Page 1

Hubbell Industrial Controls, Inc.

Euclid™ Pendants & Pushbuttons

Specification 2000 • August 2000† • Replaces Sept. 1997

Table of Contents

Series 2001 Pushbutton

Stations, Euclid

Type HD & WP ............. 2

Series 2015/2016/2017

Pushbutton Stations,

Euclid Type PBC, WPBC,

XPBC........................... 4

Series 2020 Pushbutton

Stations, Euclid

Type PBP .................... 10

Series 2030 Compact

Pendant Pushbutton

Stations ...................... 12

Series 2040 Pushbutton

Stations, Type PBM ...... 14

2000

Type 4211

Mini-Master Switch ...... 18

† Replaces all previous catalogs and specification lists.

HUBBELL

Page 2

Specifications

Pushbutton Stations

Euclid Type HD, S, WP & WSM – Pendant & Surface Mounting – Heavy Duty – NEMA 1 or 3R – Single & Two Speed

2001

Features

Euclid’s oldest line of rugged

time proven pushbutton

stations incorporate basic

modular construction and

are designed for heavy duty

applications of all kinds.

• HD & WP pushbutton

stations are furnished as

assembled stations.

• Safety yellow enclosures

for indoor and outdoor

applications.

• Ground connection at

cable entrance area.

• Single speed and two

speed cumulative

contact inserts.

riety of optional features are

available:

• Duplex stations.

• Selector switches.

• Toggle switches, etc…

Application

The HD and WP stations are

designed for long trouble

free service on electric overhead traveling (EOT) cranes,

hoist, electromagnets, etc…

wherever safety and reliability

are high priority.

Specifications

NEMA Type 1 Enclosures

The general purpose enclosure

is die formed cold rolled steel

and is provided with individual

guards over each button, to

prevent accidental operation.

Only two screws need be removed for fast easy access.

This gasket sealed enclosure

is designed to resist the most extreme outdoor conditions. The

cast cover has an integral

guard to prevent accidental

button operation.

Both pendant enclosures are engineered and manufactured to

withstand the rough usage to

which overhead crane equipment

is subjected. NEMA 1 and 3R

surface mounting enclosures of

similar design are available.

(See Type S & WSM)

The inserts are super heavy duty

and consist of a molded phenolic base with cadmium plated

3

⁄32" thick self aligning hard

drawn copper contacts. Terminals are located for easy access and wiring.

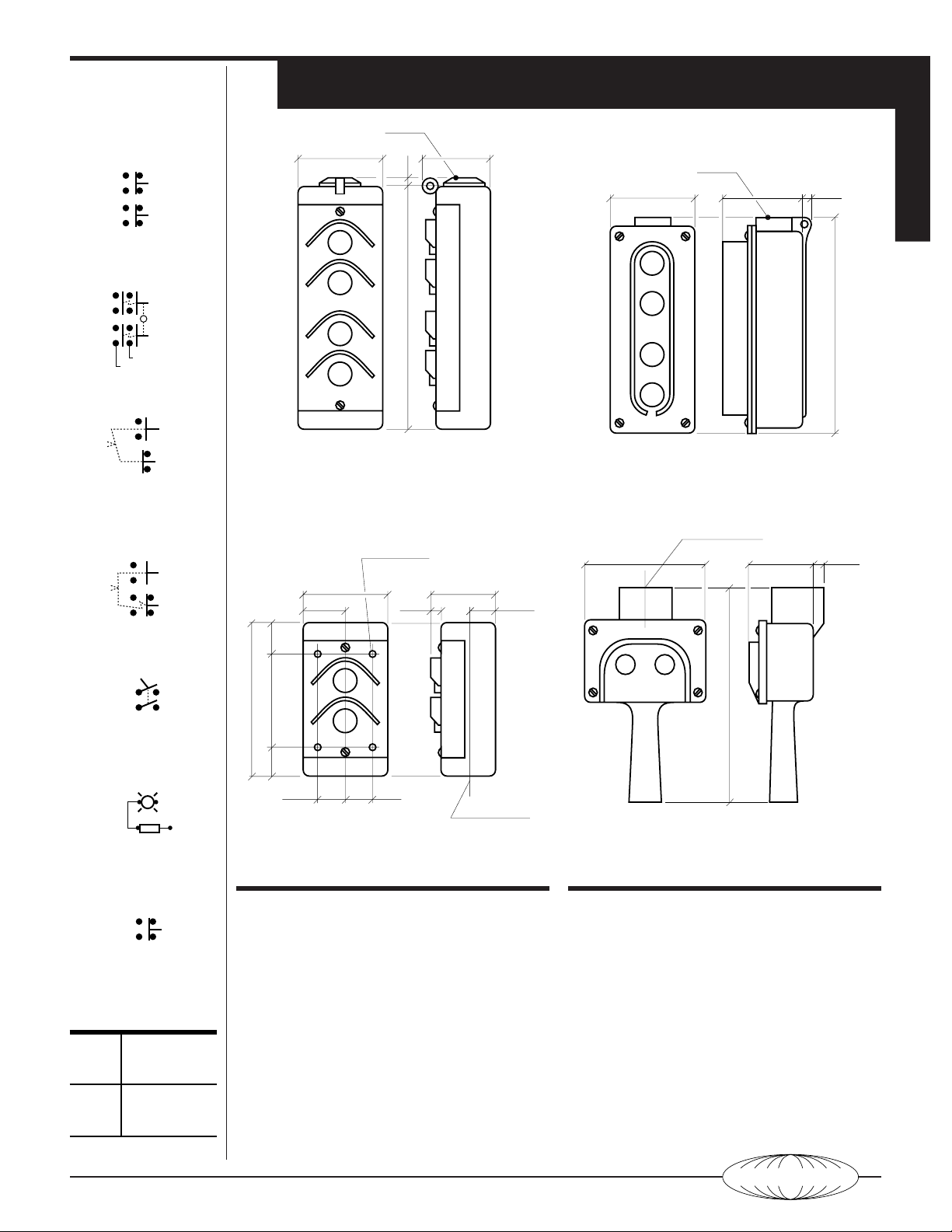

Type HD, 10 button station,

NEMA 1 pendant enclosure

HUBBELL

2

• AC and DC rated.

• Maintained contact

inserts optional.

• Enclosures engineered for

fast easy access.

3

•

⁄32" thick hard drawn

copper (cadmium plated)

contacts – self aligning.

Description

The HD and WP stations are

available as assembled stations. The steel NEMA 1 and

cast aluminum NEMA 3R

enclosures have easily removable front covers for wiring and

contact access.

