Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

About This Chapter

Purpose

1 RRU3606 User Guide

1 RRU3606 User Guide

This describes hardware configuration, software installation, and routine maintenance of the

RRU3606.

Related Versions

The following table lists the product version related to this document.

Product Name

RRU3606 V400R006

Intended Audience

This document is intended for:

l Field engineers

l System engineers

Change History

Version

Related Versions

Record

01 (2008-02-25) Initial release.

Organization

1.1 Safety Information

1.2 Hardware Configuration of the RRU3606

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

1-1

1 RRU3606 User Guide

This describes the configuration of equipment and cables of the RRU3606.

1.3 Installing Hardware for the RRU3606

This describes the hardware installation, cable distribution, and installation checklist for the

RRU3606.

1.4 Maintaining the RRU3606

This describes how to maintain the RRU3606.

1-2 Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

Issue ()

1.1 Safety Information

1.1.1 Safety Precautions

This section describes certain safety precautions and helps to choose the measurement device

and testing device. Read and follow these safety precautions before installing, operating, and

maintaining Huawei devices.

Following All Safety Precautions

Before any operation, read the instructions and precautions in this document carefully to

minimize the possibility of accidents.

The Danger, Caution, and Note items in the package of documents do not cover all the safety

precautions that must be followed. They only provide the generic safety precautions for

operations.

Symbols

1 RRU3606 User Guide

DANGER

This symbol indicates that casualty or serious accident may occur if you ignore the safety

instruction.

CAUTION

This symbol indicates that serious or major injury may occur if you ignore the safety instruction.

NOTE

This symbol indicates that the operation may be easier if you pay attention to the safety instruction.

Complying with the Local Safety Regulations

When operating the device, comply with the local safety regulations. The safety precautions

provided in the documents are supplementary. You must comply with the local safety

regulations.

General Installation Requirements

The personnel in charge of installation and maintenance must be trained and master the correct

operating methods and safety precautions before beginning work.

The rules for installing and maintaining the device are as follows:

l Only the trained and qualified personnel can install, operate and maintain the device.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

1-3

1 RRU3606 User Guide

l Only the qualified specialists are allowed to remove the safety facilities, and repair the

device.

l Any replacement of the device or part of the device (including the software) or any change

made to the device must be performed by qualified or authorized personnel of Huawei.

l Any fault or error that might cause safety problems must be reported immediately to the

personnel in charge.

Grounding Requirements

The following requirements are applicable to the device to be grounded:

l Ground the device before installation and remove the ground cable after uninstallation.

l Do not operate the device in the absence of a ground conductor. Do not damage the ground

conductor.

l The unit (or system) must be permanently connected to the protection ground before

operation. Check the electrical connection of the device before operation and ensure that

the device is reliably grounded.

Safety of Personnel

Device Safety

Ensure the following:

l When lightning strikes, do not operate the device and cables.

l When lightning strikes, unplug the AC power connector. Do not use the fixed terminal or

touch the terminal or antenna connector.

NOTE

The previous two requirements are suitable for the wireless fixed terminal.

l To prevent electric shock, do not connect safety extra-low voltage (SELV) circuits to

telecommunication network voltage (TNV) circuits.

l To prevent laser radiation from injuring your eyes, never look into the optical fiber outlet

with unaided eyes.

l To prevent electric shock and burns, wear the electrostatic discharge (ESD) clothing, gloves

and wrist strap, and remove conductors such as jewelry and watch before operation.

l Before operation, the device must be secured on the floor or other fixed objects, such as

the walls and the mounting racks.

l Do not block ventilation openings while the system is running.

l When installing the panel, tighten the screw with the tool.

1-4 Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

Issue ()

1.1.2 Electricity Safety

High Voltage

DANGER

l The high voltage power supply provides power for running the system. Direct contact with

the high voltage power supply or contact through damp objects may result in fatal danger.

l Non-standard and improper high voltage operations may result in fire and electric shock.

l The personnel who install the AC facility must be qualified to perform operations on high

voltage and AC power supply facilities.

l When installing the AC power supply facility, follow the local safety regulations.

l When operating the AC power supply facility, follow the local safety regulations.

l When operating the high voltage and AC power supply facilities, use the specific tools

instead of common tools.

1 RRU3606 User Guide

l When the operation is performed in a damp environment, ensure that water is kept off the

device. If the cabinet is damp or wet, shut down the power supply immediately.

Thunderstorm

The following requirements are suitable only for the wireless base station or the device with an

antenna or GPS antenna.

DANGER

In a thunderstorm, do not perform operations on high voltage and AC power supply facilities or

on a steel tower and mast.

High Electrical Leakage

CAUTION

Ground the device before powering on the device. Otherwise, the personnel and device are in

danger.

If the "high electrical leakage" flag is stuck to the power terminal of the device, you must ground

the device before powering it on.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

1-5

1 RRU3606 User Guide

Power Cable

Do not install and remove the power cable with a live line. Transient contact between the core

of the power cable and the conductor may generate electric arc or spark, which may cause fire

or eye injury.

l Before installing or removing the power cable, turn off the power switch.

l Before connecting the power cable, ensure that the power cable and label comply with the

Fuse

CAUTION

requirements of the actual installation.

CAUTION

To ensure that the system runs safely, when a fuse blows, replace it with a fuse of the same type

and specifications.

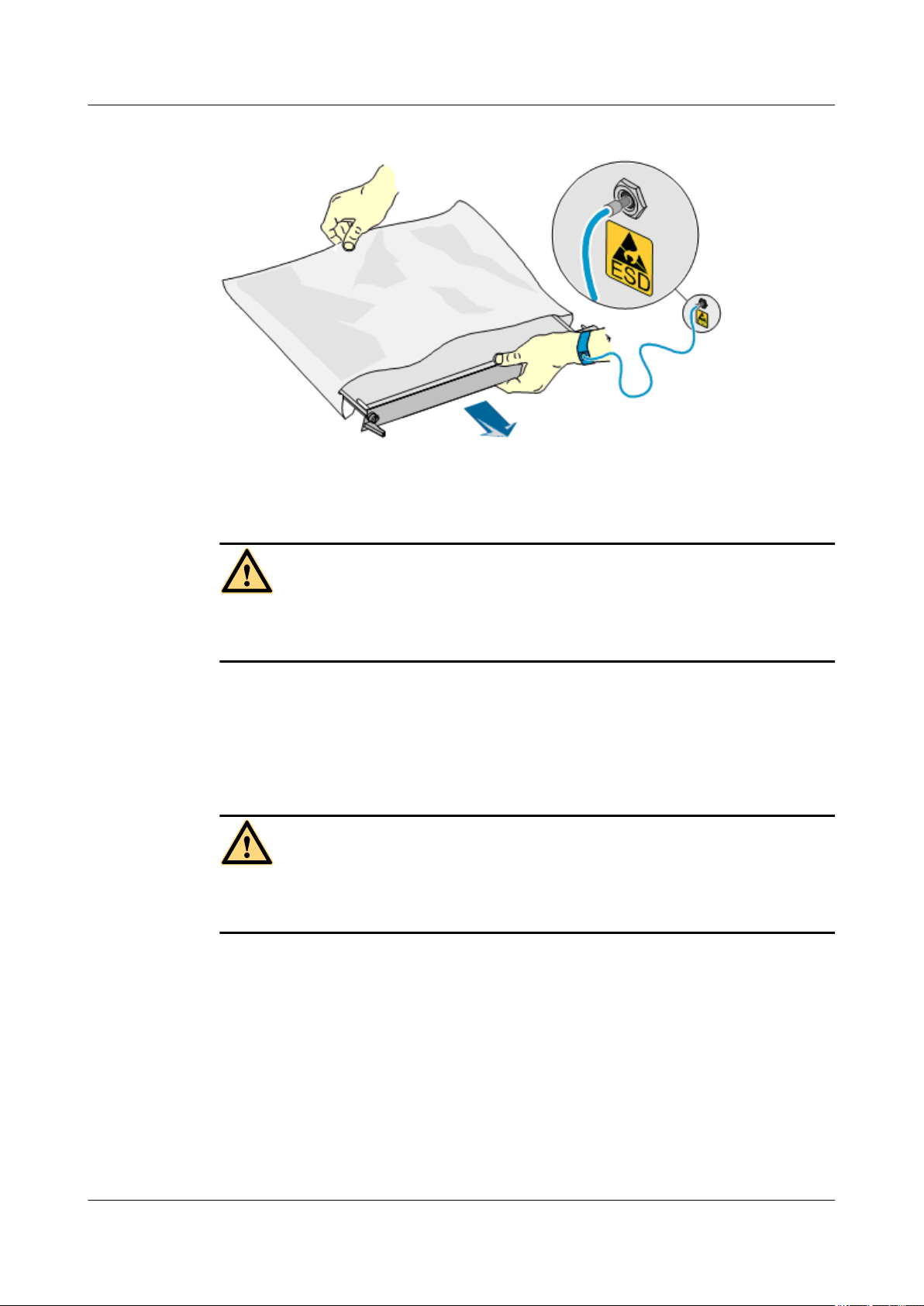

Electrostatic Discharge

CAUTION

The static electricity generated by the human body may damage the electrostatic sensitive

components on the circuit board, such as the large-scale integrated circuit (LIC).

In the following situations, the human body generates a static electromagnetic field:

l Movement of body parts

l Clothes friction

l Friction between shoes and the ground

l Holding plastic in hand

The static electromagnetic field will remain within the human body for a long time.

Before contacting the device, plug boards, circuit boards, and application specific integrated

circuits (ASICs), wear a grounded ESD wrist strap. It can prevent the sensitive components from

being damaged by the static electricity in the human body.

Figure 1-1shows how to wear an ESD wrist strap.

1-6 Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

Issue ()

Figure 1-1 Wearing an ESD wrist strap

1.1.3 Inflammable Environment

1 RRU3606 User Guide

1.1.4 Battery

Storage Battery

DANGER

Do not place the device in the environment that has inflammable and explosive air or fog. Do

not perform any operation in this environment.

Any operation of the electrical device in the inflammable environment causes danger.

DANGER

Before handling the storage battery, read the safety precautions for the handling and connection

of the storage battery.

Incorrect operation of storage batteries may cause danger. During operation, ensure the

following:

l Prevent any short-circuit.

l Prevent the electrolyte from overflowing and leakage.

