Page 1

©Husqvarna

FOREST & GARDEN

36/41

Operator’s manual

101-86 95 62

REV. 2-04/12/95

Page 2

Page 3

You will find one or more of the following warning labels on the saw In black printing on yellow background.

USA

âs WARNING A

Avoid contact between any object and the

guide bar tip. Contact can cause the chain

and guide bar to suddenly move upward

and backward, which may cause serious injury.

Use both hands on the handles. Follow all safety

precautions in the operator's manual. Failure

to follow instructions could result in serious

personal injury.

Recomm. for Husqvarna 36

Chain / Bar length / Bar nose sprocket

Husqvarna H30 / 16" /Max 10 teeth or

Husqvarna H30 / 18" /Max 10 teeth

Other low kickback comb, in operator's

manual.

Displacement below 3.8 cubic inches (62.3 cc) which comply with the kickback requirements of American National Standards Institute B 175.1 1991.

between any object

A

Avoid contact between any object and the

guide bar tip. Contact can cause the chain

and guide bar to suddenly move upward

and backward which may cause serious injury.

Use both hands on the handles. Follow all safety

precautions in the operator's manual. Failure

to follow instructions could result In serious

personal injury.

Recomm. for Husqvarna 41

Chain/Bar length / Bar nose sprocket

Husqvarna H30 / 16" /Max 10 teeth or

Husqvarna H30 / 18" /Max 10 teeth

Other low kickback comb, in operator's

manual.

WARNING

A

CAUTION! /j\ ATTENTION!

For safe operation

follow all safety

precautions and

Instructions In

operator's manual.

Chainsaws can be dangerous I

Les tronçonneuses peuvent être dangereuses !

CAN

Pour la sécurité

d'opération, observé

tous les réglements

et les instructions

dans le manuel

de l'utilisateur.

Husqvarna 36

OU001A001 O

MADE IN U.S.A

SERIAL No-PLATE

Each saw has a nameplate, fixed to the crankcase, with saw

model Identification and serial number.

On this plate Is also the country of manufacturing Identified.

Index

Before using your new chain saw..............................3

Safety Precautions.....................................................4

What is what on the saw............................................5

Technical specification...............................................5

Mounting guide bar and chain

Fuelmix and chain oil.................................................7

Start and stop

Chain brake

............................................................

...............................................................

Control and maintenance of the chain brake.............9

Maintenance and function

Starter device..........................................................11

Chain maintenance

............................................

Maintenance.......................................................14-15

Carburettor

Equipment needed

.........................................................

..................................................

General working instruction................................19-22

...................................

.......................................

12-13

16-17

10

18

6

8

9

Page 4

Safety Precautions

(ANSI B 175.1 -1985 Appendix D) Safety Precautions for Chain Saw Users

D 1. Kickback Safety Precautions

/j\ WARNING!: KICKBACK may occur when the nose

or tip of the guide bar touches an object, or when

the wood closes in and pinches the saw chain in

the cut.

• Tip contact in some cases may cause a lightning fast

reverse REACTION, kicking the guide bar up and

back towards the operator.

• Pinching the saw chain along the top of the guide

bar may push the guide bar rapidly back towards the

operator.

• Either of these reactions may cause you to lose

control of the saw which could result in serious

personal injury.

Do not rely exclusively upon the safety devices built

into your saw. As a chain saw user, you should take

several steps to keep your cutting jobs free from

accident or injury.

With a basic understanding of kickback, you can

(1)

reduce or eliminate the element of surprise. Sudden

surprise contributes to accidents.

Keep a good firm grip on the saw with both hands,

(2)

the right hand on the rear handle, and the left hand

on the front handle, when the engine is running.

Use a firm grip with thumbs and fingers encircling

the chain saw handles. A firm grip will help you

reduce kickback and maintain control of the saw.

Don’t let go.

Make sure that the area In which you are cutting is

(3)

free from obstacles. Do not let the nose of the guide

bar contact a log, branch, or any other obstruction

that could be hit while you are operating the saw.

Cut at high engine speeds.

(4)

Do not overreach or cut above shoulder height.

(5)

Follow manufacturer’s sharpening and maintenance

(6)

instructions for the saw chain.

Only use replacement bars and chains specified by

(7)

the manufacturer or the equivalent.

D 2. Other Safety Precautions

Do not operate a chain saw with one hand! Serious

(1)

injury to the operator, helpers, bystanders, or any

combinations of these persons may result from one

handed operation. A chain saw is intended for two

handed use.

Do not operate a chain saw when you are fatigued.

(2)

Use safety footwear; snug-fitting clothing; protective

(3)

gloves; and eye, hearing, and head protection

devices.

(4) Use caution when handling fuel. Move the chain

saw at least 10 feet (3 m) from the fueling point

before starting the engine.

(5) Do not allow other persons to be near the chain

saw when starting or cutting with the chain saw.

Keep bystanders and animals out of the work area.

(6) Do not start cutting until you have a clear work

area, secure footing, and a planned retreat path

from the falling tree.

(7) Keep all parts of your body away from the saw

chain when the engine is running.

(8) Before you start the engine, make sure that the saw

chain is not contacting anything.

(9) Carry the chain saw with the engine stopped, the

guide bar and saw chain to the rear, and the muffler

away from your body.

(10) Do not operate a chain saw that is damaged,

improperly adjusted, or not completely and securely

assembled. Be sure that the saw chain stops

moving when the throttle control trigger is released.

(11) Shut off the engine before setting the chain saw

down.

(12) Use extreme caution when cutting small size brush

and saplings because slender material may catch

the saw chain and be whipped toward you or pull

you off balance.

(13) When cutting a limb that is under tension be alert

for springback so that you will not be struck when

the tension in the wood fibers is released.

(14) Keep the handles dry, clean, and free of oil or fuel

mixture.

(15) Operate the chain saw only in well-ventilated areas.

(16) Do not operate a chain saw in a tree unless you

have been specifically trained to do so.

