Page 1

ESPAñOLITALIANO

FRANÇAIS

DEUTSCHENGLISH

Page 2

IIMMPPOORRTTAANNTT::

Before powering up please read

the Important Safety Instructions on

page 64 - 66!

WWIICCHHTTIIGG::

Bitte lies vor der Inbetriebnahme unbedingt

die Sicherheitshinweise auf Seite 64 - 66!

AATTTTEENNTTIIOONN ::

Avant la mise en fonction de l’appareil,

il est fortement recommandé de prendre

connaissance des mesures de prudence

présentées aux pages 64 à 66 !

IIMMPPOORRTTAANNTTEE::

Prima di utilizzare lo strumento leggete

attentamente gli avvisi di sicurezza

su pagina 64 - 66!

IIMMPPOORRTTAANNTTEE::

¡ Por favor antes de la puesta en servicio

debes leer necesariamente las instrucciones

de seguridad en la página 64 - 66 !

WARP T - MANUAL

2

2

DARK DESIRE

Page 3

Though the pamphlet you are holding in your hands

explains how to handle your new killer Warp X™ amp,

it’s far more than merely an owner’s manual. You see, it

was not the manufacturer who wrote it, but yours truly,

Mrs. Hansen (that’s my pseudonym!)

As a beta tester, I had the great good fortune of being

able to torment my neighbors and surrounding blocks

with a Warp X™. After spending a furious five minutes

unleashing a battery of bodacious staccato salvoes, it was all

but impossible to tear myself away from the awesome

object of my bench-testing attention. It was way too

much fun – certainly more than can be had in any other

legal pursuit!

So, there I was a-rocking and a-riffing when the idea

came to me that I could offer my services to the folks at

Hughes & Kettner®, perhaps capturing my euphoria for

this amp in words.

And so it came to pass - you now hold the results in

your hands. I hope I managed to explain all the tweaks

and knob-twists that made playing so much fun for

me and such an unforgettable experience for my

neighborhood and outlying areas...

REMEMBER, FEAR IS NOT YOUR FRIEND, SO PLAY IT

LOUD AND PROUD!

Mrs. Hansen

HHEERREE’’SS WWIISSHHIINNGG YYOOUU LLOOTTSS

OOFF SSUUCCCCEESSSS AANNDD FFUUNN

WWIITTHH TTHHEE WWAARRPP XX

TTMM

,,

......AANNDD TTAAKKEE CCAARREE OOFF YYOOUURR

EEAARRSS!!

WARP X - MANUAL

3

3

ENGLISH

EENNTTEERR TTHHEE DDAARRKK ZZOONNEE

DARK DESIRE

Page 4

4

4

WARP X - MANUAL

TTHHEE TTOONNEE

21st century metal is all about detuned guitars,

ponderous & ominous riffs, and big & bold effected

clean sounds. No wonder that yesteryear’s amplification

can’t cut it in this brave new world of sound.

Make no mistake; the WARP X™ is the ultimate tubedriven weapon in your nu metal arsenal. With the WARP

X™, you have satisfied your wish for more bottom end

beef and all but inexhaustible high-gain reserves.

Sporting four 6L6 tubes, the head pumps into the cabinet

a heavy helping of oomph, giving you punch unmatched

in this class. You’ll revel in your newfound ability to cut

through the din. But even an opus played at warp speed

soon becomes boring without a little tension and release

to spice things up. The WARP X™ also delivers the kind

of crisp, crystal-clear clean tone you need to heighten

the musical drama and go from overtures of glassy,

glossy arpeggios to infernal finales of paint-peeling fury.

CCOONNTTEENNTTSS

THINGS TO DO BEFORE OPERATING THE AMP . . . . . 5

POWERING UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.0 THE CHANNELS OF THE WARP X™ . . . . . . . . . . 6

2.0 CONNECTIONS AND CONTROL FEATURES . . . . . 6

3.0 STANDARD SETUP / CABLE CONNECTIONS . . . . 9

4.0 OPERATING THE WARP X™ . . . . . . . . . . . . . . . 10

5.0 REPLACING TUBES, SERVICE AND

PREVENTIVE MAINTENANCE . . . . . . . . . . . . . . 11

6.0 POSSIBLE ERROR SOURCES/

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . 13

7.0 TECHNICAL SPECIFICATIONS . . . . . . . . . . . . . . 14

IMPORTANT NOTES ON SAFETY . . . . . . . . . . . . . . . 64

DARK DESIRE

Page 5

WARP X - MANUAL

5

5

ENGLISH

TTHHIINNGGSS TTOO DDOO BBEEFFOORREE OOPPEERRAATTIINNGG TTHHEE AAMMPP

A word of caution before you operate your new amp:

It is loud. Exposure to high volume levels may cause

hearing damage. Always turn the MASTER VOLUME

knob on the front panel all the way down before

powering your amp up, and then turn it up gradually

to a level that suits the venue and is not harmful to

your ears. Always be judicious in the use of your

amplifier and its volume controls: Exercise great care

to prevent damaging your ears and the ears of the

people around you.

Check out the voltage rating displayed next to the

WARP X™'s MAINS INPUT and make sure it matches

your local mains current before you plug in. Make sure

plenty of air can circulate around your amp's ventilation

ducts. Place the amp on a sturdy, secure base and avoid

exposing it to mechanical shocks and extreme temperatures that could endanger the device or your and others'

safety. The manufacturer disclaims any liability or

responsibility whatsoever for any damage or defect in

this and other devices resulting from misuse.

PPOOWWEERRIINNGG UUPP

First plug the speaker cabinet cord into the appropriate

output on the head. To learn more about this, read

chapter 2.0 CONTROL CONNECTIONS AND FEATURES.

Plug the other end of the cord into the cabinet’s input.

The life of every all-tube amp depends on you getting

this right! If you operate tubes without a connected load

such as a speaker cabinet or with the wrong ohm load,

they will die an ugly and painful death!

Now plug the head’s AC power cord into an outlet and

switch the amp on by pressing the MAINS button. Give

the tubes some time to warm up before driving them

hard. If you get bored with the wait, gaze upon the

orange-red glow of the tubes and the red light emanating

from the amp’s interior. That should put you in the right

mood for rude, red-hot riffing.

You like your WARP X™ now, but you’ll learn to love

it later. And because love means never having to say

you’re sorry, get into the habit of twisting the MASTER

VOLUME knob all the way to the left (counterclockwise)

when you’ve finished riffing. Otherwise, you may be in

for a loud surprise next time you power up.

So, you’ve set the MASTER knob to zero? Okay, then

let’s get to it. Plug a cord into your guitar, then into the

amp. Flick the STANDBY switch to bring those glowing

tubes to life. Now you can select between different

channels...

DARK DESIRE

Page 6

6

6

WARP X - MANUAL

11..00 TTHHEE CCHHAANNNNEELLSS OOFF TTHHEE WWAARRPP XX

TTMM

The WARP X™ is equipped with two channels that will

serve you well if you like your music hard & heavy:

11..11 WWAARRPP CCHHAANNNNEELL

Dive right into the wonderful world of high gain

distortion and luxuriate in the jaw-droppingly powerful

sound of every riff that rips through speakers. Courtesy

of the tube circuitry, this sound leaps right out of the

cabinet and goes straight for the throat. The WARP channel

delivers it all, from a nasty nu metal thump to post

grunge growl, from alternative snarl to the doomsday

thunder so cherished by devotees of death and Goth

metal. By varying the WARP channel’s preamp gain and

the power amp via the MASTER VOLUME knob, you can

dial in anything from venomous to spine-chilling scream

– and all points in between.

11..22 CCLLEEAANN CCHHAANNNNEELL

Even the hardest rocking axe slingers will want to give

their head-banging audiences a break now and then.

That’s what the CLEAN channel is here for – to deliver

sweet clean sound for those softer passages that make

the next monstrous riff seem even more elephantine.

The WARP X™ offers a unique brand of ultra clean sound

that remains crisp, clear and sparkly at even very high

volumes. This ensures your sound cuts through and

ends up where it belongs – in your audience’s ears.

22..00 CCOONNNNEECCTTIIOONNSS AANNDD CCOONNTTRROOLL FFEEAATTUURREESS

So far, so good! Now you know what your new metal

machine can do for you and your music. But you need

to learn all about the connections and control features

of the WARP X™ to be able to make the most of its full

sonic glory. Let’s take a closer look:

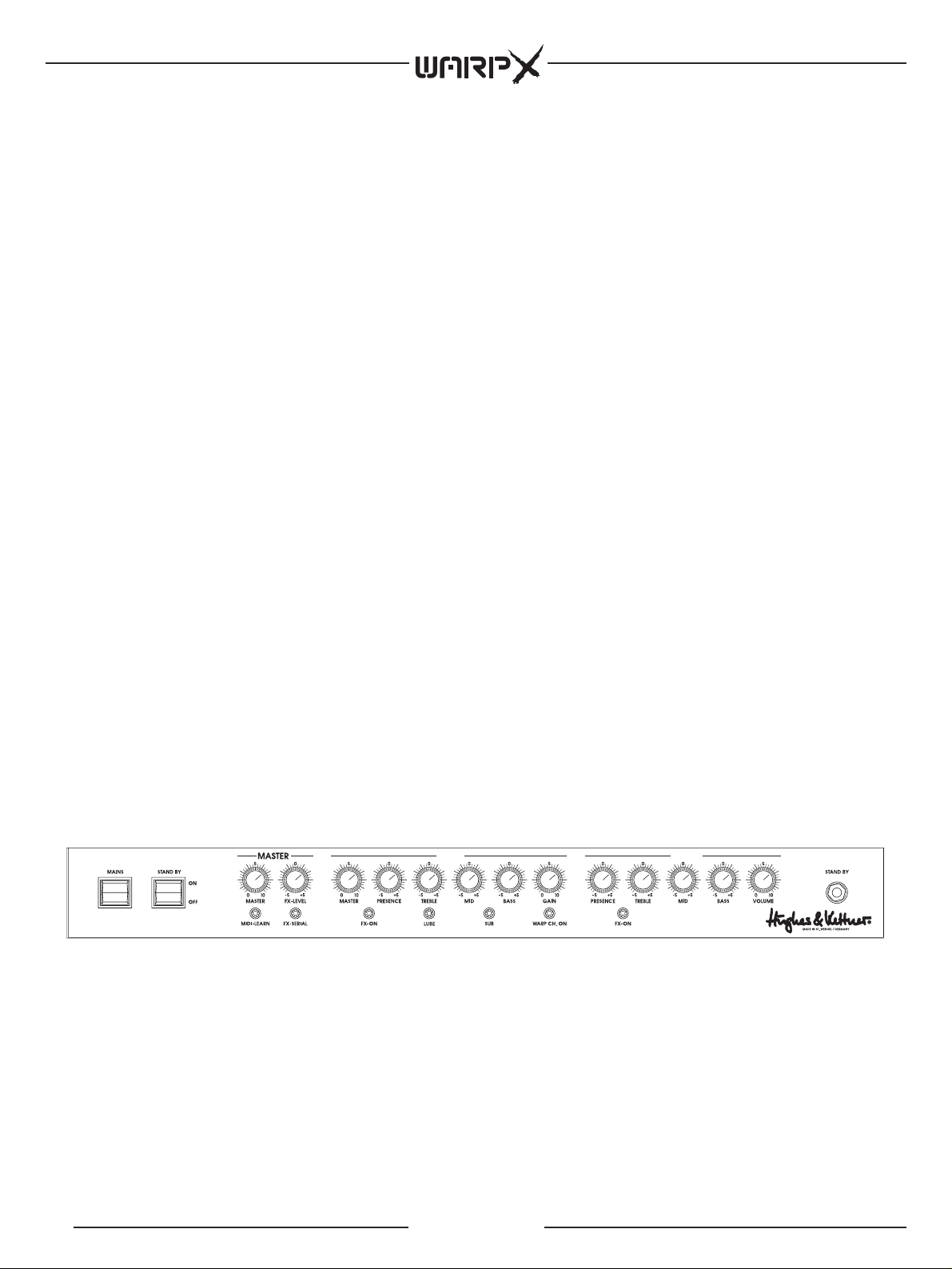

22..11 FFRROONNTT PPAANNEELL

The cockpit of the WARP X™ is divided to three

sections. On the left next to the MAINS button,

you’ll find the MASTER section.

To the right you see the WARP section and finally the

CLEAN section. Control features are arrayed from left

to right as follows:

DARK DESIRE

WARP

CLEAN

Page 7

MAINS ON/OFF

This button switches the main power supply on and

gives the tubes the opportunity to warm up for the

challenges that lie ahead.

