Page 1

SERVICE MANUAL

SEWKNITWORLD

MODEL

1200, # 1

1100

1090

1070

1050

104 72 30-26 Husqvarna service manual 1

Page 2

Contents

SEWKNITWORLD

Survey settings 4

User instructions 5

Gauges and service 6-7

Visual control of details 8-12

Electronics 13-22

Stich plate 8

Presser foot 8

Feed dog 8

Bobbin case 9

Hook cover 9

Hook 10

Driver 10

Main switch and feed dip button 10

Foot control 11

Cog belt, short 12

Cog belt, long 12

Wiring diagram 13

Service casette 14-17

Switch for presser foot lift 18

Buttonhole meter 18

Lower thread indicator 19

Stepmotors: Thread tension, sewing head, guide, side motion 20

Transformer 1050/1070/1090 21

Transformer 1100/1200 22

Electronic board 1050/1070/1090 21

Electronic board 1100/1200 22

2 Husqvarna service manual 104 72 30-26

Page 3

Setting instructions

SEWKNITWORLD

1 The hook gear 23

2 The gap between the hook cover and the driver 24

3 Presser foot, parallelism to the stitch plate 25

4 Setting the presser foot at right angles to the feeding direction 25

5 Setting of the step motor of the sewing head 26

6 Setting of the needle in relation to the presser foot 27

7 The gap between the hook and the needle 28

8 Setting the stitch plate in relation to the needle 29

9 Timing of the hook in relation to the needle 30

10 Needle height 31

11 Thread tension of the bobbin case 32

12 Upper thread tension 32

13 Setting the thread tension of the step motor 33

14 The setting of the thread take-up spring 33

15 Parallelism of the feed dog 34

16 The sideways setting of the feed dog 34

17 The feed dog height 34

18 The lengthwise movement of the feed dog 35

19 The bobbin-winding device 35

20 The balance of the stitch length 36-40

21 Pre-setting of the step motor of the guide 41

22 Pre-setting of the step motor of the side motion 42

23 The sideways setting of the feeding mechanism 43

Dismounting- and mounting instructions

Rear cover, lower cover 44

Front cover 44

Parts of the front cover 44

Parts of the front cover 1100/1200 program memory 45

Parts of the front cover 1100/1200 foil keyboard 46

Transformer 47

Main motor 48

Bobbin-stop 48

Circuit board 48

Foot control 49

Feeding guide compl 50

Connecting rod 51

Feeding mechanism unit with stitch regulator fork 51

Thread tension device compl 52

Driver 52

Lower shaft 53

Sewing head 54

Arm shaft 55

Side motion mechanism cpl 56

Fault finding diagram 57

104 72 30-26 Husqvarna service manual 3

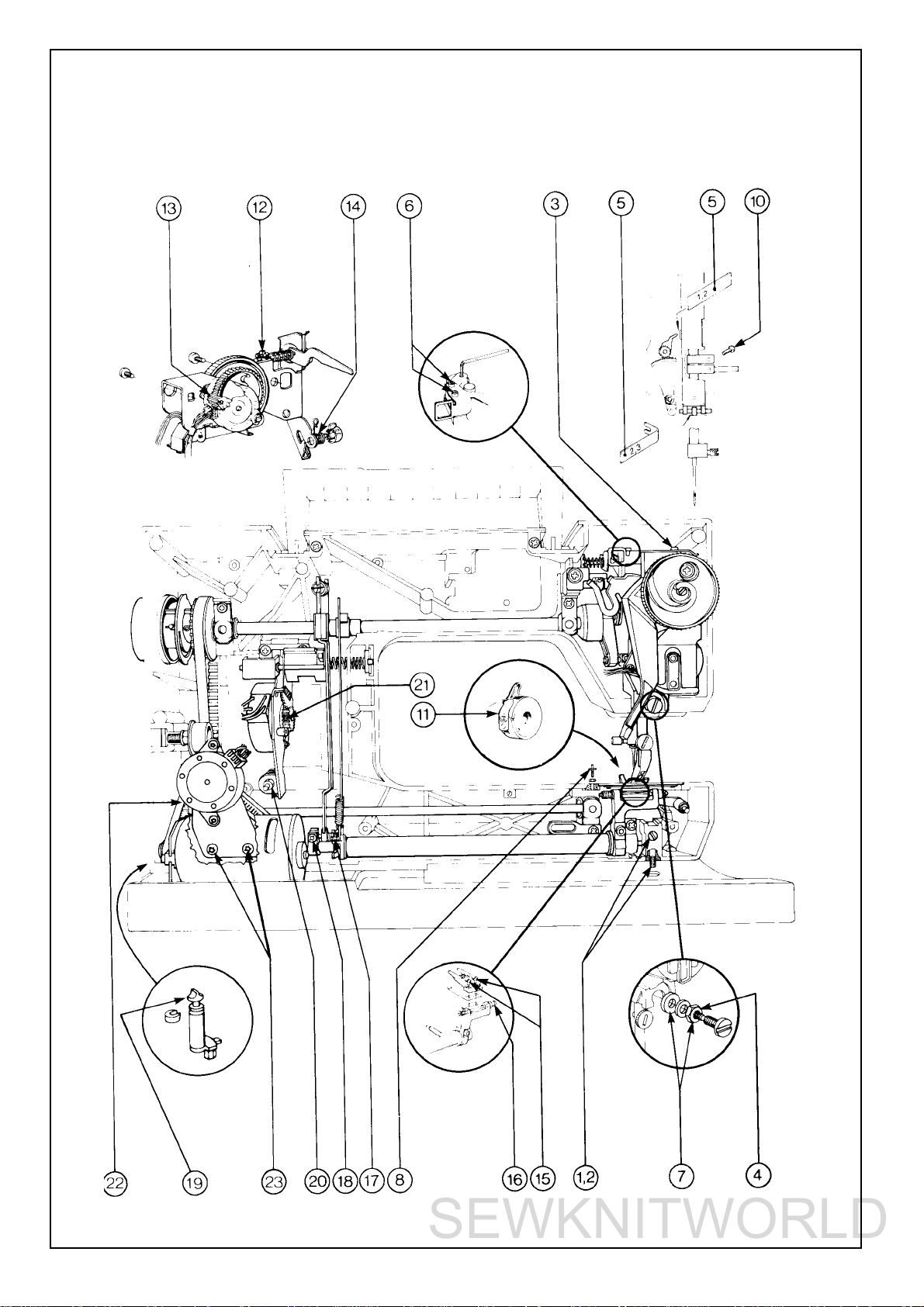

Page 4

SETTINGS

SEWKNITWORLD

4 Husqvarna service manual 104 72 30-26

Page 5

Directions for use

SEWKNITWORLD

These service instructions are intended to be used by service workshop personnel, or by

salesmen who carry out servicing their own districts. They assume a thorough knowledge

of the handling of precision appliances and accessibility to service tools.

The manual is divided into four sections and covers all service operations and checks

which should be carried out when making a complete overhaul of a sewing machine.

The first section controls the working order of the different parts.

The second section deals with the various settings which must be maintained to ensure that

the machine functions satisfactorily.

The third section covers dismantling and mounting instructions.

The fourth section contains a fault-finding diagram.

The diagrams only give indication as to where the detail or mechanism is located in the machine.

For more detailed information regarding the construction, etc., refer to the diagrams in

the spare parts list.

ESD

ATTENTION!

It is of the utmost importance that precautions are being taken in order to avoid damage of

the electronics by electro static discharges ESD (=Electro Static Discharge). To avoid

that these errors arise it is important to handle loose circuit boards in a controlled way.

Always use wrist band 412 23 02-01 when servicing.

wrist band position for wrist band

104 72 30-26 Husqvarna service manual 5

Page 6

Setting gauges

SEWKNITWORLD

A reasonable requirement in a domestic sewing machine is

that it should able to sew all types of fabrics used in the home.

The settings made when assembling and sewing-in the

machines are those most suited to give the best results in the

majority of fabrics and fabric combinations. In doing so,

consideration has been given to the requirements of different

markets. This does, however, mean that when sewing extreme

fabrics, better results may be obtained in certain cases by

altering the settings. It must be pointed out that these altered

settings can cause poorer results on more normal fabrics.

How the different standard ratings are set can be seen from

the description under each setting instruction.

The following list of setting gauges and service tools is chiefly

intended as an indication as to how service men or service

workshops should be equipped.

The needle is often used as a setting gauge. The setting ratings

are adapted to needle size 90 and when setting in the feed direction,

the needle should be set in the middle of the needle hole. (Page.29).

Be sure to use an undamaged needle.

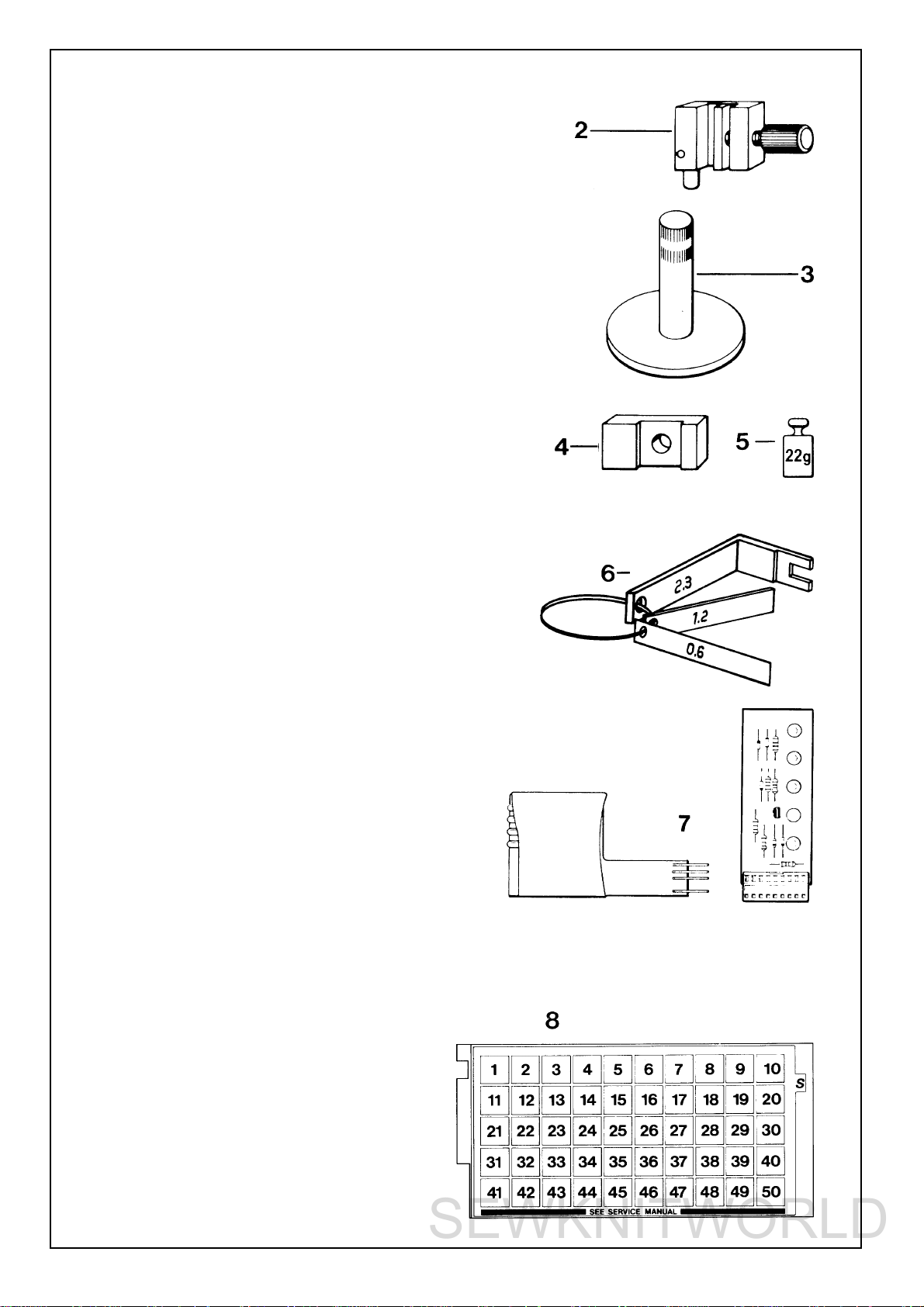

2. Gauge for setting the timing of the hook in relation to

the needle (P.30).Ref. No 411 17 52-01.

3. Gauge for the gap between the hook cover and driver.

(P.24). Ref. No 412 31 91-01.

4. Gauge for feed dog height (P.34).

Ref. No 411 49 93-01.

5. Weight for setting the thread tension of the

bobbin case (P.32).

Ref. No 412 15 83-01 (=22 g.)

6. I. Distance gauge (1,2mm) to set the step motor

of the sewing head (P.26).

II. Gauge for the centre position of the needle (P.26).

III. Distance gauge (0,6mm) for the pre-setting of the

step motor of the guide older version (P.41).

Ref. No compl. I-III. 412 27 60-01.

7. Electronic unit for testing the function of

the transformer and the stepmotors.

See separate instructions enclosed.

Ref. No 412 02 56-01.

8. Service casette for 1100, 1200 (P.14-15).

Ref. No 412 17 29-15.

