RRU3931E

V100R011C10

Installation Guide

Issue Draft A

Date 2016-03-30

HUAWEI TECHNOLOGIES CO., LTD.

Copyright © Huawei Technologies Co., Ltd. 2016. All rights reserved.

No part of this document may be reproduced or transmitted in any form or by any means without prior written

consent of Huawei Technologies Co., Ltd.

Trademarks and Permissions

and other Huawei trademarks are trademarks of Huawei Technologies Co., Ltd.

All other trademarks and trade names mentioned in this document are the property of their respective

holders.

Notice

The purchased products, services and features are stipulated by the contract made between Huawei and the

customer. All or part of the products, services and features described in this document may not be within the

purchase scope or the usage scope. Unless otherwise specified in the contract, all statements, information,

and recommendations in this document are provided "AS IS" without warranties, guarantees or

representations of any kind, either express or implied.

The information in this document is subject to change without notice. Every effort has been made in the

preparation of this document to ensure accuracy of the contents, but all statements, information, and

recommendations in this document do not constitute a warranty of any kind, express or implied.

Huawei Technologies Co., Ltd.

Address: Huawei Industrial Base

Bantian, Longgang

Shenzhen 518129

People's Republic of China

Website: http://www.huawei.com

Email: support@huawei.com

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

i

RRU3931E

Installation Guide Contents

Contents

1 RRU3931E Installation Guide..................................................................................................... 1

1.1 Changes in RRU3931E Installation Guide.....................................................................................................................4

1.2 Installation Preparations................................................................................................................................................. 4

1.2.1 Installation Environment............................................................................................................................................. 4

1.2.2 Reference Documents..................................................................................................................................................5

1.2.3 Tools and Instruments..................................................................................................................................................5

1.2.4 Skills and Requirements for Installation Personnel.....................................................................................................6

1.2.5 Installation Scenarios...................................................................................................................................................7

1.2.6 Installation Clearance Requirements........................................................................................................................... 8

1.3 Unpacking Inspection..................................................................................................................................................... 9

1.4 Obtaining the SN.......................................................................................................................................................... 11

1.5 Installation Process....................................................................................................................................................... 11

1.6 Installing a RRU3931E.................................................................................................................................................12

1.6.1 Mounting Kits............................................................................................................................................................12

1.6.2 Installing a RRU3931E on a Pole..............................................................................................................................14

1.6.3 Installing a RRU3931E on a Wall............................................................................................................................. 17

1.7 Installing Cables........................................................................................................................................................... 21

1.7.1 Cabling Requirements............................................................................................................................................... 21

1.7.2 Cable Connections.....................................................................................................................................................23

1.7.3 Opening the Maintenance Cavity Covers..................................................................................................................24

1.7.4 Installing a Power Cable............................................................................................................................................25

1.7.5 Installing an CPRI Fiber Optic Cable........................................................................................................................27

1.7.6 (Optional) Installing an CPRI Fiber Optic Cable for Cascading...............................................................................29

1.7.7 Closing the Maintenance Cavity Covers................................................................................................................... 30

1.7.8 Installing a PGND Cable........................................................................................................................................... 31

1.7.9 (Optional) Installing an RF Jumper........................................................................................................................... 33

1.8 (Optional)Replacing the Internal Antenna with External Antennas.............................................................................36

1.9 Checking the Hardware Installation............................................................................................................................. 41

1.10 Performing a Power-On Check...................................................................................................................................42

1.11 References...................................................................................................................................................................43

1.11.1 Assembling a Shielded RJ45 Connector and an Ethernet Cable............................................................................. 43

1.11.2 Checking the Appearance of Metal Contact Strips..................................................................................................47

1.11.3 Testing the Connection of Assembled Cables......................................................................................................... 49

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

ii

RRU3931E

Installation Guide Contents

1.11.4 Assembling a Tool-less Female Connector (Pressfit Type) and a Power Cable......................................................53

1.11.5 Small Cell Engineering Label..................................................................................................................................56

1.11.6 Attaching a Sign Plate Label................................................................................................................................... 57

1.11.7 SN Collection Template...........................................................................................................................................59

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

iii

RRU3931E

Installation Guide

Introduction

1 RRU3931E Installation Guide

1 RRU3931E Installation Guide

This document describes how to install a RRU3931E in different scenarios and provides the

hardware installation checklist as a reference.

Product Version

The following table lists the product versions related to this document.

Product

Name

RRU3931E

Intended Audience

This document is intended for:

l RRU3931E installation engineers

l System engineers

l Site maintenance engineers

Organization

Solution Version Product Version

l SRAN11.1 and later versions

l RAN18.1 and later versions

l eRAN11.1 and later versions

V100R011C10 and later versions

1.1 Changes in RRU3931E Installation Guide1.1 Changes in RRU3931E Installation

Guide

This section describes the changes in RRU3931E Hardware Description.

1.2 Installation Preparations1.2 Installation Preparations

This section describes the preparations for installation. Before starting the installation, you

must get the installation environment ready, obtain the required reference documents, tools,

and instruments, and familiarize yourself with the skills required.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

1

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

1.3 Unpacking Inspection1.3 Unpacking Inspection

This section describes how to unpack and check the delivered materials to ensure that all the

materials are included and intact.

1.4 Obtaining the SN1.4 Obtaining the SN

This section describes how to obtain the serial number (SN) of a RRU3931E. Before

installing the RRU3931E, record its SN for future use during commissioning.

1.5 Installation Process1.5 Installation Process

This section describes the process for installing a RRU3931E. The process includes:

l Installing a RRU3931E

l Installing cables

l Checking the hardware installation

l Performing a power-on check

1.6 Installing a RRU3931E1.6 Installing a RRU3931E

This section describes the procedure and precautions for installing a RRU3931E.

1.7 Installing Cables1.7 Installing Cables

This section describes the procedure and precautions for installing cables.

en-us_topic_0027706033.xmlen-us_topic_0027706033.xml

This section describes the procedure and precautions for adjusting the installation angles of a

RRU3931E.

1.9 Checking the Hardware Installation1.9 Checking the Hardware Installation

This section describes how to check the hardware installation after a RRU3931E is installed.

1.10 Performing a Power-On Check1.10 Performing a Power-On Check

This section describes the procedure for performing a power-on check on a RRU3931E.

1.11 References1.11 References

This section describes reference information and common operations involved during

installation.

1.1 Changes in RRU3931E Installation Guide

This section describes the changes in RRU3931E Hardware Description.

1.2 Installation Preparations

This section describes the preparations for installation. Before starting the installation, you

must get the installation environment ready, obtain the required reference documents, tools,

and instruments, and familiarize yourself with the skills required.

1.3 Unpacking Inspection

This section describes how to unpack and check the delivered materials to ensure that all the

materials are included and intact.

1.4 Obtaining the SN

This section describes how to obtain the serial number (SN) of a RRU3931E. Before

installing the RRU3931E, record its SN for future use during commissioning.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

2

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

1.5 Installation Process

This section describes the process for installing a RRU3931E.

1.6 Installing a RRU3931E

This section describes the procedure and precautions for installing a RRU3931E.

1.7 Installing Cables

This section describes the procedure and precautions for installing cables.

1.8 (Optional)Replacing the Internal Antenna with External Antennas

This section describes how to replace the RRU3931E internal antenna with external antennas.

1.9 Checking the Hardware Installation

This section describes how to check the hardware installation after a RRU3931E is installed.

1.10 Performing a Power-On Check

This section describes the procedure for performing a power-on check on a RRU3931E.

1.11 References

This section describes reference information and common operations involved during

installation.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

3

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

1.1 Changes in RRU3931E Installation Guide

This section describes the changes in RRU3931E Hardware Description.

Draft A (2016-03-30)

This is a draft.

1.2 Installation Preparations

This section describes the preparations for installation. Before starting the installation, you

must get the installation environment ready, obtain the required reference documents, tools,

and instruments, and familiarize yourself with the skills required.

1.2.1 Installation Environment

Before starting the installation, ensure that the power supply equipment, transmission

equipment, and related matching equipment are ready.

Precautions for Site Selection

l Do not install a RRU3931E near an interference source, such as a broadcast and

television tower, high and low-voltage substation, high-voltage tower, high-power radio

transmitter, and radar station.

l For the sake of surge protection, the mounting height of a RRU3931E should not be

greater than 10 m. Do not install a RRU3931E along a highway or railway or on the

mountain top, tower, standalone pole in a suburban area or open field, or standalone

rooftop in a non-urban area.

Requirements for the Upper-level Circuit Breaker

Slow-blow fuses of the gL (DIN VDE)/gG (IEC) class in accordance with IEC60269-1 are

recommended. Fuses of the same specifications must be configured for L and N wires for the

sake of O&M security.

Type C bipolar circuit breakers in accordance with IEC60934 are recommended. Circuit

breakers must be configured for L and N wires for the sake of O&M security.

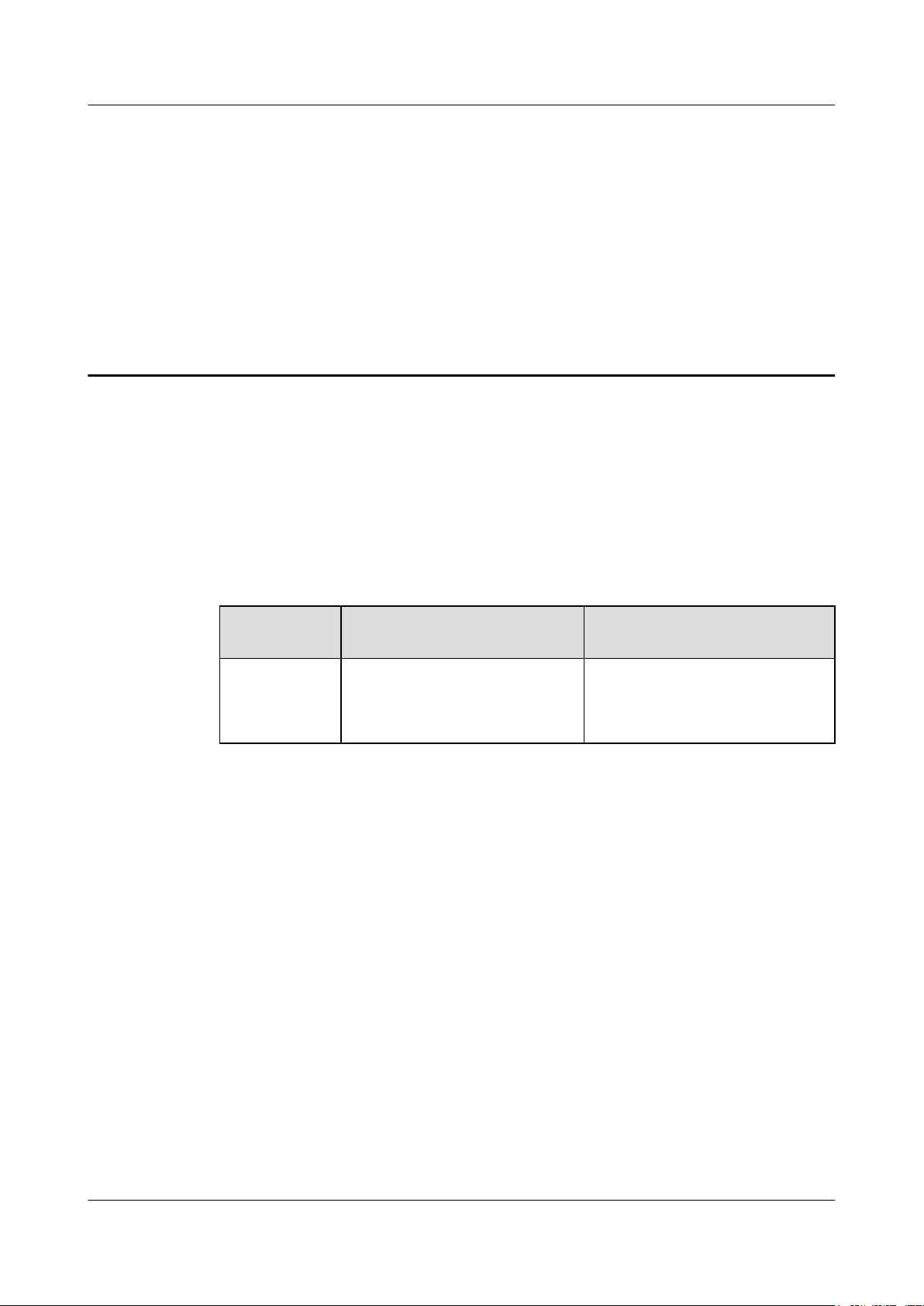

Table 1-1 describes the recommended specifications.

