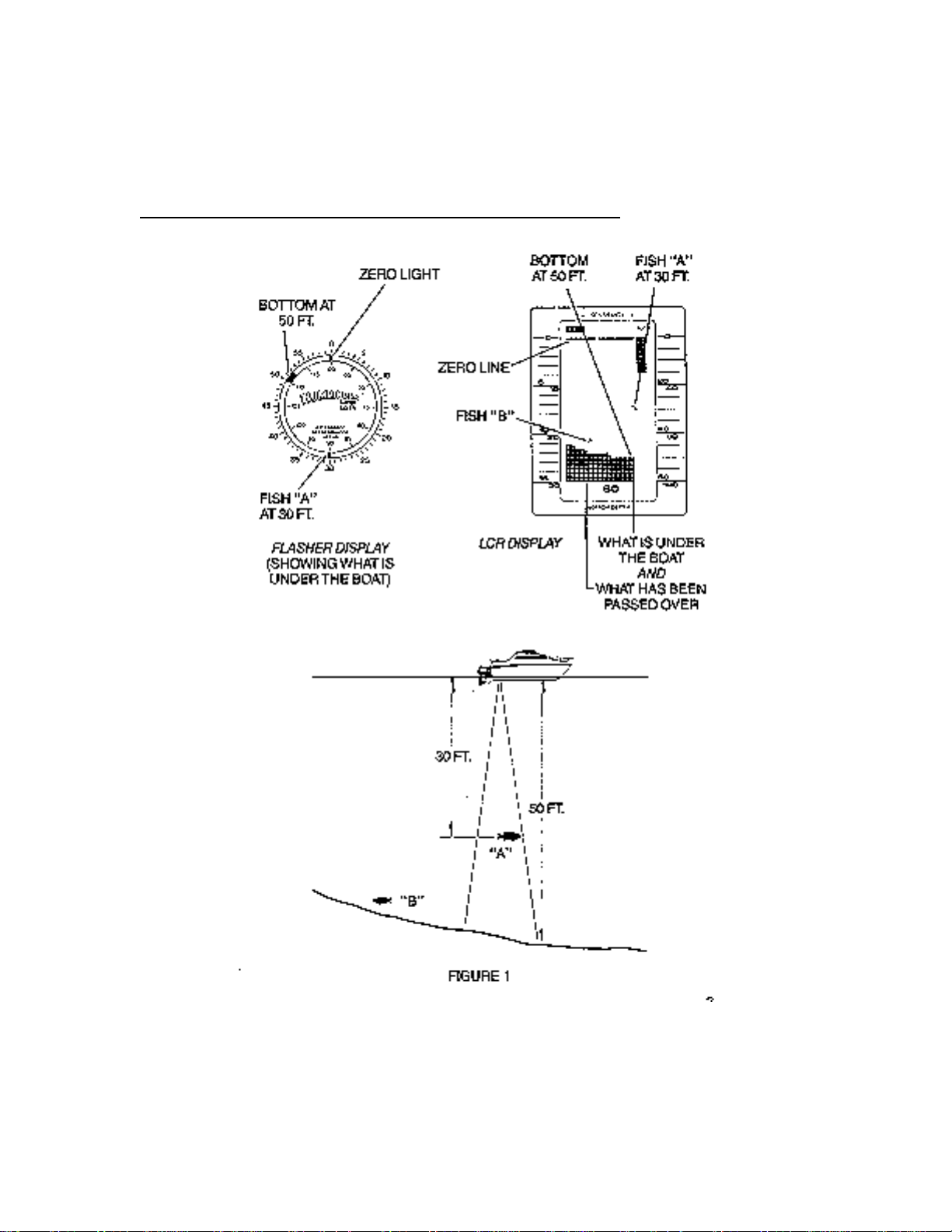

Page 1

Page 2

TRANSDUCER MOUNTING PROCEDURE

Humminbird’s high-speed transducer is supplied with your LCR. This transducer has been

designed to give good high speed readings on most all boat designs, including aluminum.

Please carefully consider the following before installing your transducer.

