GB

SE Br

DK Br

NO Br

FI

DE

FR

NL

ES

PT

IT

EE

L V

L T

HU

PL

CZ

SK

HR

RS

B A

R O

R U

U A

BG

Oper ator’ s man ual 2-23

uksan visning 24-45

ugsan visning 46-67

uksan visning 68-89

Käyttöohje 90-111

Bedien ungsanw eisung 112-134

Man uel d’utilisation 135-158

Gebr uiksaanwijzing 159-181

Man ual de instr ucciones 182-204

Instr uções par a o uso 205-227

Istr uzioni per l’uso 228-250

Käsitsemisõpetus 251-272

Lieto‰anas pamÇc¥ba 273-294

Naudojimosi instrukcijos 295-316

SI Navodila za uporabo 317-338

Használati utasítás 339-360

Instrukcja obs∏ugi 361-383

Návod k pouÏití 384-405

Návod na obsluhu 406-427

Priruãnik 428-449

Priruãnik 450-471

Uputstvo o upotrebi 472-494

Instruc ö iuni de utilizare 495-516

TR Kullanım kılavuzu 517-538

уководство по

эксплуатации 539-563

îñ´áíèê

користувача 564-587

ъководство за

експлоатациЯ 588-612

GR √‰ËÁ›Â˜ ¯Ú‹Ûˆ˜ 613-637

122C

122LD

x-series

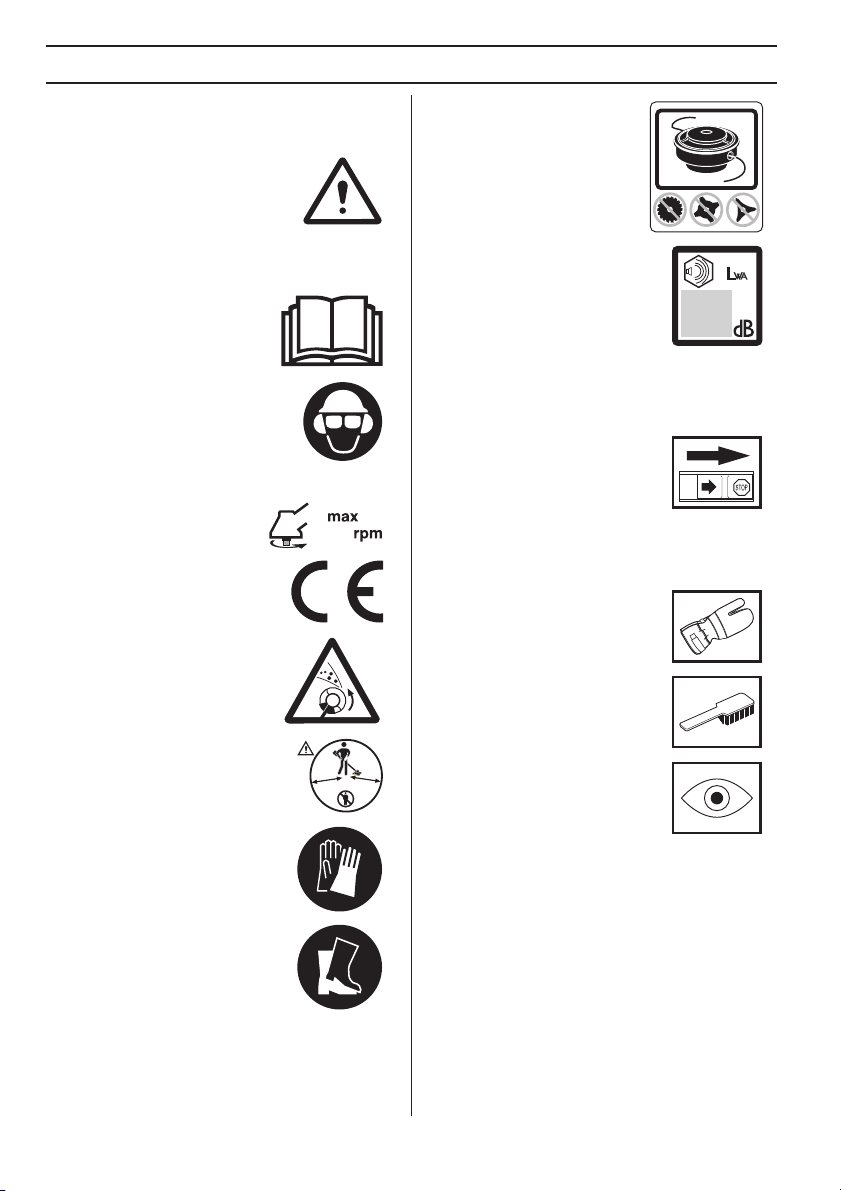

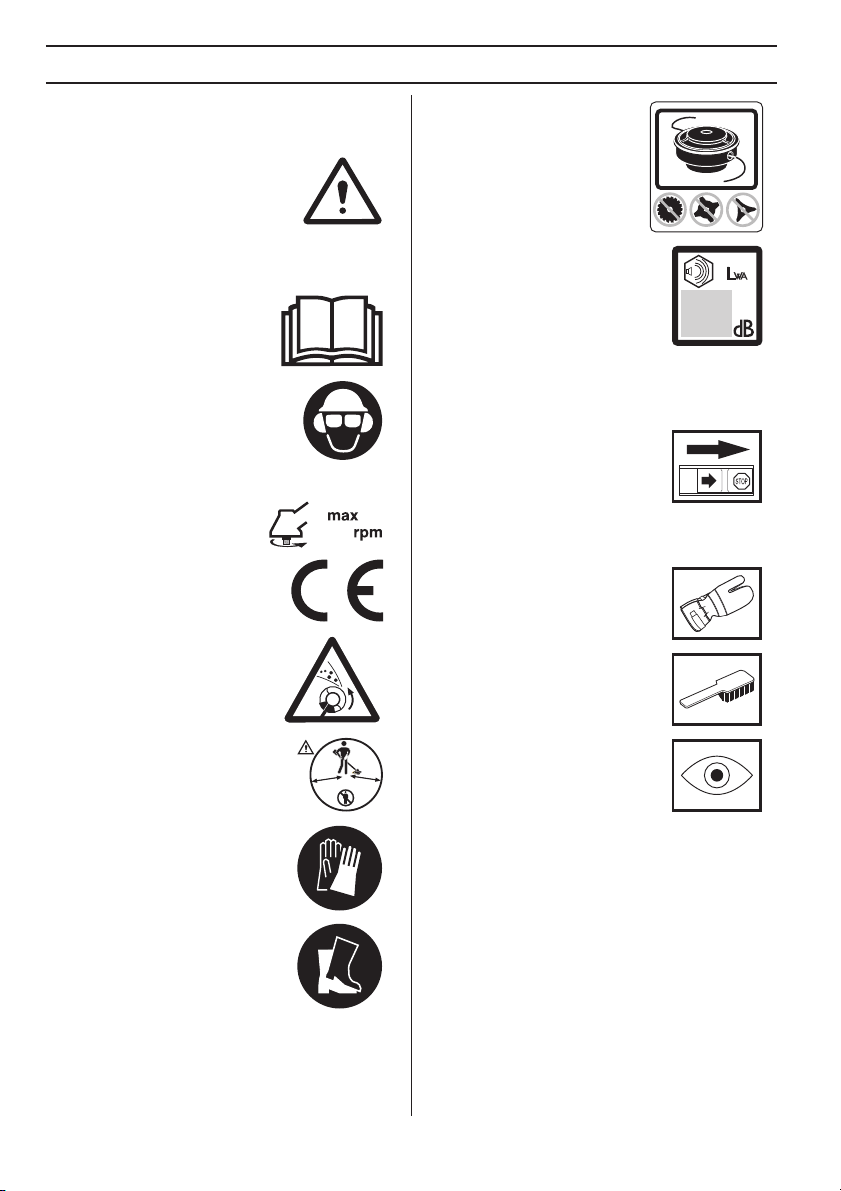

KEY T O SYMBOLS

Symbols on the mac hine and/or in

the manual:

WARNING! Clearing saws,

brushcutters and trimmers can be

dangerous! Careless or incorrect use

can result in serious or fatal injury to

the operator or others. It is extremely

important that you read and understand the contents of

the operator's manual.

Please read the operator’s manual

carefully and make sure you

understand the instructions before

using the machine.

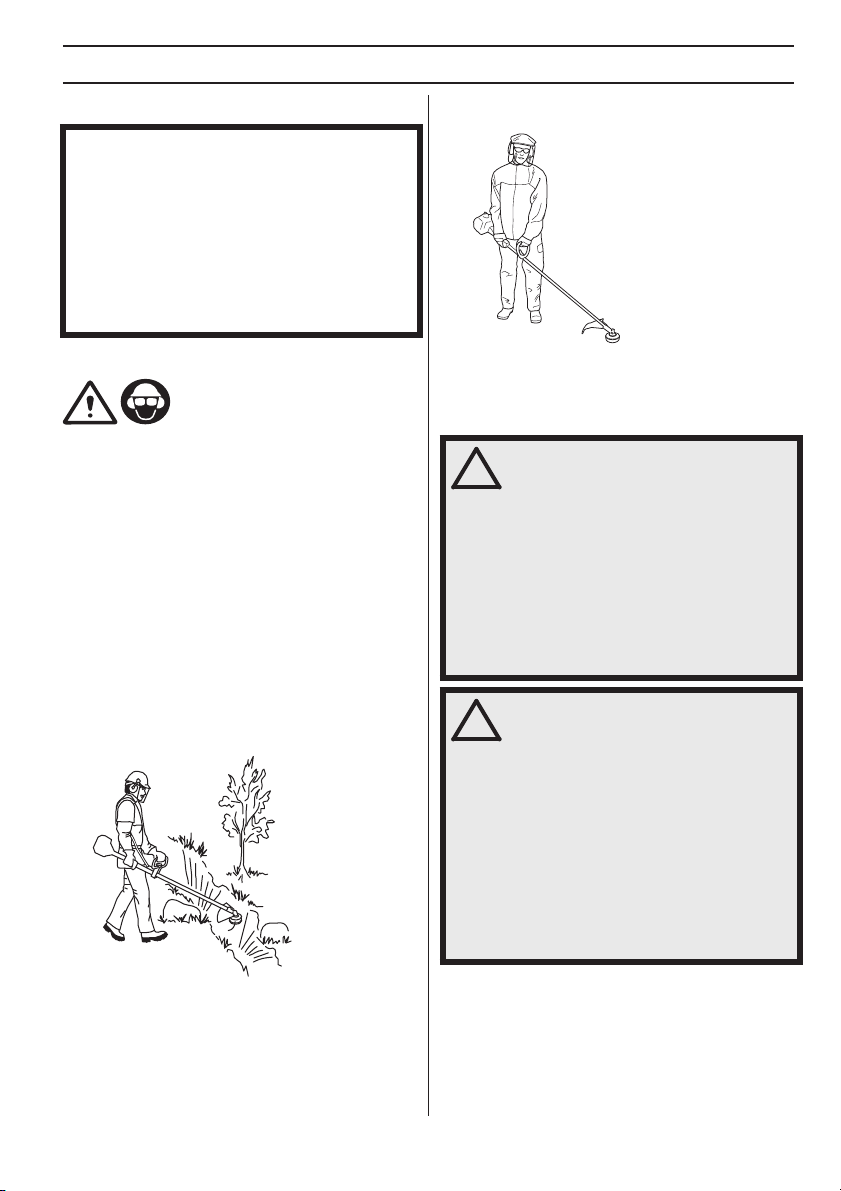

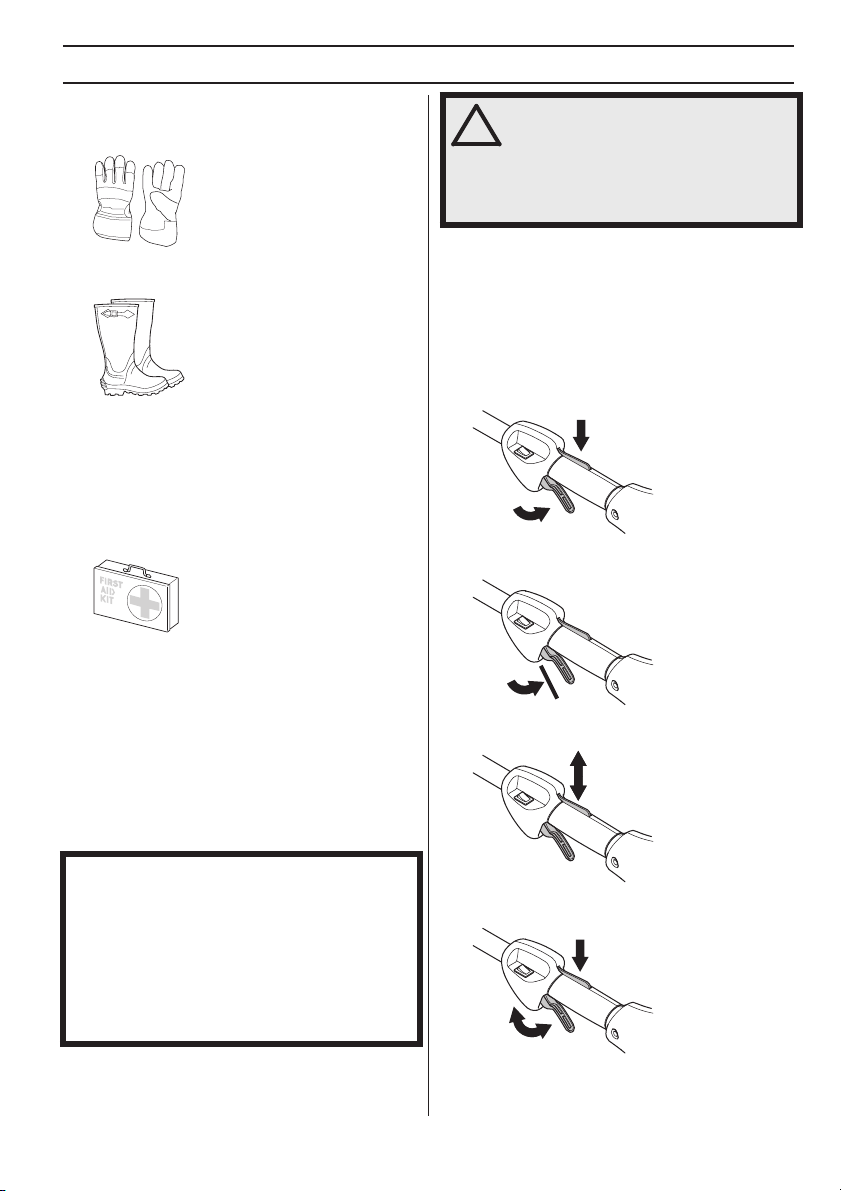

Always wear:

Wear a protective helmet where there

is a risk of falling objects

• Approved hearing protection

• Approved eye protection

Max. speed of output shaft, rpm

This product is in accordance with

applicable EC directives.

Watch out for thrown objects and

ricochets.