Table 1-1 Requirements on the upper-level circuit breakers and power cables

Power Supply

220 V AC single-phase

110 V AC dual-live-wire

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

Current of the Upperlevel AC Circuit

Breakers (or Fuses)

l Minimum value: 5 A

l Recommended value: 16

A

Cross-Sectional Area of

the Input Power Cable

1.5 mm2 to 2.5 mm

2

4

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

Power Supply Current of the Upper-

level AC Circuit

Breakers (or Fuses)

110 V AC single-phase

l Maximum value: 20 A

NOTE

l The requirements provided in the preceding table are based on the peak power of a RRU3931E and

do not represent power consumption when the RRU3931E is running.

l Minimum value: Ensures that a RRU3931E can work normally under normal circumstances.

However, lightning strikes or abnormal voltage fluctuations may trip the circuit breaker or melt the

fuse.

l Recommended value: Ensures that a RRU3931E can work normally under normal circumstances

and that the circuit breaker does not trip in the event of lightning strikes or abnormal voltage

fluctuations.

l Maximum value: Indicates the maximum rated current allowed in the product design.

Requirements for Surge Protection and Grounding

Huawei by default uses a three-core power cable to connect a RRU3931E and external power

supply equipment. The power supply side must ensure that the PE wire of the three-core

power cable can be properly grounded. In outdoor installation scenarios or outdoor cabling

scenarios, PGND cables must be used to guarantee the surge protection and grounding for the

ground terminals of the mounting kits.

Cross-Sectional Area of

the Input Power Cable

Requirements for power supply

During installation, power off the RRU3931E.

1.2.2 Reference Documents

This section describes reference documents required for installation.

Before starting the installation, you must be familiar with the following reference documents:

l Safety Information

l RRU3931E Hardware Description

1.2.3 Tools and Instruments

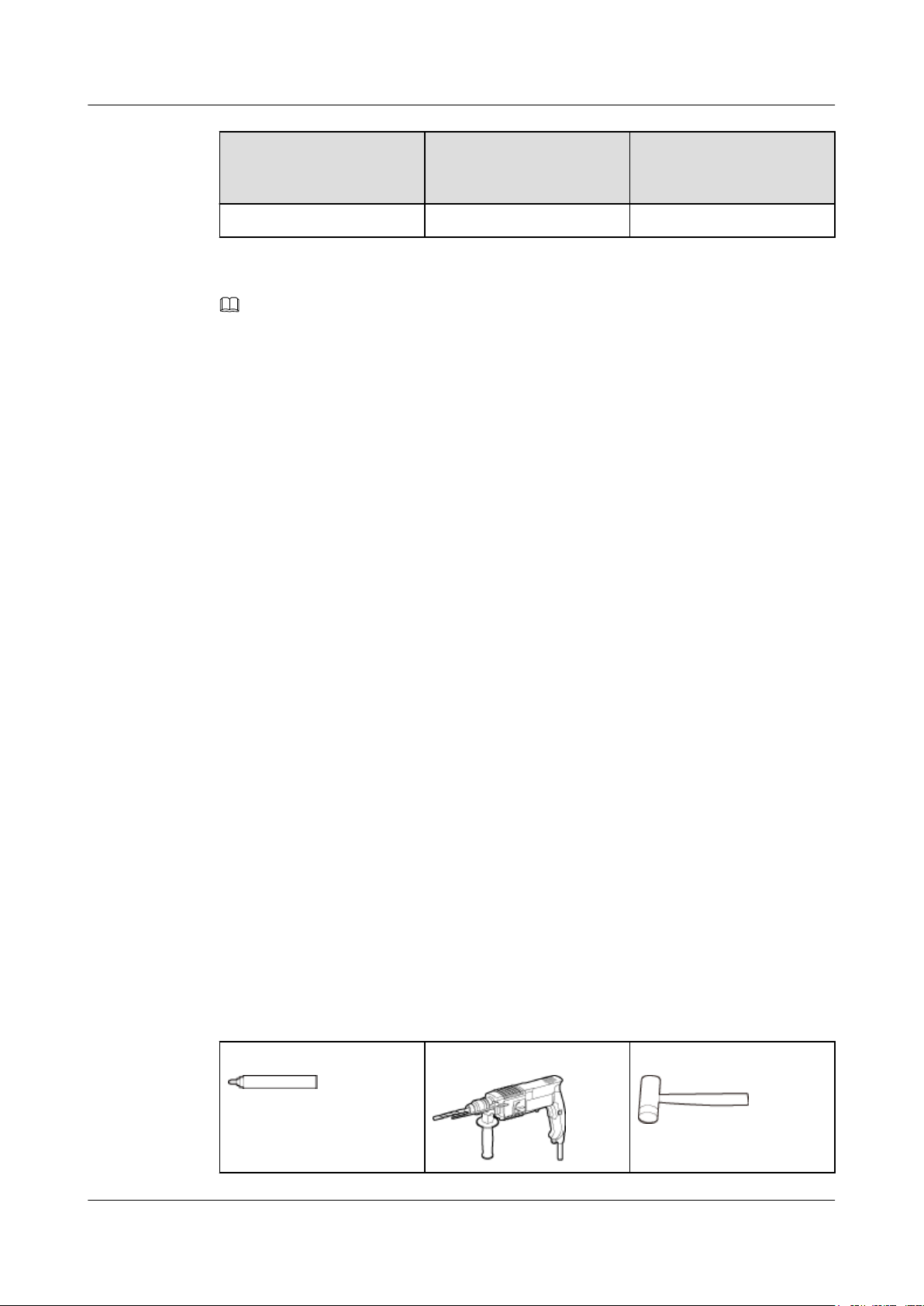

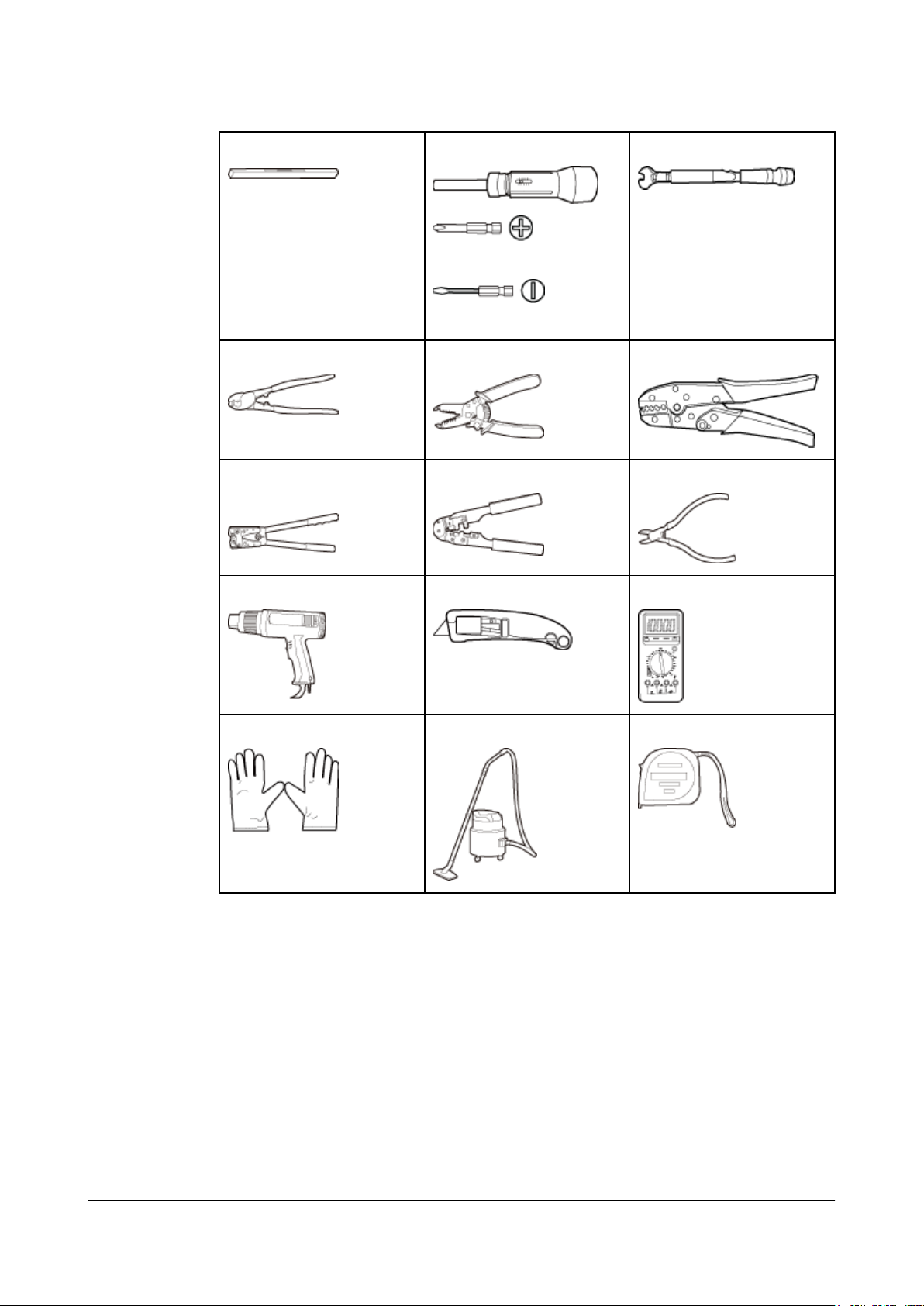

Before starting the installation, prepare the following tools and instruments.

Marker (diameter ≤ 10 mm)

Hammer drill (Ø12 bore) Rubber mallet

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

5

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

Level Torque screwdriver

Phillips (M3, M4)

Flat-head (M6, M8)

Cable cutter Wire stripper COAX crimping tool

Crimping tool for power

cables

Heat gun Utility knife Multimeter

RJ45 crimping tool Diagonal pliers

Torque wrench

ESD gloves Vacuum cleaner Measuring tape

1.2.4 Skills and Requirements for Installation Personnel

Installation personnel must be qualified, trained, and familiar with correct operation methods

and safety precautions before performing any operations.

Before starting the installation, pay attention to the following items:

l The customer's technical engineers must be trained by Huawei and be familiar with the

proper installation and engineering methods.

l The number of required installation personnel depends on the engineering schedule and

installation environment. Generally, three to five installation personnel are necessary.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

6

RRU3931E

Installation Guide

1.2.5 Installation Scenarios

The RRU3931E can be installed on a pole or a wall.

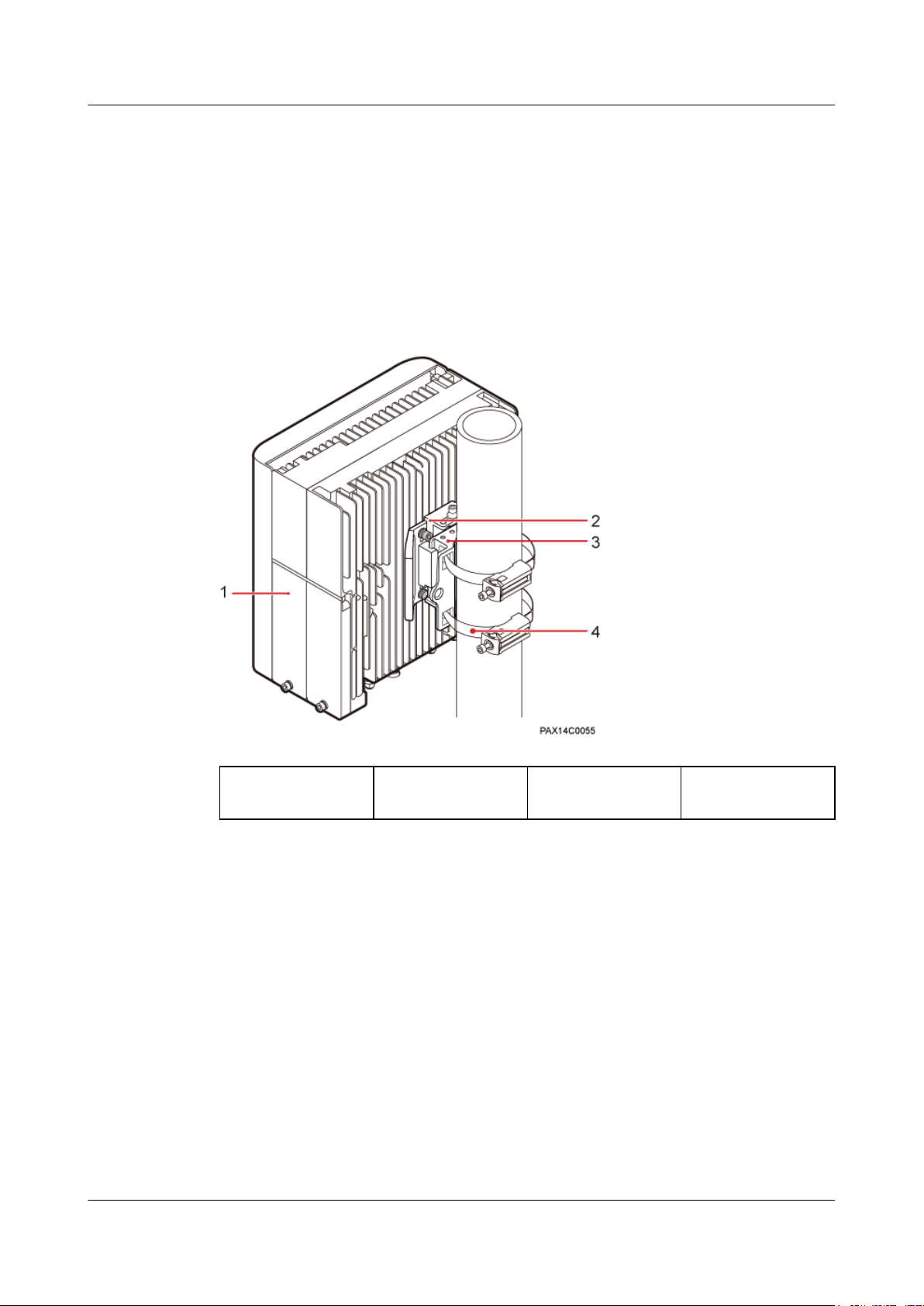

Pole-mounted Installation

A RRU3931E can be installed on a pole with a diameter of 60 mm to 381 mm.

