Page 1

V8.5 Thermal Plotter

User Guide

V8.5 Thermal Plotter is a product of iSys - The Imagaing Systems Group. © 2005

Page 2

COPYRIGHT NOTICE

This document is copyrighted by The Imaging Systems Group Inc.,

2000. No part of this publication may be reproduced, transmitted,

transcribed, or stored in a retrieval system of any kind without prior

written permission of The Imaging Systems Group Inc.

TRADEMARKS

Centronics is a U.S. registered trademark of Centronics Data

Computer Corporation.

Versatec is a registered trademark of Versatec Corporation.

DISCLAIMER

The Imaging Systems Group Inc. makes no warranties as to the

accuracy, validity or fitness for use of the contents of this manual.

The Imaging Systems Group Inc. reserves the right to revise the

information in this manual at any time without notice .

HAFTUNGSAUSSCHLUSS

Imaging Systems Group Inc. übernimmt keinerlei Garantie hinsichtlich

der Genauigkeit, Gültigkeit und Anwendbarkeit dieses Handbuches.

Imaging Systems Group Inc. behält sich das R echt vor , die in diesem

Handbuch enthaltenen Informationen jederzeit ohne vorherige

Ankündigung zu ändern.

V8.5e Rev 2.2.2002

i

Page 3

ATTENTION: The V8.5e plotter generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with

the instruction manual, may cause interference to radio

communications. It has been designed to comply with the

requirements for Class A computing devices pursuant to Sub-part J of

Part 15 of FCC Rules, which are designed to provide reasonable

protection against such interference when operated in a commercial

environment. Operation of this equipment in a residential area is likely

to cause interference in which case, the user, at his own expense, will

be required to take whatever measures may be required to correct

the interference.

ACHTUNG: Der V8.5e Plotter erzeugt, verwendet und verbreitet

Hochfrequenzenergie und kann daher, im Falle, dass er nicht gemäß

dem Benutzerhandbuch installiert und benutzt wird, zu Störungen

im Hochfrequenz Kommunikationsverkehr führen. Er wurde gemäß

den Anforderungen für Rechnergeräte der Klasse A konstruiert und

erfüllt Unterabsatz J des Teils 15 der FCC Vorschriften, die dazu gedacht

sind, einen angemessenen Schutz bei Einsatz dieser Geräte in einer

gewerblichen Umgebung zu sichern. Ein Einsatz dieser Geräte in

Wohngebieten wird wahrscheinlich Störungen verursachen, im

welchem Falle der Benutzer auf eigene Kosten die notwendigen

Maßnahmen ergreifen muß, die erforderlich sind, um solche

Störungen zu vermeiden.

ii

V8.5e Rev 2.2.2002

Page 4

Caution! – must be observed to avoid loss or damage to your

equipment.

Important: - must be observed to avoid operational impairment.

Do not proceed past any of the above notices, until you have fully

understood the implications.

Electromagnetic Compatibility (EMC) USA – This equipment

generates and radiates radio frequency energy and if not installed

and used in accordance with the instruction manual, may cause

interference to radio communications. It has been tested and found

to comply with the limits for a Class A computing device pursuant to

Subpart B of Part 15 of FCC rules, which are designed to provide

reasonable protection against such interference when operated in a

commercial environment. Operation of this equipment in a residential

area is likely to cause interference in which case the user at his own

expense will be required to take whatever measures may be required

to correct the interference . Shielded cables should be used with this

unit to ensure compliance with the Class A limits.

Europe – This digital equipment fulfils the requirements for radiation

emission according to limit B of EN55022/A1 May 1998, and the

requirements for immunity according to EN55024 1998 residential,

commercial, and light industry (Compliance is not valid for unshielded

network and printer cables).

Vorsicht! – Muss befolgt w erden, um T ot alverlust oder Beschädigung

des Gerätes zu vermeiden.

Wichtig: - Muss befolgt werden, um Beeinträchtigungen beim Betrieb

zu vermeiden.

V8.5e Rev 2.2.2002

iii

Page 5

Bitte verfahren Sie erst dann weiter, wenn Sie die Bedeutung der

vorstehenden Hinweise vollständig verstanden haben.

Elektromagnetische Kompatibilität (EMC) USA – Dieses Gerät

erzeugt und verbreitet Hochfr equenzenergie und kann daher , so fern

es nicht gemäß dem Benutzerhandbuch installiert und benutzt wird,

zu Störungen im Hochfrequenz-Kommunik ationsverkehr führ en. Es

wurde gemäß den Einschränkungen für Rechner geräte der Klasse A

konstruiert und erfüllt Unterabsatz J des Teils 15 der FCC Vorschriften,

die dazu gedacht sind, einen angemessenen Schutz bei Einsatz dieser

Geräte in einer gewerblichen Umgebung zu sichern. Ein Einsatz

dieser Geräte in Wohngebieten wird wahrscheinlich Störungen

verursachen, im welchem Falle der Benutzer auf eigene Kosten die

notwendigen Maßnahmen ergreifen muss, die erforderlich sind, um

solche Störungen zu beheben. Um die Einhaltung der Klasse-AEinschränkungen zu gewährleisten, sollte das Gerät mit geschirmten

Kabeln verwendet werden.

Europa – Dieses digitale Gerät entspricht den Anforderungen für

Strahlungsemissionen gemäß EN55022/A1 Klasse B vom Mai 1998,

sowie die Anforderungen für Störsicherheit gemäß EN55024 1998

für den häuslichen, gewerblichen und leichtindustriellen Gebrauch

(Konformität gilt nicht für ungeschirmte Netz- und Druckerkabel).

iv

V8.5e Rev 2.2.2002

Page 6

LIMITATION OF LIABILITY

The Imaging Systems Group’s total liability to the purchaser, or to

any third party, for damages from any and all causes whatsoever,

regardless of the form of action, whether in contract or in tort,

including negligence, and any infringement of proprietary rights or

any misappropriation or unlawful use of any proprietary rights or

property of any third party shall, in the aggregate, be limited to

purchase price actually paid by the purchaser for the product relating

to the damages. The limitation of liability provisions of this agreement

reflect an informed voluntary allocation of the risks (known and

unknown) that may exist in connection with the provisions of the

goods and services provided hereunder by The Imaging Systems

Group Inc., and that such voluntary risk allocation represents a

fundamental part of the agreement reached between The Imaging

Systems Group Inc. and the purchaser.

The Imaging Systems Group Inc. shall not be liable for any special,

direct or indirect, incidental, consequential, exemplary, punitive or

any similar or other damages of any nature suffered by the purchaser

whatsoever including, without limitation, loss of use or lack of

availability of the purchaser facilities, including its computer resources

and any stored dat a, loss of pro fits or re v enue , or other commercial

loss, or any claim for contribution or indemnity in respect of any

claims against the purchaser, regardless of whether The Imaging

Systems Group Inc. has been advised of the possibility of such

damages.

The Imaging Systems Group Inc.

911 28th Street N.E.

Calgary, Alberta T2A-7X1

Canada

Phone 1-866-415-4797

Fax: (403) 204-1971

e-mail: josh_wood@isys-group.com

http://www.isys-group.com

V8.5e Rev 2.2.2002

v

Page 7

Contents

1. INTRODUCTION ........................... 1-1

1.1 GENERAL DESCRIPTION .................... 1-1

1.2 MEDIA DESCRIPTION ...................... 1-1

1.3 ABOUT THIS MANUAL ..................... 1-2

2. SPECIFICATIONS .......................... 2-1

2.1 FUNCTIONAL ........................... 2-1

Operation .............................. 2-1

Media ................................. 2-3

Thermal printhead ........................ 2-3

Transport .............................. 2-4

2.2 ELECTRICAL ............................ 2-4

Interface ............................... 2-4

Power consumption ....................... 2-4

Power requirements ....................... 2-4

2.3 PHYSICAL .............................. 2-5

Dimensions ............................. 2-5

Weight ................................ 2-5

2.4 ENVIRONMENTAL ........................ 2-5

Temperature ............................ 2-5

Other ................................. 2-5

vi

3. INSTALLATION ............................ 3-1

3.1 UNPACKING ............................ 3-1

3.2 MOUNTING AND POSITIONING .............. 3-2

3.3 INTERFACE SETUP ........................ 3-3

3.4 MEDIA INSTALLATION ..................... 3-3

Installing rolled paper ..................... 3-4

Installing fan-fold paper .................... 3-8

Installing and using film .................... 3-8

Installing rolled film ....................... 3-9

V8.5e Rev 2.2.2002

Page 8

4. OPERATION .............................. 4-1

4.1 POWER SUPPLY PRECAUTIONS ............... 4-1

4.2 USING THE CONTROL PANEL ................. 4-2

4.3 CONTROL PANEL FUNCTIONS AND SETTINGS ..... 4-5

Changing function settings .................. 4-5

Default Settings .......................... 4-6

Test plot ............................... 4-6

Contrast ............................... 4-6

Speed ................................. 4-7

Media ................................. 4-8

Scaling ................................ 4-9

Emulation (vertical resolution) .............. 4-10

Form feed length ........................ 4-10

Bytes per scan .......................... 4-12

Grayscale media table number .............. 4-13

Setup headers for programming the V8.5e ...... 4-13

4.4 ERROR MESSAGES ....................... 4-16

5. THEORY OF OPERATION ..................... 5-1

5.1 INTRODUCTION .......................... 5-1

5.2 PLOTTER FUNCTIONS AND FEATURES .......... 5-1

Power supplies ........................... 5-1

Stepper motor ........................... 5-3

5.3 INTERFACE ............................. 5-3

Interface timing and signals ................. 5-3

Data rates .............................. 5-6

Scan width ............................. 5-7

Vertical resolution ........................ 5-7

Scaling ................................ 5-7

Print mode ............................. 5-8

5.4 THERMAL PRINTHEAD ..................... 5-9

Automatic Head Temperature Feedback ......... 5-9

Film media ............................ 5-10

V8.5e Rev 2.2.2002

vii

Page 9

5.5 MEDIA SENSORS ........................ 5-10

6. MAINTENANCE ............................ 6-1

6.1 MAINTENANCE GUIDELINES ................. 6-2

6.2 REGULAR MAINTENANCE ................... 6-3

Cleaning the thermal printhead ............... 6-4

Cleaning the platen roller ................... 6-5

Replacing the fuse ........................ 6-6

7. TROUBLESHOOTING ........................ 7-1

7.1 INTRODUCTION .......................... 7-1

7.2 PROBLEMS ............................. 7-2

Plotter does not plot ...................... 7-2

Plot has vertical white stripes ................ 7-3

Plot is blotchy or faded ..................... 7-4

Plot contrast is weak ...................... 7-5

Plot has black vertical lines .................. 7-6

Plot is wrong length ....................... 7-7

Paper is wrinkling or tearing along one edge ..... 7-7

Plotter has no power ...................... 7-8

Plotter display is functioning but motor ......... 7-8

Can’t make changes to control panel settings ..... 7-8

Plot output speed is erratic .................. 7-9

Burning smell during plot, or “blooming” ....... 7-10

Form feed stops before desired length ......... 7-11

Form feed does not stop at top-of-form marks ... 7-11

Plot is skewed or unreadable ................ 7-12

viii

8. WARRANTY .............................. 8-1

APPENDICES

A. ASCII TABLES ............................. A-1

V8.5e Rev 2.2.2002

Page 10

B. INTERFACE CONNECTOR PIN ASSIGNMENT ....... B-1

C. CENTRONICS INTERFACE BOARD ............... C-1

V8.5e Rev 2.2.2002

ix

Page 11

INTRODUCTION

1.1 GENERAL DESCRIPTION

The Imaging Systems Group’s V8.5e Thermal Plotter is a high-speed

plotter suitable for office or field use . Its small siz e and lightweight,

yet rugged construction makes it durable in mobile situations. The

V8.5e uses direct thermal plotting technology , so it requires no liquid

or powdered ink.