6 Husqvarna service manual 104 72 30-26

Page 7

Service tools

SEWKNITWORLD

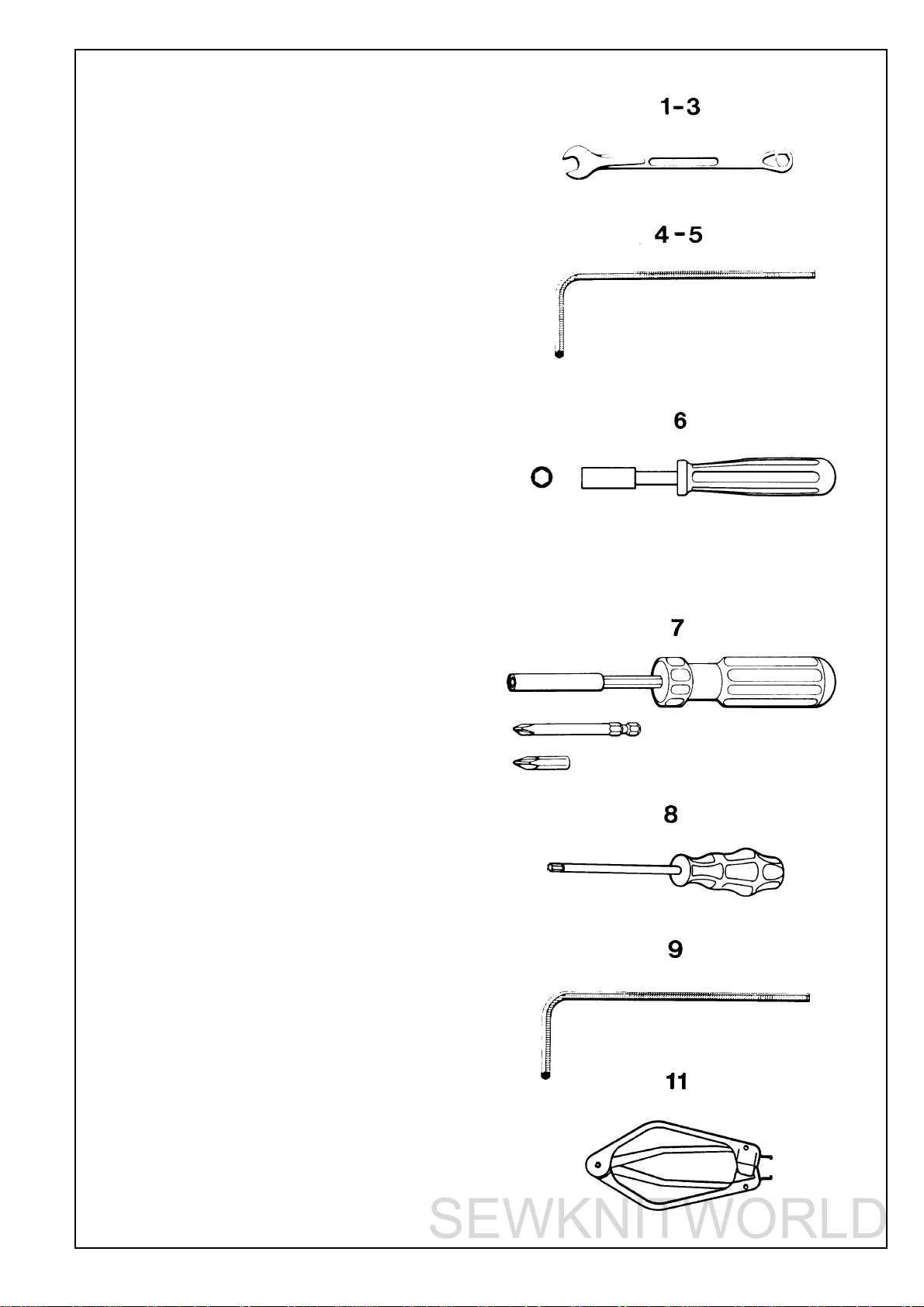

1. Fixed spanner 10mm to set the belt, long (P.12) and

the gap between the hook and the needle (P.28).

Ref. No 411 85 99-01

2. Fixed spanner 5mm to set the stitch plate in relation

to the needle (P.29).

Ref. No 411 85 98-01

3. Fixed spanner 5,5mm for the sidewards setting of the

feed dog (P.34).

Ref. No 411 54 31-01.

4. Adam keys:

-0.9mm for the timing of the step motor of the

thread tension (P.33).

Ref. No 412 27 71-01.

-1,5mm for needle clamp and step motors.

Ref. No 411 66 89-01.

-2,5mm for the timing of the hook in relation to the

needle (P.30) and for the gap between the hook

cover and the driver (P.24).

Ref. No 411 86 01-01.

5. Shortened adam key 2,5mm for the setting of the

presser foot (P.25) and of the needle in relation to

the presser foot (P.27).

Ref. No 412 27 65-01.

6. Key to set the stitch length balance (P.36-40).

Ref. No 412 27 66-01.

7. Magnetic screwdriver with two separate heads.

Ref. No 411 54 33-01.

8. Screwdriver Torx 10

Ref. No 412 36 48-01.

Screwdriver Torx 20

Ref. No 412 36 49-01.

Screwdriver Torx 25

Ref. No 412 36 50-01.

9. Angle key for Torx 6

Ref. No 412 27 67-01.

10.Wristband for ESD

Ref. No 412 23 02-01.

11.Extractor tool (p. 45).

Ref. No 412 27 98-01.

104 72 30-26 Husqvarna service manual 7

Page 8

VISUAL CONTROL OF DETAILS

SEWKNITWORLD

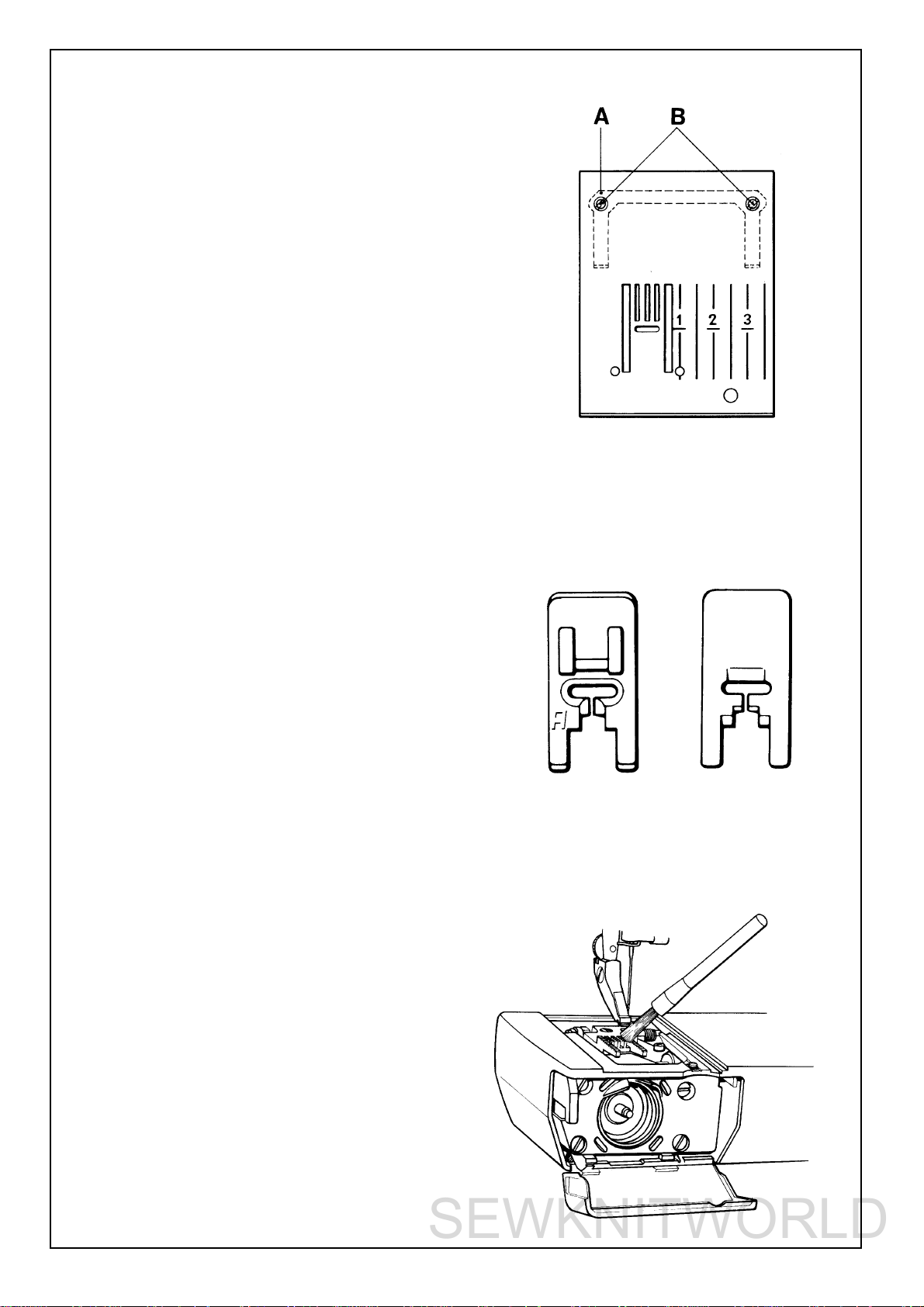

Stitch plate

Requirements

The stitch plate must not be damaged in any way.

Particular attention should be paid to possible damage or

unevenness around the needle hole.

Action

Exchange the damaged stitch plate.

Mounting of a new stitch plate

In order to get the stitch plate into the correct position it

should be first mounted with the spring (A) and screws (B)

somewhat loose. Thereafter remove the stitch plate, fasten

the screws an remount the stitch plate.

Setting to needle, (P.29).

Presser foot

Requirements

There should be no scratches on the underneath of

the presser foot.

Action

Exchange a damaged presser foot.

Comments

How the fabric is held between the presserfoot and

the stitch plate plays an important role in the stitch

formation. Refer to all presser feet.

See Operating Manual.

Feed dog

Requirements

The top side of the feed dog must not be damaged

in any way, e.g. broken teeth etc.

It should be free from fluff and pieces of thread.

Compare with Operating Manual:

”Care of the machine”.

Action

The faulty dog should be exchanged.

Remove the stitch plate.

Undo the screws and replace the feed dog.

As regards to the settings of the feed dog (P.34-35).

8 Husqvarna service manual 104 72 30-26

Page 9

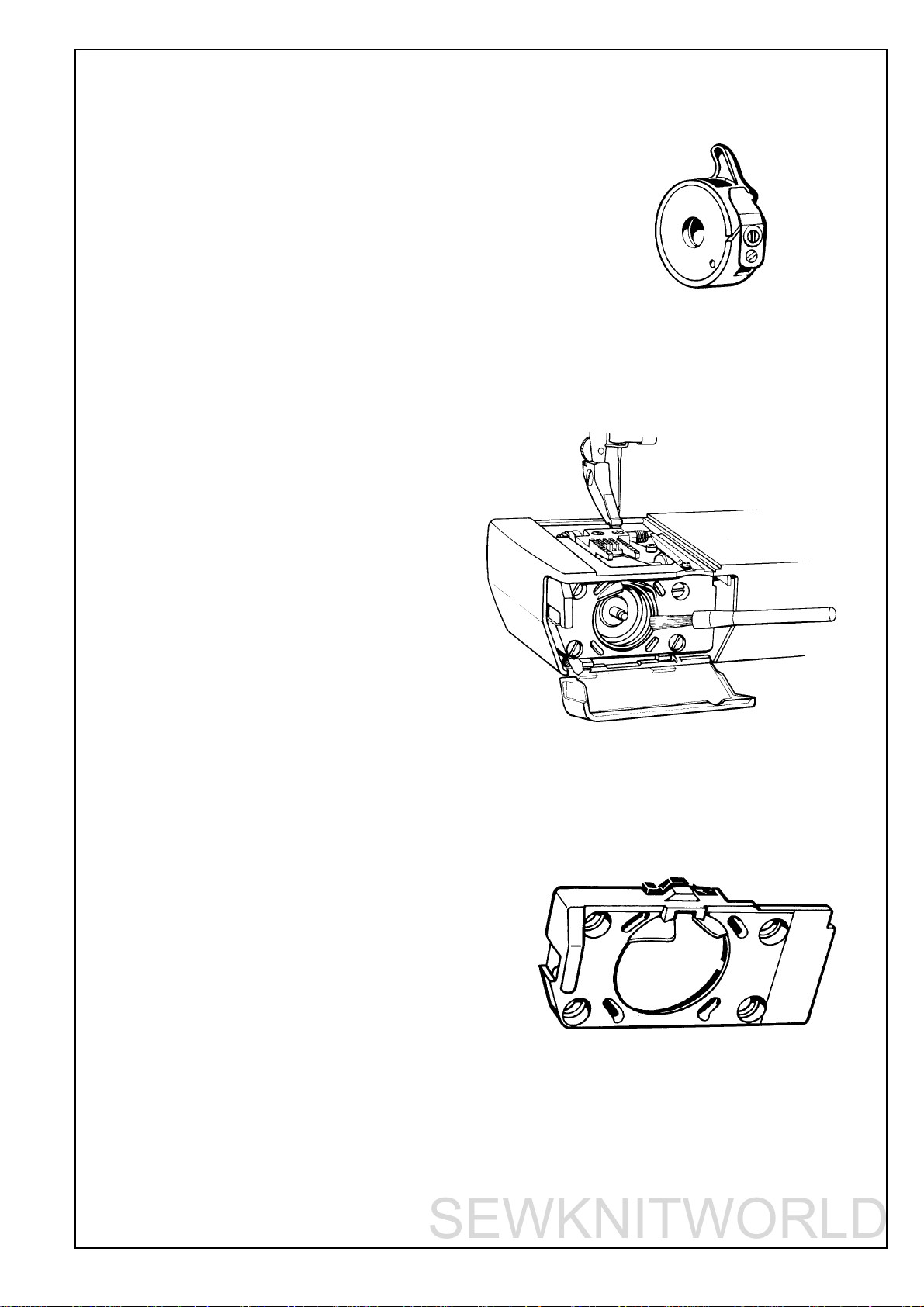

Bobbin case

SEWKNITWORLD

Requirements

The thread tension spring, in its whole width, must be

parallel to and press against the side of the bobbin case.

Action

Remove any fabric dressing which may have fastened

under the thread tension spring.

Damaged thread tension spring is to be exchanged.

Comments

Deposits from fabric or thread can fasten on the spindle

of the hook.

In that case the spindle should be carefully cleaned with

the brush in the accessory box.

At the same time make sure that pieces which may have

become wound around the spindle are removed.

Thread tension of the bobbin case, (P.32).

The hook cover

Requirements

The inside of the hook cover must not be damaged.

Action

Damaged hook cover must be exchanged.

Regarding the gap between the hook cover and the

driver , (P.24).

Comments

The inside of the hook cover forms a support for the

hook and the bridge above the finger of the bobbin

case supports the thread, so that the thread loop is

formed on the correct side of the needle.