Figure 1-1 illustrates a pole-mounted RRU3931E.

Figure 1-1 Pole-mounted installation

1 RRU3931E Installation Guide

(1) RRU3931E (2) Attachment plate (3) Mounting

bracket

Wall-mounted Installation

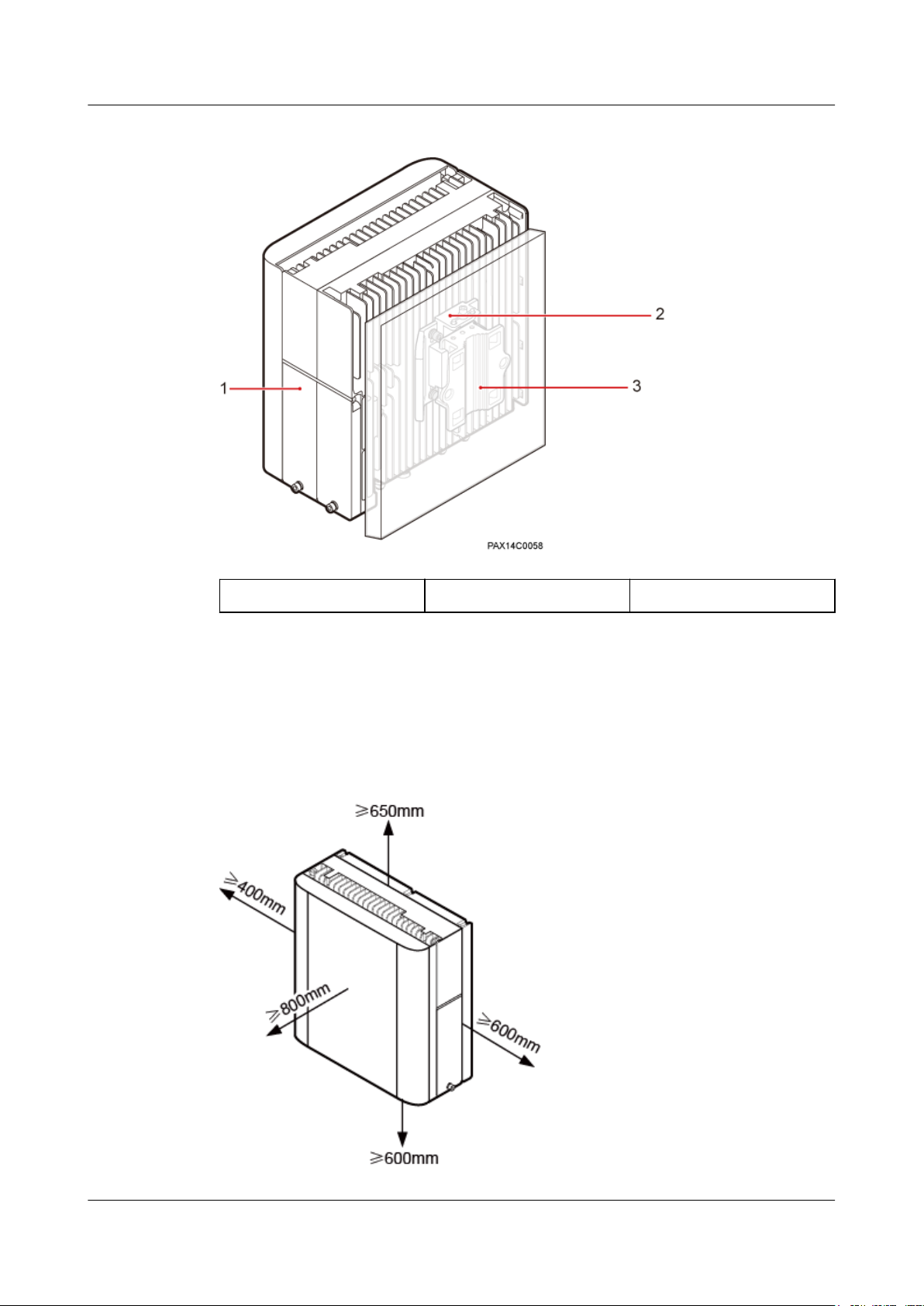

In wall-mounted installation scenarios, note the following:

l The wall has a capacity of bearing at least four times the weight of the RRU3931E to be

installed without damage.

l Expansion bolts must be torqued to 28 N·m to ensure the bolts work properly without

causing cracks on the wall.

Figure 1-2 illustrates a wall-mounted RRU3931E.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

(4) Steel belt

7

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

Figure 1-2 Wall-mounted installation

(1) RRU3931E (2) Attachment plate (3) Mounting bracket

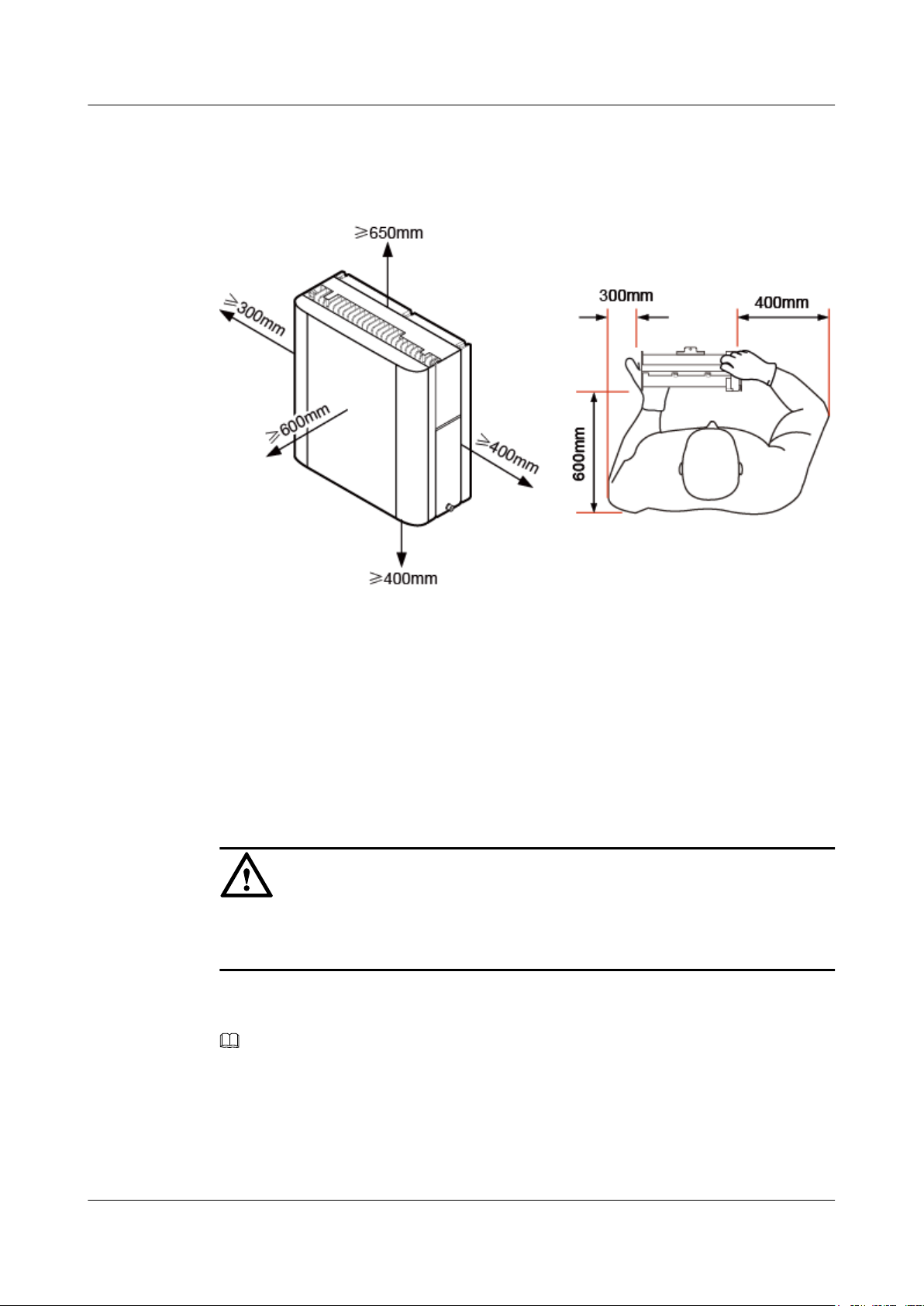

1.2.6 Installation Clearance Requirements

This section describes the clearance requirements for installing a RRU3931E on a pole or

wall.

Figure 1-3 shows the recommended installation clearances around a RRU3931E.

Figure 1-3 Recommended installation clearances around a RRU3931E

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

8

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

Figure 1-4 shows the minimum installation clearances around a RRU3931E.

Figure 1-4 Minimum installation clearances around a RRU3931E

1.3 Unpacking Inspection

This section describes how to unpack and check the delivered materials to ensure that all the

materials are included and intact.

Prerequisites

NOTICE

After a RRU3931E is unpacked, power it on within 24 hours. If the RRU3931E is powered

off for maintenance, restore power to it within 24 hours.

Context

NOTE

When transporting, moving, or installing the equipment, components, or parts, you must:

l Prevent them from colliding with doors, walls, shelves, or other objects.

l Wear clean gloves, and avoid touching the equipment, components, or parts with bare hands, sweat-

soaked gloves, or dirty gloves.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

