Husqvarna 120i operation manual

EN Operator's manual 8-28

SV Bruksanvisning 29-48

DA Brugsanvisning 49-69

NO Bruksanvisning 70-90

FI Käyttöohje 91-111

DE Bedienungsanweisung 112-135

FR Manuel d'utilisation 136-158

NL Gebruiksaanwijzing 159-182

IT Manuale dell'operatore 183-205

ES Manual de usuario 206-228

PT Manual do utilizador 229-251

120i

5

13

11

4 3

28 30 29

6

2

9

10

12

14

15

27

26

7

25

24

23 22 21

16 17 18 19 20

8

1

1

XXX XX

yyyywwxxxxx

2 3 4 5 6 7

8 9 10

14 15 16 17 18 19

20 21

22

23

24

25

11 12 13

26

27

28

B

A

C

B

A

A

B

A

A

B H F G

D

E

C

36

44

29

30

31

32

33

45

37

46

38

47

39

48

40

49

34

35

41

50

42

51

43

52

1

2

3

1

2

3

53

61

70

54

55

56

57

58

59

62

63

64

65

66

67

71

72

73

74

60

68

75

69

76

1

2

2

1

3

A

B

83

92

77

78

79

80

84

85

86

87

88

93

94

95

96

97

81

89

98

90

99

82

91

100

PITCH =

D

D

2

A

B

A

B

C

-

+

109

119

101

102

103

104

105

110

111

112

113

114

115

120

121

122

123

124

106

107

108

116

117

125

126

118

127

128

129

130

131

132

133

134

135

136

Contents

Introduction..................................................................... 8

Safety..............................................................................9

Assembly...................................................................... 15

Operation...................................................................... 15

Maintenance................................................................. 20

Introduction

Troubleshooting............................................................ 23

Transportation, storage and disposal........................... 24

Technical data.............................................................. 25

Accessories.................................................................. 26

EC Declaration of Conformity....................................... 28

Product description

This product is a chainsaw model with an electric motor.

Work is constantly in progress to increase your safety

and efficiency during operation. Speak to your servicing

dealer for more information.

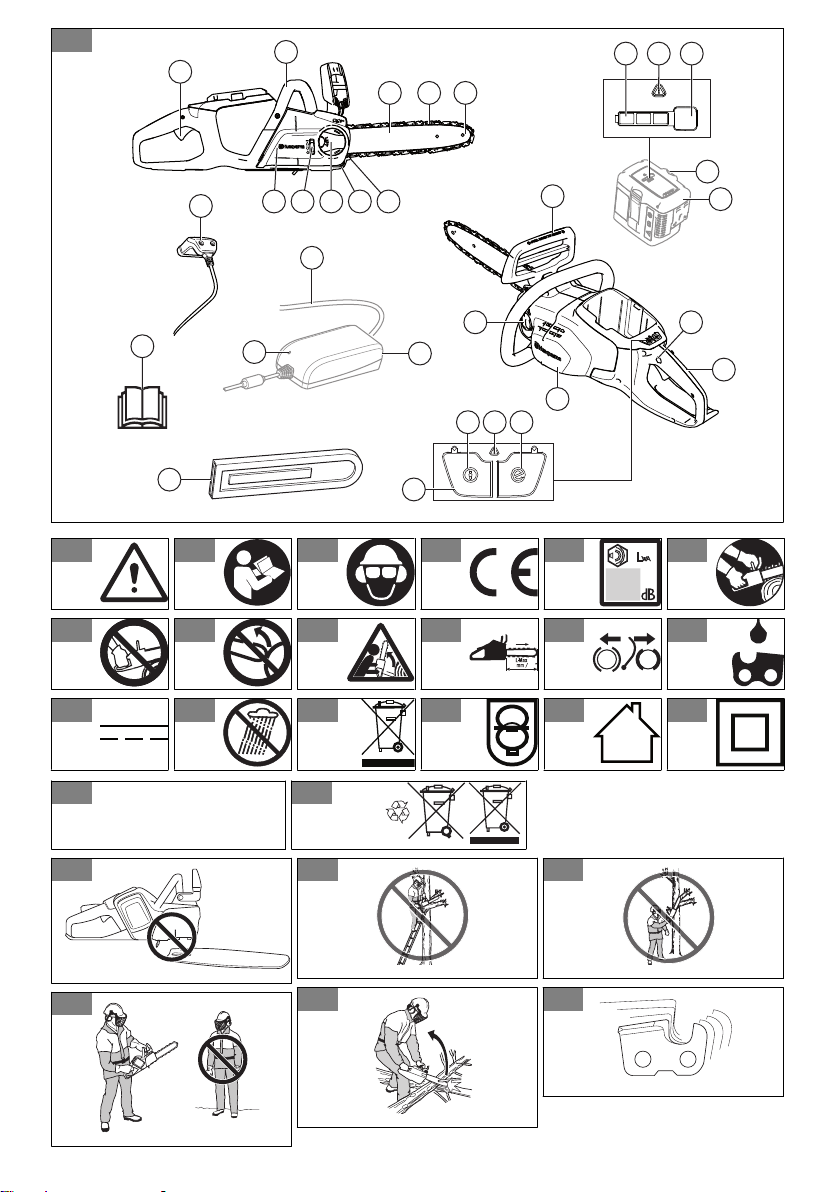

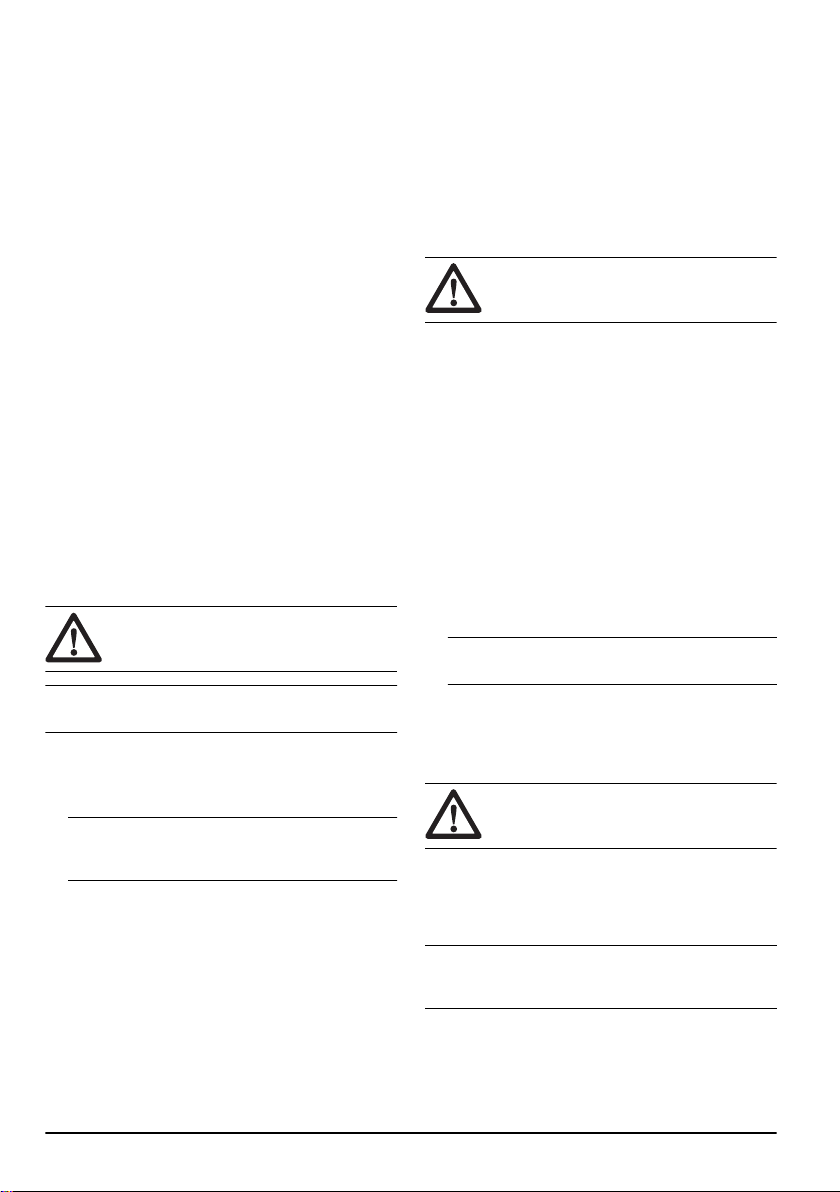

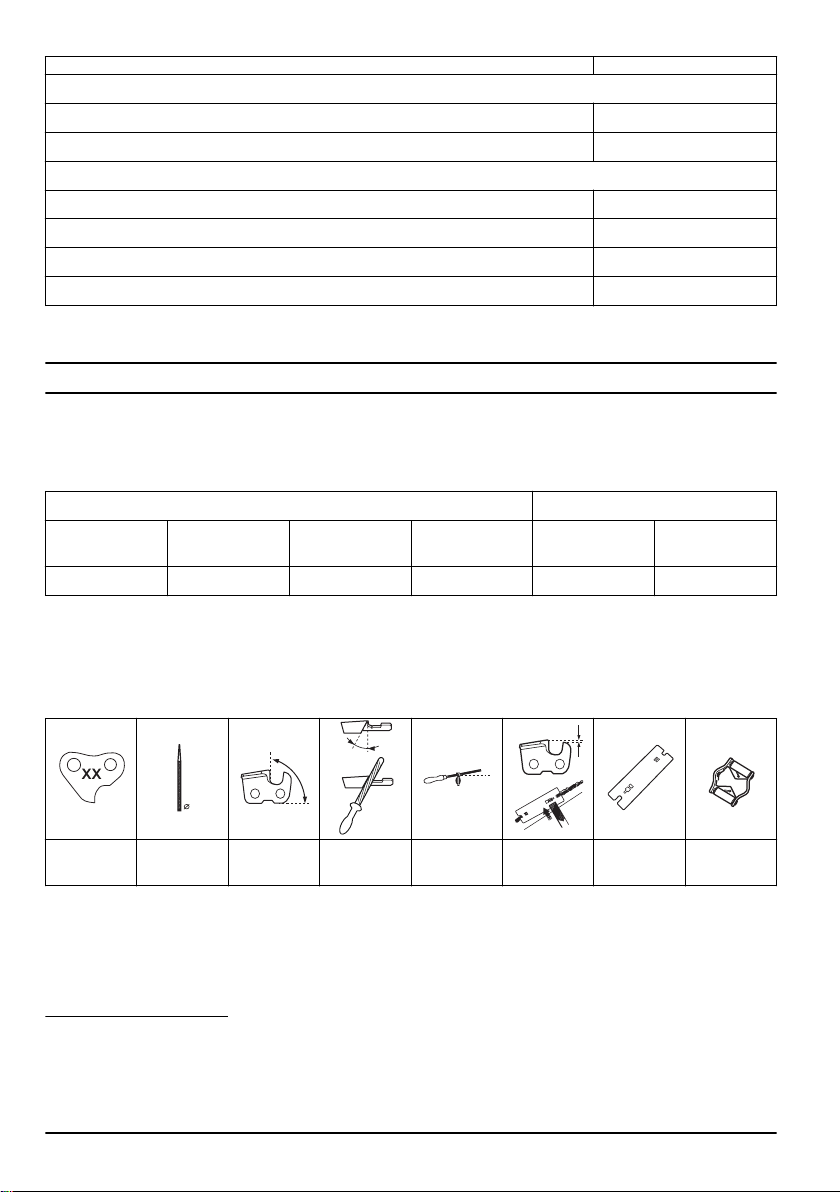

Product overview

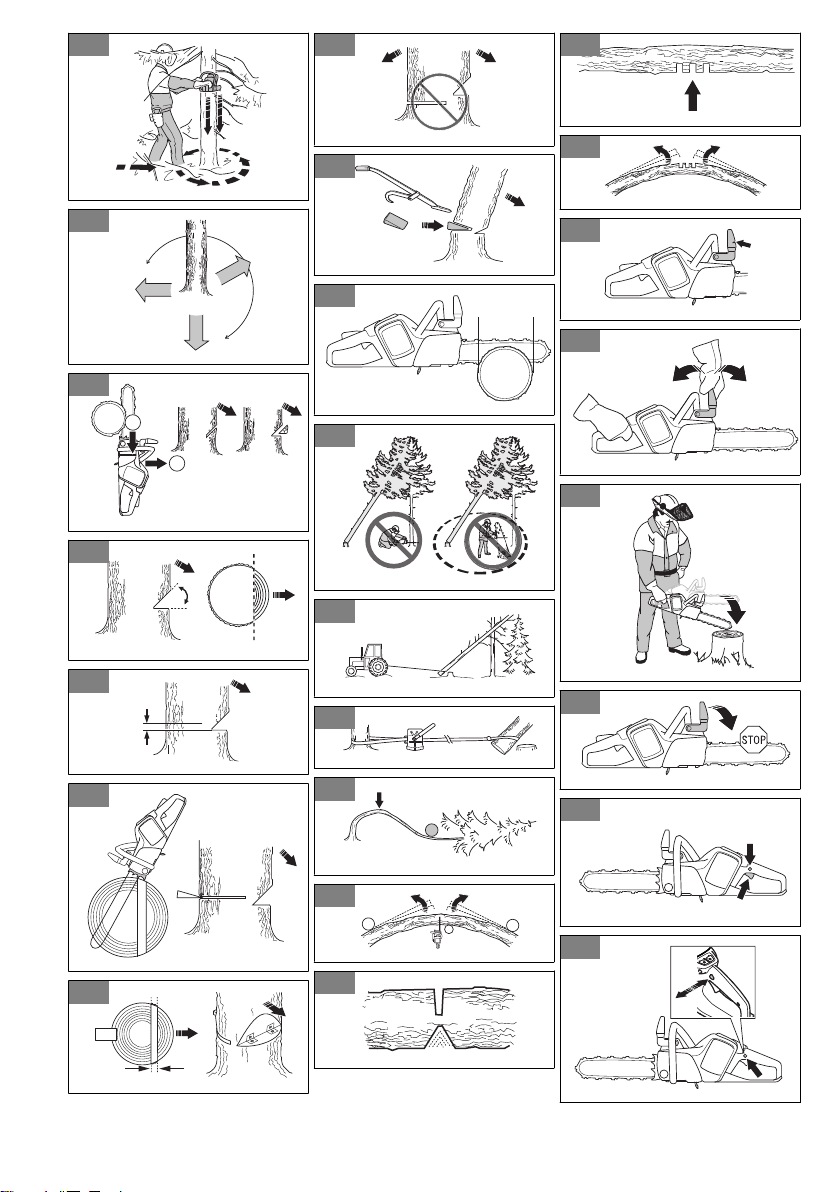

(Fig. 1)

