Page 1

USE AND CARE GUIDE

80 GALLON SINGLE STAGE

AIR COMPRESSOR

Questions, problems, missing parts?

Before returning to the store, call

Husky Customer Service

8 a.m – 6 p.m., EST, Monday-Friday

1-888-43-HUSKY

HUSKYTOOLS.COM

Item # 901032

Model # C801H

We appreciate the trust and condence you have placed in Husky through the purchase of this 80 gallon

single stage air compressor. We strive to continually create quality products designed to enhance your

home. Visit us online to see our full line of products available for your home improvement needs. Thank

THANK YOU

you for choosing Husky!

Page 2

Table of Contents

Safety Information ............................. 2

Work Area Safety ............................2

Personal Safety ..............................3

Transporting ...................................3

Air Compressor And

Pneumatic Tool Safety ....................3

Electrical Safety ..............................4

Electrical Safety

(Electrical Connection) ...................4

Electrical Safety

(Speed And Wiring) .........................4

Electrical Safety

(Grounding Instructions) ................5

Air Distribution System ...................... 5

Safety Information

This manual contains information that is

important for you to know and understand.

This information relates to protecting YOUR

SAFETY and PREVENTING EQUIPMENT

PROBLEMS. To help you recognize this

information, we use the symbols below.

Please read the manual and pay attention to

these symbols.

DANGER: Indicates an

imminently hazardous situation

which, if not avoided, will result

in death or serious injury.

WARNING: Indicates a

potentially hazardous situation

which, if not avoided, could

result in death or serious

injury.

CAUTION: Indicates a potentially

hazardous situation which, if not

avoided, may result in minor or

moderate injury.

NOTICE: Indicates a practice

not related to personal injury

which, if not avoided, may result

in property damage.

Warranty ............................................. 7

Specications ..................................... 7

Duty Cycle........................................... 7

Tools Required ................................... 8

Hardware needed (for anchoring) ...... 8

Package Contents ............................... 8

Hardware included .........................8

Assembly .......................................... 10

Operation ......................................... 12

Maintenance ..................................... 14

Storage ............................................. 18

Troubleshooting ................................ 18

WORK AREA SAFETY

1. Keep your work area clean and well lit.

Ensure oors are not slippery from wax

or dust.

2. Do not operate power

tools in explosive

atmospheres, such as in

the presence of ammable liquids, gases,

or dust. Power tools create sparks which

may ignite the dust or fumes. Keep

bystanders, children, and visitors away

while operating tools. Distractions can

cause you to lose control.

3. Operate air compressor in an open area

at least 18 in. (0.5m) away from any

wall or object that could restrict the

ow of fresh air to ventilation openings.

4. Always disconnect the air

supply and power supply before

making adjustments, servicing a

tool, or when a tool is not in use.

5. This compressor/pump is not

equipped and should not be

used to supply breathing

quality air. Additional equipment would

be necessary to properly lter and

purify the air to meet minimal

specications for Grade D breathing as

described in Compressed Gas

2

Page 3

Safety Information (continued)

Association Commodity Specication G

7.1 - 1966, OSHA 29 CF9 1910.134.

Compressed Gas Association, 4221

Walney Road, Fifth Floor, Chantilly, VA

20151-2923, (703) 788-2700, www.

cganet.com. Any such additional

equipment has not been examined and

no implication of proper use for

breathing air is intended or implied.

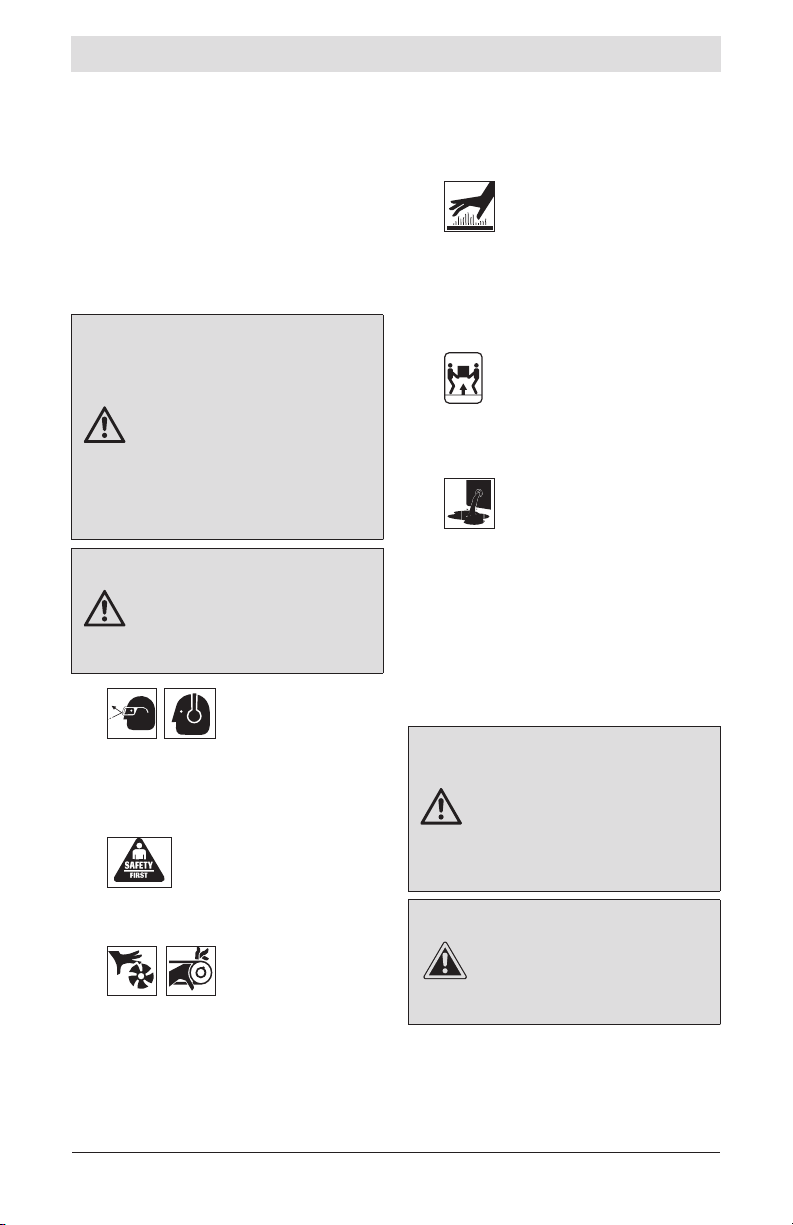

PERSONAL SAFETY

WARNING: Operating any

power tool can result in foreign

objects being thrown into your

eyes, which can result in severe

eye damage. Before beginning

operation, always wear safety

goggles, safety glasses with

side shields, or a full face shield

when needed. Always use eye

protection marked to comply

with ANSI Z87.1.

WARNING: This product

contains chemicals known to

the State of California to cause

cancer and birth defects or other

reproductive harm. Wash hands

after handling.

1. Use safety equipment.

Always wear eye

protection with side

shields when operating power tools.

Dust mask, nonskid safety shoes, hard

hat, or hearing protection must be used

for appropriate conditions.

2. Stay alert when operating a

power tool. Do not use the

tool while tired or under the

inuence of drugs, alcohol, or

medication.

3. Do not wear loose

clothing or jewelry.

Contain long hair. Keep

your hair, clothing, and gloves away

from moving parts. Loose clothes,

jewelry, or long hair can be caught in

moving parts.

4. Keep proper footing and balance at

all times. Proper footing and balance

pts-205109-051012, pts-2053019-053012, pts-206067-060612

enables better control of the tool in

unexpected situations.

5. Do not use on a ladder or unstable

support.

6. Never touch any exposed metal

parts on compressor during or

immediately after operation.

Compressor will remain hot for several

minutes after operation. Do not reach

around protective shrouds or attempt

maintenance until unit has been

allowed to cool.

8. The compressor is too heavy to be

lifted by one person. Obtain

assistance from others before

lifting.

TRANSPORTING

1. Always place compressor on a

protective mat when

transporting to protect against

damage to vehicle from leaks. Remove

compressor from vehicle immediately

upon arrival at your destination.

2. Always transport and store unit in an

upright position.

AIR COMPRESSOR AND

PNEUMATIC TOOL SAFETY

WARNING: Do not attempt

to modify this tool or create

accessories not recommended

for use with this tool. Any such

alteration or modication is

misuse and could result in a

hazardous condition leading to

possible serious personal injury.

CAUTION: Do not use in an

environment that is dusty or

otherwise contaminated. Using

the air compressor in this type of

1. Keep compressors as far from the

3

environment may cause damage

to the unit.

spraying area as possible, at least 15 ft.

(0.4m) from the spraying area and all

explosive vapors.

Please contact 1-888-43-HUSKY for further assistance.

HUSKYTOOLS.COM

Page 4

Safety Information (continued)

2. Risk of Bursting. Do not adjust

regulator to result in output

pressure greater than marked

maximum pressure of attachment. Do not

use at pressure greater than the rated

maximum pressure of this compressor.

3. If connected to a circuit protected by fuses,

use time-delay fuses with this product.

4. To reduce the risk of electric

shock, do not expose to rain.

Store indoors.

5. Ensure the hose is free of obstructions

or snags. Entangled or snarled hoses

can cause loss of balance or footing and

may become damaged.

6. Use the air compressor only for its

intended use. Do not alter or modify

the unit from the original design or

function. Never weld or drill holes in the

air tank.

7. Never leave a tool unattended with the

air hose attached.

8. Do not operate this tool if it does not

contain a legible warning label.

9. Do not continue to use a tool or hose

that leaks air or does not function

properly.

10. Do not attempt to pull or carry the air

compressor by the hose.

11. Your tool may require more air

consumption than this air compressor is

capable of providing.

12. Never direct a jet of compressed air

toward people or animals.

13. Protect your lungs. Wear a face or dust

mask if the operation is dusty.

14. Do not use this air compressor to spray

chemicals. Your lungs can be damaged

by inhaling toxic fumes. A respirator

may be necessary in dusty environments

or when spraying paint.

of electric shock if your body is grounded.

2. Do not expose power tools to rain or wet

conditions. Water entering a power tool

will increase the risk of electric shock.

3. Replace damaged cords/wiring

immediately. Damaged cords/wiring

increase the risk of electric shock.

ELECTRICAL SAFETY

(ELECTRICAL CONNECTION)

1. This air compressor is powered by a

precision built electric motor. It should

be connected to a power supply that

is 240volts, 60 Hz, AC only (normal

household current).

2. Do not operate this tool on direct

current (DC). A substantial voltage

drop will cause a loss of power and

the motor will overheat. If the air

compressor does not operate when

plugged into an outlet, double check the

power supply.

ELECTRICAL SAFETY

(SPEED AND WIRING)

1. The no-load speed of the electric motor

varies by model and specication.

The motor speed is not constant and

decreases under a load or with lower

voltage. For voltage, the wiring in a

shop is as important as the motor’s

horsepower rating.

2. A line intended only for lights cannot

properly carry a power tool motor.

Wire that is heavy enough for a short

distance will be too light for a greater

distance. A line that can support one

power tool may not be able to support

two or three tools.

WARNING: Risk of electrical

shock. Improper electrical

grounding can result in

electrical shock. The wiring

should be done by a qualied

electrician.

ELECTRICAL SAFETY

1. Avoid body contact with grounded

surfaces such as pipes, radiators, ranges,

and refrigerators. There is an increased risk

4

Page 5

Safety Information (continued)

WARNING: Risk of electrical

shock. Electrical wiring must

be located away from hot

surfaces such as manifold

assembly, compressor outlet

tubes, heads, or cylinders.

CAUTION: Improper electrical

installation of this product may

void its warranty and your re

insurance. Have circuit wiring

such as a licensed electrician

performed by qualied personnel

who is familiar with the current

national electrical code and any

prevailing local electrical codes.

A qualied electrician needs to know the

following before wiring:

1. The amperage rating of the electrical

box should be adequate. Refer to the

Specications for this information.

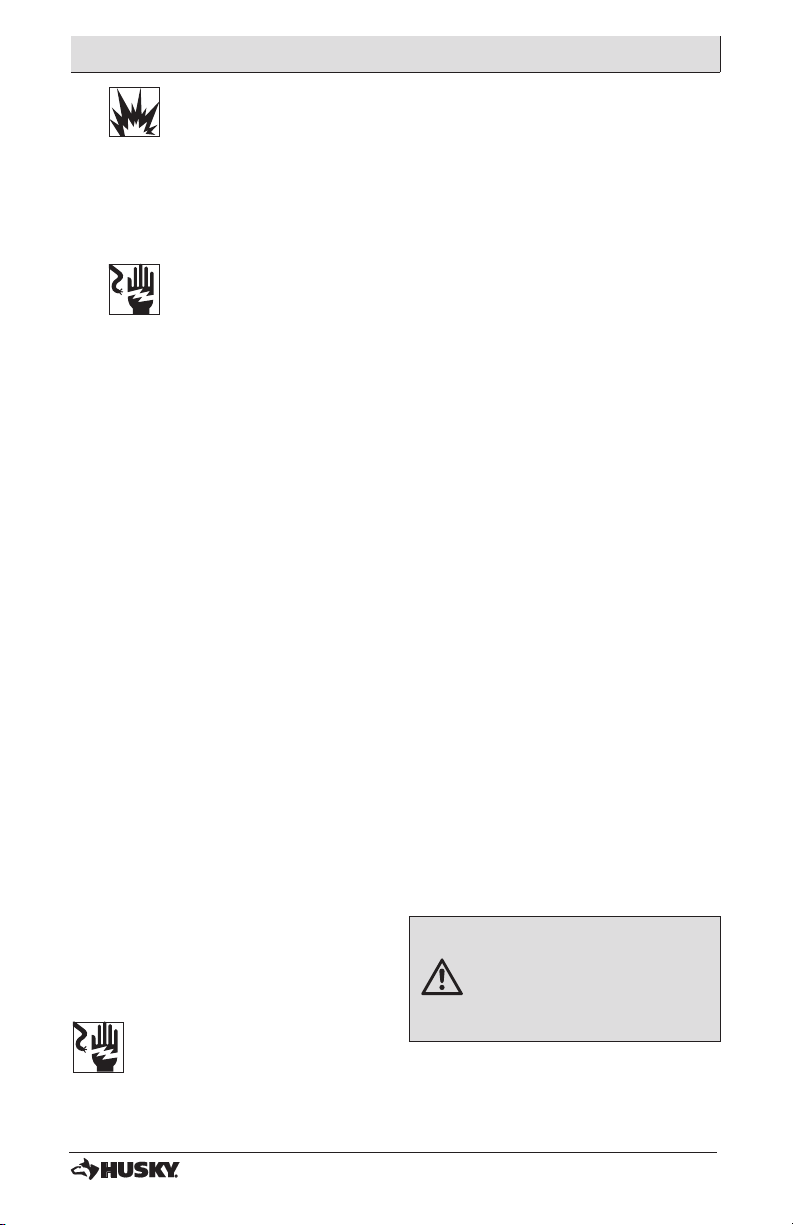

Air Distribution System

WARNING: Risk of bursting.

Plastic or PVC pipe is not

designed for use with

compressed air. Regardless of

its indicated pressure rating,

plastic pipe can burst from air

pressure. Use only metal pipe

for air distribution lines.

