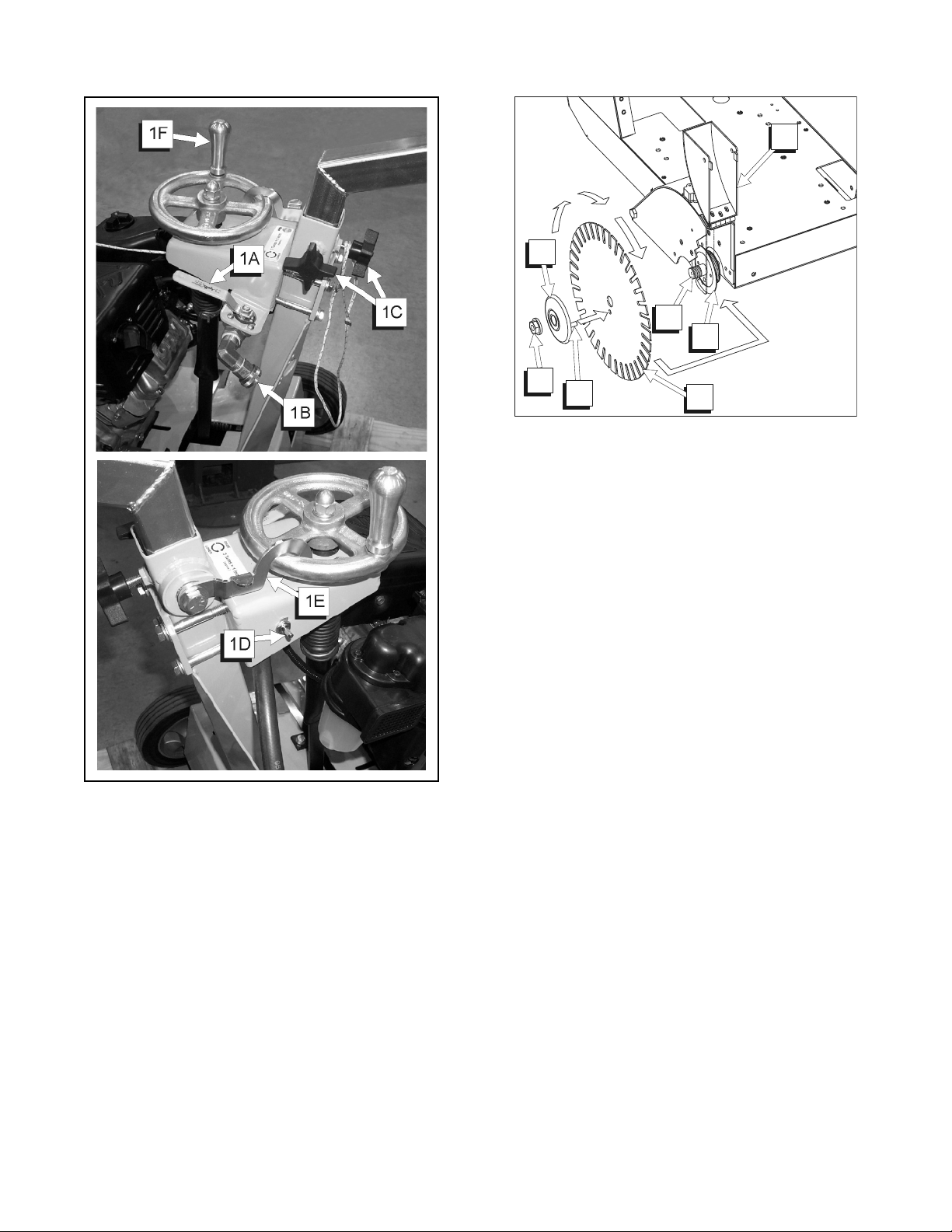

FIGURE 1

FIGURE 2

2H

2B

2 I

2F

2A

2D

2A. BLADE SHAFT NUT: Use to tighten the outer flange

against the diamond blade.

2E

1A. WATER VALVE: Use to control the water supply to

the diamond blade.

1B. WATER INLET: Connect water hose at this garden

hose connection.

1C. HANDLE ADJUSTMENT KNOBS: Use to adjust

handle height.

1D. ENGINE STOP SWITCH: Stop Switch: Push down

to stop engine.

2B. OUTER FLANGE: Use to hold the diamond blade in

position.

2C. NOT USED

2D. LOCKING PIN: Use to prevent the diamond blade

from rotating on the shaft during operation.

2E. DIAMOND BLADE: Use as the cutting tool for

concrete and asphalt surfaces.

2F. INNER FLANGE: Inside support used to hold the dia-

mond blade in position.

2G. NOT USED

2H. BLADE GUARD FRONT: The front section of the

blade guard.

2I. BLADE SHAFT: Supports the blade flanges and blade.

1E. DEPTH CONTROL LOCK: Use to lock the position

of the Depth Control Hand Wheel.

1F. DEPTH CONTROL HAND WHEEL: Controls

lowering and raising of the blade into and out of the

12

Page 13

PRE OPERATION CHECKLIST

Before leaving our factory, every machine is thoroughly tested. Follow our instructions strictly and

your machine will give you long service in normal operating conditions.

Before starting up the machine, make sure you read this entire operations manual and are familiar

with the operation of the machine.

