Huawei PLC CCO01A User Manual

Part Number: 31010VJY

PLC CCO01A

User Manual

Issue

02

Date

2016-01-10

HUAWEI TECHNOLOGIES CO., LTD.

Issue 02 (2016-01-10)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

i

Copyright © Huawei Technologies Co., Ltd. 2016. All rights reserved.

No part of this document may be reproduced or transmitted in any form or by any means without prior

written consent of Huawei Technologies Co., Ltd.

Trademarks and Permissions

and other Huawei trademarks are trademarks of Huawei Technologies Co., Ltd.

All other trademarks and trade names mentioned in this document are the property of their respective

holders.

Notice

The purchased products, services and features are stipulated by the contract made between Huawei and

the customer. All or part of the products, services and features described in this document may not be

within the purchase scope or the usage scope. Unless otherwise specified in the contract, all statements,

information, and recommendations in this document are provided "AS IS" without warranties, guarantees or

representations of any kind, either express or implied.

The information in this document is subject to change without notice. Every effort has been made in the

preparation of this document to ensure accuracy of the contents, but all statements, information, and

recommendations in this document do not constitute a warranty of any kind, express or implied.

Huawei Technologies Co., Ltd.

Address:

Huawei Industrial Base

Bantian, Longgang

Shenzhen 518129

People's Republic of China

Website:

http://www.huawei.com

Email:

support@huawei.com

PLC CCO01A

User Manual

About This Document

Issue 02 (2016-01-10)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

ii

About This Document

Purpose

This document introduces the installation, operation, maintenance, and troubleshooting of the

PLC CCO01A (PLC CCO for short). Get familiar with the PLC CCO features, functions, and

safety precautions provided in this document before installing and operating the PLC CCO.

Keep the hard copy of this document properly for future reference. You can also download the

latest manual from http://support.huawei.com.

Figures used in this document are for reference only.

Intended Audience

This document is intended for photovoltaic (PV) power station personnel and qualified

electrical technicians.