104 72 30-26 Husqvarna service manual 9

Page 10

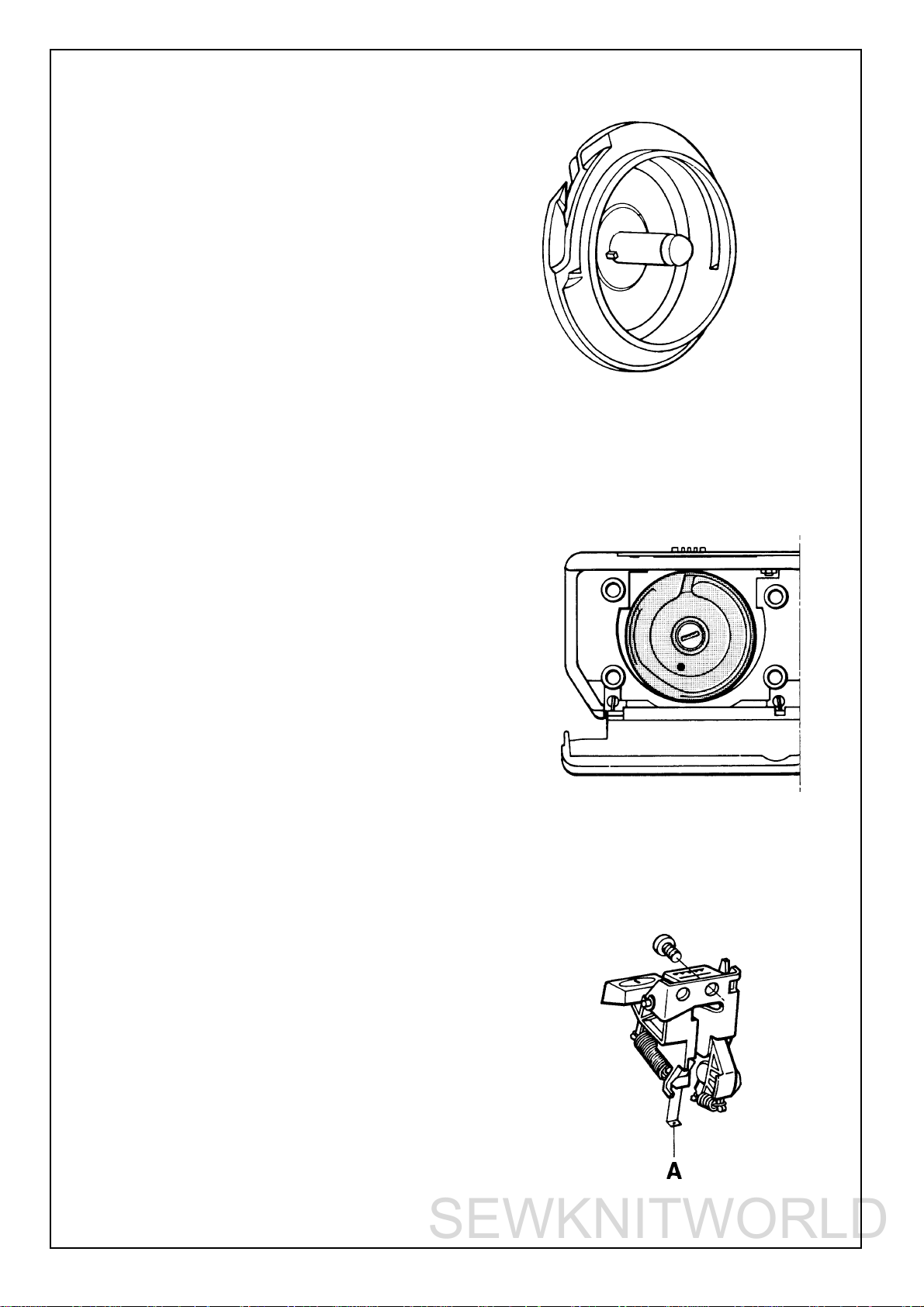

The hook

SEWKNITWORLD

Requirements

The tip of the hook (A) and surface (B) must not

be damaged.

Action

Exchange the damaged hook.

The driver

Requirements

The surface of the driver against the hook must not

be damaged, worn or uneven in any way which might

hinder the passage of the thread.

Action

Damaged hook is to be exchanged (P.52).

The main switch and feed dip button

If the main switch or the feed dip button doesn’t work

satisfactorily, remove the rear cover and front panel, (P.44).

Exchange the complete unit or spring (A).

10 Husqvarna service manual 104 72 30-26

Page 11

The foot control

SEWKNITWORLD

Requirements 1

The speed should be continuously controllable from the

lowest r/min to full speed.

Action

Test the foot control on a machine that is known to

operate properly. If it does not work, exchange the

whole control, alternatively the cord device or the

potentiometer.

Requirement 2

The cable should be easily extractable from the cord

device of the foot control and after pulling the cable

slightly it should be rewound on the cord device.

Action

The foot control or the cord device are to be exchanged.

Dismantling (P.49).

The foot control

Requirements

The speed should be continuously controllable from the

lowest r/min to full speed.

Action

Test the foot control on a machine that is known to

operate properly. If it does not work, exchange the

whole control, alternatively the potentiometer.

Dismounting (page 49).

104 72 30-26 Husqvarna service manual 11

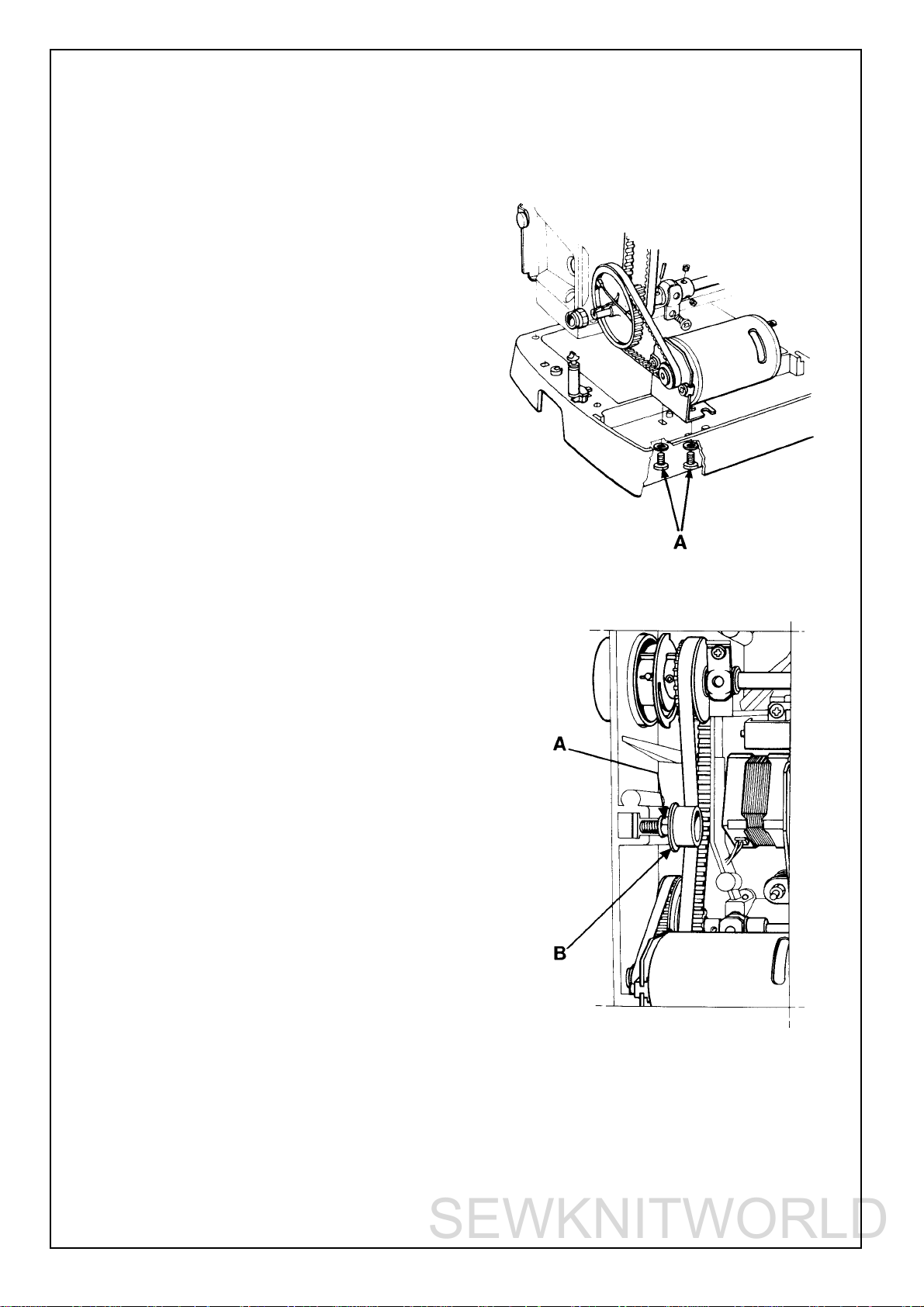

Page 12

The cog belt, short

SEWKNITWORLD

Requirements

The belt tension should not be so loose that it permits

slipping when the machine is locked and the foot control

is depressed.

A tighter tension makes more noise.

The belt must not be damaged.

Adjustment

Undo both screws (A) underneath the base plate and

shift the motor until the required tension is obtained.

Comments

The motor is driven by direct current (DC) 24 V,

whereby the demands on insulation clearance are less

than by 220 V.

The cog belt, long

Requirements

The belt tension should not be so loose that it permits

slipping when the machine is locked and the foot control

is depressed.

A tighter tension makes more noise.

The belt must not be damaged.

Adjustment

Loosen the nut (A) by means of a 10mm fixed spanner

and shift the belt tension roller belt tension roller (B)

until the required tension is obtained.

Tighten the nut.

12 Husqvarna service manual 104 72 30-26

Page 13

ELECTRONICS

SEWKNITWORLD

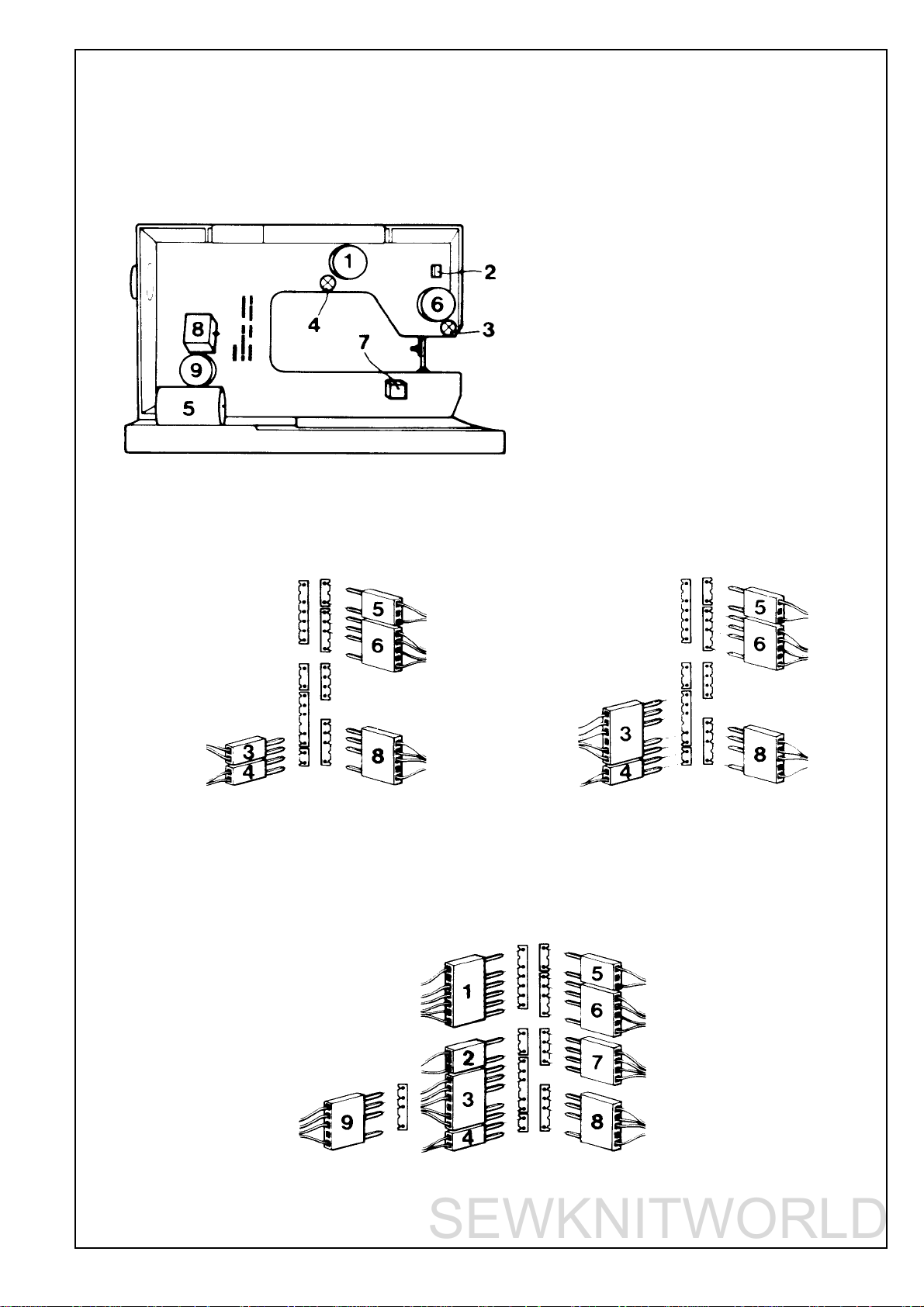

Wiring Diagram

CONNECTING EXTERNAL UNITS TO DRIVEBOARD

1 THREAD TENSON MOT OR

2 PRESSER FOOT SWITCH

3 LAMP/LENGHT SENSOR

4 LAMP

5 MAIN MOTOR

6 NEEDLE MO TOR

7 LO W THREAD INDICAT OR

8 FEEDING MOTOR

9 SIDE MOTION MOTOR

BE SURE THAT CABLES TO DRIVE-BOARD ARE CORRECTLY

CONNECTED, BEFORE SWITCHING ON MAIN SUPPLY

MODEL 1050/1090 MODEL 1070

MODEL 1100/1200/#1

104 72 30-26 Husqvarna service manual 13

Page 14

Service casette, model 1100, 1200

SEWKNITWORLD

To facilitate the control and setting of the different functions of the machine there is a

service casette.