WITH MACHINE COLD AND SETTING LEVEL:

1. Check engine oil. Fill to full mark on dip stick with 10W30 oil. DO NOT OVERFILL!!

• Gas Models: Class MS, SD, SE or better.

2. Electric Models: Verify all electrical connections are intact.

1 - 2 HOUR OPERATION CHECK:

ALWAYS park machine on a level surface with the engine “OFF” and the engine switch set in the

“OFF” position before performing any maintenance. Let the machine cool down!!

1. Tension the blade drive V-belts. DO NOT over tension!!

SCHEDULED MAINTENANCE QUICK REFERENCE:

Before performing any maintenance, ALWAYS park the machine on a level surface with the engine

“OFF” and the engine switch set in the “OFF” position.

SERVICE DAILY:

1. Check engine oil level.

2. Check blade guard for damage.

3. Check engine air filter, replace if dirty.

4. Lubricate bladeshaft bearings.

5. Lubricate front wheel bearings.

6. Check blade drive V-belt tension. DO NOT over

tension!!! Change in sets only!

SERVICE EVERY 50 HOURS:

1. Replace engine oil and filter.

2. Clean engine/motor air fins.

3. Lubricate depth control adjustment screw. (Screw

Feed version only.)

4. Check wheels for wear or damage.

NOTE: See engine manual for specific engine maintenance

for your specific model.

13

Page 14

MANDATORY

INDICATION

INFORMATION

INSTRUCTION

2 Assembly

• The Handle must be attached. Place Handle

in position and securely tighten Knobs.

WARNING

These signs will give

advice for your safety

Before leaving our factory every machine is

thoroughly tested.

Follow our instructions strictly and your machine will

give you long service in normal operating conditions.

PROHIBITION

1 Features

Use: Wet sawing of old and new concrete and asphalt.

Tools: Diamond blades — water cooled, Ø: 10", 12", 14",

18" and 20" with Arbor Ø - 1"

(For information, contact your Target supplier)

CUTTING DEPTHS

MAXIMUM MC18

BLADE SIZE BLADE DEPTH MAXIMUM DEPTH

(To Collar) (To Depth Stop)

10" (250mm) 2 3/4" (68mm) 2 1/2" (62mm)

12" (300mm) 3-3/4" (93mm) 3-1/2" (87mm)

14" (350mm) 4-3/4" (118mm) 4-1/2" (112mm)

18" (450mm) 6-3/4" (164mm) 6-1/2" (158mm)

• Check the engine oil level. Service before using. Refer

to the engine operation manual for detailed information.

3

• The Front Pointer must be checked for alignment with

• For WET SAWING, be sure the water jets in the blade

General Instructions

Remove the Blade (2E) before transport.

WARNING: DO NOT operate without the proper

blade guard over the Blade! (2E)

WARNING: DO NOT operate the saw with the

front of the Blade Guard (2H) raised!

WARNING: Blade exposure CANNOT exceed

180 degrees when operating!

the Blade (2E). It must be in line with the Blade (2E)

mounted on the Blade Shaft (2I).

guard water tubes are open and that each side of the

Blade (2E) has an adequate supply of water. Test the

water supply for pressure and quantity (flow) before

starting to saw.

Before starting up the machine, make sure you

read this entire manual and are

familiar with the operation of this

machine.

The working area must be completely clear,

well lit and all safety hazards removed.

The operator must wear

protective clothing

appropriate to the work he

is doing.

Any persons not involved in the work, should

leave the area.

Use only blades marked with a maximum

operating speed greater than the bladeshaft

speed.

WATER FLOW from 2-1/2 to 5 gallons of water

per minute MUST flow over the blade to

properly cool it and to get maximum blade

life. DO NOT use conventional (wet) diamond

blades without water!

• Saw only as deep as the specifications and job

conditions require. Sawing excessively deep is

wasteful–avoid it! Step cut in increments of 2 inches

(50 mm) for best results.

• Saw in a straight line. Mark the cutting line clearly so

the saw operator can follow the line without difficulty.

The saw should NOT be twisted from side to side trying to force the blade back on the line.

14

Page 15

4

FUEL: Check the engine maintenance manual.

• Check that the engine oil level is correct. Because the

Check Before Starting

Take into account the working conditions from

the health and safety point of view.

* Gas Models: Unleaded gasoline is recommended.

engine often operates at an angle, check the oil level

(with engine horizontal) frequently to ensure that the

oil level never falls below the lower mark on the

dipstick. 10W30 oil is recommended.

6 Starting The Power Source

Always pay extreme care and attention to the

preparation of the machine before starting.

Remove all wrenches and tools from the floor

and the machine.

Always keep blade guard and transmission

guard in place.

On Gasoline Engine Models:

1. Refer to the engine operating manual for proper engine

operation.

2. Fill the engine fuel tank and check the engine oil level.

Refer to the engine manual for detailed information.

5 Fitting The Blade

(See Fig. 1 and 2)

Always set the Engine Switch (1D) to the "OFF"

position before mounting the Blade (2E).

• Set the Engine Switch (1D) to the "OFF" position.

• Raise the machine to a high position [by cranking the

Raise/Lower Hand Wheel] or [by loosening and tightening

the E-Z Tilt Handle].

• Raise the front half of the Blade Guard (2H).

• Unscrew the Blade Shaft Nut (2A). Remove Outer

Flange (2B).