1. Front hand guard

2. Keypad

3. SavE button

4. Warning indicator

5. Start/stop button

6. Power trigger lockout

7. Rear handle with right hand guard

8. Fan housing

9. Chain oil tank

10. Battery charger

11. Power cord

12. Warning indicator

13. Connector

14. Operator's manual

15. Guide bar cover

16. Drive sprocket cover

17. Chain tensioner wheel

18. Knob

19. Chain catcher

20. Spiked bumper

21. Bar tip sprocket

22. Saw chain

23. Guide bar

24. Front handle

25. Power trigger

26. Battery

27. Battery release buttons

28. Battery status

29. Button, battery status

30. Warning indicator

Intended use

This product is intended for sawing in wood.

Note: National regulations can set limit to the operation

of the product.

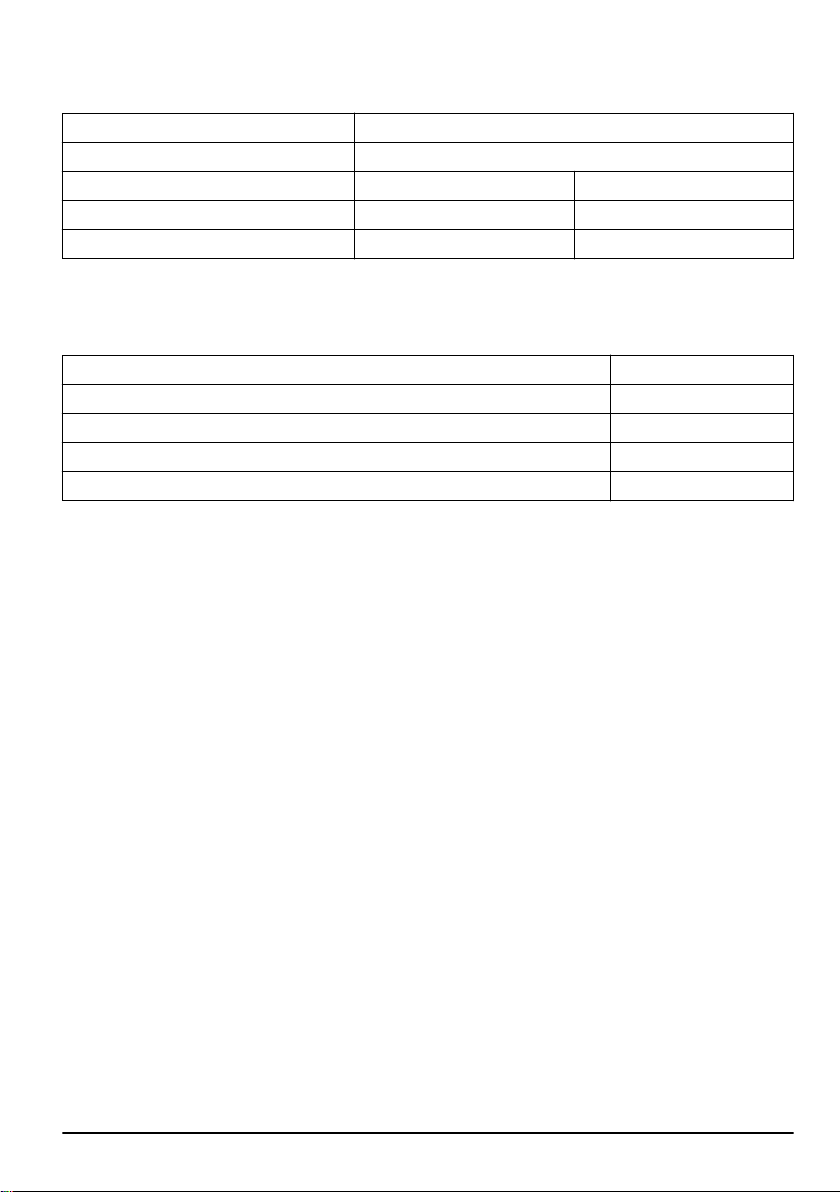

Symbols on the product

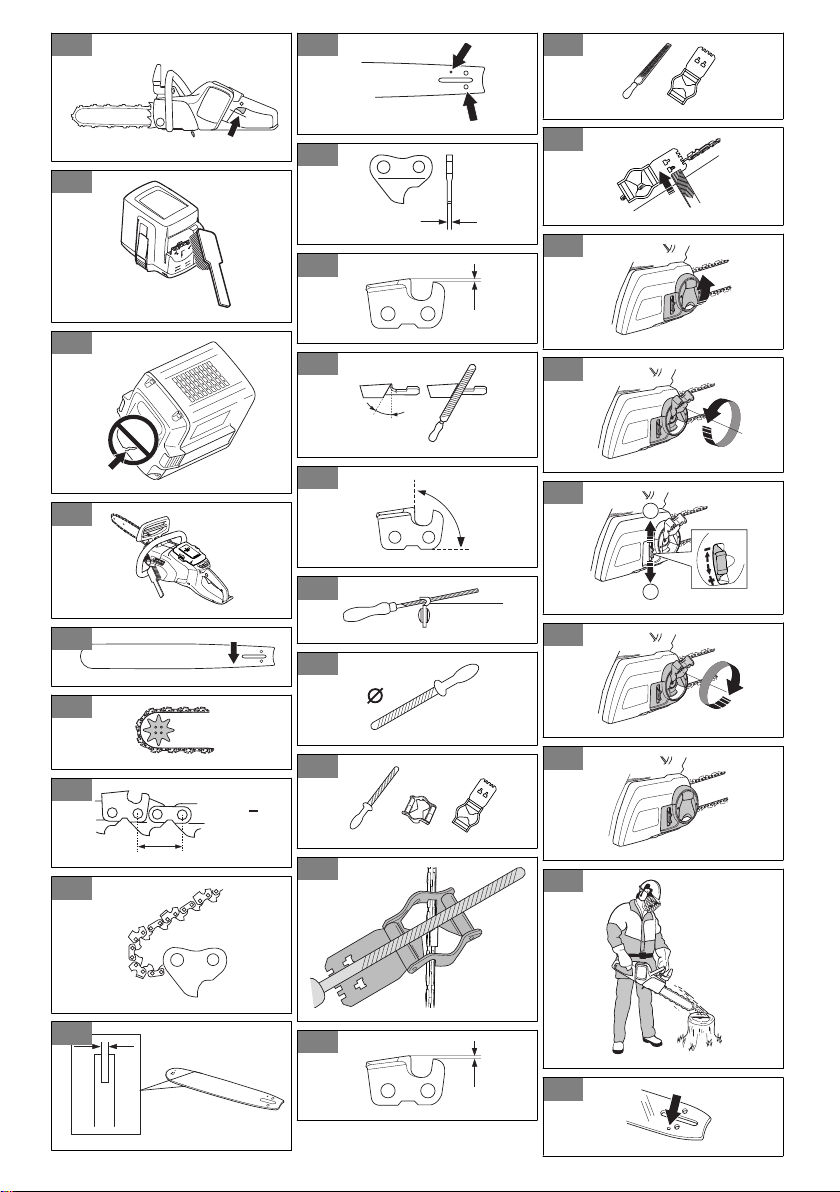

(Fig. 2) Risk of serious injury or death to the

operator or others. Be careful and use the

product correctly.

(Fig. 3) Read the operator's manual carefully and

understand the instructions before operation

of the product.

(Fig. 4) Wear approved protective helmet, hearing

and eye protection.

(Fig. 5) This product agrees with applicable EC

Directives.

(Fig. 6) Noise emissions to the environment

according to European Directive 2000/14/EC

and New South Wales legislation "Protection

of the Environment Operations (Noise

Control) Regulation 2017". Noise emission

data can be found on the machine label and

in the Technical data chapter.

(Fig. 7) Both of the operator's hands must be used

to operate the chainsaw.

(Fig. 8) Do not operate the chainsaw holding it with

one hand only.

(Fig. 9) Do not let the guide bar tip touch all objects.

(Fig. 10) Warning! Kickback can occur when the

guide bar tip touches an object. This causes

the guide bar to be thrown in the direction of

the operator. Risk of serious injury or death.

(Fig. 11) The direction in which the saw chain rotates

and maximum length of the guide bar.

8 1259 - 001 - 11.07.2019

(Fig. 12) Chain brake, engaged (right). Chain brake,

disengaged (left).

(Fig. 13) Chain oil fill.

(Fig. 14) Direct current.

(Fig. 15) Do not expose to rain.

(Fig. 16) Environmental mark. The product or

package of the product is not domestic

waste. Recycle it at a recycling station for

electrical and electronic equipment.

(Fig. 20) The rating plate shows serial number. yyyy

is the production year, ww is the production

week.

Note: Other symbols/decals on the product refer to

certification requirements for some markets.

Safety definitions

The definitions below give the level of severity for each

signal word.

WARNING: Injury to persons.

CAUTION: Damage to the product.

Note: This information makes the product easier to use.

General power tool safety warnings

WARNING: Read all safety warnings and all

instructions. Failure to follow the warnings

and instructions may result in electric shock,

fire and/or serious injury.

Note: Save all warnings and instructions for future

reference. The term "power tool" in the warnings refers

to your mains-operated (corded) power tool or batteryoperated (cordless) power tool.

Work area safety

• Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

• Do not operate power tools in explosive

atmospheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

Symbols on the battery and/or on the battery charger

(Fig. 21)

(Fig. 17) Fail-safe transformer.

(Fig. 18) Use and keep the battery charger indoors

(Fig. 19) Double insulation.

Recycle this product at a recycling station

for electrical and electronic equipment. (Applies to Europe only)

only.

Safety

Keep children and bystanders away while operating

•

a power tool. Distractions can cause you to lose

control.

Electrical safety

• Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce

risk of electric shock.

• Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

• Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

• Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving

parts. Damaged or entangled cords increase the risk

of electric shock.

• When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of

electric shock.

• If operating a power tool in a damp location is

unavoidable, use a ground fault circuit interrupter

(GFCI) protected supply. Use of a GFCI reduces the

risk of electric shock.

Personal safety

• Stay alert, monitor what you are doing and use

common sense when operating a power tool. Do not

use a power tool while you are tired or under the

influence of drugs, alcohol or medication. A moment

1259 - 001 - 11.07.2019

9

of inattention while operating power tools may result

in serious personal injury.

• Use personal protective equipment. Always wear

eye protection. Protective equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce

personal injuries.

• Prevent unintentional starting. Ensure the switch is in

the OFF-position before connecting to a power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your finger on the

switch or energising power tools that have the switch

on invites accidents.

• Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to

a rotating part of the power tool may result in

personal injury.

• Do not overreach. Keep proper footing and balance

at all times. This enables better control of the power

tool in unexpected situations.

• Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewellery or long

hair can be caught in moving parts.

• If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection

can reduce dust-related hazards.

• The vibration emission during actual use of the

power tool can differ from the declared total value

depending on the ways in which the tool is used.

Operators should identify safety measures to protect

themselves that are based on an estimation of

exposure in the actual conditions of use (taking

account of all parts of the operating cycle such as

the times when the tool is switched off and when it is

running idle in addition to the trigger).

Power tool use and care

• Do not force the power tool. Use the correct power

tool for your application. The correct power tool will

do the job better and safer at the rate for which it

was designed.

• Do not use the power tool if the switch does not turn

it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must be

repaired.

• Disconnect the plug from the power source and/or

the battery pack from the power tool before making

any adjustments, changing accessories, or storing

power tools. Such preventive safety measures

reduce the risk of starting the power tool

accidentally.

• Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the power

tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained

users.

• Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tool´s

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

• Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

• Use the power tool, accessories and tool bits etc. in

accordance with these instructions, taking into

account the working conditions and the work to be

performed. Use of the power tool for operations

different from those intended could result in a

hazardous situation.

Battery tool use and care

• Recharge only with the charger specified by the

manufacturer. A charger that is suitable for one type

of battery pack may create a risk of fire when used

with another battery pack.

• Use power tools only with specifically designated

battery packs. Use of any other battery packs may

create a risk of injury and fire.

• When battery pack is not in use, keep it away from

other metal objects, like paper clips, coins, keys,

nails, screws or other small metal objects, that can

make a connection from one terminal to another.

Shorting the battery terminals together may cause

burns or a fire.

• Under abusive conditions, liquid may be ejected from

the battery; avoid contact. If contact accidentally

occurs, flush with water. If liquid contacts eyes,

additionally seek medical help. Liquid ejected from

the battery may cause irritations or burns.

Service

• Have your power tool serviced by a qualified repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is

maintained.

Chain saw safety warnings

• Keep all parts of the body away from the saw chain

when the chain saw is operating. Before you start

the chain saw, make sure the saw chain is not

contacting anything. A moment of inattention while

operating chain saws may cause entanglement of

you clothing or body with the saw chain.

• Always hold the chain saw with your right hand on

the rear handle and your left hand on the front

handle. Holding the chain saw with a reversed hand

configuration increases the risk of personal injury

and should never be done.

• Hold the power tool by insulated gripping surface

only, because the saw chain may contact hidden

wiring or its own cord. Saw chain contacting a ”live”

wire may make exposed metal parts of the power

tool ” live” and could give the operator an electric

shock.

• Wear safety glasses and hearing protection. Further

protective equipment for head, hands, legs and feet

10

1259 - 001 - 11.07.2019

is recommended. Adequate protective clothing will

reduce personal injury by flying debris or accidental

contact with the saw chain.

• Do not operate a chain saw in a tree. Operation of

chain saw while up a tree may result in personal

injury.

• Always keep proper footing and operate the chain

saw only when standing on fixed, secure and level

surface. Slippery or unstable surfaces such as

ladders may cause a loss of balance or control of the

chain saw.

• When cutting a limb that is under tension be alert for

spring back. When the tension in the wood fibres is

released the spring loaded limb may strike the

operator and/or throw the chain saw out of control.

• Use extreme caution when cutting brush and

saplings. The slender material may catch the saw

chain and be whipped forward toward you or pull you

off balance.

• Carry the chain saw by the front handle with the

chain saw switched off and away from your body.

When transporting or storing the chain saw always fit

the guide bar cover. Proper handling of the chain

saw will reduce the likelihood of accidental contact

with the moving saw chain.

• Follow instruction for lubricating, chain tensioning

and changing accessories. Improperly tensioned or

lubricated saw chain may either brake or increase

the chance of kickback.

• Keep handles dry, clean and free from oil and

grease. Greasy, oily handles are slippery causing

loss of control.

• Cut wood only. Do not use chain saw for purposes

not intended. For example: do not use chain saw for

cutting plastic, masonry or nonwood building

materials. Use of the chain saw for operations

different than intended could result in a hazardous

situation.

• We strongly recommend that first time users practice

sawing logs on a saw horse or cradle.

Causes and operator prevention of kickback

Kickback may occur when the nose or tip of the guide

bar touches an object, or when the wood closes in and

pinches the saw chain in the cut. Tip contact in some

cases may cause a sudden reverse reaction, kicking the

guide bar up and back towards the operator. Pinching

the saw chain along the top of the guide bar may push

the guide bar rapidly back towards the operator. Either

of these reactions may cause you to lose control of the

saw which could result in serious personal injury. Do not

rely exclusively upon the safety devises built into your

saw. As a chain saw user, you should take several steps

to keep your cutting jobs free from accident or injury.

Kickback is a result of tool misuse and/or incorrect

operating procedures or conditions and can be avoided

by taking proper precautions as given below:

• Maintain a firm grip, with thumbs and fingers

encircling the chain saw handles, with both hands on

the saw and position your body and arm to allow you

to resist kickback forces.

controlled by the operator, if proper precautions are

taken. Do not let go of the chain saw.

• Do not overreach and do not cut above shoulder

height. This helps prevent unintended tip contact and

enables better control of the chain saw in

unexpected situations.

• Only use replacement bars and chains specified by

the manufacturer. Incorrect replacement bars and

chains may cause chain breakage and/or kickback.

• Follow the manufacturer’s sharpening and

maintenance instructions for the saw chain.

Decreasing the depth gauge height can lead to

increased kickback.

SAVE THESE INSTRUCTIONS.

Kickback forces can be

General safety instructions

WARNING: Read the warning instructions

that follow before you use the product.

• This product is a dangerous tool if you are not

careful or if you use the product incorrectly. This

product can cause serious injury or death to the

operator or others. It is very important that you read

and understand the contents of this operator’s

manual.

• Do not change the product without an approval from

the manufacturer. Do not use a product that has

been changed by others and always use original

accessories. Changes that are not approved from

the manufacturer can result in serious injury or death

to the operator or others.

• Long term inhalation of chain oil fumes and sawdust

can cause health problems.

• This product produces an electromagnetic field

during operation. This field may under some

circumstances interfere with active or passive

medical implants. To decrease the risk of serious

injury or death, we recommend persons with medical

implants to turn to their physician and the medical

implant manufacturer before operating this product.

Safety instructions for operation

WARNING:

that follow before you use the product.

• The information in this operator's manual is not a

replacement for professional knowledge and

experience. If you do not feel safe in the situation

that you are in, stop the product. Turn to your

servicing dealer or a professional chainsaw operator.

Do not attempt any task that you feel unsure of!

• Turn to your servicing dealer or Husqvarna if you

have questions about the operation of the product.

We can give you information about how to operate

your product effectively and safely. Participate in a

Read the warning instructions

1259 - 001 - 11.07.2019

11

training class in chainsaw operation if possible. Your

servicing dealer, forestry school or your library can

give you information about training materials and

classes that are available.

• You must understand the effects of kickback and

how to prevent them before you use this product.

See

Kickback information on page 16

questions about kickback on page 17

instructions.

• Do not use a product, battery or battery charger that

is defective.

• Do not touch a rotating saw chain. It can cause

serious injuries of death.

• Do not use the product if you are tired, while under

the influence of alcohol or drugs, medicine or

anything that could have a negative effect on your

vision, alertness, coordination or judgment.

• Working in bad weather is tiring and often brings

added risk. Due to the added risk, it is not

recommended to use the machine in very bad

weather, for instance in dense fog, heavy rain,

strong winds, intense cold, risk of lightning, etc.

• Do not start a product unless the guide bar, saw

chain and all covers are assembled correctly. If not,

the drive sprocket can come loose and cause

serious injuries. See

instructions.(Fig. 22)

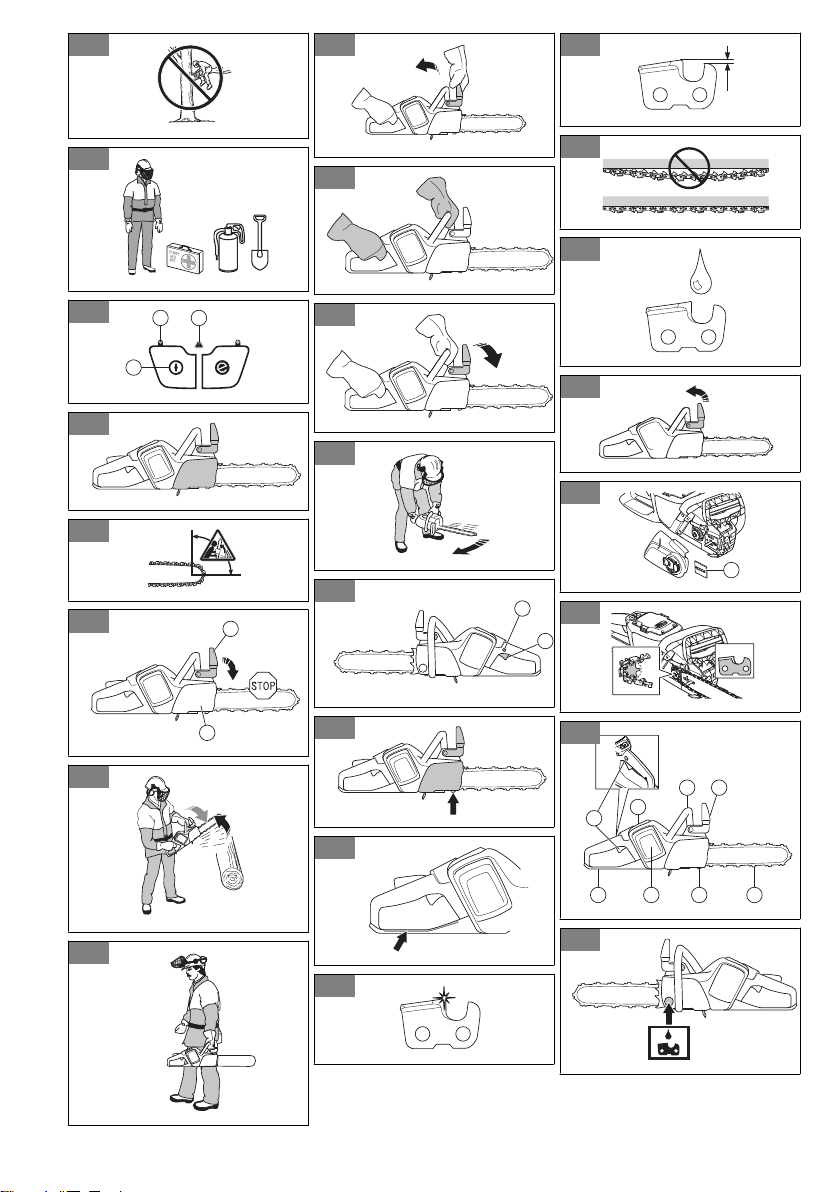

• Look around you. Make sure that there is no risk that

persons or animals touch or influence on your

control of the product.(Fig. 23)

• Do not let children use or be near the product. The

product is easy to start and children may be able to

start it if they are not fully supervised. This can mean

a risk of serious injury.

• Remove the battery when you do not have full view

of the product or leave the product for any length of

time.

• You must be stable on your feet in order to have full

control of the product. Do not use the product if you

are on a ladder or in a tree. Do not use the product if

you are not on stable ground.(Fig. 24)

• If you are not careful, the risk of kickback increases.

A kickback can occur if the kickback zone of the

guide bar accidentally touches a branch, tree or

other objects.(Fig. 25)

• Do not hold the product with one hand. This product

is not safely controlled with one hand.

• Do not use the product above shoulder height and

do not try to cut with the guide bar tip. (Fig. 26)

• Do not use a product in a situation where you can

not call for help if an accident occur.

• Stop the product and engage the chain brake before

you move the product. Hold the product with the

guide bar and saw chain pointing rearward. Put on a

transportation guard on the guide bar before

transportation or before you move it for any distance.

• When you put the product on the ground, engage the

chain brake and have a constant view of the product.

Assembly on page 15

and

for

Common

for

Stop the product and remove the battery before you

leave your product for any length of time.

• There is a risk that wood chips get stuck in the drive

system. This can cause the saw chain to get stuck.

Always stop the product and remove the battery

before you clean it.

• Make sure that you can move around safely.

Examine the conditions and the terrain around you

for possible obstacles such as roots, rocks,

branches, ditches and more. Be careful when you do

work on sloping ground.

• The vibration level increases if you cut with cutting

equipment that is incorrect or not correctly

sharpened. Cutting hardwoods, such as broadleaf

trees, causes more vibration than cutting softwoods,

such as conifers. (Fig. 27)

• Overexposure to vibration can lead to circulatory

damage or nerve damage in persons who have

decreased circulation. Speak to your physician if you

experience symptoms of overexposure to vibration.

Such symptoms include numbness, loss of feeling,

tingling, pricking, pain, loss of strength, changes in

skin colour or condition. These symptoms usually

occur in the fingers, hands or wrists increases in cold

temperatures.

• Prevent situations which you think is beyond your

capability.

• It is not possible to include each possible situation

you can face when you use this product. Always be

careful and use your common sense.(Fig. 28)

Personal protective equipment

WARNING:

that follow before you use the product.

(Fig. 29)

• Most chainsaw accidents occur when the saw chain

touches the operator. You must use approved

personal protective equipment during operation.

Personal protective equipment does not give you full

protection from injuries but it decreases the degree

of injury if an accident occurs. Speak to your

servicing dealer for recommendations about which

equipment to use.

• Your clothing must be close-fitting but not limit your

movements. Regularly do a check of the condition of

the personal protective equipment.

• Use an approved protective helmet.

• Use approved hearing protection. Long-term

exposure to noise can result in permanent damage

to the hearing.

• Use protective glasses or a face visor to decrease

the risk of injury from thrown objects. The product

can throw objects, such as wood chips, small pieces

of wood and more, at large force. This can result in

serious injury, especially to the eyes.

• Use gloves with saw protection.

Read the warning instructions

12

1259 - 001 - 11.07.2019

• Use pants with saw protection.

• Use boots with saw protection, steel toe-cap and

non-slip sole.