Interface parameter settings and other menu functions can be

accessed from either the front panel or the host computer. It is

capable of printing at four speeds; 1.0, 2.0, 3.0, and 4.0 inches per

second.

The V8.5e thermal plotter contains a completely new method of

plotting rasterized data. Each scan of data plotted can contain as

many as 64 independent intensity levels (gray scales). The thermal

print head (TPH) in the V8.5e is made up of 1728 thermal heater

nibs, and each one of these nibs can be heated to a different

energy level, producing a dot on the thermal media of varying

intensity . This type of plotting can pr oduce high-resolution images

containing many shades of gr a y.

1

The V8.5e prints in both raster and character modes, and contains

a 96-character ASCII set. It interfaces with Ver satec and optionally

Centronics data interfaces.

1.2 MEDIA DESCRIPTION

The V8.5e uses rolled or fan-folded thermal paper or rolled film.

Media width is 8.75, and 9.0 inches. The V8.5e accommodates

regular thermal paper , paper s with a protectiv e top coating, as w ell

as certain types of film media. Call your Imaging Systems Group

product representative for media recommendations.

1-1V8.5e Rev 2.2.2002

Page 12

1

INTRODUCTION

An optional fan-fold paper guide and feeder trays (which attach to

the back of the plotter , and below the rackmount plotter) are a vailable

from The Imaging Systems Group which stabilizes the paper for

smooth intake of fanfold papers. These options are useful in field

situations or where vibration is a problem.

1.3 ABOUT THIS MANUAL

Please read this manual before using the plotter, in particular the

Installation and Operation Chapters , and the “Regular Maintenance”

section in the Maintenance Chapter .

Pa y special attention to warnings, cautions and notes . The following

conventions are used in this manual:

CAUTION: Indicates possible equipment damage unless procedure

is followedcorrectly.

VORSICHT: Verweist auf die Gefahr der Beschädigung des Gerätes,

falls die Vorschriften nicht genau befolgt werden.

NOTE: Indicates a general rule for a procedure, or an exception to a

rule.

WICHTIGER HINWEIS: Verweist auf allgemeine

Verfahrensvorschriften oder eine Ausnahme zu einer Vorschrift.

This symbol indicates an area of possible concern due to

static discharge into the circuitry. When this symbol appears in the manual, please observe proper static precautions to minimize damage to the circuitry.

Dieses Symbol warnt davor, dass es in diesen Bereichen

möglicherweise zu statischen Entladungen an den Schaltkreisen

kommen kann. Wenn dieses Symbol im Handbuch erscheint, sind

die entsprechenden Vorsichtsmaßnahmen zu treffen, um eine

Beschädigung der Schaltkreise so weit wie möglich zu vermeiden.

1-2 V8.5e Rev 2.2.2002

Page 13

SPECIFICATIONS

2.1 FUNCTIONAL

Operation

Command panel Front mounted.

LED display .

Three push buttons.

Online/Offline, Data and err or LED’ s.

Command modes Bimodal Plotting mode.

Grayscale mode .

Printing mode.

Featur es Bimodal (black and white) plotting.

Grayscale plotting.

Plot speed up to 4.0 inches per second.

Microprocessor controlled.

Automatic head temperature feedback

2

P anel settings ~ On-line , o ff-line.

~ T est plot, test print.

* Contrast C1, C2, C3, C4, C5, C6, C7, C8.

* Plot speed select 1”, 2”, 3”, 4” per second.

* Media select LP, HP, LF , HF.

~ Scaling (positive and negative) S0, S1, S2,

S3, S4, S5, S6, S7, S8, S9, SA, SB, SC, SD, SE.

~ V ertical emulation.

P0, n0 for 200 dots per inch vertical

emulation. P3, n3 for 203 dots per inch

vertical emulation. P selects positive

scaling, n selects negative scaling.

2-1V8.5e Rev 2.2.2002

Page 14

2

SPECIFICATIONS

~ Form feed adjust F2, F4, F8, tF, PF - selects

formfeed of 2, 4, 8 inches, Top of Form

sensing, and programable past top of form

respectively.

~ Bytes per scan b1, b2 - selects 216 and 264

bytes per scan respectively.

~ Grayscale levels per scan g1, g2, g3, g4 -

selects 8, 16, 32, and 64 levels of gray levels

per scan respectively.

# Grayscale media calibration table number

t1, t2.

Settings marked with (*) are used exclusively with bi-modal plotting.

Settings marked with (#) are used exclusively with grayscale plotting.

Settings marked with (~) are used with both bi-modal and grayscale

plotting.

Plot speeds P aper 1.0, 2.0, 3 .0, and 4.0 inches per second

in bimodal (black and white) plotting mode.

Film: 1.0 inch per second.

Grayscale: dependent upon the number of levels

of grayscale selected.

Condition detection Media out.

Top of form.

Head temperature.

24 volt error detection.

2- 2 V8.5e Rev 2.2.2002

Page 15

SPECIFICATIONS

Media

Types Thermal sensitive paper or film.

Rolled paper with 7/16 inch spool cor e.

Rolled film.

Fan-folded paper (optional).

Width 8.75 inch rolled paper or film media.

8.75, 9.0 inch fan fold paper media.

Maximum length Rolled media: 100 feet with thick paper, 150

feet with thin paper. Maximum diameter 2.5

inches. Fan-fold: unlimited maximum.

Fan-fold guides Optional, for fan-fold paper. Adjustable for

8.75 inch and 9.0 inch media.

Feeder tray s Optional, for fan-fold paper.

2

Thermal printhead

Ty pe Linear array.

Resolution 203 dots per inch (8 dots per milimeter).

Dots per scan 1728 (metric) maximum.

Bytes per scan 2 16 bytes maximum.

Image width 8.5 inches.

2-3V8.5e Rev 2.2.2002

Page 16

2

SPECIFICATIONS

Transport

Stepper motor Micro-step.

Stepping resolution 0.004 millimeter.

6400 micro-steps per inch of media.

32 micro-steps per scan line.

2.2 ELECTRICAL

Interface

Ty pe Parallel, 8 kB buffer

Compatibility Versatec Greensheet

Centronics parallel (optional)

External SCSI

Data cable Optional

Power consumption

Idle mode 110 Watt minimum.

Plot or print mode 315 Watt maximum

Power requirements

Voltage Auto selectable input 100 Volts AC @ 60

Hertz Or 240 Volts AC @ 50 Hertz

Current 3 Amps maximum @ 110 Volts

1.5 Amps nominal @ 220 Volts

Fuse 250 Volts / 5 Amps

2- 4 V8.5e Rev 2.2.2002

Page 17

SPECIFICATIONS

2.3 PHYSICAL

Dimensions

Rackmount Desktop

Height 3.5 inches 3.5 inches

Width 19 inches 15 inches

Depth 12.5 inches 12.5 inches

Weight

Net 23 pounds 22 pounds

2.4 ENVIRONMENTAL

Temperature

Operating range 32º to 122º Fahrenheit (0º to 50º Celcius)

2

Storage range 14º to 158º Fahrenheit (-10º to 70º Celcius)