• Fit Diamond Blade (2E) on the Blade Shaft Arbor.

• Install Outer Flange (2B) into the Blade Shaft (2I)

making sure that the Locking Pin (2D) passes through the

Diamond Blade (2E) and into the Inner Flange (2F).

Note the direction of rotation of the blade. The

direction of rotation is shown by an arrow on

the Diamond Blade (2E). Make sure that the

contact surfaces on the Diamond Blade (2E),

Inner & Outer Flanges (2B & 2F) and Blade

Arbor are clean.

• Rotate Outer Flange (2B) and the Blade (2E) in the

opposite direction of blade rotation to remove backlash.

• Install and tighten Blade Flange Nut using the Blade Shaft

Wrench [50 lb.-ft. (68 N-m)] while firmly holding the

Diamond Blade (2E).

• Lower front half of Blade Guard (2H).

The Blade Shaft Nut (2A) on the Right Hand

side has Left Hand threads.

3. Start the engine. Refer to the engine manual for detailed information.

4. Let the engine warm up at half throttle. All sawing is

done at full throttle. The governor is factory set for the

correct engine speed. Do not change the Governor

setting – it is factory set for the correct speed.

WARNING: To STOP ENGINE, PUSH the Engine

Stop Switch DOWN, located on the handle

support of the saw. [Wait for all engine

movement to stop.]

On Air Models:

1. Connect the saw to an adequate air supply of 175 CFM

@ 100 PSI (120 CFM @ 90 PSI per minute).

2. Check the lubricator (located in the air manifold unit) for

the proper oil level. If you need oil, unscrew the plug and

fill with an SAE #10 Wt. detergent automotive engine oil.

The oil should always be visible in the sight glass. Do not

overfill.

3. Open the air valve located in the air manifold unit. The air

motor should be free wheeling. The lubricator should be

adjusted to feed 4 drops per minute. Monitor the drip rate

through the sight-feed dome. Turn the adjustment screw

counterclockwise to increase the drip rate and clockwise

to decrease it.

On Electric Models:

1. Single phase concrete saws are furnished with the

correct approved NEMA configuration plug on the motor

pigtail. It will be necessary to provide a matching NEMA

configuration receptacle on the extension cord into which

the motor is connected. For example: a 5 HP saw set for

230 volts operation is supplied with a NEMA #L6-30P plug

on the pigtail. The extension cord will require an L6-30R

to make the proper connection.

15

Page 16

WARNINGS!!!

Test for adequate water supply [2-1/2 to 5 gal/

min (10 to 20 lit./min)]. Low water flow will cause

damage to diamond blades.

DO turn the “ON/OFF” switch to the “OFF” position prior

to connecting the machine to the power source.

DO make sure electric powered machines are plugged

into a properly grounded circuit.

DO make sure power cords are the proper size and in

good condition.

DO follow all electrical codes in your area.

DO use correct voltage and proper extension cords.

Never carry tool by cord or yank it to disconnect it

from receptacle. Keep cord away from heat, oil and

sharp edges.

DO disconnect tools from power source when not in use,

before servicing and when changing accessories.

DO carefully maintain and clean for better and safer

performance. Follow instructions for changing

accessories. Inspect tool cords periodically and, if

damaged, have repaired by authorized service

facility.

DO NOT lay power cords in or near the water.

DO NOT leave this machine unattended with the motor

running.

DO NOT replace the motor with any motor that does not have

a special grounding connection.

2. Electric motors of any make can burn out when the voltage

supply falls 10% below the voltage rating of the motor. Use

proper heavy duty fuses in the circuit. Use No. 8 wire for

extension cord lengths up to 100 ft. long. Under-sized

wires can cause motor burnout. Check the voltage at the

motor when the saw is cutting.

3. Single phase concrete saw motors are equipped with

manual reset overloads. When the overload trips, turn the

switch to the OFF position. Allow the motor to cool 5 to

10 minutes, then push the reset button. A click indicates

reset.

7

• Set the handle bar height to a comfortable position.

• Raise the Blade (2E) as high as possible so that the

8

To Maneuver the Saw

Blade (2E) will not strike pavement when maneuvering.

To Start Sawing

If water supply is interrupted, stop cutting

immediately.

Screw Feed Version:

• Lower the blade into the cut by pulling up on the Depth

Control Lock (1E) and slowly turning the Hand Wheel

COUNTER-CLOCKWISE. When the desired depth

of cut is reached, push Depth Control Lock down to

lock it in the hand wheel.

E-Z Tilt Version:

• The blade on this saw may be lowered into the

concrete by loosening the lock handle and pushing

forward on the handle bar. The weight of the saw will

assist when lowering the blade. The blade is held at

the desired depth by tightening the lock handle on the

lock bar.

• During cutting, DO NOT exert excessive side pressure on the Handle Bars to attempt to “STEER” the

saw. Use only enough pressure to follow the previously marked line.

• If the saw should stall for any reason, (close the air

valve on the air models and turn the power switch off

on the electric models) raise the blade completely out

of the cut before starting your power source again!

• When lowering the Blade (2E) into a partially made

cut, the blade must be perfectly aligned within the cut

before starting to saw again. DO NOT FORCE the

Blade (2E) into the material by lowering the Blade too

fast, or by propelling the saw too fast.