Electrolyte overflow may damage the device. It will corrode the metal parts and the circuit

boards, and ultimately damage the device and cause short-circuit of the circuit boards.

General Operations

Before installing and maintaining the storage battery, ensure the following:

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

1-7

1 RRU3606 User Guide

l Use special insulation tools.

l Use eye protection devices and operate with care.

l Wear rubber gloves and an apron in case of an electrolyte overflow.

l Always keep the battery upright when moving. Do not place the battery upside down or tilt

Short-Circuit

Short-circuit of the battery may cause injury. Although the voltage of a battery is low, high

transient current generated by short-circuit will release a surge of power.

Keep metal objects away from the battery to prevent short circuit. If they have to be used,

disconnect the battery in use before performing any other operation.

Harmful Gas

it.

DANGER

l Do not use unsealed lead-acid storage batteries, because the gas emitted from it may result

in fire or device corrosion.

l Lay the storage battery horizontally and fix it properly.

The lead-acid storage battery in use will emit flammable gas. Therefore, store it in a place with

good ventilation and take precautions against fire.

High Temperature

High temperature may result in distortion, damage, and electrolyte overflow of the battery.

When the temperature of the battery exceeds 60oC, check whether there is acid overflow. If acid

overflow occurs, handle the acid immediately.

Acid

CAUTION

CAUTION

CAUTION

If the acid overflows, it should be absorbed and neutralized immediately.

1-8 Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

Issue ()

1 RRU3606 User Guide

When handling a leaky battery, protect against the possible damage caused by the acid. Use the

following materials to absorb and neutralize acid spills:

l Sodium bicarbonate (baking soda): NaHCO

l Sodium carbonate (soda): Na

Antacids must be used according to the instructions provided by the battery manufacturer.

Lithium Battery

There is danger of explosion if the battery is incorrectly replaced.

l Replace the lithium battery with the same or equivalent type recommended by the

l Dispose of the used battery according to the instructions provided by the manufacturer.

l Do not dispose of the lithium battery in fire.

1.1.5 Radiation

3

2CO3

CAUTION

manufacturer.

Electromagnetic Field Exposure

CAUTION

High power radio-frequency signals are harmful to human body.

Before installing or maintaining an antenna on a steel tower or mast with a large number of

transmitter antennas, the operator should coordinate with all parties to ensure that the transmitter

antennas are shut down.

The base transceiver station (BTS) has RF radiation (radiation hazard). Suggestions for the

installation and operation of BTSs are given in the following section. Operators are also required

to comply with the related local regulations on erecting BTSs.

l The antenna should be located in an area that is inaccessible to the public where the RF

radiation exceeds the stipulated value.

l If the areas where RF radiation exceeds the stipulated value are accessible to workers,

ensure that workers know where these areas are. They can shut down the transmitters before

entering these areas. Such areas may not exist; but if they exist, the areas must be within a

range of less than 10 m around the antennas.

l Each forbidden zone should be indicated by a physical barrier and striking sign to warn the

public or workers.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

1-9

1 RRU3606 User Guide

Laser

When handling optical fibers, do not stand close to, or look into the optical fiber outlet with

unaided eyes.

Laser transceivers or transmitters are used in the optical transmission system and associated test

tools. Because the laser that is transmitted through the optical fiber produces a small beam of

light, it has a very high power density and is invisible to human eyes. If a beam of light enters

the eye, the retina may be damaged.

Normally, staring into the end of an unterminated optical fiber or broken optical fiber with the

unaided eyes from a distance of more than 150 mm [5.91 in.] will not cause eye injury. Eyes

may, however, be damaged if an optical tool such as a microscope, magnifying glass or eye

loupe is used to stare into the bare optical fiber end.

Read the following guidelines to prevent laser radiation:

CAUTION

l Only the trained and authorized personnel can perform the operation.

l Wear a pair of eye-protective glasses when you are handling lasers or optical fibers.

l Ensure that the optical source is switched off before disconnecting optical fiber connectors.

l Never look into the end of an exposed optical fiber or an open connector if you cannot

ensure that the optical source is switched off.

l To ensure that the optical source is switched off, use an optical power meter.

l Before opening the front door of an optical transmission system, ensure that you are not

exposed to laser radiation.

l Never use an optical tool such as a microscope, a magnifying glass, or an eye loupe to look

into the optical fiber connector or end.

Read the following instructions before handling optical fibers:

l Only the trained personnel can cut and splice optical fibers.

l Before cutting or splicing an optical fiber, ensure that the optical fiber is disconnected from

the optical source. After disconnecting the optical fiber, use protecting caps to protect all

the optical connectors.

1.1.6 Working at Heights

CAUTION

When working at heights, ensure that the objects do not fall.

When working at heights, ensure that the following requirements must be met:

l The personnel who work at heights must be trained.

1-10 Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

Issue ()

l The operating machines and tools should be carried and handled safely to prevent them

l Safety measures, such as wearing a helmet and a safety belt, should be taken.

l In cold regions, warm clothes should be worn before working at heights.

l Ensure that the lifting appliances are well prepared for working at heights.

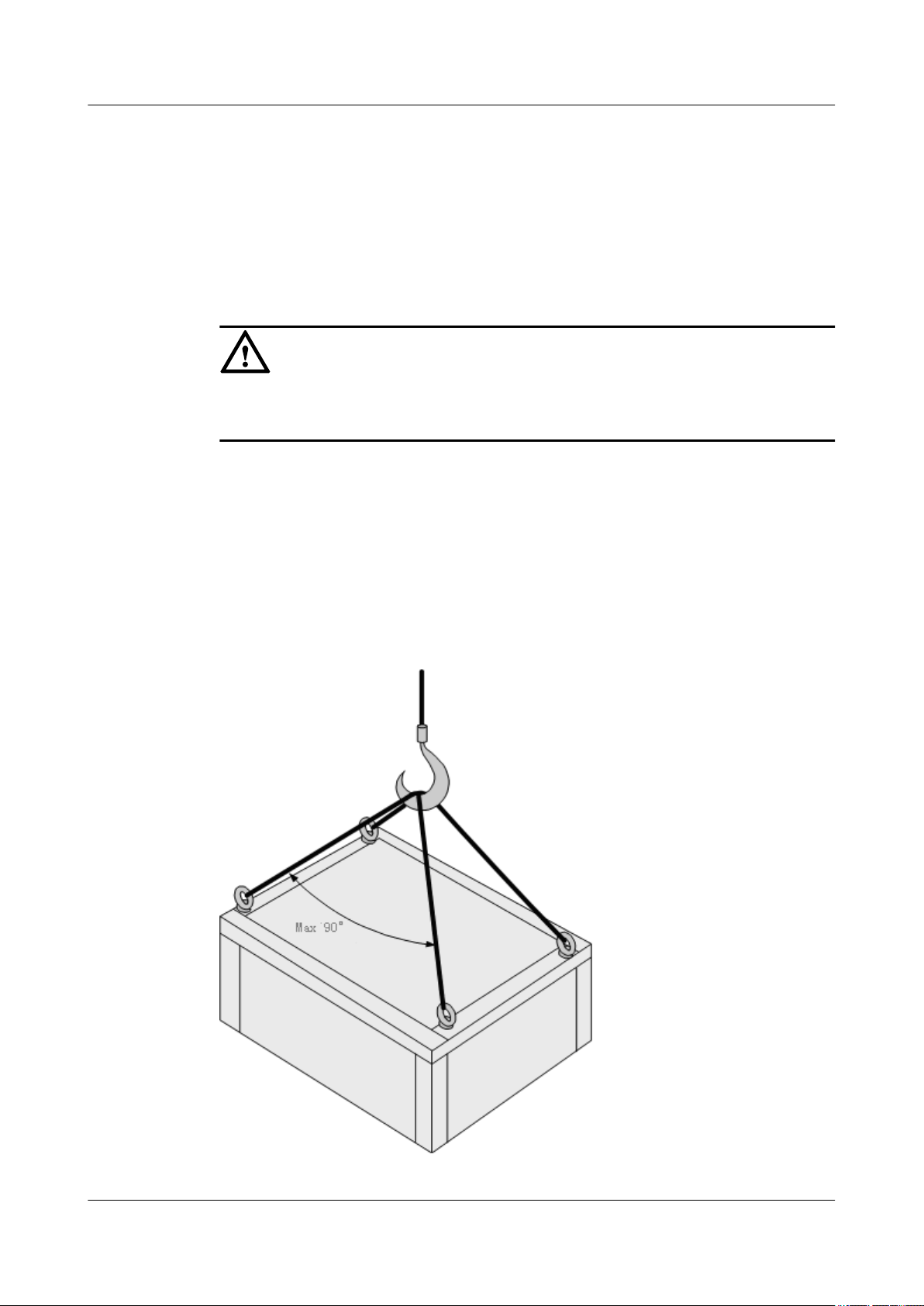

Lifting Weights

Do not access the areas under the arm of the crane and the goods in suspension when lifting

weights.

l Ensure that the operators have been trained and qualified.

l Check the weight lifting tools and ensure that they are intact.

l Lift the weight only when the weight lifting tools are firmly mounted onto the weight-

l Use a concise instruction to prevent incorrect operation.

l The angle between the two cables should be less than or equal to 90

from falling.

CAUTION

bearing object or the wall.

(See Figure 1-2).

1 RRU3606 User Guide

o

in the lifting of weights

Figure 1-2 Lifting a weight

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

1-11

1 RRU3606 User Guide

Safety Guide on Ladder Use

Checking the Ladder

l Check the ladder before using it. Check the maximum weight that the ladder can support.

l Never overload the ladder.