(17) Do not operate a chain saw above shoulder height.

(18) All chain saw service, other than the items listed in

the operator’s/owner’s safety and maintenance

instructions, should be performed by competent

chain saw service personnel. (For example, if

improper tools are used to remove the flywheel or if

an improper tool is used to hold the flywheel in

order to remove the clutch, structural damage to the

fly-wheel could occur and subsequently cause the

flywheel to burst.)

(19) When transporting your chain saw, use the approp

riate guide bar scabbard.

Note: This Annex is intended primarily for the consu

mer or occasional user.

For further safety precautions and basic cutting operations see: Operator’s Safety Manual.

Page 5

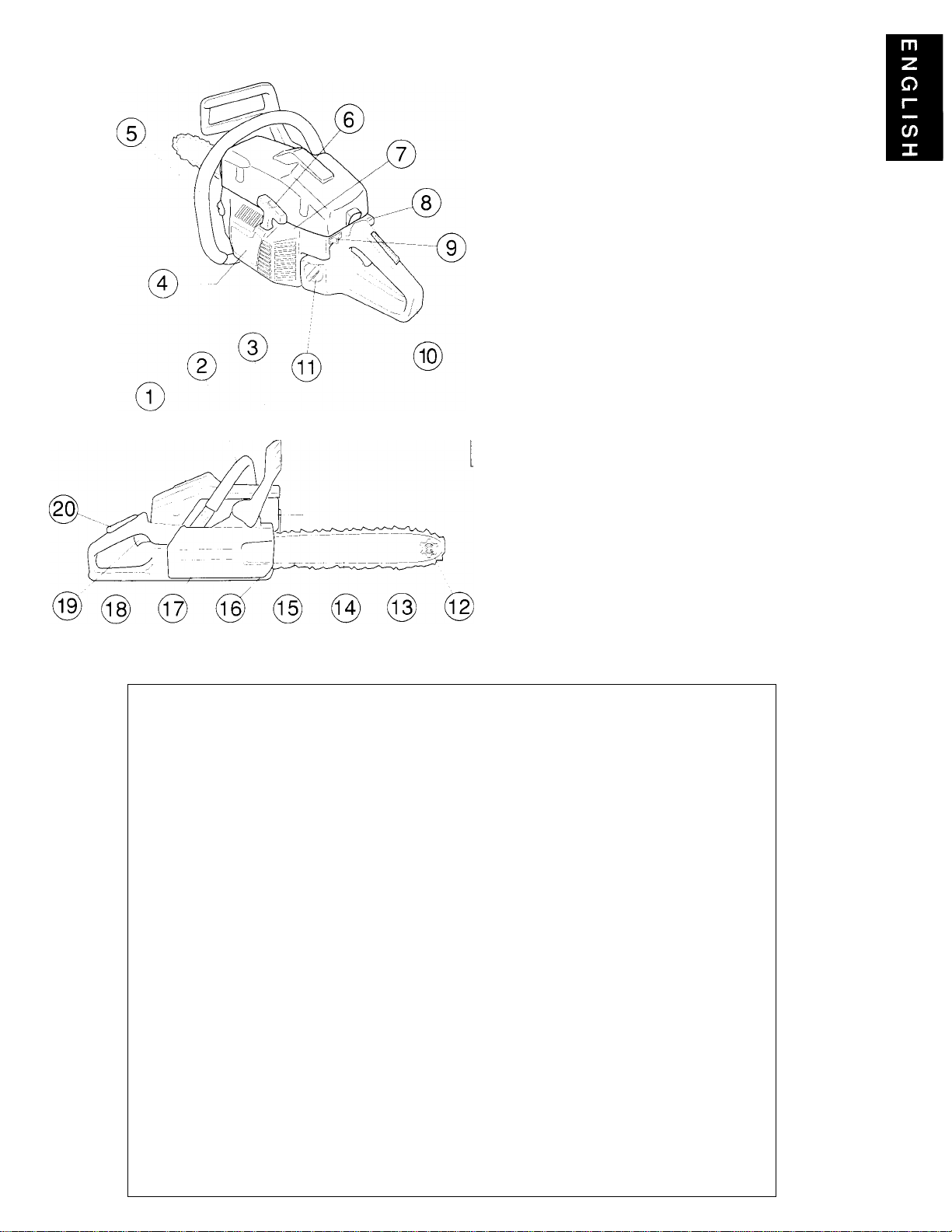

What is what on the saw

1. Cylinder cover.

2. Front handle.

3. Front hand guard.

4. Starter.

5. Chain oil tank.

6. Starter handle.

7. Adjustment screws, carburettor.

8. Choke/Throttle latch

9. Stop switch. Switches the ignition on and off.

10. Rear handle.

11. Fuel tank.

12. Sprocket nose.

13. Saw chain.

14. Guide bar.

15. Muffler.

16. Chain catcher. Catches the chain if the chain jumps or

breaks.

17. Clutch cover with a built-in chain brake.

18. Chain guard. Protects the right hand if the chain breaks

or jumps.

19. Throttle trigger.

20. Throttle trigger lockout. Prevents unintentional throttle

movement.

