Husqvarna 35935279 Owner’s Manual

HUSQVARNA

CHAINSAW

Operator's manual (EPA)

5 5 Rancher

CRAFTSMAN 359.35279

Please read these instructions carefully and make

sure you understand them before using the machine. English

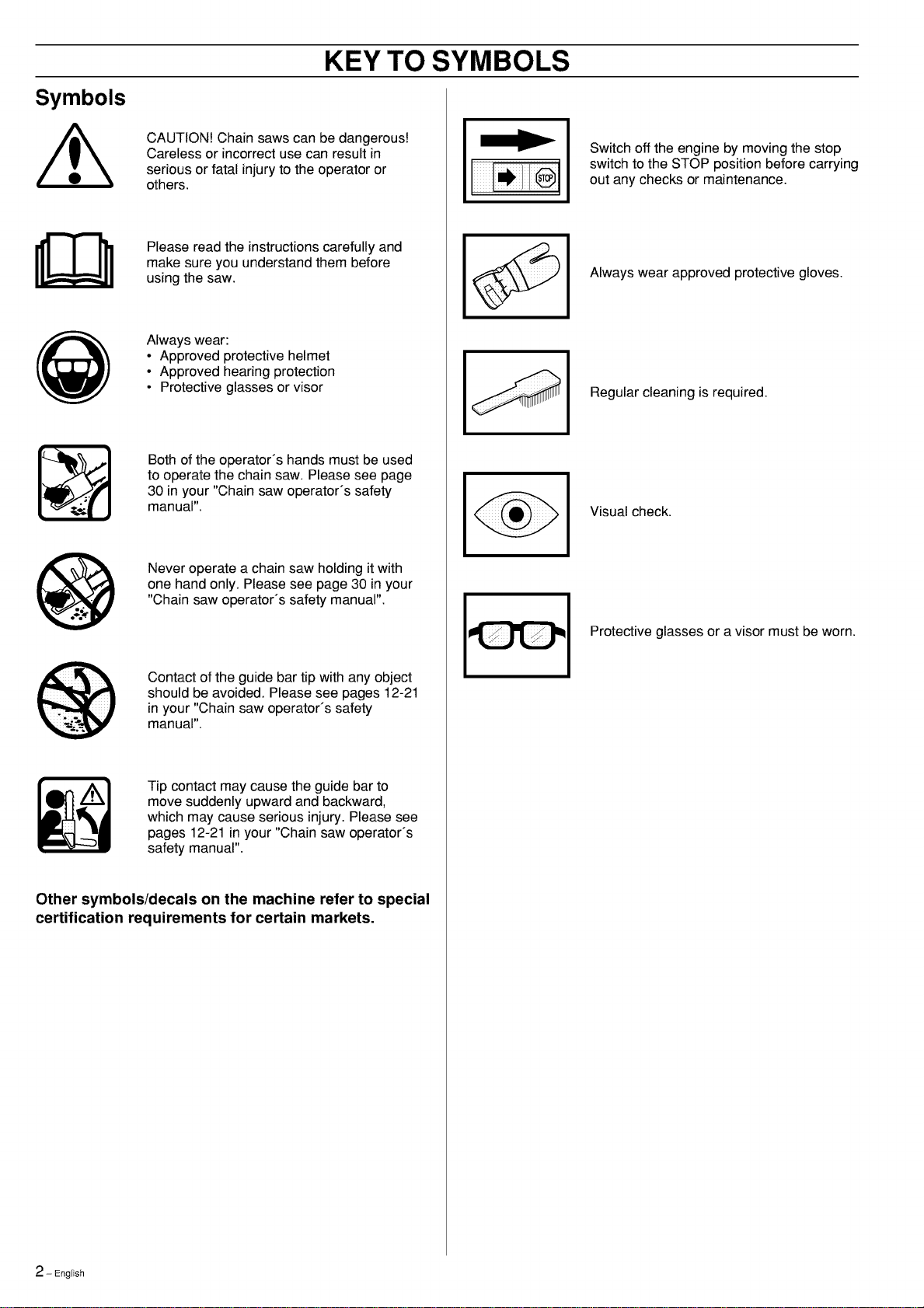

Symbols

KEY TO SYMBOLS

@

CAUTION! Chain saws can be dangerous!

Careless or incorrect use can result in

serious or fatal injury to the operator or

others.

Please read the instructions carefully and

make sure you understand them before

using the saw.

Always wear:

• Approved protective helmet

• Approved hearing protection

• Protective glasses or visor

Both of the operator's hands must be used

to operate the chain saw. Please see page

30 in your "Chain saw operator's safety

manual".

Never operate a chain saw holding it with

one hand only. Please see page 30 in your

"Chain saw operator's safety manual".

Switch off the engine by moving the stop

switch to the STOP position before carrying

out any checks or maintenance.

Always wear approved 3rotective gloves.

Regular cleaning is required.

Visual check.

Contact of the guide bar tip with any object

should be avoided. Please see pages 12-21

in your "Chain saw operator's safety

manual".

Tip contact may cause the guide bar to

move suddenly upward and backward,

which may cause serious injury. Please see

pages 12-21 in your "Chain saw operator's

safety manual".

Other symbols/decals on the machine refer to special

certification requirements for certain markets.

Protective glasses or a visor must be worn.

2 = English

CONTENTS

Before using a new saw

• Read the instructions carefully.

• Check cutting equipment is correctly fitted and adjusted.

See page 25.

• Refuel and start the saw. Check the carburetor settings.

See pages 26-29.

• Do not use the saw until sufficient chain oil has reached the

chain, see page 14.

IMPORTANT! If the carburetor mixture is too lean it greatly

increases the risk of engine failure.

Poor maintenance of the air filter will cause carbon build-up on

the spark plug and lead to difficult starting.

Ifthe chain is badly adjusted it will cause increased wear or

damage to the bar, drive sprocket and chain.

Maintenance, replacement, or repair of the emission

control devices and systems may be performed by any

nonroad engine repair establishment or individual.

WARNING

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.

You will find the following labels

on your chain saw:

Contents

Key to symbols .........................................................2

Safety instructions

Personal protective equipment .................................4

Chain saw safety equipment ......................................4

Inspecting, maintaining and servicing chain saw safety

equipment ............................................................................ 8

Cutting equipment .........................................................10

How to avoid kickback .................................................16

General safety precautions .......................................18

General working instructions ....................................19

What is what?