9 Stopping the Saw

• Screw Feed Version:

Raise the blade out of the cut by pulling up on the

depth control lock and slowly turning the hand wheel

clockwise. Raise the blade (2E) high enough out of

the cut to clear the pavement when maneuvering the

saw.

• E-Z Tilt Version:

Raise the blade out of the cut by loosening the lock

handle and pulling back on the handle bar. Raise the

blade (2E) high enough out of the cut to clear the

pavement when maneuvering the saw when tightening

the lock handle.

• Follow all of the instructions outlined above.

• Open the Water Valve (1A) FULL open. Check the

water to verify full flow, then adjust for proper amount

of water on the blade BEFORE you lower the Blade.

16

• Turn off the Water Valve (1A).

• Turn the Engine Throttle to the IDLE position.

• STOP the engine by turning the Engine Switch (1D) to

the OFF position.

Page 17

10 Maintenance

Before performing any maintenance, ALWAYS

park the machine on a level surface with the

Engine OFF and the Engine Switch in the "OFF"

position.

After each use: CLEAN the machine.

LUBRICATION:

LUBRICATE DAILY

Front Wheels and Blade Shaft Bearings

BLADE SHAFT V-BELTS:

This concrete saw is equipped with “3VX” premium V-belts.

These belts are properly tensioned at the factory. Severe

damage or breakage of the crankshaft can occur if the belts

are tensioned too tightly. Check the belt tension as set on

the new saw and NEVER set belts beyond the original tension.

Not enough tension will destroy the belts quickly, and the

belts should NEVER be allowed to slip. After one (1) hour of

use, retension the belts to make up for initial stretch. A

V-belt tension tester should be used to obtain accurate V-belt

tension settings. Check the setting in a SINGLE belt of a set

of V-belts. Apply the load at the center of the belt span.

Deflection should be 3/16" (5mm) with a 5 to 6 lb. (2.3 to 2.7

kg.) load. Replace the belts in sets only.

LUBRICATE EVERY 50 HOURS

Depth Control Adjustment Screw (Screw Feed Version Only)

NOTE: When cutting dry, lubricate blade shaft bearings 2

or 3 times daily, the grease provides an added protective

seal for the bearings. Use only a Premium Lithium 12

based Grease, conforming to NLG1 Grade #2 Consistency,

without Molybdenum Disulfide.

ENGINE OIL:

Check daily. Keep the oil clean and at the proper level.

10W30 MS, SD, SE or better is generally recommended.

Capacity levels indicated on page 10. DO NOT OVER-

FILL!! Change engine oil and oil filter every 50 HOURS of

operation. Refer to the engine manual for detailed information.

CLEAN ENGINE AIR FILTER:

Clean the air filter 2 or 3 times daily when dry cutting. Refer

to the engine manual for detailed information.

ENGINE CARE:

Refer to the engine manual for detailed information.

A. On Air Models:

A filter with a lubricator and a shut-off valve has been

provided on the saw. Lubrication of the air motor is

required. Lubrication is necessary for all internal

moving parts and rust prevention. The filter removes

excessive moisture in the air line that can cause rust

formation in the motor and might also cause ice to form

in the muffler due to expansion of air thru the motor.

The filter has a manual drain and must be drained as

frequently as necessary to keep the liquid level in the

bowl below the baffle. If the liquid level rises above the

baffle, liquid will be carried into the air motor.

B. On Electric Models:

Check the extension wire size. Under-sized wires can

cause motor burn out. Use No. 8 wire for extension

cord lengths up to 100 ft. long

11 Optional and Accessory (Field Installed)

SPECIAL OUTER FLANGE ASSY 1/2" (12.7mm)

WIDE CUT (P/N 167963)

• A Special Outer Flange Assembly is available as a field

installed accessory. It enables the MC 18 to cut

7/16" - 1/2" (11-12.7mm) wide.

WARNING: This special outer flange assembly

is for use with blade width stacks of 7/16" 1/2" (11mm-12.7mm) only! If blade width stacks

of less than 7/16" (11mm) are required, use the

standard outer flange assembly supplied with

the MC 18. The Special Outer Flange Assembly

can be identified by the COUNTERBORE on the

“Nut Side” of the flange. The Standard Outer

Flange Assembly has NO COUNTERBORE.

WATER TANK KIT

• A 6 gallon (23 liter) Water Tank Kit is available as a

Field installed accessory. Use only for dry cutting!

The water tank is designed only to suppress airborne

concrete dust.

WARNING: DO NOT use conventional (wet)

diamond blades with the water tank as the

water source, because there is not sufficient

water flow available to properly cool the blades!

TIE DOWN BRACKET KIT (P/N 167189)

• A Tie Down Bracket Kit is available as a field installed

accessory. The kit consists of two (2) tie down loops

that are installed at the front of the frame. They are to

be used only to SECURE the saw to a truck or trailer

during transport.

WARNING: DO NOT use the tie down

brackets as a device for lifting the saw!

17

Page 18

12 Governor Speed

13 Repairs

It is critical that the Governor and throttle on all internal

combustion engines be adjusted properly. The engine speed

is preset at the factory for the proper sawing speed. It is

NOT normally necessary to change this setting. It should be

periodically verified after the saw is placed into service. To

change the Governor setting, refer to the engine manual.

WARNING: Overspeeding the blade can result

in blade breakage and/or personal injury to the

operator and bystanders!! To assure the proper

Governor adjustment, determine the correct

blade shaft speed from the following chart.

