Page 1

RRU3268

Installation Guide

Issue

Date

HUAWEI TECHNOLOGIES CO., LTD.

Page 2

Copyright © Huawei Technologies Co., Ltd. 2013. All rights reserved.

No part of this document may be reproduced or transmitted in any form or by any means without prior written

consent of Huawei Technologies Co., Ltd.

Trademarks and Permissions

and other Huawei trademarks are trademarks of Huawei Technologies Co., Ltd.

All other trademarks and trade names mentioned in this document are the property of their respective holders.

Notice

The purchased products, services and features are stipulated by the contract made between Huawei and the

customer. All or part of the products, services and features described in this document may not be within the

purchase scope or the usage scope. Unless otherwise specified in the contract, all statements, information,

and recommendations in this document are provided "AS IS" without warranties, guarantees or representations

of any kind, either express or implied.

The information in this document is subject to change without notice. Every effort has been made in the

preparation of this document to ensure accuracy of the contents, but all statements, information, and

recommendations in this document do not constitute a warranty of any kind, express or implied.

Huawei Technologies Co., Ltd.

Address: Huawei Industrial Base

Bantian, Longgang

Shenzhen 518129

People's Republic of China

Website: http://www.huawei.com

Email: support@huawei.com

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

i

Page 3

RRU3268

Installation Guide About This Document

About This Document

Purpose

This document describes the process of installing a DC RRU3268 (referred to as RRU in this

document).

Product Versions

The following table lists the product versions related to this document.

Product Name Product Version

DBS3900 V100R008C00 and later versions

DBS3900 LTE V100R006C00 and later versions

Intended Audience

This document is intended for:

Base station installation engineers

Organization

1 Changes in the RRU3268 Installation Guide

This chapter describes the changes in the RRU3268 Installation Guide.

2 Installation Preparations

This chapter describes the reference documents, tools, and instruments that must be ready before

the installation. In addition, it specifies the skills and prerequisites that installation engineers

must have.

3 Information About the Installation

Before installing an RRU, you must be familiar with its exterior, ports, indicators, installation

options and installation clearance requirements.

4 Unpacking the Equipment

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

ii

Page 4

RRU3268

Installation Guide About This Document

This chapter describes how to unpack and check the delivered equipment to ensure that all the

materials are included and intact.

5 Installation Process

The installation process involves installing an RRU and RRU cables, checking the RRU

hardware installation, and powering on the RRU.

6 (Optional) Installing the Plastic Shells of the RRU

This section describes the procedure for installing the plastic shells of the RRU.

7 Hoisting an RRU and Related Cables onto a Tower

This section describes the procedure for hoisting an RRU and related cables onto a tower and

the precautions that must be taken.

8 Installing the RRU

This chapter describes the procedure for installing the RRU. The RRU can be installed on a pole,

U-steel, angle steel, wall, or an IFS06 . The procedure for installing the RRU varies depending

on installation options.

Conventions

9 Installing RRU Cables

This chapter describes the procedure for installing RRU cables.

10 Checking the RRU Hardware Installation

After an RRU is installed, check the hardware installation.

11 Powering On an RRU

After all the devices are installed, check the power-on status of an RRU.

12 Appendix

This section describes the procedure for adding an easy power receptacle (pressfit type)

connector.

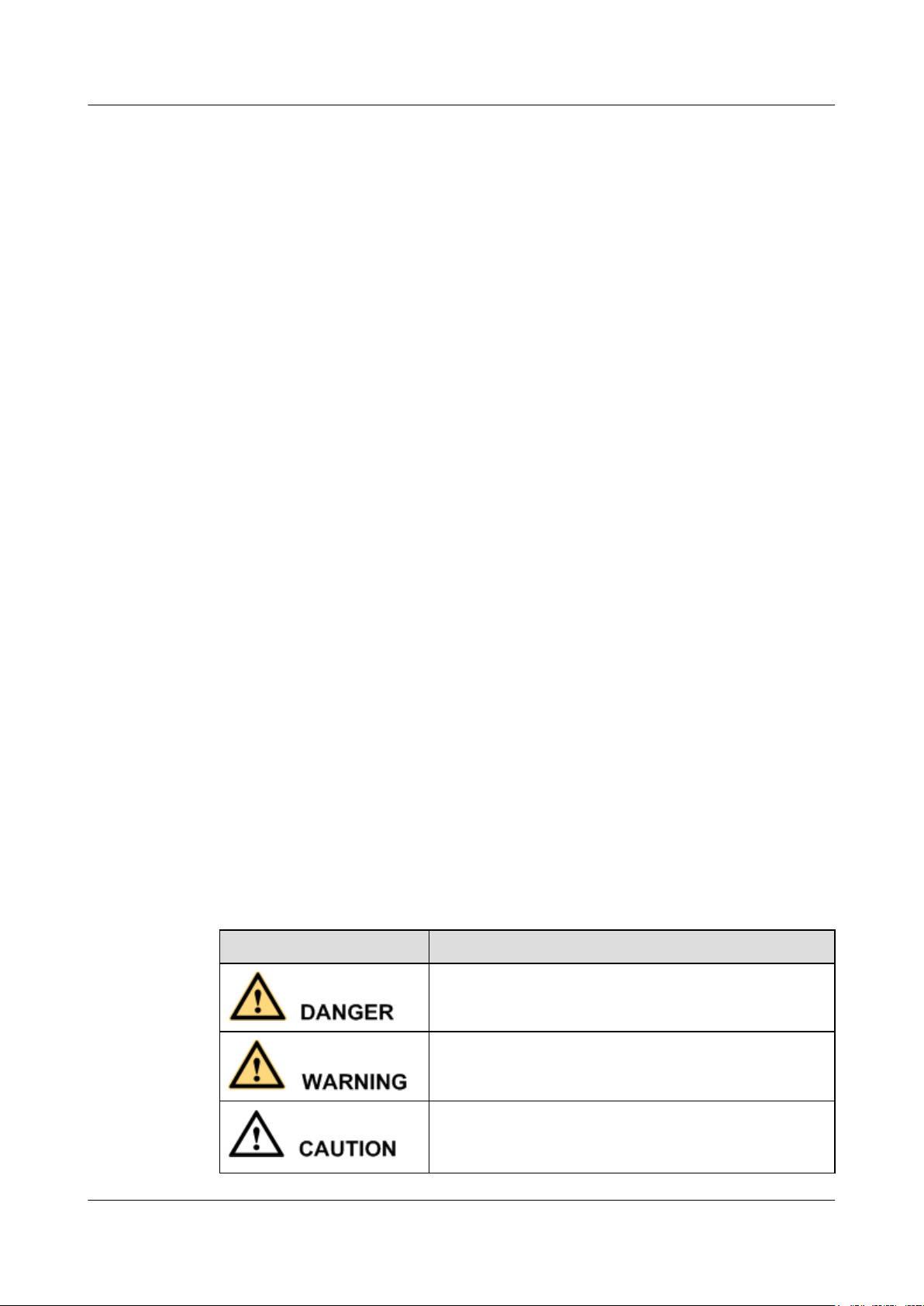

Symbol Conventions

The symbols that may be found in this document are defined as follows.

Symbol

Description

Indicates a hazard with a high level or medium level of risk

which, if not avoided, could result in death or serious injury.

Indicates a hazard with a low level of risk which, if not

avoided, could result in minor or moderate injury.

Indicates a potentially hazardous situation that, if not

avoided, could result in equipment damage, data loss,

performance deterioration, or unanticipated results.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

iii

Page 5

RRU3268

Installation Guide About This Document

Symbol Description

Indicates a tip that may help you solve a problem or save

time.

Provides additional information to emphasize or supplement

important points of the main text.

General Conventions

The general conventions that may be found in this document are defined as follows.

Convention Description

Times New Roman Normal paragraphs are in Times New Roman.

Boldface Names of files, directories, folders, and users are in

boldface. For example, log in as user root.

Italic Book titles are in italics.

Courier New

Examples of information displayed on the screen are in

Courier New.

Command Conventions

The command conventions that may be found in this document are defined as follows.

Convention

Description

Boldface The keywords of a command line are in boldface.

Italic Command arguments are in italics.

[ ] Items (keywords or arguments) in brackets [ ] are optional.

{ x | y | ... } Optional items are grouped in braces and separated by

vertical bars. One item is selected.

[ x | y | ... ] Optional items are grouped in brackets and separated by

vertical bars. One item is selected or no item is selected.

{ x | y | ... }

*

Optional items are grouped in braces and separated by

vertical bars. A minimum of one item or a maximum of all

items can be selected.

[ x | y | ... ]

*

Optional items are grouped in brackets and separated by

vertical bars. Several items or no item can be selected.

GUI Conventions

The GUI conventions that may be found in this document are defined as follows.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

iv

Page 6

RRU3268

Installation Guide About This Document

Convention Description

Boldface Buttons, menus, parameters, tabs, window, and dialog titles

are in boldface. For example, click OK.

> Multi-level menus are in boldface and separated by the ">"

signs. For example, choose File > Create > Folder.

Keyboard Operations

The keyboard operations that may be found in this document are defined as follows.

Format Description

Key Press the key. For example, press Enter and press Tab.

Key 1+Key 2 Press the keys concurrently. For example, pressing Ctrl+Alt

+A means the three keys should be pressed concurrently.

Key 1, Key 2 Press the keys in turn. For example, pressing Alt, A means

the two keys should be pressed in turn.

Mouse Operations

The mouse operations that may be found in this document are defined as follows.

Action

Description

Click Select and release the primary mouse button without moving

the pointer.

Double-click Press the primary mouse button twice continuously and

quickly without moving the pointer.

Drag Press and hold the primary mouse button and move the

pointer to a certain position.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

v

Page 7

RRU3268

Installation Guide Contents

Contents

About This Document.....................................................................................................................ii

1 Changes in the RRU3268 Installation Guide...........................................................................1

2 Installation Preparations..............................................................................................................2

2.1 Reference Documents.........................................................................................................................................3

2.2 Tools and Instruments........................................................................................................................................3

2.3 Skills and Requirements for Onsite Personnel...................................................................................................5

3 Information About the Installation...........................................................................................6

3.1 RRU Exterior......................................................................................................................................................7

3.2 RRU Ports...........................................................................................................................................................8

3.3 RRU Indicators...................................................................................................................................................9

3.4 Installation Scenarios........................................................................................................................................11

3.5 Installation Clearance Requirements of an RRU..............................................................................................21

3.5.1 Clearance for a Single RRU....................................................................................................................21

3.5.2 Clearance for Multiple RRUs..................................................................................................................24

3.5.3 Installation Spacing Between RRUs........................................................................................................28

4 Unpacking the Equipment.........................................................................................................31

5 Installation Process.....................................................................................................................33

6 (Optional) Installing the Plastic Shells of the RRU..............................................................34

7 Hoisting an RRU and Related Cables onto a Tower............................................................37

7.1 Hoisting an RRU onto a Tower........................................................................................................................38

7.2 Hoisting Fiber Optic Cables onto a Tower.......................................................................................................42

7.3 Hoisting Power Cables onto a Tower...............................................................................................................45

8 Installing the RRU.......................................................................................................................49

8.1 Mounting Kits for an RRU...............................................................................................................................50

8.2 Installing the RRU on a Pole............................................................................................................................51

8.2.1 Installing a Single RRU...........................................................................................................................51

8.2.2 Installing Two RRUs...............................................................................................................................54

8.2.3 Installing Three or More RRUs...............................................................................................................58

8.3 Installing the RRU on U-steel..........................................................................................................................63

8.4 Installing the RRU on Angle Steel...................................................................................................................68

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

vi

Page 8

RRU3268

Installation Guide Contents

8.5 Installing the RRU on a Wall...........................................................................................................................73

8.6 Installing an RRU on an IFS06.........................................................................................................................79

9 Installing RRU Cables................................................................................................................87

9.1 Cabling Requirements......................................................................................................................................89

9.2 Cable Connections............................................................................................................................................94

9.3 Installation Process...........................................................................................................................................96

9.4 RRU Cable List................................................................................................................................................97

9.5 Installing an RRU PGND Cable.......................................................................................................................99

9.6 Installing an RRU RF Jumper........................................................................................................................100

9.7 Installing an RRU AISG Multi-Wire Cable and AISG Extension Cable.......................................................103

9.8 Installing an RRU Alarm Cable......................................................................................................................106

9.9 Opening the Cover Plate of an RRU Cabling Cavity.....................................................................................107

9.10 Installing an RRU Power Cable....................................................................................................................108

9.11 Installing a CPRI Fiber Optic Cable.............................................................................................................110

9.12 Closing the Cover Plate of an RRU Cabling Cavity....................................................................................112

10 Checking the RRU Hardware Installation..........................................................................116

11 Powering On an RRU.............................................................................................................117

12 Appendix...................................................................................................................................119

12.1 Adding a Tool-Less Female Connector (Pressfit Type) to the RRU Power Cable on the RRU Side..........120

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

vii

Page 9

RRU3268

Installation Guide 1 Changes in the RRU3268 Installation Guide

1 Changes in the RRU3268 Installation Guide

This chapter describes the changes in the RRU3268 Installation Guide.

01 (2013-03-18)

This is the first official release.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

1

Page 10

RRU3268

Installation Guide 2 Installation Preparations

2 Installation Preparations

About This Chapter

This chapter describes the reference documents, tools, and instruments that must be ready before

the installation. In addition, it specifies the skills and prerequisites that installation engineers

must have.

2.1 Reference Documents

Before the installation, you must be familiar with reference documents.

2.2 Tools and Instruments

All tools and instruments required for RRU installation must be ready before the installation.

2.3 Skills and Requirements for Onsite Personnel

Onsite personnel must be qualified and trained. Before performing any operation, onsite

personnel must be familiar with correct operation methods and safety precautions.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

2

Page 11

RRU3268

Installation Guide 2 Installation Preparations

2.1 Reference Documents

Before the installation, you must be familiar with reference documents.

The following reference documents are required during RRU installation:

l RRU3268 Hardware Description

l DBS3900 Installation Guide

l OCB User Guide

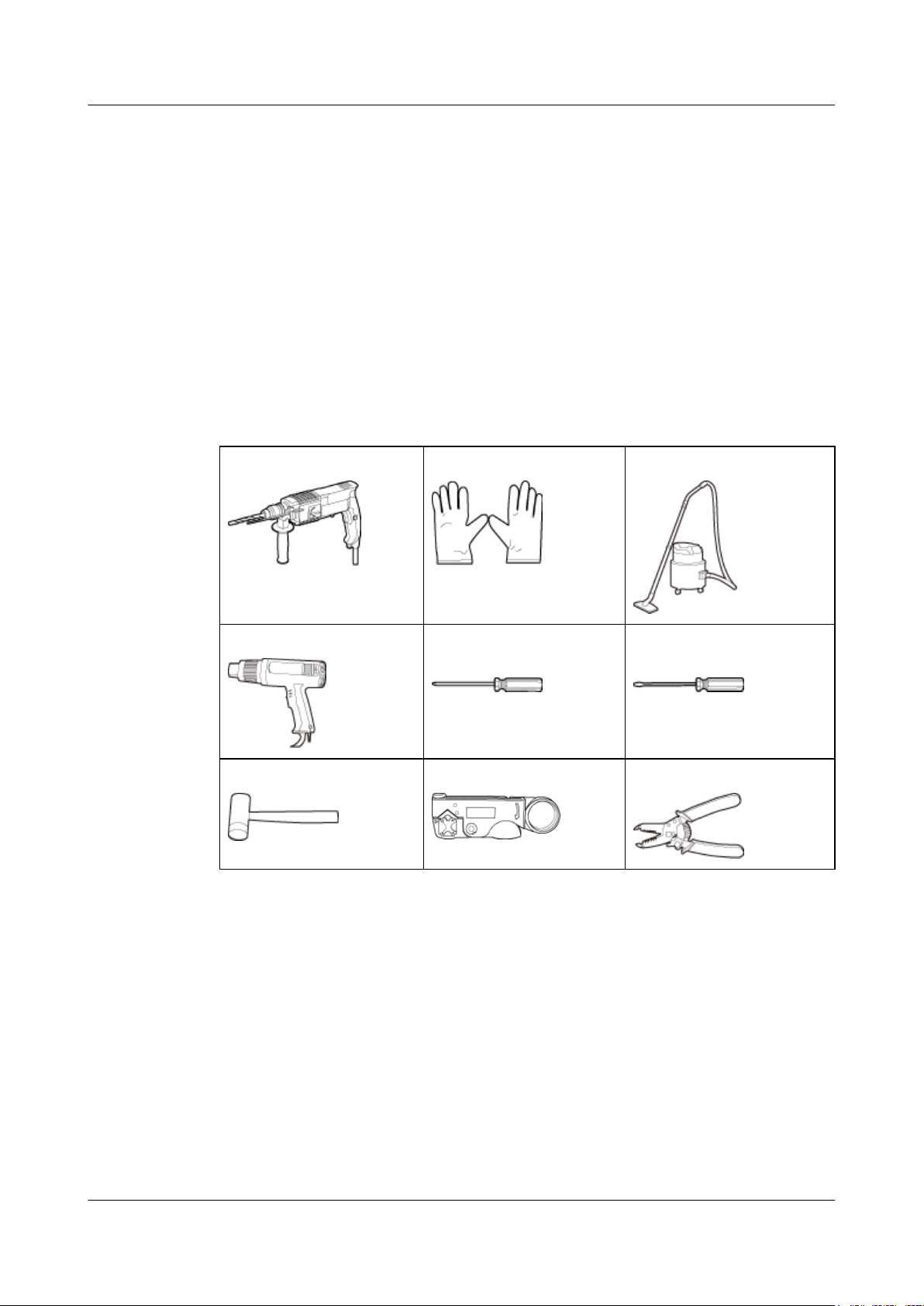

2.2 Tools and Instruments

All tools and instruments required for RRU installation must be ready before the installation.