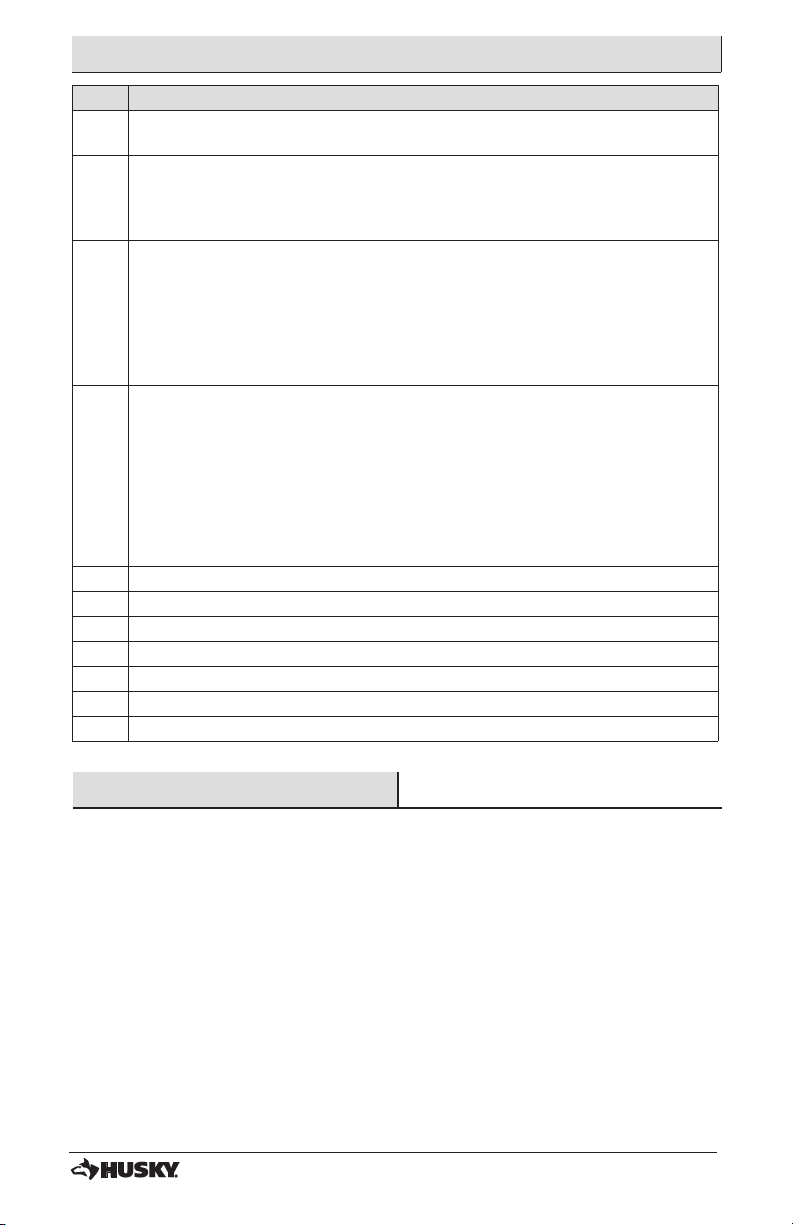

Figure 1 represents a typical air distribution

system. The following are tips to remember

when setting up the air compressor’s air

distribution system.

NOTICE: Compressed air from

oil lube air compressors will

contain wa ter condensation

and oil mist. Several drains,

traps and lters will be needed

to supply air without water

(including aerosols) or oil to

spray equipment, air tools and

accessories requiring ltered

air. Always read the in struc tions

for the air tools and accessories

pts-205109-051012, pts-2053019-053012, pts-206067-060612

being used.

2. The supply line should have the same

electrical characteristics (voltage, cycle,

phase) as the motor. Refer to the motor

nameplate, on side of motor, for this

information.

NOTICE: The wiring used

must be rated for the motor

nameplate voltage, plus or minus

10%. Refer to local codes for

recommended wire sizes, correct

wire size, and maximum wire

run; undersize wire causes high

amp draw and overheating to the

motor.

ELECTRICAL SAFETY

(GROUNDING INSTRUCTIONS)

This product should be connected to a

metallic, permanent wiring system, or an

equipment-grounding terminal or lead on

the product.

• Usepipethatisthesamesizeastheair

tank outlet. Piping that is too small will

restrict the ow of air.

• Ifpipingisover100’(30.5m)long,use

the next larger size.

• Buryundergroundlinesbelowthe

frost line and avoid pockets where

condensation can gather and freeze.

Apply pressure before underground

lines are covered to make sure all pipe

joints are free of leaks.

• Aexiblecouplingisrecommended

to be installed between the globe

valve/air discharge outlet and main air

distribution line to allow for vibration.

• Aseparateregulatorisrecommended

to control the air pressure. Air pressure

from the tank is usually too high for

individual air driven tools.

5

Please contact 1-888-43-HUSKY for further assistance.

HUSKYTOOLS.COM

Page 6

Air Distribution System (continued)

• DONOTinstalllubricatorsbetweenthe

tank and any spray equipment, air tool or

accessory requiring oil-free ltered air.

FIGURE 1

AIR FLOW

• Drainalltraps,ltersanddirtlegsdaily.

FEEDER LINES SLOPE

WITH AIR FLOW

AIR FLOW

LUBRICATOR

DRAIN

LEGS

DRAIN

VALVES

AIR

TOOL

REGULATOR

FILTER /

MOISTURE

TRAP

AIR USAGE

LINES

DIRT

LEGS

DRAIN

VALVES

AIR DISCHARGE VALVE

FLEXIBLE

COUPLING

COMPRESSED AIR

DISTRIBUTION

5 MICRON

.01 MICRON

FILTER

FOR BEST PERFORMANCE

the distance between the

compressor and the

moisture trap should be as

long as possible

TYPICAL

SYSTEM

MAIN DISTRIBUTION AIR LINES

Slope pipe in dir

W

bottom of pipe to drain legs,

preventing it from entering feeder

lines.

FILTER

REGUL ATOR

BALL

FILTER

FILTER /

MOISTURE

TRAP

DRAIN

VALVE

w.

SPR AY

GUN

6

Page 7

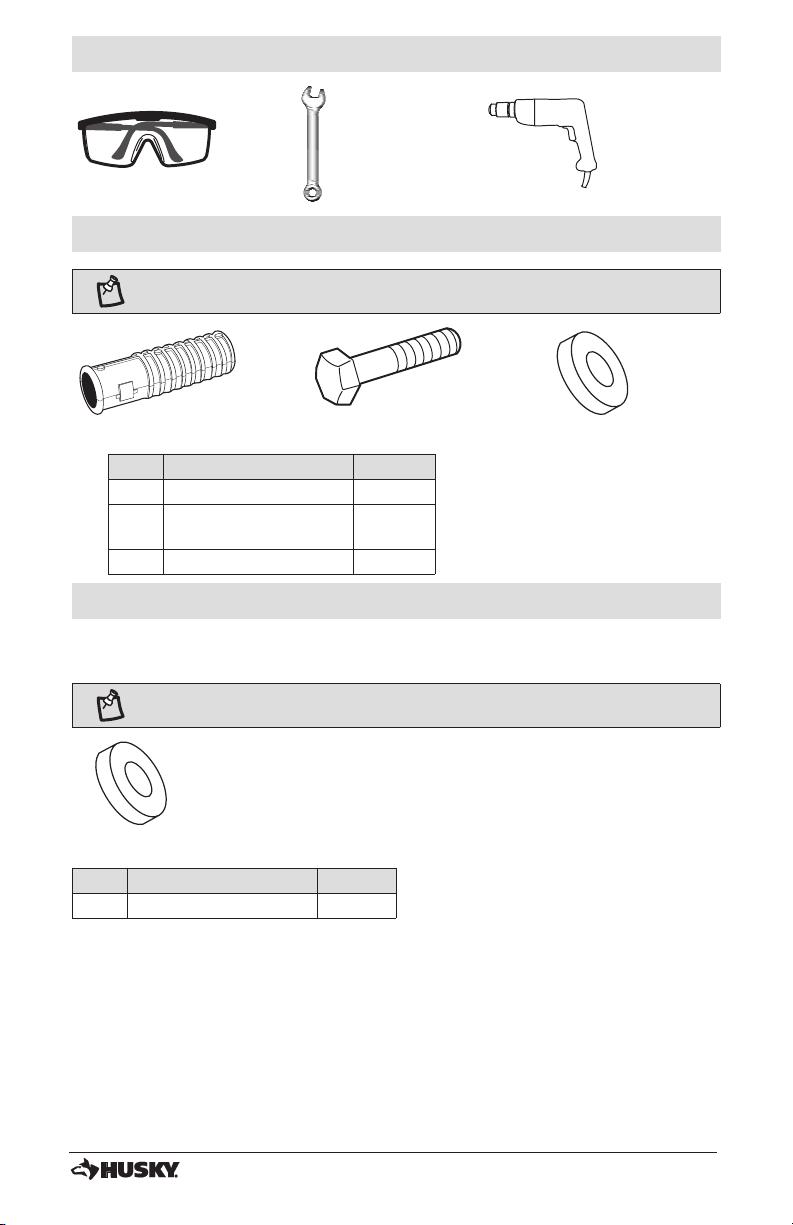

Tools Required

Safety

goggles

9/16 wrench Electric Drill

Hardware needed (for anchoring)

NOTE: Hardware not shown to actual size.

Part Description Quantity

BB Concrete Anchors 4

3/8” Lag Screw to t

CC

concrete anchors

DD Shims as needed

........BB

4

........CC

Package Contents

HARDWARE INCLUDED

NOTE: Hardware not shown to actual size.

........DD

........AA

Part Description Quantity

AA 5/8” Flatwasher 4

8

Page 8

Package Contents (continued)

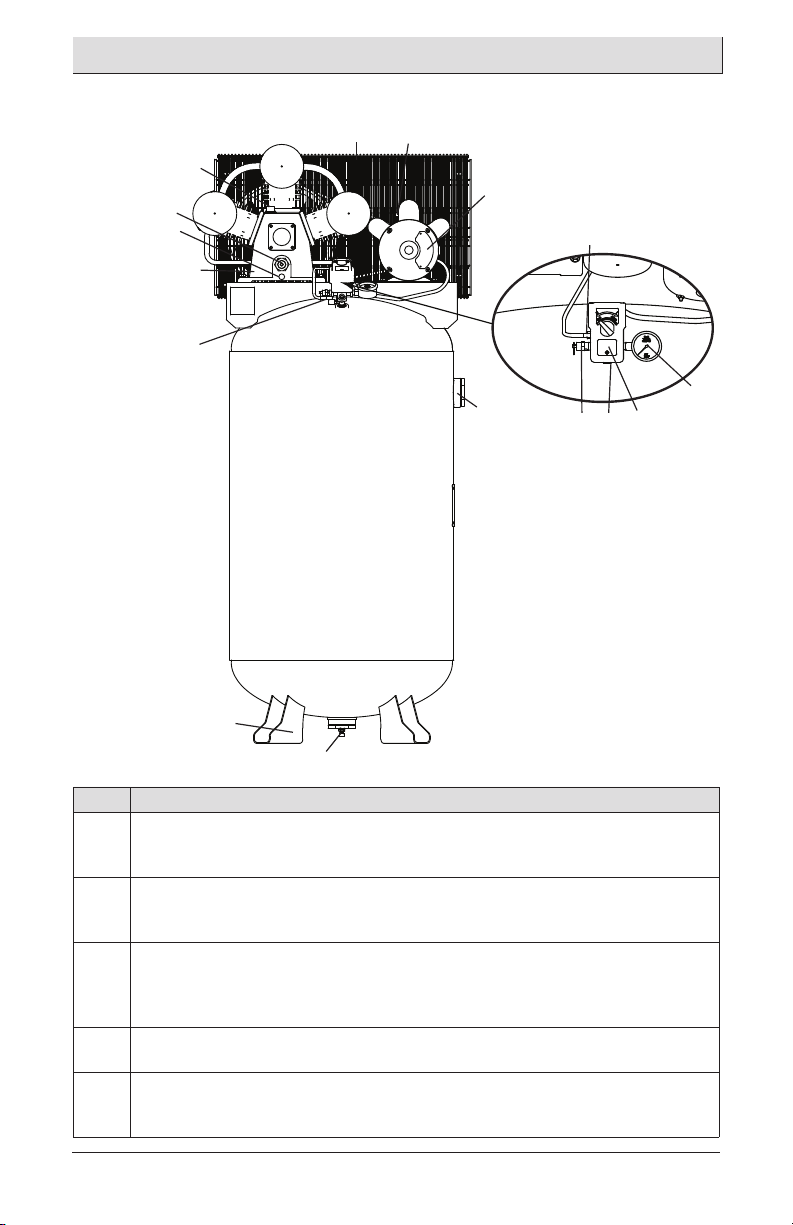

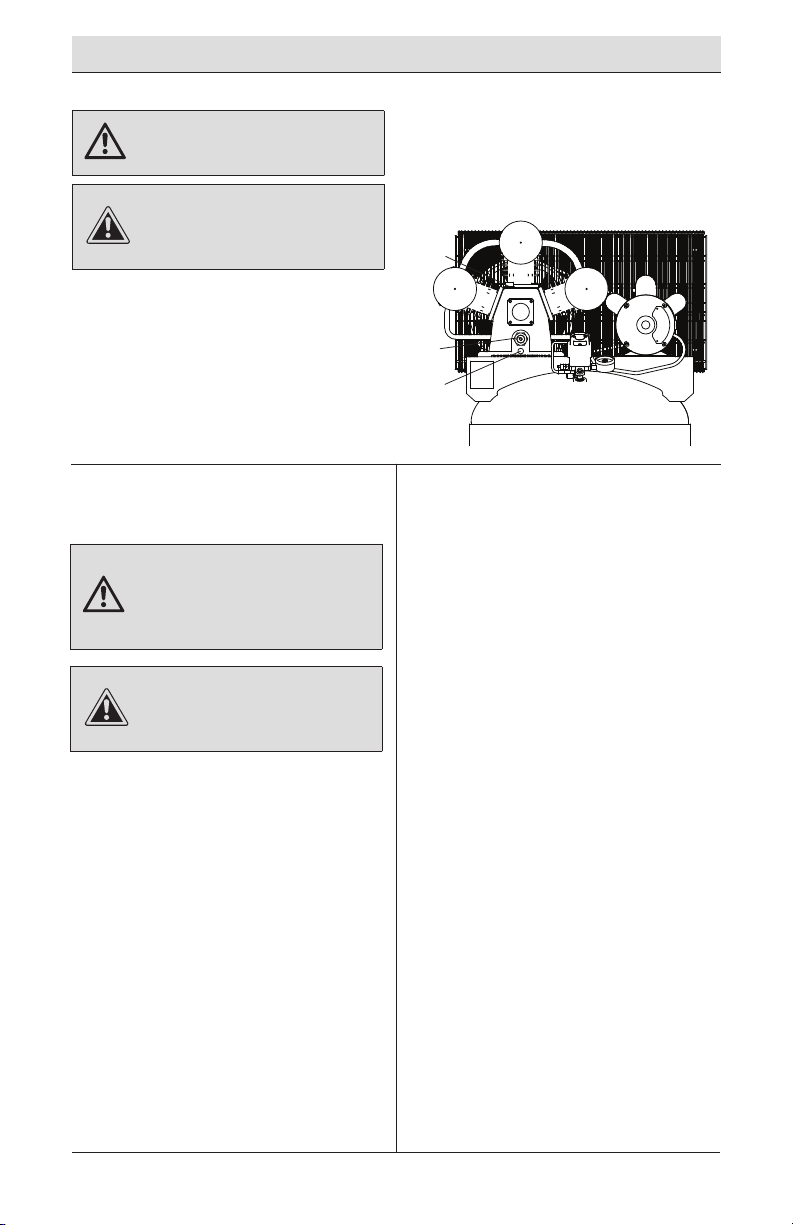

Become familiar with these controls before operating the unit (Figure 2)

I

FIGURE 2

L

N

M

E

H

FIGURE 7

K

O

P

G

D

C

A

B

Part Description

A

B

C

D

E

pts-205109-051012, pts-2053019-053012, pts-206067-060612

J

F

Auto(I)/Off(0) Switch: Turn this switch in the “Auto (I)” position to provide

automatic power to the pressure switch and “Off (O)” to remove power at the end

of each use.