STANDBY

This switch mutes the amp. After the tubes warm up,

flick the STANDBY switch to send the guitar’s signal into

the WARP X™. Use the following knobs to shape your

signal:

MASTER VOL

As the name would indicate, this knob puts the power

of 120 tube-driven between your thumb and forefinger.

Use it wisely because it can induce everything from bliss

to pain to near madness in your band mates. Though

twisting this knob can be as much fun as the law allows,

don’t unleash all this power rashly. Exercise restraint and

protect your and your fellow musicians’ hearing.

MIDI LEARN

This button serves to program the retrofit

Hughes & Kettner®MSM-1™ MIDI module. Installing

the MSM-1 MIDI module endows the WARP X™ with

MIDI capability. Once it has been installed, you can

press the MIDI LEARN button to save the current

channel/FX loop configuration.

FX LEVEL

This knob adjusts the external effect signal’s amount or

the wet level. For more on this, read section 4.3 HOW

TO CONNECT AN EFFECTOR

WWAARRPP CCHHAANNNNEELL

MASTER

Controls the level of the WARP channel. Use it to

dial in the desired balance between the CLEAN and

WARP channels, that is, to determine which side of the

WARP X™’s split personality will dominate - Dr. Jekyll

or Mr. Hyde.

PRESENCE

Fine-tunes the WARP channel’s overtones.

You can dial in razor-edge tone to make your musical

statements cut through the din.

TREBLE, MID, BASS

Tweak these three knobs according to taste, shaping

your personal WARP sound as you see fit.

LUBE

Do you want ultimate response to your touch,

a feeling that the strings are an extension of your fingers

and slaves to your will? Then press the LUBE button.

It “greases” up your strings, making riffs and licks fly

off the fret board.

SUB

Press this button to dig deep into the dark underbelly of

the WARP channel and draw up bowel-shaking sub bass

frequencies.

FX ON

Routes the external effect to the WARP channel.

If you want to switch this function via Stageboard or

MIDI, set this switch to the OFF position, that is, ensure

that it is not pressed. For more on this, read section

4.3 HOW TO CONNECT AN EFFECTOR.

GAIN

Of all the WARP X™’s many features, the GAIN knob is

the one that will shape the heart of your tone. Evoking

anything from gritty crunch to ferocious fuzz, the GAIN

knob lends your riffs and power chords precisely the

edge that you want them to have. Twist it to go from

merely dirty but tremendously punchy tone at lower

settings to a merciless evil roar at higher settings.

WARP CH. ON

Activates the WARP channel and unleashes its unbridled

tube power.

WARP X - MANUAL

7

7

ENGLISH

DARK DESIRE

Page 8

8

8

CCLLEEAANN CCHHAANNNNEELL

PRESENCE

Controls CLEAN channel overtones.

FX ON

Routes the external effect to the CLEAN channel.

TREBLE, MID, BASS

These knobs voice (shape the tone) of the CLEAN channel.

VOLUME

Determines the CLEAN channel’s volume and

compression levels.

INPUT

Located on the far right, this jack accepts your guitar

cord’s 6.3 mm (1/4”) plug.

WARP X - MANUAL

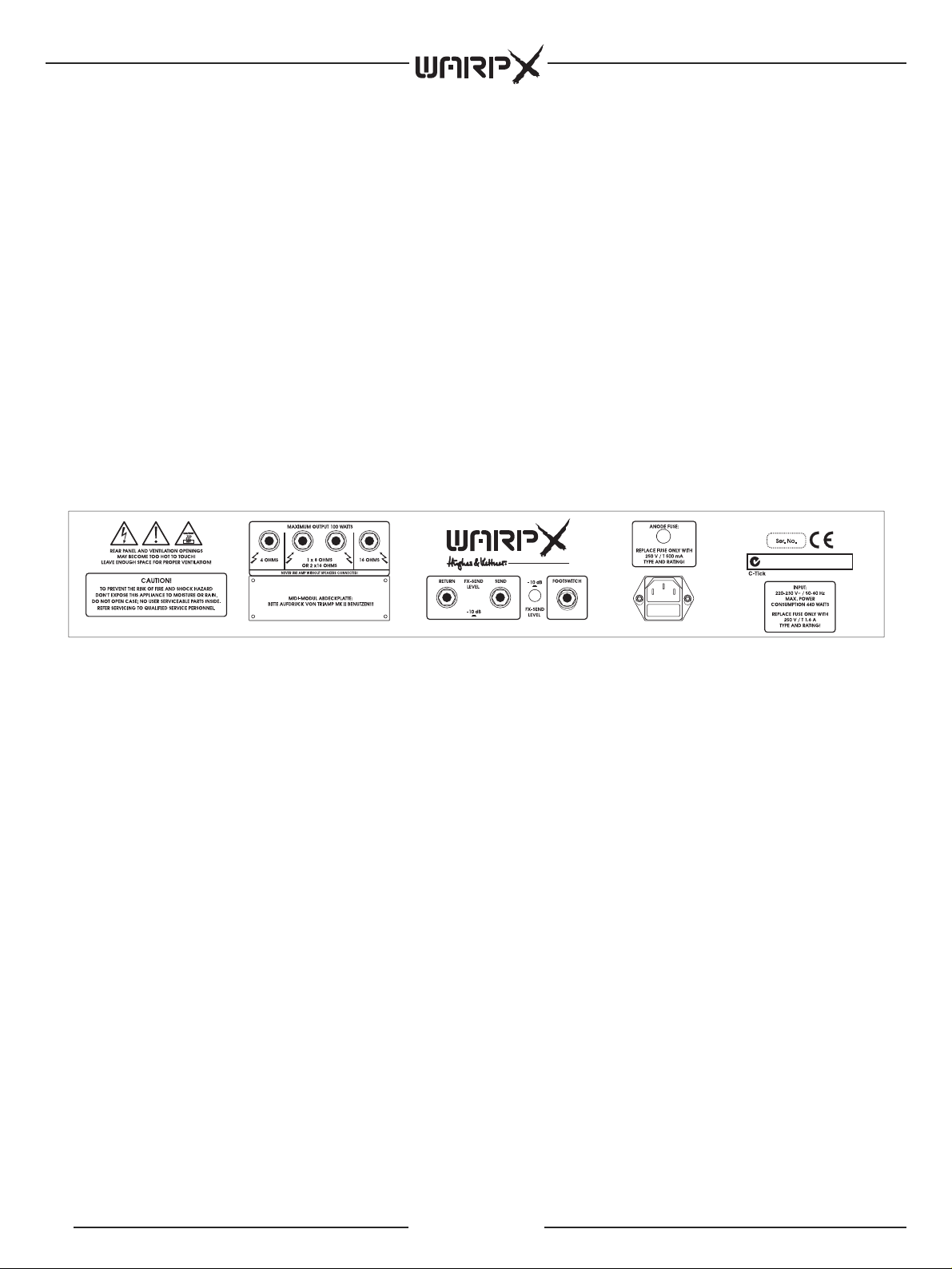

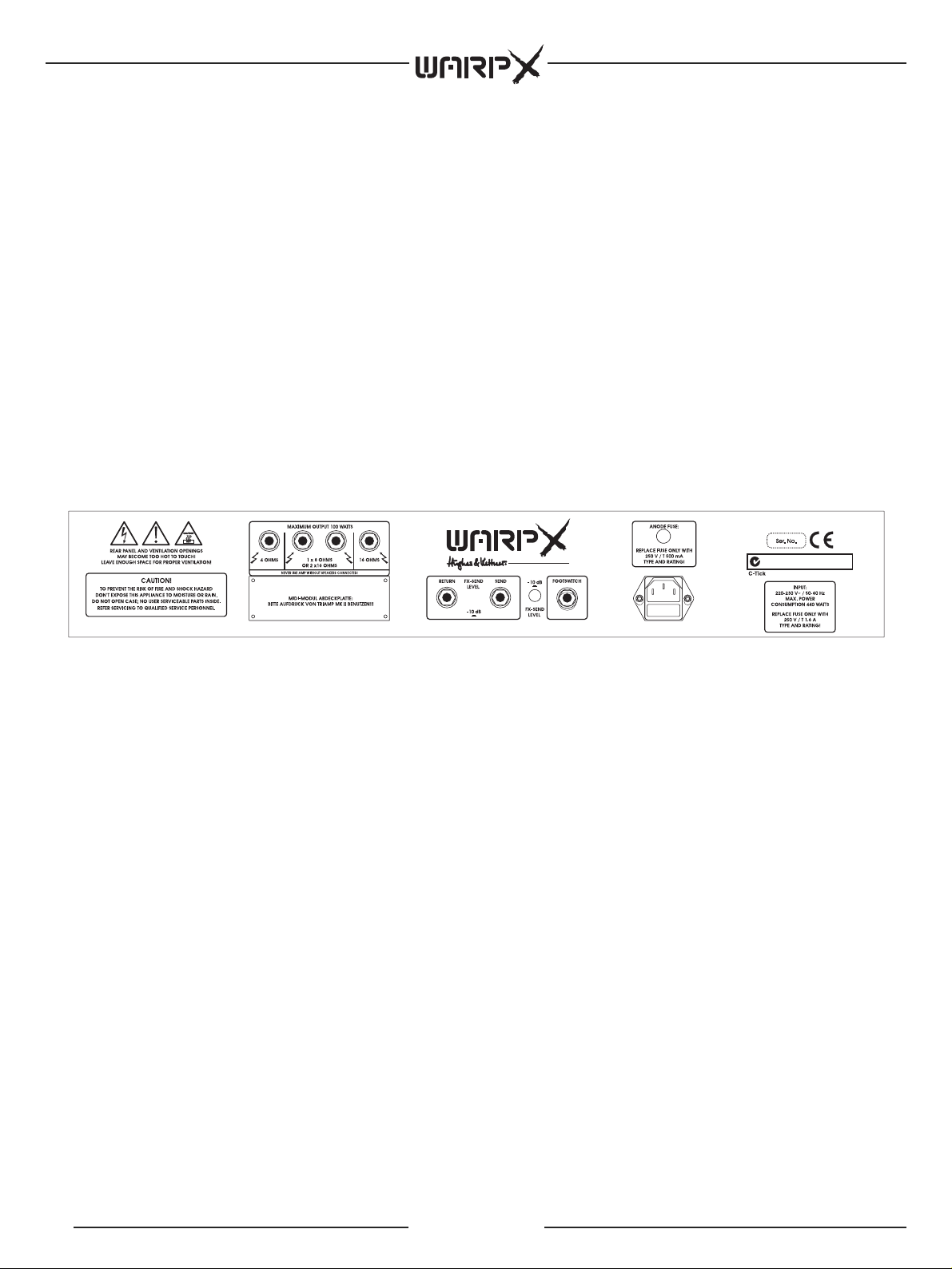

22..22 RREEAARR PPAANNEELL

You’ll find the following components mounted

on the black sheet metal panel on the back of

the amp:

MAINS

Equipped with a fuse compartment, this Euro mains

socket provides power to your amp. Before plugging

into the wall outlet, make certain the amp's voltage

rating matches your local AC voltage rating.

To find out your amp’s voltage rating, refer

to chapter 7.0 TECHNICAL SPECIFICATIONS.

FOOTSWITCH

This port accepts the two-way Hughes & Kettner®FS-2

Stageboard, which lets you switch CLEAN and WARP

channels and FX ON remotely. This feature comes in

particularly handy on stage when you need to switch

on the fly.

FX SEND

If you want to employ an effect device, connect this

jack to the signal processor’s input. You can also use this

output to send the signal to an outboard power amp or a

RED BOX

®

to patch your signal into a mixer. For more on

this, read section 4.3 HOW TO CONNECT AN EFFECTOR.

FX RETURN

Connect this jack to the effect device’s output.

FX –10DB

This button reduces the FX SEND jack’s output level by

10 dB and increases the FX RETURN jack’s input sensitivity by 10 dB to adapt the FX loop to the effect device’s

input level. Press this button when using effect devices

with inputs designed to accept instrument levels.

DARK DESIRE

Page 9

MIDI MODULE

Channels, FX ON/OFF, and FX PARALLEL/SERIAL can be

switched via the optional Hughes & Kettner®MSM-1™.

The MIDI module lets you select a MIDI channel number

or OMNI mode, in which it responds to commands on

all 16 MIDI channels.

SPEAKER OUTS

You can connect cabinets with impedances of 4, 8,

2x 16 and 16 ohms to the corresponding speaker outputs.

