Huawei ECC800 User Manual

ECC800 Data Center Controller

V100R001C40

User Manual

Issue

02

Date

2019-02-28

HUAWEI TECHNOLOGIES CO., LTD.

Issue 02 (2019-02-28)

Copyright © Huawei Technologies Co., Ltd.

i

Copyright © Huawei Technologies Co., Ltd. 2019. All rights reserved.

No part of this document may be reproduced or transmitted in any form or by any means without prior

written consent of Huawei Technologies Co., Ltd.

Trademarks and Permissions

and other Huawei trademarks are trademarks of Huawei Technologies Co., Ltd.

All other trademarks and trade names mentioned in this document are the property of their respective

holders.

Notice

The purchased products, services and features are stipulated by the contract made between Huawei and

the customer. All or part of the products, services and features described in this document may not be

within the purchase scope or the usage scope. Unless otherwise specified in the contract, all statements,

information, and recommendations in this document are provided "AS IS" without warranties, guarantees or

representations of any kind, either express or implied.

The information in this document is subject to change without notice. Every effort has been made in the

preparation of this document to ensure accuracy of the contents, but all statements, information, and

recommendations in this document do not constitute a warranty of any kind, express or implied.

Huawei Technologies Co., Ltd.

Address:

Huawei Industrial Base

Bantian, Longgang

Shenzhen 518129

People's Republic of China

Website:

http://e.huawei.com

ECC800 Data Center Controller

User Manual

About This Document

Issue 02 (2019-02-28)

Copyright © Huawei Technologies Co., Ltd.

ii

Purpose

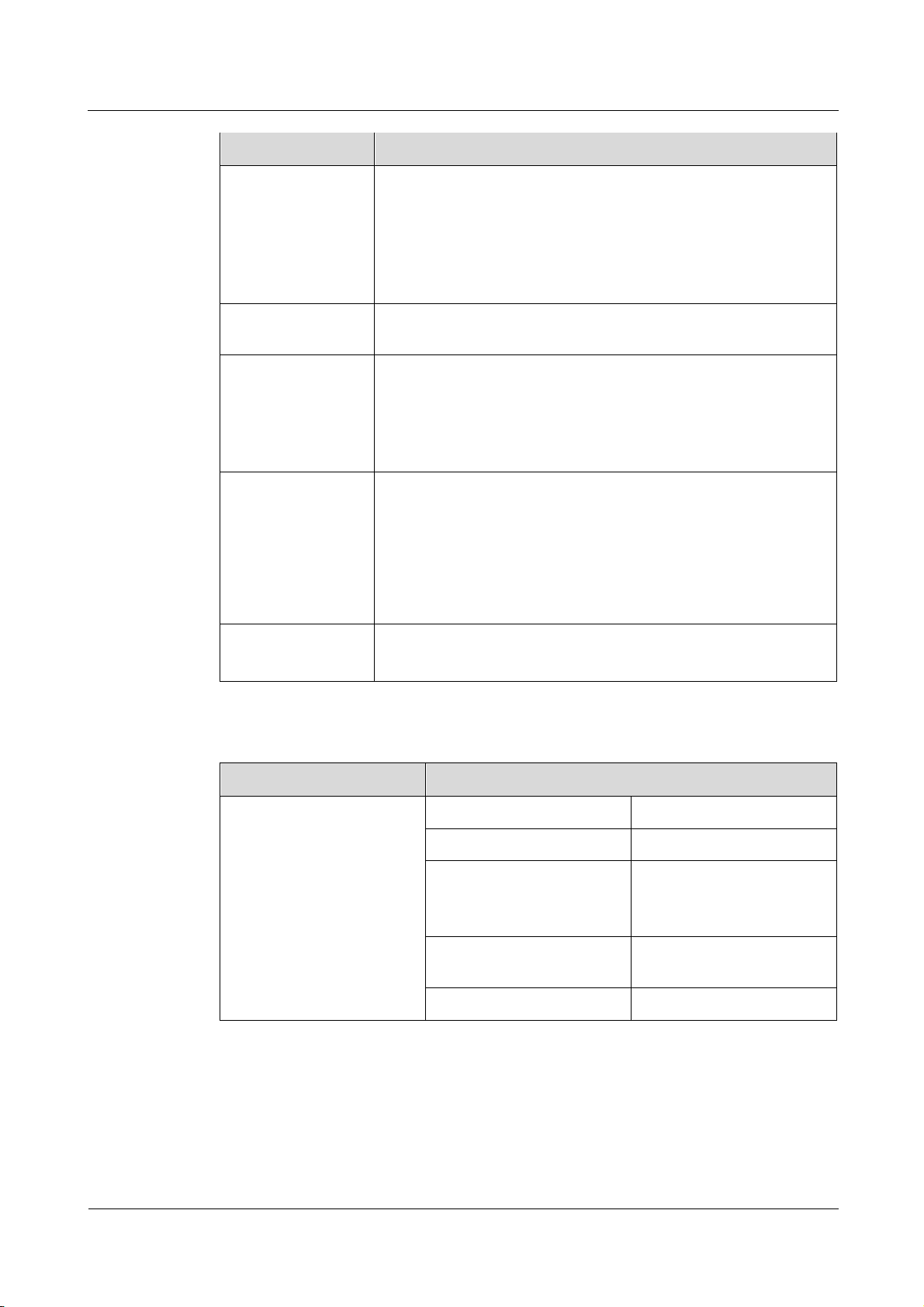

Symbol

Description

Indicates an imminently hazardous situation which, if not avoided, will

result in serious injury or death.

Indicates a potentially hazardous situation which, if not avoided, could

result in serious injury or death.

Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

About This Document

This document describes the ECC800 data center controller (including the ECC800e) in terms

of features, devices, user interfaces (UIs), and power-on commissioning, as well as frequently

asked questions (FAQ) and troubleshooting measures.

This document describes all the functions of the ECC800. Certain functions are implemented

by hardware such as the UPS and PDU, and may be unavailable if the hardware is not

connected to the ECC800.

The figures provided in this document are for reference only.

The software version is ECC800 V100R001C40SPC200.

Intended Audience

This document is intended for:

Sales engineers

Technical support engineers

Maintenance engineers

Symbol Conventions

The symbols that may be found in this document are defined as follows.

ECC800 Data Center Controller

User Manual

About This Document

Issue 02 (2019-02-28)

Copyright © Huawei Technologies Co., Ltd.

iii

Symbol

Description

Indicates a potentially hazardous situation which, if not avoided, could

result in equipment damage, data loss, performance deterioration, or

unanticipated results.

NOTICE is used to address practices not related to personal injury.

Calls attention to important information, best practices and tips.

NOTE is used to address information not related to personal injury,

equipment damage, and environment deterioration.

Change History

Changes between document issues are cumulative. The latest document issue contains all

updates made in previous issues.

Issue 02 (2019-02-28)

Added information about USB ports.

Updated some MDU screenshots.

Updated the air conditioner name to smart cooling product.

Issue 01 (2017-10-13)

This issue is used for first office application (FOA).

Change points:

Optimized the scenario-based commissioning description for certain components.

Added some FAQ.

Issue Draft A (2017-02-15)

This issue is used for first application.

ECC800 Data Center Controller

User Manual

Contents

Issue 02 (2019-02-28)

Copyright © Huawei Technologies Co., Ltd.

iv

Contents

About This Document ............................................................................................................ ii

1 Safety Precautions ................................................................................................................. 1

2 Overview ................................................................................................................................ 3

2.1 Positioning ............................................................................................................................................................................. 3

2.2 Application Scenarios ........................................................................................................................................................... 4

2.2.1 ECC800 system network diagram (FusionModule5000) ................................................................................................ 4

2.2.2 ECC800 system network diagram (FusionModule2000) ................................................................................................ 4

2.2.3 ECC800 system network diagram (FusionModule1000) ................................................................................................ 5

2.2.4 ECC800 system network diagram (FusionModule800) .................................................................................................. 6

2.2.5 ECC800e system network diagram (FusionModule500) ................................................................................................ 7

2.3 Features.................................................................................................................................................................................. 8

3 Device Description ................................................................................................................ 9

3.1 ECC800 ................................................................................................................................................................................. 9

3.2 ECC800e ............................................................................................................................................................................. 19

3.3 Southbound Device Introduction ....................................................................................................................................... 22

3.3.1 Rack Environment Unit ................................................................................................................................................... 22

3.3.2 Smart ETH Gateway........................................................................................................................................................ 24

3.3.3 General Input Unit ........................................................................................................................................................... 26

3.3.4 Power Distribution Unit .................................................................................................................................................. 28

3.3.5 Access Control System .................................................................................................................................................... 30

3.3.5.1 Aisle or Room Access Control System ....................................................................................................................... 30

3.3.5.1.1 Access Actuator ......................................................................................................................................................... 30

3.3.5.1.2 Fingerprint and Card Reader with a Keypad ........................................................................................................... 35

3.3.5.1.3 Fingerprint and Card Reader..................................................................................................................................... 36

3.3.5.1.4 Card Reader with a Keypad ...................................................................................................................................... 38

3.3.5.1.5 Magnetic Lock ........................................................................................................................................................... 39

3.3.5.2 Cabinet Access Control System ................................................................................................................................... 39

3.3.6 AC Actuator...................................................................................................................................................................... 41

3.3.7 Skylight Actuator ............................................................................................................................................................. 44

3.3.8 Multi-Functional Sensor .................................................................................................................................................. 46

3.3.9 Smoke Detector................................................................................................................................................................ 49

3.3.10 Temperature Sensor ....................................................................................................................................................... 49