What is what? .................................................................... 24

Assembly

Mounting guide bar and chain ........................................... 25

Fuel handling

Fuelmix .............................................................................. 26

Fuelling .............................................................................. 27

Start and stop

Start and stop .................................................................... 28

Maintenance

Carburetor ......................................................................... 29

Starter device .................................................................... 30

Air filter .............................................................................. 31

Spark plug ......................................................................... 31

Muffler ................................................................................ 31

Needle bearing maintenance ............................................ 31

Cooling system .................................................................. 32

Centrifugal cleaning "Air Injection". ................................... 32

Winter use ......................................................................... 32

Daily maintenance ............................................................. 33

Weekly maintenance ......................................................... 33

Monthly maintenance ........................................................ 33

Technical data

55 Rancher ........................................................................ 34

Emission Control Warranty

Statement

Your warranty rights and obligations ................................. 35

Thissawiscapableofseverekickback.

Followall safetyprecautions

Failuretofollowinstructionscouldresultinserious

personalinjury.Recommendedcuttingequipment

seeOperator°sManual(s).Otherloworreduced

kickbackcombinationsinOperator°sManual(s).

_ LISTED 54L1. LISTED IN ACCORDANCEWITH AMERICAN

intheOperator°sManual(s)

NATIONAL STANDARD SAFETY SPECIFICATIONS FOR

GASOLINE POWERED CHAIN SAWS(ANSI C175.1-2000),y

f

_Husqvarna __

HUSQVARNA AB HUSKVARNA SWEDEN EM

THIS ENGINECONFORMSTO U.S. EPA PH1

EMISSION REGULATIONFOR SMALL

IMPORTANTENGINEINFORMATION

NONROAD ENGINES. REFERTO OPERATOR'S

MANUALFOR MAINTENANCE

SPECIFICATIONSANDADJUSTMENTS.

Husqvarna AB has a policy of continuous product development

and therefore reserves the right to modify the design and

appearance of products without prior notice.

For customer assistance call: 704-921-7000

or contact us at our website: www.husqvarna.com

I

English 3

I

SAFETY INSTRUCTIONS

PERSONAL PROTECTIVE EQUIPMENT

CHAIN SAW SAFETY EQUIPMENT

This section explains the various safety features of the saw,

how they work, and basic inspection and maintenance you

should carry out to ensure safe operation. (See the "What is

what?" section tofind out where these components are on Your

saw).

Chain brake and front

hand guard

• PROTECTIVE HELMET

• HEARING PROTECTION

• PROTECTIVE GLASSES

OR VISOR

• GLOVES WITH

SAW PROTECTION

• PROTECTIVE TROUSERS

WITH SAW PROTECTION

Throttle lock

Chain catcher

4 Right hand guard

5 Vibration damping system

• BOOTS WITH SAW

PROTECTION, STEEL

TOE-CAP AND NON-SLIP

SOLE

Generally clothes should be

close-fitting without restricting

your freedom of movement.

• ALWAYS HAVE A FIRST

AID KIT NEARBY

4- English

Stop switch

Muffler

Cutting equipment (see

"Cutting equipment"

section).

SAFETY INSTRUCTIONS

1 Chain brake and front hand guard

YOUR chain saw is equipped with a chain brake that is desig-

ned to stop the chain immediately if you get a kickback.

The chain brake reduces the risk of accidents, but only You can

prevent them.

Take care when using your

saw and make sure the

kickback zone of the bar

never touches any object.

The chain brake (A) can

either be activated

manually (by your left

hand) or automatically by

the inertia release

mechanism (a free-

swinging pendulum). On

most of our models the

front hand guard acts as a

counterweight in case of

kickback.

A

B

2

The front hand guard is

not designed solely to

activate the chain brake.

Another important safety

feature is that it prevents

the chain from hitting your

left hand if you lose your

grip on the front handle.

3a

Starting

The chain brake must be

engaged when starting.

You can also use the

chain brake as a

temporary brake when you

change position or if you

put the saw down for a

short time. You should

also apply the chain brake

manually if there is a risk

of the chain accidentally

hitting anyone or anything

close by.

The brake is applied

when the front hand

guard (B) is pushed

forwards.

This movement activates

a spring-loaded

mechanism that tightens

the Brake Band (C)

around the engine drive

system (D) (Clutch Drum).

B

To release the chain brake

pull the front hand guard

backwards, towards the

front handle.

C

D

As mentioned in section A,

kickback can be very

sudden and violent.

Most kickbacks are

minor and do not always

activate the chain brake.

If this happens you

should hold the chain

saw firmly and not let

go.