10000

2

Only use non-metallic, flexible

cutting attachments, i.e. trimmer

heads with trimmer cord.

Noise emission to the environment

according to the European

Community’s Directive. The

machine’s emission is specified in

the Technical data chapter and on the

label.

Other symbols/decals on the mac hine refer to

special certification requirements for certain

markets.

The engine is switched off by moving

the stop switch to the stop position.

CAUTION! The stop switch

automatically returns to the start

position. In order to prevent

unintentional starting, the spark plug cap must be

removed from the spark plug when assembling, checking

and/or performing maintenance.

Always wear approved protective

gloves.

Regular cleaning is required.

The operator of the machine must

ensure, while working, that no

persons or animals come closer than

15 meters.

Always wear approved protective

gloves.

Wear sturdy, non-slip boots.

– English

15

m

15 m

5

0

FT

50FT

Visual check.

CONTENTS

!

!

!

Contents

KEY TO SYMBOLS

Symbols on the machine and/or in the man ual: ... 2

CONTENTS

Contents ............................................................... 3

Note the following before starting: ........................ 3

INTR ODUCTION

Dear Customer, .................................................... 4

WHAT IS WHAT?

What is what on the grass trimmer? ..................... 5

GENERAL SAFETY PRECAUTIONS

Important .............................................................. 6

Personal protective equipment ............................. 6

Machine′s safety equipment ................................. 7

Cutting equipment ................................................ 9

ASSEMBLY

Fitting the loop handle .......................................... 10

Fitting the trimmer guard and trimmer head ......... 10

Assembling and dismantling the two-piece shaft . 10

FUEL HANDLING

Fuel safety ............................................................ 12

Fuel ...................................................................... 12

Fueling .................................................................. 13

STARTING AND STOPPING

Check before starting ........................................... 14

Starting and stopping ........................................... 14

WORKING TECHNIQUES

General working instructions ................................ 15

MAINTENANCE

Carburettor ........................................................... 17

Muffler .................................................................. 17

Cooling system ..................................................... 18

Spark plug ............................................................ 18

Two-piece shaft ................................................... 18

Air filter ................................................................. 19

Maintenance schedule ......................................... 20

TECHNICAL DATA

Technical data ...................................................... 21

EC Declaration of Conformity ............................... 23

Note the f ollowing before

starting:

Please read the oper ator's manual carefully.

WARNING! Long-term exposure to noise

can result in permanent hearing

impairment. So always use approved

hearing protection.

WARNING! Under no circumstances may

the design of the machine be modified

without the permission of the

manufacturer. Always use original

accessories. Non-authorized

modifications and/or accessories can

result in serious personal injury or the

death of the operator or others.

WARNING! A clearing saw, brushcutter

or trimmer can be dangerous if used

incorrectly or carelessly, and can cause

serious or fatal injury to the operator or

others. It is extremely important that you

read and understand the contents of this

operator’s manual.

English

–

3

INTRODUCTION

Dear Customer,

Congratulations on your choice to buy a Husqvarna product! Husqvarna is based on a tradition that dates back to 1689,

when the Swedish King Karl XI ordered the construction of a factory on the banks of the Husqvarna River, for production

of muskets. The location was logical, since water power was harnessed from the Huskvarna River to create the waterpowered plant. During the more than 300 years in existence, the Husqvarna factory has produced a lot of different

products, from wood stoves to modern kitchen appliances, sewing machines, bicycles, motorcycles etc. In 1956, the first

motor driven lawn mowers appeared, followed by chain saws in 1959, and it is within this area Husqvarna is working

today.

Today Husqvarna is one of the leading manufacturers in the world of forest and garden products, with quality as our

highest priority. The business concept is to develop, manufacture and market motor-driven products for forestry and

gardening, as well as for the building and construction industry. Husqvarna

ergonomics, usability, security and environmental protection. That is the reason why we have developed many different

features to add to our products within these areas.

We are convinced that you will appreciate with great satisfaction the quality and performance of our product for a very

long time to come. The purchase of one of our products gives you access to professional help with repairs and service

whenever this may be necessary. If the retailer who sells your machine is not one of our authorised dealers, ask for the

address of your nearest service workshop.

It is our wish that you will be satisfied with your product and that it will be your companion for a long time. Think of this

operator

′s manual as a valuable document. By following its content (usage, service, maintenance, etc), the life span and

the second-hand value of the machine can be extended. If you sell this machine, make sure that the operator

is passed on to the buyer.

Thank you for using a Husqvarna product.

Husqvarna AB has a policy of continuous product development and therefore reserves the right to modify the design and

appearance of products without prior notice.

′s aim is also to be at the front edge for

′s manual

4 – English

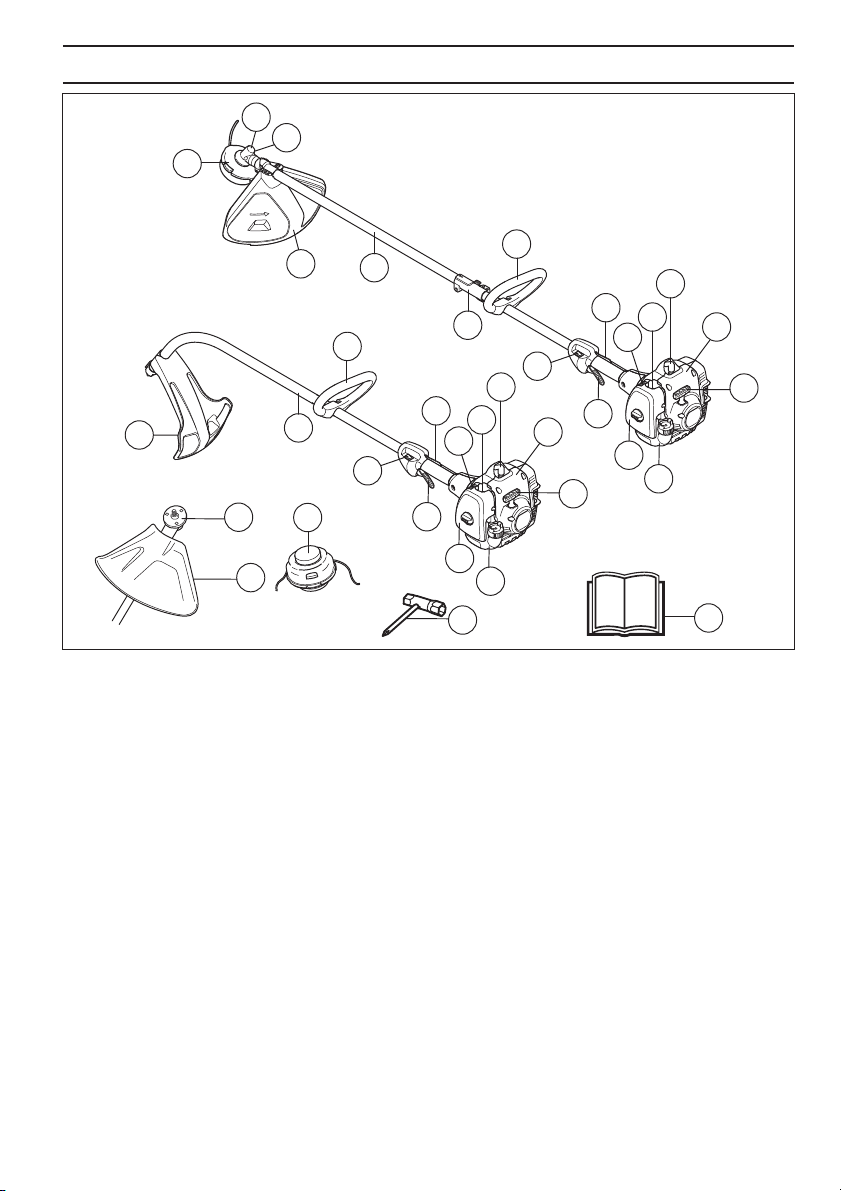

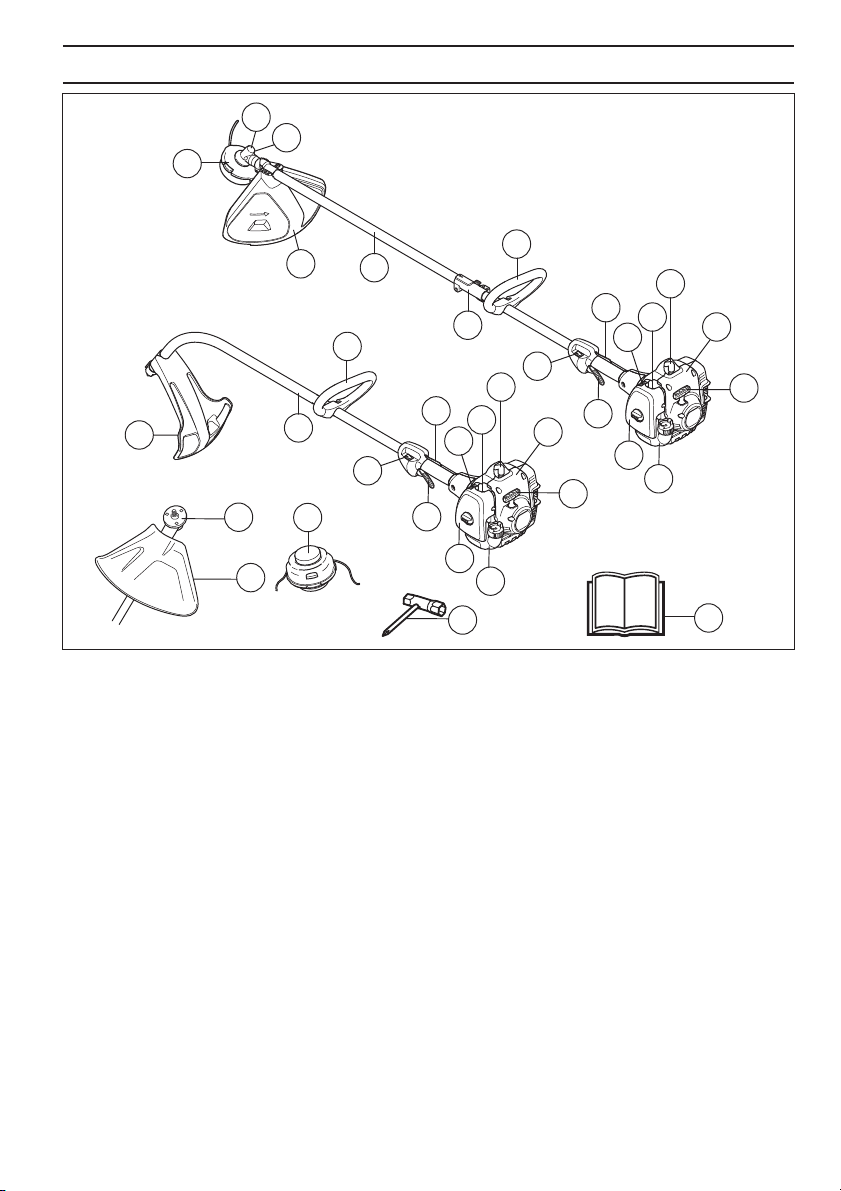

WHAT IS WHAT?

18

19

1

122LDx-series

122C

2

20

2

What is what on the grass trimmer?