Technical specification

Engine

Displacement

Bore

Stroke

Idling Speed

Recommended max speed unloaded

Ignition system

Manufacturer/type of ignition system

Spark Plug

Electrode Gap

Timing

Fuei and lubrication system

Manufacturer/type of carburettor

Fuel tank volume

Oil pump capacity at 8000 rpm

Oil tank volume

Oil pump type

Weight

With guide bar and chain, 16”

Chain and guide bar

Standard bar length

Recommended bar lengths

Chain speed at max power

Pitch

Thickness of driving links

cu.in/cc

mm

mm

rpm

rpm

Phelon

Champion

in/mm

Walbro

pint/litre

cc/min

pint/litre

Ibs/kilos

in/cm

in/cm

m/sec, t

in

in/mm

36

2.2/36

38

32

3000

13.000

CD

RCJ7Y

0.02/0,5

Fixed; Nonadjustable

WT239

0.73/0,40

6-8

0.36/0,20

automatic

12.1/5,5

16/41

15/38

16/41

18/46

16.3, 7t

3/8

.325

.050/1,3

.058/1,5

41

2.4/40

40

32

3000

13.000

00

RCJ7Y

0.02/0,5

WT 239

0.73/0,40

6-8

0.36/0,20

automatic

12.1/5,5

16/41

15/38

16/41

18/46

16.3, 7t

3/8

.325

.050/1,3

.058/1,5

Page 6

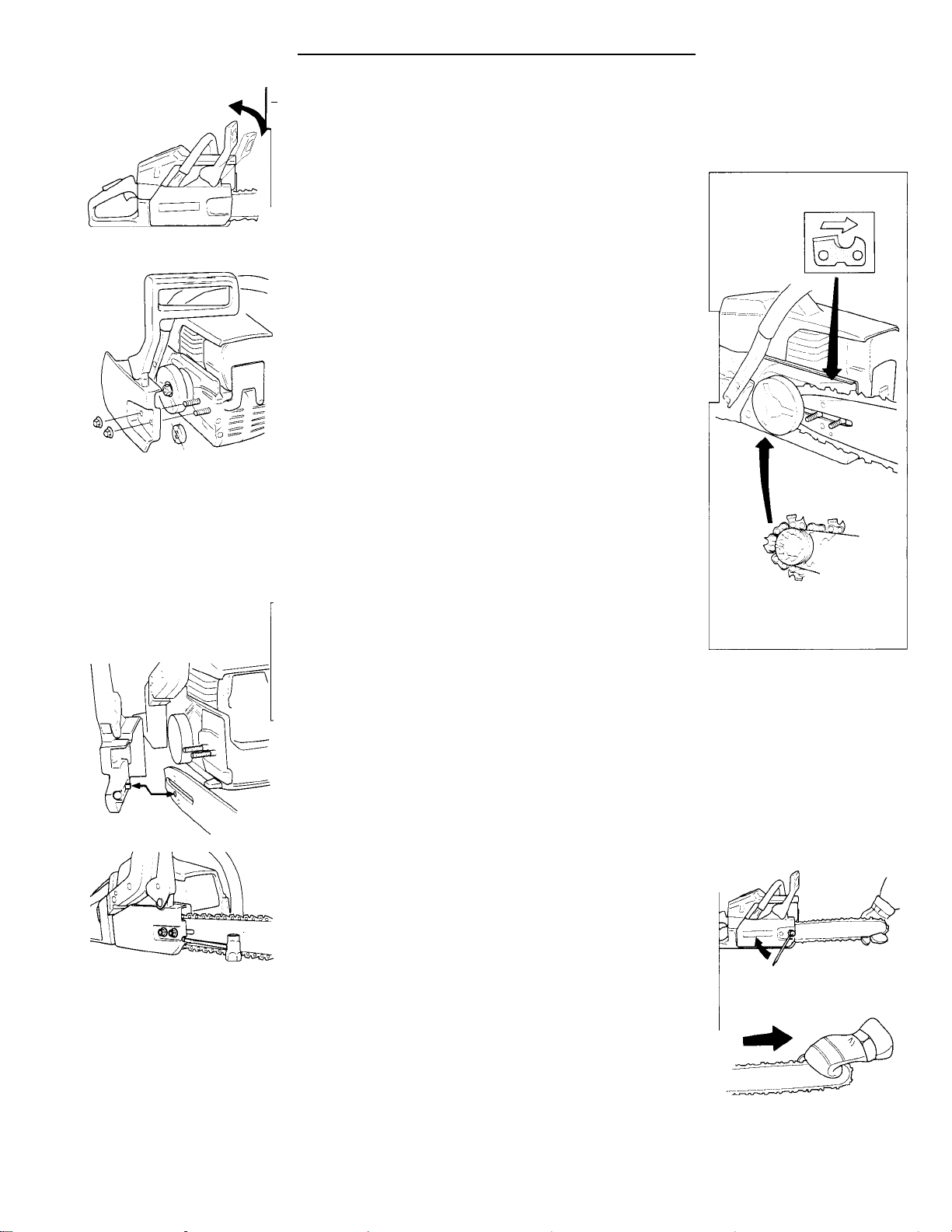

Mounting guide bar and chain

^ WARNING! Always wear gloves, when working with the chain,

‘ in order to protect your hands from injury.

Check that the chain brake is in disengaged position by moving

the front hand guard towards the front handle.

Take off the bar nuts and remove the clutch cover (chain brake).

Take off the transportation ring (A).

Fit the bar over the bar bolts. Place the bar in its rearmost

position. Place the chain over the drive sprocket and in the

groove on the bar. Begin on the top side of the bar. Make sure

that the edges on the cutting links are facing forward on the top

side of the bar.

Fit the clutch cover (chain brake) and locate the chain adjuster

pin in the hole on the bar. Check that the drive links of the chain

fit correctly on the drive sprocket and that the chain is in the

groove on the bar. Tighten the bar nuts finger tight. .

Tension the chain by using the combination wrench. Turn the

chain adjuster screw clockwise. The chain should be tensioned

until it fits snugly on the underside of the bar.

Hold up the tip of the bar and tighten the chain. The chain is

correctly tensioned when there is no slack on the underside of the

bar, but it can still be turned easily by hand. Hold up the bar tip

and tighten the bar nuts with the combination wrench.

When fitting a new chain, the chain tension has to be checked

frequently until the chain is run-in.

Check the chain tension regularly. A correctly tensioned chain

gives good cutting performance and long lifetime.