Other

Operating humidity 5% to 95 non-condensing

Certification FCC Class “A” certified for electr omagnetic

interference

2-5V8.5e Rev 2.2.2002

Page 18

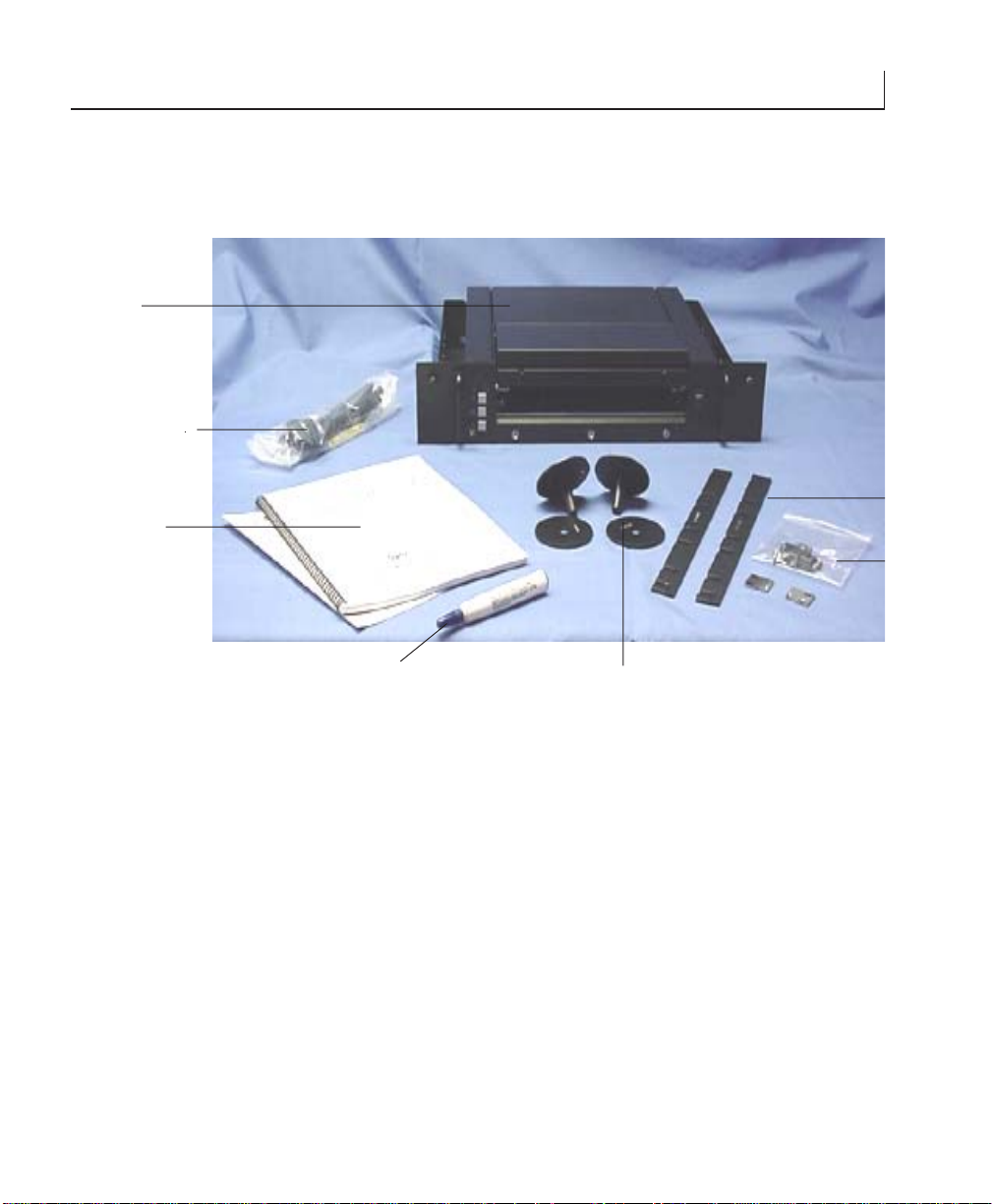

Plotter

AC Power

Cord

Manual &

W arranty Card

INSTALLATION

3.1 UNPACKING

3

Rail

Spacers

Thumb

Screw

Kit

Head Cleaning Pen

Although shipments are thoroughly checked for completeness by

The Imaging Systems Group Inc., confirm that your plotter has the

following:

1. Power cord

2. Sample Roll o f paper

3. Two spindle hubs

4. Rackmount spacers

Confirm that any specified options are present, such as a data cable

or fan-fold guide.

Spindle with Spacer disks

3-1V8.5e Rev 2.1.2001

Page 19

3

INSTALLATION

Inspect the plotter and components for any damage that may have

occurred during shipment. Report any damage to the carrier of the

shipment, and to your Imaging Systems Group Inc. product

representitive.

Keep the box and packaging for future shipping, in the event of

servicing or upgrading issues. This product must be returned to

our factory in the original or proper packaging material. Damage

caused during return shipping or due to improper packaging will

not be covered by The Imaging Systems Group Inc. During shipping

or storage, place a length of thermal paper between the printhead

and roller. This prevents damage caused by the two components

sticking together.

3.2 MOUNTING AND POSITIONING

Keep the V8.5e away from direct heat sources, including sunlight.

Do not block the vents on the sides of the plotter.

CAUTION: Make sure the thumbscrews are secured before operation.

This is particularly important in mobile situations. Damage to the plotter

or rack components could result if the plotter becomes unstable.

VORSICHT: Versichern Sie sich vor dem Betrieb des Gerätes, dass die

Flügelschrauben festgestellt sind. Das ist besonders in beweglichen

Konstellationen wichtig. Sollte der Plotter instabil werden, kann dies

zu Schäden am Plotter oder am Gestell führen.

3-2 V8.5e Rev 2.2.2002

Page 20

INSTALLATION

3.3 INTERFACE SETUP

Plug the power cord into a grounded AC outlet only. Avoid sharing

an outlet that is also powering other noise-generating equipment.

The V8.5e comes equipped with a V ersatec short line TTL (transistor

to transistor logic) interf ace. This interface can be used for dat a cable

lengths up to 50 feet.

An optional long line interface (differential) can be used for data

cable lengths up to 700 feet.

For optional Centronics interface setup, see Appendix C.

An external SCSI (Small Computer System Interface) is also a vailable.

Please contact your Imaging Systems Group Inc. product

representitive for further information.

3

3.4 MEDIA INSTALLATION

CAUTION: Do not attempt to plot or form feed without the print

medium installed. This may damage the print head and will void the

warranty.

VORSICHT: Versuchen Sie bitte nicht, einen Druckvorgang oder

Papiervorschub zu starten, wenn sich kein Druckmedium im Plotter

befindet. Dies kann zu einer Beschädigung des Druckkopfes und zum

Verlust der Garantie führen.

3-3V8.5e Rev 2.2.2002

Page 21

3

INSTALLATION

Installing rolled paper

The V8.5e plotter comes with a sample roll of thermal sensitiv e paper .

To install r olled paper:

1. Loosen the rackmount thumbscrews and pull the plotter forward

on the rails.

2. Release the lid assembly by grasping underneath the black latch

bar and pulling it upwards (Figure 3-5). Open the plotter lid by

lifting the guide straight upwards.

3. Remove the fan-fold guide by grasping the two stainless steel

rails and lifting it straight upwards.

4. Place the spindle hubs onto each end of the roll of media with the

spacer on the left hand side spindle.

5. Orient the roll so that the paper feeds off of the top of the roll.

6. Place the roll in the plotter so that the pins on the spindle hubs

snap into the slots on the spindle blocks.

7. Guide the paper over the blue platen roller and under the black

cutter bar as shown in Figure 3-3.

8. Figure 3-4 shows roll paper installed. When installing any media,

ensure that the coated side of the media is on top.