ECC800 Data Center Controller

User Manual

Contents

Issue 02 (2019-02-28)

Copyright © Huawei Technologies Co., Ltd.

v

3.3.11 Alarm Beacon................................................................................................................................................................. 50

3.3.12 Water Sensor .................................................................................................................................................................. 51

3.3.12.1 WLDS600 Water Sensor ............................................................................................................................................ 51

3.3.12.2 WLDS900 Water Sensor ............................................................................................................................................ 52

3.3.12.3 Electrode Water Sensor .............................................................................................................................................. 53

3.3.13 WiFi Converter .............................................................................................................................................................. 54

3.3.14 WiFi Module .................................................................................................................................................................. 56

3.3.15 ETH Converter............................................................................................................................................................... 57

3.3.16 Pad .................................................................................................................................................................................. 59

3.3.17 T/H Sensor ..................................................................................................................................................................... 61

3.3.17.1 T/H sensor (BOM number:33010346) ...................................................................................................................... 61

3.3.17.2 T/H Sensor (BOM number:02310NBS).................................................................................................................... 62

3.3.18 Infrared Remote Control Module ................................................................................................................................. 64

3.3.19 SMS Module .................................................................................................................................................................. 64

3.3.20 Intelligent Battery Monitoring System ......................................................................................................................... 65

3.3.20.1 CIM ............................................................................................................................................................................. 66

3.3.20.2 BIM ............................................................................................................................................................................. 76

4 UI Description ..................................................................................................................... 79

4.1 WebUI Introduction ............................................................................................................................................................ 79

4.1.1 Preparations and WebUI Login ....................................................................................................................................... 79

4.1.2 WebUI ............................................................................................................................................................................... 82

4.2 APP Introduction ................................................................................................................................................................. 84

4.2.1 Connecting to a WiFi Network ....................................................................................................................................... 84

4.2.2 Preparations and App Login ............................................................................................................................................ 86

4.2.3 Mobile Phone App ........................................................................................................................................................... 88

4.2.4 Pad App ............................................................................................................................................................................ 89

5 Power-On Commissioning ................................................................................................. 91

5.1 Setting the Date and Time .................................................................................................................................................. 91

5.2 Checking the System Type and Setting the Smart Module Name ................................................................................... 92

5.3 Setting and Adding Devices ............................................................................................................................................... 93

5.3.1 Setting Integrated UPS Parameters................................................................................................................................. 93

5.3.2 Setting and Adding a UPS2000-G .................................................................................................................................. 93

5.3.3 Setting and Adding a UPS5000-E................................................................................................................................... 95

5.3.4 Adding and Setting a SUNRISE-SCU-20K ................................................................................................................... 97

5.3.5 Setting NetCol5000-C030 Parameters (over Modbus TCP) ......................................................................................... 98

5.3.6 Setting and Adding a NetCol5000-C030 (over Modbus RTU)..................................................................................... 99

5.3.7 Setting the NetCol5000-A025 or NetCol5000-A010 Parameters(over MAC-Modbus)...........................................100

5.3.8 Setting and Adding a NetCol5000-A035 (over Modbus RTU) ..................................................................................101

5.3.9 Setting and Adding a PDU8000 or integrated PDU (over Modbus-TCP) .................................................................102

5.3.10 Setting and Adding a PDU8000 (over Modbus-RTU) ..............................................................................................102

5.3.11 Setting and Adding a PDU2000-M(C) .......................................................................................................................104

ECC800 Data Center Controller

User Manual

Contents

Issue 02 (2019-02-28)

Copyright © Huawei Technologies Co., Ltd.

vi

5.3.12 Setting Parameters for the Smart Busway..................................................................................................................105

5.3.13 Setting and Adding an ATS .........................................................................................................................................107

5.3.14 Setting and Adding a PMAC625 AC Meter ...............................................................................................................108

5.3.15 Setting and Adding a PMAC615 AC Meter ............................................................................................................... 110

5.3.16 Setting and Adding a PDC DC Meter ........................................................................................................................ 111

5.3.17 Setting and Adding an Independent Deployment AI/DI Unit ................................................................................... 112

5.3.18 Setting and Adding an Smart Cooling Product .......................................................................................................... 114

5.3.19 Setting and Adding a 48 V DC Power Supply Device .............................................................................................. 115

5.3.20 Setting and Adding an AC or DC Meter .................................................................................................................... 116

5.3.21 Setting and Adding a Hydrogen Detection System ................................................................................................... 117

5.3.22 Adding a Networked Device ....................................................................................................................................... 119

5.4 Creating a Smart Module Plan View ...............................................................................................................................120

5.5 Setting Alarm Notification by Email and SMS...............................................................................................................122

5.6 Commissioning the AC Actuator (Wireless Networking) ..............................................................................................123

5.7 Commissioning Sensors ...................................................................................................................................................125

5.7.1 Commissioning a Multi-functional Sensor ..................................................................................................................125

5.7.2 Commissioning a Smoke Sensor ..................................................................................................................................127

5.7.2.1 Commissioning a Smoke Sensor (connected to the AI/DI port on the ECC800) ...................................................127

5.7.2.2 Commissioning a Smoke Sensor (Connected to the AI/DI port on the skylight actuator) ....................................128

5.7.3 Commissioning a Water Sensor ....................................................................................................................................129

5.7.3.1 Commissioning a WLDS900 water sensor ...............................................................................................................129

5.7.3.2 Commissioning a WLDS600 Water Sensor ..............................................................................................................129

5.7.3.3 Commissioning a Electrode water sensor .................................................................................................................131

5.7.4 Commissioning a Temperature Sensor .........................................................................................................................131

5.7.4.1 Commissioning a Temperature Sensor (Connected to the AI/DI port on the ECC800) ........................................131

5.7.4.2 Commissioning a Temperature Sensor (Connected to the NTC port on the rack environment unit) ...................132

5.7.5 Commissioning a T/H Sensor .......................................................................................................................................132

5.7.5.1 Commissioning a T/H Sensor (BOM number:33010346) .......................................................................................132

5.7.5.2 Commissioning a T/H Sensor (BOM number:02310NBS) .....................................................................................134

5.7.6 Commissioning a Door Status Sensor ..........................................................................................................................136

5.7.6.1 Commissioning a Door Status Sensor (Connected to the AI/DI port on the independent deployment AI/DI unit)

..................................................................................................................................................................................................136

5.7.6.2 Commissioning a Door Status Sensor (Connected to the AI/DI port on the rack environment unit) ...................136

5.7.7 Commissioning an Access Control Device and a Cabinet Electronic Lock ..............................................................137

5.7.8 Commissioning the Exit Button, Emergency Button, and Magnetic Lock ................................................................141

5.7.9 Commissioning an Emergency Door Release Button .................................................................................................142

5.8 Commissioning CIMs and BIMs .....................................................................................................................................143

5.9 Commissioning the Cameras and VCN500 (Smart ETH Gateway Networking Scenario) .........................................144

5.9.1 Configuring the VCN500 ..............................................................................................................................................145

5.9.2 Commissioning IPC6325 Cameras ...............................................................................................................................147

5.9.3 Adding a Camera on the VCN ......................................................................................................................................150

5.9.4 Setting and Viewing Videos on the ECC800 WebUI ..................................................................................................151

ECC800 Data Center Controller

User Manual

Contents

Issue 02 (2019-02-28)

Copyright © Huawei Technologies Co., Ltd.

vii

5.9.5 Commissioning IPC6325 Camera (SD Card Configured) ..........................................................................................152

5.10 Commissioning Cameras and a VCN (LAN Switch Networking Scenario) ..............................................................154

5.10.1 Configuring the VCN500 ............................................................................................................................................155

5.10.2 Commissioning IPC6325 Cameras.............................................................................................................................157

5.10.3 Adding a Camera on the VCN500 ..............................................................................................................................159

5.10.4 Commissioning IPC6325 Camera (SD Card Configured) ........................................................................................160

5.11 Setting ECC800 Cascading ............................................................................................................................................164

6 Remote Management ........................................................................................................ 165

6.1 NetEco Management ........................................................................................................................................................165

6.1.1 Connecting the Communications Cable .......................................................................................................................165

6.1.2 Setting NetEco Parameters............................................................................................................................................165

6.1.3 Creating an ECC800 on the NetEco .............................................................................................................................166

6.2 Third-party NMS Management (over SNMP) ................................................................................................................167

6.2.1 Connecting the Communications Cable .......................................................................................................................167

6.2.2 Setting SNMP Management Parameters ......................................................................................................................168

7 Feature Description ........................................................................................................... 170

7.1 PLC Function ....................................................................................................................................................................170

7.1.1 PLC Introduction ...........................................................................................................................................................170

7.1.2 PLC Configuration Examples .......................................................................................................................................171

7.2 Linking Alarms with an Alarm Beacon ...........................................................................................................................174

7.2.1 Linking the Smoke Alarm with the Alarm Beacon......................................................................................................174

7.2.2 Linking the AI/DI Alarm with the Alarm Beacon .......................................................................................................174

7.3 Fire Linkage ......................................................................................................................................................................175

7.4 Linking the Emergency Fan .............................................................................................................................................176

7.5 Battery Shallow Discharge Test .......................................................................................................................................176

7.6 Control Management of the Infrared Remote Control Module .....................................................................................178

7.6.1 Connecting the Communications Cable .......................................................................................................................178

7.6.2 Setting and Adding an Infrared Remote Control Module ...........................................................................................178

7.6.3 Control Function of an Infrared Remote Control Module ..........................................................................................179

7.7 (Optional) iCooling Function ...........................................................................................................................................181

7.8 PUE Configuration Management.....................................................................................................................................183