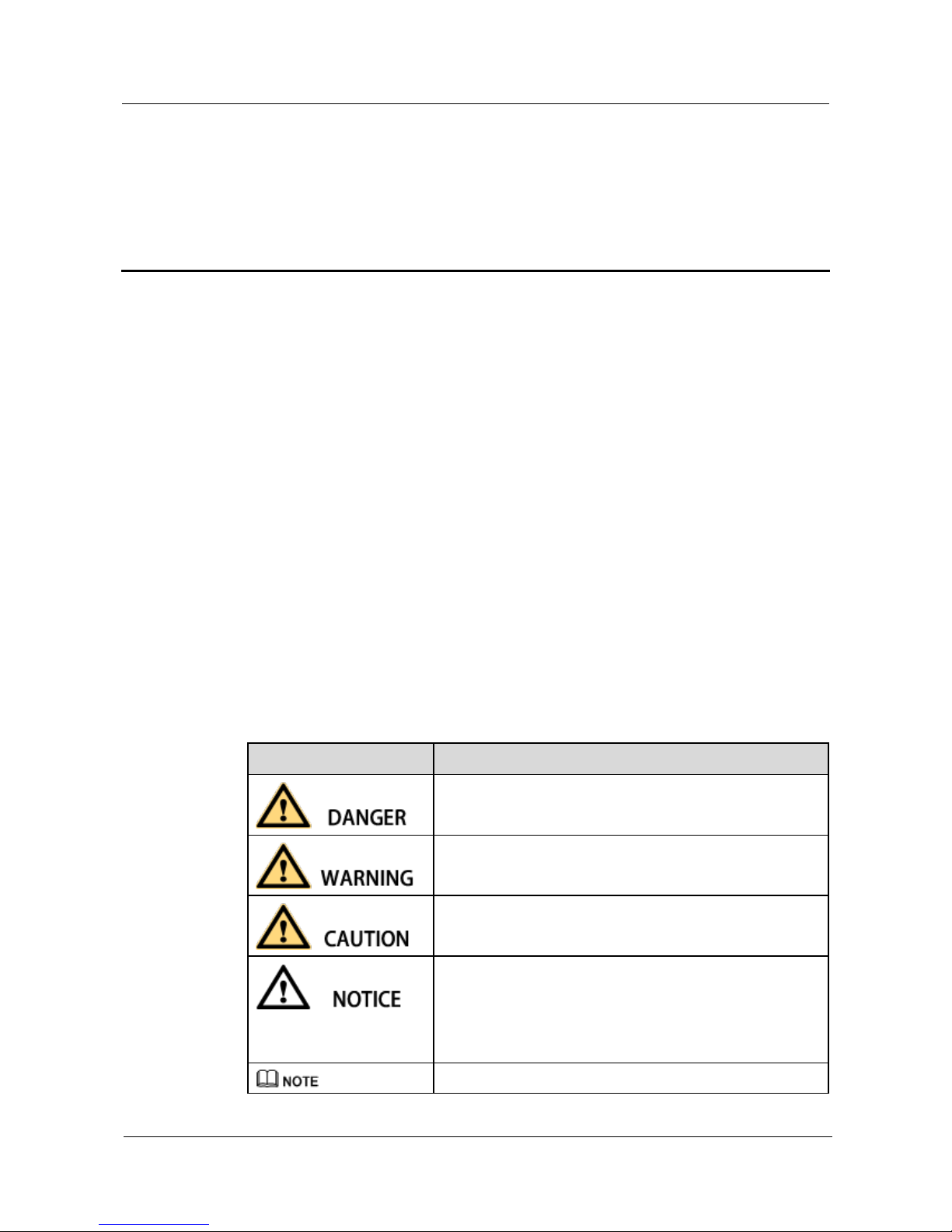

Symbol Conventions

The symbols that may be found in this document are defined as follows.

Symbol

Description

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in equipment damage, data loss,

performance deterioration, or unanticipated results.

NOTICE is used to address practices not related to personal

injury.

Calls attention to important information, best practices and

PLC CCO01A

User Manual

About This Document

Issue 02 (2016-01-10)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

iii

Symbol

Description

tips.

NOTE is used to address information not related to personal

injury, equipment damage, or environment deterioration.

Change History

Changes between document issues are cumulative. The latest document issue contains all the

changes made in earlier issues.

Issue 02 (2016-01-10)

This issue adds content about the installation and electrical connections for the PLC CCO

used in a SUN2000 communication box.

Issue 01 (2015-08-15)

This issue is the first official release.

PLC CCO01A

User Manual

Contents

Issue 02 (2016-01-10)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

iv

Contents

About This Document .................................................................................................................... ii

1 Safety Precautions ......................................................................................................................... 1

2 Overview ......................................................................................................................................... 3

2.1 Product Overview ......................................................................................................................................................... 3

2.2 Networking ................................................................................................................................................................... 4

2.3 Working Principles ....................................................................................................................................................... 6

3 Equipment Installation ................................................................................................................ 8

3.1 Checking Before Installation ........................................................................................................................................ 8

3.2 Preparing Tools ............................................................................................................................................................. 9

3.3 Determining the Installation Position ......................................................................................................................... 11

3.4 Installing the PLC CCO Using Mounting Ears (SUN2000 Communication Box Scenario) ...................................... 13

3.5 Installing the PLC CCO Using Guide Rails (Third-Party Device Scenario) .............................................................. 14

4 Electrical Connections ................................................................................................................ 17

4.1 Port Description .......................................................................................................................................................... 17

4.2 Connecting Cables (SUN2000 Communication Box Scenario) ................................................................................. 18

4.2.1 Connecting the AC Power Cable ............................................................................................................................. 20

4.2.2 Connecting the RS485 Communications Cable ....................................................................................................... 21

4.2.3 Connecting the Power Adapter Cable ...................................................................................................................... 23

4.3 Connecting Cables (Third-Party Device Scenario) ..................................................................................................... 24

4.3.1 Connecting the AC Power Cable ............................................................................................................................. 25

4.3.2 Connecting the RS485 Communications Cable ....................................................................................................... 26

4.3.3 Connecting the Power Adapter Cable ...................................................................................................................... 29

5 System Operation ........................................................................................................................ 30

5.1 Indicator Position and Meaning .................................................................................................................................. 30

5.2 Checking Before Power-On ........................................................................................................................................ 31