WARP X - MANUAL

9

9

ENGLISH

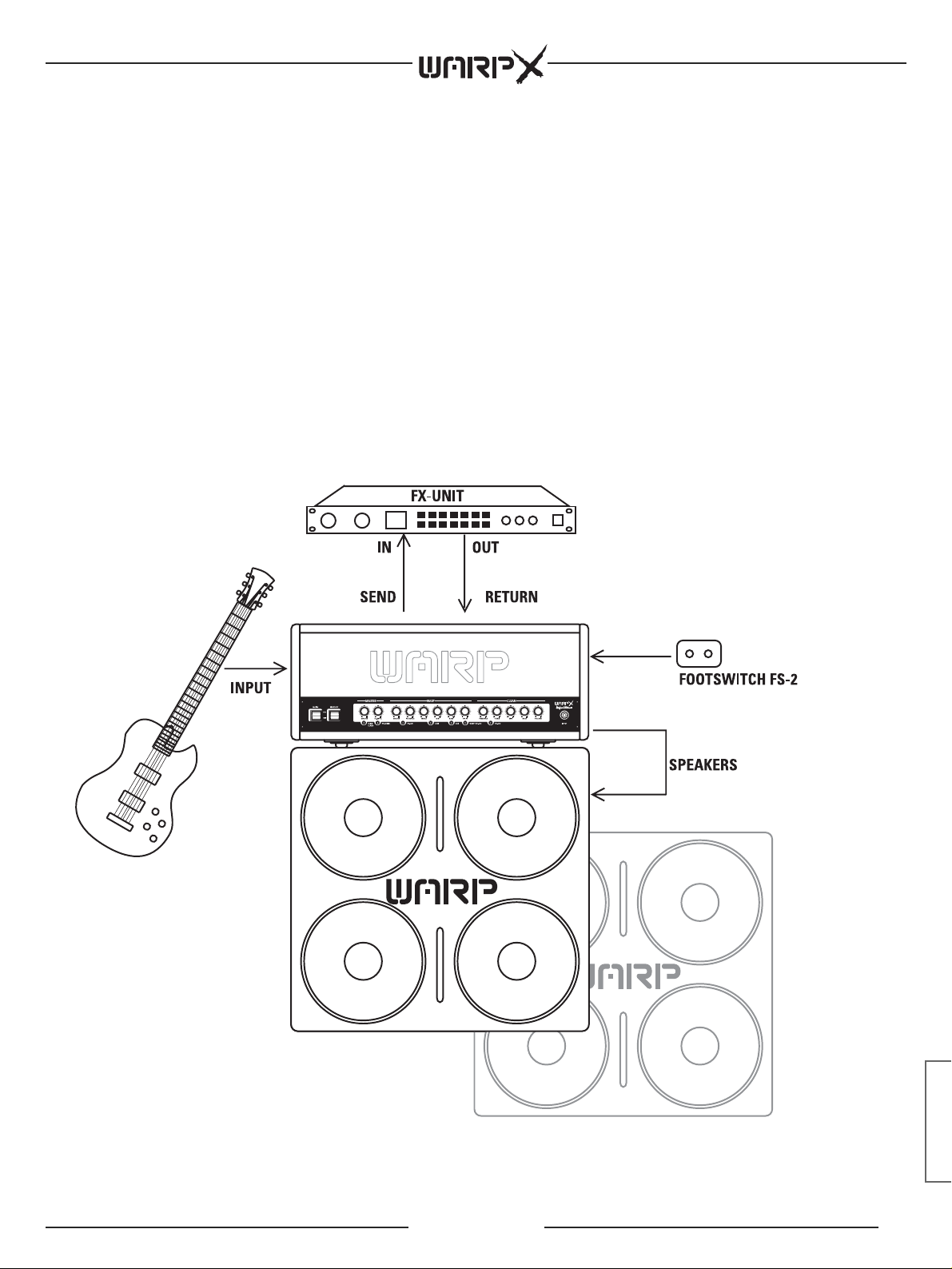

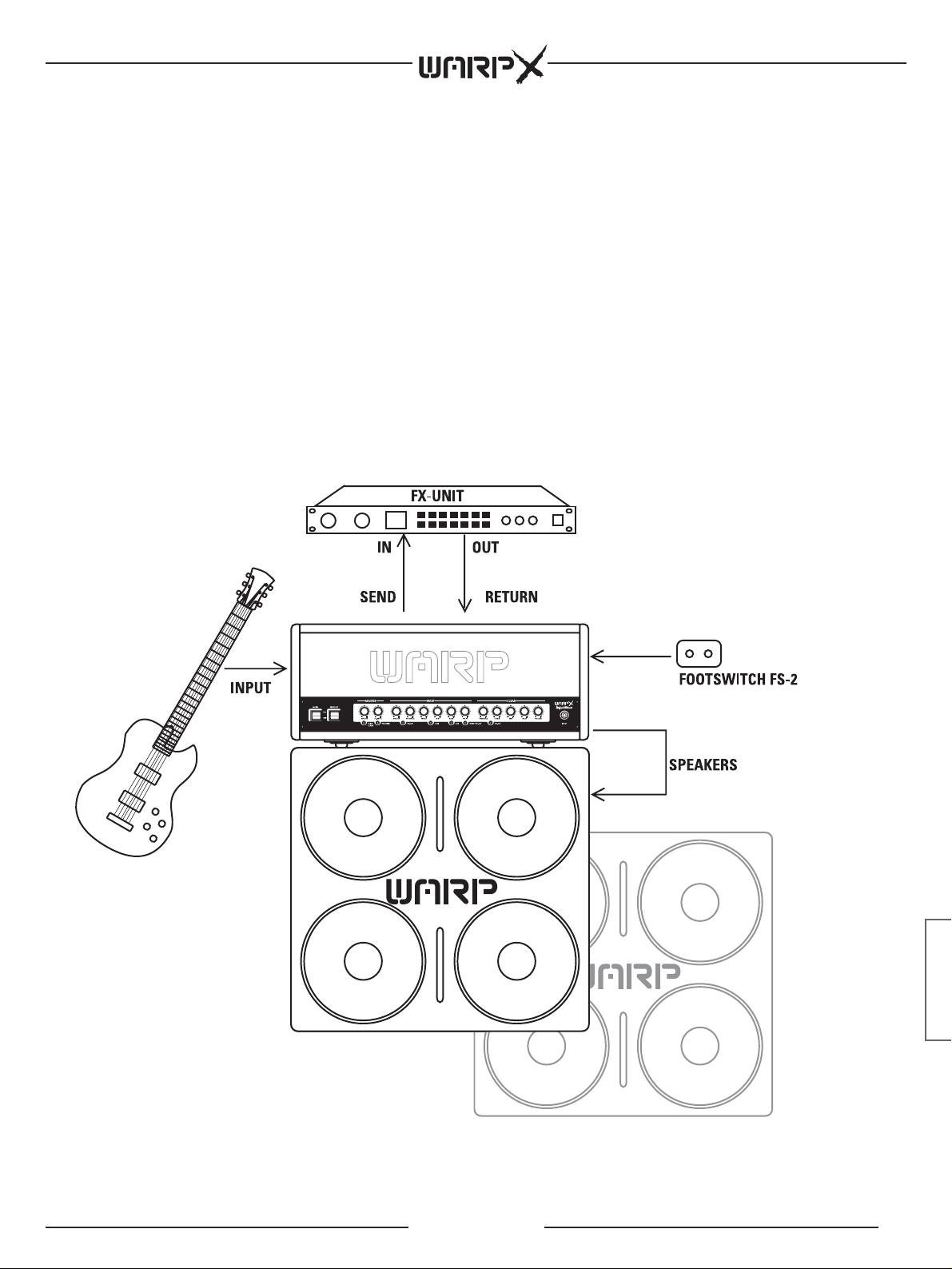

33..00 SSTTAANNDDAARRDD SSEETTUUPP // CCAABBLLEE CCOONNNNEECCTTIIOONNSS

DARK DESIRE

Page 10

Now that you know a bit about the key features of your

new amp and probably have discovered how gain the

undivided attention of neighbors, fellow musicians, and

significant others, let’s take a closer look at a couple of

tips and suggestions for handling the WARP X™ and

connecting other sound-sculpting devices:

44..11 SSEELLEECCTTIINNGG CCHHAANNNNEELLSS

Press the WARP CH. ON button to awaken Beauty or

the Beast. When the button lights up to indicate that

the amp is in high-gain mode, grab the bull by the

horns and hang on for dear life. After a breathtaking ride

on the back of the bucking beast, you may want to give

yourself and your audience a break. Press the button

again to activate the CLEAN channel and revel in the

sonic glory of a righteous clean sound.

44..22 FFRROOMM GGRRIITTTTYY RRIIFFFFSS TTOO

HHII GGAAIINN SSCCRREEAAMMIINNGG LLEEAADDSS

No one buys this breed of amp to play polka night at

the local senior citizens’ community center. So, if you

want to kick out the jams, you’ve certainly acquired the

right tool for the job: Those red-hot tubes pump out the

kind of red-hot tone thought to melt teeth fillings at a

hundred paces. Twist the WARP channel’s MASTER and

GAIN knobs to turn your amp into anything from a gritty

grindstone for cranking out meaty chords to a hi-gain

scream machine. From subtle menace to a belligerent

bellow, it’s yours for the taking.

Try this on for size: Set MASTER to 5 and GAIN to 6 or 7

for a pretty ornery growl. Now add a liberal dose of

BASS, cut the MIDs, and boost the bottom end by pressing the SUB button to conjure up a truly wicked hi gain

roar. Back off the WARP channel’s GAIN and crank the

MASTER knob to 8 or 9 and try dampening the string

with the heel of your hand. This yields rough & ready

crunch tone with an enormous low-end kick. Before you

do this, you may want to back off the MASTER VOLUME

because the sound pressure may be a bit much to handle.

Cliché time: An ounce of practice is worth a pound of

theory, so experiment to your heart’s content!

44..33 HHOOWW TTOO CCOONNNNEECCTT AANN

EEFFFFEECCTTOORR

Located on the back of the amp is an FX loop designed

to take any effector you care to connect. To insert a

device into the loop, connect its input jack to the

WARP X™’s SEND port and the device’s output jack

to the WARP X™’s RETURN port. Activate the FX loop

using the front panel FX ON button or via footswitch.

Recall that you can match the FX loop to the effect

device’s input level. Press the FX SEND LEVEL button

for effects devices like stomp boxes that are designed

for guitar signals. If the button is not pressed, the signal

level remains at standard line level, which is suitable for

most rack-mounted multi-effects processors.

When operating the loop in parallel mode, use the LEVEL

knob to determine the volume of the effect signal.

NOTE

Some signal processors introduce phase cancellations that are detrimental to the overall sound.

In this case, set the effects loop to FX SERIAL.

The effects loop now operates like a conventional

serial loop—in other words, you’ll have to adjust the

balance of levels between the original and processed

signal at the processor.

TIP

If choose not to connect a signal processor to the

FX loop, you can plug in another instrument or audio

source.

44..44 TTHHEE WWAARRPP XX

TTMM

AANNDD MMIIDDII

With the MSM-1 MIDI Module installed, you can switch

the FX loop (to include switching between serial and

parallel modes) and select WARP X™ via MIDI.

This gives you the very convenient option of switching

the WARP X™ and multi effectors simultaneously.

WARP X - MANUAL

10

10

DARK DESIRE

44..00 OOPPEERRAATTIINNGG TTHHEE WWAARRPP XX

TTMM

Page 11

55..00 RREEPPLLAACCIINNGG TTUUBBEESS,, SSEERRVVIICCEE AANNDD

PPRREEVVEENNTTIIVVEE MMAAIINNTTEENNAANNCCEE

WARP X - MANUAL

11

11

ENGLISH

The WARP X™ ships with 6L6 and 12AX7/ECC83 tubes.

Once they’ve been burned in (initial continuous operation

under a load), these tubes undergo an in-depth selection

process where their electrical values and mechanical

status (microphonics) are checked. Then they’re installed

in a test amp and their sound is auditioned by ear.

One of the most important steps is power tube matching,

a process whereby tubes with the same characteristics

are selected and combined to make matched sets.

WHEN IS IT A GOOD IDEA TO REPLACE TUBES?

The tubes in the WARP X™ are exemplary in terms

of quality, workmanship and long service life. If you

encounter a problem, please run down the following

checklist before you swap your old tubes for new ones:

Was the fault or failure of the power tube caused by the

tube itself or a flawed peripheral device or component,

perhaps a defective speaker cable? (If you don’t get to

the bottom of the problem and remedy it, it may crop

up again even after you replace the tubes.)

Did the mains voltage fluctuate or spike while the amp

was on? In all-tube amps, over-voltage surges in the

mains net can certainly blow fuses or even the amps.

Over-voltages are often caused by generators or faulty

high-current power circuits.

Did a fuse blow even though none of the tubes is actually

defective? An old fuse, tube de-ionization or mains

voltage power surges could have caused it to blow. In

this case, replacing tubes is a waste of money and time.