7.8.1 Configuring PUE Standard Mode .................................................................................................................................183

7.8.2 Configuring PUE User-defined Mode ..........................................................................................................................185

8 Maintenance ....................................................................................................................... 188

8.1 Routine Maintenance ........................................................................................................................................................188

8.2 Common Faults and Troubleshooting..............................................................................................................................189

8.3 Component Replacement .................................................................................................................................................191

8.3.1 Replacing an ECC800 Main Control Module..............................................................................................................192

8.3.2 Replacing a PSU ............................................................................................................................................................193

8.3.3 Replacing ECC800 Antennas ........................................................................................................................................194

8.3.4 Replacing a SIM Card and Micro SD Card .................................................................................................................195

ECC800 Data Center Controller

User Manual

Contents

Issue 02 (2019-02-28)

Copyright © Huawei Technologies Co., Ltd.

viii

9 FAQ ..................................................................................................................................... 197

9.1 WebUI Operations ............................................................................................................................................................197

9.1.1 How Can I View Version Information? ........................................................................................................................197

9.1.2 How to Manage WebUI Users? ....................................................................................................................................197

9.1.3 How to Restore Factory Settings? ................................................................................................................................198

9.1.4 How to Install a Network Security Certificate? ...........................................................................................................199

9.1.5 How Can I Install a Device Access Certificate? ..........................................................................................................200

9.1.6 How Can I Change the ECC800 IP Address on the WebUI? ......................................................................................201

9.1.7 How to Set Parameters for Alarm Enable, Severity, and Loudspeaker? ....................................................................201

9.1.8 How Can I View Real-Time Monitoring Data, Active Alarms, Historical Alarms, Access Event, and Operation

Logs? ........................................................................................................................................................................................202

9.1.9 How Can I View Performance Data? ...........................................................................................................................202

9.1.10 How Can I Export Historical Data and Device Data? ...............................................................................................202

9.1.11 How Can I Export or Import a Configuration File? ..................................................................................................203

9.1.12 How Can I Export Fault Information? .......................................................................................................................204

9.1.13 How Can I Synchronize Device Parameters? ............................................................................................................204

9.1.14 How to Associate an Alarm with a DO Output? ........................................................................................................205

9.1.15 How to Associate an Alarm Severity with a DO Output? .........................................................................................206

9.1.16 How Can I Handle DO Association Failure? .............................................................................................................206

9.1.17 What Do I Do If the ECC800 WebUI Display Language Changes from Chinese to English During Use? ..........207

9.1.18 How Can I Rectify Camera Access Restriction? .......................................................................................................207

9.1.19 How Should I Add the Devices Accessed Through a Smart ETH Gateway over Modbus-TCP to the ECC800

WebUI? ....................................................................................................................................................................................208

9.1.20 How Should I Add the Devices Accessed Through a Smart ETH Gateway over Modbus-MAC to the ECC800

WebUI? ....................................................................................................................................................................................209

9.1.21 How Should I Add Devices Accessed Through the ETH Converter to the ECC800 WebUI .................................210

9.1.22 How Should I Add Devices Accessed Through the ECC800 COM Port to the ECC800 WebUI .......................... 211

9.1.23 How Should I Add Devices Accessed Through the ECC800 AI/DI Port to the ECC800 WebUI ..........................213

9.1.24 How Should I Open Doors Remotely over the ECC800 WebUI ..............................................................................214

9.1.25 How Should I Turn On or Off Aisle Lights in the Smart Module over the ECC800 WebUI? ...............................215

9.1.26 How Should I Opening Skylights Remotely over the ECC800 WebUI? .................................................................216

9.1.27 How Should I Turn On or Off Smart Cooling Products over the ECC800 WebUI? ...............................................217

9.1.28 How Should I Open the Cabinet Electronic Lock over the ECC800 WebUI ..........................................................218

9.1.29 How Should I Modify Device Names over the ECC800 WebUI .............................................................................219

9.2 APP Operations .................................................................................................................................................................220

9.2.1 How to View Real-time Data? ......................................................................................................................................220

9.2.2 How Can I Export and Import Data? ............................................................................................................................220

9.2.3 How Can I Synchronize Device Parameters? ..............................................................................................................221

9.2.4 How Can I Handle App Login Failure?........................................................................................................................221

A Devices Connected to the ECC800 .................................................................................. 223

B Acronyms and Abbreviations .......................................................................................... 226

ECC800 Data Center Controller

User Manual

1 Safety Precautions

Issue 02 (2019-02-28)

Copyright © Huawei Technologies Co., Ltd.

1

General Safety

1 Safety Precautions

Ensure that the product is used in environments that meet its design specifications to

avoid causing malfunctions or damaging components and voiding the warranty.

Personnel who plan to install or maintain Huawei equipment must receive a thorough

training, understand all necessary safety precautions, and be able to correctly perform all

operations.

Comply with local laws and regulations. The safety instructions in this manual are only

supplements to local laws and regulations.

Do not operate the product or handle cables during thunderstorms.

Before using the product, remove any conductors such as jewelry or watches.

Use insulated tools for all operations that involve electrical connections.

Follow specified procedures during installation and maintenance.

Before handling a conductor surface or terminal, measure the contact point voltage with

a multimeter, and ensure that the contact point has no voltage or the voltage is within the

allowed range.

Performing maintenance or locating faults may interrupt power to the loads if batteries

are not connected or the battery reserve is insufficient.

Before laying out power cables which have been stored in a temperature lower than 0°C,

move the power cables to an environment with room temperature and store them in the

environment for at least 24 hours.

Perform routine maintenance; replace faulty components at the earliest.

Electrical Safety

Grounding requirements

− When installing a device, install the ground cable first. When uninstalling a device,

− Before operating a device, ensure that the device is properly grounded.

AC and DC power

remove the ground cable at the very end.

ECC800 Data Center Controller

User Manual

1 Safety Precautions

Issue 02 (2019-02-28)

Copyright © Huawei Technologies Co., Ltd.

2

The power system is powered by high-voltage power sources. Direct or indirect contact

(through damp objects) with high-voltage power sources may result in serious injury or

death.

Non-standard and improper operations may result in fire and electric shocks.

Before making electrical connections, turn off the protection switch on the upstream

device to cut the power supply.

Before connecting the AC power supply, ensure that electrical connections are complete.

Before connecting cables to loads or battery cables, check cable and terminal polarities

to avoid reverse connections.

Electrostatic discharge (ESD)

− To prevent electrostatic-sensitive components from being damaged by static from

human bodies, wear a grounded electrostatic discharge (ESD) wrist strap or ESD

gloves when touching circuit boards.

− When holding a board, hold its edge without touching any components, especially

chips.

− Package boards with ESD packaging materials before storing or transporting them.

Cable Layout

Mechanical Safety

Do not drill holes into a cabinet without permission. Non-standard drilling may affect the

electromagnetic shielding of the cabinet and damage interior cables. Metal shavings from

drilling may short-circuit circuit boards if they enter the cabinet.

Cables must be routed so that a sufficient distance exists between the cables and the DC

busbar, shunt, and fuse. This prevents damage to the insulation layer of the cables.

Signal cables must be bound separately from strong-current cables and high-voltage

cables.

Cables prepared by the customer must have the fire resistance capability.

Drilling holes

Before drilling holes into a cabinet, remove interior cables.

Wear goggles and protective gloves when drilling holes.

After drilling, clean up metal shavings immediately.

Moving heavy objects

− Be cautious to avoid injury when moving heavy objects.

− Wear protective gloves when moving sharp objects.

ECC800 Data Center Controller

User Manual

2 Overview

Issue 02 (2019-02-28)

Copyright © Huawei Technologies Co., Ltd.

3

2.1 Positioning

The ECC800 is an intelligent data center environment and device management system which

features flexible layout, easy maintenance, and high reliability. The ECC800 is the core

component for the smart module local management. It adopts the PoE bus for expansion, and

allows all intelligent monitoring devices to be flexibly laid out so that it can manage the

devices in the smart module.

2 Overview

The ECC800 applies to the FusionModule5000, FusionModule2000, FusionModule1000, and

FusionModule800.

Figure 2-1 ECC800 appearance

The ECC800e is a lightweight ECC800, and only applies to the FusionModule500.

Figure 2-2 ECC800e appearance

ECC800 Data Center Controller

User Manual

2 Overview

Issue 02 (2019-02-28)

Copyright © Huawei Technologies Co., Ltd.