Follow the engine manufacturer’s instruction

procedure for Governor and throttle setting.

NO LOAD BLADE SHAFT AND ENGINE R.P.M.s

BLADE SHAFT ENGINE

MODEL R.P.M. R.P.M.

5 AIR MOTOR 14"/18" 1800 2500

5E, 1PH-14"/18" 2505 3450

9R 14"/18" 2570 4000

9H 14"/18" 2610 3600

13.5R-14"/18" 2610 3600

13H-14"/18" 2610 3600

We carry out all repairs in the shortest possible time and at

the most economical prices. (See front page for our address

and phone numbers.)

14 Service Parts

For quick supply of spare parts and to avoid any lost time, it

is essential to quote the data on the manufacturer’s plate

fixed to the machine and the part number (s) to be replaced

with every order.

Write the Model Number & Serial Number here for future

reference:

Model Number:____________________

Serial Number:____________________

18

The instructions for use and spare parts found in this document are for

information only and are not binding. As part of our product quality

improvement policy, we reserve the right to make any and all technical

modifications without prior notice.

The manufacturer accepts no

responsibility caused by unsuitable

use or modifications

Page 19

NOTE:

NOTA:

19

Page 20

Diagram 1 – Frame & Axle

20

Page 21

Diagram 1 – Frame & Axle (Rev July 11, 2002)

BILL OF MATERIAL

INDEX P/N DESCRIPTION QTY

1 174939 Frame Weldment, MC18 1

2 174942 Axle, Front 1

3 174975 Axle, Pivot 1

4 020768 Washer, Flat .75 SAE 4

5 040091 Wheel Assy, 5 Inch Dia 2

6 041160 Lock Collar, .750 ID (w/ss) 2

7 020551 Screw, Set Soc Cup Pt .312-18UNC x .25 1

8 020767 Washer, Flat .625 SAE 4

9 139569 Wheel, 8 Inch Dia 2

10 049923 Lock Collar, .625 w/SS 3

11 020551 Screw, Set Soc Cup Pt .312-18UNC x .25 1

12 139638 Anchor, Spring 1

13 020323 Capscrew, Hex Hd .375-16UNC x 1.00 2

14 020199 Locknut, Fiber .375-16UNC 2

15 139582 Bolt, Tension 1

16 020140 Nut, Std Hex .500-13UNC 1

17 020766 Washer, Flat .500 SAE 1

18 020201 Locknut, Fiber .500-13UNC 1

19 139581 Spring 2

21 174946 Handle, Bent 1

22 139568 Grip, Handle 2

23 177557 Knob, 3/8-16UNC-2A x 1.00 2

24 163988 Wrench, 1-1/16" Open End 1

25 197170 Wing Bolt, M6 x 1.0 x 16 mm 1

21

Page 22

Diagram 2 – Depth Control (Screw Feed)

22

Page 23

Diagram 2 – Depth Control (Screw Feed)

BILL OF MATERIAL

INDEX P/N DESCRIPTION QTY

1 174997 Adj Nut Wldmnt w/ Grease Fit 1

2 049924 Fitting, Grease 1/8 NPT x 90° 1

3 177915 Screw, Adj., .625-8 ACME 1

4 040141 Bearing, Flange, .50 Inch ID 1

5 174944 Bracket, Screw Feed 1

6 020764 Washer, Flat .375 SAE 4

7 020786 Lockwasher, Split .375 4

8 020330 Capscrew, Hex Hd .375-16UNC x 3.00 4

9 040153 Assy, Hand Wheel 1

10 040151 Wheel, Hand - Machined 1

11 032250 Handle Assy, Revolving 1

12 020766 Washer, Flat .500 SAE 2

13 174956 Bracket, Stop 1

14 020552 Screw, Set Soc Cup Pt .312-18UNC x .50 1

15 174994 Spacer, Adjustment Screw 1

16 160164 Pin, Clevis .50 Dia x 1.13 Lg 1

17 020540 Screw, Set Soc Cup Pt .250-20UNC x .25 1

18 177239 Pin, Rue Ring - .50 DIA 1

19 040183 Rubber Boot, 3 Inch (20 ribs) 1

20 174961 Hose Clamp, Worm Drive SAE 24 Narrow 2

21 020010 Key, Woodruff #405 1

22 020012 Bolt, Carriage .250-20UNC x 1.00 2

23 020762 Washer, Flat .250 SAE 2

24 020195 Locknut, Fiber .250-20UNC 2

25 020788 Lockwasher, Split .500 1

26 030210 Nut, Acorn LT .500-13UNC 1

27 020668 Capscrew, Hex Hd .500-13UNC x .75 1

28 174998 Decal, Screw Feed 1

23

Page 24

Diagram 3 – Depth Control (Lock Bar)

24

Page 25

Diagram 3 – Depth Control (Lock Bar)

