For Husqvarna Parts Call 606-678-9623 or 606-561-4983

362XP/365/371XP

Workshop manual

101 89 83-26

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

CONTENTS

Introduction ................................................. |

1 |

Safety regulations ....................................... |

2 |

Symbols ....................................................... |

3 |

Technical data.............................................. |

4 |

Service tools ................................................ |

6 |

Trouble shooting ......................................... |

8 |

Service information ................................... |

10 |

Safety equipment ...................................... |

12 |

Recoil starter ............................................. |

16 |

Electrical system ....................................... |

18 |

Centrifugal clutch ...................................... |

22 |

Lubrication system ................................... |

24 |

Carburettor................................................. |

26 |

Tank unit..................................................... |

35 |

Anti-vibration system................................ |

37 |

Piston and cylinder ................................... |

38 |

Crankcase and crankshaft........................ |

42 |

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

INTRODUCTION

General

This manual provides a detailed description of procedures for trouble shooting, repair and testing of the chainsaw. The safety precautions that should be taken during repair work are also described.

Safety

Note! The section dealing with safety should be read and understood by all who carry out repair or service work on the chainsaw.

Warning markings are shown both in this manual and on the chainsaw itself. See page 5. If a warning mark on the chainsaw has been damaged or is missing, it must be replaced immediately in order to maximise safety when the saw is in use.

Target Audience

This workshop manual is written for personnel assuming that they have general knowledge of service and repair of small engines.

The manual should be read and understood by all personnel who will carry out service and repair work on the chainsaw. The manual is also suitable for use in the training of new employees.

Changes

As production continues, changes will be introduced successively to the chainsaw. If at any time these changes influence service and/or spares, special service announcements will be sent out, which means that this manual will cease to be current with time. In order to avoid problems, the manual should always be read together with all service announcements that apply to the specific model of chainsaw.

Arrangement

This workshop manual can be used in two different ways:

•Repair of a specific sub-assembly on the chainsaw.

•Dismantling and reassembly of the whole chainsaw.

Repair of a specific sub-assembly

When a specific sub-assembly on the chainsaw is to be repaired, proceed as follows:

1.Look up the page referring to the relevant sub-assembly.

2.Carry out the steps: Dismantling

Cleaning and inspection

Reassembly

Dismantling and reassembly of the entire chainsaw

When the entire chainsaw is to be dismantled and reassembled, proceed as follows:

1.Look up page 16, which deals with the recoil starter and carry out the instructionsundertheheading Dismantling.

2.Work forwards through the manual and carry out Dismantling instructions in the order that the sections occur.

3.Return to recoil starter on page 16 and follow the instructions under Cleaning and inspection.

4.Workforwardthroughthemanualandcarryout Cleaning and inspection in the order that the sections occur.

5.Order or fetch all the required spare parts from the spares warehouse.

6.Look up page 44 which deals with the crankcase and carry out the instructions under Assembly.

7.Work backwards through the manual and carry out Reassembly instructions as the sections occur.

In order to improve understanding, some sections begin with a Description of the relevant sub-assembly.

Tools

For specific procedures special tools are required. In this workshop manual, all the service tools required are listed. Their use is described in the appropriate section.

Always use Husqvarna original:

•Spares

•Service tools

•Accessories

Numbering

Location indicators for components shown in the figures are marked A, B, etc.

The figures are numbered 1, 2 etc.

The location indicators and figure numbers start again from A, 1 etc. at the beginning of each new section.

English – 1

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

SAFETY REGULATIONS

General instructions

Workshopswherechainsawsareservicedmustbeequipped with safety equipment in accordance with local regulations.

No one should repair the chainsaw without first having read and understood the contents of this workshop manual.

The following warning texts are to be found in this manual in certainplaces.Thewarningtextsoccurbeforetheprocedure to which they refer.

!WARNING!

The warning text indicates a risk of personal injury if instructions are not followed.

NOTE!

The warning text indicates a risk of damage to equipment if instructions are not followed.

Special instructions

The fuel used in the chainsaw poses the following hazards:

1.The fluid and its fumes are poisonous.

2.Can cause skin irritation.

3.Is highly inflammable.

The guide bar, chain and clutch cover (chain brake) must be assembled before the chainsaw is started, otherwise the clutch may come loose causing personal injury.

Wear ear defenders when testing the chainsaw.

Do not use the saw before it has been adjusted so that the chain is still when idling.

After testing, do not touch the silencer until it has cooled. Risk for burns.

Inadequate lubrication of the chain can result in the chain breaking, which can cause serious or life threatening injury.

Make sure that the starter recoil spring does not fly out and cause personal injury.

If the spring is tensioned when the cord pulley is removed, the spring can fly out causing personal injury.

When removing the pressure spring for the chain brake, ensure that the brake is in the on position, otherwise the spring can fly out causing personal injury.