This is used together with the service mode of the machine.

Handling

-Insert the service casette into the casette terminal in the front cover .

-Get into the service mode of the machine by holding the back feeding button and (-)

stitch length pressed while turning on the main switch.

Service program, model 1050, 1070,1090

To facilitate the control and setting of the different functions of the machine there is a

service program.

Handling

-Get into the service program of the machine by holding the back feeding button and (-)

stitch length pressed while turning on the main switch.

14 Husqvarna service manual 104 72 30-26

Page 15

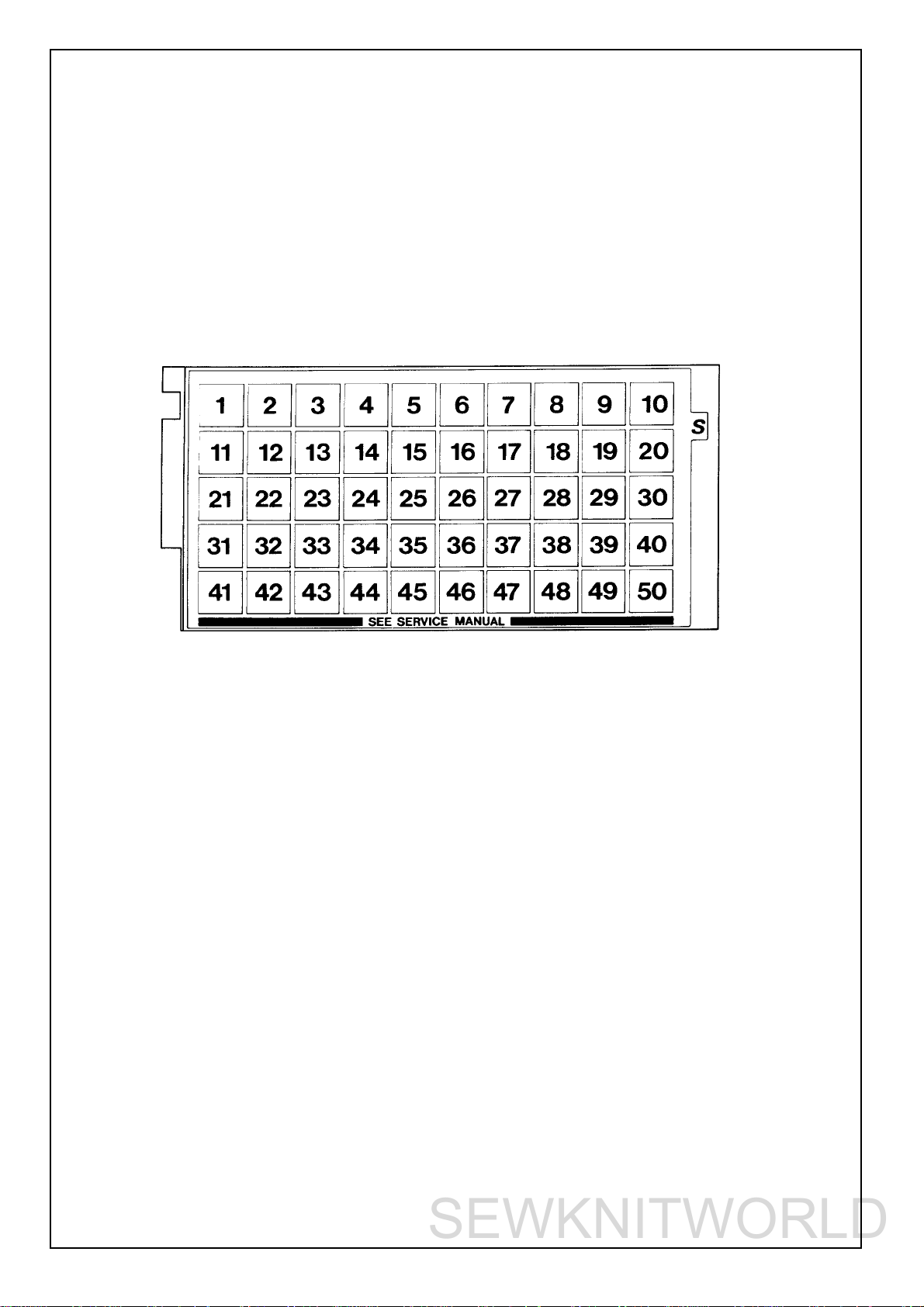

Functions on the service casette 1100, 1200

SEWKNITWORLD

Key 1 Shown in the right display.

Number of the program memory.

Which casettes the program memory contains.

Which casette is in the machine.

Check can be made that the machine reads the correct casette being inserted.

The letter of the casette has to be in accordance with the one shown on the display.

Key 2 Display test where all symbols light up on both displays.

Key 4 Check that the arm shaft sensor (stop right function) works.

The latter looks after when the step motors have to be reset,

it reads the speed and the stop right functions.

A square is shown in the right display.

If this square jumps around clockwise between 4 positions, 2 up and 2

down while ”slowly” pulling the machine around with the handwheel,

the function is correct.

Key 5 Is used when setting the step motor of the sewing head.

The step motors set themselves into the calibration position.

Setting no 5 (P.26).

Key 6 Is used when setting the step motor of the sewing head.

Setting no 5 (P.26).

The setting of the needle in relation to the presser foot.

Setting no 6 (P.27).

Key 7 Is used when setting the step motor of the thread tension.

Setting no 13 (P.33).

The step motor now takes its calibration position.

Key 8 Is used when checking the setting above.

The thread tension pulley shall set at 5.5 (=normal position).

Key 9 Is used when pre-setting the step motor of the guide. Setting no 21

(P.41). The step motor now takes its calibration position.

Key 11 Is used when setting the stitch length balance. Setting no 20 (P.39-40).

The feed dog shall stand still (0-feeding).

Key 12 Is used when setting the stitch length balance. Setting no 20 (P.39).

1100 The machine now sews a service buttonhole where both columns should have the

same length.

Key 12 Is used when setting the stitch length balance. Setting no 20 (P.40).

1200 The machine now sews stitch L-48 (rabbit) of the L-casette.

Key 13 Is used when setting the stitch length balance. Setting no 20 (P.39-40).

The machine sews the signs B,C,D,P,S,T,8.

Key 14 Is used when setting the stitch length balance. Setting no 20 (P.39-40).

The machine now sews stitch A38 which should have a rectangular

aspect.

NOTE! Not mentioned keys are not used at service or are without function.

104 72 30-26 Husqvarna service manual 15

Page 16

Functions of the service program 1070

SEWKNITWORLD

Key 1 Code letter of the program memory.

Key 2 Display test where all symbols light up on the display.

Key 4 Check that the arm shaft sensor (stop right function) works.

The latter looks after when the step motors have to be reset,

it reads the speed and the stop right functions.

The function is correct if numbers 1-4 are shown in the right part of

the display, while the handwheel is turned around slowly.

Key 5 Is used when setting the step motor of the sewing head.

The step motors set themselves into the calibration position.

Setting no 5 (P. 26).

Key 6 Is used when setting the step motor of the sewing head. Setting no 5

(P. 26). The setting of the needle in relation to the presser foot.

Setting no 6 (P. 27).

Key 7 Is used when pre-setting the step motor of the guide. Setting no 21

(P. 41). The step motor now takes its calibration position.

Key 37 Is used when setting the stitch length balance. Setting no 20 (P. 37.

The machine now sews the signs C, D, B, P, S, T, 8.

Key 40 Is used when setting the stitch length balance. Setting no 20 (P. 37.

The feed dog shall stand still (0-feeding).

Key 41 Is used when setting the stitch length balance. Setting no 20 (P. 37.

The machine now sews the stitch 41 which shall have a rectangular

look.

NOTE! Not mentioned keys are not used at service or are without

function.

16 Husqvarna service manual 104 72 30-26

Page 17

Functions of the service program 1050

SEWKNITWORLD

Key 1 Code letter of the program memory.

Key 2 Display test where all symbols light up on the display.

Key 4 Check that the arm shaft sensor (stop right function) works.The latter looks after when

the step motors have to be reset,it reads the speed and the stop right functions.

The function is correct if numbers 1-4 are shown in the right part of the display,

while the handwheel is turned around slowly.

Key 5 Is used when setting the step motor of the sewing head.

The step motors set themselves into the calibration position. Setting no 5 (P. 26).

Key 6 Is used when setting the step motor of the sewing head. Setting no 5 (P. 26).

The setting of the needle in relation to the presser foot. Setting no 6 (P. 27).

Key 7 Is used when pre-setting the step motor of the guide. Setting no 21(P. 41).

The step motor now takes its calibration position.

Menu D+ Is used when setting the stitch length balance. Setting no 20 (P. 36).

Key 6 The feed dog shall stand still (0-feeding).

Menu D+ Is used when setting the stitch length balance. Setting no 20 (P. 36).

Key 7 The machine now se ws the stitch D7 which shall have a rectangular look.

NOTE! Not mentioned keys are not used at service or are withoutfunction.

Functions of the service program 1090

Key 1 Code letter of the program memory.

Key 2 Display test where all symbols light up on the display.

Key 4 Check that the arm shaft sensor (stop right function) works.The latter looks after when

the step motors have to be reset,it reads the speed and the stop right functions.

The function is correct if numbers 1-4 are shown in the right part of the display, while

the handwheel is turned around slowly.

Key 5 Is used when setting the step motor of the sewing head.

The step motors set themselves into the calibration position. Setting no 5 (P. 26).

Key 6 Is used when setting the step motor of the sewing head. Setting no 5 (P. 26).

The setting of the needle in relation to the presser foot. Setting no 6 (P. 27).

Key 7 Is used when pre-setting the step motor of the guide. Setting no 21(P. 41).

The step motor now takes its calibration position.

Key 24 Is used when setting the stitch length balance. Setting no 20 (P. 38).

The machine sews the signs C, D, B, P, S, T, 8.

Key 38 Is used when setting the stitch length balance. Setting no 20 (P. 38).

The feed dog shall stand still (0-feeding).

Key 39 Is used when setting the stitch length balance. Setting no 20 (P. 38).

The machine now sews the stitch 39 which shall have a rectangularlook.

NOTE! Not mentioned keys are not used at service or are without function.

104 72 30-26 Husqvarna service manual 17

Page 18

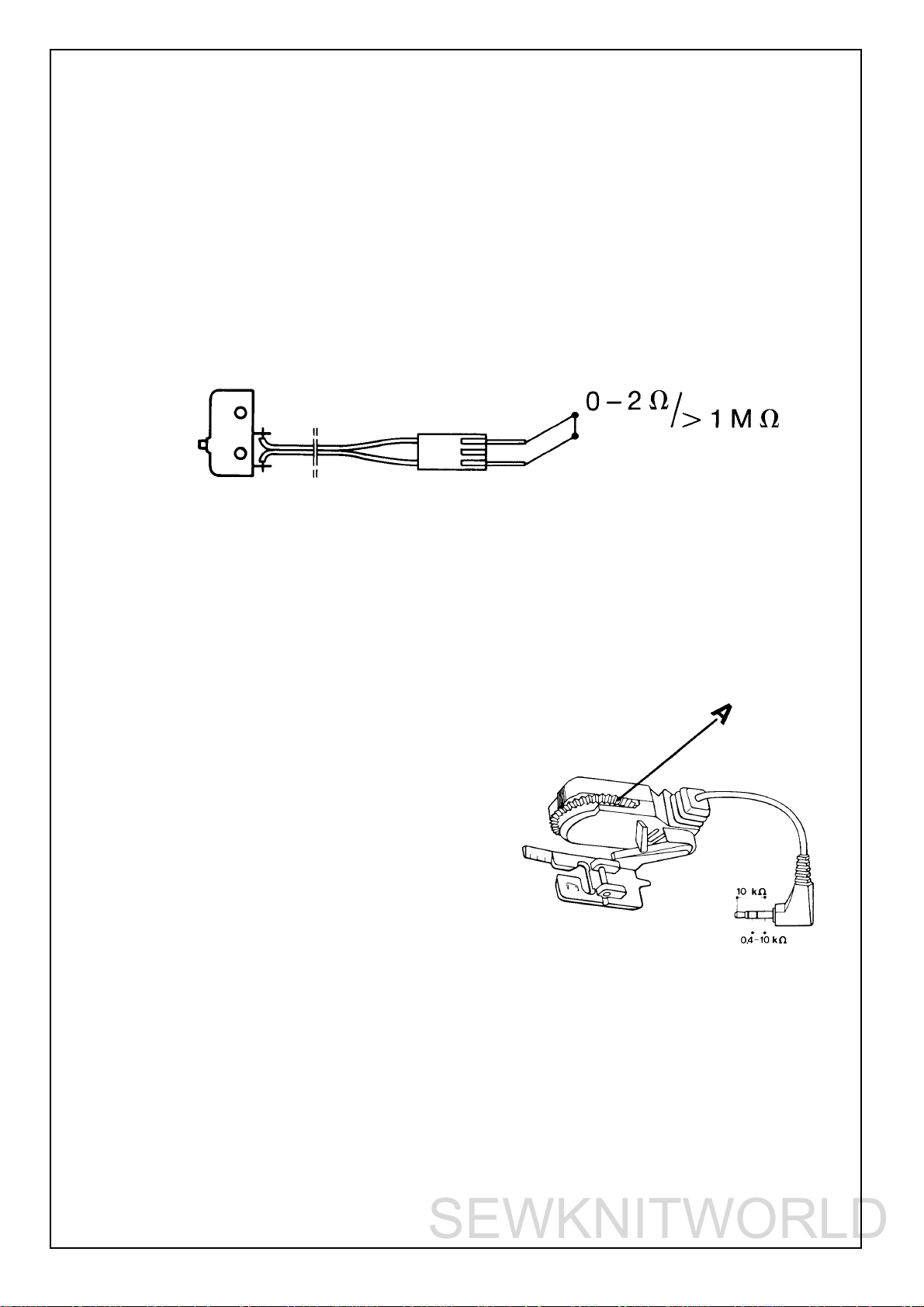

Switch for the presser foot lift

SEWKNITWORLD

In the sewing head there is a little switch that close when the presser foot is being lifted.