4

2.2 Application Scenarios

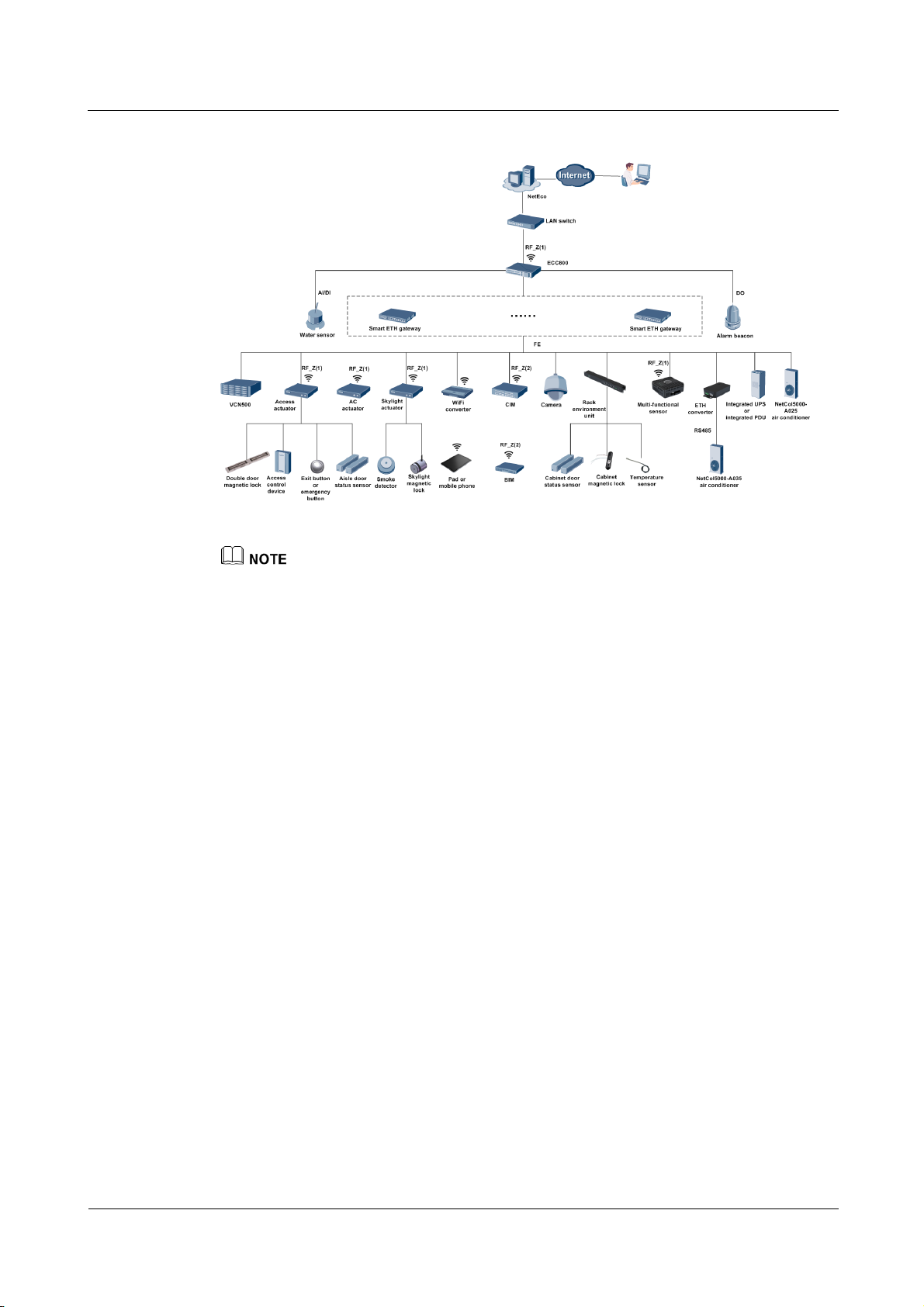

2.2.1 ECC800 system network diagram (FusionModule5000)

The system network diagram uses FusionModule5000 V100R001C02 as an example.

Figure 2-3 ECC800 system network diagram (FusionModule5000)

The new main way consists of general input units and power distribution units. It integrates the

smart ETH gateway and power distribution functions.

In the figure, RF_Z indicates wireless networking. RF_Z(1) devices can communicate with the

ECC800 in wireless mode. The RF_Z(2) BIM and CIM communicate with each other in wireless

mode. RF_Z(1) and RF_Z(2) devices use different protocols and are isolated from each other.

Wireless communication is automatically established after the access actuator, skylight actuator, and

multi-functional sensor successfully connect to and communicate with the ECC800 through PoE.

2.2.2 ECC800 system network diagram (FusionModule2000)

The system network diagram uses FusionModule2000 V500R002C01 as an example.

ECC800 Data Center Controller

User Manual

2 Overview

Issue 02 (2019-02-28)

Copyright © Huawei Technologies Co., Ltd.

5

Figure 2-4 ECC800 system network diagram (FusionModule2000)

In the figure, RF_Z indicates wireless networking. RF_Z(1) devices can communicate with the

ECC800 in wireless mode. The RF_Z(2) BIM and CIM communicate with each other in wireless

mode. RF_Z(1) and RF_Z(2) devices use different protocols and are isolated from each other.

Wireless communication is automatically established after the access actuator, skylight actuator, and

multi-functional sensor successfully connect to and communicate with the ECC800 through PoE.

2.2.3 ECC800 system network diagram (FusionModule1000)

The system network diagram uses FusionModule1000 V200R003C00 as an example.

ECC800 Data Center Controller

User Manual

2 Overview

Issue 02 (2019-02-28)

Copyright © Huawei Technologies Co., Ltd.

6

Figure 2-5 ECC800 system network diagram (FusionModule1000)

In the figure, RF_Z indicates wireless networking. RF_Z(1) devices can communicate with the

ECC800 in wireless mode. The RF_Z(2) BIM and CIM communicate with each other in wireless

mode. RF_Z(1) and RF_Z(2) devices use different protocols and are isolated from each other.

Wireless communication is automatically established after the access actuator, skylight actuator, and

multi-functional sensor successfully connect to and communicate with the ECC800 through PoE.

2.2.4 ECC800 system network diagram (FusionModule800)

The system network diagram uses FusionModule800 V100R001C01 as an example.

ECC800 Data Center Controller

User Manual

2 Overview

Issue 02 (2019-02-28)

Copyright © Huawei Technologies Co., Ltd.

7

Figure 2-6 ECC800 system network diagram (FusionModule800)

In the figure, RF_Z indicates wireless networking. The RF_Z BIM and CIM communicate with each

other in wireless mode.

2.2.5 ECC800e system network diagram (FusionModule500)

The system network diagram uses FusionModule500 V100R001 as an example.

Figure 2-7 ECC800e system network diagram (FusionModule500)

ECC800 Data Center Controller

User Manual

2 Overview

Issue 02 (2019-02-28)

Copyright © Huawei Technologies Co., Ltd.

8

2.3 Features

Efficient

− Supports access of wireless devices and provides backup routes, reducing cable

layout workload and enhancing reliability.

− Supports access right management in terms of the access card, password, and

fingerprint, providing high availability.

− Supports alarm notification by SMS and email, enabling remote maintenance.

− Supports cabinet-level magnetic locks, door status sensor, and temperature

monitoring, providing high security.

− Supports power supply and communication over the power over Ethernet (PoE) bus,

providing rich bandwidth resources and simplifying deployment.

− Supports remote upgrade, fault information export, and configuration parameter

synchronization.

− Connects to room-level access control devices and cameras.

− Cascades a maximum of three ECC800s; displays the active alarms and power

usage effectiveness (PUE) data of cascaded ECC800s on the WebUI of one

ECC800.

− Collects smart module PUE statistics and displays the statistics on a dashboard and

in curves. Users can query the power consumption of the smart module in real time.

− Supports intelligent iCooling management which allows changes in the cabinet

temperature and power consumption to cause intelligent adjustment and control for

the smart cooling product, thereby achieving energy conservation and emission

reduction. (Only FusionModule2000 supports the function.)

Simple

− Supports local WiFi hotspots. After you install the WiFi module at the USB port on

the ECC, you can connect to the ECC using the app on the mobile phone or tablet

computer to view the basic information about the smart module, such as layout,

resources, energy efficiency, environment, and alarms. This increases usability.

− Supports query of device information in real time using the pad app or mobile

phone app, facilitating operation and maintenance.

− Supports connection of monitoring devices to the PoE bus in plug-and-play mode

for auto-discovery and auto-registration requiring no configuration. This feature

enables fast delivery and higher maintainability.

Reliable

− Supports intelligent linkage management which allows customization of linkage

logic, achieving intelligent operation and maintenance.

− Supports dual power inputs, providing high reliability.

− Supports intelligent battery monitoring management, which allows monitoring of

individual cell voltage and internal resistance for discovery of failed cells.

− Supports interworking with the NetEco, supports the SNMP protocol, allowing

centralized management in various scenarios.

ECC800 Data Center Controller

User Manual

3 Device Description

Issue 02 (2019-02-28)

Copyright © Huawei Technologies Co., Ltd.