3-4 V8.5e Rev 2.2.2002

Page 22

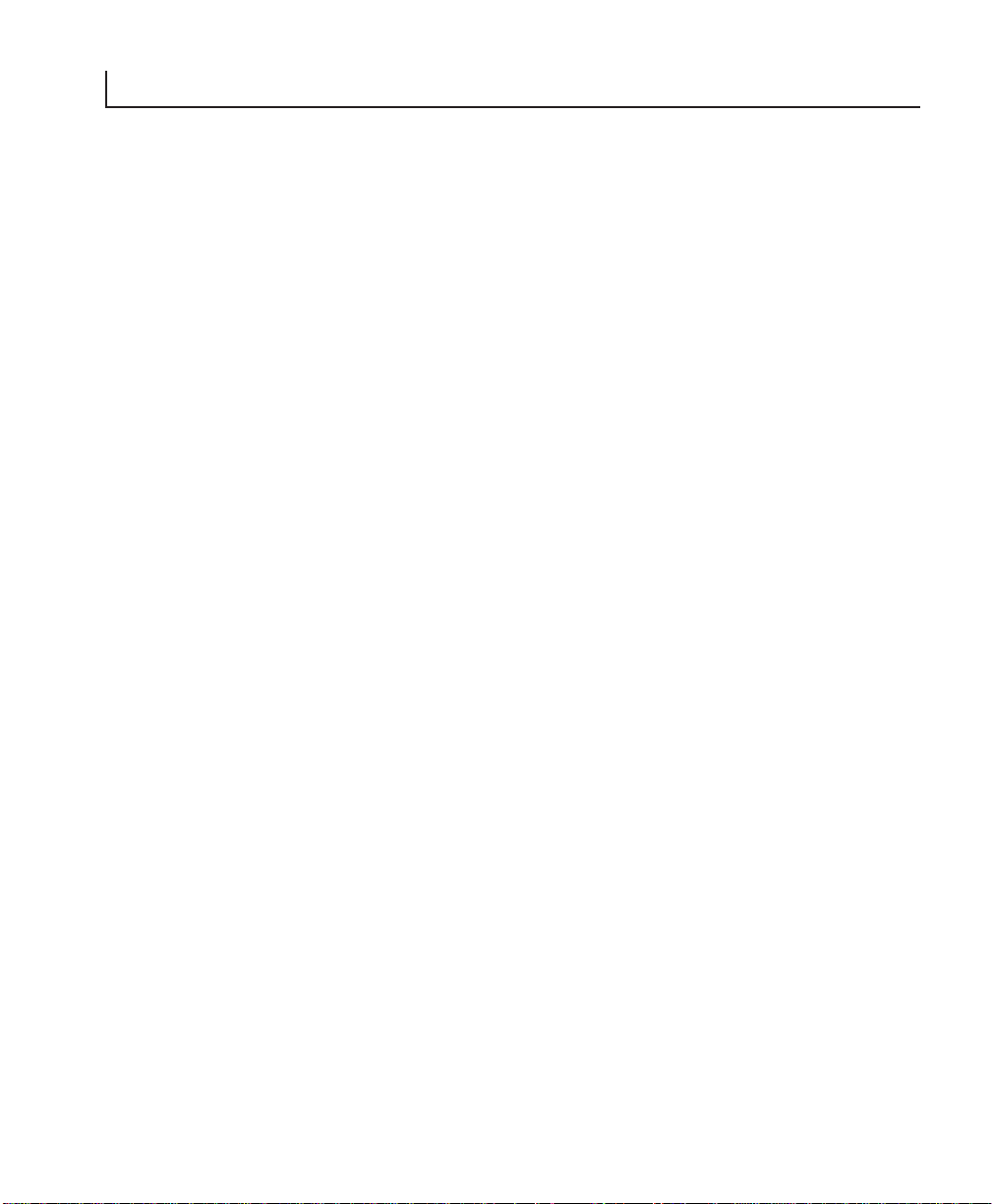

Control Panel

INSTALLATION

Latch

Figure 3-1

AC receptacle Screws

3

Power

AC Power & Fuse Back Panel Screws Data port

Figure 3-2 Back Panel

3-5V8.5e Rev 2.2.2002

Page 23

3

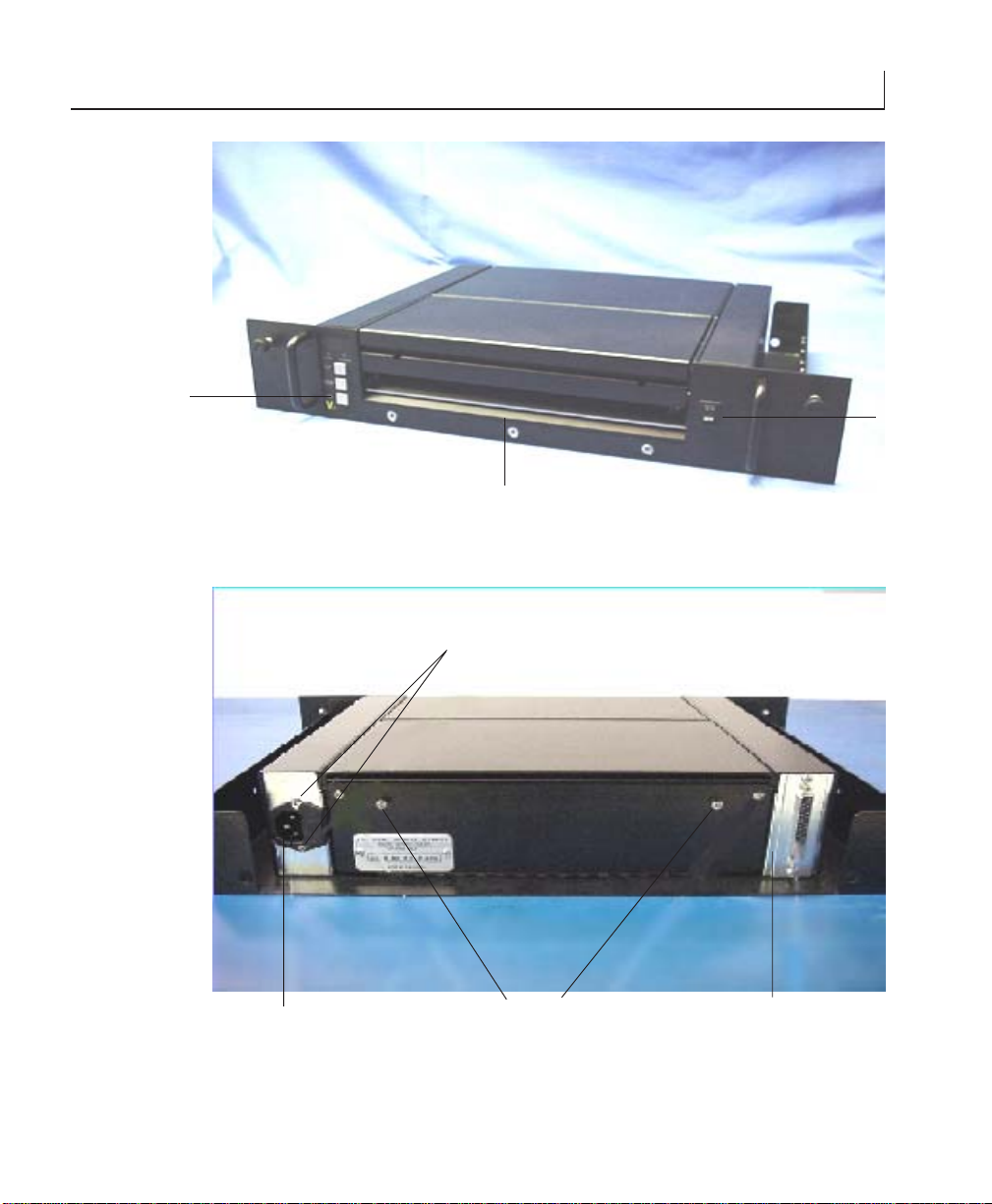

INSTALLATION

Roll

Figure 3-3. Roll paper and film path

Figure 3-4 Roll paper installed

3-6 V8.5e Rev 2.2.2002

Page 24

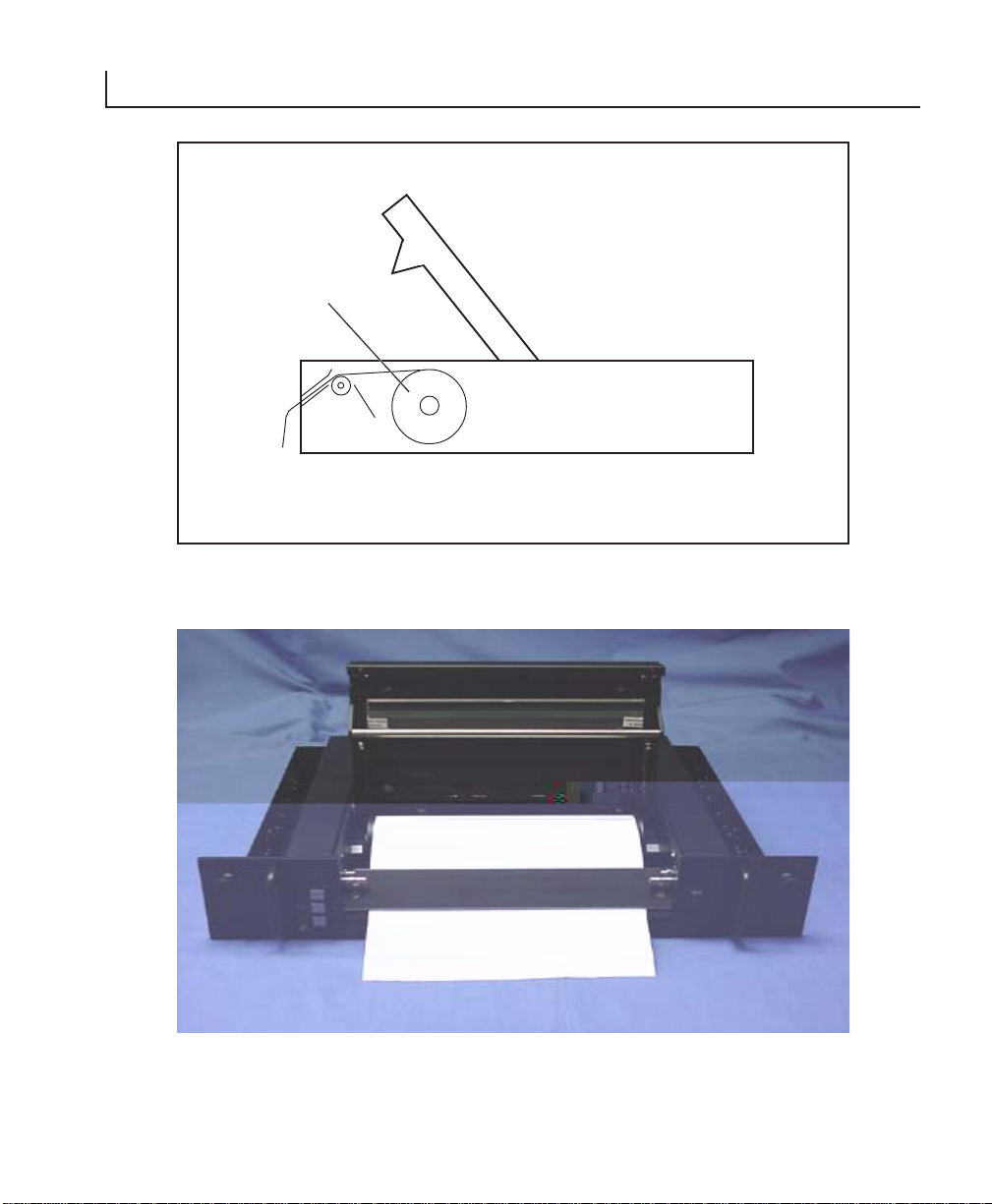

INSTALLATION

Figure 3-5 Opening the plotter Lid

3

Latch Bar

3-7V8.5e Rev 2.2.2002

Page 25

3

INSTALLATION

Installing fan-fold paper

1. Loosen the rackmount thumbscrews and pull the plotter forward

on the rails.

2. Release the lid assembly by grasping underneath the black latch

bar and pulling it upwards (Figure 3-5). Open the plotter lid by

lifting it straight upwards.

3. Remove paper roll and insert the fanfold guide over the spindle

blocks (see Figure 3-6).

4. Feed the paper thr ough the slot in the back or bottom of the plotter

depending on which fan-fold paper tray is being used.

5. If using rear load fan-fold paper, feed the media under the rear

fan-fold guide bar and over the front fan-fold guide bar.

Figure 3-4. If using bottom loaded fan-fold paper, feed the media

over the rear fan-fold guide bar and over the front fan-fold guide

bar.

6. Guide the paper over the blue platen roller and under the black

cutter bar as shown in Figures 3-3 and 3-4.

7. When installing any media, ensure that the coated side of the

media is on top and the T OF mark is on the bott om right side.

Installing and using film

Note that the plotter operates at 1.0 inch per second when using

film. Install roll film as you would paper, ensuring that the coated

side is on top.

Note that the cutter bar is designed for paper media only. Use a

sharp knife or scissors to cut film media.

3-8 V8.5e Rev 2.2.2002

Page 26

INSTALLATION

CAUTION: Before plotting or testing on any print media, make sure

that the media setting is correct. Incorrect settings may result in damage

to the printhead and warranty. The media may also be damaged.

VORSICHT: Bevor Sie mit dem Plotten oder Testdrucken auf einem

Druckmedium beginnen, versichern Sie sich, dass die Einstellungen

für das Druckmedium korrekt sind. Falsche Einstellungen können zu

einer Beschädigung des Druckkopfes und zum Verlust der Garantie

führen. Außerdem kann hierdurch auch das Druckmedium beschädigt

werden.

Installing rolled film

1. Loosen the rackmount thumbscrews and pull the plotter forward

on the rails.

2. Release the lid assembly by grasping underneath the black latch

bar and pulling it upwards (Figure 3-5). Open the plotter lid by

lifting it straight upwards.

3

2. Remove the fan-fold guide by grasping the two stainless steel

rails and lifting it straight upwards.

3. Place the spindle hubs onto each end of the roll of film with the

spacer on the left hand side spindle.

4. Orient the roll so that the film feeds off of the top of the roll.

5. Place the roll in the plotter so that the pins on the spindle hubs

snap into the slots on the spindle blocks.

6. Guide the film over the blue platen roller and under the black

cutter bar as shown in Figure 3-3.

3-9V8.5e Rev 2.2.2002

Page 27

3

INSTALLATION

Figure 3-6 Spindle blocks

Spindle blocks (1 per side)

Figure 3- 7. Fanfold guide path

3-10 V8.5e Rev 2.2.2002

Page 28

OPERATION

4.1 POWER SUPPLY PRECAUTIONS

Turn off the power switch on the plotter before doing any of the

following:

1. Unplugging the plotter

2. Cleaning the printhead

CAUTION: Take care not to discharge static into the plotter.

This may cause damage to the integrated circuits or other

electronic components. Use an approved method of static

dissipation to revent component damage.

VORSICHT: Vermeiden Sie statische Entladung am Plotter. Dies könnte

zu Schäden an den integrierten Schaltkreisen und anderen

elektronischen Bauteilen führen. Verwenden Sie ein anerkanntes

Verfahren zu Ableitung der statischen Energie, um Geräteschäden zu

vermeiden.

4

4-1V8.5e Rev 2.2.2002

Page 29

4

OPERATION

4.2 USING THE CONTROL PANEL

To turn the plotter on, press the main power switch at the front of

the plotter . The LED display “moves in cir cular motion” during bootup,

followed by the ONLINE LED illuminating. When the ONLINE LED is

on, the plotter is ready to receive data from the host. Changes to the

plotter have to be made in offline mode.

Button 1

Button 2

Button 3

Figure 4-1. Control panel

The control panel is shown in Figure 4-1. It consists of an LED

display, two condition lights, and three buttons.

