Page 1

User Service Guide

HP Integrity Superdome/sx2000 and HP 9000

Superdome/sx2000 Servers

HP Part Number: A9834-9001D_ed6

Published: September 2009

Edition: 6

Page 2

Legal Notices

© Copyright 2009 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice.

The only warranties for HP products and services are set forth in the express warranty statements accompanying such products and services.

Nothing herein should be construed as constituting an additional warranty. HP shall not be liable for technical or editorial errors or omissions

contained herein.

Intel and Itanium are trademarks or registered trademarks of Intel Corporation or its subsidiaries in the United States and other countries.

Microsoft and Windows are U.S. registered trademarks of Microsoft Corporation.

UNIX is a registered trademark of The Open Group.

Page 3

Table of Contents

About This Document.......................................................................................................13

Intended Audience................................................................................................................................13

Document Organization.......................................................................................................................13

Typographic Conventions.....................................................................................................................13

Related Information..............................................................................................................................14

Publishing History................................................................................................................................14

HP Encourages Your Comments..........................................................................................................15

1 Overview.......................................................................................................................17

Server History and Specifications.........................................................................................................17

Server Components...............................................................................................................................18

Power Subsystem..................................................................................................................................19

AC Power.........................................................................................................................................20

DC Power.........................................................................................................................................20

Power Sequencing............................................................................................................................21

Enabling 48 Volts.............................................................................................................................21

Cooling System.....................................................................................................................................21

Utilities Subsystem................................................................................................................................22

Platform Management.....................................................................................................................22

UGUY..............................................................................................................................................23

CLU Functionality...........................................................................................................................23

PM3 Functionality...........................................................................................................................23

System Clocks..................................................................................................................................24

Management Processor....................................................................................................................24

Compact Flash.................................................................................................................................25

HUCB...............................................................................................................................................25

Backplane..............................................................................................................................................26

Crossbar Chip..................................................................................................................................26

Switch Fabrics..................................................................................................................................27

Backplane Monitor and Control......................................................................................................27

I2C Bus Distribution........................................................................................................................27

Clock Subsystem..............................................................................................................................27

System Clock Distribution.........................................................................................................27

Hot-Swap Oscillator...................................................................................................................28

sx2000 RCS Module....................................................................................................................28

Cabinet ID........................................................................................................................................29

Cell ID..............................................................................................................................................29

Backplane Power Requirements and Power Distribution...............................................................29

CPUs and Memories.............................................................................................................................30

Cell Controller.................................................................................................................................31

Processor Interface...........................................................................................................................31

Processors........................................................................................................................................32

Cell Memory System.......................................................................................................................32

Memory Controller ....................................................................................................................33

DIMM Architecture....................................................................................................................33

Memory Interconnect.................................................................................................................33

Mixing Different Sized DIMMs..................................................................................................34

Memory Interleaving.................................................................................................................34

Memory Bank Attribute Table..............................................................................................34

Cell Map................................................................................................................................35

Table of Contents 3

Page 4

Link Interleaving...................................................................................................................35

Memory Error Protection...........................................................................................................35

DRAM Erasure...........................................................................................................................36

PDC Functional Changes.................................................................................................................36

Platform Dependent Hardware.......................................................................................................36

Reset.................................................................................................................................................37

Cell OL*...........................................................................................................................................37

I/O Subsystem.......................................................................................................................................37

PCI-X Backplane Functionality........................................................................................................38

SBA Chip CC-to-Ropes..............................................................................................................38

Ropes-to-PCI LBA Chip.............................................................................................................39

PCI Slots.....................................................................................................................................40

Mixed PCI-X and PCI Express I/O Chassis...........................................................................40

PCI Hot-Swap Support.........................................................................................................41

System Management Station................................................................................................................41

User Accounts..................................................................................................................................42

New Server Cabling..............................................................................................................................42

m-Link Cable...................................................................................................................................42

e-Link Cable.....................................................................................................................................42

Clock Cable......................................................................................................................................44

Firmware...............................................................................................................................................44

Itanium Firmware for HP Integrity Superdome/sx2000.................................................................44

Itanium System Firmware Functions.........................................................................................46

PA-RISC Firmware for HP 9000/sx2000 Servers..............................................................................46

PA-RISC System Firmware Functions........................................................................................47

Server Configurations...........................................................................................................................47

Server Errors.........................................................................................................................................48

2 System Specifications...................................................................................................49

Dimensions and Weights......................................................................................................................49

Component Dimensions..................................................................................................................49

Component Weights........................................................................................................................49

Shipping Dimensions and Weights.................................................................................................50

Electrical Specifications.........................................................................................................................50

Grounding.......................................................................................................................................51

Circuit Breaker.................................................................................................................................51

Power Options.................................................................................................................................51

System Power Requirements...........................................................................................................52

Component Power Requirements...................................................................................................53

IOX Cabinet Power Requirements...................................................................................................53

IOX Cabinet Power Cords...............................................................................................................53

Environmental Requirements...............................................................................................................54

Temperature and Humidity Specifications.....................................................................................54

Power Dissipation............................................................................................................................54

Acoustic Noise Specification...........................................................................................................56

Airflow.............................................................................................................................................56

3 Installing the System.....................................................................................................59

Introduction .........................................................................................................................................59

Communications Interference ........................................................................................................59

Electrostatic Discharge ...................................................................................................................59

Public Telecommunications Network Connection..........................................................................60

Unpacking and Inspecting the System.................................................................................................60

4 Table of Contents

Page 5

Verifying Site Preparation...............................................................................................................60

Gathering LAN Information......................................................................................................60

Verifying Electrical Requirements..............................................................................................60

Checking the Inventory...................................................................................................................60

Inspecting the Shipping Containers for Damage............................................................................61

Inspection Precautions...............................................................................................................62

Claims Procedures .....................................................................................................................62

Unpacking and Inspecting Hardware Components.......................................................................62

Tools Required............................................................................................................................63