Then you cannot sew and a humming sound and flashing displays warns.

If there is anything wrong with the switch the machine can sew.

The function of the switch can be checked with a multi-range instrument at the lowest range by measuring between the two pins of the plug.

Lifted presser foot = 1 .

Lowered presser foot = 0 .

If the values are correct the fault is inside the circuit board or the connection between the

circuit board and the LCD board.

(Exceptionally the fault can also be inside the LCD board).

Buttonhole meter

Check the functions according to directions for use.

Inside the buttonhole meter there is a potentiometer that

is influenced by the measuring wheel (A).

The function of the buttonhole meter can be checked by

a multi-range instrument (-measuring).

When the measuring wheel (A) is turned a value

between 0.4 - 10 k is obtained.

If the values are correct the fault is inside the circuit

board or the connection between the circuit board and

the LCD board.

(Exceptionally the fault can also be inside the

LCD board).

18 Husqvarna service manual 104 72 30-26

Page 19

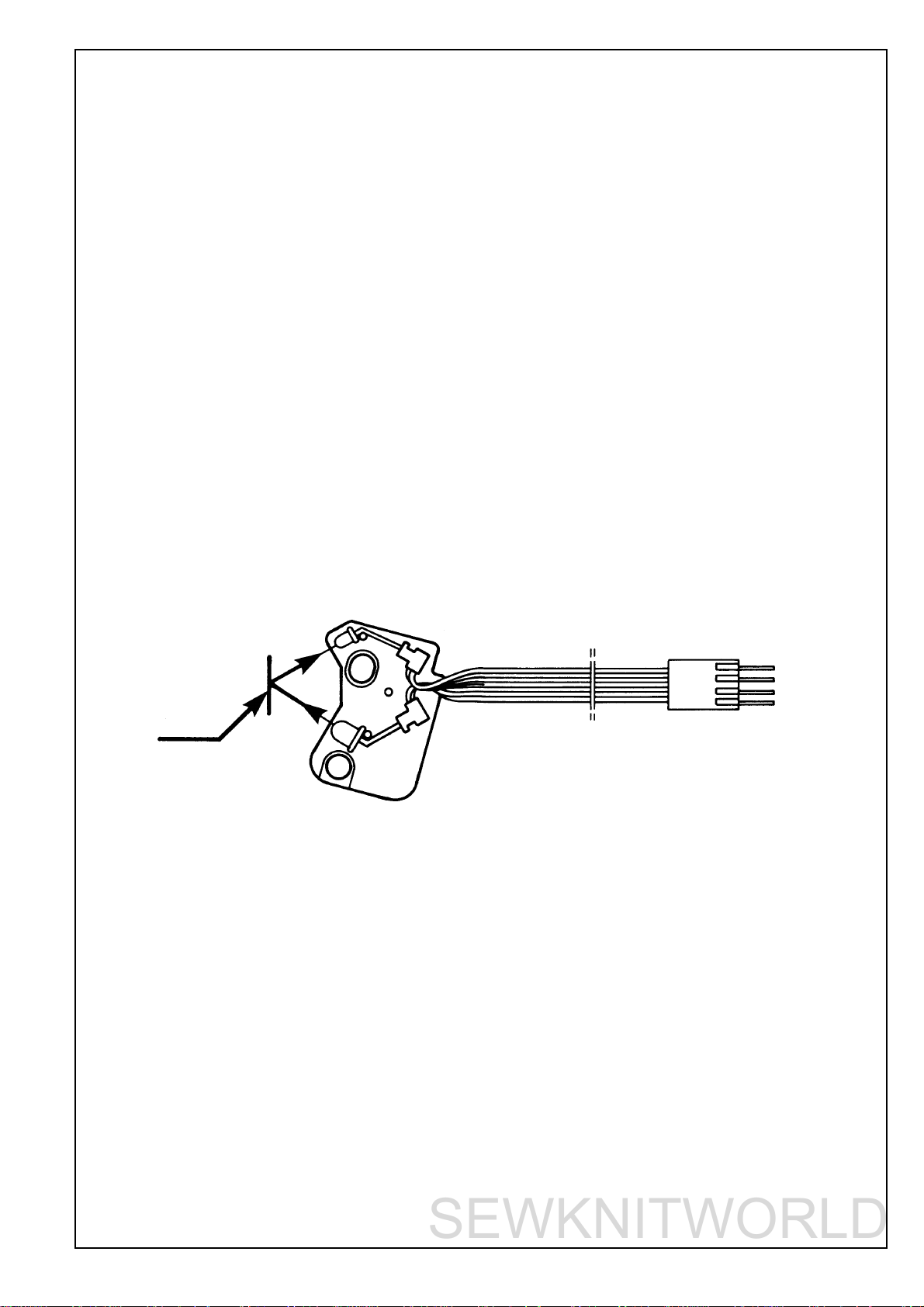

Lower thread indicator

SEWKNITWORLD

When the lower thread is almost at an end the machine gives a warning signal and a bobbin

flashes on the information display.

The lower thread indicator consists of an IR-diode that is reflected against a mirror on the

hub of the bobbin case, if the upper part of the bobbin is out of thread, and is received by a

photo transistor.

If the indicator does not work, it may be due to the indicator or the bobbin case being dirty

which makes it impossible for the IR-light to pass.

If the indicator still doesn’t work it should be replaced.

The fault may also be found on the circuit board, its connections or in some cases on the

LCD board.

You can check the indicator if you connect it to the circuit board (but don’t mount it) and

hold a mirror in front of it.

Photo transistor

(receiver)

IR-diode

(emitter)

Mirror

104 72 30-26 Husqvarna service manual 19

Page 20

Step motor thread tension

SEWKNITWORLD

The upper thread tension of the machine is automatically adjusted by a unipolar step motor

with 7.5 steps.

If the adjustment doesn’t work inspite of settings no 11 and no 12 being checked by means

of the service casette, the step motor or the thread tension device compl. should be replaced.

If the adjustment still doesn’t work the fault is in the circuit

board, its connections, or in some rare cases on the LCD board.

Step motor sewing head

The zigzag movement of the needle is done by a bipolar step motor with 7.5 steps.

If there is not any zigzag movement of the machine despite checking setting no 5 by means

of the service casette/program. Check the circuit board by means of gauge 412 02 56-01

(also check that the connections are undamaged).

If the zigzag movement still doesn’t work dismount the sewing head and check easy

running.

If this is allright try a new sewing head or step motor.

In some rare cases the fault can be in the LCD board.

The step motor of the guide (feeding)

The setting of the feeding direction from forward to backward between long and short

stitches is done by a bipolar step motor with 7.5 steps.

If this setting doesn’t work despite checking of setting no 21by means of the service casette.

Check the circuit board by means of gauge 412 02 56-01.

(Also check that the connections are undamaged).

If the adjustment still doesn’t work dismount the feeding guide compl. and check easy

running.

Is this alright try a new feeding guide or step motor.

In some rare cases the fault can be in the LCD board.

Step motor side feeding

The side feeding of the feed dog is created by a bipolar step motor with 7,5 steps.

If the side feeding of the feed dog does not work, check the pre-setting of the step motor,

the free-running of the feeding device and the sideways setting of the feed dog.

If the side feeding still does not work, check:

- the cable connection of the step motor to the circuitboard,

- the step motor,

- the smooth-running of the feeding movement,

- the circuit board,

- the LCD board.

20 Husqvarna service manual 104 72 30-26

Page 21

Transformer 1050, 1070, 1090

SEWKNITWORLD

The function of the transformer can be checked with gauge 412 02 56-01.

Electronics boards 1050

The machine has one circuit board and one foil keyboard.

The transformer board is part of the transformer compl.

Electronics boards, 1070, 1090

The machine has 2 different boards and 2 foil keyboards.

The transformer board is part of the transformer compl.

Circuit board 1050, 1070, 1090

The circuit board is on the front side in the arm and contains among other things:

- Components to stabilise the voltage,

- Main motor driving,

- Driving of the step motor of the sewing head,

- Driving of the step motor of the guide,

- LCD-display and its driving,

- Arm shaft sensor,

- Computer, memory,

- Light.

Guide board 1090

The guide board is in the front cover and contains light emitting diodes and a micro chip.

Foil keyboard 1050

The machine has one foil keyboard.

-which is placed in the upper part of the front cover with among other things buttons for

stitch width and stitch length adjustment.

Foil keyboard 1070, 1090

The machine has 2 foil keyboards.

-one of them (elliptically) is placed in the upper part of the front cover with among other

things buttons for stitch width and stitch length adjustment.

-one of them is placed into the right part of the front cover with buttons for decorative

stitches and the sewing advisor.

Main motor 1050, 1070, 1090

The main motor is a 24 volt permanent magnet motor that consumes 60 W at maximum

speed.If the main motor doesn’t work when the foot control is pressed, tr y:

1) New foot control

2) New motor (only connect to circuit board at check)

3) New circuit board

4) New transformer (if the machine doesn’t work at all)

104 72 30-26 Husqvarna service manual 21

Page 22

1100, 1200

SEWKNITWORLD

Transformer

The function of the transformer can be checked with gauge 412 02 56-01.

Electronics boards

The machine has 4 different boards and one foil keyboard. The transformer board is part of the

transformer compl.

Circuit board

The circuit board is on the front side in the arm and contains among other things:

-Components to stabilise the voltage,

-Main motor driving,

-Driving of the step motor of the sewing head,

-Driving of the step motor of the guide,

-Driving of the step motor of the thread tension,

-Driving of the step motor of the side motion, applies for model 1200,

-Arm shaft sensor,

-Buttonhole meter,

-Lower thread indicator

-Switch for the presser foot lifting,

-Light.

LCD board

The LCD board is in the front cover and contains among other things 2 LCD displays and the

driving for these, contacts (carbon pressure), for the keys beneath the scale, the computer, the

computer memories, and a warning buzzer.

The key functions are checked by means of the service casette.

Guide board

The guide board is in the front cover and contains among other things light emitting diodes

and contacts (carbon pressure) for the keys to the sewing guide.

Check by means of the service casette.

Foil keyboard

The foil keyboard is in the bottom of the casette terminal of the front cover and contains

keys from the casette and a sensor for the coding of the casette.

In the bottom of the casette terminal there is a code spring that presses on those by means of

the coding of the casette.

Check by means of the service casette.

Main motor

The main motor is a 24 volt permanent magnet motor that consumes 60 W at maximum speed.

If the main motor doesn’t work when the foot control is pressed, tr y:

1) New foot control

2) New motor (only connect to circuit board at check)

3) New circuit board

4) New transformer

The angle of view of the LCD displays

To get a clear picture on the displays independent of how you sit or how tall you are you might

have to adjust the angle of view .

This is done by turning the little pulley in the edge of the casette terminal.

22 Husqvarna service manual 104 72 30-26

Page 23

SETTING INSTRUCTIONS

SEWKNITWORLD

The best and fastest results are obtained if you make the settings in the

following order when servicing.

1 The hook gear

Tangential play

Requirements

Lock the handwheel and turn the driver forward

and back again.

The gear must not be completely tight but the play

should be as small as possible.

Adjustment

Remove the stitch plate. Loosen the stop screw (A)

and turn the shaft (B) until the required

play is obtained.

Comment I

The shaft is journalled eccentrically and must always

be set so that the screwdriver slot is to

the left of the centre of the hole (see illustration).

The same play in the hook gear can be obtained by

turning the shaft a half turn but the hook will then

lie eccentrically in relation to the hook cover.

The shaft is also shiftable.

Check therefore that the gap between the hook

cover and the driver has not been altered (P.24).

Comment II

Too little play results in slow running and increased wear.

Too big play results in noise and risks missing stitches.

Thereafter adjust:

Gap between the hook cover and the driver, (P.24).

Timing of the hook in relation to the needle, (P.30).

Gap between hook and the needle, (P.28).

Setting the stitch plate in relation to the needle, (P.29).

104 72 30-26 Husqvarna service manual 23

Page 24

2 The gap between the hook cover and driver

SEWKNITWORLD

The hook cover is mounted on four fixed supports in

the arm. On those two on the right there are distance

washers.

The distance between the hook cover and the driver

should be so big that the thread can pass freely on both

sides of the hook.

Requirements

The gap between the hook cover and the driver should

be such that when the hook is exchanged for the gauge

411 16 49-01, the gauge should have no play but must

be turnable.

Adjustment

Undo the screws which hold the hook cover.

Exchange the hook for the gauge and replace

the hook cover.

Undo the screw (A) for the hook shaft and shift

the shaft (B), without turning it, to the correct position.

Tighten the screw.

Comment

The shaft (B) is eccentrically mounted and if it is

turned it will affect the play in the hook gear.

Thereafter check:

The gap between the hook and the needle (P.28).

Setting of the stitch plate in relation to the needle, (P.29).

24 Husqvarna service manual 104 72 30-26

Page 25

3 I. Presser foot, parallelism to the stitch plate

SEWKNITWORLD

Requirements

The presser foot shall be parallel to the marking lines

(A) on the stitch plate.

Adjustment

Undo the screw (B) and turn the presser foot until

requirement is obtained.

NOTE! This setting must be correct for all the other

settings in the sewing head.

4 II. Setting the presser foot at right angles to the feeding direction.

Requirements

The sewing head should be set in such a way that

the needle hole of the presser foot is in accordance

with the needle hole of the stitch plate.

Adjustment

Undo the screws (D) (turn the pulley for the presser foot

pressure so that the right one becomes available) and

the nut (E).

Shift the sewing head until requirement is obtained.

Tighten the screws (first the left one) and the nut.

Comments

On the underneath of the buttonhole foot there is a guide,

which steers the fabric.

If the position of the presser foot is not correct in relation

to the needle, the distance between the columns

will be affected.

104 72 30-26 Husqvarna service manual 25

Page 26

5 Setting of the stepmotor of the sewing head

SEWKNITWORLD

Requirements

Set the needle at the upper turning position. The needle shall always get to the central

position, when the main switch is turned on repeatedly.

The distance between the zig-zag bearing of the needle bar frame and the stop lug shall be

equal on both sides 2,3mm.