4-2 V8.5e Rev 2.2.2002

Page 30

OPERATION

nottuB noitcnuF

.sedomENILFFOdnaENILNOneewtebselggoT

.WORRAPU.1

enilffO/enilnO

sseccaunemretfas'unem

.WORRANWOD.2

ecnavdA/deeFmroF

evaS/uneM.3

:sehsalf

.sgnittesunemsevas

ebylnonacsgnitteslenaplortnocotsegnahC

busnoitcnufstceleS.edomENILFFOniedam

dnagnisserP.ylnoedomENILFFOniskroW

.htgnelteserpehtotdeefmrofasesuacgnisaeler

.repapsecnavdayllaunamgnidlohdnagnisserP

.sseccaunemretfas'unembusnoitcnufstceleS

ybedomENILFFOniunemnoitcnufstceleS

ottsrifmorfsignillorcS.tsilehthguorhtgnillorcs

yalpsidlitnugnidlohdnagnisserP.ylnotsal

Table 4-1. Control panel button functions

Table 4-1 shows the control panel button functions. The up and

down arrows access function sub-menu settings after the menu is

accessed using the menu button.

4

4-3V8.5e Rev 2.2.2002

Page 31

4-4 V8.5e Rev 2.2.2002

4

Table 4-2.Control panel settings and organization

tseTPt

tolP

sserP

PU

/WORRA

MROF

DEEF

sseccaot

etavitcA(

ybtsettolP

gnisserp

UNEM

)nottub

Pt

tluafeD

eulaV

evitcanI1C1PL0S3P2f1b1t

tsartnoC deepS aideM gnilacS

8C

7C

6C

5C

4C

3C

2C

4

3

2

FH

FL

PH

OPERATION

lacitreV

noitalumE

ES

DS

CS

bS

AS

9S

8S

7S

6S

5S

4S

3S

2S

1S

0n

3n

0P

htgneLFF

FP

Ft

8f

4f

repsetyB

nacs

4g

3g

2g

1g

2b2t

elacsyerG

aidem

elbat

Page 32

OPERATION

4.3 CONTROL PANEL FUNCTIONS AND SETTINGS

See Table 4-2 for default settings and organization.

Changing function settings

For easy reference in this section, the buttons are referred to as

numbers 1, 2, and 3, from top to bottom. (See Table 4-1 f or button

labels and functions.)

1. Press Button 1 to turn the plotter offline. Settings can only be

changed while the plotter is offline . The gr een ONLINE status light

turns off and the display will show: —— indicating offline status.

2. Press Button 3 to scroll through the menus.

3. For each menu item, press Button 1 or 2 (up or down arrows)

until the desired setting (or sub menu item) is shown in the display

for that menu.

4

4. Save the setting by pressing and holding Button 3

(MENU/SAVE) Display shows:

NOTE: Press and hold the MENU/SAVE button immediately after the

desired function setting is displayed. Advancing through the menu

without doing so will not save your changes.

5. The display will then show the offline displa y: ——. Repeat steps

2 through 4 for each function setting.

6. Press button 1 to return to ONLINE mode. Display will be blank

and online LED will be illuminated.

4-5V8.5e Rev 2.2.2002

Page 33

4

OPERATION

Default Settings

To restore the default settings of the plotter, press and hold the

menu button (button 3) while powering the plotter on. The display

will briefly show “dF” during the boot up sequence , indicating that

the default menu items have been loaded.

Test plot

This function produces approximately six inches of plot in a

checkerboard and dither pattern in Bimodal mode. Generating a

test plot while the plotter is set to grayscale mode will result in a

grayscale plot corresponding to the number of gray levels selected

at the time. This enables the user t o verify that the plotter is creating

a plot image, feeding the paper correctly, and that contrast levels

and media settings are acceptable . The test plot will use the current

menu settings to generate the image.

1. Press Button 1 to put the plotter into OFFLINE mode.

2. Press Button 3 once. “tP” is displayed.

3. Press and hold Button 3 until the display flashes:

The test plot will be generated.

Contrast

The contrast function adjusts the density of the output. Settings

range from C 1 to C 8. Settings are relative values: C 1 is the lightest,

C 4 is normal, C 8 the darkest.

After performing a test plot or plot job, determine if the contrast is

acceptable. If the output is extremely dark, very faint, or irregular,

first check that the media setting is correct (see “Media” section of

this chapter).

4-6 V8.5e Rev 2.2.2002

Page 34

OPERATION

If the contrast needs further adjusting, change the contrast setting

by starting at the lowest value, adjust the contrast upwards one

value at a time, testing after each adjustment. This is particularly

important when using lightweight papers or papers with unknown

specifications.

CAUTION: Thermal plotting technology involves high temperatures.

Incorrect media or contrast settings can damage the printhead or

other components and void the warranty. Media damage can also

occur.

VORSICHT: Bei der thermischen Plottertechnologie entstehen hohe

Temperaturen. Ungeeignete Medien oder falsche

Kontrasteinstellungen können den Druckkopf oder andere Bauteile

beschädigen und zu Verlust der Garantie führen. Auch können

Beschädigungen an den Medien entstehen.

Speed

4

The speed function adjusts the speed of the plot output. There are

four output plot speed settings in the V8.5e: 1.0, 2.0, 3.0, and 4.0

inches per second. The default setting is 1.0 inch per second which

produces the highest quality output.

If the plot speed is erratic, or if output quality is unacceptable,

lowering the plot speed will result in an impr ov ed plot quality . Such

problems may arise when data enters the plotter at a slower rate

than the plot speed setting. Lowering the output plotting speed

enables the plotter to match a lower input data rate and produces a

smoother output plot.

When the media setting is film (LF or HF), the plotter speed defaults

to 1 inch per second. When Grayscale mode is enabled, plot speed

is dependent upon the level of grayscale selected.

4-7V8.5e Rev 2.2.2002

Page 35

4

OPERATION

Media

The media function adjusts the time that the printhead is turned on

(strobe time) to create an image on the media based upon the media

type selected. The default setting is light paper. When the plotter

is set to film or grayscale mode the printhead’s requirement for

strobe times is raised. This requires a slower plot speed in order to

maintain the high quality level of the V8.5e.

Note: there are two preprogrammed media tables for grayscale

plotting. These calibration tables can be changed for different medias

by uploading new tables which can be provided by The Imaging

Systems Group Inc. for virtually any approved thermal media. These

tables are custom tuned to provide maximum grayscale performance

on a selected media. These tables can be uploaded to the V8.5e,

where they are stored in non-volitile memory until overwritten.

Tables are uploaded two at a time overwriting the factory default

tables stored in T1 and T2.

CAUTION: Thermal plotting technology involves high temperatures.

Incorrect media or contrast settings can damage the printhead or

other components and void the warranty. Media damage can also

occur.

VORSICHT: Bei der thermischen Plottertechnologie entstehen hohe

Temperaturen. Ungeeignete Medien oder falsche

Kontrasteinstellungen können den Druckkopf oder andere Bauteile

beschädigen und zu Verlust der Garantie führen. Auch können

Beschädigungen an den Medien entstehen.

4-8 V8.5e Rev 2.2.2002

Page 36

OPERATION

Scaling

The scaling function stretches or shrinks the plot over a 36-inch

length of plot with settings being S0 through SE. The default

setting is (S2). To determine if scaling is needed, plot a job of a

known length and measure it. Adjustments can be made to the

scaling in increments of + or - 1/16-inch over 36 inches of plot. S0

= no scale,

SE = +/- 14/16” over 36 inches of plot.

Note: Positive or negative scaling is selected through the Emulation

menu setting.

4

4-9V8.5e Rev 2.2.2002

Page 37

4

OPERATION

Emulation (vertical resolution)

The emulation function adjusts the vertical resolution of the plot

(along the media length). The settings are P0, n0, P3, and n3. P0

and n0 are used with 200 scans/inch of plot data. The default

setting (P3) is 203 scans per inch (equal to 203 dots per inch- dpi).

P3 and n3 are used for 203 scans/inch of plot data. P and n stand

for Positiv e and negative scaling for the scaling menu. If n is selected,

the scaling factors are from no scale to -14/16” over 36” of output

plot. If P is selected, the scaling factors are from no scale to +14/

16” over 36” of plot.

Note that the horizontal resolution is determined by the printhead

dot density, which is 203 dpi. The plotter can emulate 200 dpi

vertical resolution (E0 and n0 settings), to match the rastered host

data (for Imperial units).

Form feed length

The form feed length function adjusts the distance that the media is

advanced in off-line mode and when a remote function is sent. To

form feed media, put the plotter in offline mode and press the

FORMFEED/ADVANCE button without holding.

Menu settings are: F2, F4, F8, tF,PF.

F2, F4, F8 cause 2”, 4”, or 8” of media to be advanced upon a

formfeed. If a T OF mark is detected before the formfeed is completed

the plotter will stop upon detecting the mark, or to what the PF

setting is.

tF results in the plotter advancing up to 18” while detecting for the

Top of Form mark on fan fold media. The top-of-form setting (tF)

allows the plotter to detect top-of-form marks. These marks signal

the plotter to stop the form feed at a consistent distance from the

perforated edge of the paper.

4-10 V8.5e Rev 2.2.2002

Page 38

OPERATION

PF - Programmable adv ance past Top of Form- This feature allows

the V8.5e to line up with the beginning of pages when a media

whose TOF marks do not meet the V8.5e specifications.

NOTE: iSys recommends only the use of approved media in the V8.5e

which has been qualified to increase plotter life and produce higher

quality plots.

Once the PF feature is selected in the menu, the V8.5e will detect

the media TOF mark and continue to advance the media by the

amount programmed when a formfeed or end of transmission is

commanded.

This feature is enabled by setting the formfeed menu to “PF”

The advance range is from 01 hex --- 10 scans (approx 0.05”)

to

ff hex --- 2550 scans (approx 12.5”)

in increments of 10 scans for each hex number.

4

Once the menu has been set to “PF”, the amount of advance past

TOF which has been programmed into the V8.5e will be used until

it is changed. The default value is 23 Hex.

To program the amount of advance past TOF, send header:

98 XY 0A (where XY is the hex# of groups of 10 scans).

If the V8.5e accepts the setup string, the display will flash

4-11V8.5e Rev 2.2.2002

Page 39

4

OPERATION

Bytes per scan

The SCANWDTH function adjust s the scan width of the plot, defined

in bytes per line. The def ault scan width is b1 (2 16 bytes per scan).

Menu settings are: b1, b2, g1, g2, g3, and g4.

b1 — 2 16 bytes/scan (bimodal).

b2 — 264 bytes/scan (bimodal).

g1 — 8 gray levels per scan, 1728 bytes/scan maximum.

g2 — 16 gray levels per scan, 1728 bytes/scan maximum.

g3 — 32 gray levels per scan, 1728 bytes/scan maximum.

g4 — 64 gray levels per scan, 1728 bytes/scan maximum.