Page 7

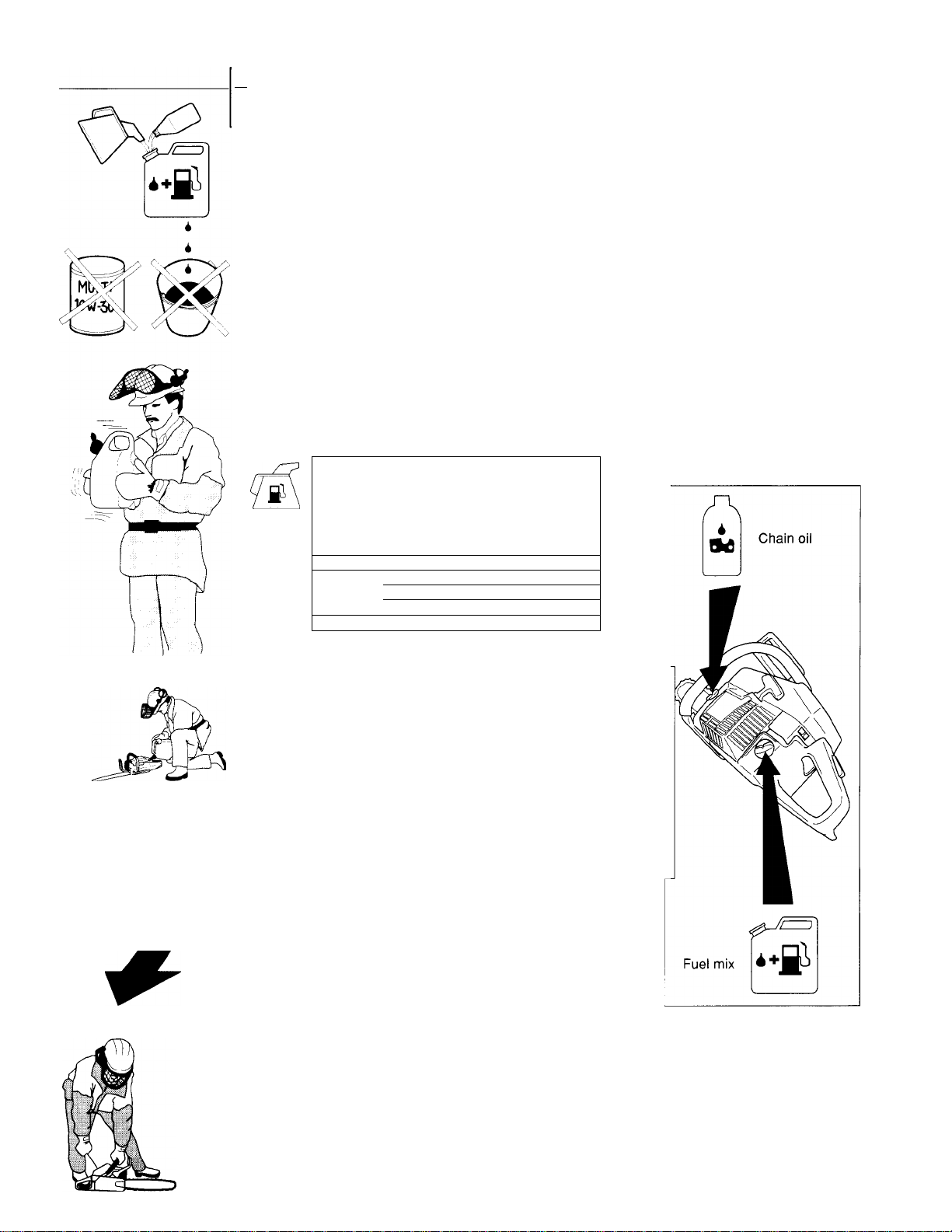

Fuelmix and chain oil

/¡\ WARNING! The chain saw is equipped with a two-stroke

engine. Always run the saw with fuel, which is mixed with oil.

Provide for good ventilation, when fueling or handling fuel.

Fuel

Always use a regular unleaded gasoline with minimum

octane number of 90.

This engine is certified to operate on unleaded gasoline.

Two-Stroke oil

• For the best performance, use Husqvarna two-stroke oil, which

is especially developed for chain saws.

Mixing ratio 1:50 (2 %).

• If Husqvarna two-stroke oil is not available, you may use

another two-stroke oil of good quality.

Mixing ratio 1:33 (3%).

• In countries where no two-stroke oil is available, motor oil SAE

30 can be used. Mixing ratio 1:25 (4%).

• Never use multi-grade oil (10 W-30) or waste oil.

• Always mix fuel and oil in a clean container.

• Always start by filling half the amount of fuel, which is to be

used. Then add the whole amount of oil. Mix (shake) the fuel

mixture. Add the remaining amount of fuel.

• Mix (shake) the fuel mix thoroughly before filling the fuel tank

on the saw.

Min 3 m

(10 ft)

Gasolin

Benzin

Essence

Gasolina

Lit.

5

10

15

20"

2%(1:50) 3%(1:33) 4%(1:25) 5%(1:20)

0,10 0,15 0,20 0,25

0,20 0,30

0,30 0,45 0,60

0,40 0,60 0,80 1,00

Chain oil

• The chain lubrication system is automatic. Always use special

chain oil with good adhesive characteristics.

• In countries where no special chain oil is available, gear box oil

EP 90 can be used.

• Never use waste oil. This results in damage to the oil pump, the

bar and the chain.

• It is important to use oil of the right viscosity according to the air

temperature.

• In temperatures below 0°C (32°F) some oils become less

viscous. This can overload the oil pump and result in damage

to the oil pump components.

• Contact your servicing dealer when choosing chain oil.

Fueling

Oil • 01 • Huile • Aceite

Lit.

0,40 0,50

0,75

Q

^WARNING!

• Always shut off the engine before refueling.

• Slowly open the fuel tank, when filling up with fuel, so that

possible over- pressure disappears.

• Tighten the fuel cap carefully, after fueling.

• Always move the saw away from the fueling area before

starting.

Before fueling, clean the tank cap area carefully, to ensure that

no dirt falls into the tank and causes malfunction. Make sure that

the fuel is well mixed by shaking the container, before fueling.