• Always have a first-aid kit with you.

• Risk of sparks. Keep fire extinguishing tools and a

shovel near to prevent forest fires.

Safety devices on the product

WARNING: Read the warning instructions

that follow before you use the product.

• Do not use a product with defective safety devices.

• Do a check of the safety devices regularly. Refer to

Maintenance and checks of the safety devices on

the product on page 20

• If the safety devices are defective, speak to your

Husqvarna servicing dealer.

Keypad

The warning indicator flashes if the chain brake is

engaged or if there is a risk of overload. The overload

protection temporarily stops the product and you can not

use the product until the temperature restores. If the

indicator shows a solid light, turn to your servicing

dealer. (Fig. 30)

The automatic stop function

The product has an automatic stop function that stops

the product if you do not use it for one minute.

Chain brake and front hand guard

Your product has a chain brake that stops the saw chain

if you get a kickback. The chain brake decreases the

risk of accidents but only you can prevent them.(Fig. 31)

WARNING:

where there is a risk of kickback. Be careful

when you use your product and make sure

that the kickback zone of the guide bar does

not touch an object.

.

Do not engage in situations

Use the chain brake as a parking brake when you start

the product and when you move short distances. This

decreases the risk that you or a person near you

touches the saw chain.(Fig. 35)

Pull the front hand guard rearward to disengage the

chain brake.(Fig. 36)

A kickback can be very sudden and intense. Most

kickbacks are small and do not always engage the chain

brake. If a kickback occurs when you use the product,

hold tightly around the handles and do not let go. (Fig.

37)

The front hand guard also decreases the risk to touch

the saw chain if your hand lets go of the front handle.

(Fig. 38)

In the felling position you cannot engage the chain brake

manually. The chain brake can in this position only be

engaged by the inertia release mechanism.(Fig. 39)

Power trigger lockout

The power trigger lockout prevents accidental operation

of the power trigger. If you put your hand around the

handle and press the power trigger lockout (A), it

releases the power trigger (B). If you release the handle,

the power trigger and the power trigger lockout move

back to their initial positions.(Fig. 40)

Chain catcher

The chain catcher catches the saw chain if it breaks or

comes loose. If you have the correct chain tension, the

risk decreases. You also decrease the risk if you do the

correct maintenance on the guide bar and saw chain.

See

To tighten the saw chain on page 22

Maintenance on page 20

Right hand guard

The right hand guard works as a protection for your

hand if the saw chain breaks or comes loose. It also

prevents interference from branches and twigs when

you use the product.(Fig. 42)

for instructions.(Fig. 41)

and

Battery safety

(Fig. 32)

The chain brake engages (A) manually by your left hand

or automatically by the inertia release mechanism. Push

the front hand guard (B) forward to engage the chain

brake manually. This movement starts a spring-loaded

mechanism that stops the drive sprocket.(Fig. 33)

How the chain brake is engaged is in relation to the

force of the kickback and position of the product. If you

get an intense kickback while the kickback zone is

farthest away from you, the chain brake engages by the

inertia release. If the kickback is small or the kickback

zone is nearer you, the chain brake engages manually

by your left hand.(Fig. 34)

1259 - 001 - 11.07.2019

WARNING:

that follow before you use the product.

• Only use the BLi batteries that we recommend for

your product. The batteries are software encrypted.

• Use the BLi batteries that are rechargable as a

power supply for the related Husqvarna products

only. To prevent injury, do not use the battery as a

power supply for other devices.

• Risk of electrical shock. Do not connect the battery

terminals to keys, screws or other metal. This can

cause a short circuit of the battery.

• Do not use batteries that are non-rechargable.

• Do not put objects into the air slots of the battery.

Read the warning instructions

13

• Keep the battery away from sunlight, heat or open

flame. The battery can cause burns and/or chemical

burns.

• Keep the battery away from rain and wet conditions.

• Keep the battery away from microwaves and high

pressure.

• Do not try to disassemble or break the battery.

• Do not let battery acid touch your skin. Battery acid

causes injuries to the skin, corrosion and burns. If

you get battery acid in your eyes, do not rub but

flush with water for minimum 15 minutes. If battery

acid has touched your skin, you must clean the skin

with a large quantity of water and soap. Get medical

aid.

• Use the battery in temperatures between -10 °C (14

°F) and 40 °C (104 °F).

• Do not clean the battery or the battery charger with

water. See

battery compartment on page 21

• Do not use a defective or damaged battery.

• Keep batteries in storage away from metal objects

such as nails, screws or jewelry.

• Keep the battery away from children.

To do a check of the battery and the

.

Battery charger safety

WARNING: Read the warning instructions

that follow before you use the product.

• Risk of electrical shock or short circuit if the safety

instructions are not obeyed.

• Use an approved grounded mains socket that is not

damaged.

• Do not use other battery chargers than the one

supplied for your product. Only use Husqvarna QC

chargers when you charge Husqvarna replacement

batteries BLi.

• Do not try to disassemble the battery charger.

• Do not use a defective or damaged battery charger.

• Do not lift the battery charger by the power cord. To

disconnect the battery charger from a mains socket,

pull out the plug. Do not pull the power cord.

• Keep all cables and extension leads away from

water, oil and sharp edges. Make sure that the cable

is not caught between doors, fences or similar.

• Do not use the battery charger near flammable

materials or materials that can cause corrosion.

Make sure that the battery charger is not covered.

Pull out the plug to the battery charger if there is

smoke or fire.

• Only charge the battery indoors in a location with

good airflow and away from sunlight. Do not charge

the battery outdoors. Do not charge the battery in

wet conditions.

• Only use the battery charger where the temperature

is between 5 °C (41 °F) and 40 °C (104 °F). Use the

charger in an environment which has a good airflow,

dry and free from dust.

• Do not put objects into the cooling slots of the

battery charger.

• Do not connect the battery charger terminals to

metal objects as this can short circuit the battery

charger.

• Use approved wall sockets that are not damaged.

Safety instructions for maintenance

WARNING: Read the warning instructions

that follow before you do maintenance on

the product.

• Remove the battery before you do maintenance,

other checks or assemble the product.

• The operator must only do the maintenance and

servicing shown in this operator's manual. Turn to

your servicing dealer for maintenance and servicing

of a larger extension.

• Do not clean the battery or the battery charger with

water. Strong detergent can cause damage to the

plastic.

• If you do not do maintenance, it decreases the life

cycle of the product and increases the risk of

accidents.

• Special training is necessary for all servicing and

repair work, especially for the safety devices on the

product. If not all checks in this operator's manual

are approved after you have done maintenance, turn

to your servicing dealer. We guarantee that there are

professional repairs and servicing available for your

product.

• Only use original spare parts.

Safety instructions for the cutting equipment

WARNING:

that follow before you use the product.

• Only use the guide bar/saw chain combinations and

filing equipment that we recommend. Refer to

Accessories on page 26

• Use protective gloves when you use or do

maintenance on the saw chain. A saw chain that

does not move can also cause injuries.

• Keep the cutting teeth correctly sharpened. Obey the

instructions and use the recommended file gauge. A

saw chain that is damaged or incorrectly sharpened

increases the risk of accidents.(Fig. 43)

• Keep the correct depth gauge setting. Obey the

instructions and use the recommended depth gauge

setting. Too large depth gauge setting increases the

risk of kickback.(Fig. 44)

• Make sure that the saw chain has the correct

tension. If the saw chain is not tight against the guide

bar, the saw chain can derail. An incorrect saw chain

tension increases wear on the guide bar, saw chain

Read the warning instructions

for instructions.

14

1259 - 001 - 11.07.2019

and chain drive sprocket. Refer to

chain on page 22

• Do maintenance on the cutting equipment regularly

and keep it correctly lubricated. If the saw chain is

.(Fig. 45)

To tighten the saw

Assembly

Introduction

WARNING: Read and understand the safety

chapter before you assemble the product.

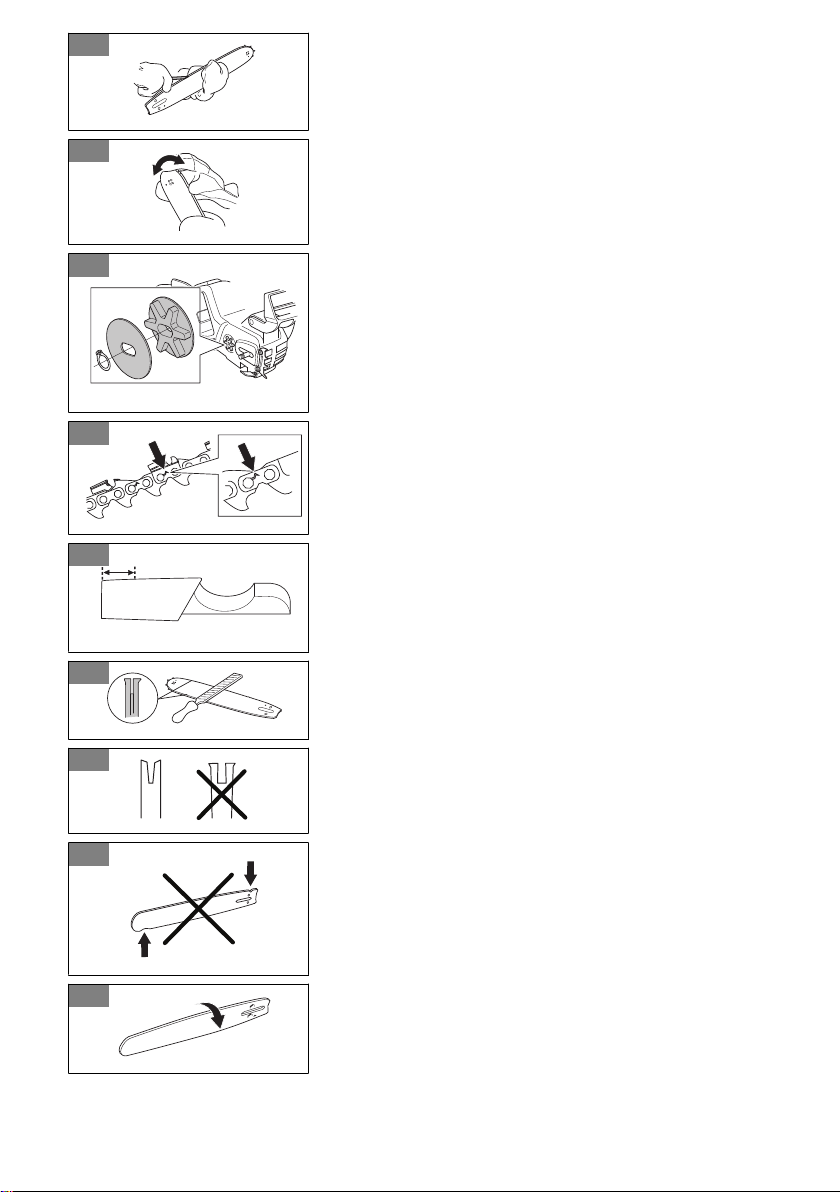

To assemble the guide bar and saw chain

WARNING: Always remove the battery

before you assemble or do maintenance on

the product.

1. Disengage the chain brake. (Fig. 47)

2. Loosen the knob and remove the drive sprocket

cover (chain brake) and the transportation guard (A).

(Fig. 48)

3. Put the guide bar on top of the bar bolt. Steer the

guide bar to its most rear position. Lift the saw chain

Operation

Introduction

WARNING: Read and understand the safety

chapter before you use the product.

To do a function check before you use the product

1. Do a check of the chain brake (A) to make sure that

it operates correctly and that it is not damaged.

2. Do a check of the rear right hand guard (B) to make

sure that it is not damaged.

3. Do a check of the power trigger and the power

trigger lockout (C) to make sure that they operate

correctly and that they are not damaged.

4. Do a check of the keypad (D) to make sure that it

operates correctly.

5. Make sure that there is no oil on the handles (E).

6. Do a check to make sure that all parts are correctly

attached and not damaged or missing.

7. Do a check of the chain catcher (F) to make sure

that it is attached correctly.

8. Do a check of the chain tension (G).

not correctly lubricated, the risk of wear on the guide

bar, saw chain and chain drive sprocket increases.

(Fig. 46)

above the drive sprocket and engage it in the groove

on the guide bar. Start on the top edge of the guide

bar. (Fig. 49)

4. Make sure that the edges of the cutting links face

forward on the top edge of the guide bar.

5. Assemble the drive sprocket cover and steer the

chain adjuster pin to the hole in the guide bar.

6. Make sure that the drive links of the saw chain fit

correctly on the drive sprocket.

7. Make sure that the saw chain is correctly engaged in

the groove in the guide bar.

8. Tighten the saw chain. See

on page 22

for instructions.

To tighten the saw chain

To assemble a spiked bumper

To assemble a spiked bumper, speak to your servicing

dealer.

9. Charge the battery (H) and make sure that it is

correctly attached to the product.

10. Make sure that the saw chain stops when you

release the power trigger. (Fig. 50)

Chain oil

All Husqvarna chainsaws have an automatic chain

lubrication system. On some models the oil flow is also

adjustable.