Hammer drill (a φ 12 bit)

Heat gun Phillips screwdriver (M3 to

Rubber mallet COAX crimping tool Wire stripper

ESD gloves Vacuum cleaner

Flat-head screwdriver (M3 to

M6)

M6)

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

3

Page 12

RRU3268

Installation Guide 2 Installation Preparations

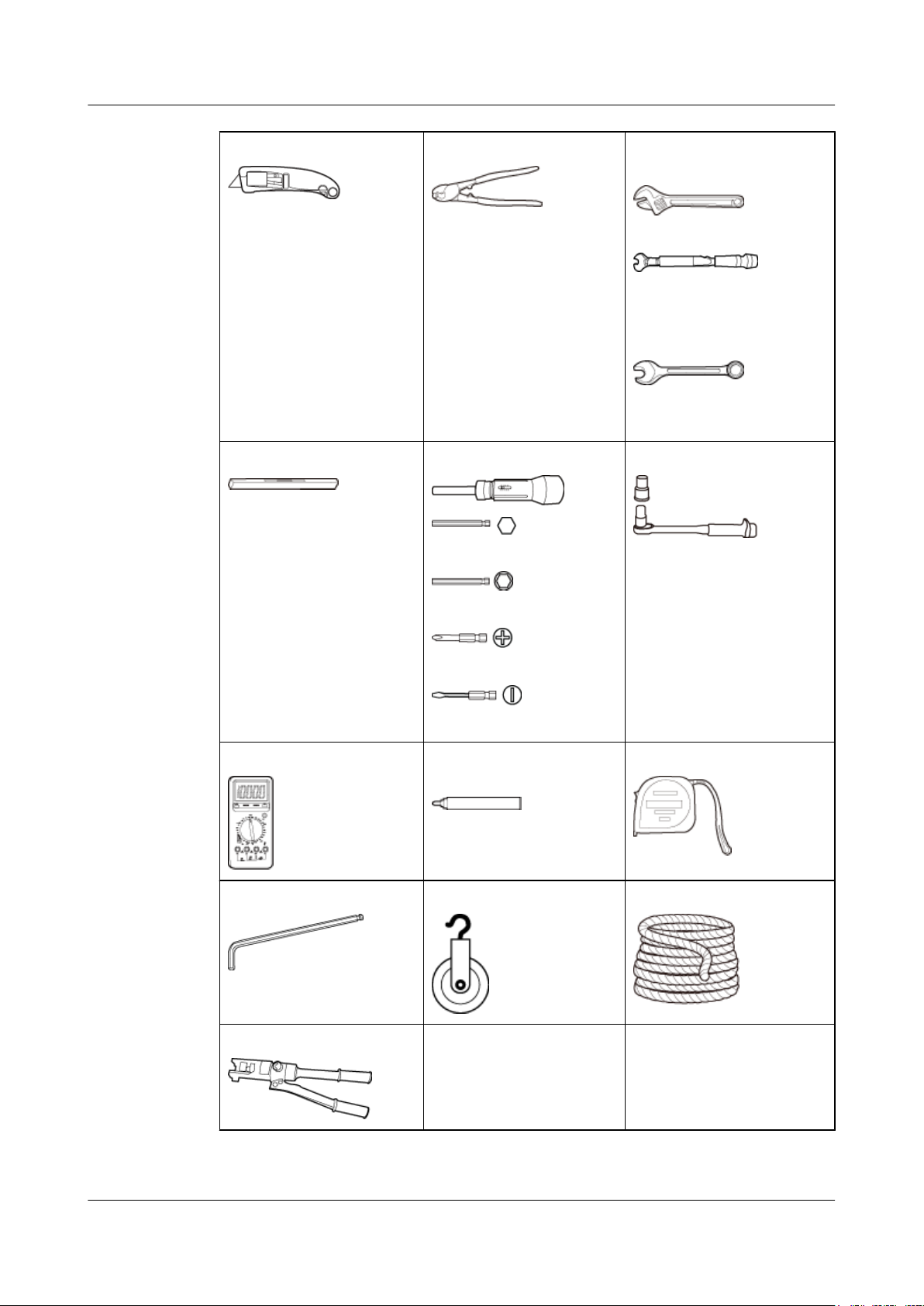

Utility knife Cable cutter Adjustable wrench (capacity

≥ 32 mm [1.26 in.])

Torque wrench

Capacity: 16 mm [0.63 in.],

and 32 mm [1.26 in.]

Combination wrench

Capacity: 16 mm [0.63 in.],

and 32 mm [1.26 in.]

Level

Multimeter

Inner hexagon spanner

Torque screwdriver

Torque socket

5 mm (0.2 in.)

5 mm (0.2 in.)

(M3 to M6)

(M3 to M6)

Marker (diameter ≤ 10 mm

Measuring tape

[0.39 in.])

Fixed pulley Rope

5 mm (0.2 in.)

Hydraulic pliers - -

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

4

Page 13

RRU3268

Installation Guide 2 Installation Preparations

2.3 Skills and Requirements for Onsite Personnel

Onsite personnel must be qualified and trained. Before performing any operation, onsite

personnel must be familiar with correct operation methods and safety precautions.

Before the installation, pay attention to the following items:

l The customer's technical engineers must be trained by Huawei and be familiar with the

proper installation and operation methods.

l The number of onsite personnel depends on the engineering schedule and installation

environment. Generally, only three to five onsite personnel are necessary.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

5

Page 14

RRU3268

Installation Guide 3 Information About the Installation

3 Information About the Installation

About This Chapter

Before installing an RRU, you must be familiar with its exterior, ports, indicators, installation

options and installation clearance requirements.

3.1 RRU Exterior

This section describes the exterior and dimensions of an RRU.

3.2 RRU Ports

This section describes ports on the RRU panels. An RRU has a bottom panel, cabling cavity

panel, and indicator panel.

3.3 RRU Indicators

This section describes six indicators on an RRU. They indicate the running status.

3.4 Installation Scenarios

An RRU can be installed on a pole, U-steel, angle steel, or IFS06. Installation scenarios must

meet heat-dissipation and waterproofing requirements of the RRU.

3.5 Installation Clearance Requirements of an RRU

This section describes the requirements for the installation clearance of a single RRU and

multiple RRUs and the requirements for the installation spacing between RRUs.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

6

Page 15

RRU3268

Installation Guide 3 Information About the Installation

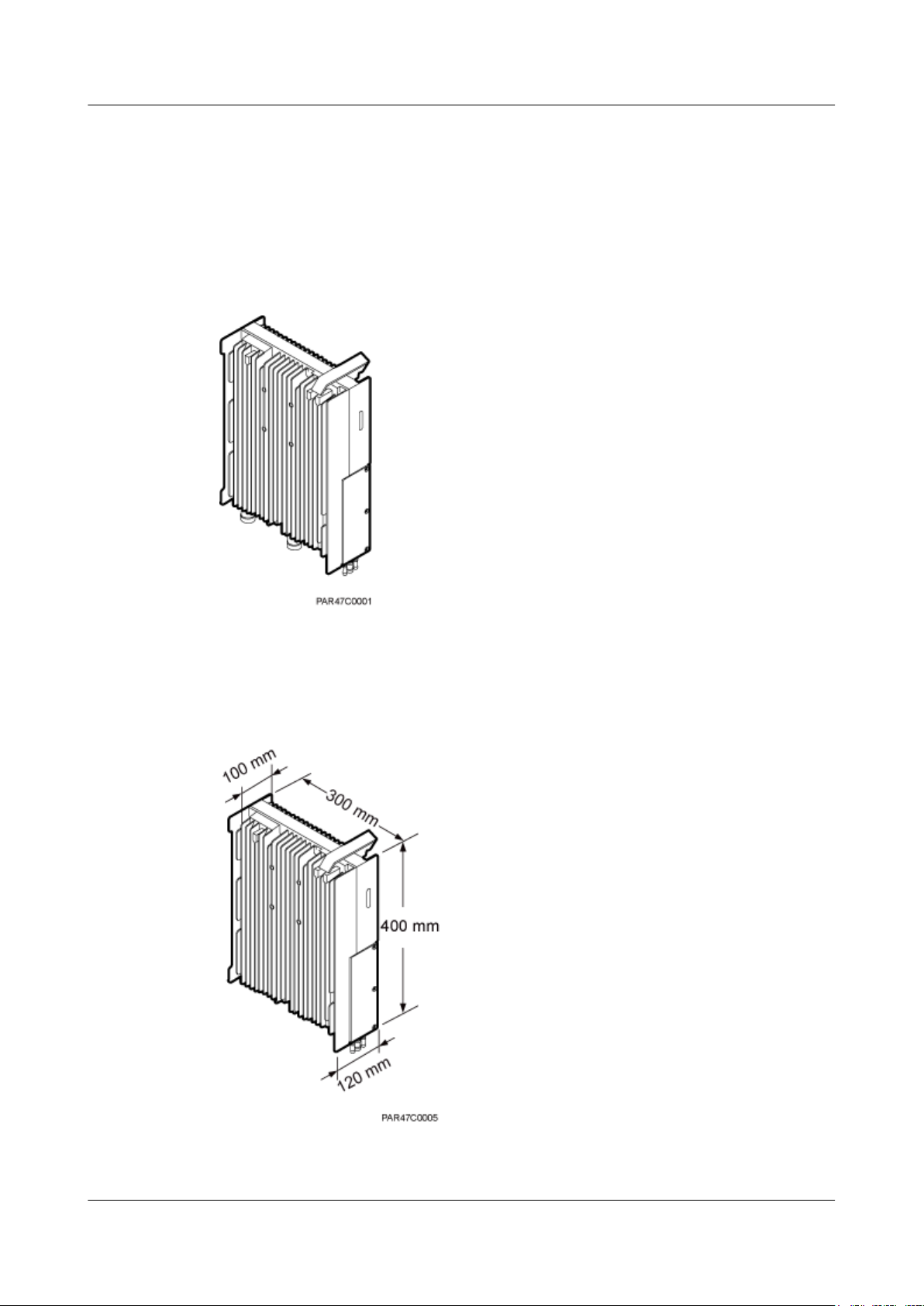

3.1 RRU Exterior

This section describes the exterior and dimensions of an RRU.

Figure 3-1 shows an RRU.

Figure 3-1 RRU exterior

Figure 3-2 shows RRU dimensions.

Figure 3-2 RRU dimensions

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

7

Page 16

RRU3268

Installation Guide 3 Information About the Installation

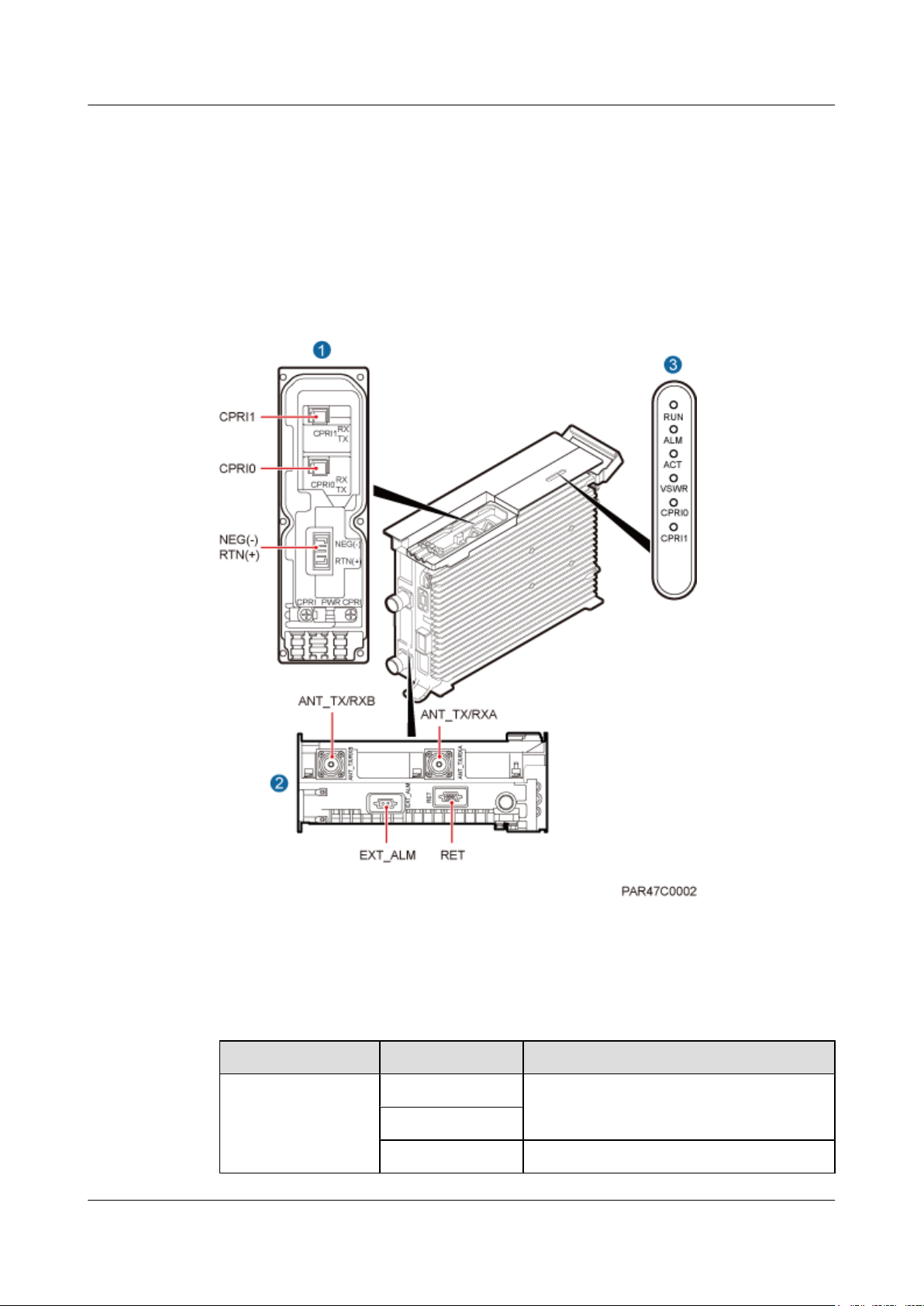

3.2 RRU Ports

This section describes ports on the RRU panels. An RRU has a bottom panel, cabling cavity

panel, and indicator panel.

Figure 3-3 shows the ports on the RRU panels.

Figure 3-3 Ports on the RRU panels

Table 3-1 describes ports and indicators on the RRU panels.

Table 3-1 RRU ports and indicators on the panels

Item

(1) Ports in the cabling

cavity

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

Silkscreen Description

RTN(+) Power port

NEG(-)

CPRI0 Optical/electrical port 0

8

Page 17

RRU3268

Installation Guide 3 Information About the Installation

Item Silkscreen Description

CPRI1 Optical/electrical port 1

(2) Ports at the bottom ANT_TX/RXA TX/RX port A, supporting RET signal

transmission

ANT_TX/RXB TX/RX port B

EXT_ALM Alarm port

RET Communication port for the RET antenna,

supporting RET signal transmission

(3) Indicators RUN For details, see 3.3 RRU Indicators.

ALM

ACT

VSWR

CPRI0

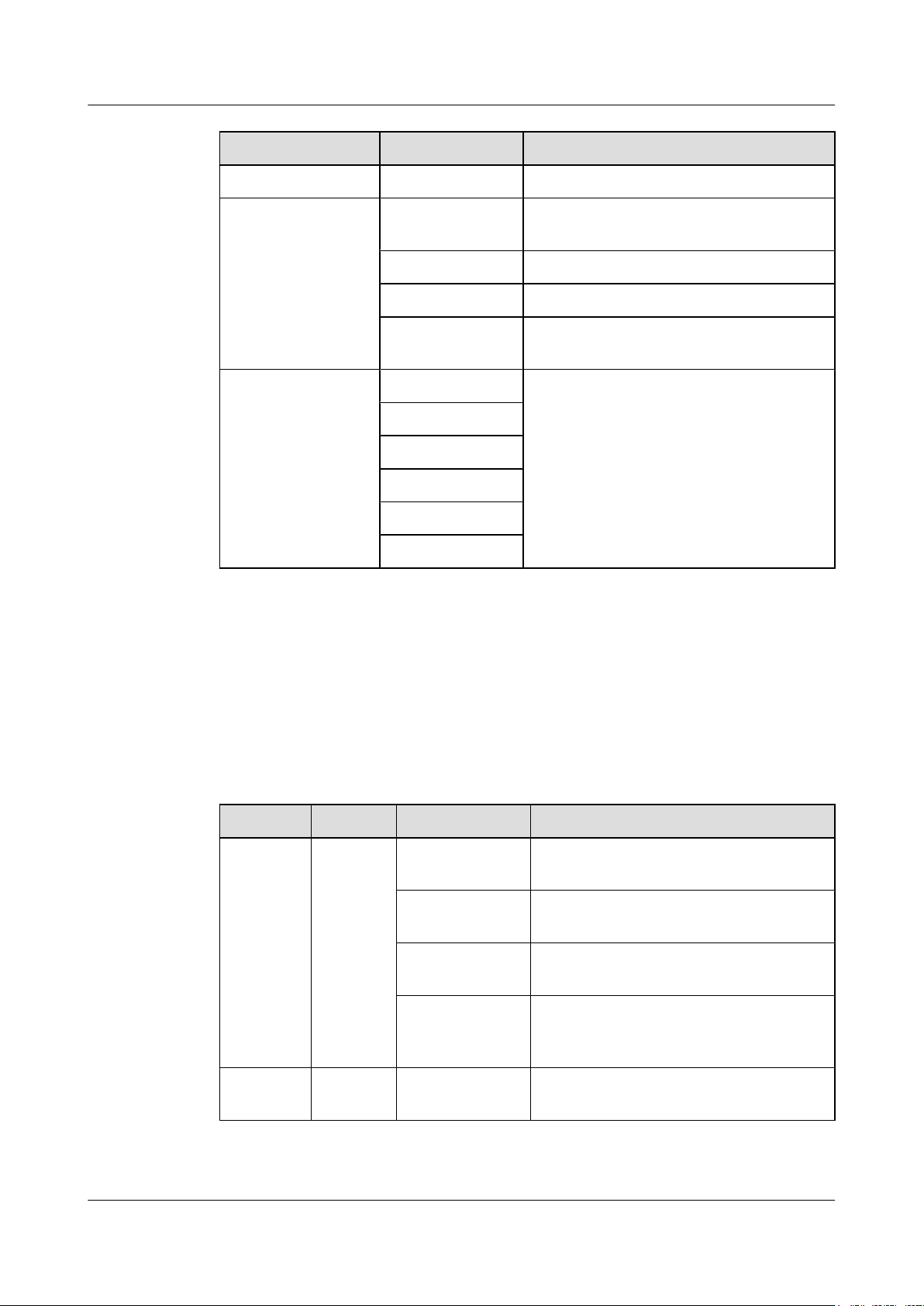

3.3 RRU Indicators

This section describes six indicators on an RRU. They indicate the running status.

For detailed positions of RRU indicators, see 3.2 RRU Ports.

Table 3-2 describes RRU indicators.

Table 3-2 RRU indicators

Indicator

RUN Green Steady on There is power supply, but the module is

CPRI1

Color Status Meaning

faulty.

Steady off There is no power supply, or the module is

faulty.

Blinking (on for

1s and off for 1s)

The board is functioning properly.

Blinking (on for

0.125s and off for

0.125s)

ALM Red Steady on Alarms are generated, and the module must

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

Software is being loaded to the module, or

the module is not started.

be replaced.