Single speed, two speed and

maintained contact inserts can

be arranged in any order. A va-

NEMA Type 3R Enclosures

The outdoor enclosure is precision manufactured of cast

aluminum alloy.

Type HD, 2 button station,

NEMA 1 pendant enclosure

440/428-1161 • Fax 440/428-7635

Type WP, 8 button station,

NEMA 3R pendant enclosure

Page 3

Pushbutton

Inserts

Single Speed or

Momentary Start-Stop

Cat# J1/J1A & K1/K1A

FWD

REV

Two Speed

Cat# J2/K2

UP

Figure 1

Type HD

NEMA 1

Diagrams & Dimensions

"P" Pipe

3.625" 2.625"

Size

"B""A"

Figure 3

Type WP

NEMA 3R

"P" Pipe

3.875" 3.437" 0.5"

Size

2001

DOWN

Low Speed

High Speed

Maintained Start-Stop

Cat#JM/KM

START

STOP

Maintained/

Momentary Lift/Drop

Cat# JN/KN

Maintained

LIFT

DROP

Momentary

Toggle Switch

Cat# JT

OFF ON

Toggle Switch

Pilot Light

Cat# JP1/JP5 & KP1/KP5

R

Pilot Light

Momentary Reset

Cat# JR/KR

Reset

Figure 2

Type S

NEMA 1

Surface

Mounting

2.25"2.25"

"A"

"B"

1.375" 1.375"

No. of “A” “B” “P” Approx. Fig.

Buttons Wt. (lbs.)

2 6.31" 0.56" 0.75" 2.00 1

4 10.00" 0.56" 0.75" 3.75 1

6 13.75" 1.63" 1.00" 4.75 1

8 17.37" 2.00" 1.25" 6.00 1

10 21.12" 2.00" 1.25" 7.50 1

Contact Ratings

Single Break

AC

NEMA

A300

NEMA

P300

120V

240V*6A3A

125V

DC

250V

OSHA limits pendant voltage

*

to 150VAC or 300VDC

1.1A

0.55A

440/428-1161 • Fax 440/428-7635

Type S Surface Mounting – NEMA 1

2 6.31" 1.81" — 2.00 2

4 10.00" 5.50" — 3.25 2

6 13.75" 9.25" — 4.50 2

8 17.37" 12.87" — 6.00 2

*

WP Station also available for surface mounting. Dimensions on request.

All dimensions are approximate and are not for construction purposes.

0.218"ø Mtg.

Hole (4) Internal

3.625" 2.625"

1.812"

Type HD Pendant – NEMA 1

0.5"

1.062" & 1.312"

Concentric

Knockouts Each End

1.062"

"A"

Figure 4

Type PB4

& WP4

Rigid Arm

Mounting

No. of “A” “B” “P” Approx. Fig.

Buttons Wt. (lbs.)

2 5.68" — 0.50" 2.50 3

4 9.19" — 0.75" 4.50 3

6 13.44" — 1.00" 6.50 3

8 17.00" — 1.25" 8.50 3

Type PB4 NEMA 1 & WP4 NEMA 3R Rigid Arm

PB4

2 2.62" —— 5.00 4

WP4

2 3.43" —— 5.00 4

5" 0.375"

Type WP* Pendant – NEMA 3R

1.25" Pipe Tap

"A"

8.625"

Mounting

HUBBELL

3

Page 4

Specifications

Euclid™ Type PBC / WPBC / XPBC Pendant

Pushbutton Stations

Features

2015/16/17

The modular, cam-operated,

PBC pushbutton insert is

used in all PBC, WPBC

and XPBC pushbutton stations. Only the style of the

housing and operator

varies to meet environmental

requirements.

• 150VAC or 300VDC

• Unique, plunger-

operated, Nylatron®

cam plates.

• Silver-to-silver self

cleaning contacts.

Contact Block

Assembly

Cam Plate

Cam Plate

• Contact blocks easily inspected and replaced.

• Up to 5–speed points.

• Up to 8 common circuits

plus feed for each direction provide unlimited

operating sequences.

• Large, mechanically

interlocked buttons.

• Grounding connection at

cable entrance area.

Mounting Rib

Plungers

Section

Contact Block

Assembly

Contact Ratings

Single Break

AC

NEMA

B150

120V

240V*3A —

Application

PBC cam-operated pushbuttons

are engineered for all heavyduty applications that require utmost reliability and the combination of single and multi-speed

performance such as crane and

mill drives.

Description

The Plungers are one-piece

molded high impact phenolic.

The button surface is concave

for easy thumb operation. In the

assembly, the plunger is protected by steel mounting

rib sections and the

recessed shape of the front

cover. Plungers are mechanically interlocked.

Return Springs — Two extra-

long, low-stress, corrosion

proof springs are provided for

each plunger. They are engineered for maximum dependability, safety and ease of

plunger operation.

Cam Plates are molded of selflubricating Nylatron® GS and

have a series of openings to allow the movable contacts to

close in sequence against the

stationary contacts. Cam plates

are keyed to the operating

plungers. Desired operating

sequences can be obtained by

inserting the proper cam plate.

The Contact Blocks, to which

the stationary and movable contacts and terminals are assembled, are compression

molded from fiberglass polyester material. This material is

highly resistant to shock, arcing

and tracking.

The heavy-butt-type silver

Stationary Contacts and terminals are riveted to the contact

block.

The Movable Contact Bar with

its silver contact-buttons is fastened to the contact block

by a post and silver coated

beryllium copper Contact

Spring arrangement. The

silver-to-silver alignment provides unusually long contact

life. A slight wiping action

of the movable contact promotes self-cleaning and optimum conductivity.

The contact block assembly is

easily replaced as a unit.

Modifications

Many modifications and special features are available for

the PBC WPBC and XPBC

pushbutton stations:

• duplex mounting

two stations

• interconnecting

conduit box

• bottom or side handles

• mushroom head

operators

• emergency stop

wobble stick

• selector switches

• special sequence

multi-speed inserts

• stepless pushbutton

inserts

• plus much more…

4

HUBBELL

NEMA

P300

250V

OSHA limits pendant voltage

*

to 150VAC or 300VDC

125V

DC

1.1A

0.55A

440/428-1161 • Fax 440/428-7635

Page 5

2015 Application Info

Euclid™ Type PBC Pushbutton Stations

Bulletin 2015 Heavy-Duty – Cam-Operated NEMA Type 1 Enclosure

Series PBC Pendant Pushbutton Stations represent

the ultimate in custom engineering for specialized applications that can benefit

from the unique operating

cam feature.