Unless you are using RLTER (remote line terminate) commands, the

plotter scan width must be set to the same byte count as the rastered

data from the host. Setting the scan width higher than the byte

count of the raster data does not create a wider plot. Setting the

scan width incorrectly results in skewed output as the data “wraps”

and finishes the scan on the next line . This condition is identifiable

on the plot in Figure 7-8.

The V8.5e contains a new method of plotting raster data. Each

scan of data plotted can contain as many as 64 independent

intensity levels (gray scales). The thermal print head (TPH) in the

V8.5e is made up of 1728 thermal heater nibs, and each one of

these nibs can be heated to a different energy level, producing a

dot on the thermal media of varying intensity. This type of plotting can produce high-resolution images containing many shades

of gray.

Change the scan width settings by pressing the up or down arrows

in the bytes/scan sub-menu.

Press and hold Button 3 until the display flashes:

4-12 V8.5e Rev 2.2.2002

Page 40

OPERATION

Grayscale media table number

t1 - media calibration table for media 1.

t2 - media calibration table for media 2.

These tables have preset values for imaging on two different medias

while in grayscale mode . These medias can be changed for different

medias by uploading new tables.

Setup headers for programming the V8.5e

NOTE: The V8.5E must be in PRINT mode for the setup

header string to work. Numeric values shown below

are hexadecimal, not ASCII.

NOTE: All menu functions can be remotely configured by

sending a setup header string from the host to the

V8.5E through the interface. The programmable

advance past TOF can be programmed in a similar

fashion.

4

NOTE: Sending a 00 hex in any of the setup string positions

listed below allows the menu item to remain

unchanged.

The format is as follows:

Byte 1: escape code =99

Byte 2: contrast C1=11 Lightest

C2=12

C3=13

C4=14

C5=15

C6=16

C7=17

C8=18 Darkest

No Change=00

4-13V8.5e Rev 2.2.2002

Page 41

4

OPERATION

Byte 3: speed 1”=21 1.0 inches/sec

2”=22 2.0 inches/sec

3”=23 3.0 inches/sec

4”=24 4.0 inches/sec

No Change=00

Byte 4: media LP=31 Light Paper

HP=32 Heavy Paper

LF=33 Light Film

HF=34 Heavy Film

No Change=00

Byte 5: scaling S0=41 No Scale

S1=42

S2=43

S3=44

S4=45

S5=46

S6=47 +/- 1/16”

S7=48 increments over 36” of

S8=49 plot up to +/- 14/16”

S9=4A

SA=4B

Sb=4C

SC=4D

Sd=4E

SE=4F

No Change=00

4-14 V8.5e Rev 2.2.2002

Page 42

OPERATION

Byte 6: emulation P0=51 200 scans/inch vertical

scaling

scaling

scaling

scaling

Byte 7: formfeed F2=61

4

with positive

n0=52 200 scans/inch vertical

with negative

P3=53 203 scans/inch vertical

with positive

n3=54 203 scans/inch vertical

with negative

No Change=00

F4=62

F8=63

tF=64 Stops on TOF Mark

PF=65 Programmable

advance past TOF

mark

No Change=00

Byte 8: bytes/scan b1=71 (216 bytes/scan)

b2=72 (264 bytes/scan)

g1=73 8 level grayscale

g2=74 16 level grayscale

g3=75 32 level grayscale

g4=76 64 level grayscale

No Change=00

Byte 9: grayscale t1=81 (media type 1)

media table t2=82 (media type 2)

No Change=00

4-15V8.5e Rev 2.2.2002

Page 43

4

OPERATION

Byte 10: line feed 0A

Example: To set the plotter to: contrast=C3

speed=1.0 ips

media=LP

scaling=S2

emulation=P3

formfeed=F2

bytes/scan=b1

grayscale media table=t1

Then send header: 99 13 21 31 43 53 61 71 81 0A

If the V8.5E accepts the setup string, the display will flash

If there are any errors in the string, such as an out of range value on

one of the numbers, or any other errors in the string format, the

plotter will not accept the string, no reconfiguration will tak e place ,

and the error LED will flash twice.

4.4 ERROR MESSAGES

1. Media Out Error: The plotter will display a small square, flashing

segments and the error LED will flash. To fix this error, reload media

into the potter. Plotter must be put back online to continue plotting.

2. Hot Head Error: The plotter will display Ht and the error LED will

flash. The plotter will display this error until the thermal printhead

cools to a temperature that is safe to plot again.

3. 24 Volts Error: The plotter will display 24 and the error LED will

flash. If this error occurs, the 24 volt power supply may be faulty. Please

contact your product representative.

4. Thermistor Error: The plotter will display tH and the error LED will

flash. If the error occurs, the thermal printhead may be faulty. Please

contact your product representative.

4-16 V8.5e Rev 2.2.2002

Page 44

OPERATION

4.4 FEHLERMELDUNGEN

1. Medien leer: Am Plotter erscheint eine kleine quadratische

blinkende Anzeige und die Fehleranzeige blinkt. Zur Behebung dieses

Fehler muss neues Aufzeichnungsmaterial geladen werden. Der

Plotter muss erneut online geschaltet werden, um den PlottingVorgang fortzuführen.

2. Druckkopfüberhitzung: Am Plotter erscheint Ht und die

Fehleranzeige blinkt. Die Anzeige bleibt solange bestehen, bis der

Druckkopf auf eine Temperatur abgekühlt ist, bei der wieder gefahrlos

geplottet werden kann.

3. 24 Volt Fehler: Am Plotter erscheint 24 und die Fehleranzeige

blinkt. Wenn dieser Fehler auftritt ist möglicherweise die 24-VSpannungsversorgung defekt. In diesem Fall nehmen Sie mit ihrem

zuständigen Vertragspartner Kontakt auf.

4. Thermistor Fehler: Am Plotter erscheint tH und die Fehleranzeige

blinkt. In diesem Fall ist möglicherweise der thermische Druckkopf

defekt. Nehmen Sie bitte mit ihrem zuständigen Vertragspartner

Kontakt auf.

4

4-17V8.5e Rev 2.2.2002

Page 45

THEORY OF OPERATION

5.1 INTRODUCTION

The V8.5e plotter uses thermal technology to convert data from the

host computer into plotted output. Host data enters the plotter main

logic circuitry via the data port, and passes through the interface to

the data buffer on the main logic board. Control and status signals

enter the main logic board at the same time as the parallel data. The

microcontroller converts the data from parallel to serial and sends

the serial data to the printhead. One horizontal line or scan, consisting

of a single row of dots, is plotted. The stepper motor advances the

paper for the next scan. This cycle repeats until the plotted or printed

image is finished.

5.2 PLOTTER FUNCTIONS AND FEATURES

Power supplies

5

The logic circuitry and printhead of the plotter are powered by a 5

Volt DC output power supply. The thermal printhead and stepper

motor are powered by a 24 Volt, 10 Amp DC power supply. Both

power supplies feature an auto-switchable input, which adapts to

different voltage or frequency inputs.

5 - 1V8.5e Rev 2.2.2002

Page 46

5 - 2 V8.5e Rev 2.2.2002

8-bit Parallel Data

Data Input

Interface

Data

Buffer

Non-

volitile

RAM

24 V C

Power

Supply

Motor

5

THEORY OF OPERATION

Input

REM

REM

REM

REM

REM

MODE

Decoder

Character generator

ROM (print mode)

Figure 5-1. Functional block diagram

5 V DC

Power

Supply

Micro controller

T emperature Feedback

Thermal

Printhead

Parallel

to serial

Sensor Pod

Page 47

THEORY OF OPERATION

Stepper motor

The V8.5e uses a bipolar, two-phase stepper motor. The motor is

micro-step driven, requiring 200 full steps for one rotation of the

motor shaft. There are 32 micro-steps per full step. Thus the motor

makes 6400 micro-steps for each rotation.

5.3 INTERFACE

The data interface may be short line or, optionally, long line (see

“Interface setup” in Chapter 3, Installation for details.) The plotter

is compatible with either the Versatec Greensheet or (optionally)

the Centronics interface (see Appendix A). Table 5-1 shows the active

level for the plotter status signals.

5

langiS

cinomenM

NILNOenilnOwoL

PAPONrepapoNhgiH

langiS

emaN

evitcA

leveL

noitarepO

rettolpehtsetacidnilevelwoL

enilnodnanoderewopsi

nirepaponsierehtsetacidI

tonsidilehtro,rettolpeht

.dehctaldnadesolcylreporp

Table 5-1 Status Signals

Interface timing and signals

The ready signal indicates the plotter’s readiness to accept data.

When READY is low, the plotter can accept one byte of data. This

byte must be accompanied by a PICLK (data str obe) pulse .

T able 5-2 sho ws the timing relationship f or maximum data transfer .

5 -3V8.5e Rev 2.2.2002

Page 48

5

THEORY OF OPERATION

langiS

-nommehN

ci

-1DNI

8DNI

KLCIP

YDAERydaerrettolPwoL

kcolc

langiS

emaN

atadtupnIhgiH

tupnilellaraP

evitcA

leveL

KLCIPayb

hgiH

eslupSn003

noitarepO

lellarapetybrofseniltupnI

deinapmoccaebtsuMatad

tneserpetybatadasebotS

ehtotni8DNI-1DNIno

muminiM.refffubtupni

sirettolpsnaemlevelwoL

atadtxeneviecerotydaer

.noitcnufetomerroetyb

rettolpsetacidnilevelhgiH

tpeccatonlliwdnaysubsi

.snoitcnufetomerroatad

Table 5-2 Data Transfer

Note that the plotter goes busy after receiving each byte . The plotter

goes busy for longer periods during the execution of remote

functions, when the input buffer is full, or when an error occurs.

Table 5-3 shows the timing relationships for the remote functions.

When the input buffer receives the number of bytes necessary to

plot a full scan, a write cycle is automatically initiated, causing the

buffer contents to be imaged on the medium.