9

Page 18

RRU3268

Installation Guide 3 Information About the Installation

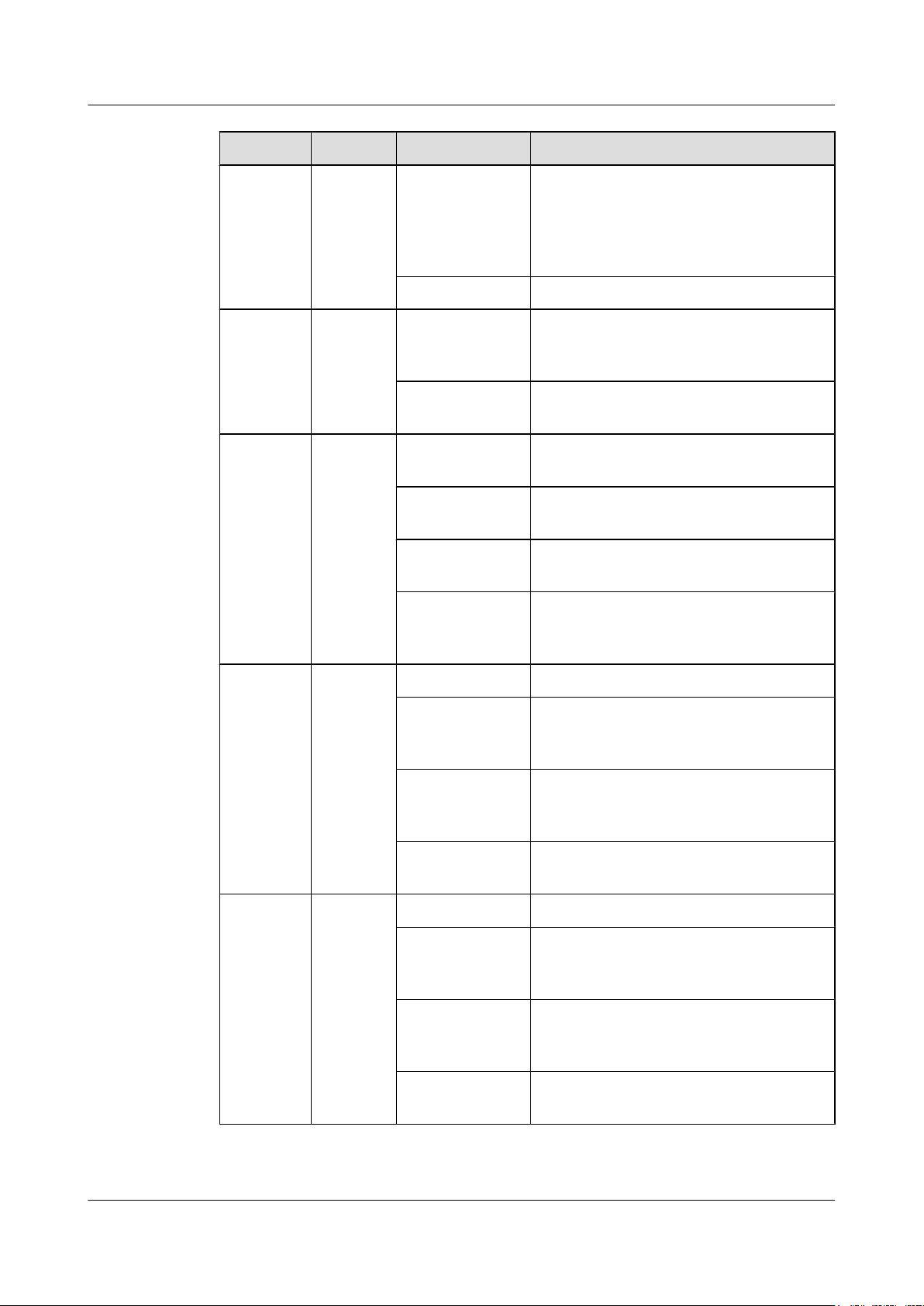

Indicator Color Status Meaning

Blinking (on for

1s and off for 1s)

Alarms are generated. The alarms may be

caused by the faults on the related boards or

ports. Therefore, you need to locate the fault

before deciding whether to replace the

module.

Steady off No alarm is generated.

ACT Green Steady on The module is running properly with TX

channels enabled or the software is being

loaded without RRU running.

Blinking (on for

1s and off for 1s)

The module is running properly with TX

channels disabled.

VSWR Red Steady off No Voltage Standing Wave Ratio (VSWR)

alarm is generated.

Blinking (on for

1s and off for 1s)

VSWR alarms are generated on the

ANT_TX/RXB port.

Steady on VSWR alarms are generated on the

ANT_TX/RXA port.

Blinking (on for

0.125s and off for

VSWR alarms are generated on the

ANT_TX/RXA and ANT_TX/RXB ports.

0.125s)

CPRI0 Red or

green

CPRI1 Red or

green

Steady green The CPRI link is functioning properly.

Steady red An optical module fails to transmit or receive

signals because the optical module is faulty

or the fiber optic cable is broken.

Blinking red (on

for 1s and off for

1s)

The CPRI link is out of lock because of a

failure in clock lock between two modes or

mismatched data rates over CPRI ports.

Steady off The optical module cannot be detected, or the

optical module is powered off.

Steady green The CPRI link is functioning properly.

Steady red An optical module fails to transmit or receive

signals because the optical module is faulty

or the fiber optic cable is broken.

Blinking red (on

for 1s and off for

1s)

The CPRI link is out of lock because of a

failure in clock lock between two modes or

mismatched data rates over CPRI ports.

Steady off The optical module cannot be detected, or the

optical module is powered off.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

10

Page 19

RRU3268

Installation Guide 3 Information About the Installation

3.4 Installation Scenarios

An RRU can be installed on a pole, U-steel, angle steel, or IFS06. Installation scenarios must

meet heat-dissipation and waterproofing requirements of the RRU.

Requirements for the Installation Scenarios

Application scenarios:

To ensure proper heat dissipation of the RRU, the following requirements must be met:

l The RRU cannot be installed in an enclosed cabinet without a cooling system.

l The RRU cannot be installed in an enclosed camouflage box.

l The RRU cannot be installed in an enclosed equipment room without a cooling system.

l When multiple RRUs are installed in centralized mode, the minimum clearance

requirements must be met. For details about the minimum clearance requirements, see 3.5.2

Clearance for Multiple RRUs and 3.5.3 Installation Spacing Between RRUs.

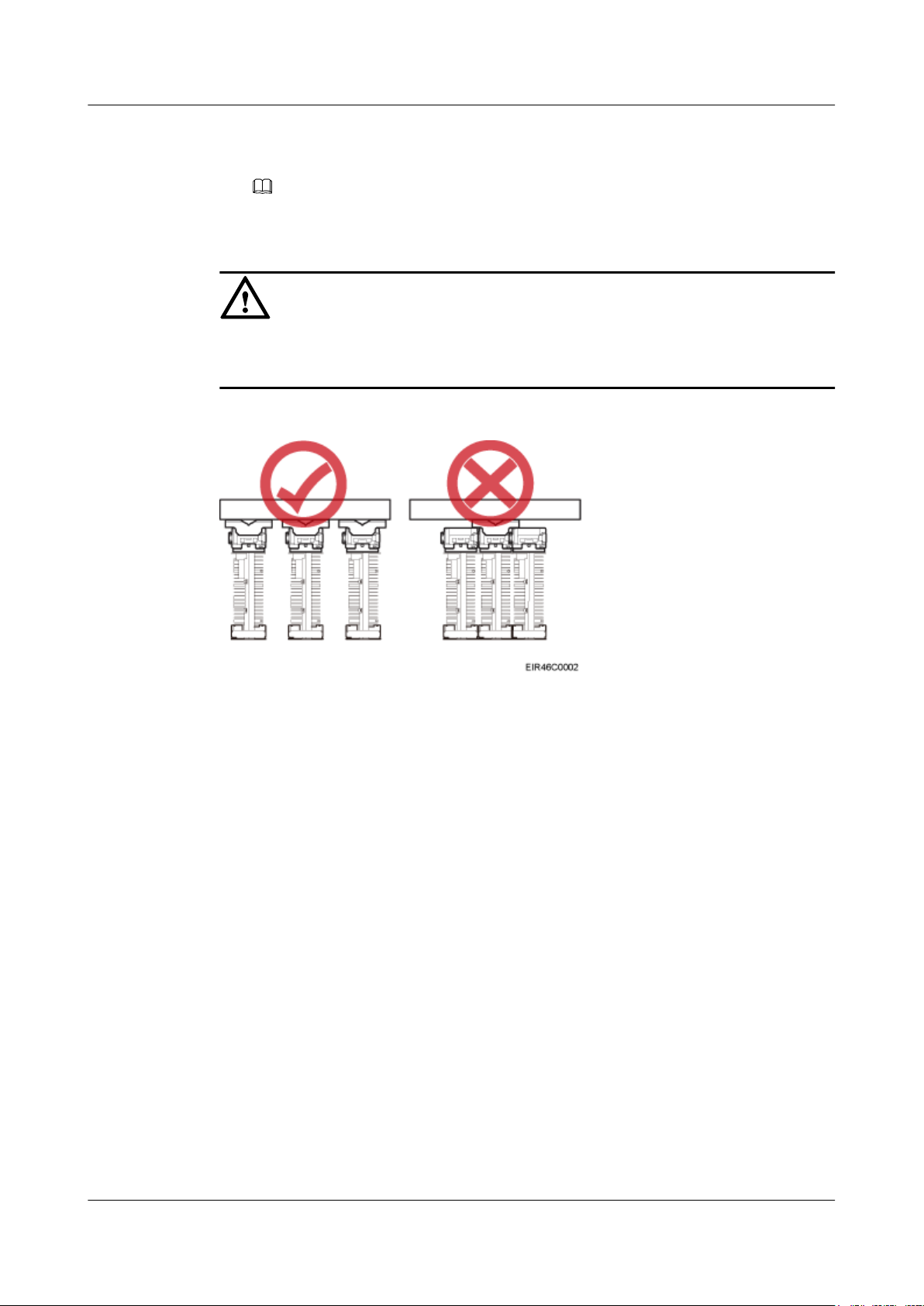

CAUTION

In improper installation scenarios, the heat dissipation efficiency decreases and therefore the

RRU may not work properly. Figure 3-4 shows an improper installation scenario.

Figure 3-4 Improper installation scenario

Method of installation:

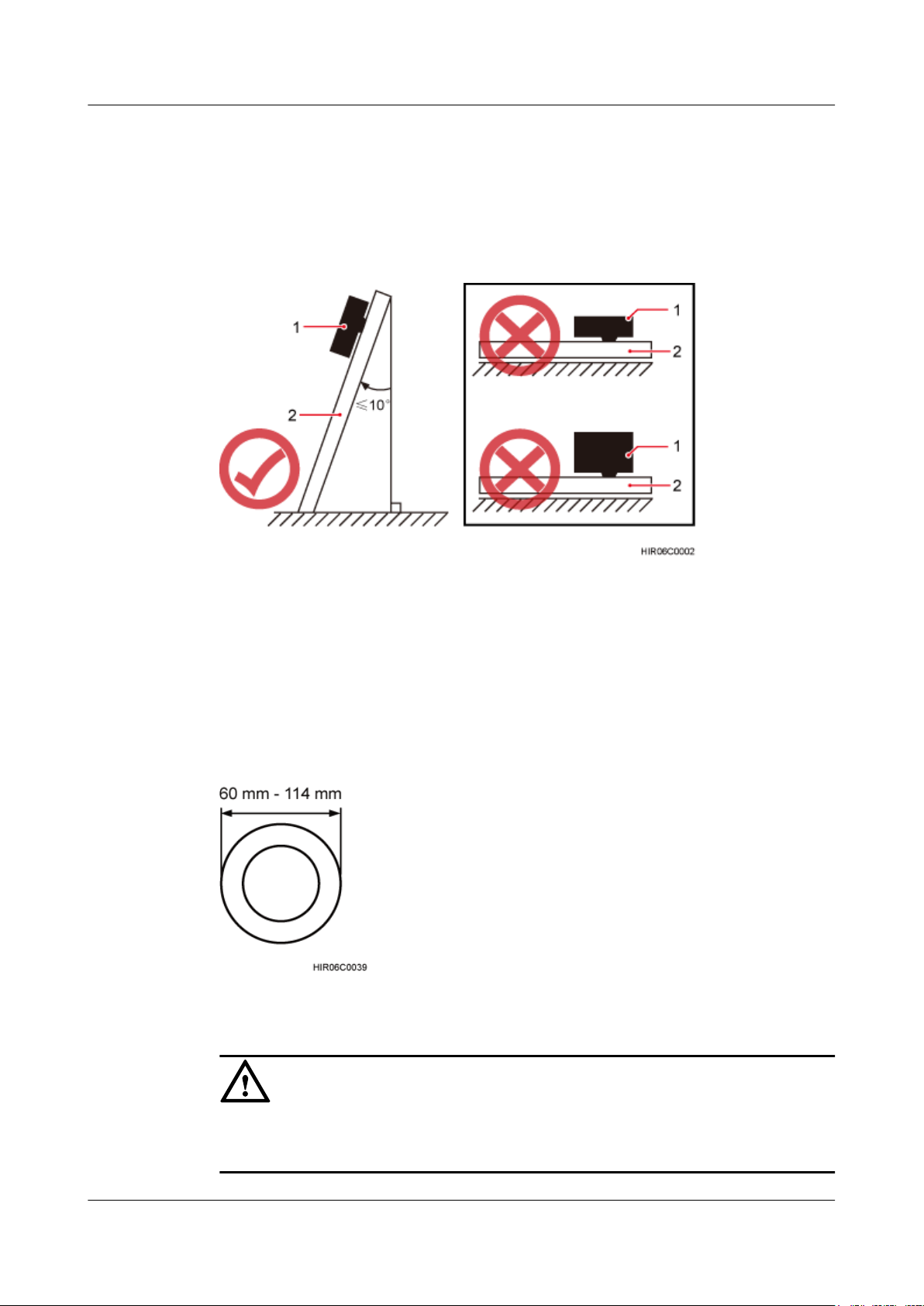

l To ensure proper heat dissipation and waterproofing of the RRU, the RRU must be installed

with the ports at the bottom and the vertical deviation angle of the RRU must be less than

or equal to 10 degrees, as shown in Figure 3-5.

l The side-mounted mode is recommended for RRUs on the main pole secured on a tower.

This installation mode allows multiple RRUs to be installed next to each other at the same

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

11

Page 20

RRU3268

Installation Guide 3 Information About the Installation

level on a pole. When the horizontal distance between the main and auxiliary poles on a

tower is equal to or greater than 810 mm (23.62 in.), the side-mounted mode is

recommended for installing RRUs on the auxiliary pole to meet the minimum clearance

requirements. Otherwise, the standard mode is recommended for installing RRUs on the

auxiliary pole.

Figure 3-5 Requirements for the vertical deviation angle of an RRU

(1) RRU (2) Installation support (pole, U-steel, angle steel, or wall)

Installing an RRU on a Pole

Figure 3-6 shows the diameter of a pole for installing an RRU.

Figure 3-6 Diameter of a pole

CAUTION

l The diameter of a pole for installing an RRU ranges from 60 mm (2.36 in.) to 114 mm (4.49

in.). The recommended diameter is 80 mm (3.15 in.).

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

12

Page 21

RRU3268

Installation Guide 3 Information About the Installation

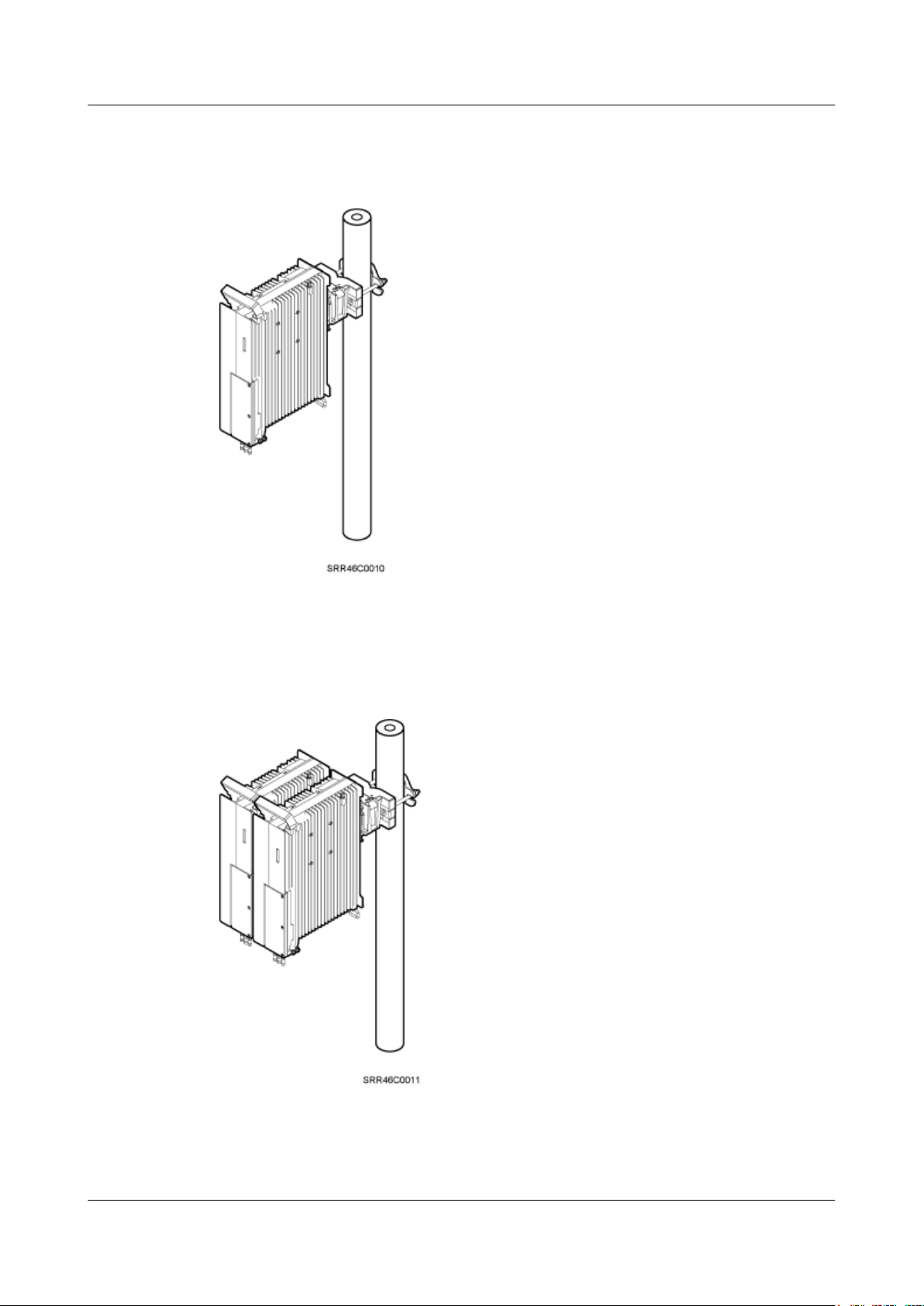

Figure 3-7 shows a single RRU installed on a pole.

Figure 3-7 A single RRU installed on a pole

Figure 3-8 shows two RRUs installed on a pole.