1 Trimmer head

2 Cutting attachment guard

3 Shaft

4 Loop handle

5 Throttle trigger

6 Stop switch

7 Throttle lockout

8 Spark plug cap and spark plug

9 Starter housing

10 Fuel tank

2

3

8

4

7

17

4

13

12

16

9

8

7

3

12

13

6

1

5

16

5

11

9

10

9

11

10

15

11 Air filter cover

12 Air purge

13 Choke control

14 Operator′s manual

15 Combination spanner

16 Starter housing

17 Shaft coupling

18 Bevel gear

19 Grease filler cap, bevel gear

20 Drive disc

14

English – 5

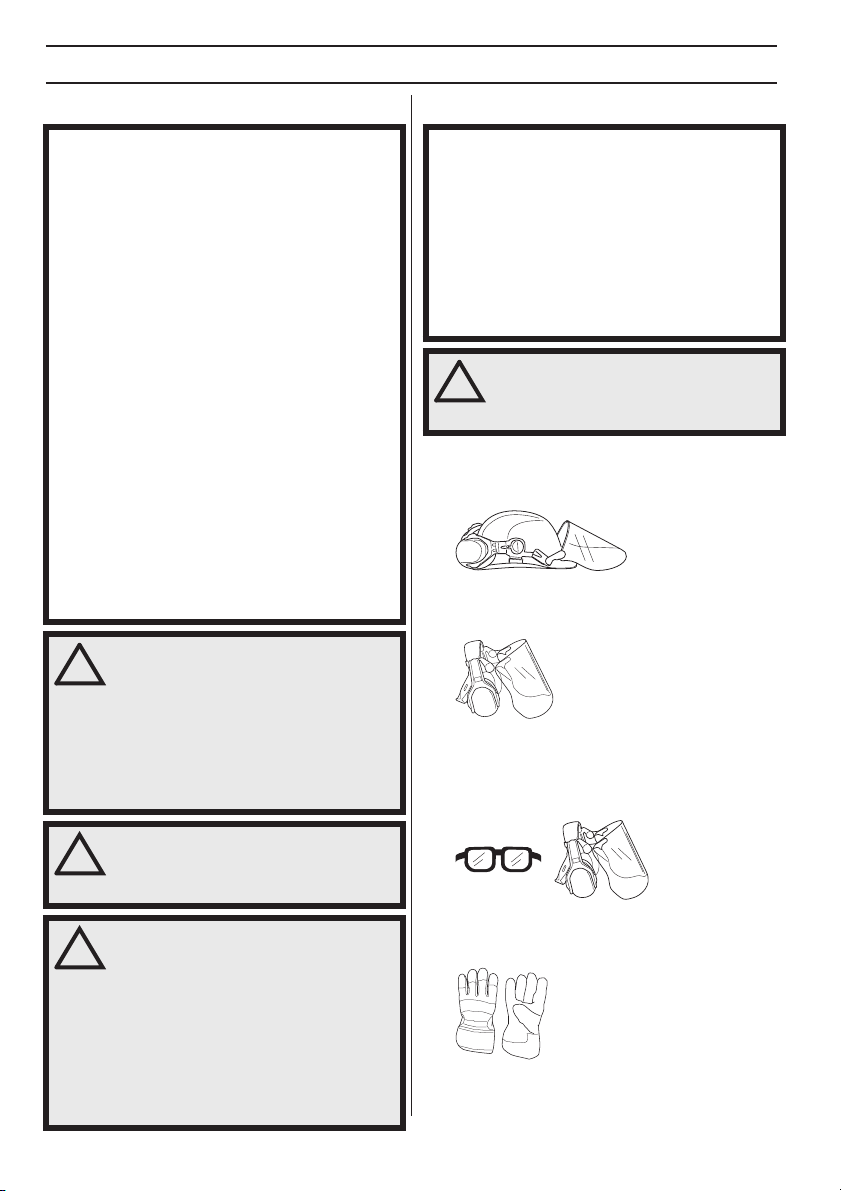

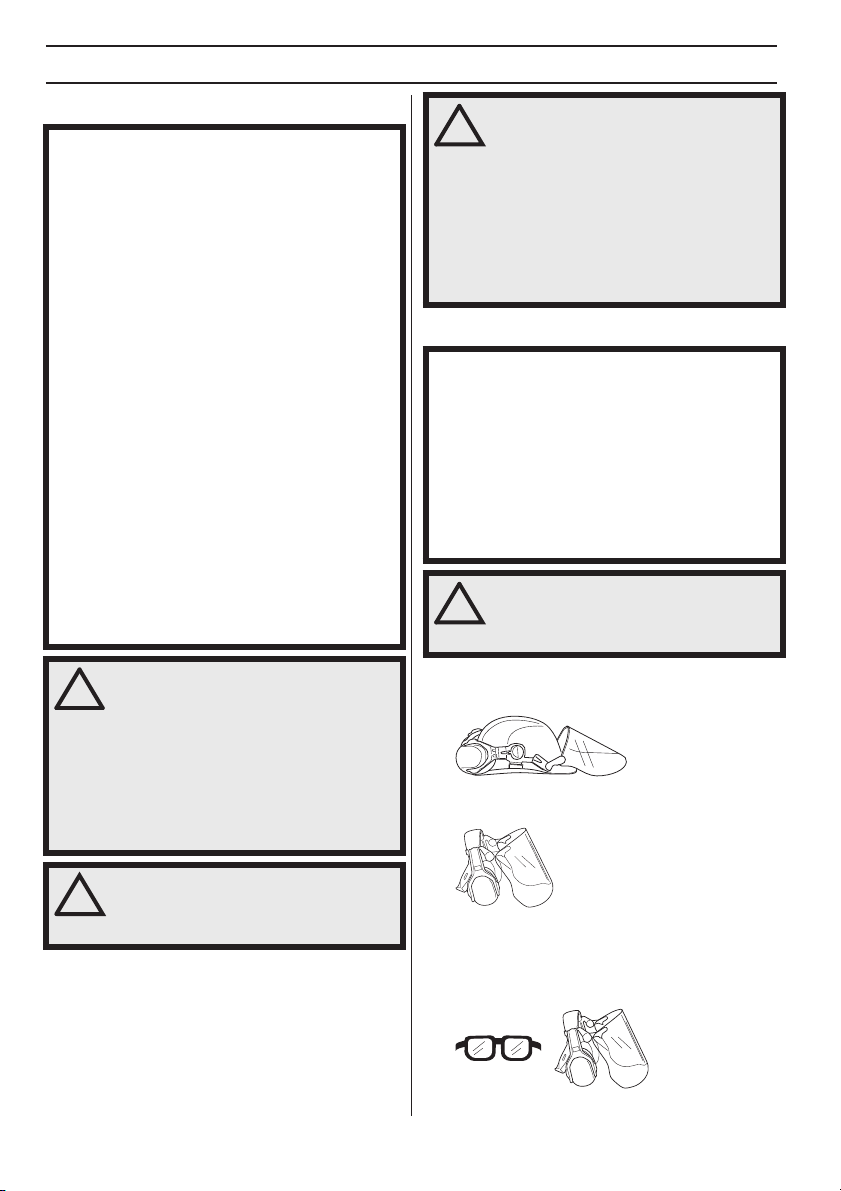

GENERAL SAFETY PRECAUTIONS

!

Important Personal protective equipment

IMPORTANT!

The machine is only designed for trimming grass.

The only accessories you can operate with this engine

unit are the cutting attachments we recommend in the

chapter on Technical data.

Never use the machine if you are tired, if you have drunk

alcohol, or if you are taking medication that could affect

your vision, your judgement or your co-ordination.

Wear personal protective equipment. See instructions

under the ”Personal protective equipment” heading.

Never use a machine that has been modified in any way

from its original specification.

Never use a machine that is faulty. Carry out the safety

checks, maintenance and service instructions described

in this manual. Some maintenance and service measures

must be carried out by trained and qualified specialists.

See instructions under the Maintenance heading.

All covers, guards and handles must be fitted before

starting. Ensure that the spark plug cap and ignition lead

are undamaged to avoid the risk of electric shock.

The machine operator must ensure that no people or

animals come closer than 15 metres while working. When

several operators are working in the same area the safety

distance should be at least 15 metres.

Carry out an overall inspection of the machine before use.

See the maintenance schedule.

WARNING! This machine produces an

electromagnetic field during operation.

!

This field may under some

circumstances interfere with active or

passive medical implants. To reduce the

risk of serious or fatal injury, we

recommend persons with medical

implants to consult their physician and

the medical implant manufacturer before

operating this machine.

IMPORTANT!

A grass trimmer can be dangerous if used incorrectly or

carelessly, and can cause serious or fatal injury to the

operator or others. It is extremely important that you

read and understand the contents of this operator’s

manual.

You must use approved personal protective equipment

whenever you use the machine. Personal protective

equipment cannot eliminate the risk of injury but it will

reduce the degree of injury if an accident does happen.

Ask your dealer for help in choosing the right equipment.

WARNING! Listen out for warning signals

or shouts when you are wearing hearing

protection. Always remove your hearing

protection as soon as the engine stops.

HELMET

Wear a protective helmet where there is a risk of falling

objects

HEARING PROTECTION

Wear hearing protection that provides adequate noise

reduction.

EYE PROTECTION

Always wear approved eye protection. If you use a visor

then you must also wear approved protective goggles.

Approved protective goggles must comply with the ANSI

Z87.1 standard in the USA or EN 166 in EU countries.

6 – English

WARNING! Running an engine in a

confined or badly ventilated area can

!

result in death due to asphyxiation or

carbon monoxide poisoning.

WARNING! Never allow children to use or

be in the vicinity of the machine. As the

!

machine is equipped with a springloaded stop switch and can be started by

low speed and force on the starter

handle, even small children under some

circumstances can produce the force

necessary to start the machine. This can

mean a risk of serious personal injury.

Therefore remove the spark plug cap

when the machine is not under close

supervision.

GLOVES

Gloves should be worn when necessary, e.g. when fitting

cutting attachments.

GENERAL SAFETY PRECAUTIONS

BOOTS

Wear sturdy, non-slip boots.

CLOTHING

Wear clothes made of a strong fabric and avoid loose

clothing that can catch on twigs and branches. Always

wear heavy, long pants. Do not wear jewellery, shorts

sandals or go barefoot. Secure hair so it is above shoulder

level.

FIRST AID KIT

Always have a first aid kit nearby.

Machine′s safety equipment

This section describes the machine′s safety equipment,

its purpose, and how checks and maintenance should be

carried out to ensure that it operates correctly. See the

”What is what?” section to locate where this equipment is

positioned on your machine.

The life span of the machine can be reduced and the risk

of accidents can increase if machine maintenance is not

carried out correctly and if service and/or repairs are not

carried out professionally. If you need further information

please contact your nearest service workshop.

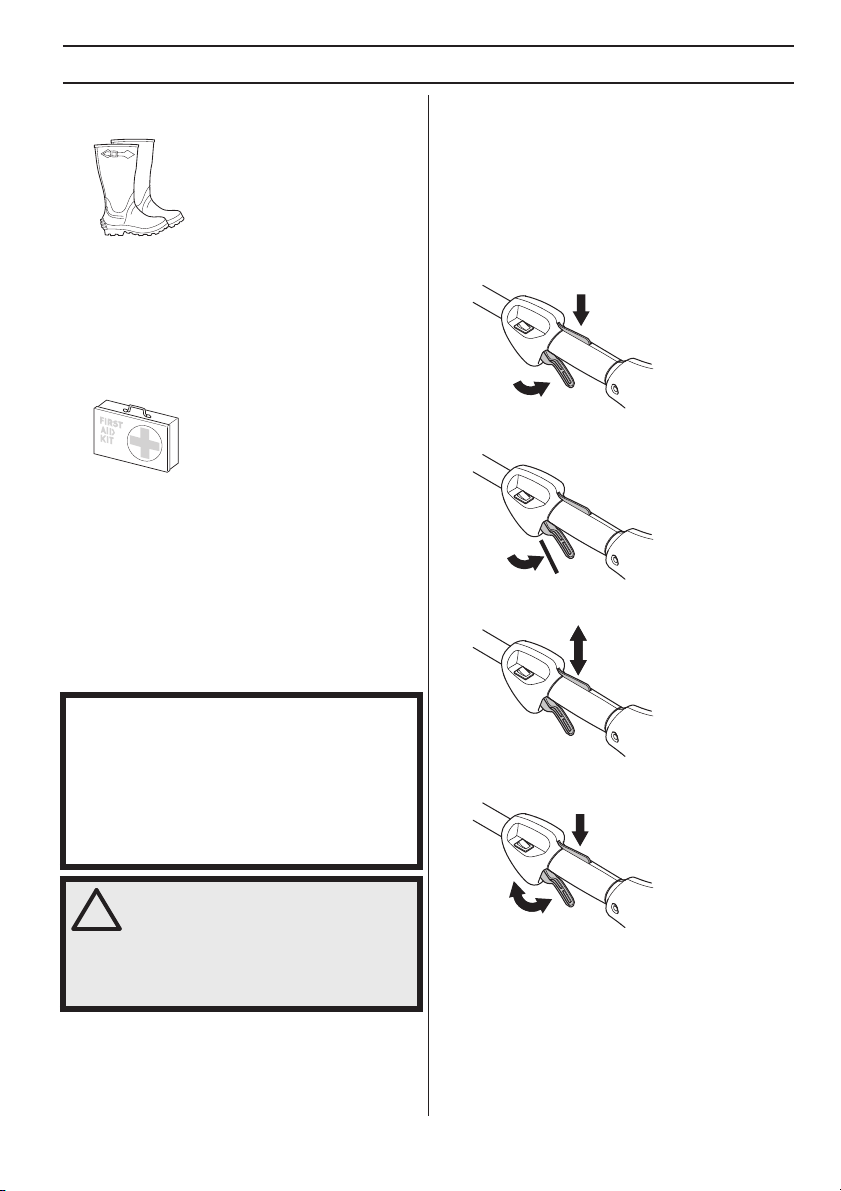

Throttle lockout

The throttle lockout is designed to prevent accidental

operation of the throttle control. When you press the lock

(A) (i.e. when you grasp the handle) it releases the throttle

control (B). When you release the handle the throttle

control and the throttle lockout both move back to their

original positions. This movement is controlled by two

independent return springs. This arrangement means that

the throttle control is automatically locked at the idle

setting.

A

B

Make sure the throttle control is locked at the idle setting

when the throttle lockout is released.

Press the throttle lockout and make sure it returns to its

original position when you release it.

IMPORTANT!

All servicing and repair work on the machine requires

special training. This is especially true of the machine

safety equipment. If your machine fails any of the

checks described below you must contact your service

agent. When you buy any of our products we guarantee

the availability of professional repairs and service. If the

retailer who sells your machine is not a servicing dealer,

ask him for the address of your nearest service agent.

WARNING! Never use a machine with

faulty safety equipment. The machine's

!

safety equipment must be checked and

maintained as described in this section.

If your machine fails any of these checks

contact your service agent to get it

repaired.

′s

Check that the throttle trigger and throttle lockout move

freely and that the return springs work properly.

See instructions under the heading Start. Start the

machine and apply full throttle. Release the throttle and

check that the cutting attachment stops and remains at a

standstill. If the cutting attachment rotates with the throttle

in the idle position then the carburettor idle setting must

be checked. See instructions under the heading

Maintenance.

English – 7

GENERAL SAFETY PRECAUTIONS

!

Stop switch

Use the stop switch to switch off the engine.

Start the engine and make sure the engine stops when

you move the stop switch to the stop setting.

Cutting attachment guard

This guard is intended to prevent loose objects from being

thrown towards the operator. The guard also protects the

operator from accidental contact with the cutting

attachment.

Check that the guard is undamaged and not cracked.

Replace the guard if it has been exposed to impact or is

cracked.

Always use the recommended guard for the cutting

attachment you are using. See chapter on Technical data.

Muffler

The muffler is designed to keep noise levels to a minimum

and to direct exhaust fumes away from the user. A muffler

fitted with a catalytic converter is also designed to reduce

harmful exhaust gases.

In countries that have a warm and dry climate there is a

significant risk of fire. We therefore fit certain mufflers with

a spark arrestor mesh. Check whether the muffler on your

machine is fitted with this kind of mesh.

8 – English

WARNING! Never use a cutting

attachment without an approved guard.

!

See the chapter on Technical data. If an

incorrect or faulty guard is fitted this can

cause serious personal injury.

For mufflers it is very important that you follow the

instructions on checking, maintaining and servicing your

machine.

Never use a machine that has a faulty muffler.

Regularly check that the muffler is securely attached to

the machine.

If the muffler on your machine is fitted with a spark

arrestor mesh this must be cleaned regularly. A blocked

mesh will cause the engine to overheat and may lead to

serious damage.

WARNING! Mufflers fitted with catalytic

converters get very hot during use and

remain so for some time after stopping.

This also applies at idle speed. Contact

can result in burns to the skin.

Remember the risk of fire!

GENERAL SAFETY PRECAUTIONS

WARNING! The inside of the muffler

contain chemicals that may be

!

carcinogenic. Avoid contact with these

elements in the event of a damaged

muffler.

WARNING! Bear in mind that:

!

The exhaust fumes from the engine are

hot and may contain sparks which can

start a fire. Never start the machine

indoors or near combustible material!