After repair, the chain brake must be checked in accordance with the instructions on page 13.

When replacing the crankshaft bearings note that the crankcase halves are hot. Use protective gloves.

When using compressed air, the air jet should never be pointed towards the body. Air can be forced into the blood stream, which can cause fatality.

2 – English

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

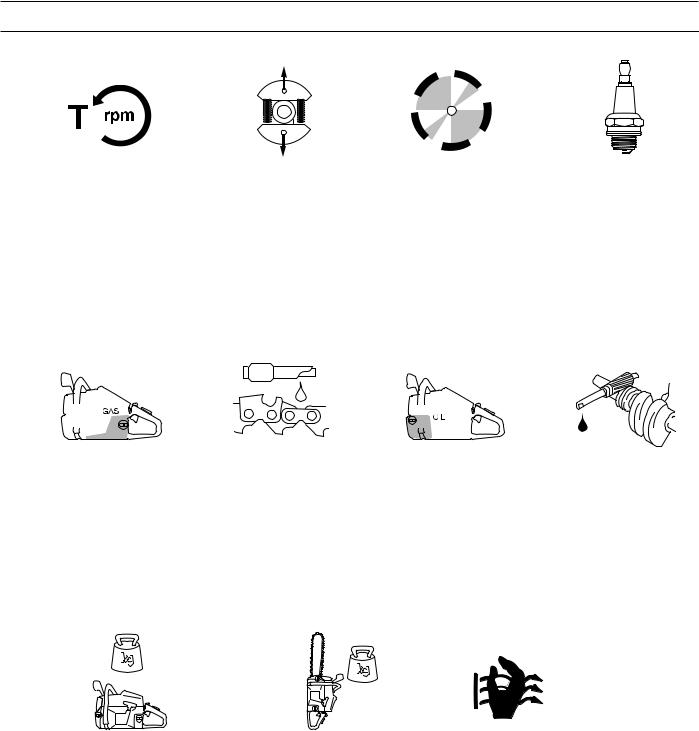

SYMBOLS

Symbols on the saw

The markings shown below are moulded into the chainsaw casing.

Symbols in this manual

!This symbol indicates a risk of personal injury if instructions are not followed.

Choke

Switch for hand grip heating

Fuel filler

STOP Stop button

Chain lubrication adjuster

Chain oil filler

English – 3

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

TECHNICAL INFORMATION

|

Displacement |

Bore |

Stroke |

Max. power/rpm |

|

cm3/ cubic inch |

Ømm/Øinch |

mm/inches |

kW/hp/ rpm |

362XP: |

62,4/3,8 |

47/1,85 |

36/1,42 |

3,4/4,6/ 9 600 |

365: |

65,1/4,0 |

48/1,89 |

36/1,42 |

3,4/4,6/ 9 300 |

371XP: |

70,7/4,3 |

50/1,97 |

36/1,42 |

3,9/5,3/ 9 600 |

|

Sparkplug gap |

Ignition system |

|

|

|

Air gap |

|

Carburettor type |

|||||||||||||

|

mm/inches |

|

|

|

mm/inches |

|

|

|

|

|

|

|

|

||||||||

362XP: |

0,5/0,02 |

FHP/CD |

0,3/0,01 |

|

|

Walbro HD6 |

|||||||||||||||

365: |

0,5/0,02 |

FHP/CD |

0,3/0,01 |

|

|

Zama C3M-EL2A |

|||||||||||||||

371XP: |

0,5/0,02 |

FHP/CD |

0,3/0,01 |

|

|

Walbro HD6 |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Guidebar length |