English - 5

SAFETY INSTRUCTIONS

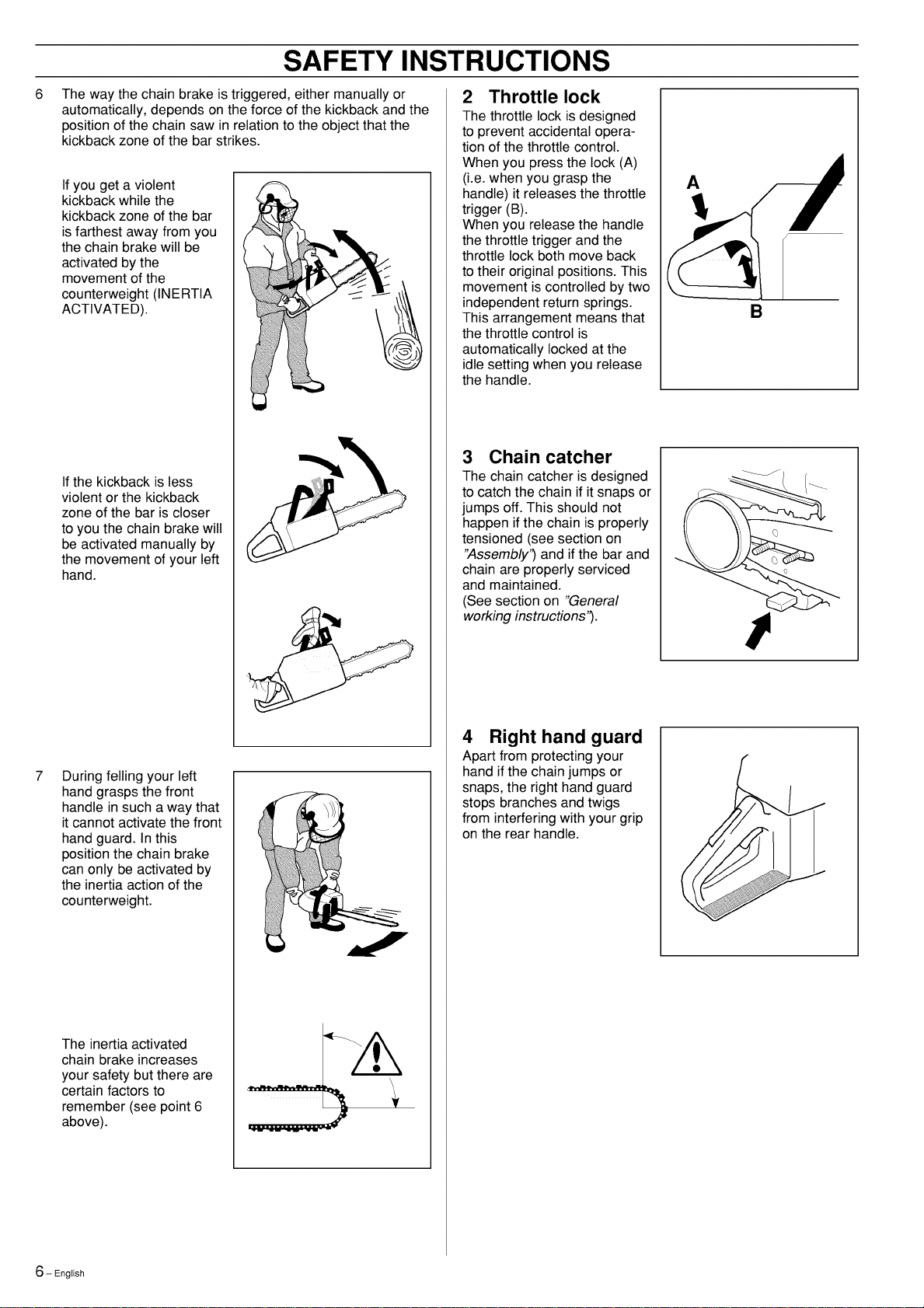

6

The way the chain brake is triggered, either manually or

automatically, depends on the force of the kickback and the

position of the chain saw in relation to the object that the

kickback zone of the bar strikes.

If you get a violent

kickback while the

kickback zone of the bar

is farthest away from you

the chain brake will be

activated by the

movement of the

counterweight (INERTIA

ACTIVATED).

If the kickback is less

violent or the kickback

zone of the bar is closer

to you the chain brake will

be activated manually by

the movement of your left

hand.

2 Throttle lock

The throttle lock is designed

to prevent accidental opera-

tion of the throttle control.

When you press the lock (A)

(i.e. when you grasp the

handle) it releases the throttle

trigger (B).

When you release the handle

the throttle trigger and the

throttle lock both move back

to their original positions. This

movement is controlled by two

independent return springs.

This arrangement means that

the throttle control is

automatically locked at the

idle setting when you release

the handle.

3 Chain catcher

The chain catcher is designed

to catch the chain if it snaps or

jumps off. This should not

happen if the chain is properly

tensioned (see section on

"Assembly') and ifthe bar and

chain are properly serviced

and maintained.

(See section on "General

working instructions').

A

B

During felling your left

hand grasps the front

handle in such a way that

it cannot activate the front

hand guard. In this

position the chain brake

can only be activated by

the inertia action of the

counterweight.

The inertia activated

chain brake increases

your safety but there are

certain factors to

remember (see point 6

above).

4 Right hand guard

Apart from protecting your

hand if the chain jumps or

snaps, the right hand guard

stops branches and twigs

from interfering with your grip

on the rear handle.