Think about the following when you select a chain oil:

(Fig. 51)

• The oil tank lasts approximately three battery

charges. This applies only if you use the correct

chain oil. If the chain oil is too thin, it will not last that

long.

• Chain oil must show good adherence to the saw

chain and also keep its flow quality during warm

summer and cold winter weather.

• Use an oil of the right grade (suitable viscosity

range) to agree with the air temperature. In

temperatures below 0°C (32°F) some oils become

too thick. This can cause the oil pump to overload

and result in damage to the oil pump components.

• Use the recommended cutting equipment. A guide

bar that is too long will use more chain oil.

1259 - 001 - 11.07.2019 15

• Turn to your servicing dealer when you select a

chain oil.

WARNING: Do not use waste oil! Waste oil

is dangerous to you and the environment.

Waste oil also causes damage to the oil

pump, the guide bar and the saw chain.

3. Put the battery in the battery holder. (Fig. 55)

4. Press on the lower part of the battery until you hear

a click sound.

CAUTION: If the battery does not move

into the battery holder easily, it is not

attached correctly into the battery holder.

WARNING: If the lubrication of the cutting

equipment is not sufficient, it can cause the

saw chain to break. This can cause serious

injury or death to the operator.

CAUTION: If you use vegetable based chain

oil, clean the groove in the guide bar and

saw chain before long-term storage.

Otherwise there is a risk of the saw chain

oxidizing, which causes the saw chain to

become stiff and that the bar tip sprocket

gets clogged.

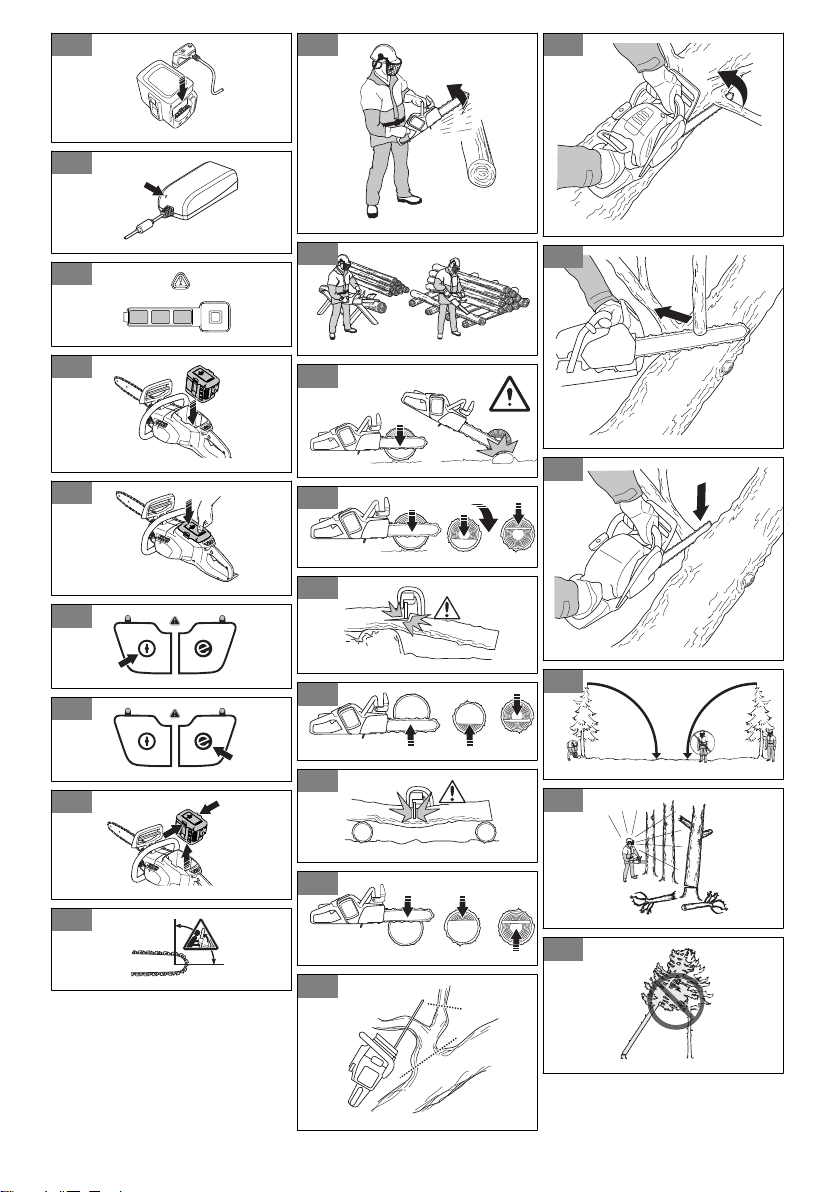

To connect the battery charger

1. Connect the battery charger to the voltage and

frequency that is specified on the rating plate.

2. Put the plug in a grounded socket outlet.

Note: The battery does not charge if the battery

temperature is more than 50 °C/122 °F. If the

temperature is more than 50 °C/122 °F, the battery

charger makes the battery become cool.

To charge the battery

Charge the battery if it is the first time that you use

Note:

it. A new battery is only 30% charged.

1. Connect the battery to the battery charger. (Fig. 52)

2. Make sure that the green charging light on the

battery charger comes on. That means that the

battery is connected correctly to the battery charger.

(Fig. 53)

3. When all LEDs on the battery come on, the battery is

fully charged. (Fig. 54)

4. To disconnect the battery charger from the mains

socket, pull the plug. Do not pull the cable.

5. Disconnect the battery from the battery charger.

Refer to the battery and battery charger manuals

Note:

for more information.

To start the product

1. Do a check of the power trigger and power trigger

lockout. See

lockout on page 21

2. Push the front hand guard forward to engage the

chain brake. (Fig. 38)

To do a check of the power trigger

.

(Fig. 56)

5. Press and hold the start/stop button until the green

LED light comes on. (Fig. 57)

To use the SavE function

This product has a power saving function, SavE. The

SavE function decreases the chain speed and gives the

longest operation time from the battery.

Note: The SavE function does not decrease the cutting

power of the product.

1. Press the SavE button on the keypad.

2. Make sure that the green LED comes on.

3. Press the SavE button again to disconnect the

function. The green LED goes out. (Fig. 58)

To stop the product

1. Press and hold the start/stop button on the keypad

until the green LED light comes off. (Fig. 57)

2. Pull out the battery and press the battery release

buttons to remove the battery from the battery

holder. (Fig. 59)

WARNING:

do not use or when you do not have full

vision of the product. This is to prevent

accidental start.

Remove the battery when you

Kickback information

WARNING:

injury or death to the operator or others. To

decrease the risk you must know the causes

of kickback and how to prevent them.

A kickback occurs when the kickback zone of the guide

bar touches an object. A kickback can occur suddenly

and with large force, which throws the product in the

direction of the operator.(Fig. 60)

Kickback always occurs in the cutting plane of the guide

bar. Usually, the product is thrown against the operator

but can also move in a different direction. It is how you

use the product when the kickback occurs that causes

the direction of the movement.(Fig. 61)

Kickback only occurs if the kickback zone of the guide

bar touches an object. Do not let the kickback zone

touch an object.(Fig. 60)

A kickback can cause serious

16

1259 - 001 - 11.07.2019

A smaller bar tip radius decreases the force of the

kickback.

Use a low kickback saw chain to decrease the effects of

kickback. Do not let the kickback zone touch an object.

WARNING: No saw chain fully prevents

kickback. Always obey the instructions.

Common questions about kickback

• Will the hand always engage the chain brake during

a kickback?

No. It is necessary to use some force to push the

front hand guard forward. If you do not use the force

necessary, the chain brake will not be engaged. You

must also hold the handles of the product stable with

two hands during work. If a kickback occurs, it is

possible that the chain brake does not stop the saw

chain before it touches you. There are also some

positions in which your hand can not touch the front

hand guard to engage the chain brake. An example

of this is in the felling position.

• Will the inertia release mechanism always engage

the chain brake during kickback?

No. First, the chain brake must operate correctly.

Refer to

Maintenance on page 20

about how to do a check of the chain brake. We

recommend you to do this each time before you use

the product. Second, the force of the kickback must

be large to engage the chain brake. If the chain

brake is too sensitive, it can engage during rough

operation.

• Will the chain brake always protect me from injury

during a kickback?

No. The chain brake must operate correctly to give

protection. The chain brake must also be engaged

during a kickback to stop the saw chain. If you are

near the guide bar, it is possible that the chain brake

does not have time to stop the saw chain before it

hits you.

WARNING:

working technique can prevent kickbacks.

Only you and the correct

for instructions

To use the cutting technique

WARNING:

decrease the speed to idle speed after each

cut.

CAUTION: Do not let the motor operate for

too long without load. This can cause

damage to the motor.

1. Put the trunk on a saw horse or runners. (Fig. 62)

Use full power when you cut and

WARNING: Do not cut trunks in a pile.

That increases the risk of kickback and

can cause serious injury or death.

2. Remove the cut pieces from the work area.

WARNING: Cut pieces in the work area

increase the risk of kickback and that

you cannot keep your balance.

To cut a trunk on the ground

1. Cut through the trunk on the pull stroke. Keep full

power but be prepared for sudden accidents. (Fig.

63)

WARNING: Make sure that the saw

chain does not touch the ground when

you complete the kerf.

2. Cut approximately ⅔ through the trunk and then

stop. Turn the trunk and cut from the opposite side.

(Fig. 64)

To cut a trunk that has support on one end

WARNING: Make sure that the trunk does

not break during cutting. Obey the

instructions below.

(Fig. 65)

1. Cut on the push stroke approximately ⅓ through the

trunk.

2. Cut through the trunk on the pull stroke until the two

kerfs touch. (Fig. 66)

To cut a trunk that has support on two ends

WARNING:

does not get caught in the trunk during

cutting. Obey the instructions below.

(Fig. 67)

1. Cut on the pull stroke approximately ⅓ through the

trunk.

2. Cut through the remaining part of the trunk on the

push stroke to complete the cut. (Fig. 68)

WARNING:

gets caught in the trunk. Use a lever to open

up the kerf and remove the product. Do not

try to pull the product out by hand. This can

result in injury when the product suddenly

breaks free.

Make sure that the saw chain

Stop the motor if the saw chain

To use the limbing technique

For thick branches, use the cutting technique.

Note:

Refer to

To use the cutting technique on page 17

.

1259 - 001 - 11.07.2019 17

WARNING: There is a high accident risk

when you use the limbing technique. Refer

to

Kickback information on page 16

instructions how to prevent kickback.

WARNING: Cut limbs one by one. Be careful

when you remove small limbs and do not cut

bushes or many small limbs at the same

time. Small limbs can get caught in the saw

chain and prevent safe operation of the

product.

Note: Cut the limbs piece by piece if it is necessary.(Fig.

69)

1. Remove the limbs on the right side of the trunk.

a) Keep the guide bar on the right side of the trunk

and keep the body of the product against the

trunk.

b) Select the applicable cutting technique for the

tension in the branch. (Fig. 70)

WARNING: If you are not sure about

how to cut the branch, speak to a

professional chainsaw operator

before you continue.

2. Remove the limbs on the top of the trunk.

a) Keep the product on the trunk and let the guide

bar move along the trunk.

b) Cut on the push stroke. (Fig. 71)

3. Remove the limbs on the left side of the trunk.

a) Select the applicable cutting technique for the

tension in the branch. (Fig. 72)

WARNING:

how to cut the branch, speak to a

professional chainsaw operator

before you continue.

Refer to

To cut trees and branches that are in tension on

for instructions on how to cut branches that

page 19

are in tension.

If you are not sure about

for

To use the tree felling technique

WARNING:

fell a tree. If possible, engage in a training

course in chainsaw operation. Speak to an

operator with experience for more

knowledge.

To keep a safe distance

1. Make sure that persons around you keep a safe

distance at a minimum of 2 1/2 tree lengths. (Fig. 73)

2. Make sure that no person is in the risk zone before

or during felling. (Fig. 74)

You must have experience to

To calculate the felling direction

1. Examine in which direction it is necessary for the

tree to fall. The goal is to fell it in a position where

you can limb and cut the trunk easily. It is also

important that you are stable on your feet and can

move about safely.

WARNING: If it is dangerous or not

possible to fell the tree in its natural

direction, fell the tree in a different

direction.

2. Examine the natural fall direction of the tree. For

example the tilt and bend of the tree, wind direction,

the location of the branches and weight of snow.

3. Examine if there are obstacles, for example other

trees, power lines, roads and/or buildings around.

4. Look for signs of damage and rot in the stem.

WARNING: Rot in the stem can mean a

risk that the tree falls before you

complete the cutting.

5. Make sure the tree has no damaged or dead

branches that can break off and hit you during

felling.

6. Do not let the tree fall onto a different standing tree.

It is dangerous to remove a caught tree and there is

a high accident risk. Refer to

on page 19

. (Fig. 75)

WARNING: During critical felling

operations, lift your hearing protection

immediately when the sawing is

complete. It is important that you hear

sounds and warning signals.

To free a trapped tree

To clear the trunk and prepare your path of retreat

Cut off all branches from your shoulder height and

down.

1. Cut on the pull stroke from the top down. Make sure

that the tree is between you and the product. (Fig.