Chain speed at max. power |

Chain pitch |

Drive link gauge |

|

|

and 9 600 rpm |

|

|

|

cm/inches |

m/s |

mm/inches |

mm/inches |

362XP: |

33-60/13-24 |

21,4 |

8,25/ 0,325 |

1,5/0,058 |

|

|

|

9,52/ 3/8 |

|

365: |

38-61/15-24 |

20,7 |

9,52/ 3/8 |

1,5/0,058 |

371XP: |

38-61/15-24 |

21,4 |

9,52/ 3/8 |

1,5/0,058 |

4 – English

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

TECHNICAL INFORMATION

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Idling speed |

Engagement speed |

Max. overspeed |

Spark plug |

|||||||||||||||||||

|

rpm |

|

|

|

|

|

|

|

|

|

rpm |

|

rpm |

|

|||||||||

362XP: |

2 700 |

3 500 |

|

|

|

13 500 |

Champion RCJ 7Y |

||||||||||||||||

365: |

2 700 |

3 500 |

|

|

|

12 500 |

Champion RCJ 7Y |

||||||||||||||||

371XP: |

2 700 |

3 500 |

|

|

|

13 500 |

Champion RCJ 7Y |

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fuel tank volume |

Oil pump capacity |

Oil tank volume |

Automatic oil pump |

|

Litres/US pints |

cm3/min |

Litres/US pints |

|

362XP: |

0,77/1,63 |

4/20 |

0,42/0,89 |

Yes |

365: |

0,77/1,63 |

4/20 |

0,42/0,89 |

Yes |

371XP: |

0,77/1,63 |

4/20 |

0,42/0,89 |

Yes |

Weight without bar and chain |

Weight with bar and chain |

Hand grip heater |

||

|

kg/lbs |

|

kg/lbs |

Watts/rpm |

362XP: |

6,0/13,2 |

15" |

7,1/15,6 |

65/ 10 000 |

|

|

20" |

7,5/16,5 |

|

362XPG: |

6,2/13,7 |

15" |

8,2/18,1 |

65/ 10 000 |

|

|

20" |

8,7/19,2 |

|

365: |

6,0/13,2 |

15" |

7,1/15,6 |

– |

|

|

20" |

7,5/16,5 |

|

371XP: |

5,9/13,0 |

15" |

7,0/15,4 |

65/ 10 000 |

|

|

20" |

7,4/16,3 |

|

371XPG: |

6,1/13,4 |

15" |

8,2/18,1 |

65/ 10 000 |

|

|

20" |

8,6/18,9 |

|

English – 5

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

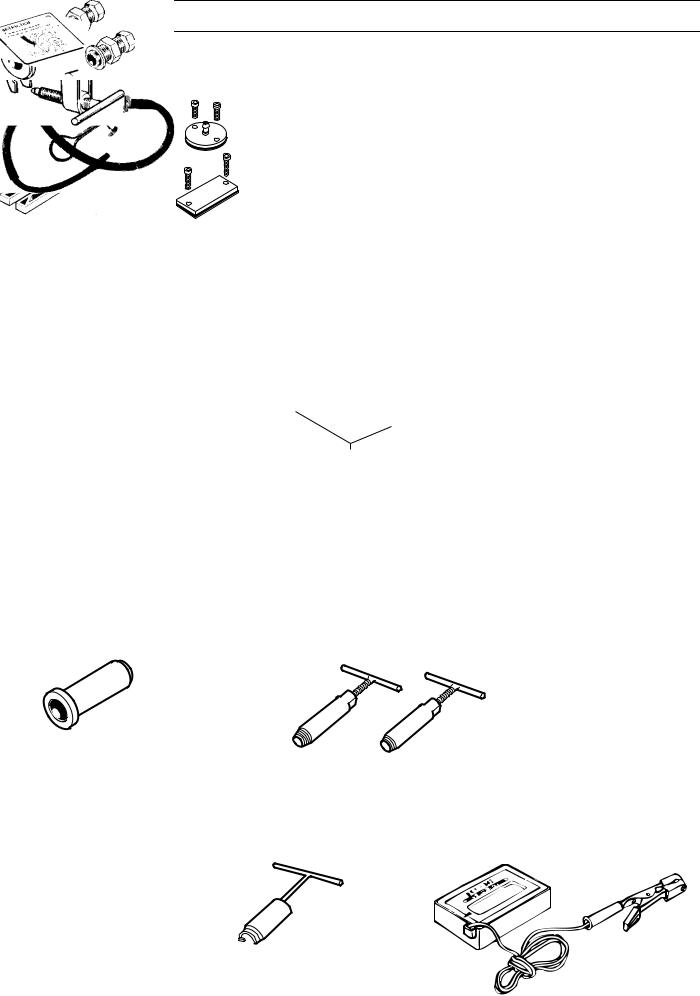

SERVICE TOOLS

1 |

2 |

4 |

5 |

3

6 |

|

|

7 |

9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8

10 |

11 |

12 |

13 |

14 |

15 |

17 |

18 |

|

|

|

|

|

|

|

|

|

6 – English

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

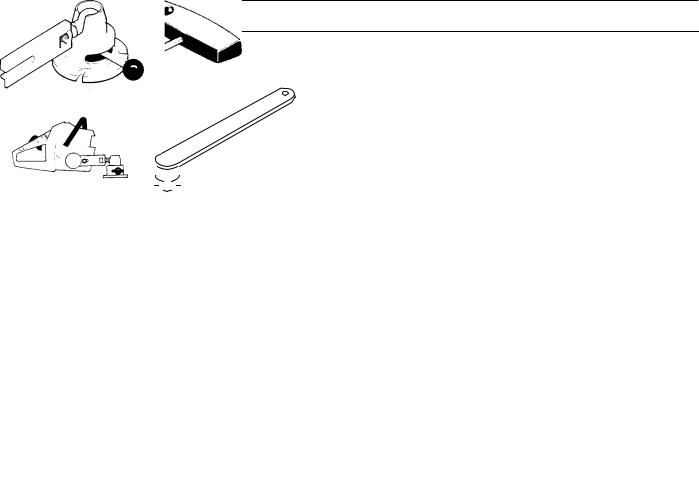

SERVICE TOOLS

19 |

20 |

21 |

22 |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

23 |

24 |

25 |

|

|

|

|

|

|

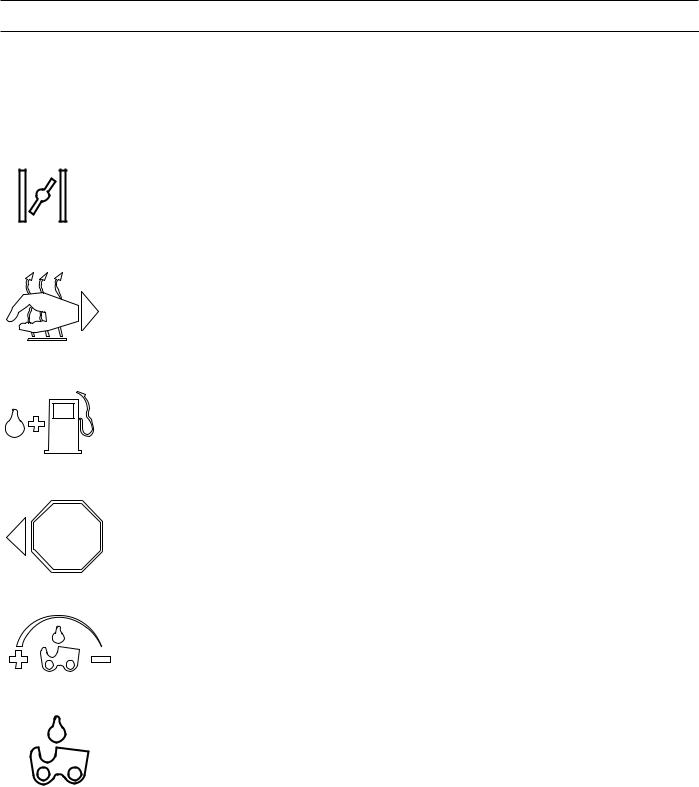