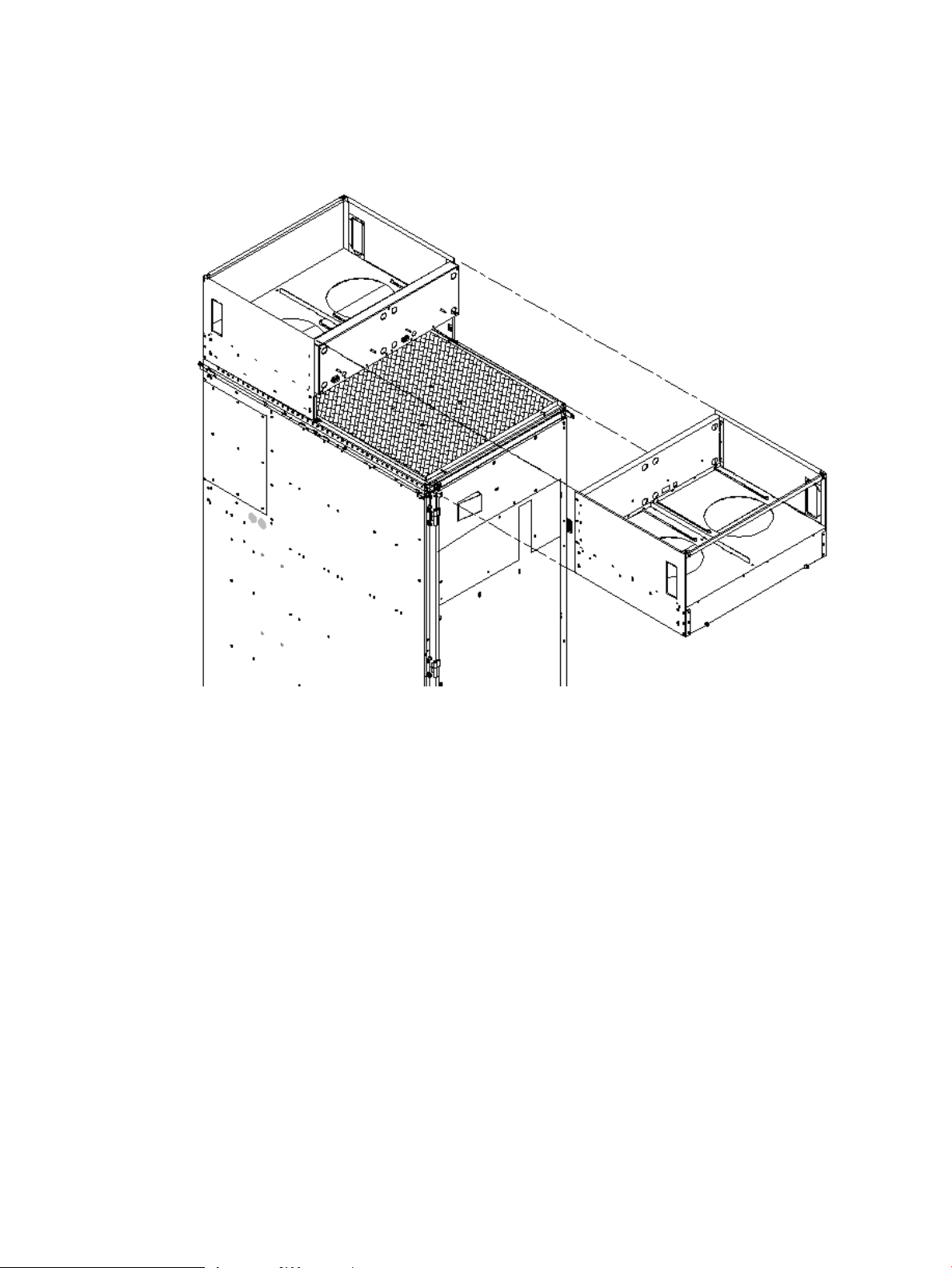

Unpacking the Cabinet...............................................................................................................63

Unpacking the PDCA......................................................................................................................71

Returning Equipment......................................................................................................................71

Setting Up the System...........................................................................................................................72

Moving the System and Related Equipment to the Installation Site ..............................................72

