Page 1

12/02 P/N 211446D

1

Toll-Free Customer Service Number for U.S: 1-800-558-5234

Internet Address: http://www.hydra-rib.com

IMPORTANT! Have any questions?...Don’t go back to the store!

We appreciate your purchasing one of our many fine products. We are sure that you will be very satisfied with your selection. Although

great care and effort have been taken, occasionally problems may occur. To ensure prompt and correct handling of any problems, or to

answer any questions, please contact our Toll-Free Customer Service Number listed below. Service will be quicker if you have your

Model Number (found on carton) and assembly instructions ready when calling. PLEASE WRITE YOUR MODEL NUMBER IN THE

SPACE PROVIDED ABOVE.

REQUIRED TOOLS AND

MATERIALS:

• Three People

• Tape Measure

• Shovel and Post Hole Digger

• Concrete, 1260 lb. (572 kg) and Container to Mix

• Carpenter’s Level

• (Two) Step Ladder 8 ft. (2.4 m)

• Wrenches: (Two) 1/2, 9/16, 3/4, 15/16 (One) 3/8

• Marker

•Vice

• Masking Tape

In-Ground Basketball System

Owners Manual

© COPYRIGHT 1999 by HUFFY SPORTS

A Huffy Sports Company

Customer Service Center

N53 W24700 South Corporate Circle

Sussex, WI 53089

U.S.A.

WRITE IN YOUR MODEL NUMBER:

SAFETY INSTRUCTIONS

Most injuries are caused by misuse and/or not following instructions.

Use caution when using this system.

• If using a ladder during assembly, use extreme caution.

• Three (3) people are reccomended for this operation.

• Seat the pole sections properly. Failure to do so could allow the pole sections to

separate during play.

• Before digging, contact utility company to locate underground power cables, gas,

and water lines. Ensure there are no overhead power lines within 20 ft. (7 m) radius

of pole location.

• Climate, corrosion, excessive use, or misuse could result in system failure.

• If technical assistance is required, contact Huffy Sports.

• Minimum operational height is 6'6" (1.98 m) to the bottom of backboard.

• This equipment is intended for home recreational use only and NOT excessive

competitive play.

• Read and understand the warning label affixed to pole. Label is shown on page 2.

• The life of your basketball pole depends on many conditions. The climate,

placement of the pole, the location of the pole, exposure to corrosives such as

pesticides, herbicides or salts are all important.

• Adult supervision is recommended when adjusting height.

• Serious injury could occur if teeth/face come in contact with backboard, net, or rim.

FAILURE TO FOLLOW THESE SAFETY INSTRUCTIONS MAY RESULT IN

SERIOUS INJURY, PROPERTY DAMAGE AND WILL VOID WARRANTY.

Owner must ensure that all players know and

follow these rules for safe operation of the system.

To ensure safety, do not attempt to assemble this system without following the

instructions carefully. Proper and complete assembly, use and supervision is

essential for proper operation and to reduce the risk of accident or injury. A

high probability of serious injury exists if this system is not installed,

maintained, and operated properly. Check entire box and inside all packing

material for parts and/or additional instructional material. Before beginning

assembly, read the instructions and identify parts using the hardware identifier

and parts list in this document.

For more information on assembly, placement, proper use and maintenance,

visit The American Basketball Council website at http://www.smarthoops.com.

Page 2

2

P/N 211446D 12/02

IMPORTANT! WRITE MODEL NUMBER FROM BOX ONTO PAGE 1 OF THIS OWNERS MANUAL

WARNING

F AILURE TO FOLLOW THESE WARNINGS MAY RESULT

IN SERIOUS INJURY AND/OR PROPERTY DAMAGE.

Owner must ensure that all players know and follow

these rules for safe operation of the system.

• See instruction manual for proper installation.

• DO NOT HANG on the rim or any part of the system

including backboard, support braces or net.

• During play, especially when performing dunk type

activities, keep player's face away from the backboard, rim

and net. Serious injury could occur if teeth/face come in

contact with backboard, rim or net.

• Do not slide , climb, shake or play on pole.

• When adjusting height, keep hands and fingers away from

moving parts.

• Do not allow children to move or adjust system.

• During play, do not wear je

welry (rings, watches,

necklaces, etc.); objects may entangle in net.

• Keep organic material away from pole base. Grass, litter,

etc. could cause corrosion and or deterioration.

• Chec

k pole system for signs of corrosion (rust, pitting,

chipping) and repaint with with exterior enamel paint. If

rust has penetrated through the steel anywhere, replace

the pole immediately.