Figure 3-8 Two RRUs installed on a pole

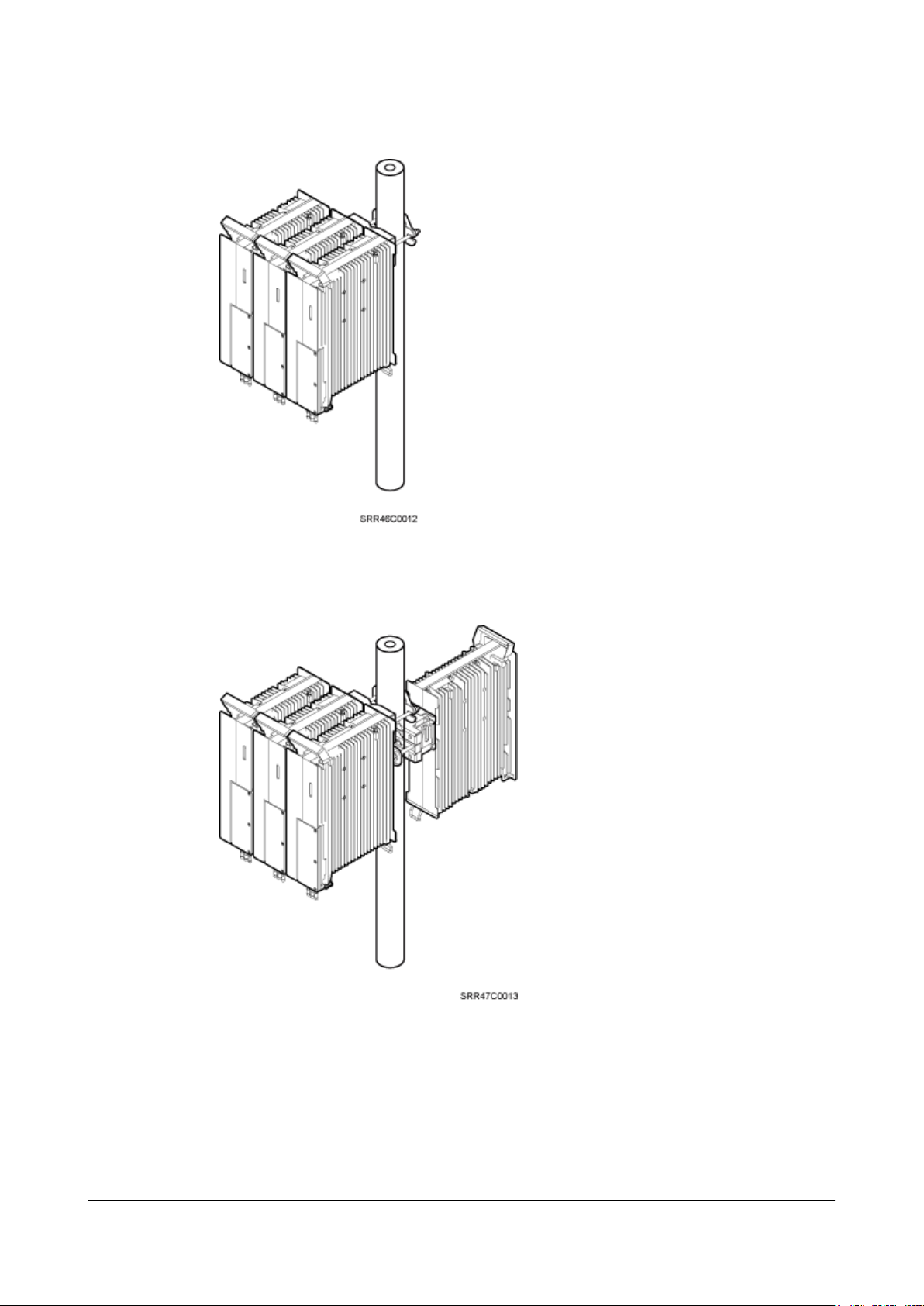

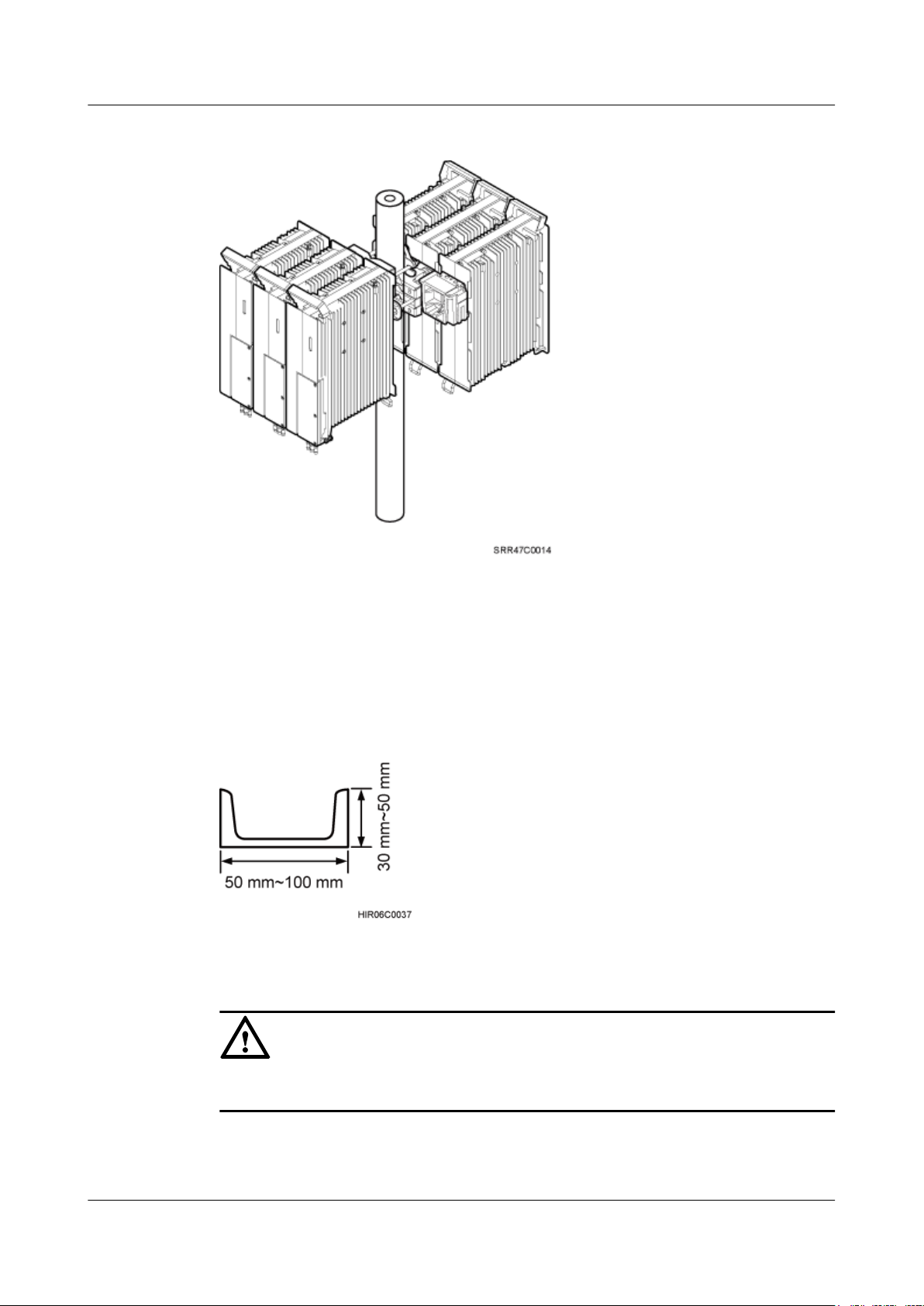

Figure 3-9, Figure 3-10, and Figure 3-11 show three or more RRUs installed on a pole.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

13

Page 22

RRU3268

Installation Guide 3 Information About the Installation

Figure 3-9 Three RRUs installed on a pole

Figure 3-10 Four RRUs installed on a pole

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

14

Page 23

RRU3268

Installation Guide 3 Information About the Installation

Figure 3-11 Six RRUs installed on a pole

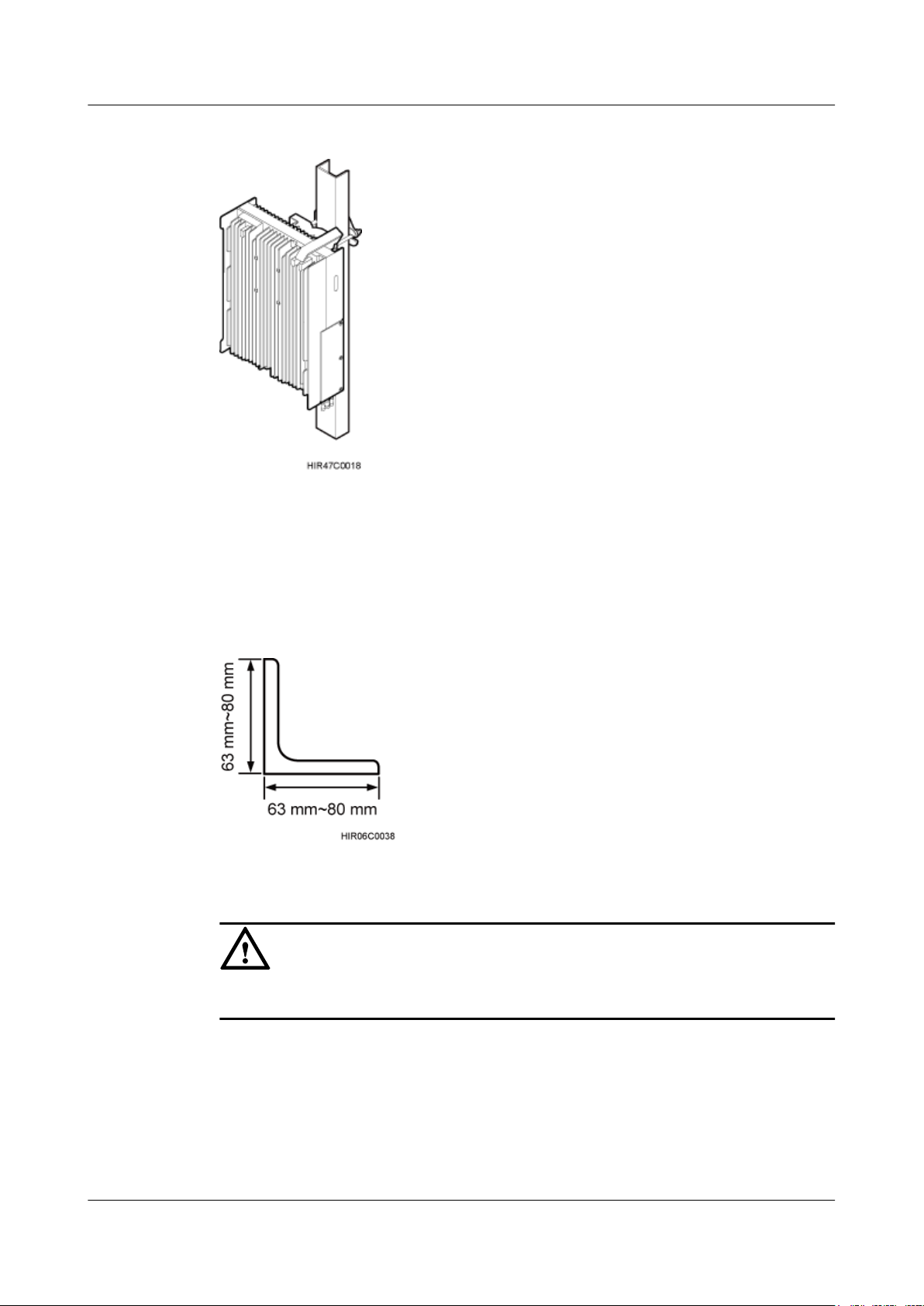

Installing an RRU on U-steel

Figure 3-12 shows U-steel specifications.

Figure 3-12 U-steel specifications

CAUTION

U-steel supports the standard or reverse installation of a single RRU only.

Figure 3-13 shows an RRU installed on U-steel.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

15

Page 24

RRU3268

Installation Guide 3 Information About the Installation

Figure 3-13 RRU installed on U-steel

Installing an RRU on Angle Steel

Figure 3-14 shows angle steel specifications.

Figure 3-14 Angle steel specifications

CAUTION

Angle steel supports the standard or reverse installation of a single RRU only.

Figure 3-15 shows an RRU installed on angle steel.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

16

Page 25

RRU3268

Installation Guide 3 Information About the Installation

Figure 3-15 RRU installed on angle steel

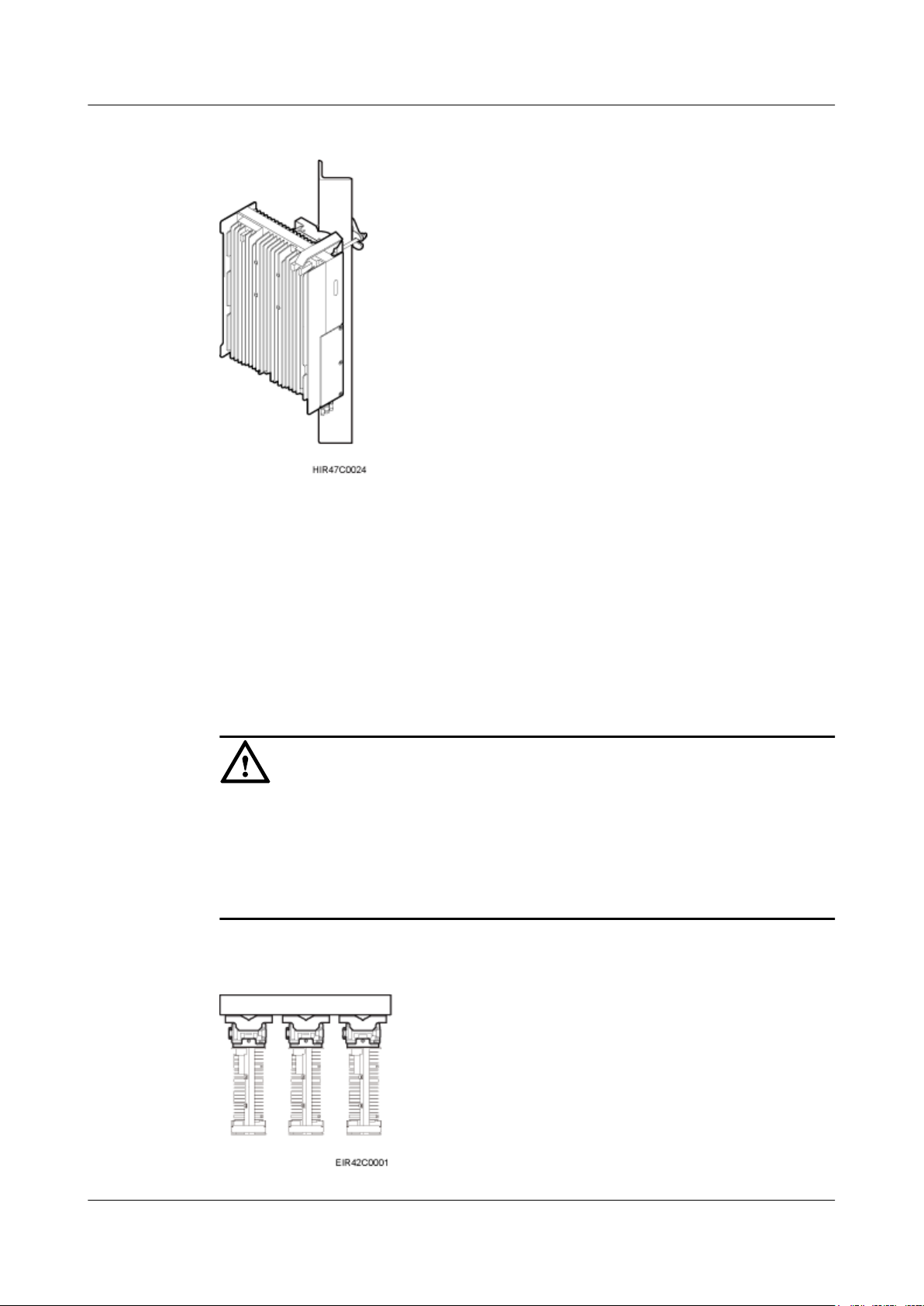

Installing an RRU on a Wall

The wall for installing RRUs must meet the following requirements:

l When a single RRU is installed, the wall has a capacity of bearing at least four times the

weight of the RRU.

l Expansion anchor bolts must be tightened to 30 N·m (265.52 lbf·in.) so that the bolts stay

secured without damaging the wall.

CAUTION

l It is recommended that the RRU be installed on a wall in standard mode.

l When multiple RRUs are installed on an outdoor wall in side-mounted mode, it is

recommended that the mounting brackets not be combined, as shown in Figure 3-16. When

multiple RRUs are installed on an indoor wall in side-mounted mode, the mounting brackets

cannot be combined, as shown in Figure 3-17.

Figure 3-16 Correct installation of mounting brackets for multiple RRUs installed on an outdoor

wall in side-mounted mode

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

17

Page 26

RRU3268

Installation Guide 3 Information About the Installation

Figure 3-17 Correct installation of mounting brackets for multiple RRUs installed on an indoor

wall in side-mounted mode

Figure 3-18 shows an RRU installed on a wall.

Figure 3-18 RRU installed on a wall

Installing an RRU on an IFS06

In an IFS06 scenario:

l The upper and lower adjustable beams on an IFS06 can be moved up and down to fit for

heights of RRUs.

l The IFS06 supports at least three RRUs when the ambient temperature is higher than or

equal to the lowest operating temperature of the RRU and at least 5°C (41°F) lower than

the highest operating temperature of the RRU. The IFS06 supports a maximum of six RRUs

when the ambient temperature is higher than or equal to the lowest operating temperature

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

18

Page 27

RRU3268

Installation Guide 3 Information About the Installation

of the RRU and at least 10°C (50°F) lower than the highest operating temperature of the

RRU.

NOTE

For details about the operating temperature of the RRU, see section "Technical Specifications of

RRUs" in 3900 Series Base Station Technical Description.

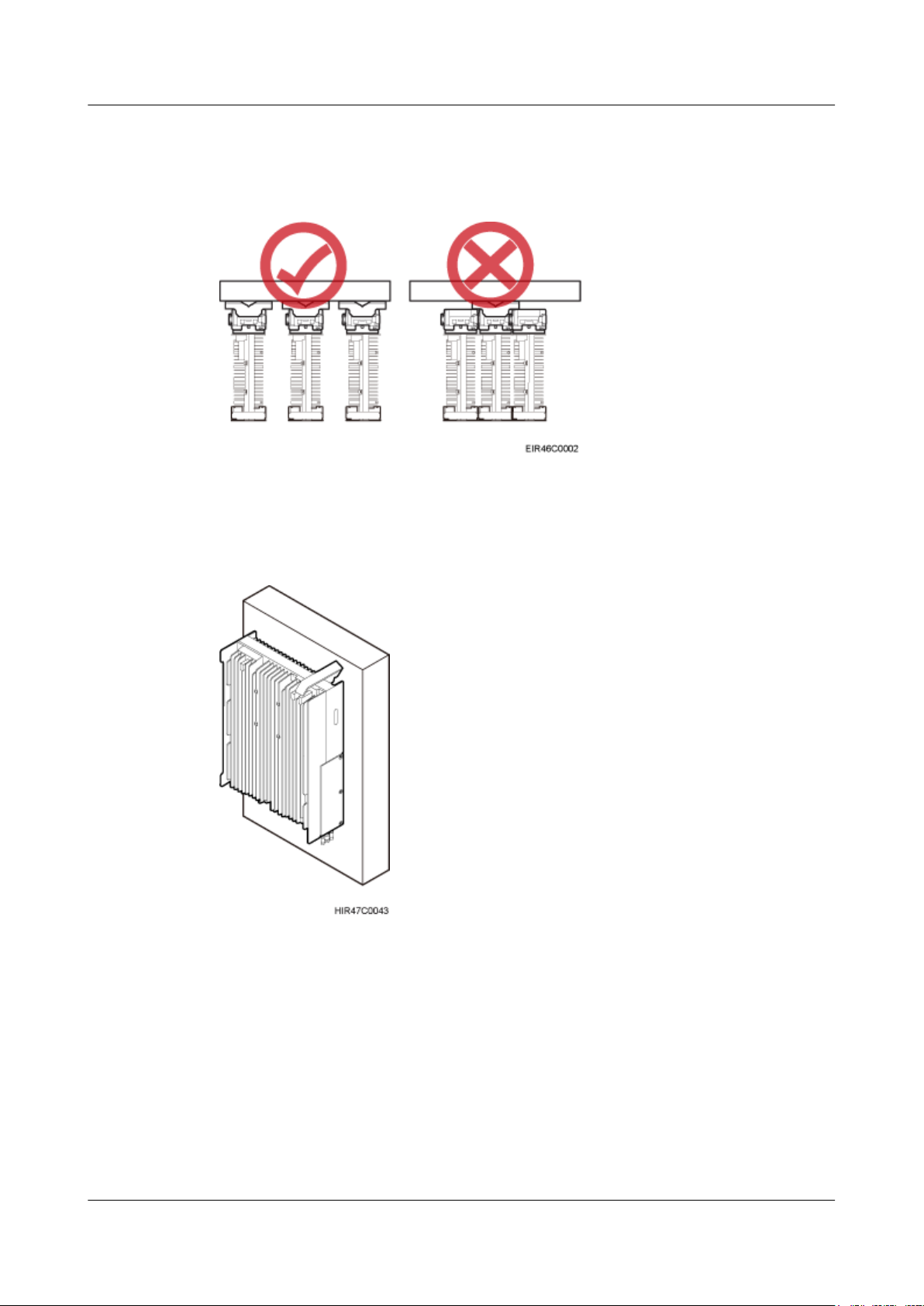

CAUTION

The mounting brackets for multiple RRUs cannot be combined when the RRUs are installed on

an IFS06, as shown in Figure 3-19.