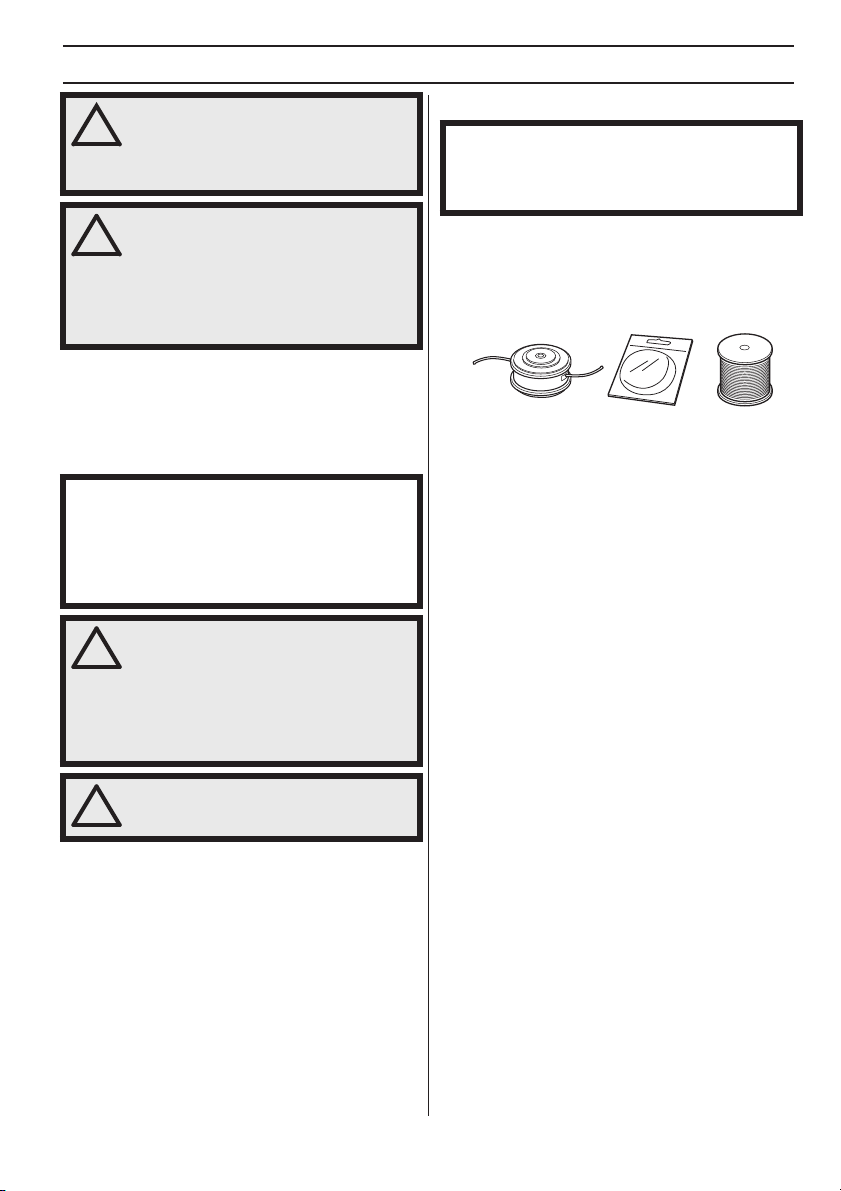

Cutting equipment

This section describes how to choose and maintain your

cutting equipment in order to:

• Obtain maximum cutting performance.

• Extend the life of cutting equipment.

IMPORTANT!

Only use cutting attachments with the guards we

recommend! See the chapter on Technical data.

Refer to the instructions for the cutting attachment to

check the correct way to load the cord and the correct

cord diameter.

WARNING! Always stop the engine

before doing any work on the cutting

!

attachment. This continues to rotate even

after the throttle has been released.

Ensure that the cutting attachment has

stopped completely and disconnect the

spark plug cap before you start to work

on it.

Trimmer head

IMPORTANT!

Always ensure the trimmer cord is wound tightly and

evenly around the drum, otherwise the machine will

generate harmful vibration.

• Only use the recommended trimmer heads and

trimmer cords. These have been tested by the

manufacturer to suit a particular engine size. This is

especially important when a fully automatic trimmer

head is used. Only use the recommended cutting

attachment. See the chapter on Technical data.

• Smaller machines generally require small trimmer

heads and vice versa. This is because when clearing

using a cord the engine must throw out the cord

radially from the trimmer head and overcome the

resistance of the grass being cleared.

• The length of the cord is also important. A longer cord

requires greater engine power than a shorter cord of

the same diameter.

• Make sure that the cutter on the trimmer guard is

intact. This is used to cut the cord to the correct length.

• To increase the life of the cord it can be soaked in

water for a couple of days before use. This will make

the cord tougher so that it lasts longer.

WARNING! A faulty cutting attachment

may increase the risk of accidents.

!

English – 9

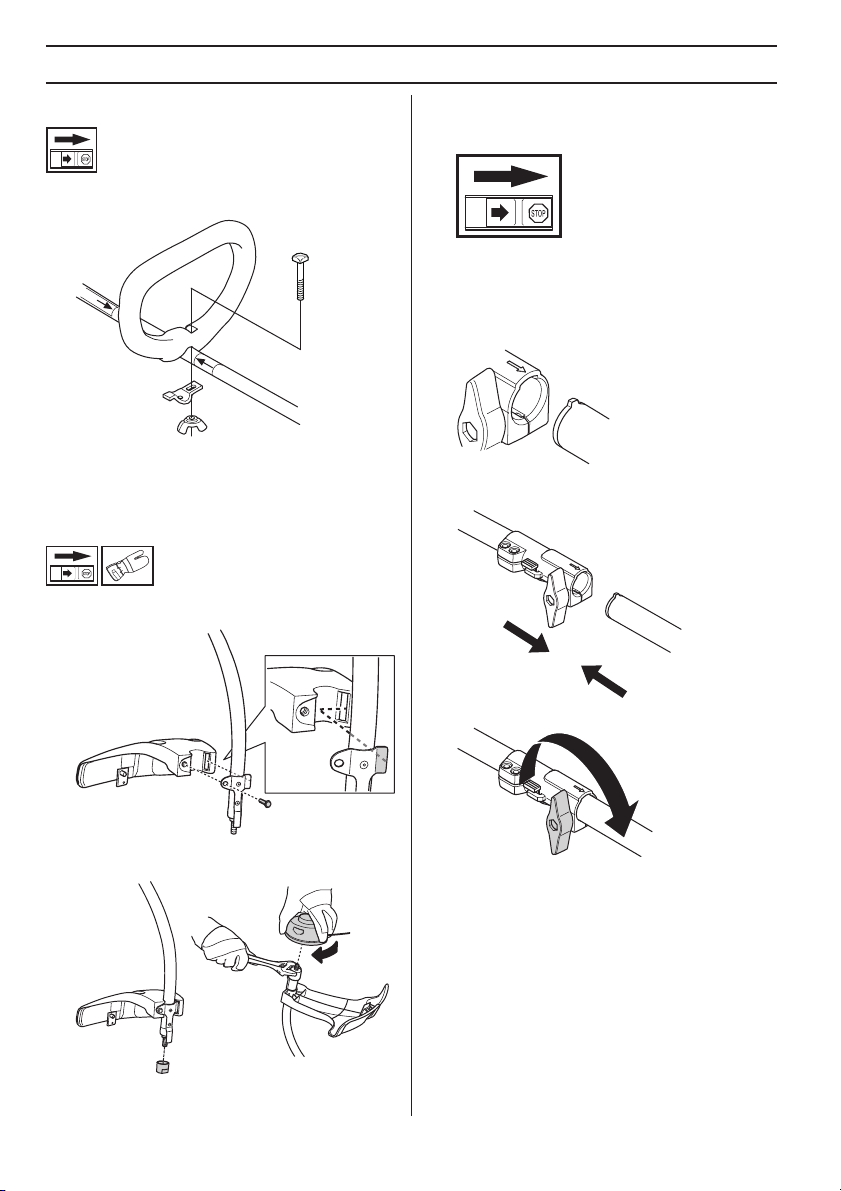

ASSEMBLY

Fitting the loop handle

• Clip the loop handle onto the shaft. Note that the loop

handle must be fitted between the arrows on the shaft.

• Fit the bolt, securing plate and wing nut as shown in

the diagram. Tighten the wing nut.

Fitting the trimmer guard and

trimmer head

• Fit the guard as shown in the diagram. Tighten

securely.

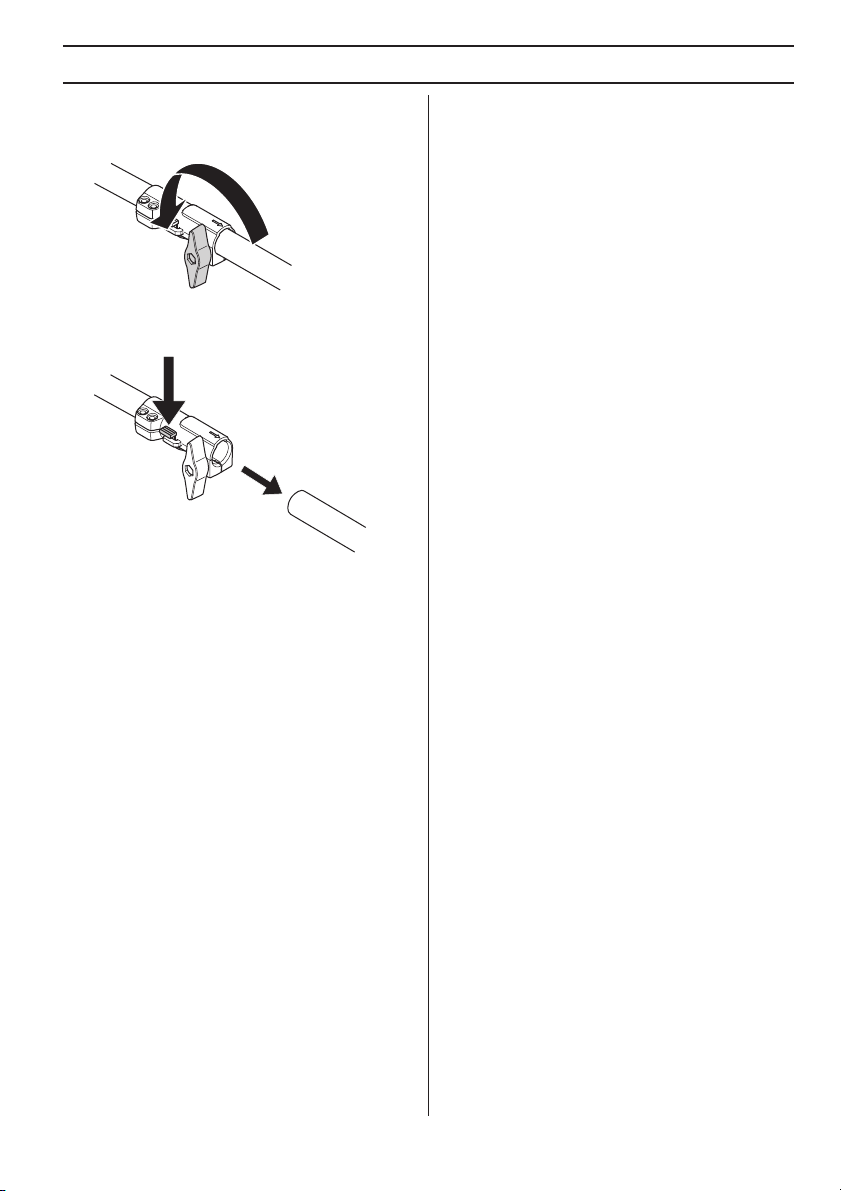

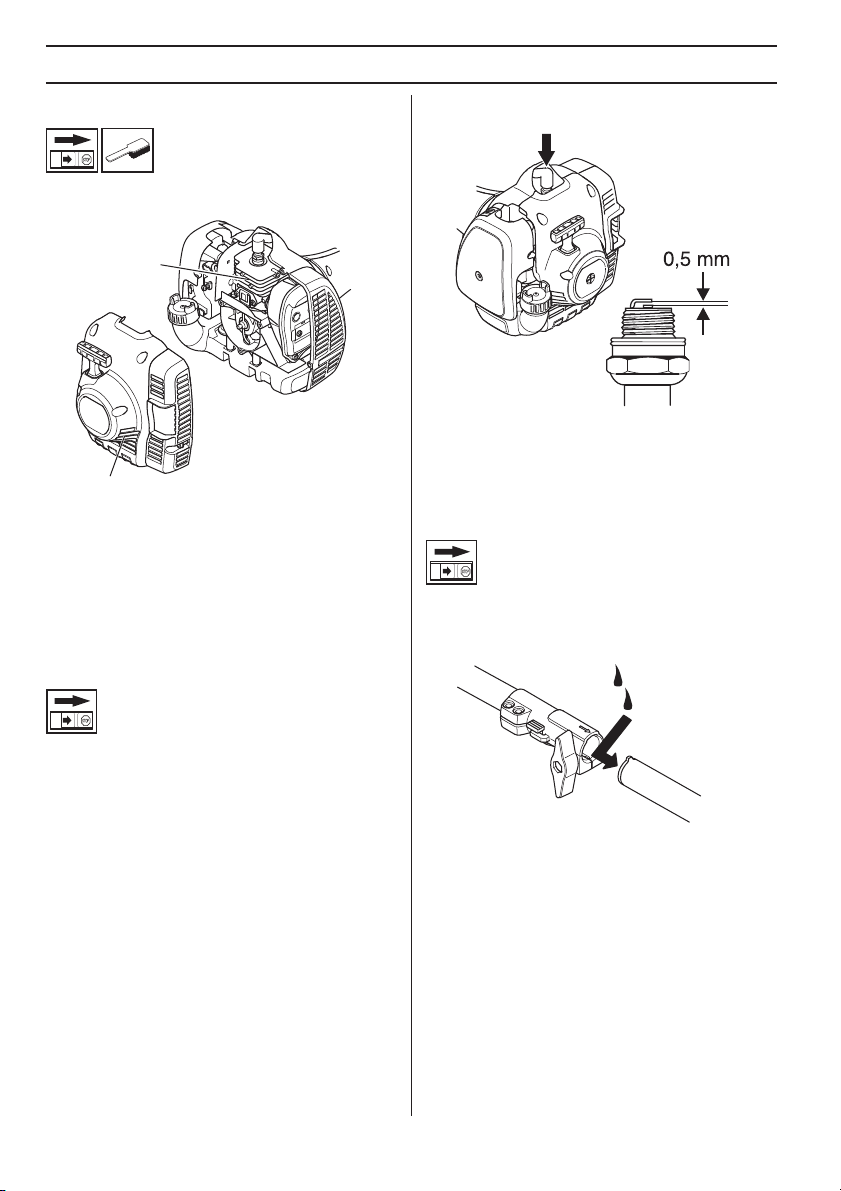

Assembling and dismantling the

two-piece shaft (122LDx-series)

Assembly:

• Loosen the coupling by turning the knob.

• Align the tab of the attachment (A) with the arrow on

the coupling (B).

B

A

• Push the attachment into the coupling until the

attachment snaps into place.

• Fit the dust cup on the shaft. The nut must be

completely covered by the dust cup.

• Hold the dust cup with a spanner to prevent the shaft

from rotating.

• Screw the trimmer head onto the shaft.

10 – English

Before using the unit, tighten the knob securely.

ASSEMBLY

Dismantling:

• Loosen the coupling by turning the knob (at least 3

times).

• Push and hold the button (C). While securely holding

the engine end, pull the attachment straight out of the

coupling.

C

English – 11

FUEL HANDLING

Fuel safety

Never start the machine:

1 If you have spilled fuel on it. Wipe off the spillage and

allow remaining fuel to evaporate.

2 If you have spilled fuel on yourself or your clothes,

change your clothes. Wash any part of your body that

has come in contact with fuel. Use soap and water.

3 If the machine is leaking fuel. Check regularly for

leaks from the fuel cap and fuel lines. In the event of

leakage, contact your service agent.

Transport and storage

• Store and transport the machine and fuel so that there

is no risk of any leakage or fumes coming into contact

with sparks or open flames, for example, from

electrical machinery, electric motors, electrical relays/

switches or boilers.

• When storing and transporting fuel always use

approved containers intended for this purpose.

• When storing the machine for long periods the fuel

tank must be emptied. Contact your local petrol

station to find out where to dispose of excess fuel.

• Ensure the machine is cleaned and that a complete

service is carried out before long-term storage.

• The transport guard must always be fitted to the

cutting attachment when the machine is being

transported or in storage.