TRANSDUCER MOUNTING OPTIONS

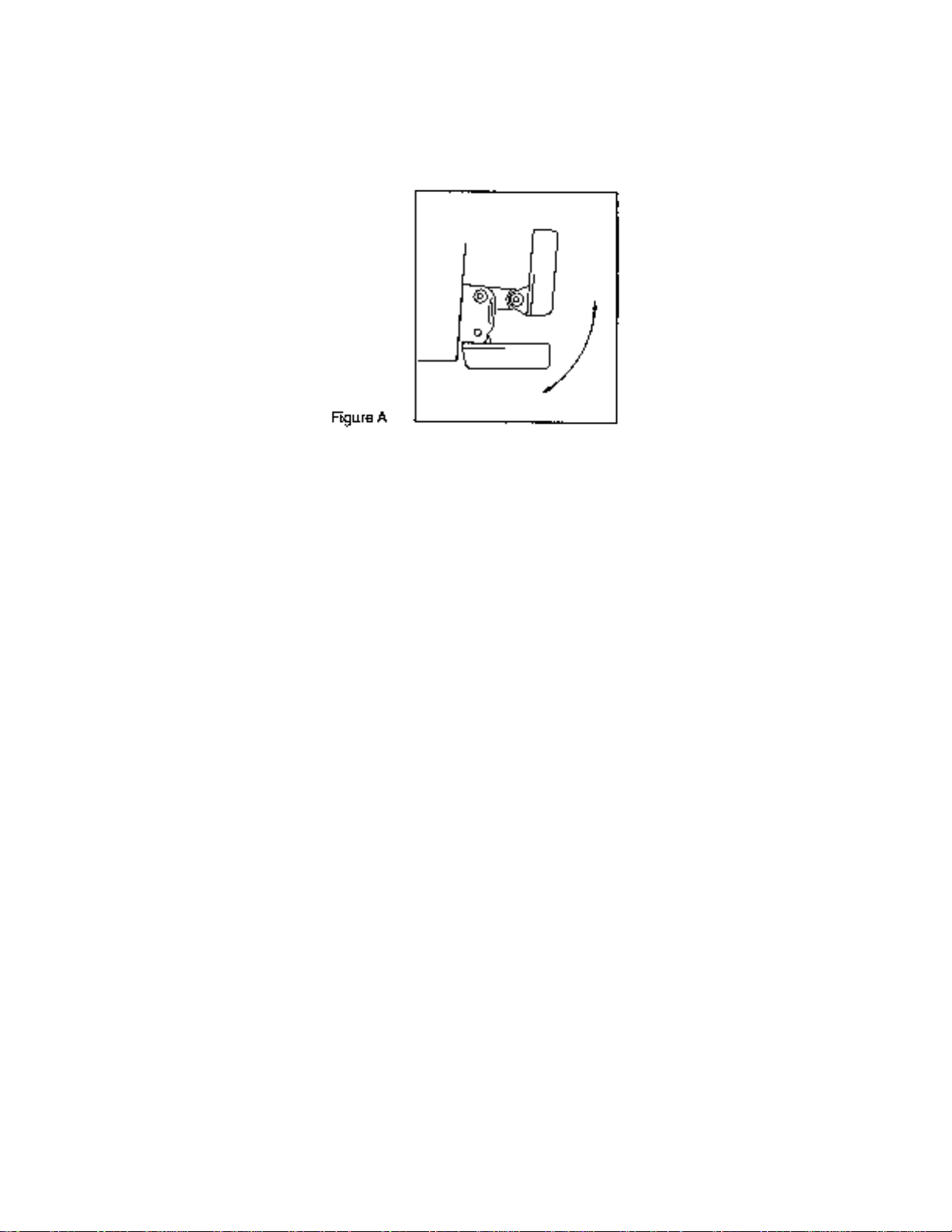

A. Transom Mount - The Humminbird high speed transducer allows the transducer element to be

mounted below the bottom of the boat hull keeping the transducer out of turbulent water and

insuring good high speed operation. The transducer will absorb the blow of any obstruction

Page 3

by rotating up out of the metal spring bracket without harming the transducer, or your boat.

The transducer can be re-engaged by simply rotating the transducer down and snapping it

back in place. (See Figure A)

B. Inside Hull Mount - The high speed transducer can be mounted inside the hull (without pivot

assembly) using the proper two-part epoxy, such as Humminbird’s epoxy kit. Even though

there is some loss of signal in shooting through the hull, your LCR will perform well with this

type of installation. You cannot shoot through the hull of an aluminum boat.

C. Trolling motor Mount - This type of transducer is not supplied with your LCR. It is designed to

mount on the foot of a trolling motor. You may exchange your un-used high speed

transducer for a trolling motor transducer. Call the Humminbird Customer Service

Department.

D. Bronz Thru-Hull Mount - This transducer is not supplied with your LCR but for an additional

cost you may exchange your un-used high speed transducer for a bronz thru-hull. The bronz

thru-hull transducer has a threaded stem which installs through a hole drilled in the boat hull,

leaving the housing exposed under the boat. This type of installation must be used for many

boats with in-board engines, because there is no suitable location on the transom away from

the noise and turbulence created by the prop. A bronz thru-hull transducer should be installed

by qualified personnel only.

The LCR will operate well at high speeds with a properly mounted transducer. Remember, a

transducer will not work transmitting through air or through air bubbles.

1. TRANSOM MOUNTING PROCEDURE

Step 1.

MOUNTING LOCATION- It is important that the transducer be mounted on the transom where

water flow is in constant contact with the transducer. You may wish to observe the rear of the

boat while it is moving through the water to determine the best mounting location.

Step 2.