76)

2. Remove undergrowth from the work area around the

tree. Remove all cut off material from the work area.

3. Do a check of the area for obstacles such as stones,

branches and holes. You must have a clear path of

retreat when the tree starts to fall. Your path of

retreat must be approximately 135 degrees away

from the felling direction.

1. The danger zone

2. The path of retreat

3. The felling direction

(Fig. 77)

18

1259 - 001 - 11.07.2019

To fell a tree

Husqvarna recommends you to make the directional

cuts and then use the safe corner method when you fell

a tree. The safe corner method helps you to make a

correct felling hinge and control the felling direction.

WARNING: Do not fell trees with a diameter

that is more than two times larger than the

guide bar length. For this, you must have

special training.

To make the directional cuts

1. Make the directional cuts. Run the directional cuts

1/4 of the diameter of the tree. Make a 45° angle

between the top cut and bottom cut.

a) Make the top cut first. Align the felling direction

mark (A) of the product with the felling direction

of the tree (B). Stay behind the product and keep

the tree on your right side. Cut with a pull stroke.

b) Make the bottom cut. Make sure that the end of

the bottom cut is at the same point as the end of

the top cut. (Fig. 78)

2. Make sure that the directional cut line is perfectly

horizontal and at right angles (90°) to the felling

direction. The directional cut line goes through the

point where the two directional cuts touch. (Fig. 79)

To make the felling cut

Note: The felling cut is made on the opposite side of the

tree from the directional cuts.

1. Make the felling cut approximately 3-5 cm/1.5-2 in

above the bottom directional cuts. The cut must be

perfectly horizontal. (Fig. 80)

2. If you have a spiked bumper, put it behind the felling

hinge.

3. Cut on the pull stroke, use full power and forward the

saw chain/guide bar slowly into the tree. Make sure

that the tree does not fall in an unwanted direction.

4. Operate a wedge or breaking bar into the cut when

the cut has accurate depth. (Fig. 81)

5. Complete the felling cut parallel with the directional

cut line. Make sure that the distance between them

is at a minimum of 1/10 of the trunk diameter. The

section of the trunk that is not cut is the felling hinge.

The felling hinge controls the felling direction. (Fig.

82)

WARNING:

felling direction if the felling hinge is

gone or if it is too thin. This also applies

to if you have not made the directional

cuts and felling cut correctly.

(Fig. 83)

You have no control of the

6. At this time, the tree will fall by its own force or with

the aid of a wedge or breaking bar. (Fig. 84)

Note: Use a guide bar that is longer than the diameter of

the tree. This helps you to make the felling cut and

directional cuts with one cutting stroke each. See

Accessories on page 26

we recommended for your product.

(Fig. 85)

to find out which bar lengths

To free a trapped tree

WARNING: It is very dangerous to remove a

trapped tree and there is a high accident

risk. Keep out of the risk zone and do not try

to fell a trapped tree.

(Fig. 86)

The safest procedure is to use one of the following

winches:

• Tractor-mounted (Fig. 87)

• Portable (Fig. 88)

To cut trees and branches that are in tension

1. Figure out which side of the tree or branch that is in

tension.

2. Figure out where the point of maximum tension is.

(Fig. 89)

3. Examine which is the safest procedure to release the

tension.

In some situations the only safe procedure is

Note:

to use a winch and not your product.

4. Keep a position where the tree or branch can not hit

you when the tension is released. (Fig. 90)

5. Make one or more cuts of sufficient depth necessary

to decrease the tension. Cut at or near the point of

maximum tension. Make the tree or branch break at

the point of maximum tension. (Fig. 91)

WARNING:

tree or branch that is in tension.

WARNING: Be very careful when you

cut a tree that is in tension. There is a

risk that the tree moves quickly before or

after you cut it. Serious injury can occur

if you are in an incorrect position or if

you cut incorrectly.

6. If you must cut across tree/branch, make 2 to 3 cuts,

1 in. apart and with a depth of 2 in. (Fig. 92)

7. Continue to cut more into the tree until the tree/

branch bends and the tension is released. (Fig. 93)

8. Cut the tree/branch from the opposite side of the

bend, after the tension is released.

Do not cut straight through a

1259 - 001 - 11.07.2019

19

Introduction

WARNING: Read and understand the safety

chapter before you do maintenance on the

product.

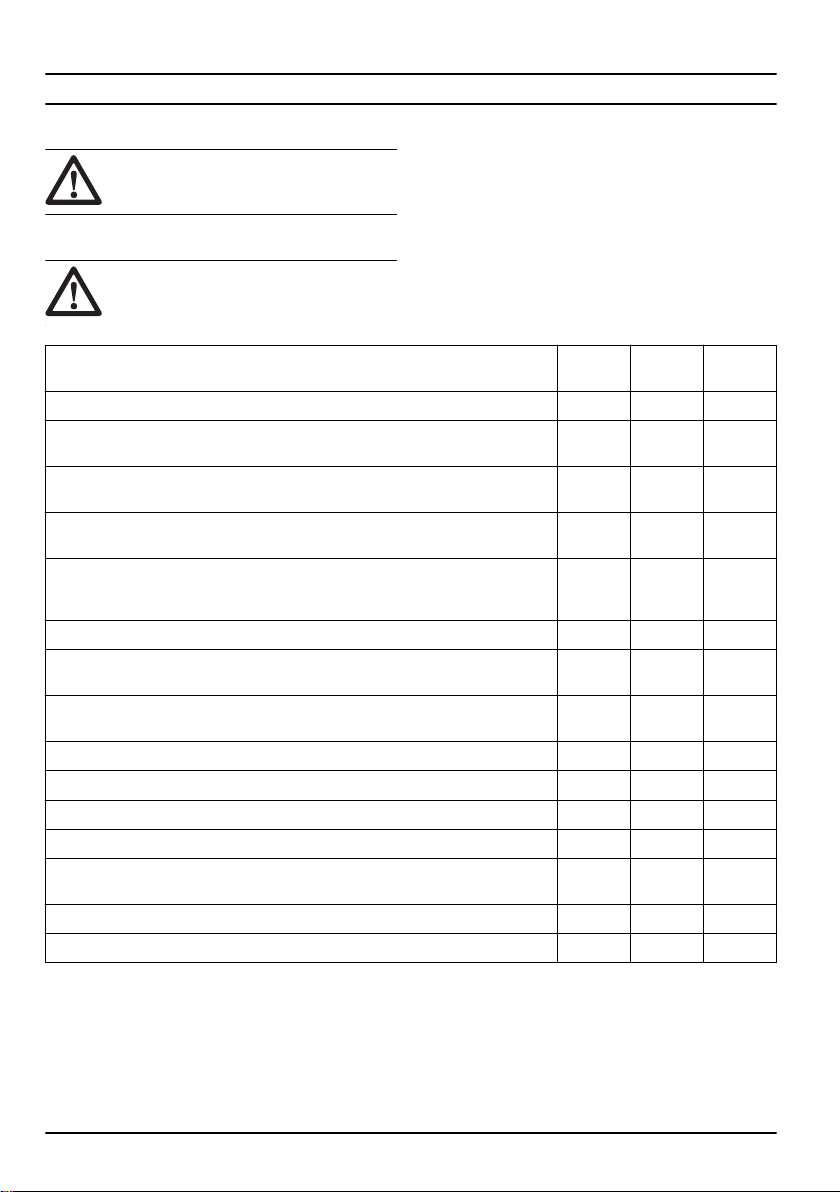

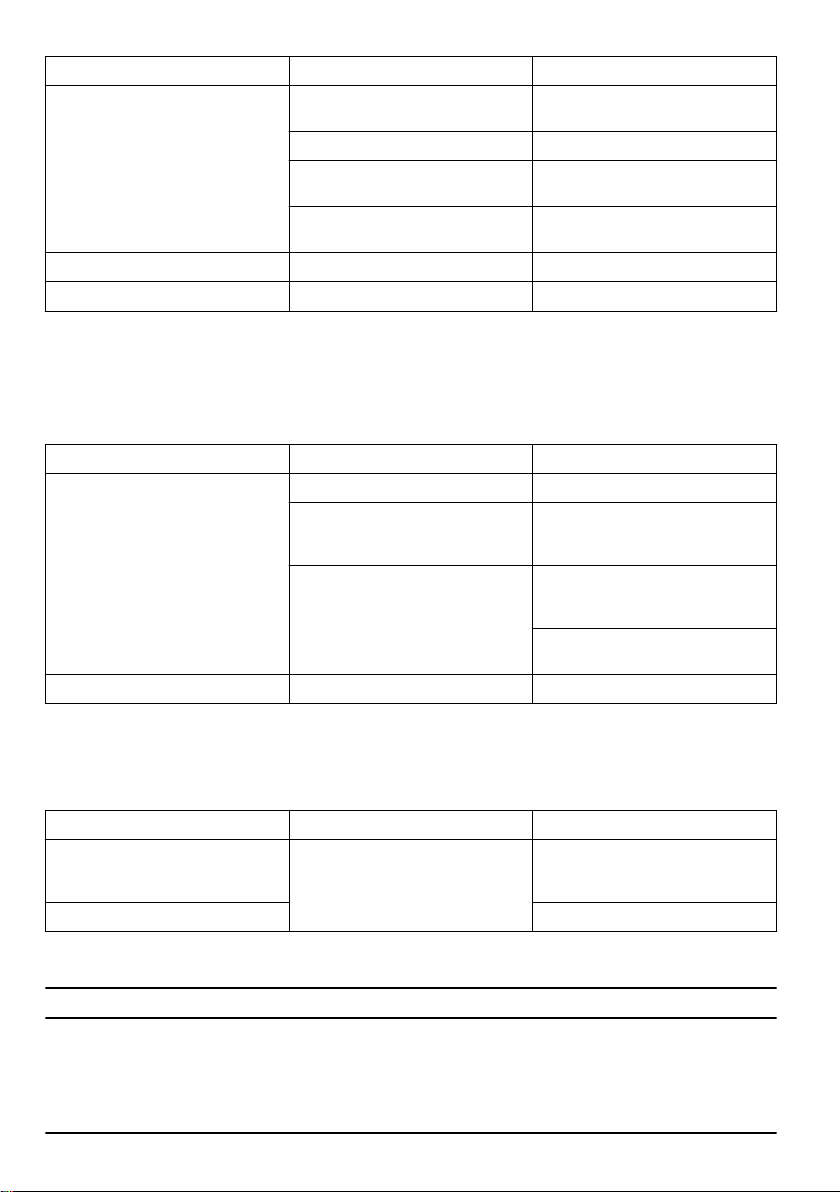

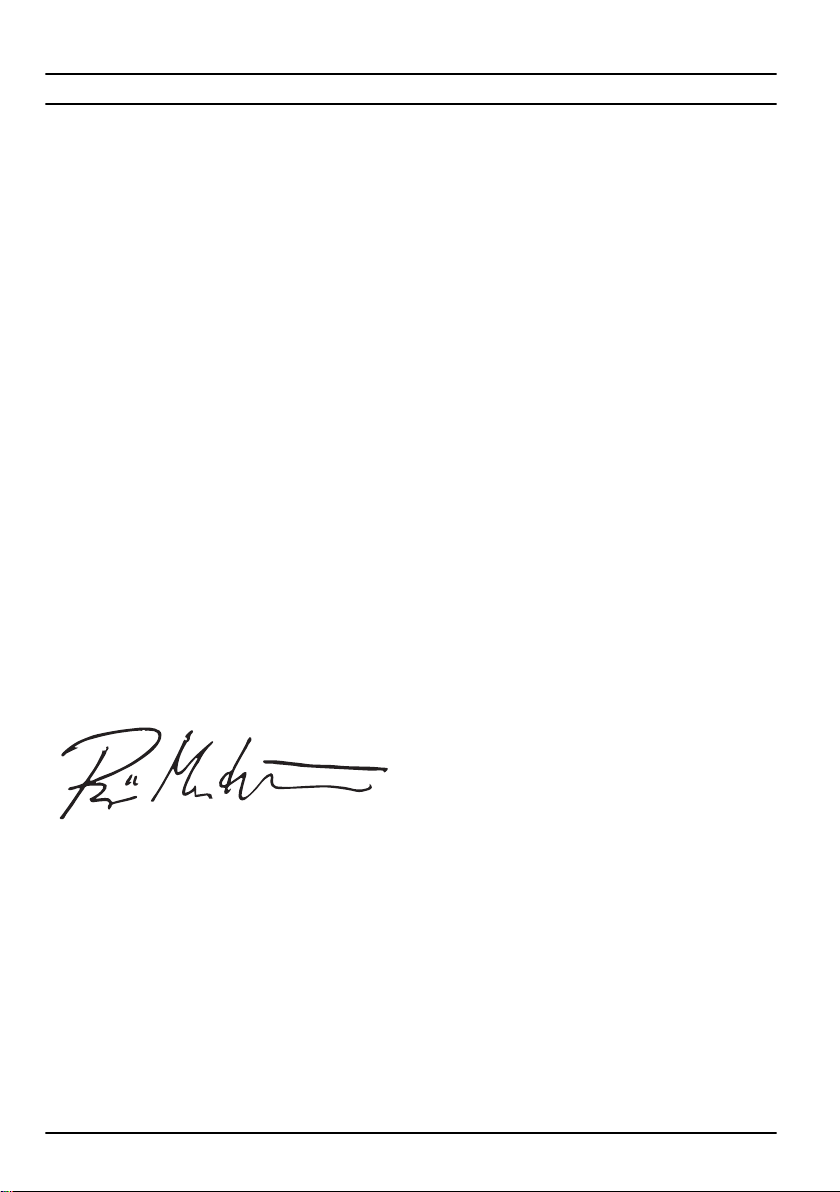

Maintenance schedule

WARNING: Remove the battery before you

do maintenance.

