Page 1

HP xw9300 Workstation

Service and Technical Reference Guide

First Edition: 02/2005

Second Edition: 04/2005

Page 2

Copyright Information

© 2005 Copyright Hewlett-Packard Development Company, L.P.

First Edition: February 2005

Second Edition: April 2005

Warranty

Hewlett-Packard Company shall not be liable for technical or editorial errors or omissions contained herein or for incidental or consequential

damages in connection with the furnishing, performance, or use of this material. The information in this document is provided “as is” without

warranty of any kind, including, but not limited to, the implied warranties of merchantability and fitness for a particular purpose, and is subject to

change without notice. The warranties for HP products are set forth in the express limited warranty statements accompanying such products.

Nothing herein should be construed as constituting and additional warranty.

This document contains proprietary information that is protected by copyright. No part of this document may be photocopied, reproduced, or

translated to another language without the prior written consent of Hewlett-Packard Company.

Trademark Credits

The HP Invent logo is a trademark of Hewlett-Packard Company in the U.S. and other countries.

Microsoft and Windows are trademarks of Microsoft Corporation in the U.S. and other countries.

Red Hat is a registered trademark of Red Hat, Inc.

Linux is a registered trademark of Linus Torvalds.

Acrobat and Acrobat Reader are trademarks of Adobe Systems Incorporated.

Energy Star is U.S. registered mark of the United States Environmental Protection Agency.

Page 3

Contents

Preface

Important Safety Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Updating BIOS, Drivers, and Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Finding Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

E-Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Additional Documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Helpful Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Using the Documentation Library and Diagnostics CD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Windows-Based Workstations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Linux-Based Workstations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Locating Regulatory Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Parts and Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Subscriber’s Choice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1 Product Overview

Product Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Front Panel Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Rear Panel Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Serial Number and COA Label Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Product Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Power Supply and Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Power Output and Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Power Supply Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Power Consumption and Cooling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

System Fans and Airflow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Resetting the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Environmental Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

PCI and PCI Express Slot Power Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

ENERGY STAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

ENERGY STAR Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Contents

2 Installing or Restoring the Operating System

Installing the Operating System and Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Microsoft Windows XP Professional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Installing or Upgrading Device Drivers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Creating a Restore Diskette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Linux-Preinstalled Workstations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Starting the Linux Operating System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Restoring the Linux Operating System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Upgrading Device Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Linux-Enabled Workstations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Verifying Hardware Compatibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Installing the Linux Operating System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Upgrading Device Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

HP Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Restoring the Operating System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Protecting the Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Ordering Backup Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Contents

3

Page 4

3 System Management

Computer Setup (F10) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

BIOS ROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Using Computer Setup (F10) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Computer Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Desktop Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Initial Configuration and Deployment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Remote System Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Software Updating and Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

HP Client Manager Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Altiris Client Management Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

System Software Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Proactive Change Notification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Subscriber’s Choice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

ROM Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Remote ROM Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

HPQFlash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

FailSafe Boot Block ROM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Replicating the Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Dual-State Power Button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

World Wide Web Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Building Blocks and Partners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Asset Tracking and Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Password Security. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Deleting a Power-On or Setup Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Hood Sensor (Smart Cover Sensor) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Cable Lock Provision (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Security Lock (Optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Universal Chassis Clamp Lock (Optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Hood Sensor (Smart Cover Sensor) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Access Panel Key Lock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Fault Notification and Recovery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Drive Protection System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

ECC Fault Prediction and Prefailure Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Surge-Tolerant Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Thermal Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

4 Removal and Replacement Procedures

Service Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Cautions, Warnings, and Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Electrostatic Discharge Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Generating Static . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Preventing Electrostatic Damage to Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Personal Grounding Methods and Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Grounding the Work Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Recommended Materials and Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Tools and Software Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Special Handling of Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Cables and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Hard Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Lithium Coin Cell Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Pre-Disassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

System Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

System Board Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

System Board Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Removal and Replacement of Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Disassembly Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

4Contents

Page 5

Security Lock (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Cable Lock (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Universal Chassis Clamp Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Access Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Front Bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Bezel Blanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Hood Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Front Panel I/O Device Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Power Button Assembly and System Speaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Memory Duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

System Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Memory Module Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Memory Module Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Peripheral Component Interconnect (PCI) Slots. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

PCI Slot Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

PCI Card Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

PCI Express . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

PCI or PCI-X . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Front Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Power Connections to Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Optical Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Diskette Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Hard Disk Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Installing a SCSI Hard Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Installing an External SCSI Hard Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Installing a SATA Hard Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

CPU Heatsink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

CPU Heatsink A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

CPU Heatsink B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

System Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Contents

5 System Diagnostics and Troubleshooting

E-Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Help & Support Center (HSC) and E-Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Troubleshooting Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

LED Color Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

HP Insight Diagnostics Offline Edition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Key Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Diagnostic Utility on CD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Download the ISO Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Survey Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Test Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Status Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Log Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Saving and Printing Information in HP Insight Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Diagnostic Light Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Troubleshooting Scenarios and Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Solving Minor Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Solving Power Supply Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Testing Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Solving Diskette Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Solving Hard Drive Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Contents

5

Page 6

Solving Display Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Solving Audio Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Solving Printer Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Solving Keyboard and Mouse Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Solving Front Panel Component Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Solving Hardware Installation Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Solving Network Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Solving Memory Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Solving Processor Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Solving CD-ROM and DVD Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Solving Internet Access Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Power On Self Test (POST) and Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

A SCSI Devices

SCSI Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Using SCSISelect with SCSI Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

SMART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Jumpers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

B SATA Devices

SATA Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

SATA RAID Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

C Connector Pins

Enhanced Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Mouse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Ethernet RJ-45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Serial Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

IEEE 1394 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Microphone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Headphone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Line-in Audio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Line-out Audio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Ultra SCSI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

SATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Monitor (VGA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Monitor (DVI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

ATA/ATAPI (IDE) Standard Drive Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

24-Pin Power (Main) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

8-Pin Power (for Processors) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

6-Pin Power (Auxiliary PCI Express). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

D System Board Designators

E Power Cord Set Requirements

F Routine Care

General Cleaning Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Maximizing the Airflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Cleaning the Workstation Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Cleaning the Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Cleaning the Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Cleaning the Mouse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

6Contents

Page 7

G Additional Password Security and Resetting CMOS

Resetting the Password Jumper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Clearing and Resetting the CMOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Using Computer Setup to Reset CMOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Using the CMOS Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

H Quick Troubleshooting Flows

Initial Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

No Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

No Power, Part 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

No Power, Part 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

No Power, Part 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

No Video . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

No Video, Part 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

No Video, Part 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

No Video, Part 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Error Messages, Part 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Error Messages, Part 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Error Messages, Part 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

No OS Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

No OS Loading from Hard Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

No OS Loading from Hard Drive, Part 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

No OS Loading from Hard Drive, Part 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

No OS Loading from Hard Drive, Part 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

No OS Loading from Diskette Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

No OS Loading from CD-ROM Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

No OS Loading from Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Non-functioning Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Contents

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Contents

7

Page 8

8Contents

Page 9

Preface

This preface contains the following information.