6- English

SAFETY INSTRUCTIONS

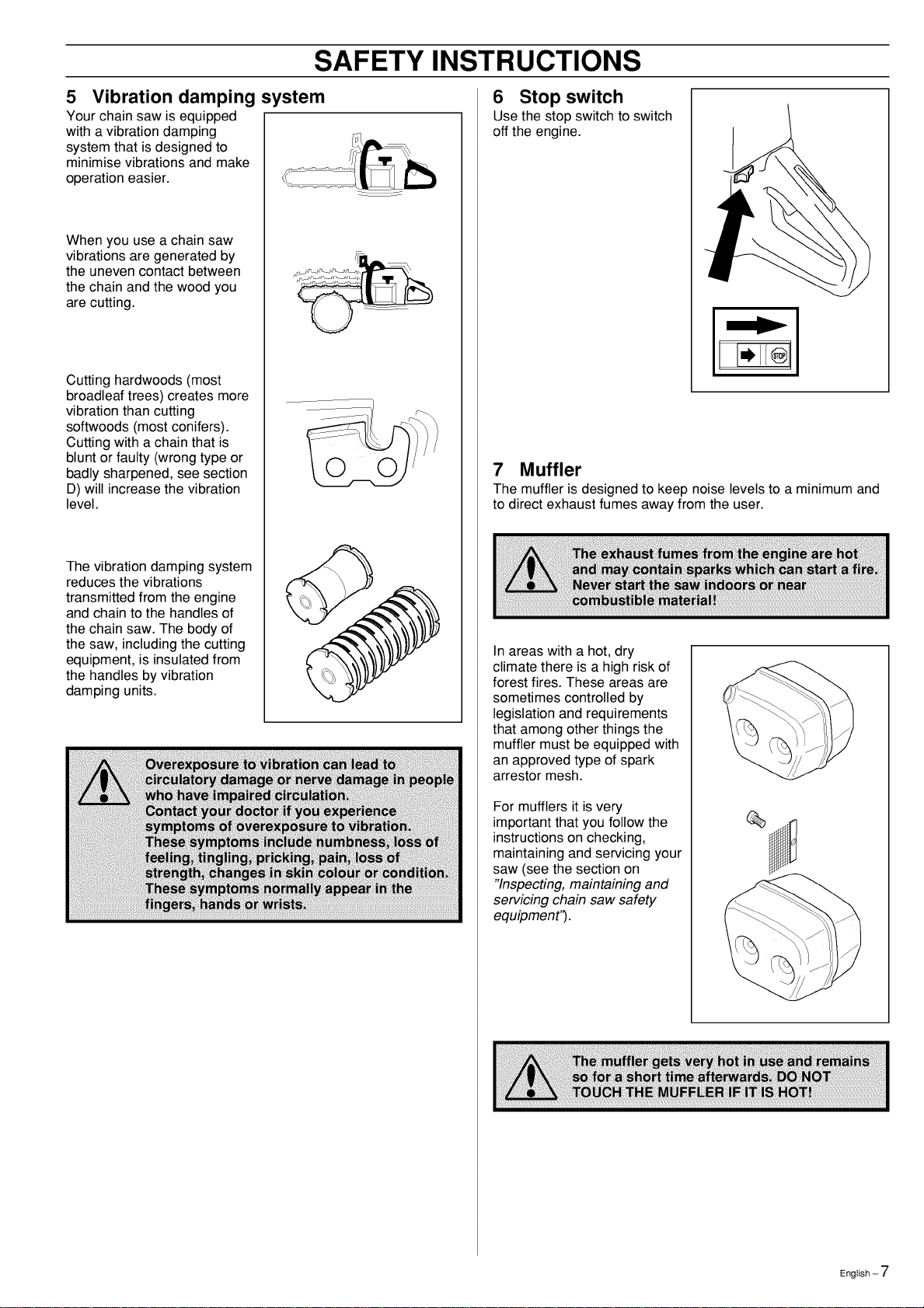

5 Vibration damping system

Your chain saw is equipped

with a vibration damping

system that is designed to

minimise vibrations and make

operation easier.

When you use a chain saw

vibrations are generated by

the uneven contact between

the chain and the wood you

are cutting.

Cutting hardwoods (most

broadleaf trees) creates more

vibration than cutting

softwoods (most conifers).

Cutting with a chain that is

blunt or faulty (wrong type or

badly sharpened, see section

D) will increase the vibration

level.

©

6 Stop switch

Use the stop switch to switch

off the engine.

7 Muffler

The muffler is designed to keep noise levels to a minimum and

to direct exhaust fumes away from the user.

The vibration damping system

reduces the vibrations

transmitted from the engine

and chain to the handles of

the chain saw. The body of

the saw, including the cutting

equipment, is insulated from

the handles by vibration

damping units.

In areas with a hot, dry

climate there is a high risk of

forest fires. These areas are

sometimes controlled by

legislation and requirements

that among other things the

muffler must be equipped with

an approved type of spark

arrestor mesh.

For mufflers it is very

important that you follow the

instructions on checking,

maintaining and servicing your

saw (see the section on

"Inspecting, maintaining and

servicing chain saw safety

equipment').

English - 7

SAFETY INSTRUCTIONS

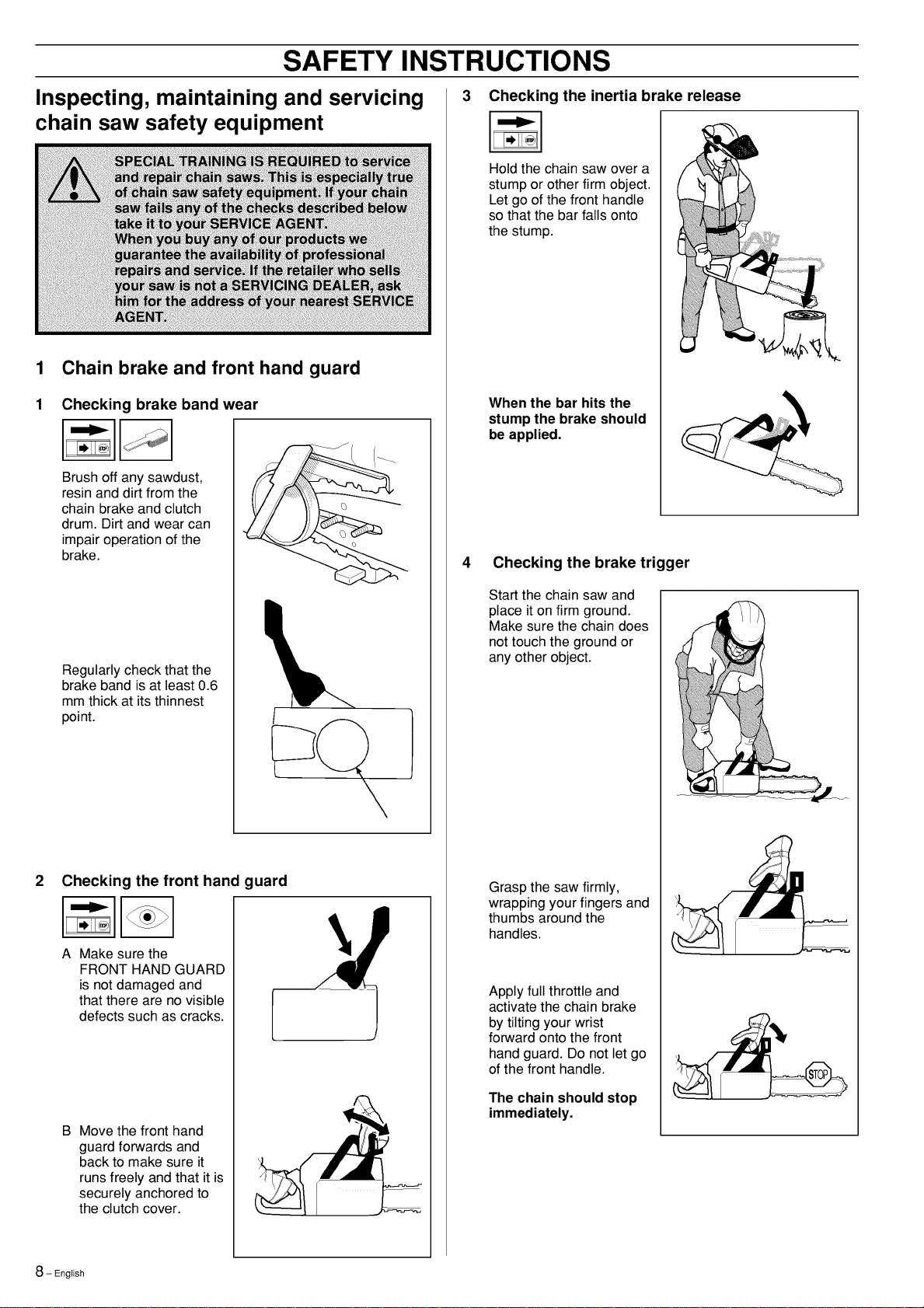

Inspecting, maintaining and servicing

chain saw safety equipment

1

Chain brake and front hand guard

1

Checking brake band wear

Brush off any sawdust,

resin and dirt from the

chain brake and clutch

drum. Dirt and wear can

impair operation of the

brake.

3 Checking the inertia brake release

Hold the chain saw over a

stump or other firm object.

Let go of the front handle

so that the bar falls onto

the stump.

When the bar hits the

stump the brake should

be applied.