• Check system before each use for proper ballast, loose

hardware, excessive wear and signs corrosion and repair

before using.

• Check system before eac

h use for instability.

• Never play on damaged equipment.

• Keep pole top covered with cap at all times.

201255 2/99

1-800-558-5234

37

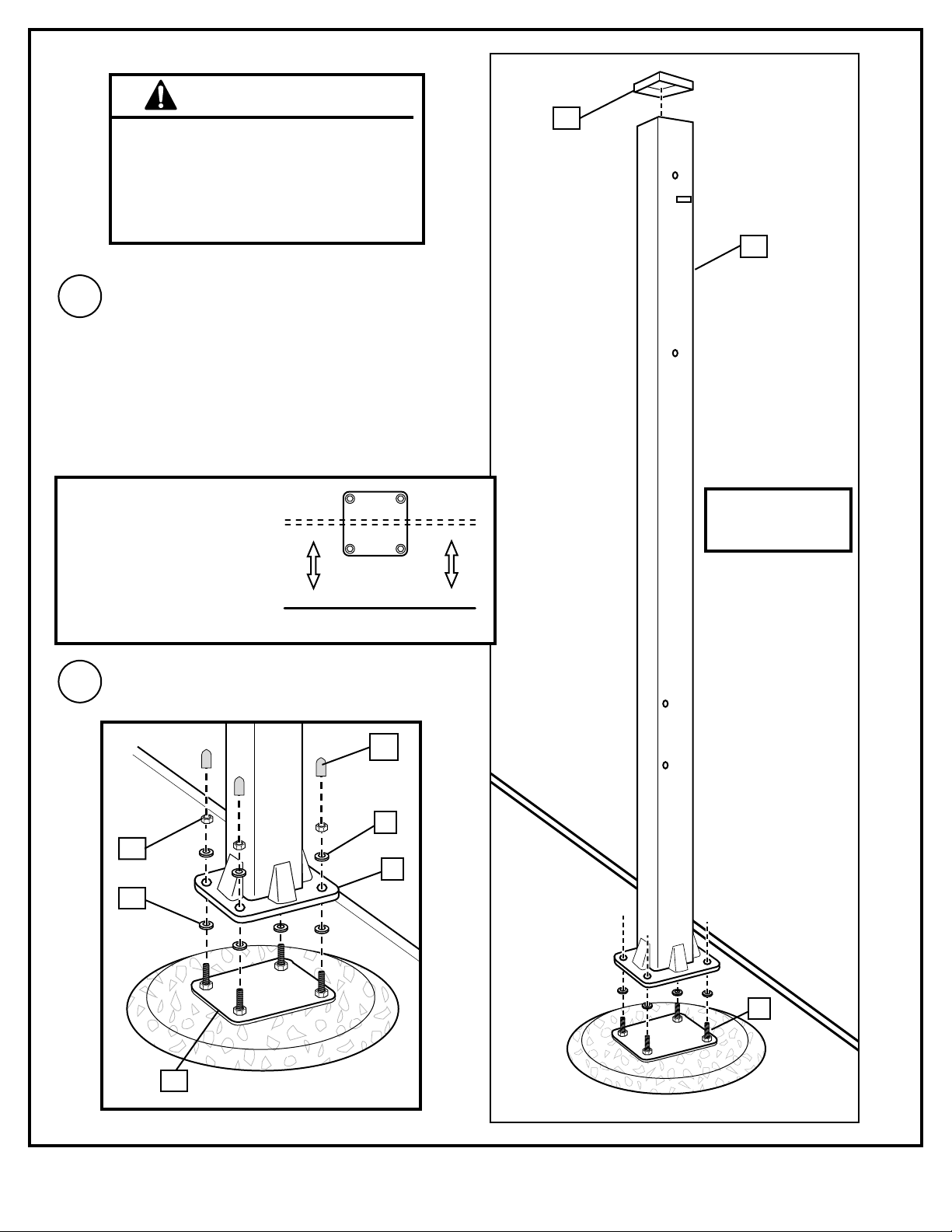

Page 3

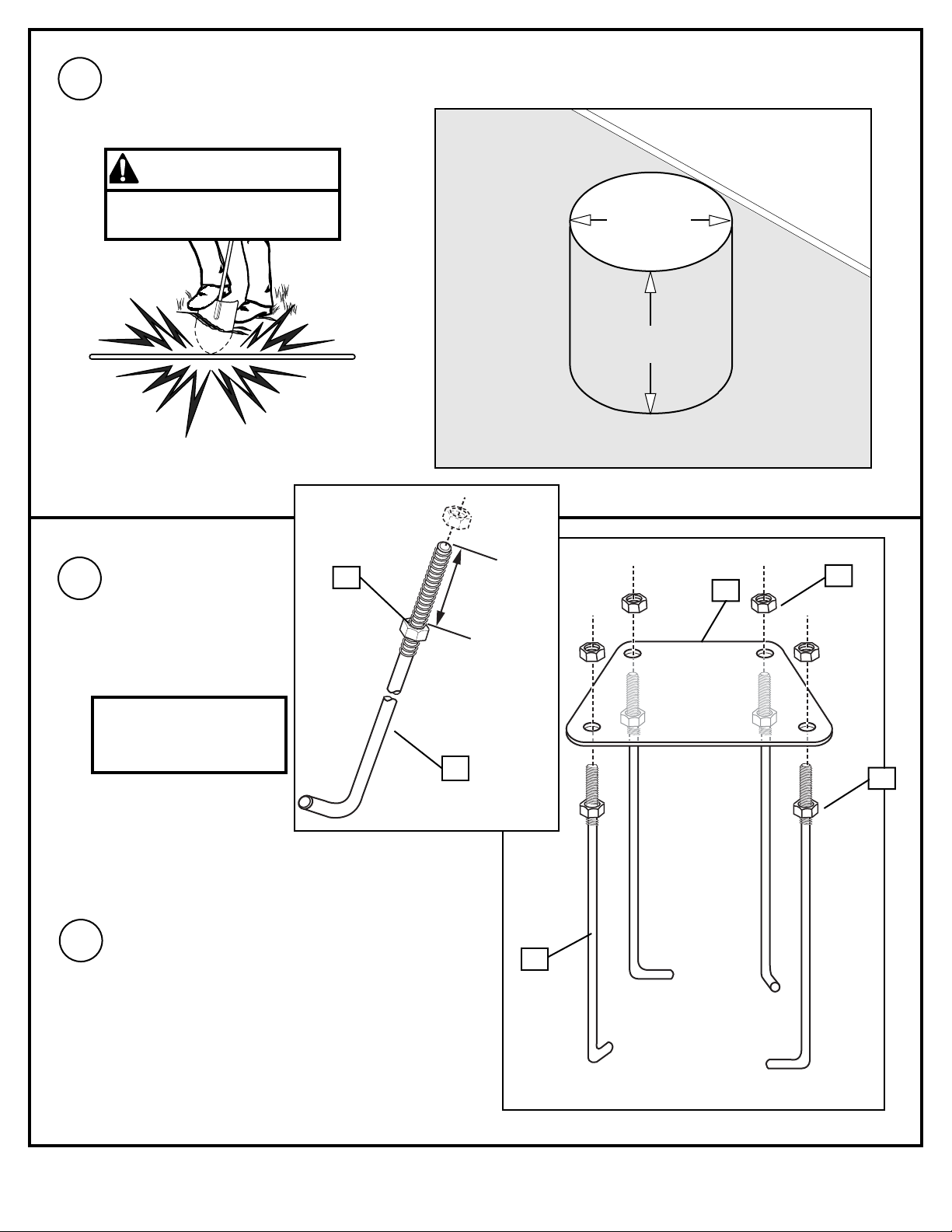

Ensure ground is level with playing

surface, then dig pole hole.

GROUND

SURFACE

PLAYING

SURFACE

1.

Install threaded ends of J-bolts (1) through holes in

mounting plate (3) and secure as shown.

NOTE: Make sure J-bolts (1) are in the illustrated

position.

NOTE: Nuts on the top of plate are used for leveling

the pole after system is fully assembled.

2.

3

2

2

2

1

3.

1

3

12/02 P/N 211446D

CONTACT UTILITIES

BEFORE DIGGING.

Install nut (2) to J-bolt (1)

as shown. Repeat

procedure for other three

J-bolts (1).

WARNING

2”

(5.08 cm)

IMPORTANT!

Make sure nuts are 2”

(5.08 cm) from top of J-Bolts.