Pressure Switch: The pressure switch automatically starts the motor when the air

tank pressure drops below the factory set “cut-in” pressure. It stops the motor when

the air tank pressure reaches the factory set “cut-out” pressure.

Safety Valve: If the pressure switch does not shut off the air compressor at its

“cut-out” pressure setting, the safety valve will protect against high pressure by

“popping out” at its factory set pressure (slightly higher than the pressure switch

“cut-out” setting).

Tank Pressure Gauge: The tank pressure gauge indicates the reserve air pressure

in the tank.

Air Compressor Pump: Compresses air into the air tank. Working air is not

available until the compressor has raised the air tank pressure above that required

at the air outlet.

9

Please contact 1-888-43-HUSKY for further assistance.

HUSKYTOOLS.COM

Page 9

Package Contents (continued)

Part Description

Drain Valve: The drain valve is located at the base of the air tank and is used to

F

drain condensation at the end of each use.

Check Valve: When the air compressor is operating, the check valve is “open”,

allowing compressed air to enter the air tank. When the air compressor reaches

G

“cut-out” pressure, the check valve “closes”, allowing air pressure to remain inside

the air tank.

Pressure Release Valve: The pressure release valve located on the side of the

pressure switch, is designed to automatically release compressed air from the

compressor head and the outlet tube when the air compressor reaches “cut-out”

H

pressure or is shut off. The pressure release valve allows the motor to restart freely.

When the motor stops running, air will be heard escaping from this valve for a few

seconds. No air should be heard leaking when the motor is running or after the unit

reaches “cut-out” pressure.

Motor Overload Reset: This motor has a manual thermal overload protector. If the

motor overheats for any reason, the overload protector will shut off the motor. The

motor must be allowed to cool down before restarting. To restart:

1. Place the Auto/Off switch in the “Off” position.

I

2. Allow the motor to cool.

3. Depress the red reset button on the motor.

4. Place the Auto/Off switch in the “Auto” postion to restart the motor.

J Compressor Feet

K Belt Guard

L Pump Oil Fill

M Pump Oil Drain

N Pump Oil Sight Glass

O Motor

P Air Outlet

Assembly

Location of the air

1

compressor

1. Locate the air compressor in a clean,

dry, and well ventilated area.

2. Located the air compressor at least

18 in. (0.5m) away from the wall or

other obstructions that will interfere

with the ow of air.

3. Locate the air compressor as

close to the main power supply as

possible to avoid using long lengths

of electrical wiring. NOTE: Long

lengths of electrical wiring could

cause power loss to the motor.

4. The air lter must be kept clear of

obstructions which could reduce air

ow to the air compressor.

10

Page 10

Assembly (continued)

Anchoring of the air

2

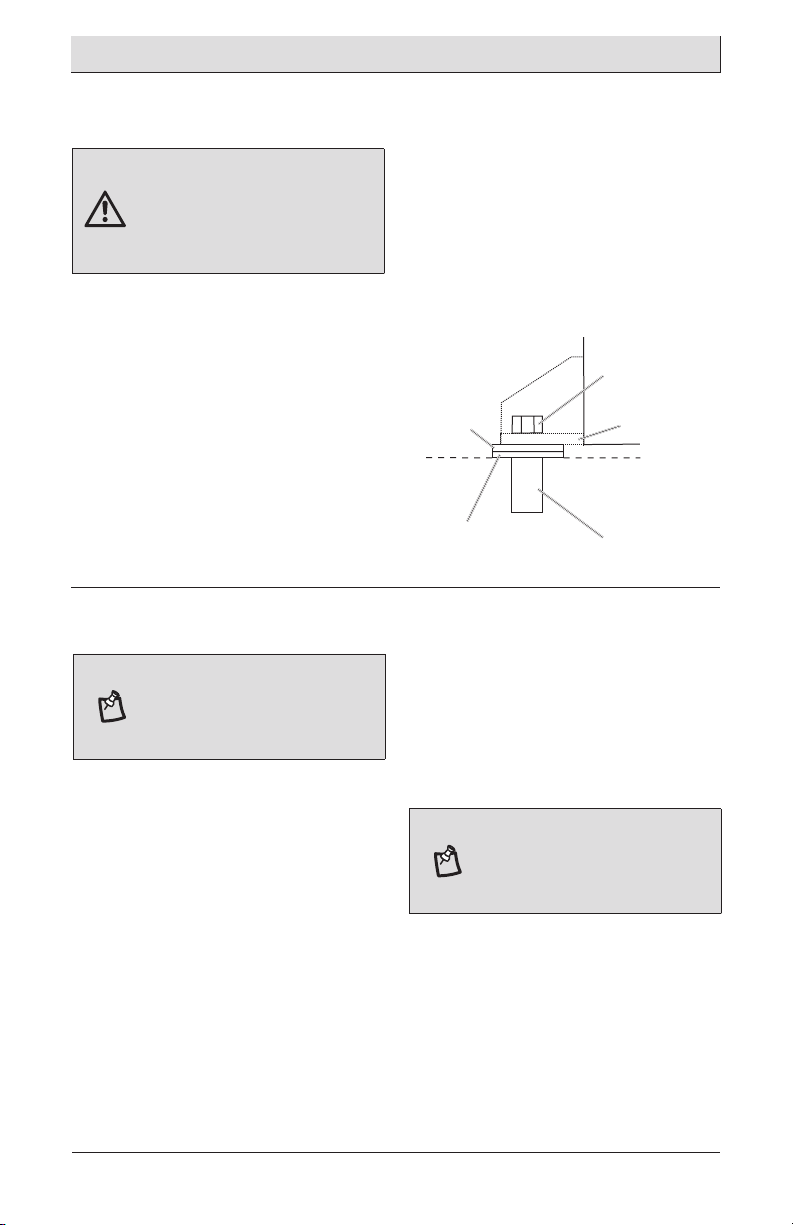

compressor (Figure 3)

WARNING: Risk of bursting.

Excessive vibration can

weaken the air tank and

cause an explosion. The

compressor must be properly

mounted.

The air compressor MUST be bolted to a level,

solid concrete surface. Use 3/8” lag screws,

washers (supplied) and concrete anchors. If

help is needed anchoring the air compressor

consult a licensed contractor.

1. Place the air compressor on a level,

solid concrete surface. Make sure the

concrete is in good condition with no

cracks or damage.

2. Mark the surface using the holes in the

air compressor feet (J) as a template.

3. Drill holes in the surface for the concrete

anchors. Install concrete anchors (BB).

Breaking in the pump

3

NOTICE: Risk of property

damage. Serious damage may

result if the following breakin instructions are not closely

followed.

This procedure is required before the air

compressor is put into service and when the

check valve or a complete compressor pump

has been replaced.

1. Make sure the Auto/Off switch (A) is in

the “Off” position.

2. Check oil level in pump. See Oil

paragraph in the Maintenance

section for instructions.

3. Recheck all wiring. Make sure wires

are secure at all terminals connections.

Make sure all contacts move freely and

are not obstructed.

4. Open the drain valve (F) fully to permit

air to escape and prevent air pressure

build up in the air tank during the

pts-205109-051012, pts-2053019-053012, pts-206067-060612

break-in period.

4. Line-up holes in surface with holes in

air compressor feet (J).

5. Place the washers (AA, supplied)

between the oor and air compressor

feet, see gure. If needed use shims

(DD) to level the unit.

6. Place the 3/8” lag screws (CC) through

the air compressor feet (J), washers

(AA) and into the anchors (BB).

7. Torque 3/8” lag screws to 7-10 ft.-lbs

(9.5-13.5 Nm).

FIGURE 3

AA

(supplied)

DD

(not supplied)

5. Move the Auto/Off switch (A) to “Auto”

position. The compressor will start.

6. Run the air compressor for 20 minutes.

Make sure the drain valve and all

air lines are open so there is only a

minimal air pressure build-up in tank.

7. Check all air line ttings and connections/

piping for air leaks by applying a soap

solution. Correct if necessary.

NOTICE: Minor leaks can

cause the air compressor to

overwork, resulting in premature

breakdown or inadequate

performance.

8. Check for excessive vibration. Readjust

or shim air compressor feet, if necessary.

9. After 20 minutes, close the drain valve.

The air receiver will ll to “cut-out”

pressure and the motor will stop.

The air compressor is now ready for use.

11

Please contact 1-888-43-HUSKY for further assistance.

(not supplied)

CC

(not supplied)

J

Surface Line

BB

HUSKYTOOLS.COM

Page 11

Operation

Draining the tank

1

(Figure 2, 4)

WARNING: Risk of unsafe

operation. Air tanks contain high

pressure air. Keep face and other

body parts away from outlet

of drain. Use eye protection

[ANSI Z87.1 (CAN/CSA Z94.3)]

when draining as debris can be

kicked up into face.

WARNING: Risk from noise.

Use ear protection (ANSI

S12.6 (S3.19) as air ow noise

is loud when draining.

WARNING: Risk of bursting.

Water will condense in the

air tank. If not drained, water

will corrode and weaken the

air tank causing a risk of air

tank rupture.

NOTICE: Risk of property

damage. Drain water from air

tank may contain oil and rust

which can cause stains.

NOTICE: All compressed air

systems generate condensate that

accumulates in any drain point (e.g.,

tanks, lter, aftercoolers, dryers). This

condensate contains lubricating oil

and/or substances which may be

regulated and must be disposed of

in accordance with local, state, and

federal laws and regulations.

NOTICE: If drain valve is

plugged, release all air pressure.

The valve can then be removed,

cleaned, then reinstalled.

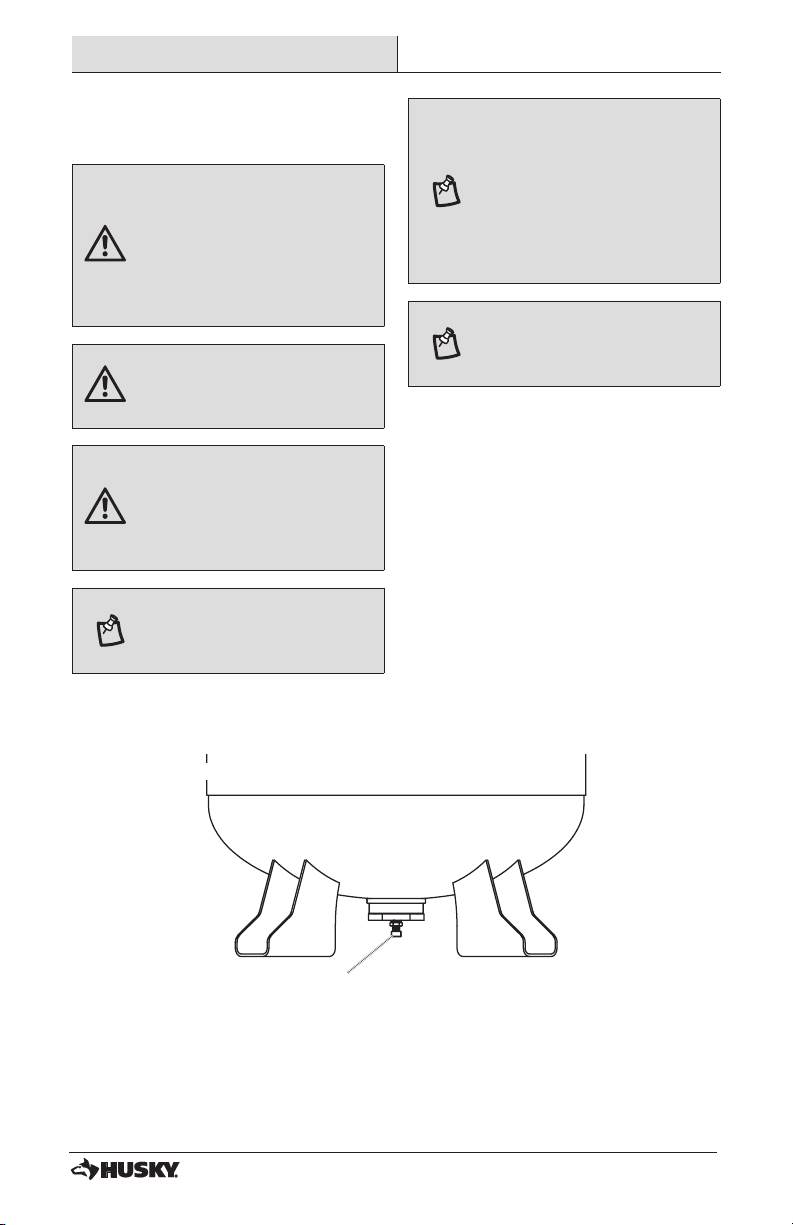

1. Set the Auto/Off switch (A, Figure 2) to

“Off”.

2. Slowly bleed the air from the air tank

and air distribution system until tank

pressure is approximately 20 psi.

3. Drain water from air tank by opening

drain valve (F) on bottom of tank.

4. After the water has been drained, close

the drain valve. The air compressor can

now be stored.

FIGURE 4

F

12

Page 12

Operation (continued)

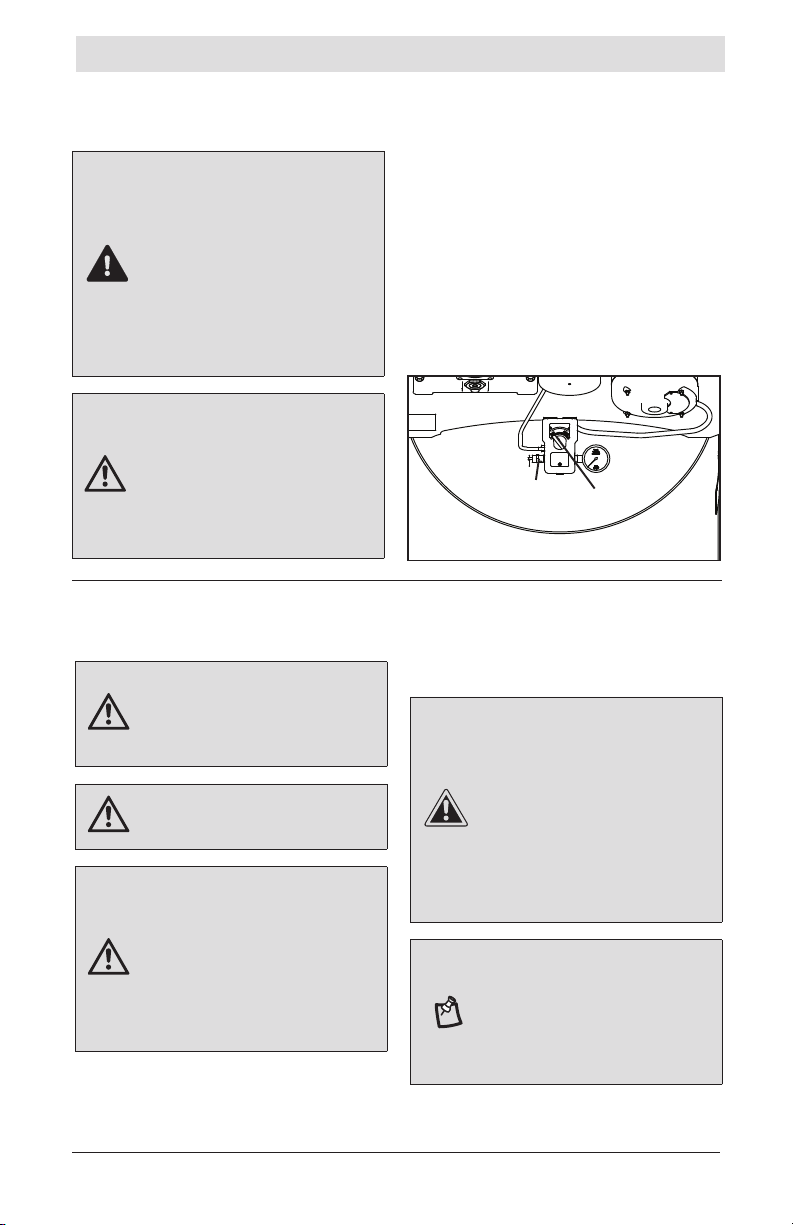

Checking the safety valve

2

(Figure 5)

DANGER: Do not tamper with the

safety valve. Items loosened from

this device could y up and hit

you. Failure to heed this warning

could result in death or serious

personal injury. The safety valve

automatically releases air when

the receiver pressure exceeds the

preset maximum. Check the valve

before each day of use by pulling

the ring by hand.