• Secure the machine during transport.

• In order to prevent unintentional starting of the engine,

the spark plug cap must always be removed during

long-term storage, if the machine is not under close

supervision and when performing all service

measures.

WARNING! Take care when handling fuel.

Bear in mind the risk of fire, explosion

!

and inhaling fumes.

Fuel

CAUTION! The machine is equipped with a two-stroke

engine and must always be run using a mixture of petrol

and two-stroke oil. It is important to accurately measure

the amount of oil to be mixed to ensure that the correct

mixture is obtained. When mixing small amounts of fuel,

even small inaccuracies can drastically affect the ratio of

the mixture.

WARNING! Fuel and fuel fumes are

highly inflammable and can cause

!

serious injury when inhaled or allowed to

come in contact with the skin. For this

reason observe caution when handling

fuel and make sure there is adequate

ventilation.

Petrol

CAUTION! Always use a quality petrol/oil mixture at least

90 octane (RON). If your machine is equipped with a

catalytic converter (see chapter on Technical data) always

use a good quality unleaded petrol/oil mixture. Leaded

petrol will destroy the catalytic converter.

Use low-emission petrol, also known as alkylate petrol, if

it is available.

Ethanol blended fuel, E10 may be used (max 10%

ethanol blend). Using ethanol blends higher than E10 will

create lean running condition which can cause engine

damage.

• The lowest octane recommended is 90 (RON). If you

run the engine on a lower octane grade than 90 socalled knocking can occur. This gives rise to a high

engine temperature, which can result in serious

engine damage.

• When working at continuous high revs a higher octane

rating is recommended.

Two-stroke oil

• For best results and performance use HUSQVARNA

two-stroke engine oil, which is specially formulated for

our air-cooled two-stroke engines.

• Never use two-stroke oil intended for water-cooled

engines, sometimes referred to as outboard oil (rated

TCW).

• Never use oil intended for four-stroke engines.

• A poor oil quality and/or too high oil/fuel ratio may

jeopardise function and decrease the life time of

catalytic converters.

• Mixing ratio

1:50 (2%) with HUSQVARNA two-stroke oil.

1:33 (3%) with oils class JASO FB or ISO EGB

formulated for air-cooled, two-stroke engines.

Petrol, litre

5 0,10 0,15

10 0,20 0,30

15 0,30 0,45

20 0,40 0,60

Two-stroke oil,

litre

2% (1:50) 3% (1:33)

12 – English

FUEL HANDLING

!

Mixing

• Always mix the petrol and oil in a clean container

intended for fuel.

• Always start by filling half the amount of the petrol to

be used. Then add the entire amount of oil. Mix

(shake) the fuel mixture. Add the remaining amount of

petrol.

• Mix (shake) the fuel mixture thoroughly before filling

the machine’s fuel tank.

• Do not mix more than one month’s supply of fuel at a

time.

• If the machine is not used for some time the fuel tank

should be emptied and cleaned.

WARNING! The catalytic converter

muffler gets very hot during and after

!

use. This also applies during idling. Be

aware of the fire hazard, especially when

working near flammable substances and/

or vapours.

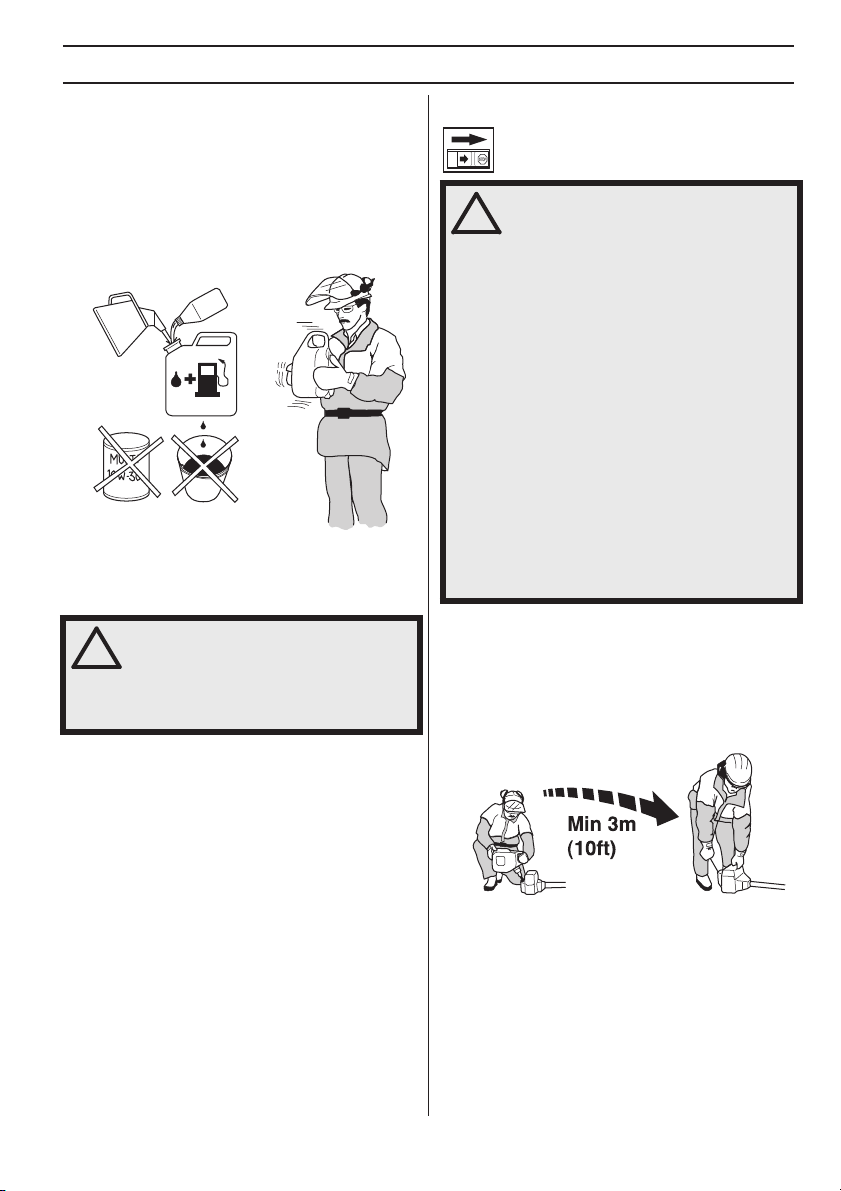

Fueling

WARNING! Taking the following

precautions, will lessen the risk of fire:

Mix and pour fuel outdoors, where there

are no sparks or flames.

Do not smoke or place hot objects near

fuel.

Always shut off the engine before

refuelling.

Always stop the engine and let it cool for

a few minutes before refuelling.

When refuelling, open the fuel cap slowly

so that any excess pressure is released

gently.

Tighten the fuel cap carefully after

refuelling.

Always move the machine away from the

refuelling area and source before

starting.

• Always use a fuel container with an anti-spill valve.

• If you have spilled fuel on it. Wipe off the spillage and

allow remaining fuel to evaporate.

• Clean the area around the fuel cap. Contamination in

the tank can cause operating problems.

• Ensure that the fuel is well mixed by shaking the

container before filling the tank.

English – 13

STARTING AND STOPPING

!

Check before starting

• Check that the trimmer head and trimmer guard are

not damaged or cracked. Replace the trimmer head or

trimmer guard if they have been exposed to impact or

are cracked.

• Never use the machine without a guard nor with a

defective guard.

• All covers must be correctly fitted and undamaged

before you start the machine.

Starting and stopping

WARNING! The complete clutch cover and

shaft must be fitted before the machine is

!

started, otherwise the clutch can come

loose and cause personal injury.

Always move the machine away from the

refuelling area and source before

starting. Place the machine on a flat

surface. Ensure the cutting attachment

cannot come into contact with any object.

Make sure no unauthorised persons are

in the working area. Otherwise there is a

risk of serious personal injury. The safety

distance is 15 meters.

Starting

Primer bulb: Press the air purge repeatedly until fuel

begins to fill the bulb. The bulb need not be completely

filled.

Choke: Set the choke control in the choke position.

WARNING! When the engine is started

with the choke in choke position the

cutting attachment will start to rotate

immediately.

Hold the body of the machine on the ground using your

left hand (CAUTION! Not with your foot!). Grip the starter

handle, slowly pull out the cord with your right hand until

you feel some resistance (the starter pawls grip), now

quickly and powerfully pull the cord.

starter cord around your hand.

Repeat pulling the cord until the engine starts. When the

engine starts, return choke control to run position and

apply full throttle; the throttle will automatically disengage

from the start setting.

CAUTION! Do not pull the starter cord all the way out and

do not let go of the starter handle when the cord is fully

extended. This can damage the machine.

Never twist the

Stopping

Stop the engine by switching off the ignition.

14 – English

CAUTION! The stop switch automatically returns to the

start position. In order to prevent unintentional starting,

the spark plug cap must be removed from the spark plug

when assembling, checking and/or performing

maintenance.

WORKING TECHNIQUES

!

!

General working instructions

IMPORTANT!

This section takes up the basic safety precautions for

working with a trimmer.

If you encounter a situation where you are uncertain

how to proceed you should ask an expert. Contact your

dealer or your service workshop.

Avoid all usage which you consider to be beyond your

capability.

You must understand the difference between forestry

clearing, grass clearing and grass trimming before use.

6 Always hold the machine with both hands. Hold the

machine on the right side of your body.

Basic safety rules

1 Look around you:

• To ensure that people, animals or other things cannot

affect your control of the machine.

• To ensure that people, animals, etc., do not come into

contact with the cutting attachment or loose objects

that are thrown out by the cutting attachment.

• CAUTION! Do not use the machine unless you are

able to call for help in the event of an accident.

2 Inspect the working area. Remove all loose objects,

such as stones, broken glass, nails, steel wire, string,

etc. that could be thrown out or become wrapped

around the cutting attachment.

3 Do not use the machine in bad weather, such as

dense fog, heavy rain, strong wind, intense cold, etc.

Working in bad weather is tiring and often brings

added risks, such as icy ground.

4 Make sure you can move and stand safely.

7 Keep the cutting attachment below waist level.

8 The engine must be switched off before moving.

9 Never put the machine down with the engine running

unless you have it in clear sight.

WARNING! Neither the operator of the

machine nor anyone else may attempt to

remove the cut material while the engine

is running or the cutting equipment is

rotating, as this can result in serious

injury.

Stop the engine and cutting equipment

before you remove material that has

wound around the blade shaft as

otherwise there is a risk of injury. The

bevel gear can get hot during use and

may remain so for a while afterwards. You

could get burnt if you touch it.

WARNING! Watch out for thrown objects.

Always wear approved eye protection.

Never lean over the cutting attachment

guard. Stones, rubbish, etc. can be

thrown up into the eyes causing

blindness or serious injury.

Keep unauthorised persons at a

distance. Children, animals, onlookers

and helpers should be kept outside the

safety zone of 15 metres. Stop the

machine immediately if anyone

approaches. Never swing the machine

around without first checking behind you

to make sure no-one is within the safety

zone.

5 Keep a good balance and a firm foothold. Do not

overreach. Keep proper footing and balance at all

times.

English – 15

WORKING TECHNIQUES

Basic working techniques

Always slow the engine to idle speed after each working

operation. Long periods at full throttle without any load on

the engine can lead to serious engine damage.

WARNING! Sometimes branches or

grass get caught between the guard and

!

cutting attachment. Always stop the

engine before cleaning.

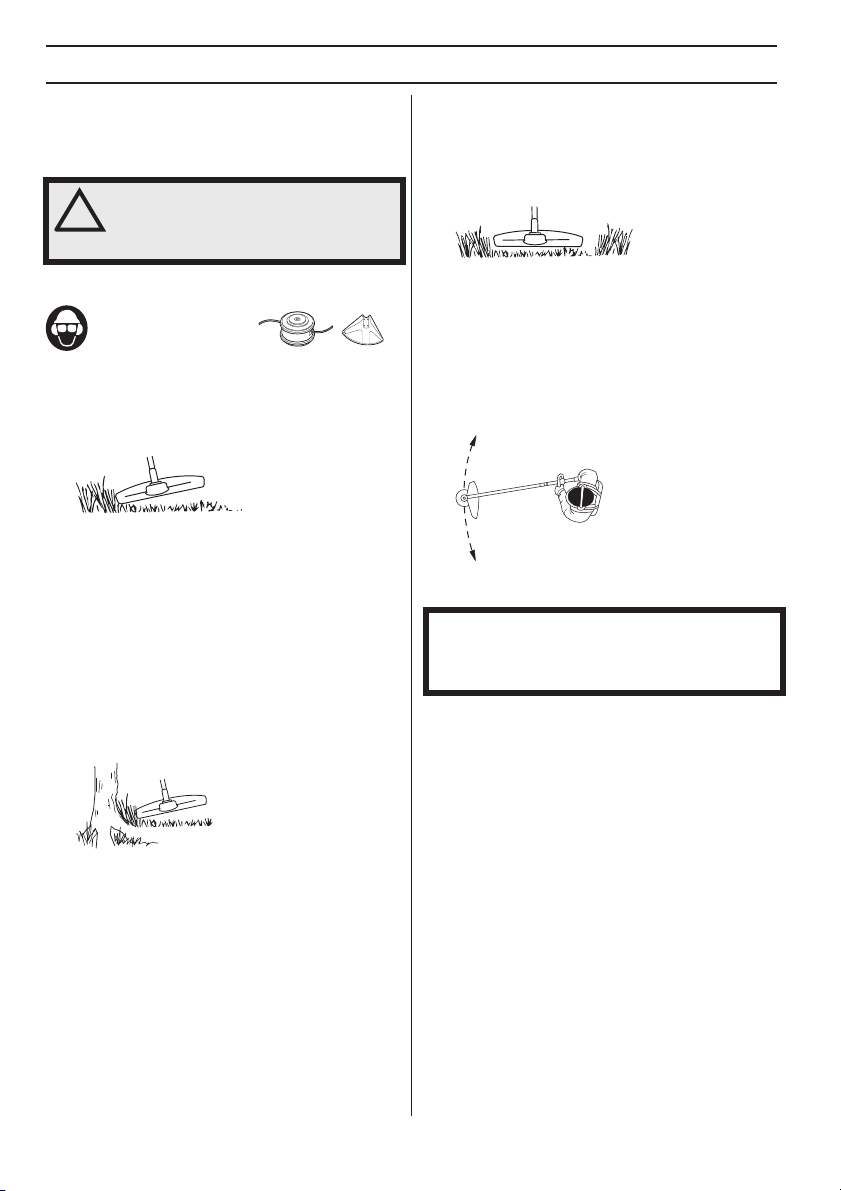

Grass trimming with a trimmer head

Trimming

• Hold the trimmer head just above the ground at an

angle. It is the end of the cord that does the work. Let

the cord work at its own pace. Never press the cord

into the area to be cut.

• The cord can easily remove grass and weeds up

against walls, fences, trees and borders. However it

can also damage sensitive bark on trees and bushes,

and damage fence posts.