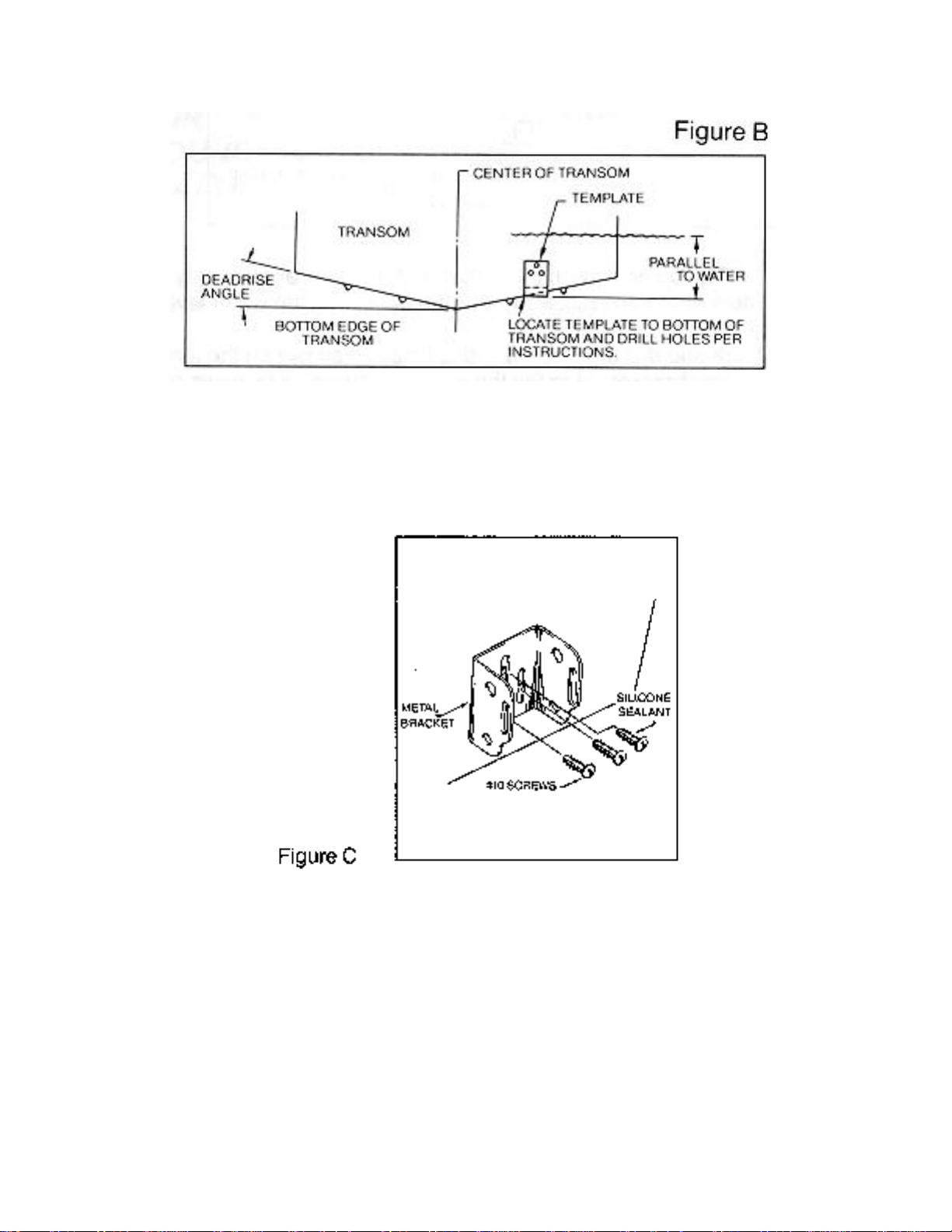

BRACKET INSTALLATION (Aluminum Boats)- To install the metal bracket on an aluminum boat

locate the template on the transom between rows of rivets, or ribs that are on the bottom of the

boat. Align the template so that the bottom corner of the template nearest the center of the

transom is on the bottom edge of the transom.

Page 4

Once the location is determined mark and drill three 7/64” dia.. holes noted on the template.

Attach the metal bracket using three #10 self threading screws supplied. Be sure to align holes in

the center of the

Bracket slots. On some aluminum boats it may be necessary to use a wood back-up plate. It is

important to use a silicone sealant between the screwhead and bracket in order to prevent

leaking. (See Figure C)

Step 2.