The tools listed here are the service tools required for this model of chainsaw. In addition to these tools, a normal kit of hand tools is required.

Item |

Name |

Usage |

Ordering No. |

|

|

|

|

1 |

Piston stop |

Locking the crankshaft |

502 50 33-01 |

2 |

Cover plate: crankcase inlet |

Sealing off inlet |

502 54 05-01 |

3 |

Cover plate: exhaust |

Sealing off exhaust outlet |

502 71 39-01 |

4 |

Pressure tester |

Pressurising for pressure testing |

502 50 38-01 |

5 |

Extractor |

Removing crankshaft |

502 51 61-01 |

6 |

Puller |

Removing bearings from the crankshaft |

504 90 90-01 |

7 |

Holding tool |

Flywheel removal |

502 51 49-01 |

8 |

Puller |

Flywheel removal |

502 50 26-01 |

9 |

Piston ring clamp |

Fitting the piston |

502 50 70-01 |

10 |

Oil seal driver |

Inserting clutch side oil seal |

502 52 21-01 |

11 |

Oil seal driver |

Inserting flywheel side oil seal |

502 52 20-01 |

12 |

Extractor |

Removing clutch side crankcase seal |

502 50 55-01 |

13 |

Extractor |

Removing flywheel side crankcase seal |

504 91 40-01 |

14 |

Assembly tool |

Reassembling crankshaft |

502 50 30-15 |

15 |

Feeler gauge, air gap |

Setting ignition unit |

502 51 34-02 |

17 |

Extractor |

Removing large AV-springs |

502 52 18-02 |

18 |

Tachometer |

Setting the carburettor |

502 71 14-01 |

19 |

Test spark plug |

Testing ignition unit |

502 71 13-01 |

20 |

Clutch tool |

Clutch dismantling and assembly |

502 52 22-01 |

21 |

Assembly pliers |

Assembling spark plug guard |

502 50 06-01 |

22 |

Fuel filter hook |

Withdrawing the fuel filter |

502 50 83-01 |

23 |

Clamp stand |

Clamping the saw |

502 51 02-01 |

24 |

Allen driver, 3 mm |

For M4-bolts |

502 50 86-01 |

24 |

Allen driver, 4 mm |

For M5-bolts |

502 50 87-01 |

25 |

Allen key, 3 mm |

For M4-bolts |

502 50 19-01 |

25 |

Allen key, 4 mm |

For M5-bolts |

502 50 18-01 |

25 |

Allen key, 5 mm |

For M6-bolts |

502 50 64-01 |

|

|

|

|

English – 7

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

TROUBLE SHOOTING

Trouble shooting schematic

Faults that can develop on the chainsaw are divided into four groups as follows. In each category, possible malfunctions are shown on the left, with a list of possible faults on the right. The most probable fault is given first and so on.