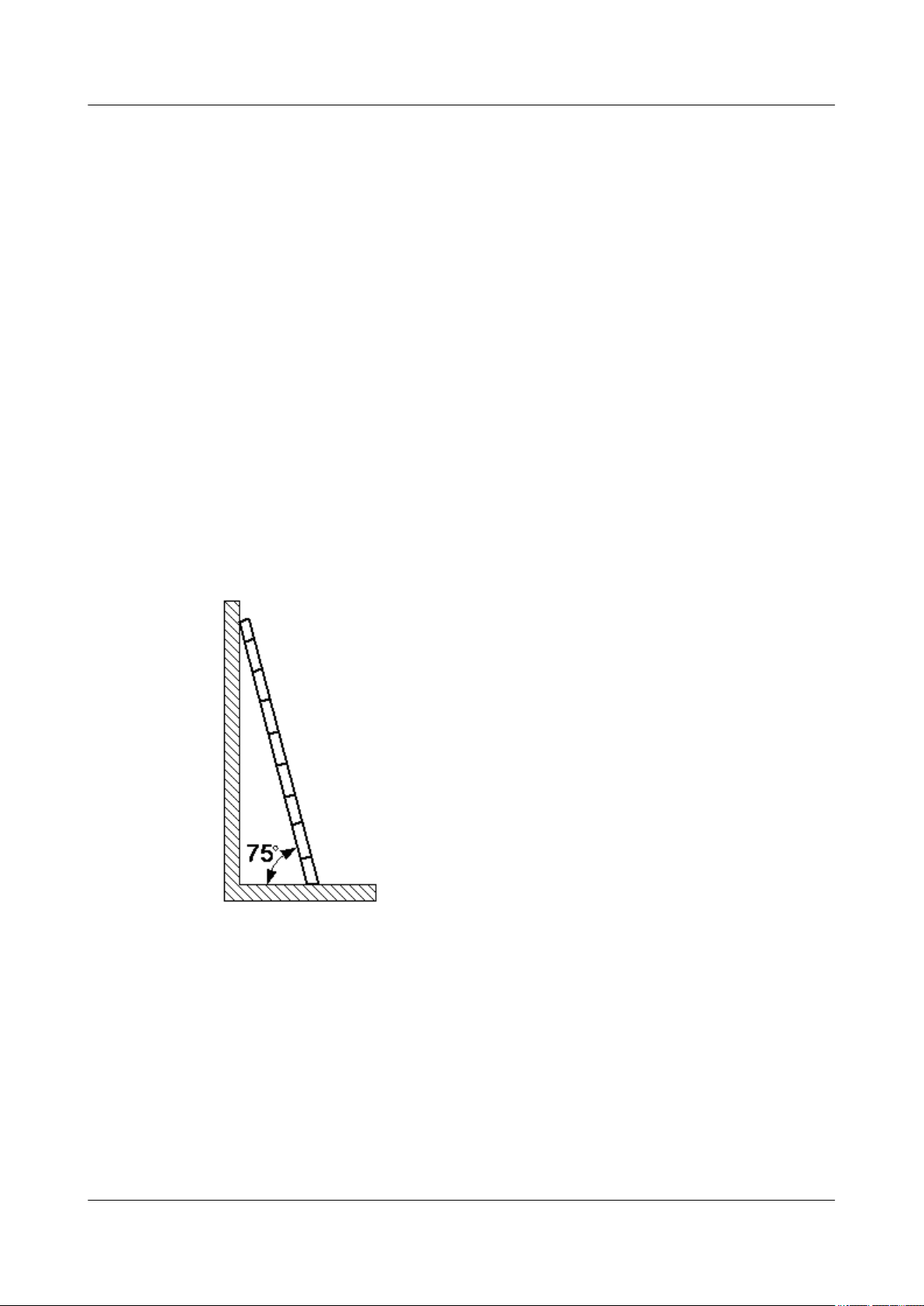

Placing the Ladder

l The slant angle is preferred to be 75

o

. The slant can be measured with the angle square or

with arms, as shown in Figure 1-3. When using a ladder, place the wider end of the ladder

on the ground and take protective measures on the base of the ladder against slippage. Place

the ladder on a stable ground.

When climbing the ladder, ensure the following:

l The gravity of the body does not shift from the edge of the ladder.

l Keep balance on the ladder before performing any operation.

l Do not climb higher than the fourth highest step of the ladder.

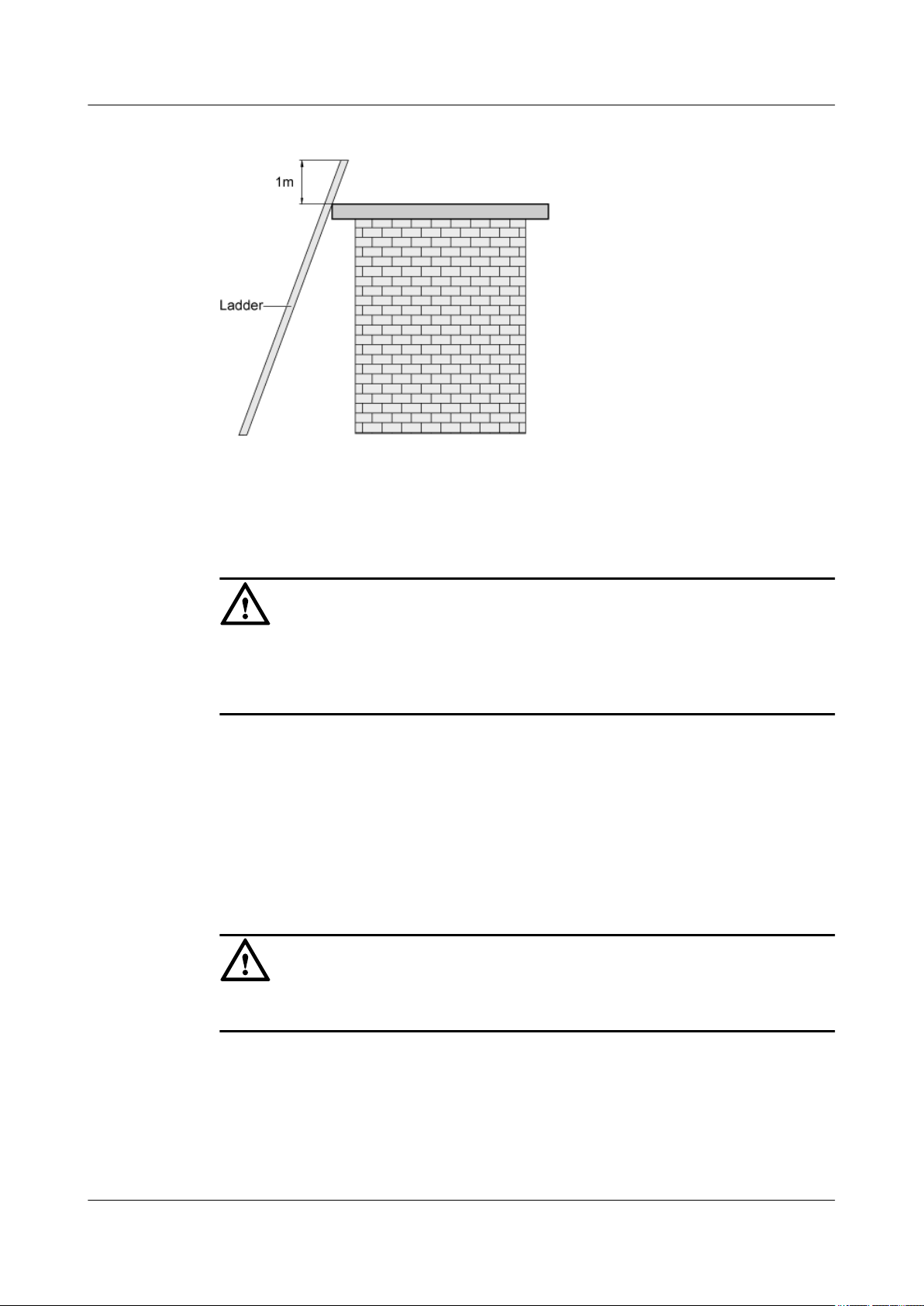

If you tend to climb to the roof, the length of the ladder should be at least one meter higher than

the eave, as shown in Figure 1-4.

Figure 1-3 Slant angle

1-12 Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

Issue ()

Figure 1-4 One meter higher than the eave

1.1.7 Mechanical Safety

Drilling

1 RRU3606 User Guide

CAUTION

Do not drill on the cabinet without permission. Inappropriate drilling on the cabinet may damage

the electromagnetic shielding and internal cables. Metal shavings from the drilling may result

in a short-circuit of the circuit board if they get into the cabinet.

l Before drilling a hole on the cabinet, remove the cables from the cabinet.

l During the drilling, wear blinkers to protect your eyes.

l During the drilling, wear the protective gloves.

l Prevent the metal shavings from getting into the cabinet. After drilling, clean the metal

shavings in time.

Handling Sharp Objects

CAUTION

When carrying the device by hand, wear the protective gloves to prevent injury by sharp objects.

Handling Fans

l When replacing a component, place the component, screw, and tool at a safe place to prevent

them from falling into the running fan.

l When replacing the ambient equipment around the fan, do not place the finger or board

into the running fan until the fan is switched off and stops running.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

1-13

1 RRU3606 User Guide

Moving Heavy Objects

Wear the protective gloves when moving heavy objects.

CAUTION

l Be careful when moving heavy objects.

l When moving the chassis outwards, be aware about the unfixed or heavy objects on the

chassis to prevent injury.

l Two persons should be available to move a chassis; one person must not move a heavy

chassis. When moving a chassis, keep your back straight and move stably to prevent a

sprain.

l When moving or lifting a chassis, hold the handle or bottom of the chassis. Do not hold the

handle of the installed modules in the chassis, such as the power module, fan module, or

board.

1.1.8 Others

Inserting and Removing a Board

CAUTION

When inserting a board, wear the ESD wrist strap or gloves. Insert the board gently to prevent

any bent pins on the backplane.

l Insert the board along the guide rail.

l Avoid contact of one board with another to prevent short-circuit or damage.

l Do not remove the active board before powering off.

l When holding a board in hand, do not touch the board circuit, components, connectors, or

connection slots.

Bundling Signal Cables

CAUTION

Bundle the signal cables separately from the strong current cables or high voltage cables.

Cabling Requirements

At a very low temperature, movement of the cable may damage the plastic skin of the cable. To

ensure the construction safety, comply with the following requirements:

1-14 Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

Issue ()

1 RRU3606 User Guide

l When installing cables, ensure that the environment temperature is above 0

l If cables are stored in the place below 0

o

C, move the cables into a place at a room

temperature and store the cables for more than 24 hours before installation.

l Move the cables with care, especially at a low temperature. Do not drop the cables directly

from the vehicle.