• 150VAC or 300VDC

• NEMA 1 – General Pur-

pose, Indoor Service

• Steel enclosure body.

• Fiberglass rear access/

insulating cover.

• Up to five speed points

and eight common circuits

for each direction.

• One to twelve button

models, plus toggle

switch.

• Easy one-hand operation.

• More than twelve buttons

available on special order.

Application

PBC pushbutton stations are

designed for all heavy-duty applications that require the combination of single and multispeed units and operation with

special contact sequencing.

Description

The enclosure’s front plate and

end cups are die formed from

heavy gauge steel and welded

into an unbreakable unit. The

protective plunger guards are

integral to the front plate. The

double suspension cable

hanger and threaded conduit

fitting are an integral part of the

top cap.

The front plate is designed to

provide a bearing surface for

the pushbutton plungers and a

trough for the control wires.

The “U” shaped access cover,

which serves as the sides and

back of the enclosure, is

molded of high strength fiberglass and is easily removed for

inspection or maintenance of

the pushbutton inserts. Interior

assemblies may be inspected

and contact block assemblies

are easily replaced. Interior assemblies consist of overlapping

mounting rib sections to which

the contact blocks are attached.

Each unit is fastened to the front

plate with two screws. This design permits easy replacement

of individual parts or a complete two button assembly.

2015/16/17

Options available with PBC

Pendants include: A pilot light

to signal when power is on, a

circuit-disconnect toggle switch,

reset button and maintained

contacts. Other options are

available, on request, to meet

your special needs.

All PBC stations are supplied

with a grounding connection.

440/428-1161 • Fax 440/428-7635

HUBBELL

5

Page 6

2016 Application Info

Euclid™ Type WPBC Pushbutton Stations

Bulletin 2016 Heavy-Duty – Cam-Operated NEMA Types 3R, 4 or 13 Enclosure

2015/16/17

WPBC stations use the

same pushbutton inserts

as the PBC Stations. The

WPBC enclosures are made

of machined extruded

aluminum.

• 150VAC or 300VDC

• NEMA 3R – Rainproof &

Sleet Resistant, Outdoor

Service (Standard)

• Up to five speed points

and eight common circuits

for each direction.

• One to fourteen buttons.

• Easy one-hand operation.

• Pendant and surface

mounting models.

• More than fourteen

buttons available on

special order.

Optional

• NEMA 13 – Oil-tight

& Dust-tight, Indoor

Service

• NEMA 4 – Watertight

& Dust-tight, Indoor &

Outdoor Service

Application

WPBC Pushbutton Stations

are designed for all heavy-duty

applications (i.e., crane or

mill-type drives) that require

the combination of single and

multi-speed performance and

where conditions require a

NEMA 3R rainproof enclosure

for outdoor service.

WPBC stations can also be

supplied in NEMA 13 enclosures for oil-tight and dust-tight

indoor service.

For watertight and dust-tight, indoor and outdoor service, the

NEMA 4 enclosure is available. This enclosure has a

drain plug on the bottom and

a space heater inside the

enclosure to minimize

moisture buildup.

Description

The front, back and end plates

of the WPBC pushbutton enclosures are machined of extruded

aluminum. The removable side

covers are machined aluminum

extrusions with neoprene gaskets to insure a tight seal.

Large, flexible, neoprene boots

cover the operating plungers.

This boot has flanges which

engage machined channels

and make a leakproof seal

with the top plate. Options

available include: A pilot light

to signal when power is on, a

circuit-disconnect toggle switch,

reset button and maintained

contact inserts. Other options

are available to meet your

special needs.

All WPBC stations are supplied

with a grounding connection.

6

HUBBELL

440/428-1161 • Fax 440/428-7635

Page 7

2017 Application Info

Euclid™ Type XPBC Pushbutton Stations

Bulletin 2017 Heavy-Duty – Cam-Operated NEMA Type 7 Class 1, Group C or D, Div. 1 or 2 Indoor Enclosures

XPBC Stations use inserts

similar to the PBC and

WPBC stations. XPBC

enclosures are made of

cast aluminum and are

engineered to meet hazardous duty requirements.

• 150VAC or 300VDC.

• Rated for NEMA Type 7,

Class 1, Group C or D,

Div. 1 or 2, Indoor

Hazardous Locations.

• Up to five speed points

and eight common circuits

for each direction.

• Stainless steel operating

plungers.

• Pendant and surface

mounted models.

Application

XPBC Pushbutton Stations are

engineered for all heavy-duty

applications (i.e., crane or

mill-type drives) that require the

combination of single and

multi-speed performance. They

are designed to meet explosionproof standards as stipulated

for NEMA Type 7, Class 1,

Group C or D, Div. 1 or 2,

hazardous locations. Not for

outdoor use or paint booth

applications.

Description

The XPBC explosion-proof enclosure is comprised of three

dense aluminum castings match

machined to close tolerances.

All mating surfaces provide

ample flame path. The front

cover is designed with long

bearing surfaces for the operating plungers as well as the nec-

essary flame path. The plunger

guards are also an integral part

of the front casting. The top

casting is tapped to accommodate an approved sealing

chamber unit.

Removal of the rear case exposes the pushbutton inserts for

easy inspection and maintenance without disturbing wiring.

Options available include a:

Circuit disconnect toggle

switch, Pilot lights, Selector

switches, Maintained contact

inserts, and Bottom holdinghandle. Other options are

available to meet your

special needs.

All XPBC stations are supplied

with a grounding connection.

2015/16/17

• Optional features

440/428-1161 • Fax 440/428-7635

available.

HUBBELL

7

Page 8

Dimensions

All dimensions are approximate and

are not for construction purposes.

No. of “A”“B”“C” Approx.