5 - 4 V8.5e Rev 2.2.2002

Page 49

THEORY OF OPERATION

5

langiS

cinomenM

RAELCraelcetomeRwoL.reffubtupniehtsraelC

TESERteseRetomeRwoL

RETLR

emaNlangiS

eniletomeR

etanimret

langiS

leveL

woL

noitarepO

sezilaitini-erdnarettolpehtsteseR

.detressasilangisehtelihwcigollla

siteserelihwhgihsniamerydaeR

.detressa

yltnerrucatadreffubehtsetanimreT

ylsuoiverpllasesuac,dedaolgnieb

,ecneuqesnituptuoebotataddedaol

tsujatadreffubehtstuptuoneht

sihT.ecneuqesnidetanimret

deviecerfiderongisidnammoc

sahnacsllufaretfayeltaidemmi

.detanimretyllacitamotuaneeb

DEFFR

RTOER

Table 5-3. Remote function signals

deef

fo

mrofetomeR

dneetomeR

noissimsnart

woL

woL

yltnerrucatadreffubehtsetanimreT

ylsuoiverpllasesuac,dedaolgnieb

nituptuoebotatadreffubdedaol

reffubehtstuptuoneht,ecneuqes

.ecneuqesnidetanimrettsujatad

.decnavdanehtsirepaP

5 -5V8.5e Rev 2.2.2002

Page 50

5

THEORY OF OPERATION

Data rates

The plotter accommodates a wide range of data rates. The speed of

the plotter can be set to 1.0, 2.0, 3.0, 4.0 inches per second. To

achieve a consistent plot rate at a certain speed setting requires

minimum data rates. If data rates are inconsistent, and lower than

these minimum rates, that plot speed will not be sustained. Table

5-4 shows the minimum data rates at the four speed settings.

tolpfodeepS etaratadmuminiM

dnocesrephcni0.1ces/BK44

dnocesrepsehcni0.2ces/BK88

dnocesrepsehcni0.3ces/BK231

dnocesrepsehcni0.4ces/BK671

Table 5-4. Minimum data rates

As with all thermal plotters, slower speeds produce the highest

quality output. Plotting at a speed too high for the data may result

in the deterioration of fine details. Stops and starts caused by

inconsistent data rates may also result in a lower quality output.

5 - 6 V8.5e Rev 2.2.2002

Page 51

THEORY OF OPERATION

Scan width

Scan width settings sent from host software can specify the number

of bytes of dat a that will be plotted on a line . The maximum setting

that data can be rastered to is 264 bytes per scan.

NOTE: The thermal head holds a maximum of 216 bytes of data. When

the plotter is set to 264 bytes per scan, the first 216 bytes of data from

the host are loaded into the thermal head to be plotted and the last 48

are discarded.

For rastered data less than the current byte count setting on the

plotter, the scan may be terminated at any byte count by a RLTER

command. If a RLTER command is asserted, the scan is terminated

and the plot continues on the next line .

Vertical resolution

The vertical resolution of the plot can be changed from the default

value of 203 dpi (n3or P3) to 200 dpi (n0 or P0, also known as

Imperial unit setting). See “Emulation”, in Chapter 4, Operation, for

information on control panel settings.

5

The plotter emulates the 200 dpi resolution by stretching the plot

length. This is accomplished by inserting micro-steps at regular

intervals, so that 200 scans cover one inch of plot.

Scaling

The scaling function either stretches or shrinks the plot by removing

or adding a micro-step at a set interval. A djustments can be made to

the scaling in increments of +/- 1/16” over 36” of plot length. The

interval is determined by the scaling setting on the control panel.

See “Scaling” in Operation, Chapter 4, P age 4-9, f or information on

control panel settings.

5 -7V8.5e Rev 2.2.2002

Page 52

5

THEORY OF OPERATION

Print mode

When the host asserts the PRINT mode signal, the plotter can

generate ASCII characters . T able 5-5 show s the timing relationships

for print mode signals.

langiS

cinomenM

TNIRPedoMtnirPhgiH

PPS

emaNlangiS

suoenatlumiS

edomtolp/tnirp

evitcA

leveL

woLdesutoN

noitarepO

tolprotnirprehtiestceleS

,hgihsilangisnehW.edom

.edomtnirpnisirettolp

Table 5-5. Mode signals

ASCII characters are produced as plot patterns on a 16 x 20 dot

matrix through the use of a Character Generator ROM. When one

complete print line of ASCII-coded data is received, the data is

converted into plot patterns. Each character line is executed over

20 plot scans.

5 - 8 V8.5e Rev 2.2.2002

Page 53

THEORY OF OPERATION

5.4 THERMAL PRINTHEAD

The thermal printhead is comprised of a row of 1728 heater elements

(nibs). Each bit within a scan addresses an individual nib. Plot patterns

are generated one scan at a time , each scan consisting of a horizontal

row of dots. A nib produces a dot if the corresponding scan bit in

the buffer is a logic level “1”. Nibs in the printhead are heated, causing

a thermo-chemical reaction with the coating on the media. The

intensity or period for which the nib is heated is called the burn

strobe.

Automatic Head Temperature Feedback

The thermal printhead rises in temperature as it plots images on

paper, thus, less energy is required to activate each nib as the plot

proceeds to create an image of the same intensity. A thermistor

embedded in the head measures the head temperature and provides

feedback information to the main logic board. The main logic board

decreases the burn strobe accordingly to keep the contrast of the

plotted image consistent as the plot proceeds.

5

If the printhead temperature reaches 60º C, the Automatic Head

Temperature Feedback circuit stops the plotter in order to let the

head cool down. The control panel display reads hot (Ht) and the

error light flashes. When the thermistor measures that the printhead

temperature has cooled to 45º C, the plot resumes with no loss of

data.

5 -9V8.5e Rev 2.2.2002

Page 54

5

THEORY OF OPERATION

Film media

When the plotter is set to film mode, the strobe length is increased

to accommodate the thicker media. The plot speed is set to

1.0 inch per second to allow the longer strobe length and to maintain

plot quality .

5.5 MEDIA SENSORS

The top-of-form (also known as the “I-mark”) sensor and the media

sensor are contained on a media sensor board .

The top-of-form sensor consists of a focused infrared beam and

receptor that reacts to black top-of-form marks. The receptor sends

a “stop form feed” command to the logic circuitry if a mark stops

the beam from reflecting back into the receptor.

The paper sensor consists of an unfocused infrared beam and

receptor . If the r eceptor receives enough r eflected light, the receptor

sends no command. If the reflected light is below the required level

the receptor sends a “media out” command to the logic circuitry

and plotting stops. The “no media” indicator is displayed on the

control panel.

5 - 10 V8.5e Rev 2.2.2002

Page 55

MAINTENANCE

NOTE: Do not attempt to repair or modify any component of the

V8.5e. If a component fails, it may be replaced free of charge in accordance with the warranty procedures in this manual. Attempting unauthorized repairs or modifications will void the warranty and invalidate

safety approvals.

WICHTIGER HINWEIS: Versuchen Sie nicht, irgendwelche Bauteile

des V8.5e zu reparieren oder zu modifizieren. Falls ein Bauteil versagt,

kann es gemäß den in diesem Handbuch enthaltenen

Garantiebedingungen kostenfrei ersetzt werden. Bei nicht

genehmigten Reparaturen oder Modifizierungen erlischt der

Garantieanspruch und Sicherheitszertifikate werden ungültig.

WARNING: There are voltage hazards inherent in the printhead power

supply and AC input wiring. Take reasonable precautions to avoid

electrical shock. Never service any electrical component of the V8.5e

while the power cord is connected. Severe electrical shock may result.

WARNUNG: Am Druckkopf und am Wechselstromanschluss bestehen

gefährliche Spannungen. Lassen Sie angemessene Vorsicht walten, um

Stromschläge zu vermeiden. Ziehen Sie den Netzstecker, bevor Sie an

irgendwelchen elektrischen Bauteilen des V8.5e arbeiten. Andernfalls

kann es zu erheblichen Stromschlägen kommen.

6

CAUTION: Take care not to discharge static into the plotter. This may

cause damage to integrated circuits or other electronic components.

Dissipate static by wearing a static disipating wrist strap, before using

tools on the plotter or touching internal components.

VORSICHT: Vermeiden Sie statische Entladung am Plotter. Dies kann

Schäden an den integrierten Schaltkreisen und anderen elektronischen

Bauteilen verursachen. Leiten Sie statische Elektrizität ab, indem Sie

ein Antistatik-Armband anlegen, bevor Sie am Plotter mit Werkzeugen

hantieren oder interne Bauteile berühren.

6-1V8.5e Rev 2.2.2002

Page 56

6

MAINTENANCE

This symbol indicates an area of possible concern due

to static discharge into the circuitry. When you see this

symbol in the manual, please observe proper static precautions to minimize damage to the circuitry.

Dieses Symbol warnt davor, dass es in diesen Bereichen möglicherweise

zu statischen Entladungen an den Schaltkreisen kommen kann. Wenn

dieses Symbol im Handbuch erscheint, sind die entsprechenden

Vorsichtsmaßnahmen zu treffen, um eine Beschädigung der

Schaltkreise so weit wie möglich zu vermeiden.

6.1 MAINTENANCE GUIDELINES

In order to minimize the complexity of troubleshooting and repairs,

the V8.5e plotter is composed, wherever possible, of fieldreplaceable units (FR Us). The Imaging Systems Group Inc . does not

recommend troubleshooting at a component level, but rather to the

level of these FRUs. This chapter and the troubleshooting chapter

of this manual follows this approach, resulting in faster and easier

repairs. R eplacing or repairing FR Us, rather than smaller components,

minimizes downtime and simplifies procedures.

Use caution while troubleshooting the V8.5e. Turn the power off and

unplug the power cord to prevent electrical shock.

Seien Sie bei der Fehlerbehebung am V8.5e vorsichtig. Schalten Sie

den Strom ab und ziehen Sie den Netzstecker, um Stromschläge zu

vermeiden.

6 -2 V8.5e Rev 2.2.2002

Page 57

MAINTENANCE

6.2 REGULAR MAINTENANCE

The V8.5e thermal plotter is engineered to require minimal

prevent ative maintenance. If the thermal printhead and platen r oller

are cleaned regularly, and the plotter is kept free of debris, extra

maintenance should rarely be required.

This minimal preventative maintenance is the customers

responsibility . Damage to the plotter that has in The Imaging Sy stem

Group’s opinion resulted from neglect or misuse will not be covered

under warranty.

CAUTION: No parts of the V8.5e require lubrication. All bearings are

sealed and self-lubricating. These bearings must be replaced in pairs if

one fails by authorized repair depot.

VORSICHT: Kein Teil des V8.5e erfordert Schmierung. Alle Kugellager

sind geschlossen und selbstschmierend. Diese Lager dürfen nur

paarweise durch eine autorisierte Servicewerkstatt ausgetauscht

werden, falls eines defekt wird.

6

6 - 3V8.5e Rev 2.2.2002

Page 58

6

MAINTENANCE

Cleaning the thermal printhead

After prolonged use, the thermal printhead pick s up fibres fr om the

media passing under it. These fine fibres collect and compact on

portions of the printhead, blocking the contact it makes with the

paper during a plot and causing faded patches. P oor contact between

the printhead and paper may also cause the affected heating

elements (nibs) to fail prematurely because of improper heat

dissipation to the paper.

Clean the printhead every time you install a new roll of paper or

film.

1. Turn the plotter power off.

Figure 6-1

Print Head

6 -4 V8.5e Rev 2.2.2002

Page 59

MAINTENANCE

2. Moisten (do not soak) a soft, lint-free cloth or cotton swab with

99% pure isopropyl alcohol. Rub gently along the length of the

printhead, removing any buildup of residue on the printhead.