Tubes definitely show signs of wear when their service

life nears its end, including increased microphonics,

noise, muddier tone through loss of high-end frequencies,

degraded performance, etc. Take these indications

seriously and replace old tubes. Not only do these

side effects take their toll on sound quality, they are

also a sure sign that the tube is about to fail.

NOTE

Though it may be tempting to find out what an amp

sounds like with different tubes, please refrain from

replacing tubes for experimentation purposes. This

can damage the amp and cost a small fortune to

repair.

WHAT SHOULD YOU KEEP IN MIND WHEN YOU’RE

REPLACING TUBES?

The golden rule: Replacing tubes is a job best left to

qualified professionals. Accordingly, these guidelines are

addressed to qualified technicians who earn their living

with a screwdriver:

Pull the mains plug of the WARP X™ and allow for a

discharge time of at least two minutes before removing

the sheet metal panel on the rear of the amp. Once the

panel is off, you can cautiously ease the tubes out of

their sockets. A single power tube may only be replaced

if the replacement tube precisely matches the original,

in other words, if it has exactly the same characteristics.

If you’re replacing power tubes, use matched sets only.

If you’re installing a new set of power tubes whose

characteristics are identical to those of the old set,

it is not absolutely necessary to re-bias the amp.

On the other hand, if you install a new set with different

characteristics, be sure to re-bias the amp. Again, biasing

an amp is not a DIY task. It requires experience and an

extensive working knowledge of measuring techniques,

which is why this job should be carried out only by

qualified technicians with tube amp tuning experience.

DARK DESIRE

Page 12

HOW DO YOU EXTEND THE SERVICE LIFE OF THE

WARP X™’S TUBES?

• Never operate the WARP X™ without connecting a

load (loudspeaker)! Always use high-quality, heavyduty speaker cables that won’t crimp or snap...

• Use the STANDBY switch! Warming tubes up unneces-

sarily wears them out that much quicker. Make a habit

of cutting anode voltage via the STANDBY function and

you’ll enjoy many more hours of operation.

• Avoid exposing the amp to vibrations, especially when

it’s powered up. Switch the amp off a good while

before moving it, allowing plenty of time for the tubes

to cool off completely.

• Ensure plenty of air can circulate around the amp’s

ventilation slots at all times – your WARP X™’s life

depends on it.

• Definitely avoid exposure to extreme heat, dust and

particularly moisture.

• Be very careful about the kind of peripheral devices

you connect to your amp and always check out their

specs before you plug them in. Never connect speaker

cabinets with an impedance (ohm) rating lower than

the WARP X™ is designed to handle.

• Never connect devices with high output signal levels

(e.g. power amps) to the WARP X™’s input.

• Ensure the AC power source delivers the current that

your amp is designed to handle before you plug it in.

When in doubt about the local rating, ask the venue’s

sound technician or a stage hand.

• Refrain from performing DIY repairs! To be on the

safe side, you should also have a qualified technician

replace internal fuses.

WARP X - MANUAL

12

12

DARK DESIRE

Page 13

WARP X - MANUAL

13

13

ENGLISH

66..00 PPOOSSSSIIBBLLEE EERRRROORR SSOOUURRCCEESS //

TTRROOUUBBLLEESSHHOOOOTTIINNGG

THE WARP X™ WON’T POWER UP WHEN YOU

SWITCH IT ON:

• It‘s not getting AC power. Check the mains cable to

see if it‘s connected properly.

• The mains fuse is defective. Ensure it is replaced with

another fuse of the same rating.

THE WARP X™ IS CONNECTED PROPERLY, BUT NO

SOUND IS AUDIBLE:

• The amp is set to STANDBY

• One or several GAIN and MASTER controls are turned

all the way down

• The anode fuse has tripped. Before replacing the fuse

with another fuse of the same rating, have the power

tubes checked to learn if they are defective.

• The fuse for the tube heater has tripped

(the tubes don’t glow). When replacing this fuse, make

absolutely certain that it is replaced with a fuse bearing

the same rating. Be sure to have a service technician

replace the fuse.

THE FX LOOP IS ON WHEN IT SHOULDN’T BE:

• The FX LOOP is deactivated when the front panel

button, the Stageboard button and the MIDI module

switching function are off. If any of these three switches

is on, the FX LOOP is active.

THE SOUND IS THIN AND MUDDY WHEN YOU SWITCH

AN EFFECTS PROCESSOR ON.

• The signal processor provides a wet signal that is

blended with the dry or original signal. Depending on

the type of effect, the processor may be returning a

dry signal back along with wet signal, which causes

phase cancellations when mixed to the dry signal in

the WARP X™’s parallel loop. To prevent phase cancellations, switch the FX LOOP to SERIAL or turn the dry

signal all the way down on the signal processor.

YOUR AMP IS PRODUCING RINGING NOISES OR

TENDS TO FEEDBACK:

• One or several tubes are microphonic. Replace the

defective tube with another of the same type.

AFTER JUST A FEW HOURS OF OPERATION, YOUR

AMP IS DISPLAYING THE TYPICAL CHARACTERISTICS

OF OLD TUBES (INCREASED MICROPHONICS AND

NOISE, TREBLE LOSS, WEAK POWER OUTPUT, MUDDY

SOUND):

• The wrong tubes were installed when old tubes were

replaced or the amp was not biased properly. Take the

amp to a professional amp technician to correct the

problem.

DARK DESIRE

Page 14

77..11 HHEEAADD

All level specifications relate to 0 dBV (1V RMS )

INPUTS

INST. INPUT:

Port: 6.3 mm (1/4”)

Type: unbalanced

Input impedance: 1 MΩ

Sensitivity: - 32 dB

Max. input level: +8 dB

FX LOOP Return L/R:

Port: 6.3 mm (1/4”)

Type: unbalanced

Input impedance: 48 kΩ

Max. sensitivity:

•10dB button pressed -18 dB

•not pressed -8 dB

Max. input level:

•10dB button pressed + 5 dB

•not pressed +15dB

OUTPUTS

FX LOOP Send L/R:

Port: 6.3 mm (1/4”)

Type of output: unbalanced

Input impedance: 2,2 kΩ

Input level: - 6 dB

Max. output level:

•10dB button pressed + 2 dB

• not pressed +12 dB

SPEAKER OUTS

Number: 4

Port: 6.3 mm (1/4”) jack

Type: unbalanced

Impedance: 1 X 4Ω ; 1 X 8Ω or

2 X 16Ω ; 1 X 16Ω

GENERAL ELECTRICAL DATA

Variable AC voltages Protection Class 1

Max. current consumption:

1.35 A @ 230V AC, 4-8-16Ω

2.55 A @ 117V AC, 4-8-16Ω

2.85 A @ 100V AC, 4-8-16Ω

Max. power consumption:

383 VA @ 253 V AC, 4-8-16Ω

Mains voltage tolerance range:

+/- 10 %

Ambient temperature range:

- 10 ∞C to + 60 ∞C

External fuses:

1 x T 500 mA (anode)

Internal fuses:

1 x TT 10 A Slo Blo (tube heater and front panel lighting)

2 x T 630 mA (switching; FX loop )

GENERAL MECHANICAL DATA

Dimensions:

Width: 655 mm (incl. corners)

Height: 280 mm (incl. handles

and feet)

Depth: 255 mm (incl. corners)

Weight: 20.5 kg

WARP X - MANUAL

14

14

DARK DESIRE

77..00 TTEECCHHNNIICCAALL SSPPEECCIIFFIICCAATTIIOONNSS

Page 15

WARP X - MANUAL

15

15

DEUTSCH

DARK DESIRE

Dieses Werk, welches in Deinen Händen ruhend,

Dir den Umgang mit Deinem neu erstandenen KillerAmp Warp X™ erklären soll, ist nicht einfach nur eine

Gebrauchsanweisung. Nein, sie wurde auch nicht vom

Hersteller verfasst, sondern von mir: "Frau Hansen" (das

ist mein Künstlername!)

Ich hatte das Glück als Beta-Tester mit einem Exemplar

des Warp X™ meine Nachbarn und die umliegenden

Häuserblocks zu drangsalieren. Nach den ersten

fünf Minuten in einem wahren Gewitter aus saftigen

Stakkato-Salven war ich kaum mehr aus dem Schallkegel

des Testobjektes zu bewegen. Es macht einfach einen

Höllenspaß!

Und wie ich da so vor mich hin fetzte und vor

Wollust fast verging, hatte ich die Idee den Jungs von

Hughes & Kettner®meine Dienste anzubieten, und

meine Euphorie im Umgang mit dem guten Stück in

Worte zu fassen. Und so kam es.

Das Ergebnis hältst Du nun in Deinen Händen. Ich hoffe

es ist mir gelungen, die Wege aufzuzeigen, die mir zu

einer Menge Spaß...und diversen Beschwerden wegen

der Lautstärke verholfen haben...

ABER, WER LEISE SPIELT HAT ANGST!

Frau Hansen

VVIIEELL EERRFFOOLLGG UUNNDD SSPPAASSSS

MMIITT DDEEIINNEEMM WWAARRPP XX

TTMM

,,

......UUNNDD GGIIBB AAUUFF DDEEIINNEE

OOHHRREENN AACCHHTT..

EENNTTEERR TTHHEE DDAARRKK ZZOONNEE

Page 16

WARP X - MANUAL

16

16

DARK DESIRE

DDEERR SSOOUUNNDD

Das Soundverständnis im Metal des 21. Jahrhunderts

wird von heruntergestimmten Gitarren, bösartigen Riffs

und wabernden, cleanen Effektklängen geprägt.

Klar, dass in dieser neuen Soundwelt die Amps von

gestern versagen...

Der Warp X™ ist die ultimative Röhren-Waffe

im NU-Metal-Battle. Deinen Wunsch nach mehr

Pfund im Bass-Bereich und schier unerschöpflichen

Reserven im High-Gain Sektor hast Du Dir mit dem

Warp X™ erfüllt.

Das mit 4 6L6 Röhren bestückte Head versorgt die Box

mit ordentlich Power und verleiht Dir ein in dieser Sparte

bislang ungeahntes Durchsetzungsvermögen im alltäglichen Riff-Leben. Gleichzeitig versorgt der Warp X™

Dich aber genauso gut mit dem crispen, klaren CleanSound, der als Ouvertüre vor das infernalische Finale

gesetzt, dem Opus erst die adäquate Dramatik verleiht.

IINNHHAALLTT

VOR DER INBETRIEBNAHME . . . . . . . . . . . . . . . . . . 17

INBETRIEBNAHME . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.0 DIE KANÄLE DES Warp X™ . . . . . . . . . . . . . . 18

2.0 ANSCHLÜSSE UND BEDIENELEMENTE . . . . . . 18

3.0 STANDARD SET UP/ VERKABELUNG . . . . . . . . . 21

4.0 BEDIENUNG DES Warp X™ . . . . . . . . . . . . . . . 22

5.0 RÖHRENTAUSCH, WARTUNG UND PFLEGE . . . 23

6.0 FEHLERBESEITIGUNG/TROUBLESHOOTING . . . . 25

7.0 TECHNISCHE DATEN . . . . . . . . . . . . . . . . . . . . . 26

WICHTIGE SICHERHEITSHINWEISE . . . . . . . . . . . . . . 64

Page 17

WARP X - MANUAL

17

17

DEUTSCH

DARK DESIRE

VVOORR DDEERR IINNBBEETTRRIIEEBBNNAAHHMMEE

Ein Wort der Vorsicht, bevor du Deinen neuen Amp

in Betrieb nimmst: Er ist laut! Hohe Laustärke-Pegel

können Gehörschäden verursachen. Drehe immer das

MASTER VOLUME-Poti auf Linksanschalg, bevor du

den Amp einschaltest, und drehe es dann vorsichtig

im Uhrzeigersinn bis zu einem Pegel, der zu den

Räumlichkeiten passt und nicht in Deinen Ohren

schmerzt! Sei vernünftig im Umgang mit den

Lautstärke-Reglern Deines Amps: übe große Vorsicht,

um dauerhafte Gehörschäden an Dir und Deinen

Zuhörern zu vermeiden.

Vergewissere Dich vor dem Anschluss des Warp X™,

dass der am MAINS INPUT angegebene Spannungswert

mit der ortsüblichen Netzspannung übereinstimmt.

Stelle eine ausreichende Luftzufuhr zu den Kühlflächen

des Gerätes sicher. Achte auf einen festen Stellplatz,

der mechanische und thermische Fremdeinwirkungen,

welche die Betriebssicherheit des Gerätes oder die

Sicherheit von Personen beeinträchtigen könnten,

ausschließt.

Für Schäden am Gerät oder anderer Geräte, die durch

unsachgemäßen Betrieb entstehen, wird seitens des

Herstellers keine Haftung übernommen.

