Page 1

Edit the Document Title Variable

AUTODESK®

LUSTRE

®

2007

A Discreet® Systems product

HP xw8400 WORKSTATION

Hardware Setup Guide

Page 2

Autodesk® Lustre® 2007

© 2000-2006 Autodesk Canada Co./Autodesk, Inc. and/or its licensors. All rights reserved.

All user documentation ("User Documentation") contains proprietary and confidential information of Autodesk Canada Co./Autodesk, Inc. and/or its licensors. The User

Documentation is protected by national and international intellectual property laws and treaties. All rights reserved. Use of the Documentation is subject to the terms of the

software license agreement that governs the use of the software product to which the User Documentation pertains ("Software").

This publication, or parts thereof, may not be reproduced in any form, by any method, for any purpose.

Autodesk Canada Co./Autodesk, Inc., reserves the right to revise and improve its products as it sees fit. This publication describes the state of this product at the time of its

publication, and may not reflect the product at all times in the future.

AUTODESK CANADA CO./AUTODESK, INC., MAKES NO WARRANTY, EITHER EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE REGARDING THESE MATERIALS, AND MAKES SUCH MATERIALS

AVAILABLE SOLELY ON AN "AS-IS" BASIS.

IN NO EVENT SHALL AUTODESK CANADA CO./AUTODESK, INC., BE LIABLE TO ANYONE FOR SPECIAL, COLLATERAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES IN CONNECTION WITH OR ARISING OUT OF PURCHASE OR USE OF THESE MATERIALS. THE SOLE AND EXCLUSIVE LIABILITY TO AUTODESK

CANADA CO./AUTODESK, INC., REGARDLESS OF THE FORM OF ACTION, SHALL NOT EXCEED THE PURCHASE PRICE OF THE MATERIALS DESCRIBED

HEREIN.

Autodesk Trademarks

The following are registered trademarks or trademarks of Autodesk, Inc., in the USA and other countries: 3DEC (design/logo), 3December, 3December.com, 3ds Max, ActiveS hapes, Actrix,

ADI, Alias, Alias (swirl design/logo), AliasStudio Alias|Wavefront (design/logo), ATC, AUGI, AutoCAD, AutoCAD Learning Assistance, AutoCAD LT, AutoCAD Simulator, AutoCAD SQL

Extension, AutoCAD SQL Interface, Autodesk, Autodesk Envision, Autodesk Insight, Autodesk Intent, Autodesk Inventor, Autodesk Map, Autodesk MapGuide, Autodesk Streamline,

AutoLISP, AutoSnap, AutoSketch, AutoTrack, Backdraft, Built with ObjectARX (logo), Burn, Buzzsaw, CAiCE, Can You Imagine, Character Studio, Cinestream, Civil 3D, Cleaner, Cleaner

Central, ClearScale, Colour Warper, Combustion, Communication Specification, Constructware, Content Explorer, Create>what’s>Next (design/logo), Dancing Baby (image), DesignCenter,

Design Doctor, Designer's Toolkit, DesignKids, DesignProf, DesignServer, DesignStudio, Desi gn|Studio (design/logo), Design Your World, Design Your World (design/logo), DWF, DWG,

DWG Linking, DWG (logo), DWG Tru eConvert, DWG TrueView, DXF, EditDV, Education by Design, Extending the Design Team, FBX, Filmbox, GDX Driver, Gmax, Heads-up Design,

Heidi, HOOPS, HumanIK, i-drop, iMOUT, Incinerator, IntroDV, Kaydara, Kaydara (design/logo), LocationLogic, Lustre, Maya, Mechanical Desktop, MotionBuilder, ObjectARX,

ObjectDBX, Open Reality, PolarSnap, PortfolioWall, Powered with Autodesk Technology, Productstream, ProjectPoint, Re actor, RealDWG, Real-time Roto, Render Queue, Revit, ShowCase,

SketchBook, StudioTools, Topobase, Toxik, Visual, Visual Bridge, Visual Constr uction, Visual Drainage, Visual Hydro, Visual Landscape, Visual Roads, Visual Survey, Visual Syllabus, Visual

Toolbox, Visual Tugboat, Visual LISP, Voice Reality, Volo, and Wiretap.

Autodesk Canada Co. Trademarks

The following are registered trademarks of Autodesk Canada Co. in the US A and/or Canada and other countries: Discreet, Fire, Flame, Flint, Frost, Inferno, River, Smoke, Sparks, Stone, Wire.

The following are trademarks of Autodesk Canada Co., in the USA, Canada, and/or other countries: Backburner, Multi-Master Editing.

Third-Party Trademarks

All other brand names, product names, or trademarks belong to their respective holders.

GOVERNMENT USE

Use, duplication, or disclosure by the U.S. Government is subject to restrictions as set forth in FAR 12.212 (Commercial Computer Software-Restricted Rights) and DFAR

227.7202 (Rights in Technical Data and Computer Software), as applicable. Manufacturer is Autodesk Canada Co./Autodesk, Inc., 10 Duke Street, Montreal, Quebec, Canada,

H3C 2 L7.

.

Third-Party Copyright Notices

Portions relating to Copyright © 2003 NetGroup, Poliecnico di Torino. All rights reserved.

Title: Hardware Setup Guide for HP xw8400 Workstations

Document Version: 2

Date: February 9, 2007

Page 3

contents

Contents

1 Introduction 1

Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

About This Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

The Lustre Workgroup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Optional Lustre Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Typical Configuration Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Workflow for Hardware Setup and Application Installation . . . . . . . . . . . . . . . . . . . 5

Related Documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Hardware Configuration Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Notation Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Contacting Customer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2Connecting Peripherals 15

Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Workflow for Connecting Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Connection Diagram for the HP xw8400 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Connecting the Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Connecting the Keyboard, Mouse, and Monitor Calibration Device . . . . . . . . . . . . 18

Connecting Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Network Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3 Connecting System Components 21

Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

iii

Page 4

Con

tents

Workflow for Connecting System Components in the Lustre Workgroup . . . . . . . 21

Connecting the Autodesk Control Surface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Assigning an IP Address to the Autodesk Control Surface . . . . . . . . . . . . . . . . . . . . . 25

Configuring Lustre to Connect to the Autodesk Control Surface . . . . . . . . . . . . . . . 27

Connecting a Stand-Alone Tablet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Connecting the Slave Renderer to a Lustre Workstation. . . . . . . . . . . . . . . . . . . . . . . 28

Connecting Video I/O to a Master or HD Station. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Connecting to a High-Speed Data Link Device (HSDL) . . . . . . . . . . . . . . . . . . . . . . . 32

Index 35

iv

Page 5

Summary

About This Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

The Lustre Workgroup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Optional Lustre Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Typical Configuration Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Workflow for Hardware Setup and Application Installation . . . . . . . . . . . . . . . . 5

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Hardware Configuration Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Notation Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Contacting Customer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

About This Guide

This guide describes how to set up the HP xw8400 workstation and the other hardware

components of your Autodesk® Lustre® 2007 workgroup. The HP xw8400 workstation is

available for Lustre systems on Windows®, as well as for Autodesk Incinerator™ Lustre systems

on Linux®. To install and configure hardware and software components, use this guide in

conjunction with the following documents: the Autodesk Lustre Software Installation Guide for

Windows Workstations, the Autodesk Incinerator 2007 Installation and User’s Guide for Lustre

with Incinerator, and the Stone Direct Configuration Guide for this release.