4 Checking the brake trigger

Regularly check that the

brake band is at least 0.6

mm thick at its thinnest

point.

2 Checking the front hand guard

A Make sure the

FRONT HAND GUARD

is not damaged and

that there are no visible

defects such as cracks.

Start the chain saw and

place it on firm ground.

Make sure the chain does

not touch the ground or

any other object.

Grasp the saw firmly,

wrapping your fingers and

thumbs around the

handles.

Apply full throttle and

activate the chain brake

by tilting your wrist

forward onto the front

hand guard. Do not let go

of the front handle.

B Move the front hand

guard forwards and

back to make sure it

runs freely and that it is

securely anchored to

the clutch cover.

8 - English

The chain should stop

immediately.

SAFETY INSTRUCTIONS

2 Throttle lock

Make sure the throttle

control is locked at the

idle setting when you

release the throttle lock.

Press the throttle lock and

make sure it returns to its

original position when you

release it.

Check that the throttle

control and throttle lock

move freely and that the

return springs work

properly.

4 Right hand guard

Check that the right hand

guard is not damaged and

that there are no visible

defects, such as cracks.

5 Vibration damping system

Regularly check the

vibration damping units

for cracks or deformation

Make sure the vibration

damping units are

securely attached to the

engine unit and handles.

Start the saw and apply

full throttle. Release the

throttle control and check

that the chain stops and

remains stationary. If the

chain rotates when the

throttle is on idle setting

you should check the

carburetor idle

adjustment. See the

section on "Maintenance".

3

Chain catcher

Check that the CHAIN

CATCHER is not

damaged and is firmly

attached to the body of

the saw.

6 Stop switch

Start the engine and

make sure the engine

stops when you move the

stop switch to the stop

setting.

English - 9

SAFETY INSTRUCTIONS

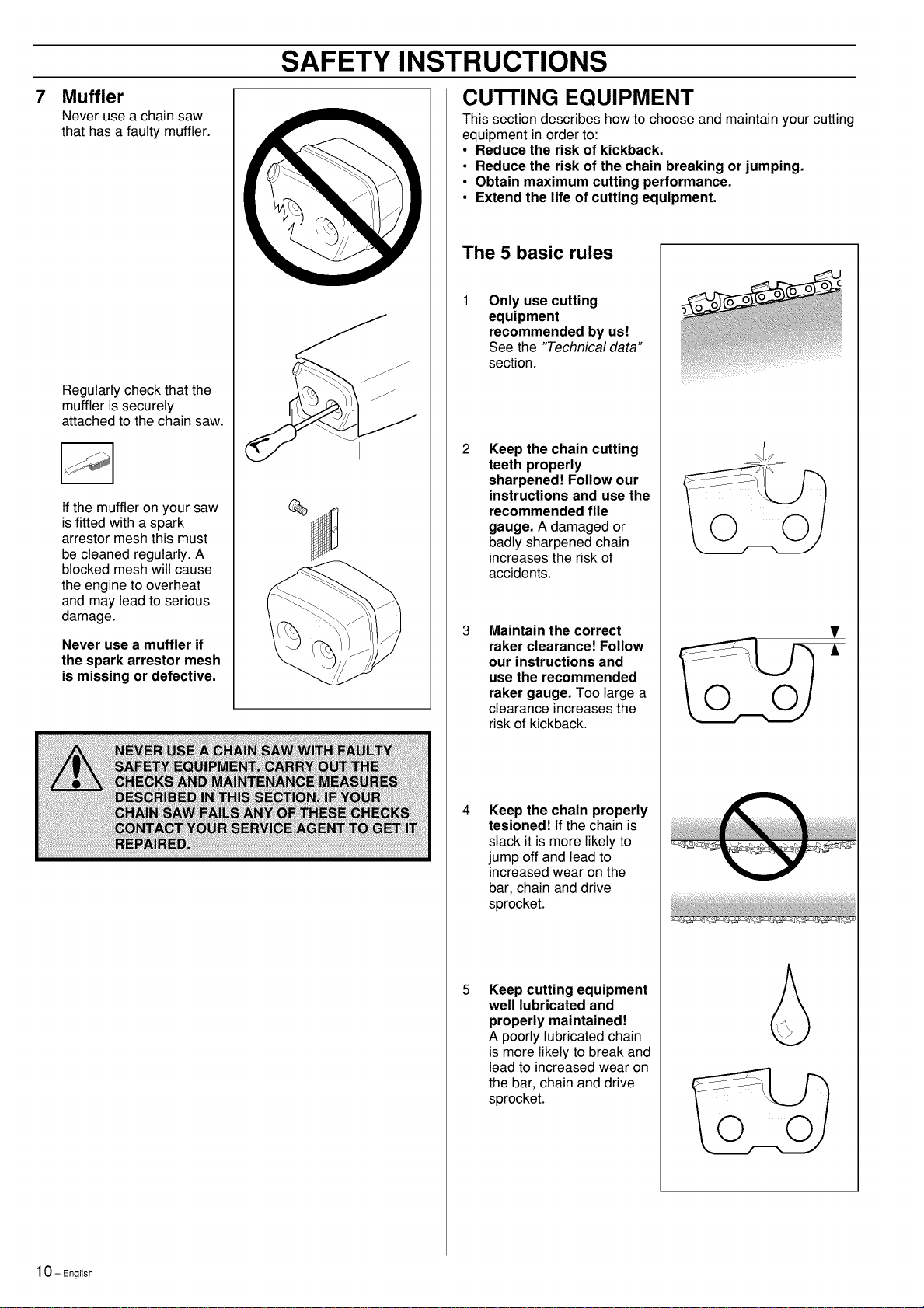

7 Muffler

Never use a chain saw

that has a faulty muffler.

Regularly check that the

muffler is securely

attached to the chain saw.

If the muffler on your saw

is fitted with a spark

arrestor mesh this must

be cleaned regularly. A

blocked mesh will cause

the engine to overheat

and may lead to serious

damage.

Never use a muffler if

the spark arrestor mesh

is missing or defective.

CUTTING EQUIPMENT

This section describes how to choose and maintain your cutting

equipment in order to:

• Reduce the risk of kickback.

• Reduce the risk of the chain breaking or jumping.

• Obtain maximum cutting performance.

• Extend the life of cutting equipment.

The 5 basic rules

Only use cutting

equipment

recommended by us!

See the "Technical data"

section.

Keep the chain cutting

teeth properly

sharpened! Follow our

instructions and use the

recommended file

gauge. A damaged or

badly sharpened chain

increases the risk of

accidents.

