Page 1

Hubbell Industrial Controls, Inc.

S2MC Compact Primary Thyristor Controller 4922C

For Hoists Without Mechanical Or Eddy Current Brakes

Catalog 4922C • May 1993

General

The Type 4922C S2MC primary thyristor static

reversing controller system provides speed-regulated control of hoist with wound rotor motors and without load

brakes. The Type 4922C system includes the controller

and for separate mounting the Type 5410 tachometer/overspeed switch assembly and Type 3000 secondary

resistor.

The operator control is a Type 4216 stepless mill

master switch. Type 4211 stepless mini master switch or

Type 2015/6/7 stepless pendant pushbutton station. Full

range of motor speed from minimum to maximum is adjusted by the stepless operator. Hoisting speed, with or

without load, is closely controlled by varying the motor primary voltage with thyristors. No-load lowering speed is

handled in the same manner. Lowering speed of an overhauling load at subsynchronous speeds is controlled via

counter-torque control.

4922C controllers are available from 10 to 250 HP

at 460/3/60 VAC.

Operation

Hoisting: When the hoisting direction is selected,

the M contactor closes and hoisting torque is produced by

the motor when selected primary thyristor modules begin

conduction. The amount of thyristor modules begin conduction. The amount of thyristor conduction and hence,

motor hoisting torque, is determined by the master switch

speed reference signal and the tachometer speed feedback

signal. In this manner, stepless adjustable speed control is

obtained for hoisting.

Lowering: When the lowering direction is selected, the M contactor closes and the selected primary

thyristor modules begin conduction.

If the hook is empty or lightly loaded, the controller

will maintain the motor in a stepless speed regulated "driving lower" condition.

If the load overhauls the motor, the controller will

turn off (2) of the thyristor modules and turn on the other (2)

thyristor modules. This transition converts the motor operation from a driving lower condition to a counter-torque

condition with hoisting torque controlling the descending

overhauling load in a controlled stepless manner.

As full speed is reached, the controller reverts

back to a drive down mode and the motor is placed into

regeneration. When leaving the regenerative lowering

mode, the controller reverts back to counter-torque lowering.

Features

The Type 4922C standard controller includes the

following major components/features:

S2MC Compact Variable Speed Control As-

sembly consisting of (1) regulator PC board and (2) firing

circuit board. All adjustments, potentiometers, and test

points for setup and fine-tuning plus status lights are frontpanel-mounted and clearly identified. Simple test setup

readings require use only of a VOM meter.

Five (5) conservatively rated Type 5410 Full

Wave Thyristor Power Modules with MOV transient voltage protection and snubbing circuits to limit rate of voltage

rise. Thyristor modules for 40HP/460 volt and under are

mounted with the S

bly. Over 40HP the thyristor modules are separate mount

within the controller enclosure.

the tachometer feedback signal and shuts down the controller in the event of an open tachometer signal.

controller features a three-pole main knife switch. NEMA

rated mainline contactor, (3) Inverse time trip overload relays, fused control knife switch, 120 volt control transformer, low voltage relay and a shunt brake relay.

2

MC Tachometer Continuity Module monitors

S

In addition to the S

2

MC Compact Speed Regulator Assem-

2

MC modules the Type 4922C

Optional Features

Full Speed Contactor: The 4945C hoist system

requires a secondary slip resistor to provide optimum

torque at reduced speeds, but results in a 20% slip at full

load/full speed. The full speed contactor shorts out this

resistor at high speed and allows the motor to obtain its

maximum rated base speed.

Extended Slow Speed Operation: This option

allows the hoist to operate at reduced speeds for an extended period of time. Recommended for die handling

cranes and turbine handling cranes.

Five Step Reference Board: This option allows

the controller to operate from a standard 5 step sequential

master switch or pendant. Each step can be independently

set for a fixed speed.

Multi-panel Construction: This option provides

two or more controllers to be mounted in a common enclosure and interwired with a mainline contactor panel.

Other standard modifications and options are

available. Consult factory for assistance.

Page 1 of 2

Page 2

Hubbell Industrial Controls, Inc.

