Husqvarna 41 User Manual

.

36/41

Operator’smanual

Manueld’utilisation

101-869562

REV. 2-04/1 2/95

Beforeusingyour newchain saw

c

Read the Operator’s Manual carefully.

● Check the assembly and adjustment of the cutting equipment (page 6).

● Start the saw and check the carburetor adjustment (page 16-17).

s Do not start sawing until a sufficient amount of chain oil has reached the chain (page 7,12-13).

IMPORTANT! A too lean carburetor adjustment increases the risk of serious engine malfunction.

Insufficient air filter maintenance increases the deposits on the spark plug. This can cause starting

difficulties. Incorrectly adjusted chain increases the wear and damage on the bar, the drive

sprocket and the chain.

You will find one or more of the following warning labels on the saw in black printing on yellow background.

USA

/-

A

Avoid contact between any object and the

guide bar tip. Contact can cause the chain

and guide bar to suddenly move upward

and backward, which may cause serious injury.

Use both hands on the handles. Follow all safety

precautions in the operator’s manual. Failure

to follow instructions could result in serious

personal injury.

Recomm. for

Chain /Bar length

Husqvarna H30

Huaqvarna H30 / 18”

Other low kickback comb. in operator’s

manual.

.

Displacementbelow3.8 cubic inches(62.3cc)whichcomplywiththe kickbackrequirementsofAmericanNationalStandardsInstitutaB 175.1– 1991.

WARNING

Husqvarna 36

/ Bar nose sprocket

/ 16” I Max 10 teeth or

I Max 10 teeth

\

A

/

A

Avoid contact between any object and the

guide bar tip. Contact can cause the chain

and guide bar to suddenly move upward

and backward which may cause serious injury.

Use both hands on the handles. Follow all safety

precautions in the operator’s manual Failure

to follow instructions could result in serious

personal injury.

Recomm. for Huaqvarna 41

Chain / Bar length

Huaqvarna H30

Huaqvarna H30

Other low kickback comb. in operator’s

manual.

\

WARNING

/ 16”

/ 18”

(

Husqvarna 36

0 IJOOIAOOI O

MADE IN U.S.A

/ Bar nose sprocket

/ Max 10 teeth or

/ Max 10 teeth

)

.

/-

A

CAUTION! I ATTENTION!

For safe operation Pour la securite

follow all safety

precautions and

instructions

operator’smanual. clansIemanuel

Chainsawscanbedangerous!

Lestron~onneusespauvent@tredangereuses!

‘.-

CAN

●

(b

d’operation, observe

tous Ies reglements

in et Iesinstructions

de I’utilisateur.

SERIAL No-PLATE

Each saw has a nameplate, fixed to the crankcase, with saw

model identification and serial number.

On this plate is also the country of manufacturing identified.

>

/

Index

Before using your new chain saw ...............................3

Safety Precautions .....................................................4

What is what on the saw. ............................................5

Technical specification ...............................................5

Mounting guide bar and chain ....................................6

Fuelmix and chain oil ..................................................7

Start and stop .............................................................8

Chain brake ........

Control and maintenance of the chain brake ..............9

Maintenance and function ........................................10

Starter device ........................................................... 11

Chain maintenance .............................................12 -13

Maintenance ........................................................14-15

Carburetor ..........................................................16-17

Equipment needed ................................................... 18

General working instruction ................................. 19-22

........................................................

9

3

(ANSI B 175.1-1985 Appendix D)

Safety Precautions

for Chain Saw Users

II

D 1. Kickback Safety Precautions

(1)

(2)

(3)

(4)

(5)

(6)

(7)

D 2. Other Safety Precautions

(I) Do notoperateachain saw with one hand! Serious

(2) Do not operate a chain saw when you are fatigued.

(3) Use safety footwear; snug-fitting clothing;

Safety Precautions

~ WARNING!: KICKBACK may occur when the nose

or tip of the guide bar touches an object, or when

the wood closes in and pinches the saw chain in

the cut.

DTip contact in some cases may cause a lightning fast

reverse REACTION, kicking the guide bar up and

back towards the operator.

DPinching the saw chain along the top of the guide

bar may push the guide bar rapidly back towards the

operator.

DEither of these reactions may cause you to lose

control of the saw which could result in serious

personal injury.