• “Important Safety Warnings” on page 10

• “Updating BIOS, Drivers, and Software” on page 13

• “Finding Information” on page 14

Preface

9

Page 10

Important Safety Warnings

WARNING! Avoiding Electrical Shocks. To avoid electrical shock, do not open the power supply. There

are no user-serviceable parts inside.

To avoid electrical shock and harm to your eyes by laser light, do not open the DVD laser module. The

laser module should be serviced by service personnel only. Do not attempt to make any adjustment to the

laser unit. Refer to the label on the DVD for power requirements and wavelength. This product is a class I

laser product.

WARNING! Grounding your Equipment. For your safety, always connect the equipment to a grounded

wall outlet. Always use a power cord with a properly grounded plug, such as the one provided with the

equipment, or one in compliance with your national safety standards. This equipment can be

disconnected from the power by removing the power cord from the power outlet. This means the

equipment must be located close to an easily accessible power outlet.

WARNING! Protecting your Ears. If your system is a multimedia model, or if you have installed a sound

card in your system, always turn the volume down before connecting the headphones or speakers. This

prevents discomfort from unexpected noise or static. Listening to loud sounds for prolonged periods of time

may permanently damage your hearing. Before putting on headphones, place them around your neck

and turn the volume down. When you put on the headphones, slowly increase the volume until you find a

comfortable listening level. When you can hear comfortably and clearly, without distortion, leave the

volume in that position.

WARNING! Removing and Replacing the Cover. For your safety, never remove the system side cover

without first disconnecting the power cord from the power outlet and removing any connection to a

telecommunications network. If a Power Protection Device is fitted to your system, you must shut down your

computer using its on/off switch, then remove the power cord before removing the system’s side cover.

Remove the Power Protection Device cables before any servicing operation. Always replace the side cover

before switching the system on again.

WARNING! Getting Battery Safety Information. There is a danger of explosion if the battery is incorrectly

installed. For your safety, never attempt to recharge, disassemble, or burn an old battery. Replace the

battery with the same or equivalent type, as recommended by the manufacturer.

The battery in this system is a lithium battery that does not contain any heavy metals. However, to protect

the environment, do not dispose of batteries in household waste. Return used batteries either to the shop

from which you bought them, to the dealer from whom you purchased your system, or to HP so that they

can either be recycled or disposed of in the correct way. Returned batteries will be accepted free of

charge.

10

Page 11

WARNING! Avoiding Metallic Particulates. They can be especially harmful around electronic equipment.

This type of contamination may enter the data center environment from a variety of sources, including, but

not limited to, raised floor tiles, worn air conditioning parts, heating ducts, rotor brushes in vacuum

cleaners, or printer component wear. Because metallic particulates conduct electricity, they have an

increased potential for creating short circuits in electronic equipment. This problem is exaggerated by the

increasingly dense circuitry of any electronic equipment.

Over time, very fine whiskers of pure metal can form on electroplated zinc, cadmium, or tin surfaces. If

these whiskers are disturbed, they might break off and become airborne, possibly causing failures or

operational interruptions. For over 50 years, the electronics industry has been aware of the relatively rare,

but possible, threat posed by metallic particulate contamination. During recent years, a growing concern

has developed in computer rooms where these conductive contaminants are formed on the bottom of some

raised floor tiles.

Although this problem is relatively rare, it might be an issue within your computer room. Since metallic

contamination can cause permanent or intermittent failures on your electronic equipment, Hewlett-Packard

strongly recommends that your site be evaluated for metallic particulate contamination before installation

of electronic equipment.

WARNING! Avoiding Burn Injuries. Some parts inside the computer will be hot. Turn off and unplug the

system, then wait approximately three to five minutes for it to cool down before opening the system access

panels or touching internal components.

WARNING! Avoiding Electrical Problems with Phone Lines. If you have a modem:

Do not attempt to connect this product to the phone line during a lightning storm. Never install telephone

jacks in wet locations unless the telephone line has been disconnected at the network interface. Never

touch uninsulated telephone wires or terminals unless the telephone line has been disconnected at the

network interface. Use caution when installing or modifying telephone lines. Avoid using a telephone

(other than a cordless type) during an lightning storm. There may be a risk from lightning.

Do not use the telephone to report a gas leak in the vicinity of the leak.

Never touch or remove the communications board without first removing the connection to the telephone

network.

CAUTION: Avoiding Static Electricity. Static electricity can damage electronic components. Turn OFF all

equipment and disconnect the power cable before installing an accessory card. Do not let your clothes

touch any accessory card. Handle the card as little as possible and with care.

Preface

CAUTION: Getting Information on Ergonomic Issues. It is strongly recommended that you read the

ergonomics information in the Safety and Comfort Guide on the Documentation Library and Diagnostics

CD before using your system. You can access more extensive ergonomics information at

http://www.hp.com/ergo.

Important Safety Warnings

11

Page 12

NOTE: Recycling Your System. HP has a strong commitment toward the environment. Your HP system has

been designed to respect the environment as much as possible. HP can also take back your old system for

recycling when it reaches the end of its useful life. HP has a product take-back program in several

countries. The collected equipment is sent to an HP recycling facilities in Europe or the U.S.A. As many

parts as possible are reused. The remainder is recycled. Special care is taken for batteries and other

potential toxic substances, these are reduced into non-harmful components through special chemical

processes. If you require more details about the HP product take-back program, contact your local dealer

or your nearest HP Sales Office.

12

Page 13

Updating BIOS, Drivers, and Software

HP continually strives to implement new enhancements that will increase functionality, performance, and

reliability of your HP Workstation. To ensure that your system takes advantage of the latest enhancements,

HP recommends that you install the latest BIOS, driver, and software updates on a regular basis.

To download available updates, choose one of the two following options:

• If you have the Help & Support Center installed on your system (most factory-installed Windows XP

operating systems do), click Start > Help & Support Center. Click the icon above HP Software

& Drivers Download and review or select available updates.

• Visit the HP Support Web site:

a. Go to http://www.hp.com/go/workstationsupport

b. Select your HP Workstation from the list.

c. In the “I would like to” section, click download drivers and software.

d. In the “select operating system” section, select your OS.

e. Locate the BIOS, driver, or software and click download next to your desired file. Follow the on-

screen instructions to complete installation.

.

Preface

Updating BIOS, Drivers, and Software

13

Page 14

Finding Information

E-Support

For online access to technical support information and tools, go to http://www.hp.com/support. Support

resources include Web-based troubleshooting tools, technical knowledge databases, driver and patch

downloads, online communities, and proactive notification services.

The following sites are also available to you.

• http://www.hp.com

• http://www.hp.com/support/workstation_manuals

• http://welcome.hp.com/country/us/eng/wwcontact.html

technical support phone numbers.

—Provides useful product information.

Additional Documentation

Refer to the Documentation Library and Diagnostics CD for additional product information in PDF format.