2

S

MC Compact Secondary Thyristor Controller 4922C

For Hoists with Eddy Current Brakes

Catalog 4922C.a • May 1993

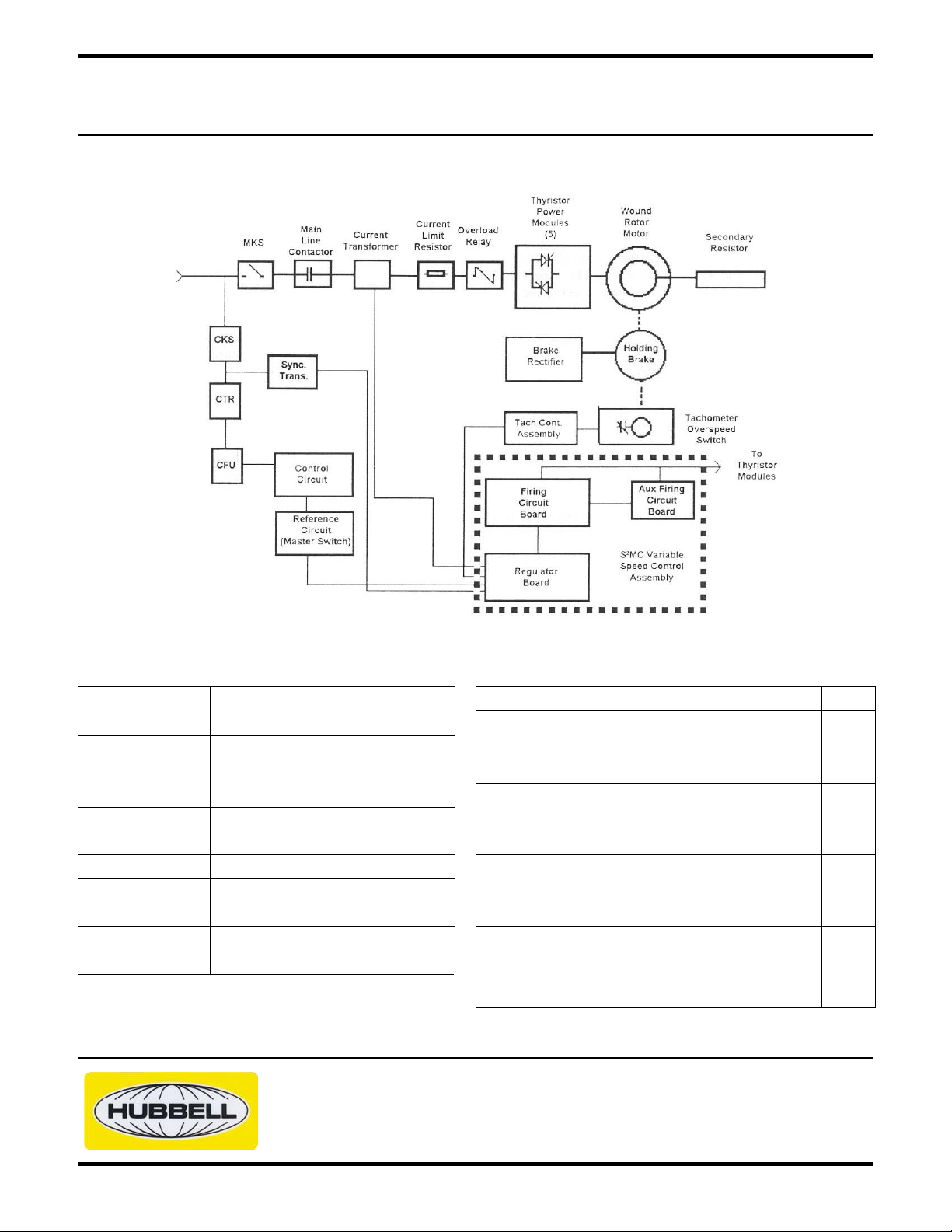

Block Diagram

Input Power

Horsepower Range

Speed Range

Speed Regulation

Control

Configuration

Temperature

Range

Specifications Bill of Material (Standard)

Standard: 230/460 60hz.,

Other voltages available

5 - 30HP for Compact Construction.

50 - 250HP with external SCR's

Typical 10 to 1

10% Typical

Static reversing.

- 40 degree C to

+ 55 degree C.

Type 4922C Variable Speed Control Assembly

Type 5410 Thyristor Power Module

Directional Relays

Syncronous Transformer

Current Transformer

Main Knife

Main Line Contactor

Overload Relay

Control Circuit Knife Switch

Control Circuit Transformer

Control Circuit Fuses

Tachometer Continuity Assembly

Description Symbol Qty.

Hubbell Industrial Controls, Inc.

A subsidiary of Hubbell Incorporated

4301 Cheyenne Dr., Archdale, NC. 27262

Telephone (336) 434-2800 • FAX (336) 434-2803

http://www.hubbell-icd.com

Sales@hubbell-icd.com

VSC

TPM

CR

ST

CT

MKS

M

OL

CKS

CTR

CFU

TCA

1

5

2

1

1

1

1

3

1

1

2

1

Loading...

Loading...