BILL OF MATERIAL

INDEX P/N DESCRIPTION QTY

1 139560 Bar, Lock 1

2 049513 Washer, Friction .531 ID 2

3 139562 Washer 2

4 139556 Stud, Depth Control 1

5 174679 Lever, Adjustment 1

6 160164 Pin, Clevis .50 Dia x 1.13 Lg 1

7 020540 Screw, Set Soc Cup Pt .250-20UNC x .25 1

8 177239 Pin, Rue Ring - .50 DIA 1

9 139626 Pointer, Depth 1

10 020461 Screw, Mach Ph Hd #10-24UNC x .875 1

11 020194 Locknut, Fiber #10-24UNC 1

12 139633 Decal, Depth of Cut 1

13 020552 Screw, Set Soc Cup Pt .312-18UNC x .50 1

14 196000 Bracket, Switch 1

15 020740 Washer, Flat .188 Dia 2

16 020782 Lockwasher, Split #10 2

17 196034 Screw, Rd Hd Mach 10-24 x .625 Cross Z/P 2

25

Page 26

Diagram 4 – Pointer & Belt Guard

26

Page 27

Diagram 4 – Pointer & Belt Guard

BILL OF MATERIAL

INDEX P/N DESCRIPTION QTY

1 174328 Guard, Shaft - Weldment 1

2 020785 Lockwasher, Split .313 2

3 020399 Capscrew, Hex Hd .312-18UNC x 3.25 2

4 174977 Bracket, Pointer Mount 1

5 167908 Bar, Pointer - Offset 1

6 167906 Bar, Pointer - Straight 1

7 041231 Rod, Pointer 1

8 041220 Wheel, 3in Dia 1

9 020786 Lockwasher, Split .375 1

10 020136 Nut, Std Hex .375-16UNC 1

11 020199 Locknut, Fiber .375-16UNC 1

12 172137 Rope, Pointer 1

13 162761 Clamp 2

14 020395 Capscrew, Soc Hd .250-20UNC x .625 2

15 020195 Locknut, Fiber .250-20UNC 2

16 139749 Capscrew, Hex Hd M10 x 1.50 x 25mm 4

17 139748 Locknut, Fiber M10 x 1.50 4

18 040550 Hinge Block, Pointer 1

19 020786 Lockwasher, Split .375 1

20 020323 Capscrew, Hex Hd .375-16UNC x 1.00 1

21 177696 Draw Bolt, 3/8-16UNC 1

22 020199 Locknut, Fiber .375-16UNC 1

27

Page 28

Diagram 5 – Guards & Water Distribution

28

Page 29

Diagram 5 – Guards & Water Distribution

BILL OF MATERIAL

INDEX P/N DESCRIPTION QTY

1 174953 Guard, Belt 1

2 020785 Lockwasher, Split .313 4

3 020313 Capscrew, Hex Hd .312-18UNC x .75 4

4 174992 Water Valve Assy, MC18 1

5 139021 Water Valve 1

6 169196 Elbow, 1/2NPT Male x 90° Brass 1

7 040270 Hose Adapter 1

8 045640 Filter Washer 1

9 040254 Washer, Hose 1

10 139616 Hose Assy, Water - MC18 1

11 020782 Lockwasher, Split #10 2

12 196039 Screw, Rd Hd Mach 10-24 x .500 Cross Z/P 2

13 196042 Assy, Blade Guard - 18in Tgt Blue 1

14 020743 Washer, Flat .375 Dia 1

15 020233 Capscrew, Hex Hd .375-16UNC x 3.75 1

16 020199 Locknut, Fiber .375-16UNC 1

17 020742 Washer, Flat .313 Dia 1

18 020785 Lockwasher, Split .313 1

19 020313 Capscrew, Hex Hd .312-18UNC x .75 1

29

Page 30

Diagram 6 – Blade Guard

30

Page 31

Diagram 6 – Blade Guard (Rev July 11, 2002)

BILL OF MATERIAL

INDEX P/N DESCRIPTION QTY

1 ------ Rear Guard Weldment - 18 Inch 1

2 139075 Hinge (Note A) 1

2A 195127 Hinge (Note A) 1

3 139596 Front Guard Weldment, 18 Inch (Note A) 1

3A 195120 Front Guard Weldment, 18 Inch (Note A) 1

4 020762 Washer, Flat .250 SAE (Note A) 6

4A 173059 Washer, Flat M8 (Note A) 6

5 139761 Capscrew, Hex Hd M6 x 1.0 x 20mm (Note A) 6

5A 167478 Capscrew, Hex Hd M8 x 1.25 x 25mm (Note A) 6

6 139745 Locknut, Fiber M6 x 1.0 (Note A) 6

6A 139738 Locknut, Fiber M8 x 1.25 (Note A) 6

7 139098 Splash Flap 1

8 167761 Capscrew, Hex Hd M5 x 0.8 x 20mm 4

9 173047 Washer, Flat M5 2

10 172316 Locknut, Fiber M5 x 0.8 2

11 020782 Lockwasher, Split #10 2

12 172011 Nut, Hex Hd M5 x 0.80 4

13 040330 Spring, .375 OD x .054 Dia 1

14 049212 Clamp, Water Tube 2

15 167818 Capscrew, Slot Flat Hd M6 x 1.0 x 16mm 4

16 139745 Locknut, Fiber M6 x 1.0 8

17 167046 Water Tube, 18 Inch 2

18 020864 Plug, Soc Hd 1/8 NPT Brass 2

19 139051 Gasket, Water Manifold 1

20 139045 Water Manifold, Machined 1

21 040275 Adapter, 3/8 NPT x Male Garden Hose 1

22 167551 Capscrew, Hex Hd M6 x 1.0 x 40mm 4

NOTE A:

For P/N 195127 Hinge (1/4” Thick) use P/N 195120 Front Guard Weldment – 18”

and use hardware (Item 4A, 5A & 6A).