9

RRU3931E

Installation Guide

Procedure

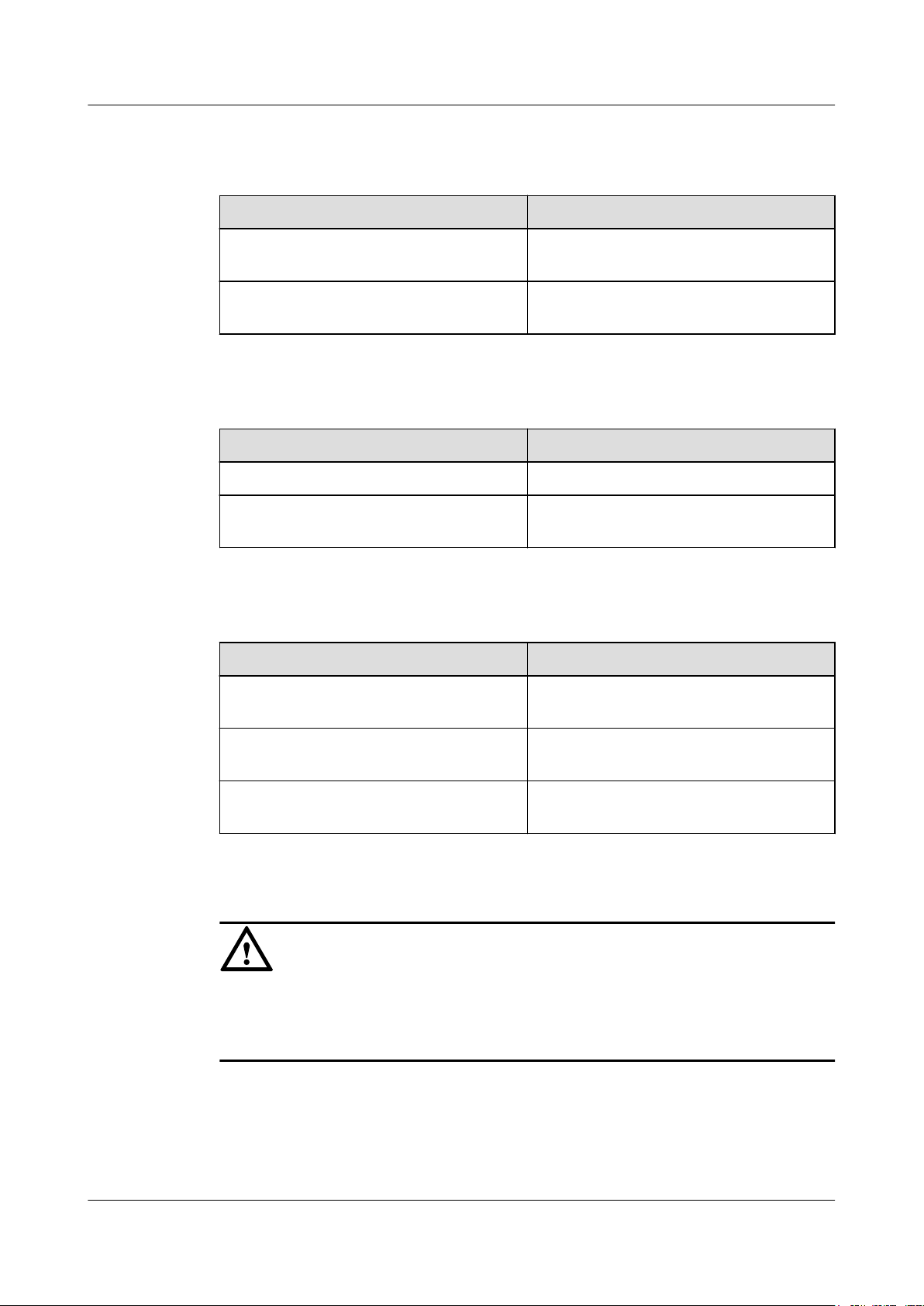

Step 1 Check the total number of articles in each packing case against the packing list.

1 RRU3931E Installation Guide

If... Then...

The total number tallies with the packing

list

The total number does not tally with the

packing list

Step 2 Check the exterior of each packing case.

If...

The outer packing is intact Go to Step 3.

The packing case is severely damaged or

soaked

Step 3 Check the type and quantity of the equipment in each packing case against the packing list.

If...

The type and quantity tallies with the

packing list

Go to Step 2

Find out the cause and contact the local

Huawei office.

Then...

Find out the cause and contact the local

Huawei office.

Then...

Sign the Packing List with the customer.

There is any shipment shortage or wrong

shipment

There is damaged shipment Fill in and submit the Article Replacement

Fill in and submit the Cargo Shortage and

Mishandling Report.

Report.

NOTICE

To protect the equipment from damage, keep the unpacked equipment and packing materials

indoors. To help find out the cause of any damage in the future, take photos of the storeroom,

rusted or eroded equipment, packing cases, and packing materials, and then file the photos.

----End

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

10

RRU3931E

Installation Guide

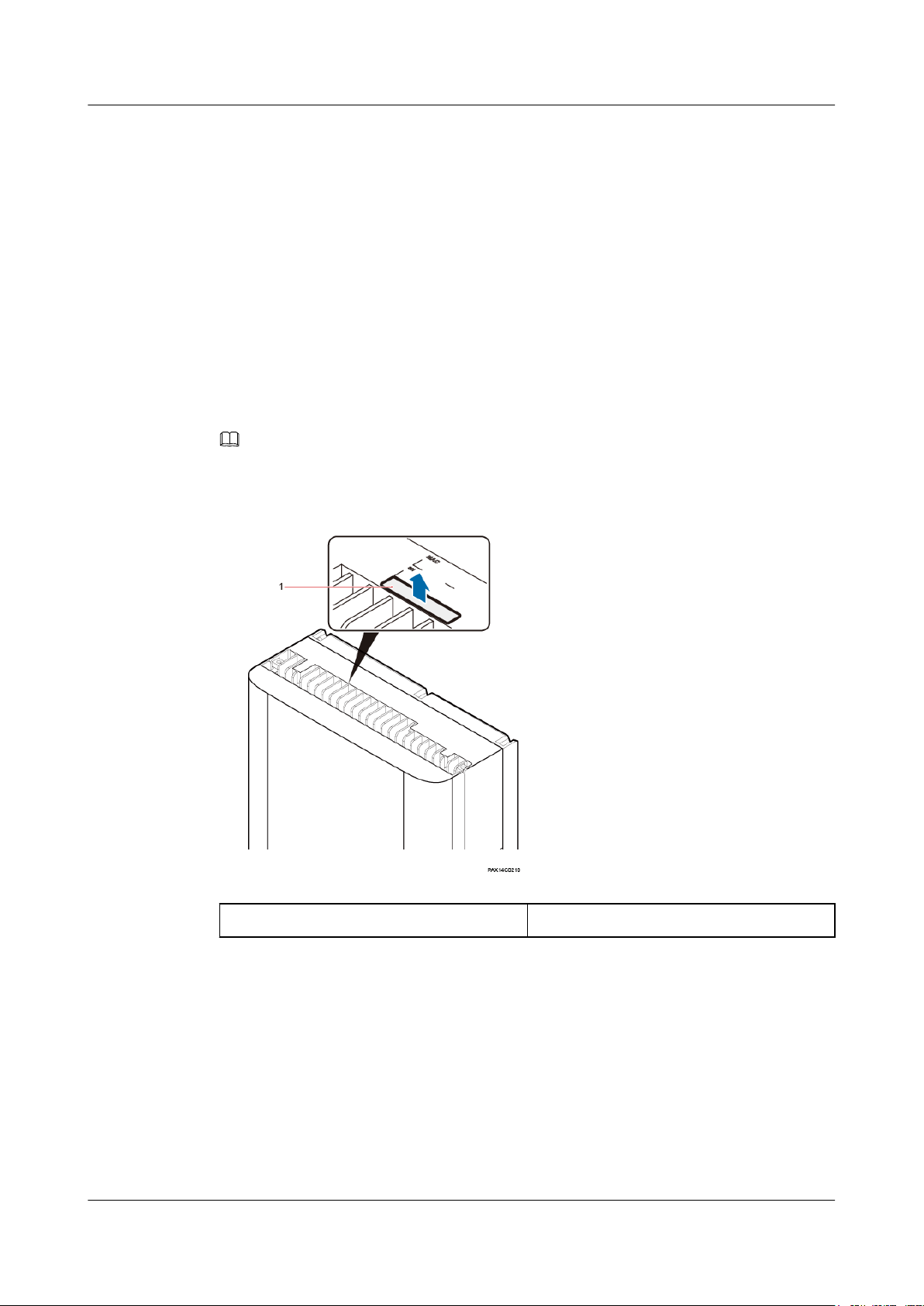

1.4 Obtaining the SN

This section describes how to obtain the serial number (SN) of a RRU3931E. Before

installing the RRU3931E, record its SN for future use during commissioning.

Context

The SN uniquely identifies a device and is required during commissioning. The SN label of a

RRU3931E is attached to the surface of the RRU3931E.

Procedure

Step 1 Remove the backup SN label from the surface of the RRU3931E. See Figure 1-5

NOTE

Before removing the backup SN label, photograph it.

Figure 1-5 Removing the SN label

1 RRU3931E Installation Guide

(1) Backup SN label -

Step 2 Record the SN by using the template described in section 1.11.7 SN Collection Template,

and report it to the RRU3931E commissioning personnel.

----End

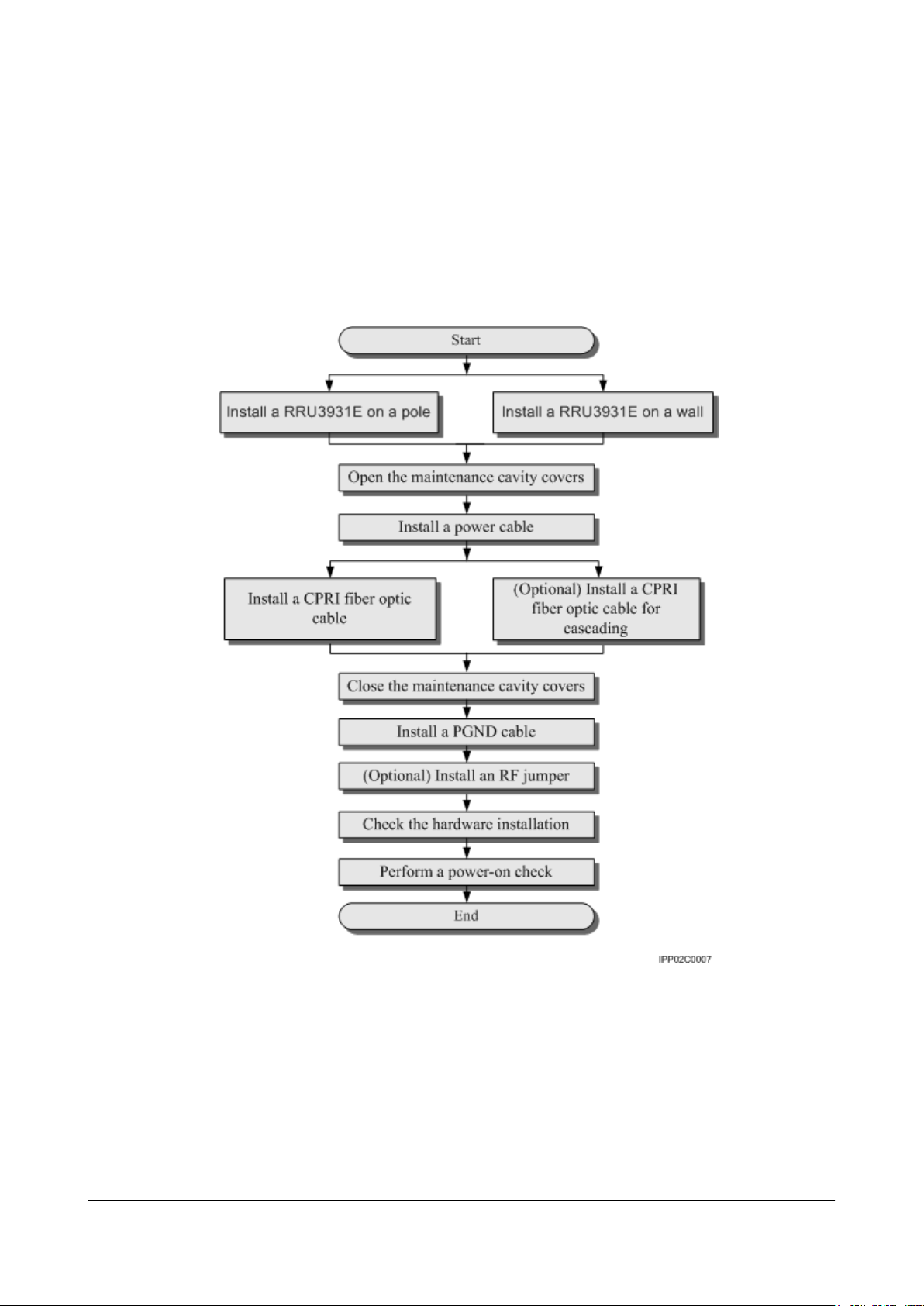

1.5 Installation Process

This section describes the process for installing a RRU3931E.

The process includes:

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

11

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

l Installing a RRU3931E

l Installing cables

l Checking the hardware installation

l Performing a power-on check

Figure 1-6 outlines the process for installing a RRU3931E.

Figure 1-6 Process for installing a RRU3931E

1.6 Installing a RRU3931E

This section describes the procedure and precautions for installing a RRU3931E.