• Reduce the risk of damaging plants by shortening the

cord to 10-12 cm and reducing the engine speed.

Clearing

• The clearing technique removes all unwanted

vegetation. Keep the trimmer head just above the

ground and tilt it. Let the end of the cord strike the

ground around trees, posts, statues and the like.

CAUTION! This technique increases the wear on the

cord.

Cutting

• The trimmer is ideal for cutting grass that is difficult to

reach using a normal lawn mower. Keep the cord

parallel to the ground when cutting. Avoid pressing the

trimmer head against the ground as this can ruin the

lawn and damage the tool.

• Do not allow the trimmer head to constantly come into

contact with the ground during normal cutting.

Constant contact of this type can cause damage and

wear to the trimmer head.

Sweeping

• The fan effect of the rotating cord can be used for

quick and easy clearing up. Hold the cord parallel to

and above the area to be swept and move the tool side

to side.

• When cutting and sweeping you should use full

throttle to obtain the best results.

IMPORTANT! To avoid unbalance and vibrations in

handles trimmer head cover need to be cleaned every

time cord is refilled. In addition, check other part of the

head if needed to be cleaned.

• The cord wears quicker and must be fed forward more

often when working against stones, brick, concrete,

metal fences, etc., than when coming into contact with

trees and wooden fences.

• When trimming and clearing, you should use less than

full throttle (80%) so that the cord lasts longer and to

reduce the wear on the trimmer head.

16 – English

MAINTENANCE

!

Carburettor

Adjustment of the idle speed

Before any adjustments are made, make sure that the air

filter is clean and the air filter cover is fitted.

Adjust the idle speed using the idle adjustment screw T, if

it is necessary to readjust. First turn the idle adjustment

screw T clockwise until the cutting attachment starts to

rotate. Then turn the screw anticlockwise until the cutting

attachment stops. The idle speed is correctly adjusted

when the engine will run smoothly in every position. The

idle speed should also be well below the speed at which

the cutting attachment starts to rotate.

Recommended idle speed: See the Technical data

section.

WARNING! If the idle speed cannot be

adjusted so that the cutting attachment

!

stops, contact your dealer/service

workshop. Do not use the machine until

it has been correctly adjusted or

repaired.

cause fire if directed against dry and combustible

material.

Some mufflers are equipped with a special spark arrestor

mesh. If your machine has this type of muffler, you should

clean the mesh at least once a week. This is best done

with a wire brush. On mufflers without a catalytic

converter the mesh should be cleaned weekly, or

replaced if necessary. On mufflers fitted with a catalytic

converter the mesh should be checked, and if necessary

cleaned, monthly.

replaced.

sign that the performance of the catalytic converter is

impaired. Contact your dealer to inspect the muffler. A

blocked mesh will cause the machine to overheat and

result in damage to the cylinder and piston.

If the mesh is damaged it should be

If the mesh is frequently blocked, this can be a

Muffler

CAUTION! Some mufflers are fitted with a catalytic

converter. See chapter on Technical data to see whether

your machine is fitted with a catalytic converter.

The muffler is designed to reduce the noise level and to

direct the exhaust gases away from the operator. The

exhaust gases are hot and can contain sparks, which may

CAUTION! Never use a machine with a defective muffler.

WARNING! Mufflers fitted with catalytic

converters get very hot during use and

remain so for some time after stopping.

This also applies at idle speed. Contact

can result in burns to the skin.

Remember the risk of fire!

English – 17

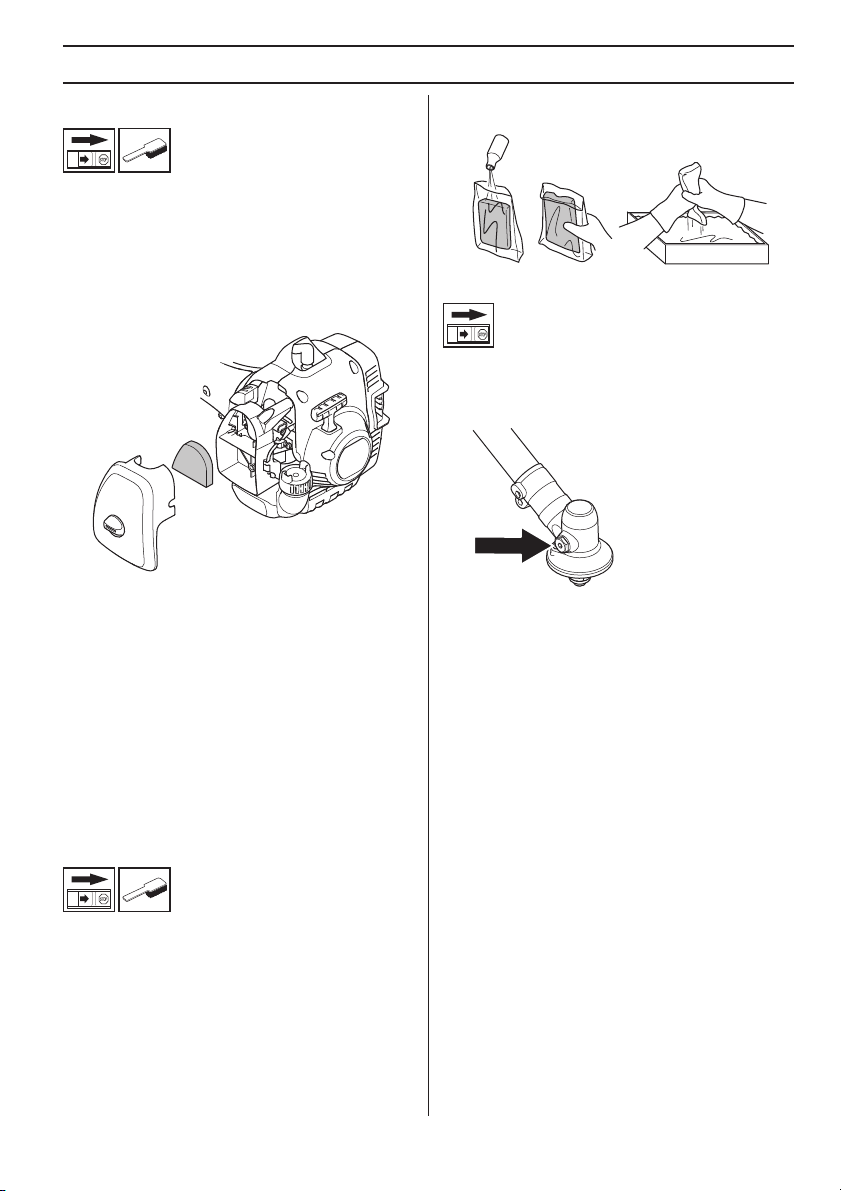

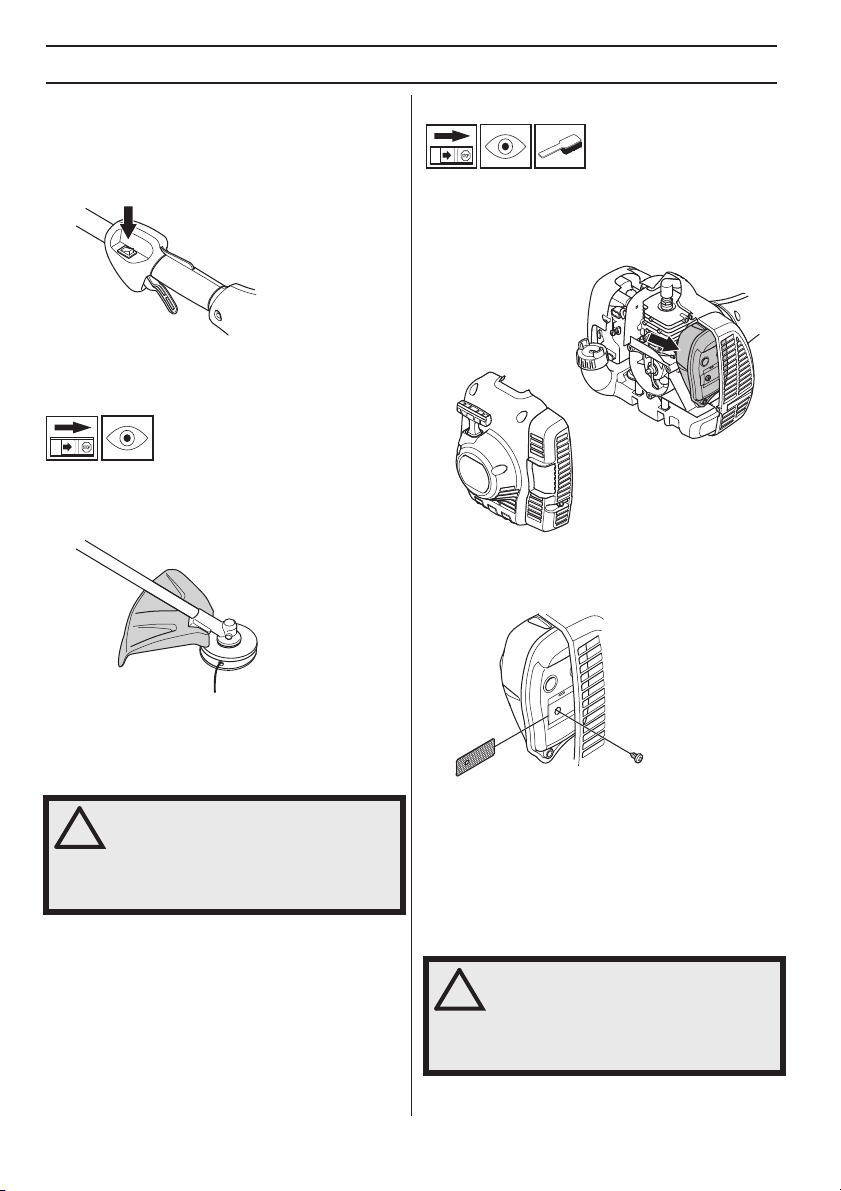

MAINTENANCE

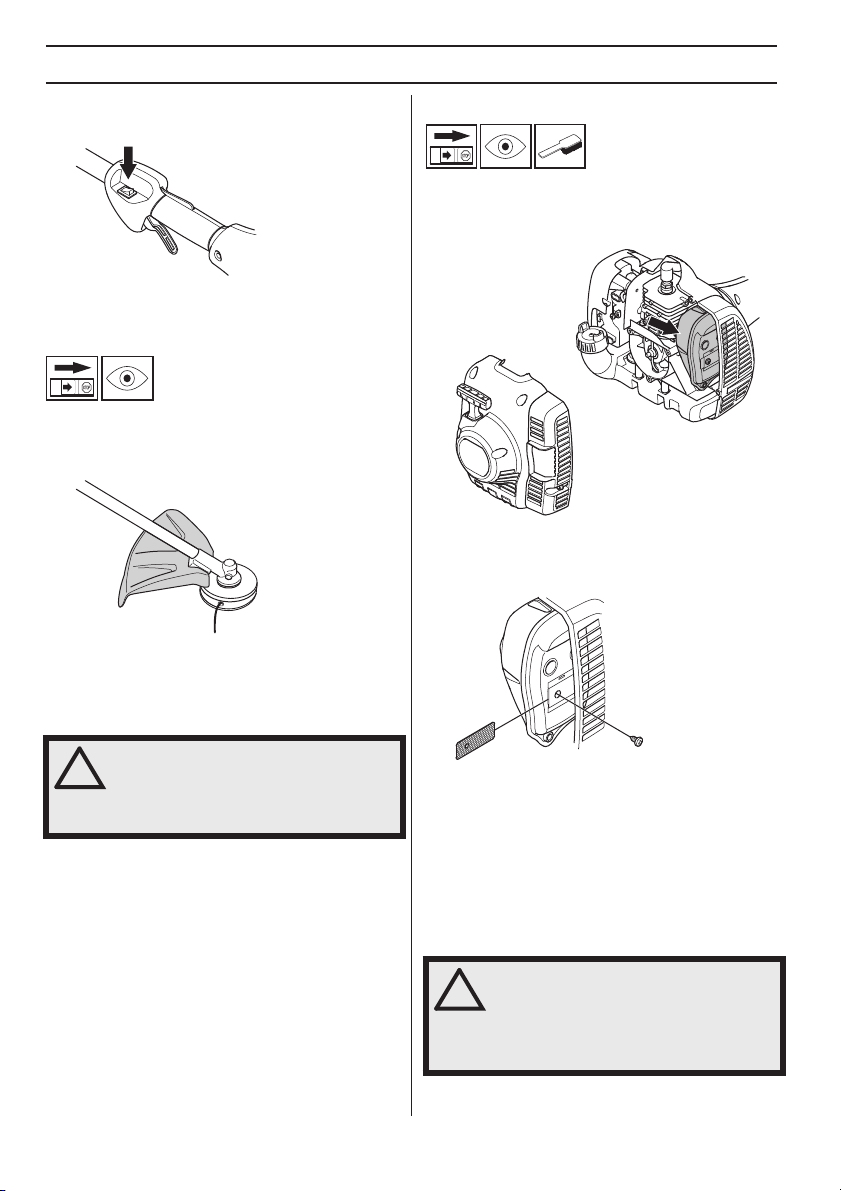

Cooling system

To keep the working temperature as low as possible the

machine is equipped with a cooling system.

2

1

The cooling system consists of:

1 Air intake on the starter.

2 Cooling fins on the cylinder.

Clean the cooling system with a brush once a week, more

often in demanding conditions. A dirty or blocked cooling

system results in the machine overheating which causes

damage to the piston and cylinder.

Spark plug

spark plug should be replaced after about a month in

operation or earlier if necessary.

CAUTION! Always use the recommended spark plug

type! Use of the wrong spark plug can damage the piston/

cylinder. Check that the spark plug is fitted with a

suppressor. Ask your dealer or Husqvarna should you

need more information.