The CD contains the following:

• Setup and Troubleshooting Guide (available in print and PDF on library CD)—Helps you set up

hardware and factory-provided software; also includes basic troubleshooting information should you

encounter any problems during initial startup.

• Safety and Comfort Guide (PDF on library CD)—Provides safety and ergonomic information to assist

you in setting up a safe and comfortable workstation environment.

• Safety & Regulatory Information Guide (PDF on library CD)—Provides safety and regulatory

information that ensures compliance with U.S., Canadian, and various international regulations.

—Provides the latest online documentation.

—Provides a listing of the worldwide

Helpful Links

The following links can also be accessed for additional information:

• Product Bulletin—The product bulletin contains the QuickSpecs and is available at:

http://h18000.www1.hp.com/products/quickspecs/productbulletin.html

• For information about the Microsoft® Windows® operating system:

http://www.microsoft.com

• For information about the Linux operating system:

http://www.redhat.com

• Additional product information is available from the HP Web site at http://www.hp.com/go/

workstations.

14

Page 15

Using the Documentation Library and Diagnostics CD

To access the contents of the Documentation Library and Diagnostics CD, follow the steps that are

applicable to your workstation.

Windows-Based Workstations

Insert the CD into the CD-ROM drive. The CD Autorun feature begins.

If there is no CD-ROM drive activity for two minutes or more, the Autorun feature might not be enabled on

the workstation. To run the CD:

1. Click Start > Run.

2. In the text box, enter:

X:\index.htm

(where X is the drive letter designator for the CD-ROM drive)

3. Click OK.

Linux-Based Workstations

If the workstation is running a Linux operating system, browse the CD and click the index.htm file to

launch the CD interface. To view the documents on the CD, download and install Adobe® Acrobat®

Reader for Linux from http://www.adobe.com

.

Locating Regulatory Information

Refer to the Safety & Regulatory Information guide on the Documentation Library and Diagnostics CD for

product class information. You can also refer to the label on the rear of the chassis.

Parts and Accessories

For complete and current information on supported accessories and components, visit

http://partsurfer.hp.com

.

Subscriber’s Choice

Preface

Subscriber’s Choice, an HP program, enables you to sign up to receive driver and software alerts,

proactive change notifications (PCNs), the HP newsletter, and more. Sign up today at

http://www.hp.com/go/subscriberschoice

.

Finding Information

15

Page 16

16

Page 17

1Product Overview

This chapter presents an overview of the hardware components of the HP xw9300 Workstation.

• “Product Features” on page 18

• “Product Specifications” on page 22

• “Power Supply and Cooling” on page 23

• “Environmental Specification” on page 30

• “PCI and PCI Express Slot Power Specifications” on page 31

• “ENERGY STAR” on page 32

Product Overview

17

Page 18

Product Features

This section contains the following information:

• “Exploded View” on page 18

• “Rear Panel Components” on page 20

• “Serial Number and COA Label Location” on page 21

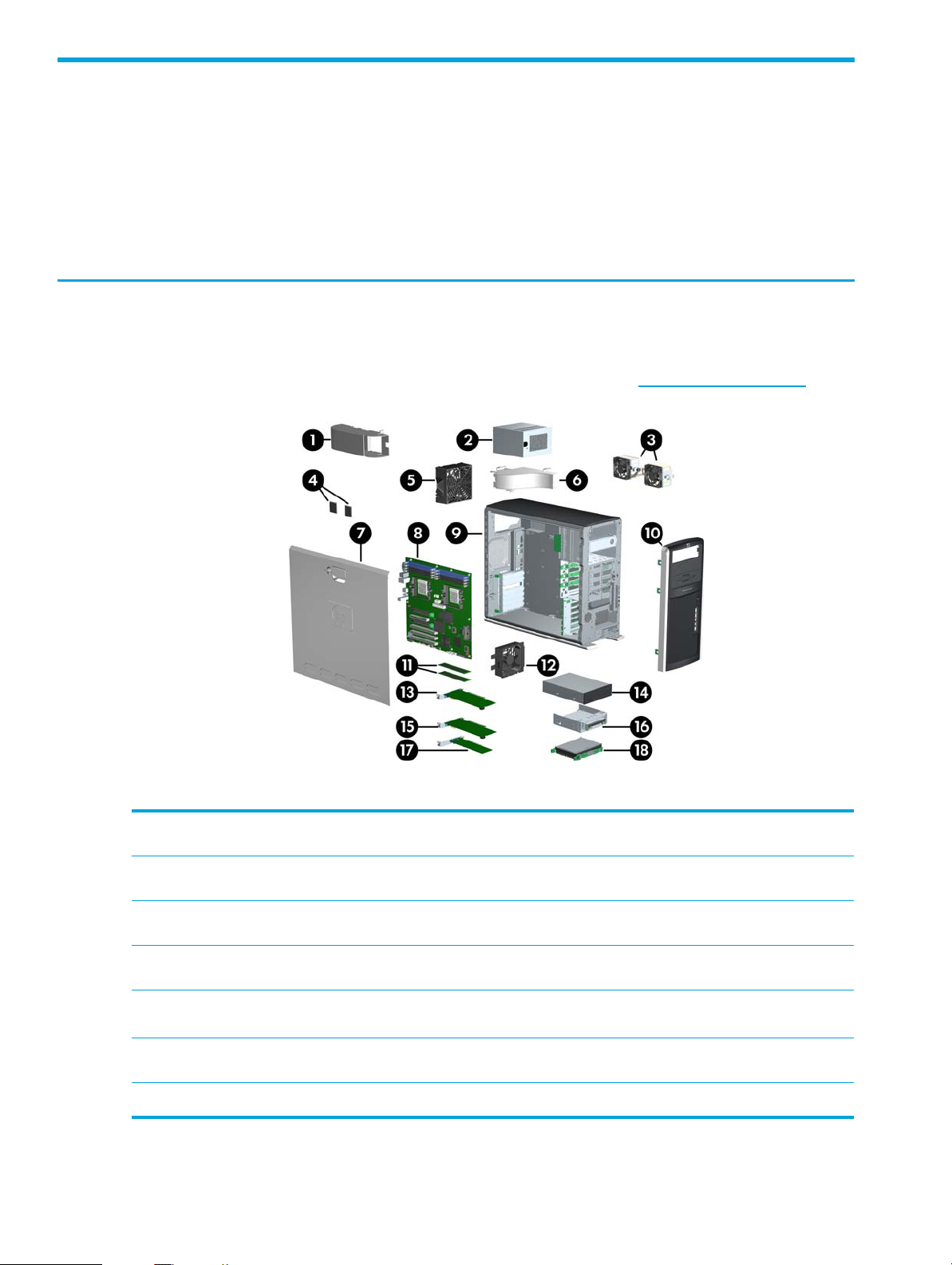

Exploded View

The following image shows a typical HP xw9300 Workstation (drive configurations can vary).

For complete information on supported accessories and components, visit http://partsurfer.hp.com

Table 1-1 Exploded View

CPU Airflow Duct

1

Access Panel

7

PCI Express Card

=

.