1.2 Hardware Configuration of the RRU3606

This describes the configuration of equipment and cables of the RRU3606.

1.2.1 RRU3606

The RRU3606 transmits and receives radio signals to realize the communication between the

wireless network and the MSs.

1.2.2 RRU3606 Cables

This describes the PGND cable, power cable, CPRI optical cable, and alarm cable of the

RRU3606.

1.2.1 RRU3606

The RRU3606 transmits and receives radio signals to realize the communication between the

wireless network and the MSs.

o

C.

The functions of the RRU3606 are described as follows:

l The RRU3606 receives RF signals from the antenna system, down-converts the signals to

IF signals, and then transmits them to the BBU3900 or the macro BTS after amplification,

analog-to-digital conversion, digital down-conversion, and matched filtering.

l The RRU3606 receives downlink baseband signals from the BBU3900 or the macro BTS,

forwards data from its cascaded RRU3606, performs filtering and data conversion, and upconverts RF signals to meet the transmitting frequency requirements.

l The RRU3606 multiplexes RX and TX signals over RF channels, enabling the RX signals

and TX signals to share the same antenna path. In addition, the RRU3606 filters the RX

signals and TX signals.

1.2.1.1 Appearance of the RRU3606

This describes the dimensions and appearance of the RRU3606.

1.2.1.2 Panels of the RRU3606

The RRU3606 has a bottom panel, cabling cavity panel, and indicator panel.

1.2.1.3 Physical Ports of the RRU3606

The physical ports of the RRU3606 are power supply ports, transmission ports, grounding ports,

and RF ports.

1.2.1.4 Technical Specifications of the RRU3606

This describes the technical specifications of the RRU3606.

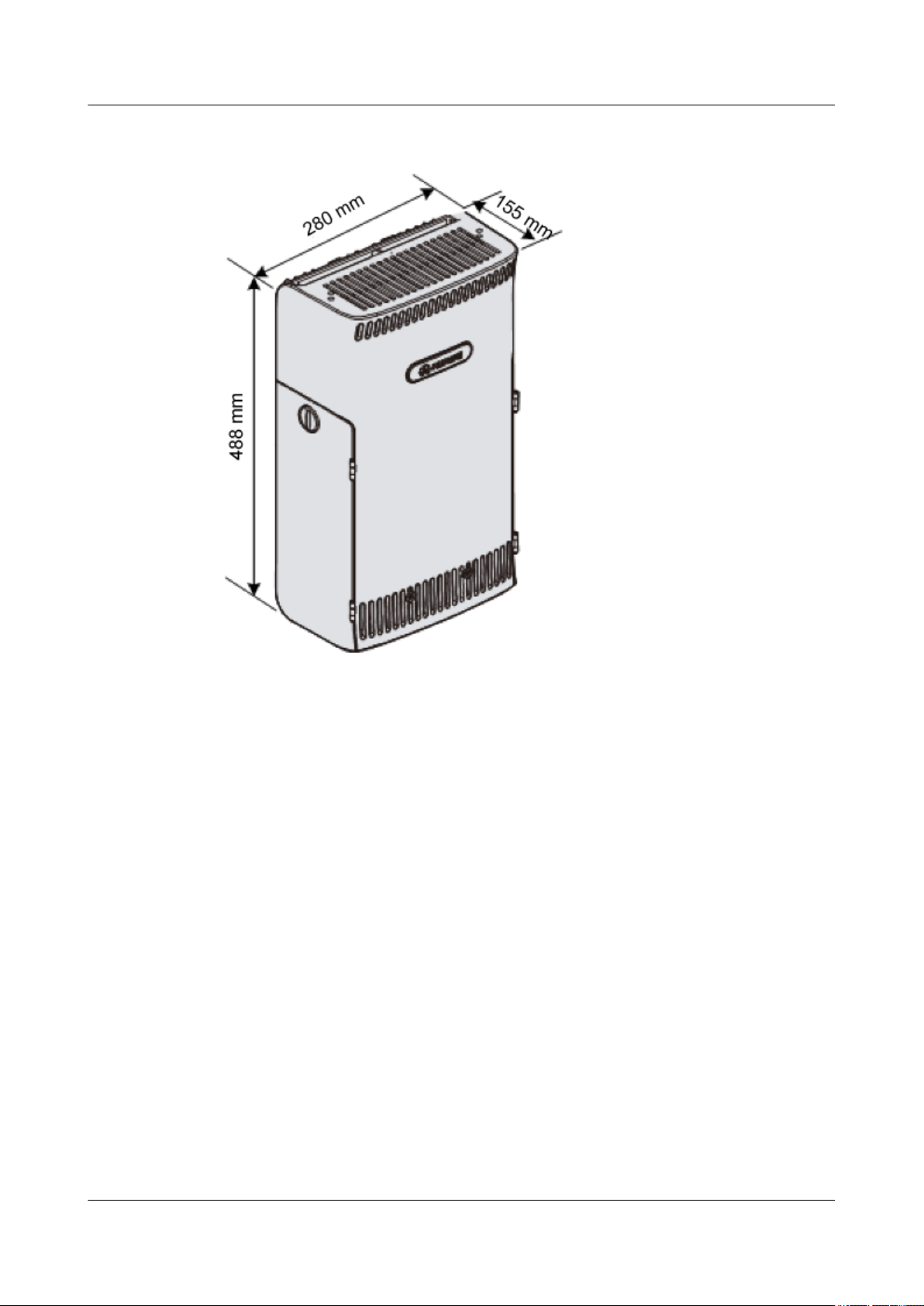

Appearance of the RRU3606

This describes the dimensions and appearance of the RRU3606.

The dimensions of the RRU3606 are as follows:

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

1-15

1 RRU3606 User Guide

l Height x Width x Depth (without the housing) = 480 mm [18.90 in.] x 270 mm [10.63 in.]

l Height x Width x Depth (with the housing) = 488 mm [19.21 in.] x 280 mm [11.02 in.] x

The RRU3606 features a modular structure with its ports at the bottom of the RRU3606 and on

the cabling cavity. Figure 1-5 and Figure 1-6 shows the appearance of the RRU3606.

x 140 mm [5.51 in.]

155 mm [6.10 in.]

1-16 Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

Issue ()

Figure 1-5 Appearance of the RRU3606 (without the housing)

1 RRU3606 User Guide

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

1-17

1 RRU3606 User Guide

Figure 1-6 Appearance of the RRU3606 (with the housing)

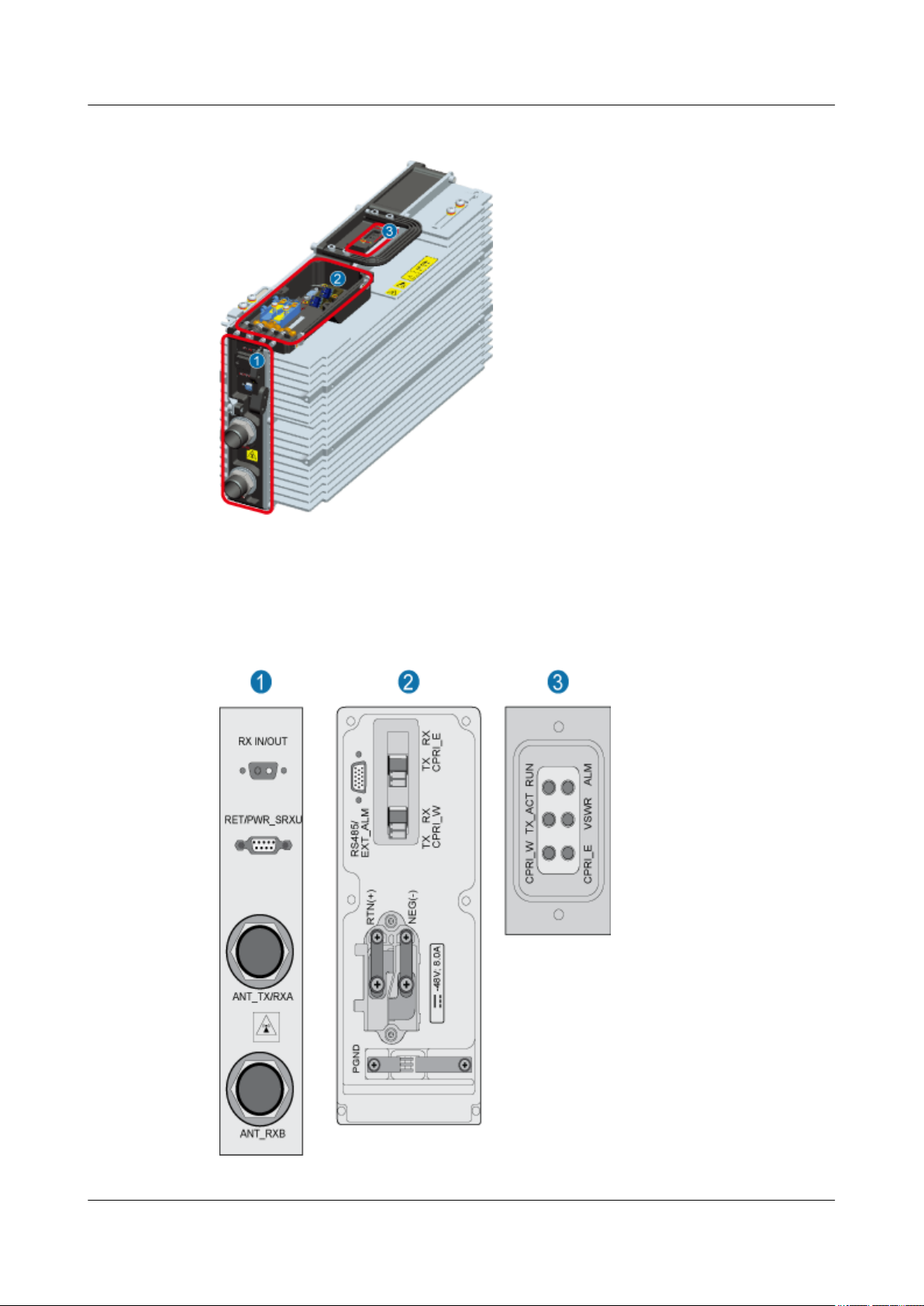

Panels of the RRU3606

The RRU3606 has a bottom panel, cabling cavity panel, and indicator panel.

