Hubbell Industrial Controls, Inc.

EUCLID TYPE C/MEDIUM - HIGH SPEED/CENTRIFUGAL

General Information

Type C Speed Responsive switches assure

maximum protection of material handling

systems and rotating equipment. They provide overspeed and underspeed protection

with precise speed sensing and highly repetitive accuracy. These switches have

excellent repetitive accuracy and are basically unaffected by temperature variations.

•

NEMA Type enclosures for indoor,

outdoor & hazardous environments.

•

Contacts easily adjustable while run-

ning.

•

High-speed operation to 4700 RPM.

•

Low-speed operation from 10 RPM.

•

Snap-Action or Slow-Action contacts, or

pneumatic valve.

•

Oversize bearings providing low-friction.

•

Surface or flange mounting.

•

5/8" dia. input shaft & rugged construc-

tion.

•

± 5% repeatability.

SPECIFICATIONS

2210

Feb. 1977

Replace: June 1972

SPEED RESPONSIVE SWITCH

Application

Type C switch provide overspeed & underspeed protection and precise speed sensing

with highly repetitive accuracy to indicate

slipping or broken conveyor belts, preventing

material pileups … prevent overspeed of

motors, generators, fans & pumps … control

starting of diesel engines … prevent damage

to rotating industrial machinery when speeds

increase or decrease from safe values … for

plugging applications to assure quick & safe

stops … sequential control of functions at

specific speeds.

Description

Housing & Enclosures - Standard Type C

centrifugal switch housings are molded of

tough fiberglass reinforced polyester resin,

for the flyweight compartment and a cast

aluminum housing for the contact compartment. The standard molded housings are

resistant to most acid, alkali and salt compounds.

When flange mounting is specified, the flange

and the flyweight section of the housing are

precisely machined from a single aluminum

casting.

Adaptation can be provided to meet special

mounting requirements.

NEMA Type 3/13 enclosures are supplied for

indoor/outdoor industrial applications.

NEMA Type 4 enclosure (water-tight) for

indoor/outdoor applications with a double

shaft seal & grease fitting for lubrication and

purging as standard equipment ensuring

longer bearing life.

NEMA Type 7, 9 and 10 explosion proof

enclosures are available also. These enclosures have accurately machined cast aluminum housings, either surface mounted or

flange mounted. The NEMA Type 7 and 9

housings are designed in accordance with

specifications for switches in Class 1 Group

C or D and Class 2 Groups E, F and G hazardous locations. NEMA Type 10 enclosures

have been certified by the Bureau of Mines

as meeting the requirements of Schedule 2G

for explosion-proof construction. File No.

X/P-943 has been assigned to those EUCLID

switches. Use this reference when specifying

Euclid.

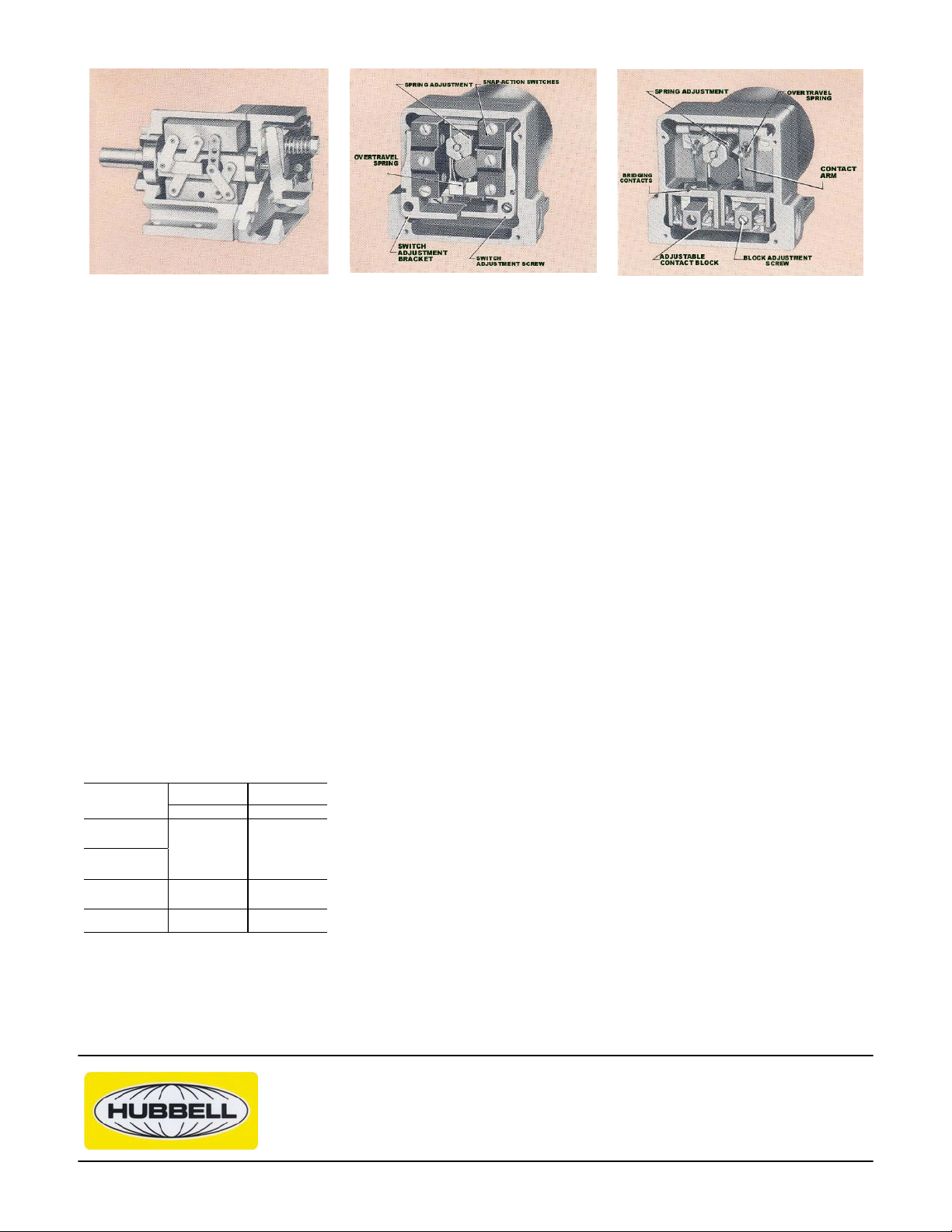

Flyweight System - The flyweight and linkage system (mounted in a separate compartment from the contacts) is completely

