Page 1

Item # 911-625

C

Model # C602H

USE AND CARE GUIDE

60-GALLON STATIONARY AIR COMPRESSOR

Questions, problems, missing parts?

Before returning to the store, call

Husky Customer Service

8 a.m. - 6 p.m., EST, Monday - Friday

1-888-43-HUSKY

HUSKYTOOLS.COM

We appreciate the trust and confidence you have placed in Husky through the purchase of this air compressor.

We strive to continually create quality products designed to enhance your home. Visit us online to see our full line of

products available for your home improvement needs. Thank you for choosing Husky!

THANK YOU

Page 2

Table of Contents

Safety Information ....................................2

Work Area Safety ...................................2

Personal Safety .....................................3

Moving the Compressor .........................3

Air Compressor and

Pneumatic Tool Safety ...........................4

Electrical Safety .....................................5

Warranty ...................................................7

Pre-Operation ...........................................8

Specifications ........................................8

Duty Cycle ..............................................8

Package Contents ..................................8

Safety Information

This manual contains information that is important for

you to know and understand. This information relates

to protecting your safety and preventing equipment

problems. To help you recognize this information, we

use the symbols below. Please read the manual and pay

attention to these symbols.

System Components ..............................9

Placement of the Air Compressor ........10

Air Distribution System ........................11

Tool Usage............................................13

Breaking in the Pump ..........................14

Installation ..............................................15

Operation.................................................16

Maintenance ...........................................19

Care and Cleaning ..................................24

Troubleshooting ......................................25

Service Parts ..........................................27

DANGER: Indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury.

CAUTION: Indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury.

NOTICE: Indicates a practice not related to personal injury which, if

not avoided, may result in property damage.

WORK AREA SAFETY

□ Keep your work area clean and well lit. Ensure

floors are not slippery from wax or dust.

□ Operate the air compressor in an open area at least

18 in. (0.5 m) away from any wall or object that

could restrict the flow of fresh air to ventilation

openings.

WARNING: Do not operate power tools in explosive

atmospheres, such as in the presence of flammable

liquids, gases, or dust. Power tools create sparks which

may ignite the dust or fumes. Keep bystanders, children,

and visitors away while operating tools. Distractions can

cause you to lose control.

2

WARNING: This compressor is not equipped for, and

should not be used to supply breathing air. Additional

equipment would be necessary to properly filter and

purify the air to meet minimal specifications for Grade D

breathing, as described in Compressed Gas Association

Commodity, Specification G 7.1 - 1966, OSHA 29 CF9

1910.134. Compressed Gas Association, 4221 Walney

Road, Fifth Floor, Chantilly, VA 20151-2923, (703) 788-2700,

www.cganet.com. Any such additional equipment has

not been examined and no implication of proper use for

breathing air is intended or implied.

CAUTION: Always disconnect the air supply and power

supply before making adjustments, servicing a tool, or

when a tool is not in use.

Page 3

Safety Information (continued)

PERSONAL SAFETY

□ Keep proper footing and balance at all times.

Proper footing and balance enables better control

of the tool in unexpected situations.

□ Do not use on a ladder or unstable support.

WARNING: Operating any power tool can result in foreign

objects being thrown into your eyes, which can result in

severe eye damage. Before beginning operation, always

wear safety goggles, safety glasses with side shields, or

a full face shield when needed. Always use eye protection

marked to comply with ANSI Z87.1.

WARNING: This product contains chemicals known to

the State of California to cause cancer and birth defects or

other reproductive harm. Wash hands after handling.

WARNING: Use safety equipment. Always wear eye

protection with side shields when operating power tools.

A dusk mask, non-skid safety shoes, hard hat, or hearing

protection must be used for appropriate conditions.

MOVING THE AIR COMPRESSOR

□ When transporting the compressor in a vehicle,

trailer, etc., make sure the tank is drained and the

unit is secured with straps to prevent tipping. Use

care when driving to prevent tipping the unit over in

the vehicle. Damage can occur to the compressor

or surrounding items if the compressor is tipped.

Always use two people when lifting and lift from

the recommended lifting points.

WARNING: Stay alert when operating a power tool. Do

not use the tool while tired or under the influence of drugs,

alcohol, or medication.

WARNING: Do not wear loose clothing or jewelry.

Contain long hair. Keep your hair, clothing, and gloves away

from moving parts. Loose clothes, jewelry, or long hair can

be caught in moving parts.

WARNING: Never touch any exposed metal parts on

compressor during or immediately after operation. The

compressor will remain hot for several minutes after

operation. Do not reach around protective shrouds or

attempt maintenance until the unit has been allowed to

cool.

CAUTION: The compressor is too heavy to be lifted by

one person. Obtain assistance from others before lifting.

WARNING: Risk of unsafe operation. Ensure proper

footing and use caution when rolling the compressor so

that the unit does not tip or cause loss of balance.

3 HUSKYTOOLS.com

Please contact 1-888-43-HUSKY for further assistance.

Page 4

Safety Information (continued)

AIR COMPRESSOR AND

PNEUMATIC TOOL SAFETY

□ Keep compressors as far from the spraying area as

possible: at least 15 ft. (4.6 m) from the spraying

area and all explosive vapors.

□ If connected to a circuit protected by fuses, use time-

delay fuses with this product.

□ Ensure the hose is free of obstructions or snags.

Entangled or snarled hoses can cause loss of

balance or footing, and may become damaged.

□ Use the air compressor only for its intended use. Do

not alter or modify the unit from the original design

or function. Never weld or drill holes in the air tank.

□ Never leave a tool unattended with the air hose

attached.

□ Do not operate this tool if it does not contain a

legible warning label.

□ Do not continue to use a tool or hose that leaks air or

does not function properly.

□ Do not attempt to pull or carry the air compressor

by the hose.

□ Your tool may require more air consumption than

this air compressor is capable of providing.

□ Never direct a jet of compressed air toward people

or animals.

□ Protect your lungs. Wear a face or dust mask if the

operation is dusty.

□ Do not use this air compressor to spray chemicals.

Your lungs can be damaged by inhaling toxic

fumes. A respirator may be necessary in dusty

environments or when spraying paint.

□ This compressor is equipped with a thermal

overload protector which will shut off the motor if it

becomes overheated.

WARNING: Do not attempt to modify this tool or create

accessories not recommended for use with this tool.

Any such alteration or modification is misuse and could

result in a hazardous condition leading to possible serious

personal injury.

CAUTION: Do not use the compressor in an environment

that is dusty or otherwise contaminated. Using the air

compressor in this type of environment may cause damage

to the unit.

CAUTION: Risk of bursting. Do not adjust the regulator

to result in output pressure greater than the marked

maximum pressure of the attachment. Do not use at

pressure greater than the rated maximum pressure of this

compressor.

CAUTION: To reduce the risk of electric shock, do not

expose the compressor to rain. Store indoors.

4

Page 5

Safety Information (continued)

ELECTRICAL SAFETY (EXTENSION CORDS)

□ Use only 3-wire extension cords that have 3-prong

grounding plugs and 3-pole receptacles that accept

the product’s plug. Make sure your extension

cord is not damaged. When using a power tool at

a considerable distance from the power source,

use an extension cord heavy enough to carry the

current that the product will draw. An undersized

extension cord will cause a drop in line voltage,

resulting in a loss of power and causing the motor

to overheat.

□ Use the chart provided below to determine the

minimum wire size required in an extension cord.

Only round jacketed cords listed by Underwriter’s

Laboratories (UL) should be used.

□ Only use 50 feet or less, round jacketed cords listed

by Underwriter’s Laboratories (UL).

□ When operating a power tool outside, use an

outdoor extension cord marked “W-A” or “W”.

These cords are rated for outdoor use and reduce

the risk of electric shock.

Ampere rating

(on air compressor data plate)

14-16

Cord

Length

25 ft. 16

50 ft. 12

Used on 12 gauge - 20 amp circuit.

NOTE: AWG=American Wire Gauge

Wire Size (AWG)

WARNING: When using an extension cord, keep it clear

of the working area. Position the cord so that it will not get

caught on lumber, tools, or other obstructions while you

are working with a power tool. Failure to do so can result

in serious personal injury.

WARNING: Check extension cords before each use.

If damaged, replace immediately. Never use the air

compressor with a damaged cord since touching the

damaged area could cause electrical shock resulting in

serious personal injury.

WARNING: Improperly connecting the equipment-

grounding conductor can result in a risk of electrical

shock.

CAUTION: Avoid body contact with grounded surfaces

such as pipes, radiators, ranges, and refrigerators. There

is an increased risk of electric shock if your body is

grounded.

CAUTION: Do not expose power tools to rain or wet

conditions. Water entering a power tool will increase the

risk of electric shock.

CAUTION: Replace damaged cords/wiring immediately.

Damaged cords/wiring increase the risk of electric shock.

NOTICE: Use longer air hoses instead of long extension cords. Your

air compressor will run better and last longer.

ELECTRICAL SAFETY (ELECTRICAL

CONNECTION)

□ This air compressor is powered by a precision built

electric motor. It should be connected to a power

supply that is 230 volts, 60 Hz, AC only (normal

household current).

□ Do not operate this tool on direct current (DC). A

substantial voltage drop will cause a loss of power

and the motor will overheat. If the air compressor

does not operate when plugged into an outlet,

double check the power supply.

5 HUSKYTOOLS.com

Please contact 1-888-43-HUSKY for further assistance.

Page 6

Safety Information (continued)

ELECTRICAL SAFETY (SPEED AND WIRING)

□ The no-load speed of this product is approximately

1,200 rpm. This speed is not constant and

decreases under a load or with lower voltage.

□ For voltage, the wiring in a shop is as important as

the motor’s horsepower rating. A line intended only

for lights cannot properly carry a power tool motor.

Wire that is heavy enough for a short distance will

be too light for a greater distance. A line that can

support one power tool may not be able to support

two or three products.

ELECTRICAL SAFETY (GROUNDING

INSTRUCTIONS)

□ This product must be connected to a grounded,

metallic, permanent wiring system, or an

equipment-grounding terminal or lead on the

product.

6

Page 7

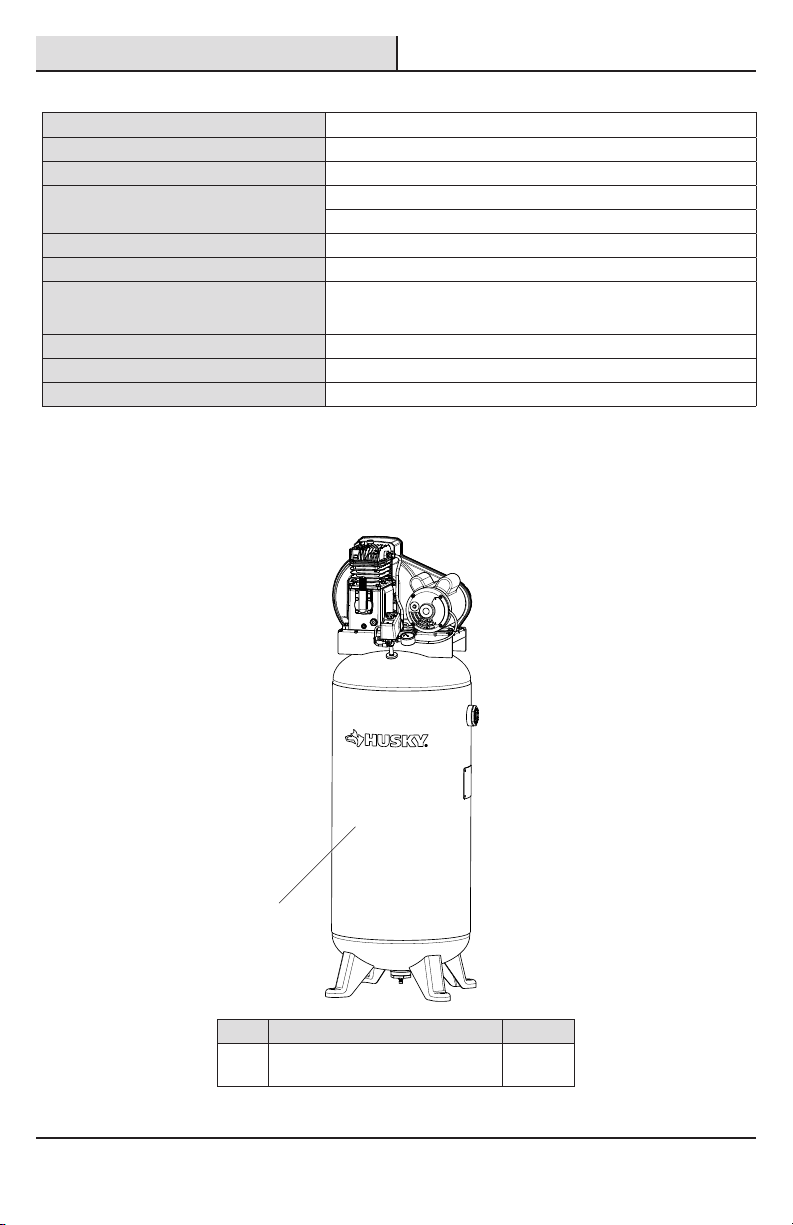

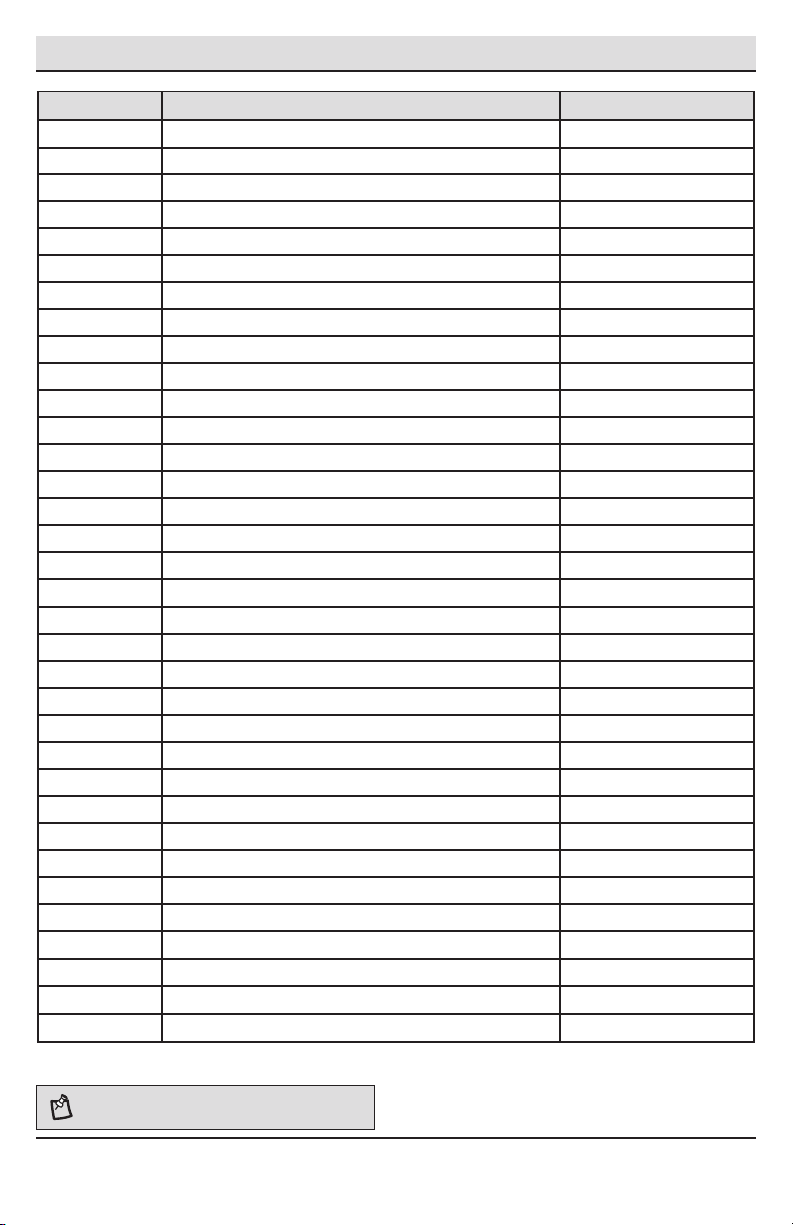

Pre-Operation

SPECIFICATIONS

Running horsepower

Air tank capacity

Air pressure

Air delivery

Tank fill time

Lubrication

Input

Minimum branch circuit requirement

Fuse type

Net weight

DUTY CYCLE

This air compressor pump is capable of running continuously. However, to prolong the life of your air compressor,

it is recommended that a 50% average duty cycle be maintained; that is, the air compressor pump should not run

more than 30 minutes in any given hour.