24" (61 cm)

36" (91.4 cm)

Page 4

4

P/N 211446D 12/02

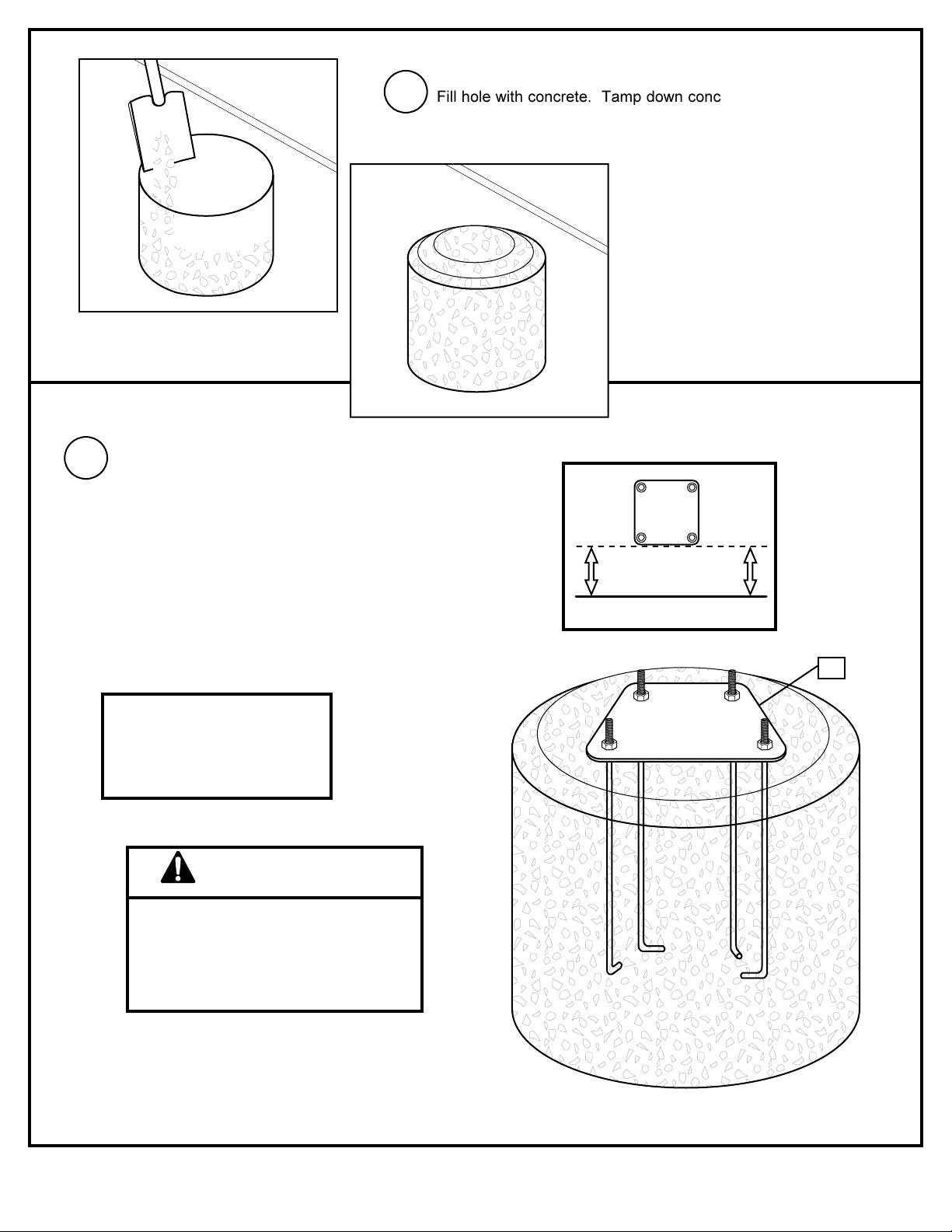

Fill hole with concrete. Tamp down concrete

to release air pockets and build drainage hill.

Insert J-bolts (1) from mounting plate (3) into

cement as shown. Move assembly around to

release any air pockets in cement, then rest

mounting plate on cement drainage hill. Apply

some pressure to level mounting plate on top of

drainage hill. Level mounting plate and square

with playing surface. Clean off any excess

cement on mounting plate at this time.

NOTE: Check leveling of mounting plate (3)

several times while concrete is curing.

4.

5.

IMPORTANT!

Front of mounting plate (3)

must be parallel with playing

surface.

DO NOT PROCEED TO STEP 6 UNTIL

CONCRETE HAS CURED FOR A

MINIMUM OF 72 HOURS. ALLOW

ADDITIONAL TIME FOR COLD, WET

OR HUMID WEATHER.

WARNING

PLAYING SURFACE

3

Page 5

5

12/02 P/N 211446D

Upright pole (5). Assemble lower pole flange onto

protruding J-bolts (1) as shown. The flange will

then rest on the nuts (2) from Step 2.

Secure pole (5) flange to mounting plate

(3) as shown. Tighten completely.

6.

7.