suspended on the 3/4" square part of the

stainless steel shaft by 8 bearings. The

bearing suspension of the flyweight and linkage system provides a very low-friction

means of transmitting the centrifugal force

through a small concentric shaft to the switch

contact compartment. The shaft is supported

by 2 oversize ball bearings. No lubrication of

the ball-bearing suspension system is required and, because the main shaft bearings

are permanently lubricated, no access should

be needed into the flyweight compartment

into the flyweight compartment for servicing.

-

-

-

Brass inserts molded into the flyweight

housing retain the 2 shaft bearings.

Speed Adjustment - Speed points at which

contacts operate are easily adjustable in the

field within the standard operating ranges.

Switches are factory-set at minimum ascending speeds as listed in the Price List

2210. Other contact settings may be specified as an option. EACH SET OF SNAPACTION INDEPENDANTLY ADJUSTABLE

FROM THE REAR WHILE THE SWITCH IS

ROTATING. Also the speed setting of both

sets of contacts can be changed at the same

time by varying the tension on the adjustment

spring with the adjustment nut. Turning the

spring adjustment nut or the contact adjustment screws in a clockwise direction will

cause the contacts to operate at a higher

speed, but making these adjustments in a

counter-clockwise direction will cause the

contacts to operate at a lower speed.

Contact - The contact compartment provides

several basic contact-making means as required for various applications. Slow-action

butt-type bridging contacts for rapid speedchange conditions or snap-action contacts for

slow speed changes can be supplied.

MAXIMUM CONTACT INTERRUPTING RATINGS

TYPE OF

CONTACT

*SLOW ACTION

Non Directional

(Butt-Type)

*SLOW ACTION

Directional

(Butt-Type)

*SNAP ACTION

*SNAP ACTION

* Rating based on a min. of 1/32" contact gap.

AMPERES

AC 35% PF

120v 240v 480V 125v 250v

3 15 .75 .75 .35

3 1.5 .75 .25 .12

AC Type

……… .60 .25

DC Type

DC

INDUCTIVE

One set or two sets of normally open and/or

normally closed single-throw contacts …

each set independently adjustable … are

available in the slow-action type. One set or

two sets of normally open and normally

closed single-pole, double-throw, snap-action

switches are also available with each set

independently adjustable.

These two separate sets of contacts can be

adjusted for operation at different speeds so

that two separate operations can be controlled from one speed sensitive switch.

Therefore, it is possible to perform two different functions at two different speeds.

A directional sensing form of the switch employs slow-action butt-type bridging contacts

in normally open position only.

Type C Centrifugal Switches are available for

operating in various speed ranges of adjustment between 10 and 4700 RPM on increasing speed. The specific range of adjustment that is selected determines the flyweight assembly and the adjustment spring

that is used.

The contact adjustment ranges of centrifugal

switches with 2 contacts (shown in the table

of the price list) are for both contacts operating simultaneously. The 2 contacts can be

adjusted independently, however, that operation changes the adjustment range from that

shown.

The ranges of adjustment listed are for

switches mounted horizontally. Vertically

mounted switches with the shaft extension

down have different ranges of adjustment. A

special wide range adjustment can be supplied on special order.

The recommended maximum running speed

of a switch with heavy flyweights is 1800

RPM, with medium flyweights is 4000 RPM

and with light flyweights is 5000 RPM.

OPTIONAL FEATURES

Manual Reset - When specified, EUCLID

Type C Centrifugal Switches can be furnished with one or two manual reset buttons

(one for each set of A-C precision contacts).

A metal guard prevents accidental damage to

the buttons by impact. The Code Letter "M"

designates one set of manually reset A-C

snap-action contacts.

Flexible Couplings - A Flexible Coupling

should be used to connect the Centrifugal

Switch shaft to customer's shaft in order to

compensate for minor misalignment of the

shafts. Couplings can be supplied with a

1/2", 5/8" or 3/4" bore for customer's shaft

and a 5/8" bore for our shaft. Standard keyways can be furnished. Specify by catalog

number on Price List 2210.

Magnetic Vibration Dampeners - counteracts destructive action of the "dither". Specify by catalog number on Price List 2210.

Air Valve Actuating - Type AV, air valve

instead of electrical contacts for pneumatic

systems. Refer to factory with application

data.

Speed Increaser - 3 to 1 ratio can be

mounted at the factory which permits the

input shaft speed of the speed increaser to

be 1/3 the normal input shaft speed. Specify

by suffix number "S" for Single Speed Increaser and "SS" for Double Speed Increaser. Refer to Price List 2210.

Hubbell Industrial Controls, Inc.

A subsidiary of Hubbell Incorporated

4301 Cheyenne Dr., Archdale, NC. 27262

Telephone (336) 434-2800 • FAX (336) 434-2803

http://www.hubbell-icd.com

Sales@hubbell-icd.com

Loading...

Loading...