5.3 Powering On and Commissioning the PLC CCO ....................................................................................................... 31

5.4 Powering Off the PLC CCO ....................................................................................................................................... 32

6 Maintenance and Troubleshooting ......................................................................................... 33

6.1 Routine Maintenance .................................................................................................................................................. 33

6.2 Troubleshooting .......................................................................................................................................................... 33

PLC CCO01A

User Manual

Contents

Issue 02 (2016-01-10)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

v

6.3 Parts Replacement ...................................................................................................................................................... 34

7 PLC CCO Disposal ..................................................................................................................... 36

8 Technical Specifications ............................................................................................................ 37

A Acronyms and Abbreviations .................................................................................................. 38

PLC CCO01A

User Manual

1 Safety Precautions

Issue 02 (2016-01-10)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

1

1 Safety Precautions

Personnel Requirements

Only qualified and trained electrical technicians are allowed to install and operate the

PLC CCO.

Operators should understand the components and functioning of a grid-tied PV power

system, and they should be familiar with relevant local standards.

Label Protection

Do not remove or damage the bar code and label on the PLC CCO because they contain

important product information.

Installation

Read this document before installation. Huawei shall not be liable for any consequence

caused by violation of the regulations specified in this document.

Before installation and cable connections of the PLC CCO, ensure that the PLC CCO is

not connected to a power supply and is not powered on.

Before connecting cables, ensure that the switch to be connected to the PLC CCO AC

power cable is off.

Install the PLC CCO in an environment with good ventilation to ensure efficient and

long-term system performance.

Ensure that the PLC CCO is free from strong electromagnetic interference.

Ensure that the PLC CCO is away from heat sources.

Ensure that the PLC CCO air exhaust vents are free from blockage.

Operation

PLC CCO01A

User Manual

1 Safety Precautions

Issue 02 (2016-01-10)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

2

Perform operations in strict accordance with safety precautions specified in this document and

other relevant documents.

Follow local laws and regulations when operating the device.

Maintenance and Replacement

A faulty PLC CCO requires overall maintenance. If the PLC CCO is faulty, contact the

supplier or Huawei technical support.

Maintain the PLC CCO with sufficient knowledge of this document and proper tools and

testing equipment.

When maintaining the PLC CCO, observe ESD precautions.

Before replacing the PLC CCO and maintaining PLC CCO cables, power off the PLC

CCO.