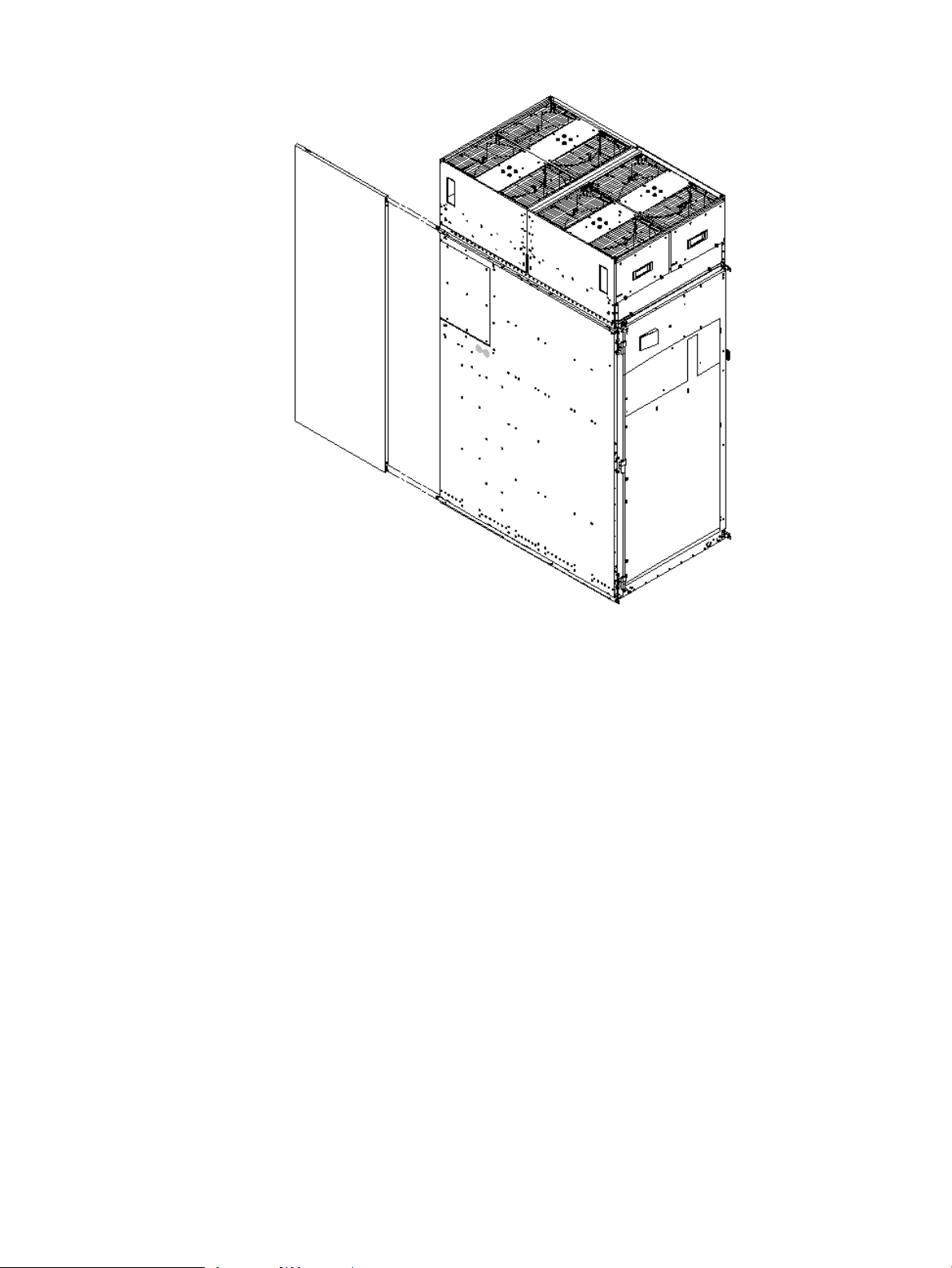

Unpacking and Installing the Blower Housings and Blowers........................................................72