WARNING: If air leaks after

releasing the safety valve ring

or if the valve is stuck, do not

use the air compressor until the

safety valve has been replaced.

Using the air compressor in this

condition could result in serious

personal injury.

Before each start-up

3

(Figure 5)

WARNING: Risk of unsafe

operation. Firmly grasp air

hose in hand when installing

or disconnecting to prevent

hose whip.

WARNING: Risk of unsafe

operation. Do not use

damaged or worn accessories.

WARNING: Risk of bursting.

Too much air pressure causes

a hazardous risk of bursting.

Check the manufacturer’s

maximum pressure rating

for air tools and accessories.

The regulator outlet pressure

must never exceed the

maximum pressure rating.

1. Place Auto/Off switch (A, Figure 5) to

“Off”.

2. Close the air discharge outlet.

pts-205109-051012, pts-2053019-053012, pts-206067-060612

1. Set the Auto/Off switch (A) to “On”. and

wait for the tank to ll. The compressor

automatically shuts off when the pressure

reaches the preset maximum.

2. Set the Auto/Off switch (A) to “Off”.

3. Pull the ring on the safety valve (C) for

20 seconds to release the air.

4. Release the ring. Air stops escaping at

about 20 psi. If air continues to escape

after releasing the safety valve ring,

discontinue use and seek service before

using the air compressor again.

FIGURE 5

C

3. Visually inspect air lines and ttings for

leaks.

4. Check safety valve. See Checking the

Safety Valve paragraph.

CAUTION: Risk of unsafe

operation. Compressed air

from the unit may contain

wa ter condensation and oil

mist. Do not spray un l tered

air at an item that could be

13

damaged by moisture. Some

air tools and accessories may

require ltered air. Read the

in struc tions for the air tools

and accessories.

NOTICE: A regulator MUST be

installed when using accessories

rated at less than 135 psi.

The hose or accessory will require

a quick connect plug if the air

outlet is equipped with a quick

connect socket.

Please contact 1-888-43-HUSKY for further assistance.

A

HUSKYTOOLS.COM

Page 13

Operation (continued)

How to start (Figure 2)

4

1. Turn the Auto/Off switch (A, Figure2))

to “Auto” and allow tank pressure

to build. Motor will stop when tank

pressure reaches “cut-out” pressure.

2. When the tank pressure reaches “cutout” pressure open the air discharge

valve.

Maintenance

GENERAL MAINTENANCE

Condensate forms in the tank when

there is humidity in the air. Depending

on the environmental conditions, drain

the condensate daily and/or every hour.

For instructions, see Draining the tank

paragragh under Operation.

The safety valve automatically releases air

when the receiver pressure exceeds the

preset maximum.

Inspect the tank annually for rust, pin holes,

or other imperfections that could cause it to

become unsafe.

Avoid using solvents when cleaning plastic

parts. Most plastics are susceptible to

damage from various types of commercial

solvents and may be damaged by their use.

Use clean cloths to remove dirt, dust, oil,

grease, etc.

WARNING: Risk of bursting. If

any unusual noise or vibration

is noticed, stop the air

compressor immediately and

have it checked by a trained

service technician.

NOTICE: When using regulator

and other accessories refer to the

manufacturers instructions.

WARNING: Do not allow brake

uids, gasoline, petroleum based

products, etc., to come in contact

with plastic parts. Chemicals can

weaken or destroy plastic which,

may result in serious personal

injury.

WARNING: When servicing, use

only identical Husky replacement

parts. Use of any other parts may

create a hazard or cause product

damage.

WARNING: Always disconnect

the air compressor from the

power supply, release all

pressure, and allow it to cool

before cleaning or making repairs

on the air compressor.

Oil (Figure 6)

1

NOTICE: Risk of property

damage. Use air compressor oil

only. Multi-weight automotive

engine oils like 10W30 should

not be use in air compressors.

They leave carbon deposits

on critical components, thus

reducing performance and

compressor life.

NOTE: Use 30W compressor oil or a heavy

duty SAE 30W, non-detergent, SF grade

or better oil. DO NOT use multi-weight

automotive engine oils, they will reduce

compressor life. Under extreme winter

condition use SAE-10 weight oil.

NOTE: Crankcase oil capacity is

approximately 29 uid ounces (857,6 ml).

Checking

1. The oil level should be to the middle of

the sight glass (N).

2. If needed remove oil ll plug (L) and

slowly add oil until it reaches the

middle of the sight glass.

14

Page 14

Maintenance (continued)

Changing

WARNING: Drain tank to release

air pressure before removing the

oil ll cap or oil drain plug.

CAUTION: Overlling with

oil will cause premature air

compressor failure. Do not

1. Remove the oil ll plug (L).

2. Remove the oil drain plug (M) and drain

3. Replace the oil drain plug (M) and

4. Slowly add compressor oil until it reaches

overll.

oil into a suitable container.

tighten securely

the middle of the sight glass (N).

Air Filter

2

WARNING: Hot surfaces. Risk

of burn. Compressor heads are

exposed when lter cover is

removed. Allow compressor to

cool prior to servicing.

CAUTION: Keep the air lter

clean at all times. Do not operate

the air compressor with the air

lter removed.

NOTE: When lling the crankcase, the

oil ows very slowly into the pump. If the

oil is added too quickly, it will overow

and appear to be full.

5. Replace oil ll plug (L) and tighten securely.

FIGURE 6

L

N

M

BELT GUARD – REMOVAL

3

1. Turn air compressor off, lock out

the power supply, and relieve all air

pressure from the air tank.

2. Remove the 4 quarter turn fasteners

from the belt guard. The front belt guard

can now be lifted up and away from unit.

A dirty air lter will not allow the air

compressor to operate at full capacity. Keep

the air lter clean at all times.

1. Remove the air lter cover.

2. Remove the air lter from lter cover.

4. Place new air lter into lter cover.

5. Replace air lter cover to pump.

pts-205109-051012, pts-2053019-053012, pts-206067-060612

15

Please contact 1-888-43-HUSKY for further assistance.

HUSKYTOOLS.COM

Page 15

Maintenance (continued)

Belt - Replacement

4

WARNING: Serious injury or

damage may occur if parts of

the body or loose items get

caught in moving parts. Never

operate the outt with the belt

guard removed. The belt guard

should be removed only when

the air compressor power is

disconnected.

1. Turn air compressor off, lock out

the power supply, and relieve all air

pressure from the air tank.

2. Remove the belt guard.

3. Mark pump position on saddle.

4. Loosen the motor mounting screws

and slide the motor toward the air

compressor.

5. Remove the belt and replace with a new

one.

6. See the Adjust Belt Tension before

tightening motor mounting screws.

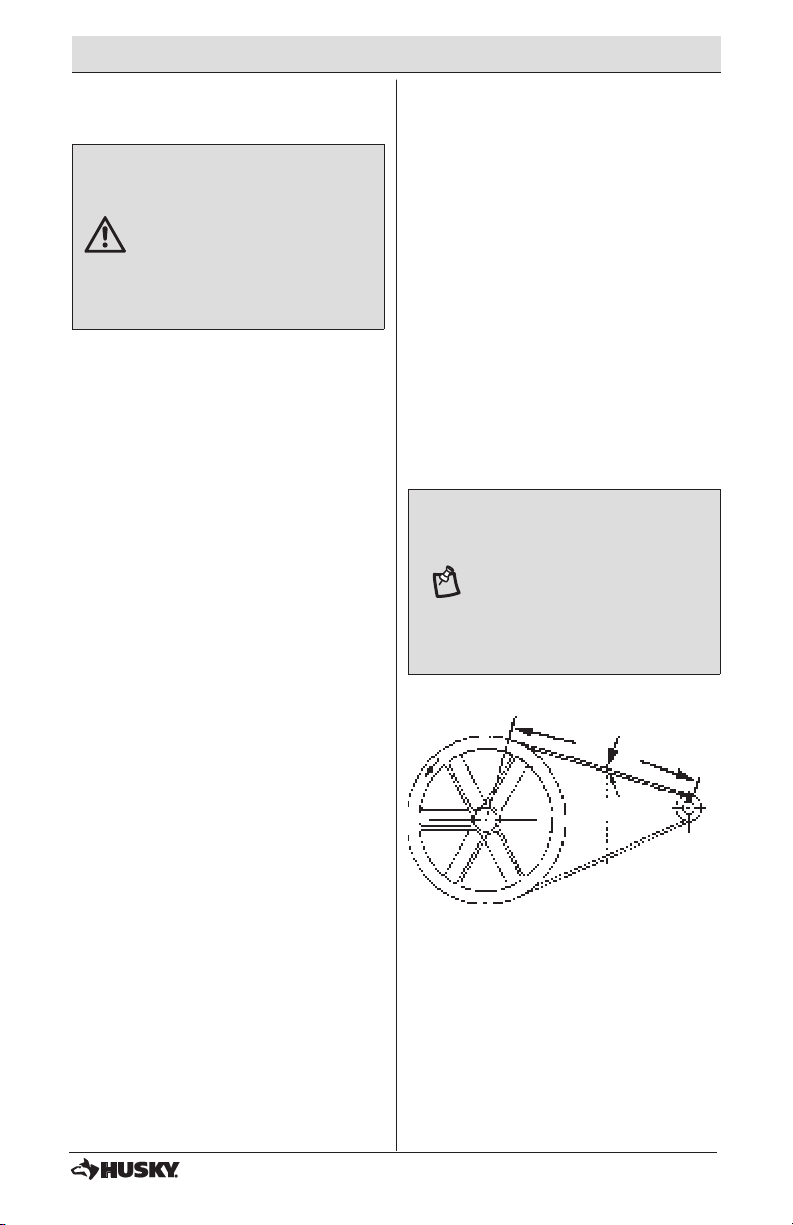

Adjusting Belt Tension

5

(Figure 7)

1. Slide motor into original position, line

the motor up with the mark made

earlier on saddle.

2. Tighten two outside motor mounting

screws enough to hold the motor in

place for checking pulley and ywheel

alignment.

3. The belt should deect 3/16” (4.8mm)

at midway between the pulley and the

ywheel when a 5 pound (2.26kg.)

weight is applied at the midway point.

4. When proper belt tension is achieved,

tighten all four motor mounting screws.

Torque to 20-25 ft-lbs

(27.1–33.9 Nm).

NOTICE: Once the engine

pulley has been moved from its

factory set location, the grooves

of the ywheel and pulley must

be aligned to within 1/16”

(1.6mm) to prevent excessive

belt wear. Verify the alignment by

performing the following Pulley

and Flywheel - Alignment.

16

FIGURE 7

Downward Force

Deection

Page 16

Maintenance (continued)

Motor Pulley/Flywheel

6

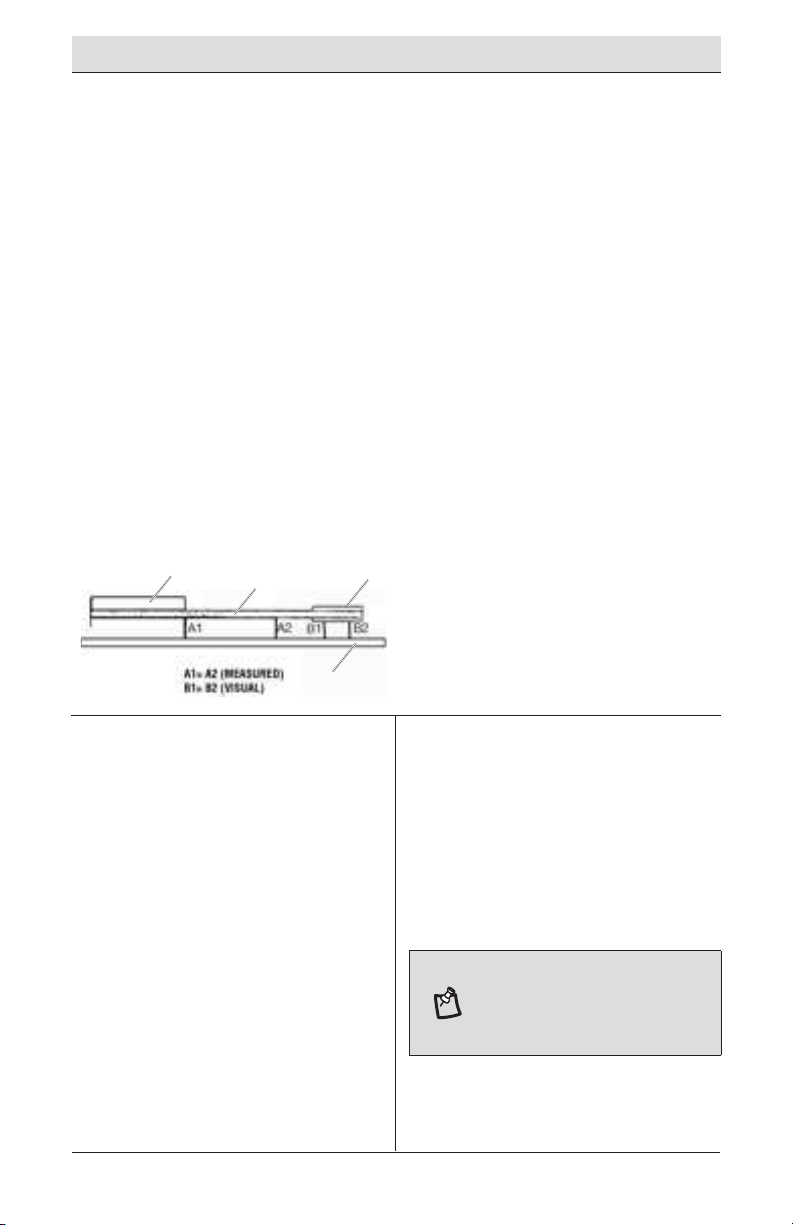

Alignment (Figure 8)

The air compressor ywheel and motor pulley

must be in-line (in the same plane) within

1/16” (1.6 mm) to assure belt retention within

ywheel belt grooves. To check alignment,

perform the following steps:

1. Turn air compressor off, lock out

the power supply, and relieve all air

pressure from the air tank.

2. Remove belt guard.

3. Place a straightedge (S) against the

outside of the ywheel (P) and the

motor drive pulley (R).

4. Measure the distance between the edge

of the belt (Q) and the straightedge

at points A1 and A2 in gure. The

difference between measurements

should be no more than 1/16” (1.6 mm).

FIGURE 8

P

Q R

5. If the difference is greater than 1/16”

(1.6 mm) loosen the set screw holding

the motor drive pulley (R) to the shaft

and adjust the pulley’s position on the

shaft until the A1 and A2 measurements

are within 1/16” (1.6 mm) of each other.

6. Tighten the motor drive pulley set screw.

7. Visually inspect the motor drive pulley

to verify that it is perpendicular to the

drive motor shaft. Points B1 and B2 of

Figure should appear to be equal. If

they are not, loosen the setscrew of the

motor drive pulley and equalize B1 and

B2, using care not to disturb the belt

alignment performed in step 2.