Maintain the correct

raker clearance! Follow

our instructions and

use the recommended

raker gauge. Too large a

clearance increases the

risk of kickback.

Keep the chain properly

tesioned! If the chain is

slack it is more likely to

jump off and lead to

increased wear on the

bar, chain and drive

sprocket.

Keep cutting equipment

well lubricated and

properly maintained!

A poorly lubricated chain

is more likely to break and

lead to increased wear on

the bar, chain and drive

sprocket.

©

10- English

SAFETY INSTRUCTIONS

1 Cutting equipment designed to minimise

kickback

The only way to avoid kickback is to make sure that the kick-

back zone of the bar never touches anything.

By using cutting equipment with "built-in" kickback protection

and keeping the chain sharp and well-maintained you can

reduce the effects of kickback.

A Bar

The smaller the tip radius the

smaller the kickback zone and

the lower the chance of

kickback.

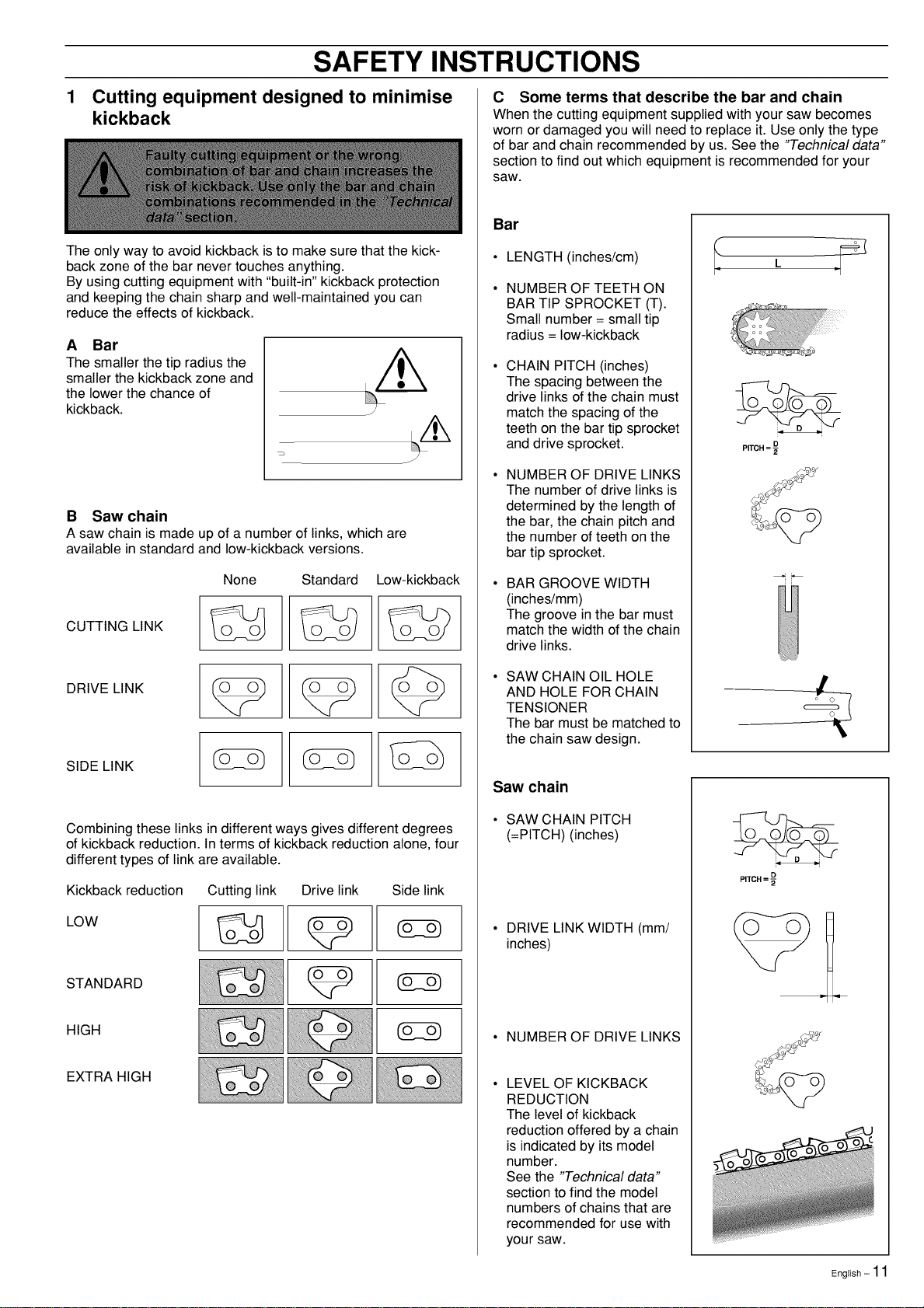

B Saw chain

A saw chain is made up of a number of links, which are

available in standard and low-kickback versions.

None Standard

CUTTING LINK _ _

Low-kickback

C Some terms that describe the bar and chain

When the cutting equipment supplied with your saw becomes

worn or damaged you will need to replace it. Use only the type

of bar and chain recommended by us. See the "Technical data"

section to find out which equipment is recommended for your

saw.

Bar

• LENGTH (inches!cm)

NUMBER OF TEETH ON

BAR TIP SPROCKET (T).

Small number = small tip

radius = low-kickback

CHAIN PITCH (inches)

The spacing between the

drive links of the chain must

match the spacing of the

teeth on the bar tip sprocket

and drive sprocket.

NUMBER OF DRIVE LINKS

The number of drive links is

determined by the length of

the bar, the chain pitch and

the number of teeth on the

bar tip sprocket.

BAR GROOVE WIDTH

(inches!mm)

The groove in the bar must

match the width of the chain

drive links.

PITCH = D

DRIVE LINK _) (_

SIDE LINK _

Combining these links in different ways gives different degrees

of kickback reduction. In terms of kickback reduction alone, four

different types of link are available.

Kickback reduction Cutting link

LOW

STANDARD

HIGH

EXTRA HIGH

Drive link Side link

SAW CHAIN OIL HOLE

AND HOLE FOR CHAIN

TENSIONER

The bar must be matched to

the chain saw design.

Saw chain

• SAW CHAIN PITCH

(=PITCH) (inches)

PITCH = D

• DRIVE LINK WIDTH (mm/

inches)

• NUMBER OF DRIVE LINKS

LEVEL OF KICKBACK

REDUCTION

The level of kickback

reduction offered by a chain

is indicated by its model

number.