Introduction

N

OTE

:

In most cases, both hardware setup and application installation are done on delivery by an

authorized technician, so you may not need to perform some of the procedures in these guides.

The latest versions of a ll guides are available in PDF format from t he Web at www.autodesk.com/

discreet-documentation. For best results viewing and printing these PDF files, use Adobe®

Acrobat® Reader™ 6 or later, or Xpdf viewer.

1

Page 6

1

Introduction

N

OTE

:

If you do not have Acrobat Reader, you can download a free copy from the Adobe Web site

(

www.adobe.com

Web site (

www.foolabs.com/xpdf/

Revision History

This document is updated as necessary throughout the life cycle of the release. This section

describes all additions and modifications made to this document since its initial publication.

N

OTE

:

Minor changes that do not have an impact on the technical content of this guide, such as

typographical errors or changes to section names, are not included in the revision history.

Modification Item Page Released At

Added

Updated

Updated

Updated

Updated

Updated

Updated

Updated

Updated

). If you do not have Xpdf viewer, you can download a free copy from the Xpdf

).

Revision History

Contacting Customer Support; Japan

Linux-Based Connection Diagram for the HP xw8400

Connecting the Monitor (EIZO 24-inch LCD)

Monitor Calibration Device on Linux Workstations

Connecting the Autodesk Control Surface

Configuring the Autodesk Control Surface on Linux

Connecting the Slave Renderer

Connecting Video I/O to a Master or HD Station

22007

13 2007

16 2007

17 2007

18 2007

22 2007

25 2007

28 2007

30 2007

The Lustre Workgroup

Lustre is a modular system that you can configure and expand to suit your needs. The features

you purchase determine the hardware included with your system.

Central to any system is the Master Station or HD Station. The Master Station is a high-end

Windows- or Linux-based PC designed to accommodate real-time interactivity in a clientattended or supervised session. You can add a Lustre Station to improve the efficiency of your

pipeline.

Master Station —

where the colorist works together with the cinematographer. Contains an extensive creative

toolset for more elaborate visual design and grading using up to 4K resolution and 16-bit files

and for completing tasks like dust busting, conforming, rotoscoping and capture/playout.

HD Station —

mastering short-form and long-form HDTV projects, as well as HD film projects. Input up to

10-bit 2K and output HD and SD.

2

Includes the full Lustre toolset and is designed for GPU-accelerated sessions

Cost-effective GPU workstation for conforming, preparing, grading and

Page 7

Optional Lustre Components

Lustre Station —

Tasks that do not require the direct intervention or supervision of the

colorist can be efficiently handled by a Lustre Station. Multiple Lustre Stations can work in

parallel to increase throughput and can be used for tasks such as dust-busting, preparatory

work, fine-tuning creative sessions, conforming data from EDLs, updating editorial changes

using change lists, and mastering to different formats using the real-time deliverables function.

Lustre Workstation Features

The following table describes the features available to each Lustre workstation.

N

OTE

:

The features of Lustre 2007 may vary based on your hardware platform. Consult the

Notes

for your release for specific system information.

Station Configuration

Master Station

Lustre HD Station

Lustre Station

Default —

HSDL video formats and the DI Pack, which consists of infrared channel

dust removal and support for all standard input and output resolutions

and bit-depths. Certain features require add-on licensing.

Add-Ons —

configuration: the Slave Renderer and up to three panels for the Autodesk

control surface. The Slave Renderer requires a separate license.

Default —

Station description). File input is limited to 2K resolution. File output is

limited to HD resolution, 10-bit. Certain features require add-on licensing.

Add-Ons —

configuration: SD and HD I/O, dual link and HSDL video formats, the Slave

Renderer, and up to three panels for the Autodesk control surface. The

Slave Renderer requires a separate license.

Default —

colour grading. The DI Pack (see the Master Station description) is also

included, along with full dust removal functionality, and the ability to

create geometries and masks.

With Primary Colour Correction —

option as well as primary colour grading.

Add-Ons —

configuration or the With Primary Colour Correction configuration, and

require an additional license: SD and HD I/O, dual link and HSDL video

formats, and up to three panels for the Autodesk control surface.

The Slave Renderer requires a separate license.

All features are available including SD and HD I/O, dual link and

The following features can be added to the Default

Includes all features except for the DI Pack (see the Master

The following features can be added to the Default

All features are available except for primary and secondary

Includes all features of the default

The following features are available for either the Default

Release

Optional Lustre Components

You can expand the features of your Lustre system and improve the efficiency of your workflow

by adding any of the following components.

3

Page 8

1

Introduction

Control Surface —

The Autodesk control surface provides improved interactiv ity when colour

grading film and video footage. You can perform many of the same tasks you do in the Lustre

user interface using the control surface.

Video I/O —

Video I/O is provided by the DVS Centaurus® board, which consists of an HD/

SD board and a breakout box. This configuration provides real-time SDI input and output of

uncompressed 8- or 10-bit HD or SD video in both YUV (4:2:2) and RGB formats (4:4:4 or

4:2:2).

For a list of supported video formats, see the Autodesk Lustre 2007 User’s Guide.

Slave Renderer —

The Slave Renderer is a rack-mounted server that is connected directly to

the Lustre workstation. It frees system resources by off-loading render tasks on an ‘as-needed’

basis, thus ensuring real-time interaction on the Lustre system.

Background Renderer —

Background rendering frees up Lustre workstations for colour

grading. You can use up to eight background rendering machines to process your final frames.