8. Retighten the motor drive pulley

setscrew. Torque to 145–165 in lbs

(16.4–20.3Nm).

9. Reinstall belt guard.

Air Compressor Pump

7

Intake and Exhaust Valves

Once a year bring the compressor to a service

center. and have a Trained Service Technician

check the air compressor pump intake and

exhaust valves.

pts-205109-051012, pts-2053019-053012, pts-206067-060612

S

INSPECT AIR LINES AND

8

FITTINGS FOR LEAKS

1. Turn air compressor off, lock out

the power supply, and relieve all air

pressure from the air tank.

2. Apply a soap solution to all air line

ttings and connections/piping.

3. Correct any leaks found.

NOTICE: Even minor leaks can

cause the air compressor to

overwork, resulting in premature

breakdown or inadequate

performance.

17

Please contact 1-888-43-HUSKY for further assistance.

HUSKYTOOLS.COM

Page 17

Maintenance (continued)

Air compressor Head

9

Bolts - Torquing

The air compressor pump head bolts should

be kept properly torqued. Check the torques

of the head bolts after the rst ve hours of

operation.

Torque to 14–16ft.-lbs. (19.0–21.7 Nm).

10

Disassembly or service of the air compressor

beyond what is covered in this manual is

not recommended. If additional service is

required, contact 1-888-43-HUSKY for further

assistance.

Storage

Before you store the air compressor, make

sure you do the following:

1. Review the Maintenance section

on the preceding pages and perform

scheduled maintenance as necessary.

2. Drain water from air tank. See To Drain

Tank under Operation.

Troubleshooting

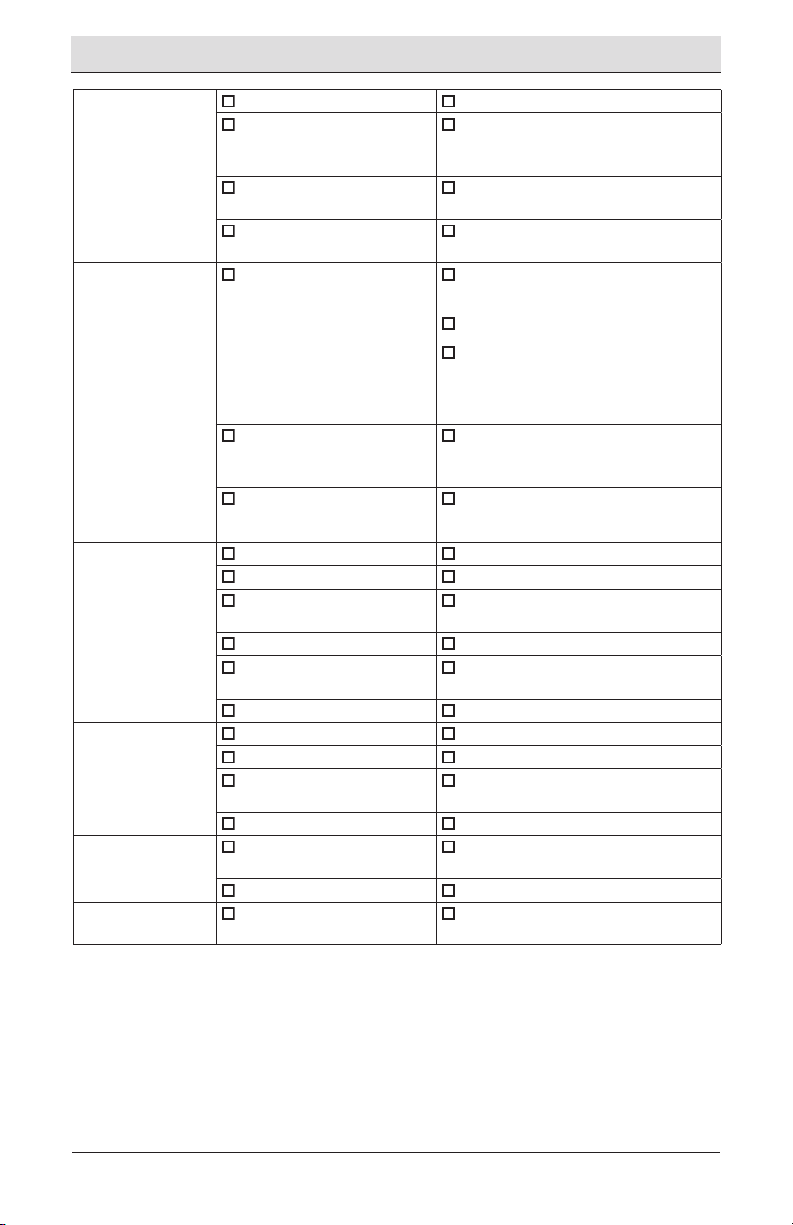

Problem Possible Cause Solution

Compressor does

not run.

Tank has insufcient

pressure.

No electrical power. Verify wiring connection inside

Blown stop/house fuse. Replace the shop/house fuse.

Tripped shop/home

breaker.

Thermal overload is open. Place the Auto/Off switch in the

Loss of power or

overheating.

Pressure switch is bad. Replace the pressure switch.

When the tank pressure drops, the

Reset the shop/home breaker and

Allow the motor to cool.

Depress the red reset button on

Place the Auto/Off switch in the

Verify wiring.

NOTE: Long lengths of electrical

Additional Service

WARNING: Water will condense

in the air tank. If not drained,

water will corrode and weaken

the air tank causing a risk of air

tank rupture.

compressor will turn on to cut-in

pressure.

pressure switch and terminal box

area.

determine the underlying cause.

“Off” position.

the motor.

“Auto” postion to restart the

motor.

wiring could cause power loss to

the motor.

18

Page 18

Troubleshooting (continued)

Motor hums but

does not run or

runs slowly.

Fuses blow or

circuit breaker trips

repeatedly.

Knocking Noise

Excessive belt wear

Squealing sound

Restricted air

intake

Low voltage. Check voltage with a voltmeter.

Loose electrical

connections.

Verify wiring connection inside

pressure switch and terminal box

area.

Shorted or open motor

winding.

Defective check valve or

unloader.

Incorrect fuse size, circuit

overload.

Bring the compressor to a service

center.

Bring the compressor to a service

center.

Verify proper fuse size is being

used.

Use time-delay fuses.

Disconnect other electrical

appliances from the circuit or

operate compressor on its own

branch circuit.

Loose electrical

connections.

Verify wiring connection inside

pressure switch and terminal box

area.

Defective check valve or

unloader.

Bring the compressor to a service

center.

Loose pulley. Tighten pulley set screw.

Loose ywheel. Tighten ywheel screw.

Compressor mounting

Tighten mounting screws.

screws loose.

Loose belt. Check belt tension.

Carbon build-up in pump. Bring the compressor to a service

center.

Belt too tight. Check belt tension.

Loose belt. Check belt tension.

Tight belt. Check belt tension.

Loose pulley. Bring the compressor to a service

center.

Pulley misalignment. Align pulley/ywheel.

Compressor pump has no

Check pump oil

oil.

Loose belt. Check belt tension.

Dirty air lter. Clean or replace air lter.

pts-205109-051012, pts-2053019-053012, pts-206067-060612

19

Please contact 1-888-43-HUSKY for further assistance.

HUSKYTOOLS.COM

Page 19

Troubleshooting (continued)

Oil and/or moisture

in tank and/or air

lines

Water condensation

Oil blow-by in pump

It is normal for oil lube air

compressor pumps to release some

oil into the tank and air lines. Air

compressors will also generate

water condensation that will form

in the tank and air lines. Install

water and oil lter traps when

needed. The Typical Compressed

Air Distribution System provides

a guideline. Contact a call Husky

Customer Service for more

information.

IMPORTANT: If the tank or air

lines have excessive water and/

or oil, bring the compressor to a

service center.

20

Page 20

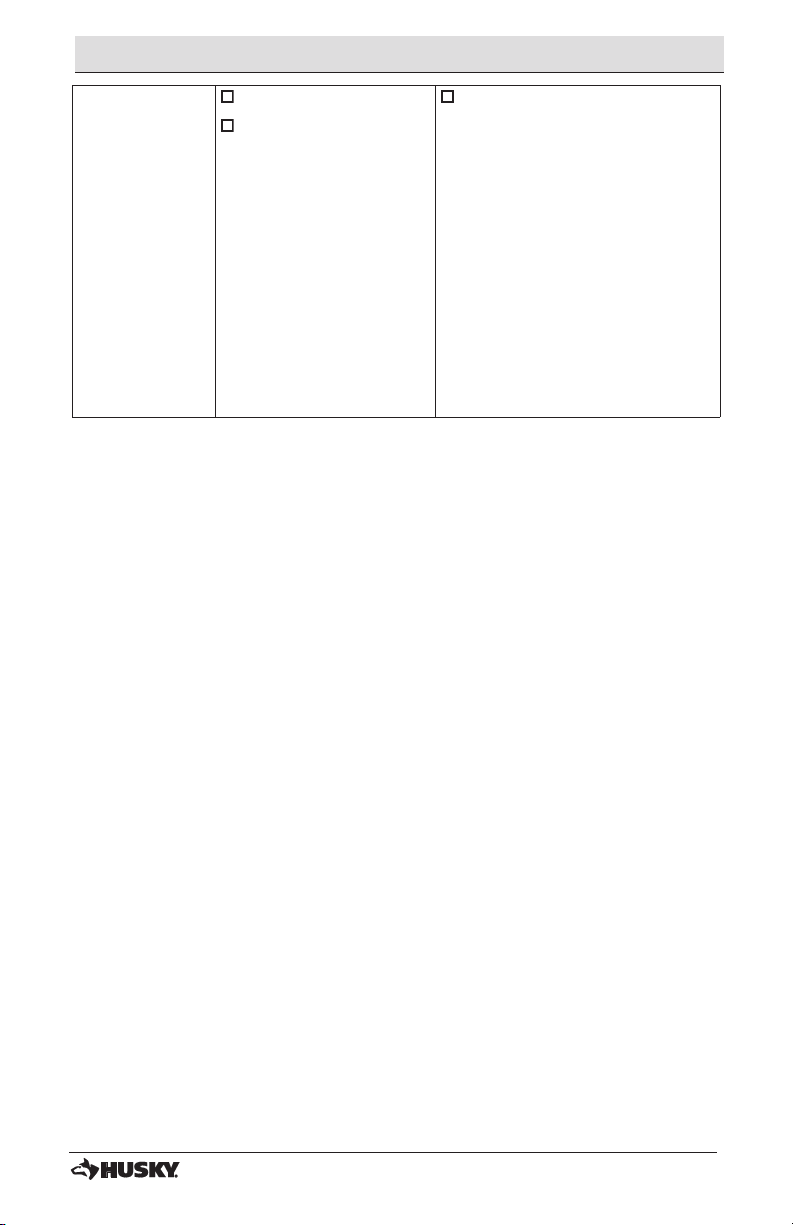

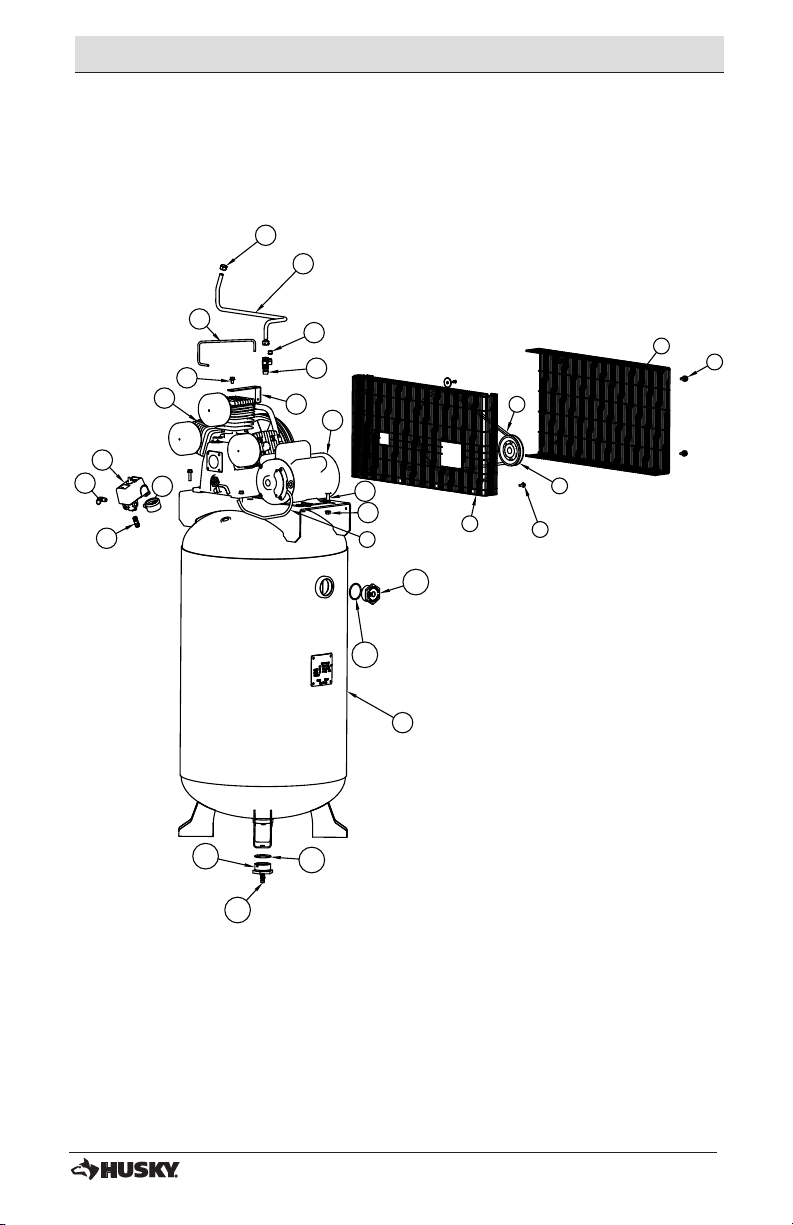

Exploded View - Motor/Pump Assembly

pts-205109-051012, pts-2053019-053012, pts-206067-060612

NOTES:

Torque to 9-12 lbs-ft

Serrez de 9 À 12 lbs-ft

Torsión hasta 12,2-16,3 N•m

Torque to 14-16 lbs-ft

Serrez de 14 À 16 lbs-ft.

Torsión hasta 19,0-21,7 N•m

Torque to 97 lb-in. ± 10

Serrez de 97 lbs-in. ± 10

Torsión hasta 11,0 N•m ± 10

21

Please contact 1-888-43-HUSKY for further assistance.