Starting

Difficult starting |

Adjust L-screw |

|

Air filter blocked |

|

Choke not working |

|

Worn choke pivot |

|

Worn choke butterfly |

|

Fuel filter blocked |

|

Fuel line blocked |

|

Piston ring seized |

|

Blocked impulse channel |

|

|

Carburettor leaking |

Loose or faulty fuel pipe |

fuel |

Hole in diaphragm |

|

Worn needle valve |

|

Needlevalveassemblysticking |

|

Needle valve set too high |

|

Leak in metering system (air or |

|

fuel) |

|

Loose cover on carburettor |

|

pump side |

|

|

Flooding when motor |

Worn needle valve |

not running |

Needle valve set too high |

|

Needlevalveassemblysticking |

|

|

Idling (low rpm) |

|

|

|

Will not idle |

Adjust L-screw |

|

Leaking air intake (rubber) |

|

Loose carburettor mounting |

|

bolts |

|

Loose or faulty fuel pipe |

|

Fuel filter blocked |

|

Fuel line blocked |

|

Fuel tank ventilator blocked |

|

Throttle valve pivot stiff |

|

Throttle cable sticking |

|

Defective throttle return spring |

|

Bent throttle stop |

|

Faulty diffuser jet |

|

|

Idling too rich |

Adjust L-screw |

|

Worn needle valve |

|

Needle valve set too high |

|

Worn needle valve lever |

|

Leaking control diaphragm/ |

|

cover plate |

|

Needlevalveassemblysticking |

|

|

Idling (low rpm) (cont.)