PACKAGE CONTENTS

3.7 HP

60 gal.

155 PSI max.

13.4 SCFM at 40 PSI

11.5 SCFM at 90 PSI

7 minutes

Oil lube

240V, 60 Hz, Single phase

AC only, 13.5 Amps.

20 A

Time delay

218 lbs.

A

Pièce Description Quantity

Air Compressor Unit (fully

A

assembled)

8

1

Page 8

Pre-Operation (continued)

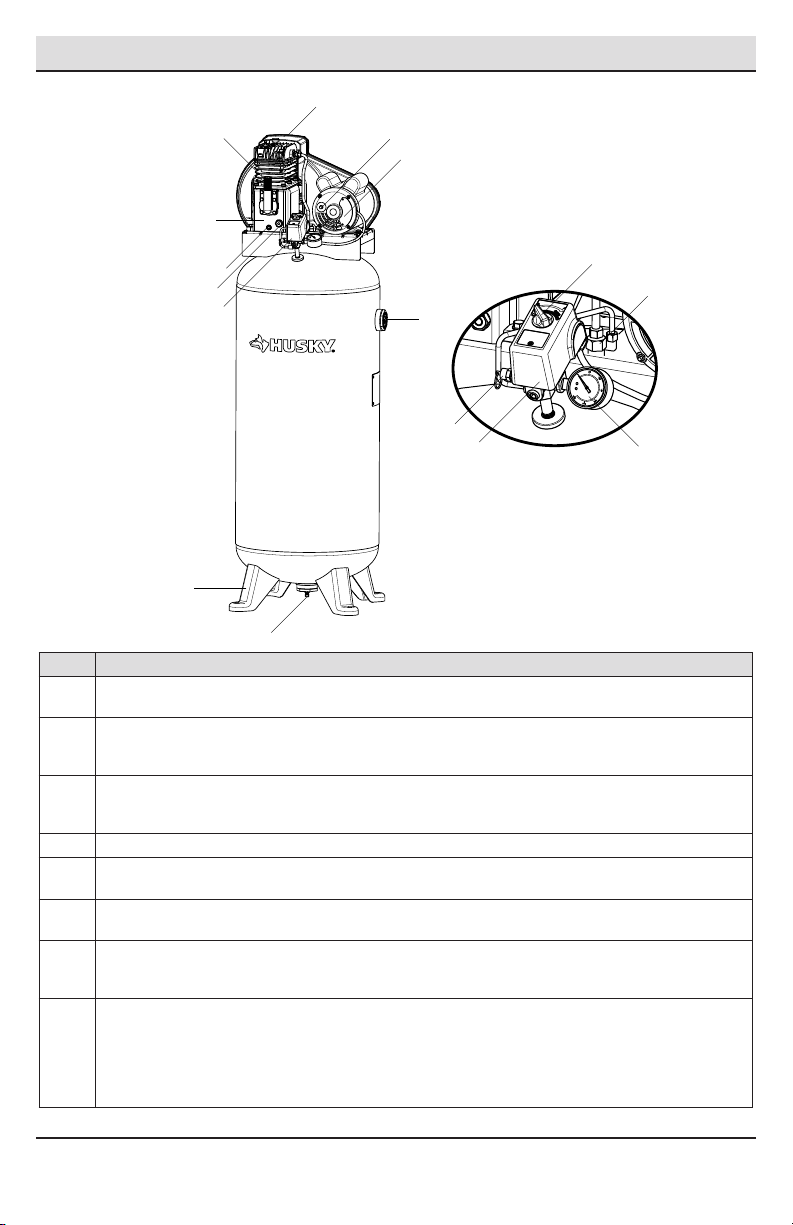

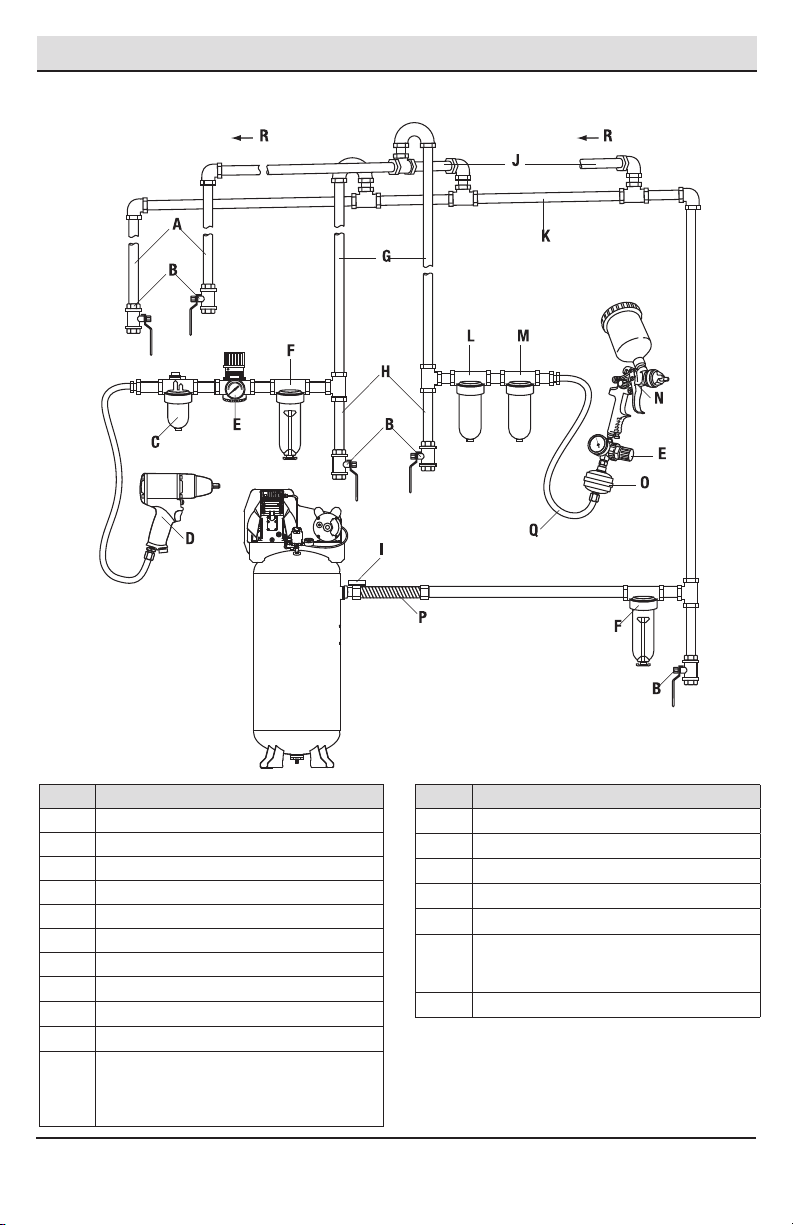

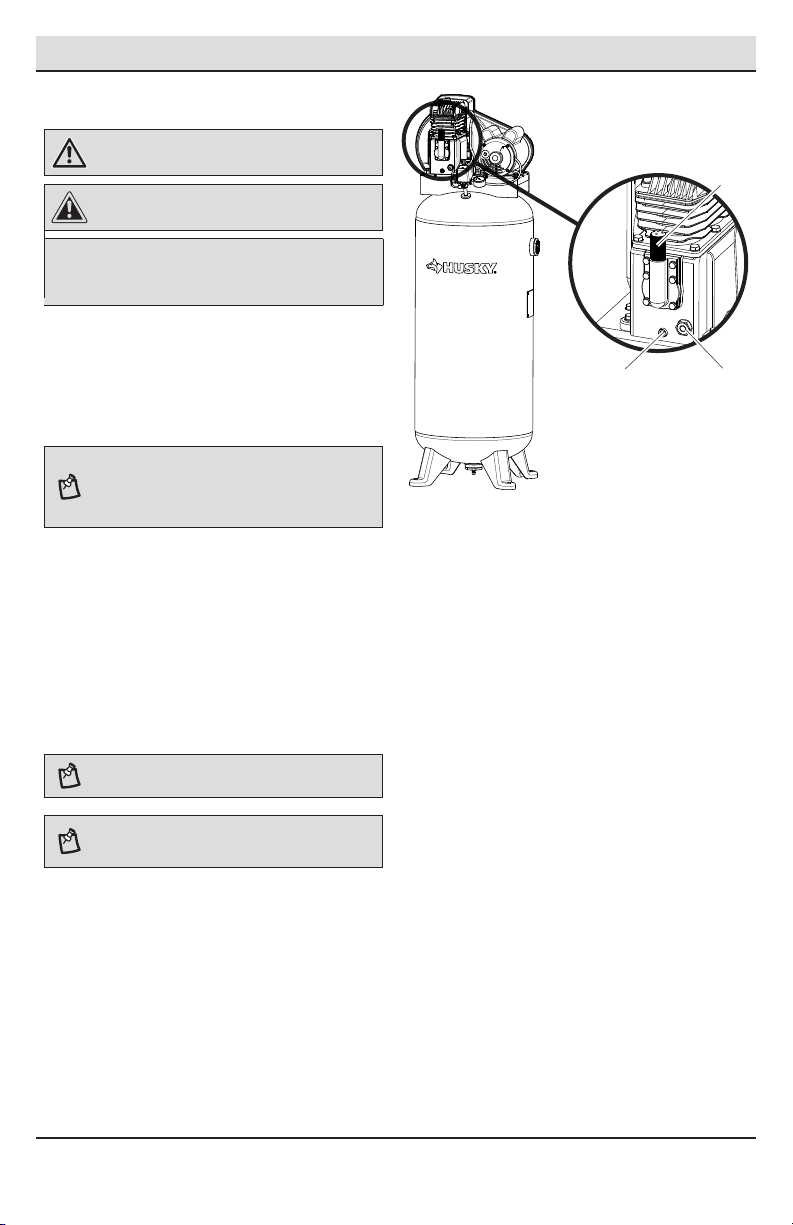

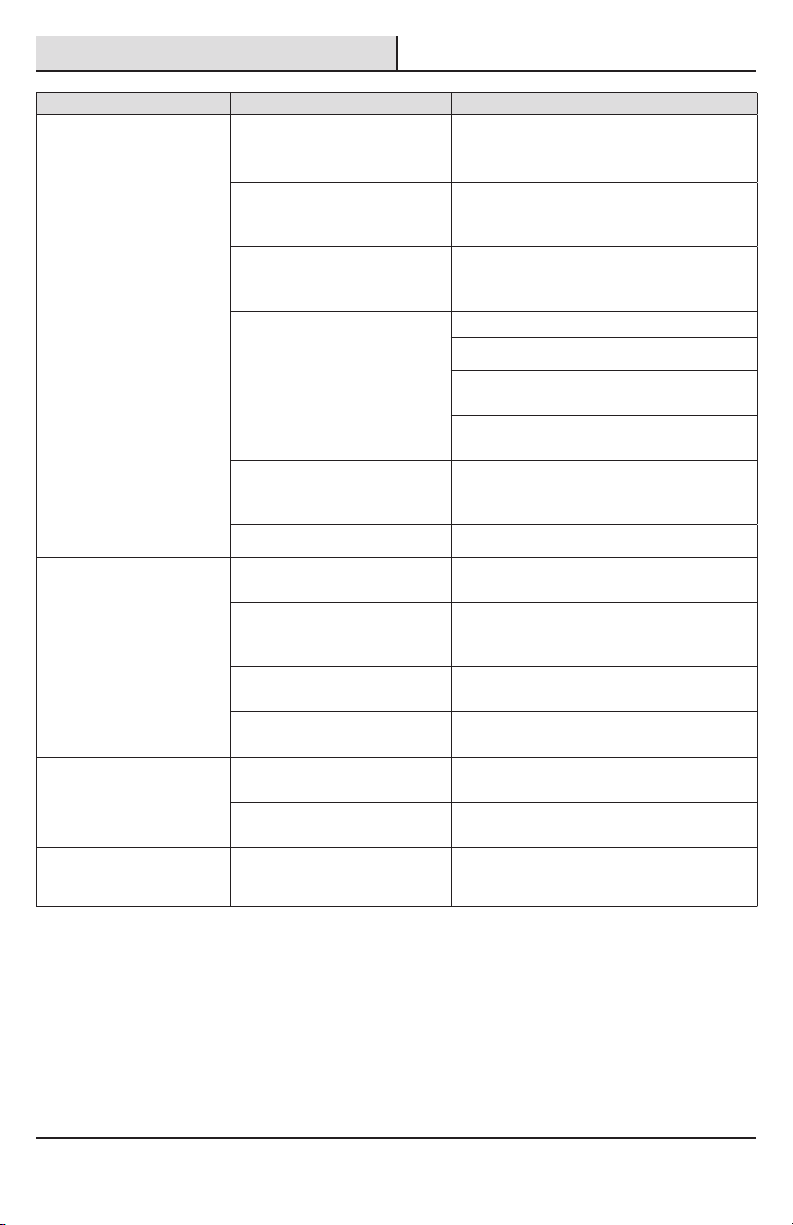

SYSTEM COMPONENTS

L

E

M

N

H

J

K

I

O

A

P

C

B

F

Part Description

AUTO(I)/OFF(0) Switch: Turn this switch in the “Auto (I)” position to provide automatic power to the

A

pressure switch and “Off (O)” to remove power at the end of each use.

Pressure Switch: The pressure switch automatically starts the motor when the air tank pressure drops

B

below the factory set “cut-in” pressure. It stops the motor when the air tank pressure reaches the

factory set “cut-out” pressure.

Safety Valve: If the pressure switch does not shut off the air compressor at its “cut-out” pressure

C

setting, the safety valve will protect against high pressure by “popping out” at its factory set pressure

(slightly higher than the pressure switch “cut-out” setting).

D

Tank Pressure Gauge: The tank pressure gauge indicates the reserve air pressure in the tank.

Air Compressor Pump: Compresses air into the air tank. Working air is not available until the compressor

E

has raised the air tank pressure above that required at the air outlet.

Drain Valve: The drain valve is located at the base of the air tank and is used to drain condensation at

F

the end of each use.

Check Valve: When the air compressor is operating, the check valve is “open”, allowing compressed air

G

to enter the air tank. When the air compressor reaches “cut-out” pressure, the check valve “closes”,

allowing air pressure to remain inside the air tank.