N

OTE

:

For a list of Incinerator system components, refer to the

Installation and User’s Guide

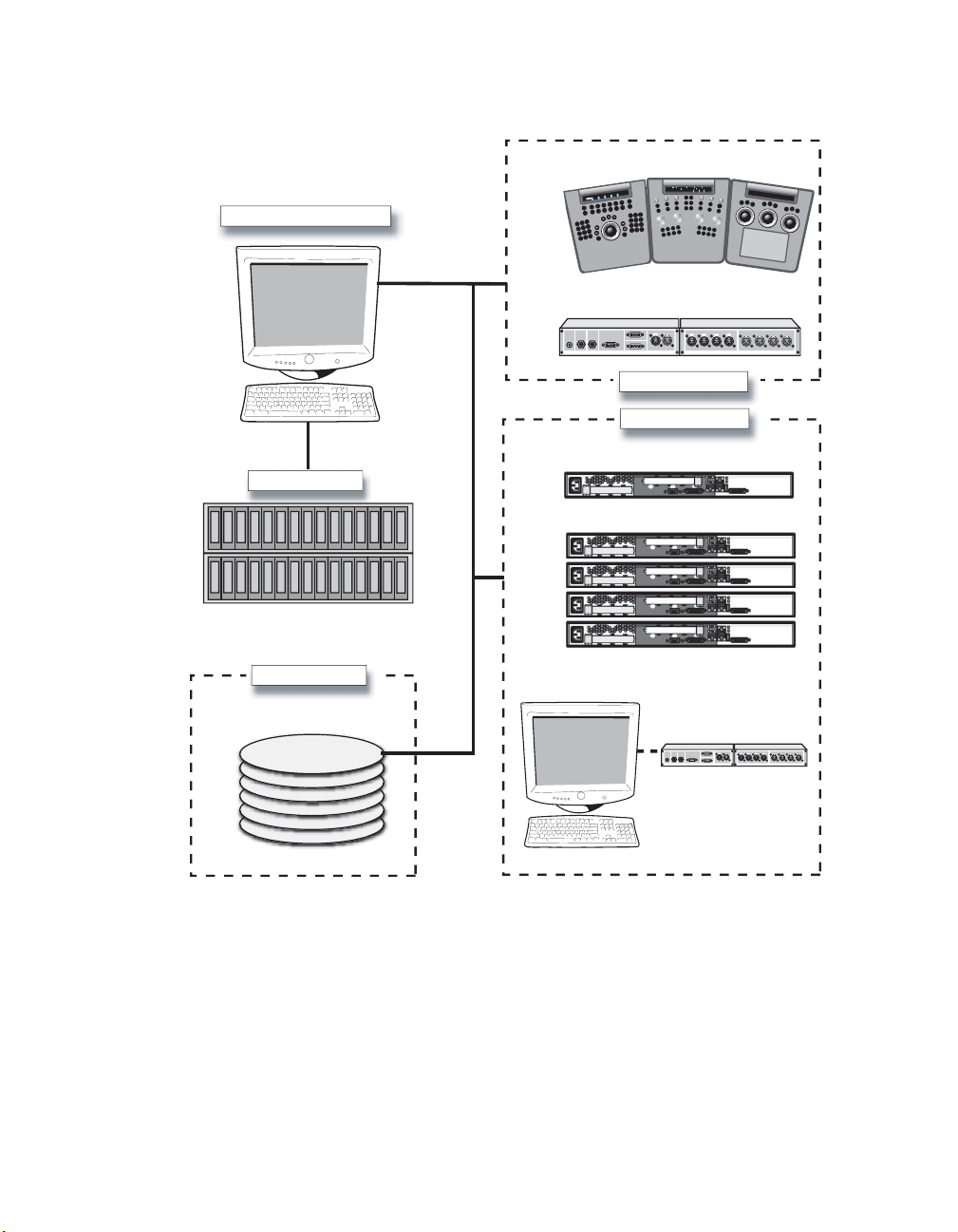

Typical Configuration Overview

The following illustration shows a typical configuration, including the Master Station, Lustre

Station, and other optional components.

Autodesk Incinerator 2007

4

Page 9

Lustre Master Workstation

Workflow for Hardware Setup and Application Installation

Control Surface

Sh Mid

High

R G B

BrightBright

Hue Brightness Saturation

+

G+ B+R+

G - B -R -

Proxy

Sp

li

t

e

p

Wi

Multi

ll

ti

S

O/P

Matte

Out

In

LTC

-

A

T

L

1/2

3/4 5/6 7/8 1/2 3/4 5/6 7/8

In

Shadow Contrast Brightnes

F

2

F

1

F

3

s

F

5

F

4

F

6

F

8

F

7

F

9

Out

9

1

0

0

0

.0

1

0

0

0

#

c

is

M

S

&

e

P

id

s

t

u

m

O

o

e

e

G

sid

y

In

e

K

e

urv

C

e

d

a

r

r

G

tP

u

O

r

P

In

E

R

O

CM

S

I

M

S

&

P

M

O

E

G

Y

E

K

S

E

V

R

EO

U

R

C

O

M

E

D

A

R

G

T

U

IN

9

8

7

6

5

4

O

D

DO

E

R

O

D

N

U

T

R

E

V

E

R

OR

RS

U

C

OFFSET

L

L

CA

E

R

A

P

I

CL

3

2

1

P

M

O

C

.

0

+/-

GRADE

R

E

T

N

E

CUE

/B

T

L

A

Video I/O (DVS Centaurus + Break out box)

OutOut

RS422A

RS422BGPICVBSWclkAudio

Peripheral Options

Lustre Storage

SAN access

Lustre Station

Storage Volume

N

OTE

:

For an Incinerator system configuration overview, refer to the

Installation and User’s Guide

Network Options

Slave Renderer

Background Rendering (burn)

In Out

OutOut

RS422A

RS422BGPICVBSWclkAudio

LTC

Video I/O

Autodesk Incinerator 2007

1/2

3/4 5/6 7/8 1/2 3/4 5/6 7/8

In

Out

Workflow for Hardware Setup and Application Installation

The following procedure provides the general workflow for installing Lustre on an HP xw8400

workstation running Windows.

5

Page 10

1

Introduction

For workflow information related to the HP xw8400 running on Linux for Incinerator, refer to

the Autodesk Incinerator Installation and User’s Guide.

To install Lustre on an HP xw8400 workstation:

1. Review the guidelines for working with hardware components. See “Hardware

Configuration Guidelines” on page 7.

2. Connect all peripherals (mouse, keyboard, graphics monitor, storage, etc.) to each

workstation in your workgroup, and connect each workstation to the network. See Chapter

2, “Connecting Peripherals,” on page 15.

3. Connect your workstation to Autodesk Stone® Direct storage. See the Stone Direct

Configuration Guide.

4. Connect your Master or HD Station to a Slave Renderer, a control surface, tablet, and video

I/O components. See Chapter 3, “Connecting System Components,”

N

OTE

:

The Slave Renderer is not used in Incinerator configurations.

5. Perform the procedures in the Autodesk Lustre 2007 Software Installation Guide or the

on page 21.

Autodesk Incinerator 2007 Installation and User’s Guide to install and license Lustre and

Incinerator.

Related Documentation

The following table describes the documentation associated with your application. For a

detailed list of the latest documentation, see your release notes.

User Guides Provides

Autodesk Lustre 2007 User’s Guide

Autodesk Control Surface User’s Guide

Autodesk Lustre 2007 What’s New

Autodesk Lustre 2007 Hot Keys Card

Autodesk Lustre (and Incinerator) Release

Notes

(for this release)

Autodesk Lustre (and Incinerator) Fixed

and Known Bug List

(for this release)

6

Detailed instructions on using the software.

Detailed instructions on using the Autodesk

control surface and the Tangent CP100.

A list of the new features for this release.