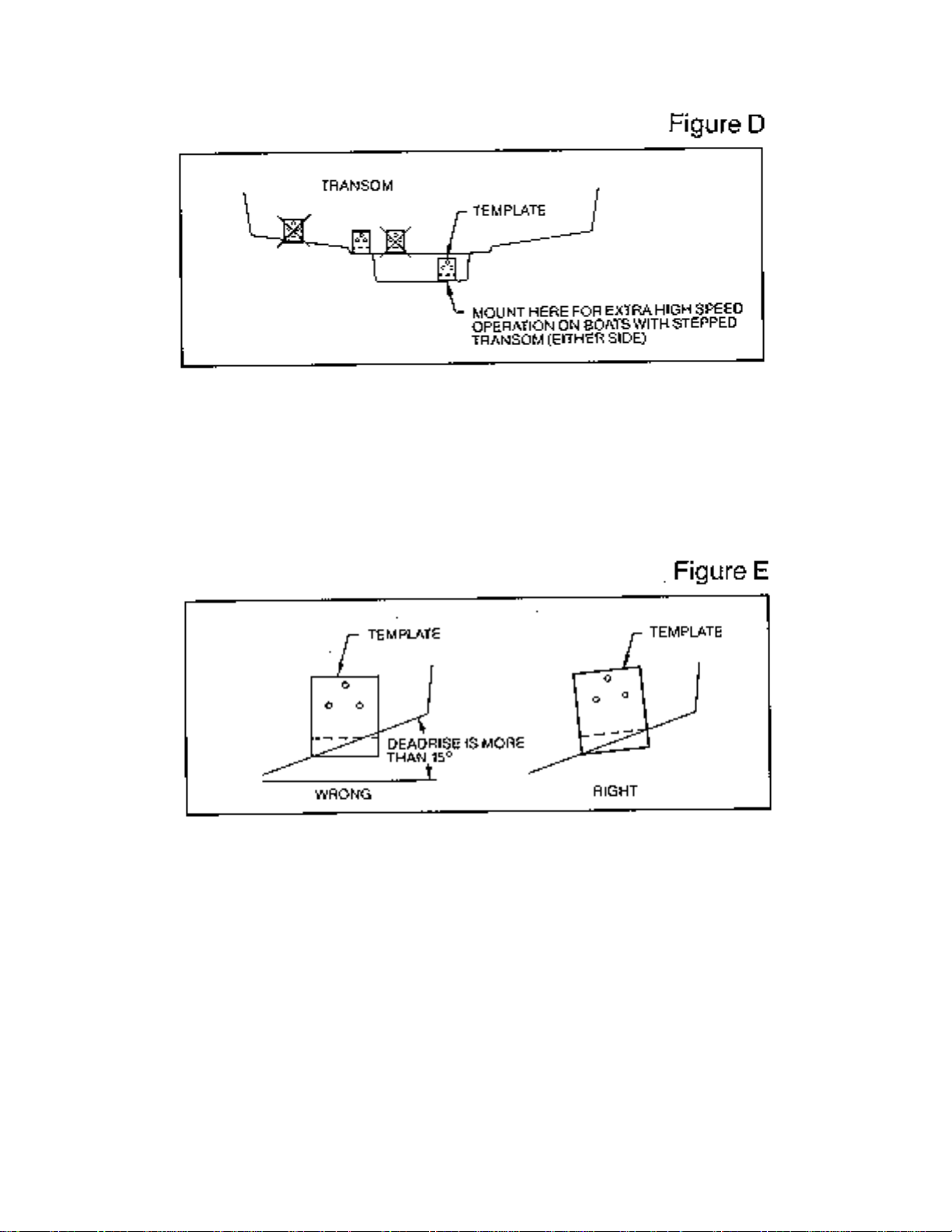

BRACKET INSTALLATION (Fiberglass Boats)- If your boat has a stepped transom located

below and under the main transom, the compact transducer design allows mounting in this area.

This mounting location is recommended for good reading at very high speeds. (See Figure D)

To install the metal bracket on a fiberglass boat, locate the template on the transom in the same

manner as for an aluminum boat. (See Figure C)

Page 5

NOTE: On boats with more than 15 degree deadrise angle it may be necessary to mount the

transducer slightly off parallel with the water level. (See Figure E)

Mark and drill the three 9/64” dia. holes as shown on the template. Attach the metal bracket using

the three #10 self threading screws supplied. Be sure to align the holes so that they are centered

vertically in the three slots found in the bracket. It is important to use a silicone sealant between

the screwhead and bracket in order to prevent leaking.

Step 3.