The volume of the chain oil tank and the fuel tank are adjusted to

each other. Therefore, always fill up with chain oil and fuel at the

same time.

Page 8

start and stop

start and stop

^WARNING!

’ • Never start the saw engine without the bar, chain and clutch

cover (chain brake) assembled - or else the clutch can come loose

and cause personal injuries.

• Always move the saw away from the fueling area before

starting.

• Place the saw on clear ground and make sure that the chain is

not contacting anything. Also, make sure that you have a secure

footing.

• Keep people and animals well away from the working area.

Start

Grip the front handle with your left hand and hold the saw down

by putting your right foot in the rear handle.

Pull the starter handle with your right hand and pull out the starter

cord slowly until the starter pawls engage. Then pull sharply.

Push in the choke control immediately when the engine ignites

and make repeated starting attemps.

When the engine starts, rapidly give full throttle. Then the throttle

latch will disengage.

CAUTION! Do not release the starter handle from fully pulled out

position as this can cause damage on the saw.

Cold engine

CHAIN BRAKE: Disengage the chain brake by pulling the hand

IGNITION: Move the ignition switch to the left.

CHOKE: Pull out the choke control

FAST IDLE: Combined choke/fast idle is received when the

guard towards he front handle.

choke is moved to choke position.

Warm engine

Use the same procedure as for starting cold engine but without

choke. Fast idle is recived by pulling out the choke fully first, and

then pressing it back again.

Stop

The engine is stopped by switching off the ignition.

(Move the ignition switch to the right.)

Page 9

Chain brake

The saw is equipped with a chain brake. The brake is designed to

stop the chain immediately in the event of a kick-back. The brake

activates when the hand guard is pushed forward (1).

If the brake is aiready activated, it is disengaged by pulling the

front hand guard back towards the front handle (2).

When working with the saw, the chain brake must be disengaged.

Use the chain brake as a ’’parking brake”, if you move the saw

with the engine running.

Inertia activated chain brake

The inertia activated chain brake is activated when the front hand

guard is pushed forward, either manuaily or by a weight in the

hand guard.

The advantage of the inertia brake is that the brake is activated

after kick-back, even if the user’s left hand does not contact the

hand guard, i.e., also when the saw is in the feliing position.

Control and maintenance of the chain brake

Braking function control:

The chain brake must be checked several times daily. Place the

saw on firm ground. Hold the handles with both hands and apply

full throttle. Activate the chain brake by turning your left wrist

against the hand guard, without releasing your grip around the

front handle. The chain should stop immediately (illustr.).

Inertia activating function control

The chain brake must be checked several times daiiy. Hold the

chain saw approx. 35 cm (14") above a trunk or other firm object

(illustr.).

CAUTION! The engine must be shut off.

Release your grip around the front handle and let the saw by its

own weight rotate around the rear handle. When the tip of the bar

hits the trunk, the brake should activate.

Maintenance:

/j\ WARNING! Dirt and wear affect the function of the brake.

’ Follow all maintenance instructions, carefully. If anything is

incorrect with your chain brake contact your servicing dealer.

With the engine shut off, the hand guard can be moved back and

forth, to ensure that the mechanism works freely and also that the

brake activates. If necessary, clean the brake from resin and

chips. Lubricate the mechanism and bearing surfaces with oil.

Check that the brake band is at least 0.65 mm (.026 in) thick, at

the most worn part.

Page 10

Maintenance and function

Air filter

The air filter must be regularly cleaned from dust and dirt in order

to avoid:

• Carburettor malfunctions

• Starting problems

• Engine power reduction

• Unnecessary wear on the engine parts

• Abnormal fuel consumption

• Harmful emissions

Clean the air filter daily or more often if the air is exceptionally

dusty in the working area. Disassemble the air filter by removing

the cylinder cover and unscrew the filter. When reassembling,

make sure that the filter is tight against the filter holder. Clean the

filter by brushing or shaking it. A more thorough cleaning of the

filter is obtained by washing it in water and soap.

Do not use gasoline or any other flammable liquid to clean the

filter; doing so can create a fire hazard and produce harmful

evaporative emissions.

An air filter, which is used for some time, cannot be cleaned

completely. Therefore it must be replaced by a new one, with

regular intervals.

IMPORTANT! A damaged air filter must always be replaced.

Muffler

The muffler is designed in order to reduce the noise level and to

direct the exhaust gases away from the operator. The exhaust

gases are hot and can contain sparks, which may cause fire if

directed against dry and combustible material. Some mufflers are

equipped with a special screen. If your saw has this type of

muffler, you should clean the screen at least once a week. This is

done with a wire brush. The screen must be replaced, if

damaged. The saw will be overheated, if the screen is clogged.

This results in damage on the cylinder and the piston.

CAUTION! Never use a saw with a clogged or defective muffler.

!

M

«D

•O

0,5 mm I Spark plug

The spark plug condition is influenced by:

• An incorrect carburettor setting.

• Wrong fuel mixture (too much oil in the gasoline).

• A dirty air filter.

These factors cause deposits on the spark plug electrodes,

which may result in malfunction and starting difficulties. If the

engine is low on power, difficult to start or runs poorly at

idling speed, always check the spark plug first. If the spark

plug is dirty, clean it and check the electrode gap. Readjust if

necessary. The correct gap is 0.5 mm (.020"). The spark plug

should be replaced yearly, or earlier if the electrodes are badly

eroded.

IMPORTANT! Always use the recommended spark plug type.

Wrong type may ruin the piston/cylinder.

Clutch drum/chain sprocket

The clutch drum is equipped with one of the following chain

sprockets:

• Spur sprocket (A) (the chain sprocket is welded on the drum)

• Rim sprocket (B) (exchangeable)

Both versions have buit-in neeldie bearing at the drive shaft,

whitch has to be greased regularly (once a week).

NOTE! Use only high quality bearing grease.

10

Page 11

starter device

A WARNING!

• When the recoil spring is assembled in the starter housing, it is in

tensioned position and can when treated carelessly, pop out and

cause injuries.