Buttons Conduit Size Wt. (lbs.) Figure

Type PBC Pendant – w/o Toggle Switch

2 7.81" 1.25" — 3.75 1

4 13.06" 1.25" — 6.50 1

2015/16/17

6 17.81" 1.25" — 9.00 1

8 22.56" 1.50" — 11.50 1

10 27.31" 1.50" — 14.00 1

12 32.06" 1.50" — 16.50 1

Type PBC Pendant – w/ Toggle Switch

2 11.06" 1.25" — 4.50 2

4 15.81" 1.25" — 7.25 2

6 20.56" 1.50" — 9.75 2

8 25.56" 1.50" — 12.25 2

10 30.06" 1.50" — 14.75 2

12 34.81" 1.50" — 17.25 2

Type WPBC Pendant

2 6.75" 1.25" — 5.00 3

4 12.00" 1.25" — 9.75 3

6 16.75" 1.25" — 14.50 3

8 22.25" 1.50" — 19.00 3

10 26.25" 1.50" — 24.00 3

12 32.00" 1.50" — 28.75 3

14 35.75" 1.50" — 33.50 3

Figure 1

Type PBC,

NEMA 1

Enclosure

"B" Pipe

Size

3.12" 3.38"0.5"

"A"

"B" Pipe

Size

3.12" 3.38"0.5"

0.38" Suspension

Cable Hole (2)

0.38" Suspension

Cable Hole (2)

Type SWPBC Pendant

2 7.88" 1.25" 8.75" 5.50 4

4 13.12" 1.25" 14.00" 10.25 4

6 17.88" 1.25" 18.75" 15.00 4

8 23.38" 1.50" 24.25" 19.50 4

10 27.38" 1.50" 28.25" 24.50 4

12 32.12" 1.50" 33.00" 29.25 4

14 36.88" 1.50" 37.75" 34.00 4

Type XPBC Pendant

2 9.38" 1.50" — 12.00 5

4 15.12" 1.50" — 17.50 5

6 19.88" 1.50" — 23.00 5

8 25.63" 1.50" — 28.50 5

10 30.12" 1.50" — 34.00 5

Type SXPBC Pendant

2 9.63" 1.50" 8.38" 12.00 6

4 15.38" 1.50" 14.12" 17.50 6

6 20.12" 1.50" 18.88" 23.00 6

8 25.88" 1.50" 24.63" 28.50 6

10 30.38" 1.50" 29.12" 34.00 6

Type 2XPBC Pendant

12 19.88" 1.50" — 47.00 7

16 25.63" 1.50" — 58.00 7

20 30.12" 1.50" — 69.00 7

Figure 2

Type PBC,

NEMA 1

Enclosure

with Toggle

Space

Figure 3

Type WPBC,

NEMA 3/4/13

Enclosure

"A"

0.75"

0.88"

"A"

0.38" Suspension

Cable Hole (2)

"B" Pipe

Size

4.00" 4.00"

8

HUBBELL

440/428-1161 • Fax 440/428-7635

Page 9

6.00"

5.88"

2.00"0.5"

"A"

"B" Pipe Size (2)

0.63" Mtg. Hole (2)

8.5"

6.00"

14.5"

All dimensions are approximate and

are not for construction purposes.

0.34"ø Mtg.

Hole (4)

0.44"

4.00" 2.12"

"B" Pipe

Size

Dimensions

"B" Pipe

0.63" Mtg. Hole (2)

6.00" 5.88"

Size

2.00"0.5"

2015/16/17

"C"

2.00"

2.75"

Figure 4

Type SWPBC,

NEMA 3/4/13

Enclosure

Surface Mounting

0.44"ø Mtg. Hole (4)

0.75"0.38" 0.12"

6.00" 6.12"

4.00"

4.88"

"B" Pipe Size

"A"

Figure 5

Type XPBC,

NEMA 7

Enclosure

2.00"

"C"

"A"

0.75"

6.50" 0.5"

7.50"

Figure 6

Type SXPBC,

NEMA 7

Enclosure

Surface Mounting

440/428-1161 • Fax 440/428-7635

5.88" 0.12"

Figure 7

Type 2XPBC,

NEMA 7

Enclosure

Duplex

HUBBELL

9

Page 10

Specifications

Euclid™ PBP Pendant Pushbutton Station

Weather-Proof Rubber Enclosure NEMA 3R — Plug In Inserts — 1 To 5–Speed

Over a half century of Euclid

2020

experience in pushbutton design and manufacturing has

been incorporated into the

unique PBP design. These

highly reliable pendants feature maximum safety and durability, ease of installation

and maintenance and minimum down time.

• PBP Pushbutton Stations

can be ordered completely assembled or in

component kit form from

stock. Refer to price list

for catalog numbers and

prices.

• Electrically insulated,

highly durable weatherproof nitrile-vinyl rubber

enclosure with a durometer reading exceeding

that of an automobile tire.

• Molded enclosure, high

visibility safety yellow.

• Ground connection at the

conduit entrance/cable

support area.

• AC and DC rated.

• Choice of 1, 2, 3

or 4 motion enclosures.

• Plug-in single through five

speed inserts for easy installation, inspection or

replacement without

disturbing wiring.

• Mechanical interlock prevents activating both buttons simultaneously.

• Optional features and special construction available.