1.6.1 Mounting Kits

This section describes the kits for mounting a RRU3931E on a pole or wall.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

12

RRU3931E

Installation Guide

Slim Attachment Plate

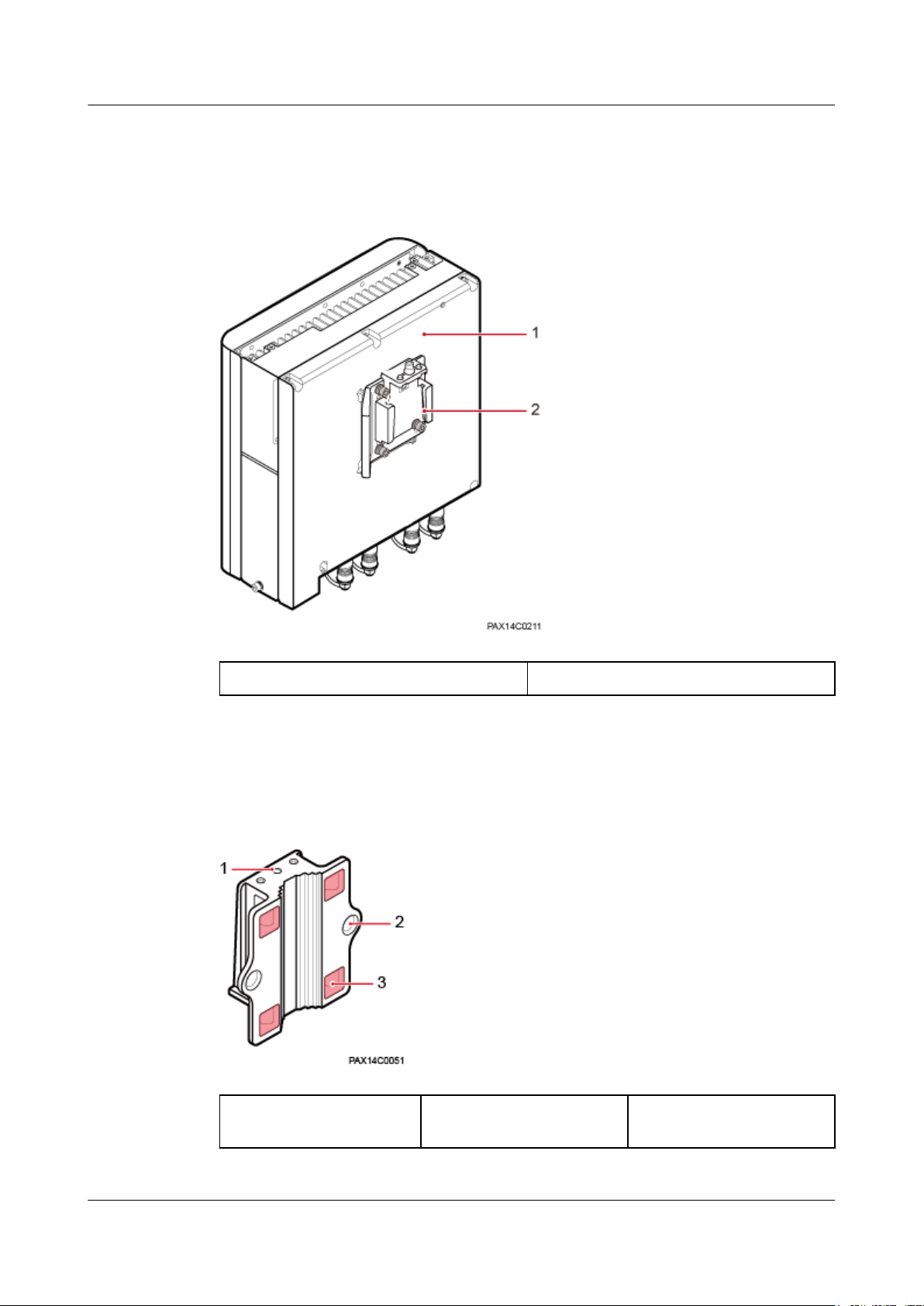

Figure 1-7 shows the appearance of a slim attachment plate.

Figure 1-7 Slim attachment plate

1 RRU3931E Installation Guide

(1) RRU3931E (2) Slim attachment plate

Mounting Bracket

Figure 1-8 shows the appearance of a Mounting bracket.

Figure 1-8 Mounting bracket

(1) Hole for a fastening

screw

(2) Mounting hole for an

expansion bolt

(3) Mounting hole for a steel

belt

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

13

RRU3931E

Installation Guide

1.6.2 Installing a RRU3931E on a Pole

This section describes the procedure and precautions for installing a RRU3931E on a pole.

Procedure

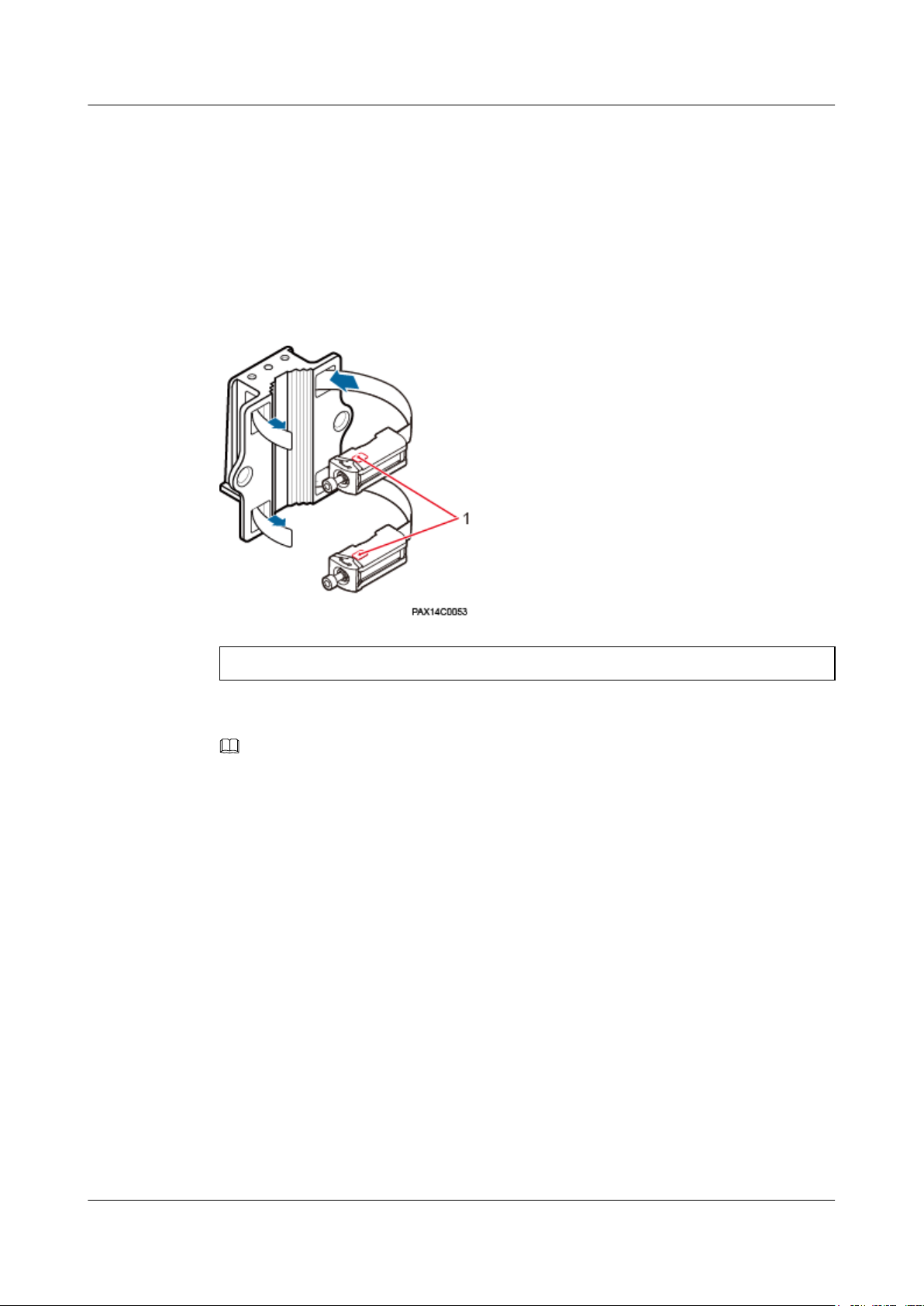

Step 1 Route two steel belts separately through the up and down mounting holes on the Mounting

bracket, but do not route the steel belts through the buckles. See Figure 1-9.

Figure 1-9 Routing steel belts

1 RRU3931E Installation Guide

(1) Visible window

NOTE

Before installing a steel belt, check the rotation axis from the visible window. If the rotation axis is not

connected to the end of the bolt, loose the bolt and adjust the rotation axis to the end of the bolt. The

position of the rotation axis is shown in Figure 1-11.

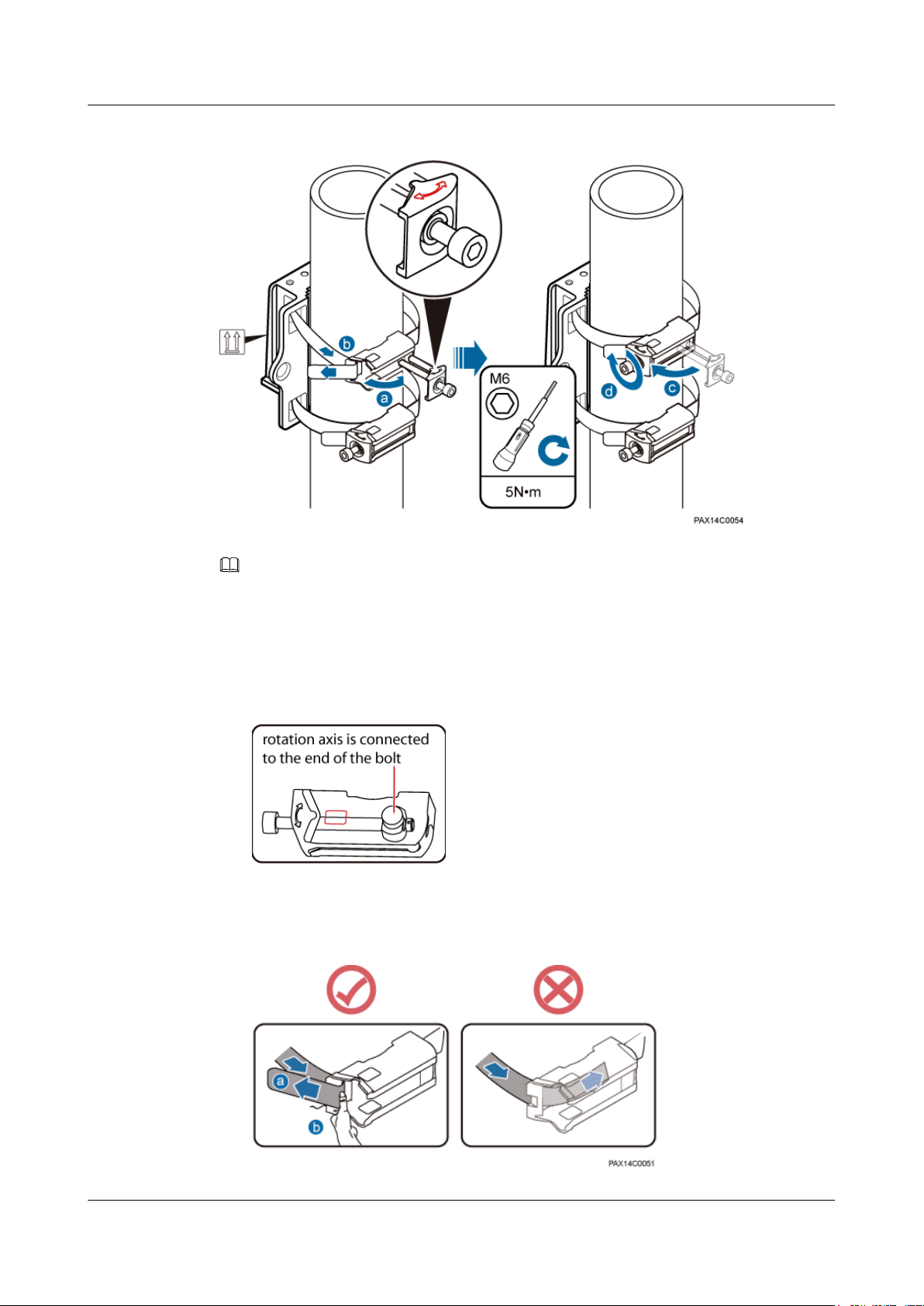

Step 2 Fit the Mounting bracket onto the target pole. See Figure 1-10.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

14

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

Figure 1-10 Fitting the Mounting bracket onto the target pole

NOTE

Redundant steel belts must be bound.

1. Open the bolt on each steel belt according to the arrow direction on the mounting base,

and ensure that the rotation axis is connected to the end of the bolt, as shown in Figure

1-11.

Figure 1-11 Position of the rotation axis

2. Partially tighten each steel belt with the force not less than 50 N, bend it by 180°, and

press the steel belt at turns firmly. See Figure 1-12.

Figure 1-12 Tighten steel belts

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

15

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

3. Restore the bolt in position on the mounting base of the steel belt. See Figure 1-13.

Figure 1-13 Restoring the bolt in position on the mounting base

4. Use an M6 hex key screwdriver to torque the bolts to 7 N·m.

Check the steel belt installation status from the visible window. If the rotation axis is close to

the end of the bolt, remove the steel belt and fasten it again. See Figure 1-13.