Pressure Release Valve: The pressure release valve located on the side of the pressure switch, is

designed to automatically release compressed air from the compressor head and the outlet tube when

the air compressor reaches “cut-out” pressure or is shut off. The pressure release valve allows the

H

motor to restart freely. When the motor stops running, air will be heard escaping from this valve for a few

seconds. No air should be heard leaking when the motor is running or after the unit reaches “cut-out”

pressure.

G

D

9 HUSKYTOOLS.com

Please contact 1-888-43-HUSKY for further assistance.

Page 9

Pre-Operation (continued)

Part Description

Thermal Overload Reset: This motor has a manual thermal overload protector. If the motor overheats

for any reason, the overload protector will shut off the motor. The motor must be allowed to cool down

before restarting. To restart:

1. Place the AUTO/OFF switch in the “Off” position.

I

2. Allow the motor to cool.

3. Depress the red reset button on the motor.

4. Place the Auto/Off switch in the “Auto” postion to restart the motor.

Compressor Feet: The compressor feet are used to stabilize the compressor and used as brackets when

J

mounting to the floor.

K

Belt Guard: The belt guard is a protective enclosure for moving parts.

L

Pump Oil Fill: The pump oil fill is used to add oil to the crankcase.

Pump Oil Drain: The pump oil drain is used to purge old oil from the pump. Loosening the drain plug will

M

allow oil to exit the pump crankcase.

N

Pump Oil Sight Glass: The pump oil sight is a visual identifier for oil level in the crank case.

Motor: The motor is the drive component powered by electricity to rotate the pump by a belt pulley

O

system.

P

Air Outlet: The air outlet is connection point to provide useable air for the tools.

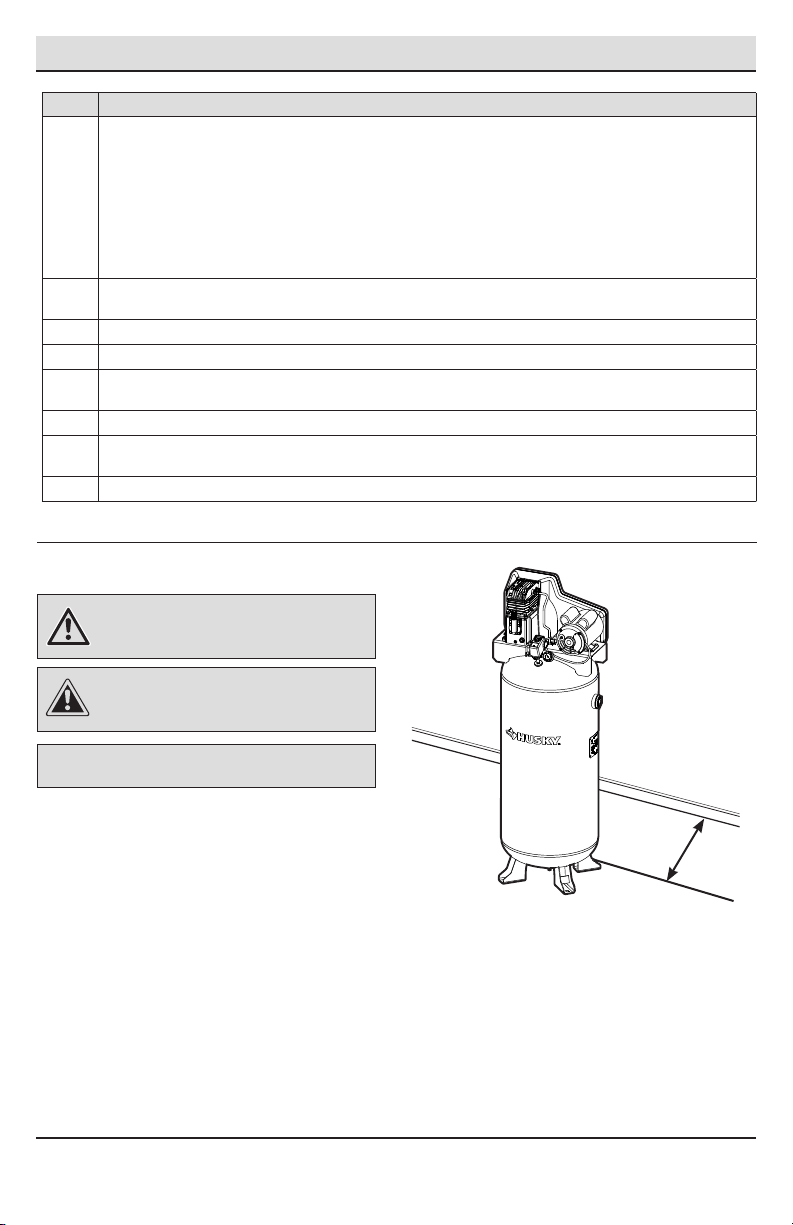

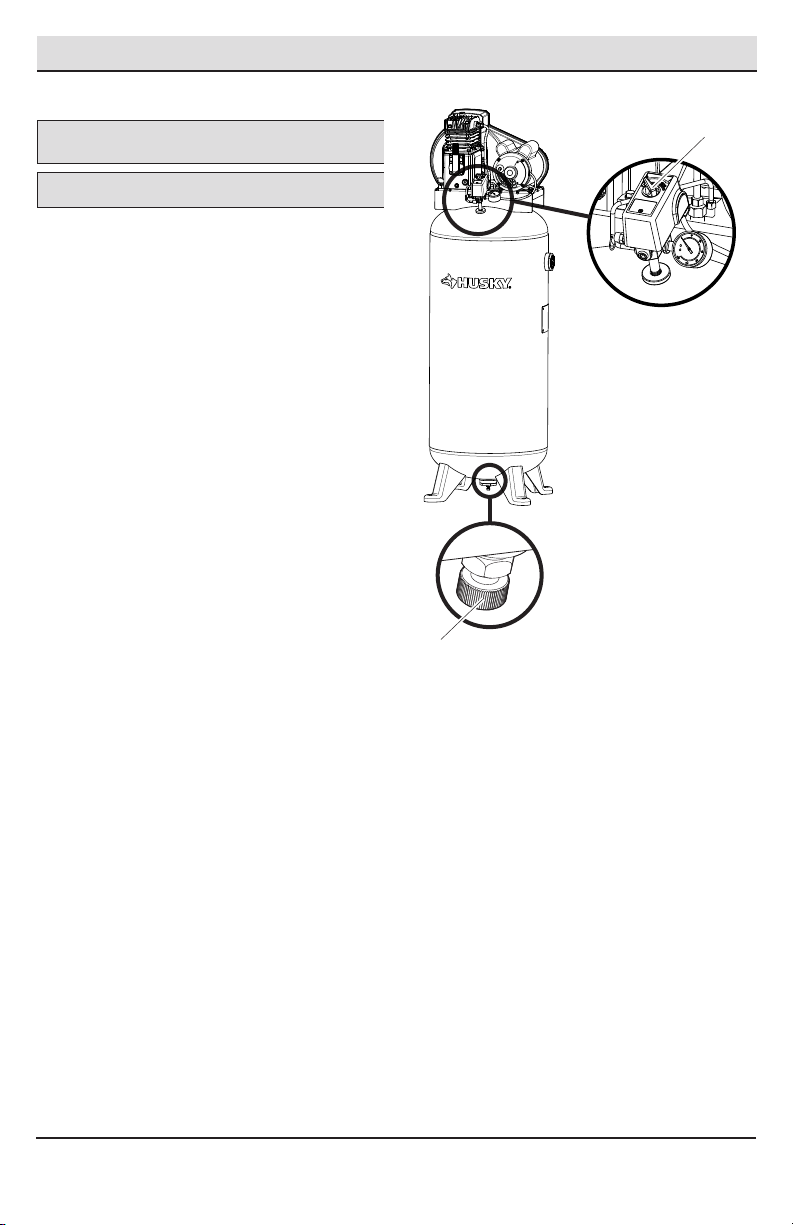

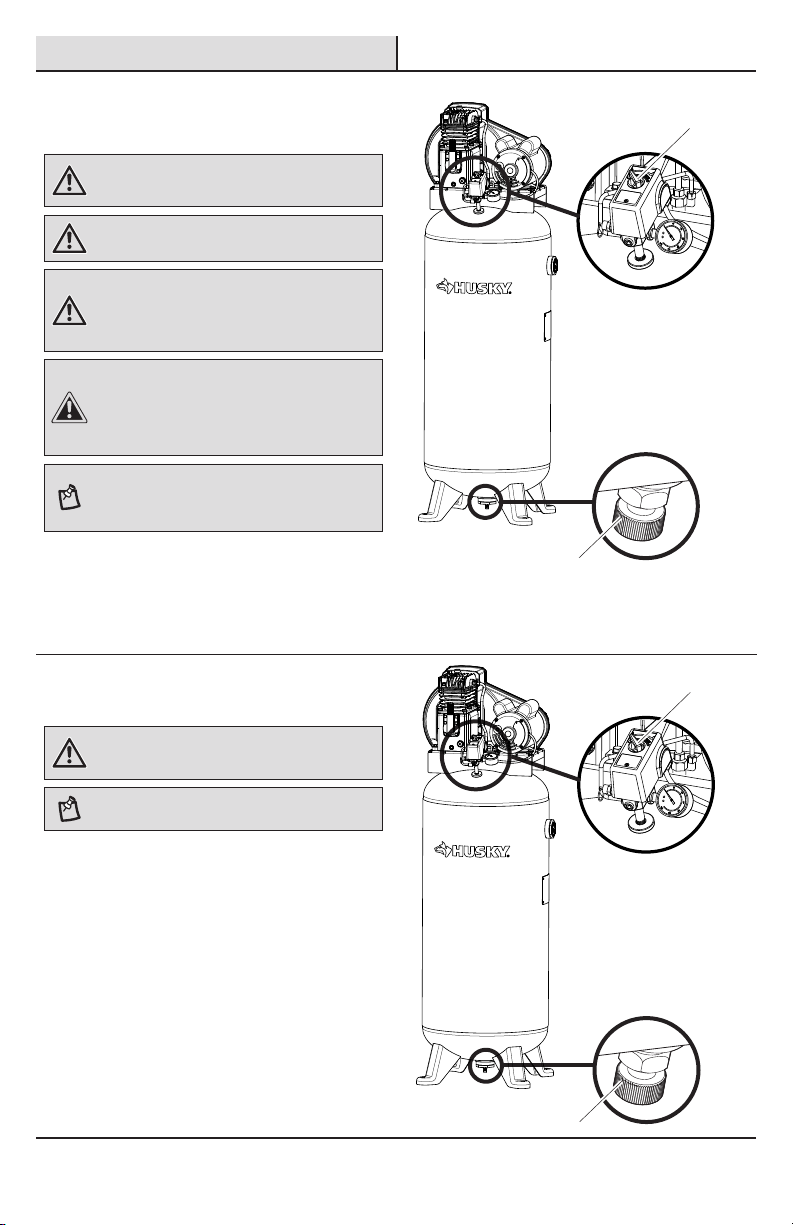

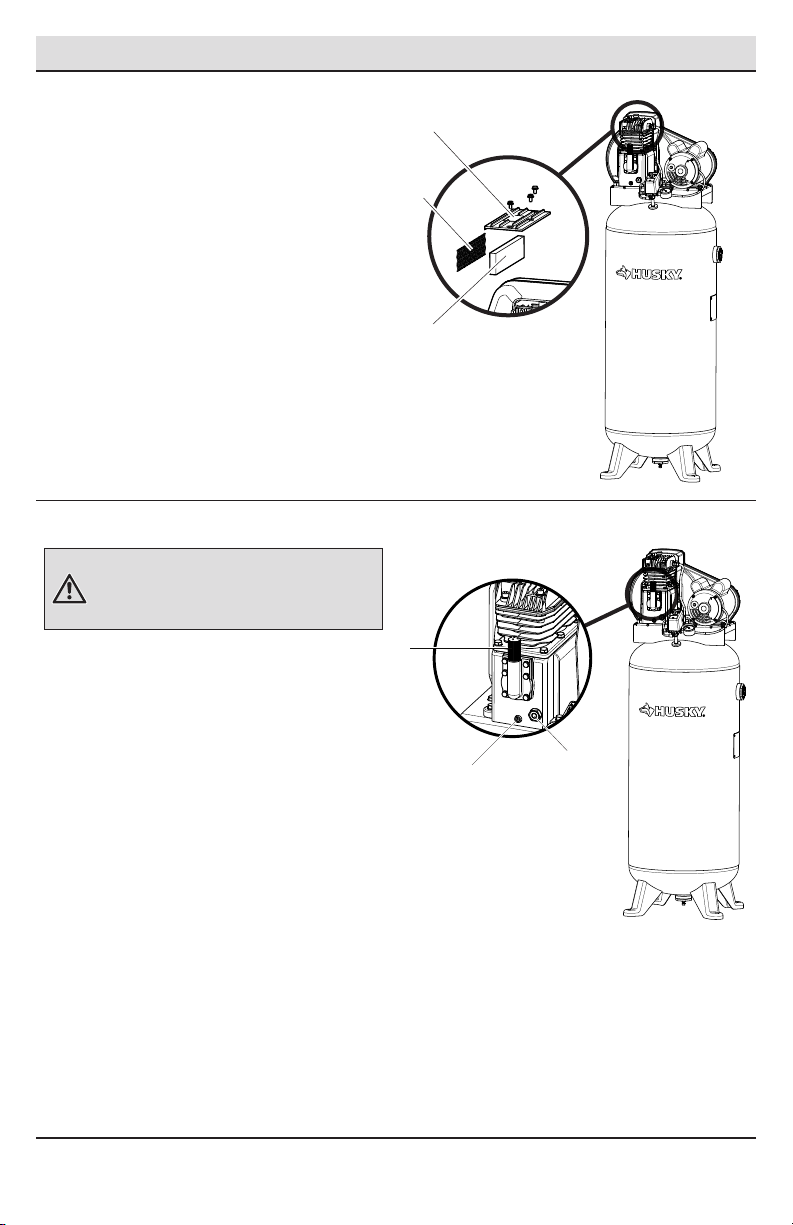

PLACEMENT OF THE AIR COMPRESSOR

WARNING: If any parts are damaged or missing do

not operate this product until the parts are replaced.

Failure to heed this warning could result in serious

personal injury.

CAUTION: Do not use in an environment that is dusty

or otherwise contaminated. Using the air compressor

in this type of environment may cause damage to

the unit.

NOTICE: Long lengths of electrical wiring could cause power loss

to the motor.

□ Place the air compressor in a clean, dry, and well

ventilated area.

□ The air compressor must be positioned at least 18

in. (0.5 m) away from the wall or other obstructions

that will interfere with the flow of air.

□ Locate the air compressor as close to the main

power supply as possible to avoid using long

lengths of electrical wiring.

□ The air filter must be kept clear of obstructions

which could reduce the air flow to the air

compressor.

10

18 in.

(0.5 m)

Page 10

Pre-Operation (continued)

AIR DISTRIBUTION SYSTEM

The diagram on the following page represents a

typical air distribution system. The following are tips

to remember when setting up the air compressor’s air

distribution system.

□ Use a pipe that is the same size as the air tank

outlet. Piping that is too small will restrict the flow

of air.

□ If the piping is over 100 ft. (30.5 m) long, use the

next larger size.

□ Bury underground lines below the frost line and

avoid pockets where condensation can gather and

freeze. Apply pressure before the underground lines

are covered to make sure all the pipe joints are free

of leaks.

□ A flexible coupling is recommended to be installed

between the globe valve/air discharge outlet and

the main air distribution line to allow for vibration.