HUSKYTOOLS.COM

Page 21

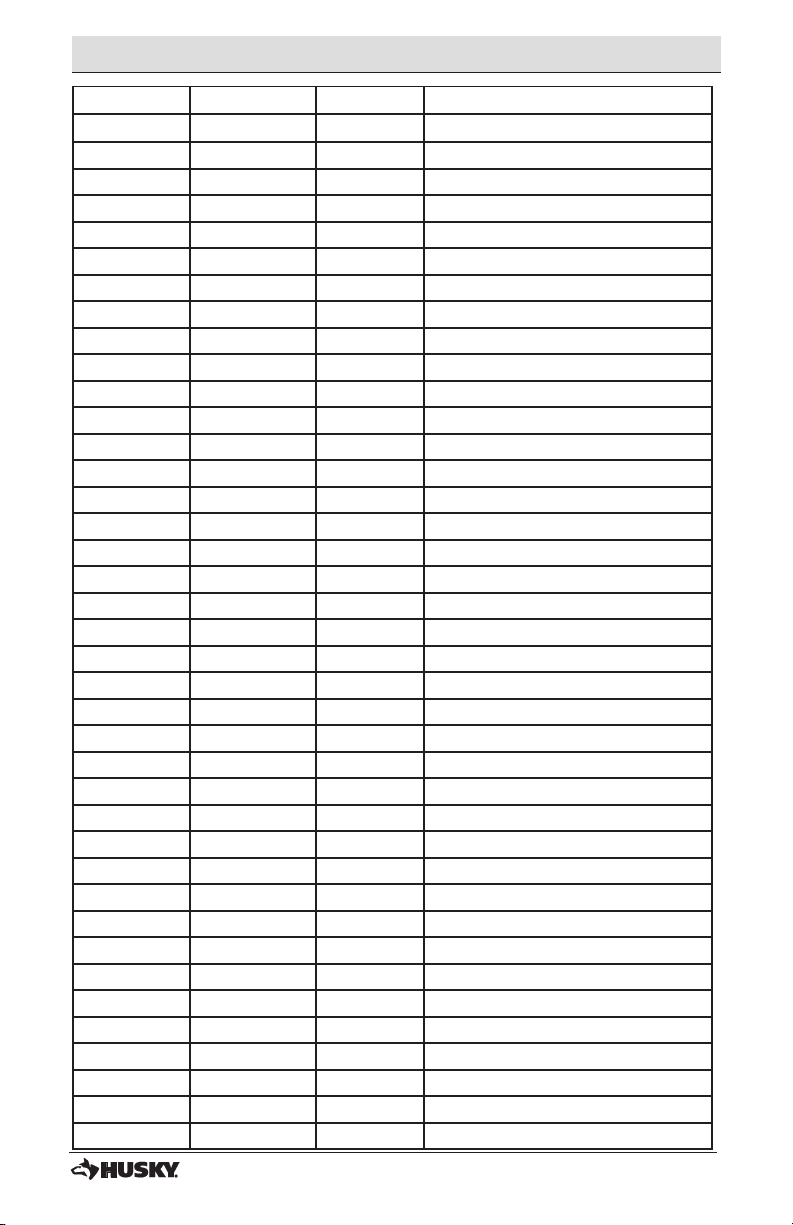

Parts List - Motor/Pump Assembly

ITEM NUMBER PART NUMBER QUANTITY DESCRIPTION

1 NA 12 SCREW, M8 X 65

2 NA 12 WASHER, M8

3 042-0117 3 HEAD

4 019-0222 3 FILTER CANISTER ASSEMBLY (includes item 4A)

4A 019-0221 3 ELEMENT, FILTER REPLACEMENT

7 058-0016 1 COMPRESSION NUT

8 069-0025 1 TEE FITTING

9 145-0447 2 FINNED TUBE (includes item 10 - qty. 2)

10 NA 4 AIRFLOW NUT

11 069-0024 1 TEE FITTING

12 064-0077 1 ELBOW

13 046-0286 3 GASKET, HEAD TO VALVE PLATE

14 043-0194 3 VALVE PLATE ASSEMBLY

15 046-0287 3 GASKET, VALVE PLATE TO CYLINDER

16 NA 12 NUT, M8

17 NA 12 STUD, M8*22

18 NA 23 LOCK WASHER, M8

19 050-0062 3 CYLINDER

20 046-0288 3 GASKET, CYLINDER TO CRANKCASE

21 054-0241 3 RING SET

22 048-0117 3 PISTON ASSEMBLY

23 047-0094 1 ROD (MIDDLE)

23A 056-0068 1 OIL DIPPER, STRAIGHT

24 047-0095 2 ROD (OUTER)

24A 056-0069 2 OIL DIPPER, BEND

25 056-0070 1 OIL FILL PLUG

26 NA 4 SCREW, M6 X 18

27 NA 4 LOCKWASHER, M6

28 077-0180 1 CAP, REAR END

29 046-0289 1 GASKET, REAR END

30 032-0071 1 OIL SIGHT GLASS W/ O-RING

31 NA 1 OIL DRAIN PLUG, 3/8˝ NPT

32 049-0051 1 CRANKCASE

33 051-0099 2 BEARING

34 053-0105 1 CRANKSHAFT, EXTENDED

35 146-0026 1 KEY, 5MM X 20MM

36 046-0290 1 OIL SEAL

37 046-0291 1 GASKET, CARRIER

38 077-0181 1 CARRIER

22

Page 22

Parts List - Motor/Pump Assembly (cont)

ITEM NUMBER PART NUMBER QUANTITY DESCRIPTION

39 056-0071 1 BREATHER (includes item 40)

40 NA 1 BREATHER WASHER, 22MM DIA

41 NA 4 SCREW, M8 X 20

42 044-0063 1 FLYWHEEL, 12˝ A GROOVE

43 060-0183 1 FLYWHEEL WASHER

44 NA 1 SCREW, M8 X 35

NA: These are standard parts available at your local hardware store.

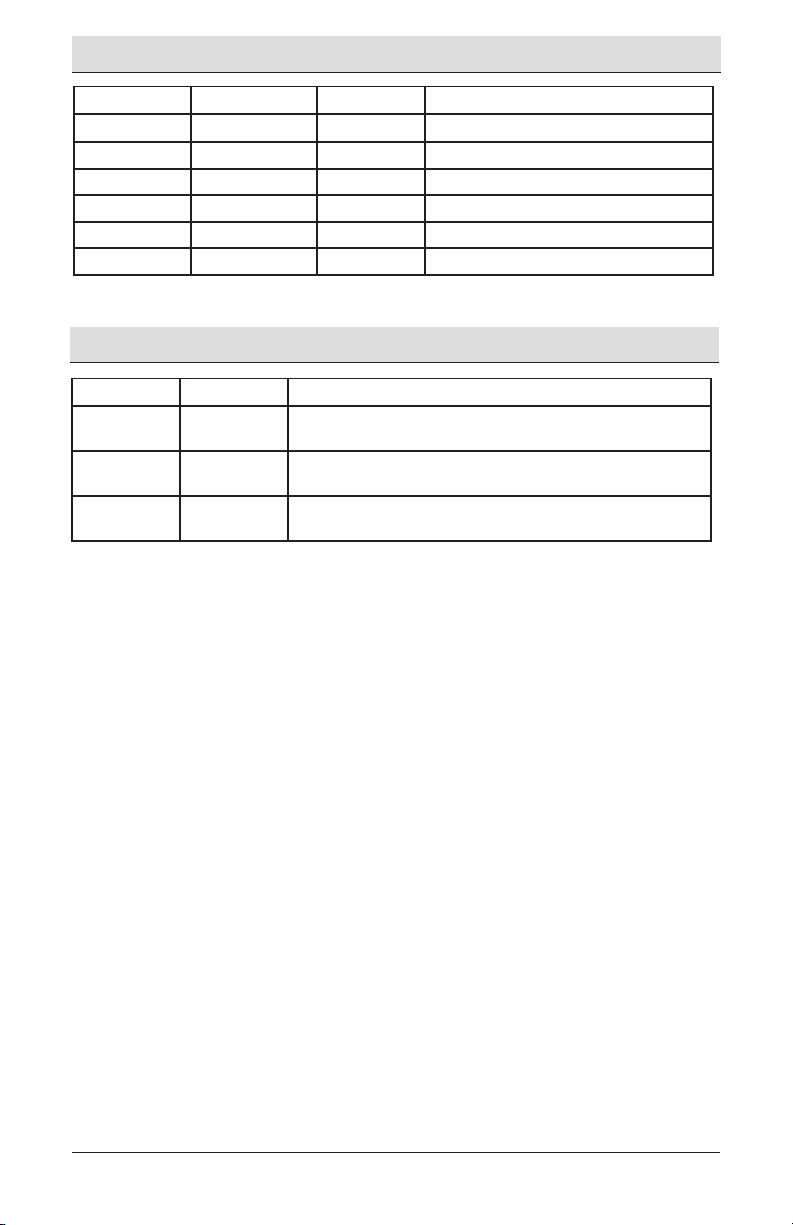

Kits Available

KIT # PART # DESCRIPTION

45 046-0292 GASKETS, COMPLETE SET

46 165-0265 OVERHAUL KIT

040-0348 PUMP ASSEMBLY

(includes items 13,15, 20, 29, 36 and 37)

(includes items 13, 14, 15, 20, 21, 29, 37 and 4A)

(includes items 1-41)

pts-205109-051012, pts-2053019-053012, pts-206067-060612

23

Please contact 1-888-43-HUSKY for further assistance.

HUSKYTOOLS.COM

Page 23

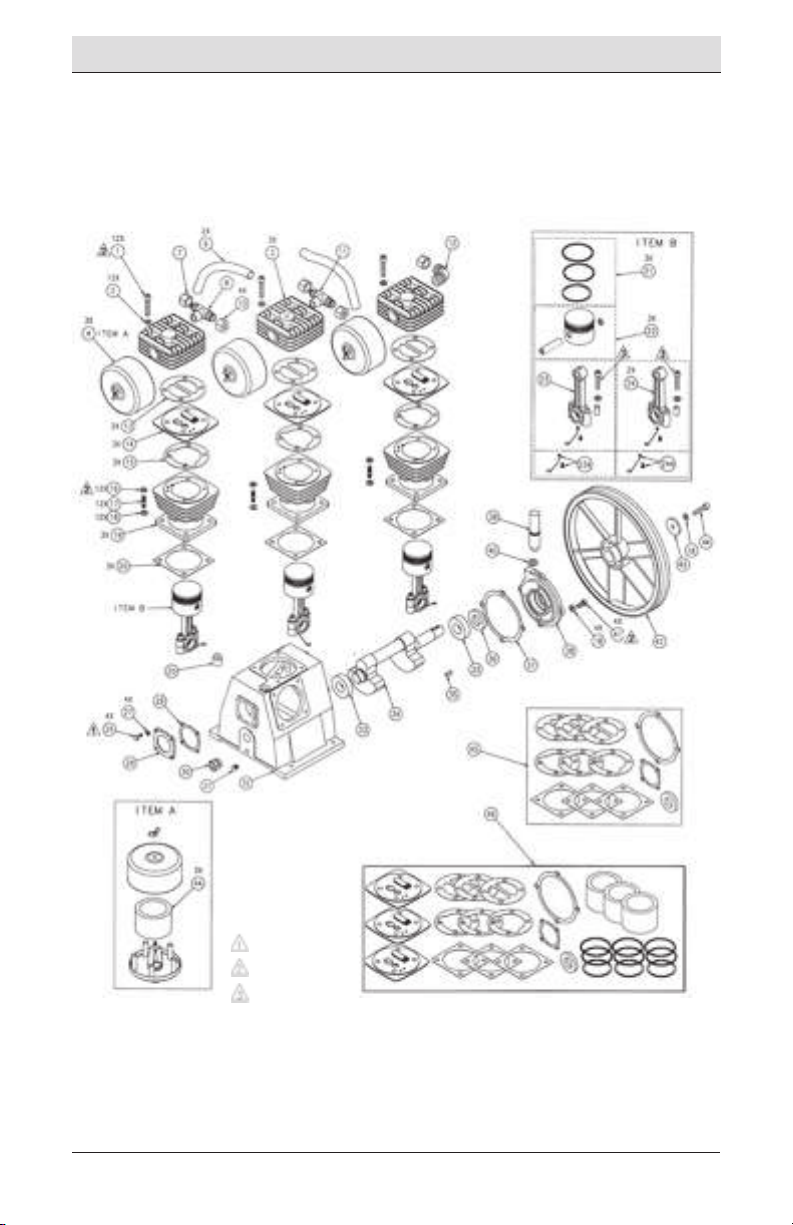

Exploded View - Unit Assembly

15

17

18

14

13

20

22

23

21

12B

16

19

25

24

10

11

9

12A

12D

12

12D

7

8

4

3

1

2

12C

24

Page 24

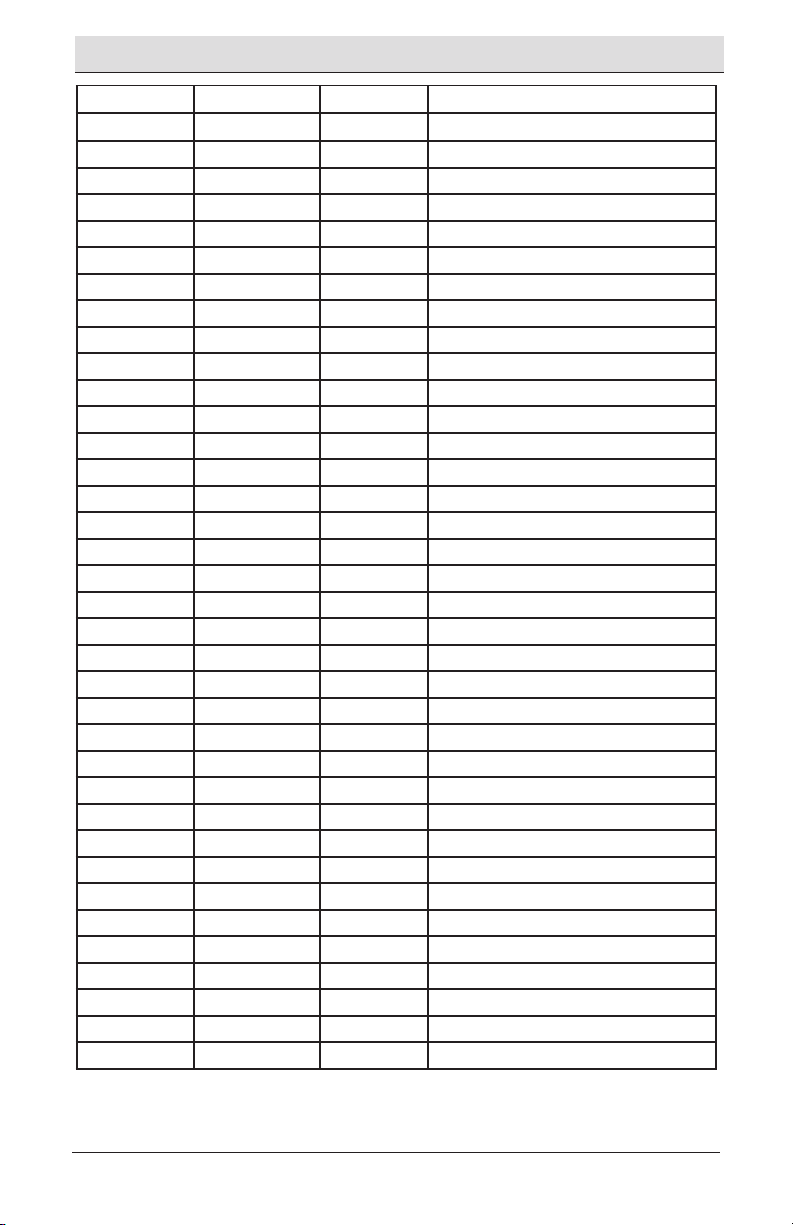

Parts List - Unit Assembly

ITEM NUMBER PART NUMBER QUANTITY DESCRIPTION

1 E106014 1 BELTGUARD (OUTER)

2 NA 5 1/4 TURN FASTENER

3 NA 9 BOLT, 1/4-20 X .75 THR FORM

4 E106015 1 BELTGUARD (INNER)

5 NA 2 SETSCREW

6 NA 1 KEY 5MM X 20MM

7 E106019 1 BELT 4L-540 "A" SECTION

8 E106020 1 PULLEY

9 E106021 1 CORD INTERCONNECT

10 NA 4 BOLT 5/16-18 X .75

11 NA 4 NUT 5/16-18 UNC

12 E106022 1 TANK ASSEMBLY PAINTED

12A E105993 1 BUSHING 2" NPSM X 3/8" NPT

12B E105994 1 BUSHING 2" NPSM X 1/4" NPTF

12C NA 1 1/4" NPT DRAIN VALVE

12D E105995 2 O-RING 2"

13 E106023 1 PUMP ASSEMBLY 755H

14 NA 1 BOLT 5/16-18 X .50 UNC

15 E106024 1 1/2" OD TUBE COMPRESSION NUT ASSEMBLY

16 E105999 1 1/4" OD TUBE COMPRESSION NUT ASSEMBLY

17 E106025 1 OUTLET TUBE

18 E106026 1 PRESSURE RELIEF TUBE

19 E106027 1 CHECK VALVE 1/2" NPT X 3/8" OD TUBE

20 E106003 1 PRESSURE SWITCH

21 NA 1 NIPPLE 1/4" NPT-18 X 2.00

22 E106004 1 VALVE, ASME 175 PSI

23 E106005 1 GAUGE 300 PSI 1/4" NPT SIDE MOUNT

24 E106028 1 MOTOR

24A E106029 1 START CAPACITOR

24B E106030 1 RUN CAPACITOR

24C E106031 1 START CAPACITOR COVER

24D E106032 1 RUN CAPACITOR COVER

25 E106033 1 BRACKET BELTGUARD PAINTED

26 E106011 1 WARNING LABEL

27 E106012 1 HOT SURFACE WARNING LABEL

28 E106013 1 DRAIN TANK WARNING LABEL

NA: These are standard parts available at your local hardware store.

pts-205109-051012, pts-2053019-053012, pts-206067-060612

25

Please contact 1-888-43-HUSKY for further assistance.