PLC CCO01A

User Manual

2 Overview

Issue 02 (2016-01-10)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

3

2 Overview

2.1 Product Overview

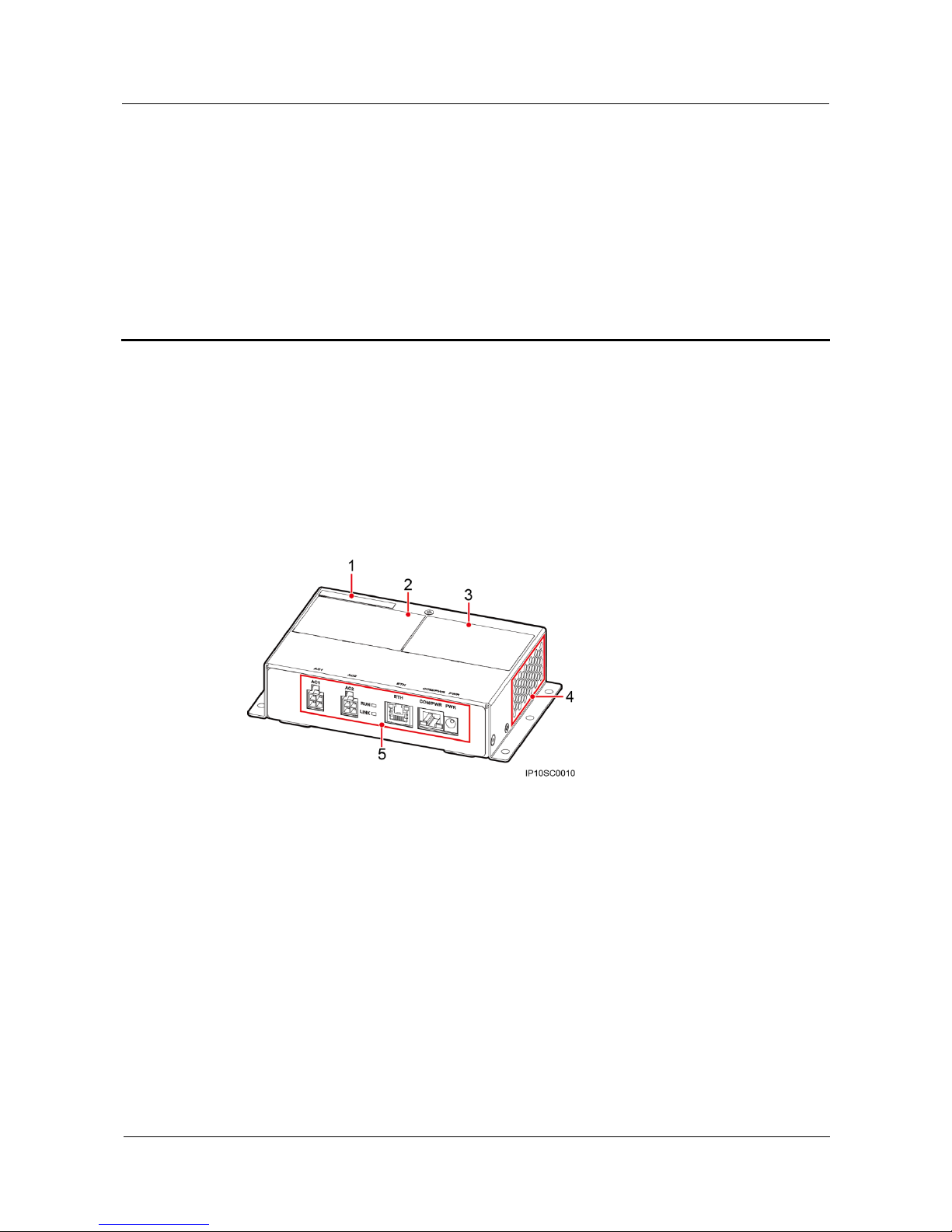

Exterior

Figure 2-1 shows a PLC CCO.

Figure 2-1 PLC CCO exterior

(1) ESN label

(2) Product label

(3) Qualification certificate

(4) Air exhaust vents

(5) Ports and indicators

Functions

The PLC CCO can connect to SUN2000 inverters that support power line

communication (PLC) functions to transmit data over the power line.

The PLC CCO can connect to the data collector using an RS485 communications cable

to transmit data and convert between PLC and RS485 communication.

PLC CCO01A

User Manual

2 Overview

Issue 02 (2016-01-10)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

4

Benefits

The PLC networking mode uses the existing power line for communication and does not

require additional communications cable, which reduces the construction and maintenance

costs and improves communication reliability and efficiency.