□ A separate regulator is recommended to control the

air pressure. Air pressure from the tank is usually

too high for individual air driven tools.

□ Do not install the lubricators between the tank

and any spray equipment, air tool, or accessory

requiring oil-free, filtered air.

□ Drain all traps, filters, and dirt legs daily.

WARNING: Risk of bursting. Plastic or PVC pipe is not

designed for use with compressed air. Regardless of its

indicated pressure rating, plastic pipe can burst from air

pressure. Use only metal pipe for air distribution lines.

WARNING: Risk of bursting. Always use metal piping

and fittings.

NOTICE: Compressed air from the oil lube air compressors will

contain water condensation and oil mist. Several drains, traps, and

filters will be needed to supply air without water (including aerosols) or

oil to the spray equipment, air tools, and accessories requiring filtered

air. Always read the instructions for the air tools and accessories being

used.

11 HUSKYTOOLS.com

Please contact 1-888-43-HUSKY for further assistance.

Page 11

Pre-Operation (continued)

TYPICAL COMPRESSED AIR DISTRIBUTION SYSTEM

Part Description

A Drain Legs

B Drain Valves

C Lubricator

D Air Tool

E Regulator

F Filter / Moisture Trap

G Air Usage Lines

H Dirt Legs

I Air Discharge Valve

J Feeder Lines Slope with Air Flow

Main Distribution Air Lines - Slope pipe

in direction of air flow. Water condensate

K

flows along bottom of pipe to drain legs,

preventing it from entering feeder lines.

12

Part Description

L 5 Micron Filter

M .01 Micron Filter

N Spray Gun

O Ball Fitter

P Flexible Coupling

For Best Performance - The distance

Q

between the compressor and the moisture

trap should be as long as possible.

R Air Flow

Page 12

Pre-Operation (continued)

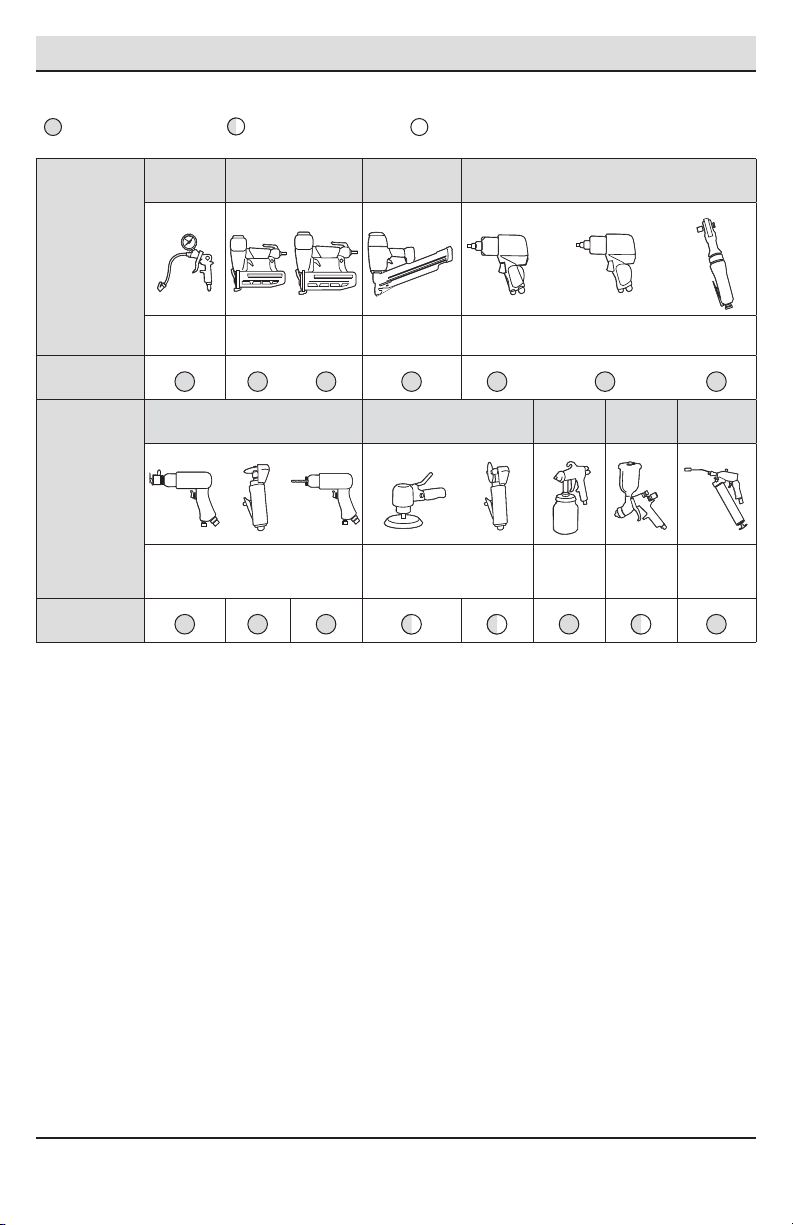

TOOL USAGE

= Continuous = Intermittent = Not Recommended

Tool

Recommended

Tool Use

Tool

Recommended

Tool Usage

Inflation Finishing nailing

Inflator

Air hammer

Brad

nailer

Cutting/Drilling Surface Prep Painting

Cut off

tool

Stapler

Drill/

Impact

driver

Framing/

Roofing

Finished/Roof-

ing nailer

Sander Grinder Paint gun Paint gun Grease Gun

Impact

Wrench

Bolting

Heavy duty 1/2 in. and 3/4

in. impact wrench

HVLP

Painting

Air ratchet

Grease

Gun

13 HUSKYTOOLS.com

Please contact 1-888-43-HUSKY for further assistance.

Page 13

Pre-Operation (continued)

BREAKING IN THE PUMP

NOTICE: Risk of property damage. Serious damage may result if the

following break-in instructions are not closely followed.

NOTICE: Minor leaks can cause the air compressor to overwork,

resulting in premature breakdown or inadequate performance.

This procedure is required before the air compressor is

put into service and when the check valve or a complete

compressor pump has been replaced.

□ Make sure the AUTO/OFF switch (1) is in the “Off”

position.

□ Check oil level in the pump. See the Maintenance

section for instructions.

□ Check all the wiring. Make sure the wires are

secure at all terminals and connections. Make sure

all contacts move freely and are not obstructed.

□ Open the drain valve (2) fully to permit air to escape

and prevent air pressure build-up in the air tank

during the break-in period.

□ Move the AUTO/OFF switch (1) to the “AUTO”

position. The compressor will start.

□ Run the air compressor for 20 minutes. Make sure

the drain valve and all air lines are open so there is

only a minimal air pressure build-up in the tank.

□ Check all the air line fittings and connections/

piping for air leaks by applying a soap solution.

Correct if necessary.

□ Check for excessive vibration. Readjust or shim the

air compressor feet, if necessary.

□ After 20 minutes, close the drain valve (2). The air

receiver will fill to “cut-out” pressure and the motor

will stop.

The air compressor is now ready for use.

1

2

14

Page 14

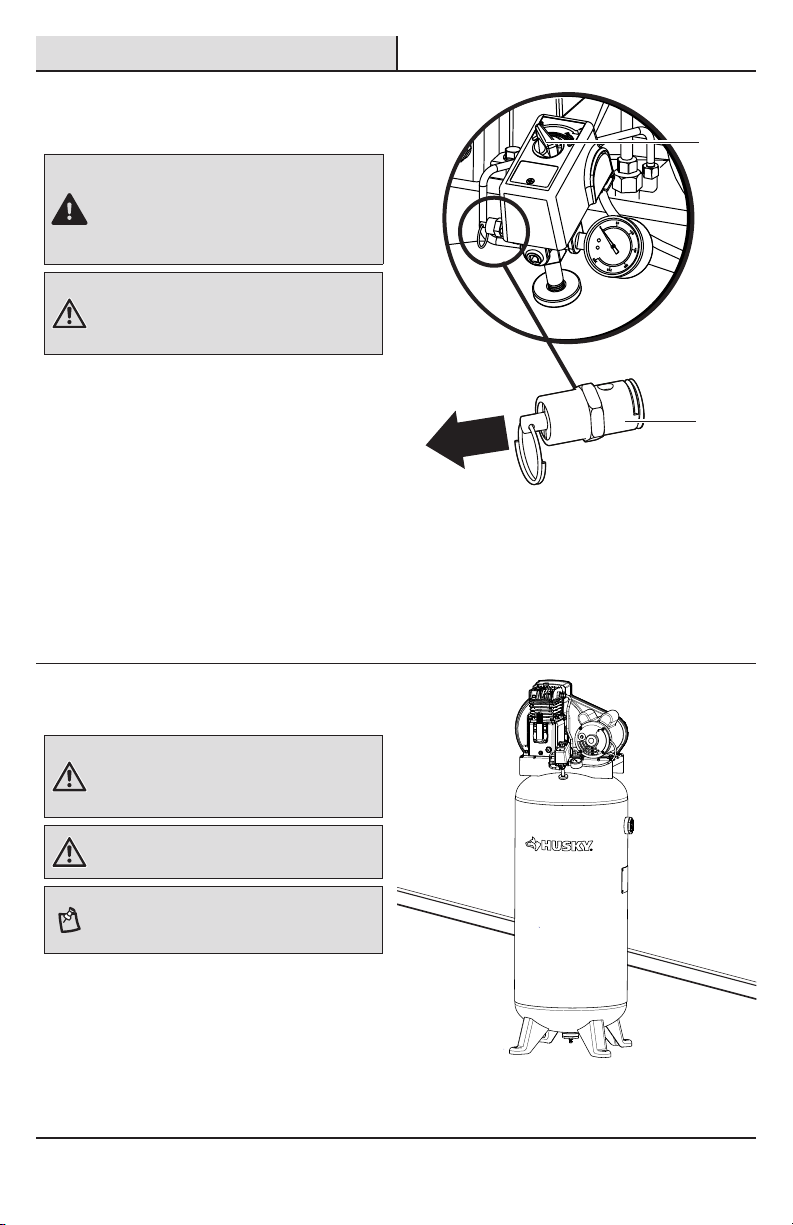

Installation

Anchoring of the air compresor

1

WARNING: Risk of bursting. Excessive vibration

can weaken the air tank and cause an explosion. The

compressor must be properly mounted.

The air compressor must be bolted to a level, solid

concrete surface. Use the lag screws (CC), washers

(AA), and concrete anchors (BB). If help is needed

anchoring the air compressor, consult a licensed

contractor.

□ Place the air compressor on a level, solid

concrete surface. Make sure the concrete is in

good condition with no cracks or damage.

□ Mark the surface using the holes in the air

compressor feet (J) as a template.

□ Drill holes in the surface for the concrete

anchors. Install the concrete anchors (BB).

□ Line-up the holes in the surface with the holes in

the air compressor feet (J).

□ Place the washers (AA) between the floor and

the air compressor feet, as shown. If needed, use

shims (DD) to level the unit.

□ Place the lag screws (CC) through the air

compressor feet (J), washers (AA), and into the

anchors (BB).

□ Torque the lag screws (CC) to 7-10 ft.-lbs (9.5-13.5

Nm).

AA

CC

J

Surface Line

DD

BB

15 HUSKYTOOLS.com

Please contact 1-888-43-HUSKY for further assistance.

Page 15

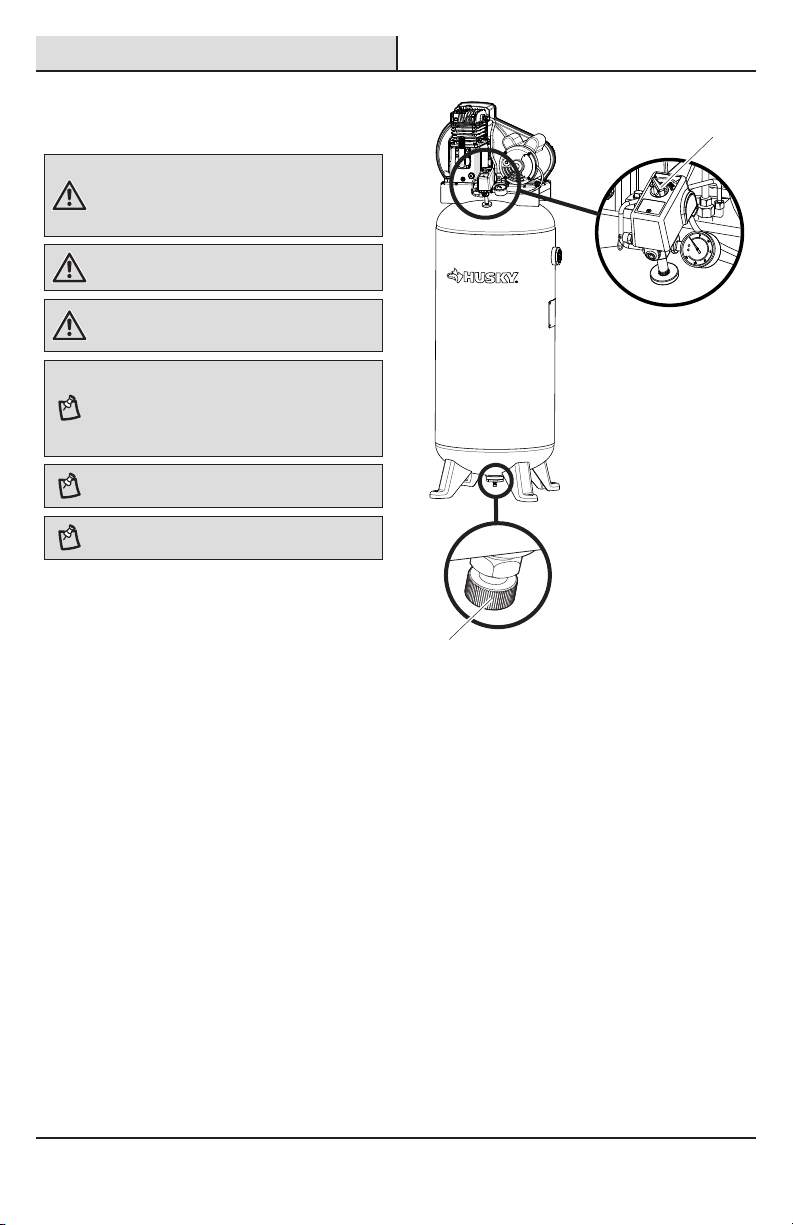

Operation

Preparing for start-up

1

WARNING: Risk of unsafe operation. Firmly grasp air

hose in hand when installing or disconnecting to prevent

hose whip.

WARNING: Risk of unsafe operation. Do not use

damaged or worn accessories.

WARNING: Risk of bursting. Too much air pressure

causes a hazardous risk of bursting. Check the

manufacturer’s maximum pressure rating for air tools and

accessories. The regulator outlet pressure must never

exceed the maximum pressure rating.

CAUTION: Risk of unsafe operation. Compressed air

from the unit may contain wa ter condensation and oil

mist. Do not spray un fil tered air at an item that could be

damaged by moisture. Some air tools and accessories may

require filtered air. Read the in struc tions for the air tools

and accessories.

NOTE: A regulator MUST be installed when using

accessories rated at less than 150 psi. The hose or

accessory will require a quick connect plug if the air outlet

is equipped with a quick connect socket.

□ Turn the AUTO ( I ) / OFF ( O ) switch (1) to the

OFF ( O ) position.

□ Close the drain valve (2).

□ Visually inspect air lines and fittings for leaks.