A list of the most frequently used hot keys.

A complete list of documentation and information

on late-breaking features.

A complete list of fixed and known bugs for this

release.

Page 11

Hardware Configuration Guidelines

Installation and Configuration Guides Provides

Hardware Setup Guide

(for your workstation)

Stone Direct Configuration Guide

(for this release)

Autodesk Lustre 2007 Software Installation

Guide

(for your operating system)

Stone and Wire Filesystem and Networking

Guide

(for this release)

Other Guides Provides

Autodesk Lustre Sparks API Reference

Guide

Autodesk Backburner 2007 Installation and

User’s Guide

Information on how to set up your workstation

and video I/O peripherals.

Provides detailed connectivity diagrams and

configuration procedures for your Stone storage

arrays.

Information about installing and licensing your

Autodesk Lustre software.

Note: For Lustre and Incinerator, see the Autodesk

Incinerator Installation and User’s Guide.

Procedures for configuring your Wiretap™

services.

Instructions for developing Sparks® plugins for

Lustre.

Information on how to install, set up, and use

Backburner™.

Consult the Autodesk Web site at www.autodesk.com/discreet-documentation for the latest

version of guides, release notes, and fixed and known bugs documents.

Hardware Configuration Guidelines

In most cases, hardware integration and application installation is done on delivery by an

authori zed technician, and some of the pro cedures in this guide may not be necessary. Still, it is

a good idea to read through all chapters to familiarize yourself with the configuration

procedures for the following reasons:

• Many suspected problems with your Lustre system may be due to loosened connections or

improperly configured devices. This guide helps you troubleshoot problems by providing

information about properly configured systems.

• If you need to call Customer Support, familiarity with this guide puts you in a better position

to provide diagnostic information.

• If you want to move your Lustre system at any time , or upgr ade ce rtain hardware components ,

information in this guide is crucial.

Although this guide, in conjunction with the Autodesk Stone Direct Configuration Guide,

provides complete inform ation regardi ng hardware comp onent configu ration, it s hould only b e

undertaken by an experienced hardware integrator. This individual should be familiar with the

7

Page 12

1

Introduction

Windows or Linux operating systems, HP xw8400 workstations, and peripherals associated

with professional high-performance video and post production of film.

Your Lustre system consists of high-performance hardware that must be configured in an

environment suited to its operational needs. Other considerations include minimizing the risk

of damage due to static discharge and ensuring all components are properly grounded.

Verifying and Updating The System BIOS Version

System configuration is performed by an authorized te chnici an p rior to delivery. As such, some

of the procedures here may not be necessary. Workstation BIOS settings are provided for

informational purposes.

The system BIOS on your workstation must correspond to the certified version required by

your software version. If the BIOS version on your system does not correspond to the table

below, you must update to the certified version.

Product Version Certified BIOS Version

2007 1.15

The BIOS version installed on your system appears onscreen while booting the workstation.

The following procedures describe how to update the BIOS on your workstation.

W

ARNING

:

You should only update the BIOS if you find that it is not at the version listed in this

guide, or if your are advised to do so by Customer Support. Do not update the BIOS with a more

recent version published by the hardware vendor, if it has not been certified by Autodesk

Customer Support.

To update the BIOS on a Windows workstation:

1. Get the BIOS upgrade utility and burn it to a CD.

2. Insert the CD into the CD-ROM drive

3. Reboot the workstation and press F10 to enter BIOS.

4. Select a language.

5. From the File menu, select Flash System ROM.

The Select a Drive menu appears.

6. Click Optical Drive.

The Select a Drive confirmation menu appears.

7. Press F10 to confirm.

8. Select the 7D5_0115.bin file.

8

Page 13

Hardware Configuration Guidelines

The Flash System ROM confirmation menu appears.

9. Press F10 to confirm.

10. Press any key.

System ROM Flash was successful appears.

11. Verify system BIOS settings. See “Verifying BIOS Settings” on page 10.

12. From the File menu, select Save Changes and Exit.

To update the BIOS on a Linux workstation:

1. Load the DKU CD in the DVD-ROM drive on the workstation.

2. Open a terminal.

3. Ty p e :

cd /mnt/cdrom/Utils/BIOS/

Each supported platform has its own directory that contains an .iso file.

N

OTE

:

For more information about updating the BIOS on your workstation, refer to the

README file located in your platform’s directory.

4. Ty p e :

cd ./<platform>

5. Burn the .iso file for your platform onto a CD-ROM and place it in the DVD-ROM drive on

the workstation.

6. Reboot the workstation and press F10 to enter BIOS.

7. Select a language.

8. From the File menu, select Flash System ROM.

The Select a Drive menu appears.

9. Click Optical Drive.

The Select a Drive confirmation menu appears.

10. Press F10 to confirm.

11. Select the 7D5_0115.bin file.

The Flash System ROM confirmation menu appears.

12. Press F10 to confirm.

13. Press any key.

9

Page 14

1

Introduction

System ROM Flash was successful appears.

14. Verify system BIOS settings. See “Verifying BIOS Settings” on page 10.

15. From the File menu, select Save Changes and Exit.

Verifying BIOS Settings

You do not normally need to adjust BIOS settings on your workstation. BIOS settings for the

workstation are provided here for informational purposes only.

To enter the system BIOS, press F10 while booting the workstation.

W

ARNING

:

Before installing Red Hat Linux, it is recommended that you verify the workstation’s

BIOS settings. If the storage SATA emulation option is not set correctly (to Separate IDE Controller),

you must redo Red Hat Linux installation.

The following table lists the proper Autodesk certified BIOS settings. Items not listed are set to

their default factory settings.

BIOS Menu Item Value

Storage, Storage options SATA Emulation Separate IDE

Controller

Storage Boot Order Optical Drive

USB Device

Hard Drive,

Integrated SATA

Hard Drive,

Integrated IDE

Storage, Power, OS Power Management Runtime Power

Management

Storage, Power, OS Power Management Idle Power Savings Normal

Storage, Power, OS Power Management ACPI S3 Support Disabled

Storage, Advanced, Device Options S5 Wake on LAN Disabled

Advanced Slot5 - PCI 133 Slot5 speed

Disabled

100Mhz PCI-x m1

10

Restoring BIOS to Default Factory Settings

The following procedure restores the default factory BIOS settings.

To restore default factory BIOS settings:

1. Press F10 while booting the workstation to enter the system BIOS.

2. From the File menu select Default setup | Restore Factory Settings as

Default.

Page 15

Hardware Configuration Guidelines

3. Press F10 to accept the changes.

4. Select Apply Defaults and Exit.

This restores the original factory system defaults.

Ensuring Proper Environmental Conditions

You should consider the following environmental guidelines for all hardware configuration:

• Make sure the rack in which hardware components are installed is open or ventilated. Follow

the ventilation specifications that apply to your system.