Idles when L-screw closed |

Worn needle valve |

|

|

Leaking control |

diaphragm/ |

|

cover plate |

|

|

Needlevalveassemblysticking |

|

|

Worn needle valve lever |

|

|

Faulty diffuser jet |

|

|

|

|

Idling uneven |

Fuel filter blocked |

|

|

Fuel line blocked |

|

|

Leaking air intake (rubber) |

|

|

Loose carburettor mounting |

|

|

bolts |

|

|

Worn throttle butterfly pivot |

|

|

Loose throttle butterfly screw |

|

|

Worn throttle butterfly |

|

|

Needlevalveassemblysticking |

|

|

Leak in metering system (air or |

|

|

fuel) |

|

|

Controldiaphragmcentreknob |

|

|

is worn |

|

|

Hole in diaphragm |

|

|

Leaking control |

diaphragm/ |

|

cover plate |

|

|

Crankcase leaking |

|

|

|

|

L-screw requires |

Fuel line blocked |

|

constant adjustment |

Needle valve set too high |

|

|

Needlevalveassemblysticking |

|

|

Leak in metering system (air or |

|

|

fuel) |

|

|

Leaking control |

diaphragm/ |

|

cover plate |

|

|

Faulty diffuser jet |

|

|

Crankcase leaking |

|

|

|

|

Too much fuel at idling |

Needle valve set too high |

|

|

Needlevalveassemblysticking |

|

|

Metering system damaged |

|

|

Worn needle valve |

|

|

Leaking control |

diaphragm/ |

|

cover plate |

|

|

Metering system |

incorrectly |

|

assembled |

|

|

|

|

8 – English

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

TROUBLE SHOOTING

High rpm

Will not run at full |

Adjust H-screw |

throttle |

Blocked air filter |

|

Blocked fuel tank ventilator |

|

Blocked fuel filter |

|

Fuel line blocked |

|

Loose or damaged fuel line |

|

Impulse channel leaking |

|

Impulse channel blocked |

|

Loose cover on carburettor |

|

pump side |

|

Faulty pump diaphragm |

|

Leaking air intake (rubber) |

|

Loose carburettor mounting bolts |

|

Needle valve set too low |

|

Metering system damaged |

|

Metering system incorrectly |

|

assembled |

|

Leaking control diaphragm/cover |

|

plate |

|

Needle valve assembly sticking |

|

Blocked silencer |

|

|

Low power |

Adjust H-screw |

|

Blocked fuel tank ventilator |

|

Blocked fuel filter |

|

Impulse channel leaking |

|

Impulse channel blocked |

|

Loose cover on carburettor pump |

|

side |

|

Faulty pump diaphragm |

|

Blocked air filter |

|

Needle valve assembly sticking |

|

Leak in metering system (air or fuel) |

|

Metering system incorrectly |

|

assembled |

|

Loose diaphragm |

|

Hole in diaphragm |

|

Leaking control diaphragm/cover |

|

plate |

|

|

Will not “four-stroke” |

Blocked fuel tank ventilator |

|

Blocked fuel filter |

|

Fuel line blocked |

|

Loose or damaged fuel line |

|

Impulse channel leaking |

|

Impulse channel blocked |

|

Loose cover on carburettor pump |

|

side |

|

Faulty pump diaphragm |

|

Leaking air intake (rubber) |

|

Loose carburettor mounting bolts |

|

Needle valve set too low |

|

Leak in metering system (air or fuel) |

|

Metering unit incorrectly |

|

assembled |

|

Loose diaphragm |

|

Hole in diaphragm |

|

Leaking control diaphragm/cover |

|

plate |

|

|

Acceleration and retardation

Does not accelerate |

Adjust H-screw |

Adjust L-screw |

Blocked air filter |

|

Blocked fuel tank ventilator |

|

Blocked fuel filter |

|

Fuel line blocked |

|

Loose or damaged fuel line |

|

Impulse channel blocked |

|

Loose cover on carburettor |

|

pump side |

|

Faulty pump diaphragm |

|

Leaking air intake (rubber) |

|

Loose carburettor mounting |

|

bolts |

|

Needle valve set too low |

|

Metering system incorrectly |

|

assembled |

|

Needle valve assembly sticking |

|

Faulty diffuser jet |

|

Blocked silencer |

|

|

Motor stalls when throttle |

Adjust L-screw |

released |

Adjust H-screw |

|

Faulty pump diaphragm |

|

Needle valve set too high |

|

Needle valve assembly sticking |

|

Faulty diffuser jet |

|

|

Over rich acceleration |

Adjust L-screw |

|

Adjust H-screw |

|

Blocked air filter |

|

Faulty pump diaphragm |

|

Faulty diffuser jet |

|

|

Trouble shooting methods

In addition to faults given in the above schematic, trouble shooting can be carried out on a specific component or subsystem of the chainsaw.The different testing procedures are described in respective sections and are as follows:

1. Pressure testing the carburettor. |

See page 31. |

2.Pressure testing the crankcase and cylinder. See page 41.

3.Pressure testing the decompression valve. See page 39.