Figure 1-14 Check the rotation axis status

(1) Rotation axis

Step 3 Fit the RRU3931E onto the Mounting bracket, and use an M6 hex key screwdriver to torque

the screw to 5 N·m. See Figure 1-15.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

16

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

Figure 1-15 Fitting a RRU3931E onto a Mounting bracket

NOTICE

Gently take and fit the RRU3931E onto the Mounting bracket.

----End

1.6.3 Installing a RRU3931E on a Wall

This section describes the procedure and precautions for installing a RRU3931E on a wall.

Procedure

Step 1 Place the Mounting bracket against the wall, use a level to verify that the mounting bracket is

placed horizontally, and use a marker to mark anchor points. See Figure 1-16.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

17

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

Figure 1-16 Marking anchor points

(1) Mounting

bracket

(2) Level (3) Mounting holes (4) Marker

NOTICE

To prevent inhalation or eye contact with dust, take adequate preventive measures when

drilling holes.

Step 2 Drill holes at the anchor points, and install expansion bolts. See Figure 1-17.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

18

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

Figure 1-17 Drilling holes and installing expansion bolts

(1) M10x80

expansion bolt

1. Use a hammer drill with Ф12 bore to drill holes vertically at the marked anchor points.

Ensure that the holes have the same depth ranging from 55 mm to 60 mm.

2. Use a vacuum cleaner to clear the dust from inside and around the holes, and measure

the inter-hole spacing. If the spacing is too wide or too narrow, relocate positions and

drill holes again.

3. Partially tighten an expansion bolt and vertically insert it into each hole.

4. Use a rubber mallet to hit the expansion bolts until the entire expansion sleeve is in each

hole.

5. Remove the M10×80 bolt, nut, spring washer, and flat washer in sequence.

(2) Nut (3) Spring

washer

(4) Flat washer (5) Expansion

sleeve

NOTICE

Level the front of each expansion sleeve with the wall after disassembling an expansion bolt.

Otherwise, the mounting bracket will not be securely installed on the wall.

Step 3 Fit the Mounting bracket onto the wall through the four expansion bolts, and use an M10

socket wrench to torque the four expansion bolts to 28 N·m. See Figure 1-18.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

19

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

Figure 1-18 Fitting a Mounting bracket onto the wall

(1) Nut (2) Spring washer (3) Flat washer (4) Swell fixture

Step 4 Fit the RRU3931E onto the Mounting bracket, and use an M6 hex key screwdriver to torque

the screw to 5 N·m. See Figure 1-19.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

20

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

Figure 1-19 Fitting a RRU3931E onto a Mounting bracket

NOTICE

The narrow space of the RRU3931E toward the wall allows you only to fit the RRU3931E

onto the Mounting bracket in barehanded way, instead of using the attachment plate hander.

Do gently in the whole process.

----End

1.7 Installing Cables

This section describes the procedure and precautions for installing cables.

1.7.1 Cabling Requirements

Cables must be routed according to the specified cabling requirements to prevent interference

between signals.

NOTE

If a cable listed below is not required, skip the cabling requirements of the cable.

General Cabling Requirements

The bending radius of the cables must meet the following specifications:

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

21

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

l The bending radius of a 7/8'' feeder must be greater than 250 mm, and the bending radius

of a 5/4'' feeder must be greater than 380 mm.

l The bending radius of a 1/4'' jumper must be greater than 35 mm. The bending radius of

a super-flexible 1/2'' jumper must be greater than 50 mm, and the bending radius of an

ordinary 1/2'' jumper must be greater than 127 mm.

l The bending radius of a power cable or PGND cable must be at least five times its

diameter.

l The bending radius of a fiber optic cable must be at least 20 times its diameter.

l The bending radius of a signal cable must be at least five times its diameter.

The cables must be bound as follows:

l Cables must be bound tightly and neatly. The sheaths of cables must not be damaged.

l Cable ties must face the same direction, and those at the same horizontal line must be in

a straight line. The excess of cable ties must be cut off.

l Labels or nameplates must be attached to the cables after they are installed.

The cables must be routed as follows:

l Cables of different types must be routed separately in an untangled and orderly fashion.

l Cables of different types must be parallel to each other or separated by using dedicated

separators.

l Cables must be routed away from sharp objects or wall burrs. If these positions are

inevitable, cables must be protected with protection pipes.

l Cables must be routed away from heat sources, or heat-insulation materials must be

added between cables and heat sources.

l Sufficient slack must be provided in cables at turns or the position close to a device,

facilitating cable and device maintenance. The recommended slack is 0.1 m.

l AC power cables and PGND cables must be tubed when routed.

l Drip loops must be reserved for cable layout at connection points and thru-wall points

indoors/outdoors.

l All cables cannot be routed overhead. Cables laid out outdoors should be buried in the

ground.

Special Cabling Requirements

Power cables must be routed as follows:

l Multiple power cables must be bound when routed.

l Power cables must be installed in the positions specified in engineering design

documents.

l If the length of power cables is insufficient, the power cables must be replaced instead of

adding connectors or soldering joints to lengthen the cables.

l Cabling activities require strict organization and coordination, and are allowed only

when qualified personnel and communication facilities are available.

l Cables must be routed in an untangled and orderly fashion.

l AC power cables must be tubed when routed.

PGND cables must be routed as follows:

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

22

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

l PGND cables for a RRU3931E must be connected to the same ground bar.

l PGND cables must be buried in the ground or routed indoors. They must not be routed

overhead before they are led into the equipment room.

l The exterior of a coaxial wire and the shield layer of a shielded cable must have proper

electrical contact with the metal surface of the equipment to which they are connected.

l PGND cables and signal cables must be bound separately in an untangled and orderly

fashion. A certain distance must be reserved between them to prevent mutual

interference.

l Fuses or switches must not be installed on PGND cables.

l Other devices must not be used for electrical connections of PGND cables.

l All the metal parts in the housing of the RRU3931E must be reliably connected to the

ground terminal.

l PGND cables must be tubed when routed.

Signal cables must be routed as follows:

l Signal cables must not cross power cables, PGND cables, or RF cables when routed. If

transmission cables are routed parallel to power cables, PGND cables, or RF cables, the

spacing between them must be greater than 30 mm.

l Signal cables must be routed straightly and bound neatly with cable ties.

l Sufficient slack must be provided in signal cables at turns.

Fiber optic cables must be routed as follows:

l A minimum of three qualified and trained personnel are required to route fiber optic

cables.

l The operating temperature of fiber optic cables ranges from -40oC to +60oC. If the

current temperature is out of the range, additional protection measures must be taken or

the cable routing must be changed.

l Cables must be routed in an untangled and orderly fashion.

l Fiber optic cables must not be bound at turns.

l Fiber optic cables cannot be stretched with too much force or stepped on, and they must

be far away from sharp objects. Heavy objects cannot be placed on fiber optic cables.

l When fiber optic cables are routed, the excess of the cables must be coiled around

special devices, such as a fiber coiler.

l Fiber optic cables must be coiled gently and must not be bent in a forcible manner.

l Vacant optical connectors must be covered with dustproof caps.

l Fiber optic cables cannot be squeezed by a cabinet door when routed through a cabinet.

l When routed on the tower platform, the fiber optic cables must be laid out along the

guardrail within the shortest distance.

l When routed close to a device on the tower, the fiber optic cables must be secured to the

guard rail or pole with cable clips. The RRU3931E must not be far away from the

position for securing the fiber optic cables.

l The excess of the fiber optic cables must be coiled and secured on the tower.

1.7.2 Cable Connections

This section describes the connections of the canles.

Figure 1-20 shows the cable connections for a RRU3931E.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

23

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

Figure 1-20 RRU3931E cable connections

(1) PGND cable (2) CPRI fiber optic

(3) Power cable (4) RF Jumper

cable

NOTE

When routing cables from a maintenance cavity, observe the following:

l Route the power cable through the cable hole on the upper-layer rubber strip

l Route the other cables (except power cables) through cable holes on the lower-layer rubber strip

preferentially

l Route cables through cable holes on the same side of ports, and do not cross cables.

1.7.3 Opening the Maintenance Cavity Covers

This section describes the procedure and precautions for opening the maintenance cavity

covers of a RRU3931E.

Procedure

Step 1 Use an M6 hex key screwdriver to loosen the captive screw on both the maintenance cavity

covers. Open the maintenance cavity covers.

Figure 1-21 shows the maintenance cavity structure.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

24

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

Figure 1-21 Maintenance cavity structure

(1) CPRI1 (2) CPRI0 (3) PWR

Step 2 Remove the waterproof blocks for the cables to be installed.

----End

1.7.4 Installing a Power Cable

This section describes the procedure and precautions for installing a power cable for a

RRU3931E. The power cable connects the RRU3931E and external power supply equipment.

Context

Table 1-2 lists the specifications of a power cable.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

25

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

Table 1-2 Power cable specifications

Procedure

Step 1 Make a power cable.

Cable Color One End The Other

Remarks

End

Input power

cable for a

RRU3931E

L Brown AC-EPC1

connector

N Blue

PE Yellow and

green

Depends on

the external

power

supply

equipment.

Black jacket

NOTE

The color and structure of a power cable varies with countries and regions. A locally purchased power

cable must be a pure copper outdoor three-core cable that has a cross-sectional area of 1.5 mm2 to 2.5

mm2 and a maximum outer diameter of 8.9 mm to 10.2 mm and complies with local specifications.

l Cut the cable to a length suitable for the actual cable route.

l Add a cord end terminal to one end of the cable by following instructions provided in

section 1.11.4 Assembling a Tool-less Female Connector (Pressfit Type) and a Power

Cable1.11.4 Assembling a Tool-less Female Connector (Pressfit Type) and a Power

Cable. At the other end, add a terminal that matches the external power supply

equipment.

Step 2 Installing the power cable. Connect the terminal of the power cable to the PWR port on the

RRU3931E. See Figure 1-22.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

26

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

Figure 1-22 Installing a power cable

----End

Follow-up Procedure

1. Route the cable by following instructions provided in section 1.7.1 Cabling

Requirements"1.7.1 Cabling Requirements" and then use cable ties to bind the cable.

2. Attach labels to the installed cables by following instructions in 1.11.6 Attaching a Sign

Plate Label.

1.7.5 Installing an CPRI Fiber Optic Cable

This section describes the procedure and precautions for installing an CPRI fiber optic cable.

Context

l The single-mode optical modules to be installed must match the data rate at the optical

ports.

l Do not twist, bend, stretch, or squeeze fiber optic cables during installation.

l The cable route depends on actual requirements.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

27

RRU3931E

Installation Guide

Procedure

Step 1 Remove the dustproof cap from the CPRI0 or CPRI1 port. Keep the cap secure.

Step 2 Insert an optical module into the CPRI0 or CPRI1 port, and remove the dustproof cap from

Step 3 Remove the dustproof cap from the optical fiber connector, tidy the optical fibers, and insert

1 RRU3931E Installation Guide

NOTICE

Long-time exposure to the air causes performance exceptions on an optical module.

Therefore, optical modules must be connected to fiber optic cables within 20 minutes

after being unpacked.

the optical module.

the DLC connector into the optical module. See Figure 1-23.

Figure 1-23 Installing a fiber optic cable

----End

Follow-up Procedure

1. Route the cable by following instructions provided in section 1.7.1 Cabling

Requirements"1.7.1 Cabling Requirements" and then use cable ties to bind the cable.

2. Attach labels to the installed cables by following instructions in 1.11.6 Attaching a Sign

Plate Label.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

28

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

1.7.6 (Optional) Installing an CPRI Fiber Optic Cable for Cascading

This section describes the procedure and precautions for installing an CPRI fiber optic cable

used for cascading two RRU3931Es.

Context

l The single-mode optical modules to be installed must match the data rate at the optical

ports.

l Do not twist, bend, stretch, or squeeze fiber optic cables during installation.

l The cable route depends on actual requirements.

NOTICE

Long-time exposure to the air causes performance exceptions on an optical module.

Therefore, optical modules must be connected to fiber optic cables within 20 minutes

after being unpacked.

Procedure

Step 1 For both RRU3931Es, remove the dustproof cap from the CPRI0 or CPRI1 port. Keep the cap

Step 2 For both RRU3931Es, insert an optical module into the CPRI0 or CPRI1 port, and remove the

Step 3 Remove the dustproof cap from the optical fiber connector, tidy the optical fibers, and insert

secure.

dustproof cap from the optical module.

the DLC connector into the optical module. See Figure 1-24.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

29

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

Figure 1-24 Installing a fiber optic cable for cascading

----End

Follow-up Procedure

1. Route the cable by following instructions provided in section 1.7.1 Cabling

Requirements"1.7.1 Cabling Requirements" and then use cable ties to bind the cable.