Adjustment

- Remove the sewing head from the machine (p.52)

but let the cables be connected to the circuit board.

- Place the service casette into the front cover.

- Enter the service mode of the machine by pressing

the reverse feeding button and (-) stitch length

button while turning on the main switch.

-Turn the handwheel until the feed dog reaches its

highest position.

- Press button no(5) on the service casette/program

(= calibration position).

- Check the distance (=1,2mm) between the

calibration wing (A) and the calibration stop (C)

with the distance gauge 412 27 60-01.

Adjust by loosening the screw of the calibration

wing (A) and set distance.

- Press button no(6) on the service casette/program

(= centre position).

- Check the distance(2,3mm) between the zig-zag

bearing of the needle bar frame and the stop lug

with distance gauge 412 27 60-01).

- Adjust by undoing the screw of the cog wheel (B)

and turn the cog wheel until the correct distance is

obtained.

- Mount the sewing head into the machine, (P.54).

Thereafter set:

Setting the presser foot at right angles to the feeding direction (P.25).

The gap between the hook and the needle (P.28).

Setting the stitch plate in relation to the needle (P.29).

26 Husqvarna service manual 104 72 30-26

Page 27

6 Setting of the needle in relation to the presser foot

SEWKNITWORLD

Requirements

When the machine is set at straight stitching centre

position, the needle bar shall be set in such a way that a

needle 90 passes through the centre of the needle hole

in the presser foot.

1 = seen from the front

2 = seen from the side

Adjustment

Switch on the mainswitch

Keep the machine set at straight stitching centre

position (alt. service mode/program button no 6).

Undo the screws (A) by means of an adam key

412 27 65-01.

Put the adam key into the hole (B) and move the needle Needlepoint

bar until requirement obtains.

Tighten the screws.

Check the setting by switching mains on and off a

couple of times.

Thereafter check:

The gap between the hook and the needle (P.28).

Setting of the stitch plate in relation to the needle (P.29).

104 72 30-26 Husqvarna service manual 27

Page 28

7 The gap between the hook and the needle

SEWKNITWORLD

Requirements

Set the machine for straight stitching.

Insert a new needle 90.

Lay the back of the machine on the table.

Turn the handwheel until the tip of the hook gets

behind the needle (see fig.).

Press the hook against the driver.

The gap between the needle and the tip of

the hook should be as little as possible.

Comments

To enable the thread loop to go between

the hook and the driver a certain axial

play must be possible.

Contact between needle and hook can

therefore result and cause a sound, which can

be heard when the machine is running without thread.

This contact damages neither the hook nor

the needle, as long as a needle with a groove

according to system 705 H is used.

Adjustment

The position of the needle is adjusted by moving

the sewing head in the feeding direction.

Loosen the nut (A).

Shift the sewing head by turning the lower

adjustment nut (B) until the required position is reached.

Hold the adjustment nut in position and tighten

the locking nut.

Check the setting.

28 Husqvarna service manual 104 72 30-26

Page 29

8Setting the stitch plate in relation to the needle (in the feeding direction)

SEWKNITWORLD

Requirements

The stitch plate must be centred in relation to the needle in the feeding direction.

Adjustment

Insert a new needle 90.

Adjust the stitch plate to the needle.

Loosen the nut (A) on the underneath of the arm.

Adjust the stitch plate to the correct position.

Fix the stitch plate by hand and tighten the nut.

Comments Needle 120

The gap between the centre line of the needle and the Needle 80

flat part of the needle base varies with the thickness of Stitch plate

the needle.

To enable the needle 120 to move freely from the front

edge of the underneath of the needle hole, set the stitch

plate so that the needle 90 is between points (A) and (B).

Needle 80 will lie slightly behind the centre of the needle

hole.

NOTE! The angled position of the needle.

104 72 30-26 Husqvarna service manual 29

Page 30

9 Timing of the hook in relation to the needle

SEWKNITWORLD

Requirements

Switch on main switch, and set the machine for straight

stitching.

As the needle is moving upward the tip of the hook

should pass the centre line of the needle when

the needle is 2,5mm above the lower turning position

(the distance for forming the loop).

Check

Remove the rear cover, the lamp cover and the handwheel.

Remove the hook cover.

1. Turn the arm shaft by means of the driver pin so

that the needle reaches its lower turning position.

2. Place the setting gauge 411 17 52-01 on the

needle bar until the spring-loaded stud (A)

touches the needle bar frame and tighten the

screw.

3. Move the needle up by pulling the short cog belt

in toward the machine until the spring-loaded

stud rests against its stop in the gauge, according

to the figure on the right.

The needle has now moved up 2,5mm from the

turning position (the distance for forming the

loop).

Hold the hook back so that it is pushed downward

and backward. The tip of the hook shall now be in

the centre of the needle.

Adjustment

-Remove the pointed screw (B) and undo the other

two screws.

-Repeat the checking points 1,2 and 3.

- Hold the arm shaft and turn the hook and the driver

by pulling the short cog belt in toward the machine

until the tip of the hook comes in front of the centre

of the needle.

When tightening the screws on the pulley, the pointed

screw should change places with the black screw that

was unsrewed earlier. Otherwise the pointed screw

might retake its earlier position.

Mount the hook cover, the rear cover, the lamp cover and the handwheel.

(Note! the position of the handwheel in the screen).

Comments

By moving the needle all the time by means of the short cog belt, this

will counteract any possible play between the long cog belt and the cog wheels.

NOTE!

The axial play of the arm shaft might change when loosening the screws.

Maximum play may be 0,05 mm.

30 Husqvarna service manual 104 72 30-26

Page 31

10 The needle height

SEWKNITWORLD

Requirements

Set the machine for zig-zag, right-hand position,

Setting 6 mm stitch width.

Move the needle upward by pulling the short cog Right hand position

position belt in toward the machine and at the same

time holding the hook downward, backward.

When the tip of the hook reaches the centre line of

the needle, the underneath of the tip should be in line

with the top edge of the needle eye.

Comment I

The gap between the tip of the hook and the needle eye

is influenced by the timing of the hook in relation to the

needle. Therefore check the timing according to the

previous page before making any adjustment.

Comment II

The gap between the tip of the hook and the needle

eye, with the needle at the centre position (1.5mm)

is the starting measurement but as this is difficult to

estimate, use the corresponding measurement with

the needle at the right-hand position instead.

Adjustment

Set the machine for zig-zag, right-hand position, 6mm.

Move the needle upward by pulling the shor t cog belt

in toward the machine until the tip of the hook reaches

the centre line of the needle.

Push the hook downward and hold it, so that the catch

of the hook rests against the left side of the slot in

the driver.Loosen the screw (A).

Move the needle bar in such a way until the underneath

of the tip of the hook is in line with the top edge of

the needle eye.

Tighten the screw (A).

NOTE!

Check that the needle eye is at right angles to the hook

by fitting a twin needle and observing the needle

positions in the needle hole of the stitch plate.

104 72 30-26 Husqvarna service manual 31

Page 32

Thread tension

SEWKNITWORLD

11 The thread tension of the bobbin case

Requirements

The thread tension spring of the bobbin case

shall give a thread resistance of 18-22 g when

pulling the tread slowly.

Check weight 22g ref.n 412 15 83-01.

Adjustment

Remove any loose pieces of thread collected

under the thread tension spring.

Attach the thread to the weight and hold the

bobbin case, letting the thread hang vertically

in direction of the bobbin case finger. When

the thread tension is correctly set the weight

shall pull the thread slowly from the bobbin case.

Adjust the thread tension by means of the screw.

12 Upper thread tension

Requirements, model 1050/1070/1090

When the machine is set at straight stitching resp. zig-zag,

a correct take-up should be obtained, when the catch of the

thread tension pulley (5,5) is right in front of the index.

Requirements, model 1100/1200

When the sewing guide of the machine is set at non

elastic normal and straight stitching resp. zig-zag, a

correct take-up should be obtained, when the catch of

the thread tension pulley (5,5) is right in front of the index.

Comment 1

The sewing guide adjusts the thread tension to the fabric resp.

to the sewing at which the machine is set.This is done by means

of the computer and the step motor of the machine.

Comment 2

The thread tension that is set now is to be regarded as a general indication.

This general indication can be risen and lowered by means of the thread

tension pulley and remains as long as the main switch is on.

Adjustment

Remove the rear cover, (P.44).

At the side of the thread tension dial there is an adjustment screw (A) for the setting of

the upper thread tension.

This is accessible from the rear by means of a screwdriver.

Set the catch of the thread tension dial in the middle of the index.

When test sewing with normal fabric and thread turn the adjustment screw until the correct

take-up is obtained for straight stitching and zig-zag.

32 Husqvarna service manual 104 72 30-26

Page 33

13 Setting the thread tension of the step motor

SEWKNITWORLD

Requirements

The thread tension pulley shall always be at its starting position (5,5) when the main switch is

switched on and off repeatedly.

Adjustment

- Remove the front cover (P.35) but leave the cables connected to the circuit

board.

- Dismount the thread tension compl. (P.39), but leave the cable connected to the

circuit board.

-Insert the service casette into the front cover.

-Get into the service mode of the machine by pressing

the reverse feeding and (-) stitch length buttons while

switching on the main switch.

- Loosen the screw in the cog wheel (B) of the step motor.

- Turn the thread tension pulley to 0.

- Press button n 7 on the service casette.

- Tighten the screw.

- Check according to requirements.

14 The setting of the thread take-up spring

Requirements

The casing (C) should be set in such a way, that the thread take-up spring has finished its

movement when the needle eye reaches the fabric after a completed stitch.

Check at straight stitching 2.5 mm in fine fabric.

Adjustment

The stop in the adjustment casing, i.e. the limitation of the movement of the spring, can be

adjusted by means of a screwdriver, which should be applied at the upper part of the casing.

Exchange of the thread tension device.

(P.52).

104 72 30-26 Husqvarna service manual 33

Page 34

The setting of the feed dog

SEWKNITWORLD

15 I The parallelism of the feed dog

Requirement A

The feed dog should be parallel with the grooves in the

stitch plate.

Adjustment

Set the feed dog in its highest position.

Remove the stitch plate and loosen the screws (A) which

hold the feed dog, fit the stitch plate and adjust the feed

dog until it lies parallel with the grooves in the stitch plate.

Then remove the stitch plate without moving the feed dog.

Tighten the screws and check that the feed dog is positioned

correctly in the stitch plate.

16 II The sideways setting of the feed dog

Requirements B, model 1050/1070/1090/1100

The feed dog should move freely in the grooves of the

stitch plate (sideways).

Requirements B,model 1200

At side feeding the feed dog should move

freely in both side positions

(goes for all 4 feed dog rows).

Adjustment

Turn the nut (B) until requirements is reached.

17 III The feed dog height

Requirements

The feed dog should be between

1.0 and 1.1 mm above the stitch plate

when the feed dog is

in its highest position.

Adjustment

Set the feed dog at its highest position.

Put setting gauge 411 49 93-01 above the feed dog.

Loosen nut (A) and turn the screw (B) until requirements is reached.

34 Husqvarna service manual 104 72 30-26

Page 35

18 IV The lengthwise movement of the feed dog

SEWKNITWORLD

Requirements

The feed dog must not strike against the

stitch plate when the machine is set at

maximum stitch length and speed.

Adjustment

Set the machine at stitch length 0 mm

and the feed dog at its highest position.

Loosen the screw (A) and shift the feed

dog until it comes in the middle of the

stitch plate.

Tighten the screw.

Check according to requirements.

NOTE!

Check that the stitch setting fork (B) is parallel with

the connecting rod (C) after tightening.

19 The bobbin-winding device

Limiting when bobbin-winding

Requirements

When bobbin-winding the machine shall stop when the

bobbin is full with thread up to approx. 1 mm from the

edge of the bobbin.

Adjustment

Loosen the locking ring (A) by means of a tool.

Thereafter turn the scanner (B) until you switch off

when there is an adequate amount of

thread on the bobbin (see illustration).

After the adjustment the scanner is secured from

being turned by means of the locking ring.

104 72 30-26 Husqvarna service manual 35

Page 36

20 The balance of the stitch length - model 1050

SEWKNITWORLD

Requirements

A Both the columns of the buttonhole shall have the

same tightness.

B The machine shall sew a pattern according to the symbol.

C The machine shall sew stitch D7 which is to have a rectangular look.

D 7

Check

- Get into the service program of the machine by

pressing the reverse feeding and (-) stitch length

buttons while turning on the main switch.

- Select menu D.

- Press button no 7.

The machine will now sew a pre-programmed stitch

D7 whose left and right side must not differ in length

with more than 2 mm the (see illustration).

Coarse adjustment

Select menu D.

Press button no 6 (=feeding 0).

Turn the nut (A) until the feed dog comes to a stand

still when the foot control is pressed down.

Fine adjustment

Select menu D.

Press button no 7 and turn the nut (A) until the machine

sews a stitch D7 according to illustration.

Check that both the columns of the buttonhole have

the same tightness.

36 Husqvarna service manual 104 72 30-26

Page 37

2 0 The balance of the stitch length - 1070

SEWKNITWORLD

Requirements

A Both the columns of the buttonhole shall have the same tightness.

B The machine shall sew a pattern and letters according to the symbol.

C The machine shall sew stitch 41 which is to have a rectangular look.

41

Check

- Get into the service program of the machine by

pressing the reverse feeding and (-) stitch length

buttons while turning on the main switch.

- Press button no 41.

The machine will now sew a pre-programmed stitch

41 whose left and right side must not differ in length

with more than 2 mm the (see illustration).

- Press button no 37.

The machine will now sew the signs C, D, B, P, S,T,8

which should have the correct aspect.

Coarse adjustment

Press button no 40 (=feeding 0).

Turn the nut (A) until the feed dog comes to a stand

still when the foot control is pressed down.

Fine adjustment

Press button no 41 and turn the nut (A) until the machine

sews a stitch 41 according to illustration.

Check the aspect of the follwing signs:

C, D, B, P, S, T, 8 and that both columns of the

buttonhole have the same tightness.

104 72 30-26 Husqvarna service manual 37

Page 38

2 0 The balance of the stitch length - 1090

SEWKNITWORLD

Requirements

A Both the columns of the buttonhole shall have the same tightness.

B The machine shall sew a pattern and letters according to the symbol.