• Always be careful, when changing the recoil spring or the starter

cord. Always wear safety goggles for eye protection.

Changing a broken or worn starter cord

Loosen the screws, that hold the starter device against the

crankcase and remove the starter device.

Pull out the cord approx. 30 cm and lift it up into the notch in the

pulley.

Zero-set the recoil spring by letting the pulley rotate slowly

backwards.

Undo the screw in the centre of the pulley and remove the pulley.

Insert and fasten a new starter cord in the pulley.

Wind approx. 4 turns of the starter cord on to the pulley.

Assemble the starter pulley against the recoil spring, so the end

of the spring engages to the pulley.

Fit the screw in the centre of the pulley.

Carry the starter cord through the hole in the starter housing and

the starter handle. Make a knot on the starter cord.

Tensioning the recoil spring

Lift the starter cord up in the notch on the starter pulley and turn

the starter pulley 2 turns clockwise.

NOTE! Check that the starter pulley can be turned at least half a

turn, when the starter cord is entirely pulled out.

Changing the broken recoil spring

Lift the starter pulley. (See, Changing a broken or worn starter

cord). The recoil spring is disassembled from the starter device,

with its inside facing down. Tap the starter lightly against a

working bench or similar. Put a new recoil spring in the right

position. If the spring pops out when assembling, it should be

mounted again, out and in towards the centre.

Lubricate the recoil spring with thin oil.

Assemble the starter pulley, and tension the recoil spring.

Starter device assembly

Assemble the starter device, by pulling the starter cord out first,

then place the starter against the crankcase. Then slowly release

the starter cord so that the pulley engages with the pawls.

Assemble and tighten the screws, which hold the starter.

Page 12

Chain maintenance

Chain maintenance safety

For the personal safety, it is

of great importance, that the

bar and chain combinations

of so called low kick type are

used and that the cutting

equipment is maintained

correctly.

Important notes:

• Chain tension

• Sharpening

• Lubrication

• Check - maintenance

Recommended cutting equipment for Husqvarna chain saws

Following is a list of recommended cutting equipment for saws below 3.8 cu. in.(62,3 cc)

cylinder displacement. The combinations of powerhead, bar and chain have been investigated

in accordance with the kickback requirements of ANSI B 175.1.

The guide bar nose radius is determined by either the maximum number of teeth in the nose

sprocket or the corresponding maximum nose radius of a solid bar.

The following list is the chain saw manufacturers recommendations. There may be other

combinations available, which will also achieve kickback protection.

As we are listing the maximum guide bar nose radius, you may use a guide bar with smaller

nose radius then in our list. For guide bars of the same length, all sprocket-nose guide bars of

the same pich and having the same number of sprocket teeth may be considered to have

equivalent kickback energy. A hard nose bar having the same length and nose radius as a

sprocket-nose bar may be considered to have equivalent or less kickback energy then the

sprocket-nose bar.

Low kickback saw chain is a chain which has met the kickback performance requirements of

ANSI B 175.1 safety requirements for gasoline-powered chainsaws when tested on the

representative sample of chain saws below 3.8 cu.in. specified in ANSI B 175.1 These are

marked with an asterix * in the table below. We recommend that you as replacement use the

listed chains or "Low kickback saw chains" which are available at your dealer.

NOTE: The second number in the Oregon part number indicate the thickness of the drive link.

You are free to choose between 0.050" and 0.058" drive link for the corresponding bar.

HUSQVARNA H30 and OREGON 33 indicates 0.05071.3 mm

OREGON 34 indicates 0.05871.5 mm

Saw Chain

Husqvarna H30

Oregon 91SG *

Oregon 34SL *

Oregon 34LG *

Length inch Pitch inch

15, 16, & 18 .325

14&16 3/8

16&18 .325

16 & 18 .325

Max nose radius

lot

9t

lot

lot

Chain tension

A too loose chain may jump off the bar and cause injuries. This is

also the most frequent cause of chain problems. A too loose

chain can also ruin the chain, bar and drive sprocket.

Chain tension should be checked frequently during work and

corrected if necessary.

/j\ WARNING! Make sure that the engine is shut off.

Tension the chain as tight as possibie, but so it can stiii be

pulled easily along the bar by hand.

CAUTION! Check after tensioning by pulling the chain in the

normal direction of rotation. Always wear gloves to protect your

hands from injury.

Chain lubrication

Fill up the chain oil tank with chain oil each time you fuel. Never

run the chain dry. Insufficient oil may cause friction which leads to

cracks in the links. Waste oil must be avoided for the same

reason. Always use a proper chain oil which is off the non-fling

type and stands the pressure of the cutters. Bars provided with

nose sprockets are to be lubricated when refilling. Clean bar

groove and oil filling hole regularly.

Checking the lubrication

Direct the nose of the guide bar against a bright object, at a

distance of abt 20 cm (8"). Run the saw at 3/4 full throttle for 1/2-

1 minute and check that there is oil sprayed on the object.

12

Check daily for:

• Cracks in rivets and links of the chain.

• Excessive wear on side links and cutters or stiffness in the

chain.

• A cutter should never be filed to less than 5/32 inch or 4 mm.

• Correct depth gauge setting.

NOTE! Change the drive sprocket each time you fit a new chain.

Page 13

Chain maintenance

Sharpening

Never cut with a dull saw chain. A chain which does not cut

unless you press it hard against the wood is damaged, dull or

B

incorrectly filed. In order to file the chain correctly you need;

round file (A), file gauge (B), flat file (C) and a depth gauge tool

(D). By using the correct file size (see the table) and an file gauge

with a marked filing angle, it is easier to receive a good result.

NOTE! Check that the drive link does not have a too large play in

the bar groove. This can give an incorrect filing result. Always file

from the inside of the teeth and out. Then turn the saw and file on

the other side. In order to receive a straight cut in the wood, all

the teeth should be filed to the same length. If the chain is filed

regularly, only a few strokes are needed on every saw tooth. For

the best performance, every chain type has different cutting

angles, file sizes and filing depth (see the table).