Position of Panels of the RRU3606

Figure 1-7 shows the panels of the RRU3606.

1-18 Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

Issue ()

1 RRU3606 User Guide

Figure 1-7 Position of panels of the RRU3606

(1) Bottom (2) Cabling cavity (3) Indicator

Figure 1-8 shows the panels of the RRU3606.

Figure 1-8 Panels of the RRU3606

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

1-19

1 RRU3606 User Guide

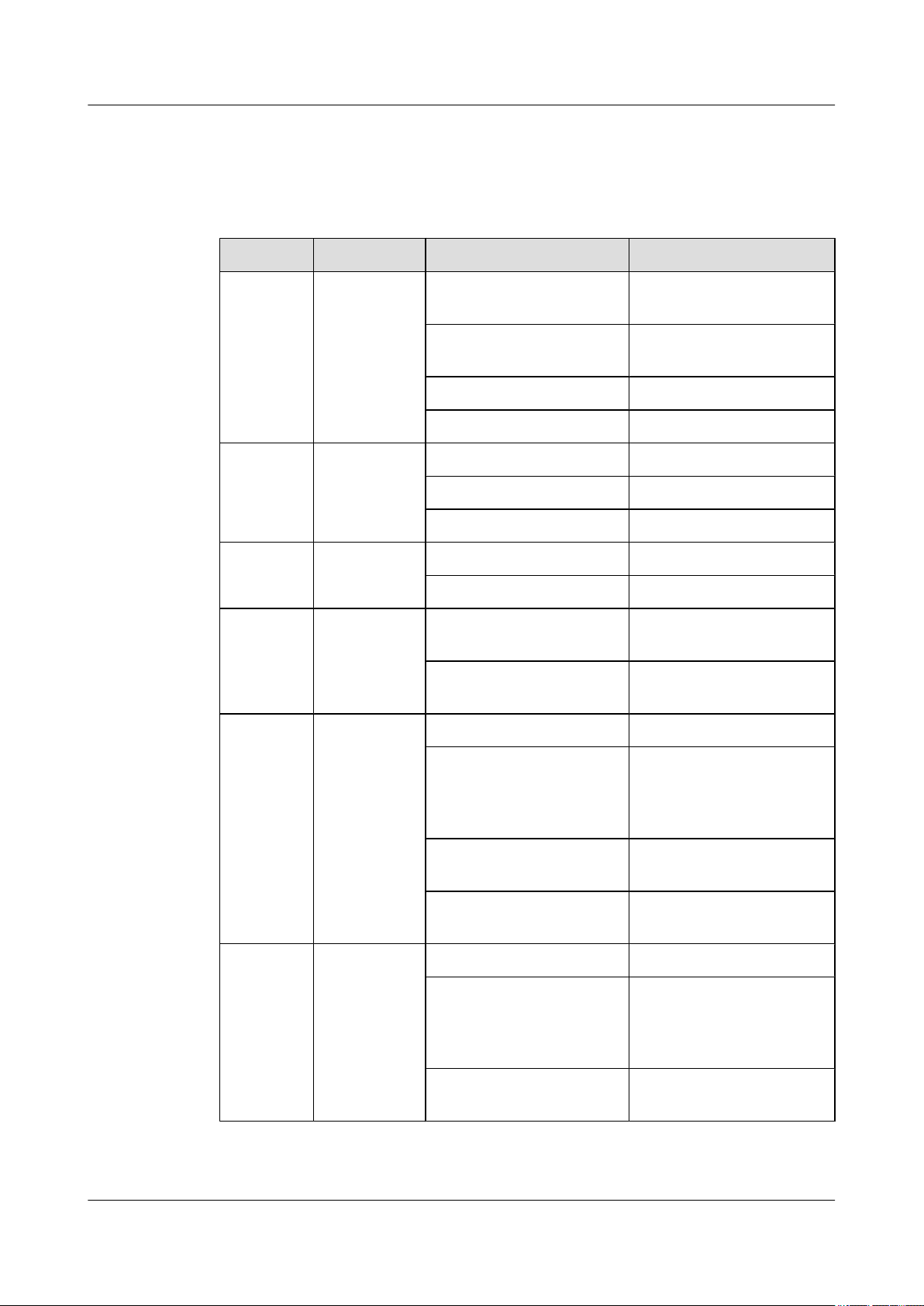

Indicators

Table 1-1 lists the indicators on the RRU3606 panel.

Table 1-1 Indicators on the RRU3606 panel

Mark Color Status Description

RUN Green ON The power input is normal,

but the board is faulty.

OFF There is no power input, or

alarms are generated.

ON for 1s and OFF for 1s The board operates normally.

ON for 0.5s and OFF for 0.5s Software is being loaded.

ALM Red ON Fatal alarms

Blinking at 0.5 Hz Minor alarms

OFF No alarm is generated.

TX_ACT Green ON The board operates normally.

OFF

VSWR Red ON Standing wave alarms are

generated.

OFF No standing wave alarm is

generated.

CPRI_W Red/green ON (green) The CPRI link is normal.

ON (red) The optical module receives

exceptional alarms, that is,

local alarms related to the

Loss of Signal (LOS).

ON for 0.5s and OFF for 0.5s

(red)

OFF The optical module is not in

CPRI_E Red/green ON (green) The CPRI link is normal.

ON (red) The optical module receives

The CPRI link is out of lock.

position or is powered off.

exceptional alarms, that is,

local alarms related to the

Loss of Signal (LOS).

ON for 0.5s and OFF for 0.5s

(red)

1-20 Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

The CPRI link is out of lock.

Issue ()

Ports

1 RRU3606 User Guide

Mark Color Status Description

OFF The optical module is not in

position or is powered off.

Table 1-2 lists the ports on the RRU3606 panel.

Table 1-2 Ports on the RRU3606 panel

Item Label on the Front Panel Description

Ports at the bottom RX_IN/OUT Reserved port

RET/PWR_SRXU Reserved port

ANT_TX/RXA Main RF transmitting/receiving

port

Ports on the

cabling cavity

Physical Ports of the RRU3606

The physical ports of the RRU3606 are power supply ports, transmission ports, grounding ports,

and RF ports.

Table 1-3 lists the physical ports of the RRU3606.

Table 1-3 Physical ports of the RRU3606

Type

Port Description QuantityConnector Type

ANT_RXB Diversity RF receiving port

RS485/EXT_ALM Alarms port

CPRI_E CPRI ports

CPRI_W

RTN(+) Power supply ports

NEG(-)

PGND PGND crimp piece

Power

supply

ports

Transmis

sion ports

Issue () Huawei Proprietary and Confidential

RTN(+) -48 V DC power

supply

NEG(-)

CPRI_E CPRI ports 1 ESFP socket

CPRI_W CPRI ports 1 ESFP socket

Copyright © Huawei Technologies Co., Ltd.

1 OT terminal

1-21

1 RRU3606 User Guide

Type Port Description QuantityConnector Type

Alarms

port

Groundin

g port

RF port ANT_TX/RXA Main

Reserved

port

NOTE

The specifications for the RRU3606 alarm port are: 0.2 kohm for the closed resistance; 51 kohms for the

open resistance.

RS485/

EXT_ALM

- - 4 -

ANT_RXB Diversity

RX_IN/OUT Reserved - -

RET/

PWR_SRXU

RS485 x1 signal

port

transmitting/

receiving port

receiving port

Reserved - -

Technical Specifications of the RRU3606

1 DB15

1 Round and waterproof

DIN connector

1 Round and waterproof

DIN connector

This describes the technical specifications of the RRU3606.

Table 1-4 lists the specifications of the RRU3606.

Table 1-4 Technical specifications of the RRU3606

Item

Voltage -48 V (-37 V DC to -60 V DC)

Power consumption

Weight The weight of the RRU3606 and housing is no more

Cabinet dimensions (height x width

x depth)

1.2.2 RRU3606 Cables

This describes the PGND cable, power cable, CPRI optical cable, and alarm cable of the

RRU3606.

Specification

≤ 300 W

than 17.5 kg [38.58 lb.].

Height x Width x Depth (with the housing): 488 mm

[19.21 in.] x 280 mm [11.02 in.] x 155 mm [6.10 in.]

1.2.2.1 PGND Cable of the RRU3606

The PGND cable ensures the grounding of the RRU3606.

1-22 Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

Issue ()

1.2.2.2 Power Cable of the RRU3606

This describes the power cable of the RRU3606. The -48 V DC power cable feeds external -48

V DC power to the RRU3606 to provide power supply for the RRU3606.

1.2.2.3 RRU3606 Optical Fibers

RRU3606 optical fibers are used for the connection between the BBU3900 and the RRU3606.

1.2.2.4 Alarm Cable of the RRU3606

The alarm cable leads one RS485 alarm signal from external devices to the RRU3606, thus

monitoring the external devices.

PGND Cable of the RRU3606

The PGND cable ensures the grounding of the RRU3606.

Structure

The green and yellow PGND cable has a cross-sectional area of 16 mm2 [0.02 in.2]. Both ends

of the cable are 2-hole OT terminals. If the PGND cable is provided by the customer, a copper-

core cable with a minimum cross-sectional area of 16 mm2 [0.02 in.2] is recommended.