9

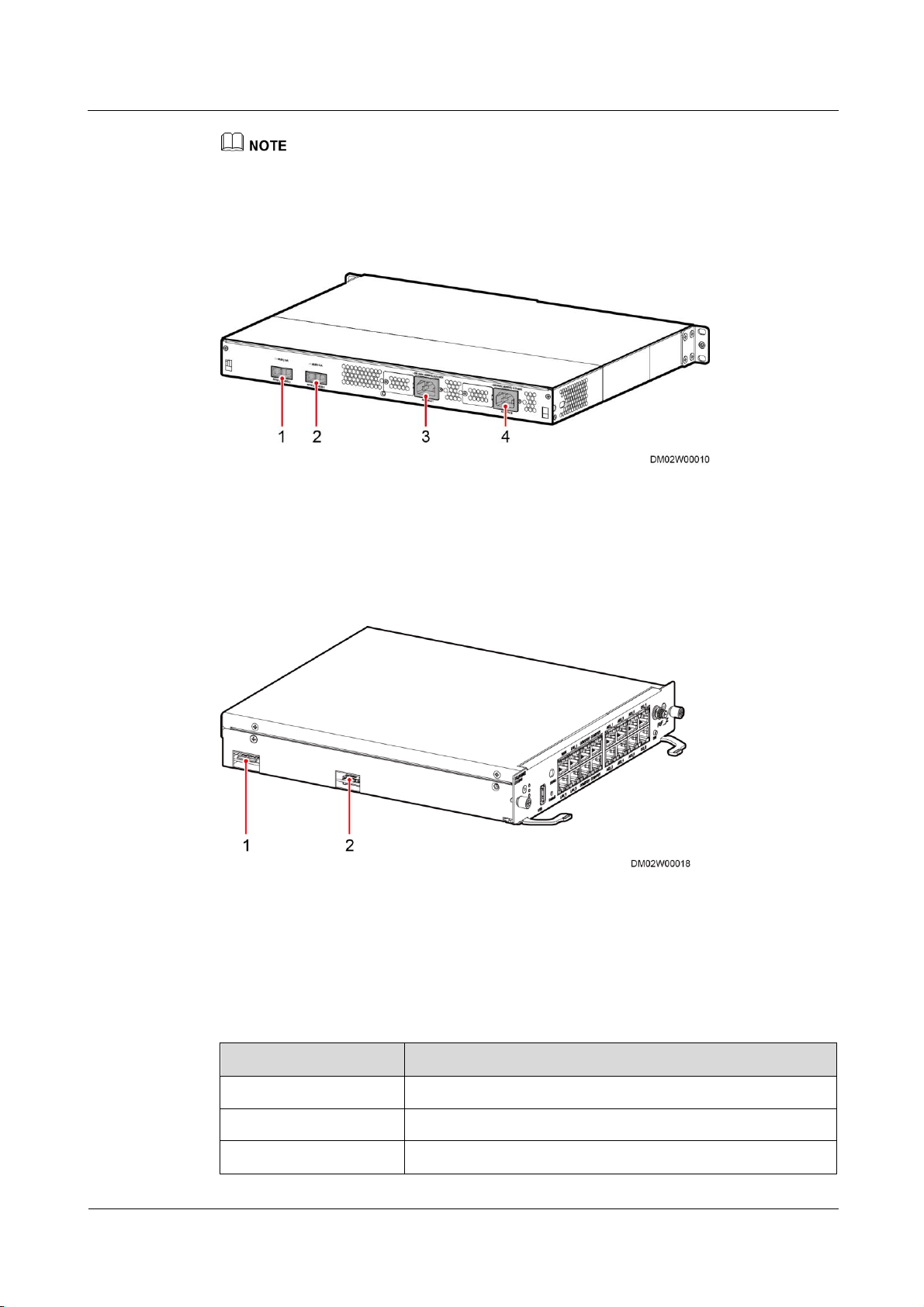

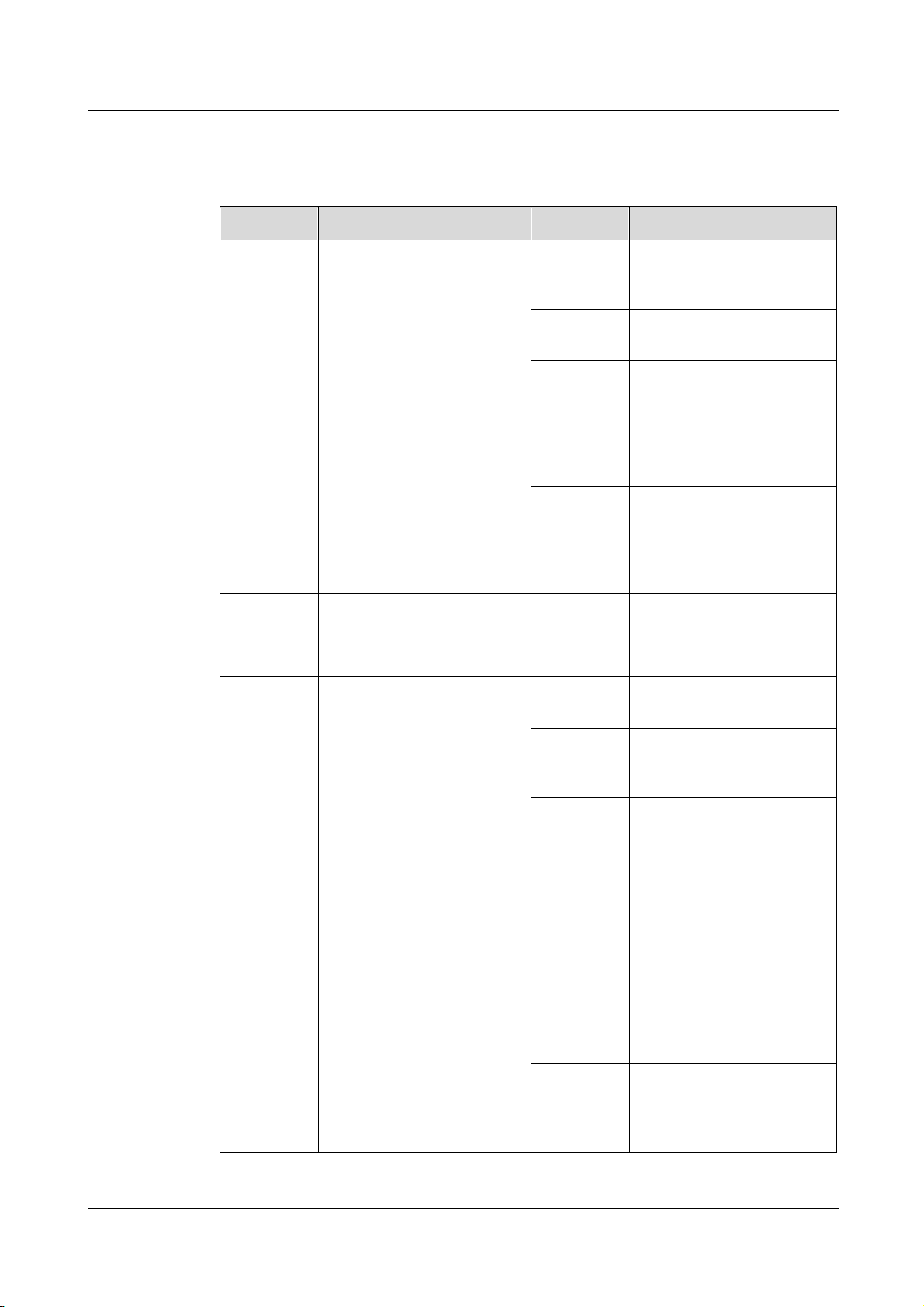

3.1 ECC800

(1) PSU 1

(2) PSU 2

(3) Status indicator

(4) 3G/4G antenna port

Manufacturer: Guangdong

Shenglu Telecommunication Tech.

Co., Ltd.

Model: SL10802U

(5) FE ports

(WAN_1–WAN_2 and

LAN_1–LAN_2)

(6) AI/DI_1–6 sensor

input port

(7) RF_Z antenna port

Manufacturer: Guangdong

Shenglu Telecommunication Tech.

Co., Ltd.

Model: SL15334H

(8) SW button

(9) DO_1–2 dry contact

output

(10) RS485 port (COM1–4/12V)

(11) Default button

(12) USB port

(13) ECC800 main control module

The ECC800 consists of power supply units (PSUs) and an ECC800 main control module and

monitors the equipment and environment in the smart module.

Figure 3-1 ECC800 (front view)

3 Device Description

ECC800 Data Center Controller

User Manual

3 Device Description

Issue 02 (2019-02-28)

Copyright © Huawei Technologies Co., Ltd.