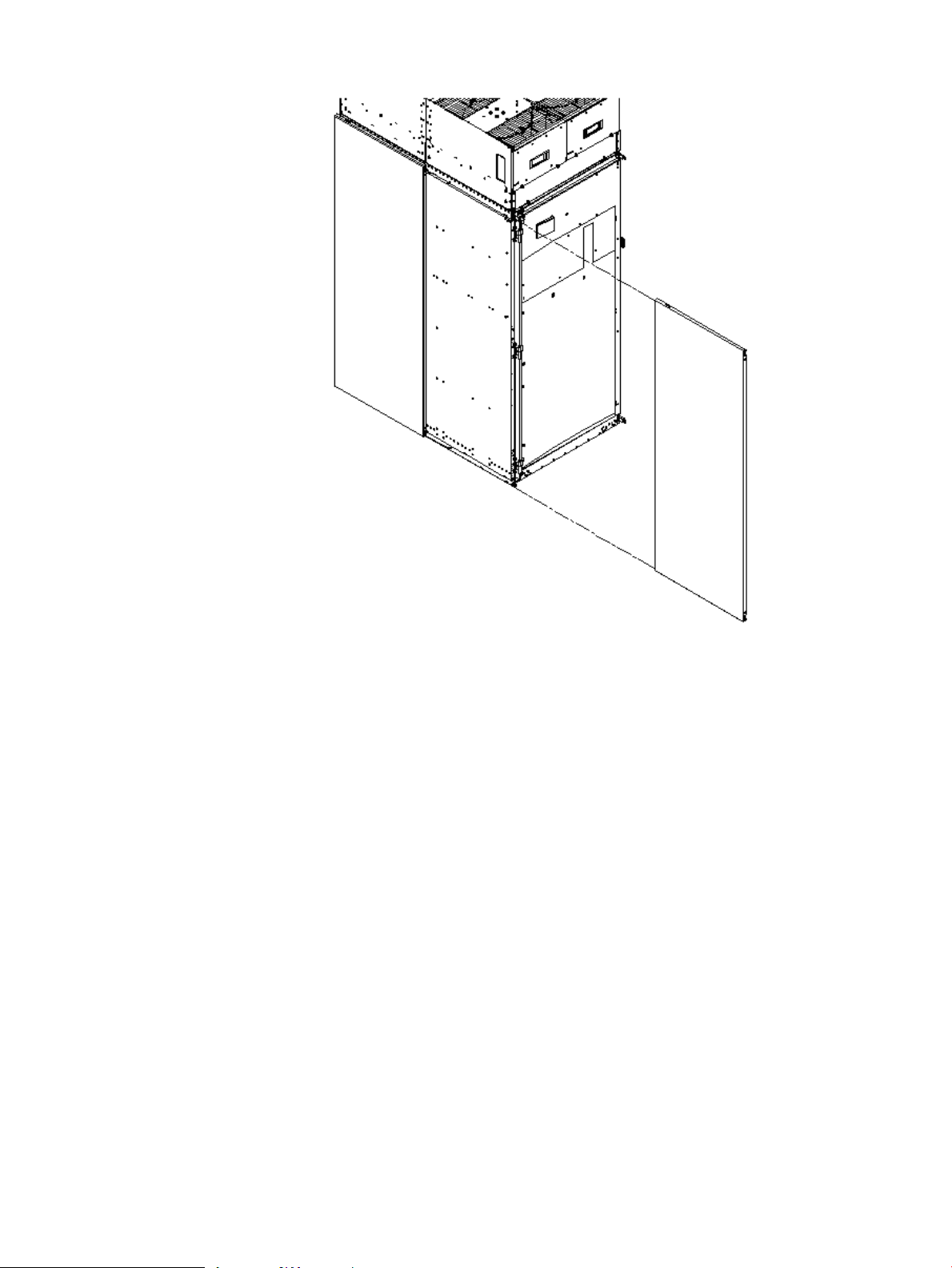

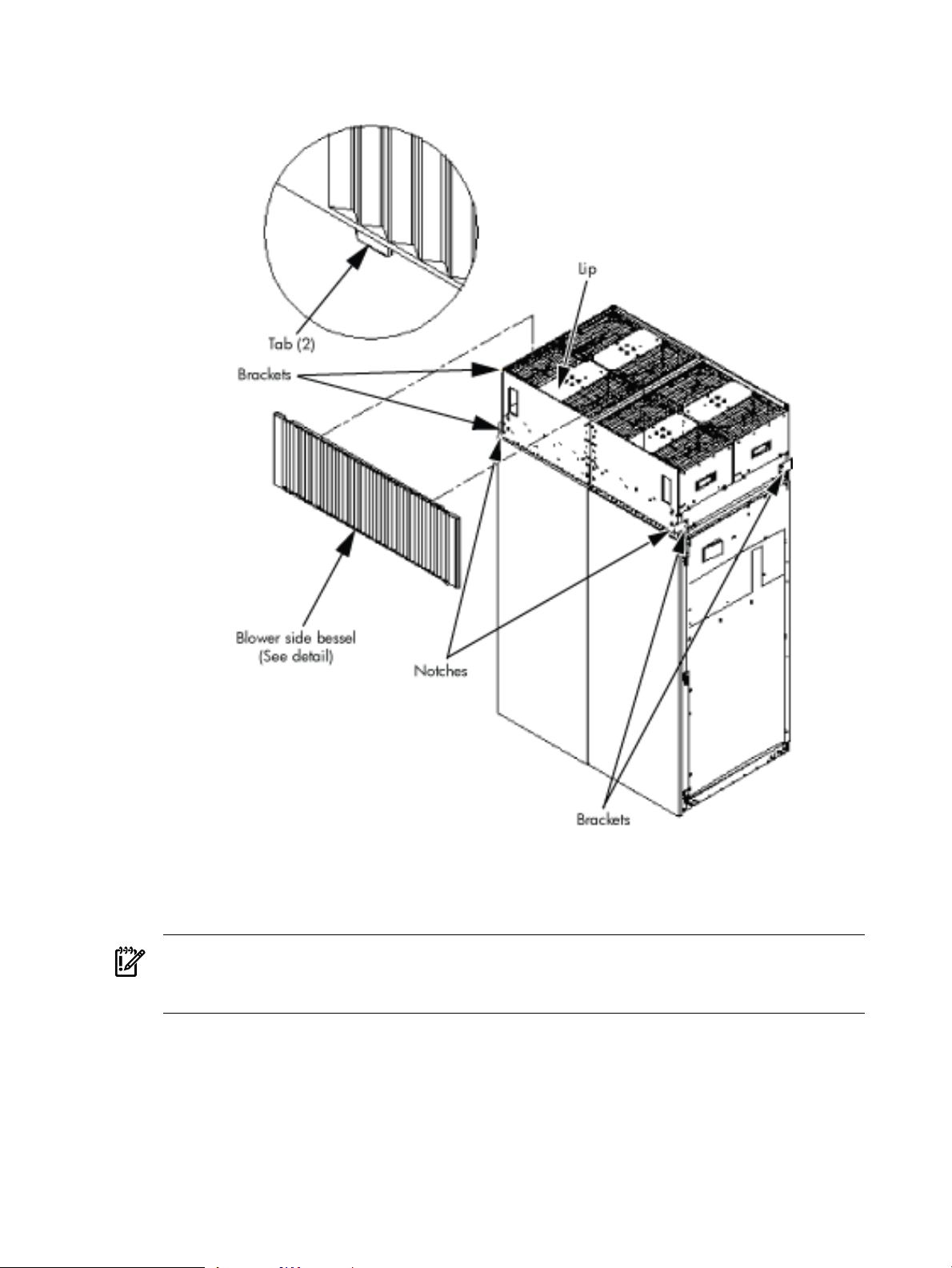

Attaching the Side Skins and Blower Side Bezels...........................................................................75

Attaching the Side Skins............................................................................................................75

Attaching the Blower Side Bezels...............................................................................................77

Attaching the Leveling Feet and Leveling the Cabinet...................................................................79

Installing the Front Door Bezels and the Front and Rear Blower Bezels .......................................79

Installing the Front Door Bezels.................................................................................................79

Installing the Rear Blower Bezel................................................................................................81

Installing the Front Blower Bezel...............................................................................................82

Wiring Check...................................................................................................................................83

Installing and Verifying the PDCA.................................................................................................84

Checking Voltage.............................................................................................................................88

Removing the EMI Panels...............................................................................................................89

Connecting the Cables.....................................................................................................................91