For P/N 139075 Hinge (1/8” Thick) use P/N 139596 Front Guard Weldment – 18”

and use hardware (Item 4, 5 & 6).

31

Page 32

Diagram 7 – Engine & Bladeshaft

32

Page 33

Diagram 7 – Engine & Bladeshaft

BILL OF MATERIAL

INDEX P/N DESCRIPTION QTY

1 174973 Group, Bladeshaft R&L 4.5 (9H,13H,13R) 1

- 196003 Group, Bladeshaft R&L 4.5 (9R Only) 1

2 177569 Bladeshaft Assy, Complete (9H,13H,13R) 1

- 196004 Bladeshaft Assy, Complete (9R Only) 1

3 167185 Collar, Inner 4.50 OD 2

4 167962 Collar, Outer 4.50 OD Assy 1

5 167964 Pin, Drive 1

6 167846 Nut, LH Thread, Bladeshaft 1

7 167847 Nut, RH Thread, Bladeshaft 1

8 020067 Key, Square .250 x 1.25 Lg 1

9 139300 Pulley Assy, 3GR 3V 3.65 (9H,13H,13R) 1

- 196005 Pulley Assy, 3GR 3V 4.12 (9R Only) 1

10 020541 Screw, Set Soc Cup Pt .250-20UNC x .375 4

11 162633 Bearing, 1in Pillowblock BB 2

12 174962 Spacer, Bearing 2

13 020743 Washer, Flat .375 Dia 8

14 020330 Capscrew, Hex Hd .375-16UNC x 3.00 4

15 020199 Locknut, Fiber .375-16UNC 4

16 177958 Engine, 13HP Honda - Modified 1

-- 196010 Engine, 13HP Robin - Modified 1

-- 167751 Engine, 9HP Honda - Modified 1

-- 196008 Engine, 9HP Robin - Modified 1

17 174962 Spacer, Bearing (9R,13R,13H) 2

18 174736 Plate, Adapter (13H Only) 2

19 020743 Washer, Flat .375 Dia 8

20 020786 Lockwasher, Split .375 (13H Only) 7

21 020377 Capscrew, Hex Hd .375-16UNC x 1.50 (13H) 4

-- 020380 Capscrew, Hex Hd .375-16UNC x 1.75 (9H) 4

-- 020509 Capscrew, Hex Hd .375-16UNC x 2.00 (9R,13R) 4

22 020322 Capscrew, Hex Hd .375-16UNC x .75 (13H) 3

23 048740 Capscrew, Hex Hd .375-16UNC x 1.25 (13H) 1

24 020199 Locknut, Fiber .375-16UNC 4

25 167133 Adapter, M12 x 10mm Hose Barb (9H,13H) 1

-- 167138 Adapter, M14 x 1.5M x .25NPTF (9R,13R) 1

-- 15700887 Fitting, .25NPT x .375HB (9R,13R-Not Shown) 1

26 167305 Hose Assembly, Oil Drain 1

27 020049 Hose Clamp, Worm Drive 1

28 167306 Cap, Blanking 1

29 167622 Tube Nut, M16 1

30 174999 Assy, Cord 1

31 167746 Pulley Assy, 3G3V 2.65 Dia (w/ss) 1

32 020540 Screw, Set Soc Cup Pt .250-20UNC x .25 2

33 020067 Key, Square .250 x 1.25 Lg 1

34 139613 V-Belt, 3VX300 [set of 3](9R,13H,13R) 1

-- 139614 V-Belt, 3VX280 [set of 3](9H Only) 1

35 047455 V-Belt, 3VX300 (9R,13H,13R) 3

-- 058020 V-Belt, 3VX280 (9H Only) 1

33

Page 34

Diagram 8 – Electric Motor

34

Page 35

Diagram 8 – Electric Motor

BILL OF MATERIAL

INDEX P/N DESCRIPTION QTY

1 060143 Pulley, 2G3V 2.65 x .875 Bore 1

2 020550 Screw, Set Soc Cup Pt .312-18UNC x .375 2

3 139612 V-Belt, 3VX280 (Set of 2) 1

4 058020 V-Belt, 3VX280 2

5 139306 Motor, 5HP 230/60 Alt Wiring 1

- 000923 Motor, 5HP 3450 208-230/460/60 1

6 139540 Adapter, L.H. 1

7 139538 Adapter, R.H. 1

8 020743 Washer, Flat .375 Dia 8

9 048740 Capscrew, Hex Hd .375-16UNC x 1.25 4

10 020199 Locknut, Fiber .375-16UNC 8

11 020762 Washer, Flat .250 SAE 2

12 020784 Lockwasher, Split .250 2

13 020301 Capscrew, Hex Hd .250-20UNC x .625 2

35

Page 36

Diagram 9 – Air Motor

36

Page 37

Diagram 9 – Air Motor

BILL OF MATERIAL

INDEX P/N DESCRIPTION QTY

1 139644 Air Motor Mount 1

2 139624 Air Motor 1

3 020785 Lockwasher, Split .313 4

4 020313 Capscrew, Hex Hd .312-18UNC x .75 4

5 020293 Nipple, Close 1/2 NPT 4

6 020730 Tee, Female, 1/2 NPT, Galvanized 1

7 020810 Elbow, Street, 90° x 1/2 NPT 2

8 048740 Capscrew, Hex Hd .375-16UNC x 1.25 4

9 020743 Washer, Flat .375 Dia 4

10 020199 Locknut, Fiber .375-16UNC 4

11 139646 Air Valve Mount 1

12 020739 Washer, Flat #10 SAE 4