Maintenance

The following is a list of the maintenance steps that you

must do on the product. See

for more information.

Maintenance on page 20

Maintenance Before

use

Clean the external parts of the product. X

Make sure that the power trigger and the power trigger lockout function correctly

from a safety point of view.

Clean the chain brake and make sure that it operates safely. Make sure that the

chain catcher is not damaged. Replace it if necessary.

Turn the guide bar for more equal wear. Make sure that the lubrication hole in

the guide bar is not clogged. Clean the bar groove.

Make sure that the cutter and cutter guard have no cracks and that they are not

damaged. Replace the cutter or cutter guard if they have cracks or if they have

been exposed to impact.

Make sure that the guide bar and saw chain have sufficient oil. X

Do a check of the saw chain. Look for cracks and make sure that the saw chain

is not rigid or unusually worn. Replace if necessary.

Sharpen the saw chain. Do a check of its tension and condition. Do a check for

wear on the drive sprocket and replace is necessary.

Clean the air inlet on the product. X

Make sure that the screws and nuts are tight. X

Make sure that the keypad works correctly and that it is not damaged. X

Use a file to remove burrs from the edges of the guide bar. X

Do a check of the connections between the battery and the product. Do a check

of the connection between the battery and the battery charger.

Empty and clean the oil tank. X

Blow through the product and battery cooling slots gently with compressed air. X

Weekly Monthly

X

X

X

X

X

X

X

Maintenance and checks of the safety devices on the product

To do a check of the front hand guard

Regularly do a check of the front hand guard and the

inertia brake release.

20 1259 - 001 - 11.07.2019

1. Make sure that the front hand guard is not damaged

and that there are no defects, such as cracks. (Fig.

94)

2. Make sure that the front hand guard moves freely

and that it is attached safely to the product. (Fig. 95)

3. Put the product, with the motor off, on a stump or

other stable surface.

4. Hold the rear handle and let go of the front handle.

Let the product fall against the stump. (Fig. 96)

5. Make sure that the chain brake engages as the

guide bar hits the stump.

To do a check of the brake trigger

1. Put the product on stable ground and start it. See

Introduction on page 15

WARNING: Make sure that the saw

chain does not touch the ground or other

objects.

2. Wrap your fingers and thumbs around the handles

and hold the product tight. (Fig. 37)

3. Apply full power and tilt your left wrist against the

front hand guard to engage the chain brake. The

saw chain must stop immediately. (Fig. 97)

WARNING: Do not let go of the front handle!

.

To do a check of the power trigger lockout

1. Make sure that the power trigger and power trigger

lockout move freely and that the return spring works

correctly. (Fig. 98)

2. Press down the power trigger lockout and make sure

that it goes back to its initial position when you

release it. (Fig. 99)

3. Make sure that the power trigger is locked at the idle

position when the power trigger lockout is released.

(Fig. 100)

4. Start the product and apply full power.

5. Release the power trigger and make sure that the

saw chain stops and stays stationary. If the saw

chain rotates when the power trigger is in the idle

position, turn to your servicing dealer.

To do a check of the chain catcher

1. Make sure that there is no damage on the chain

catcher.

2. Make sure that the chain catcher is stable and

attached to the body of the product. (Fig. 41)

To do a check of the keypad

1. Start the product. See

2. Press the start/stop button again.

3. Make sure that the product stops when you press

and hold the button. The green LED will go off. (Fig.

57)

Operation on page 15

To do a check of the battery and the battery compartment

1. Clean the battery and the battery compartment with

a soft brush. (Fig. 101)

2. Make sure that the cooling slots and battery

connectors are clean.

3. Make sure that the battery is not damaged and there

are no other defects, such as cracks. (Fig. 102)

To do a check of the battery charger

1. Make sure that the battery charger and the power

supply cord is not damaged. Look for cracks and

other defects.

To clean the cooling system

The product has a cooling system that keeps the

temperature of the product as low as possible.

The cooling system includes an air intake on the left side

of the product and a fan on the motor.

1. Clean the cooling system with a brush weekly or

more frequently if necessary. (Fig. 103)

2. Make sure that the cooling system is not dirty or

blocked.

CAUTION: A dirty or blocked cooling

system can cause the product to

become too hot. This causes damage to

the piston and cylinder.

To sharpen the saw chain

Information about the guide bar and saw chain

WARNING:

use or do maintenance on the saw chain. A

saw chain that does not move can also

cause injuries.

Replace a worn or damaged guide bar or saw chain with

the guide bar and saw chain combination recommended

by Husqvarna. This is necessary to keep the safety

functions of the product. Refer to

26

, for a list of replacement bar and chain

combinations that we recommend.

• Guide bar length, in/cm. Information about the guide

bar length can usually be found on the rear end of

the guide bar.(Fig. 104)

• Number of teeth on bar tip sprocket (T).(Fig. 105)

• Chain pitch, in. The distance between the drive links

of the saw chain must align with the distance of the

teeth on the bar tip sprocket and drive sprocket.(Fig.

106)

• Number of drive links. The number of drive links is

decided by the type of guide bar.(Fig. 107)

Use protective gloves when you

Accessories on page

1259 - 001 - 11.07.2019

21

• Bar groove width, in/mm. The groove width in guide

bar must be the same as the chain drive links width.

(Fig. 108)

• Chain oil hole and hole for chain tensioner. The

guide bar must align with product.(Fig. 109)

• Drive link width, mm/in.(Fig. 110)

General information about how to sharpen the cutters

Do not use a blunt saw chain. If the saw chain is blunt,

you must apply more pressure to push the guide bar

through the wood. If the saw chain is very blunt, there

will be no wood chips but sawdust.

A sharp saw chain eats through the wood and the wood

chips becomes long and thick.

The cutting tooth (A) and the depth gauge (B) together

makes the cutting part of the saw chain, the cutter. The

difference in height between the two gives the cutting

depth (depth gauge setting).(Fig. 111)

When you sharpen the cutter, think about the following:

• Filing angle.(Fig. 112)

• Cutting angle.(Fig. 113)

• File position.(Fig. 114)

• Round file diameter.(Fig. 115)

It is not easy to sharpen a saw chain correctly without

the correct equipment. Use Husqvarna file gauge. This

will help you to keep maximum cutting performance and

the kickback risk at a minimum.

WARNING: The force of the kickback

increases a lot if you do not follow the

sharpening instructions.

Note: Refer to

information about sharpening of the saw chain.

To sharpen the cutters on page 22

for

To sharpen the cutters

1. Use a round file and a file gauge to sharpen the

cutting teeth. (Fig. 116)

Refer to

Note:

information about which file and gauge that

Husqvarna recommends for your saw chain.

2. Apply the file gauge correctly on to the cutter. Refer

to the instruction supplied with the file gauge.

3. Move the file from the inner side of the cutting teeth

and out. Decrease the pressure on the pull stroke.

(Fig. 117)

4. Remove material from one side of all the cutting

teeth.

5. Turn the product around and remove material on the

other side.

6. Make sure that all cutting teeth are the same length.

Accessories on page 26

for

General information about how to adjust the depth gauge setting

The depth gauge setting (C) decreases when you

sharpen the cutting tooth (A). To keep maximum cutting

performance you must remove filing material from the

depth gauge (B) to receive the recommended depth

gauge setting. See

instructions about how to receive the correct depth

gauge setting for your saw chain.

(Fig. 118)

Accessories on page 26

WARNING: The risk of kickback increases if

the depth gauge setting is too large!

for

To adjust the depth gauge setting

Before you adjust the depth gauge setting or sharpen

the cutters, refer to

for instructions. We recommend you to adjust the depth

gauge setting after each third operation that you

sharpen the cutting teeth.

We recommend that you use our depth gauge tool to

receive the correct depth gauge setting and bevel for the

depth gauge.

(Fig. 119)

1. Use a flat file and a depth gauge tool to adjust the

depth gauge setting. Only use Husqvarna depth

gauge tool to get the correct depth gauge setting and

bevel for the depth gauge.

2. Put the depth gauge tool on the saw chain.

See the package of the depth gauge tool for

Note:

more information about how to use the tool.

3. Use the flat file to remove the part of the depth

gauge that extends through the depth gauge tool.

(Fig. 120)

To sharpen the cutters on page 22

To tighten the saw chain

WARNING:

tension can come loose from the guide bar

and cause serious injury or death.

The more you use a saw chain the longer it becomes. It

is important to adjust the saw chain regularly.

Do a check of the saw chain tension each time you refill

with chain oil.

A new saw chain has a running-in period during

Note:

which you must do a check of the tension more

frequently.

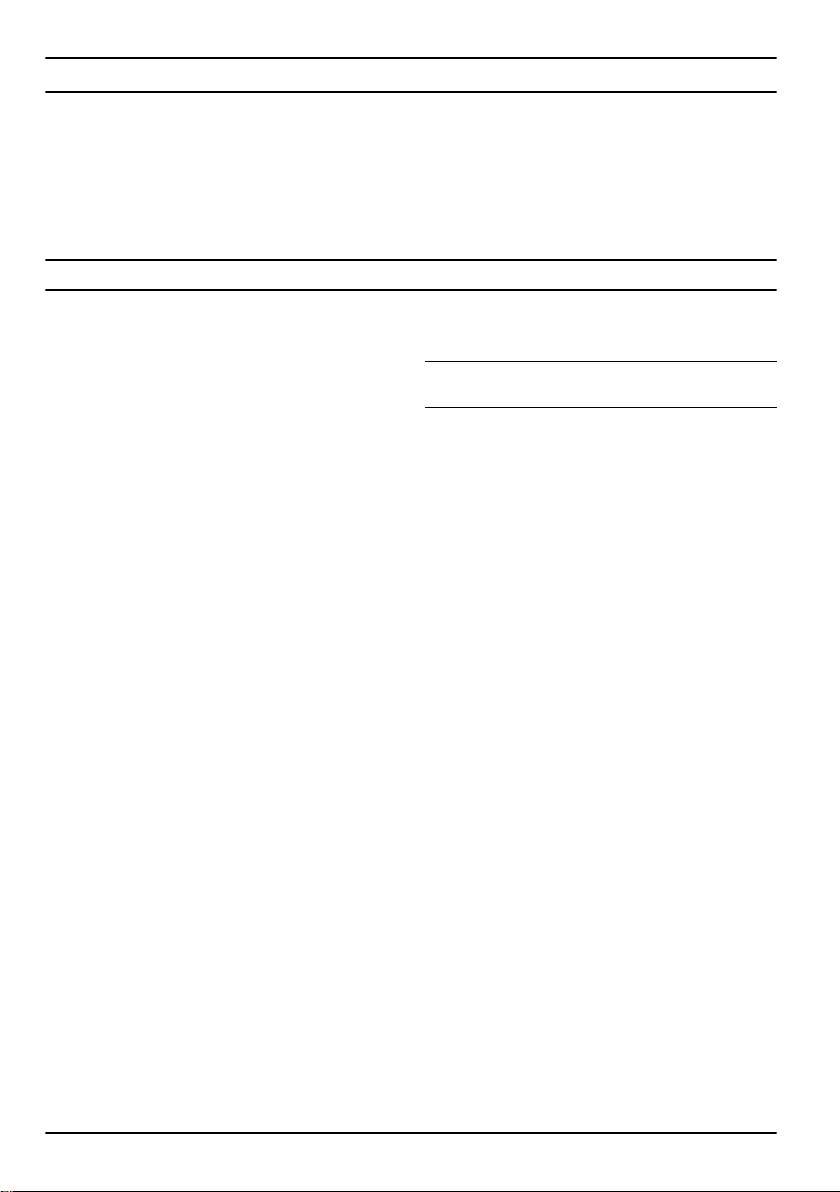

1. Fold the knob out until it opens. (Fig. 121)

2. Turn the knob counterclockwise to loosen the drive

sprocket cover. (Fig. 122)

A saw chain without the correct

,

22

1259 - 001 - 11.07.2019

3. Turn the chain tensioner wheel to adjust the tension

on the saw chain. The saw chain must be tight

against the guide bar. (Fig. 123)

Note: Turn the wheel down (+) for more tension and

up (-) for less tension. The saw chain is tightened

correctly when you can turn is easily by hand but is

tight against the guide bar.

4. Turn the knob clockwise to tighten the bar knob.

(Fig. 124)

5. Fold down the knob to lock the tension. (Fig. 125)

To do a check of the saw chain lubrication

Do a check of the saw chain lubrication each third

battery charge.

1. Start the product and let it run at 3/4 power. Hold the

bar approximately 20 cm (8 inches) above a light

coloured surface.

2. If the saw chain lubrication is correct, you will see a

clear line of oil on the surface after 1 minute. (Fig.