4. Checking operation of the chain brake. |

See page 13. |

English – 9

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

SERVICE INFORMATION

●

●

15

14

10

10

■

▲

●

▲

8

8

6

Key to diagrams |

|

|

Figures next to components which are attached using bolts |

|

|

● |

||

give the appropriate tightening torques in Nm. |

|

|

▲ = Lubricate with two-stroke oil. |

|

|

■ = Lubricate with (chainsaw) chain oil. |

|

|

● = Lubricate with grease. |

|

|

10 – English |

|

|

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

SERVICE INFORMATION

1,5

4

10

15

10

15

4

▲

6

6

▲

▲

▲

35

4 |

● |

English – 11

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

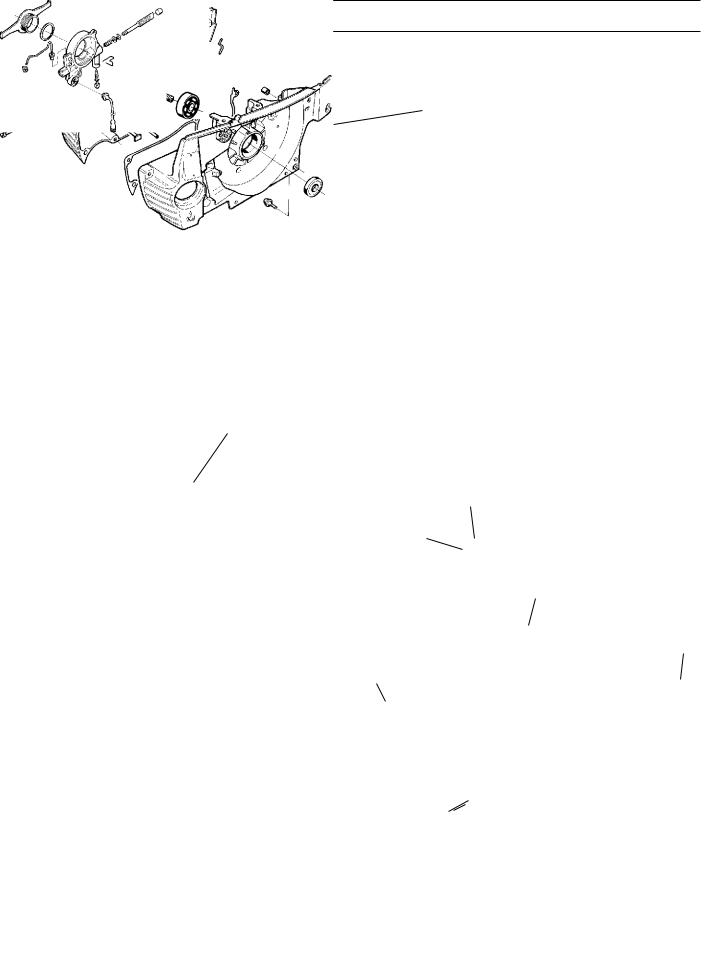

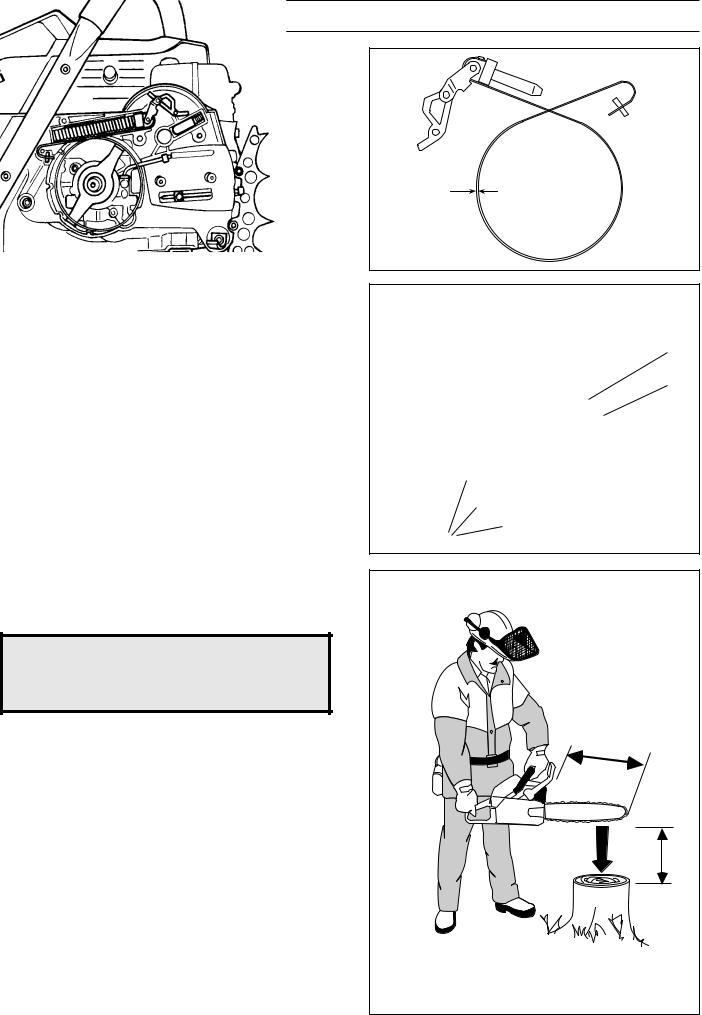

SAFETY EQUIPMENT

Chain brake

Dismantling

1.First remove the following components:

•Chain and guide bar. See instruction book.

•Centrifugal clutch. See page 22.

2.Push the hand guard forward so that the chain brake is on. See fig. 1

3.Unscrew hand guard, two bolts. Note sleeving on the starter side. See fig. 2.

4.Remove bolt (A) and chain guide-plate. See fig. 1.

5.Undo the four bolts (B) and remove the chain brake assembly cover. See fig. 1.

!WARNING!

Check that the chain brake is in the on position. If it is not, the pressure spring can fly up causing personal injury.

6.Press down the retaining bush (C) and remove the lever arm (D). See fig 3.

7.Remove the pressure spring by freeing the rearward end with a screwdriver. See fig 4.

8.Remove the toggle joint (E) with attached brake-strap. See fig 4.

9.Disconnect the brake-strap from the toggle joint. 10.Take out the retaining bush (C) and spring. See fig 3.