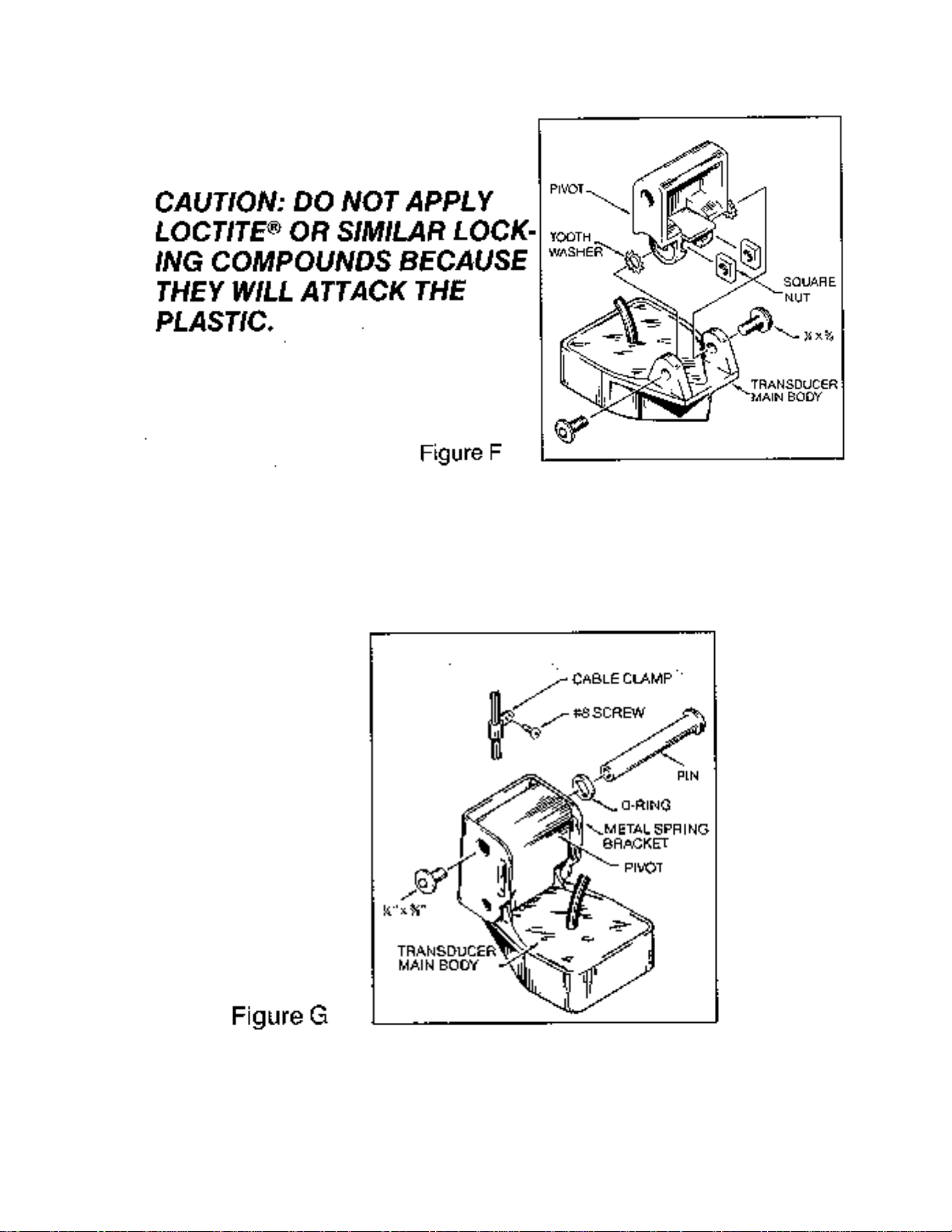

TRANSDUCER PIVOT ASSEMBLY - Assemble the pivot to the transducer main body using the

two ¼”x5/8” allen head screws, two 3/8” tooth washers and two, ¼” square nuts. Make sure the

tooth washers are sandwiched between the transducer main body and the pivot. The square nuts

are trapped inside the pivot and will not rotate as the allen head screws are tightened.

HOWEVER, DO NOT TIGHTEN AT THIS POINT. (See Figure F)

Page 6

Step 4

TRANSDUCER ASSEMBLY - Insert the transducer assembly into the metal bracket from the

bottom. Push up until the holes in the plastic pivot align with the uppermost holes in the bracket.

Slide the O-ring on to the headed pin and insert it through the two parts. Assemble by screwing

the ¼”x3/8” allen head screw into the end of the pin and tighten. (See Figure G)

Step 5

ANGLE ALLIGHMENT- Set the transducer angle so that it is parallel with the bottom of the boat

hull. Once proper alignment is achieved, tighten the two allen head screws using the 5/32” allen

Page 7

wrench provided. The screws are visible through the access holes on each side of the metal

bracket. Check to make sure the transducer main body is rigidly fas tened to the pivot. (See

Figure H)

Step 6

CHECK POSITION OF TRANSDUCER- At this point, check to see that the bottom of the

transducer is a minimum of ¼” below the bottom of the transom. (However, as noted in STEP 2,

the top of the transducer cannot fall below the bottom of the transom). If it is not, remove the

transducer assembly from the metal bracket by removing the pin installed during STEP 3. Loosen

the metal bracket mounting screws, re-position the bracket utilizing it’s slotted holes, tighten and

re-assemble. It may be necessary to replace the silicone sealant after this adjustment is made.

NOTE: It may be necessary to make several high speed runs to adjust transducer either

UP/DOWN or to re-adjust the angle to achieve optimum results.

Step 7

CABLE CLAMPS- Install cable clamps as necessary by drilling a 1/8” dia. hole for the # 8 screw

supplied.