126)

3. If the saw chain lubrication is not correct, do the

following checks.

a) Do a check of the oil channel in the guide bar to

make sure that it is not blocked. Clean if

necessary. (Fig. 127)

b) Do a check of the groove in the edge of the guide

bar to make sure that it is clean. Clean if

necessary. (Fig. 128)

c) Make sure that the bar tip sprocket turns freely

and that the lubricating hole in the guide bar tip

sprocket is not blocked. Clean and lubricate if

necessary. (Fig. 129)

4. If the saw chain lubrication does not work after

following the steps above, speak to your servicing

dealer.

To do the maintenance on the chain drive sprocket

The drive system has a drive sprocket.

(Fig. 130)

Do the following maintenance on the chain drive

sprocket:

1. Regularly do a check of the degree of wear on the

drive sprocket. Replace the chain drive sprocket if

there is too much wear.

2. Replace the drive sprocket when you replace the

saw chain.

To examine the cutting equipment

1. Make sure that there are no cracks in rivets and links

and that no rivets are loose. Replace if it is

necessary. (Fig. 131)

2. Make sure that the saw chain is easy to bend.

Replace the saw chain if it is rigid.

3. Compare the saw chain with a new saw chain to

examine if the rivets and links are worn.

4. Replace the saw chain when the longest part of the

cutting tooth is less than 4 mm/0.16 in. Also replace

the saw chain if there are cracks on the cutters. (Fig.

132)

To do a check of the guide bar

1. Make sure that the oil channel is not blocked. Clean

if it is necessary. (Fig. 127)

2. Examine if there are burrs on the edges of the guide

bar. Remove the burrs using a file. (Fig. 133)

3. Clean the groove in the guide bar. (Fig. 128)

4. Examine the groove in the guide bar for wear.

Replace the guide bar if it is necessary. (Fig. 134)

5. Examine if the guide bar tip is rough or very worn.

(Fig. 135)

6. Make sure that the bar tip sprocket turns freely and

that the lubricating hole in the bar tip sprocket is not

blocked. Clean and lubricate if it is necessary. (Fig.

129)

7. Turn the guide bar daily to extend its life cycle. (Fig.

136)

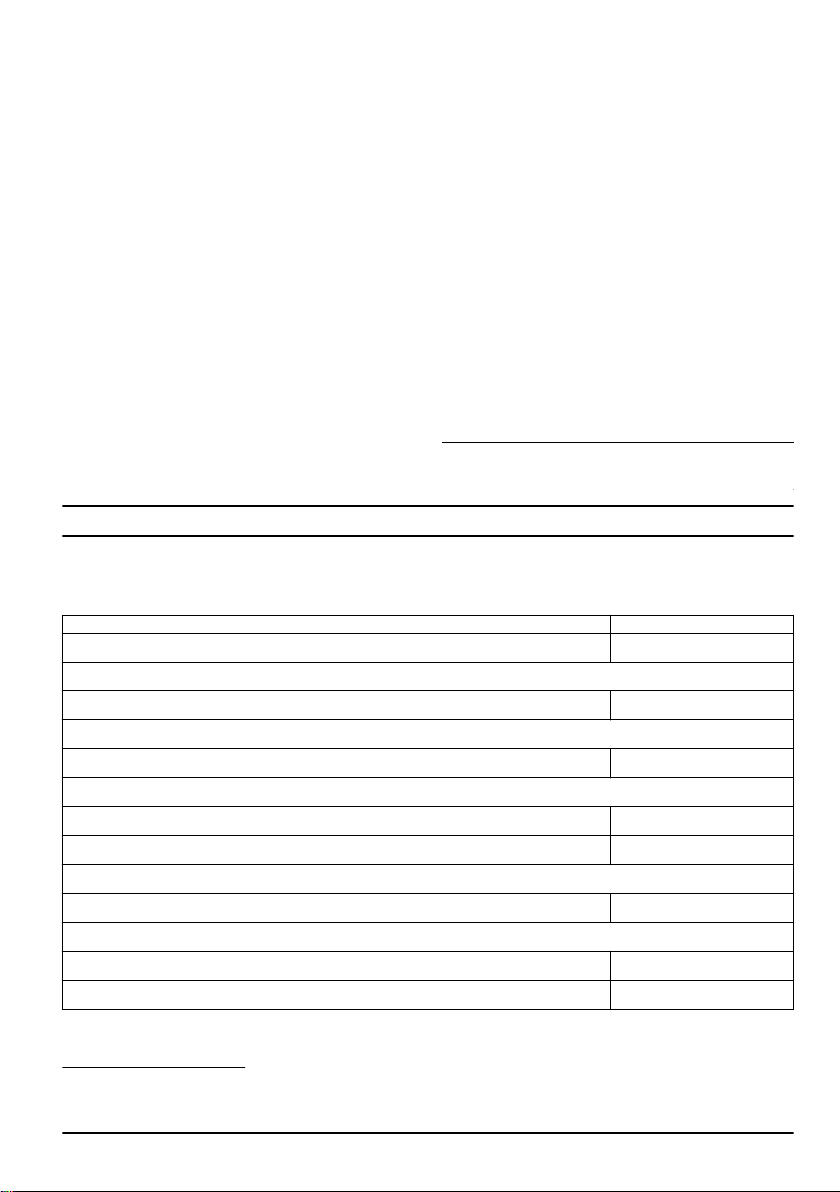

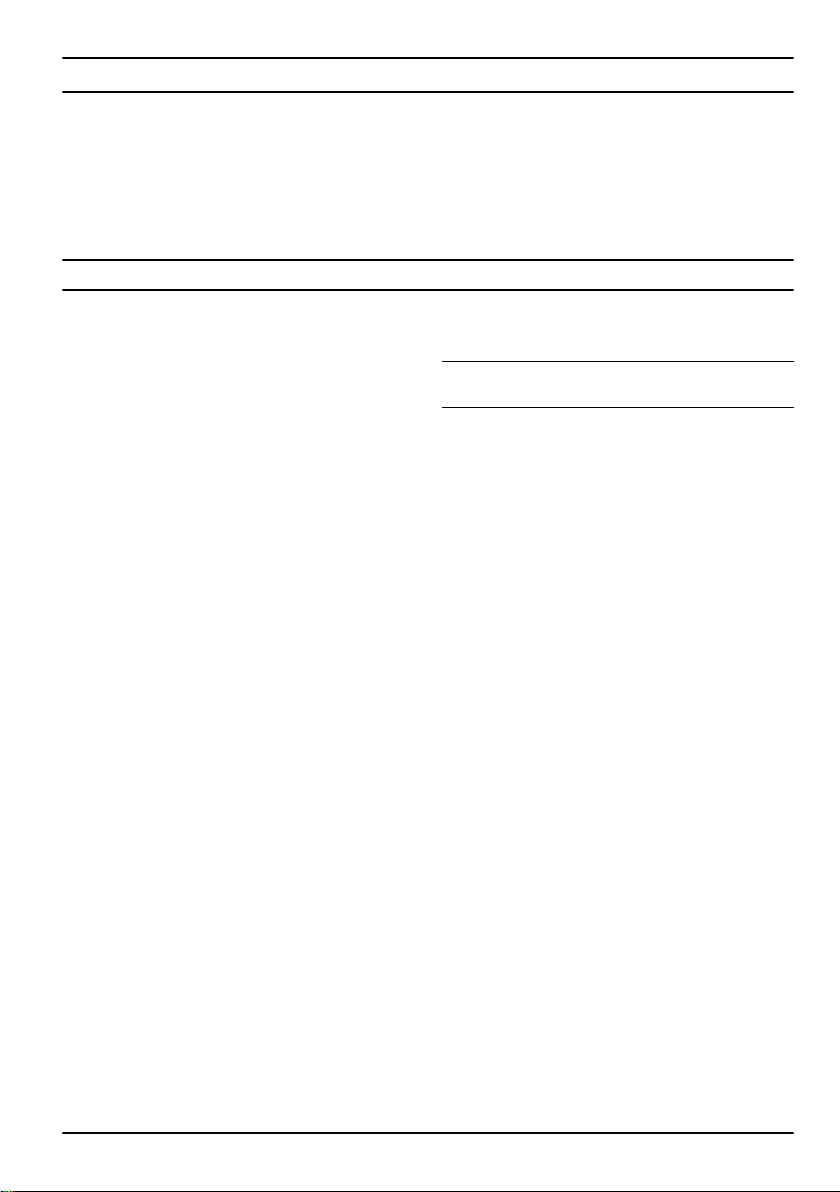

Troubleshooting

Troubleshooting schedule

Table 1: Keypad

Possible fault codes on the keypad of the product.

1259 - 001 - 11.07.2019 23

LED display Possible faults Possible action

Warning indicator flashing. Chain brake engaged. Pull back the front hand guard to re-

Temperature deviation. Allow the product to cool down.

Overload. Cutting attachment jammed.

The power trigger and the activate

button are pressed at the same time.

Green activate LED flashing. Low battery voltage. Charge the battery.

Warning indicator lit. Service. Turn to your servicing dealer.

Table 2: Battery

Troubleshooting the battery and/or the battery charger during charging.

LED display

Warning indicator flashing. The battery is discharged. Charge the battery.

Warning indicator lit. Cell difference is too much (1V). Turn to your servicing dealer.

Possible faults Possible action

Temperature deviation. Use the battery in surroundings

Over voltage. Check that the mains voltage corre-

lease the chain brake.

The cutting attachment is jammed.

Release the cutting attachment.

Release the power trigger and the

product is active.

where tempereatures are between

-10 °C/14°F and 40°C/104°F.

sponds with that stated on the rating

plate on the product.

Remove the battery from the battery

charger.

Table 3: Battery charger

LED display

Warning indicator flashing. Temperature deviation. Use the battery in surroundings

Warning indicator lit. Turn to your servicing dealer.

Possible faults Possible action

where temperatures are between

5°C/41°F and 40°C/104°F.

Transportation, storage and disposal

Transportation and storage

• The supplied Li-ion batteries obey the Dangerous

Goods Legislation requirements.

24 1259 - 001 - 11.07.2019

• Obey the special requirement on package and labels

for commercial transportation, including by third

parties and forwarding agents.

• Speak to a person with special training in dangerous

material before you send the product. Obey all

applicable national regulations.

• Use tape on open contacts when you put the battery

in a package. Put the battery in the package tightly

to prevent movement.

• Remove the battery for storage or transportation.

• Put the battery and the battery charger in a space

that is dry and free from moisture and frost.

• Do not keep the battery in an area where static

electricity can occur. Do not keep the battery in a

metal box.

• Put the battery in storage where the temperature is

between 5°C/41°F and 25°C/77°F and away from

open sunlight.

• Put the battery charger in storage where the

temperature is between 5 °C/41 °F and 45°C/113°F

and away from open sunlight.

• Use the battery charger only when the surrounding

temperature is between 5°C/41°F and 40°C/104°F.

• Charge the battery 30% to 50% before you put it in

storage for long periods.

• Put the battery charger in storage in a space that is

closed and dry.

• Keep the battery away from the battery charger

during storage. Do not let children and other not

approved persons to touch the equipment. Keep the

equipment in a space that you can lock.

• Clean the product and do a full servicing before you

put the product in storage for a long time.

• Use the transportation guard on the product to

prevent injuries or damage on the product during

transportation and storage.

• Attach the product safely during transportation.

Disposal of the battery, battery charger and product

The symbol below means that the product is not

domestic waste. Recycle it at a recycling station for

electrical and electronic equipment. This helps to

prevent damage to the environment and to persons.

Speak to local authorities, domestic waste service or

your dealer for more information.

(Fig. 21)

Note: The symbol shows on the product or package of

the product.

Technical data

Technical data

120i

Platform CS100EU

Motor

Type BLDC (brushless) 36V

Features

Low energy mode savE

Lubrication system

Type of oil pump Automatic

Oil tank capacity, liter 0,20

Weight

Chainsaw without battery, guide bar, saw chain and empty chain oil tank, kg 2,95

Noise emissions

Sound power level, measured dB(A) 98

Sound power level, guaranteed LWA dB(A) 101

1

1

Noise emissions in the environment measured as sound power (LWA) in conformity with EC directive

2000/14/EC.

1259 - 001 - 11.07.2019 25

Sound levels

Equivalent sound pressure level at the operator's ear, dB(A) 88

Vibration levels

Saw chain/guide bar

Recommended bar lengths, inch/cm 12/30

Usable cutting length, inch/cm 10/26

Type of drive sprocket/number of teeth Spur/6

Maximum chain speed / (savE), m/s 11,5 (10)

2

3

120i

3,8

Accessories

Guide bar and saw chain combinations

The following cutting attachments are approved for

Husqvarna 120i.

Guide bar Saw chain

Length, in Chain pitch, in Gauge, mm Max. nose radius Type Length, drive

12 3/8 1,1 7T Husqvarna H38 45

links (no.)

Filing equipment and filing angles

Using Husqvarna file gauge will give you the correct

filing angles. We recommend you to always use a

Husqvarna file gauge to restore the sharpness of the

38

11/64 in/4,5

mm

75° 30° 0°

saw chain. The part numbers are given in the table

below.

If you do not know which saw chain you have on your