Power Supply

2

CPU Heatsinks

3

Processors

4

System Fan

5

Memory Airflow Duct

6

*An optical drive is a CD-ROM, CD-R/RW, DVD-ROM, DVD+R/RW, or CD-RW/DVD combo drive.

Product Overview18

System Board

8

Chassis

9

Front Bezel

:

Memory Modules

q

Front Fan

<

Optical Drive*

>

PCI-X Card

?

Diskette Drive with bracket

@

PCI Card

u

Hard Drive

B

Page 19

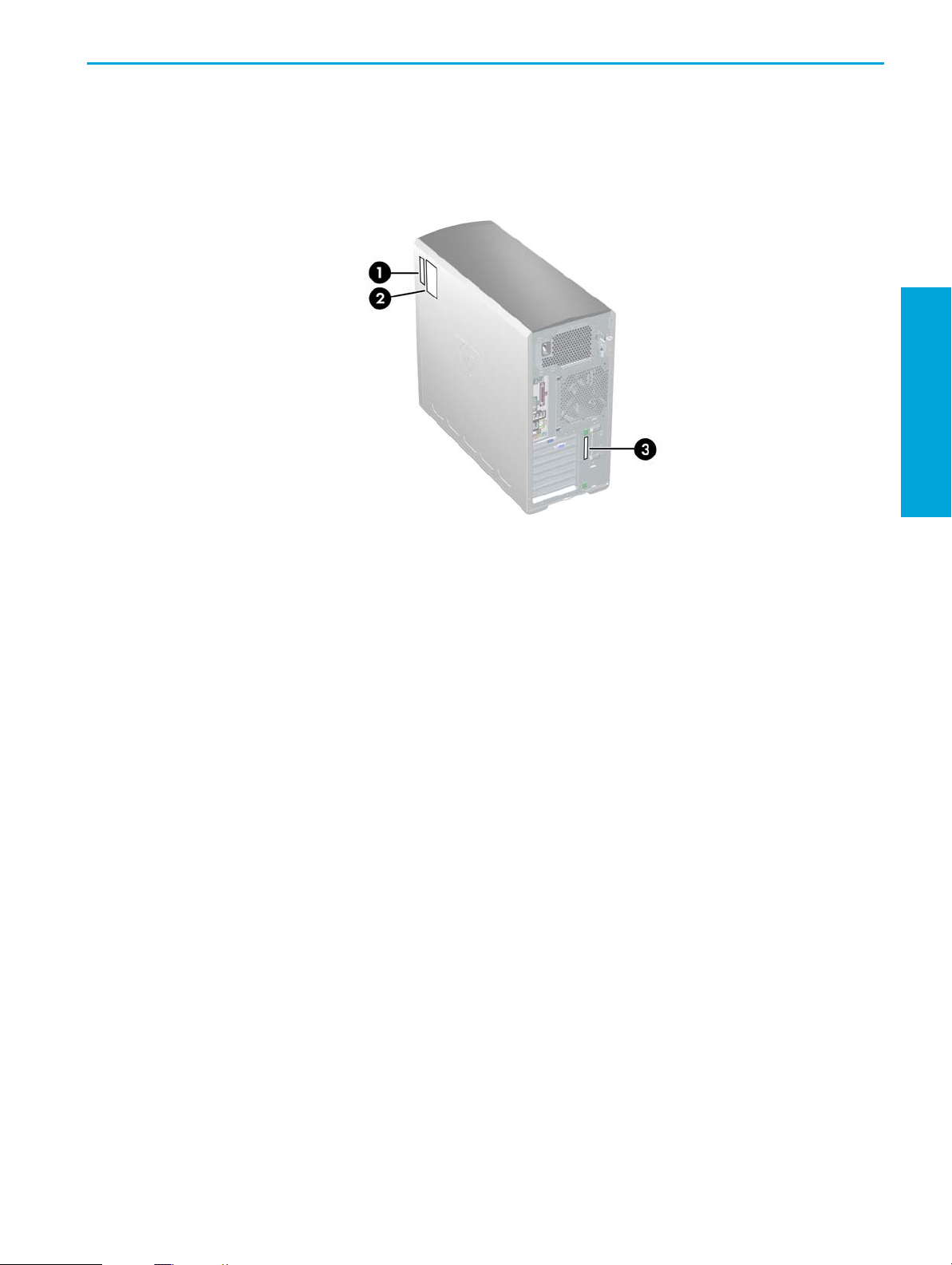

Front Panel Components

The following image shows a typical HP xw9300 Workstation. Drive configurations can vary.

Table 1-2 Front Panel View

Optical Drive Eject Button

1

Power On Light

2

Power Button

3

Hard Drive Activity Light

4

*An optical drive is a CD-ROM, CD-R/RW, DVD-ROM, DVD+R/RW, or CD-RW/DVD combo drive.

**The bottom optical bay is depth restricted to 165mm. A diskette drive with an adapter will fit.

Universal Serial Bus (USB)

5

(x2)

Headphone Connector

6

Microphone Connector

7

IEEE-1394 Connector

8

5.25-Inch Drive Bays (x2)**

9

Optical Drive Activity Light

:

Optical Drive*

;

Product Overview

Product Features

19

Page 20

Rear Panel Components

Table 1-3 Rear Panel Components

Universal Chassis Clamp Opening

1

Access Panel Keys

2

Padlock Loop

3

Cable Lock Slot

4

PS/2 Mouse Connector (green)

5

RJ-45 Network Connector

6

Audio Line-In Connector (light blue)

7

Audio Line-Out Connector (lime)

8

NOTE: To assist you in connecting your peripheral devices, the rear panel connectors are labeled and color-coded

according to industry standards.

Graphics Adapter

9

Microphone Connector (pink)

:

IEEE 1394 Connector

;

USB (x4)

<

PS/2 Keyboard Connector (purple)

=

Serial Connector (teal)

>

Power Supply Built-In Self Test (BIST) LED

?