C The machine shall sew stitch 39 which is to have a rectangular look.

39

Check

- Get into the service program of the machine by

pressing the reverse feeding and (-) stitch length

buttons while turning on the main switch.

- Press button no 39.

The machine will now sew a pre-programmed stitch

41 whose left and right side must not differ in length

with more than 2 mm the (see illustration).

- Press button no 24.

The machine will now sew the signs C, D, B, P,S,T,8

which should have the correct aspect.

Coarse adjustment

Press button no 38 (=feeding 0).

Turn the nut (A) until the feed dog comes to a stand

still when the foot control is pressed down.

Fine adjustment

Press button no 39 and turn the nut (A) until

the machine sews a stitch 39 according to illustration.

Check the aspect of the follwing signs:

C, D, B, P, S, T, 8 and that both columns of the

buttonhole have the same tightness.

38 Husqvarna service manual 104 72 30-26

Page 39

20 The balance of the stitchlength 1100

SEWKNITWORLD

Requirements

A Both the columns of the buttonhole shall have the same tightness.

B The machine shall sew a pattern and letters according to the symbol.

C The machine shall sew stitch A 38 of the A-casette which is to have a rectangular look.

A 38

Check

-Insert the service casette into the front cover.

-Get into the service mode of the machine by pressing

the reverse feeding and (-) stitch length buttons while

turning on the main switch.

-Press button no 14 on the service casette.

The machine will now sew stitch A 38 of the

A-casette whose left and right side must not differ in

length with more than 2 mm the (see illustration). The

length of the stitch is pre-programmed.

-Press button n13.

The machine will now sew the signs C,D,B,P,S,T,8

which should have the correct aspect.

Coarse adjustment

Press button n11 on the service casette (=feeding 0).

Turn the nut (A) until the feed dog comes to a stand

still when the foot control is pressed down.

Fine adjustment

Press button n12 on the service casette and turn the nut (A) until the machine sews a

service buttonhole whose columns are of the same length (see illustration).

Check the aspect of the folling signs: C,D,B,P,S,T,8 and that the columns of the

buttonhole have the same tightness.

104 72 30-26 Husqvarna service manual 39

Page 40

20 The balance of the stitch - 1200

SEWKNITWORLD

Requirements

The machine shall sew patterns and letters according to the symbol.

NOTE!

When checking and adjusting the stitch

length balance test sewing is to be carried

out on a simple cotton cloth with pads

(Stitch’n tear) and a thin and smooth

lower thread (=normal synthetic thread)

is to be used.Otherwise the balance of the

omnigram stitches might be influenced.

Check

-Insert the service casette into the front cover.

-Get into the service mode of the machine by pressing

the reverse feeding and (-) stitch length buttons while

turning on the main switch.

-Press button no 12 on the service casette.

The machine will now sew stitch L 48 (the rabbit) of

the L-casette.

-The chin of the rabbit must not show much difference

in height.

-Press button n13.

The machine will now sew the signs C,D,B,P,S,T,8

which should have the correct aspect.

Coarse adjustment

Press button no 11 on the service casette (=feeding 0). Turn the nut (A) until

the feed dog comes to a stand still when the foot control is pressed down.

Fine adjustment

Press button no 12 on the service casette and turn the nut (A) until the machine

sews stitch L-48 according to illustration.

Check the aspect of the folling signs: C,D,B,P,S,T,8 and that the columns of

the buttonhole have the same tightness.

40 Husqvarna service manual 104 72 30-26

Page 41

21 Pre-setting of the step motor of the guide, version 1

SEWKNITWORLD

Get into the service mode of the machine by pressing the reverse feeding

button and (-) stitch length while the main switch is turned on.

For 1100 use the service casette and press button no 9

For 1050/1090 press button no 7

Requirements

The distance between pin (A) of the

cog wheel and stop lug (B) shall be 0.6 mm.

Adjustment

Loosen screw (C) in the cog wheel (D)

and turn until requirements 0.6 mm is reached.

Tighten the screw and check.

Thereafter set:

The balance of the stitch length (P.36-40).

21 Pre-setting of the step motor of the guide, version 2

Get into the service mode of the machine by pressing the reverse feeding

button and (-) stitch length while the main switch is turned on.

For 1200 use the service casette and press button no 9.

For 1050/1070/1090 press button no 7

Requirements

The distance between pin (A) of the cog wheel

and stop lug (B) shall be 0.0 - 0.1 mm.

Adjustment

Loosen screw (C) in the cog wheel (D) and turn until

requirements 0.0 - 0.1 mm is reached.

Tighten the screw and check.

Thereafter set:

The balance of the stitch length (P.36-40).

104 72 30-26 Husqvarna service manual 41

Page 42

2 2 Pre-setting of the step motor for the side feeding

SEWKNITWORLD

Reqirements

Dismount the side feeding mechanism (page 56)

Set the handwheel so that the step motor switches between its 2 positions.

Choose a side feeding stitch from casette L.

Turn the handwheel in such a way that the step motor changes between its 2 positions.

The distance between the pin (B) and the side of the segment shall be equally large in both

positions

(see fig. 1).

Adjustment

Turn on the mains switch of the machine.

Choose a side feeding stitch from casette L.

Loosen screw (A) and place the cog segment in such a way that pin (B) arrives in the middle of

the opening of the cog segment (see fig. 2).

Tighten screw (A). Check according to requirements.

Fig.1 Fig. 2

42 Husqvarna service manual 104 72 30-26

Page 43

23 Setting the feeding mechanism sideways

SEWKNITWORLD

Requirements

Set the machine on a stitch from casette L with side feeding. A play of at least 0.3 mm shall be:

in one side feeding position between bearing/bearing clamp (B) and link (C) of the feeding

device and in the other side feeding position between bearing/bearing clamp (D) and link (E) of

the feeding device.

Adjustment

Loosen screws (A) and push the step motor unit with the feeding device sideways.

Tighten the screws.

Check the play according to requirements.

NOTE!

The spherical bearings (B) and (D) must be trued so that the feeding device can move easily.

Min 0,3 Min 0,3

104 72 30-26 Husqvarna service manual 43

Page 44

Rear cover

SEWKNITWORLD

Dismounting

Upper cover

Undo the two screws behind the handle.

Insert a screwdriver from the side of the recess for

the handle and carefully push out the upper edge.

At the same time push the cover upward.

Lower cover

Loosen the screw and push the cover to the right.

Front cover

Dismounting

Turn off the main switch.

Dismount the rear cover and the lamp

guard (A).

Loosen the screw in the cable groove (B).

Loosen the four screws (C).

Press the buttons for On/Off and for the

feed dip.

Push the cover carefully upward.

Remove the two cables that are connected

to the circuit board.

The parts of the front cover

Loosen the three cords from the LCD-board (A).

Loosen the screws that hold the LCD-board and

the printed circuit for the guide (B).

The LCD-board may now be removed and

thereafter the guide board.

Mounting

Fit in the 3 pushbutton assemblies (C) into

their guides.

Fit the printed circuit for the guide into

its place.

Attach the display board under the hook on

the lower edge, fit support (D) into its place.

Fit the insulating plate and tighten the screws.

Connect the cords.

44 Husqvarna service manual 104 72 30-26

Page 45

MEMO-CHIP 1100/1200

SEWKNITWORLD

The Husqvarna 1100/1200 has an exchangeable memo-chip

in which the characteristics and stitches of the machine are stored.

Exchange of the memo-chip

In order to be able to dismount without damaging the

LCD-board a special extractor tool sshall be used.

Furthermore use a wrist band so that the components

of the LCD-board are not to be damaged by static

electricity (ESD).

Ref. no: Extractor tool 412 27 98-01

Wrist band 412 23 02-01

Pull out the mains cable.

Connect the wrist band to the presser bar of the sewing machine.

Dismount rear cover: (P.44).

Dismount front cover: (P.44).

Insert the extractor tool into the socket so that its plastic part

comes to rest against the surface of the socket. (See ill.1).

Cautiously press the pliers together. (See ill. 2).

Check that the pliers lift the chip straight out of the socket.

(See ill.3). Put the memo-chip into the ESD-package.

Put the new memo-chip into the socket.

Check that its bevel is correctly positioned (See ill.4).

Push the memo-chip into the socket.

Mount rear cover and front cover.

NOTE!

After the exchange of the memo-chip it might be necessary

to ”clear” it. Use the service cassette and enter the service

programme of the machine by holding down the buttons for

backwards feeding and minus stitch length while turning on

the mains switch. First press button 29 and then button 30.

The machine is now ”cleared”.

Also check the stitch length balance.

104 72 30-26 Husqvarna service manual 45

Page 46

Exchange of the foil keyboard

SEWKNITWORLD

1100/1200

Dismount rear cover, front cover, LCD-board and guide board (P.44).

Dismount code spring (A).

Dismount foil keyboard (C). Remove glue residues from the surface. Remount in reverse order.

NOTE!

When mounting code spring (A) an interlayer (B) is to be used between the code spring and the

foil keyboard in order to avoid to damage the contact surfaces

46 Husqvarna service manual 104 72 30-26

Page 47

The transformer

SEWKNITWORLD

Remove the 4 screws holding the transformer.

Loosen the cord from the transformer.

Exchanging the circuit board of the

transformer

- Put on the wrist band and connect it to the presser bar of the sewing machine.

- Unscrew the three screws (A) holding together the upper part and the lower part of the

transformer.

- Use the tin solder from the 7 connections of thetransformer to the circuit board by means

of a soldering pencil and tin exhauster.

- Remove the circuit board.

- Solder the circuit board into the transformer.

- Remount the upper part and lower part of the transformer.

- Try the transformer by means of the transformer tester

(which is part of the diagnoser set 412 02 56-01).

- Try the transformer in a sewing machine.

104 72 30-26 Husqvarna service manual 47

Page 48

Main motor

SEWKNITWORLD

Loosen the motor cable from the circuit board.

Loosen the screws (A) which secure the attachment for

motor to the base plate.

NOTE!

The cables are connected according to the wiring

diagram (P.13). The motor can be checked without

being mounted into the machine. Belt tension (P.12).

Bobbin-stop

Remove the transformer (P.47).

Remove the 3 screws (A) which secure the base

plate to the arm. Thereafter the bobbin-stop can

be pushed downward. Setting (P.35).

Circuit board 1100/1200

Dismounting

Remove the rear cover (P.44).

Remove the front cover (P.44).

Loosen all cables rearwisen from the circuit board.

Loosen screw (A) at the lower edge, the screw (B)

holding the plate for the transistors and the screw (C)

holding the arm shaft transmitter.

Loosen the cable (D) for the transformer from the board.

Wiring instruction (P.13).

Circuit board 1050/1070/1090

Dismounting

Remove the rear cover (P. 44).

Remove the front cover (P. 44).

Loosen all cables rearwisen from the

circuit board. Loosen screws (A) and the

screws (B) holding the plate of the arm

shaft transmitter. Loosen the cable (D)

for the transformer from the board.

Wiring instruction (P. 13).

48 Husqvarna service manual 104 72 30-26

Page 49

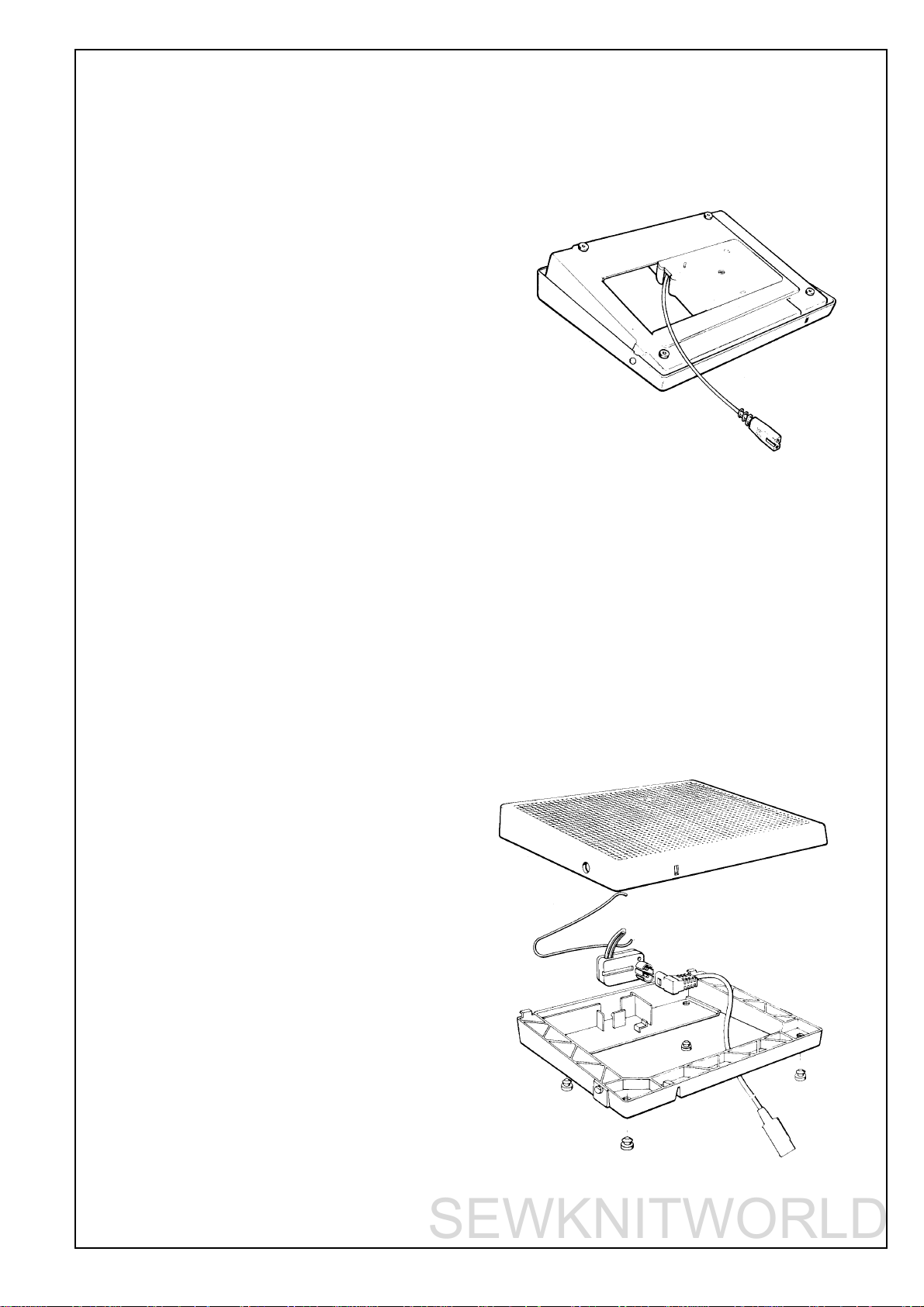

The foot control

SEWKNITWORLD

Dismounting

Turn it upside down.