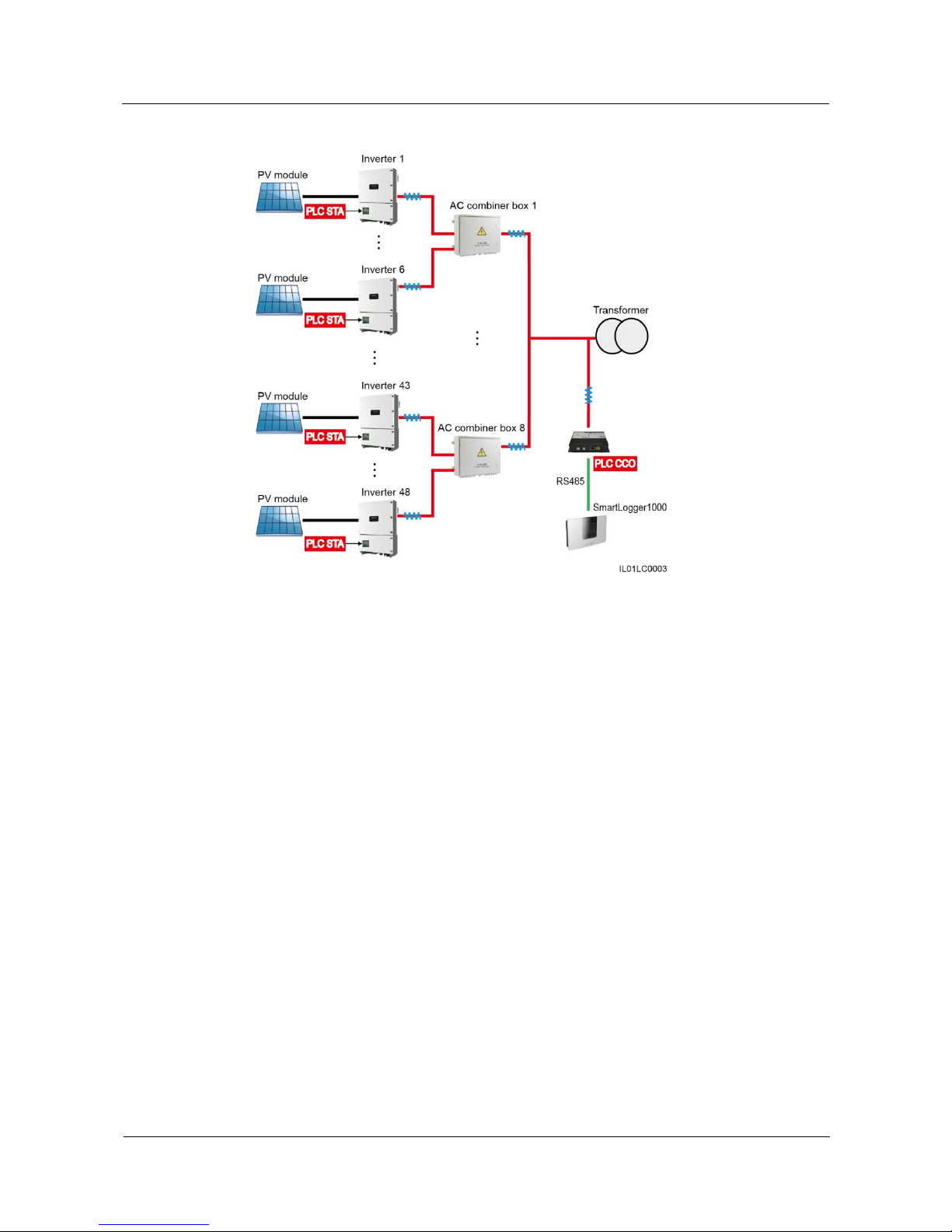

2.2 Networking

A PLC module consists of the station (STA) and central controller (CCO). Figure 2-2 shows

the typical PLC networking.

As the slave unit of the PLC, the STA is installed inside the SUN2000 as a

communications board. The STA converts the RS485 communications data received

from the inverter monitoring board and sends the converted data to the AC power cable.

In addition, it converts the data received from the AC power cable and sends the

converted data to the inverter monitoring board.

As the master unit of the PLC, the CCO is installed in a SUN2000 communication box

or box-type transformer as a standalone device. The CCO converts RS485

communications data received from the data collector and sends the converted data to the

AC power cable. In addition, it converts the data received from the AC power cable and

sends the converted data to the data collector.

The PLC CCO can connect to a maximum of 80 PLC STAs. Generally, a PLC CCO is configured

for each grid-tied point.

The PLC CCO supports only the Modbus RTU protocol.