• Place all components in an air-conditioned environment. All hardware components generate

heat and must be kept cool. See “Power and Air Conditioning Requirements”

• Keep all hardware components in a clean, dust-free location.

• Minimize vibration and humidity.

• Do not block the vents on the component housing.

• Do not drape anything, such as a jacket or a blanket, over hardware components.

• Minimize electromagnetic noise by separating digital data and power cables from analog

audio cables and running them in different cable ducts.

on page 11.

Power and Air Conditioning Requirements

The values for power consumption and heat output were recorded on an Autodesk certified

system with all of the required peripheral and certified components.

N

OTE

:

These values can fluctuate if uncertified hardware components or third-party applications

are added to your system. The use of uncertified hardware components or third-party applications

is not supported. Please consult the manufacturer’s documentation for standardized minimum

and maximum values.

The following table summarizes the power consumed by the HP xw8400 system and the heat it

generates under the maximum processing load produced by your Lustre application. For

detailed specifications, including noise output, see the documentation provided by the

manufacturer.

Component Quantity Startup Amps

(120V / 240V)

HP xw8400 1 3.5 / 1.8 2.8 / 1.4 336 1146.4

You must be able to meet the startup power requirement and have a climate control system with

the capacity to maintain the temperature of this component under the maximum processing

11

Max. Amps

(120V / 240V)

Watts Heat

(BTUs)

Page 16

1

Introduction

load. Refer to the following table for standard conversion benchmarks and an example of how

they are used to establish climate control requirements.

Unit Conversion Example

1 Watt = 3.413 BTU 480 Watts = 1638 BTU

12000 BTU = 1 Ton of air conditioning 1638 BTU = 0.137 Ton of air conditioning

Avoiding Damage from Static Electricity

When installing any hardware equipment, take the following precautions to prevent damage to

sensitive components from static discharge:

• Make sure power is turned off on the component you are working on. It is a good idea to

unplug components until all other connections are configured.

• Always wear a grounded static wrist strap. Attach the strap’s alligator clip to any grounded

metal surface on the component’s chassis that you are working on. Place the wristband around

your wrist.

• Do not handle any components unnecessarily, particularly boards and cards that slide in and

out of slots on their parent hardware components.

Grounding Hardware Components

It is important to properly ground any audio components used with Lustre to avoid ground

loops and humming. To ensure audio components are properly grounded, use the XLR-3

cables. Using any other cables may cause humming in the system.

Receiving Your Lustre System

When you receive the shipment containing your Lustre, check all the boxes for dents or other

markings that may indicate damage during transport. If you suspect a component is damaged,

carefully inspect it before setting up the system. If you receive a damaged component, call

Customer Support.

Use the enclosed packing checklist to ensure you received all parts.

Notation Conventions

A number of style conventions are used throughout this guide. These conventions and examples

of their use are shown as follows.

12

Page 17

Convention Example

Text that you enter in a command line or shell appears in

Courier bold. You must press the Enter key after each

command.

Variable names appear in Courier, enclosed in angle brackets.

No spaces are allowed in variable names.

Variables that appear enclosed in square brackets are

optional.

Feedback from the command line or shell appears in Courier.

Directory names, filenames, URLs, and command line utilities

appear in italics.

Contacting Customer Support

You can contact Autodesk Media and Entertainment Customer Support at www.autodesk.com/

support or through one of the following ways:

Location: Contact Information:

Within the Americas: Hotline (North America): 1-800-925-6442

Direct dial: 415-507-5256 (Country code = 1)

8 AM to 8 PM EST Monday to Friday, excluding holidays

me.support@autodesk.com

Contacting Customer Support

rpm -qa

<variable_name>

[<filename>]

limit coredumpsize

/usr/discreet

Within Europe, Middle-East and

Africa:

Within Asia Pacific:

(Excluding India, China, Australia,

New Zealand and Japan)

Within India: Hotline (from Mumbai): +91-22-6695-2244

Within Japan: Hotline (from Tokyo): 0120-107-290

13

Hotline (from London, UK): +44-207-851-8080

9 AM to 5:30 PM (local time)

Monday to Friday, excluding holidays

me.emea.support@autodesk.com

Hotline (from Singapore): +65-6555-0399

9 AM to 6 PM (local time)

Monday to Friday, excluding holidays

me.support.singapore@autodesk.com

9:30 AM to 6:30 PM (local time)

Monday to Friday, excluding holidays

me.support.india@autodesk.com

Direct dial: +81-3-6221-1810

10 AM to 6 PM (local time)

Monday to Friday, excluding holidays

med-sys-support-jp@autodesk.com

Page 18

1

Introduction

Location: Contact Information:

Within China: Direct dial: +86-10-6505-6848

9 AM to 6 PM (local time)

Monday to Friday, excluding holidays

me.support.china@autodesk.com

Within Australia and New Zealand: Hotline (from Melbourne): +1-300-36-8355

Direct dial: +61-3-9876-8355

8 AM to 6 PM AEST

Monday to Friday, excluding holidays

me.support.anz@autodesk.com

Customer support is also available through your Autodesk reseller. To find a reseller near you,

consult the reseller look-up database on the Autodesk web site at www.autodesk.com/resellers.

14

Page 19

Connecting Peripherals

Summary

Workflow for Connecting Peripherals

Connection Diagram for the HP xw8400

Connecting the Monitor

Connecting the Keyboard, Mouse, and Monitor Calibration Device

Connecting Storage

Network Connections

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Workflow for Connecting Peripherals

You must connect peripherals (monitor, keyboard, mouse, storage, and network) to each Lustre

workstation before you connect the workstations to video I/O, a control surface, or to other

components in the workgroup.

Connect all hardware peripherals before you boot your workstation.

See the following table for a summary of the steps necessary to connect peripherals to your

Lustre workstation.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . 18

Step: Refer to:

1. Review the connection diagram for your workstation.

2. Connect a monitor to the workstation.

3. Connect a keyboard, mouse, and calibration device to

your workstation.

4. Connect the workstation to storage.

15

“Connection Diagram for the HP

xw8400”

“Connecting the Monitor”

17.

“Connecting the Keyboard, Mouse,

and Monitor Calibration Device”

page 18.

“Connecting Storage”

on page 16.

on page

on

on page 18.

Page 20

2

T

:4

Connecting Peripherals

Step: Refer to:

5. Connect the workstation to your network.

6. After you connect all the peripherals to your Lustre

workstations, you can connect the workgroup

components together.

Connection Diagram for the HP xw8400

The following diagrams show the connections for the HP xw8400 workstation.

N

OTE

:

These diagrams provide an overview of video I/O connections. For more details, see

“Connecting Video I/O to a Master or HD Station”

HP xw8400 Workstation

(Windows Configuration)

on page 30.

“Network Connections”

on page

19.

Chapter 3, “Connecting System

Components,”

HD-SDI (V2) Out

0:2:2/4:0:0 to 4:4:4

display device or VTR

HD-SDI (V1) Out 4:2:2 to 4:2:2 or 4:4

display device or VTR

on page 21.