/!\ WARNING! If a too small filing size is used or the file is kept

too deep in the cutting tooth, the chain will be dangerously

aggressive. This means that kick-back can occur.

Depth gauge

In order to receive the best performance and life time of the

chain, always keep the prescribed depth gauge setting.

/!\ WARNING ! A too big depth gauge makes the chain

dangerously aggressive. This means that kickback can occur.

The depth gauge of the cutting tooth is checked with a depth

gauge tool (measurement, see table).

NOTE! The chain should be filed before the depth gauge is

checked. An adjustment of the depth gauge is done with a flat file

Round off the corner of the depth gauge, afterwards.

13

Page 14

14

Page 15

Maintenance

Below you will find some generai maintenance instructions,

if you have more questions, contact your servicing dealer.

“1 Use only genuine Husqvarna replacement parts.

Daily maintenance:

1. Check the throttle trigger for smooth operation. If any binding

occurs, or if engine fails to return to idle, the saw should be

taken to your dealer, before it is used again. Also, be sure that

the trigger cannot be pulled until the throttle trigger lockout is

depressed.

2. Clean the chain brake and check its function according to the

instructions. Make sure that the chain catcher is undamaged.

Otherwise replace it immediately.

3. Clean or replace the air filter as necessary. Check for damage

or holes.

4. The bar should be turned daily for more even wear. Check the

lubrication hole in the bar, to be sure it is not clogged. Clean

the bar groove, if the bar has a sprocket tip, this should be

lubricated.

5. Check the function of the oiler to be sure the bar and chain

receive proper lubrication.

6. Sharpen the chain and check its tension and condition. Check

the drive sprocket for wear. Replace if necessary.

7. Check the starter and starter cord for wear or damage. Clean

the air intake slots on the starter housing.

8. Check for any loose nuts and screws and retighten if necessary.

9. Test the stop switch to be sure it shuts off the engine.

23

Weekly maintenance:

10. Check that the AV elements are not soft or torn.

11. Lubricate the clutch drum bearing.

12. File off burrs, if any, on the sides of the bar.

13. Clean the spark plug and check the gap. The correct gap is

0.5 mm (.020 in).

14. Check the starter and the recoil spring. Clean the fins on the

flywheel.

15. Clean the cooling fins on the cylinder.

16. Clean or change the screen in the muffler.

17. Clean the carburettor body and air box.

Monthly maintenance:

18. Check the brake band on the chain brake for wear.

19. Check the clutch centre, clutch drum and clutch spring for

wear.

20. Clean the outside of the carburettor.

21. Check the fuel filter. Change if necessary.

22. Flush the inside off the fuel tank with gasoline.

23. Flush the inside of the oil tank with gasoline.

24. Check all cables and connections.

15

Page 16

Carburettor

Functioning, Basic setting, Final setting

/¡\ WARNING! Do not start the saw without the bar, chain and clutch

' cover (chain brake) assembled. If you do, the clutch might come

loose and cause severe injuries.

Functioning

• The carburettor governs the engine speed via the throttle

trigger. In the carburettor, air/fuel is mixed. This air/fuel mixture

is adjustable. If you want to take advantage of the maximum

output of the engine, the setting must be correct.

• The setting of the carburettor means that the engine is adjusted

to local conditions, for example climate, altitude, petrol and type

of two-stroke oil.

• The carburettor has three adjustment possibilities:

L=Low speed needle

H=High speed needle

T=ldle speed adjustment screw

• The fuel quantity required in proportion to the airflow the

throttle trigger level allows is adjusted by means of the L- and

H-needles. Turning the needles clockwise gives a leaner fuel

mixture (less fuel), turning them counter-clockwise gives a

richer fuel mixture (more fuel). A lean mixture gives higher

rpm;s and a rich one lower rpm:s.

NOTE: Your unit is equipped with limiter caps, do not attempt

to adjust the needles beyond the stop as damage can occur.

• The idling speed screw T regulates the position of the throttle

lever in the idling speed position. Turn the idling speed screw

clockwise gives a higher idling speed, turn it counter-clockwise

a lower idling speed.

Basic setting

• The carburettor is adjusted to a basic setting when the saw is tested

at the factory. The basic setting is richer than the optimum setting

and shall be maintained during the first working hours. Thereafter, do

the final setting of the carburettor. The basic setting can vary

between: H=2-1/8 to 2-7/8 turn respectively L=1-1/2 to 2-1/4 turn.

NOTE! If the chain rotates in the idling position, turn the idling speed

screw counter-clockwise until the chain stops.

Final setting

• After the “break in” period (about 5 hours), the final setting is to

be done. This setting is done to ensure that your unit is running

at peak performance and producing the least amount of

harmful emissions. Have the final setting done by quali

fied service personnel. This service is not covered by war

ranty.

First, adjust the low speed needle L, then the high speed

needle H, and finally the idling speed screw T. The carbure

tor should be set according to the following RPM limits:

Max. speed (no load)=13,000 rpm

Idling speed=2800/3200 rpm

Conditions

• Before all settings are done the air filter must be clean and the

cylinder cover mounted.

’ Set the needles marked T, L, and H to the mid point of the

limiter cap.

• Start the saw according to the starting instructions and warm it

up during 10 minutes.

NOTE! if the chain rotates in the idling position, turn the idling

speed screw counter-clockwise until the chain stops.

• Put the saw on a flat surface, the bar pointing in the opposite

direction of you. Avoid that bar and chain get into contact with

the surface or other objects.

16

Page 17

Page 18

Equipment needed

Clothing

The proper clothing and equipment (as shown) protect you from

many potential hazards such as lacerations, thrown objects, and

hearing loss.