Power Cord Connector

@

Product Overview20

Page 21

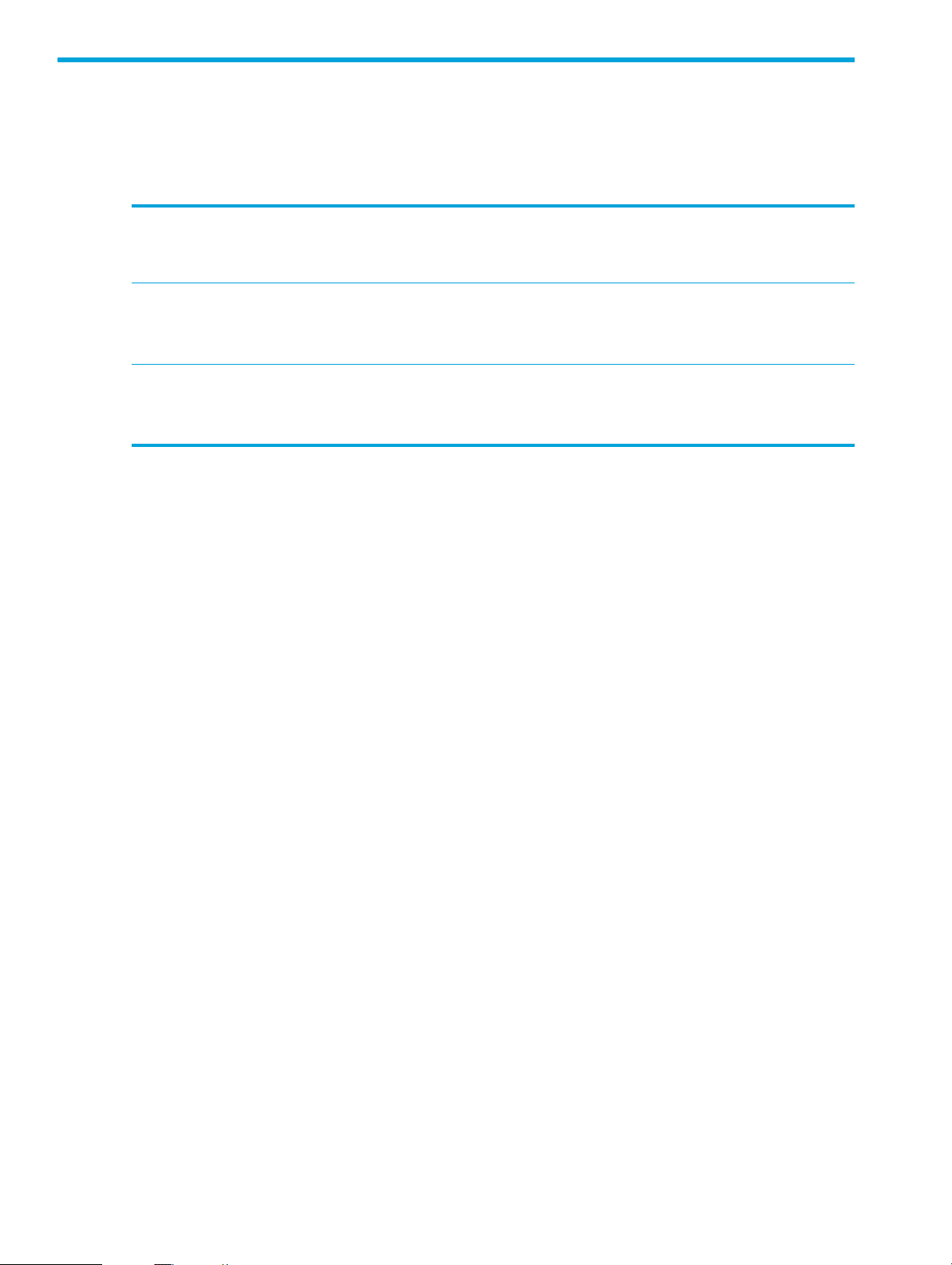

Serial Number and COA Label Location

Each HP Workstation has two unique serial number labels. The serial number labels are located on the

side panel

service for assistance. Systems preinstalled with Windows XP also have a certificate of authentication

(COA) label

1 of the unit and on the rear panel 3. You need this number when contacting customer

2.

Product Overview

Product Features

21

Page 22

Product Specifications

The following table lists the physical dimensions of the HP xw9300 Workstation.

Table 1-4 Physical Characteristics

Weight

(dependent on

configuration)

Tower Dimensions 455mm (17.9 inches) tall

Rack Mount Dimensions

(top cover and foot

removed)

19–24kg (42–54 lb)

210mm (8.3 inches) wide

525mm (20.7 inches) deep

210mm (8.3 inches) tall

440mm (17.3 inches) wide

525mm (20.7 inches) deep

Product Overview22

Page 23

Power Supply and Cooling

This section contains the following information:

• “Power Supply Specifications” on page 26

• “Power Consumption and Cooling” on page 27

• “System Fans and Airflow” on page 28

• “Resetting the Power Supply” on page 29

Product Overview

Power Supply and Cooling

23

Page 24

Power Output and Cooling

The HP xw9300 Workstation power supply contains 9 outputs:

• +3.3V—used with PCI, PCI-X, PCI-E, NVIDIA nForce Professional 2000 series MCPs, AMD8131,

LS1030, IEEE 1394, Audio, Super I/O, on-board logic

• +5V—used with storage (disk, optical, diskette), PCI, PCI-X, PCI-E, IEEE 1394, NVIDIA nForce

Professional 2000 series MCPs, USB, input to on-board regulators (1.2V, 1.5V, 1.8V, and 2.5V), SCSI

hard drives, and on-board logic

• +12V-A—used with PCI, PCI-X, PCI-E, IEEE 1394, system fans

• +12V-B—used with storage (disk, optical, floppy)

• +12V-C—used with PCI Express x16 auxiliary connectors

• +12VCPU0—input to onboard regulator that supplies power for CPU0, Mem0, and respective fan

• +12VCPU1—input to onboard regulator that supplies power for CPU1, Mem1, and respective fan

• -12V—used by PCI, PCI-X

• 5VSB—used for sleep circuitry

Table 1-5 Power Supply and Cooling (Voltage)

Voltage Minimum Maximum

3.3V 3.17V 3.47V

5V 4.85V 5.25V

12V CPU0 11.52V 12.6V

12V CPU1 11.52V 12.6V

12V-A 11.52V 12.6V

12V-B 11.52V 12.6V

12V-C 11.52V 12.6V

V12N -11.4V -12.6V

5VSB 4.85V 5.25V

Table 1-6 Power Supply and Cooling (Current)

Current Minimum Operating Continuous Maximum

3.3V 0A 3.1A 25A 35.0A

5V 0A 2.3A 23A 28.0A

12V CPU0 0A 3.1A 12.6A 16.0A

12V CPU1 0A 0A 12.6A 16.0A

12V-A 0A 0A 15A 18.5A

12V-B 0A 0A 3.8A 11.7A

Product Overview24

Page 25

Table 1-6 Power Supply and Cooling (Current)

Current Minimum Operating Continuous Maximum

12V-C 0A 0A 12.5A 14.0A

V12N 0A 0A 0.5A 0.8A

5VSB 0A 0A 2.0A 2A

WARNING! Do not exceed 136W of a 5V and 3.3V power combination.

WARNING! Do not exceed 55A (660W) of 12V (CPU0/CPU1/A/B/C) power combination.

WARNING! Do not exceed 700W of total continuous output power.

Product Overview

Power Supply and Cooling

25

Page 26

Power Supply Specifications

The following table lists the power supply specifications.