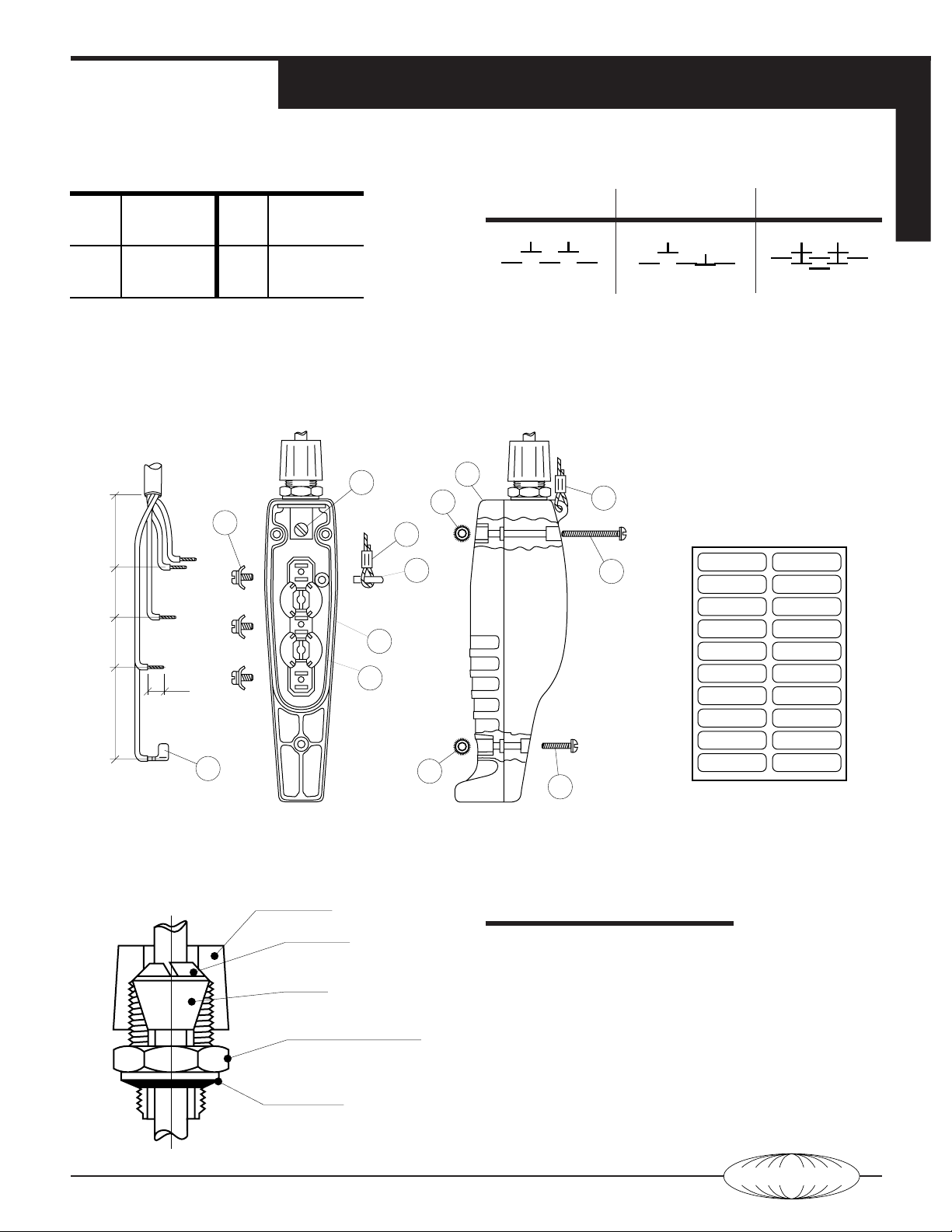

Description

Euclid PBP Pushbutton Stations

are comprised of modular components (see illustration): A specially compounded, durable, nitrile-vinyl, all rubber enclosure

with removable back and front

guards; high dielectric strength

molded terminal base; optional

pilot light; plug-in type pushbutton inserts with bayonet-type vibration resistant, silver-plated

terminals; neoprene button covers (boots) to insure weatherproofing; nitrile vinyl rubber

guards to protect buttons from

physical damage and accidental operation.

The plug-in inserts permit any

unit to be inspected or replaced

without disturbing the originally

installed wiring, hence, mini-

mal down time. The modular

units can be easily arranged in

any order in the pendant station.

The reversing inserts consists

of two buttons mechanically

interlocked to prevent simultaneous operation.

All modular inserts are keyed to

prevent improper installation.

A variety of optional features

are available:

• Duplex stations.

• Inter-connecting conduit

boxes.

• Handles.

• Selector switches, pilot

lights, push/pull buttons,

toggle switches, etc.

Refer to factory or local sales office for additional information.

Application

Euclid PBP Pushbutton Stations

are commonly employed for

control of electrically powered

industrial equipment such as

electric overhead traveling

(EOT) cranes, hoists, electromagnets, etc…wherever

safety and reliability are of

greatest concern.

Nameplate marking kits are furnished with the enclosure. Special markings can also be provided at an additional cost.

Specifications

The nitrile-vinyl rubber pushbutton enclosure with neoprene

pushbutton covers (boots) is suitable for exposure to:

• Air

• Ozone

• Hydrogen

• Carbon Monoxide

• Methane

• Hydrocarbon Gases

• Greases

• Oils

• Aromatic Fuels

• Transformer Lubricants

At Room Temperatures:

• Detergents

• Ammonia

• Mild Acids

• Alkalies

The PBP Pushbutton Stations

are suitable for most industrial

environmental conditions, indoor and outdoor, within the

following temperature range:

0° to 180°F (–18° to 82°C).

The Pushbutton inserts are high

impact and shock resistant and

high dielectric strength molded

phenolic with oversize silver

contacts that operate with a

positive wiping action offering

excellent contact reliability. The

multi-speed inserts have a one

piece self-lubricating ‘’Nylatron”

plunger-cam for easier operation and greater durability.

Kellems grips are available and

provide positive strain relief for

the multi-conductor cable, increasing its service life many

times, thus avoiding unnecessary downtime and maintenance costs. Refer to price

sheet for part numbers and

cord diameters.

10

HUBBELL

440/428-1161 • Fax 440/428-7635

Page 11

Single Speed

Plug-In Inserts

Momentary N.O.

Cat# PG1

Momentary N.O. & N.C.

Maintained N.O. & N.C.

Maintained/Momentary Lift-Drop

Cat# PG2/3/4

Momentary/Maintained Start-Stop

Momentary Start-Stop/Reset-Stop

Cat# PG5/6

top

FWD

REV

rear view

top

FWD

REV

rear view

top

START

STOP

Back Cover

Specifications

Universal Hanger

Bracket

Pilot Light

2020

Pilot Light

Nameplate

Pilot Lens

Function

Nameplate

Button Cover

Momentary Stop-Start/Stop-Reset

rear view

Cat# PG7

top

STOP

START

rear view

Multi-Speed

Plug-In Inserts

Two and Three Speed – Cat# MS2

(1A)

3

(L1)

1

(R)

2

(2A)

4

3 Speed rear view

(for 2 Speed do not use Terminal 3)

Four and Five Speed – Cat# MS5

(3A)

5

(1A)

3

1

(L1)

(R)

2

(2A)

4

6

(4A)

5 Speed rear view

(for 4 Speed do not use Terminal 6)

PG4 and PG5 inserts have one

button maintained and one button

momentary. “Off-On” buttons recommended to comply with provision of NEMA ICS 3-442.15.

321123

(2A)

4

Up/Fwd.

(F)

2

Jumper by

Customer

(L1)

1

Down/Rev.

(1A)

3

321123

5432112345

(4A)

6

(2A)

4

Up/Fwd.

(F)

2

Jumper by

Customer

(L1)

1

(1A)

3

Down/Rev.

5

(3A)

5432112345

Terminal Base

Dimensions

Cable Entrance - Threaded

1" ID, 1.25" OD

3.25" 3.50"0.88"

"A"

Plug-In Insert

0.38" Suspension

Cable Hole (2)

Enclosure

Hard Rubber Guard

Number of Approx.

Buttons ”A” Wt. (lbs.)

2 7.87" 2.5

†

5

†

7

†

9

†

Enclosures include extra 30mm hole at top for

13.69" 4.5

18.00" 5.5

22.31" 7.0

pilot light, toggle switch, etc.

(N/A for 2 button case).