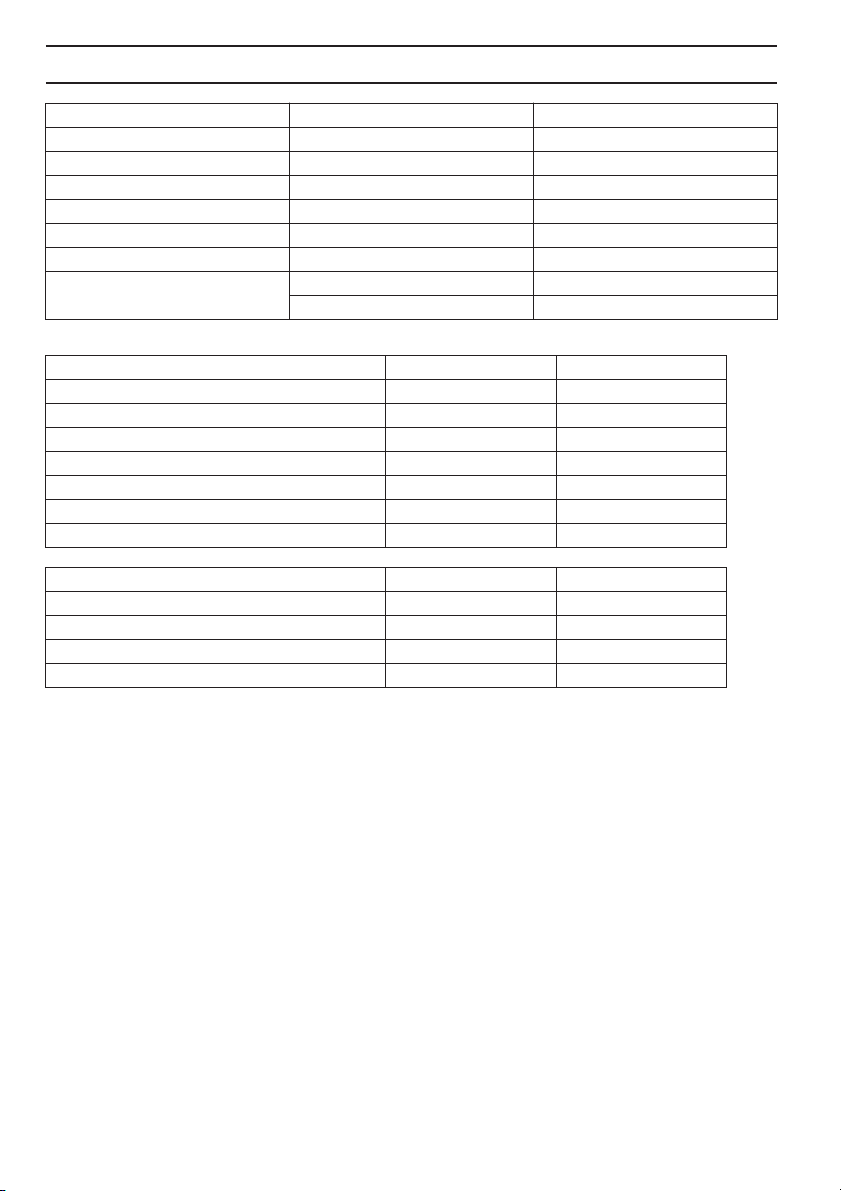

Two-piece shaft

The drive shaft end in the lower shaft should be lubricated

with grease every 30 hours. There is a risk that the drive

shaft ends (splined coupling) on models with two-piece

shafts will seize if they are not lubricated regularly.

The spark plug condition is influenced by:

• Incorrect carburettor adjustment.

• An incorrect fuel mixture (too much or incorrect type

of oil).

• A dirty air filter.

These factors cause deposits on the spark plug

electrodes, which may result in operating problems and

starting difficulties.

If the machine is low on power, difficult to start or runs

poorly at idle speed: always check the spark plug first

before taking any further action. If the spark plug is dirty,

clean it and check that the electrode gap is 0,5 mm. The

18 – English

MAINTENANCE

Air filter

The air filter must be regularly cleaned to remove dust

and dirt in order to avoid:

• Carburettor malfunctions

• Starting problems

• Loss of engine power

• Unnecessary wear to engine parts.

• Excessive fuel consumption.

use common engine oil. This would drain through the filter

quite quickly and collect in the bottom.

Bevel gear

The bevel gear is filled with the right quantity of grease at

the factory. However, before using the machine you

should check that the bevel gear is filled three-quarters

full with grease. Use HUSQVARNA special grease.

Clean the filter every 25 hours, or more regularly if

conditions are exceptionally dusty.

Cleaning the air filter

Remove the air filter cover and take out the filter. Wash it

clean in warm, soapy water. Ensure that the filter is dry

before refitting it.

An air filter that has been in use for a long time cannot be

cleaned completely. The filter must therefore be replaced

with a new one at regular intervals.

must always be replaced.

If the machine is used in dusty conditions the air filter

should be soaked in oil. See instructions under the

heading Oiling the air filter.

A damaged air filter

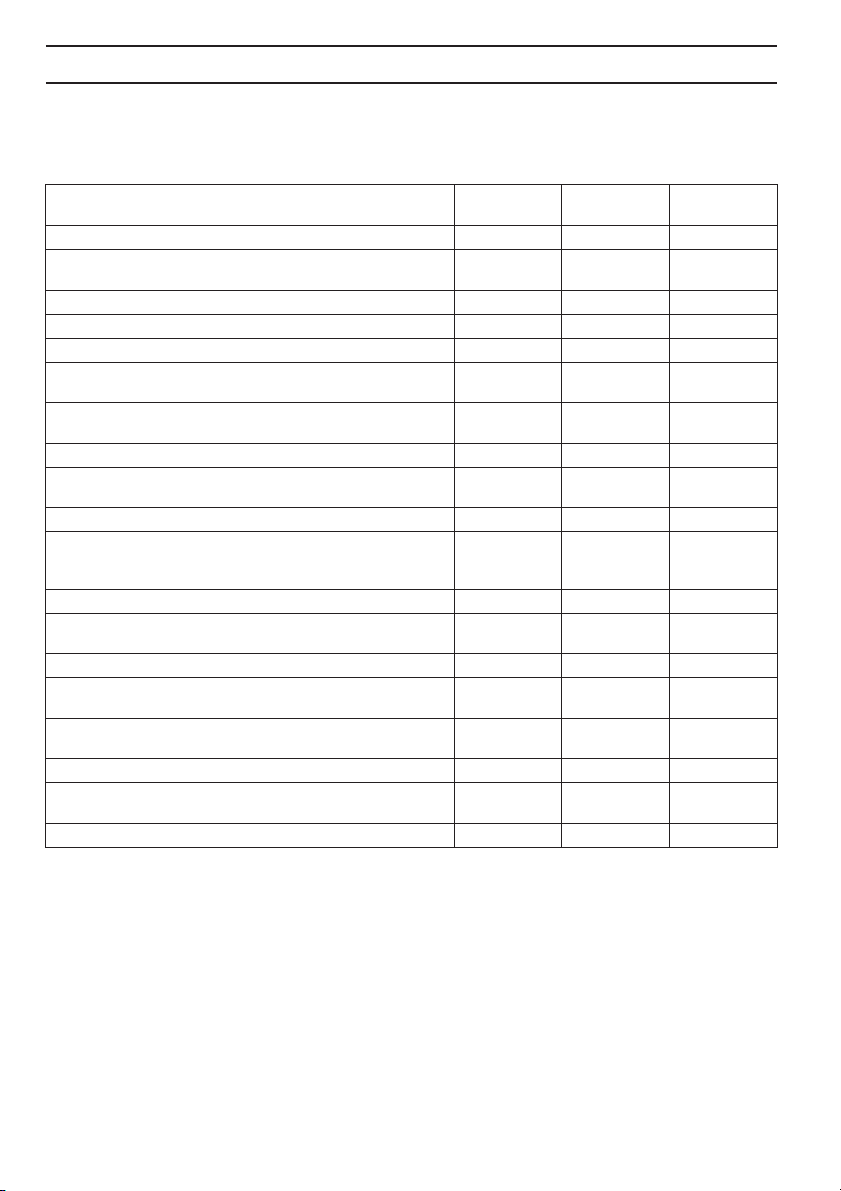

Oiling the air filter

Always use HUSQVARNA filter oil, art. no. 531 00 92-48.

The filter oil contains a solvent to make it spread evenly

through the filter. You should therefore avoid skin contact.

Put the filter in a plastic bag and pour the filter oil over it.

Knead the plastic bag to distribute the oil. Squeeze the

excess oil out of the filter inside the plastic bag and pour

off the excess before fitting the filter to the machine. Never

The grease in the bevel gear does not normally need to

be changed except if repairs are carried out.

English – 19

MAINTENANCE

Maintenance schedule

The following is a list of the maintenance steps that must be performed on the machine. Most of the items are described

in the Maintenance section. The user must only carry out the maintenance and service work described in this Operator's

Manual. More extensive work must be carried out by an authorized service workshop.

Maintenance

Clean the outside of the machine. X

Make sure the throttle trigger lock and the throttle function

correctly from a safety point of view.

Check that the stop switch works correctly. X

Check that the cutting attachment does not rotate at idle. X

Clean the air filter. Replace if necessary. X

Check that the guard is undamaged and not cracked. Replace

the guard if it has been exposed to impact or is cracked.

Check that the trimmer head is undamaged and not cracked.

Replace the trimmer head if necessary.

Check that nuts and screws are tight. X

Check that there are no fuel leaks from the engine, tank or fuel

lines.

Check the starter and starter cord. X

Clean the outside of the spark plug. Remove and check the

electrode gap. Adjust the gap to 0.5 mm or replace the spark

plug.

Clean the machine’s cooling system. X

Clean or replace the spark arrestor mesh on the muffler (only

applies to mufflers without a catalytic converter).

Clean the outside of the carburettor and the space around it. X

Check that the bevel gear is filled three-quarters full with

lubricant. Fill if necessary using special grease.

Check the fuel filter for contamination and the fuel hose for cracks

or other defects. Replace if necessary.

Check all cables and connections. X

Check the clutch, clutch springs and the clutch drum for wear.

Replace if necessary by an autorized service workshop.

Replace the spark plug. X

NOTE!

Ask your dealer or Husqvarna should you need more information.

Daily

maintenance

X

X

X

X

Weekly

maintenance

X

X

X

Monthly

maintenance

X

X

20 – English

TECHNICAL DATA

Technical data

122C 122LDx-series

Engine

Cylinder displacement, cm

Cylinder bore, mm 32,0 32,0

Stroke, mm 27 27

Idle speed, rpm 2900 2900

Recommended max. speed, rpm 7200 9100

Speed of output shaft, rpm 7200 6232

Max. engine output, acc. to ISO 8893, kW/ rpm 0,6/7800 0,6/7800

Catalytic converter muffler Ye s Ye s

Speed-regulated ignition system No No

Ignition system

Spark plug NGK CMR6A NGK CMR6A

Electrode gap, mm 0,5 0,5

Fuel and lubrication system

Fuel tank capacity, litre 0,3 0,3

Weight

Weight without fuel, cutting attachment and guard, kg 4,4 4,8

Noise emissions

(see note 1)

Sound power level, measured dB (A) 102 104

Sound power level, guaranteed LWA dB (A) 104 108

Noise levels

(see note 2)

Equivalent sound pressure level at the operator’s ear,

measured according to EN ISO 11806 and ISO 22868,

dB(A):

Vibration levels

(see note 3)

Equivalent vibration levels (a

measured according to EN ISO 11806 and ISO 22867,

2

m/s

Equipped with trimmer head (original), left/right 5,0/3,6 3,6/3,5

Note 1: Noise emissions in the environment measured as sound power (LWA) in conformity with EC directive 2000/14/

EC. Reported sound power level for the machine has been measured with the original cutting attachment that gives the

highest level. The difference between guaranteed and measured sound power is that the guaranteed sound power also

includes dispersion in the measurement result and the variations between different machines of the same model

according to Directive 2000/14/EC.

Note 2: Reported data for equivalent sound pressure level for the machine has a typical statistical dispersion (standard

deviation) of 1 dB (A).

Note 3: Reported data for equivalent vibration level has a typical statistical dispersion (standard deviation) of 1 m/s2.

3

hv,eq

21,7 21,7

88 90

) at handles,

English – 21

TECHNICAL DATA

122LDx-series

Approved accessories Type Cutting attachment guard, Art. no.

Blade shaft thread M10

Trimmer head T25 (Ø 2.0 - 2.7 mm cord) 574 19 87-01

122C

Approved accessories Type Cutting attachment guard, Art. no.

Blade shaft thread 3/8 R

Trimmer head

The following attachments are recommended for the specified models.

Approved accessories Art No. Use with

Clean sweep attachment with shaft SR600 537 19 67-01 122LDx-series

Hedge trimmer attachment with shaft HA 850 537 19 66-06 122LDx-series

Edger attachment with shaft 537 19 69-01 122LDx-series

Saw attachment with shaft PA 1100 537 18 33-16 122LDx-series

Saw attachment without shaft PA 537 18 33-11 122LDx-series

Cultivator attachment with shaft CA 150 537 42 54-01 122LDx-series

Trimmer attachment with shaft TA 850 537 35 35-01 122LDx-series

Approved accessories Art No. Use with

Cultivator attachment CAC 952 71 19-07 122LDx-series

Edger attachment EAC 952 71 19-08 122LDx-series

Pole saw attachment PAC 952 71 19-10 122LDx-series

Blower attachment BAC 952 71 19-11 122LDx-series

T25 (Ø 2.0 - 2.7 mm cord) 574 47 95-01

T25C (Ø 2.0 - 2.7 mm cord) 574 47 95-01

22 – English

TECHNICAL DATA

EC Declaration of Conformity (Applies to Europe only)

We, Husqvarna AB, SE-561 82 Huskvarna, Sweden, tel: +46-36-146500, declare that the grass trimmers Husqvarna

122C and 122LD

by the serial number), comply with the requirements of the COUNCIL’S DIRECTIVE:

- of May 17, 2006 ”relating to machinery” 2006/42/EC

- of December 15, 2004 ”relating to electromagnetic compatibility” 2004/108/EC.

- of May 8, 2000 ”relating to the noise emissions in the environment” 2000/14/EC. Conformity assessment according

to Annex V. For information relating to noise emissions, see the Technical data chapter.

The following standards have been applied:

EN ISO 12100:2010, EN ISO 11806-1:2011, ISO 14982:1998, CISPR 12:2007

SMP Svensk Maskinprovning AB, Box 7035, SE-750 07 Uppsala, Sweden, has performed voluntary type examination

on behalf of Husqvarna AB. The certificates are numbered: 122C -

Furthermore, conformity with Appendix V of Council Directive 2000/14/EG is certified. The certificate has the number:

122C -

01/164/068, 122LD - 01/164/067

Huskvarna 31 July 2013.

Per Gustafsson, Development manager (Authorized representative for Husqvarna AB and responsible for technical

documentation.)

with serial numbers dating from 2010 onwards (the year is clearly stated on the rating plate, followed

SEC/10/2271, 122LD - SEC/10/2272

English – 23

SYMBOLFÖRKLARING

Symboler på maskinen och/eller i

bruksanvisningen

VARNING! Röjsågar, buskröjare och

trimmers kan vara farliga! Slarvigt eller

felaktigt användande kan resultera i

allvarliga skador eller dödsfall för

användaren eller andra. Det är mycket

viktigt att du läser och förstår innehållet i

bruksanvisningen.

Läs igenom bruksanvisningen

noggrant och förstå innehållet

innan du använder maskinen.

Använd alltid:

Använd skyddshjälm där det finns risk

för fallande föremål

• Godkända hörselskydd

• Godkända ögonskydd

Max. varvtal på utgående axel,

rpm

Denna produkt överensstämmer

med gällande EG-direktiv.

10000

Avsedd endast för icke-metallisk

flexibel skärutrustning, d v s

trimmerhuvud med trimmerlina.

Bulleremissioner till omgivningen

enligt Europeiska Gemenskapens

direktiv. Maskinens emission anges i

kapitel Tekniska data och på dekal.

Övriga på maskinen angivna symboler/dekaler

avser specifika krav för certifieringar på vissa

marknader.

Motorn stängs av genom att

stoppkontakten förs till stoppläge.