Table 1-7 Power Supply Specifications

Full Ranging Input (No Line Select Switch) Yes

Active Power Factor Correction (APFC) (Input Current is

nearly half of that of a non-APFC PS)

Passive Power Factor Correction (PFC) No

Operating Voltage Range 90–264VAC / 118VAC

Rated Voltage Range 100–240VAC

Rated Line Frequency 50–60Hz / 400Hz

Operating Line Frequency Range 47–66Hz / 393–407Hz

Rated Input Current 11.9A / 9.98A

Maximum Rated Power Supply Power

Maximum System Rated Power

Heat Dissipation Typical 1184.311 btu/hr

Power Supply Fan 92mm variable speed

PS Size (wide x high x deep) 98mm x 160mm x 200mm

Yes

750 W

700W

Maximum 3656.78 btu/hr

ENERGY STAR Compliant Yes

FEMP Standby Power Compliant(<2W in S5 - Power Off) No

Power Consumption in ES Mode - Suspend to RAM (S3)

(Instantly Available PC)

BIST LED Yes

Surge Tolerant Full Ranging Power Supply Withstands power surges up to 2000V

9W

Product Overview26

Page 27

Power Consumption and Cooling

The following table shows the power consumption for a typical configuration (based on primary power

consumptions):

• Two processors (2.4GHz Opteron)

• 2GB memory (4x512MB)

• Two hard drives (2xSATA 40G B)

• DVD-ROM drive

• PCI Express graphics card (FX1300)

• Diskette drive

• One monitor

Table 1-8 Power Consumption and Cooling

Input Power Consumption

Typical operating mode 347W = 1184 btu/hr

a

@ 120VAC/60Hz

Windows XP idle 262W = 894 btu/hr

Standby mode (S3) 9W = 30.7 btu/hr

Hibernate mode (S4) 7W = 23.9 btu/hr

Power Off (S5) 7W = 23.9 btu/hr

a. Approximate values

NOTE: When you turn off your workstation with the power button on the front panel, the power

consumption falls below 10W. To reach zero power consumption, either unplug the workstation from the

power outlet or use a power strip with a switch.

For additional information on power-saving features, refer to your operating system documentation.

Product Overview

Power Supply and Cooling

27

Page 28

System Fans and Airflow

The workstation includes one rear system fan, one CPU heatsink for each processor (CPU), one power

supply fan, plus a front system fan if two CPUs are installed. For airflow, this system includes a memory

airflow duct and a CPU airflow duct, which is required if two CPUs are installed.

Product Overview28

Page 29

Resetting the Power Supply

If an overload triggers the power supply overload protection, all power is immediately cut. To reset the

power supply unit:

1. Disconnect the power cord.

2. Determine what caused the overload and fix the problem.

3. Reconnect the power cord and reboot the workstation.

When you power down the workstation through the operating system, power consumption falls below the

low power consumption but does not reach zero. This on/off feature extends the life of the power supply.

Product Overview

Power Supply and Cooling

29

Page 30

Environmental Specification

The following table describes environmental specifications for the HP xw9300 Workstation.

Table 1-9 Environmental Specifications

Temperature Operating: 5° to 35° C (40° to 95° F)

Non-operating: -40° to 60° C (-40° to 140° F)

NOTE: Derate by one degree C (1.4 degrees F) for every

305m (1,000 ft.) altitude over 1,524m (5,000 ft.)

Humidity Operating: 8% to 85% RH, non-condensing

Non-operating: 8% to 90% RH

Shock

Vibration (operating) Operating random: 0.5g (RMS), 5–300Hz

Maximum Altitude Operating: 3,048m (10,000 ft)

Operating: 1/2-sine: 40g, 2–3ms

Non-operating:

• 1/2-sine: 160cm/s, 2–3ms, (~100g)

•square: 422cm/s, 20g

NOTE: Values represent individual shock events and do not

indicate repetitive shock events.

Non-operating random: 2.0g (RMS), 10–500Hz

NOTE: Values do not indicate continuous vibration.

Non-operating: 9,144m (30,000 ft)

Product Overview30

Page 31

PCI and PCI Express Slot Power Specifications

The following table describes the slots, card types, and maximum slot power.

Table 1-10 PCI and PCI Express Slot Power Specifications

Slot Slot Type Slot Power (Maximum)

Product Overview

1

2

3

4

5

6

* In addition to these slot power specifications, the overall power consumption of the system (including I/O cards, processor, and

memory) must not exceed 700W.

** Includes 75W maximum from the system board connector, and 75W maximum from the auxiliary graphics power connector.

NOTE: If a graphics card requiring more than 75W is installed, HP recommends not using the slot

immediately below the graphics card (for example, if PCI Express in slot 1, do not use slot 2). In addition

to these slot power specifications, the overall power consumption of the system (including I/O cards,

processors, memory, drives) must not exceed 700W.

PCI Express x16 graphics 150W**

PCI 25W*

PCI Express x16 graphics 150W**

PCI-X 100 25W*

PCI-X 100 25W*

PCI-X 133 25W*

For hardware specifications of other system components, such as graphics cards or optical drives, refer to

the Web site of the specific manufacturer.

PCI and PCI Express Slot Power Specifications

31

Page 32

ENERGY STAR

The ENERGY STAR® program, a government-backed initiative, promotes energy efficiency by identifying

ways to reduce energy consumption. Select HP workstations participate in the ENERGY STAR program.

NOTE: ENERGY STAR is not supported on Linux-based workstations.

For those workstations that support ENERGY STAR and have it enabled, the power management features

will be set as follows:

• Monitor—goes into sleep mode after 20 minutes of inactivity.

• System—goes into Standby mode after 20 minutes of inactivity.

• Hard Drive—goes into power savings mode after the system goes into Standby mode.

NOTE: If you have to restore the operating system, reset the ENERGY STAR settings (if applicable) after

the restore.

To verify the factory default power settings for your product, select Start > Control Panel and

double-click Power Options.

ENERGY STAR Compliance

HP products purchased with the ENERGY STAR configuration are compliant with the U.S. Environmental

Protection Agency (EPA) ENERGY STAR Computers Program. The EPA ENERGY STAR configuration does

not imply endorsement by the EPA. As an ENERGY STAR Partner, HP has determined that products with the

ENERGY STAR configuration meet the ENERGY STAR guidelines for energy efficiency.

The ENERGY STAR Computers Program was created by the EPA to promote energy efficiency and reduce

air pollution through more energy-efficient equipment in homes, offices, and factories. HP products achieve

this by reducing the power consumption when not being used.

ENERGY STAR on HP Workstations uses ACPI power management. The system can wake as a result of a

user action (keyboard or mouse) or from the network or a modem.

The Power Management feature, when used in conjunction with an external ENERGY STAR-compliant

monitor, will support the power-down features of the monitor. The Power Management feature allows an

external monitor to go into low-power mode when the energy save timeout occurs.

CAUTION: Using the Energy Save Monitor feature with non-ENERGY STAR-compliant monitors might

cause video distortion when the Energy Save timeout occurs.

Product Overview32

Page 33

2 Installing or Restoring the Operating

System

This chapter describes the installation and restoration of the operating system.