3. Allow the alcohol to ev aporate completely before using the plotter .

CAUTION: Do not touch the printhead with your fingers or other objects. Skin oil will contaminate the printhead, which diminishes plot

quality and shortens the life span of the printhead.

VORSICHT: Den Druckkopf nicht mit den Fingern oder irgendwelchen

Gegenständen berühren. Fett oder Öl verschmutzt den Druckkopf,

wodurch die Druckqualität vermindert und die Lebensdauer des

Druckkopfes verkürzt wird.

Cleaning the platen roller

After prolonged use , the platen roller picks up fibres fr om the paper

passing above it. These fine fibres collect and compact on portions

of the platen roller , creating bumps . The uneven surface o f the roller

may cause the printhead to contact the passing paper unevenly,

producing a blotchy or faded plot.

6

Clean the platen roller when it appears dirty , or after appr oximately

three rolls of paper or film have been plotted.

Lightly wipe the roller with a soft, lint-free cloth moistened in 99%

pure isopropyl alcohol, turning the roller as necessary to remove

paper fragments and dust.

6 - 5V8.5e Rev 2.2.2002

Page 60

6

MAINTENANCE

Replacing the fuse

The fuse is located in a clip next to the AC receptacle. Figure 3-2.

1. Unplug the power cable from the AC receptacle.

2. Insert a small screwdriver into the slot on the fuse clip to release

it from the A C r eceptacle.

3. Remo ve the fuse from the clip. R eplace the fuse and insert the clip.

WARNING: Replace only with a fuse of identical specifications. Other

fuses may cause a fire hazard. See Chapter 2, Specifications, for fuse

specifications.

WARNUNG: Beim Auswechseln der Sicherungen nur solche mit

gleicher Spezifikation verwenden. Andere Sicherungen können Brände

verursachen. Siehe Kapitel 2, Spezifikationen, hinsichtlich der

Spezifikation der Sicherungen.

WARNING: Consistent damage to the plotter AC fuse indicates a serious problem and should be repaired immediately. Contact your authorized service center.

WARNUNG: Andauernder Ausfall der Wechselstromsicherung des Plotters verweist auf ein ernstes Problem, das sofort behoben werden sollte.

Nehmen Sie Kontakt mit ihrer autorisierten Servicewerkstatt auf.

6 -6 V8.5e Rev 2.2.2002

Page 61

TROUBLESHOOTING

7.1 INTRODUCTION

This chapter provides a list of problems that may be encountered

with the V8.5e, and gives possible causes and solutions for these

problems.

T o use this chapter , locate the problem fr om the list. Follo w the steps

in order, referring to Chapter 6, Maintenance, where necessary.

7

7-1V8.5e Rev 2.2.2002

Page 62

7

TROUBLESHOOTING

7.2 PROBLEMS

Plotter does not plot

Possible causes: Plotter has no paper or film

Lid is not securely closed

Thermal printhead is overheated

Latch pins need adjustment

Solutions:

1. Check the media supply. Install more media if necessary as

described in Chapter 3, Installation.

2. Check that the media is installed correctly and the plotter lid is

securely closed. The top of the lid should be flush with the top of

the side panels.

3. If plotting has stopped in mid-task, the printhead may be

overheated.

Do not intervene . The plotter will resume plotting from wher e it left

off with no loss of dat a when the printhead has cooled sufficiently.

When the printhead temperature reaches 60ºC, the plotter stops

and asserts a “busy” signal to the host. Plotting resumes when the

head temperature has cooled to 45ºC. This prevents printhead

damage caused by overheating.

4. If the lid does not close securely, or if the head pressure is too

low, contact your authorized service center.

7-2 V8.5e Rev 2.2.2002

Page 63

TROUBLESHOOTING

Plot has vertical white stripes

Figure 7-3 . Plot with vertical white stripes

Possible causes: Lid is not securely closed

The printhead is dirty

Some printhead nibs are burnt out

7

Solutions:

1. Check that the media is installed correctly and the plotter lid is

securely closed. The top of the lid should be flush with the top of

the side panels.

2. Clean the printhead as described in Chapter 6, page 6-3.

3. The thermal printhead has one or more burnt out nibs so it must

be replaced. Contact your authorized service center.

7-3V8.5e Rev 2.2.2002

Page 64

7

TROUBLESHOOTING

Plot is blotchy or faded

Figure 7-4 . Blotchy or faded plot

This problem originates from inconsistent printhead pressure across

the platen roller during plotting.

Possible causes: Lid is not securely closed

Latch pins need adjustment

Solutions:

1. Check that the media is installed correctly and the plotter lid is

securely closed. The top of the lid should be flush with the top of

the side panels.

2. If the plot is fading on one side, test by pressing down on that

side of the lid while the plotter is plotting. If this helps, the latch pin

needs to be adjusted on that side. Cont act y our authorized service

center.

7-4 V8.5e Rev 2.2.2002

Page 65

TROUBLESHOOTING

Plot contrast is weak

Possible causes: Lid is not securely closed

Latch pins need adjustment

Media setting is incorrect

Contrast setting is too low

24 V power supply is malfunctioning

Solutions:

1. Check that the media is installed correctly and the plotter lid is

securely closed. The top of the lid should be flush with the top of

the side panels.

2. If the lid does not close securely, or if the head pressure is too

low, contact your authorized service center.

3. Check that the media setting is correct. See Chapter 4, page 4-8.

7

4. Adjust the contrast setting as described in Chapter 4, page 4-6.

7-5V8.5e Rev 2.2.2002

Page 66

7

TROUBLESHOOTING

Plot has black vertical lines

Figure 7-6 . Plot with black vertical lines

Possible Cause: One or more bits in each byte going to the

plotter are “stuck high”.

Solution:

1. If your plotted output from the host shows these lines, run a test

plot. If the lines are not present on the test plot, the problem

originates with the host data. Check the interface data cable from

the host and replace it if neccesary.

7-6 V8.5e Rev 2.2.2002

Page 67

TROUBLESHOOTING

Plot is wrong length

If you suspect that a plot is the wrong length, plot a job of a known

length and measure it.

Possible causes: Paper is not moving freely

Scaling is incorrectly applied

V ertical emulation is incorr ectly applied

Solutions:

1. Check the media feed path. Ensure that the paper is installed

correctly and that the paper feed is not obstructed.

2. Adjust or reset the scaling setting as described in Chapter 4,

Operation.

3. Determine if your data requires vertical emulation and adjust the

vertical resolution setting appropriately. See “Emulation” in

Chapter 4, Page 4-10.

7

Paper is wrinkling or tearing along one edge

Possible causes: Paper feed is misaligned

P aper is incorrectly inst alled

Lid is not securely closed

Latch pins need adjustment

Solutions:

1. Ensure that paper is correctly aligned while feeding. If using fanfold paper, you may wish to leave the paper in the box.

2. Check that the paper is installed correctly (see “Media Installation”

in Chapter 3, Installation) and the plotter lid is securely closed. The

top of the lid should be flush with the top of the side panels.

7-7V8.5e Rev 2.2.2002

Page 68

7

TROUBLESHOOTING

3. If the lid does not close securely, or if the head pressure is too

low, contact your authorized service center.

Plotter has no power

Possible Cause: If the plotter is plugged in to a functioning

outlet, then the A C fuse has blo wn.

Solution:

1. Replace the fuse as described in Chapter 6.

Plotter display is functioning but motor does not function

Possible Cause: Either the 5 V or 24 V power supply is

malfunctioning.

Solution:

1. Contact your authorized service center.

Can’t make changes to control panel settings

Possible Cause: Plotter is in ONLINE mode.

Solution:

1. Press the ON/OFFLINE button.

7-8 V8.5e Rev 2.2.2002

Page 69

TROUBLESHOOTING

Plot output speed is erratic

Possible Cause: Plotter speed is set too high. This is most likely

to occur on the HIGH setting. Lowering the

plot speed enables the plotter to match the

rate of data and produces a more steady

output.

Solution:

1. Lower the plot speed setting on the control panel as described in

Chapter 4, Page 4-7.

7

7-9V8.5e Rev 2.2.2002

Page 70

7

TROUBLESHOOTING

Burning smell during plot, or “blooming” present on output

Figure 7-7 . “Blooming” plot

Possible Cause:Media setting is incorrect. The thermal

printhead operating temperature is too high

and is burning the media.

Solution:

1. Change the media setting on the control panel as described in

Chapter 4. If unsure of the media specifications, st art at the L T P APER

setting and then increase the setting, testing plot output after each

change.

CAUTION: Thermal plotting technology involves high temperatures.

Incorrect media or contrast settings can damage the printhead or other

components and void the warranty. Media damage can also occur.

7-10 V8.5e Rev 2.2.2002

Page 71

TROUBLESHOOTING

VORSICHT: Bei der thermischen Plottertechnologie entstehen hohe

Temperaturen. Ungeeignete Medien oder falsche

Kontrasteinstellungen können den Druckkopf oder andere Bauteile

beschädigen und zu Verlust der Garantie führen. Auch können

Beschädigungen an den Medien entstehen.

Form feed stops before desired length

Possible Cause: The form feed length is too short. The form

feed stops before the paper sensor can read

the “top of form” mark.

Solution:

1. Adjust the FFLENGTH setting on the control panel as described

in Chapter 4, Page 4-10.

Form feed does not stop at top-of-form marks

7

Possible Cause: The top-of-form sensor is not reading the

marks.

Solution:

1. Contact your authorized service center.

7-11V8.5e Rev 2.2.2002

Page 72

7

TROUBLESHOOTING

Plot is skewed or unreadable

Figure 7-8 . Skewed plot

Possible Cause: The scan width is incorrect.

Solution:

1. Adjust the scan width (b yte count) in y our host software

to 216 bytes or less.

7-12 V8.5e Rev 2.2.2002

Page 73

WARRANTY

The Imaging Systems Group Inc. (iSys) warrants our V8.5e plotters

to be free from defects in materials and workmanship as follows:

· Labour and parts are warranted for a period of one (1) year

from the date of purchase.

· This warranty applies only to products purchased from an

authorized dealer or agent, and extends only to the original

retailer purchaser.

· This warranty only covers defects arising under normal usage

within the duty cycles per specifications, and does not cover

malfunction or failures resulting fr om misuse, abuse or neglect.

· Consumable accessories are not included in this warranty.

· iSys will extend to customers during the warranty period a Hot

Swap Program to further expedite warranty repair.

8

Hot Swap warranty is one (1) year for the V8.5e Thermal Plotter.

During the warranty period, iSys will exchange the plotter within

24 Hours (North America ONLY) free of charge to the customer.

Included with the thermal plotter will be an RMA Kit, which will