Starting the compressor

2

1

2

1

WARNING: Risk of bursting. If any unusual noise or

vibration is noticed, stop the air compressor immediately

and have it checked by a trained service technician.

NOTE: When using the regulator and other accessories,

refer to the manufacturer’s instructions.

□ Plug the power cord into a proper receptacle.

□ Turn the AUTO ( I ) / OFF ( O ) switch (1) to the

AUTO ( I ) position, and allow the tank pressure

to build. The motor will stop when the tank

pressure reaches “cut-out” pressure.

16

2

Page 16

Operation (continued)

Checking the safety valve

3

DANGER: Do not tamper with the safety valve. Items

loosened from this device could fly up and hit you. Failure

to heed this warning could result in death or serious

personal injury. The safety valve automatically releases air

when the receiver pressure exceeds the preset maximum.

Check the valve before each day of use by pulling the ring

by hand.

WARNING: If air leaks after releasing the safety valve

ring or if the valve is stuck, do not use the air compressor

until the safety valve has been replaced. Using the air

compressor in this condition could result in serious

personal injury.

□ Set the AUTO ( I ) / OFF ( O ) switch (1) to the

on position, and wait for the tank to fill. The

compressor automatically shuts off when the

pressure reaches the preset maximum.

□ Set the AUTO ( I ) / OFF ( O ) switch (1) to the

off position.

□ Pull the ring on the safety valve (2) for 20

seconds to release the air.

□ Release the ring. Air stops escaping at

about 20 psi. If air continues to escape after

releasing the safety valve ring, discontinue

use and seek service before using the air

compressor again.

1

2

Running the air compressor

4

WARNING: Always ensure the switch is in the OFF

position and using a regulator (not supplied) ensure

pressure gauge reads zero before changing air tools or

disconnecting the hose from the air outlet. Failure to do so

could result in possible serious personal injury.

WARNING: Your tool may require more air consumption

than this air compressor is capable of providing. Check tool

manual to avoid damage to the tool or risk personal injury.

NOTE: Always use the minimum amount of air flow

using a pressure regulator (not supplied). Using a higher

pressure than needed will drain air from the tank more

rapidly and cause the unit to cycle on more frequently.

□ Never leave the unit plugged in and/or running

unattended.

□ When finished, always drain the tank and unplug

the unit if applicable.

17 HUSKYTOOLS.com

Please contact 1-888-43-HUSKY for further assistance.

Page 17

Operation (continued)

Draining the tank

5

WARNING: Risk of unsafe operation. Air tanks contain

high pressure air. Keep face and other body parts away

from outlet of drain. Use eye protection [ANSI Z87.1 (CAN/

CSA Z94.3)] when draining, as debris can be kicked up

into face.

WARNING: Risk from noise. Use ear protection (ANSI

S12.6 (S3.19), as air flow noise is loud when draining.

WARNING: Risk of bursting. Water will condense in the

air tank. If not drained, water will corrode and weaken the

air tank causing a risk of air tank rupture.

NOTE: All compressed air systems generate condensate

that accumulates in any drain point (e.g., tanks, filter,

after-coolers, dryers). This condensate contains lubricating

oil and/or substances which may be regulated and must

be disposed of in accordance with local, state, and federal

laws and regulations.

NOTE: If drain valve is plugged, release all air pressure.

The valve can then be removed, cleaned, then reinstalled.

NOTE: Risk of property damage. Drained water from the

air tank may contain oil and rust which can cause stains.

□ Set the AUTO ( I ) / OFF ( O ) switch (1) to the OFF

( O ) position.

□ Slowly bleed the air from the compressor

tank by pulling the safety valve to allow the

pressure to escape from the tank until the

pressure is approximately 20 psi.

□ Drain the water from the tank by opening the

drain valve (2) on the bottom of the tank.

□ After the water has been drained, close the

drain valve (2). The air compressor can now

be stored.

1

2

18

Page 18

Maintenance

GENERAL MAINTENANCE

□ Condensate forms in the tank when

there is humidity in the air. Depending on

the environmental conditions, drain the

condensate daily and/or every hour. For

instructions, see Draining the tank.

□ The safety valve automatically releases air

when the receiver pressure exceeds the preset

maximum.

□ Inspect the tank annually for rust, pin holes,

or other imperfections that could cause it to

become unsafe.

□ Avoid using solvents when cleaning plastic

parts. Most plastics are susceptible to damage

from various types of commercial solvents and

may be damaged by their use.

□ Use clean cloths to remove dirt, dust, oil,

grease, etc.

WARNING: When servicing, use only identical Husky

replacement parts. Use of any other parts may create a

hazard or cause product damage.

WARNING: Always release all pressure, disconnect from

power supply, and allow unit to cool to the touch before

cleaning or making repairs on the air compressor.

WARNING: Do not at any time let brake fluids, gasoline,

petroleum-based products, penetrating oils, etc., come

in contact with plastic parts. Chemicals can damage,

weaken or destroy plastic which may result in serious

personal injury. Electric tools used on fiberglass material,

wallboard, spackling compounds, or plaster are subject to

accelerated wear and possible premature failure because

the fiberglass chips and grindings are highly abrasive to

bearings, brushes, commutators, etc. Consequently, we

do not recommended using this tool for extended work on

these types of materials. However, if you do work with any

of these materials, it is extremely important to clean the

tool using compressed air.

19 HUSKYTOOLS.com

Please contact 1-888-43-HUSKY for further assistance.

Page 19

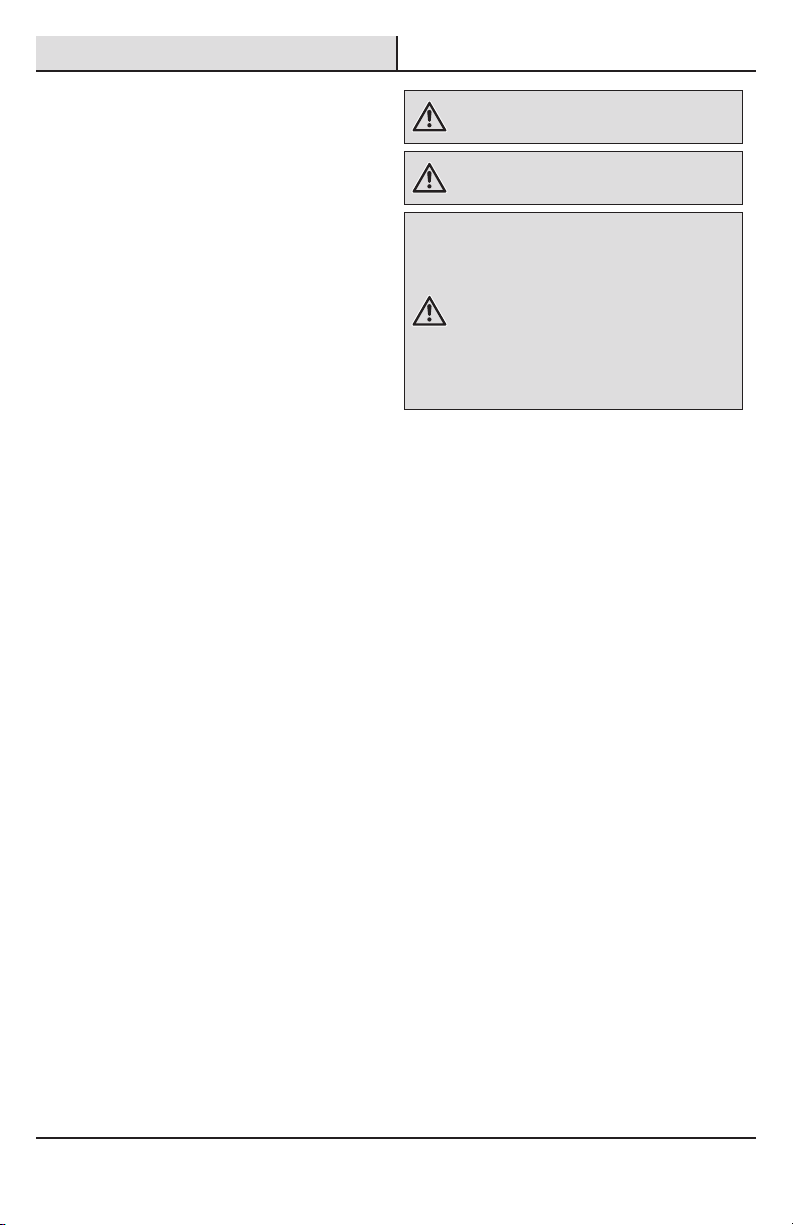

Maintenance (continued)

CHECKING THE OIL

WARNING: Drain the tank to release the air pressure

before removing the oil fill cap or oil drain plug.

CAUTION: Overfilling with oil will cause premature air

compressor failure. Do not overfill.

NOTICE: Risk of property damage. Use air compressor oil only.

Multi-weight automotive engine oils like 10W30 should not be

use in the air compressors. They leave carbon deposits on critical

components, thus reducing performance and compressor life.

□ The oil level should be to the middle of the sight

glass (3).

□ If needed, remove the oil fill plug (1) and slowly

add the oil until it reaches the middle of the sight

glass.

NOTE: Use 30W compressor oil or a heavy duty SAE

30W, non-detergent, SF grade or better oil. Do not use

multi-weight automotive engine oils, as they will reduce

compressor life. Under extreme winter condition use

SAE-10 weight oil.

CHANGING THE OIL

□ Remove the oil fill plug (1).

□ Remove the oil drain plug (2) and drain the oil

into a suitable container.

□ Replace the oil drain plug (2) and tighten

securely.

□ Slowly add the compressor oil until it reaches

the middle of the sight glass (3).

1

2

3

NOTE: Crankcase oil capacity is approximately 10.6 fluid

ounces (313,5 ml).

NOTE: When filling the crankcase, the oil flows very

slowly into the pump. If the oil is added too quickly, it will

overflow and appear to be full.

□ Replace the oil fill plug (1) and tighten securely.

20

Page 20

Maintenance (continued)

CLEANING THE AIR FILTER

From time to time, the air filter needs to be removed

and cleaned.

□ Turn the air compressor OFF ( O ).

□ Unplug the air compressor.

□ Unsnap the air filter cover (1) to remove.

□ Remove the air filter (2) from the air filter

housing (3).

□ Blow compressed air through the air filter for

10-15 seconds.

REPLACING THE BELT

WARNING: Serious injury or damage may occur if parts

of the body or loose items get caught in moving parts.

Never operate the outfit with the belt guard removed.

The belt guard should be removed only when the air

compressor power is disconnected.

□ Turn the air compressor off, lock out the power

supply, and relieve all air pressure from the air

tank.

□ Remove the four fasteners from the belt guard.

The front belt guard can now be lifted up and

away from the unit.

□ Mark the pump position on the saddle.

□ Loosen the motor mounting screws and slide the

motor toward the air compressor.

□ Remove the belt and replace with a new one.

□ Mark the pump position on the saddle.

□ See Adjusting the Belt Tension before tightening

the motor mounting screws.

3

1

2

L

M

N

21 HUSKYTOOLS.com

Please contact 1-888-43-HUSKY for further assistance.

Page 21

Maintenance (continued)

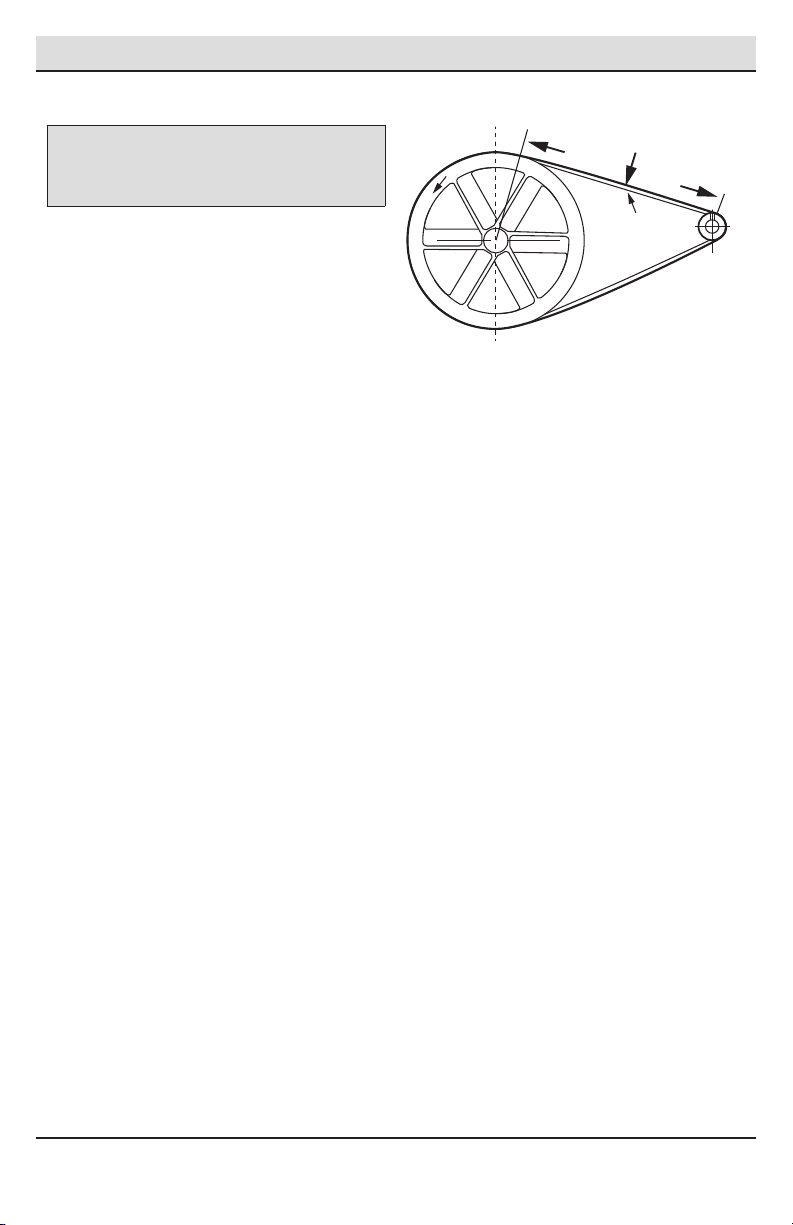

ADJUSTING THE BELT TENSION

NOTICE: Once the engine pulley has been moved from its factory

set location, the grooves of the flywheel and pulley must be aligned

to within 1/16 in. (1.6 mm) to prevent excessive belt wear. Verify the

alignment by performing the MOTOR PULLY/FLYWEEL ALIGNMENT on

the following page.

□ Slide the motor into the original position, and

line the motor up with the mark made earlier on

the saddle.

□ Tighten the two outside motor mounting screws

enough to hold the motor in place for checking

the pulley and flywheel alignment.

□ The belt should deflect 3/16 in. (4.8 mm) at

midway between the pulley and the flywheel

when a five-pound (2.26 kg.) weight is applied at

the midway point.

□ When proper belt tension is achieved, tighten all

four motor mounting screws. Torque to 20-25

ft-lbs (27.1–33.9 Nm).