10

(1) 53.5 V DC_OUT1

(2) 53.5 V DC_OUT2

(3) AC_INPUT1

(4) AC_INPUT2

(1) SIM card slot

(2) Micro-SD card slot

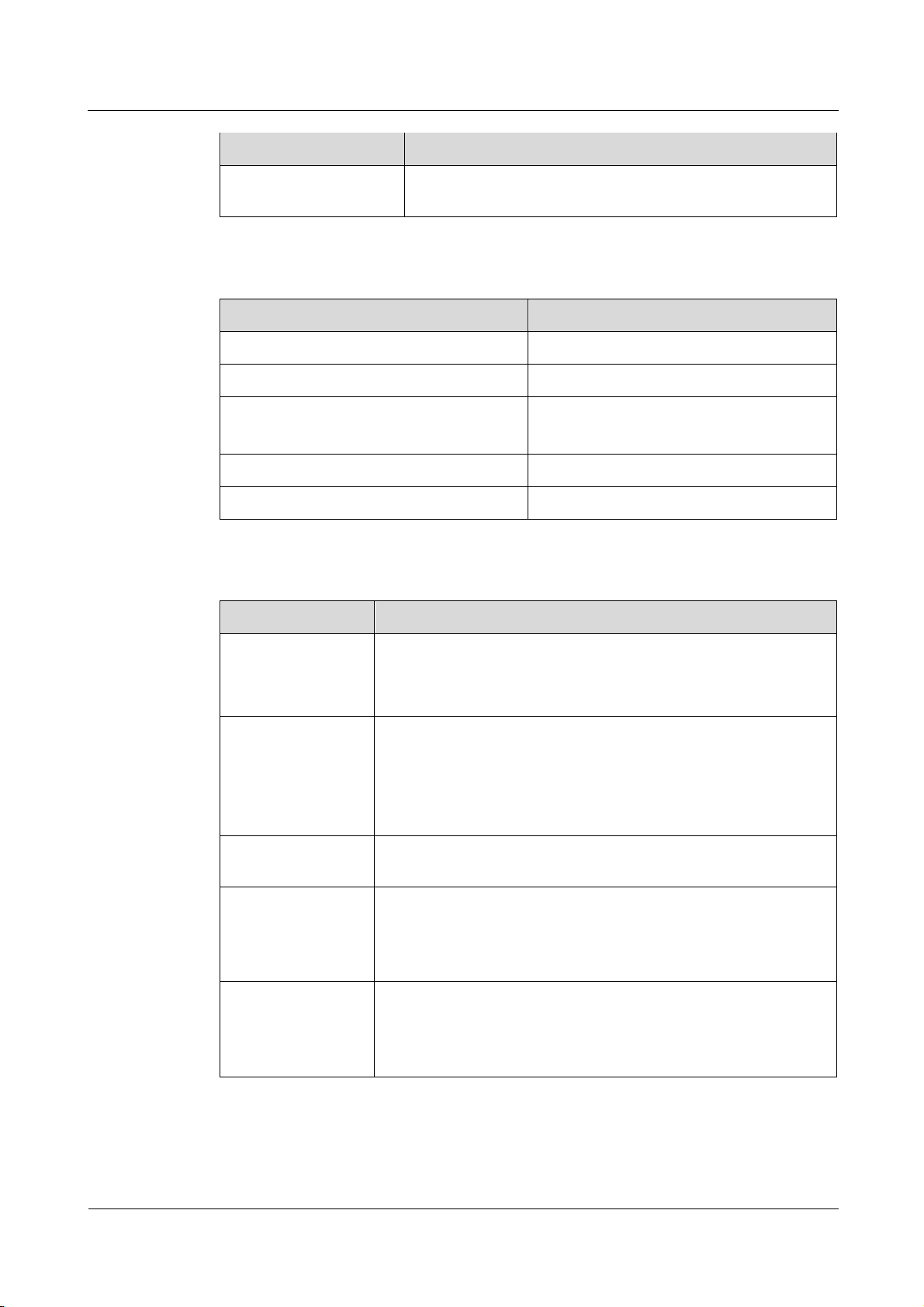

Item

Specifications

Working temperature

–20°C to +50°C

Storage temperature

–40°C to +70°C

Relative humidity

5%–95% RH (non-condensing)

The ECC800 shown in the figure is fully configured with PSUs. PSUs 1 and 2 are optional depending on

the application scenario.

Figure 3-2 ECC800 (rear view)

Figure 3-3 ECC800 main control module (side view)

ECC800 Specifications

Table 3-1 ECC800 environmental specifications

ECC800 Data Center Controller

User Manual

3 Device Description

Issue 02 (2019-02-28)

Copyright © Huawei Technologies Co., Ltd.

11

Item

Specifications

Altitude

0–4000 m (When the altitude is between 3000 m and 4000 m,

the temperature decreases by 1°C for each additional 200 m.)

Item

Specifications

Dimensions (L x W x H)

442 mm x 330 mm x 43.6 mm

Color

Black

Installation

Installed in a standard 1 U cabinet

Installed in a 19-inch rack

Environmental protection

RoHS5

Mean time between failures (MTBF)

500,000 hours

Item

Specifications

Power input

Supports two AC inputs

Rated voltage: 200–240 V AC/100–120 V AC

Rated frequency: 50 Hz/60 Hz

Power output

Output voltage: 42–58 V DC (rated voltage: 53.5 V DC)

Output power of two power supplies: 2000 W (176–300 V AC);

940 W (linear derating at 85–175 V AC)

Output power of a single power supply: 1000 W (176–300 V

AC); 470 W (linear derating at 85–175 V AC)

FE port expansion

Supports two WAN ports, two LAN ports, and 10/100M

communications rate

RS485 serial port

expansion

Supports four RS485 ports with the default communications rate

of 9600 bit/s.

Each port provides 12 V DC power with the rated current of 450

mA.

AI/DI expansion

(RJ45)

Supports six AI/DI ports to connect to smoke sensors, water

sensors, and temperature sensors.

Each port provides 12 V DC power with the rated current of 85

mA.

Table 3-2 ECC800 structural specifications

Table 3-3 ECC800 technical specifications

ECC800 Data Center Controller

User Manual

3 Device Description

Issue 02 (2019-02-28)

Copyright © Huawei Technologies Co., Ltd.

12

Item

Specifications

DO expansion

(RJ45)

Two DO ports. Each port supports passive and active DO.

Supports passive (dry contact) DO ports with contact point

capacity of 20 W, maximum withstand voltage of 60 V DC, and

rated current of 500 mA.

Supports active DO ports with the output voltage of 12 V DC

and output current of 450 mA.

Wireless

communication

Supports wireless communication that complies with

IEEE802.15.4.

3G (optional)

Supports 3G (WCDMA) communication and is compatible with 2G

(GSM) communication. A standard SIM card slot is provided.

NOTE

The prerequisite for using a SIM card is that the site has signal coverage.

Supports only SMS but not data services.

USB After installing the WiFi module, connect the WiFi module to

the ECC using the app on the mobile phone or tablet computer

to view the basic information about the smart module, such as

layout, resources, energy efficiency, environment, and alarms.

Insert a USB flash drive to export historical data, device data,

fault information, and configuration files, and import or export

the device configuration data and historical data.

Button SW: wireless network pairing button

Default: restores the default IP address

Model Name

Specifications

ECC800

RF_Z operation frequency

2405 MHz–2480 MHz

RF_Z E.I.R.P.Power (Max.)

5 dBm

3G/4G Operation Frequency

WCDMA BAND: 850

MHz–2100 MHz

GSM: 850 MHz–1900 MHz

3G/4G E.I.R.P.Power

(Max.)

36 dBm

Driver version

V100

Table 3-4 ECC800 RF parameters

ECC800 Data Center Controller

User Manual

3 Device Description

Issue 02 (2019-02-28)

Copyright © Huawei Technologies Co., Ltd.

13

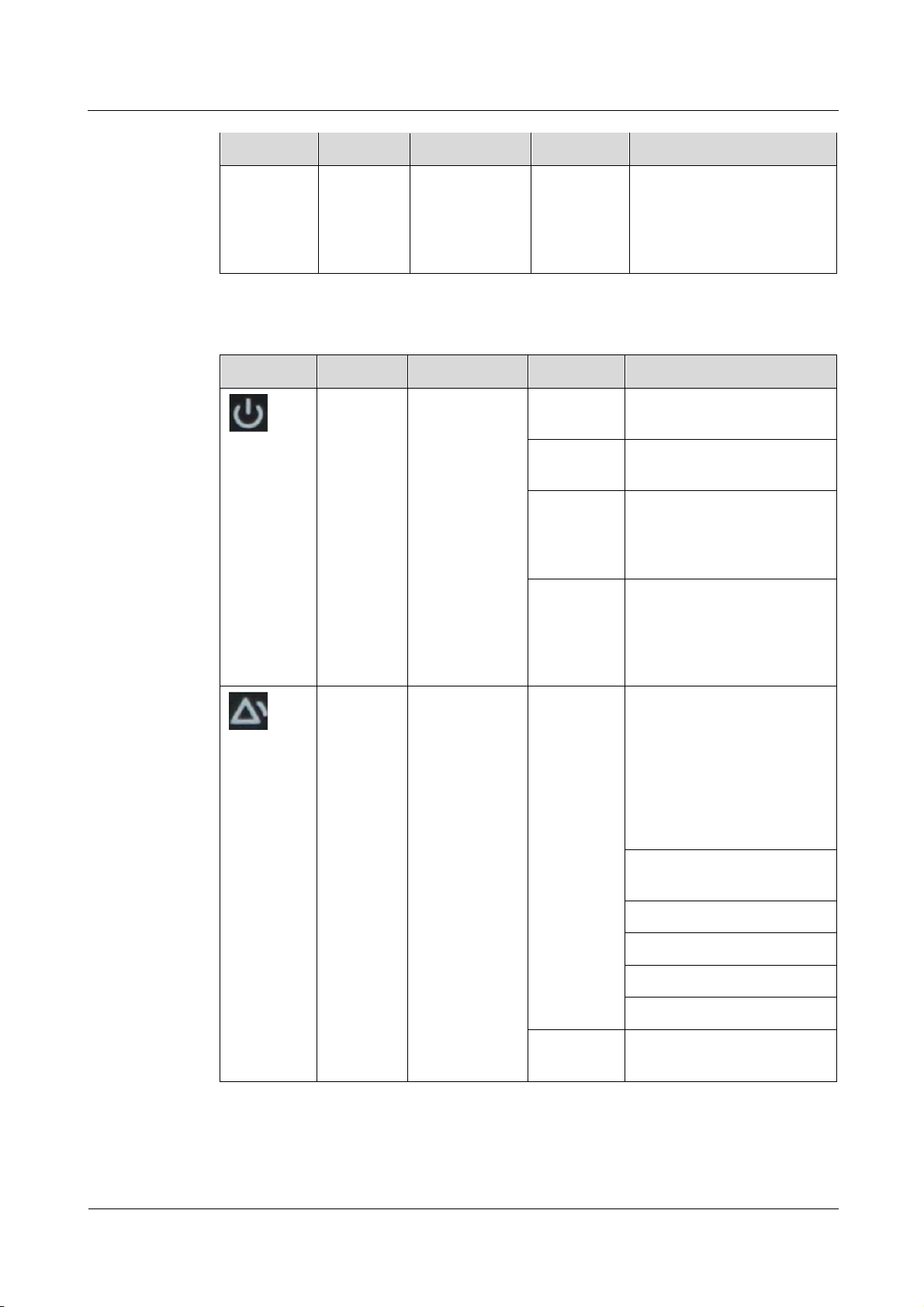

Indicators

Indicator

Color

Name

Status

Description

RUN

Green

Running status

indicator

Steady on

The power supply is normal,

the program is being loaded,

or WiFi WPS is pairing.

Off

The power supply is

abnormal.

Blinking at

long

intervals

The software runs properly

(the indicator blinks at 0.5

Hz, on for 1s and then off

for 1s) or the ECC800

registers with the NetEco

successfully.