IINNBBEETTRRIIEEBBNNAAHHMMEE

Zuerst gehört das Boxenkabel in den entsprechenden

Ausgang am Head. Mehr dazu findest Du im Kapitel

2.0 ANSCHLÜSSE UND BEDIENELEMENTE. Das andere

Ende das Kabels kommt in den Eingang der Box.

Das ist für Vollröhren-Amps lebenswichtig! Werden

Röhren ohne angeschlossene Box oder an falscher

Ohm-Zahl betrieben, dann sterben sie!

Jetzt den Netzstecker des Heads in die Steckdose, dann

das Aggregat mit dem MAINS-Schalter einschalten und

den Röhren eine kurze Gnadenfrist gewähren, bevor sie

losrotzen müssen. Während dieser Zeit kann man sich

vom orange-roten Glühen der Röhren und dem aus dem

Inneren des Aggregates hervor kriechenden roten Licht

in die entsprechende Stimmung versetzten lassen.

Eine Pflichtübung sollte man sich im Umgang mit dem

Warp X™ sofort angewöhnen: Nach dem letzten TieftonRiff unbedingt das MASTER VOLUME-Poti auf Linksanschlag drehen, ansonsten wartet das Aggregat beim

neuerlichen Einschalten unter Umständen mit einer zu

lauten Überraschung auf.

Also, Master auf Null? Okay, dann kann es weitergehen.

Stecker in die Klampfe, dann in den Amp und mit dem

STAND BY-Schalter den glühenden Röhren Leben einhauchen. Jetzt kannst Du zwischen unterschiedlichen

Kanälen wählen...

Page 18

WARP X - MANUAL

18

18

DARK DESIRE

11..00 DDIIEE KKAANNÄÄLLEE DDEESS WWAARRPP XX

TTMM

Der Warp X™ verfügt über die zwei Kanäle, die für

Musik der härteren Gangart vonnöten sind:

11..11 WWAARRPP--KKAANNAALL

Tauche ein in die Welt der hochgradigen Verzerrung und

genieße die kraftvolle Entfaltung eines jeden durch die

Lautsprecher gejagten Riffs, welches dank der RöhrenBestückung mit brachialer Gewalt aus der Box springt.

Dies bietet Dir der WARP-Kanal in Reinkultur: Sei es der

Hi-Gain-Sound der angesagten NU-Metal-Ära, der freigelassen werden will, oder ein deftiges Riff-Brett im

Gothic-Metal-Stil. Durch die Variation von VorstufenVerzerrung im WARP-Kanal und der Endstufen-Zerrung

mit dem MASTER VOLUME-Poti sind der Spielarten

keine Grenzen gesetzt.

11..22 CCLLEEAANN--KKAANNAALL

Wie zu Beginn bereits erwähnt, dürstet es selbst den

härtesten Axe-Man dann und wann nach einer ruhigen

Passage in Form eines richtig schönen Clean-Sounds;

und sei es nur, um die nächsten Mörder-Riffs um so

deftiger ertönen zu lassen. Der Warp X™ bietet Dir einen

Ultra-Clean-Sound, der selbst bei hoher Lautstärke keine

Einbrüche in der Brillanz und Klarheit spürbar werden

lässt. Dadurch ist garantiert, dass der Sound immer da

ankommt, wo er hingehört ... in das Ohr des Publikums.

22..00 AANNSSCCHHLLÜÜSSSSEE UUNNDD BBEEDDIIEENNEELLEEMMEENNTTEE

Soweit, so gut! Du weißt nun zumindest um die

Möglichkeiten, die Dir Dein neues Metal-Aggregat

bietet. Aber um die Möglichkeiten des Teils in ihrer

gesamten Schönheit auszuschöpfen bedarf es einer kurzen

Beschreibung der Anschlüsse und Bedienelemente des

Warp X™.

22..11 VVOORRDDEERRSSEEIITTEE

Das Cockpit des Warp X™ ist ein drei Sektionen unterteilt: Es beginnt links neben den Schaltern der Hauptstromversorgung mit der MASTER-Abteilung

und führt über die WARP-Sektion zum CLEAN-Bereich.

Von links nach rechts findest Du die folgenden BedienElemente vor:

WARP

CLEAN

Page 19

WARP X - MANUAL

19

19

DEUTSCH

DARK DESIRE

MAINS ON/OFF

Dieser Schalter öffnet die Hauptstromzufuhr und gibt

den Röhren die Chance, sich auf die bevorstehenden

Prüfungen vorzubereiten.

STANDBY

Gibt den Weg in Richtung Endstufe und Box frei. Nach

der Aufwärmphase der Röhren ist mit dem Einschalten

des STAND BY-Schalters das Vordringen des GitarrenSignals ins Innere des Warp X™ eingeleitet. Regulierend

wirkt dabei der folgende Regler:

MASTER VOL

Wie der Name schon vermuten lässt, hältst Du mit

diesem Potentiometer die Macht über die 120 Watt

Röhren-Power zwischen Daumen und Zeigefinger, die

bei Deinen Band-Kollegen je nach Wunsch für gnadensuchende bis dem Wahnsinn nahe Gesichtsausdrücke

sorgen. Denn wehe, wenn sie losgelassen! Aus diesem

Grunde ist im Umgang mit diesem Regler ein gewisses

Maß an Spaß garantiert und Vorsicht geboten.

MIDI LEARN

Dieser Knopf dient zur Programmierung des nachrüstbaren MIDI-Moduls Hughes & Kettner®MSM-1™. Mit der

Installation des MSM-1™ Moduls wird der Warp X™

MIDI-fähig. Die MIDI LEARN-Taste speichert dann

auf einfachen Knopfdruck die aktuelle Kanal-/

FX Loop-Kombination.

FX LEVEL

Mit diesem Regler lässt sich der Effektanteil des externen Effektgerätes steuern. Näheres dazu im Kapitel

4.3 ANSCHLUSS EINES EFFEKTGERÄTES.

WWAARRPP--KKAANNAALL

MASTER

Dieses Poti zeigt sich für die Lautstärke des WARPKanals zuständig, und bildet mit dem VOLUME-Regler

des CLEAN-Kanals die Möglichkeit, die LautstärkenVer hältnisse der beiden "Gesichter" des Warp X™ "böse"

und "zahm" abzustimmen.

PRESENCE

Regelt die Obertöne des WARP-Kanals und lässt die

Töne messerscharf durch das musikalische Geschehen

schneiden.

TREBLE, MID, BASS

Über diese drei Regler bestimmst du Deinen persönlichen

Wunsch-WARP-Sound.

LUBE

Der Leichtspielfaktor! „Lubrification“ bedeutet soviel wie

„Schmierung“. Durch eine Variation des dynamischen

Ver haltens der Verzerrung des WARP-Kanals gleiten die

Seiten wie von selbst unter Deinen Fingen von Lick zu

Lick und Riff zu Riff.

SUB

Dieser Knopf greift in das schier unendliche Reich der

tiefen Frequenzen des WARP-Kanals ein: Die Sub-Bässe!

FX ON

Bestimmt, ob im WARP-Kanal der externe Effekt zu

hören ist. Achtung: Soll diese Schaltfunktion via

Stageboard oder MIDI erfolgen, darf dieser Schalter

nicht gedrückt sein. Näheres dazu findest im Kapitel

4.3 ANSCHLUSS EINES EFFEKTGERÄTES

GAIN

Im wahrsten Sinne Dreh- und Angelpunkt des gitarristischen Schaffens im Umgang mit dem Warp X™ ist:

der GAIN-Regler! Mit Ihm liegt es in Deiner Hand, den

Lautsprechern den Sound zu entlocken, der Deine Riffs

und Power-Chords so an den Mann bzw. die Frau bringt,

dass es nur so scheppert. Dabei bietet Dir der Amp mit

diesem Drehregler die Möglichkeit von angerautem

Chrunch bis hin zur gnadenlosen Hi-Gain-Wand alle

Schattierungen abzudecken.

WARP CH. ON

Aktiviert den WARP-Kanal und lässt die ungezügelte

Kraft der glühenden Röhren hervorbrechen.

Page 20

WARP X - MANUAL

20

20

DARK DESIRE

CCLLEEAANN--KKAANNAALL

PRESENCE

Regelt die Obertöne des CLEAN-Kanals.

FX ON

Bestimmt, ob im CLEAN-Kanal der externe Effekt

zu hören ist.

TREBLE, MID, BASS

Klangregelung des CLEAN-Kanals.

VOLUME

Regelt gleichzeitig Lautstärke und Kompression des

CLEAN-Kanals

INPUT

Ganz rechts befindet sich eine 6.3mm Klinkenbuchse

zum Anschluss Deines Instrumentes an

den Warp X™.

22..22 RRÜÜCCKKSSEEIITTEE

In dem schwarzen lackierten Stahlblech der Rückseite

sind folgende Einbauteile zu finden:

NETZANSCHLUSS

Die Eurobuchse mit Schublade für die Netz-Sicherung

stellt die Energieversorgung des Aggregates sicher.

Denn was schwer arbeitet will gut versorgt sein. Aber

Obacht! Es ist sicherzustellen, dass die vorhandene

Netzspannung mit der aktuellen Einstellung des Amps

und der Bestückung der Sicherungen übereinstimmt!

Die Daten findest Du im Kapitel 7.0 TECHNISCHE DATEN

FOOTSWITCH

Die Anschlussbuchse für den 2-fach Fußschalter

Hughes & Kettner®FS2, mit welchem die Kanäle sowie

FX ON geschaltet werden können, garantiert Dir einen

akkuraten Bühneneinsatz.

FX SEND

Falls Du ein Effektgerät verwenden möchtest,

so verbinde diese Buchse mit dem Eingang des

Effektgerätes. Weiterhin ist hier der Anschluss einer

zusätzliche Endstufe oder einer RED BOX®zwecks

Signalführung zum Mischpult möglich. Näheres dazu im

Kapitel 4.3 ANSCHLUSS EINES EFFEKTGERÄTES

FX RETURN

Verbinde diese Buchse mit dem Ausgang

des Effektgerätes.

FX –10DB

Dieser Schalter verringert den Ausgangspegel der

FX-Send Buchse um 10dB und erhöht die Eingangsempfindlichkeit der FX-Return Buchse um 10dB zum

Anpassen des Effektweges an den Eingangspegel des

Effektgerätes. Bei Verwendung von Effektgeräten, deren

Eingang für Instrumentenpegel ausgelegt ist, diesen

Schalter bitte in gedrückte Position bringen.

Page 21

WARP X - MANUAL

21

21

DEUTSCH

DARK DESIRE

MIDI MODULE

Mit dem optionalen Hughes & Kettner®MSM-1™ können

die Kanäle, und FX-ON/OFF sowie FX-PARALLEL/SERIELL

geschaltet werden. Am Modul kann die MIDI-Kanal

Nummer oder der OMNI-Mode, in dem es auf alle

16 Midi-Kanäle reagiert, angewählt werden.

BOXEN-AUSGÄNGE

4, 8, 2 x 16 und 16 Ohm dienen zum Anschluss von

Boxen mit entsprechender Impedanz.

33..00 SSTTAANNDDAARRDD--SSEETT UUPP UUNNDD VVEERRKKAABBEELLUUNNGG

Page 22

WARP X - MANUAL

22

22

DARK DESIRE

Nachdem nun die wesentlichen Bestandteile Deiner

neuen Errungenschaft erklärt sind und vermutlich

schon die ersten lautstarken Schreie von Nachbarn,

Mitmusikern, Freundinnen o.ä. zu hören sind, gibt es

im folgenden noch ein paar Tipps und Anregungen für

den Umgang mit dem Warp X™:

44..11 DDAASS AANNWWÄÄHHLLEENN

DDEERR KKAANNÄÄLLEE

Durch Drücken des WARP CH. ON-Tasters wählst Du

"die Schöne" oder das "Biest", Du rufst "Dr. Jekyll" oder

"Mr. Hyde", tanzt mit dem "Wolf und den 7 Saitlein".

Leuchtet der Taster auf, so bewegst Du Dich im Bereich

der fetten Verzerrung, und nimmst den Kampf mit dem

Biest, Dr. Jekyll und einem ganzen Rudel Wölfe auf.

Als Entspannung von der Schlacht tut dann ab und an

auch der durch erneutes Drücken des Tasters aktivierte

CLEAN-Kanal ganz gut.

44..22 VVOOMM CCHHRRUUNNCCHH RRIIFFFF BBRREETTTT

ZZUUMM HHII GGAAIINN SSCCHHRREEII

Wer sich ein solches Gerät zulegt, will damit zweifellos

nicht handzahme Rentner-Mucke machen, sondern es

krachen lassen...und was kracht schon schöner als die

geballte Kraft der rot leuchtenden Glaskolben. Hier bietet

der Warp X™ die Möglichkeit, durch die Abstimmung

des MASTER- und des GAIN-Reglers im WARP-Kanal

übergangslos zwischen hämmerndem Crunch und fettem

Hi-Gain zu wählen. Dazwischen sind Deinen SoundVorstellungen keine Grenzen gesetzt.