13 020408 Screw, Mach Rd Hd #10-24UNC x 0.75 4

14 020194 Locknut, Fiber #10-24UNC 4

15 139537 Water Valve, 1/2 NPT 1

16 020836 Elbow, 45° Female 1/2 NPT 1

17 139641 Air Filter Regulator Unit 1

18 020762 Washer, Flat .250 SAE 4

19 020416 Screw, Mach Rd Hd .250-20UNC x .75 4

20 020195 Locknut, Fiber .250-20UNC 4

21 139649 Bushing, 1/2 NPT x 1/4 NPT 1

22 139642 Air Relief Valve, 125psi 1

23 162657 Restricted Nipple, 3/4 NPT x 1/2 NPT 1

24 139640 Muffler 1

25 161117 Coupling 1

26 139643 Air Hose Assy 1

27 139651 Pulley Assy, 2G3V2.65 w/Taper Hub 1

28 139652 Pulley, 2G3V2.65 1108 T-L 1

29 161099 Hub, Taper 1108 -.75 Bore 1

30 167744 V-Belt, 3VX280 (Set of 2) 1

31 167743 V-Belt, 3VX280 2

37

Page 38

Diagram 10 – Kit, Water Tank (174957)

BILL OF MATERIAL

INDEX P/N DESCRIPTION QTY

1 196035 Bracket, Water Tank 1

2 174648 Water Tank (w/cap), 7 Gallon 1

3 020764 Washer, Flat .375 SAE 4

4 020509 Capscrew, Hex Hd .375-16UNC x 2.00 2

5 020199 Locknut, Fiber .375-16UNC 4

6 020322 Capscrew, Hex Hd .375-16UNC x .75 2

7 139722 Hose, 3/8 ID x 4.4 1

8 020049 Hose Clamp, Worm Drive 2

9 174016 Fitting, Hose Barb 3/8 ID x 3/4 Male 1

10 174741 Kit: Quick Disconnect Garden Hose w/Valve 1

11 196037 Fitting, 3/4 FGH SWV x 1/4 HB Nylon 1

12 187667 Hose, 1/4 ID x 7in 1

13 196038 Fitting, 1/4 Y Nylon LP 1

14 187667 Hose, 1/4 ID x 9in 2

38

Page 39

NOTE:

NOTA:

39

Page 40

Target Corporate Office

Customer Service...………………….... 800-288-5040

Corp. Office...………………………..... 913-928-1000

Cust. Service FAX …………………… 800-825-0028

Corp. Office FAX ..………………….... 913-438-7951

Cust. Service, Int’l. …………………… 913-928-1300

Int’l. E-mail ......…………….…. rcoats@db-inc.com

Target Latin America, Mexico, Caribbean,

Central and South America

17400 West 119th Street

Olathe, Kansas 66061

Phone ……………………………….…. 913-928-1255

FAX ………………………………….…. 913-438-7938

E-mail ……………………………. hleon@db-inc.com

Target Australia, New Zealand/Dembicon Pty. Ltd

29 Kinkaid Avenue

North Plympton, Adelaide SA 5037

Australia

Phone ………………….…………..…... 61-83751000

FAX …………………….………….….… 61-83710990

E-mail ……………..….. enquiries@dembicon.com.au

Internet ……..………….……. www.dembicon.com.au

Target Brazil

Pix Do Brasil

Rua José de Oliveira Coutinho

São Paulo, Brazil CEP 01144-020

Phone ………………………………. 55 11 3611-8383

FAX ………………………….……... 55 11 3619-3022

E-mail …………………………. pixbrasil@uol.com.br

Target Canada

17400 West 119th Street

Olathe, Kansas 66061

Customer Service …………….…….... 800-288-5040

E-mail …………………………… rbaker@db-inc.com

Target Hong Kong, China

Diamant Boart Pte Ltd.

Unit E, 13/F., Infotech Centre,

21 Hung To Road, Kwun Tong,

Hong Kong

Phone ……………………..…………. 852-2516-6602

FAX ………………………..…………. 852-2516-6605

E-mail …………………….... targethk.netvigator.com

Target Japan, Korea, Taiwan

1803-36 Oyama-Machi

Machida-Shi, Tokyo 194-0212

Japan

Phone ………………………………… 8142-797-0212

FAX …………………………………… 8142-798-7515

E-mail ………………… fwnh9794@mb.infoweb.ne.jp

Target Singapore, Thailand, Vietnam,

Malaysia, Indonesia

Phone ………………………………….. 65-9628-6175

FAX ……………………………………… 65-234-2896

e-mail …………………………. reeh@singnet.com.sg

European Headquarters

DB Construction Business Group

Avenue Du Pont De Luttre, 74

1190 Brussels, Belgium

Phone ……………………………….. (32-2) 348-3669

FAX ………………………………….. (32-2) 348-3136

Internet …………………….. www.diamant-boart.com

Target Internet …………….. www.targetblue.com

22

!

WARNING

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.

!

Loading...

Loading...