5

THREE PERSON MINIMUM REQUIRED

FOR THIS PROCEDURE. NOT

FOLLOWING RECOMMENDATION

MAY RESULT IN SERIOUS BODILY

INJURY AND/OR PROPERTY

DAMAGE.

WARNING

PLAYING SURFACE

PLAYING

SURFACE

IMPORTANT!

Holes in pole must be parallel

with playing surface.

4

38

3

2

6

IMPORTANT!

Note: Offset holes go

to back of system.

4

5

1

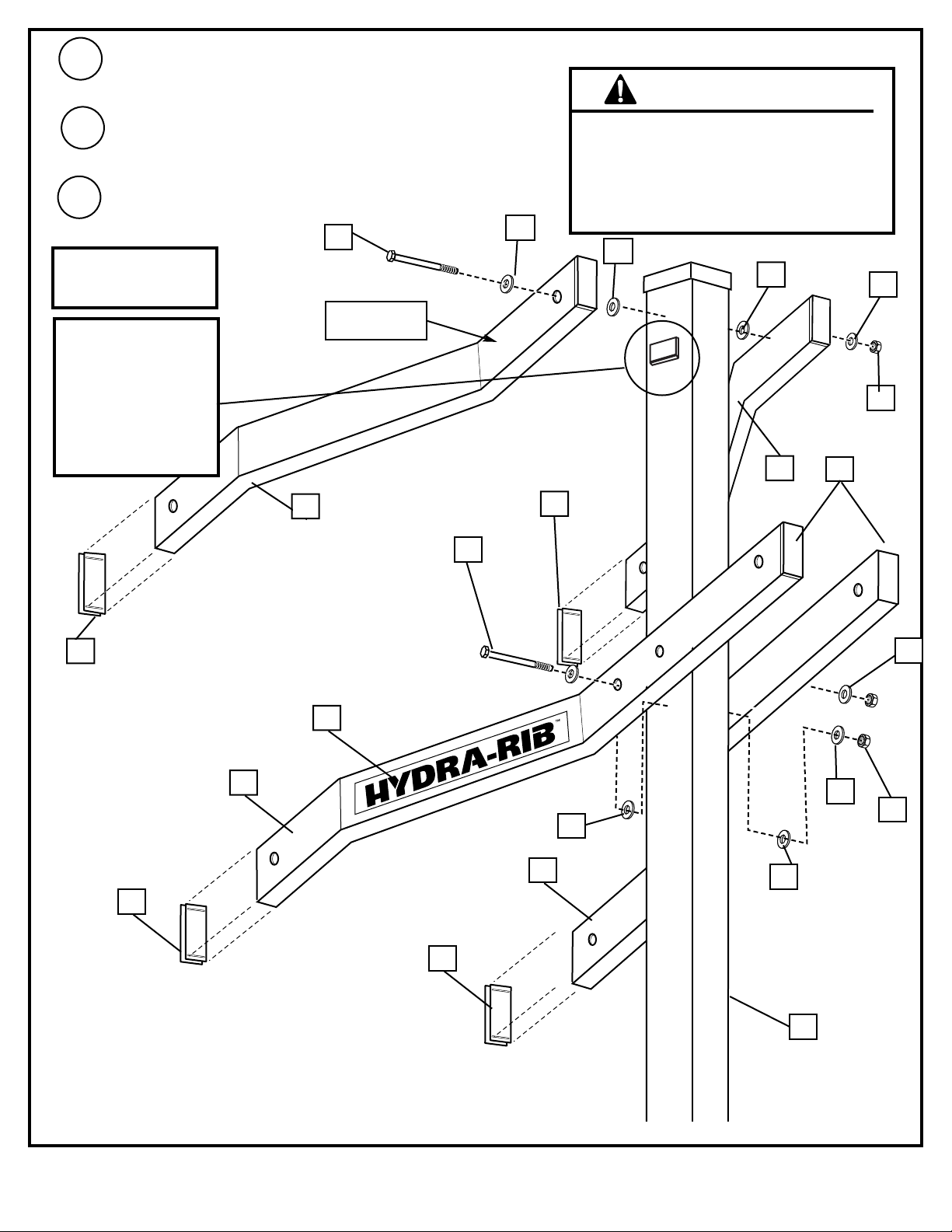

Page 6

6

P/N 211446D 12/02

8.

Insert caps (8) into end of each support arm (9 &

10) as shown. Tap firmly in position.

Apply logo label (11) to lower support arms (10)

as shown. Repeat for opposite side.

Beginning with upper support arms (9) secure

support arms to pole. Continue by securing lower

support arms (10) as shown.

9.

IMPORTANT!

Do not over tighten.