MASTER auf 5 und GAIN auf 6 bis 7 lässt es schon

gehörig krachen. Bässe rein und Mitten raus - zusammen

mit dem Tiefen-Booster, dem sogenannten SUB-Taster,

erschallt der ultimative Hi-Gain Schrei. Reduziert man den

GAIN und fährt mit dem MASTER des WARP-Kanals in

Richtung 8-9, so stellt sich bei entsprechend abgedämpfter

Anschlagtechnik ein rauher Crunch mit enormem Punch in

den Tiefen ein. Zuweilens solltest Du das MASTERVOLUME etwas nachregeln, weil Du ansonsten dem

Schalldruck kaum entweichen kannst...Aber auch hier

gilt: probieren geht über studieren!

44..33 AANNSSCCHHLLUUSSSS EEIINNEESS

EEFFFFEEKKTTGGEERRÄÄTTEESS

Mit dem auf der Rückseite des Gehäuses untergebrachten

Einschleifweg hast Du die Möglichkeit ein beliebiges

Effektgerät anzuschließen. Dazu musst Du die SENDBuchse mit dem INPUT und die RETURN-Buchse mit

dem OUTPUT des Effektgerätes verbinden. Aktiviere

den Effektweg mittels des FX ON-Schalters auf der

Frontplatte oder dem Fußschalter. Denke an die

Anpassung des Effektweges an den Eingangspegel

des Effektgerätes. Für Effektgeräte, deren Eingang auf

Gitarrenpegel ausgelegt ist, sollte der FX SEND LEVELSchalter gedrückt sein. Ist der Schalter nicht gedrückt,

arbeitet der Effektweg auf dem für Multieffektgeräte

üblichen Line-Pegel.

Mit dem LEVEL-Regler wird die Lautstärke des

Effektsignals im Parallel-Betrieb eingestellt.

HINWEIS

Manche Effektgeräte verursachen Phasenverschiebungen, die den Gesamtsound nachteilig verändern.

Schalte in diesem Fall den Effektweg auf FX SERIAL.

Der Effektweg arbeitet jetzt wie ein konventioneller

serieller Effektweg, d.h. das Lautstärkeverhältnis

zwischen Original und Effektsignal wird am

Effektgerät eingestellt.

TIP

Ist kein Effektgerät am Effektweg eingeschleift, so

lässt sich die RETURN-Buchse zum Anschluss eines

zweiten Instrumentes oder beliebiger Audioquellen

verwenden.

44..00 BBEEDDIIEENNUUNNGG DDEESS WWAARRPP XX

TTMM

Page 23

WARP X - MANUAL

23

23

DEUTSCH

DARK DESIRE

44..44 DDEERR WWAARRPP XX

TTMM

UUNNDD MMIIDDII

Ist das MSM-1™ Modul eingebaut, können die Kanäle

des WARP X™ und der Effektweg (auch die Umschaltung

von Seriell- auf Parallel-Betrieb) via MIDI geschaltet

werden.

Das somit mögliche gleichzeitige Umschalten von

WARP X™ und Multieffektgeräten bedeutet bestmöglichen

Spielkomfort.

55..00 RRÖÖHHRREENNTTAAUUSSCCHH,, WWAARRTTUUNNGG UUNNDD SSEERRVVIICCEE

Der Warp X™ ist ab Werk mit 6L6 und 12AX7/ECC83

Röhren bestückt. Sie werden nach dem „Burn-In“ (ein

erster Dauerlauf unter Last) in aufwendigen Selektionsverfahren auf ihre elektrischen Werte, mechanische

Beschaffenheit (Mikrofonie), und darüber hinaus im

akustischen Test am fertigen Gerät auf ihr Soundverhalten

geprüft. Einer der wichtigsten Schritte ist dabei das

„Matching“ (also Zusammenstellen von Röhrensätzen

gleicher Kennlinie) für die Endstufenbestückung.

WANN IST EIN RÖHRENTAUSCH SINNVOLL?

Die im Warp X™ eingesetzten Röhren zeichnen sich

durch vorbildliche Verarbeitungsqualität und eine hohe

Lebensdauer aus. Sollte dennoch einmal ein Problem

auftauchen, so überprüfe vor einem Röhrentausch bitte

folgende Fragen:

Lag die Ursache des Fehlers bzw. Ausfalls an der Röhre

selbst oder vielleicht an der Geräteperipherie, z.B. defektes

Speaker-Kabel als Ursache für defekte Endstufenröhre?

(Falls der Fehler nicht behoben wird, könnte das Problem

nach einem Röhrentausch erneut auftreten).

War während des Betriebes die Netzspannung konstant?

Bei Vollröhren-Amps kann eine Überspannung im Netz

die Ursache für einen Ausfall sein. Überspannungen entstehen z.B. bei Strom-Generatoren oder unsachgemäß

ausgeführten Starkstromverbindungen.

Hat vielleicht nur eine Sicherung angesprochen,

ohne dass ein wirklicher Defekt vorliegt? „Gealterte“

Sicherungen, Teilchenentladungen in einer Röhre oder

Überschläge durch Netzspannungsspitzen könnten

die Ursache sein. Ein Röhrentausch wäre dann

wenig sinnvoll.

Röhren zeigen nach entsprechender Betriebsdauer

Verschleißerscheinungen (erhöhte Mikrofonie, Brummempfindlichkeit, Höhenverluste, Leistungsverluste etc.).

Solche Anzeichen machen einen Austausch nötig, denn

sie führen nicht nur zu schlechteren Klangergebnissen,

sondern sind Vorboten für ein bevorstehendes Ausfallen

der betroffenen Röhre.

HINWEIS

Von einem Röhrentausch aus Spaß am Soundexperiment ist abzusehen. Die hierbei entstehenden

Kosten könnten bei unsachgemäßem Handeln unerwartet hoch ausfallen.

WAS IST BEIM RÖHRENTAUSCH ZU BEACHTEN?

Der Röhrentausch sollte ausschließlich durch technisch

qualifiziertes Fachpersonal erfolgen! Folgende Hinweise

sind deshalb nur für Service-Techniker gedacht:

Vor dem Entfernen des Bleches auf der Rückseite ist der

Netzstecker des Warp X™ zu ziehen und eine Mindestentladungszeit von 2 Minuten abzuwarten! Ist das Blech

demontiert, so können die Röhren vorsichtig aus ihren

Sockeln gezogen werden. Eine einzelne Endstufenröhre

darf nur dann getauscht werden, wenn sie exakt in das

Match passt (gleiche Kennlinie aufweist). Für die Endstufenröhren grundsätzlich nur gematchte Sätze einsetzen.

Wird ein neuer Satz gematchter Endstufenröhren mit

den gleichen Kennliniendaten des alten Satzes verwendet,

so ist ein Bias-Abgleich (Ruhestrom-Abgleich) nicht

zwingend notwendig. Wird dagegen ein Match mit

abweichenden Kennliniendaten verwendet, so muss ein

Bias-Abgleich erfolgen. Der Abgleich setzt umfangreiche

Messkenntnisse voraus und ist ausschließlich von

im Röhren-Amp Bereich qualifizierten Technikern

vorzunehmen.

Page 24

WARP X - MANUAL

24

24

DARK DESIRE

WIE KANN MAN DIE LEBENSDAUER

DES WARP X™ VERLÄNGERN?

• Betreibe den den Warp X™ niemals ohne Last

(Lautsprecher)! Ein hochwertiges, knicksicheres

Boxenkabel ist daher zwingend notwendig.

• Nutze den STAND BY Schalter! Häufiges Aufheizen der

Röhren erhöht den Verschleiß. Das Abschalten der

Anodenspannung mit der STAND BY-Funktion spart

Betriebsstunden.

• Vermeide Erschütterungen, insbesondere bei laufendem Gerät. Vor dem Transport den Amp ausschalten

und die Röhren abkühlen lassen.

• Sorge immer für eine technisch einwandfreie Geräteperipherie! Freie Lüftungsschlitze für eine ungestörte

Luftzirkulation sind lebenswichtig für den Warp X™

• In jedem Fall zu vermeiden sind extreme Hitze, das

Eindringen von Staub und insbesondere Nässe.

• Die Spezifikationen von Zusatzgeräten müssen

genauestens beachtet werden. Niemals Lautsprecherboxen mit zu kleiner Impedanz (Ohmzahl) am Warp X™

betreiben.

• Nie Geräte mit zu großem Pegel (z.B. Endstufen) an

die Eingänge des Warp X™ anschließen.

• Vor Anschluss des Gerätes immer die vorhandene

Netzspannung prüfen. Im Zweifelsfall den Bühnentechniker, Hausmeister o.ä. kontaktieren.

• Keine ”do it yourself” Reparaturen bei Problemen!

Auch der Tausch interner Sicherungen muß von einem

erfahrenen Techniker vorgenommen werden.

Page 25

WARP X - MANUAL

25

25

DEUTSCH

DARK DESIRE

66..00 MMÖÖGGLLIICCHHEE FFEEHHLLEERRQQUUEELLLLEENN //

TTRROOUUBBLLEESSHHOOOOTTIINNGG

DER WARP X™ LÄSST SICH NICHT EINSCHALTEN

• Es liegt keine Netzspannung an. Überprüfe den

korrekten Anschluss des Netzkabels.

• Die Netzsicherung ist defekt. Achte auf den für die

Netzspannung vorgesehenen Sicherungswert für den

Ersatz.

DER WARP X™ IST KORREKT VERKABELT, ABER ES IST

NICHTS ZU HÖREN

• Das Gerät ist auf STANDBY geschaltet.

• Gain- bzw. Masterregler sind abgedreht.

• Die Anodensichererung ist angesprochen.

Vor dem Austausch der Sicherung gegen eine dem

vorgeschriebenen Wert entsprechende Ersatzsicherung

sind die Endstufenröhren auf Defekt zu prüfen.

• Die Sicherung für die Röhrenheizung hat angesprochen

(Röhren glühen nicht). Achte beim Austausch der

Sicherung unbedingt auf den korrekten Wert. Den

Austausch sollte nur ein Service-Techniker vornehmen.

DER EFFEKTWEG IST UNGEWOLLT AKTIV

• Der FX LOOP ist deaktiviert, wenn der Frontplattenschalter, der Stageboardschalter und die Schaltfunktion

des MIDI-Moduls offen sind. Ist einer dieser Schalter

geschlossen ist der FX LOOP aktiv.

BEI AKTIVEM EFFEKTGERÄT WIRD DER SOUND INDIFFERENT UND “MATSCHIG”

• Das Effektgerät liefert ein Direktsignal, das im parallelen

Effektweg dem Originalsignal zugemischt wird. Je nach

verwendetem Effekt kann die Phasenlage des Direktsignals beim parallelen Zusammenmischen im Warp X™

zu Phasenauslöschungen führen. Um diese zu vermeiden, schalte den Effektweg auf SERIAL oder drehe das

Direktsignal im Effektgerät ab.

BEIM SPIELEN SIND “KLINGELGERÄUSCHE” ZU

HÖREN, DER AMP TENDIERT ZUM “PFEIFEN”

• Eine oder mehrere Röhren sind mikrofonisch. Ersetzen

Sie die Röhre durch eine neue entsprechenden Typs.

SCHON WENIGE BETRIEBSSTUNDEN NACH EINEM

RÖHRENTAUSCH ZEIGEN SICH WIEDER TYPISCHE

MERKMALE FÜR RÖHRENVERSCHLEIß (HÖHENVERLUSTE, RAUSCHEN, MIKROFONIE, “MULMIGER”

SOUND):

• Beim Röhrentausch wurden falsche Typen eingesetzt

oder der Ruhestrom wurde nicht optimal eingestellt.

Bringe bitte den Amp zu einem Fachmann, um den

Fehler beheben zu lassen.