HUSKYTOOLS.COM

Page 25

Questions, problems, missing parts? Before returning to the store call

Husky Customer Service

8 a.m. - 6 p.m., EST, Monday-Friday

1-888-43-HUSKY

HUSKYTOOLS.COM

Retain this manual for future use.

Document Number: E105555

Page 26

Page 27

Page 28

GUIDE D’UTILISATION

ET D’ENTRETIEN

COMPRESSEUR D’AIR FIXE DE 227

LITRES (60 GALLONS)

Questions, problèmes, pièces

manquantes? Avant de retourner

au magasin, veuillez communiquer avec le service à la clientèle

Husky entre 8h00 et 18h00, HNE,

du lundi au vendredi au

Article # 911625

Modèle # C601H

1-888-43-HUSKY

HUSKYTOOLS.COM

Nous vous remercions d’avoir fait conance à Husky en achetant ce compresseur d’air xe de 227 litres (60

gallons). Nous nous efforçons en permanence de créer des produits de qualité conçus pour perfectionner

votre maison. Vous pouvez visiter notre site en ligne pour consulter notre gamme complète de produits

pour vos besoins de rénovation résidentielle. Merci d’avoir choisi Husky!

MERCI

Page 29

Table des matières

Consignes de sécurité ........................ 2

Sécurité de l’aire de travail .............2

Sécurité de l’utilisateur ..................3

Transport ........................................3

Sécurité du compresseur d’air et des

outils pneumatiques .......................4

Sécurité électrique ..........................4

Sécurité électrique

(Branchements électriques) ............5

Sécurité électrique

(Vitesse et câblage) ........................5

Sécurité électrique

(Instructions de mise à la terre) ......5

Système de distribution d’air ............. 6

Consignes de sécurité

Ce guide contient des informations qu’il vous

est important de connaître et de comprendre.

Ces informations ont trait à VOTRE SÉCURITÉ et à la PRÉVENTION DES PROBLÈMES

D’ÉQUIPEMENT. Pour vous aider à identifier

ces informations, nous utilisons les symboles

ci-dessous. Veuillez lire ce guide et prêter

particulièrement attention à ces symboles.

DANGER : Indique une situation

imminément dangereuse qui, si

elle n’est pas évitée, résultera

en mort d’homme ou des

blessures graves.

MISE EN GARDE : Indique

une situation potentiellement

dangereuse qui, si elle n’est

pas évitée, pourrait résulter

en mort d’homme ou des

blessures graves.

ATTENTION : Indique une situation

potentiellement dangereuse qui,

si elle n’est pas évitée, pourrait

résulter en blessures mineures

ou modérées.

AVIS: Indique une pratique non

associée à des blessures, qui, si elle

n’est pas évitée, pourrait résulter

en des dommages matériels.

Garantie .............................................. 7

Caractéristiques.................................. 8

Cycle de service .................................. 8

Outils requis ....................................... 9

Quincaillerie requise (pour l’ancrage) 9

Contenu de l’emballage ..................... 9

Quincaillerie fournie .......................9

Assemblage ...................................... 11

Utilisation ......................................... 14

Entretien ........................................... 16

Entreposage ..................................... 21

Dépannage ....................................... 22

SÉCURITÉ DE L’AIRE DE TRAVAIL

1. Gardez l’aire de travail propre et bien

éclairée. Faites en sorte que les sols ne

soient pas glissants du fait de cire ou de

poussière.

2. N’utilisez pas d’outil

électrique en présence

de vapeurs explosives,

comme celles dégagées par des liquides,

des gaz ou des poussières inammables.

Les outils électriques produisent des

étincelles qui peuvent mettre le feu à la

poussière ou aux vapeurs. Éloignez les

curieux, les enfants et les visiteurs

pendant que vous utilisez des outils. Une

distraction peut vous faire perdre le

contrôle de l’outil.

3. Utilisez le compresseur d’air dans un

espace ouvert à une distance d’au

moins 0,5 m (18 po) de tout mur ou

objet qui pourrait limiter le ux d’air

frais aux orices de ventilation.

4.

5. Ce compresseur/pompe n’est

Débranchez toujours l’alimentation

en air et l’alimentation en courant

électrique avant tout réglage,

entretien d’un outil ou lorsque l’outil n’est

pas utilisé.

pas équipé(e) et ne devrait pas

2

Page 30

Consignes de sécurité (suite)

être utilisé(e) pour fournir de l’air

respirable. Des équipements

supplémentaires seraient nécessaires

pour ltrer et purier l’air correctement

an de satisfaire les critères minimaux de

l’air respirable de Grade D tels que

décrits dans la norme Commodity

Specication G 7.1 établie par la

Compressed Gas Association - 1966,

OSHA 29 CF9 1910.134. Compressed

Gas Association, 4221 Walney Road, Fifth

Floor, Chantilly, VA 20151-2923, (703)

788-2700, www.cganet.com. Un

équipement supplémentaire de ce type

n’a pas été étudié et aucune implication

d’utilisation correcte pour de l’air

respirable n’est voulue ou sous-entendue.

SÉCURITÉ DE L’UTILISATEUR

MISE EN GARDE : L’utilisation

de n’importe quel outil électrique

peut entraîner la projection d’objets

étrangers dans les yeux, ce qui peut

occasionner des blessures oculaires

graves. Avant de commencer

l’utilisation, mettez toujours des

lunettes protectrices, des lunettes de

sécurité munies d’écrans latéraux

ou un masque protecteur complet

si nécessaire. Utilisez toujours une

protection oculaire portant une

étiquette indiquant qu’elle est

conforme à la norme ANSI Z87.1.

MISE EN GARDE : Ce produit

contient des produits chimiques,

reconnus par l’état de Californie

comme pouvant causer le cancer,

des anomalies congénitales ou

d’autres dommages aux fonctions

reproductrices. Lavez vos mains

après avoir manipulé l’outil.

1. Portez un équipement

de protection. Portez

toujours des lunettes

de protection avec des écrans latéraux

lorsque vous utilisez des outils

électriques. Vous devez porter un

masque anti-poussière, des chaussures

de sécurité anti-dérapantes, un casque

de sécurité ou des protecteurs

pts-205109-051012, pts-2053019-053012, pts-206067-060612

auriculaires en fonction des conditions.

2. Demeurez vigilant lorsque

vous utilisez un outil

électrique. N’utilisez pas

l’outil si vous êtes fatigué ou lorsque

vous avez consommé de la drogue, de

l’alcool ou des médicaments.

3. Évitez de porter des

vêtements amples ou

des bijoux. Attachez

les cheveux longs. Gardez les cheveux,

les vêtements et les gants à l’écart des

pièces mobiles. Les vêtements amples,

bijoux ou cheveux longs pourraient se

prendre dans les pièces mobiles.

4. Campez fermement vos pieds au sol et

gardez votre équilibre en tout temps.

Un appui stable et un bon équilibre

permettent de mieux contrôler l’outil

dans des situations inattendues.

5. N’utilisez pas l’outil sur une échelle ou

sur une surface instable.

6. Ne touchez jamais les pièces en

métal exposées sur le

compresseur pendant ou

immédiatement après utilisation. Le

compresseur restera chaud pendant

plusieurs minutes après son utilisation.

Ne touchez à rien derrière les écrans

protecteurs et ne tentez aucun entretien

sans avoir laissé à l’appareil le temps de

refroidir.

8. Le compresseur est trop lourd

pour être soulevé par une seule

personne. Faites-vous aider par

d’autres personnes avant de soulever.

TRANSPORT

1. Placez toujours le compresseur

sur un petit tapis de protection

lors de son transport pour

protéger le véhicule contre tout

dommage dû à des fuites. Retirez le

compresseur du véhicule immédiatement

une fois arrivé à destination.

2. Transportez et entreposez toujours

l’appareil dans la position verticale.

3

Veuillez composer le 1 888 43-HUSKY pour

une assistance supplémentaire.

HUSKYTOOLS.COM

Page 31

Consignes de sécurité (suite)

SÉCURITÉ DU COMPRESSEUR

D’AIR ET DES OUTILS

PNEUMATIQUES

MISE EN GARDE : Ne tentez pas

de modier cet outil ou de créer

des accessoires dont l’utilisation

n’est pas recommandée avec

cet outil. Une telle altération

ou modication est considérée

comme une utilisation

inappropriée et risque de créer

une situation dangereuse pouvant

entraîner des blessures graves.

ATTENTION : N’utilisez pas

l’outil dans un environnement

qui est poussiéreux ou contaminé

d’une façon quelconque. Toute

1. Gardez les compresseurs aussi éloignés

2. Risque d’éclatement. Ne réglez

3. Si branché sur un circuit protégé par des

4. Pour réduire le risque de choc

5. Assurez-vous que le tuyau exible n’est pas

6. Utilisez le compresseur d’air seulement

utilisation du compresseur d’air

dans un environnement de ce type

pourrait endommager l’appareil.

que possible de la zone de pulvérisation,

soit à 4,5 m (15 pi) au moins de la zone

de pulvérisation et de toutes vapeurs

explosives..

pas le régulateur d’une manière

telle que la pression de sortie

soit supérieure à la pression maximale

indiquée sur l’accessoire. Ne l’utilisez

pas à une pression supérieure à la

pression maximale homologuée de ce

compresseur.

fusibles, utilisez des fusibles temporisés

avec ce produit.

électrique, ne l’exposez pas à la

pluie. Entreposez-le à l’intérieur.

obstrué et ne présente aucun accroc. Des

tuyaux exibles emmêlés ou enchevêtrés

peuvent vous faire perdre l’équilibre ou

tomber et pourraient être endommagés.

aux ns pour lesquelles il a été conçu.

N’altérez pas et ne modiez pas

l’appareil par rapport à sa conception

ou sa fonction originale. Ne soudez

ni ne percez jamais des trous dans le

réservoir d’air.

7. Ne laissez jamais l’outil sans surveillance

avec le tuyau exible d’air raccordé.

8. N’utilisez pas cet outil s’il ne présente pas

une étiquette de mise en garde lisible.

9. Ne continuez pas à utiliser un outil ou

un tuyau exible avec une fuite d’air ou

qui ne fonctionne pas correctement.

10. Ne tentez pas de tirer ou de porter le

compresseur d’air par le tuyau exible.

11. Votre outil peut consommer plus d’air que

ce compresseur d’air est capable de fournir.

12. Ne dirigez jamais un jet d’air comprimé

vers une personne ou un animal.

13. Protégez vos poumons. Portez un

masque protecteur ou un masque

anti-poussière si l’utilisation est

poussiéreuse.

14. N’utilisez pas ce compresseur d’air

pour pulvériser des produits chimiques.

Vos poumons peuvent être abîmés par

l’inhalation de vapeurs toxiques. Porter un

masque ltrant peut s’avérer nécessaire

dans les environnements poussiéreux ou

lors de la pulvérisation de peinture.

SÉCURITÉ ÉLECTRIQUE

1. Évitez tout contact corporel avec les

surfaces mises à la terre, telles que

conduites, radiateurs, cuisinières

et réfrigérateurs. Le risque de choc

électrique est accru si votre corps est

mis à la terre.

2. N’exposez pas les outils électriques à la

pluie ou à des conditions mouillées. Les

risques de choc électrique sont plus élevés

si de l’eau s’inltre dans un outil électrique.

3. Remplacez tout cordon/câble endommagé

immédiatement. Les cordons/câbles

endommagés augmentent le risque de

choc électrique.

4

Page 32

Consignes de sécurité (suite)

SÉCURITÉ ÉLECTRIQUE

(BRANCHEMENTS ÉLECTRIQUES)

1. Ce compresseur d’air est alimenté par

un moteur électrique construit avec

précision. Il doit être branché sur un circuit

d’alimentation de 240 volts, 60 Hz, c.a.

uniquement (courant résidentiel normal).

2. N’utilisez pas cet outil sur du courant

continu (c.c.). Une chute de tension

importante entraînera une perte de

puissance et le moteur surchauffera. Si le

compresseur d’air ne fonctionne pas une

fois branché dans une prise de courant,

re-vériez la source de courant électrique.

SÉCURITÉ ÉLECTRIQUE

(VITESSE ET CÂBLAGE)

1. La vitesse à vide du moteur électrique

est fonction du modèle et de ses

caractéristiques. La vitesse du moteur

n’est pas constante et diminue avec une

charge ou une tension plus basse. Pour

la tension, le câblage dans un atelier

est aussi important que la puissance

nominale en chevaux-vapeur du moteur.

2. Une ligne conçue pour l’éclairage ne

peut pas correctement alimenter le

moteur d’un outil électrique. Un câble

sufsamment gros pour une courte

distance sera trop léger pour une plus

grande distance. Une ligne qui peut

alimenter un outil électrique peut ne

pas pouvoir en alimenter deux ou trois.

MISE EN GARDE : Risque de

choc électrique. Une mise à la

terre incorrecte peut entraîner

des chocs électriques. Le

câblage doit être effectué par

un électricien qualié.

MISE EN GARDE : Risque de

choc électrique. Le câblage

électrique doit être situé loin

des surfaces chaudes telles que

collecteurs, tubes de sortie, têtes

ou cylindres de compresseur.

ATTENTION : Une installation

électrique incorrecte de ce

produit peut en annuler la

garantie ainsi que votre

assurance incendie. Faites faire

qualié tel qu’un électricien

le câblage par un professionnel

accrédité qui connaît bien le code

national de l’électricité actuel

ainsi que tout code local de

l’électricité en vigueur.

Un électricien qualié doit savoir ce qui suit

avant d’effectuer le câblage :

1. L’intensité nominale de la

boîte électrique devrait être

adéquate. Consultez la section

Caractéristiques pour cette

information.

2. La ligne d’alimentation électrique

devrait avoir les mêmes caractéristiques

électriques (tension, cycle, phase)

que le moteur. Consultez la plaque

signalétique du moteur, sur le côté du

moteur, pour cette information.

AVIS : Le câblage utilisé

doit être homologué pour la

tension indiquée sur la plaque

signalétique du moteur, plus

ou moins 10 %. Consultez les

codes locaux pour les calibres

de l recommandés, le calibre

de l correct et la longueur de l

maximum; des câbles d’un trop

petit calibre causeront un débit

en ampères trop élevé et une

surchauffe du moteur.