Contact Ratings – Single Break

Single Speed Multi Speed

AC

NEMA

A300

NEMA

P300

240V*6A3A

125V

DC

250V

OSHA limits pendant voltage to 150VAC or 300VDC

*

1.1A

0.55A

†

Closest NEMA rating.

120V

AC

NEMA

A300

DC

NEMA

R300

120V

240V*6A3A

125V

†

250V

0.4A

0.2A

440/428-1161 • Fax 440/428-7635

HUBBELL

11

Page 12

Specifications

Compact Pendant Pushbutton

Station

Hubbell’s Compact Pendant

2030

Stations are typically used to

control industrial cranes and

hoists or the remote control

of industrial machines.

This high-quality pendant station features a tough molded

polymer housing that meets

the most rigorous requirements

of industrial applications and

their environments for control

of electric hoists. The compact

pendant is rated NEMA 4X

when used with the cord

connector kit.

• Safety Yellow high impact

polymer enclosures.

• A compact pendant station engineered to fit the

hand comfortably.

• Choice of single-speed,

two-speed, or on-off

capabilities.

NEMA Type 4X Enclosure

• Mechanical interlock on

reversing stations prevents

actuating both pushbuttons

simultaneously.

• UL and CSA listed.

• Ambient Temperature

Range –20° to 158°F

(–29° to 70°C)

• Optional - Cord Connector Kit - to permit use in

NEMA 4X watertight,

dust-tight, and corrosion resistant applications or for outdoor use.

Application

Industrial plants have

expanded the use of

electric motor driven

hoists (over the chainfall

types) as the need for

greater hoist capacity has

increased. These electric

motor hoists are an excel-

lent application for the

Hubbell Compact Pendant. Especially in areas

where the stations are sub-

ject to operational abuse.

Locations include jib cranes

on building columns, small

overhead hoists on gantry

cranes, and even the operation

of hoists applied to single

girder cranes.

These pendant stations are

designed for the comfort of the

operator in controlling the hoists

and built to withstand hostile

environments in the industrial

arena.

Most of the electric hoists have

reversing electrical relays or

contactors which can be controlled from a single control contact and these pendant stations

are designed for those hoist applications, not for the direct

power handling of the motor

current in the pendant station.

12

HUBBELL

U

®

Jogging operation of floormounted machines away from

the main operator’s station is

generally associated with only

one motion, easily handled by

the pendant station applied to

an umbilical cord.

L

These stations have also been

used very successfully for winch

control on recreational vehicles

and tow trucks and for dock

control with carriers in the

food industries.

440/428-1161 • Fax 440/428-7635

Page 13

Diagrams & Dimensions

)

n

Contact Ratings – Single Break

Single Speed Two Speed

AC

NEMA

A300

NEMA

240V*6A3A

125V

DC

250V

P300

OSHA limits pendant voltage to 150VAC or 300VDC

*

1.1A

0.55A

120V

AC

NEMA

B300

DC

120V

240V*3A1.5A

125V

250V——

Compact

Pendant

Assembly

3

Cable Stripped Length

.4"

2.5" 1.5" 1.5" 2.0"

12

Crimp

Cord Connector Kit

not included.

2

Ground Screw

(green)

Internal Strain

Relief

1

6

Insure gasket is

seated properly.

Wiring Diagrams

Single – Speed

†

Momentary (on/off) Two – Speed

†

2030

Top

N/O 1 Com. N/O 2

†

Single-speed and two-speed stations are mechanically interlocked to

prevent actuating both buttons simultaneously.

Ctr.

External Strai

7

8

Top

Bott.

N/O 1 Com. N/C 1

Relief

5

5

4

9

8

10

Ctr.

Bott.

Top

N/O 1 2nd

Label Pack

UP

ON

IN

FWD

RIGHT

RAISE

START

OPEN

NORTH

EAST

DOWN

OFF

OUT

REV

LEFT

LOWER

STOP

CLOSE

SOUTH

WEST

Speed

Tab

Bott.

N/O 2

Cord Connector Kit Assembly

Connector Cap

Gotcha Ring

(Blue: 0.37"–0.50" or

Brown: 0.50"–0.62")

Bushing

(0.37"–0.50" or 0.50"–0.62"

1

⁄2" NPT Connector Housing

(Max. Torque 50 In.-Lbs.)

Sealing Washer

(UL Listed for hand tightening)

440/428-1161 • Fax 440/428-7635

Compact Assembly Parts List

Part

No. Qty. Assembly Parts Listing

1 1 Front Housing

2 11⁄2" NPT Locknut Gnd. Brkt.

3 3 Terminal Clamps

4 1 Pin

5 1 Crimp Sleeve

6 1 Gasket

7 1 Rear Housing

8 3 #8-32 Hex Nut

9 2 #8-32 x 13⁄4" Lg. R.H.M.S.

10 1 #8-32 x 1" Lg. R.H.M.S.

11 1 Button Labels

12 190° Terminal

Discard items no. 4 and 5 if not used as shown.

*

*

(not shown)

(Two-Speed Only)

*

HUBBELL

13

Page 14

Specifications

Euclid

™

PBM Pendant Pushbutton Stations

The Multi-Purpose PBM Pen-

2040

dant Pushbutton Stations have

been designed to use 22mm

NEMA 4X pushbutton elements to provide full flexibility.

Spacing of the mounting holes

will permit enlarging the hole

to install the larger 30mm

pushbutton elements if desired. Each enclosure is provided with a full complement

of standard self-adhesive

nameplates to meet most pendant pushbutton applications.

The multiple screws used for

fastening the front and back

portions of the enclosures provide rigidity to the enclosures

for added strength to withstand operational abuse and

provide a watertight seal.

• Light Weight, Rugged

Molded Enclosures,

“Safety Yellow.”

• Molded-in Stainless Steel

hanger brackets for exter-

nal strain-relief cable. Provisions for internal strain

relief are also provided.

• Five Enclosure sizes, 3 to

11 button with provision

for single function option

— pilot light, selector

switch, push-pull unit, etc.

• Enclosures gasketed for

NEMA 4X rating; Watertight, Dust-tight, Corrosion

Resistant.

• Enclosure arranged for

internal grounding screw.

• Optional Connector Kits:

3

⁄4" NPT (19mm) for 2

and 4-button enclosures

1" NPT (25mm) for 6, 8,

and 10-button enclosures

• 22mm NEMA 4X pushbutton elements available

from stock.