Figure 3-19 Correct installation of mounting brackets for RRUs installed on an IFS06

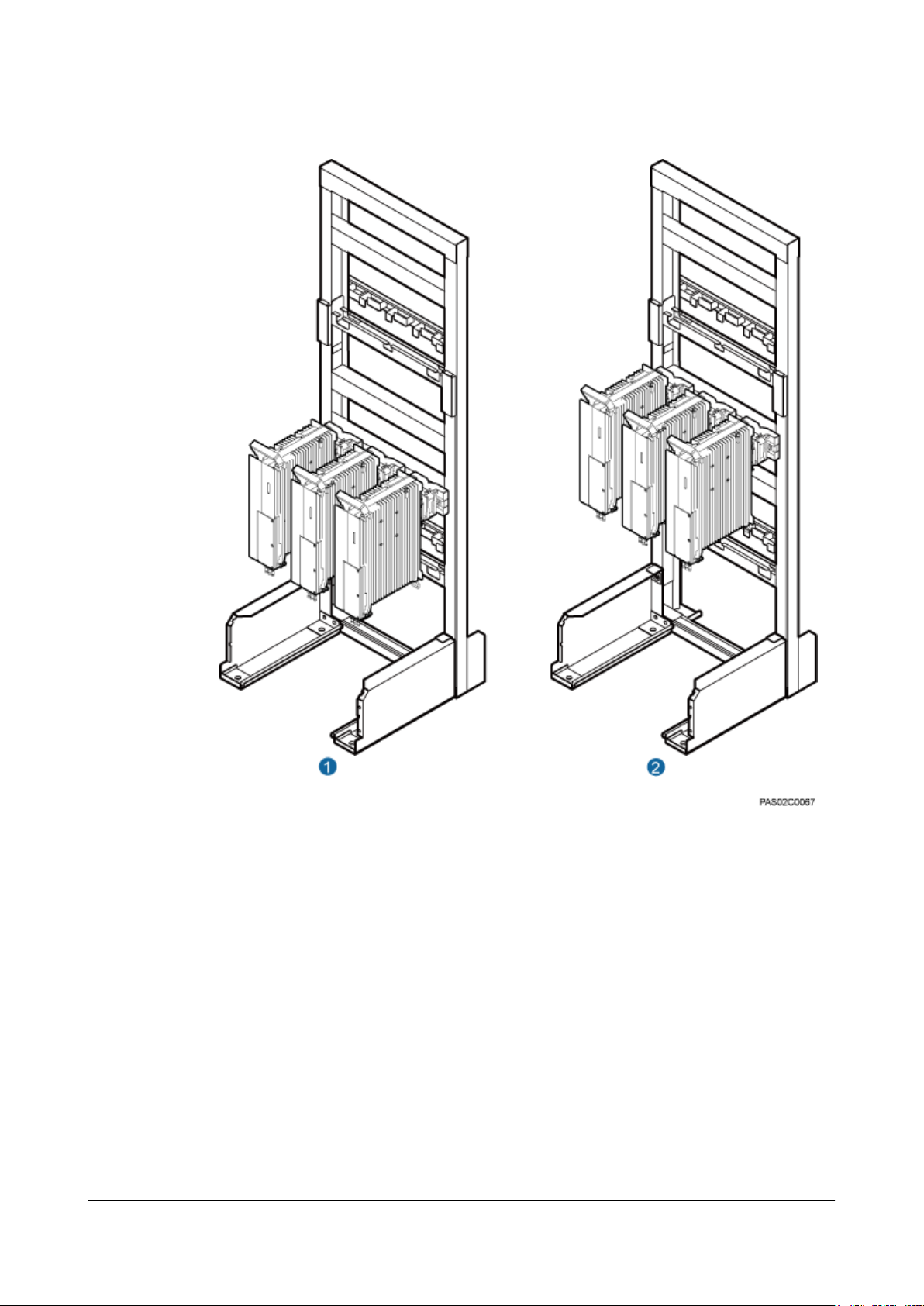

Figure 3-20 and Figure 3-21 show RRUs installed on an IFS06.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

19

Page 28

RRU3268

Installation Guide 3 Information About the Installation

Figure 3-20 Three RRUs installed on an IFS06

(1) Height-restricted scenario (2) Height-unrestricted scenario

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

20

Page 29

RRU3268

Installation Guide 3 Information About the Installation

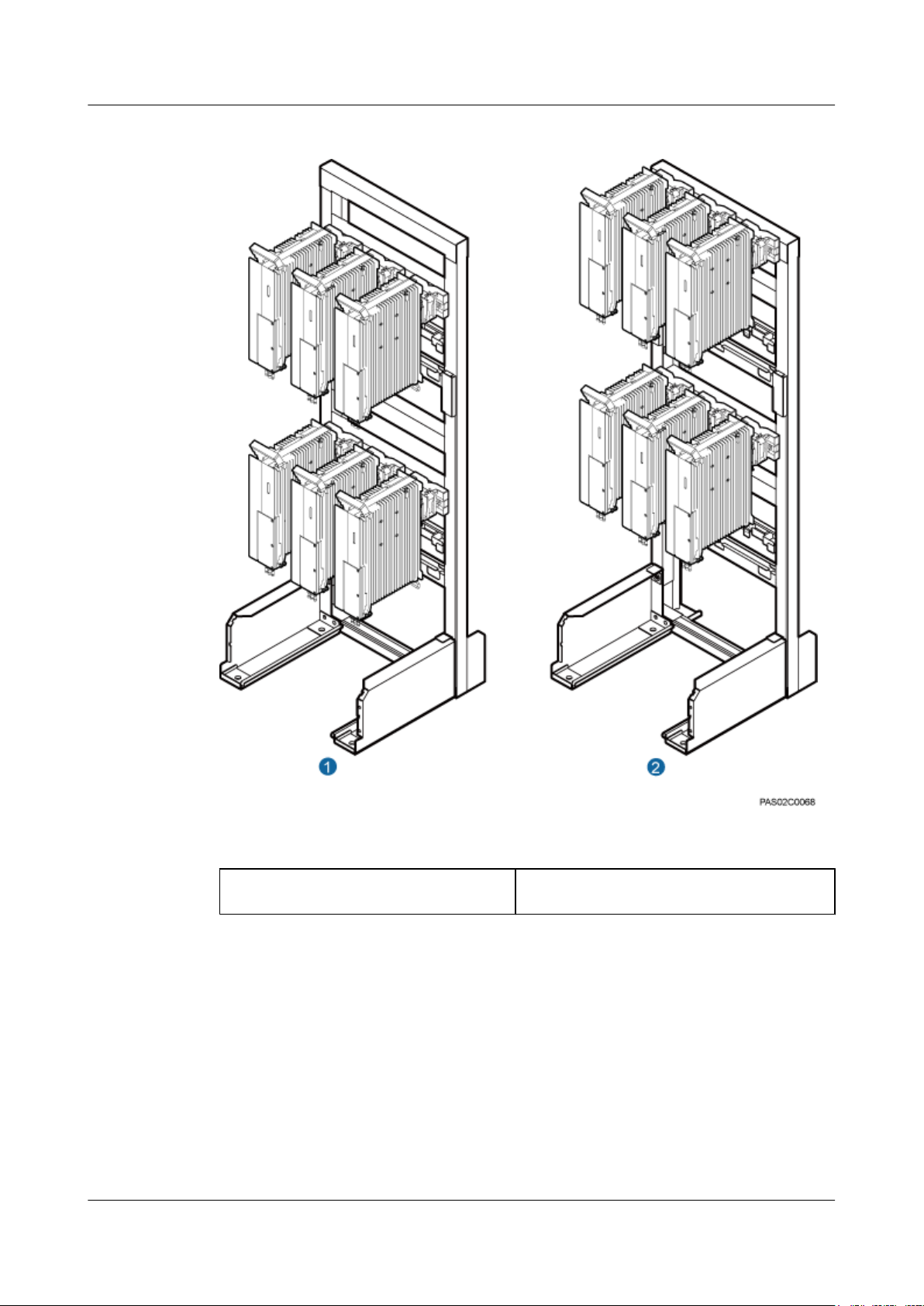

Figure 3-21 Six RRUs installed on an IFS06

(1) Height-restricted scenario

(2) Height-unrestricted scenario

3.5 Installation Clearance Requirements of an RRU

This section describes the requirements for the installation clearance of a single RRU and

multiple RRUs and the requirements for the installation spacing between RRUs.

3.5.1 Clearance for a Single RRU

This section describes the recommended and minimum clearance for a single RRU.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

21

Page 30

RRU3268

Installation Guide 3 Information About the Installation

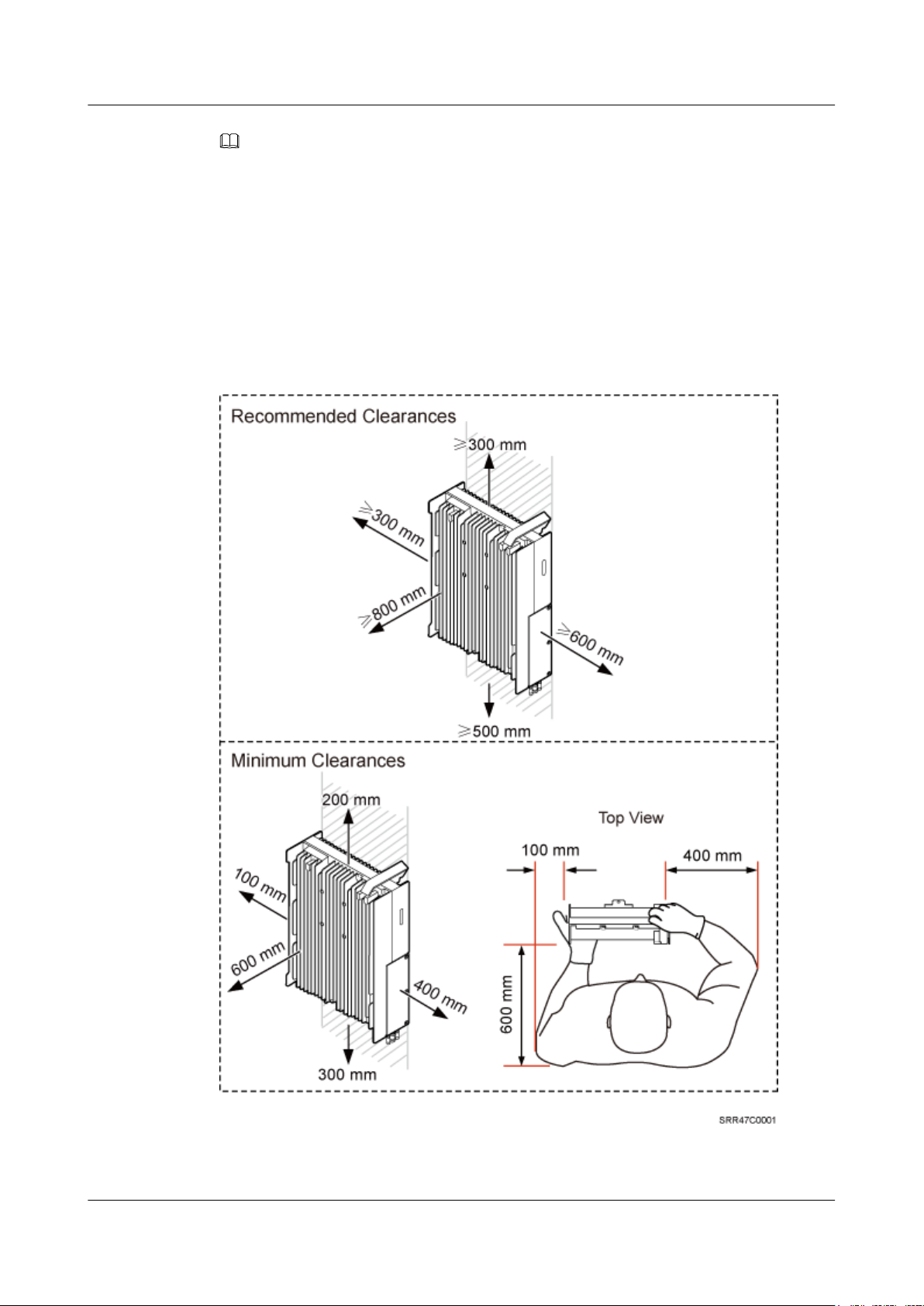

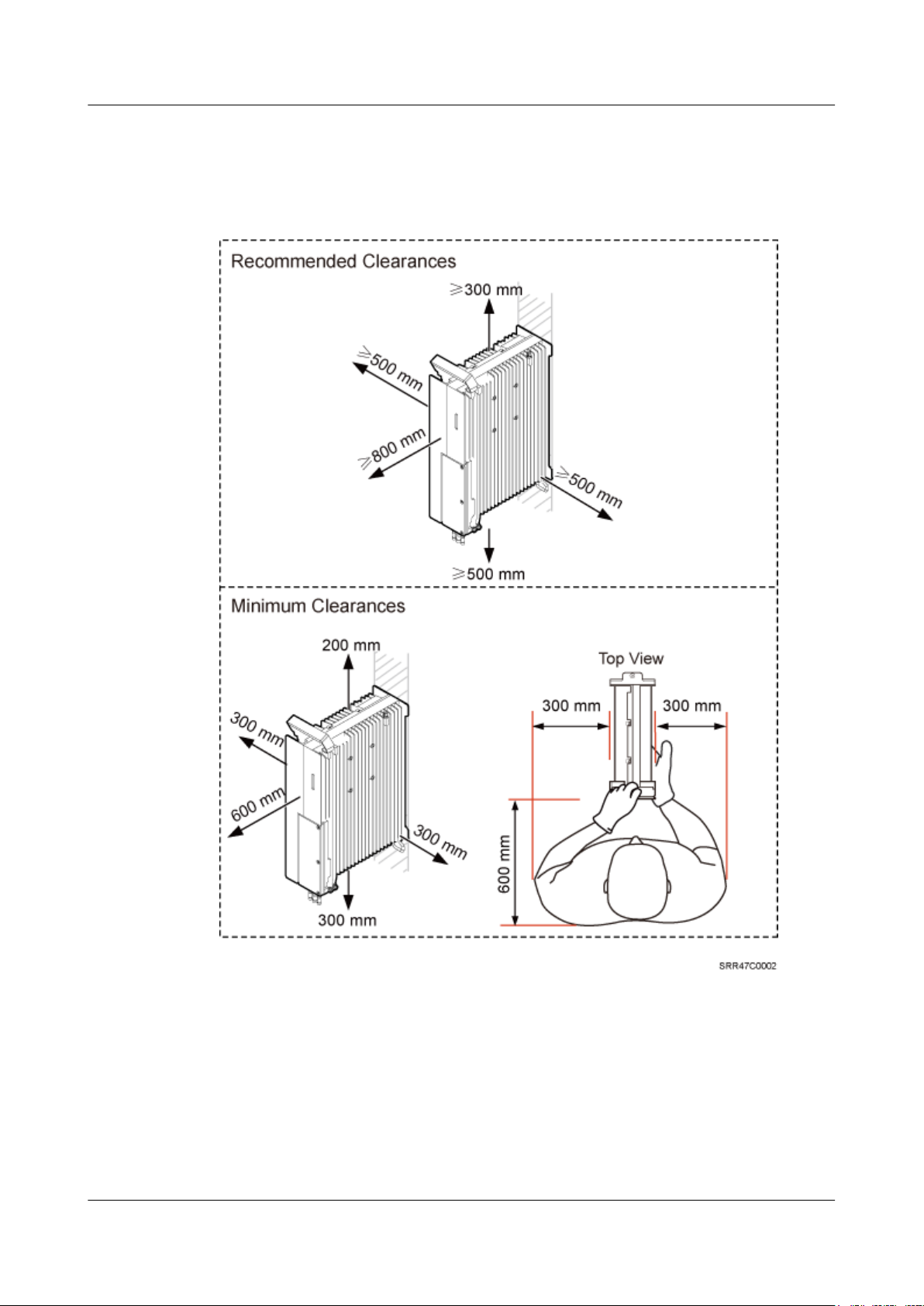

NOTE

l The recommended clearance ensures normal running and provides an appropriate space for operation

and maintenance (OM). If there is sufficient space, leave the recommended clearance after installing

the equipment.

l The minimum clearance ensures normal running and heat dissipation, but OM activities such as

checking indicator status and opening the cabling cavity cannot be properly conducted. If the

installation space is restricted, leave the minimum clearance after installing the equipment.

Clearances for a Single RRU in Standard or Reverse Mode

Figure 3-22 shows the clearances for a single RRU in standard or reverse mode.

Figure 3-22 Clearances for a single RRU in standard or reverse mode

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

22

Page 31

RRU3268

Installation Guide 3 Information About the Installation

Clearances for a Single RRU in Side-Mounted Mode

Figure 3-23 shows the clearances for a single RRU in side-mounted mode.