Page 26

WARP X - MANUAL

26

26

DARK DESIRE

77..11 HHEEAADD

Alle Pegelangaben beziehen sich auf 0 dBV (1V RMS)

EINGÄNGE

INST. INPUT:

Buchse: Klinke

Bauart: unsymmetrisch

Eingangsimpedanz: 1 MΩ

Empfindlichkeit: - 32 dB

max. Eingangspegel: +8 dB

FX LOOP- RETURN L/R:

Buchse: Klinke

Bauart: unsymmetrisch

Eingangsimpedanz: 48 kW

max. Empfindlichkeit:

•10dB Schalter gedrückt -18 dB

• nicht gedrückt -8 dB

max. Eingangspegel:

•10dB Schalter gedrückt + 5 dB

• nicht gedrückt +15dB

AUSGÄNGE

FX LOOP- Send L/R:

Buchse: Klinke

Bauart Ausgang: unsymmetrisch

Ausgangsimpedanz: 2,2 kΩ

Ausgangspegel: - 6 dB

max. Ausgangspegel:

•10dB Schalter gedrückt + 2 dB

• nicht gedrückt +12 dB

LAUTSPRECHERANSCHLÜSSE:

Anzahl: 4

Ausführung: Klinkenbuchsen

Bauart: unsymmetrisch

Impedanz: 1 X 4Ω ; 1 X 8Ω oder

2 X 16Ω ; 1 X 16Ω

ALLGEMEINE ELEKTRISCHE DATEN

schaltbare Netzspannungen

Schutzklasse 1

max. Stromaufnahme:

1,35 A @ 230V AC, 4-8-16Ω

2,55 A @ 117V AC, 4-8-16Ω

2,85 A @ 100V AC, 4-8-16Ω

max. Leistungsaufnahme:

383 VA @ 253 V AC, 4-8-16Ω

Netzspannungstoleranzbereich:

+/- 10 %

Umgebungstemperaturbereich:

- 10 ∞C bis + 60 ∞C

externe Sicherungen:

1 x T 500 mA (Anodenspannung)

interne Sicherungen:

1 x TT 10 A „superträge“ ( Röhren-Heizung und

Frontbeleuchtung )

2 x T 630 mA ( Umschaltung; Effektweg )

ALLGEMEINE MECHANISCHE DATEN

Abmessungen:

Breite: 655 mm (mit Ecken)

Höhe: 280 mm (mit Griff

und Füßen)

Tiefe: 255 mm ( mit Ecken )

Gewicht: 20,5 kg

77..00 TTEECCHHNNIISSCCHHEE DDAATTEENN

Page 27

WARP X - MANUAL

27

27

FRANÇAIS

DARK DESIRE

Le présent ouvrage, grâce auquel vous vous apprêtez

à faire connaissance avec votre nouveau Killer-Amp

Warp X™, n’a rien d’un manuel d’utilisation classique.

Au contraire, il n’a même pas été rédigé par le fabricant,

mais par moi, « Mme. Hansen » (mon nom d’artiste).

En tant que testeur alpha, j’ai eu le privilège d’utiliser un

Warp X™, un ampli démoniaque qui a plongé tout le

voisinage dans la tourmente. Après 5 minutes d’un véritable déluge sonore ponctué de salves diaboliques en

staccatos, j’étais envoûté par cette machine infernale.

Elle a tout simplement une pêche d’enfer !

Et à mesure que je m’éclatais sur les morceaux et

que je tombais en pâmoison devant ce véritable délice

sonore, j’ai eu l’idée de proposer mes services chez

Hughes & Kettner®en couchant sur papier l’euphorie

qu’avait suscité en moi ce matériel de premier choix.

Et nous y voilà.

C’est le résultat final que vous tenez entre vos mains.

J’espère que je suis parvenu à indiquer les voies que j’ai

suivies pour obtenir un maximum de sensations... et

recevoir pas mal de plaintes des voisins à cause du

volume trop élevé...

MAIS APRÈS TOUT, CEUX QUI BAISSENT LE VOLUME

SONT DES DÉGONFLÉS !

Mme. Hansen

NNOOUUSS VVOOUUSS SSOOUUHHAAIITTOONNSS

BBEEAAUUCCOOUUPP DDEE SSUUCCCCÈÈSS EETT DDEE

PPLLAAIISSIIRR MMUUSSIICCAALL AAVVEECC

VVOOTTRREE WWAARRPP XX

TTMM

!!

EENNTTEERR TTHHEE DDAARRKK ZZOONNEE

Page 28

WARP X - MANUAL

28

28

DARK DESIRE

LLEE SSOONN

Le son Metal du 21e siècle est l’apanage des guitares «

detuned », des riffs agressifs et des effets clean empreints de vibrato. Il est clair que, dans ce nouvel

environnement sonore, les amplis d’hier ne vous

sont plus d’aucune utilité...

Le Warp X™, c’est l’arme absolue dans la lutte NU-Metal.

Vous désiriez plus de pêche dans les basses et des

réserves presque illimitées en High Gain ? C’est désormais possible grâce à votre Warp X™. En le combinant

avec sa tête à lampes et son enceinte 4 x 12", il libère

vraiment tout son potentiel.

Dotée de 4 lampes 6L6, la tête prodigue sa puissance

à l’enceinte et vous donne un pouvoir sans précédent

dans ce domaine, ce qui vous permettra de vous imposer

dans vos riffs quotidiens. Parallèlement, le Warp X™

vous délivre tout aussi bien des sons clean croustillants

et nets, une propriété qui donne tout son caractère

dramatique à votre œuvre, juste avant l’assaut final.

SSOOMMMMAAIIRREE

AVANT LA MISE EN FONCTION . . . . . . . . . . . . . . . . 29

MISE EN FONCTION . . . . . . . . . . . . . . . . . . . . . . . . 29

1.0 LES CANAUX DU Warp X™ . . . . . . . . . . . . . . 30

2.0 RACCORDEMENTS ET COMMANDES . . . . . . . . 30

3.0 REGLAGES STANDARD ET CABLAGE . . . . . . . . 33

4.0 FONCTIONNEMENT DU Warp X™ . . . . . . . . . . 34

5.0 REMPLACEMENT DES LAMPES,

SERVICE ET ENTRETIEN . . . . . . . . . . . . . . . . . . 35

6.0 DEPISTAGE DES PANNES . . . . . . . . . . . . . . . . . 37

7.0 CARACTERISTIQUES TECHNIQUES . . . . . . . . . . . 38

CONSIGNES DE SECURITE IMPORTANTES . . . . . . . . 65

Page 29

WARP X - MANUAL

29

29

FRANÇAIS

DARK DESIRE

AAVVAANNTT LLAA MMIISSEE EENN FFOONNCCTTIIOONN

Avant de faire fonctionner votre nouvel ampli, souvenez-vous d’une chose : il a du coffre ! Le volume

élevé peut entraîner des troubles de l’audition. Avant

de brancher l’ampli, veillez donc à toujours tourner

le potentiomètre MASTER VOLUME jusqu’à la butée

de gauche, puis tournez-le doucement dans le sens

des aiguilles d’une montre jusqu’à obtention d’un

niveau sonore adapté à la pièce et qui n’affecte pas

vos tympans ! Soyez raisonnable avec le bouton

du volume de votre ampli : adoptez la plus grande

prudence afin de ne pas vous exposer – ni vous, ni

votre public – à des troubles durables de l’audition.

Avant de brancher le WARP™, assurez-vous que la

valeur de tension indiquée près de la prise de branchement (MAIN INPUT) correspond bien à la tension secteur

disponible. Veillez à garantir une aération suffisante des

surfaces de refroidissement de l’appareil. Assurez-vous

que l’appareil soit disposé sur un emplacement stable,

à l’abri de toute influence mécanique ou thermique

extérieure susceptible de porter préjudice à sa sécurité

ou à celle de son utilisateur. Le fabricant décline toute

responsabilité en cas de dommages à l’appareil ou à

d’autres appareils, résultant d’une utilisation inappropriée

de l’appareil.

MMIISSEE EENN FFOONNCCTTIIOONN

Premièrement, branchez le câble d’enceinte dans la

sortie appropriée sur la tête. Pour de plus amples

informations à ce sujet, veuillez consulter le point

2.0 RACCORDEMENTS ET COMMANDES. L’autre

extrémité du câble vient se loger dans l’entrée de l’enceinte. Il s’agit d’un point primordial pour les amplis

entièrement à lampes ! En effet, tout fonctionnement

des lampes sans qu’une enceinte ne soit branchée ou

à une valeur mauvaise ohmique peut entraîner leur

destruction !

À présent, branchez la fiche secteur de la tête dans la

prise, puis enclenchez l’appareil via l’interrupteur

MAINS. Pensez à accorder un court instant de répit aux

lampes afin de les laisser chauffer. Pendant ce temps,

vous pouvez vous laisser emporter par les reflets orangerouge des lampes et par la lueur rouge émanant du

cœur de l’appareil.

Lors de l’utilisation du Warp X™, vous devrez systématiquement vous livrer à une opération obligatoire : après

le dernier riff en basse, vous veillerez toujours à tourner

le potentiomètre MASTER VOLUME jusqu’à la butée de

gauche, faute de quoi l’ampli risque de vous réserver

une surprise de taille lors de son prochain branchement.

Le potentiomètre Master est bien sur zéro ?

Très bien, alors continuons. Branchez le connecteur sur

la guitare, branchez-le sur l’ampli, puis activez l’interrupteur STAND BY pour donner vie aux lampes incandescentes. Vous pouvez maintenant sélectionner différents

canaux...

Page 30

WARP X - MANUAL

30

30

DARK DESIRE

11..00 LLEESS CCAANNAAUUXX DDUU WWAARRPP XX

TTMM

Le Warp X™ dispose de deux canaux indispensables à la

musique pure et dure :

11..11 CCAANNAALL WWAARRPP

Plongez dans le monde de la distorsion intense et

découvrez l’épanouissement personnel grâce aux riffs

crachés par les haut-parleurs et qui, grâce aux lampes

d’une puissance phénoménale, jaillissent littéralement

de l’enceinte. C’est l’essence même du canal WARP :

qu’il s’agisse du son Hi-Gain de l’ère NU-Metal annoncée

et qui ne demande qu’à jaillir, ou des riffs soignés du

style Gothic-Metal. Grâce à la variation de la distorsion

du préampli dans le canal WARP et à celle du préampli

avec le potentiomètre MASTER VOLUME, vous pouvez

maintenant laisser libre cours à votre imagination.

11..22 CCAANNAALL CCLLEEAANN

Comme expliqué précédemment, même les guitaristes

les plus rudes recherchent ça et là un passage calme

sous la forme d’un son clean vraiment agréable, ne

serait-ce que pour mieux faire exploser leurs riffs

ravageurs par la suite. C’est pourquoi le Warp X™

vous offre un son ultra-clair qui, même avec le volume

obligatoirement élevé, garantira un son d’une clarté et

d’une brillance ininterrompues. Bref, de quoi faire en

sorte que ce dernier arrive à bon port… dans

l’oreille de votre public.

22..00 RRAACCCCOORRDDEEMMEENNTTSS EETT CCOOMMMMAANNDDEESS

Voilà, au moins maintenant, vous connaissez maintenant

les possibilités qui vous sont offertes par votre nouveau

bijou. Mais afin que vous soyez en mesure d’exploiter

pleinement ces possibilités, nous devons tout de même

effectuer une brève description des raccordements et

des commandes du Warp X™.

22..11 FFAACCEE AAVVAANNTT

Les commandes du Warp X™ sont réparties en trois

sections qui vont de l’interrupteur d’alimentation

principale avec la section MASTER à gauche

à la section CLEAN à droite, en passant par la section

WARP. De gauche à droite, les commandes se répartissent comme suit :

WARP

CLEAN

Page 31

WARP X - MANUAL

31

31

FRANÇAIS

DARK DESIRE

MAINS ON/OFF

Cet interrupteur alimente l’appareil en courant et permet

aux lampes de se préparer à leur mise à l’épreuve.

STANDBY

Libère l’accès à l’étage de puissance et aux enceintes.

Une fois la phase d’échauffement des lampes terminée,

l’actionnement de l’interrupteur STAND BY permet d’envoyer le signal de la guitare dans le cœur du Warp X™.

C’est le potentiomètre suivant qui est chargé d’en régler

l’amplitude.

MASTER VOL

Comme son nom l’indique, ce potentiomètre est bien

celui qui vous met une puissance de 120 watts entre les

mains – de quoi observer les membres de votre groupe

vous adresser des regards implorants, voire les rendre

complètement fous. Car une fois que vous lui lâchez la

bride, place à l’apocalypse ! C’est pourquoi il est recommandé d’utiliser avec prudence ce potentiomètre qui

vous fera vivre des moments inoubliables.

MIDI LEARN

Ce bouton sert à la programmation du module MIDI

Hughes & Kettner®MSM-1™, disponible séparément.

L’installation du module MSM-1™ permet au Warp X™

de fonctionner en mode MIDI. Par simple pression sur

un bouton, la touche MIDI LEARN sauvegarde alors la

combinaison canal / FX Loop en cours.

FX LEVEL

Ce potentiomètre règle le rapport d’effet de l’unité

d’effets externe. Pour de plus amples informations à ce

sujet, consultez le point 4.3 BRANCHEMENT DE L’UNITÉ

D’EFFETS.