See the "Technical data"

section to find the model

numbers of chains that are

recommended for use with

your saw.

English - 11

SAFETY INSTRUCTIONS

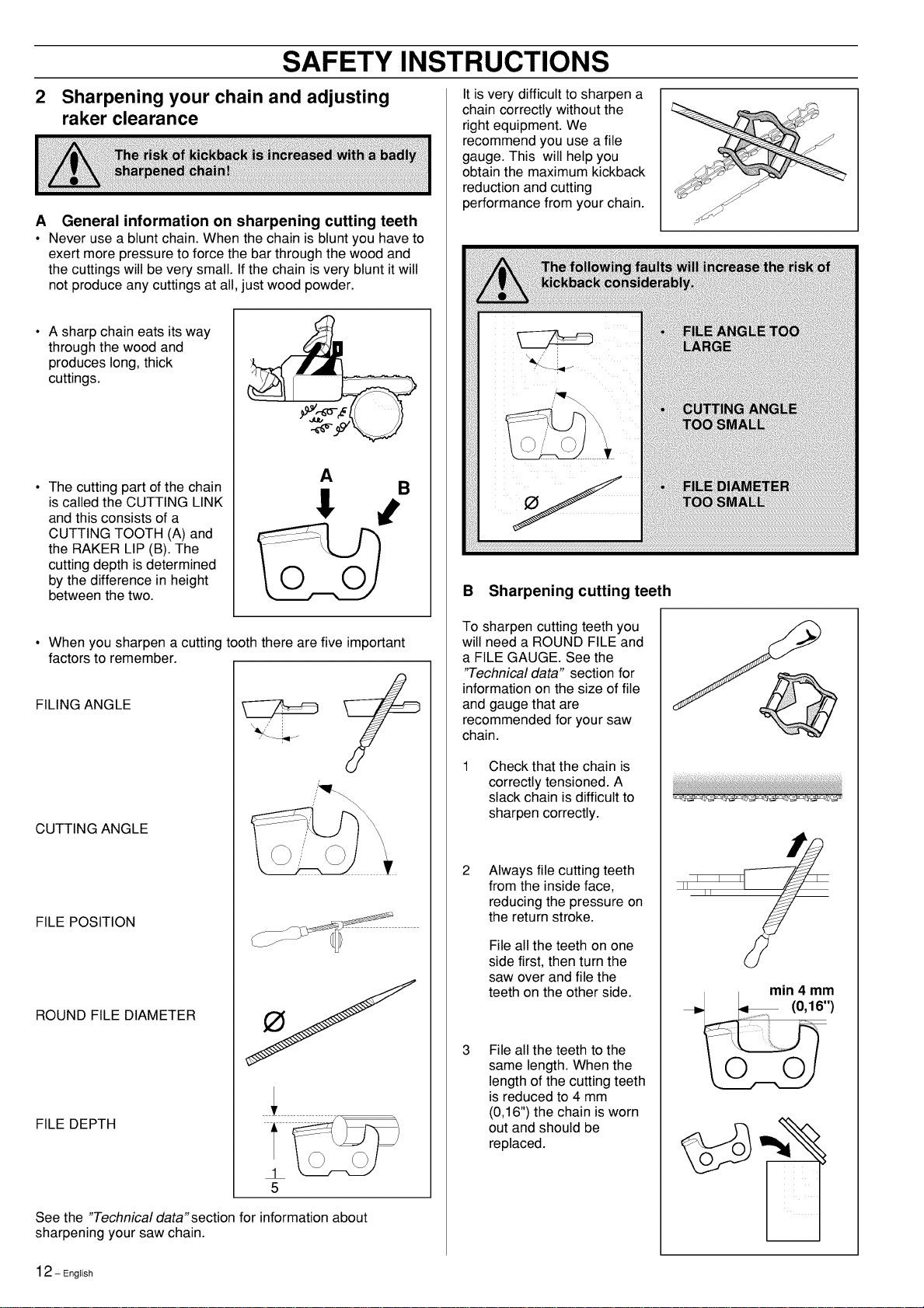

2 Sharpening your chain and adjusting

raker clearance

A General information on sharpening cutting teeth

• Never use a blunt chain. When the chain is blunt you have to

exert more pressure to force the bar through the wood and

the cuttings will be very small. If the chain is very blunt it will

not produce any cuttings at all, just wood powder.

• A sharp chain eats its way

through the wood and

produces long, thick

cuttings.

A

• The cutting part of the chain

is called the CUTTING LINK

and this consists of a

CUTTING TOOTH (A) and

the RAKER LIP (B). The

cutting depth is determined

by the difference in height

between the two.

O

It is very difficult to sharpen a

chain correctly without the

right equipment. We

recommend you use a file

gauge. This will help you

obtain the maximum kickback

reduction and cutting

performance from your chain.

B Sharpening cutting teeth

• When you sharpen a cutting tooth there are five important

factors to remember.

FILING ANGLE

CUTTING ANGLE

FILE POSITION

ROUND FILE DIAMETER

FILE DEPTH

To sharpen cutting teeth you

will need a ROUND FILE and

a FILE GAUGE. See the

"Technical data" section for

information on the size of file

and gauge that are

recommended for your saw

chain.

Check that the chain is

correctly tensioned. A

slack chain is difficult to

sharpen correctly.

Always file cutting teeth

from the inside face,

reducing the pressure on

the return stroke.

File all the teeth on one

side first, then turn the

saw over and file the

teeth on the other side.

File all the teeth to the

same length. When the

length of the cutting teeth

is reduced to 4 mm

(0,16") the chain is worn

out and should be

replaced.

___°_°_

min 4 mm

5

See the "Technical data"section for information about

sharpening your saw chain.

12 - English

SAFETY INSTRUCTIONS

C General advice on setting raker clearance

• When you sharpen the

cutting teeth you reduce the

RAKER CLEARANCE

(cutting depth). To maintain

cutting performance you

must file back the raker

teeth to the recommended

height.

See the "Technical data"

section to find the raker

clearance for your saw

chain.

• On a low-kickback cutting

link the front edge of the

raker lip is rounded. It is

very important that you

maintain this radius or bevel

when you adjust the raker

clearance.

• We recommend the use of a

raker gauge to achieve the

correct clearance and bevel

on the raker lip.

D Setting the raker clearance

Before setting the raker clearance the cutting teeth should be

newly sharpened.

We recommend that you adjust the raker clearance every

third time you sharpen the chain. NOTE! This

recommendation assumes that the length of the cutting teeth

is not reduced excessively.