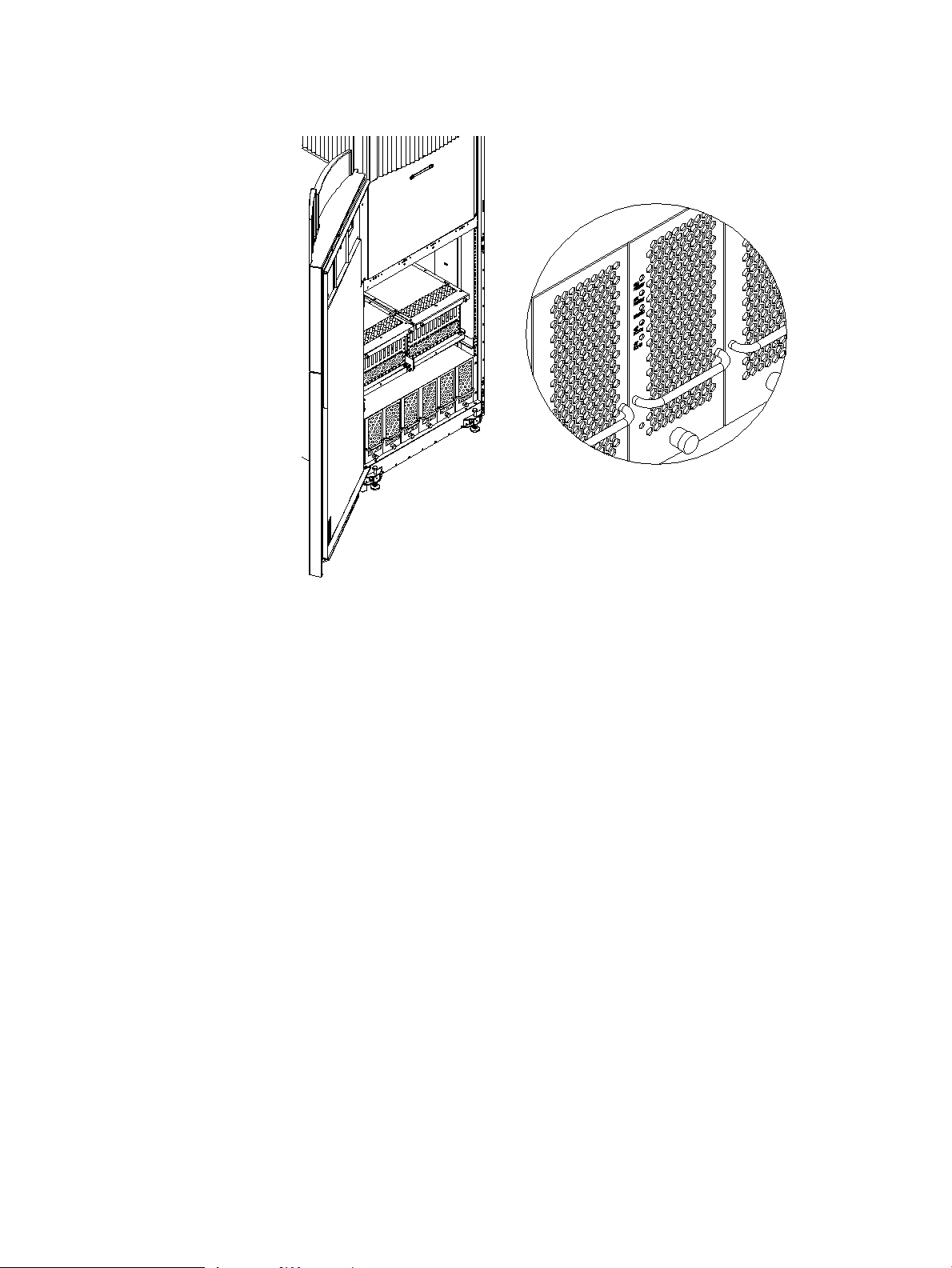

Routing the I/O Cables....................................................................................................................91

Installing the Support Management Station.........................................................................................93

Installing the SMS Support Shelf..........................................................................................................93

Connecting the SMS to the Superdome................................................................................................94

SMS Software and Superdome Firmware Downloading Procedure....................................................94

Configuring the Event Information Tools.............................................................................................95

Turning On Housekeeping Power........................................................................................................96

Connecting the MP to the Customer LAN...........................................................................................98

Connecting the MP to the Network.................................................................................................98

Setting the Customer IP Address....................................................................................................99

Booting and Verifying the System......................................................................................................101

Connecting to the MP....................................................................................................................101

Powering On the System 48 V Power Supply................................................................................104

Booting the HP Integrity Superdome/sx2000 to an EFI Shell........................................................104

Booting an HP 9000 sx2000 Server to BCH....................................................................................106

Verifying the System......................................................................................................................106

Running JET Software.........................................................................................................................108

Running JUST ...............................................................................................................................108

Power Cycling After Using JET.....................................................................................................109

Offline Diagnostic Environment.........................................................................................................109

Attaching the Rear Kick Plates............................................................................................................109

Performing a Visual Inspection and Completing the Installation......................................................110

Conducting a Post-Installation Check.................................................................................................112

4 Booting and Shutting Down the Operating System...............................................113

Operating Systems Supported on Cell-based HP Servers..................................................................113

Table of Contents 5

Page 6

System Boot Configuration Options...................................................................................................114

HP 9000 Boot Configuration Options............................................................................................114

HP Integrity Boot Configuration Options.....................................................................................114

Booting and Shutting Down HP-UX...................................................................................................118

HP-UX Support for Cell Local Memory........................................................................................118

Adding HP-UX to the Boot Options List.......................................................................................118

Booting HP-UX..............................................................................................................................119

Standard HP-UX Booting.........................................................................................................120

Single-User Mode HP-UX Booting...........................................................................................123

LVM-Maintenance Mode HP-UX Booting...............................................................................126

Shutting Down HP-UX..................................................................................................................127

Booting and Shutting Down HP OpenVMS I64.................................................................................128

HP OpenVMS I64 Support for Cell Local Memory.......................................................................129

Adding HP OpenVMS to the Boot Options List............................................................................129

Booting HP OpenVMS...................................................................................................................131

Shutting Down HP OpenVMS.......................................................................................................132

Booting and Shutting Down Microsoft Windows..............................................................................133

Microsoft Windows Support for Cell Local Memory....................................................................133

Adding Microsoft Windows to the Boot Options List...................................................................134

Booting Microsoft Windows..........................................................................................................135

Shutting Down Microsoft Windows..............................................................................................137

Booting and Shutting Down Linux.....................................................................................................138

Linux Support for Cell Local Memory..........................................................................................138

Adding Linux to the Boot Options List.........................................................................................139

Booting Red Hat Enterprise Linux................................................................................................140

Booting SuSE Linux Enterprise Server .........................................................................................141

Shutting Down Linux....................................................................................................................142

A sx2000 LEDs..............................................................................................................145

B Management Processor Commands........................................................................149

BO Command .....................................................................................................................................149

CA Command.....................................................................................................................................149

CC Command......................................................................................................................................150

CP Command......................................................................................................................................151

DATE Command.................................................................................................................................152

DC Command.....................................................................................................................................152

DF Command......................................................................................................................................153

DI Command.......................................................................................................................................154

DL Command......................................................................................................................................155

EL Command......................................................................................................................................155

HE Command.....................................................................................................................................156

ID Command.......................................................................................................................................157

IO Command.......................................................................................................................................158

IT Command.......................................................................................................................................159

LC Command......................................................................................................................................159

LS Command.......................................................................................................................................160

MA Command....................................................................................................................................160

ND Command.....................................................................................................................................161

PD Command......................................................................................................................................161

PE Command......................................................................................................................................162

PS Command.......................................................................................................................................163

RE Command......................................................................................................................................164

6 Table of Contents

Page 7

RL Command......................................................................................................................................165