• Optional Mechanical

Interlocks

Application

PBM Pendant Pushbutton Stations

are designed for control of electrically powered industrial equipment such as electric overhead

traveling (E.O.T.) cranes or hoists

where one to five speed motors

are used. The lightweight ergonomically designed enclosures fit

comfortably into an operators

hand and yet are built using a

polymer selected to resist shock.

Standard indicator plate markings (self-adhesive) are included

with each enclosure, but special nameplates or markings

can be provided.

Select standard 22mm

NEMA 4X contact elements

from tables or specify the type

required for your completed

control station.

Specifications

Enclosures:

• Enclosures are rated

NEMA 3, 3R, 4, 4X

when equipped with

Hubbell PBM NEMA 4X

inserts and Hubbell Cord

Connector Kits or comparable approved devices.

Contact Ratings:

• NEMA A600 & A300 AC

Cord Connector Kits:

•3⁄4" NPT Corrosion Resistant

Nylon for cable diameter

7

⁄8" (15.7mm to 22.2mm)

to

•

1" NPT Corrosion Resistant

Nylon for cable diameters

1

⁄8" (22.2mm to 28.6mm)

to 1

Operators:

• 22mm NEMA 4X Elements

• Neon Pilot Lights, 120V,

60 Hz, Red, Green, Amber

• Incandescent Pilot Lights,

120VAC/DC; 250VDC;

Red, Green, Amber

• Extended Pushbuttons,

1 speed, NO/NC contacts, Red, Green, Black

• Extended Pushbuttons,

2 speed, Black

• Mushroom Head

Pushbuttons, 1 speed,

NO/NC contacts, Red,

Green, Black

• 2 and 3 position Selector

Switches

5

⁄8"

7

⁄8"

14

HUBBELL

U

®

• NEMA P300 &

R300 DC

L

440/428-1161 • Fax 440/428-7635

Page 15

Contact Sequence

*

Circuits

A

B

Speeds

12

Specifications

Standard Pushbuttons

Hubbell’s standard 22 mm pushbuttons feature polyester construction for superior

corrosion resistance, and the #6 terminal screws have self-lifting captive wire clamps to

accommodate #22 through 2 – #12 wires per terminal. The pushbuttons mount in a round

22 mm or

and 13 installations and are UL/CSA approved.

Mushroom Head Pushbuttons

7

⁄8" hole. These pushbuttons are rated for NEMA 1, 2, 3/3R, 4/4X, 12

No. of No. of Contacts Button

Speeds NO NC Color Part No.

One 1 1 Black 80320-100

One 1 1 Red 80320-101

One 1 1 Green 80320-102

One 1 0 Black 80320-103

One 0 1 Red 80320-104

One 1 0 Green 80320-105

Two

*

One 2 2 Black 80320-400

One 2 2 Red 80320-401

One 2 2 Green 80320-402

2 0 Black 80320-110

2040

Hubbell’s mushroom head pushbuttons are constructed to the same standards and quality as

the standard pushbuttons. Mushroom heads are available in either black, red, green, or a

special "Stop" red. Mushroom caps be easily replaced or interchanged in the field without

special tools.

No. of No. of Contacts Button

Speeds NO NC Color Part No.

One 1 1 Black 80322-100

One 1 1 Red 80322-101

One 1 1 Green 80322-102

One 1 1 “Stop” Red 80322-103

One 2 2 Black 80322-400

One 2 2 Red 80322-401

One 2 2 Green 80322-402

One 2 2 “Stop” Red 80322-403

Maintained Pushbuttons

Hubbell’s maintained pushbuttons are available in two variations. Single button

mushroom head “push/pull” units are stand alone buttons that are commonly used for

a maintained “emergency stop” function which has “push-to-stop/pull-to-start” operation.

Single maintained buttons are used with another operator and an MRI “maintained reset

interlock” to provide two button operation for either “maintained/maintained” or

“maintained/momentary” action.

Type of No. of Contacts Button

Head NO NC Color Part No.

440/428-1161 • Fax 440/428-7635

“Push/Pull” 1 1 Black 80323-100

“Push/Pull” 1 1 Red 80323-101

“Push/Pull” 1 1 Green 80323-102

Button 1 1 Black 80323-103

Button 1 1 Red 80323-104

Button 1 1 Green 80323-105

HUBBELL

15

Page 16

Specifications

Selector & Toggle Switches

Hubbell’s selector switches are available in 2 or 3 position maintained or spring return

operators. Hubbell also has a 2 position toggle switch that is rated at 10 amps.

Circuits Type of Return

2040

Symbol Key

M – Maintained Position; S – Spring Return Position

X – Contact Closed; O – Contact Open

Operator

Selector

Toggle

Selector

Selector

Selector

Selector

Selector

Selector

M

M

M

M

M

Part No.

M

MM

M

M

M

M

M

M

M

M

M

S

S

M

S

S

80321-100

80321-101

80321-301

80321-302

80321-303

80321-304

80321-305

80321-306

Illuminated Pilot Lights

Hubbell’s pilot lights are available in either 120VAC/DC or 250VAC/DC and are

constructed to the same standards and quality as the pushbuttons. The pilot light bulb

and lenses are easily removed for maintenance. Additional color lenses are available.

Type of Voltage Lens

Bulb AC/DC Color Part No.

Neon 120V Red 80324-100

Neon 120V Amber 80324-101

Neon 120V Green 80324-102

Incandescent 120V Red 80324-210

Incandescent 120V Amber 80324-211

Incandescent 120V Green 80324-212

Incandescent 250V Red 80324-213

Incandescent 250V Amber 80324-214

Incandescent 250V Green 80324-215

Two Button – Five Speed Element

Hubbell’s two button – five speed element is specifically designed to meet the most severe

conditions. The two buttons are mechanically interlocked which prevents both buttons from

being depressed simultaneously. These switches are ideal for pendant or other control applications that require multi-speed operation.

No. of No. of Button

Speeds Contacts Color Part No.