Do not rely exclusively upon the safety devices built

into your saw. As a chain saw user, you should take

several steps to keep your cutting jobs free from

accident or injury.

With a basic understanding of kickback, you can

reduce or eliminate the element of surprise. Sudden

surprise contributes to accidents.

Keep a good firm grip on the saw with both hands,

the right hand on the rear handle, and the left hand

on the front handle, when the engine is running.

Use a firm grip with thumbs and fingers encircling

the chain saw handles. A firm grip will help you

reduce kickback and maintain control of the saw.

Don’t let go.

Make sure that the area in which you are cutting is

free from obstacles. Do not let the nose of the guide

bar contact a log, branch, or any other obstruction

that could be hit while you are operating the saw.

Cut at high engine speeds.

Do not overreach or cut above shoulder height.

Follow manufacturer’s sharpening and maintenance

instructions for the saw chain.

Only use replacement bars and chains specified by

the manufacturer or the equivalent.

mju to the operator, helpers, bystanders, or any

7

com inations of these persons may result from onehanded operation. A chain saw is intended for twohanded use.

protective

gloves; and eye, hearing, and head protection

devices.

Use caution when handling fuel. Move the chain

(4)

saw at least 10 feet (3 m) from the fueling point

before starting the engine.

(5)

Do not allow other persons to be near the chain

saw when starting or cutting with the chain saw.

Keep bystanders and animals out of the work area.

Do not start cutting until you have a clear work

(6)

area, secure footing, and a planned retreat path

from the falling tree.

(7)

Keep all parts of your body away from the saw

chain when the engine is running.

Before you start the engine, make sure that the saw

(8)

chain is not contacting anything.

(9)

Carry the chain saw with the engine stopped, the

guide bar and saw chain to the rear, and the muffler

away from your body.

Do not operate a chain saw that is damaged,

(lo)

improperly adjusted, or not completely and securely

assembled. Be sure that the saw chain stops

moving when the throttle control trigger is released.

(11)

Shut off the engine before setting the chain saw

down.

Use extreme caution when cutting small size brush

(12)

and saplings because slender material may catch

the saw chain and be whipped toward you or pull

you off balance.

(13)

When cutting a limb that is under tension be alert

for springback so that you will not be struck when

the tension in the wood fibers is released.

Keep the handles dry, clean, and free of oil or fuel

(14)

mixture.

Operate the chain saw only in well-ventilated areas.

(15)

Do not operate a chain saw in a tree unless you

(16)

have been specifically trained to do so.

(17)

Do not operate a chain saw above shoulder height.

All chain saw service, other than the items listed in

(18)

the operator’s/owner’s safety and maintenance

instructions, should be performed by competent

chain saw service personnel. (For example, if

improper tools are used to remove the flywheel or if

an improper tool is used to hold the flywheel in

order to remove the clutch, structural damage to the

fly-wheel could occur and subsequently cause the

flywheel to burst.)

When transporting your chain saw, use the approp-

(19)

riate guide bar scabbard.

Note: This Annex is intended primarily for the consumer or occasional user.

For further safety precautions and basic cutting operations see: Operator’s Safety Manual.