CCAANNAALL WWAARRPP

MASTER

Ce potentiomètre règle le volume du canal WARP.

En le combinant avec le potentiomètre VOLUME du

canal CLEAN, vous pourrez déterminer le rapport de

force entre les deux « visages » du Warp X™, le « dur »

et le « tendre ».

PRESENCE

Règle les harmoniques du canal WARP et livre des sons

tranchants au cours de la performance.

TREBLE, MID, BASS

Ces trois potentiomètres vous permettent de régler

votre son WARP selon vos propres désirs..

LUBE

Le bouton qui « met de l’huile » ! « Lube » signifie «

lubrification ». Grâce à une variation dynamique de la

distorsion du canal WARP, les cordes glissent d’ellesmêmes sous vos doigts au gré des licks et des riffs.

SUB

Ce bouton vous permet de plonger jusqu’au tréfonds du

royaume des basses fréquences du canal WARP, pour

des basses abyssales !

FX ON

Détermine si l’effet externe est perçu dans le canal

WARP. Attention : Si cette opération s’effectue via

Stageboard ou MIDI, ce bouton ne peut en aucun cas

être enclenché. Pour de plus amples informations à ce

sujet, consultez le point 4.3 BRANCHEMENT DE L’UNITÉ

D’EFFETS.

GAIN

La pierre angulaire de votre création musicale avec

votre Warp X™ a un nom : GAIN ! Ce potentiomètre

permettra aux haut-parleurs d’exprimer pleinement

leur potentiel et de restituer fidèlement vos riffs ou vos

accords rythmiques. Il permet ainsi à votre ampli de

couvrir tous les registres, des Crunch rugueux aux

impitoyables passages Hi-Gain.

WARP CH. ON

Active le canal WARP et laisse déferler la puissance

débridée des lampes incandescentes.

Page 32

WARP X - MANUAL

32

32

DARK DESIRE

CCAANNAALL CCLLEEAANN

PRESENCE

Règle les harmoniques du canal CLEAN.

FX ON

Détermine si l’effet externe doit être perçu dans le canal

CLEAN.

TREBLE, MID, BASS

Règle la tonalité du canal CLEAN.

VOLUME

Règle à la fois le volume et la compression du canal

CLEAN.

INPUT

Ce jack (6,3 mm), situé à l’extrême droite de l’appareil,

sert à connecter votre instrument au Warp X™.

22..22 FFAACCEE AARRRRIIÈÈRREE

Le panneau noir situé sur la face arrière de l’appareil

regroupe les éléments suivants :

RACCORDEMENT AU SECTEUR

Cette prise conforme aux normes européennes, avec

logement incorporé pour le fusible de secteur, garantit

l’alimentation de l’appareil. Car un appareil soumis à

rude épreuve doit être bien alimenté. Veillez donc à ce

que la tension du secteur corresponde aux paramètres

de l’ampli et à utiliser des fusibles appropriés !

Ces données figurent au point 7.0 CARACTÉRISTIQUES

TECHNIQUES.

FOOTSWITCH

La prise de raccordement pour le double pédalier

Hughes & Kettner®FS2, lequel permet d’enclencher les

canaux et FX ON, vous garantit des performances de

premier ordre sur scène.

FX SEND

Si vous désirez utiliser une unité d’effets, raccordez-la

à cette prise. Par ailleurs, elle permet également la connexion d’un étage de puissance supplémentaire ou d’une

RED BOX®afin de transmettre le signal à une table de

mixage. Pour de plus amples informations à ce sujet,

consultez le point 4.3 BRANCHEMENT DE L’UNITÉ

D’EFFETS.

FX RETURN

Reliez ce jack à la sortie d’une unité d’effets.

FX –10DB

Cet interrupteur diminue l’impédance de sortie de la

prise FX-Send de 10 dB et augmente la sensibilité en

entrée de la prise FX-Return de la même valeur afin

d’adapter la boucle d’effets à l’impédance d’entrée de

l’unité d’effets. En cas d’utilisation d’une unité d’effets

dont l’entrée est réglée sur l’impédance de l’instrument,

veuillez enclencher cet interrupteur.

Page 33

WARP X - MANUAL

33

33

FRANÇAIS

DARK DESIRE

MIDI MODULE

Avec la Hughes & Kettner®MSM-1™ disponible séparément, ce module permet de sélectionner les canaux,

de permuter entre FX-ON et FX-OFF ainsi qu’entre

FX-PARALLEL et FX-SERIAL. Il permet de sélectionner

le numéro de canal MIDI ou le code OMNI, dans la

mesure où il réagit aux 16 canaux MIDI.

SORTIES ENCEINTES

Les sorties 4, 8, 2 x 16 et 16 ohms servent à connecter

des enceintes de ces impédances.

33..00 RREEGGLLAAGGEESS SSTTAANNDDAARRDD EETT CCAABBLLAAGGEE

Page 34

WARP X - MANUAL

34

34

DARK DESIRE

Maintenant que vous avez pris connaissance des principaux éléments de votre nouvelle acquisition et qu’à

n’en pas douter, les voisins, les membres de votre groupe

et vos amis se sont déjà manifestés, voici quelques

conseils et suggestions pour l’utilisation de votre

Warp X™:

44..11 SSEELLEECCTTIIOONN DDEESS CCAANNAAUUXX

En poussant sur le bouton WARP CH. ON, vous choisissez « la Belle » ou « la Bête », vous appelez « Dr. Jekyll »

ou « Mr. Hyde ». Si l’interrupteur s’allume, c’est que

vous avez opté pour la distorsion, le combat contre

la Bête et Dr. Jekyll. Pour se remettre de cette lutte

acharnée, une simple pression sur le bouton d’activation

du canal CLEAN suffit.

44..22 DDUU RRIIFFFF CCHHRRUUNNCCHH AA LLAA

PPLLAAIINNTTEE HHII GGAAIINN

Quand on se procure un tel appareil, ce n’est certainement pas pour lui laisser couler des jours paisibles, mais

plutôt pour lui faire cracher les flammes de l’enfer... et

qu’y a-t-il de plus beau que la sonorité de ces lampes

incandescentes pour ce faire ? En réglant les potentiomètres MASTER et GAIN du Warp X™, vous pourrez

directement passer des martèlements Crunch aux

Hi-Gain onctueux, tandis que vous aurez la liberté

la plus totale pour placer entre ces deux extrêmes

tous les sons que vous pourrez imaginer.

En réglant le bouton MASTER sur 5 et le bouton GAIN

entre 6 et 7, l’ampli fait déjà parler la poudre. Basses

rentrées et médiums extériorisés – associées au booster

de basses (le capteur SUB), la plainte Hi-Gain ultime

s’exprime. Si l’on réduit le GAIN et que, via le MASTER,

on amène le canal WARP en position 8-9, on obtient

alors un Crunch rugueux au punch incroyable dans les

basses. Il arrivera de temps à autre que vous deviez affiner

le réglage au niveau du MASTER VOLUME, faute de

quoi vous échapperez difficilement à la pression sonore...

Quoi qu’il en soit, comme toujours, rien ne vaut

la pratique !

44..33 BBRRAANNCCHHEEMMEENNTT DDEE

LL’’UUNNIITTÉÉ DD’’EEFFFFEETTSS

Avec la boucle d’effets située au dos de l’appareil, vous

avez la possibilité de brancher l’unité d’effets de votre

choix. Pour ce faire, reliez la prise SEND avec l’INPUT, et

la prise RETURN avec l’OUTPUT de votre unité d’effets.

Activez ensuite la boucle d’effets via l’interrupteur

FX ON sur la face avant ou via le pédalier. Pensez à

adapter la boucle d’effets à l’impédance d’entrée de

l’unité d’effets. Il conviendra d’enfoncer l’interrupteur

FX SEND LEVEL pour les unités d’effets dont l’entrée

est réglée sur l’impédance de la guitare. Si l’interrupteur

n’est pas enfoncé, la boucle d’effet fonctionnera sur le

niveau Line destiné généralement aux appareils multieffets.

Le potentiomètre LEVEL règle le volume du signal de

l’effet en fonctionnement en parallèle.

REMARQUE

Certaines unités d’effets provoquent des décalages

de phase qui nuisent à la sonorité globale. Le cas

échéant, placez la boucle d’effets sur FX SERIAL, ce

qui lui permettra de fonctionner en mode classique

(en série). Autrement dit, le rapport de volume entre

l’original et le signal de l’effet sera réglé dans l’unité

d’effets.

ASTUCE

Si aucune unité d’effets n’est mise en boucle sur la

boucle d’effets, la prise RETURN peut être utilisée

pour brancher un deuxième instrument ou la source

audio de votre choix.

44..00 FFOONNCCTTIIOONNNNEEMMEENNTT DDUU WWAARRPP XX

TTMM

Page 35

WARP X - MANUAL

35

35

FRANÇAIS

DARK DESIRE

44..44 LLEE WWAARRPP XX

TTMM

EETT MMIIDDII

Si vous possédez le module MSM-1™, il vous est

possible de sélectionner les canaux du WARP X™ et de

l’unité d’effets (mais aussi de passer du fonctionnement

en série au fonctionnement en

parallèle) via MIDI. Cette transition simultanée entre le

WARP X™ et les appareils multi-effets vous garantit un

confort de jeu optimal.

55..00 RREEMMPPLLAACCEEMMEENNTT DDEESS LLAAMMPPEESS,,

SSEERRVVIICCEE EETT EENNTTRREETTIIEENN

Le Warp X™ est équipé d’origine de lampes 6L6 et

12AX7/ECC83 . Après la phase de « burn-in » (premier

fonctionnement continu sous charge), elles font l’objet

d’une procédure de sélection complexe afin de vérifier

leurs valeurs électriques et leur aptitude mécanique

(microphonie), avant d’être soumises à un essai acoustique dans l’appareil fini, destiné à contrôler leur qualité

sonore. L’une des phases les plus importantes est le «

matching » (regroupement de jeux de lampes présentant

la même courbe caractéristique) pour l’équipement

d’étages de puissance.

QUAND FAUT-IL REMPLACER LES LAMPES ?

Les lampes utilisées pour le Warp X™ se distinguent

par leur qualité de traitement exemplaire et leur durée

de vie élevée. En cas de problème persistant, il convient

cependant de vérifier les points suivants avant de

procéder au remplacement des lampes :

Le défaut ou la panne est-il lié à la lampe proprement

dite ou à des appareils périphériques (p. ex. câble de

haut-parleur défectueux) ? (Si le défaut n’est pas éliminé,

le problème pourrait réapparaître après le remplacement

d’une lampe).

La tension secteur était-elle constante durant le fonctionnement ? Dans le cas d’amplificateurs entièrement à

lampes, une surtension secteur peut causer une panne.

Les surtensions peuvent notamment apparaître sur des

générateurs ou des liaisons à courant fort non conformes.

Peut-être le déclenchement du fusible n’est-il pas lié à

une panne réelle ? Le défaut peut en effet résulter d’un

vieillissement extrême des fusibles, du déchargement de

particules dans une lampe ou de décharges disruptives

dues à des crêtes de tension secteur. Dans ce cas, le

remplacement d’une lampe ne se justifierait pas.

Après un certain temps d’utilisation, les lampes présentent des traces d’usure (augmentation de la microphonie,

sensibilité aux ronflements, pertes dans les aigus, pertes

de puissance, etc.). Ces signes annoncent la nécessité

d’un remplacement, car ils dégradent non seulement

le résultat sonore, mais précèdent aussi la défaillance

imminente de la lampe concernée.

REMARQUE

Il est déconseillé de remplacer une lampe pour

le simple plaisir d’expérimenter un nouveau son.

Les coûts qui en découleraient en cas de fausse

manœuvre risqueraient de ne pas vous faire plaisir

du tout !

Page 36

WARP X - MANUAL

36

36

DARK DESIRE

À QUOI FAUT-IL PRÊTER ATTENTION LORS DU REMPLACEMENT D’UN LAMPE ?

Le remplacement de lampes doit être exclusivement

confié à un personnel qualifié ! Les remarques suivantes

sont donc rédigées à sa seule attention :

Avant de retirer le panneau arrière, il convient de

débrancher le Warp X™ du secteur et de patienter au

moins deux minutes (temps de décharge minimal) ! Une

fois le panneau démonté, les lampes peuvent être prudemment enlevées de leurs socles. Une lampe d’étage

de puissance individuelle ne peut être remplacée que

par une lampe équivalente (c’est-à-dire présentant la

même courbe caractéristique). Les lampes destinées à

l’étage de puissance ne doivent en principe être uniquement remplacées par des jeux appariés. Si vous utilisez

à cet effet un nouveau jeu de lampes appariées pour