6-NO/Button

Five Sequentially Black 80825-000*

Closed

CSA Approved

*

HUBBELL

16

Contact Sequence

56

34

12

21

43

65

440/428-1161 • Fax 440/428-7635

Top

54321

Jumper by Customer

54321

Rear View

32145

Up/Fwd

Down/Rev

32145

Page 17

;;

;;

;

;

;

;

Dimensions

Standard Pushbuttons

Maintained Pushbuttons

Specifications

Selector Switches

(16)

0.63"

0.86" (22) 0.86" (22) 0.91" (23)

1.42" (36)

Maintained “Push-Pull” Buttons

1.34" (34)

0.86" (22) 0.98" (25)

1.42" (36)

Mushroom Head Pushbuttons

1.14" (29)

0.86" (22) 0.86" (22) 1.10" (28)

1.42" (36)

Cord Connector

Kit Assembly

Connector Cap

Gotcha Ring

Bushing

3

⁄4" or 1" NPT Connector Housing

1.22" (31)

(16)

1.22" (31)

0.86" (22) 0.91" (23)

0.63"

1.42" (36)

Toggle Switches

(19)

0.75"

0.86" (22) 1.10" (28)

1.42" (36)

Pilot Lights

(18)

1.22" (31)

0.86" (22) 1.14" (29)

0.71"

1.42" (36)

Enclosure Dimensions

Cat No. “A” Length “B” Conduit

ME2 8.156"

ME4 12.50"

ME6 16.84" 1" NPT

ME8 21.18" 1" NPT

ME10 25.53" 1" NPT

Inches Size

1.22" (31)

1.22" (31)

1.22" (31)

3

⁄4" NPT

3

⁄4" NPT

(18)

0.71"

0.91" (23) 0.98" (25)

1.42" (36)

Two Button – Five Speed Elements

"A"

0.63"

(16)

2.00"4.00"

2.00"

0.79" (20) 2.00" (51)

1.10" (28)

1.73" (44)

1.89" (48) 3.50" (89)

0.75"

External Strain

Relief Hole (2)

3.25"

"B" Cable Entrance

3.43"

1.22" (31)

2040

ELK1 Label Pack

O

T

N

B

C

R

A

N

E

POWER ON

OFF ON

R

H

R

O

O

I

L

I

D

L

S

G

E

T

O

E

Y

F

F

ELK2 Label Pack

M

A

T

A

I

N

H

O

I

S

T

T

U

R

R

X

O

O

L

L

H

L

L

O

E

E

I

Y

Y

S

#

#

T

1

2

440/428-1161 • Fax 440/428-7635

E

H

H

M

O

O

E

I

I

R

S

S

G

T

T

S

#

#

T

1

2

O

P

Contact Ratings –

N

O

F

U

R

W

P

T

D

H

S

D

O

R

O

U

E

W

T

V

N

H

O

N

M

P

A

O

G

W

N

E

E

O

R

T

F

F

S

R

E

A

S

T

W

E

S

T

U

P

D

O

W

N

R

F

T

I

E

W

A

G

S

D

R

H

E

T

T

T

S

S

L

E

F

T

L

I

F

T

D

R

O

P

R

T

T

E

O

O

V

P

P

R

R

O

I

A

INC

P

G

I

H

S

T

E

L

L

O

E

W

F

E

T

R

W

E

N

C

L

O

C

O

U

C

S

T

W

E

Single Speed Multi Speed

AC

NEMA

A600

NEMA

120V

240V*6A3A

125V

DC

250V

P300

OSHA limits pendant voltage to 150VAC or 300VDC

*

1.1A

0.55A

†

Closest NEMA rating.

AC

NEMA

A300

DC

NEMA

R300

†

Single Break

120V

240V*6A3A

125V

250V

0.4A

0.2A

HUBBELL

17

Page 18

Specifications

Mini-Master Switch

The Euclid Mini-Master

4211

Switch uses a handle operated cam switch mechanism

in a NEMA rated housing.

It is engineered for use

where master switch control

is preferred, for CMAA duty

overhead crane and similar

applications.

• Housings for surface or

flush mounting.

• NEMA Types 1, 3, 4

and 13.

• Very compact size.

• Choice of spring return

vertical handle or maintained position vertical

handle.

Application

Euclid Mini-Master Switches are

engineered to meet the need for

a small, multi-circuit master

switch for installations such as:

small crane cabs, and mill

auxiliaries.

Description

The operating head is molded

of tough fiberglass reinforced

polyester resin. The housing is

engineered for extra strength

and impact resistance. The

stainless steel operating rod has

1

⁄8" diameter tough plastic

a 1

knob. The lever is supported

within the operating head by

oil-impregnated bushings. The

operating mechanism within the

head is comprised of precision

machined components carefully

assembled and tested to assure

a long, trouble-free service life.

The enclosure to which the

head is fastened is a dieformed metal stamping. On

NEMA 1 housings, two

knockouts are supplied. The operating head is gasketed for

sealing to the enclosure or customers panel on flush mounting

switches.

3

⁄4"

The cam-operated inserts are

similar to those used with type

PBC & WPBC pushbutton stations, with the following modifications: The operating plungers

are glass-fibre reinforced plastic

with a special lip overhang to

interlock with the operating lever. Plungers are also equipped

with location detents, corresponding to the cam development and speed points. This

feature provides the operator

with a “positive position feel.”

• Plunger detents give

operator “positive

position feel.”

• Heavy-duty, cam-operated

switch units.

• Up to 5–speed points in

each direction.

• Up to 16 circuits plus

feed for each direction

provide unlimited operation sequences.

• Jam-proof mechanism for

contact protection.

Stepless Mini-Master

Switch

18

HUBBELL

440/428-1161 • Fax 440/428-7635

Page 19

Diagrams & Dimensions

Max. Travel

5.75"

2.25"2.50"

2.88"0.75"

3.50"0.44"

4.38"

0.75"

0.31"

Flush Mounted Mini-Master Switch

Contact Ratings

Single Break

0.44"0.31"

Off

5.25"

6.12"

6.75"

44°44°

5" Rad.

Max. Travel

0.22"ø Mtg.

Holes (4)

Max. Travel

5.31"1.75"

2.25"3.75"

0.31"

0.75" Conduit

Knockout

3.00"0.69"

4.38"

Surface Mounted Mini-Master Switch

5.38"

3.00"0.25" 0.25"

3.50"

Off

5.00"0.88"

6.75"

0.22"ø Mtg.

Holes (4)

44°44°

Max. Travel

4211

5" Rad.

AC

NEMA

B150

DC

NEMA

P300

120V

240V3A—

125V

250V

1.1A

0.55A

0.38" 0.38"

3.06"

3.06"

0.41" 0.41"

0.22"ø Mtg.

Holes (6)

Cutout and Drilling for Flush Mounted Mini-Master Switch

440/428-1161 • Fax 440/428-7635

HUBBELL

19

Page 20

Prices Are Subject To Change Without Notice

HUBBELL

JPS-800-2M © 2000

Printed in U.S.A.

Hubbell Industrial Controls, Inc.

a subsidiary of Hubbell Incorporated

50 Edwards Street, Madison, Ohio 44057

(440) 428-1161 • Fax (440) 428-7635

Loading...

Loading...