4

I

5

o

o

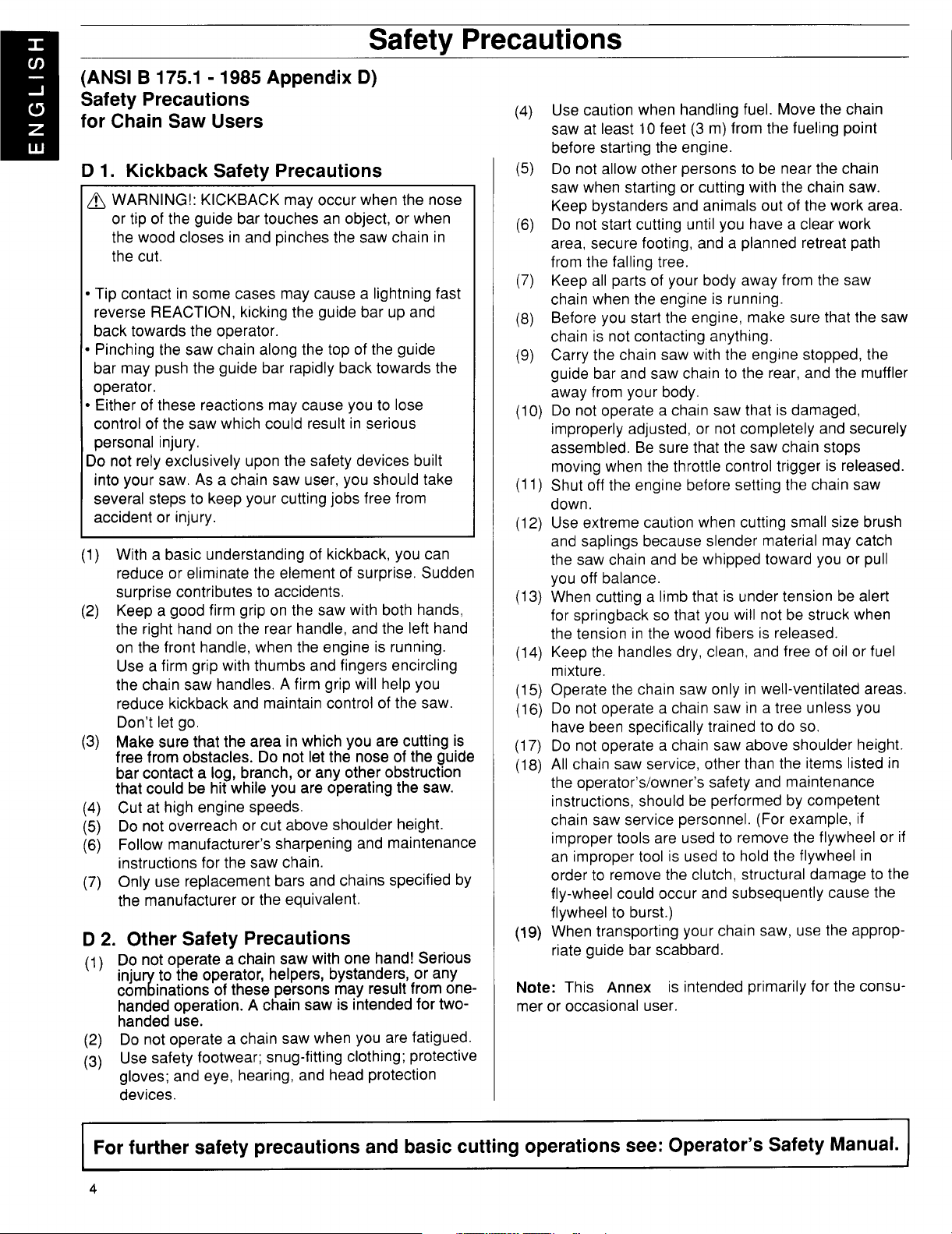

What is what on the saw

I

1, Cylinder cover,

2, Front handle.

3. Front hand guard.

4, Starter.

5, Chain oil tank.

6. Starter handle.

7. Adjustment screws, carburetor.

8. Choke/Throttle latch

9. Stop switch. Switches the ignition on and off.

10, Rear handle.

11, Fuel tank.

12, Sprocket nose.

13. Saw chain.

14. Guide bar.

15. Muffler,

16.

3 ~

o

2

o

1

o

11

0

10

Chain catcher. Catches the chain if the chain jumps or

breaks.

17, Clutch cover with a built-in chain brake.

18, Chain guard. Protects the right hand if the chain breaks

or jumps.

19, Throttle trigger.

20, Throttle trigger lockout, Prevents unintentional throttle

movement.