PLC CCO01A

User Manual

2 Overview

Issue 02 (2016-01-10)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

5

Figure 2-2 PLC networking applied to typical medium-voltage grid-tied scenarios

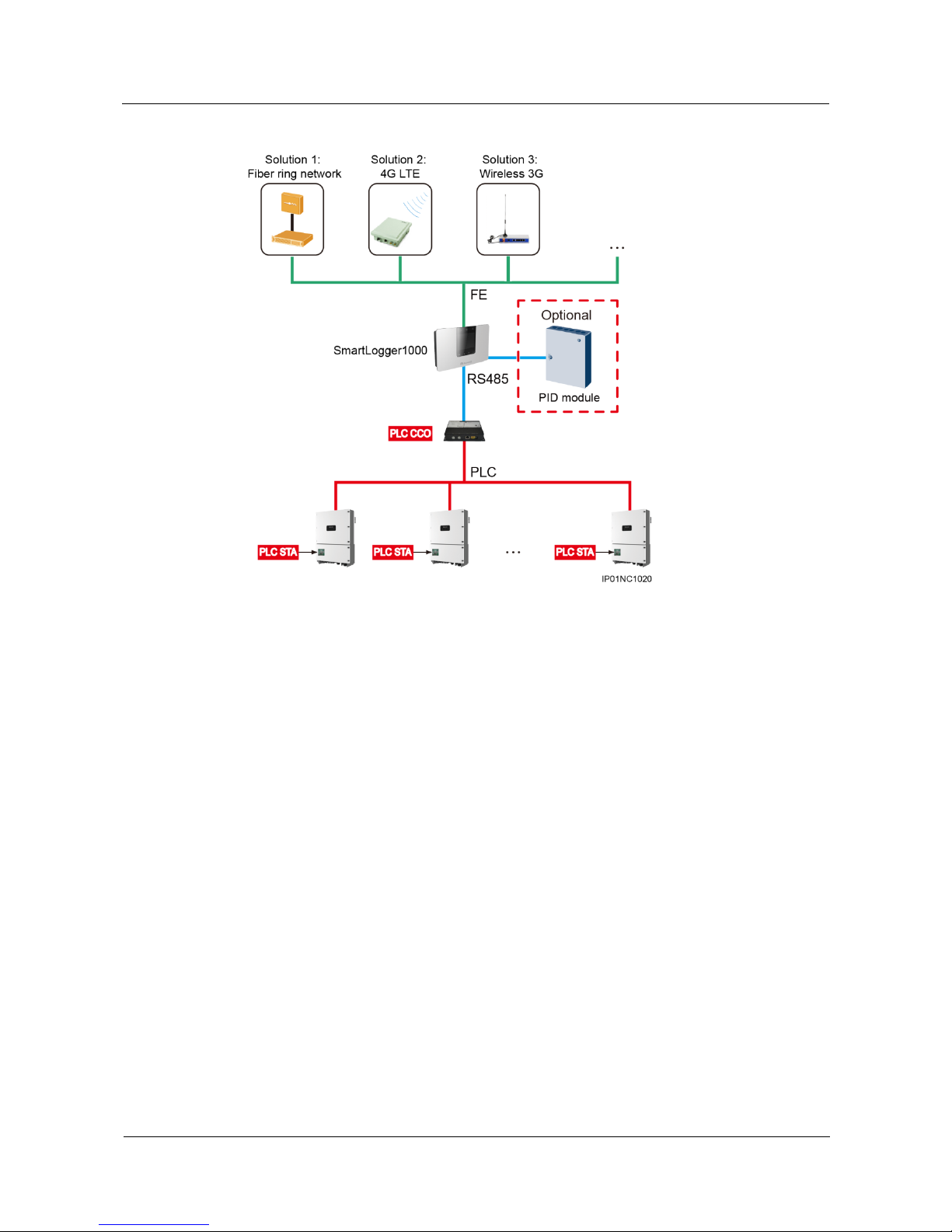

Figure 2-3 shows the location of the PLC CCO in a PV array network.