Ref In from sync gen

Connect to second

o USB extender for mouse,

keyboar, monitor calibrator

To Slave Renderer

To DVS BOB

To GFX monitor

To storage

1, 4 to SAN; 2, 3 to Stone

Ref In from sync gen

0 to control surface,

1 to LAN, 3 to SAN

16

DVI out on the

main FX5500 card

HD-SDI Out (B) to

4:4:4 VTR

(dual link 0:2:2)

HD-SDI In (B) from

4:4:4 VTR

(dual link 0:2:2)

DVI2 Out to FX5500

SDI daughter card

HD-SDI Out (A) to 4:2:2

VTR (or 4:4:4 dual link)

HD-SDI In (A) from 4:2:2

VTR (or 4:4:4 dual link)

Page 21

T

o USB extender for mouse,

:4

VTR (or 4:4:4 dual link)

keyboar, monitor calibrator

To Incinerator

GigE switch

To DVS BOB

To GFX monitor

To InfiniBand

switch

Ref In from sync gen

0 to control surface,

1 to LAN, 3 to SAN

Connecting the Monitor

HP xw8400 Workstation

(Linux - Incinerator only)

HD-SDI (V2) Out

0:2:2/4:0:0 to 4:4:4

display device or VTR

HD-SDI (V1) Out 4:2:2 to 4:2:2 or 4:4

display device or VTR

Ref In from sync gen

Connect to second

DVI out on the

main FX5500 card

HD-SDI Out (B) to

4:4:4 VTR

(dual link 0:2:2)

HD-SDI In (B) from

4:4:4 VTR

(dual link 0:2:2)

DVI2 Out to FX5500

SDI daughter card

HD-SDI Out (A) to 4:2:2

VTR (or 4:4:4 dual link)

HD-SDI In (A) from 4:2:2

N

OTE

:

The Slave Renderer option is not available for Lustre with Incinerator.

Connecting the Monitor

Connect the monitor to the DVI connection on the Lustre workstation’s graphics card. You can

use the DVI extender cable (DL.CAB-HDTV-FO-82-MM) to extend the cable to a machine

room.

To connect the monitor:

h Use the DVI cable to connect the DVI OUT1 port of the NVIDIA® Quadro® FX5500

graphics card to the DVI-D IN port of the monitor.

N

OTE

:

Although the DVI fiber cable connectors are identical, their functions are different.

Ensure that the connector labeled Send is connected to the Lustre workstation, and that the

17

connector labeled Receive is connected to the monitor.

Page 22

2

Connecting Peripherals

Connecting the Keyboard, Mouse, and Monitor Calibration Device

Connect the mouse, keyboard, and monitor calibration device to the workstation via the 4-port

USB extender (TP.USB-EXT-400).

To connect the keyboard and mouse:

1. Connect the USB keyboard to port 2 on the remote unit of the USB extender.

2. Connect the USB mouse to port 3 on the remote unit of the USB extender.

3. Connect the monitor calibration device (TP.MON-CAL-LCDCRT) to port 4 on the remote

unit of the USB extender.

4. Use an RJ-45 cable to connect the remote unit of the USB extender to the local unit of the

USB extender.

5. Connect the local unit of the USB extender to USB1 port on the workstation.

To enable the Eye-One calibration utility driver:

h Do one of the following:

•

For Windows-based workstations, if the driver is not already installed, you will be prompted

to install the monitor calibration device driver when you restart the workstation. The driver is

available from the

Driver

directory.

• For Linux workstations, once the software installation has been completed, start the

eyeone27 daemon on the workstation. Type: /etc/init.d/eyeone27 start

C:\Program Files\discreet\lustre3.0\Utils\Calibration\Eye-One USB

Connecting Storage

The storage connections for your system depend on whether you are running Lustre on the

Windows or Linux operating system.

Storage for Windows-Based Workstations

Your workstation is configured with a 4-port ATTO Celerity FC-44ES fibre channel adapter.

Consult the “Connection Diagram for the HP xw8400”

channel adapter location and connections.

18

on page 16 as a reference for the fibre

Page 23

You can connect your workstation to two types of storage:

• One or more Stone Direct disk arrays that provide storage to individual workstations. Refer to

the Stone Direct 2007 Configuration Guide for information on connecting disk arrays to your

workstation.

• A Storage Area Network (SAN) that provides shared storage for multiple workstations. Refer

to the Autodesk Stone Shared Installation and Configuration Guide for information on

connecting your workstation to a SAN.

Storage for Linux-Based Workstations

Lustre systems on Linux are used in conjunction with Incinerator 2007 and do not require local

storage. Instead, your workstation is configured with an Infiniband 9000 DDR dual port HCA,

which allows it to connect to the Incinerator high-speed Infiniband network.

Refer to the Autodesk Incinerator 2007 Installation and User’s Guide for information on how to

connect your workstation to the Incinerator high-speed Infiniband network.

Network Connections

Your workstation is configured with a 4-port Broadcom network card, and an integrated

network port.

Network Connections

4-Port Broadcom Adapter

Connect the workstation to your facility’s network to access background rendering nodes,

other Lustre Stations, and the facility’s NAS or SAN centralized storage (if applicable). You

connect the ports on the Broadcom card as follows:

• Connect Port 0 to the Autodesk control surface hub or the control surface itself.

• Connect Port 1 to your house network.

• Connect Port 2 to a SAN private network (optional).

For more details about configuring the Autodesk control surface, see “Connecting the

Autodesk Control Surface” on page 22.

Integrated Network Adapter

For Windows-based workstations, connect the integrated network port to the Slave Renderer.

For more details about configuring the Autodesk control surface, see “Connecting the Slave

Renderer to a Lustre Workstation” on page 28.

19

Page 24

2

Connecting Peripherals

For Linux-based workstations, connect the integrated network port to the Incinerator private

port. Refer to the Incinerator Installation and User’s Guide for information on how to connect

your workstation to the Incinerator private network.

20

Page 25

Connecting System Components

Summary

Workflow for Connecting System Components in the Lustre Workgroup

Connecting the Autodesk Control Surface

Assigning an IP Address to the Autodesk Control Surface

Configuring Lustre to Connect to the Autodesk Control Surface

Connecting a Stand-Alone Tablet

Connecting the Slave Renderer to a Lustre Workstation

Connecting Video I/O to a Master or HD Station

Connecting to a High-Speed Data Link Device (HSDL)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . 27

. . . . . . . . . . . . . . . . . . . . 28

. . . . . . . . . . . . . . . . . . . . . . . . . . . 30

. . . . . . . . . . . . . . . . . . . . . 32

Workflow for Connecting System Components in the Lustre

Workgroup

After you have connected peripherals to your workstation, you are ready to connect it to the

Autodesk control surface, to video I/O hardware, and to a Slave Renderer.