RR Command......................................................................................................................................166

RS Command......................................................................................................................................166

SA Command......................................................................................................................................167

SO Command......................................................................................................................................167

SYSREV Command.............................................................................................................................168

TC Command......................................................................................................................................169

TE Command......................................................................................................................................169

VM Command.....................................................................................................................................170

WHO Command.................................................................................................................................170

XD Command.....................................................................................................................................171

C Powering the System On and Off ...........................................................................173

Shutting Down the System.................................................................................................................173

Checking System Configuration....................................................................................................173

Shutting Down the Operating System...........................................................................................175

Preparing the Partitions for Shutdown..........................................................................................176

Powering Off the System...............................................................................................................177

Turning On Housekeeping Power......................................................................................................178

Powering On the System Using the PE Command.............................................................................180

D Templates....................................................................................................................183

Templates............................................................................................................................................183

Equipment Footprint Templates....................................................................................................185

Computer Room Layout Plan........................................................................................................185

Index...............................................................................................................................197

Table of Contents 7

Page 8

List of Figures

1-1 Superdome History.......................................................................................................................17

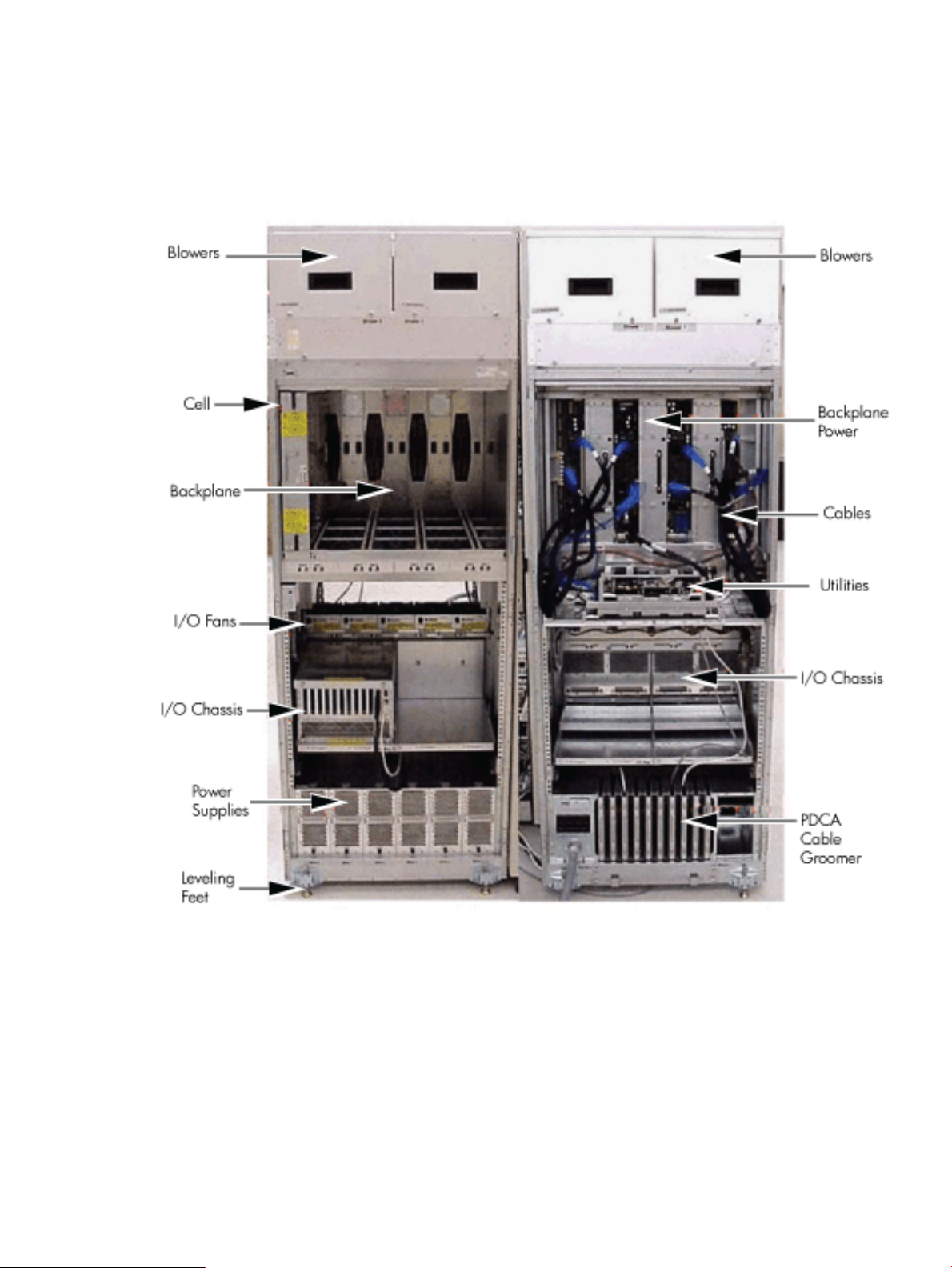

1-2 Superdome Cabinet Components.................................................................................................19

1-3 UGUY............................................................................................................................................23

1-4 Management Processor.................................................................................................................25

1-5 HUCB.............................................................................................................................................26