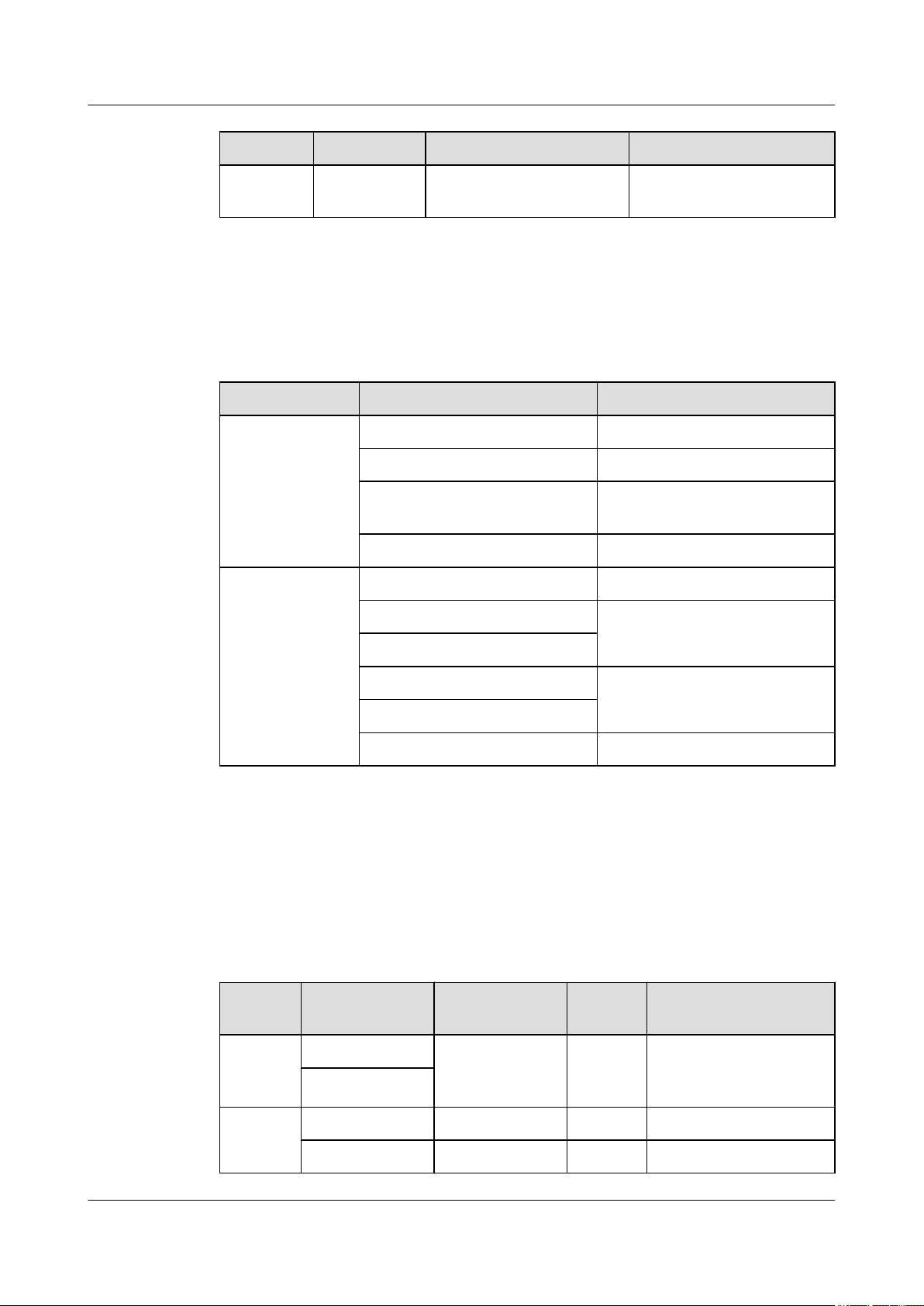

Figure 1-9 shows the structure of the PGND cable.

1 RRU3606 User Guide

Figure 1-9 Structure of the PGND cable

(1) 2-hole OT terminal

NOTE

l The OT terminals of the grounding cable are made on site.

l The color of the PGND cable is selected according to the local specifications.

Position of the Cable

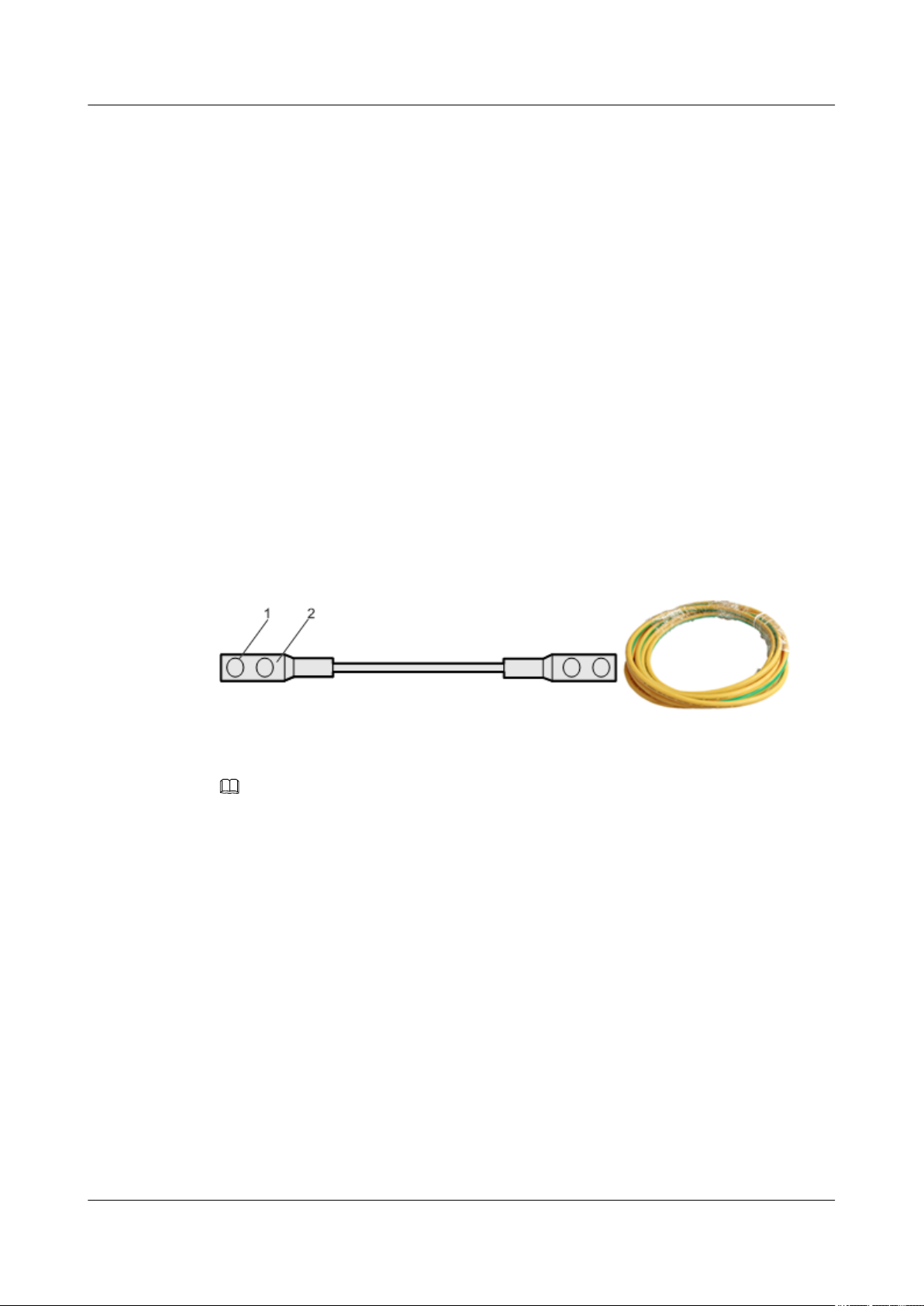

For the PGND cable of the RRU3606, one end is connected to the grounding hole on the

RRU3606, and the other end is connected to the ground nearby. Figure 1-10 shows the

connections of the PGND cables.

(2) Heat shrink tube

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

1-23

1 RRU3606 User Guide

Figure 1-10 Installation position of the PGND cable

Power Cable of the RRU3606

This describes the power cable of the RRU3606. The -48 V DC power cable feeds external -48

V DC power to the RRU3606 to provide power supply for the RRU3606.

Structure

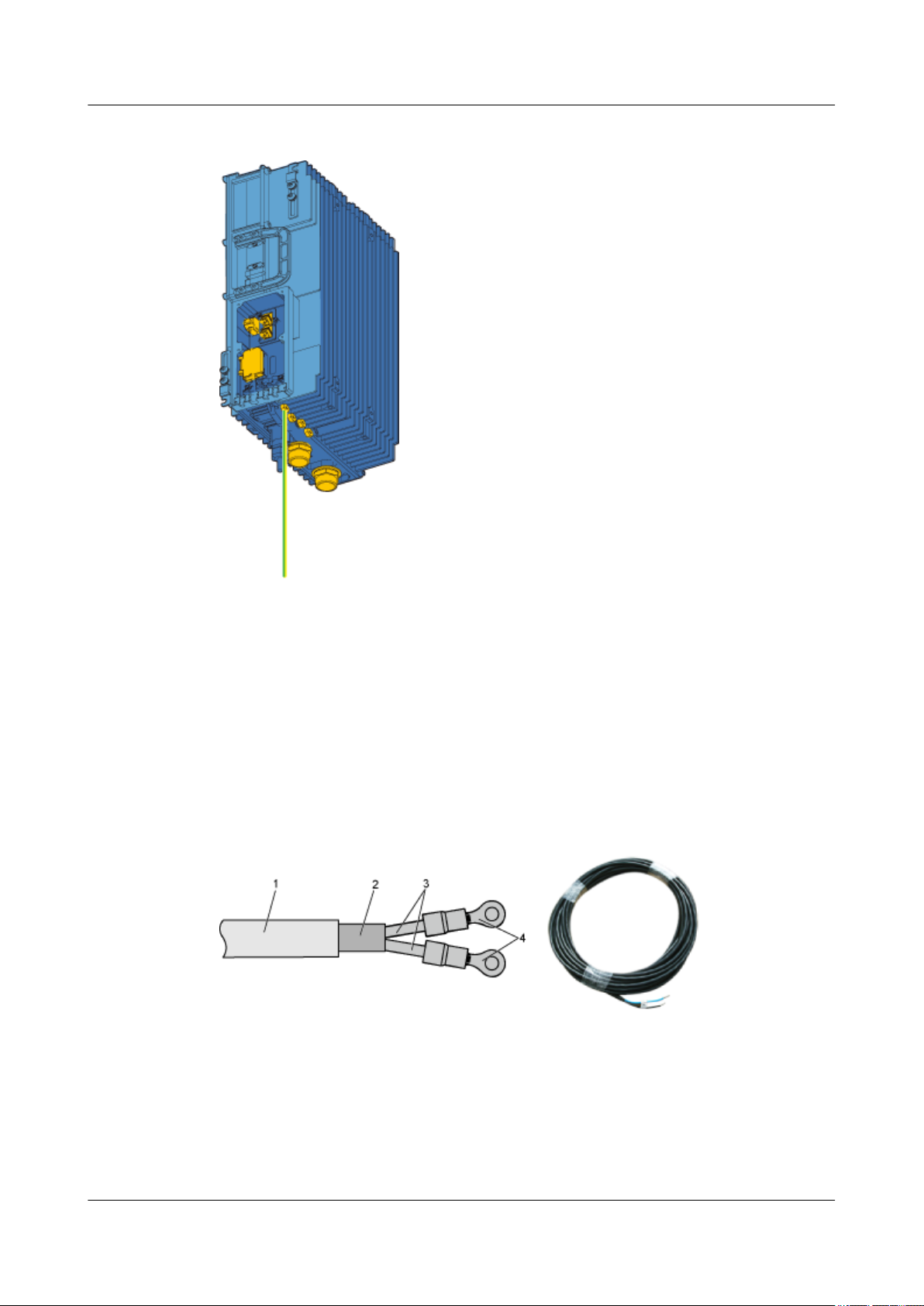

The RRU3606 uses the -48 V DC shielded power cable. One end of the cable has two OT

terminals, and the other end is bare. Figure 1-11 shows the power cable of the RRU3606.