Insert a screwdriver between the sections and carefully bend the pins (A) out of their positions.

Part the sections.

Push the plug (B) of the cord device out of the potentiometer (C).

The potentiometer can now be dismounted.

Carefully bend aside the two pegs (D) holding the cord device in place and push the cord device

out of the foot control.

Mount in the reverse order.

The foot control

Dismounting

Turn it upside down.

Insert a screwdriver between the sections and carefully bend the pins (A) out of their positions.

Part the sections.

Push the plug (B) device out of the potentiometer (C).

The potentiometer can now be dismounted.

Mount in the reverse order.

104 72 30-26 Husqvarna service manual 49

Page 50

Feeding guide compl. (step motor)

SEWKNITWORLD

Dismounting

Turn off the main switch.

Remove the rear cover.

Remove the screws for the cable groove.

Remove the cable of the step motor from the circuit board.

Note the position of the nut (A) on the screw and remove it.

Remove the screws (B).

The feeding guide can now be removed.

Mounting

Fit the block (C) into the guide (D) (see illustration).

Push aside the stitch regulator fork (E).

Mount the feeding guide into the machine and thread the stud of the fork into the hole of the

block.

Tighten the screws (B).

Tighten the nuts (A).

Connect the cables to the circuit board.

Mount the cable groove.

Thereafter set:

The stitch length balance (P.36-40).

50 Husqvarna service manual 104 72 30-26

Page 51

The connecting rod

SEWKNITWORLD

Dismounting

Remove the cable groove and all cables from the circuit board.

Loosen the spring (A) on the lower part of the connecting rod.

Lift up the connecting rod and remove it.

Mounting is done in the reverse order.

Check that the stud (B) is hooked in correctly into the feeding

mechanism.

NOTE!

Connecting the cables, see the wiring diagram (P.13).

Feeding mechanism unit with stitch regulator fork

Dismounting

Remove the cable groove and all the cables

from the circuit board.

Dismount the feeding guide with the step

motor (P.50).

Dismount the main motor and the stitch plate.

Dismount the clips of the side motion, for

1200 (P.43).

Dismount the connecting rod (P.51).

Hook off the spring (A).

Loosen the screws (B) for the rear and front

bearing clamps.

Remove the feeding mechanism compl. and

the stitch regulator fork.

Mounting

Insert the feeding mechanism in such a way

that the two bearings (C) come into their place

and that the link at the front edge is placed

under the lifting clamp (D) of the feed dog.

Tighten the screws (B).

Thread the spring (E) onto its studs between

the the stitch regulator fork and the arm.

Mount the feeding guide compl.

Fit the dolly (F) onto the stitch regulator fork and hook on the spring (A).

Mount the clips of the side motion, for 1200.

Mount the connecting rod.

Mount the main motor.

NOTE!

Connecting the cables, see the wiring diagram (P.13).

Therafter set:

The setting of the feed dog sideways (P.34). The feed dog height (P.34).

The lengthwise movement of the feed dog (P.35). (the stitch regulator fork has to be parallel

with the rod)

The stitch length balance (P.36-40).

104 72 30-26 Husqvarna service manual 51

Page 52

Thread tension device compl.

SEWKNITWORLD

Dismounting

Remove the rear cover (P.44).

Remove the front cover (P.44).

Loosen the cables of the step motor and of the lamp

from the the circuit board.

Loosen the two screws (A) holding the thread tension

device.

The thread take-up spring (B) can be exchanged if the

wedge is pushed out of the adjustment

casing and if the latter is removed from the plate.

Thread tension discs with spring (C) can be replaced by

unscrewing the adjustment screw (D) of the plate.

Mount in the reverse order.

NOTE!

Connecting the cables, see wiring diagram (P.13).

The driver

Dismounting

Remove the bobbin case.

Loosen the 4 screws of the hook cover and remove the hook.

Set the slot of the driver under the feed dog.

Undo the locking screw (A) of the driver which is accessible

through the base plate.

Push out the driver by pressing on the shaft (B) from the rear.

Mount in the reverse order.

NOTE!

The position of the groove of the shaft.

Thereafter set:

The cog play of the hook gear (P.23).

The gap between the hook cover and the driver (P.24).

The gap between the hook and the needle (P.28).

Setting the stitch plate in relation to the needle (P.29)

Setting the timing of the hook in relation to the needle

(P.30).

52 Husqvarna service manual 104 72 30-26

Page 53

The lower shaft

SEWKNITWORLD

Dismounting

Dismount transformer and motor.

Dismount the side feeding mechanism, applicable to 1200 (P.56).

Dismount the feeding mechanism compl. with the stitch regulator fork (P.51).

Remover the belt stretcher for the long cog belt.

Loosen screws (A) for the bearing clamp of the lower shaft.

Remove the dust shield (B). Thereafter the lower shaft can be removed.

Mount in the reverse order.

Adjust the axial play of the lower shaft by means of stop ring (C).

The must not exceed 0.05 mm.

Therafter set:

The cog play of the hook gear (P.23).

The gap between the hook cover and the driver (P.24).

The gap between the hook and the needle (P.28).

The setting of the stitch plate in relation to the needle (P.29).

The timing of the hook in relation to the needle (P.30).

The feed dog height (P.34).

The lengthwise movement of the feed dog (P.35).

The stitch length balance (P.36-40).

Position of the side motion, applicable for 1200 (P.43).

104 72 30-26 Husqvarna service manual 53

Page 54

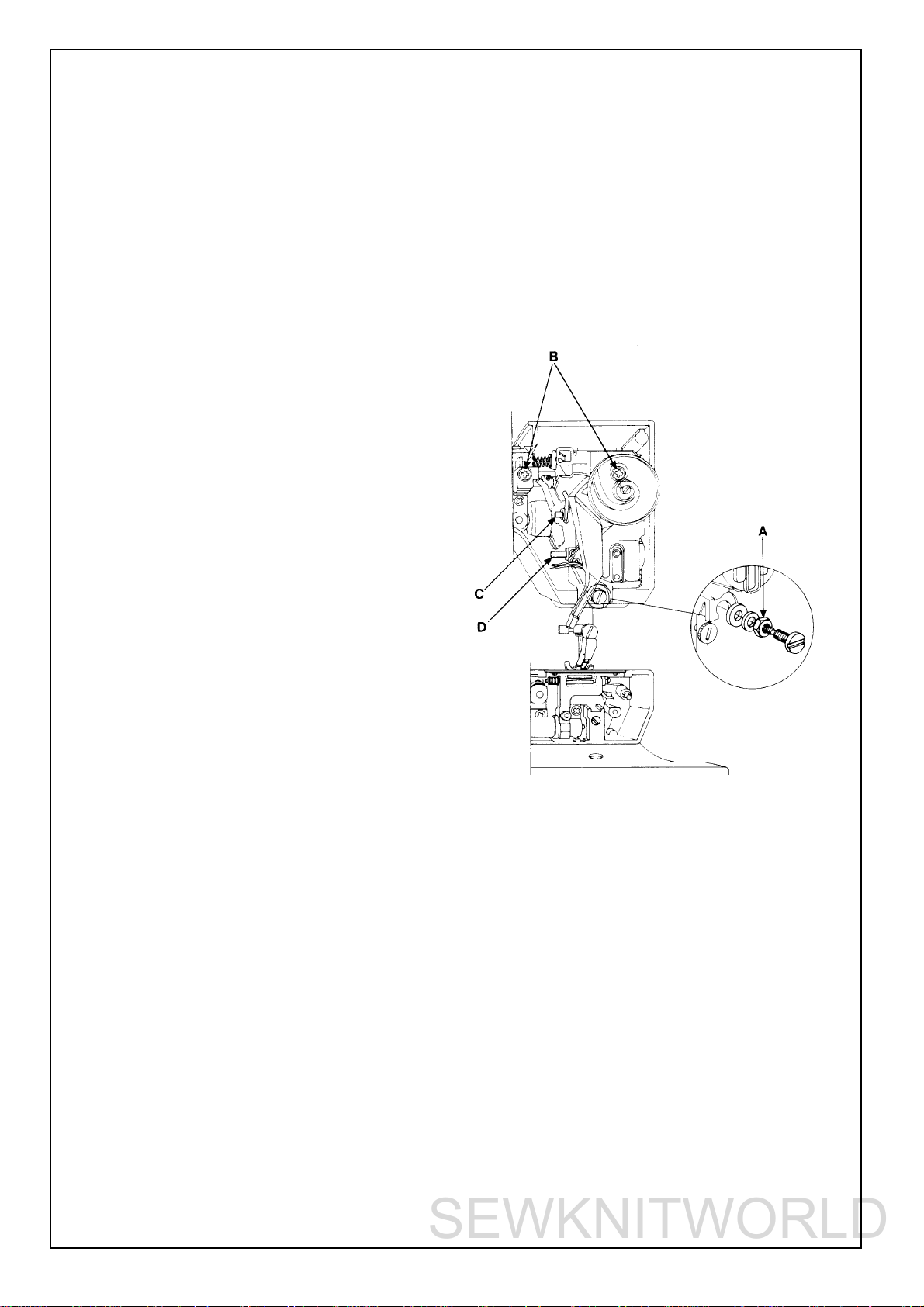

The sewing head

SEWKNITWORLD

Dismounting

Remove the needle and the presser foot.

Set the thread take-up lever at its lower turning position.

Dismount the rear cover (P.44).

Remove the cords to the step motor, the lamp holder and

the sensor for the presser foot lever from the circuit board.

Dismount the lamp holder.

Turn the pulley in order to reach the screw at the rear.

Loosen the nut (A) and the 2 screws (B).

Pull the upper part of the sewing head outward carefully

and release it first from the pivot (C) of the thread

take-up lever and then from the pivot (D) of the needle

bar.

Use the handwheel.

Mounting

First insert pivot (D) of the needle bar and then pivot

(C) into their bearings.

Put the sewing head in position.

Use the handwheel.

Tighten the screws (B) and the nut (A).

Mount the lamp holder.

Connect the cords to the circuit board.

Wiring diagram (P.13).

Thereafter set:

The setting of the presser foot at right angles to the

feeding direction (P.25).

The gap between the hook and the needle (P.28).

The setting of the stitch plate in relation to the needle

(P.29).

The height of the needle (P.31).

54 Husqvarna service manual 104 72 30-26

Page 55

Arm shaft

SEWKNITWORLD

Dismounting

Dismount: rear cover (P.44).

sewing head (P.54).

connecting rod (P.51).

and tilt the stitch regulator fork (B)

outward (P.51).

Remove the belt tensioner (C).

Remove the handwheel.

Loosen the screws for the bearing clamps (D).

Remove the arm shaft. Note! Do not damage the arm shaft transmitter.

Mount in the reverse order.

NOTE!

The axial play of the arm shaft is adjusted by means of belt wheel (E).

The play must not exceed 0.005 mm.

Thereafter set:

The setting of the presser foot at right angles to the feeding direction (P.25).

The gap between the hook and the needle (P.28).

The setting of the stitch plate in relation to the needle (P.29).

The timing of the hook in relation to the needle (P.30).

104 72 30-26 Husqvarna service manual 55

Page 56

Dismounting the side feeding mechanism

SEWKNITWORLD

Dismount cover, upper arm and cover, free-arm and main motor.

Loosen the clip (B) between the feeding device and the side feeding mechanism by pushing

it downwards.

Loosen screws (A) and remove the side feeding mechanism.

The step motor is connected to the circuit board according to the wiring plan.

Mount in the reverse order.

Thereafter set:

- The pre-setting of the step motor of the side feeding (P.42).

- The sideways setting of the feed dog (P.34).

- The stitch length balance (P.40).

56 Husqvarna service manual 104 72 30-26

Page 57

Fault-finding diagram

SEWKNITWORLD

A. The keys of the cassette do not function.

1. Check that none of the keys of the machine stayspressed.

(applies to all keys of the front panel)

2. Check that there is no bad contact in the connection from the

foil keyboard of the front cover (and in other cable connections).

3. Try a new front cover, compl. with foil keyboard or just foil keyboard (P.46).

4. Try a new guideboard (P.44).

5. Try a new LCD- board (P.44).

B. The keys of the cassette give a seam from another cassette.

1. Check by means of the ser vice cassette that the machine reads the

correct cassette.

2. Check that the keying on the left of the cassette is correct.

Compare with another cassette.

3. If not. Check that the code spring of the cassette is freed from or

is pressing sufficiently against its contact points on the foil

keyboard. If not exchange code spring (P.46).

4. Try a new front cover,compl. with foil keyboard or just foil keyboard (P.46).

C. All or some of the keys below the panel do not function.

1. Check that none of the keys of the machine stays pressed.

2. Try a new LCD-board (P.44).

D.All or some of the keys of the sewing advisor do not function.

1. Check that none of the keys of the machine stays pressed.

2. Check the connection to the guideboard.

3. Try a new guide-board (P.44).

E. All or some of the keys of the upper foil keyboard do not function.

1050/1070/1090

1. Check the cable connection of the foil keyboard to the circuit board.

2. Try a new foil keyboard.

3. Try a new circuit board (P.48).

F. All or some of the keys of the lower foil keyboard do not function.

1050/1070/1090

1. Check the cable connection of the foil keyboard to the circuit board.

2. Try a new foil keyboard.

3. Try a new circuit board (P.48).

G.None of the keys of the machine functions.

1. Check that none of the keys of the machine stays pressed.

2. Replace the memo-chip (P.45).

3. Try a new LCD-board (P.44).

104 72 30-26 Husqvarna service manual 57

Page 58

H.The machine only runs at reduced speed.

SEWKNITWORLD