—

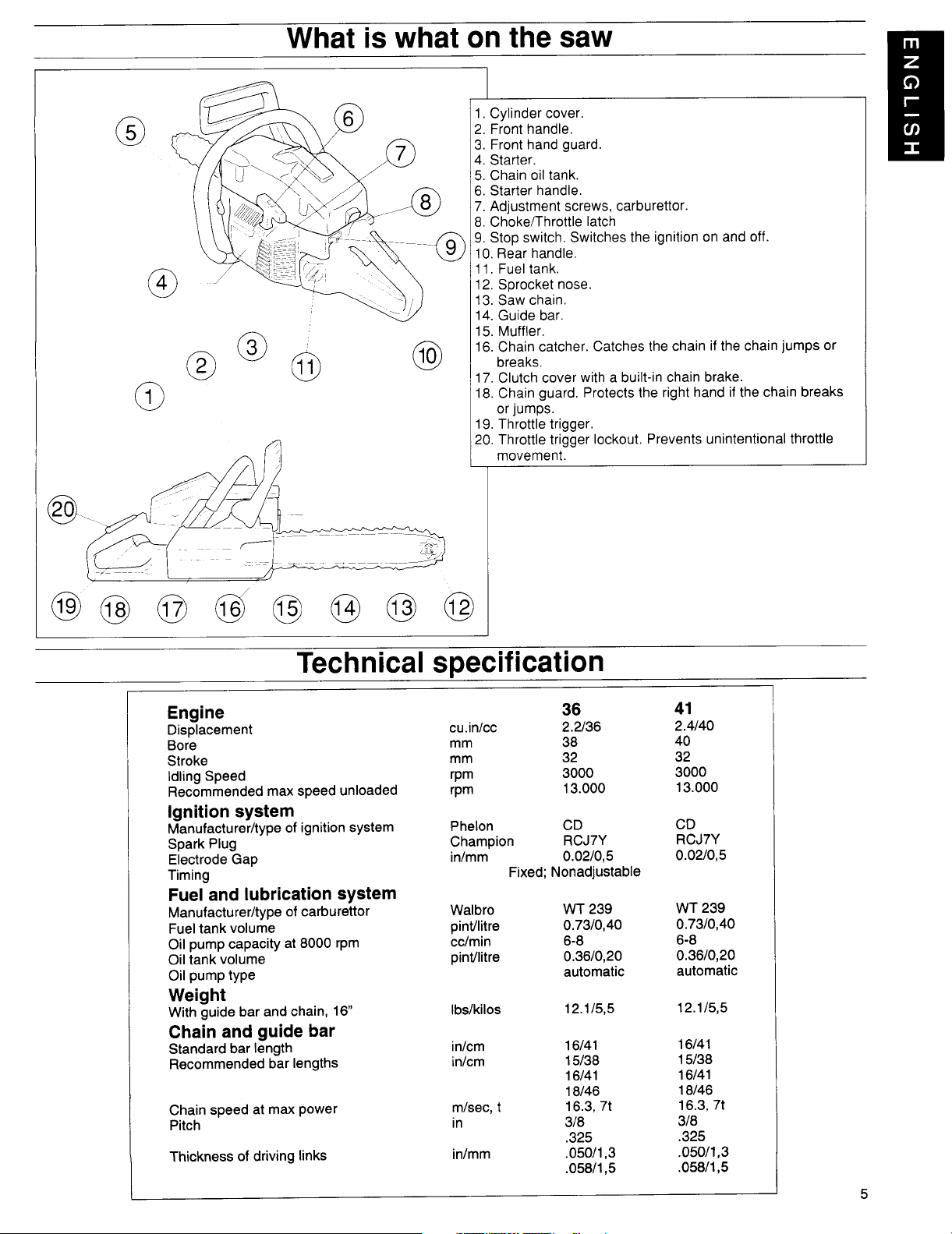

Technicalspecification

Engine

Displacement

Bore

Stroke

Idling Speed

Recommended max speed unloaded

Ignitionsystem

Manufacturer/type of ignition system

Spark Plug

Electrode Gap

Timing

Fueland lubricationsystem

Manufacturer/type of carburetor

Fuel tank volume

Oil pump capacity at 8000 rpm

Oil tank volume

Oil pump type

Weight

With guide bar and chain, 16”

Chainand guidebar

Standard bar length

Recommended bar lengths

Chain speed at max power

Pitch

Thickness of driving links

m

36

cu.inicc

mm 38

mm

rpm

rpm

Phelon

Champion

inlmm

Fixed; Nonadjustable

Walbro

pint/litre 0.73/0,40

cc/rein

pint/litre

lbs/kilos

inlcm

inlcm

m/see, t

in

inlmm

2.2136

32

3000

13.000

CD

RCJ7Y

0.02/0,5

WT 239

6-8

0.36/0,20

automatic

12.1/5,5

16/41

15/38

16/41

18146

16.3, 7t

3/8

.325

.050/1,3

.058/1,5

—

41

2.4/40

40

32

3000

13.000

CD

RCJ7Y

0.02/0,5

WT 239

0.73/0,40

6-8

0.36/0,20

automatic

12.1/5,5

16/41

15/38

16/41

18146

16.3, 7t

3/8

.325

,050/1,3

.058/1,5

5

— ‘ — -—

\—

———

/

~r -

/

/-’ ,’