Figure 1-11 Structure of the -48 V DC power cable

(1) -48 V DC power cable

(2) Shielding layer (3) Wire (4) OT terminal

Cable Specifications

The -48 V DC cable is a 2-wire cable, as shown in Table 1-5 and Table 1-6.

1-24 Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

Issue ()

Table 1-5 Pin assignment of the -48 V DC power cable (standard in North America)

Name Color

NEG cable Blue

RTN cable Black

Table 1-6 Pin assignment of the -48 V DC power cable (standard in Europe)

Name Color

NEG cable Blue

RTN cable Brown

Position of the Cable

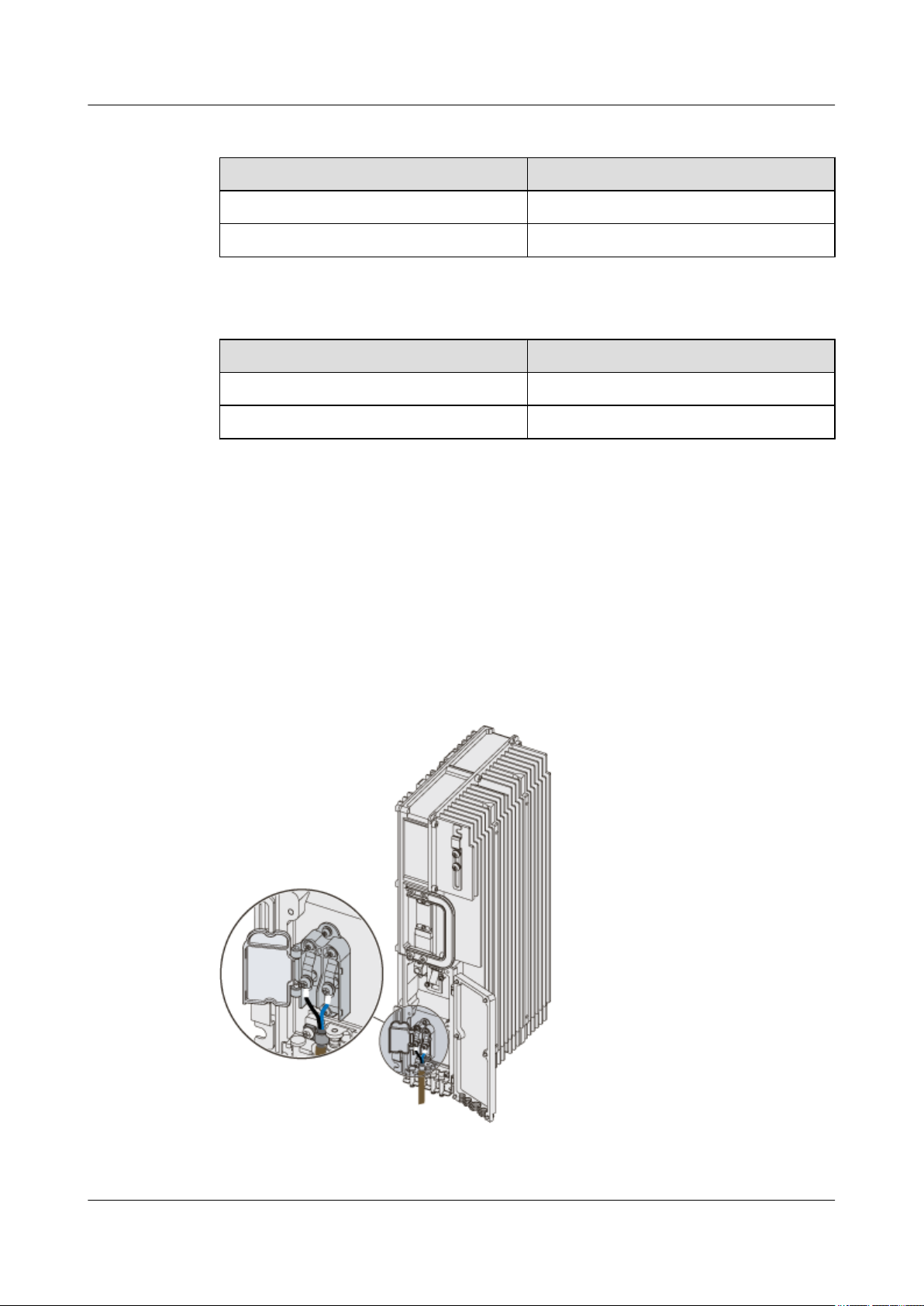

Connect the OT terminal of the blue wire of the -48 V DC power cable to the NEG (-) port on

the RRU3606 cabling cavity, and connect the black or brown wire to the RTN (+) port of the

RRU3606.

1 RRU3606 User Guide

Connect the other end of the -48 V DC power cable to the power supply system at the installation

site.

Figure 1-12 shows the installation position of the power cable on the RRU3606 side.

Figure 1-12 Installation of the power cable on the RRU3606 side

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

1-25

1 RRU3606 User Guide

RRU3606 Optical Fibers

RRU3606 optical fibers are used for the connection between the BBU3900 and the RRU3606.

Structure

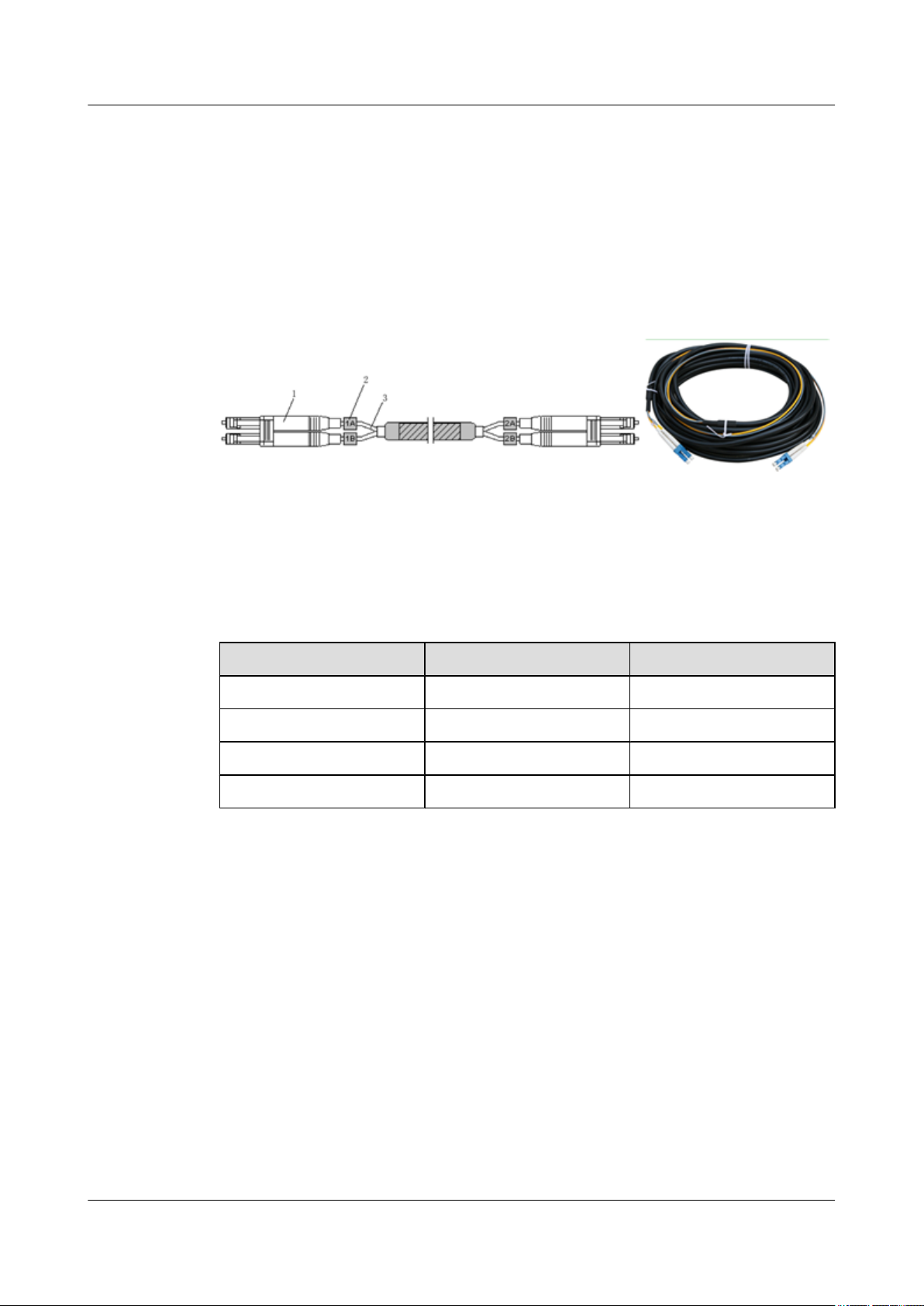

The CPRI optical cable is a multi-mode 2-wire cable with LC connectors at both ends. Figure

1-13 shows the CPRT optical fiber.