2. INSIDE HULL MOUNTING PROCEDURE

Warning: In order to achieve proper results with this type installation, it is important that the

transducer be mounted by someone familiar with the use of two part epoxy adhesives. For this

reason, Techsonic Industries, Inc. will not be responsible for any damage due to the mounting of

your transducer in this manner.

NOTE: An Epoxy Kit (Part N. EPK) is available from Humminbird. This Epoxy Kit has been

formulated for Inside Hull Transducer Installation.

1. Select as flat an area as possible near the aft end and center of boat where the hull is thin

and not double. If the bottom has a runner down the center of boat, select an area to one side

of the runner, but as close to the runner as possible.

2. Clean the inside of the boat with lacquer thinner in the area transducer is to be mounted.

Outside of boat in this area should also be cleaned. (Not with lacquer thinner).

3. Put approximately one inch of water in the bottom of the boat.

4. Put transducer in the water. The bottom of the transducer should be in a flat area and should

be in good contact with the bottom of the boat.

5. Operate the LCR with the boat operating at high speed. The transducer may have to be

moved in order to find an area where satisfactory operation is observed.

6. When an area is found that produces satisfactory operation, mark the location of the

transducer.

Page 8

7. Remove the water and transducer and clean the marked area and the bottom of the

transducer thoroughly.

8. Using the Humminbird Epoxy Kit or equivalent, mix an ample amount of epoxy without

causing it to bubble and pour it in the area the transducer is to be mounted. The puddle

should be larger than the bottom of the transducer.

9. Coat the bottom of the transducer with epoxy, then put it in the center of the puddle and push

down on the transducer while moving it around in a circular motion. This forces out any air

bubbles that may be trapped between the bot tom of the transducer and the hull of the boat.

10. Let epoxy cure then the transducer is ready to operate. No water is now required in the

bottom of the boat and gas and oil that is spilled inside of the boat will not degrade

performance as it will if the transducer is placed only in water.

CAUTION: Do not use the silicone seal or any soft adhesive to bond the transducer to the

hull. This will reduce the sensitivity of the unit.

CAUTIONS

1. Occasionally the “eye“ of your transducer may become dirty from storage or from contact with

oils present in boats or marina environments. (Oil will cause the “eye” to lose the intimate

contact with the water which is necessary for efficient operation.) The “eye” may be cleaned

with liquid detergent.

2. Improper installation of the transducer can alter the efficiency and accuracy of the entire

system.

3. If your boat of transducer is out of the water for a period of time, it may take a short period of

time for the transducer to become thoroughly “wetted” when returned to the water. Also, reentry may cause turbulence, which will create air bubbles in the “eye” of the transducer. The

bubbles will disappear in a short time or can be removed by rubbing the transducer “eye” with

your fingers while the transducer is in the water.

4. If your instrument should fail to function, be sure to check all the electrical connections before

removing the transducer or calling a serviceman.

5. Inspect your transducer cable and make sure that it has not been cut or damaged to the point

where it will affect the performance of the transducer. A slight nick or cut, exposing the outer

cable, can be repaired by wrapping with electrical tape. A transducer can be damaged if the

inner cable and outer cable are allowed to make contact. Such a problem can sometimes be

corrected by properly splicing the coaxial cable. This should only be attempted by a qualified

service technician.

6. If your LCR is not working properly and you suspect the problem might be in your transducer,

we would recommend you borrow a unit from a friend and try it on your boat. If the symptoms

are the same, you can almost be certain that the problem is in the transducer.

INSTALLING THE LCR

The LCR should be mounted on a flat, solid surface for maximum stability. The low profile swivel

mount has four holes drilled in the base. It is recommended that all four holes be used.

Position the swivel base and drill four ¼” diameter holes. Note: The LCR hole pattern Is the same

as for all Humminbird flasher units. Use hardware provided to mount this base to the boat.

Next place the gimbal bracket on the swivel base and attach with four small machine screws,

provided.

Place the LCR in the gimbal mount and make certain the rubber washers provided are placed

between the unit and the gimbal bracket Important: Note which side of the gimbal faces forward.

(Slots on gimbal bracket go towards rear). Also, rubber washer must be located between the unit

and the gimbal bracket.

Page 9

Install the mounting knobs and tighten snugly. The unit can now be swiveled and tilted to any

desired position.

Page 10

d is not recommended since the unit cannot be rotated.

OTHER MOUNTING OPTIONS

1. The LCR gimbal bracket can also be mounted on the SM-4, quick disconnect swivel mount.

2. The LCR gimbal bracket can also be mounted directly to the dash without the swivel mount,

however, this metho

INSTALLING THE CABLES

Your LCR comes equipped with Humminbird’s new Angle-Lock power and transducer

connectors. The power connector is identified with the letter P on the back of the plug.