1-+

,k\

A

Mountingguide bar and chain

I

[

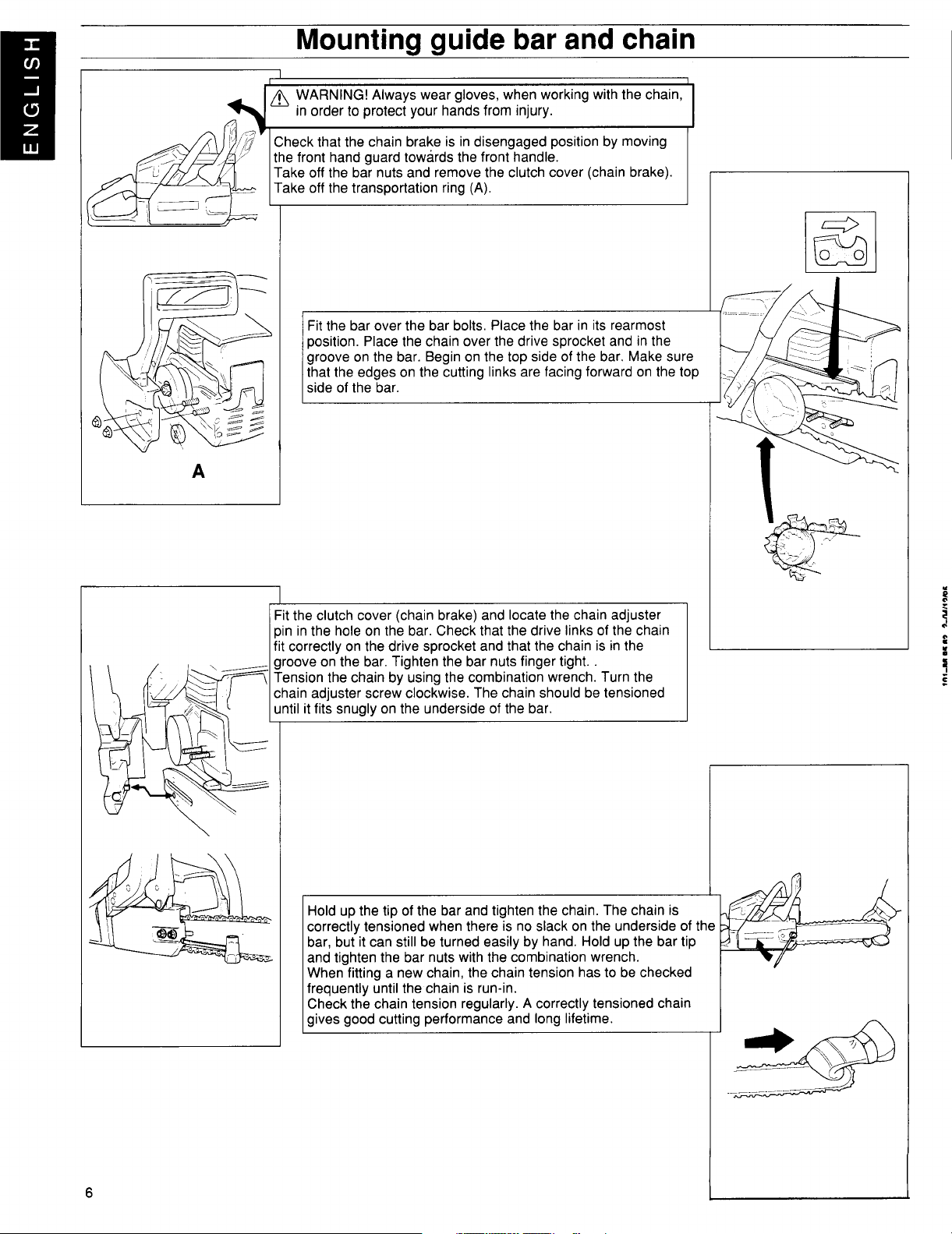

~ WARNING! Always weargloves,when working with the chain,

A

—

\

m order to protect your hands from injury.