Downward Force

Deflection

22

Page 22

Maintenance (continued)

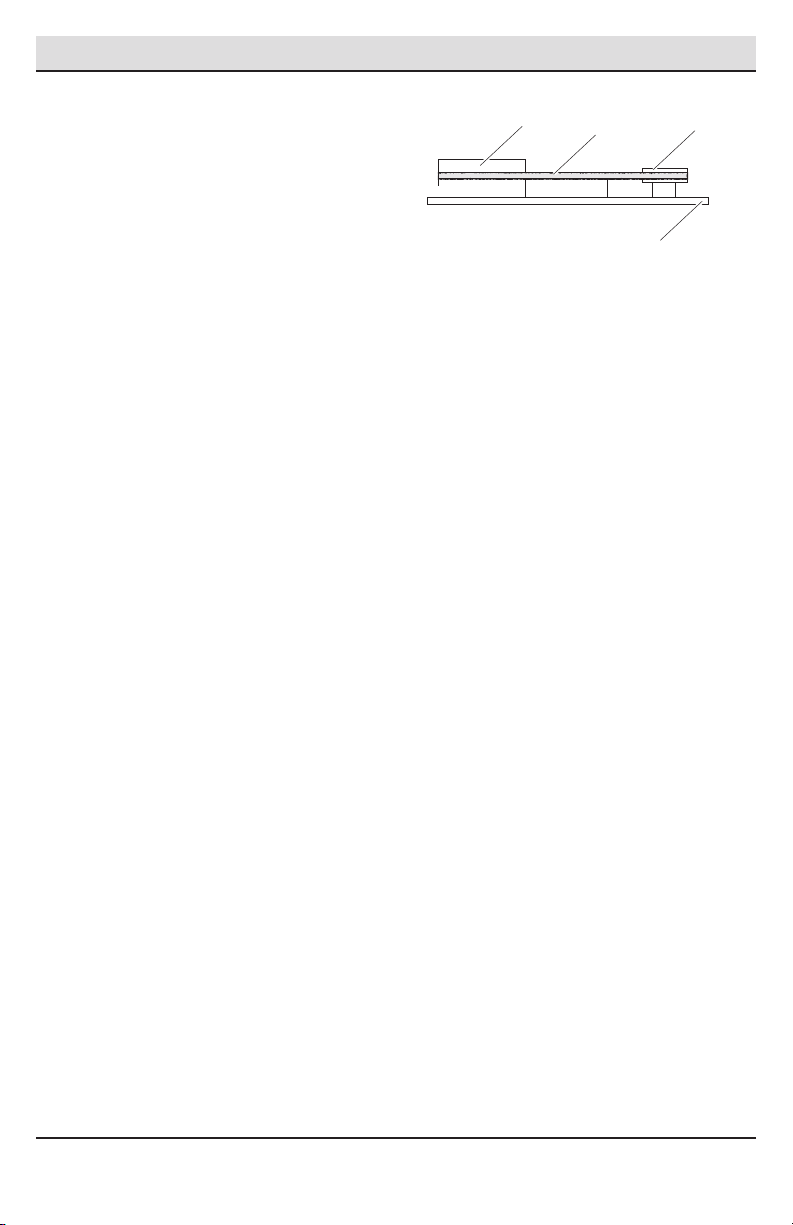

MOTOR PULLEY/FLYWHEEL ALIGNMENT

The air compressor flywheel and motor pulley must be

in-line (in the same plane) within 1/16 in. (1.6 mm) to

assure belt retention within the flywheel belt grooves.

To check the alignment, perform the following steps:

□ Turn the air compressor off, lock out the power

supply, and relieve all air pressure from the air

tank.

□ Remove belt guard.

□ Place a straightedge (4) against the outside of

the flywheel (1) and the motor drive pulley (3).

□ Measure the distance between the edge of the

belt (2) and the straightedge at points A1 and A2.

The difference between measurements should

be no more than 1/16 in. (1.6 mm).

□ If the difference is greater than 1/16 in.

(1.6 mm), loosen the set screw holding the

motor drive pulley (3) to the shaft and adjust the

pulley’s position on the shaft until the A1 and A2

measurements are within 1/16 in. (1.6 mm) of

each other.

□ Tighten the motor drive pulley set screw.

□ Visually inspect the motor drive pulley to verify

that it is perpendicular to the drive motor shaft.

The points (B1 and B2) should appear to be

equal. If they are not, loosen the setscrew of the

motor drive pulley and equalize B1 and B2, using

care not to disturb the belt alignment performed

previously.

□ Retighten the motor drive pulley setscrew.

Torque to 145–165 in.-lbs. (16.4–20.3 Nm).

□ Reinstall the belt guard.

1

A1 A2 B1 B2

A1= A2 (MEASURED)

B1= B2 (VISUAL)

2

4

3

23 HUSKYTOOLS.com

Please contact 1-888-43-HUSKY for further assistance.

Page 23

Maintenance (continued)

AIR COMPRESSOR INTAKE AND EXHAUST

VALVES

Once a year bring the compressor to a service center

and have a trained service technician check the air

compressor pump intake and exhaust valves.

INSPECT AIR LINES AND FITTINGS FOR

LEAKS

NOTICE: Even minor leaks can cause the air compressor to

overwork, resulting in premature breakdown or inadequate

performance.

□ Turn the air compressor off, lock out the power

supply, and relieve all air pressure from the air

tank.

□ Apply a soap solution to all air line fittings and

connections/piping.

□ Correct any leaks found.

TORQUING THE AIR COMPRESSOR HEAD

BOLTS

The air compressor pump head bolts should be kept

properly torqued. Check the torques of the head bolts

after the first five hours of operation.

□ Torque to 14–16 ft.-lbs. (19.0–21.7 Nm).

Care and Cleaning

□ Drain the air tank of moisture after operation.

□ When not in use, store the compressor in a cool, dry place.

□ Disconnect the air hose and hang open ends down to allow any moisture to drain.

□ Protect the electrical cord and air hose from damage (such as being stepped on or run over).

24

Page 24

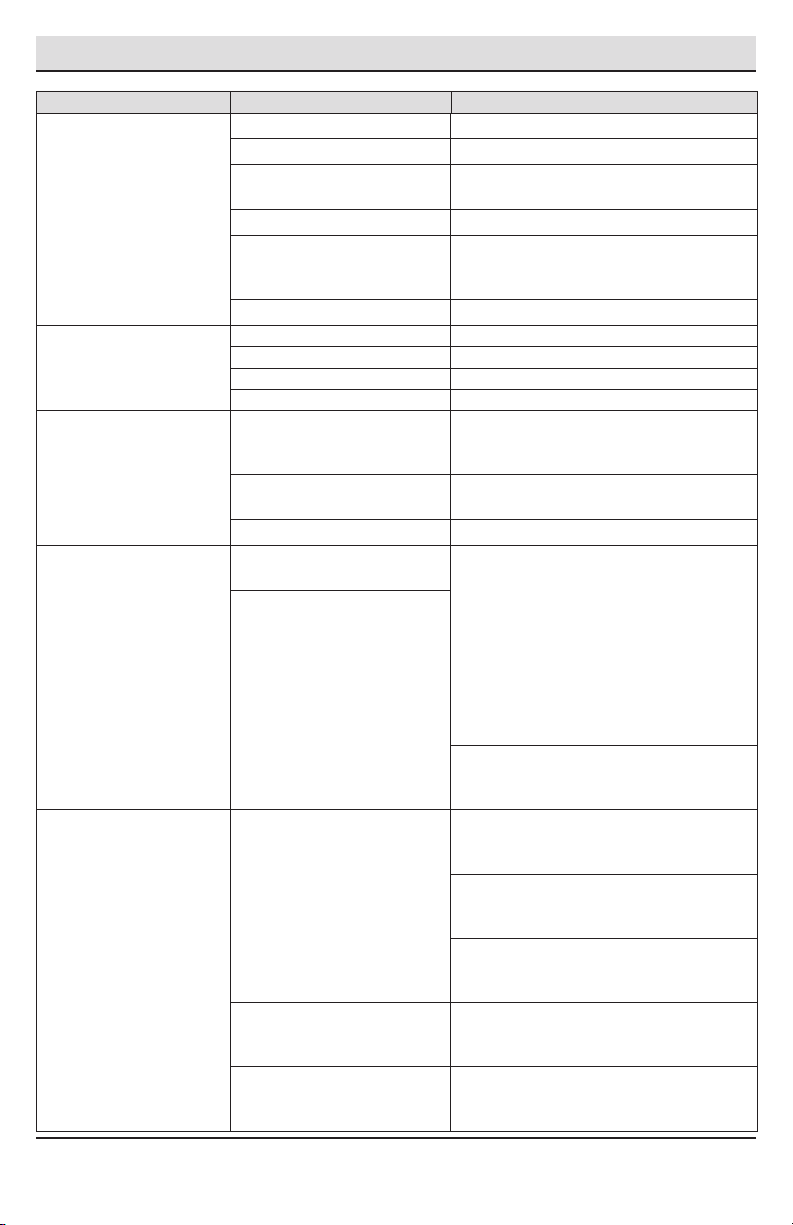

Troubleshooting

Problem Possible Cause Solution

The compressor does not

run.

□ The tank has insufficient

pressure.

□ There is no eletrical power

to the unit.

□ The circuit breaker has

tripped or a fuse has blown

at the main power source.

□ The thermal overload

protector is actuated.

□ When the tank pressure drops, the

compressor will turn on to cut-in

pressure.

□ Verify the wiring connection inside the

pressure switch and the terminal box

area.

□ Check the fuse/breaker to determine the

underlying cause.

□ Turn the air compressor OFF ( O ).

□ Wait until the compressor cools down.

□ Depress the red reset button on the

motor.

□ Turn the air compressor to AUTO ( I ).

The motor hums while

running slowly, or it does not

run at all.

The compressor is making

squealing sounds.

The compressor is

experiencing restricted air

intake.

□ There is loss of power or

overheating.

□ The pressure switch is bad. □ Replace the pressure switch.

□ There is low voltage from

the power source.

□ There are loose eletrical

connections.

□ There is a shorted or open

motor wiring.

□ There is a defective check

valve or unloader.

□ The compressor pump has

no oil.

□ The belt is too loose. □ Check the belt tension.

□ The air filter is dirty. □ Clean or replace the air filter.

□ Verify the wiring.

NOTE: Long lengths of electrical wiring

could cause power loss to the motor.

□ Check the voltage with a voltmeter.

□ Verify the wiring connections inside the

pressure switch and the terminal box

area is secure.

□ Bring the compressor to a service center.

□ Bring the compressor to a service center.

□ Check the pump oil.

25 HUSKYTOOLS.com

Please contact 1-888-43-HUSKY for further assistance.

Page 25

Troubleshooting (continued)

Problem Possible Cause Solution

The compressor is making

knocking sounds.

There is excessive belt wear. □ The belt is too loose. □ Check the belt tension.

There is oil and/or moisture

in the tank and/or air lines.

There is excessive moisture

in the discharge air.

The fuses blow or the circuit

breaker trips repeatedly.

□ There is a loose pulley. □ Tighten the pulley set screw.

□ There is a loose flywheel. □ Tighten the flywheel screw.

□ The compressor mounting

screws are loose.

□ The belt is too loose. □ Check the belt tension.

□ An excessive amount of

carbon has build-up in the

pump.

□ The belt is too tight. □ Check the belt tension.

□ The belt is too tight. □ Check the belt tension.

□ The pully is loose. □ Bring the compressor to a service center.

□ The pulley is misaligned. □ Align the pulley/flywheel.

□ The connections (fittings,

tubing, etc.) are loose and

leaking.

□ The drain valve is loose

or open.

□ The check valve is leaking. □ Bring the compressor to a service center.

□ There is excessive water in

the air tank.

□ The oil blow-by has

accumulated in the pump.

□ The incorrect fuse size is

being used, or the circuit is

overloading.

□ Tighten the mounting screws.

□ Bring the compressor to a service center.

□ Check all the connections with a soap

and water solution and tighten.

□ Tighten the drain valve.

□ It is normal for oil lube air compressor

pumps to release some oil into the tank

and air lines. Air compressors will also

generate water condensation that will

form in the tank and air lines. Install

water and oil filter traps when needed.

The Typical Compressed Air Distribution

System section provides a guideline.

Contact or call Husky Customer Service

for more information.

□ IMPORTANT: If the tank or air lines have

excessive water and/or oil, bring the

compressor to a service center.

□ Verify the proper fuse size is being used.

□ Use time-delay fuses.

□ There are loose eletrical

connections.

□ There is a defective check

valve or unloader.

26

□ Disconnect other electrical appliances

from the circuit or operate the

compressor on its own branch circuit.

□ Verify the wiring connection inside the

pressure switch and the terminal box

area.

□ Bring the compressor to a service center.

Page 26

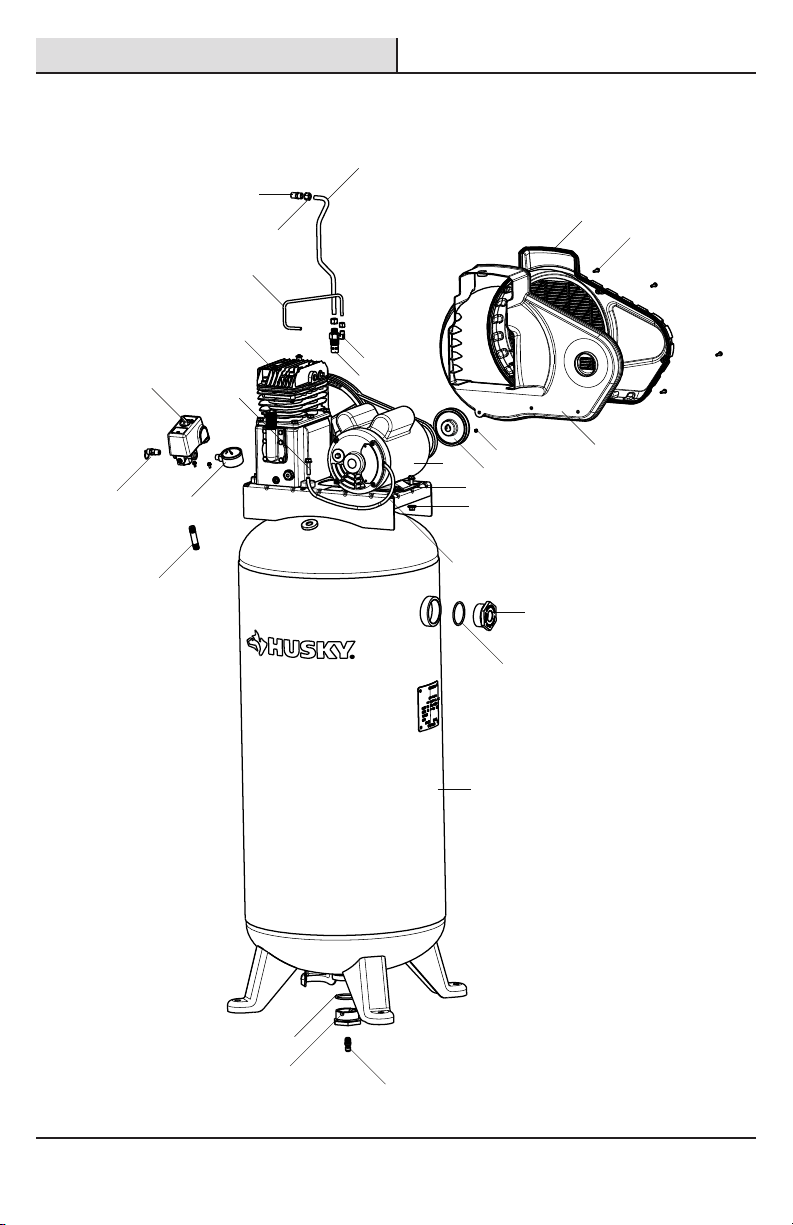

Service Parts

C602H, AIR COMPRESSOR

20

13

17

14

1

15

18

16

3

19

2

22

21

23

24

5

8

10

11

9

12A

12D

12

4

12D

12B

27 HUSKYTOOLS.com

Please contact 1-888-43-HUSKY for further assistance.