PLC CCO01A

User Manual

2 Overview

Issue 02 (2016-01-10)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

6

Figure 2-3 Location of the PLC CCO in a PV array network

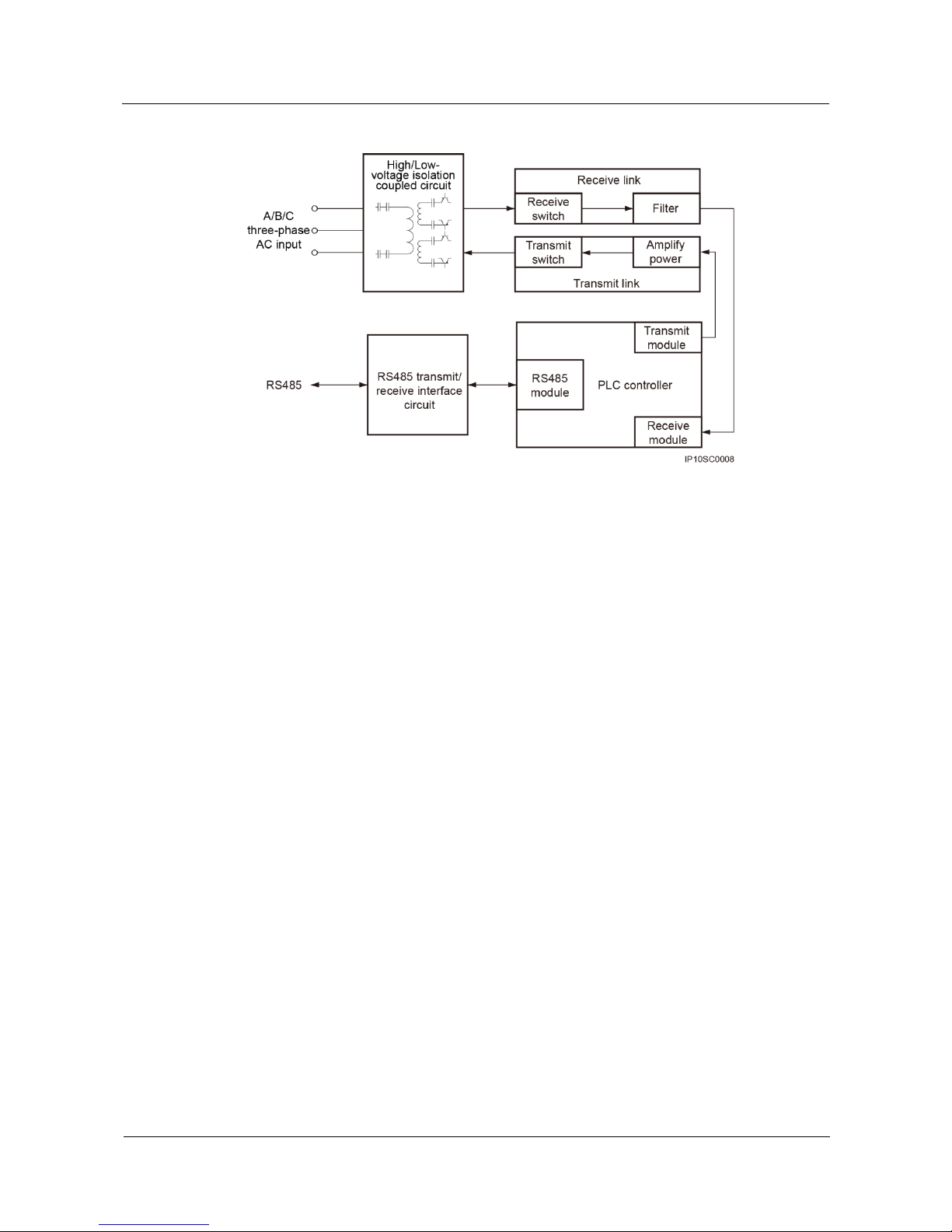

2.3 Working Principles

Figure 2-4 shows the PLC CCO circuit diagram.

PLC CCO01A

User Manual

2 Overview

Issue 02 (2016-01-10)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

7

Figure 2-4 Circuit diagram

The working principles of the PLC CCO are as follows:

Uses the high/low voltage isolation coupled circuit to isolate low-frequency three-phase

AC power from board low voltages, thereby ensuring board safety. In addition, the PLC

CCO provides the high-frequency circuit for injecting and extracting PLC signals.

Filters and processes PLC signals over the receive link. The signals are extracted from

the AC power cable.

Amplifies the power of PLC signals and injects the PLC signals into the AC power cable

over the transmit link.

Converts between PLC and RS485 signals through the PLC controller.

Provides the channel for sending and receiving RS485 signals over the RS485

transmit/receive interface circuit to communicate with the data collector.