SÉCURITÉ ÉLECTRIQUE

(INSTRUCTIONS DE MISE À LA

TERRE)

Ce produit doit être connecté à un système

de câblage en métal permanent, ou une

borne ou mise à la terre d’équipement ou un

conducteur de sortie sur le produit.

pts-205109-051012, pts-2053019-053012, pts-206067-060612

5

Veuillez composer le 1 888 43-HUSKY pour

une assistance supplémentaire.

HUSKYTOOLS.COM

Page 33

Système de distribution d’air

MISE EN GARDE : Risque

d’éclatement. Les conduites

en plastique ou en PVC

ne sont pas conçues pour

être utilisées avec de l’air

comprimé. Quelle que soit la

pression nominale indiquée,

les conduites en plastique

peuvent éclater sous la

pression de l’air. Utilisez

seulement des conduites en

métal pour distribuer l’air.

La Figure 1 représente un système type

de distribution de l’air. Voici des conseils

pratiques à se rappeler lors de l’installation

du système de distribution d’air du

compresseur d’air.

FIGURE 1

PIEDS DE

PURGE

ROBINETS

DE PURGE

DÉBIT D'AIR

AVIS: Le câblage utilisé

doit être homologué pour la

tension indiquée sur la plaque

signalétique du moteur, plus

ou moins 10 %. Consultez les

codes locaux pour les calibres

de l recommandés, le calibre

de l correct et la longueur de l

maximum; des câbles d’un trop

petit calibre causeront un débit

en ampères trop élevé et une

surchauffe du moteur.

• Utilisezuneconduitequialemême

diamètre que la sortie du réservoir d’air.

Des conduites trop étroites limiteront le

débit d’air.

PENTE DES CANALISATIONS

D'ALIMENTATION SELON LE

DÉBIT D'AIR

CANALISATIONS

D'UTILISATION D'AIR

CANALISATIONS PRINCIPALES DE DISTRIBUTION D'AIR

Penchez la conduite dans la direction du débit d'air. Le

condensat d'eau s'écoule le long du bas de la conduite

jusqu'aux pieds de purge, l'empêchant ainsi de pénétrer

dans les canalisations d'alimentation.

DÉBIT D'AIR

LUBRIFICATEUR

OUTIL

PNEUMATIQUE

AVERTISSEMENT :

RISQUE

D'ÉCLATEMENT.

TOUJOURS utiliser

des conduites et des

raccords métalliques

RÉGULATEUR

PIÈGE À

HUMIDITÉ

DU FILTRE

FILTRE DE

5 MICRONS

COLLECTEURS

DE DÉBRIS

ROBINETS DE

PURGE

VANNE D'ÉVACUATION D'AIR

RACCORD FLEXIBLE

SYSTÈME TYPE DE

DISTRIBUTION D'AIR

COMPRIMÉ

6

FILTRE DE

0,01 MICRON

PISTOLET DE

PULVÉRISATION

RÉGULATEUR

FILTRE

SPHÉRIQUE

POUR OBTENIR LES MEILLEURS RÉSULTATS

La distance entre le compresseur et le piège

à humidité doit être aussi grande que possible.

PIÈGE À

HUMIDITÉ

DU FILTRE

ROBINET

DE PURGE

Page 34

Caractéristiques

COMPRESSEUR D’AIR

Puissance de

fonctionnement en

cheval-vapeur

Capacité du réservoir

d’air

Pression d’air 1068 kPa (155 PSI) max.

Débit d’air 0,38 m3/min (13,4 pi3/min) à 276 kPa (40 psi)

Lubrication Huile de graissage

Entrée

Spécication minimum du

circuit de dérivation

Type de fusible Temporisé

Poids net 98,7 kg (218 lb)

3,7 CV

227 litres (60 gal)

0,32 m3/min (11,5 pi3/min) à 620 kPa (90 psi)

240 V, 60 Hz, c.a. monophasé

uniquement, 13,5 A

20A

Cycle de service

La pompe du compresseur d’air peut fonctionner en continu. Toutefois, pour prolonger la vie

de service de votre compresseur d’air, il est recommandé de maintenir un cycle de service

moyen de 50 %, à savoir la pompe du compresseur d’air ne devrait pas fonctionner plus de 30

minutes pour chaque heure donnée.

8

Page 35

Outils requis

Lunettes

protectrices

Clé de 1,43 cm

(9/16 po)

Quincaillerie requise (pour l’ancrage)

REMARQUE : Les pièces de quincaillerie ne sont pas illustrées à grandeur nature.

Pièce Description Quantité

BB Chevilles pour béton 4

CC

DD Cales selon les besoins

........BB

Tire-fond 9,5 mm (3/8 po) correspondant

aux chevilles pour béton

........CC

4

Contenu de l’emballage

QUINCAILLERIE FOURNIE

REMARQUE : Les pièces de quincaillerie ne sont pas illustrées à grandeur nature.

Perceuse

électrique

........DD

pts-205109-051012, pts-2053019-053012, pts-206067-060612

........AA

Pièce Description Quantité

AA Rondelle plate 1,6 cm (5/8 po) 4

9

Veuillez composer le 1 888 43-HUSKY pour

une assistance supplémentaire.

HUSKYTOOLS.COM

Page 36

Contenu de l’emballage (suite)

Familiarisez-vous avec ces commandes avant d’utiliser l’appareil (Figure 2)

FIGURE 7

FIGURE 2

L

E

N

M

H

K

I

O

C

B

P

G

D

A

J

F

Pièce Description

INTERRUPTEUR AUTO(I)/ARRÊT(0) : Mettez cet interrupteur dans la position «Auto

A

(I)» pour fournir une alimentation électrique continue au pressostat et sur la position

«Arrêt (0)» pour couper l’alimentation électrique à la n de chaque utilisation.

Pressostat : Le pressostat démarre automatiquement le moteur quand la pression

dans le réservoir d’air tombe en dessous de la pression d’«intervention» pré-établie

B

en usine. Il arrête le moteur quand la pression dans le réservoir d’air atteint la

pression de «coupure» pré-établie en usine.

Soupape de sûreté : Si le pressostat n’éteint pas le compresseur d’air à la pression

de «coupure» pré-établie en usine, la soupape de sûreté protégera contre les hautes

C

pressions en «ressortant» à sa pression seuil pré-établie en usine (légèrement plus

élevée que la pression de «coupure» du pressostat).

Manomètre du réservoir : Le manomètre du réservoir indique la pression de l’air

D

stocké dans le réservoir.

10

Page 37

Pièce Description

Pompe du compresseur d’air : Comprime l’air dans le réservoir d’air. Aucun air

E

comprimé n’est disponible tant que le compresseur n’a pas augmenté la pression de

l’air dans le réservoir au-dessus de la pression requise à la sortie d’air.

Robinet de purge : Le robinet de purge se trouve à la base du réservoir d’air et sert

F

à éliminer la condensation à la n de chaque utilisation.

Clapet anti-retour : Quand le compresseur d’air fonctionne, le clapet anti-retour

est «ouvert» ce qui permet à l’air comprimé d’entrer dans le réservoir d’air. Quand

G

le compresseur d’air parvient à la pression de «coupure», le clapet anti-retour «se

ferme» ce qui permet de maintenir la pression de.

Clapet de décharge : Le clapet de décharge se trouve à côté du pressostat; il sert

à libérer automatiquement de l’air comprimé au niveau de la tête du compresseur et

du tube de sortie lorsque le compresseur d’air atteint la pression de «coupure» ou est

H

éteint. Le clapet de décharge permet au moteur de redémarrer librement. Lorsque le

moteur s’arrête de fonctionner, on peut entendre l’air s’échapper par ce clapet pendant

quelques secondes. Aucune fuite d’air ne devrait être entendue lorsque le moteur

fonctionne ou une fois que l’appareil a atteint la pression de «coupure».

Réinitialisation de la protection contre la surcharge du moteur : Ce moteur

est doté d’une protection manuelle contre les surcharges thermiques. Si le moteur

surchauffe pour une raison quelconque, la protection contre la surcharge éteindra

le moteur. Il faut laisser refroidir le moteur avant de pouvoir le redémarrer. Pour le

redémarrer :

I

1. Mettez l’interrupteur Auto/Arrêt en position «Arrêt».

2. Laissez le moteur refroidir.

3. Appuyez sur le bouton rouge de réinitialisation situé sur le moteur.

4. Mettez l’interrupteur Auto/Arrêt en position «Auto» pour redémarrer le moteur.

J Pieds du compresseur

K Garde-courroie

L Remplissage de l’huile de la pompe

M Vidange de l’huile de la pompe

N Regard en verre du niveau d’huile de la pompe

O Moteur

P Sortie d’air

Assemblage

Emplacement du

1

1. Installez le compresseur d’air dans

2. Installez le compresseur d’air à

pts-205109-051012, pts-2053019-053012, pts-206067-060612

compresseur d’air

un espace propre, sec et bien aéré.

une distance d’au moins 0,5 m

(18 po) de tout mur ou toute autre

obstruction qui gênerait le ux d’air.

3. Installez le compresseur d’air

aussi près que possible d’une

source d’alimentation électrique

pour éviter d’avoir à utiliser

des longueurs importantes de

l électrique. REMARQUE : De

grandes longueurs de l électrique

pourraient résulter en une perte de

puissance arrivant au moteur.

4. Le ltre à air doit être conservé

exempt de toute obstruction qui

pourrait réduire le débit d’air

arrivant au compresseur d’air.

11

Veuillez composer le 1 888 43-HUSKY pour

une assistance supplémentaire.

HUSKYTOOLS.COM

Page 38

Assemblage (suite)

Ancrage du compresseur

2

d’air (Figure 3)

MISE EN GARDE : Risque

d’éclatement. Des vibrations

excessives peuvent affaiblir

le réservoir d’air et provoquer

une explosion. Le compresseur

doit être correctement monté.

Le compresseur d’air DOIT être boulonné

sur une surface plane, robuste en béton.

Utilisez les tire-fond 9,5 mm (3/8 po), les

rondelles (fournis) et des chevilles pour

béton. Si vous avez besoin d’aide pour

ancrer le compresseur d’air, faites appel à un

entrepreneur accrédité.

1. Installez le compresseur d’air sur

une surface plane, robuste en béton.

Assurez-vous que le béton est en bon

état sans aucun dommage ou ssure.

2. Marquez la surface en utilisant les trous

dans les pieds (J) du compresseur d’air

comme gabarit.

3. Percez les trous dans la surface pour

les chevilles pour béton. Installez les

chevilles pour béton (BB).

4. Alignez les trous dans la surface

avec les trous dans les pieds (J) du

compresseur d’air.

5. Installez les rondelles (AA, fournies)

entre le sol et les pieds du compresseur

d’air, consultez la gure. Au besoin,

utilisez les cales (DD) pour mettre

l’appareil de niveau.

6. Enlez les tire-fond 9,5 mm (3/8 po) (CC)

dans les pieds (J) du compresseur d’air,

les rondelles (AA) et les chevilles (BB).

7. Appliquez un couple de 9,5 à 13,5 Nm (7 à

10 pi-lb) sur les tire-fond 9,5 mm (3/8 po).

FIGURE 3

AA

(fournies)

DD

(non fournies)

Ligne de surface

(non fournies)

CC

(non fournies)

J

BB

Rodage de la pompe

3

AVIS : Risque de dommages

matériels. Manquer de suivre

à la lettre les consignes de

rodage ci-dessous peut causer

des dommages matériels.

Cette procédure est requise avant de mettre

en service le compresseur d’air et si le

clapet anti-retour ou la pompe entière du

compresseur ont été remplacés.

1. Assurez-vous que l’interrupteur Auto/

Arrêt (A) est en position «Arrêt».

2. Vériez le niveau d’huile dans la pompe.

Consultez le paragraphe Huile dans la

section Entretien pour les instructions.

3. Re-vériez le câblage. Vériez que

tous les ls sont solidement et

sécuritairement raccordés au niveau de

toutes les connexions de bornes. Vériez

que tous les contacts se déplacent

librement et ne sont pas bouchés.

4. Ouvrez le robinet de purge (F)

complètement pour laisser l’air

s’échapper et empêcher l’air de monter

en pression dans le réservoir pendant la

période de rodage.

5. Mettez l’interrupteur Auto/Arrêt (A)

en position «Auto». Le compresseur

démarrera.

6. RFaites fonctionner le compresseur

d’air pendant 20 minutes. Vériez

que le robinet de purge et toutes les

canalisations d’air sont ouverts de sorte

que la montée en pression de l’air soit

minimale dans le réservoir.

7. Inspectez tous les raccords des

canalisations d’air et toutes les

connexions/conduites à la recherche de

fuites d’air en appliquant une solution

savonneuse. Corrigez au besoin.

12

Page 39

Assemblage (suite)

AVIS : Des fuites mineures

peuvent entraîner un surmenage

du compresseur d’air, et résulter

dans des pannes prématurées ou

un rendement inadéquat.

8. Inspectez pour rechercher un excès de

vibration. Re-réglez ou calez les pieds

du compresseur d’air au besoin.

9. Au bout de 20 minutes, fermez le

robinet de purge. Le réservoir d’air se

remplira jusqu’à atteindre la pression de

«coupure» et le moteur s’arrêtera.

Le compresseur d’air est désormais prêt

à être utilisé.

pts-205109-051012, pts-2053019-053012, pts-206067-060612

13

Veuillez composer le 1 888 43-HUSKY pour

une assistance supplémentaire.

HUSKYTOOLS.COM

Page 40

Utilisation

Purge du réservoir (Figure

1

2, 4)

MISE EN GARDE : Risque de

fonctionnement non sécuritaire.

Les réservoirs d’air contiennent

de l’air à haute pression.

Gardez le visage et les autres

parties du corps éloignés de

la sortie de purge. Utilisez

des protections oculaires

[ANSI Z87.1 (CAN/ACN Z94.3)]

lorsque vous purgez car des

débris peuvent être projetés

dans votre visage.

MISE EN GARDE : Risque

associé au bruit. Utilisez des

protection auriculaire (ANSI

S12.6 (S3.19) car l’écoulement

d’air émet un bruit fort

pendant la purge.

MISE EN GARDE : Risque

d’éclatement. De l’eau

condensera dans le réservoir

d’air. Si elle n’est pas

éliminée, l’eau corrodera et

affaiblira le réservoir d’air

créant ainsi un risque de

rupture du réservoir d’air.

AVIS : Risque de dommages

matériels. L’eau purgée du

réservoir d’air peut contenir de

l’huile et de la rouille qui peuvent

causer des taches.

AVIS : Tous les systèmes d’air

comprimé génèrent des condensats

qui s’accumulent dans tout point

de purge (par exemple, réservoirs,

ltres, refroidisseurs, séchoirs). Ce

condensat contient de l’huile de

graissage et/ou des substances

qui peuvent être sujettes à des

réglementations et par conséquent

il doit être éliminé conformément

aux réglementations et aux

législations locales, régionales et

nationales.

AVIS : Si le robinet de purge

est bouché, relâchez toute la

pression de l’air. Le robinet peut

alors être retiré, nettoyé puis

réinstallé.

1. Réglez l’interrupteur Auto/Arrêt (A,

Figure 2) sur «Arrêt».

2. Laissez s’échapper lentement l’air

du réservoir d’air et du système de

distribution d’air jusqu’à ce que la

pression dans le réservoir tombe à

environ 138 kPa (20 psi).

3. Purgez l’eau du réservoir d’air en

ouvrant le robinet de purge (F) en bas

du réservoir.

4. Une fois que toute l’eau a été éliminée,

fermez le robinet de purge. Le

compresseur d’air peut maintenant être

entreposé.

FIGURE 4

F

14

Page 41

Utilisation (suite)

Vérication de la soupape

2

de sûreté (Figure 5)

DANGER : N’altérez pas la

soupape de sûreté. Les éléments