• “Installing the Operating System and Software” on page 34

• “Restoring the Operating System” on page 39

• “Protecting the Software” on page 40

• “Ordering Backup Software” on page 41

If the workstation was shipped with a preinstalled OS, it is configured automatically the first time the

workstation is turned on.

CAUTION: Adding optional hardware devices to your workstation before the operating system

successfully installs can cause errors and prevent the operating system from installing properly.

CAUTION: After the automatic installation has begun, DO NOT TURN OFF THE WORKSTATION UNTIL

THIS PROCESS COMPLETES. Turning off the workstation during the installation process might damage the

software that runs the system.

Installing or Restoring the

Operating System

33

Page 34

Installing the Operating System and Software

The following section discusses the operating system and HP software installation procedures.

• “Microsoft Windows XP Professional” on page 34

• “Linux-Preinstalled Workstations” on page 35

• “Linux-Enabled Workstations” on page 37

• “HP Software” on page 38

Microsoft Windows XP Professional

The first time you turn on your workstation, you are prompted to select a language for the operating

system. After selecting the language, read and follow the instructions on the screen to complete the

installation of the operating system. This takes approximately 10 minutes, depending on the system

hardware configuration. During the process, do not turn off your workstation unless you are directed to

do so.

Installing or Upgrading Device Drivers

To install hardware devices, such as a printer, display adapter, or network adapter after the operating

system is installed, the operating system needs access to the appropriate software drivers for the devices.

To copy the drivers to your system, perform one of the following actions:

• Copy the drivers from the CD that was supplied with the peripheral device because manufacturers

usually send drivers on the CD.

• Go to the Help & Support Center installed on your system (on most factory-installed Windows XP

operating systems), click Start > Help & Support. Click the icon above HP Software & Drivers

Download and review or select available updates.

• Visit the HP Support Web site:

a. Go to http://www.hp.com/go/workstationsupport

b. Select your HP Workstation from the list.

c. In the “I would like to” section, click download drivers and software.

d. In the “select operating system” section, select your OS.

e. Locate the driver and click download next to your desired file. Follow the on-screen instructions to

complete installation.

• Visit the Web site of the manufacturer of the peripheral device if no drivers can be found with the other

methods.

Creating a Restore Diskette

To create a restore diskette for Windows XP, select Start > All Programs > Accessories > System

Tools > System Restore and follow the on-screen instructions.

.

Installing or Restoring the Operating System34

Page 35

Linux-Preinstalled Workstations

If you have a Linux-preinstalled HP Workstation, follow the instructions in this section to set up your OS and

software.

After the boot process completes, you can view additional HP Linux documentation by opening your

Internet browser (the browser is automatically set to use the local HP documentation page as its default).

You can also access Linux Web links for Red Hat (Internet access required) by using your Internet browser.

NOTE: For additional information on setting up Linux-preinstalled or Linux-enabled workstations, refer to

the HP User Manual for Linux, which is located at http://www.hp.com/support/linux_user_manual

more information about HP and Linux, visit http://www.hp.com/linux.

Starting the Linux Operating System

The first time the workstation is booted, the Red Hat First Boot utility displays. This program enables you to

enter your password, network, graphics, time, and keyboard settings for your workstation.

CAUTION: After the automatic installation has begun, DO NOT TURN OFF THE WORKSTATION UNTIL

THE PROCESS IS COMPLETE. Turning off the workstation during the installation process might damage the

software that runs the workstation or prevent its proper installation.

. For

NOTE: When you enable the YPBind feature in the Network tab of the Linux Setup Tool, you might get a

blank screen for 15–30 seconds after you have selected, saved all of your settings, and have exited the

utility. This is normal behavior. The boot process continues its execution after the screen returns.

Restoring the Linux Operating System

NOTE: To restore the Linux OS, the HP Driver CD and Red Hat box set are required. To get any new

enhancements, download the latest HP Driver CD.

NOTE: Linux does not support mixed drive types for a manufacturing preload. When restoring the

operating system, mixed drive types can be handled with the restoring media.

Downloading the Latest HP Driver CD

1. Download the ISO image to a local hard drive from the HP support Web site at

http://www.hp.com/go/workstationsupport

a. Select your HP Workstation from the list.

Installing or Restoring the

Operating System

.

b. Click download drivers and software.

c. Select the Linux OS that matches your box set.

d. Select the latest version from the Utility Tools section.

e. Download and unpack it (tar zxvf

filename

.tgz).

Installing the Operating System and Software 35

Page 36

2. Copy the ISO image to CD-R bootable media. On another Linux workstation, use the cdrecord utility.

Identify the device address for the CD burner (cdrecord --scanbus).

The default is usually 2, 0, 0.

Example:

cdrecord -v -eject dev=2,0,0 CD0_golden.iso

Installing with the HP Driver CD

To install with the HP Driver CD:

1. Boot the workstation from the Red Hat box set Binary CD 1.

2. Insert the Linux operating system CDs from the Red Hat box set as prompted.

3. Continue following the prompts until the operating system is successfully installed.

4. Configure the X server to start on reboot.

5. Reboot the workstation.

6. Follow the prompts to set up your system with the Red Hat First Boot utility.

7. When prompted in First Boot to add additional CDs, insert the HP Driver CD into the CD-ROM tray of

the workstation.

8. Click Install next to “Additional CDs.”

The HP Driver CD window opens.

9. Click Press to begin install...

10.When the install is done, you will have two options, “Reboot now...” on the left side and “Press to

continue, reboot later...” on the right side. Click Reboot now...

Upgrading Device Drivers

If you must upgrade a Linux device driver, visit the HP Workstation support Web site at

http://www.hp.com/go/workstationsupport

To install hardware devices, such as a printer, a display adapter, or a network adapter after the operating

system is installed, the operating system needs access to the appropriate software drivers for the devices.

Device drivers are usually provided on a CD supplied with the peripheral device.

Some existing peripheral devices might not have been shipped with drivers developed for Linux. To locate

the most current device drivers:

1. Go to http://www.hp.com/go/workstationsupport

2. Select your HP Workstation from the list.

3. Click download drivers and software.

4. Select your Linux OS version.

5. Scroll down and download the desired driver.

If no driver is found, visit the Web site of the manufacturer of the peripheral device.

.

.

Installing or Restoring the Operating System36

Page 37

Linux-Enabled Workstations

Linux-enabled HP Workstations require the HP Installer Kit for Linux and the purchase of a Red Hat box set.

The Installer Kit includes the HP CDs necessary to complete the installation of all versions of the Red Hat

box set that have been verified to work on HP Workstation hardware.