PLC CCO01A

User Manual

3 Equipment Installation

Issue 02 (2016-01-10)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

8

3 Equipment Installation

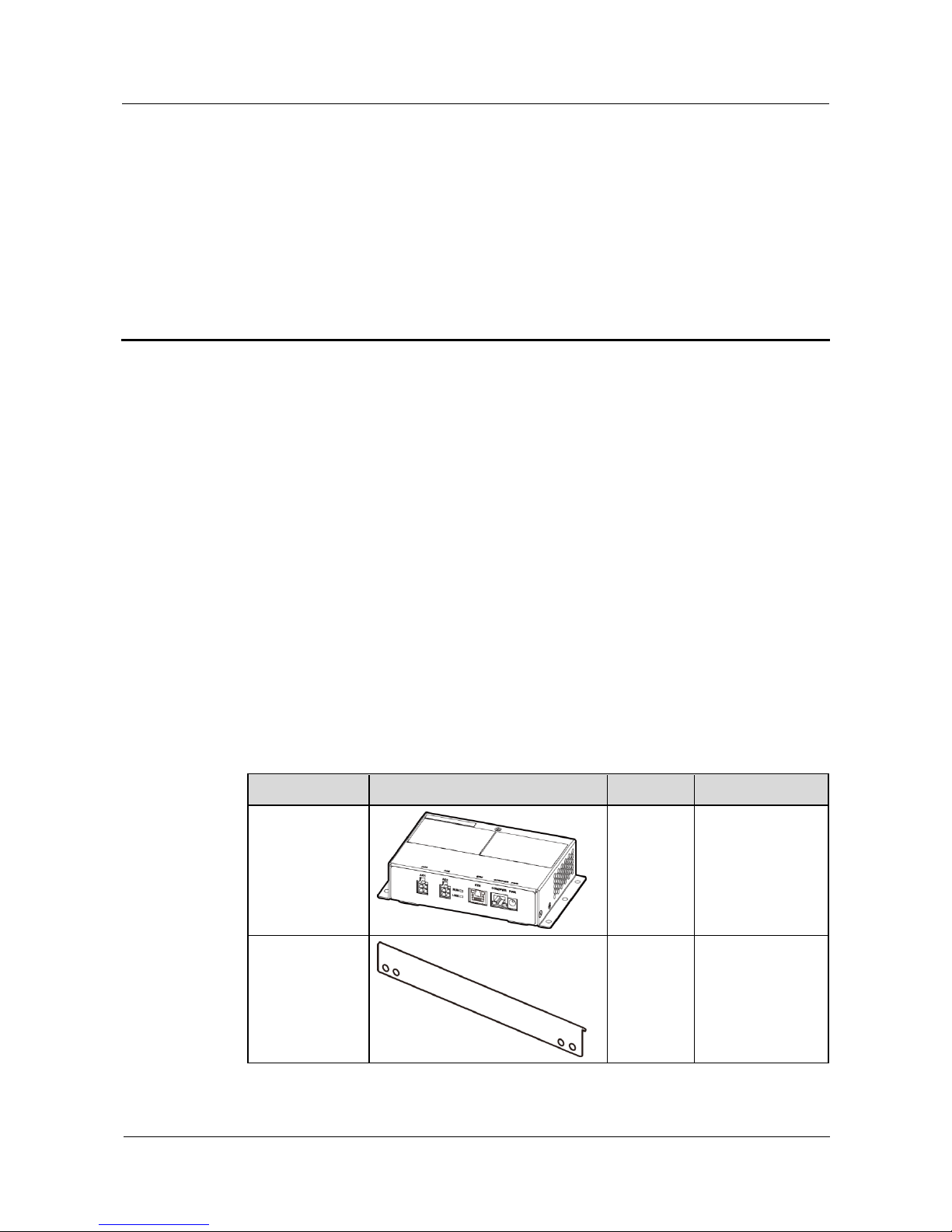

3.1 Checking Before Installation

Before unpacking, check that the product is intact. After unpacking, check that product and

accessories are complete.

Checking Outer Packing Materials

Check the outer packing materials for damage, such as holes and cracks, before unpacking the

PLC CCO. If any damage is found, do not unpack the PLC CCO and contact the supplier or

Huawei technical support promptly.

Checking the Product and Accessories

After unpacking the PLC CCO, check whether the product and accessories are intact and

complete. If any item is missing or damaged, contact the supplier or Huawei technical

support.

Table 3-1 shows the product and accessories included in the delivery.

Table 3-1 PLC CCO product and accessories

Name

Exterior

Quantity

Description

PLC CCO

1 PCS

N/A

Support 1

1 PCS

Applies when a

guide rail is used

for the installation.

Loading...

Loading...