. . . . 21

See the following table for a summary of the steps necessary to connect components in your

workgroup.

Step: Refer to:

1. Connect the control surface to your

workstation.

2. If necessary, connect a tablet to your

workstation.

3. Connect a Slave Renderer to the Lustre

workstation (Windows only).

21

For the Autodesk control surface:

the Autodesk Control Surface”

“Assigning an IP Address to the Autodesk Control

Surface”

on page 25, and

Connect to the Autodesk Control Surface”

page 27.

“Connecting a Stand-Alone Tablet”

“Connecting the Slave Renderer to a Lustre

Workstation”

on page 28.

“Configuring Lustre to

“Connecting

on page 22,

on

on page 27.

Page 26

3

Connecting System Components

Step: Refer to:

4. Connect the workstation to video I/O

components.

5. Connect the workstation to a high-speed

data link device.

“Connecting Video I/O to a Master or HD Station”

on page 30.

“Connecting to a High-Speed Data Link Device

(HSDL)”

on page 32.

Connecting the Autodesk Control Surface

The Autodesk control surface consists of three panels. You can use any combination of one or

all of them. If using more than one panel, you must use the network switch included with your

shipment to cross-connect them.

Refer to the Autodesk Control Surface User’s Guide for information on how to use the control

surface with Lustre.

N

OTE

:

The illustrations in this procedure only show the central module, i.e. the colour grading

panel. This is the only panel that has a USB connection for the integrated tablet, and a network

port. The other two panels only have a network port which you connect to the network switch.

22

Page 27

Connecting the Autodesk Control Surface

To connect the Autodesk control surface:

1. Use the AC power adapter cables to connect each panel to a power supply.

2. Use a network cable to connect port 0 (the far right port) of the Broadcom network card on

your workstation to port 1 on the Netgear ProSafe FS108 network switch.

HP xw8400 Workstation

To USB extender

Network switch

Ports 3 and 4 to

additional panels

NETGEAR

PWR

1345678

2

To port 1 on USB Extender

Autodesk Control Surface

Power

5V DC 4A Ethernet

-

+

Link

System

23

Activity

Autodesk

Tab le t

Page 28

3

Connecting System Components

If you are using only one panel, you can connect that panel directly to the workstation,

instead of using the switch.

HP xw8400 Workstation

To USB extender

24

Autodesk Control Surface

To port 1 on USB Extender

Power

5V DC 4A Ethernet

-

+

Link

System

Activity

3. If you are using more than one panel, use network cables to connect each of the panels to the

network switch.

4. If you are using the panel that includes the tablet, use a USB cable to connect the panel to a

USB port on the back of your workstation.

Autodesk

Tab le t

Page 29

Assigning an IP Address to the Autodesk Control Surface

N

OTE

:

The above diagrams represent a Windows-based configuration. Components may differ

slightly for the Linux configuration but the control surface connections are identical.

Assigning an IP Address to the Autodesk Control Surface

After you have connected the Autodesk control surface, you must assign it an IP address.

To configure the Autodesk control surface on Windows-based workstations:

1. Click Start | Settings | Network Connections.

N

OTE

:

You can also access Network Connections from the Control Panel.

2. Right-click the port that the control surface switch or panel is connected to and choose

Properties.

3. In the Local Area Connections Properties dialog box, select Internet Protocol (TCP/IP) and

click Properties.

The Internet Protocol (TCP/IP) Properties dialog box opens.

25

Page 30

3

Connecting System Components

4. Select the Use the following IP address option.

5. Set a static IP and Subnet mask address for the port. Select values that do not conflict with

any other machine on your network. Consider using the following values:

26

• IP address: 192.168.125.10

• Subnet mask: 255.255.255.0

W

ARNING

:

The last digits of the IP address must not conflict with the panel IDs included in the

lustre.config

6. Click OK twice.

To configure the Autodesk control surface on Linux-based workstations:

h On the Lustre workstation, use a text editor such as nedit to configure the network port

connected to the control surface with an unrelated static IP address that does not interfere

with any of the IP addresses on the network. Also assign an appropriate subnet mask. Type:

nedit /etc/sysconfig/network-scripts/ifcfg-eth<port#>

Modify the IPADDR and NETMASK values. For example:

IPADDR=192.168.125.10

NETMASK=255.255.255.0

file.

Page 31

Configuring Lustre to Connect to the Autodesk Control Surface

W

ARNING

:

The last digits of the IP address must not conflict with the panel IDs included in the

lustre.config

file.

Configuring Lustre to Connect to the Autodesk Control Surface

After you have configured the IP address of the control surface, you must configure Lustre to

use the control surface.

To configure Lustre to use the Autodesk control surface on Windows- or Linux-based

workstations:

1. Turn the power on for each of the modules and look at the top display panel on the module.

It should display the panel name and ID.

2. After you install Lustre 2007, you must manually edit the lustre.config file for each project

and the init.config file in the application home directory. See the Autodesk Lustre 2007 User’s

Guide.

3. Enter the following keywords for each of the panels you want to enable.

Uncomment Keyword: To enable:

AutodeskPanels

Panel-BT <panel_ID>

Panel-K <panel_ID>

Panel-T <panel_ID>

The Autodesk control surface

The Colour Grading panel

The Function panel

The Navigation panel

N

OTE

:

The above keywords are not present by default in the

4. After each panel keyword, enter the panel ID.

lustre.config

and

init.cfg

files.

The keyword section should look similar to the following example.

AutodeskPanels

Panel-BT 1

Panel-K 2

Panel-T 3

5. Start Lustre. The following message should appear in the Console:

Panel #<panel_ID> is detected

This confirms that the Autodesk control surface is enabled.

Connecting a Stand-Alone Tablet

If you do not have the modular Autodesk control surface panel that includes the tablet, you can

connect a stand-alone tablet.

27

Page 32

3

Connecting System Components

To connect a stand-alone tablet, connect the tablet to USB Out 1 on the USB extender.

N

OTE

:

On Windows-based workstations you may need to restart Windows for the tablet to be

recognized. On Linux-based workstations, re-starting the Xserver prompts tablet recognition.

Press

CTRL+ALT+BACKSPACE

to start the Xserver.

Connecting the Slave Renderer to a Lustre Workstation

The Slave Renderer is available for the Master Station, the Lustre Station, and the Lustre HD

Station, all of which must be running on a Windows-based workstation. The Slave Renderer is

is not available for the Linux-based version of Lustre since it uses Incinerator to obtain real-time

rendering and playback.

Although the Slave Renderer is connected using a network connection, a higher Category 6

grade cable is needed to accommodate the data that is transmitted. For information on

configuring the IP addresses of the network ports that connect the two workstations, see the

Autodesk Lustre 2007 Software Installation Guide for Windows Workstations.

To connect the Slave Renderer to a Windows-based workstation:

1. Connect the Category 6 crossover cable to the on-board network port at the back of the

Lustre workstation.