Blinking at

short

intervals

The ECC800 does not

register with the NetEco (the

indicator blinks at 4 Hz, on

for 0.125s and then off for

0.125s).

ALM

Red

Alarm indicator

Steady on

A system failure alarm is

generated.

Off

The system is normal.

3G

Green

3G status

indicator

Steady on

The 3G module is powered

on.

Off

The 3G module stops

running, or no 3G module is

configured.

Blinking at

long

intervals

The 3G module succeeds in

dial-up (the indicator blinks

at 0.5 Hz, on for 1s and then

off for 1s).

Blinking at

short

intervals

The 3G module registers

with the operator network

successfully (the indicator

blinks at 4 Hz, on for 0.125s

and then off for 0.125s).

RF_Z

Green

Communication

status indicator

Steady on

No network parameters

exist, or a network is to be

created.

Blinking at

long

intervals

A network is set up, and no

node access is allowed (the

indicator blinks at 0.5 Hz, on

for 1s and then off for 1s).

Table 3-5 Indicators on the ECC800 main control module

ECC800 Data Center Controller

User Manual

3 Device Description

Issue 02 (2019-02-28)

Copyright © Huawei Technologies Co., Ltd.

14

Indicator

Color

Name

Status

Description

Blinking at

super short

intervals

A network is set up, and

node access is allowed (the

indicator blinks at 10 Hz, on

for 0.05s and then off for

0.05s).

Indicator

Color

Name

Status

Description

Green

Power indicator

Steady on

The converter has a power

input.

Off

The converter has no power

input or is faulty.

Blinking at

long

intervals

The converter is being

queried (the indicator blinks

at 0.5 Hz, on for 1s and then

off for 1s).

Blinking at

short

intervals

The converter application

program is being loaded (the

indicator blinks at 4 Hz, on

for 0.125s and then off for

0.125s).

Yellow

Alarm indicator

Steady on

The converter generates a

forewarning indicating that

power will be limited due to

ambient overtemperature, or

generates a protection

shutdown alarm due to

ambient overtemperature or

undertemperature.

Power input overvoltage or

undervoltage protection

Reverse DC input connection

Slight current imbalance

Output overvoltage

Hibernation

Off

The converter generates no

protection alarms.

Table 3-6 PSU indicator description

ECC800 Data Center Controller

User Manual

3 Device Description

Issue 02 (2019-02-28)

Copyright © Huawei Technologies Co., Ltd.

15

Indicator

Color

Name

Status

Description

Blinking at

long

intervals

The communication between

the converter and the outside

is interrupted (the indicator

blinks at 0.5 Hz, on for 1s

and then off for 1s).

Red

Fault indicator

Steady on

The converter locks out due

to output overvoltage.

The converter delivers no

output due to internal faults.

Off

The converter is working

properly.

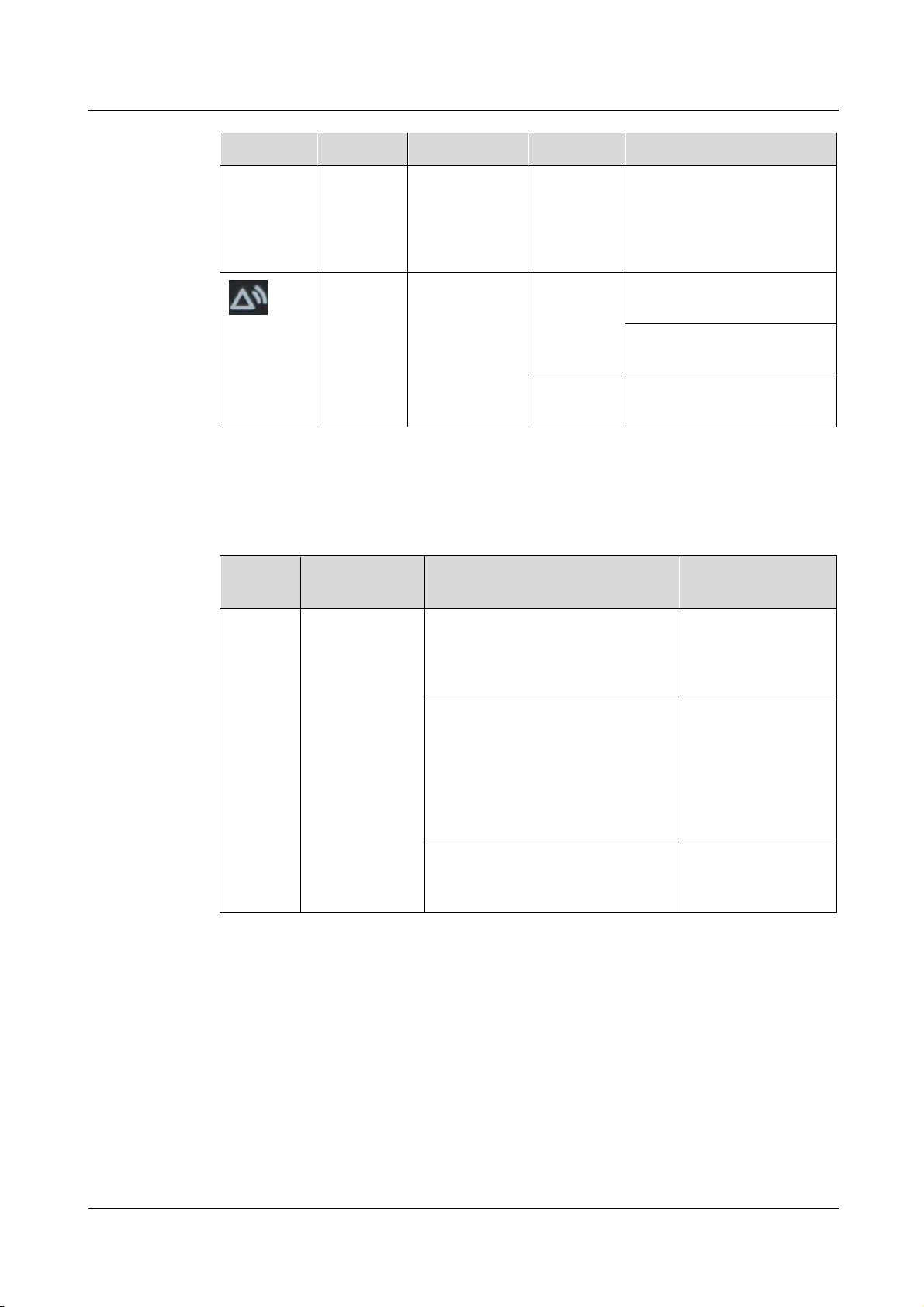

Button

Name

Function

Description

Operation Description

Indicator Status

SW

Wireless

network RF_Z

(802.15.4)

pairing

In non-wireless network (802.15.4)

pairing mode, press and hold down

the button for 1.2s to 5s to enter the

wireless network pairing mode.

The RF_Z indicator

is blinking at super

short intervals.

In wireless network (802.15.4)

pairing mode, press and hold down

the button for 1.2s to 5s to exit the

pairing mode; or the system

automatically exits the pairing mode

after 30 minutes without pressing

the button.

The RF_Z indicator

is blinking at long

intervals.

Press and hold down the button for

more than 6s to clear network

parameters.

The RF_Z indicator

is on.

Wireless Network Pairing (SW) and IP Address Reset (Default) Buttons

Table 3-7 Wireless network pairing and IP address reset buttons

ECC800 Data Center Controller

User Manual

3 Device Description

Issue 02 (2019-02-28)

Copyright © Huawei Technologies Co., Ltd.

16

Button

Name

Function

Description

Operation Description

Indicator Status

WiFi pairing

button

NOTE

This function is

supported only

in a scenario

where the WiFi

converter is

configured.

In non-WiFi pairing mode, press the

button for less than 1.2s to enter the

WiFi pairing mode.

When the system

enters the pairing

mode, the RUN

indicator is

steady on.

After pairing

succeeds, the

RUN indicator

blinks just as

before WiFi

pairing.

If pairing does

not succeed in 3

minutes, the RUN

indicator blinks

just as before

WiFi pairing.

Default

IP address reset

Press and hold down the button for

3s. Then the IP address for the

ECC800 WAN_1 port will restore

to the default address 192.168.1.10.

None

Item

Description

Pin sequence

Pin 1

TX+

Communications Ports

The ECC800 provides the following communications ports. Figure 3-4 shows the pins of the

RJ45 port.

Figure 3-4 RJ45 port pins

There are four FE ports, that is, two WAN ports (WAN_1 and WAN_2) and two LAN ports

(LAN_1 and LAN_2). Table 3-8 provides the FE port pin definitions.

Table 3-8 FE port pin definitions

ECC800 Data Center Controller

User Manual

3 Device Description

Issue 02 (2019-02-28)

Copyright © Huawei Technologies Co., Ltd.

17

Item

Description

Pin 2

TX-

Pin 3

RX+

Pin 4

N/A

Pin 5

N/A

Pin 6

RX-

Pin 7

N/A

Pin 8

N/A

Indicator

Green

indicator

Linked, steady on

Yellow

indicator

ACT data communication, blinking

Item

Description

Pin sequence

Pin 1

RS485+

Pin 2

RS485–

Pin 3

12 V DC_OUT

Pin 4

RS485+

Pin 5

RS485–

Pin 6

N/A

Pin 7

N/A

Pin 8

GND

Indicator

Green

indicator

Power output indicator

Steady on: The 12 V DC output is normal.

Off: No 12 V DC output is provided.

There are four RS485 ports (COM1/12V–COM4/12V). Table 3-9 provides the RS485 port pin

definitions.