IMPORTANT!

MAKE SURE TOP

SET OF ELEVATOR

ARMS ARE RESTING

ON THIS MAUAL

STOP BEFORE

ATTACHING

9

10

11

10

8

8

8

8

12

7

14

14

9

5

14

14

14

14

10.

THREE PERSON MINIMUM REQUIRED

FOR THIS PROCEDURE. NOT

FOLLOWING RECOMMENDATION MAY

RESULT IN SERIOUS BODILY INJURY

AND/OR PROPERTY DAMAGE.

WARNING

7

14

14

SHORT END

8

12

Page 7

7

12/02 P/N 211446D

11.

16

14

3

9

14

7

13

14

10

7

14

10

7

14

16

14

7

14

9

16

14

16

THREE PERSON MINIMUM REQUIRED

FOR THIS PROCEDURE. NOT

FOLLOWING RECOMMENDATION MAY

RESULT IN SERIOUS BODILY INJURY

AND/OR PROPERTY DAMAGE.

WARNING

IMPORTANT!

Do not over tighten.

Secure H-frame board assembly to support arms

(9 & 10).

Page 8

Position U-joint of crank jack (20) as shown.

Where tubes on crank jack join, hold steady

to keep both tubes from rotating. Rotate

handle clockwise on crank jack to the fully

extended position. Upright crank jack.

8

P/N 211446D 12/02

12.

Secure jack brackets (17

& 18) to lower holes in

pole as shown.

7

14

17

14

18

15

15

14

14

7

13.

REAR VIEW

IMPORTANT!

HOLD HERE

20

Page 9

9

12/02 P/N 211446D

14.

Install crank jack (20) U-joint to lower set

of support arms (10) as shown.

10

14

20

7

14

21

12

10

THREE PERSON MINIMUM REQUIRED

FOR THIS PROCEDURE. NOT

FOLLOWING RECOMMENDATION MAY

RESULT IN SERIOUS BODILY INJURY

AND/OR PROPERTY DAMAGE.

WARNING

REAR VIEW

IMPORTANT!

Do not over tighten.

Page 10

10

P/N 211446D 12/02

15.

Rotate jack handle clockwise to raise H-frame (13) to

approximately 7’ (2.1 m) from ground. Secure crank jack

(20) to jack brackets (17 &18) as shown.

NOTE: Some adjustment will be necessary to align the lower

crank jack bushing to jack brackets (17 & 18).

THREE PERSON MINIMUM REQUIRED

FOR THIS PROCEDURE. NOT

FOLLOWING RECOMMENDATION MAY

RESULT IN SERIOUS BODILY INJURY

AND/OR PROPERTY DAMAGE.

WARNING

19

17

20

14

7

14

18

REAR VIEW

Page 11

11

12/02 P/N 211446D

RIM ASSEMBLY & INSTALLATION

WARNING

17.

Install carriage bolt (41) through rim (25),

washers (4) and (27) as shown. Tighten

nut (43) completely. Place nut (42) about

half-way up carriage bolt (41) as shown.

25

4

41

27

43

TWO PERSON MINIMUM REQUIRED FOR THIS

PROCEDURE. NOT FOLLOWING RECOMMENDATION

MAY RESULT IN SERIOUS BODILY INJURY AND/OR

PROPERTY DAMAGE.

Apply foam pad (22)behind bracket (39) and attach

bracket (39) to backboard and support structure by

inserting bolts (26) and washers (24) through top

holes in bracket (39), Tighten nuts (23) completely.

26

39

24

23

24

18.

23

24

24

40

26

Insert inner bracket (40) into bracket (39) as shown.

Insert bolts (26) and washers (24) through top holes

of inner bracket (40) as shown, Tighten nuts (23)

completely.

19.

39

40

39

42

41

27

22

Page 12

12

P/N 211446D 12/02

20.

25

39

40

Insert spacer (45) through rim assembly (25). Place rim assembly on bracket (39) so that carriage bolt (41) is

inserted through hole on top of inner bracket (40). Install hex bolt (44), washers (27) and nut (42) through top

holes on bracket (39) through spacer (45) as shown.Tighten completely.

Install rubber grommet (28), concave washer

(29) and center lock nut (30) to carriage bolt (41)

as shown.

28

41

30

29

BOTTOM VIEW

45

25

41

Do not over tighten as rim will not flex

properly. See leveling instructions to

determine how much to tighten nuts

(42) and (30).

21.

44

27

27

45

42

NOTE

27

Page 13

13

12/02 P/N 211446D

22.

23.

24.