28

2. Connect the other end of the cable to the network port 1 of the Slave Renderer machine.

The Slave Renderer should be connected as shown in the following diagram:

Page 33

Connecting the Slave Renderer to a Lustre Workstation

HP xw8400 Workstation

(Windows-based)

Slave Render Station (HP DL140 G3)

Port 1

29

Page 34

3

Connecting System Components

Connecting Video I/O to a Master or HD Station

You use the video components to set up video I/O and a broadcast monitor. The only video

hardware you must provide are: a sync generator, a VTR, and an SD or HD SDI broadcast

monitor. The following components are included in your hardware shipment.

DVS Centaurus board and DVS Breakout Box II —

The DVS Centaurus board provides

video I/O. Use the DVS Breakout Box II for serial control of a VTR or other slave device and LTC

output to an audio device.

NVIDIA Quadro FX5500 graphics board —

The NVIDIA Quadro FX graphics board

provides output to your computer monitor, to the broadcast monitor, and to a VTR (for realtime deliverables).

EIZO® 24-inch or Sony™ 21-inch wide screen LCD graphics monitor —

The EIZO and

Sony LCD graphics monitors provide a 16:9 widescreen aspect ratio for film or HD projects.

With these monitors, the application runs at a maximum resolution of 1920x1200. For

instructions on connecting the graphics monitor, see “Connecting the Monitor”

Altinex® DA1804NT video distribution amplifier —

The Altinex video distribution

on page 17.

amplifier can serve a bi-level (SD) or tri-level (HD) sync signal to up four video hardware

devices from a single sync source/generator. It serves the sync signal to the NVIDIA graphics

board and the DVS Centaurus board.

Video I/O for Real-Time Deliverables

The following diagram describes the video I/O wiring for the Real-time deliverables

configuration, which allows Lustre to play out to a VTR directly through the NVIDIA graphics

board.

N

OTE

:

The backplanes depicted here represent a Windows-based configuration, but it is also

accurate for a Linux-based configuration, where the ATTO fibre-channel adapter is replaced by the

Infiniband HCA.

30

Page 35

HP xw8400 Workstation

Real-Time Deliverables*

Video 1 Out to (HD) SDI VTR Input 1

or 4:2:2 on Display Device*

Video 2 Out to (HD) SDI VTR Input 2

or 0:2:2/4 :0:0 gfx feed on Display Device*

From Altinex Comp Sync

Connecting Video I/O to a Master or HD Station

VTR Control

RS-422

GPI

AUDIO

WClk CVBS

DVS Centaurus Breakout Box

RS 422A

RS.422B

AES/EBU AUDIO

RS 422C

RS.422D

To LTC on VTR

or other slave device

IN OUT

1/2 3/4 7/85/6 1/2 3/4 5/6 7/8

LTC

Graphics Monitor

From HD or SD Analog

Sync Generator

VIDEO

INPUT

Altinex

Distribution

amplifier

ALTINEX

Video Distribution Amplifier (Computer/ntsc/pal)

DA1804NT

OUT 1 OUT 2

OUT 3 OUT 4

Altinex Out 1 to

FX5500 Comp Sync

POWER

9V 600NA

Altinex Out 2 to

Centaurus Ref In

DIGITAL AUDIO

AES/EBU AUDIO

OUT

(Front)

(Back)

IN

SYSTEM

(HD) SDI Out A to VTR (4:2:2)

(HD) SDI In A from VTR (4:2:2)

Video I/O without Real-Time Deliverables

The following illustration shows the video I/O wiring for a configuration that does not support

playout to a VTR through the NVIDIA board (Real-time deliverables).

31

Page 36

3

Connecting System Components

HD/SDI Display Device

4:2:2 gfx feed

0:0:2/4:0:0 gfx feed

From Altinex Comp Sync

(HD) SDI In B from VTR (4:4:4)*

(HD) SDI Out B to VTR (4:4:4)*

HP xw8400 Workstation

No Real-Time Deliverables*

HD/SDI out (V1)

HD/SDI out (V2)

Used in 4:4:4

mode only

VTR Control

RS-422

RS 422A

GPI

AUDIO

WClk CVBS

DVS Centaurus Breakout Box

RS.422B

AES/EBU AUDIO

RS 422C

RS.422D

To LTC on VTR

or other slave device

IN OUT

LTC

Graphics Monitor

From HD or SD Analog

Sync Generator

POWER

OUT 1 OUT 2

OUT 3 OUT 4

9V 600NA

VIDEO

INPUT

Altinex

Distribution

amplifier

(HD) SDI Out A to VTR (4:2:2)

(HD) SDI In A from VTR (4:2:2)

ALTINEX

Video Distribution Amplifier (Computer/ntsc/pal)

DA1804NT

1/2 3/4 7/85/6 1/2 3/4 5/6 7/8

DIGITAL AUDIO

AES/EBU AUDIO

OUT

(Front)

(Back)

IN

SYSTEM

Altinex Out 1 to

FX5500 Comp Sync

Altinex Out 2 to

Centaurus Ref In

Connecting to a High-Speed Data Link Device (HSDL)

If you have purchased an HSDL license, you can connect to an HSDL device through the DVS

Centaurus.

32

Page 37

Connecting to a High-Speed Data Link Device (HSDL)

Connect both the A and B in/out ports on the DVS main board and daughter card to your HSDL

device.

33

Page 38

3

Connecting System Components

34

Page 39

inde x

Index

A

air conditioning

requirements

Autodesk control surface

assigning an IP address 25

configuration file 27

connecting 22

B

BIOS settings

HP xw8400

breakout box

connecting 30

broadcast monitor

connecting 30

C

configuration guidelines

grounding hardware 12

connecting peripherals

workflow 15

connecting system components

workflow

connection diagram

HP xw8400 16

control surface

Autodesk control surface, connecting 22

conventions, in guide 12

D

documentation

set of guides

DVS I/O

11

10

21

6

connecting 30

G

graphics monitor

connecting 30

grounding hardware 12

guide

conventions 12

H

hardware

breakout box 30

DVS board 30

graphics monitor 30

HD/SDI monitor 30

HSDL device 32

Slave Renderer 28

video distributor amplifier 30

VTR 30

hardware configuration guidelines 7

HSDL device

connecting 32

I

installation

overview

K

keyboard

connecting 18

M

monitor

2

35

Page 40

Index

connecting 17

mouse

connecting

18

N

network

connection

19

P

peripherals

monitor 17

mouse and keyboard 18

network 19

tablet 27

power

requirements

11

R

real-time deliverables

wiring 30

S

SAN

Stone Shared 18

Slave Renderer

connecting 28

Stone Direct

connecting

Stone Shared

connecting 18

storage

connecting 18

18

W

workflow

hardware setup and software installation

8

T

tablet

connecting

27

V

video distributor amplifier

connecting 30

video IO connections

31

wiring

wiring for real-time deliverables 30

VTR

connecting

36

30

Loading...

Loading...