Figure 3-23 Clearances for a single RRU in side-mounted mode

Clearances for a Single Tower-mounted RRU

Figure 3-24 and Figure 3-25 show the clearances for a single tower-mounted RRU in standard

or reverse mode and in side-mounted mode, respectively.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

23

Page 32

RRU3268

Installation Guide 3 Information About the Installation

Figure 3-24 Minimum clearance for a single tower-mounted RRU in standard or reverse mode

Figure 3-25 Minimum clearance for a single tower-mounted RRU in side-mounted mode

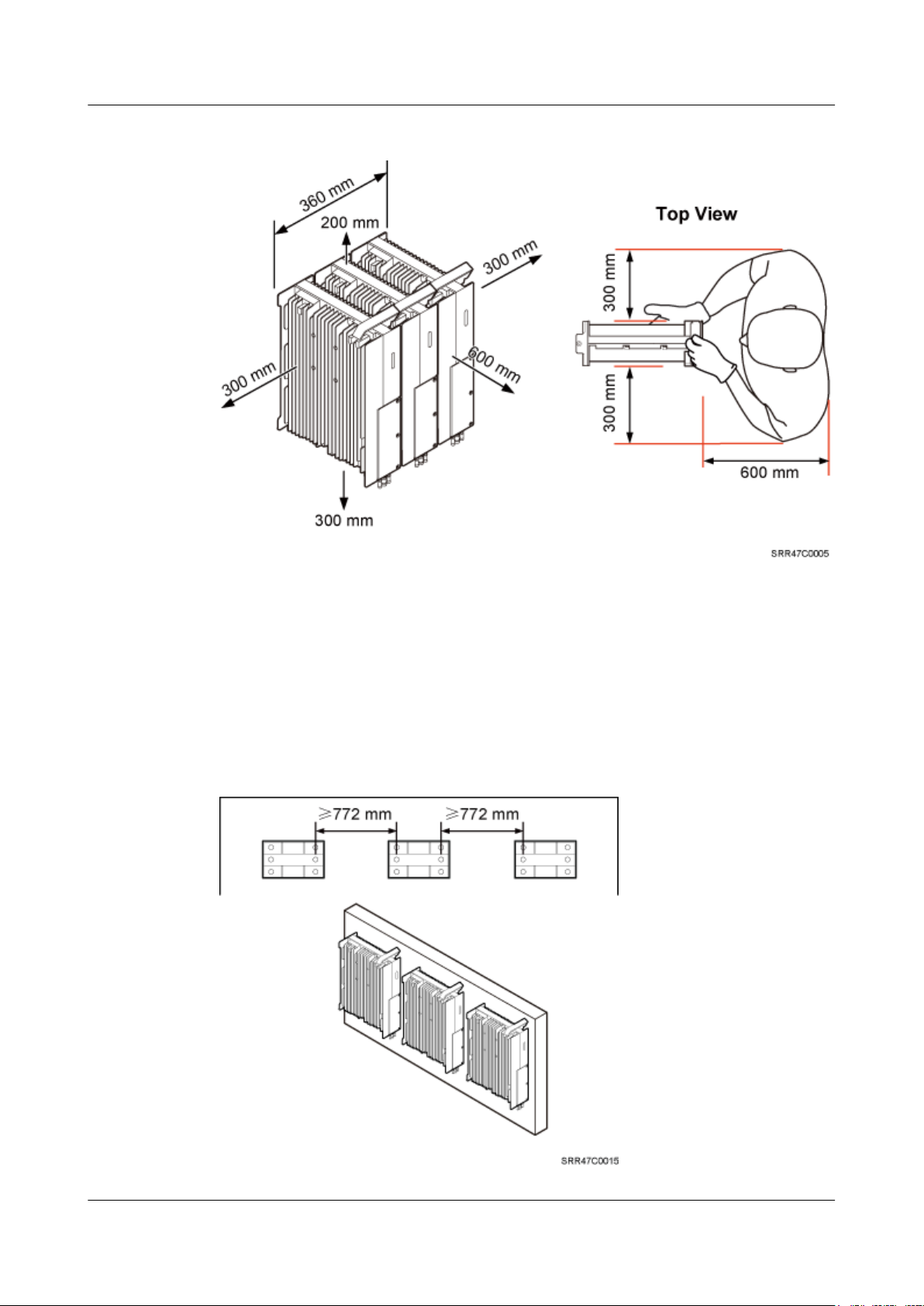

3.5.2 Clearance for Multiple RRUs

This section describes the recommended and minimum clearance for multiple RRUs.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

24

Page 33

RRU3268

Installation Guide 3 Information About the Installation

NOTE

l The recommended clearance ensures normal running and provides an appropriate space for operation

and maintenance (OM). If there is sufficient space, leave the recommended clearance after installing

the equipment.

l The minimum clearance ensures normal running and heat dissipation, but OM activities such as

checking indicator status and opening the cabling cavity cannot be properly conducted. If the

installation space is restricted, leave the minimum clearance after installing the equipment.

Recommended Clearance for Multiple RRUs Installed in Centralized Mode

Figure 3-26 shows the recommended clearance for multiple RRUs installed in centralized mode.

Figure 3-26 Recommended clearances for three or more RRUs installed on a pole

Minimum Clearance for Multiple RRUs Installed in Centralized Mode

Figure 3-27 shows the minimum clearance for multiple RRUs installed in centralized mode.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

25

Page 34

RRU3268

Installation Guide 3 Information About the Installation

Figure 3-27 Minimum clearances for multiple RRUs installed in centralized mode

Recommended Clearance for Multiple RRUs Installed on a Wall in Standard Mode

Figure 3-28 shows the recommended clearance for multiple RRUs installed on a wall in standard

mode.

Figure 3-28 Recommended clearances for three or more RRUs installed on a wall in standard

mode

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

26

Page 35

RRU3268

Installation Guide 3 Information About the Installation

Minimum Clearance for Multiple RRUs Installed on a Wall in Standard Mode

Figure 3-29 shows the minimum clearance for multiple RRUs installed on a wall in standard

mode.

Figure 3-29 Minimum clearances for three or more RRUs installed on a wall in standard mode

Recommended Clearance for Multiple RRUs Side-Mounted on a Wall

Figure 3-30 shows the recommended clearance for multiple RRUs side-mounted on a wall.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

27

Page 36

RRU3268

Installation Guide 3 Information About the Installation

Figure 3-30 Recommended clearances for three or more RRUs installed on a wall in sidemounted mode

3.5.3 Installation Spacing Between RRUs

This section describes the horizontal and vertical spacing between RRUs.

Recommended Horizontal Spacing Between RRUs

Figure 3-31 shows the recommended horizontal spacing between RRUs.

Figure 3-31 Recommended horizontal spacing between RRUs

Minimum Horizontal Spacing Between RRUs

Figure 3-32 shows the minimum horizontal spacing between RRUs.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

28

Page 37

RRU3268

Installation Guide 3 Information About the Installation

Figure 3-32 Minimum horizontal spacing between RRUs

Recommended Vertical Spacing Between RRUs

Figure 3-33 shows the recommended vertical spacing between RRUs.

Figure 3-33 Recommended vertical spacing between RRUs

Minimum Vertical Spacing Between RRUs

Figure 3-34 shows the minimum vertical spacing between RRUs.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

29

Page 38

RRU3268

Installation Guide 3 Information About the Installation

Figure 3-34 Minimum vertical spacing between RRUs

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

30

Page 39

RRU3268

Installation Guide 4 Unpacking the Equipment

4 Unpacking the Equipment

This chapter describes how to unpack and check the delivered equipment to ensure that all the

materials are included and intact.

Context

Procedure

Step 1 Check the total number of articles in each case according to the packing list.

NOTE

When transporting, moving, or installing the equipment, components, or parts, you must:

l Ensure that they are transported in the delivered packages instead of being unpacked or in non-

standard packages. If boards are used for a trial and then transported to sites, pack the boards again

before transportation.

l Prevent them from colliding with doors, walls, shelves, or other objects.

l Wear clean gloves, and avoid touching the equipment, components, or parts with bare hands, sweat-

soaked gloves, or dirty gloves.

CAUTION

l After a cabinet or an BBU is unpacked, it must be powered on within 7 days.

l After an RRU is unpacked, it must be powered on within 24 hours.

If ...

Then ...

The total number tallies with the packing

list

The total number does not tally with the

packing list

Step 2 Check the exterior of the packing case.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

Go to Step 2.

Find out the cause and report any missing

articles to the local Huawei office.

31

Page 40

RRU3268

Installation Guide 4 Unpacking the Equipment

If ... Then ...

The outer packing is intact Go to Step 3.

The outer packing is severely damaged or

soaked

Find out the cause and report it to the local

Huawei office.

The shockwatch label is red Stop unpacking the wooden crate, and then

report it to the transportation company.

Step 3 Check the type and quantity of the equipment in the cases according to the packing list.

If ... Then ...

Types and quantity of the article tally with

Sign the Packing List with the customer.

those on the packing list

Either shipment shortage, wrong shipment

Report to the local Huawei office.

or damaged articles.

WARNING

To protect the equipment and prevent damage to the equipment, you are advised to keep the

unpacked equipment and packing materials indoors, take photos of the stocking environment,

packing case or carton, packing materials, and any rusted or eroded equipment, and then file the

photos.

----End

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

32

Page 41

RRU3268

Installation Guide 5 Installation Process

5 Installation Process

The installation process involves installing an RRU and RRU cables, checking the RRU

hardware installation, and powering on the RRU.

Figure 5-1 shows the process of installing an RRU.

Figure 5-1 Process of installing an RRU

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

33

Page 42

RRU3268 Installation Guide 6 (Optional) Installing the Plastic Shells of the RRU

6 (Optional) Installing the Plastic Shells of the

RRU

This section describes the procedure for installing the plastic shells of the RRU.

Context

Procedure

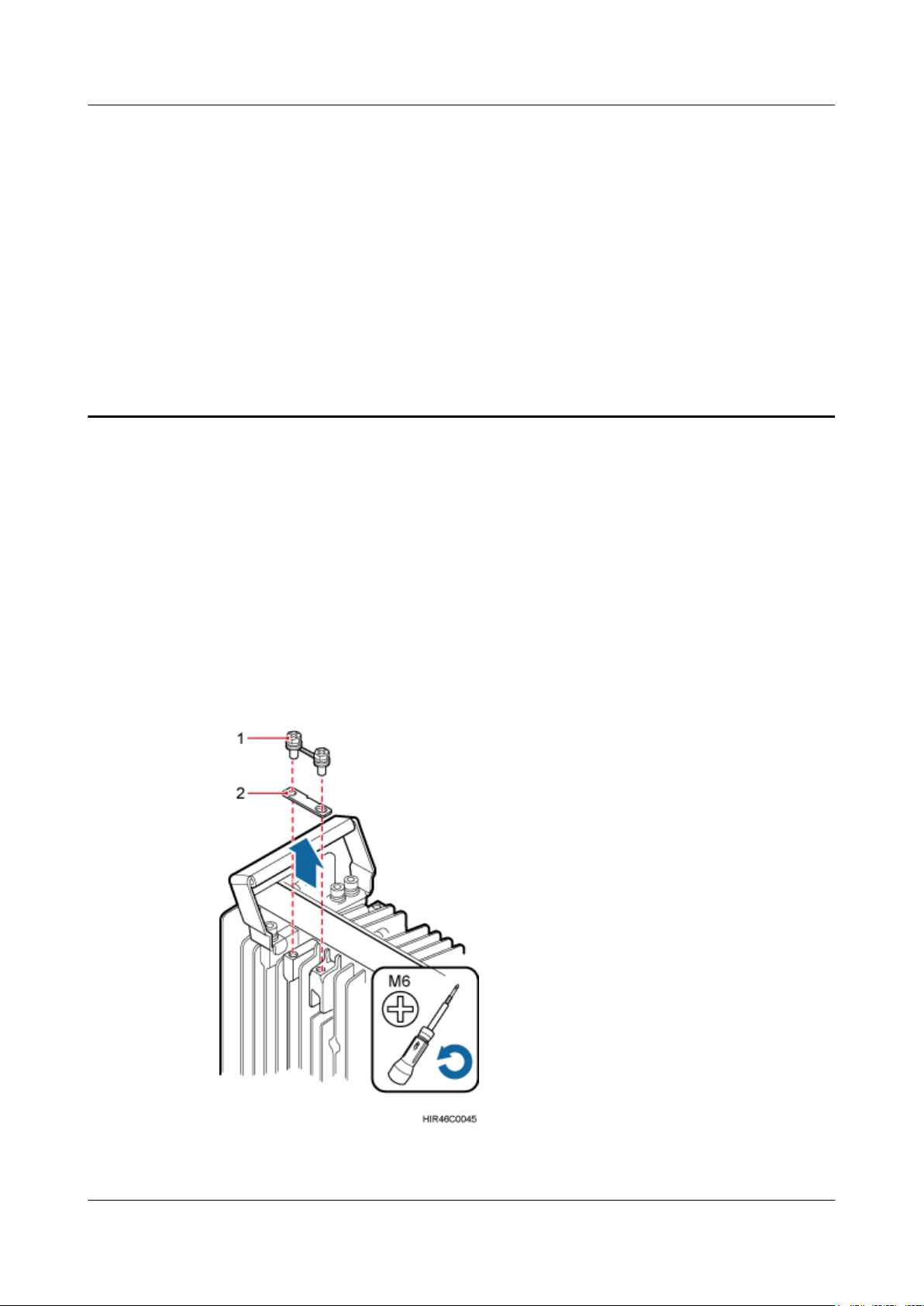

Step 1 Use an M6 Phillips screwdriver to loosen the two screws on the metal sheet of the RRU and

An RRU is equipped with a plastic shell only when necessary.

remove the metal sheet, as shown in Figure 6-1.

Figure 6-1 Removing the metal sheet

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

34

Page 43

RRU3268

Installation Guide 6 (Optional) Installing the Plastic Shells of the RRU

(1) Screw (2) Metal sheet

Step 2 Install a buckle on each side at the bottom of the RRU, and use an M4 torque wrench to tighten

the screws on the buckles to 1.4 N•m (12.39 lbf•in.), as shown in Figure 6-2.

Figure 6-2 Installing buckles at the bottom

(1) Buckle

(2) Screw

Step 3 Use four hex screws to secure the plastic shells onto the RRU and use an M6 hex key wrench

to tighten the screws to 2.8 N•m (24.78 lbf•in.), as shown in Figure 6-3.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

35

Page 44

RRU3268

Installation Guide 6 (Optional) Installing the Plastic Shells of the RRU

Figure 6-3 Installing the plastic shells of the RRU

----End

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

36

Page 45

RRU3268 Installation Guide 7 Hoisting an RRU and Related Cables onto a Tower

7 Hoisting an RRU and Related Cables onto a

Tower

About This Chapter

This section describes the procedure for hoisting an RRU and related cables onto a tower and

the precautions that must be taken.

7.1 Hoisting an RRU onto a Tower

This section describes the procedures and precautions for hoisting an RRU and its mounting kits

onto a tower. In tower-mounted scenario, the RRU can be installed on a pole, U-steel, or angle

steel.

7.2 Hoisting Fiber Optic Cables onto a Tower

This section describes the procedure for hoisting fiber optic cables onto a tower and the

precautions that must be taken.

7.3 Hoisting Power Cables onto a Tower

This section describes the procedure for hoisting power cables onto a tower and the precautions

that must be taken.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

37

Page 46

RRU3268

Installation Guide 7 Hoisting an RRU and Related Cables onto a Tower

7.1 Hoisting an RRU onto a Tower

This section describes the procedures and precautions for hoisting an RRU and its mounting kits

onto a tower. In tower-mounted scenario, the RRU can be installed on a pole, U-steel, or angle

steel.

Prerequisites

When the RRU is used with an AC/DC power module, you need to install the AC/DC power

module onto the RRU before hoisting the RRU onto a tower. For details about how to install an

AC/DC power module onto the RRU, see Installing an AC/DC Power Module onto an RRU.

CAUTION

l Do not stand the RRU upright because the RF ports cannot support the weight of the RRU.

l Place a foam pad or cardboard under the RRU to protect the RRU housing from damage

during the installation.

Procedure

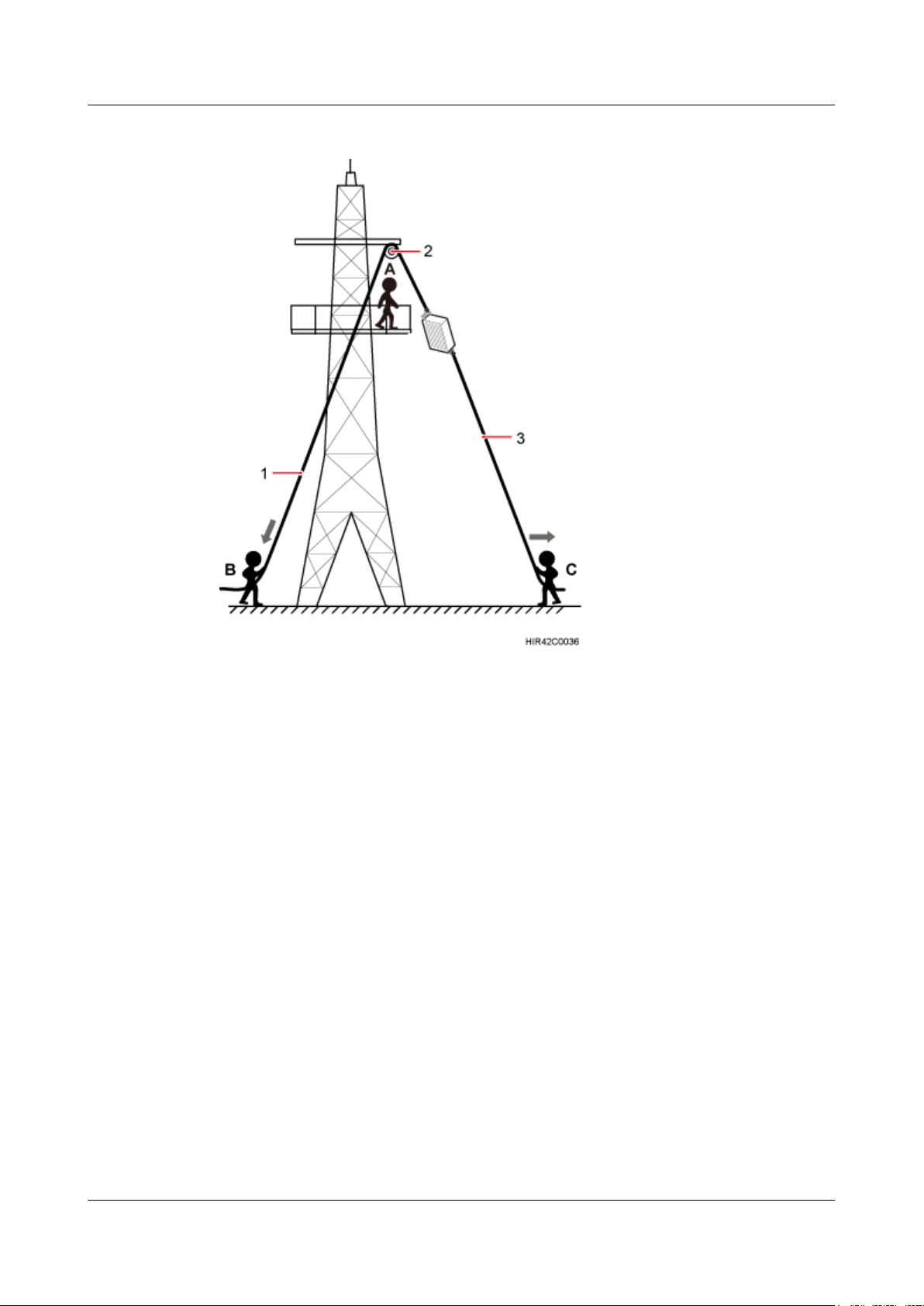

Step 1 Hoist the RRU and mounting kits onto the tower respectively, as shown in Figure 7-1.

NOTE

Hoist mounting kits onto the tower and then install the mounting kits before hoisting the RRU onto the

tower. When hoisting the mounting kits and RRU, protect them from colliding with the tower.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

38

Page 47

RRU3268

Installation Guide 7 Hoisting an RRU and Related Cables onto a Tower

Figure 7-1 Hoisting the RRU onto the tower

(1) Lifting sling (2) Fixed pulley (3) Traction sling

1. After climbing up to the tower, installation engineer A secures the fixed pulley to the tower

platform support and leads the lifting sling through the fixed pulley.