Page 11

It plugs into the outlet on the back of the unit marked “Power”. The transducer connector is

identified with the letter T and plugs into the outlet on the back of the unit marked “Transducer”.

Note: An adapter (AD-4) is available to allow use of an old waterproof (BNC) transducer with the

LCR, but be sure that the transducer is a 16degree. A 32-degree transducer cannot be used.

A 11/8” hole must be drilled to pull through the transducer connector. After drilling the hole, pull

the transducer connector up through the hole. If you are installing two units, both transducer

connectors can be pulled through this 1 1/8” inch hole. Next, push the power cable wires down

through the hole. A hole cover has been provided which will dress and hold the wires. Install the

hole cover after determining the necessary wire length from the hole.

The power cable has a red lead to the positive (+) post and the black lead to the negative (-) post.

Install a 1 amp fuse between the red cable and positive post of your 12-volt battery.

If a fuse panel is available, we recommend wiring the power cable into the fuse panel. Note: The

LCR must be fused separately from any other accessory.

Your Angle-Lock connectors can only be plugged in one way. Position the connector so the letter

P or T can be read and the 90 degree bend is pointed downward. Push the connector in as far as

it will go. Turn the positive locking ring as far as it will go clockwise until you feel it lock. Locking

ring as far as it will go clockwise until you feel it lock. Your connector is now locked into place.

Note: For easy access to the connectors, simply loosen the mounting knobs and tilt your LCR

forward. The connectors are now in full view and easy to plug or unplug.

Page 12

TESTING THE INSTALLATION

After installing your Platinum ID, transducer, and cables, you should test the installation.

Testing should be performed on the water, since that is the only way to check your transducer's

performance.

With your boat at idle, press the POWER button to turn the unit on. The Platinum ID

performs a self-test on its electronics, then automatically selects the right depth range and

sensitivity level for conditions.

Momentarily, you'll see the reading start to "march" across the screen from right to left.

Increase your boat speed to ensure that you get a continuous bottom reading as the boat

moves. Your Platinum ID and its transducer are designed to operate at up to 75 mph; however,

use caution when operating any boat at high speed.

If the Platinum ID performs well at idle or slow speeds, but the display is not continuous

at higher speeds, the transducer is not installed properly. Air bubbles or turbulence from the boat

hull are passing across the transducer face, blocking the transmitting signal. By following the

instructions in "Mounting the Transducer," you can make simple adjustments that should fix the

problem.

NOTE: If other problems occur, see "Troubleshooting" later in this manual for tips from the

Humminbird engineers. If you don't find the solution there, call our Customer Service Hotline.

USING THE PLATINUM ID

This section provides complete information on operating the Plat inum ID through its front

panel controls. You are encouraged to read this information completely as you first learn to use

the Platinum ID; doing so will ensure you make the most of its many features and functions.

The first part of this section explains the use of the built-in simulator, which you can use

to practice selecting functions through the front panel. The remaining instructions, which can be

followed while using the simulator or in actual operation, explain each function and are organized

according to the front panel layout.

Page 13

USING THE BUILT-IN SIMULATOR

The Platinum ID includes a built-in simulator that helps you learn to

use your new equipment. The simulator displays a typical underwater

scene, and lets you practice with the controls.

The unit must be turned off before you start the simulator. To

activate it, press down and hold the POWER button until a chirping sound

begins. Release the button, and the built-in simulator begins displaying a

typical Platinum ID reading.

You can use the simulator to learn the functions explained in the

following pages, just as if you were getting actual on-the-water readings

(but note that "Sensitivity" is disabled). To turn off the simulator, turn off the

unit by pressing the POWER button again.

Of course, the best way to learn the Platinum ID is with actual use,

especially in familiar waters. If you know what's below and see it onscreen, you'll quickly become and Platinum ID expert.

PLATINUM ID FUNCTIONS

The Platinum ID offers several functions that you can adjust with the front panel buttons.

(Note that to select something with a button, you must press it fully so that you can hear a "chirp"

sound.)

You can get acquainted with these features by actual operation, or when using the

simulator.

POWER: Press the button once to turn the Platinum ID on, then press again to turn the

unit off. When the unit is off, keeping POWER pressed for about 2 seconds starts the built-in

simulator.

STOP: Press this button to "freeze" the display so you can study it. Press it again to

restart the display movement.

SELECT: This button is used to access the following functions for further adjustment:

-ID

-Units

-Sensitivity

-Bottom Alarm

-Fish Alarm

-Zoom Range

-Bottom Lock

-Display Speed

-Depth Range

-Trip Log

To adjust any of these, press SELECT until the function you want appears. Each

function's display tells you how to use the arrow buttons and ONOFF for adjustment; when first

learning, you should also refer to the following instructions.

Page 14

The three position bottom hardness scale at the bottom of the screen helps differentiate

between grass or muddy (soft) bottoms and structure or rock (hard) bottoms.