2. Attach labels to the installed cables by following instructions in 1.11.6 Attaching a Sign

Plate Label.

1.7.7 Closing the Maintenance Cavity Covers

This section describes the procedure and precautions for closing the maintenance cavity

covers of a RRU3931E.

Procedure

Step 1 Insert waterproof blocks into vacant cable troughs in both the cabling holes. See Figure 1-25.

CAUTION

Ensure that cables or waterproof blocks are properly inserted into troughs.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

30

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

Figure 1-25 Checking that vacant cable troughs are properly waterproofed

Step 2 Close the maintenance cavity covers of the RRU3931E. Use an M6 hex key screwdriver to

torque the screws on the covers to 4.8 N·m. See Figure 1-26.

Figure 1-26 Closing the maintenance cavity covers

----End

1.7.8 Installing a PGND Cable

This section describes the procedure and precautions for installing a PGND cable.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

31

RRU3931E

Installation Guide

Context

1 RRU3931E Installation Guide

The length of a PGND cable must not exceed 30 m. When the required PGND cable is longer

than 30 m, deploy the ground bar nearer the RRU3931E. Table 1-3

Table 1-3 PGND cable specifications

Cable One End The Other End Color

rocedure

PGND cable OT terminal (M6, 6

mm2)

Step 1 Make a PGND cable for the RRU3931E.

l Cut the cable to the required length based on the actual cable route.

l Add an OT terminal to each end of the PGND cable by following instructions provided

in section "Assembling the OT Terminal and the Power Cable" of Installation Reference.

Step 2 Install the PGND cable.

Connect the M6 OT terminal at one end of the PGND cable to the ground terminal at the

RRU3931E bottom and the M8 OT terminal at the other end to the external ground bar. See

Figure 1-27.

Figure 1-27 Installing a PGND cable

OT terminal (M8, 6

mm2)

Yellow and green

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

32

RRU3931E

Installation Guide

NOTE

When installing the PGND cable, crimp OT terminals in correct positions. See Figure 1-28.

Figure 1-28 Crimping an OT terminal

----End

Follow-up Procedure

1. Route the cable by following instructions provided in section 1.7.1 Cabling

Requirements"1.7.1 Cabling Requirements" and then use cable ties to bind the cable.

2. Attach labels to the installed cables by following instructions in 1.11.6 Attaching a Sign

Plate Label.

1 RRU3931E Installation Guide

1.7.9 (Optional) Installing an RF Jumper

This section describes how to install an RF jumper for a RRU3931E. This operation is

required when the RRU3931E uses an external antenna.

Context

l The cable route depends on actual requirements.

l The RRU3931E RF jumper can connect the RRU3931E and external antenna system, or

connect the RRU3931E and GPS antenna system. The following section takes installing

an RF jumper between the RRU3931E and external antenna system as an example.

NOTE

It is good practice to use an RF jumper when installing the external antenna system for the

RRU3931E. If the RRU3931E RF jumper is not used, install the antenna on the RRU3931E

through the normal type N female connector, and waterproof the connector by following

instructions provided in Step 5.

Procedure

Step 1 Remove the plastic waterproof cap from the RF port. See Figure 1-29.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

33

RRU3931E

Installation Guide

Step 2 Connect the Smart-type N male connector at one end of the RF jumper to the RF port on the

1 RRU3931E Installation Guide

Figure 1-29 Removing a waterproof cap

RRU3931E.

When installing an RF jumper, hold tightly the metal part (in the red dotted circle in Figure

1-30) of the Smart-type N male connector and push the connector upwards. A slight crack

will be heard when the connector is properly installed. See Figure 1-30.

Figure 1-30 Installing an RF jumper

NOTICE

Do not exert force on the non-metal part, that is, the black part, as shown in Figure 1-30

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

34

RRU3931E

Installation Guide

Step 3 (Optional) If an RF port is not used, retain and waterproof the waterproof cap on the port.

1 RRU3931E Installation Guide

Figure 1-31 Waterproofing a waterproof cap

(1) Waterproof cap (2) PVC insulation tape (3) Waterproof tape

1. Verify that waterproof caps are not removed.

2. Wrap a layer of PVC insulation tape around the connector from bottom up.

3. Tightly wrap three layers of waterproof tape around the connector, with the first layer

from bottom up, the second layer from top down, and the third layer from bottom up.

4. Tightly wrap three layers of PVC insulation tape around the connector with the first layer

from bottom up, the second layer from top down, and the third layer from bottom up.

5. Bundle cable ties 3 mm to 5 mm away from the end of insulating tape.

NOTE

l Before wrapping waterproof tape, stretch the tape evenly until the length of the tape is twice its

original length.

l Do not stretch the PVC insulation tape before wrapping.

l Wrap each layer of tape around the connector tightly and neatly, and ensure that each layer of tape

overlaps more than 50% of the preceding layer

l Ensure that the side with adhesive tape is covered on the wrapped tape.

l When cutting off the cable tie, reserve a surplus length of 3 mm to 5 mm.

Step 4 Connect the type N male connector at the other end of the RRU3931E RF jumper to the RF

port on the external antenna system. See Figure 1-32.

Figure 1-32 Connecting an RF jumper to the external antenna system

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

35

RRU3931E

Installation Guide

Step 5 Wrap the connector of the RF jumper. See Figure 1-33.

1 RRU3931E Installation Guide

Figure 1-33 Wrapping the connector of an RF jumper

(1) PVC insulation tape (2) Waterproof tape

1. Wrap a layer of PVC insulation tape around the connector from bottom up.

2. Tightly wrap three layers of waterproof tape around the connector, with the first layer

from bottom up, the second layer from top down, and the third layer from bottom up.

3. Tightly wrap three layers of PVC insulation tape around the connector, with the first

layer from bottom up, the second layer from top down, and the third layer from bottom

up.

4. Bundle cable ties 3 mm to 5 mm away from the end of the PVC insulation tape.

NOTE

l Before wrapping waterproof tape, stretch the tape evenly until the length of the tape is twice its

l Do not stretch the PVC insulation tape before wrapping.

l Wrap each layer of tape around the connector tightly and neatly, and ensure that each layer of tape

l Ensure that the side with adhesive tape is covered on the wrapped tape.

l When cutting off the cable tie, reserve a surplus length of 3 mm to 5 mm.

----End

Follow-up Procedure

1. Route the cable by following instructions provided in section 1.7.1 Cabling

Requirements"1.7.1 Cabling Requirements" and then use cable ties to bind the cable.

2. Attach labels to the installed cables by following instructions in 1.11.6 Attaching a Sign

Plate Label.

original length.

overlaps more than 50% of the preceding layer

1.8 (Optional)Replacing the Internal Antenna with External Antennas

This section describes how to replace the RRU3931E internal antenna with external antennas.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

36

RRU3931E

Installation Guide

Procedure

Step 1 Remove the RRU3931E antenna connector.

1 RRU3931E Installation Guide

When removing a RRU3931E antenna connector, hold tightly the metal parts (red-marked

parts in Figure 1-34) of the antenna terminals, and pull down the terminals.

Figure 1-34 Removing the antenna connector

Step 2 Remove the screws from the antenna.

1. Use an M4 hex key to loosen the three M4x14 screws at the bottom of the RRU3931E.

2. Push the RRU3931E antenna downwards, as shown in Figure 1-35.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

37

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

Figure 1-35 Removing screws

Step 3 Connect the Smart-type N male connector at one end of the RF jumper to the RF port on the

RRU3931E.

When installing an RF jumper, hold tightly the metal part (in the red dotted circle in Figure

1-36) of the Smart-type N male connector and push the connector upwards. A slight crack

will be heard when the connector is properly installed. See Figure 1-36.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

38

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

Figure 1-36 Installing an RF jumper

NOTICE

Do not exert force on the non-metal part, that is, the black part, as shown in Figure 1-36

Step 4 (Optional) If an RF port is not used, retain and waterproof the waterproof cap on the port.

Figure 1-37 Waterproofing a waterproof cap

(1) Waterproof cap

(2) PVC insulation tape (3) Waterproof tape

1. Verify that waterproof caps are not removed.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

39

RRU3931E

Installation Guide

Step 5 (Optional) If a normal type N female connector is used for the antenna to be installed, perform

1 RRU3931E Installation Guide

2. Wrap a layer of PVC insulation tape around the connector from bottom up.

3. Tightly wrap three layers of waterproof tape around the connector, with the first layer

from bottom up, the second layer from top down, and the third layer from bottom up.

4. Tightly wrap three layers of PVC insulation tape around the connector with the first layer

from bottom up, the second layer from top down, and the third layer from bottom up.

5. Bundle cable ties 3 mm to 5 mm away from the end of insulating tape.

NOTE

l Before wrapping waterproof tape, stretch the tape evenly until the length of the tape is twice its

original length.

l Do not stretch the PVC insulation tape before wrapping.

l Wrap each layer of tape around the connector tightly and neatly, and ensure that each layer of tape

overlaps more than 50% of the preceding layer

l Ensure that the side with adhesive tape is covered on the wrapped tape.

l When cutting off the cable tie, reserve a surplus length of 3 mm to 5 mm.

Step 4 to Step 5.

Step 6 (Optional) If the DIN-type female connector is used for the antenna to be installed, perform

the following steps:

1. Connect the DIN male and N female connector to the RF port of the external antenna

system.

2. Connect the type N male connector at one end of the RF jumper of the RRU3931E to the

DIN male and N female connector.

3. Waterproof the port connecting the DIN male and N female connector and the external

antenna system and the port connecting the RF jumper of the RRU3931E and the DIN

male and N female connector. See Figure 1-38.

Figure 1-38 Waterproofing the ports

(1) PVC insulation tape

(2) Waterproof tape

a. Wrap a layer of PVC insulation tape around the connector from bottom up.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

40

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

b. Tightly wrap three layers of waterproof tape around the connector, with the first

layer from bottom up, the second layer from top down, and the third layer from

bottom up.

c. Tightly wrap three layers of PVC insulation tape around the connector, with the first

layer from bottom up, the second layer from top down, and the third layer from

bottom up.

d. Bundle cable ties 3 mm to 5 mm away from the end of the PVC insulation tape.

NOTE

– Before wrapping waterproof tape, stretch the tape evenly until the length of the tape is twice its

original length.

– Do not stretch the PVC insulation tape before wrapping.

– Wrap each layer of tape around the connector tightly and neatly, and ensure that each layer of

tape overlaps more than 50% of the preceding layer

– Ensure that the side with adhesive tape is covered on the wrapped tape.

– When cutting off the cable tie, reserve a surplus length of 3 mm to 5 mm.

----End

Follow-up Procedure

Route the cable by following instructions provided in section

1.7.1 Cabling Requirements, and then use cable ties to bind the cable.

1.9 Checking the Hardware Installation

This section describes how to check the hardware installation after a RRU3931E is installed.

Table 1-4 provides the checklist for the RRU3931E hardware installation.

Table 1-4 RRU3931E hardware installation checklist

SN

1 The installation position conforms to the engineering drawing and meets the

2 The RRU3931E is securely installed, and the screws are tightened.

3 In wall-mounted scenarios, the mounting holes on the mounting bracket are

Item

clearance requirements. Sufficient space is reserved for equipment

maintenance.

well aligned with those of the expansion bolts. In addition, the mounting

bracket is secured on the wall evenly and steadily.

4 In pole-mounted scenarios, the mounting bracket is secured on the pole.

5 The angle adjustment error of the RRU3931E is less than 3° in the horizontal

direction and is not more than 3° in the vertical direction.

6 Vacant cable troughs in both maintenance cavities are covered with

waterproof blocks, and the maintenance cavity covers are fastened.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

41

RRU3931E

Installation Guide

SN Item

7 None of power cables and PGND cables are short-circuited, reversely

connected, damaged, or broken.

8 Power cables and PGND cables are separately bound from other cables.

9 All modules are connected using equipotential cables and then connected to

the closest ground bar by using PGND cables.

10 The connectors of each signal cable are intact and securely linked, and these

cables are not damaged or broken.

11 Labels are correct, legible, and complete at both ends of each cable.

1.10 Performing a Power-On Check

This section describes the procedure for performing a power-on check on a RRU3931E.

1 RRU3931E Installation Guide

Context

Figure 1-39 shows the RRU3931E power-on check procedure.

Figure 1-39 Power-on check

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

42

RRU3931E

Installation Guide

Procedure

Step 1 Check that the cables are correctly connected.

Step 2 Check that the input voltage of the RRU3931E is 110 V AC to 240 V AC, and the frequency

ranges from 50 Hz to 60 Hz.