Verifying Hardware Compatibility

To see which Linux versions have been verified to work on HP Workstation hardware:

1. Go to http://www.hp.com/support/workstation_manuals

2. Select your HP Workstation model.

3. Click the Hardware Support Matrix for Linux link.

Installing the Linux Operating System

To install the Linux operating system on your Linux-enabled system:

1. Follow the instructions for “Restoring the Linux Operating System” on page 35 in the previous section.

2. Follow the instructions for “Starting the Linux Operating System” on page 35 in the previous section.

NOTE: For more information on setting up Linux-preinstalled or Linux-enabled HP Workstations, refer to

the HP User Manual for Linux, which is located at http://www.hp.com/support/linux_user_manual

more information about HP and Linux, visit http://www.hp.com/linux.

Upgrading Device Drivers

If you must install new drivers, go to http://www.hp.com/go/workstationsupport or refer to “Upgrading

Device Drivers” on page 36 in the previous section for more instructions.

.

. For

Installing or Restoring the

Operating System

Installing the Operating System and Software 37

Page 38

HP Software

The following HP software is installed the first time the HP Workstation is turned on:

• Computer Setup (F10) Utilities and diagnostic features

• HP Support Software including device drivers

• HP Client Manager Software (available for download from http://www.hp.com/go/easydeploy

• System Software Manager (available for download from http://www.hp.com/go/ssm

• Power Management Setup with Energy Saver features (not supported on Linux)

• Security Management tools

• Software Support Management tools

Certain drivers and utilities are available only in selected languages. You can obtain the latest version of

these files, in English and selected other languages, in one of four ways:

• Support Software CD

• HP Web site at http://www.hp.com

• Restore Plus! CD, which is supplied with Windows-based workstations

• HP Workstations Red Hat Linux with HP Additions CD, which is supplied with Linux-based workstations

NOTE: Additional HP software might be required in certain situations.

)

)

Installing or Restoring the Operating System38

Page 39

Restoring the Operating System

To restore the original Windows operating system and factory-installed software, insert the Restore Plus!

CD that came with your HP Workstation. Carefully read and follow the instructions provided with the

Restore Plus! CD.

NOTE: If you restore your system using the Restore Plus! CD, some settings, such as your power

management settings (such as the Energy Star® settings), will need to be reapplied.

In some scenarios, such as if the system is bootable to Windows, an alternative method is to use the

System Restore feature included with Windows XP. To restore Windows to a previous state, select Start >

All Programs > Accessories > System Tools > System Restore and follow the on-screen

instructions.

For more information about restoring the Linux OS or software, see “Restoring the Linux Operating System”

on page 35.

Installing or Restoring the

Operating System

Restoring the Operating System 39

Page 40

Protecting the Software

To protect software from loss or damage, keep a backup copy of all system software, applications, and

related files stored on the hard drive. See the operating system or backup utility documentation for

instructions on making backup copies of data files.

Installing or Restoring the Operating System40

Page 41

Ordering Backup Software

All software that shipped with the workstation, including the Restore Plus! CD, can be ordered from HP as

a single set, or you can order the various software packages separately.

NOTE: Before calling HP to order the software, be sure to have the serial number of the workstation

available. See “Serial Number and COA Label Location” on page 21.

Installing or Restoring the

Operating System

Ordering Backup Software 41

Page 42

Installing or Restoring the Operating System42

Page 43

3 System Management

This section describes the various tools and utilities that allow for the system management of the

workstation.

• “Computer Setup (F10)” on page 44

• “Desktop Management” on page 54

43

System Management

Page 44

Computer Setup (F10)

This section contains the following information to help you use Computer Setup.

• “BIOS ROM” on page 45

• “Using Computer Setup (F10)” on page 46

• “Computer Setup Menu” on page 47

The Computer Setup (F10) utilities enable you to:

• Change current settings from the factory default settings and set, view, change, or verify the system

configuration, including settings for processor, graphics, memory, audio, storage, communications,

and input devices.

• Determine if all of the devices installed on the workstation are recognized by the system and

functioning properly.

• Determine information about the operating environment of the workstation.

• Solve system configuration errors detected but not automatically fixed during the Power-On Self-Test

(POST).

• Establish and manage passwords and other security features.

• Establish and manage energy-saving timeouts (not supported for Linux platforms).

• Modify or restore factory default settings.

• Set the system date and time.

• Modify the boot order of bootable devices, such as hard drives, diskette drives, optical drives, or LS-

120 drives.

• Configure the boot priority of SATA and SCSI hard drive controllers.

• Enable Quick Boot, which is faster than Full Boot but does not run all of the diagnostic tests run during

a Full Boot. You can set your system to:

•always Quick Boot (default)

• periodically Full Boot (from every 1 to 30 days)

• always Full Boot

• Enable or disable Network Server Mode, which enables the workstation to boot the operating system

when the power-on password is enabled with or without a keyboard or mouse attached. When

attached to the system, the keyboard and mouse remain locked until the power-on password is entered.

• Select POST Messages Enabled or Disabled to change the display status of POST messages. POST

Messages Disabled suppresses most POST messages, such as memory count, product name, and other

non-error text messages. If a POST error occurs, the error is displayed regardless of the mode selected.

To manually switch to POST Messages Enabled during POST, press any key (except F1 through F12).

• Establish an Ownership Tag, the text of which is displayed each time the system is turned on or

restarted.

• Enter the Asset Tag or property identification number assigned by your company to this workstation.

• Enable power-on password prompting during system restarts (warm boots) as well as during power-on.

• Secure the integrated I/O functionality, including the serial, USB, or parallel ports, audio, or

embedded NIC, so that the I/O functionality cannot be used until they are unsecured.

• Enable or disable removable media boot ability.

• Enable or disable removable media write ability (when supported by hardware).

• Replicate your system setup by saving system configuration information on diskette and restoring it on

one or more workstations.

System Management44

Page 45

• Execute self-tests on specified SATA hard drives (when supported by the drive).

BIOS ROM

The Basic Input/Output System (BIOS) of the computer is a collection of machine language programs

stored as firmware in read-only memory (ROM). The BIOS ROM includes such functions as POST, PCI

device initialization, Plug 'n Play (PnP) support, power management activities, and the Setup utility. The

firmware contained in the BIOS ROM supports the following systems and specifications:

• Dual AMD Opteron 2xx series

• Memory for DDR333 and DDR400

• Hyper-transport setup and initialization

• Chipset (includes NVIDIA nForce4 Pro, AMD 8131 PCI-X bridge, all applicable device support in

chipsets, SCSI LSI 1030, SIO5)

• ACPI 1.0b with ACPI 2.0 extensions for 64-bit support, according to Microsoft Logo Requirements. S1,

S3, S4, S5 and S5 with Remote Power On by way of LAN wake packet.

• SMBIOS Spec 2.3.4 implementation and field definitions that accurately represent hardware

configurations and OEM ID

• BBS 1.01

• DOS and Windows based BIOS flash tools

• Microsoft SDG 3.0 compliant as applicable

• PMM 1.01 as applicable

• MPS 1.4 as applicable

• PXE 2.1

• USB 1.1/USB 2.0

• PCI 2.2 or later

• “El Torito” Bootable CD 1.0

System Management