12C

Page 27

Service Parts (continued)

Item Number Description Part Number

1 Beltguard (Outer) E107832

2 #10 Plastite Screw NA

3 Bolt, 5/16-18 x 1.25 Thr Form NA

4 Beltguard (Inner) E107833

5 Setscrew NA

6 Key 5MM x 20MM NA

7 Belt 4L-520 "A" Section E107831

8 Pulley E105990

9 Cord Interconnect E105991

10 Bolt 5/16-18 x .75 NA

11 Nut 5/16-18 UNC NA

12 Tank Assembly Painted E107834

12A Bushing 2in. NPSM x 3/4in. NPTF E106539

12B Bushing 2in. NPSM x 1/4in. NPTF E105994

12C 1/4in. NPT Drain Valve NA

12D O-Ring 2in. E105995

13 Pump Assembly 755H E105996

14 Connector Male 1/4in. NPT x 3/8in. OD Tube E105997

15 3/8in. OD Tube Compression Nut Assembly E105998

16 1/4in. OD Tube Compression Nut Assembly E105999

17 Outlet Tube E107867

18 Pressure Relief Tube E106001

19 Check Valve 1/2in. NPT x 3/8in. OD Tube E106002

20 Pressure Switch E106003

21 Nipple 1/4in. NPT-18 x 2.00 NA

22 Valve, Asme 175 PSI E106004

23 Gauge 300 PSI 1/4in. NPT Side Mount E106005

24 Motor E106006

24A Start Capacitor E106007

24B Run Capacitor E106008

24C

24D

25

26

Start Capacitor Cover

Run Capacitor Cover

Warning Label

Hot Surface Warning Label

E106009

E106010

E106011

E106012

NOTE: Any part number field without a number listed is

not available. Descriptions are provided for reference only.

28

Page 28

Questions, problems, missing parts? Before returning to the store call

Husky Customer Service

8 a.m. - 6 p.m., EST, Monday-Friday

1-888-43-HUSKY

HUSKYTOOLS.COM

Retain this manual for future use.

Document Number: E107114

03/25/2014

Page 29

Article N° 911-625

C

Modèle N° C602H

GUIDE D’UTILISATION ET

D’ENTRETIEN

COMPRESSEUR D’AIR STATIONNAIRE DE 60 GALLONS

Questions, problèmes, pièces manquantes?

Avant de retourner ce produit au magasin,

appeler le Service clientèle de Husky entre

8h et 18h, Heure de l’Est, du lundi au vendredi.

1-888-43-HUSKY

HUSKYTOOLS.COM

Nous nous efforçons continuellement de créer des produits de qualité conçus pour améliorer votre résidence.

Nous apprécions la confiance que vous faites à Husky en achetant ce compresseur d’air.

Rendez-nous visite en ligne pour voir notre gamme complète de produits disponibles pour répondre à vos besoins

d’amélioration de votre résidence. Merci d’avoir choisi Husky!

MERCI

Page 30

Table des matières

Informations relatives à la sécurité .........2

Sécurité sur le lieu de travail .................2

Sécurité personnelle .............................3

Déplacement du compresseur ...............3

Consignes de sécurité pour les

compresseurs d’air et les outils

pneumatiques ........................................4

Sécurité électrique .................................5

Garantie .....................................................7

Avant la mise en marche ..........................8

Spécifications ........................................8

Cycle de fonctionnement .......................8

Informations sur la sécurité

Ce manuel contient des informations qu’il est important

que vous connaissiez et compreniez. Ces informations

portent sur la protection de votre sécurité et la prévention

de problèmes pouvant affecter vos équipements. Pour

vous aider à reconnaître ces informations, nous utilisons

les symboles ci-dessous. Veuillez lire le mode d’emploi et

faire attention à ces symboles.

Contenu de la boîte ................................8

Composants du système ........................9

Placement du compresseur d’air .........11

Système de distribution d’air ...............12

Utilisation d’outils ..............................14

Rodage de la pompe ............................15

Installation ..............................................16

Fonctionnement ......................................17

Maintenance ...........................................22

Entretien et nettoyage ............................27

Diagnostic de défaillance .......................28

Pièces de rechange ...............................31

DANGER : Indique une situation dangereuse imminente

qui, si elle n’est pas évitée, causerait la mort ou des

blessures graves.

AVERTISSEMENT : Indique une situation

potentiellement dangereuse qui, si elle n’est pas évitée,

pourrait causer la mort ou des blessures graves.

MISE EN GARDE : Indique une situation

potentiellement dangereuse qui, si elle n’est pas évitée,

pourrait causer des blessures mineures ou modérées.

AVIS : Indique une pratique sans rapport avec des blessures

personnelles qui, si elle n’est pas évitée, pourrait causer des

dommages aux biens.

SÉCURITÉ SUR LE LIEU DE TRAVAIL

□ Maintenez votre zone de travail propre et bien

éclairée. Assurez-vous que le sol n’est pas

glissant à cause de la présence de poussière ou

d’encaustique.

□ Utilisez le compresseur d’air dans une zone ouverte

à au moins 18 po (50 cm) de distance de tout mur

ou objet pouvant réduire l’arrivée d’air dans les

ouvertures de ventilation.

AVERTISSEMENT : N’utilisez pas d’outils électriques

dans des atmosphères explosives, comme en présence

de liquides, gaz ou poussières inflammables. Les outils

électriques produisent des étincelles qui risqueraient de

mettre feu à la poussière ou aux vapeurs. Maintenez les

observateurs, enfants et visiteurs à une distance suffisante

pendant que vous utilisez cet outil. Les distractions

pourraient vous faire perdre le contrôle de l’outil.

2

AVERTISSEMENT : Ce compresseur n’est pas équipé

pour fournir de ventilation de l’air ambiant, et il ne doit pas

être utilisé pour cela. Des équipements supplémentaires

seraient nécessaires pour filtrer et purifier l’air de façon

appropriée afin de répondre aux normes de qualité d’air

ambiant de grade D, conformément à ce qui est décrit

dans la norme Compressed Gas Association Commodity

Specification G 7.1 - 1966, OSHA 29 CF9 1910.134.

Compressed Gas Association, 4221 Walney Road, Fifth

Floor, Chantilly, VA 20151-2923, (703) 788-2700, www.

cganet.com. De tels équipements additionnels n’ont

pas été examinés, et aucune implication d’utilisation

appropriée pour la ventilation de l’air ambiant n’est

spécifiée, même implicitement.

MISE EN GARDE : Déconnectez toujours l’alimentation

en air et l’alimentation électrique avant de faire des

réglages ou d’effectuer des opérations d’entretien, ou

quand l’outil n’est pas utilisé.

Page 31

Informations sur la sécurité (suite)

SÉCURITÉ PERSONNELLE

□ Soyez bien équilibré et stable sur vos pieds à

tous moments. La stabilité et l’équilibre vous

permettent de mieux contrôler votre outil en cas de

circonstances inattendues.

□ Ne travaillez pas sur des échelles ou d’autres supports

instables.

AVERTISSEMENT : l’utilisation de tout outil électrique

peut avoir pour effet la projection de corps étrangers dans

vos yeux, ce qui pourrait causer des lésions graves aux

yeux. Avant de commencer à vous servir de votre outil,

mettez toujours des lunettes de sécurité, des lunettes

de protection avec un écran latéral ou un masque facial

complet suivant le cas. Portez toujours un dispositif de

protection des yeux indiqué comme étant conforme à la

norme ANSI Z87.1

AVERTISSEMENT : ce produit contient des produits

chimiques qui, selon l’État de Californie, cause des cancers

et des malformations congénitales ou autres problèmes de

reproduction. Lavez-vous les mains après toute manipulation.

AVERTISSEMENT : Utilisez des équipements de

sécurité. Portez toujours des équipements de protection

des yeux lorsque vous utilisez des outils électriques.

Un masque antipoussière, des chaussures de sécurité

antidérapantes, un casque ou un protège-oreilles doivent

être utilisés si les conditions le justifient.

DÉPLACEMENT DU COMPRESSEUR D’AIR

□ Lorsque vous transportez le compresseur dans un

véhicule, une remorque, etc., assurez-vous que le

réservoir a été purgé et que le compresseur est

arrimé correctement pour ne pas risquer qu’il se

renverse pendant le transport. Faites attention

quand vous conduisez pour éviter de causer son

renversement dans le véhicule en marche. Si le

compresseur se renversait, il risquerait d’être

endommagé ou d’endommager les objets autour

de lui. Demandez toujours de l’aide à une autre

personne quand vous soulevez le compresseur, et

utilisez les points de levage recommandés.

AVERTISSEMENT : Faites preuve de vigilance lorsque

vous utilisez un outil électrique. N’utilisez pas l’outil

lorsque vous êtes fatigué ou si vous êtes sous l’influence

de médicaments, d’alcool ou de drogues.

AVERTISSEMENT : Ne portez pas de bijoux ou de

vêtements flottants. Attachez les cheveux longs. Maintenez

vos cheveux, vêtements et gants à une distance suffisante

des pièces mobiles. Les bijoux, les vêtements flottants ou

les cheveux longs peuvent être attrapés dans des pièces

mobiles.

AVERTISSEMENT : Ne touchez jamais de pièces

avec du métal exposé sur le compresseur pendant le

fonctionnement ou immédiatement après. Le compresseur

restera très chaud pendant plusieurs minutes après avoir

été arrêté. Ne soulevez pas les capots de protection et

n’effectuez aucune opération d’entretien avant que le

compresseur ait suffisamment refroidi.

MISE EN GARDE : Le compresseur est trop lourd pour

pouvoir être soulevé par une seule personne. Faites-vous

aider par quelqu’un avant de tenter de le soulever.

AVERTISSEMENT : risque de fonctionnement

dangereux. Soyez bien stable et prenez des précautions

lorsque vous roulez le compresseur pour qu’il ne bascule

pas et qu’il ne vous fasse pas perdre l’équilibre..

3 HUSKYTOOLS.com

Veuillez contacter 1-888-43-HUSKY pour plus d’assistance.

Page 32

Informations sur la sécurité (suite)

CONSIGNES DE SÉCURITÉ POUR LES

COMPRESSEURS D’AIR ET LES OUTILS

PNEUMATIQUES

□ Maintenez les compresseurs aussi loin que

possible des zones de pulvérisation : au moins à 15

pi (4,6 m) de la zone de pulvérisation et de toutes

les vapeurs explosives.

□ Si vous le connectez à un circuit protégé par des

fusibles, utilisez des fusibles à délai de temporisation

avec ce produit.

□ Assurez-vous que le tuyaux flexible n’est oas

obstrué ou coudé. Des tuyaux emmêlés ou vrillés

pourraient vous faire perdre l’équilibre ou affecter

votre stabilité, et ils pourraient également être

endommagés.

□ Utilisez seulement le compresseur pour l’emploi

prévu. Il ne faut pas altérer ou modifier le

compresseur afin de l’utiliser dans un but autre que

celui pour lequel il a été conçu ou

□ Ne laissez jamais un outil sans supervision avec le

tuyau à air attaché.

□ Ne vous servez pas de cet outil s’il ne contient pas

une étiquette d’avertissement lisible.

□ Ne continuez pas à utiliser un outil ou un tuyau

avec des fuites d’air ou qui ne fonctionne pas

correctement.

□ Ne tentez pas de tirer ou de transporter le

compresseur d’air par le tuyau flexible.

□ Votre outil a peut-être besoin de plus d’air que ce

que ce compresseur est en mesure de lui fournir.

□ Ne dirigez jamais un jet d’air comprimé vers des

gens ou des animaux.

□ Protégez vos poumons. Portez un masque facial ou

un masque antipoussière si vous travaillez dans un

environnement poussiéreux.

□ N’utilisez pas ce compresseur d’air pour pulvériser

des produits chimiques. L’inhalation de vapeurs

toxiques pourrait être nuisible à vos poumons. Un

appareil respiratoire peut être nécessaire lorsque

vous travaillez dans un environnement poussiéreux

ou lorsque vous appliquez de la peinture au

pistolet.

□ Ce compresseur est muni d’un protecteur pour

surcharge thermique qui arrêtera le moteur en cas

de surchauffe.

AVERTISSEMENT : ne tentez pas de modifier cet outil

ou de créer des accessoires non recommandés en vue

d’emploi avec cet outil. Une telle altération ou modification

serait considérée comme une utilisation abusive et

pourrait être dangereuse, causant des risques de blessures

personnelles graves.

MISE EN GARDE : n’utilisez pas le compresseur

dans un environnement poussiéreux ou contaminé par

ailleurs. L’utilisation du compresseur d’air dans ce type

d’environnement pourrait causer des dommages à

l’équipement.

MISE EN GARDE : Risque d’éclatement. N’ajustez

pas le régulateur de manière à produire une pression de

sortie plus élevée que la pression nominale maximum de

l’accessoire. N’utilisez pas le compresseur à une pression

plus élevée que la pression nominale maximum prévue.

Si vous le connectez à un circuit protégé par des fusibles,

utilisez des fusibles à délai de temporisation avec ce

produit.

MISE EN GARDE : Pour réduire le risque de choc

électrique, n’exposez pas le compresseur à la pluie.

Rangez-le à l’intérieur.

4

Page 33

Informations sur la sécurité (suite)

SÉCURITÉ ÉLECTRIQUE (RALLONGES)

□ Utilisez seulement des cordons de rallonge à

trois fils ayant des fiches de mise à la terre à

trois broches et des réceptacles à trois pôles

compatibles avec la fiche du produit. Assurez-vous

que votre cordon d’alimentation de rallonge n’est

pas endommagé. Lorsque vous utilisez un outil

électrique à une distance considérable de la source

d’alimentation électrique, utilisez un cordon de

rallonge assez robuste pour transporter le courant

dont le produit a besoin. Un cordon de rallonge

inadéquat causera une chute de tension pouvant

entraîner une coupure de courant et une surchauffe

du moteur.

□ Utilisez le tableau fourni ci-dessous pour

déterminer la taille de fil minimum requise

pour le cordon de rallonge. Il ne faut utiliser

que des cordons à gaine ronde homologués par

Underwriter’s Laboratories (UL).

□ Utilisez seulement des cordons à gaine ronde

homologués par Underwriter’s Laboratories (UL)

d’une longueur maximum de 50 pi (15 m).

□ Lorsque vous utilisez un outil électrique à

l’extérieur, employez un cordon de rallonge pour

usage extérieur marqué « W-A » ou « W ». Ces

cordons peuvent être utilisés à l’extérieur et

réduisent le risque de choc électrique.

AVERTISSEMENT : Lorsque vous utilisez un cordon

de rallonge, maintenez-le à bonne distance de la zone de

travail. Positionnez le cordon de façon qu’il ne soit pas

attrapé par du bois, des outils ou d’autres obstructions

pendant que vous travaillez avec un outil électrique. Sinon,

vous risqueriez de subir une blessure grave.

AVERTISSEMENT : Inspectez les cordons de rallonge

avant chaque emploi. S’ils sont endommagés, remplacezles immédiatement. N’utilisez jamais le compresseur d’air

avec un cordon endommagé étant donné que tout contact

avec une section endommagée pourrait causer un choc

électrique entraînant une blessure grave.

AVERTISSEMENT : Une connexion incorrecte du

conducteur de mise à la terre de l’équipement pourrait

causer un choc électrique.