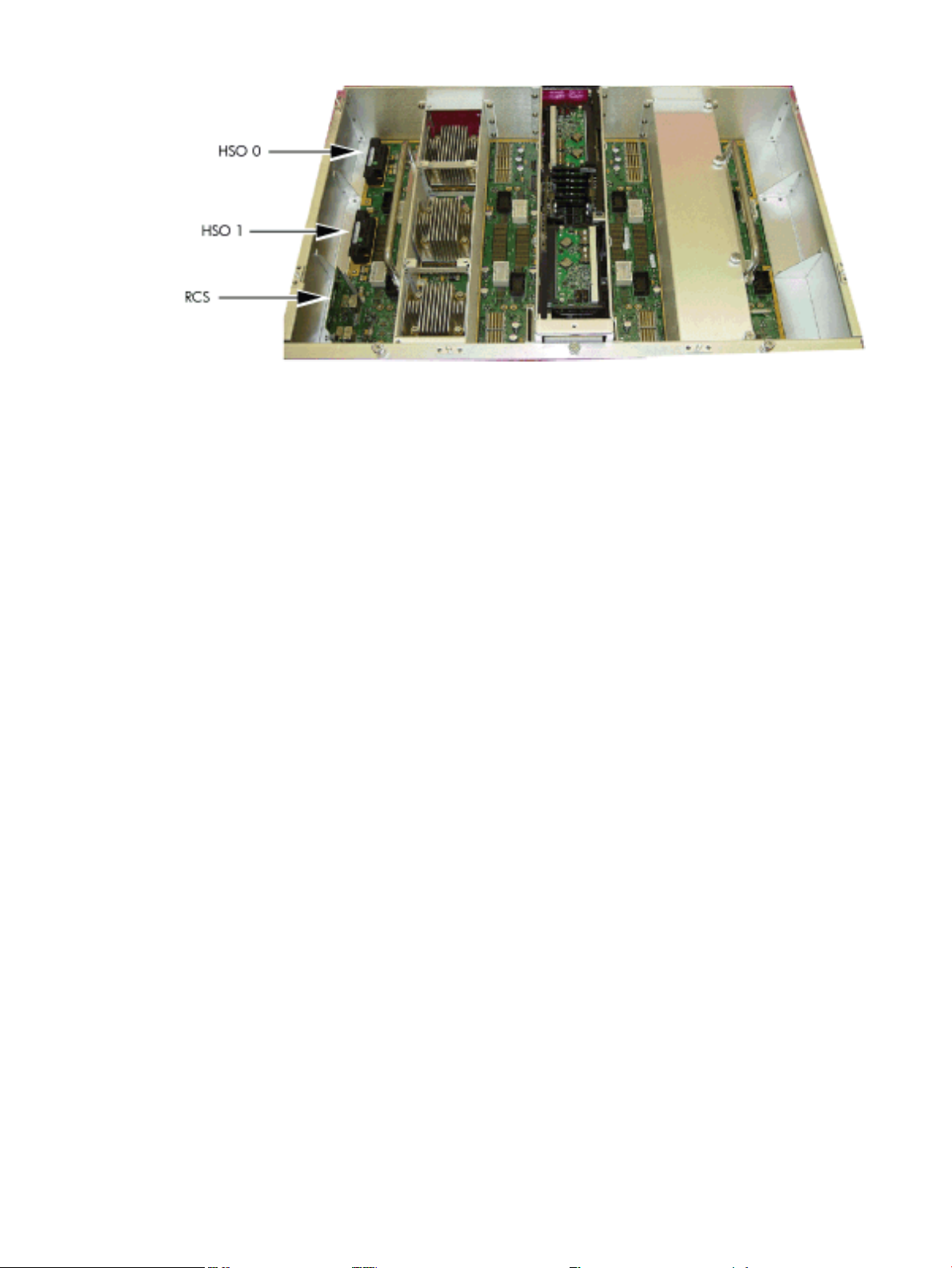

1-6 HSO and RCS Locations................................................................................................................29

1-7 Backplane Power Supply Module.................................................................................................30

1-8 Backplane (Rear View)..................................................................................................................30

