Hunter Engineering Quick Tread Brochure

™

Quick Tread

Drive over tread depth system

NEW!

Quick Tread™ At-A-Glance

Driven by Hunter’s award-winning WinAlign® software,

Quick Tread™ — Hunter’s drive over tread depth unit

— automatically measures the tread depth of each tire

in seconds.

Quick Tread measures tread depth, analyzes the data on-site

and instantly displays results on your Quick Check

Quick Tread operation

connection and there are no recurring monthly charges.

Track Data with HunterNet

does not require an internet

™

™

console*.

✔ Store tread depth records

✔ Use customer history in your

marketing efforts

Results in 10 seconds

✔ Eliminate trips

around vehicle

✔ Capture accurate

tread info on

all vehicle traffi c

✔ No technician needed to determine

tread depth

*Quick Tread requires a Quick Check console.

Built-In Accuracy

Point Cloud Measurement Technology

✔ Eliminate human

error and

guesswork

✔ Measure a two-inch tire segment, not a single point

✔ 280,000 data points (800x350)

✔ Generate three-dimensional models of the customer’s tire

2 in.

Durable Design

✔ Powder-coated stainless steel

construction to resist corrosion

✔ Self-cleaning air knife

✔ Mechanical shutter protects

sensors

✔ Completely sealed sensor housing

protects electronic components

Customizable Printouts*

✔ Easy-to-understand

printouts help sell tires

✔ Multiple printout options

✔ Displays up to six

measurements per tire

Developing Quality Technology

Featuring Sigmavision’s patented tire measurement technology, Hunter’s drive over tread depth measurement system

is the industry’s fastest and most accurate. See Sigmavision’s U.S. Patent No. 8625105 to learn more.

* Sample printout shown requires system with Quick Check alignment sensors.Vehicle OE warranty policies vary, please consult OE guidelines when establishing vehicle inspection policies.

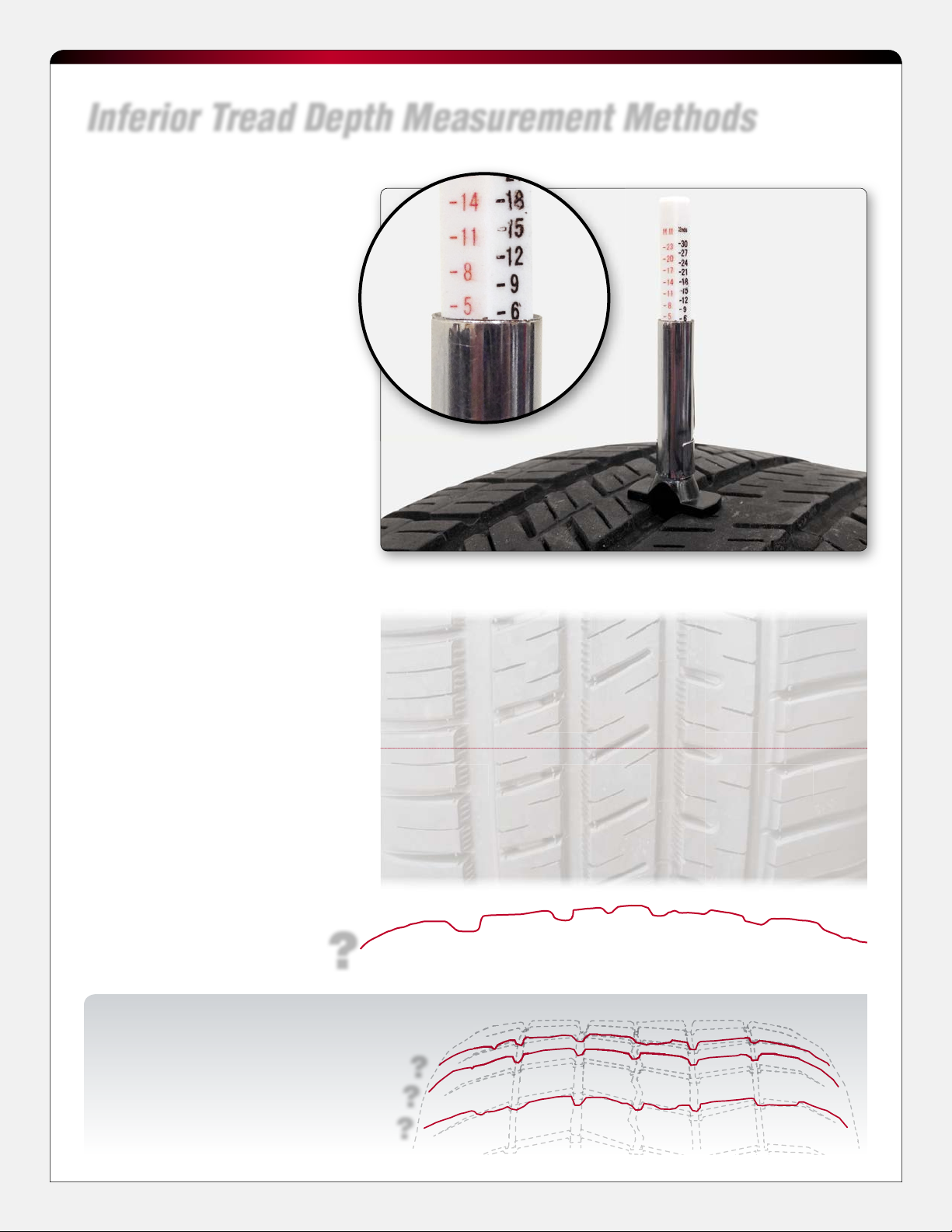

Inferior Tread Depth Measurement Methods

Basic Hand-Held

Measurement is Obsolete

Prior to digital measurement

technology, tread depth was

measured using a hand-held,

plunger-type measurement tool.

✔ Measurements often written

down, creating additional

paperwork

✔ Required technicians to manually

interpret each reading

✔ Accuracy could vary by ±3/32 or

more depending on operator

Random Line Scan

Measurement

Other drive over tread depth

measurement tools collect data

points across a single line of a tire.

✔ This small amount of data

is used to measure overall

tire health

✔ The results can vary greatly

depending on what part of the

tread is measured

?

Single-line scans can vary greatly.

Sipes and other obstructions can affect

the results of a single-line scan —

even scans taken in close proximity

to one another.

Results displayed as a single line

?

?

?

Loading...

Loading...