B

A

Fig. 1

Fig. 2

Fig. 3

E

Fig. 4

12 – English

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

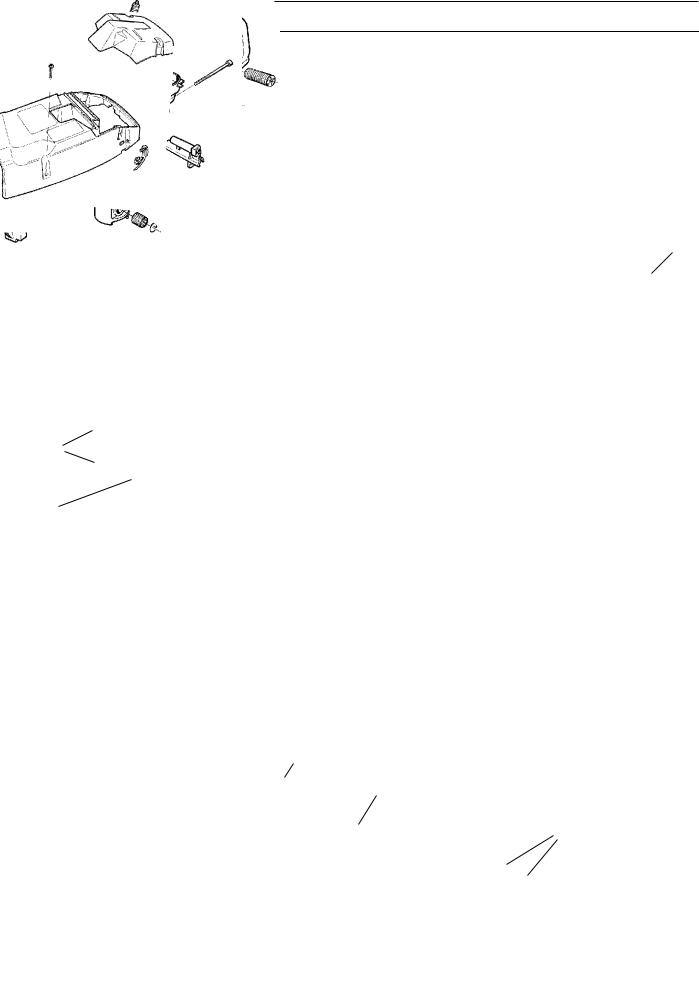

SAFETY EQUIPMENT

Inspection

Clean and inspect all components.

The brake-strap thickness must not be less than 0.8 mm at any point. See fig. 5.

Reassembly

Assemble the chain brake as follows:

1.Reattach the toggle joint and brake-strap. See fig. 5.

2.Grease the toggle joint (E) moving parts and locate the assembly in the chainsaw. See fig. 6.

3.Grease and insert the lever arm (D). See fig. 3.

4.Grease and insert the retaining bush (C) and spring. See fig. 3.

5.Locate the chain brake assembly cover, four bolts (B). Tighten the screws to 4 Nm. See fig. 1.

6.Locate the chain guide-plate with bolt (A). See fig. 1.

7.Attach the hand guard with the sleeving on the starter side. See fig. 2.

8.Draw back the hand guard so that the chain brake is in the off position.

9.Check that the brake-strap is seated correctly in the recess (F) in the crankcase. See fig. 6.

10.Assemble the following components:

•Centrifugal clutch. See page 23.

•Chain and guide bar. See instruction book.

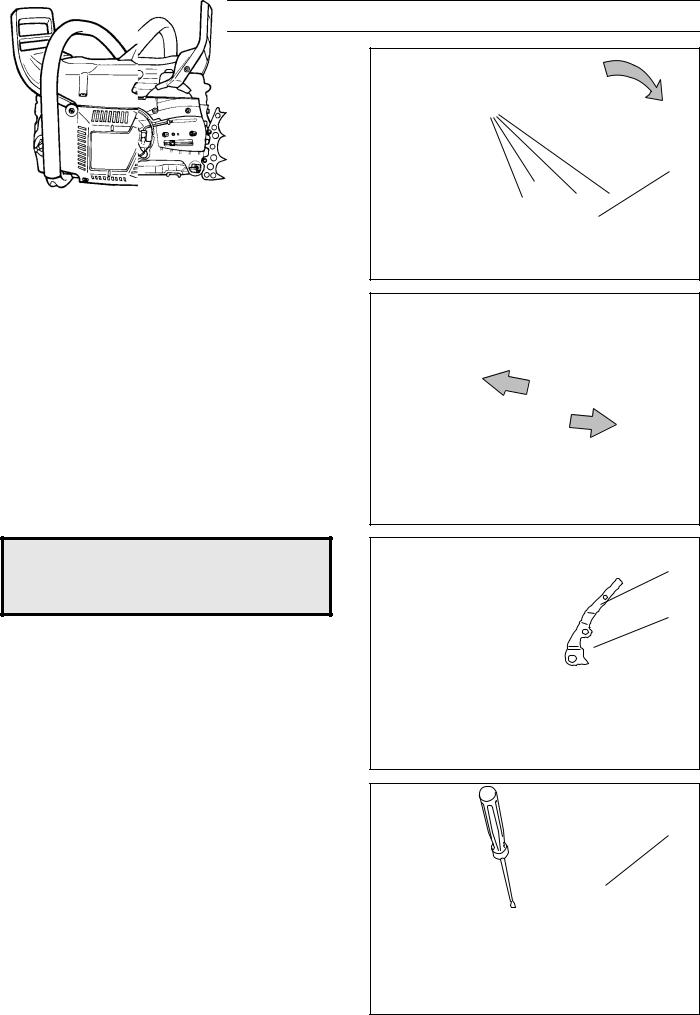

Checking brake operation

!WARNING!

After repair, the chain brake must be checked in accordance with the following instructions.

For this test, the motor should not be running. Test the chain brake cut in as follows:

1.Hold the saw over a stable surface as shown in fig. 7. The distance between the guide bar and the surface is given in the table below.

Guide bar length, L |

Height, H |

|

|

|

|

15-20 |

inches |

50 cm |

21-28 |

inches |

70 cm |

29-32 |

inches |

80 cm |

|

|

|

2.Let go of the front hand grip and let the chainsaw pivot round on the rear hand grip.

3.When the guide bar hits the surface, the chain brake should cut in.

min. 0.8 mm

Fig. 5

Fig. 6

L

H

Fig. 7

English – 13

www.mymowerparts.com