2. Installation engineer C binds the RRU mounting kits properly using a lifting sling, as shown

in Figure 7-2, and binds the RRU using a lifting sling and a traction sling, as shown in

Figure 7-3.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

39

Page 48

RRU3268

Installation Guide 7 Hoisting an RRU and Related Cables onto a Tower

Figure 7-2 Binding mounting kits for the RRU

Figure 7-3 Binding the RRU

(1) Handle

(2) Lifting sling (3) Traction eye (4) Traction sling

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

40

Page 49

RRU3268

Installation Guide 7 Hoisting an RRU and Related Cables onto a Tower

CAUTION

l The load-bearing capacity of each sling must be greater than 200 kg (441 lb) and the

diameter of each sling must be less than 25 mm (0.98 in.).

l When hoisting the RRU onto a tower, protect them from colliding with the tower and

ground.

l Hoist the RRU onto the tower before it is installed on a pole, angle steel, or U-steel.

l Do not hoist any thing by the traction eye.

l Do not hoist the RRU by the handle or traction eye only, as shown in Figure 7-4 and

Figure 7-5.

Figure 7-4 Incorrect binding method

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

41

Page 50

RRU3268

Installation Guide 7 Hoisting an RRU and Related Cables onto a Tower

Figure 7-5 Incorrect binding method

3. Installation engineer B pulls the lifting sling downwards, and installation engineer C pulls

the traction sling outwards to protect the RRU from colliding with the tower.

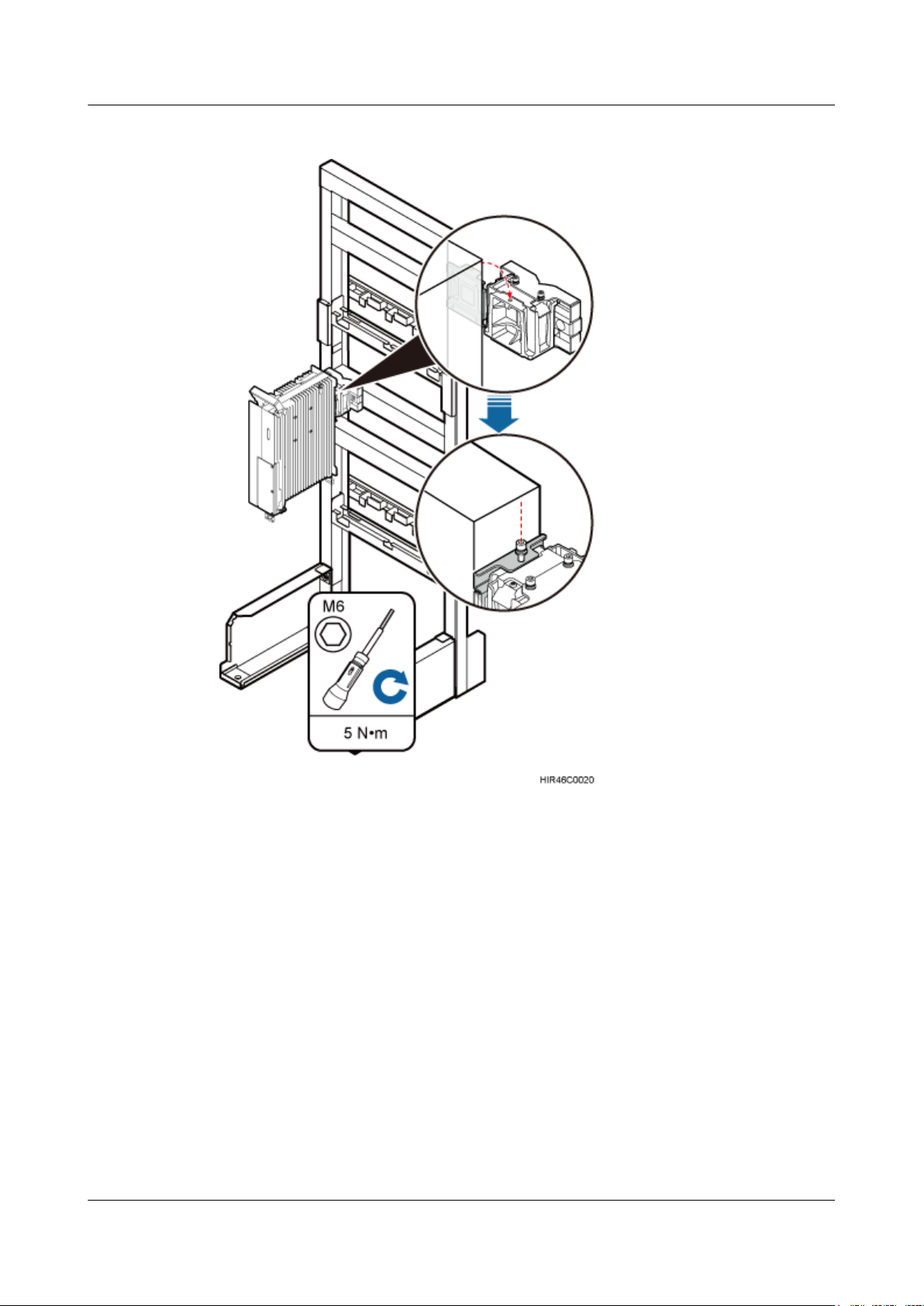

Step 2 Installation engineer A catches the RRU, install the RRU on the main bracket, use an inner

hexagon screwdriver to tighten the captive screw into the hole of the attachment plate to 5 N·m

(44.25 lbf·in.) for connecting the attachment plate and the main bracket, see 8 Installing the

RRU.

Step 3 Remove the lifting sling and traction sling.

NOTE

The procedure for hoisting the RRU and mounting kits onto the tower is for your reference only.

----End

7.2 Hoisting Fiber Optic Cables onto a Tower

This section describes the procedure for hoisting fiber optic cables onto a tower and the

precautions that must be taken.

Context

Cabling requirements for power cables are met. For details, see 9.1 Cabling Requirements.

Procedure

Step 1 Hoist the fiber optic cables onto the tower, as shown in Figure 7-6.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

42

Page 51

RRU3268

Installation Guide 7 Hoisting an RRU and Related Cables onto a Tower

Figure 7-6 Hoisting fiber optic cables onto the tower

(1) Lifting sling (2) Fixed pulley (3) Traction sling

CAUTION

Before hoisting fiber optic cables onto the tower, connect the fiber optic cables to the RRU or

BBU based on the labels on both ends of the cables and determine the hoisting direction.

1. After climbing up to the tower, installation engineer A secures the fixed pulley to the tower

platform support and leads the lifting sling through the fixed pulley.

2. Installation engineer B places the fiber coiler for coiling fiber optic cables on the fiber

spools, and installation engineer D lead the lifting sling through the stretch sling of the fiber

optic cables and use the other sling as a traction sling to secure the cables 4 m (13.12 ft)

away from the lifting sling, as shown in Figure 7-7.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

43

Page 52

RRU3268

Installation Guide 7 Hoisting an RRU and Related Cables onto a Tower

Figure 7-7 Binding fiber optic cables

(1) Lifting sling (2) Stretch sling (3) Traction sling

CAUTION

Do not remove the stretch sling and protection pipe or bind fiber optic cables using one

sling, as shown in Figure 7-8.

Figure 7-8 Incorrect binding method

3. Installation engineer B rotates the fiber spools at the speed of 5 m (16.4 ft) to 15 m (49.21

ft) per minute to coil the fiber optic cables.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

44

Page 53

RRU3268

Installation Guide 7 Hoisting an RRU and Related Cables onto a Tower

4. Installation engineer C pulls the lifting sling downwards, and installation engineer D pulls

the traction sling outwards to protect the fiber optic cables from colliding with the tower.

Step 2 Secure the fiber optic cables to the tower vertically using cable clips.

Step 3 Remove the lifting sling, traction sling, and protection pipe.

NOTE

The procedure for hoisting the fiber optic cables onto the tower is for your reference only.

----End

7.3 Hoisting Power Cables onto a Tower

This section describes the procedure for hoisting power cables onto a tower and the precautions

that must be taken.

Context

Cabling requirements for power cables are met. For details, see 9.1 Cabling Requirements.

Procedure

Step 1 Hoist the power cables onto the tower, as shown in Figure 7-9.

The procedure for adding a connector to the RRU power cable on the RRU side is done under

the tower.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

45

Page 54

RRU3268

Installation Guide 7 Hoisting an RRU and Related Cables onto a Tower

Figure 7-9 Hoisting power cables onto the tower

(1) Lifting sling (2) Fixed pulley

1. After climbing up to the tower, installation engineer A secures the fixed pulley to the tower

platform support and leads the lifting sling through the fixed pulley.

2. Installation engineer B secures three cable ties to the power cable connector, and then

secures the power cable to the lifting sling, as shown in Figure 7-10.

NOTE

The connector on the power cable in the figure is only an example. The actual connector may vary

according to the situation.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

46

Page 55

RRU3268

Installation Guide 7 Hoisting an RRU and Related Cables onto a Tower

Figure 7-10 Binding cable ties

3. Installation engineer B wraps the power cable connector with a layer of PVC insulation

tape, as shown in Figure 7-11.

NOTE

Wrap the PVC insulation tape from 30 mm (1.18 in.) away from one end of the connector until it

reaches the other end of the connector. The total length of the wrapped connector is 100 mm (3.94

in.).

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

47

Page 56

RRU3268

Installation Guide 7 Hoisting an RRU and Related Cables onto a Tower

Figure 7-11 Wrapping the PVC insulation tape

4. Installation engineer C pulls the lifting sling downwards, and installation engineer B pulls

the other end of the lifting sling outwards to protect the power cables from colliding with

the tower.

Step 2 Secure the power cables to the tower vertically using cable clips.

Step 3 Remove the cable ties, PVC insulation tape, and lifting sling.

NOTE

The procedure for hoisting the power cables onto the tower is for your reference only.

----End

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

48

Page 57

RRU3268

Installation Guide 8 Installing the RRU

8 Installing the RRU

About This Chapter

This chapter describes the procedure for installing the RRU. The RRU can be installed on a pole,

U-steel, angle steel, wall, or an IFS06 . The procedure for installing the RRU varies depending

on installation options.

8.1 Mounting Kits for an RRU

This section describes the bracket assembly and the attachment plate for an RRU.

8.2 Installing the RRU on a Pole

One or more RRUs can be installed on a pole.

8.3 Installing the RRU on U-steel

This section describes the procedure and precautions for installing the RRU on U-steel. An RRU

can be installed on U-steel secured on the ground or a tower. Each piece of U-steel allows only

one RRU to be installed in standard or reverse mode.

8.4 Installing the RRU on Angle Steel

This section describes the procedure and precautions for installing the RRU on angle steel. An

RRU can be installed on angle steel secured on the ground or a tower. Each piece of angle steel

allows only one RRU to be installed in standard or reverse mode.

8.5 Installing the RRU on a Wall

This section describes the procedure and precautions for installing the RRU on a wall.

8.6 Installing an RRU on an IFS06

This section describes the procedure and precautions for installing an RRU on an IFS06.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

49

Page 58

RRU3268

Installation Guide 8 Installing the RRU

8.1 Mounting Kits for an RRU

This section describes the bracket assembly and the attachment plate for an RRU.

Figure 8-1 shows the front and rear of an RRU.

Figure 8-1 Front and side view of an RRU

(1) Attachment plate

Figure 8-2 shows the bracket assembly for an RRU.

Figure 8-2 12 L blade RRU mounting kit

(1) Main bracket

Issue () Huawei Proprietary and Confidential

(2) Pole installation

bracket

Copyright © Huawei Technologies Co., Ltd.

(3) Auxiliary bracket (4) Nut (5) Square-neck

bolt

(6) Hoist clamp on

the main bracket

50

Page 59

RRU3268

Installation Guide 8 Installing the RRU

8.2 Installing the RRU on a Pole

One or more RRUs can be installed on a pole.

8.2.1 Installing a Single RRU

This section describes the procedure and precautions for installing a single RRU on a pole.

Prerequisites

Before you install an RRU on a pole secured on a tower, the RRU and its mounting brackets are

hoisted onto the tower. For details, see 7.1 Hoisting an RRU onto a Tower.

The hoist clamp on the main bracket is secured properly.

CAUTION

Procedure

Step 1 Determine a position for installing the mounting brackets.

l Do not stand the RRU upright because the RF ports cannot support the weight of the RRU.

l Place a foam pad or cardboard under the RRU to protect the RRU housing from damage

during the installation.

l If the pole must be installed on a tower, determine a position for installing the mounting

brackets according to the instructions in 3.5.1 Clearance for a Single RRU.

l If the pole must be installed on the ground, determine a position for installing the mounting

brackets according to Figure 8-3.

Figure 8-3 Distance between the mounting brackets and the ground

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

51

Page 60

RRU3268

Installation Guide 8 Installing the RRU

NOTE

It is recommended that the mounting brackets be installed at a height of 1200 mm (47.24 in.) to 1600

mm (62.99 in.) above the ground.

Step 2 Install the RRU mounting brackets, as shown in Figure 8-4.

Figure 8-4 Installing the RRU mounting brackets

NOTE

Verify that the arrows on the mounting brackets are pointing up.

1. Adjust the position of the nut and remove one end of the square-neck bolt from the slot on

the auxiliary bracket.

2. Slide the mounting brackets onto the pole horizontally and insert the square-neck bolt into

the slot.

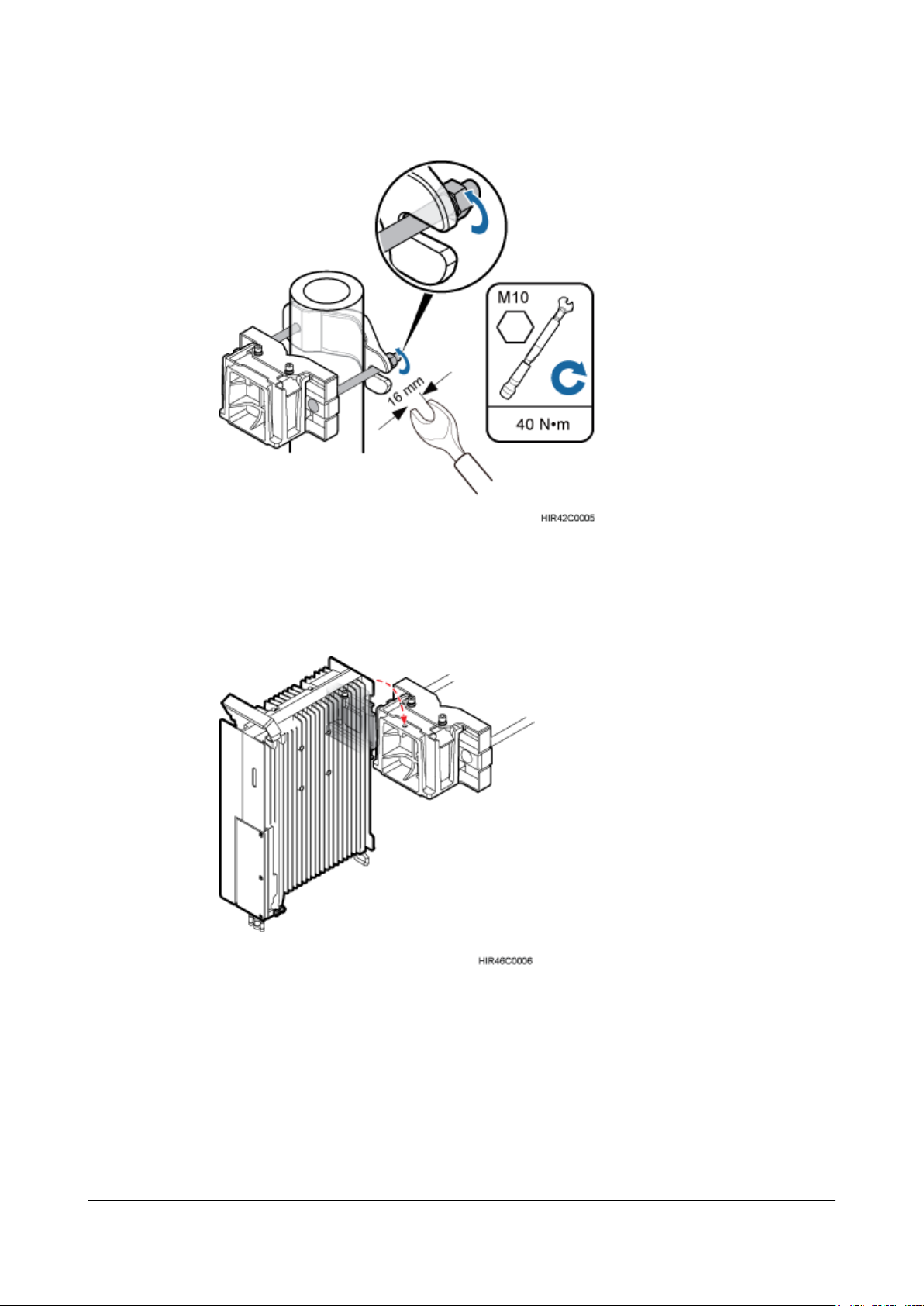

Step 3 Use a 16 mm (0.63 in.) M10 torque wrench to tighten the nuts to 40 N·m (354.03 lbf·in.) so that

the mounting brackets are secured onto the pole, as shown in Figure 8-5.

CAUTION

Tighten the nuts on the two square-neck bolts alternatively. After the main and auxiliary brackets

are secured properly, measure the spacing between the brackets on both sides and ensure that

the spacing is the same on the two sides.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

52

Page 61

RRU3268

Installation Guide 8 Installing the RRU

Figure 8-5 Securing the RRU mounting brackets

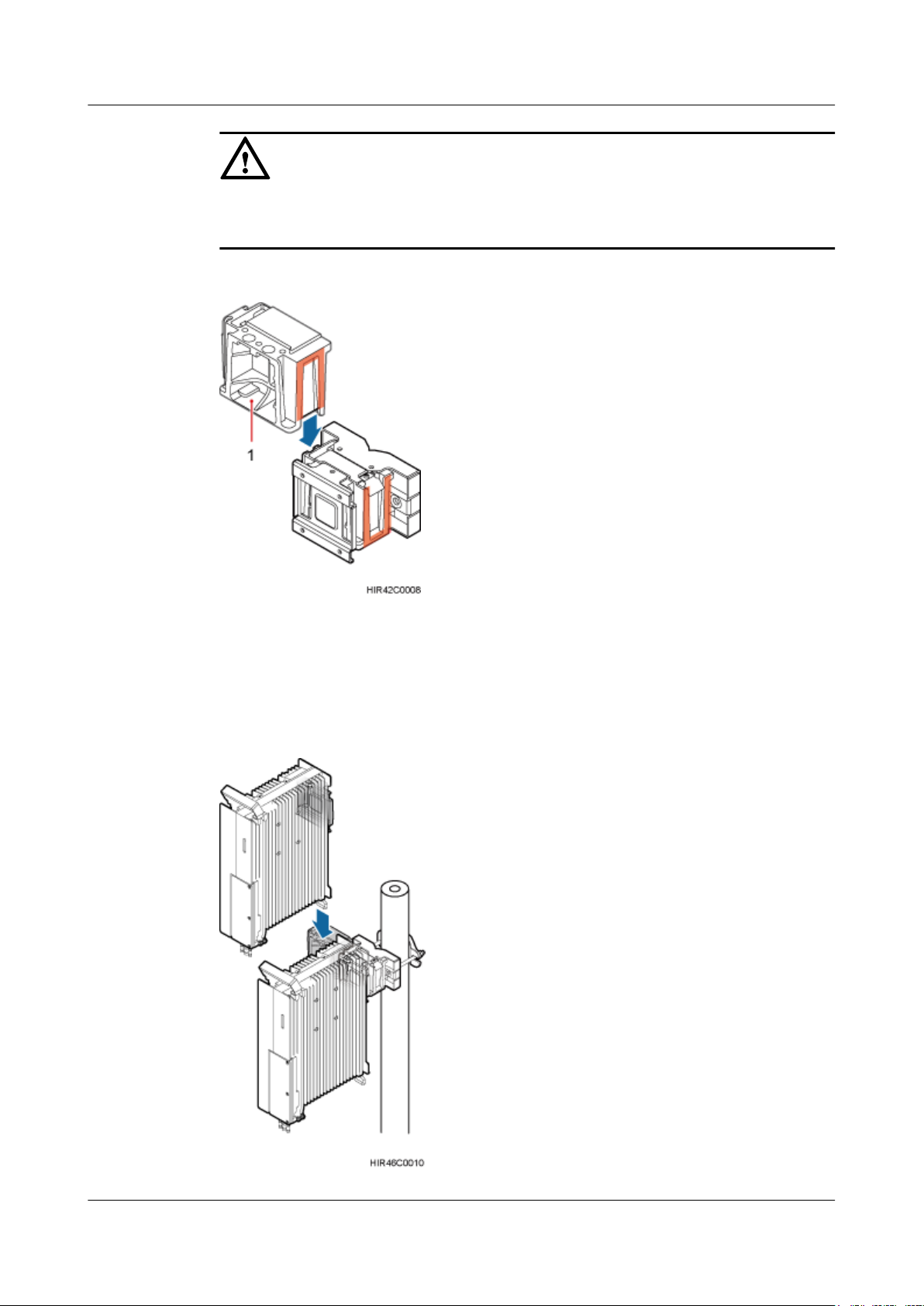

Step 4 Install the RRU onto the main bracket, as shown in Figure 8-6.