After you adjust any function, the display returns to its full-screen reading. If the menu

doesn't stay on the screen long enough, press the STOP button to hold the menu on the screen.

NOTE: The last function you select remains "active" -that is, you can adjust it without having to

press SELECT again. For example, if the bottom alarm was the last function used, you can

readjust the alarm by pressing one of the arrow buttons. Or, if you often use Zoom, you can

select it once, then switch it on and off simply by pressing ON-OFF.

1. Selecting ID;

Factory Setting: Fish symbols

Page 15

ID identifies targets not attached to the bottom and displays them with either a fish symbol or an

arch. Three different size symbols are used to represent the returned signal strength, a good

indicator of fish size. Use the up and down arrow keys to switch between fish or arches, or use

the ON-OFF key to disable ID.

2. Selecting Units;

Factory Setting: MPH/SM

If you are using the trolling speed accessory with your Platinum ID, you can switch the units of

measurement between miles per hour (MPH) or knots (ARTS). This selection also affects Trip

Log where recorded distance will be displayed in statute miles (Bill) or nautical miles (NM).

3. Selecting Sensitivity

Factory setting: +0

The Platinum ID automatically adjusts to the

proper amount of sensitivity for conditions (i.e. depth). You

can bias the setting + or - 5 levels to suit your personal

taste. Increasing the sensitivity adjustment can cause the

display of very small targets and thermoclines which might

not be displayed at the +0 setting.

If you want to manually adjust Sensitivity, select

SENS and press the UP or DOWN arrow button to adjust

the display.

Page 16

4. Enabling Bottom Alarm;

Factory Setting: OFF

The Bottom Alarm lets you specify the minimum

depth you want to maintain. To use it, select BOTTOM

ALARM; then press the ON-OFF button to activate the

alarm, and the UP or DOWN arrow button to adjust the

depth at which the alarm will sound. A dashed line

appears at the alarm depth when this function is on.

When Bottom Alarm is on, you'll hear a

continuous chirping sound when the bottom is shallower

than you defined. This is very handy for alerting you to

shallow water or helping you to maintain position over

structure.

5. Enabling Fish Alarm;

Factory Setting: OFF

The Fish Alarm alerts you with a chirping sound

whenever the Platinum ID detects fish (or another object

not attached to the bottom). To activate it, select FISH

ALARM and press the ON-OFF button.

Initially, the fish alarm will sound when any target

not attached to the bottom is detected. The word "ALL" is

displayed on the menu and two fish are shown on the lower

part of the display. By pressing either arrow button, the

word "LARGE" appears on the display and the alarm will

only sound when a large target is detected. A single fish

symbol is shown on the bottom of the display to represent

that large fish only is selected. While there is some

variation in sonar characteristics of different species,

typically, the strength of the return is relative to the size of

the fish.

Page 17

6. Using Zoom Range;

Factory Setting: OFF

Zoom Range provides an up-close view. To

activate it, select ZOOM RANGE and press ONOFF. The

Zoom view begins initially at the surface; press the UP or

DOWN arrow to adjust Zoom depth. The range of the

display is shown when Zoom is on.

The Zoom range depends on the current Depth

Range: 7 l/2' in the 15' and 30' Depth Ranges; 15' feet in

the 60', 120' and 180' Depth Ranges; and 30' in the 240',

360' 480', and 600' Depth Ranges

You can adjust zoom depth before activating

zoom, in which case the zoom range will be shown with

horizontal dotted lines.

7. Using Bottom-Lock;

Factory setting: OFF

Bottom-Lock provides an up-close view like Zoom

Range, except that in this case the zoomed view

automatically moves up or down to stay on the bottom. To

use this feature, select BOTTOM LOCK and press ONOFF. The range of the display is shown when BottomLock is on.

This is an ideal feature for finding structure or

locating fish near the bottom.

Remember: If Bottom-Lock is the last function you

selected, you can use the ON-OFF button to switch

Bottom-Lock on and off without having to press SELECT

first.

Page 18

8. Setting Display Speed;

Factory Setting: One level below maximum

The Platinum ID display is "updated" (advances

across the screen) as you move through the water. The

speed at which the display is updated depends on the

Display Speed setting. To adjust it, select DISPLAY

SPEED, and press the UP arrow button for a faster setting

or the DOWN arrow for a slower setting.

In general, higher Display Speed settings provide

faster updates, while slower Display Speeds provide more

detailed information.

11. Trip Log

Factory Setting: Off

The Platinum ID Trip Log provides a full screen of

information on current conditions. To display it, select TRIP

LOG and press ON-OFF.

All log information is continuously updated as long

as the Platinum ID remains powered on. If you want to

reset Average Speed, Elapsed Speed, and Elapsed

Distance, press the STOP button.

Pressing On-OFF exits the Trip Log and returns

you to normal Platinum ID operation.

NOTE: Trip Log requires proper input from the speed

accessory on the transom of the boat.

Loading...

Loading...