Apply logo label (33) to cover plate (31). Install

cover plate (18) on rim (25) using self tapping

screws (32) as shown.

LEVELING INSTRUCTIONS:

Place level on rim (25) and adjust nut (42) until

level. Tighten nut (30) to set rim tension for

playing.

Secure net (34) to

rim (25).

1

2

3

34

25

NOTE ORIENTATION OF COVER PLATE

OUTSIDE VIEW

4

32

31

33

42

25

30

10 feet

(3.05 m)

NOTE: Official rim height is

10’ (3.05 m) from top of rim

to playing surface.

Page 14

14

P/N 211446D 12/02

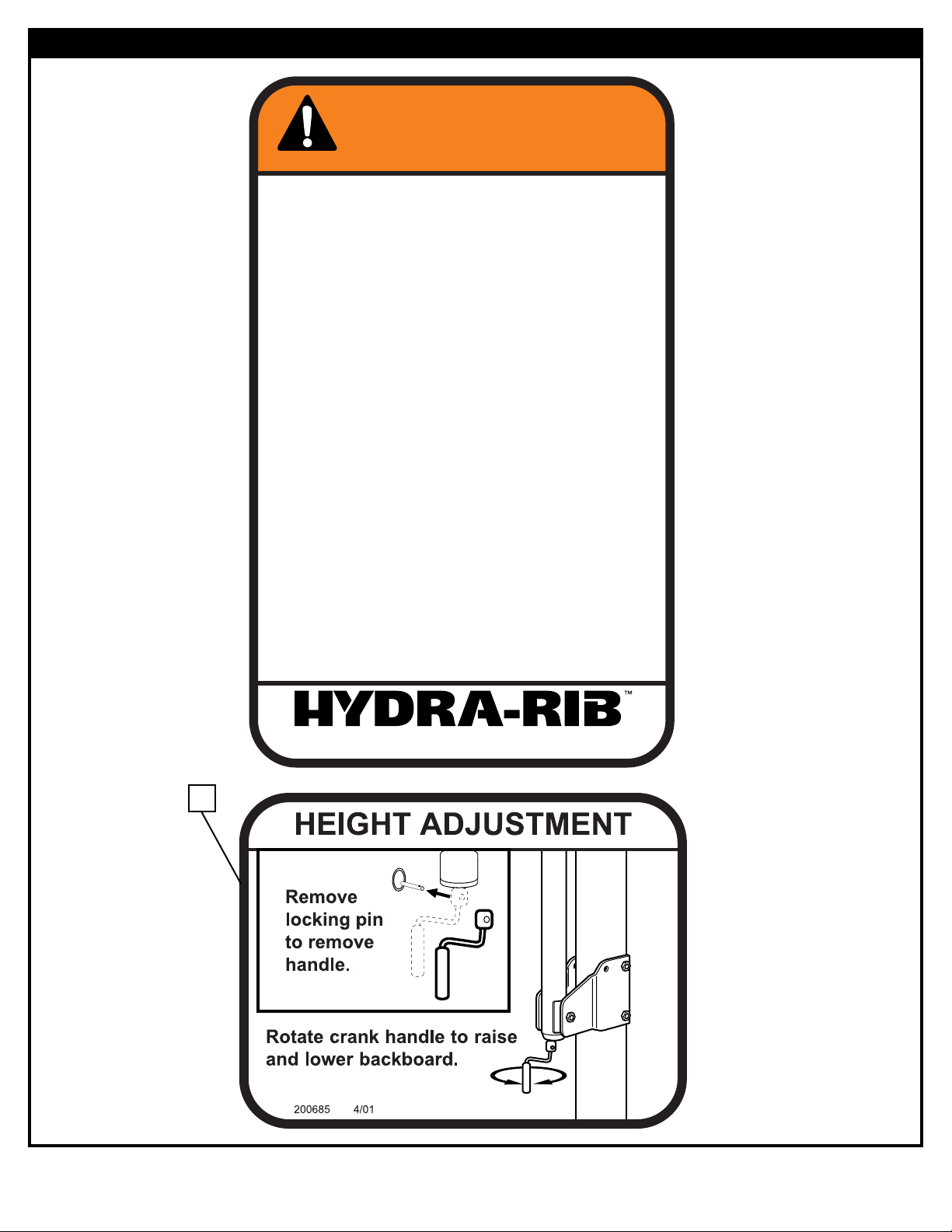

Apply height adjustment

label (37) to front of pole

as shown.

26.

10 feet

(3.05 m)

REGULATION

RIM HEIGHT IS

10 FEET (3.05 m).

37

25.