OBS! Stoppkontakten återgår

automatiskt till startläge. För att

undvika ofrivillig start, måste därför

alltid tändhatten avlägsnas från tändstiftet vid montering,

kontroll och/eller underhåll.

Använd alltid godkända

skyddshandskar.

Varning för utslungade föremål och

rikoschetter.

Användare av maskinen ska under

arbetets gång se till att inga

människor eller djur kommer närmare

än 15 meter.

Använd alltid godkända

skyddshandskar.

Använd halkfria och stadiga stövlar.

24 – Svenska

Regelbunden rengöring krävs.

Okulär kontroll.

15

m

15 m

5

0

FT

50FT

INNEHÅLL

!

!

!

Innehåll Innan start måste följande

SYMBOLFÖRKLARING

Symboler på maskinen och/eller i

bruksanvisningen ................................................. 24

INNEHÅLL

Innehåll ................................................................. 25

Innan start måste följande observeras: ................ 25

INLEDNING

Bäste kund! .......................................................... 26

VAD ÄR VAD?

Vad är vad på trimmern? ...................................... 27

ALLMÄNNA SÄKERHETSINSTRUKTIONER

Viktigt .................................................................... 28

Personlig skyddsutrustning ................................... 28

Maskinens säkerhetsutrustning ............................ 29

Skärutrustning ...................................................... 31

MONTERING

Montering av loophandtag .................................... 32

Montering av trimmerskydd och trimmerhuvud .... 32

Montering och demontering av delbart riggrör ..... 32

BRÄNSLEHANTERING

Bränslesäkerhet ................................................... 34

Drivmedel ............................................................. 34

Tankning ............................................................... 35

START OCH STOPP

Kontroll före start .................................................. 36

Start och stopp ..................................................... 36

ARBETSTEKNIK

Allmänna arbetsinstruktioner ................................ 37

UNDERHÅLL

Förgasare ............................................................. 39

Ljuddämpare ........................................................ 39

Kylsystem ............................................................. 40

Tändstift ................................................................ 40

Delbart riggrör ...................................................... 40

Luftfilter ................................................................. 41

Underhållsschema ................................................ 42

TEKNISKA DATA

Tekniska data ....................................................... 43

EG-försäkran om överensstämmelse ................... 45

observeras:

Läs igenom bruksanvisningen noggrant.

VARNING! Långvarig exponering för

buller kan ge bestående hörselskador.

Använd därför alltid godkända

hörselskydd.

VARNING! Under inga förhållanden får

maskinens ursprungliga utformning

ändras utan tillstånd från tillverkaren.

Använd alltid originaltillbehör. Icke

auktoriserade ändringar och/eller

tillbehör kan medföra allvarliga skador

eller dödsfall för föraren eller andra.

VARNING! En röjsåg, buskröjare eller

trimmer kan felaktigt eller slarvigt

använd vara ett farligt redskap, som kan

orsaka allvarliga skador eller dödsfall för

användaren eller andra. Det är mycket

viktigt att du läser och förstår innehållet i

denna bruksanvisning.

Svenska – 25

INLEDNING

Bäste kund!

Gratulerar till Ditt val att köpa en Husqvarna-produkt! Husqvarna har anor som går tillbaka till 1689 då kung Karl XI lät

uppföra en fabrik på stranden av Huskvarnaån för tillverkning av musköter. Placeringen vid Huskvarnaån var logisk,

eftersom ån användes för att alstra vattenkraft och på så sätt utgjorde ett vattenkraftverk. Under de mer än 300 år som

Husqvarna-fabriken funnits har otaliga produkter tillverkats, allt från vedspisar till moderna köksmaskiner, symaskiner,

cyklar, motorcyklar mm. 1956 lanserades den första motorgräsklipparen som följdes av motorsågen 1959 och det är

inom detta område Husqvarna idag verkar.

Husqvarna är idag en av världens ledande tillverkare av skogs- och trädgårdsprodukter med kvalitet och prestanda som

högsta prioritet. Affärsidén är att utveckla, tillverka och marknadsföra motordrivna produkter för skogs- och

trädgårdsbruk samt bygg- och anläggningsindustrin. Husqvarnas mål är också att vara i framkant vad gäller ergonomi,

användarvänlighet, säkerhet och miljötänkande, varför en mängd olika finesser tagits fram för att förbättra produkterna

inom dessa områden.

Vi är övertygade om att Ni med tillfredsställelse kommer att uppskatta vår produkts kvalitet och prestanda under en lång

tid framöver. Ett köp av någon av våra produkter ger Dig tillgång till proffessionell hjälp med reparationer och service om

något ändå skulle hända. Om inköpsstället för maskinen inte var någon av våra auktoriserade återförsäljare, fråga dem

efter närmaste serviceverkstad.

Vi hoppas att Du kommer att vara nöjd med Din maskin och att den ska få vara Din följeslagare under en lång tid

framöver. Tänk på att denna bruksanvisning är en värdehandling. Genom att följa dess innehåll (användning, service,

underhåll etc) kan Du väsentligt höja maskinens livslängd och även dess andrahandsvärde. Om Du säljer Din maskin,

se till att överlåta bruksanvisningen till den nya ägaren.

Tack för att du använder en Husqvarna-produkt!

Husqvarna AB arbetar ständigt med att vidareutveckla sina produkter och förbehåller sig därför rätten till ändringar

beträffande bl.a. form och utseende utan föregående meddelande.

26 – Svenska

VAD ÄR VAD?

18

19

1

122LDx-series

2

Vad är vad på trimmern?

1 Trimmerhuvud

2 Skydd för skärutrustning

3 Riggrör

4 Loophandtag

5 Gasreglage

6 Stoppkontakt

7 Gasreglagespärr

8 Tändhatt och tändstift

9 Startapparat

10 Bränsletank

122C

20

2

2

3

8

4

7

17

4

13

12

16

9

8

7

3

12

13

6

1

5

16

5

11

9

10

9

11

10

15

11 Luftfilterkåpa

12 Bränslepump

13 Chokereglage

14 Bruksanvisning

15 Kombinyckel

16 Startapparat

17 Riggrörskoppling

18 Vinkelväxel

19 Påfyllning av smörjmedel, vinkelväxel

20 Medbringare

14

Svenska – 27

ALLMÄNNA SÄKERHETSINSTRUKTIONER

!

!

Viktigt

VIKTIGT!

Maskinen är endast konstruerad för grästrimning.

De enda tillbehör du får använda motorenheten som

drivkälla till är de skärutrustningar vi rekommenderar i

kapitel Tekniska data.

Använd aldrig maskinen om du är trött, om du har

druckit alkohol eller om du tar mediciner, som kan

påverka din syn, ditt omdöme eller din kroppskontroll.

Använd personlig skyddsutrustning. Se anvisningar

under rubrik ”Personlig skyddsutrustning”.

Använd aldrig en maskin som modifierats så att den ej

längre överensstämmer med originalutförandet.

Använd aldrig en maskin som är felaktig. Följ

underhålls-, säkerhetskontroll- och serviceinstruktioner

i denna bruksanvisning. Vissa underhålls- och

serviceåtgärder skall utföras av tränade och

kvalificerade specialister. Se anvisningar under rubrik

Underhåll.

Samtliga kåpor, skydd och handtag måste vara

monterade före start. Se till att tändhatt och tändkabel

är oskadade för att undvika risk för elektrisk stöt.

Användare av maskinen ska se till att inga människor

eller djur under arbetet kommer närmare än 15 meter.

Då flera användare arbetar med samma arbetsställe

ska säkerhetsavståndet vara minst 15 meter.

Inspektera hela maskinen innan användning. Följ

underhållsschemat under kapitel Underhåll.

VARNING! Denna maskin alstrar under

drift ett elektromagnetiskt fält. Detta fält

!

kan under vissa omständigheter ge

påverkan på aktiva eller passiva

medicinska implantat. För att reducera

risken för allvarliga eller livshotande

skador rekommenderar vi därför

personer med implantat att rådgöra med

läkare samt tillverkaren av det

medicinska implantatet innan denna

maskin används.

VARNING! Tillåt aldrig barn att använda

eller vara i närheten av maskinen.

Eftersom maskinen är utrustad med

återfjädrande stoppkontakt och kan

startas med låg hastighet och kraft på

starthandtaget, kan även små barn under

vissa omständigheter åstadkomma den

kraft som behövs för att starta maskinen.

Detta kan innebära risk för allvarlig

personskada. Avlägsna därför

tändhatten när maskinen inte är under

uppsikt.

Personlig skyddsutrustning

VIKTIGT!

En grästrimmer kan felaktigt eller slarvigt använd vara

ett farligt redskap, som kan orsaka allvarliga skador eller

dödsfall för användaren eller andra. Det är mycket viktigt

att du läser och förstår innehållet i denna

bruksanvisning.

Vid all användning av maskinen skall godkänd personlig

skyddsutrustning användas. Personlig skyddsutrustning

eliminerar inte skaderisken, men den reducerar effekten

av en skada vid ett olyckstillbud. Be din återförsäljare

om hjälp vid val av utrustning.

VARNING! Var alltid uppmärksam på

varningssignaler eller tillrop när

hörselskydd används. Tag alltid av

hörselskydden så snart motorn stoppats.

HJÄLM

Använd skyddshjälm där det finns risk för fallande föremål

HÖRSELSKYDD

Hörselskydd med tillräcklig dämpeffekt ska användas.

28 – Svenska

VARNING! Att köra en motor i ett instängt

eller dåligt ventilerat utrymme kan

!

orsaka dödsfall genom kvävning eller

kolmonoxidförgiftning.

ÖGONSKYDD

Godkända ögonskydd skall alltid användas. Används visir

måste även godkända skyddsglasögon användas. Med

godkända skyddsglasögon menas de som uppfyller

standard ANSI Z87.1 för USA eller EN 166 för EU-länder.

ALLMÄNNA SÄKERHETSINSTRUKTIONER

!

HANDSKAR

Handskar ska användas när det behövs, t ex vid

montering av skärutrustning.

VARNING! Använd aldrig en maskin med

defekt säkerhetsutrustning. Maskinens

säkerhetsutrustning ska kontrolleras och

underhållas som beskrivits i detta

avsnitt. Om din maskin inte klarar alla

kontrollerna ska serviceverkstad

uppsökas för reparation.

STÖVLAR

Använd halkfria och stadiga stövlar.

KLÄDSEL

Använd rivstarkt material i klädseln och undvik alltför vida

kläder som lätt hakar fast i ris och grenar. Använd alltid

kraftiga långbyxor. Bär inte smycken, kortbyxor eller

sandaler och gå inte barfota. Se till att håret inte hänger

nedanför axlarna.

FÖRSTA FÖRBAND

Första förband ska alltid finnas till hands.

Maskinens säkerhetsutrustning

I detta avsnitt förklaras vilka maskinens säkerhetsdetaljer

är, vilken funktion de har samt hur kontroll och underhåll

skall utföras för att säkerställa att de är i funktion. Se

kapitel Vad är vad?, för att hitta var dessa detaljer är

placerade på din maskin.

Maskinens livslängd kan förkortas och risken för olyckor

kan öka om underhåll av maskinen inte utförs på rätt sätt

och om service och/eller reparationer inte utförs

fackmannamässigt. Om du behöver ytterligare

upplysningar kontakta närmaste serviceverkstad.

Gasreglagespärr

Gasreglagespärren är konstruerad att förhindra ofrivillig

aktivering av gasreglaget. När spärren (A) trycks ner i

handtaget (= när man håller om handtaget) frikopplas

gasreglaget (B). När greppet om handtaget släpps

återställes både gasreglaget samt gasreglagespärren till

sina respektive ursprungslägen. Detta sker via två av

varandra oberoende returfjädersystem. Detta läge

innebär att gasreglaget automatiskt låses på tomgång.

A

B

Kontrollera att gasreglaget är låst i tomgångsläge när

gasreglagespärren är i sitt ursprungsläge.

Tryck in gasreglagespärren och kontrollera att den

återgår till sitt ursprungsläge när den släpps.

VIKTIGT!

All service och reparation av maskinen kräver

specialutbildning. Detta gäller särskilt maskinens

säkerhetsutrustning. Om maskinen inte klarar någon av

nedan listade kontroller ska du uppsöka din

serviceverkstad. Ett köp av någon av våra produkter

garanterar att du kan få en fackmannamässig reparation

och service utförd. Om inköpsstället för maskinen inte

är en av våra servande fackhandlare, fråga dem efter

närmaste serviceverkstad.

Kontrollera att gasreglaget och gasreglagespärren går lätt

samt att deras returfjädersystem fungerar.

Se anvisningar under rubrik Start. Starta maskinen och

ge full gas. Släpp gasreglaget och kontrollera att

skärutrustningen stannar och att den förblir stillastående.

Svenska – 29

ALLMÄNNA SÄKERHETSINSTRUKTIONER

!

Om skärutrustningen roterar med gasreglaget i

tomgångsläge ska förgasarens tomgångsjustering

kontrolleras. Se anvisningar under rubrik Underhåll.

Stoppkontakt

Stoppkontakten ska användas för att stänga av motorn.

Starta motorn och kontrollera att motorn stängs av när

stoppkontakten förs till stoppläget.

Skydd för skärutrustning

Detta skydd är avsett att förhindra att lösa föremål

slungas iväg mot användaren. Skyddet förhindrar också

användaren från att komma i kontakt med

skärutrustningen.

Ljuddämpare

Ljuddämparen är konstruerad för att ge så låg ljudnivå

som möjligt samt för att leda bort motorns avgaser från

användaren. Ljuddämpare utrustad med katalysator är

även konstruerad för att reducera skadliga ämnen i

avgaserna.

I länder med varmt och torrt klimat är risken för bränder

påtaglig. Vi har därför utrustat vissa ljuddämpare med ett

sk. gnistfångarnät. Kontrollera om din maskins

ljuddämpare har ett sådant nät.

Kontrollera att skyddet är oskadat och fritt från

sprickbildning. Byt skydd om det utsatts för slag eller har

sprickor.

Använd alltid rekommenderat skydd för den specifika

skärutrustningen. Se kapitel Tekniska data.

VARNING! Under inga omständigheter

får någon skärutrustning användas utan

!

att godkänt skydd monterats. Se kapitel

Tekniska data. Om fel eller defekt skydd

monteras, kan detta orsaka allvarlig

personskada.

30 – Svenska

För ljuddämpare är det mycket viktigt att instruktionerna

för kontroll, underhåll och service följs.

Använd aldrig en maskin som har en defekt ljuddämpare.

Kontrollera regelbundet att ljuddämparen sitter fast på

motorn.

Är din maskins ljuddämpare utrustad med ett

gnistfångarnät, skall detta rengöras regelbundet. Ett

igensatt nät leder till varmkörning av motorn med allvarlig

motorskada som följd.

VARNING! Katalysatorljuddämparen blir

mycket het såväl vid användning som

efter stopp. Detta gäller även vid

tomgångskörning. Beröring kan orsaka

brännskador på huden. Var uppmärksam

på brandfaran!

Loading...

Loading...