MISE EN GARDE : Évitez tout contact corporel avec

des surfaces mises à la terre telles que des canalisations,

des radiateurs, des fours ou des réfrigérateurs. Il existe

un risque accru de choc électrique si votre corps est relié

à la terre.

MISE EN GARDE : N’exposez pas des outils

électriques à la pluie ou à l’humidité. La pénétration

d’eau dans un outil électrique augmente le risque de choc

électrique.

MISE EN GARDE : Remplacez immédiatement les

cordons/fils endommagés. Des cordons/fils endommagés

augmentent le risque de choc électrique.

REMARQUE : Utilisez des tuyaux à air plus longs à la place de

cordons de rallonge. Votre compresseur d’air fonctionnera mieux et

durera plus longtemps.

SÉCURITÉ ÉLECTRIQUE (BRANCHEMENTS

ÉLECTRIQUES)

□ Ce compresseur d’air est entraîné par un moteur

électrique haute précision. Il doit être connecté à

une alimentation c.a. de 230 volts, 60 Hz seulement

(courant résidentiel normal).

□ N’utilisez pas cet outil avec du courant continu

(c.c.). Une chute de tension substantielle causera

une coupure d’alimentation et une surchauffe du

moteur. Si le compresseur d’air ne fonctionne pas

(sur la plaque signalétique du compresseur d’air)

Longueur

du cordon

25 ft. 16

50 ft. 12

Utilisé sur un circuit de calibre 12 – 20 ampères

REMARQUE : AWG = American Wire Gauge

Intensité nominale

14-16

Calibre des fils (AWG)

quand il est branché dans une prise de courant,

assurez-vous que le celle-ci est sous tension.

5 HUSKYTOOLS.com

Veuillez contacter 1-888-43-HUSKY pour plus d’assistance.

Page 34

Informations sur la sécurité (suite)

SÉCURITÉ ÉLECTRIQUE (VITESSE ET

CÂBLAGE)

□ La vitesse à vide de ce produit est d’environ 1 700

tr/min. Cette vitesse n’est pas constante et diminue

avec une charge ou si la tension est plus basse.

□ Pour la tension, le câblage dans un atelier est aussi

important que la puissance nominale du moteur.

Un circuit électrique conçu exclusivement pour

l’éclairage ne conviendra pas à l’alimentation

du moteur d’un outil électrique. Un câble qui est

approprié pour une courte distance sera insuffisant

pour une distance supérieure. Un circuit pouvant

supporter un outil électrique ne pourra peut-être

pas supporter deux ou trois produits.

SÉCURITÉ ÉLECTRIQUE (INSTRUCTIONS DE

MISE À LA TERRE)

□ Ce produit doit être connecté à un système de

câblage métallique permanent et mis à la terre, ou

à un conducteur ou une borne de mise à la terre de

l’équipement sur le produit.

6

Page 35

Avant la mise en marche

SPÉCIFICATIONS

Puissance de fonctionnement (en HP)

Capacité du réservoir d’air

Pression de l’air

Débit d’air

Réservoir temps de remplissage

Lubrification

Entrée

Spécifications minimales pour le circuit

de dérivation

Type de fusible

Poids net

CYCLE DE FONCTIONNEMENT

La pompe de ce compresseur d’air est capable de fonctionner de manière ininterrompue. Cependant, pour prolonger

la durée de vie de votre compresseur d’air, il est recommandé qu’un cycle de fonctionnement moyen de 50 % soit

maintenu; en d’autres termes, la pompe du compresseur d’air ne devrait pas fonctionner plus de 30 minutes par

heure.

CONTENU DE LA BOÎTE

3.7 HP

60 gallons

155 PSI max.

13.4 pi3/min à 40 psiI

11.5 pi3/min à 90 psiI

7 minutes

Huile de graissage

240 V, 60 Hz, monophasé

c.a. seulement, 13.5 ampères

20 A

Délai de temporisation

218 lbs.

A

Pièce Description Quantité

Compresseur d’air (complètement

A

assemblé)

8

1

Page 36

Avant la mise en marche (suite)

COMPOSANTS DU SYSTÈME

K

L

E

I

O

M

N

H

J

F

P

C

B

A

Pièce Description

Interrupteur Auto(I)/Arrêt(0) : Mettez cet interrupteur dans la position «Auto (I)» pour fournir une

A

alimentation électrique continue au pressostat et sur la position «Arrêt (0)» pour couper l’alimentation

électrique à la fin de chaque utilisation.

Manostat : Le manostat démarre automatiquement le moteur lorsque la pression du réservoir d’air

B

chute en dessous de la pression « d’enclenchement » réglée en usine. Il arrête le moteur lorsque la

pression du réservoir d’air atteint la pression « de coupure » réglée en usine.

Soupape de sûreté : Si le manostat ne ferme pas le compresseur d’air à son réglage de pression de

coupure (« cut-out »), la soupape de sûreté le protégera contre le risque de pression excessive en «

C

sortant » à son réglage de pression d’origine (légèrement plus élevé que le réglage de pression de

coupure susmentionné).

Indicateur de pression du réservoir : L’indicateur de pression du réservoir indique la pression de l’air

D

de réserve dans le réservoir.

Pompe du compresseur d’air : Elle comprime l’air dans le réservoir d’air. L’air de travail n’est pas

disponible avant que le compresseur ait élevé le niveau de pression du réservoir d’air au-dessus de ce

E

qui est requis à l’orifice de sortie d’air.

Robinet de purge : Le robinet de purge est situé à la base du réservoir d’air et est utilisé pour purger la

F

condensation après chaque emploi.

G

D

9 HUSKYTOOLS.com

Veuillez contacter 1-888-43-HUSKY pour plus d’assistance.

Page 37

Avant la mise en marche (suite)

Pièce Description

Clapet anti-retour : Quand le compresseur d’air fonctionne, le clapet anti-retour est «ouvert» ce qui

permet à l’air comprimé d’entrer dans le réservoir d’air. Quand le compresseur d’air parvient à la

G

pression de «coupure», le clapet anti-retour «se ferme» ce qui permet de maintenir la pression de l’air

dans le réservoir d’air.

Soupape de décharge (non illustrée) : La soupape de décharge située sur le côté du manostat est

conçue afin de libérer automatiquement l’air comprimé de la tête de compresseur et du tube de sortie

lorsque le compresseur atteint la pression « de coupure » ou est arrêté. La soupape de décharge permet

H

au moteur de redémarrer librement. Lorsque le moteur s’arrête, de l’air qui s’échappe de cette soupape

se fait entendre pendant quelques secondes. Aucune fuite d’air ne doit se faire entendre quand le

moteur tourne ou une fois que le compresseur atteint la pression « de coupure ».

Réinitialisation de la surcharge thermique (non illustrée) : Ce moteur comporte un protecteur manuel

contre les surcharges thermiques. Si le moteur surchauffe pour quelque raison que ce soit, le protecteur

contre les surcharges arrêtera le moteur. Il faut attendre que le moteur ait refroidi avant de la remettre

en marche. Pour le remettre en marche:

I

1. Mettez l’interrupteur Auto/Arrêt en position «Arrêt».

2. Laissez le moteur refroidir.

3. Appuyez sur le bouton rouge de réinitialisation situé sur le moteur.

4. Mettez l’interrupteur Auto/Arrêt en position «Auto» pour redémarrer le moteur.

Pieds du compresseur : Les pieds du compresseur sont utilisés pour stabiliser le compresseur, et ils

J

servent de supports d’attache pendant le montage du compresseur au sol.

K

Protection de courroie : La protection de courroie est une enceinte qui protège les pièces mobiles.

Trou de remplissage d’huile de pompe : Le trou de remplissage d’huile de pompe sert à ajouter de

L

l’huile au carter.

Purgeur d’huile de la pompe : Le purgeur d’huile de pompe sert à vidanger l’huile usagée de la pompe.

M

Pour laisser l’huile sortir du carter de la pompe, il faut desserrer le bouchon de vidange.

Vitre d’observation du niveau d’huile : La vitre d’observation du niveau d’huile permet de vérifier

N

visuellement le niveau d’huile dans le carter.

Moteur : Le moteur est l’élément d’entraînement alimenté par électricité qui permet de faire tourner la

O

pompe au moyen d’un système de poulie à courroie.

Sortie d’air : La sortie d’air est un point de connexion qui fournit de l’air pouvant être utilisé pour les

P

outils.

10

Page 38

Avant la mise en marche (suite)

PLACEMENT DU COMPRESSEUR D’AIR

AVERTISSEMENT : Si de quelconques pièces sont

endommagées ou manquantes, ne vous servez pas de

ce produit avant que ces pièces n’aient été remplacées.

REMARQUE : Des fils électriques très longs pourraient causer une

perte de puissance du moteur.

□ Placez le compresseur d’air dans un endroit propre,

□ Le compresseur d’air doit être positionné à au moins

□ Placez le compresseur d’air aussi près que possible

□ Le filtre à air doit être nettoyé régulièrement de

Le non-respect de cet avertissement pourrait causer des

blessures graves.

MISE EN GARDE : n’utilisez pas le compresseur

dans un environnement poussiéreux ou contaminé par

ailleurs. L’utilisation du compresseur d’air dans ce type

d’environnement pourrait l’endommager.

sec et bien ventilé.

18 po (50 cm) de distance de tout mur ou autre

obstruction pouvant affecter la circulation de l’air.

de la source d’alimentation électrique principale

pour éviter de devoir utiliser des fils électriques

très longs.

façon à éviter les obstructions qui pourraient

réduire l’arrivée d’air dans le compresseur d’air.

18 po

(0.5 m)

11 HUSKYTOOLS.com

Veuillez contacter 1-888-43-HUSKY pour plus d’assistance.

Page 39

Avant la mise en marche (suite)

SYSTÈME DE DISTRIBUTION D’AIR

Le diagramme de la page suivante représente un

système de distribution d’air ordinaire. Les conseils

suivants sont à considérer quand vous montez le

système de distribution d’air du compresseur d’air.

□ Utilisez un tuyau de la même dimension que

l’orifice de sortie du réservoir d’air. Si le tuyau est

trop petit, il restreindra le débit de l’air.

□ Si la longueur du tuyau dépasse 30,5 m (100 pi),

utilisez la taille supérieure suivante.

□ Enterrez les conduites souterraines en dessous

de la ligne de gel et évitez les poches où l’eau de

condensation peut s’accumuler et geler. Faites

passer de la pression avant de recouvrir les

conduites pour vous assurer qu’il n’y a pas de fuites

au niveau des raccordements de tuyaux.

□ Il est recommandé d’installer un couplage flexible

entre le robinet à soupape/la bouche d’évacuation

d’air et la conduite de distribution d’air principal

pour tenir compte des vibrations.

□ Il est recommandé d’utiliser un régulateur séparé

pour contrôler la pression d’air. La pression d’air

provenant du réservoir est habituellement trop

élevée pour les outils à entraînement pneumatique

individuels.

□ N’installez pas les lubrificateurs entre le réservoir

et tout équipement de pulvérisation, outil

pneumatique ou accessoire qui exige de l’air filtré

exempt d’huile.

□ Videz quotidiennement tous filtres, pièges

d’écoulement et tuyaux d’évacuation des saletés.

AVERTISSEMENT : Risque d’éclatement. Les tuyaux

en plastique ou en PVC ne sont pas conçus pour une

utilisation avec de l’air comprimé. Quelle que soit sa

pression nominale indiquée, un tuyau en plastique peut

éclater à cause de la pression d’air. N’utilisez que des

tuyaux en métal pour les conduites de distribution d’air.

AVERTISSEMENT : Risque d’éclatement. Utilisez

toujours des tuyaux et des raccords en métal.

REMARQUE : L’air comprimé provenant des compresseurs d’air

lubrifiés à l’huile contiendra de la condensation d’eau et des vapeurs

d’huile. Certains purgeurs, pièges et filtres seront nécessaires

pour fournir de l’air exempt d’eau (aérosols inclus) ou d’huile à

des équipements de pulvérisation, des outils pneumatiques et des

accessoires exigeant de l’air filtré. Lisez toujours le mode d’emploi des

outils pneumatiques et des accessoires utilisés.

12

Page 40

Avant la mise en marche (suite)

LA SECTION SYSTÈME TYPIQUE DE DISTRIBUTION D’AIR

Pièce Description

A Tuyaux de vidange

B Robinets de vidange

C Lubrificateur

D Outil pneumatique

E Régulateur

F Filtre / Piège à humidité

G Conduites d’utilisation d’air

H Tuyaux d’évacuation de saleté

I Vanne d’évacuation d’air

Les conduites d’alimentation s’inclinent

J

avec le débit d’air

13 HUSKYTOOLS.com

Veuillez contacter 1-888-43-HUSKY pour plus d’assistance.

Pièce Description

Conduites de distribution d’air principales -

Inclinez le tuyau dans le sens du débit d’air.

L’eau de condensation s’écoule le long de la

K

surface inférieure des tuyaux vers les tuyaux

de vidange, empêchant ainsi l’entrée d’eau

dans les conduites d’alimentation.

L Filtre de 5 microns

M Filtre de .01 microns

N Pistolet de pulvérisation

O Boule filtre

P Raccord flexible

Pour des résultats optimums, - La distance

Q

entre le compresseur et le piège à humidité

doit être aussi longue que possible.

R Débit d’air

Page 41

Avant la mise en marche (suite)

UTILISATION D’OUTILS

= Continue = Intermittente = Non recommandée

Outil

Utilisation

d’outils

recommandée

Outil

Utilisation

d’outils

recommandée

Gonflage Clouage de finition

de matériaux

de couverture

Ossature/pose

Dispositif de

gonflage

Cloueuse

à pointes

de vitrier

Agrafeuse

finition/cloueuse

de matériaux de

couverture

Coupe/perçage Préparation de surface Peinture

Marteau

pneumatique

Outil de

découpe

Perceuse/

visseuse à

percussion

Ponceuse Meuleuse

Clé à

percussion

Boulonnage

Clé à percussion de 1/2

po et 3/4 po pour usage

intensif

Peinture

à haut

volume

et basse

pression

Pistolet à

peinture

Pistolet à

peinture

Cliquet

pneuma-

tique

Pistolet à

graisse

Pistolet à

graisse

14

Page 42

Avant la mise en marche (suite)

RODAGE DE LA POMPE

AVIS : Risque de dommages matériels. Manquer de suivre

à la lettre les consignes de rodage ci-dessous peut causer

des dommages matériels.

AVIS : Des fuites mineures peuvent entraîner un

surmenage du compresseur d’air, et résulter dans des

pannes prématurées ou un rendement inadéquat.

Ce procédure est requise avant la mise en service du

compresseur d’air et quand le clapet ou une pompe

complète de compresseur a été remplacé.

□ Assurez-vous que l’interrupteur Automatique/Arrêt

(1) se trouve sur la position « Arrêt ».

□ Contrôlez le niveau d’huile dans la pompe.

Reportez-vous à la rubrique Maintenance pour les

instructions.

□ Vérifiez la totalité du câblage. Assurez-vous que

tous les câbles sont solidement fixés sur les bornes

et les connexions. Assurez-vous que tous les

contacts bougent librement et sans obstruction.

□ Ouvrez le robinet de purge (2) à fond pour

permettre à l’air de s’échapper afin d’en éviter une

accumulation dans le réservoir d’air pendant la

période de rodage.

□ Mettez l’interrupteur Automatique/Arrêt (1) sur la

position « Automatique ». Le compresseur démarre.

□ Faites fonctionner le compresseur d’air pendant

20 minutes. Assurez-vous que le robinet de purge