Check leveling at this time. Pole should

be level in all directions. NOTE: If

adjustment is necessary, adjust system by

rotating the nuts (2) between mounting

plate (3) and pole flange. (Refered to in

Step 6.) After system is leveled,

completely tighten nuts (7) above pole

flange.

Page 15

15

12/02 P/N 211446D

27.

A. LOWER BACKBOARD UNTIL RIM IS 7 FEET OFF THE GROUND.

B. APPLY THIN WHITE STRIP TO BOTTOM EDGE OF OUTER CRANK TUBE AS SHOWN.

C. APPLY LARGE DECAL TO BACK OF POLE SO THAT 7 FOOT MARK ON LARGE DECAL IS LINED UP WITH THIN

WHITE STRIP.

Add height adjustment decal (35)

ADDING HEIGHT INDICATORS

B

Page 16

16

P/N 211446D 12/02

Rotate crank handle to raise and lower backboard.

NOTE: If height adjustment is difficult to operate, you may

have over tightened the areas indicated. Refer to Step 10

and Step 14.

29.

Secure pole pad (36) as

shown.

28.

36

Height Adjustment

NOTE: Pole pad may

NOT be included in

this model.

Page 17

17

12/02 P/N 211446D

Item Qty. Part No. Description

1 4 200573 J-Bolt, 5/8”-11”

2 12 265575 Nut, Hex 5/8”-11”

3 1 920880 Mounting Plate

4 8* 203470 Washer, Flat 5/8” I.D. x 1.5” O.D.

5 1 980880 Pole

6 1 200544 Pole Cap, Square

7 10* 206340 Nylon Insert Lock Nut, Hex 1/2”-13

8 8 220589 Cap, Arm Support Insert

9 2 916880 Support Arm, 42” Long, (Upper)

10 2 926880 Support Arm, 52” Long, (Lower)

11 2 220586 Logo Label, 15” x 1 3/4”

12 3 200574 Bolt, Hex Flange 1/2”-13 x 10”

13 1 906880 H-Frame Board Assembly

14 24 203474 Washer, Flat 1/2”x 1” O.D.

15 2 201640 Bolt, Hex, 1/2”-13 x 7.25”

16 4 202856 Bolt, Hex Head,1/2”-13 x 4”

17 1 900656 Bracket, Jack Support (Left)

18 1 900658 Bracket, Jack Support (Right)

19 1 206251 Bolt, Hex, 1/2”-13 x 5”

20 1 222880 Crank Jack

21 1 200576 Spacer, Zinc .75” x 6”

22 1 203274 Foam Pad 5x 5

23 4 203100 Nut, Hex Flange 5/16”-18

Item

Qty. Part No. Description

24 8 203218 Washer, Flat 5/16” x 7/8” O.D.

25 1 920263 Rim, Orange

26 4 201611 Bolt, Hex Flange, 5/16”-18 x 3”

27 5* 203232 Washer, 3/4 O.D.

28 1 220041 Grommet, Rubber

29 1 220043 Washer, Large Concave

30 1 201124 Nut, Hex Locking, 5/16-18

31 1 920043 Cover Plate, Orange

32 2 220140 Screw, Self Tapping, 1/4 - 20 x 1/2

33 1 220569 Label Logo Circle

34 1 204282 Net

35 1 200787 Label, Height Indicator

36 1 206555 Pole Pad (May Not Be Included)

37 1 200685 Label, Height Adjustment

38 4 200655 Bolt Covers

39 1 920262 Bracket, Orange

40 1 920038 Inner Bracket, Black

41 1 220065 Bolt, Carriage 3/8 x 5 1/2

42 2 203063 Nut, Hex Nylon Locking 3/8

43 1 203017 Nut, Hex 3/8

44 1 203439 Bolt, Hex 3/8 x 6

45 1 220064 Spacer, 5 x 1/2” O.D.

* You May Have Extra Parts With This Model.

PARTS LIST

Item #16 (4)

Item #29 (1)

Item #26 (4)

HARDWARE IDENTIFIER

Item #4 (8)*

Item #19 (1)

Item #7 (10)

Page 18

18

P/N 211446D 12/02

Item #41 (1)

Item #24 (8)

Item #30 (1)

Item #32 (2)

Item #28 (1)

Item #23 (4)

Item #42 (2)

HARDWARE IDENTIFIER

Item #44 (1)

Item #45 (1)

Item #43 (1)

WARRANTY CARD:

Please remember to complete your product

registration form on-line at:

www.hydrarib.com/warrantycard

Item #27 (5)*

Loading...

Loading...