Table 3-9 RS485 port pin definitions

There are six AI/DI dry contact inputs (AI/DI_1–6). Table 3-10 provides the AI/DI port pin

definitions.

Pins 1, 2, 4, and 5 identify sensor types.

Pin 3 and Pin 8 are power output ports.

ECC800 Data Center Controller

User Manual

3 Device Description

Issue 02 (2019-02-28)

Copyright © Huawei Technologies Co., Ltd.

18

Item

Description

Pin sequence

Pin 1

Type_1

Pin 2

Type_2

Pin 3

12 V DC

Pin 4

Type_3

Pin 5

Type_4

Pin 6

DI-

Pin 7

DI+

Pin 8

GND

Indicator

Green

indicator

Power output indicator

Steady on: The 12 V DC output is normal.

Off: No 12 V DC output is provided.

Item

Description

Pin sequence

Pin 1

N/A

Pin 2

N/A

Pin 3

12 V DC_OUT

Pin 4

N/A

Pin 5

N/A

Pin 6

DO_NO

Pin 7

DO_COM

Pin 8

GND

Indicator

Green

indicator

Power output indicator

Steady on: The 12 V DC output is normal.

Off: No 12 V DC output is provided.

Pin 6 and Pin 7 collect sensor data. Pin 7 can detect current type sensors (4–20 mA). Pin 6 and Pin 7

can detect the output status of passive dry contact type sensors. Pin 3 and Pin 7 can detect

temperature sensors.

Table 3-10 AI/DI port pin definitions

There are two DO dry contact outputs (DO_1 and DO_2). Table 3-11 provides the DO port

pin definitions.

Table 3-11 DO port pin definitions

ECC800 Data Center Controller

User Manual

3 Device Description

Issue 02 (2019-02-28)

Copyright © Huawei Technologies Co., Ltd.

19

Item

Description

Pin sequence

Pin 1

5 V

Pin 2

DM

Pin 3

DP

Pin 4

GND

Power Ports

Port Type

Pin

Description

AC

Pin 1

L

Pin 2

PE

Pin 3

N

DC

Pin 1

48V+

Pin 2

48VGND

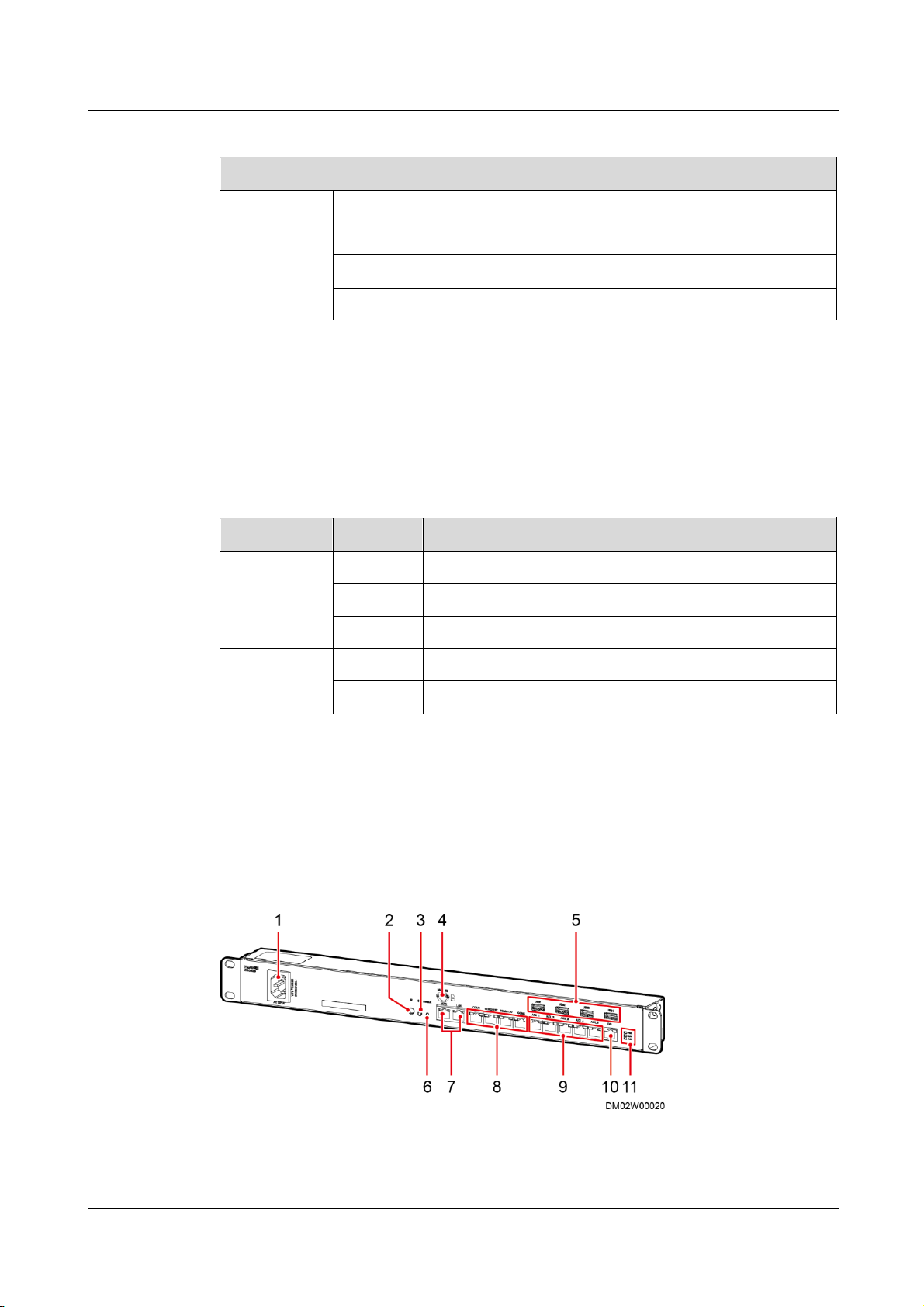

(1) Power input

(2) Infrared receiver (IR)

(3) SW button

Table 3-12 USB port pin definitions

The ECC800 provides four power ports, including two AC input ports (AC_INPUT1 and

AC_INPUT2) and two DC output ports (DC_OUTPUT1 and DC_OUTPUT2). Table 3-13

provides the power port pin definitions.

Table 3-13 Power port pin definitions

3.2 ECC800e

The ECC800e monitors the equipment and environment inside the smart module.

Figure 3-5 ECC800e appearance

ECC800 Data Center Controller

User Manual

3 Device Description

Issue 02 (2019-02-28)

Copyright © Huawei Technologies Co., Ltd.

20

socket

(4) Port for installing

a micro SD card

(5) USB (USB1–USB4) port

(6) Default button

(7) FE port (WAN

port and LAN port)

(8) RS485 port (COM1,

COM2–3/12V) and CAN port

(COM4)

(9) AI/DI_1–5 sensor input

ports

(10) DO dry contact

(11) Status indicator

Item

Specification

Power Input

Supports one AC input.

Rated operating voltage: 100-240 V AC.

Rated operating frequency: 50 Hz/60 Hz.

Input current: MAX 0.5 A.

FE port expansion

Supports one WAN port, one LAN port, with the 10/100M

communications rate.

RS485 serial port

expansion

Reserves three RS485 ports with the default communications

rate of 9600 bit/s.

COM2–3 ports providing 12 V DC power with the rated current

of 450 mA.

NOTE

The Pin 1, Pin 2, Pin 4, and Pin 5 in the COM4 port provide the RS485

signal. These four pins are shared with the COM3 port.

The Pin 7 and Pin 8 in the COM4 port provide the CAN signal.

AI/DI expansion

(RJ45)

Supports five AI/DI ports to connect to smoke sensors, water

sensors, and temperature sensors.

Each port provides 12 V DC power with the rated current of 85

mA.

DO expansion

(RJ45)

One DO port supports passive and active DO.

Supports passive (dry contact) DO port with contact point

capacity of 20 W, maximum withstand voltage of 60 V DC, and

rated current of 0.5 A.

Supports active DO port with the output voltage of 12 V DC and

output current of 450 mA.

Table 3-14 Technical specifications

ECC800 Data Center Controller

User Manual

3 Device Description

Issue 02 (2019-02-28)

Copyright © Huawei Technologies Co., Ltd.

21

Item

Specification

USB After installing the WiFi module, connect the WiFi module to

the ECC using the app on the mobile phone or tablet computer

to view the basic information about the smart module, such as

layout, resources, energy efficiency, environment, and alarms.

Insert the SMS module. When an alarm is reported, the ECC can

send information to the user through the 3G module.

Insert a USB flash drive to export historical data, device data,

fault information, and configuration files, and import or export

the device configuration data and historical data.

Buttons

SW: wireless network pairing button.

Default: button of restoring the default IP address.

Indicator

Color

Name

Status

Description

RUN

Green

Module running

status indicator

Steady on

The power supply is normal,

the program is being loaded,

or WiFi WPS is pairing.

Off

The power supply is

abnormal.

Blinking

at long

intervals

The software runs properly

(the indicator blinks at 0.5

Hz, on for 1s and then off

for 1s) or the ECC800e

registers with the NetEco

successfully.

Blinking

at short

intervals

The ECC800e does not

register with the NetEco (the

indicator blinks at 4 Hz, on

for 0.125s and then off for

0.125s).

ALM

Red

Alarm indicator

Steady on

A system failure alarm is

generated.

Off

The system is normal.

PWR

Green

Power indicator

Steady on

The power supply for the

system is normal.

Off

The power supply for the

system is abnormal.

Table 3-15 Indicators on the ECC800e main control module