Step 3 Power on the RRU3931E. Wait 3 to 5 minutes and then observe the indicator status of the

RRU3931E. If the RUN indicator blinks (on for 1s and off for 1s) and the ALM indicator is

off, the RRU3931E is working properly.

NOTE

l A RRU3931E takes about 3 minutes to complete the startup procedure, during which the indicator

status is negligible.

l During a startup, a RRU3931E reads and writes the flash memory and therefore the indicators

blinking quickly may blink irregularly for 1s to 2s, which does not affect services.

----End

1.11 References

1 RRU3931E Installation Guide

This section describes reference information and common operations involved during

installation.

1.11.1 Assembling a Shielded RJ45 Connector and an Ethernet Cable

This section describes how to assemble a shielded RJ45 connector and an Ethernet cable. A

straight-through cable is used as an example.

Context

Figure 1-40 shows the components of an RJ45 connector and an Ethernet cable.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

43

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

Figure 1-40 Components of an RJ45 connector and an Ethernet cable

Procedure

Step 1 Remove the outer jacket (25 mm) of the Ethernet cable, tip the braided layer outwards evenly,

(1) Core wire (2) Aluminum foil (3) Braided layer

(4) Outer jacket (5) RJ45 connector -

and cut off the aluminum foil and guard space. See Figure 1-41

NOTICE

l Do not damage the shield layer when removing the jacket.

l Do not damage the insulation layer of the Ethernet cable when removing the shield layer.

Figure 1-41 Removing the jacket of an Ethernet cable

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

44

RRU3931E

Installation Guide

Step 2 Sequence the twisted pair wires neatly by color, and cut the wire end evenly, with a remaining

1 RRU3931E Installation Guide

length of 16 mm. See Figure 1-42.

Figure 1-42 Arranging twisted pair wires

Table 1-5 Pin assignment

Pin SN

Wire Color

1 White and orange

2 Orange

3 White and green

4 Blue

5 White and blue

6 Green

7 White and brown

8 Brown

Step 3 Insert the sequenced twisted pair wires into the RJ45 connector. See Figure 1-43.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

45

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

Figure 1-43 Inserting wires into the RJ45 connector

NOTICE

l When inserting the wires, ensure that the braided layer that was tipped outwards has

inserted inside the connector.

l Observe the side or front of the RJ45 connector to ensure that the core wires are inserted to

the bottom of the RJ45 connector.

Step 4 Use a crimping tool to crimp the connector. See Figure 1-44.

Figure 1-44 Crimping the connector

Step 5 Use a cable cutter to evenly cut off the protruding braided layer of the connector along the

wire holder. See Figure 1-45

Figure 1-45 Cutting off the excess braided layer

----End

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

46

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

1.11.2 Checking the Appearance of Metal Contact Strips

This topic describes how to check the metal contact strips and how to check whether an

assembled RJ45 connector is qualified.

Context

l To ensure proper contact between the crimped parts and the core wires, the heights and

sizes of the metal contact strips must be uniform and standard.

l The metal contact strips must be parallel to each other, with an offset less than 5°. The

top margin of a strip must be parallel to the axis of the connector, with an offset less than

10°.

l To ensure expedite conduction, the surface of the metal contact strips must be clean.

l The metal contact strips must be in good contact with the RJ45 socket. The plastic septa

must remain intact and must be aligned properly.

l The soldering edge of a metal contact strip must surpass the ends of the core wires. The

ends of the core wires must be in contact with the edge of the RJ45 trough. In principle,

the distance between them must be less than 0.5 mm (0.02 in.).

Procedure

Step 1 Hold the crimped connector, with the front side facing you, and check whether the metal

contact strips are of the same height. In principle, the height is 6.02 mm (0.237 in.) ± 0.13 mm

(0.005 in.). If a measuring tool is not available, you can compare the connector with a

standard connector. Figure 1-46 shows an unqualified piece, and Figure 1-47 shows a

qualified piece.

NOTE

All unqualified pieces must be crimped again.

Figure 1-46 Metal contact strips of different heights

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

47

RRU3931E

Installation Guide

Step 2 Hold an RJ45 connector and turn it by 45°. Observe the top edges of the metal contact strips.

1 RRU3931E Installation Guide

Figure 1-47 Metal contact strips of the same height

Figure 1-48 shows an unqualified piece.

Figure 1-48 Unparallel metal contact strips of different heights

Step 3 Check whether the metal contact strips are clean. If they are not clean and the dirt cannot be

removed, replace it with a new RJ45 connector. Figure 1-49 shows an unqualified piece.

Figure 1-49 Dirt on a metal contract strip

Step 4 Check whether the metal contact strips and the plastic septa are well aligned and intact. If a

part is skewed and it cannot be fixed, replace it with a new RJ45 connector. Figure 1-50

shows an unqualified piece.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

48

RRU3931E

Installation Guide

Step 5 Hold the connector, with the side facing towards you, and check whether you can see the

1 RRU3931E Installation Guide

Figure 1-50 Skew plastic septa

cross-sections of the core wires. Ensure that the ends of the core wires are in good contact

with the edge of the RJ45 trough, and that the soldering edge of a metal contact strip

surpasses the ends of the core wires and is reliably crimped with the core wires. If not, replace

it with a new RJ45 connector. Figure 1-51 shows an unqualified piece.

Figure 1-51 Core wires not in good contact with the edge of the RJ45 trough

----End

1.11.3 Testing the Connection of Assembled Cables

This topic describes how to test an assembled Ethernet cable, thus ensuring that the

connectors and wires at both ends are correctly connected. This topic illustrates how to test a

straight-through cable.

Context

Huawei provides two types of Ethernet cables: straight-through cables and crossover cables.

l Straight-through cables are connected in a one-to-one manner. They are used to connect

network adapters to equipment such as switches or hubs. Table 1-6 lists the connections

of core wires in a straight-through cable.

Table 1-6 Connections of core wires in a straight-through cable

RJ45 Connector 1

2 2 Orange Twisted

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

RJ45 Connector 2 Core Wire Color Twisted or Not

49

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

RJ45 Connector 1 RJ45 Connector 2 Core Wire Color Twisted or Not

1 1 Orange-White

6 6 Green Twisted

3 3 Green-White

4 4 Blue Twisted

5 5 Blue-White

8 8 Brown Twisted

7 7 Brown-White

l Crossover cables are connected in a crossover manner. They are used to connect network

adapters to equipment such as switches or hubs. Table 1-7 lists the connections of core

wires in a crossover cable.

Table 1-7 Connections of core wires in a straight crossover cable

RJ45 Connector 1

RJ45 Connector 2 Core Wire Color Twisted or Not

6 2 Orange Twisted

3 1 Orange-White

2 6 Green Twisted

1 3 Green-White

4 4 Blue Twisted

5 5 Blue-White

8 8 Brown Twisted

7 7 Brown-White

Figure 1-52 shows the pins of an RJ45 connector.

Figure 1-52 Pins of an RJ45 connector

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

50

RRU3931E

Installation Guide

Procedure

Step 1 Feed both connectors of the cable into the ports of the cable tester.

Step 2 After the connectors are properly inserted, turn on the tester. If the indicators from 1 to G turn

1 RRU3931E Installation Guide

on simultaneously, you can infer that the pins work normally and the wires are correctly

connected.

NOTE

Turn the switch to the S position and check whether the indicators turn on simultaneously, as shown in

Figure 1-53.

Figure 1-53 Testing the conduction and connections of wires

Step 3 Gently shake the connector and repeat Step 2 to check whether the metal contact strips are in

good contact with the core wires and Ethernet ports, as shown in Figure 1-54.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

51

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

Figure 1-54 Checking the reliability

The procedure for testing a crossover cable is the same as that for testing a straight-through

cable except for the sequence in which the indicators turn on. You need to refer to the wire

connections of a crossover cable.

The Ethernet cable is qualified if the indicators turn on in the following sequence:

At the master (left) section of the tester, the indicators turn on in the sequence of 1-8-G. At the

slave (right) section of the tester, the indicators turn on in the sequence of 3-6-1-4-5-2-7-8-G.

Otherwise, the Ethernet cable is unqualified.

NOTE

If a tester is not available, you can use a multimeter to perform a simple test, as shown in Figure 1-55.

Figure 1-55 Testing the connection of an Ethernet cable

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

52

RRU3931E

Installation Guide

----End

1 RRU3931E Installation Guide

1.11.4 Assembling a Tool-less Female Connector (Pressfit Type) and a Power Cable

This section describes the procedure for making a tool-less female connector (pressfit type)

for a RRU3931E power cable.

Context

DANGER

Strictly follow the procedure described herein to make a tool-less female connector (pressfit

type). Any incompliance may cause damage to the RRU3931E or personal injuries.

Procedure

Step 1 Unwind the required length of the power cable for different operations based on the scale. See

Figure 1-56 shows the scale for making a power cable for the RRU3931E.

Figure 1-56 RRU3931E power cable-making scale

(1) RRU3931E power cable-making scale

Figure 1-57

Figure 1-57 Determining the power cable length

Step 2 Remove the outer jacket of the power cable. See Figure 1-58

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

53

RRU3931E

Installation Guide

Step 3 Remove the outer jacket of each core wire. The length of the removed outer jacket must

1 RRU3931E Installation Guide

Figure 1-58 Removing the outer jacket of a cable

match the tool-less female connector (pressfit type). See Figure 1-59.

Figure 1-59 Removing the outer jacket of core wires

Step 4 Use PVC insulation tapes to wrap the outer jackets of the three core wires and the adjacent

section of the AC power cable. See Figure 1-60.

Figure 1-60 Insulating a power cable

NOTE

It is good practice to wrap the three core wires for 16 mm and the adjacent section of the AC power

cable section for about 10 mm.

Step 5 Assemble a tool-less female connector (pressfit type) and the three core wires. See Figure

1-61.

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

54

RRU3931E

Installation Guide

1 RRU3931E Installation Guide

Figure 1-61 Adding a tool-less female connector (pressfit type) to core wires

1. Push the sliding block on the connector outwards along the arrow direction.

2. Use an M3 Phillips torque screwdriver to loosen the two screws.

3. Use the M3 Phillips torque screwdriver to loosen the screw on the other side.

4. Insert the brown core wire into the L port, the blue core wire into the N port, and the

yellowish green core wire to the PE port.

DANGER

Ensure that the positive and negative wires of all power cables are correctly connected.

Any incorrect power cable connection (such as reverse polarity connection) may cause

damage to equipment or unexpected personal injuries.

5. Use the M3 Phillips torque screwdriver to torque the screw to 0.5 N·m.

6. Use the M3 Phillips torque screwdriver to torque the two screws on the other side to 0.5

N·m.

7. Push the sliding block back in position along the arrow direction.

8. Use cable ties to bind the core wires to the connector.

Step 6 Gently pull each core wire to check that the connections are secure. The core wires can

remain fastened under external force of 30 N. Ensure that all copper wires are inserted into the

wiring terminal sockets and no copper wire is exposed outside the connector.

----End

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

55

RRU3931E

Installation Guide

1.11.5 Small Cell Engineering Label

This section describes the content and presents the exterior of Small Cell engineering labels.

Label Content

The Small Cell engineering labels include the power label, ground label, alarm label, antenna

system label, optical transmission label, FE/GE electrical port label, and GPS label.

The labels are printed before delivery. Therefore, writing or printing is not required on site.

Table 1-8 describes the content of engineering labels.

Table 1-8 Small Cell Engineering Label Content

1 RRU3931E Installation Guide

Label Content

Power

label

Ground

label

Alarm

label

Antenna

system

label

Optical

transmiss

ion label

Small Cellx

PWR

Small Cell

PGNDx

Small Cellx

EXT-ALM

Small Cellx

DBG

Small Cellx

Small Cellx

FE/GE2

Small Cellx

FE/GE3

, ,

,

Description Corresponding port on

the base station

Label for the BTSx power

cable.

Label for the BTS ground

cable or equipotential cable.

Label for the BTSx alarm

cable.

Label for the BTSx alarm

cable.

Label for the BTSx TX/RX

antenna port.

Label for the BTSx fiber

optic cable.

PWR

EXT-ALM

DBG

, , ,

FE/GE2

FE/GE3

FE/GE

electrical

port label

GPS

label

Issue Draft A (2016-03-30) Huawei Proprietary and Confidential

Small Cellx

FE/GE0

Small Cellx

FE/GE1

Small Cellx

GPS

Copyright © Huawei Technologies Co., Ltd.

Label for the BTSx Ethernet

cable.

Label for the BTSx GPS

cable.

FE/GE0

FE/GE1

GPS

56

RRU3931E

Installation Guide

Label Structure

1 RRU3931E Installation Guide

NOTE

l In the label content, Small Cell identifies a Huawei micro base station.