Check that the chain brake is in disengaged position by moving

the front hand guard towards the front handle.

Take off the bar nuts and remove the clutch cover (chain brake)

Take off the transportation ring (A).

Fit the bar over the bar bolts. Place the bar in its rearmost

position. Place the chain over the drive sprocket and in the

groove on the bar. Begin on the top side of the bar. Make sure

that the edges on the cutting links are facing forward on the top

side of the bar.

00

P!l

.—J.—.—

Fit the clutch cover (chain brake) and locate the chain adjuster

pin in the hole on the bar. Check that the drive links of the chain

fit correctly on the drive sprocket and that the chain is in the

groove on the bar. Tighten the bar nuts finger tight.

Tension the chain by using the combination wrench. Turn the

chain adjuster screw clockwise. The chain should be tensioned

until it fits snugly on the underside of the bar.

I

\

Hold up the tip of the bar and tighten the chain. The chain is

correctly tensioned when there is no slack on the underside of tt

bar, but it can still be turned easily by hand. Hold up the bar tip

and tighten the bar nuts with the combination wrench.

When fitting a new chain, the chain tension has to be checked

frequently until the chain is run-in.

Check the chain tension regularly. A correctly tensioned chain

gives good cutting performance and long lifetime.

*

————-——

6

~

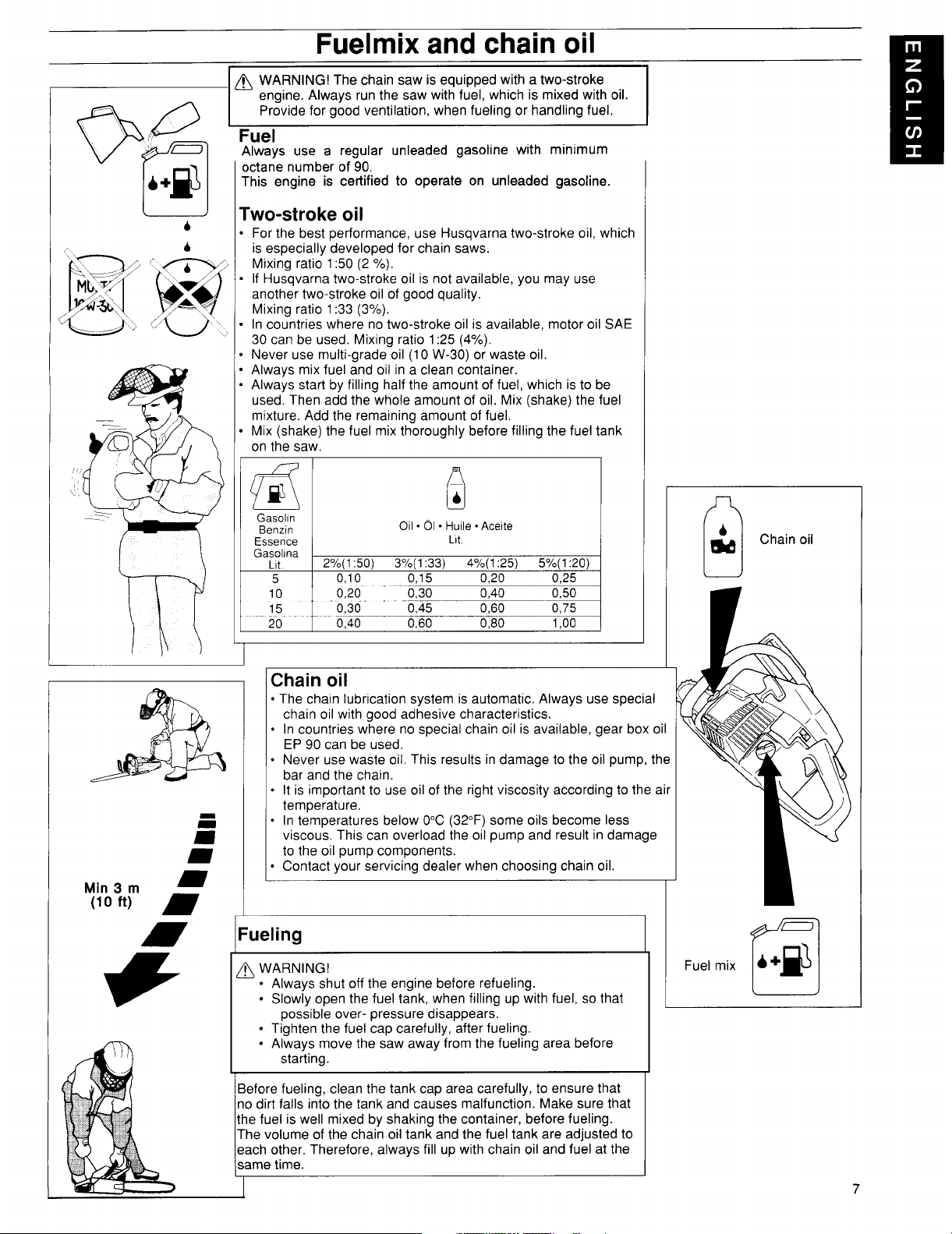

WARNING! The chain saw is equippedwith a two-stroke

engine. Always run the saw with fuel, which is mixedwith oil.

Providefor good ventilation, when fueling or handling fuel.

Fuel

Always use a regular unleaded gasoline with minimum

octane number of 90.

This engine is certified to operate on unleaded gasoline.

Two-stroke oil

.

For the best performance, use Husqvarnatwo-stroke oil, which

(.

..

.> ~

‘ \,

‘.

–-->”

M’‘

-Q,, “ h

J!Erp~

.—..

is especially developed for chain saws.

Mixing ratio 1:50 (2 0/0),

.

If Husqvarnatwo-stroke oil is not available, you may use

another two-stroke oil of good quality.

