Page 1

Hubbell Industrial Controls, Inc.

QUICK BREAK POWER LIMIT SWITCH

General Information

Euclid quick break limit switches for

hoists are normally closed by the

weight of the striking lever. The

movement of the lever on its upward

travel, when engaged by the hoist

hook block on its upward travel,

causes the switch to quickly break the

circuit to the motor with very little upward movement of the crane hook.

The switch is automatically reset by

the weight of the striking lever when

the hook is lowered.

♦ NEMA & CEMA ratings 1, 3, 4, 9

general purpose, weather proof, watertight, explosion-proof enclosures.

♦ Mill duty construction.

♦ Reversible finger tips and seg-

ments for longer life.

♦ Easy maintenance and access to

fingers, contact tips, drum segments

and tension springs.

♦ Moving and stationary contacts

are made from hard drawn copper.

♦ Automatic reset.

Application

Euclid quick break hoist limit switches

are used with reversing drum and

magnetic controllers on cranes and

hoists, either as a main line limit

switch or as a pilot circuit limit switch

to operate magnetic contactors in

main line motor circuits.

CATALOG

NUMBER

Description

There are two general types of main

line limit switches - - - the standard

and the plugging type. The plugging

limit switch utilizes the motor to stop

the upward travel by plugging the motor when the limit switch is tripped.

This is accomplished by the switch

quickly reversing two lines of the motor, plugging it to a stop and then lowering the hook until the limit switch

resets. Some motors require plugging

resistors when such a limit switch is

AC & DC HOIST MOTOR APPLICATIONS

MAXIMUM HORSEPOWER RATINGS

AC DC

220

VOLTS

440-550

VOLTS

115

VOLTS

NON-PLUGGING DUTY

230

VOLTS

Specification

4225

February 2006

Repl.: Nov. 1986

Schedule E5

used. Consult our representative or

the factory for recommendations on

such applications.

All switches in the line are furnished

with reversible finger tips that can be

easily replaced. The drum segments

are easily replaced. Both the finger

tips and segments are made of harddrawn copper. Tension is maintained

on the fingers by means of high quality

tension springs that are easily replaced.

NO.

OF

POLES

4225-LS-900

4225-LS-1950B

4225-LS-312

3

10

25

3

10

25

1

2.5

5

2

5

10

3

3

3

Page 2

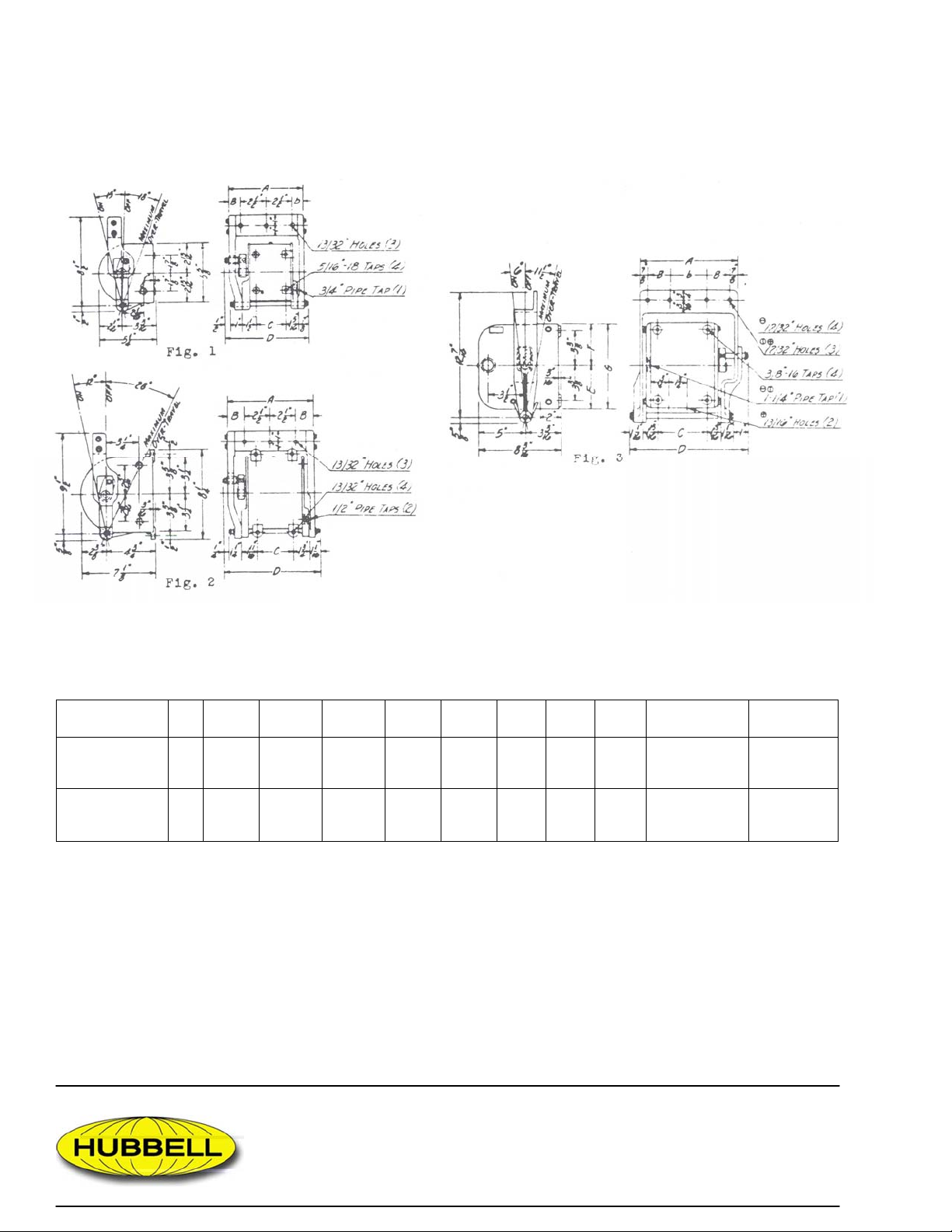

APPROXIMATE DIMENSIONS

(NEMA 1 ENCLOSED)*

Three Pole Non-Plugging Type – A.C.

4225-LS-900

4225-LS-1950B

4225-LS-312 •

• Purchaser to provide striking plate & additional weight at 12” radius to reset.

* NEMA 3, 4, 9 enclosure dimensions available upon request.

1 8-7/16” 1-13/16” 1-5/8” 3-15/16” 9-1/8” - - - - - - - - - - - - - - - 2 Pounds 20

2 9-3/4” 2-3/8” - - - - - 4-1/2” 10-1/4” - - - - - - - - - - - - - - - 5 Pounds 34

3 11-3/4” 3” 4” 6-1/4” 13” 4-1/4” 4-1/4” 8-1/2” 30 Pounds 60

Hubbell Industrial Controls, Inc.

a subsidiary of Hubbell Inc.

4301 Cheyenne Dr., Archdale, NC 27263

Telephone (336) 434-2800 • FAX (336) 434-2803

http://www.hubbell-icd.com

sales@hubbell-icd.com

Loading...

Loading...