To adjust the raker

clearance you will need a

FLAT FILE and a RAKER

GAUGE.

• Place the gauge over the

raker lip.

Place the file over the part

of the lip that protrudes

through the gauge and file

off the excess. The

clearance is correct when

you no longer feel any

resistance as you draw the

file over the gauge.

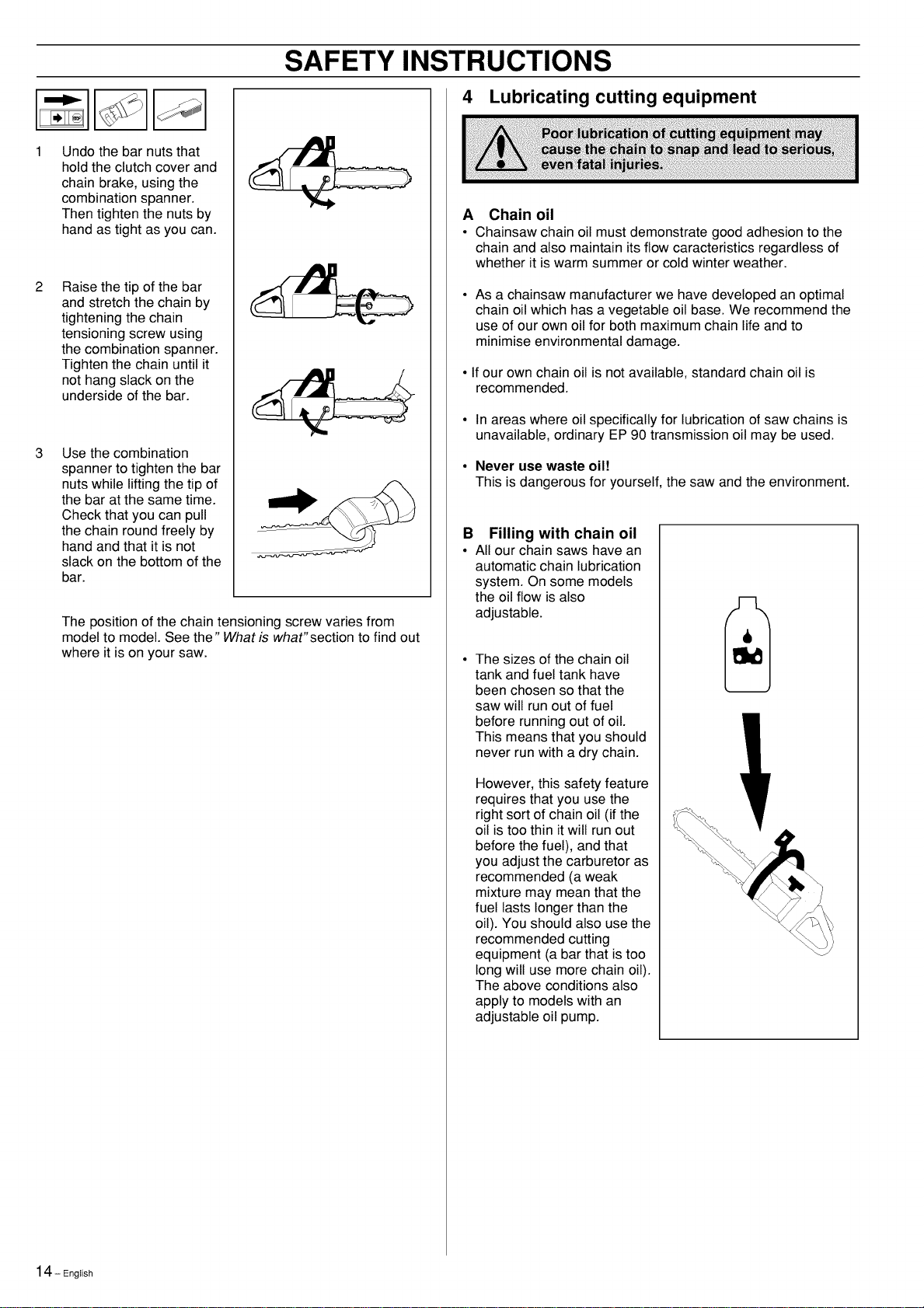

3 Tensioning the chain

The more you use a chain the longer it becomes. It is

therefore important to adjust the chain regularly to take up the

slack.

Check the chain tension every time you refuel.

NOTE! A new saw chain has a running-in period during which

you should check the tension more frequently.

Tension the chain as tightly

as possible, but not so tight

that you cannot pull it round

freely by hand.

English - 13

SAFETY INSTRUCTIONS

Undo the bar nuts that

hold the clutch cover and

chain brake, using the

combination spanner.

Then tighten the nuts by

hand as tight as you can.

2

Raise the tip of the bar

and stretch the chain by

tightening the chain

tensioning screw using

the combination spanner.

Tighten the chain until it

not hang slack on the

underside of the bar.

3 Use the combination

spanner to tighten the bar

nuts while lifting the tip of

the bar at the same time.

Check that you can pull

the chain round freely by

hand and that it is not

slack on the bottom of the

bar.

The position of the chain tensioning screw varies from

model to model. See the" What is what" section to find out

where it is on your saw.

4 Lubricating cutting equipment

A Chain oil

• Chainsaw chain oil must demonstrate good adhesion to the

chain and also maintain its flow caracteristics regardless of

whether it is warm summer or cold winter weather.

As a chainsaw manufacturer we have developed an optimal

chain oil which has a vegetable oil base. We recommend the

use of our own oil for both maximum chain life and to

minimise environmental damage.

• If our own chain oil is not available, standard chain oil is

recommended.

• In areas where oil specifically for lubrication of saw chains is

unavailable, ordinary EP 90 transmission oil may be used.

• Never use waste oil!

This is dangerous for yourself, the saw and the environment.

B Filling with chain oil

• All our chain saws have an

automatic chain lubrication

system. On some models

the oil flow is also

adjustable.

The sizes of the chain oil

tank and fuel tank have

been chosen so that the

saw will run out of fuel

before running out of oil.

This means that you should

never run with a dry chain.

However, this safety feature

requires that you use the

right sort of chain oil (if the

oil is too thin it will run out

before the fuel), and that

you adjust the carburetor as

recommended (a weak

mixture may mean that the

fuel lasts longer than the

oil). You should also use the

recommended cutting

equipment (a bar that is too

long will use more chain oil).

The above conditions also

apply to models with an

adjustable oil pump.

14- English

Loading...

Loading...