Mixing ratio 1:33 (3%).

.\,

.

In countries where no two-stroke oil is available, motor oil SAE

‘G

30 can be used. Mixing ratio 1:25 (4%).

.

Never use multi-grade oil (1OW-30) or waste oil.

.

Always mix fuel and oil in a clean container.

.

Always start by filling half the amount of fuel, which is to be

used, Then add the whole amount of oil. Mix (shake) the fuel

mixture, Add the remaining amount of fuel,

.

Mix (shake)the fuel mix thoroughly before filling the fuel tank

on the saw.

Fuelmixandchainoil

l\

Min 3 m

(lo ft)

*

m

fci

Gasolin

Benzin

Essence

Gasolina

Lit

5

10 0,20”

15

20-

2%(1

0,10

0,30 0,45

0,40

Oil .01. Huile . Aceite

3“/0(1:33)

:50)

b

f)

Lit.

0,15 0,20 0,25

0,30

0,60 0,80

4%(1 :25)

0,40 0,50

0,60

5%(1:20)

0,75

1,00

&

Chain oil

D

Chain oil

● The chain lubrication svstem is automatic, Alwavs use s~ecial

chain oil with oood adhesive characteristics. ‘

.

In countries w;ere no specialchain oil is available, gear box oil

EP 90 can be used,

.

Never use waste oil. This results in damage to the oil pump, the

bar and the chain.

.

It is important to use oil of the right viscosity according to the a

9

9

:

m

m

m

I

~ WARNING!

temperature.

●

In temperatures below OOC(320F)some oils become less

viscous. This can overload the oil pump and result in damage

to the oil pump components.

✎

Contact your servicing dealer when choosing chain oil.

Fueling

● Always shut off the engine before refueling.

● Slowly open the fuel tank, when filling up with fuel, so that

possible over- pressure disappears.

● Tighten the fuel cap carefully, after fueling.

● Always move the saw away from the fueling area before

starting.

i

Before fueling, clean the tank cap area carefully, to ensure that

no dirt falls into the tank and causes malfunction. Make sure that

the fuel is well mixed by shakingthe container, before fueling.

The volume of the chain oil tank and the fuel tank are adjustedto

each other. Therefore, always fill up with chainoil and fuel at the

same time.

Loading...

Loading...