Always wear:

• safety helmet

• ear protection

• visor or goggles

• heavy-duty non-slip gloves

• safety pants or chaps

• boots with steel toe caps and no-slip soles

First aid kit

A first aid kit approved by the Red Cross or an organization of

similar stature should always be carried in case of injury in the

field. A kit should contain large dressings for lacerations, splints

and slings for fractures, antiseptic and other optional items for

your safety and convenience such as insect repellent.

___________

Forestry tools

Wedge - You should carry at least one non-metal wedge to help

remove a stuck saw safely.

Axe - Useful for trimming and clearing work that is hazardous or

not recommended for a chain saw.

Felling lever and hook - The felling lever is used to assist in

felling a tree, and the hook can be used to move a felled tree.

18

Page 19

General working instruction

General

Avoid cutting in adverse weather conditions, such as dense fog, heavy

rain, high winds, etc. Adverse weather is often tiring to work in and

creates potentially dangerous conditions such as slippery ground. High

winds may force the tree to fall in an unexpected direction causing

property damage or personal injury.

Never use a chain saw to pry or for any purpose for which it is not

intended.

Avoid stumbling on obstacles such as stumps, roots, rocks, branches

and fallen trees. Watch out for holes and ditches. Be extremely

cautious when working on slopes or uneven ground. Shut off the saw

when moving from one work place to another.

Always cut a wide-open throttle. A slow moving chain can easily catch

and force the saw to jerk.

Don’t be embarrassed to ask for help if you get into a cutting situation

that seems dificult to you. To continue could be dangerous. For

example - an obstacle such as power lines, close to the cutting area.

When cutting with the bottom part of the chain the reactive force will

pull the saw away from you towards the wood you are cutting.

The saw will control the feeding speed and sawdust will be directed

towards you.

Always keep a firm grip on the saw with your right hand on the

rear handle, your left hand on the front handle, and with your

thumbs and fingers encircling the handle. With your hands in this

position, you can best oppose and absorb reactive forces of your

chain saw. Make sure your chain saw handles are in good

condition, and free from moisture, oil and grease.

____________

/j\ WARNINGI Never use the saw with only one hand. You

' cannot control the saw properly and you may lose control and

injure yourself severely.

The safest method is to cut with the bottom part of the chain.

Sawing with the upper part makes it much more difficult to control

the saw and increase the risk of kickback.

WARNINGI A majority of kickback accidents occur during

limbing. Do not use the nose of the guide bar. Be extremely

cautious and avoid contacting the log, other limbs or objects

with the nose of the guide bar. Be extremely cautious of limbs

under tension. They can spring back towards you and cause

loss of control resulting in injury.

19

Page 20

General working instruction

Basic rules for felling trees

Normally the felling consists of two main cutting operations -

notching and making the felling cut.

Notching

Start making the upper notch cut on the side of the three facing

the felling direction.

Look through the kerf as you saw the lower cut so you do not saw

too deep into the trunk.

The notch should be deep enough to create a hinge of sufficient

width and strength. The notch opening should be wide enough to

direct the fall of the tree as long as possible.

Felling cut

Saw the felling cut from the other side of the tree and (3-5 cm)

above the edge of the notch.Never saw completely through the

trunk. Always leave a hinge. The hinge guides the tree. If the

trunk is completely cut through, you lose control over the felling

direction.

Insert a wedge or a felling lever in the cut well before the tree

becomes unstable and starts to move. This will prevent the

guidebar from binding in the felling cut if you have misjudged the

failing direction. Make sure no people have come into the range

of the falling tree before you push it over.

Felling cut, trunk diameter less than guide bar length

Saw either with a pushing chain (top of guide bar) ... or with a

pulling chain (bottom of guide bar).

Felling cut, trunk diameter greater than guide bar length

Make a boring cut. Watch out for kickbacks. Do not use the upper

tip quadrant of the guide bar tip.

Saw with a pushing chain. Leave a sufficient hinge.

Complete the felling cut by sawing around the trunk with a pulling

chain.

20

Page 21

General working instruction

Limbing

Limbing is removing the branches from a felled tree.

A WARNING! A majority of kickback accidents occur during

^ limbing. Do not use the nose of the guide bar. Be extremely

cautious and avoid contacting the log, other limbs or objects

with the nose of the guide bar. Be extremely cautious of limbs

under tension. They can spring back towards you and cause

loss of control resulting in injury.

Stand on the left side of the trunk. Maintain a secure footing and

rest the saw on the trunk. Hold the saw close to you so that you

are in full control of it. Keep well away from the chain. Move only

when the trunk is between you and the chain. Watch out for

spring back of limbs under tension.

Limbing thick branches

When limbing thick branches, the guide bar may get pinched

easily. Branches under tension often snap up, so cut troublesome

branches in small steps. Apply the same principles as for cross

cutting.

Think ahead and be aware of the possible consequences of all

your actions.

____________________

_

Cross cutting/bucking

Before starting to cut through the log, try to imagine what is going

to happen. Look out for stresses in the log and cut through in

such a manner that the guide bar will not get pinched.

Cross cutting logs, pressure on top

Firm stance. Begin with an upper cut. Do not cut too deeply -

about 1/3 of the log diameter is enough. Finish with a bottom cut.

The saw cuts should meet.

Cross cutting logs, pressure on bottom

Firm stance. Begin with a bottom cut. The depth of the cut should

be about 1/3 of the log diameter. Finish with an upper cut. The

saw cuts should meet.

If the saw gets stuck

stop the engine.

Raise the log or change its position, using a thick branch or pole

as a lever.

Do not try to pull the saw free. If you do, you can deform the

handle or be injured by the saw chain if the saw is suddenly

released.

_____

21

Page 22

General working instruction

Common sense

We have already pointed out that a chain saw is a

dangerous tool, if used carelessly, or if improperly

maintained. If you use your chain saw as intended,

it is an excellent tool. Should you lack information in

any respect, should you feel uncertain about

anything, please contact us or one of our servicing

dealers. Feel free to visit our servicing dealers at

any time. They will give you continuous information

about new features on our saws, safety devices,

new products, new accessories, etc.

22

Loading...

Loading...