Figure 1-13 Structure of the CPRI optical fiber

(1) DLC connector (2) Label (3) Fiber tail

Cable

Table 1-7 describes the pin assignment for the fiber tails.

Table 1-7 Pin assignment for the fiber tails

Label

1A Orange RX port on the RRU3606

1B Gray TX port on the RRU3606

2A Orange TX port on the BBU3900

2B Gray RX port on the BBU3900

Position of the Cable

One end of the CPRI optical fiber is connected to the SFP port of the BBU3900 or to the ODF,

and the other end is connected to the CPRI optical port of the RRU3606. Figure 1-14 shows the

installation position of the CPRI optical fiber on the RRU3606 side.

Color Connection Position

1-26 Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

Issue ()

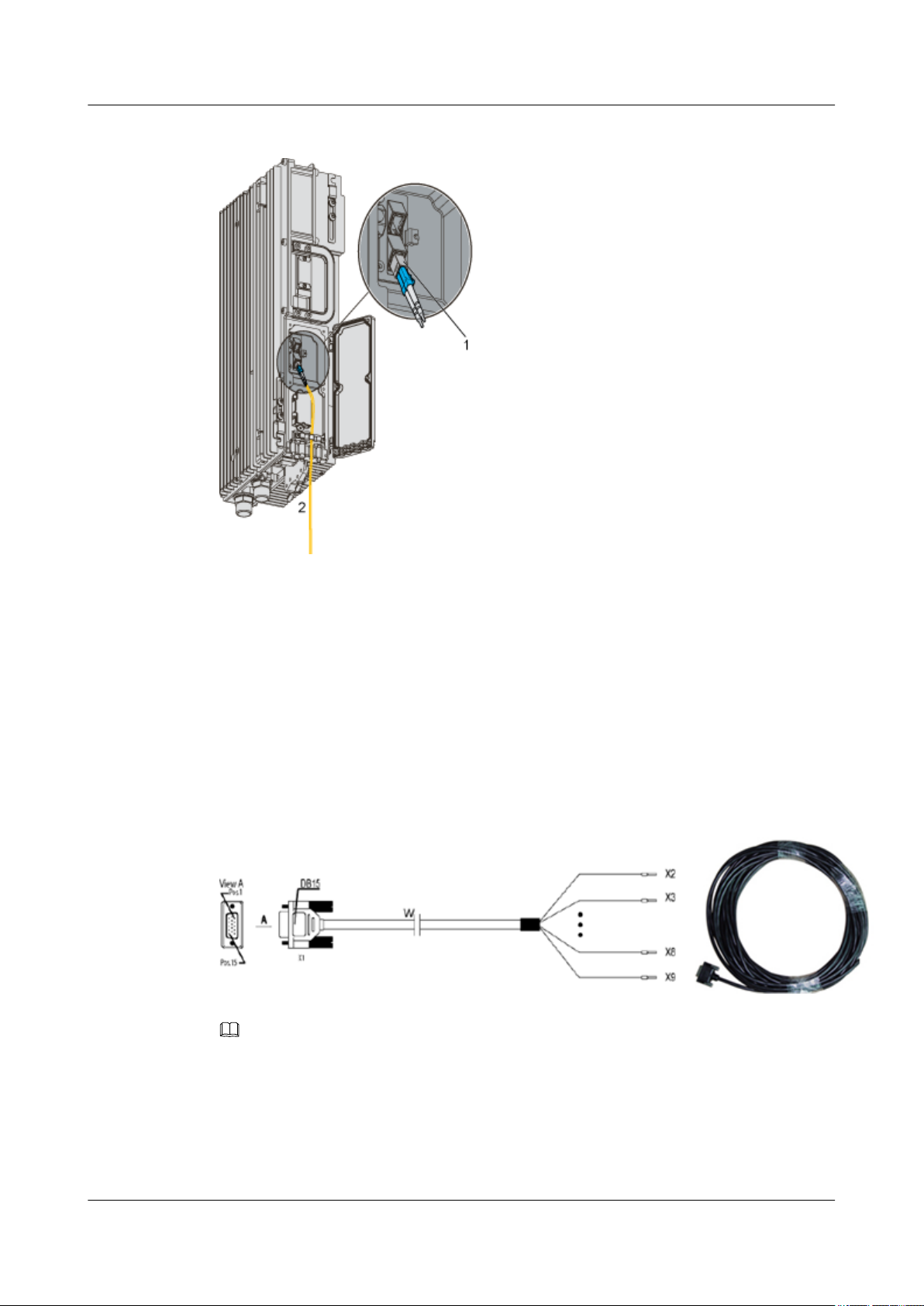

Figure 1-14 Structure of the CPRI optical cable

1 RRU3606 User Guide

(1) Pluggable optical modules (2) To the BBU3900 or the ODF

Alarm Cable of the RRU3606

The alarm cable leads one RS485 alarm signal from external devices to the RRU3606, thus

monitoring the external devices.

Structure

One end of the alarm cable is a DB15 female connector, and the other end has 8 cord end

terminals, as shown in Figure 1-15.

Figure 1-15 Structure of the alarm cable of the RRU3606

NOTE

If the connector of the alarm cable and the port of the alarm device do not match, remove the cord end

terminals. Prepare the connector on site based on the port type of the alarm device.

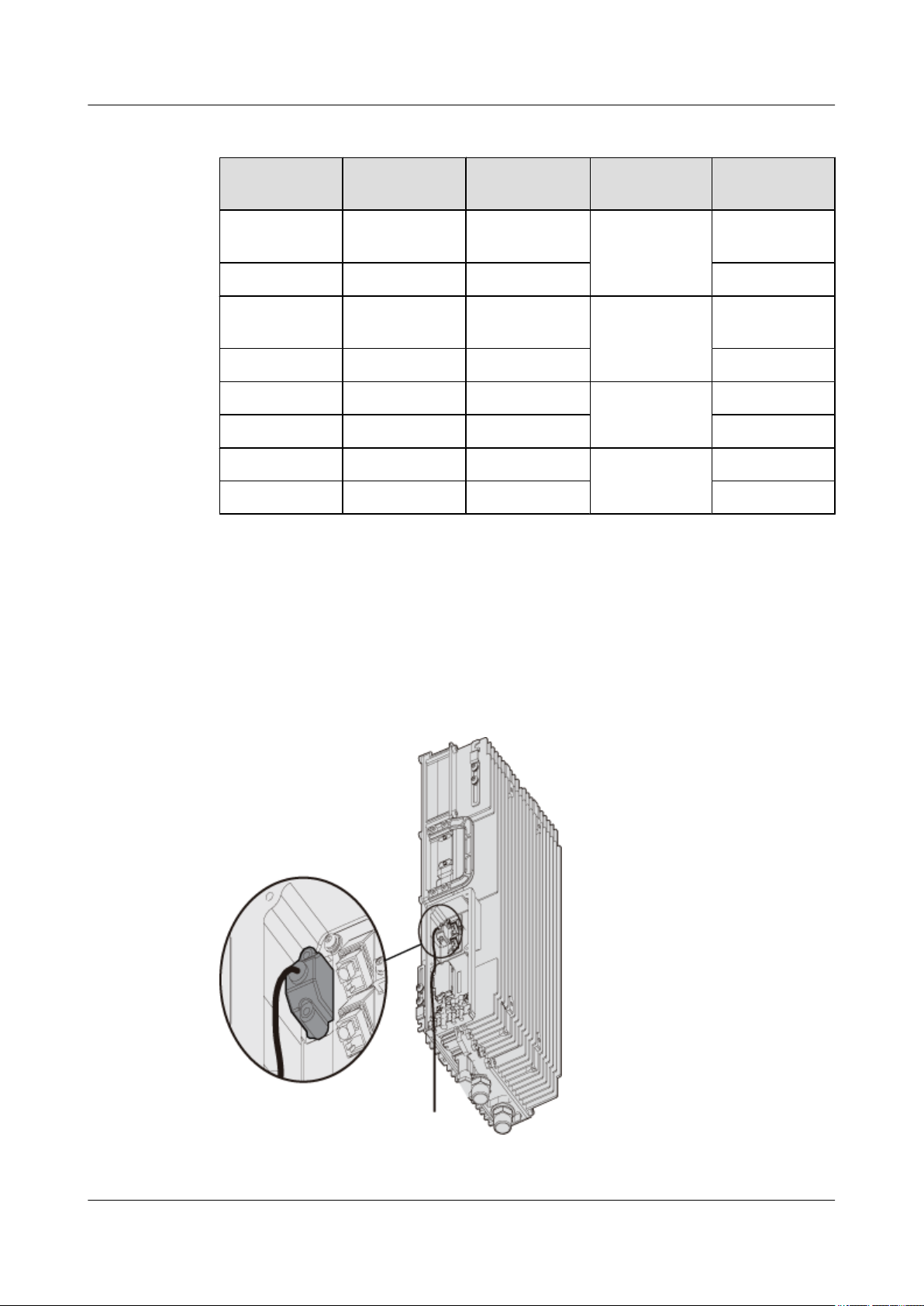

Cable

The alarm cable supports one RS485 alarm signal. Table 1-8 lists the pin assignment for the

wires of the RRU3606.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

1-27

1 RRU3606 User Guide

Table 1-8 Alarm cable of the RRU3606

X1 Pin Cord End

X1.2 X2 White/blue Twisted pair

X1.3 X3 Blue GND

X1.6 X4 White/orange Twisted pair

X1.7 X5 Orange GND

X1.10 X6 White/green Twisted pair

X1.11 X7 Green RS485_TX+

X1.13 X8 White/brown Twisted pair

X1.14 X9 Brown RS485_RX+

Position of the Cable

The DB15 male connector of the alarm cable is connected to the RS485/EXT_ALM port on the

RRU3606 cabling cavity, and the other end is connected to the port for Boolean alarm signals

on the external device. Figure 1-16 shows the installation position of the alarm cable on the

RRU3606 side.

Terminal

Wire Color Wire Type Label

SWITCH_INP

cable

cable

cable

cable

UT0+

SWITCH_INP

UT1+

RS485_TX-

RS485_RX-

Figure 1-16 Installation of the alarm cable on the RRU3606 side

1-28 Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

Issue ()

Loading...

Loading...