Figure 8-6 Installing the RRU onto the main bracket

Step 5 Use an inner hexagon torque screwdriver to tighten the captive screw into the holes on the top

of the attachment plate and main bracket to 5 N·m (44.25 lbf·in.) so that the attachment plate

and main bracket are firmly secured, as shown in Figure 8-7.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

53

Page 62

RRU3268

Installation Guide 8 Installing the RRU

Figure 8-7 Securing the captive screw into the connection hole

----End

8.2.2 Installing Two RRUs

This section describes the procedure and precautions for installing two RRUs on a pole.

Prerequisites

The hoist clamp on the main bracket is secured properly.

CAUTION

l Do not stand the RRU upright because the RF ports cannot support the weight of the RRU.

l Place a foam pad or cardboard under the RRU to protect the RRU housing from damage

during the installation.

Procedure

Step 1 Install the first RRU onto the main bracket, as shown in Figure 8-8. For details, see 8.2.1

Installing a Single RRU.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

54

Page 63

RRU3268

Installation Guide 8 Installing the RRU

Figure 8-8 Installing the first RRU onto the main bracket

Step 2 Use an M6 inner hexagon screwdriver to remove the four inner hexagon screws from the second

set of mounting brackets, and remove the main bracket from the auxiliary bracket, as shown in

Figure 8-9.

Figure 8-9 Removing the RRU main bracket

(1) Main bracket

(2) Pole installation bracket

Step 3 Install the removed main bracket on one side of the first main bracket, as shown in Figure

8-10.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

55

Page 64

RRU3268

Installation Guide 8 Installing the RRU

CAUTION

The second main bracket must be installed with the opening ends of U-shaped slots on both sides

facing downwards.

Figure 8-10 Installing the second main bracket

(1) Removed main bracket

Step 4 Install the second RRU onto the main bracket, as shown in Figure 8-11.

Figure 8-11 Installing the second RRU onto the main bracket

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

56

Page 65

RRU3268

Installation Guide 8 Installing the RRU

CAUTION

After installing each RRU on its main bracket, use an inner hexagon torque screwdriver to tighten

the captive screw into the holes of the attachment plate and main bracket to 5 N·m (44.25 lbf·in.)

so that the attachment plate and main bracket are firmly secured, as shown in Figure 8-12.

Figure 8-12 Securing the captive screw into the connection hole

Step 5 Install the metal sheet for neighboring RRUs, as shown in Figure 8-13.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

57

Page 66

RRU3268

Installation Guide 8 Installing the RRU

Figure 8-13 Installing the metal sheet

(1) Screw (2) Metal sheet

1. Use an M6 Phillips screwdriver to loosen the screw on the metal sheet farther from the

handle of the first RRU and remove the screw.

2. Use an M6 Phillips screwdriver to loosen the screw on the metal sheet closer to handle of

the first RRU. Then rotate the metal sheet to align the vacant hole in the metal sheet with

a hole on the top of the second RRU.

3. Insert the removed screw into the hole on the top of the second RRU and use an M6 torque

screwdriver to tighten the screw to 5 N·m (44.25 lbf·in.).

----End

8.2.3 Installing Three or More RRUs

The section describes the procedure and precautions for installing three or more RRUs on a pole.

Prerequisites

The hoist clamp on the main bracket is secured properly.

CAUTION

l Do not stand the RRU upright because the RF ports cannot support the weight of the RRU.

l Place a foam pad or cardboard under the RRU to protect the RRU housing from damage

during the installation.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

58

Page 67

RRU3268

Installation Guide 8 Installing the RRU

Context

A pole supports the installation of three, four, or six RRUs. The procedures for installing them

are the same. Following is the procedure of installing four RRUs on a pole.

Procedure

Step 1 Install the two RRUs, as shown in Figure 8-14. For details, see 8.2.2 Installing Two RRUs.

Figure 8-14 Two RRUs installed on a pole

Step 2 Use an M6 inner hexagon screwdriver to remove the four inner hexagon screws from the second

set of mounting brackets, and remove the main bracket from the auxiliary bracket, as shown in

Figure 8-15.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

59

Page 68

RRU3268

Installation Guide 8 Installing the RRU

Figure 8-15 Removing the RRU main bracket

(1) Main bracket (2) Pole installation bracket

Step 3 Install the third main bracket and install the third RRU onto the third main bracket. Then use an

inner hexagon torque screwdriver to tighten the captive screw into the connection holes on the

top of the attachment plate and main bracket for the RRU, with a torque of 5 N·m (44.25 lbf·in.),

as shown in Figure 8-16.

CAUTION

The third main bracket must be installed with the opening ends of U-shaped slots on both sides

facing downwards.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

60

Page 69

RRU3268

Installation Guide 8 Installing the RRU

Figure 8-16 Installing the third RRU onto the third main bracket

Step 4 Install the metal sheet for neighboring RRUs, as shown in Figure 8-17.

Figure 8-17 Installing the metal sheet

(1) Screw

(2) Metal sheet

1. Use an M6 Phillips screwdriver to loosen the screw on the metal sheet farther from the

handle of the first RRU and remove the screw.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

61

Page 70

RRU3268

Installation Guide 8 Installing the RRU

2. Use an M6 Phillips screwdriver to loosen the screw on the metal sheet closer to handle of

the first RRU. Then rotate the metal sheet to align the vacant hole in the metal sheet with

a hole on the top of the second RRU.

3. Insert the removed screw into the hole on the top of the second RRU and use an M6 torque

screwdriver to tighten the screw to 5 N·m (44.25 lbf·in.).

Step 5 At a position 80 mm (3.15 in.) above or below the first set of RRU mounting brackets, install

the second set of RRU mounting brackets, as shown in Figure 8-18.

Figure 8-18 Installing the second set of RRU mounting brackets

Step 6 Install the fourth RRU onto the fourth main bracket, use an inner hexagon torque screwdriver

to tighten the captive screw into the holes of the attachment plate and main bracket to 5 N·m

(44.25 lbf·in.) so that the attachment plate and main bracket are firmly secured, as shown in

Figure 8-19.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

62

Page 71

RRU3268

Installation Guide 8 Installing the RRU

Figure 8-19 Installing the fourth RRU onto the fourth main bracket

----End

8.3 Installing the RRU on U-steel

This section describes the procedure and precautions for installing the RRU on U-steel. An RRU

can be installed on U-steel secured on the ground or a tower. Each piece of U-steel allows only

one RRU to be installed in standard or reverse mode.

Prerequisites

Before you install an RRU on U-steel secured on a tower, the RRU and its mounting brackets

are hoisted onto the tower. For details, see 7.1 Hoisting an RRU onto a Tower.

The hoist clamp on the main bracket is secured properly.

CAUTION

l Do not stand the RRU upright because the RF ports cannot support the weight of the RRU.

l Place a foam pad or cardboard under the RRU to protect the RRU housing from damage

during the installation.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

63

Page 72

RRU3268

Installation Guide 8 Installing the RRU

Context

Figure 8-20 shows the top view of the RRU installed on U-steel.

CAUTION

When the width of the narrower edges of the U-steel is less than 40 mm (1.57 in.), only the a

and b modes are supported.

Figure 8-20 Top view of the RRU

(1) U-steel

Procedure

Step 1 Determine a position for installing the mounting brackets.

l If the RRU must be installed on U-steel secured on a tower, see 3.5.1 Clearance for a

Single RRU to determine a position.

l If the RRU must be installed on U-steel secured on the ground, see Figure 8-21 to determine

a position.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

64

Page 73

RRU3268

Installation Guide 8 Installing the RRU

Figure 8-21 Distance between the mounting brackets and the ground

NOTE

It is recommended that the mounting brackets be installed at a height of 1200 mm (47.24 in.) to 1600

mm (62.99 in.) above the ground.

Step 2 Install the RRU mounting brackets, as shown in Figure 8-22.

Figure 8-22 Installing the RRU mounting brackets

NOTE

Verify that the arrows on the mounting brackets are pointing up.

1. Adjust the position of the nut and remove one end of the square-neck bolt from the slot on

the auxiliary bracket.

2. Slide the mounting brackets onto the U-steel horizontally and insert the square-neck bolt

into the slot.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

65

Page 74

RRU3268

Installation Guide 8 Installing the RRU

Step 3 Use a 16 mm (0.67 in.) M10 torque wrench to tighten the nuts to 40 N·m (354.03 lbf·in.) so that

the mounting brackets are secured onto the U-steel, as shown in Figure 8-23.

CAUTION

Tighten the nuts on the two square-neck bolts alternatively. After the main and auxiliary brackets

are secured properly, measure the spacing between the brackets on both sides and ensure that

the spacing is the same on the two sides.

Figure 8-23 Securing the RRU mounting brackets

Step 4 Use an inner hexagon screwdriver to remove the attachment plate from one side of the RRU,

reinstall the attachment plate onto the rear of the RRU, and tighten the four stainless screws to

5 N·m (44.25 lbf·in.), as shown in Figure 8-24.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

66

Page 75

RRU3268

Installation Guide 8 Installing the RRU

Figure 8-24 Installing the attachment plate onto the rear of the RRU

Step 5 Install the RRU onto the main bracket, as shown in Figure 8-25.

Figure 8-25 Installing the RRU onto the main bracket

Step 6 Use an inner hexagon screwdriver to tighten the captive screw into the holes on the top of the

attachment plate and main bracket to 5 N·m (44.25 lbf·in.) so that the attachment plate and main

bracket are firmly secured, as shown in Figure 8-26.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

67

Page 76

RRU3268

Installation Guide 8 Installing the RRU

Figure 8-26 Securing the captive screw into the connection hole

----End

8.4 Installing the RRU on Angle Steel

This section describes the procedure and precautions for installing the RRU on angle steel. An

RRU can be installed on angle steel secured on the ground or a tower. Each piece of angle steel

allows only one RRU to be installed in standard or reverse mode.

Prerequisites

Before you install an RRU on angle steel secured on a tower, the RRU and its mounting brackets

are hoisted onto the tower. For details, see 7.1 Hoisting an RRU onto a Tower.

The hoist clamp on the main bracket is secured properly.

CAUTION

l Do not stand the RRU upright because the RF ports cannot support the weight of the RRU.

l Place a foam pad or cardboard under the RRU to protect the RRU housing from damage

during the installation.

Context

Figure 8-27 shows the top view of the RRU installed on angle steel.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

68

Page 77

RRU3268

Installation Guide 8 Installing the RRU

Figure 8-27 Top view of the RRU

(1) Angle steel

Procedure

Step 1 Determine a position for installing the mounting brackets.

l If the RRU must be installed on angle steel secured on a tower, see 3.5.1 Clearance for a

Single RRU to determine a position.

l If the RRU must be installed on angle steel secured on the ground, see Figure 8-28 to

determine a position.

Figure 8-28 Distance between the mounting brackets and the ground

NOTE

It is recommended that the mounting brackets be installed at a height of 1200 mm (47.24 in.) to 1600

mm (62.99 in.) above the ground.

Step 2 Install the RRU mounting brackets, as shown in Figure 8-29.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

69

Page 78

RRU3268

Installation Guide 8 Installing the RRU

Figure 8-29 Installing the RRU mounting brackets

NOTE

Verify that the arrows on the mounting brackets are pointing up.

1. Adjust the position of the nut and remove one end of the square-neck bolt from the slot on

the auxiliary bracket.

2. Slide the mounting brackets onto the angle steel horizontally and insert the square-neck

bolt into the slot.

Step 3 Use a 16 mm (0.67 in.) M10 torque wrench to tighten the nuts to 40 N·m (354.03 lbf·in.) so that

the mounting brackets are secured onto the angle steel, as shown in Figure 8-30.

CAUTION

Tighten the nuts on the two square-neck bolts alternatively. After the main and auxiliary brackets

are secured properly, measure the spacing between the brackets on both sides and ensure that

the spacing is the same on the two sides.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

70

Page 79

RRU3268

Installation Guide 8 Installing the RRU

Figure 8-30 Securing the RRU mounting brackets

Step 4 Use an inner hexagon screwdriver to remove the attachment plate from one side of the RRU,

reinstall the attachment plate onto the rear of the RRU, and tighten the four stainless screws to

5 N·m (44.25 lbf·in.), as shown in Figure 8-31.

Figure 8-31 Installing the attachment plate onto the rear of the RRU

Step 5 Install the RRU onto the main bracket, as shown in Figure 8-32.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

71

Page 80

RRU3268

Installation Guide 8 Installing the RRU

Figure 8-32 Installing the RRU onto the main bracket

Step 6 Use an inner hexagon screwdriver to tighten the captive screw into the holes on the top of the

attachment plate and main bracket to 5 N·m (44.25 lbf·in.) so that the attachment plate and main

bracket are firmly secured, as shown in Figure 8-33.

Figure 8-33 Securing the captive screw into the connection hole

----End

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

72

Page 81

RRU3268

Installation Guide 8 Installing the RRU

8.5 Installing the RRU on a Wall

This section describes the procedure and precautions for installing the RRU on a wall.

Prerequisites

The hoist clamp on the main bracket is secured properly.

CAUTION

l Do not stand the RRU upright because the RF ports cannot support the weight of the RRU.

l Place a foam pad or cardboard under the RRU to protect the RRU housing from damage

during the installation.

Context

Procedure

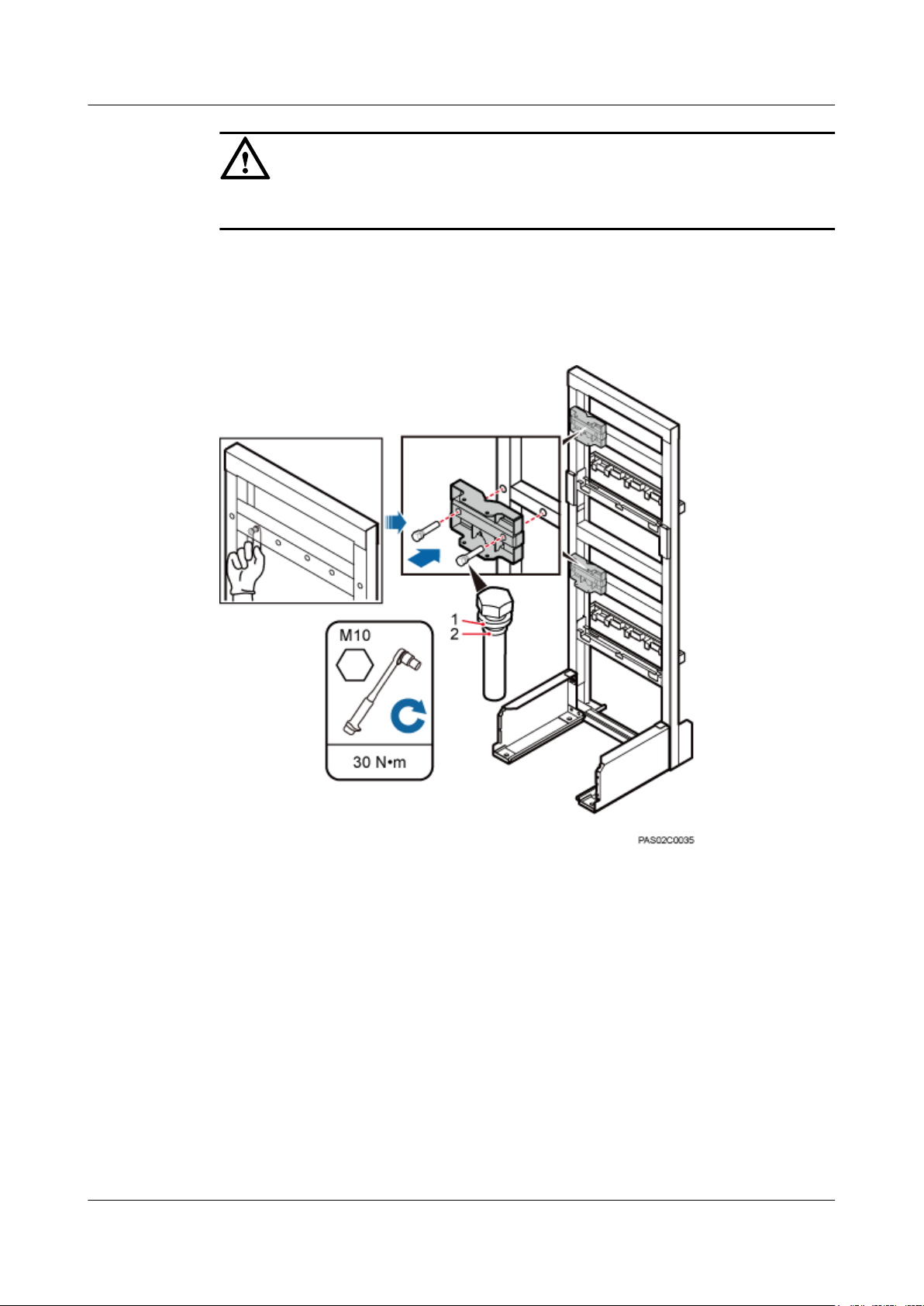

Step 1 Disassemble the RRU mounting brackets, as shown in Figure 8-34.

The wall on which RRUs are installed must meet the following requirements:

l When a single RRU is installed, the wall must be capable of bearing at least four times the

weight of the RRU.

l Expansion anchor bolts must be tightened to 30 N·m (265.52 lbf·in.) so that the bolts stay

secured without damaging the wall.

Issue () Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

73

Page 82

RRU3268

Installation Guide 8 Installing the RRU

Figure 8-34 Disassembling the mounting brackets

(1) Main bracket (2) Square-neck bolt (3) Pole installation bracket (4) Auxiliary bracket

(5) Flat washer (6) Spring washer (7) Nut (8) Plastic cap

1. Use an M6 inner hexagon torque screwdriver to remove the four inner hexagon screws on

the pole installation bracket, and remove the main bracket from the pole installation bracket.

2. Use an M10 torque wrench to loosen the nuts on the two square-neck bolts, and remove