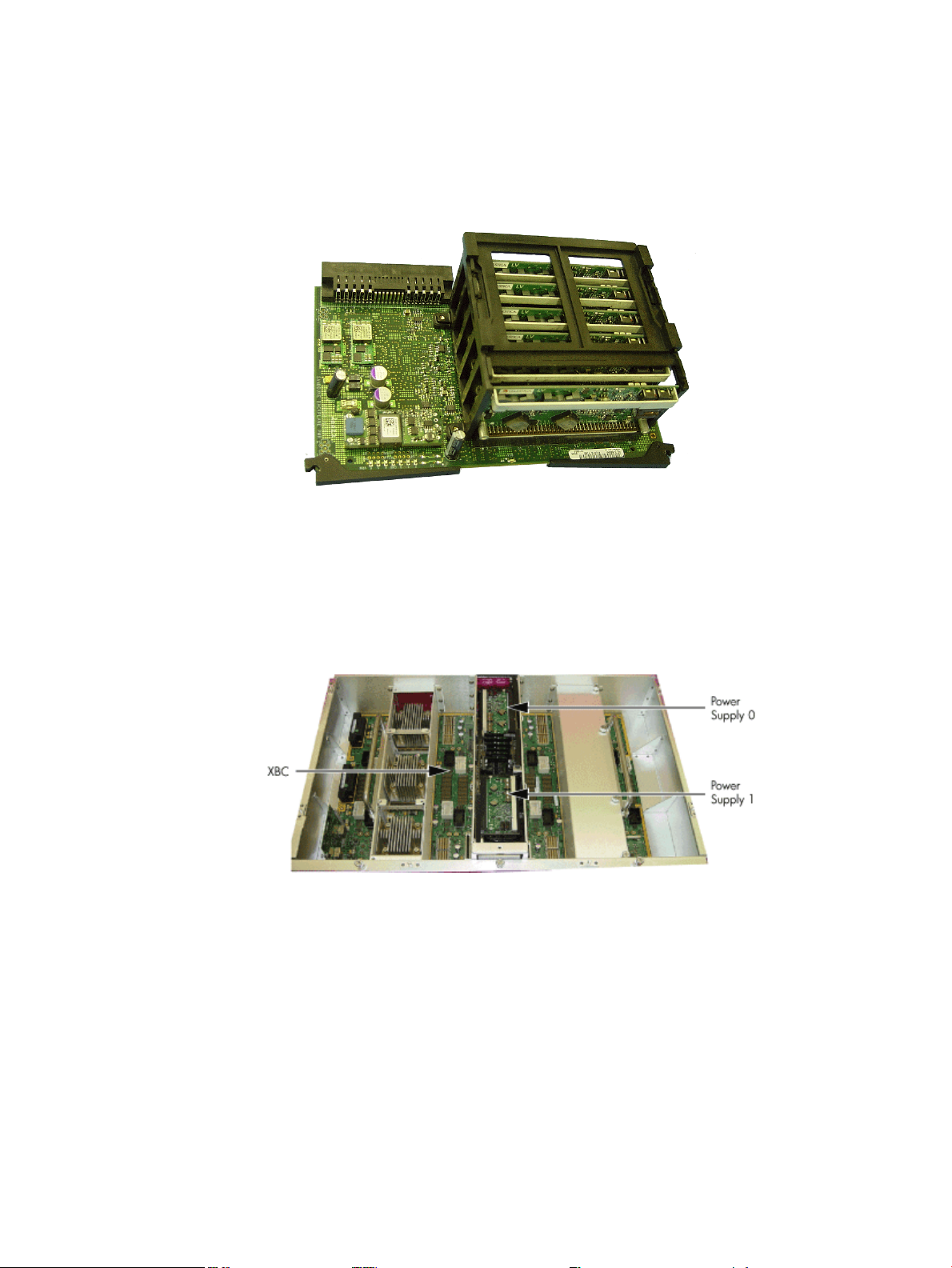

1-9 Cell Board......................................................................................................................................31

1-10 Cell Memory..................................................................................................................................33

1-11 PCI-X I/O Rope Mapping..............................................................................................................39

1-12 PCIe I/O Rope Mapping................................................................................................................41

1-13 e-Link Cable...................................................................................................................................43

1-14 Backplane Cables...........................................................................................................................44

1-15 Itanium Firmware Interfaces.........................................................................................................45

1-16 PA-RISC Firmware Interfaces........................................................................................................47

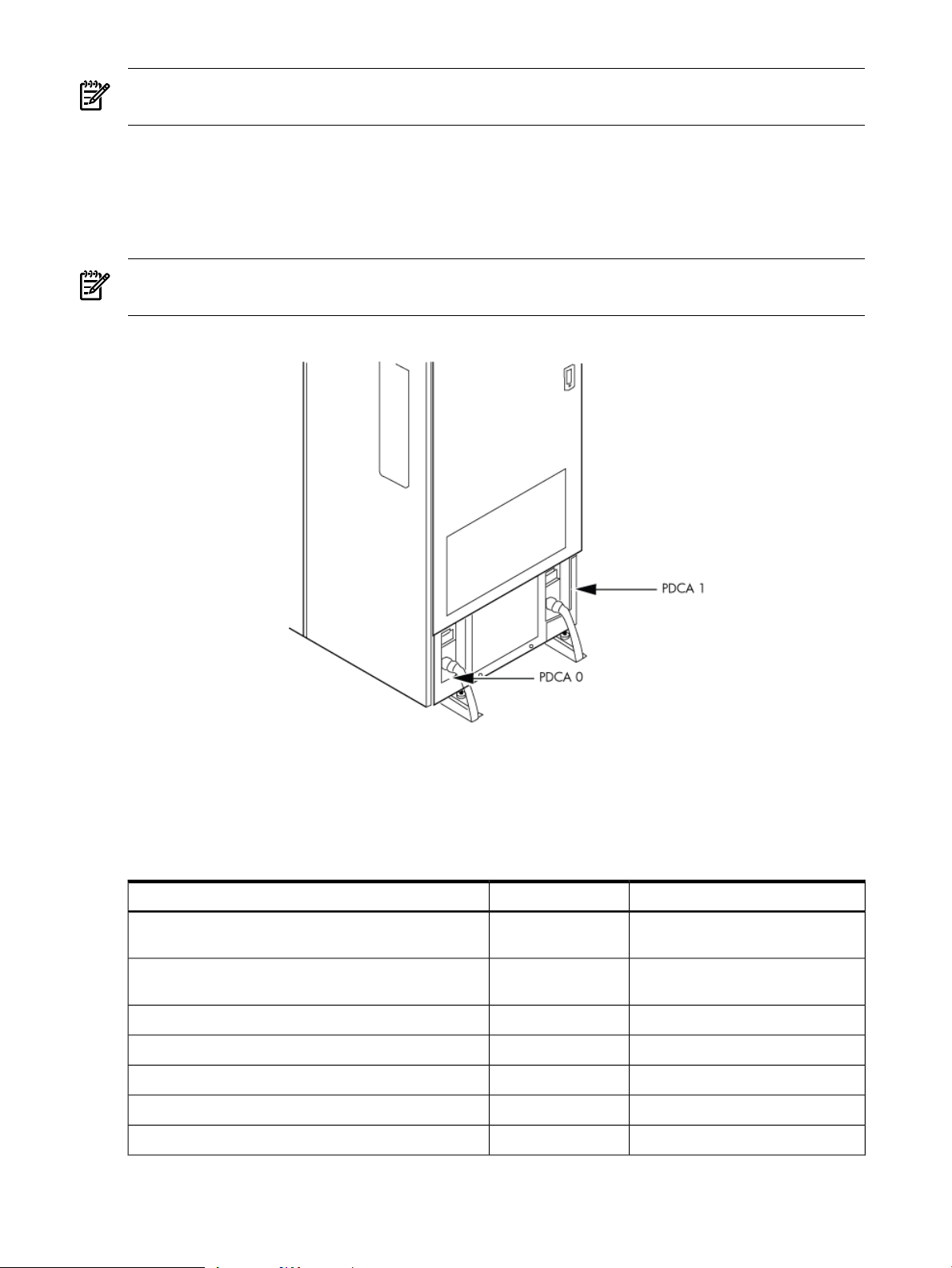

2-1 PDCA Locations............................................................................................................................52

2-2 Airflow Diagram...........................................................................................................................57

3-1 Normal Tilt Indicator....................................................................................................................61

3-2 Abnormal Tilt Indicator ................................................................................................................62

3-3 Front of Cabinet Container............................................................................................................64

3-4 Cutting the Polystrap Bands..........................................................................................................64

3-5 Removing the Ramps from the Pallet............................................................................................65

3-6 Power Supply Mounting Screws Location....................................................................................66

3-7 I/O Chassis Mounting Screws.......................................................................................................66

3-8 Shipping Strap Location................................................................................................................68

3-9 Removing the Mounting Brackets.................................................................................................69

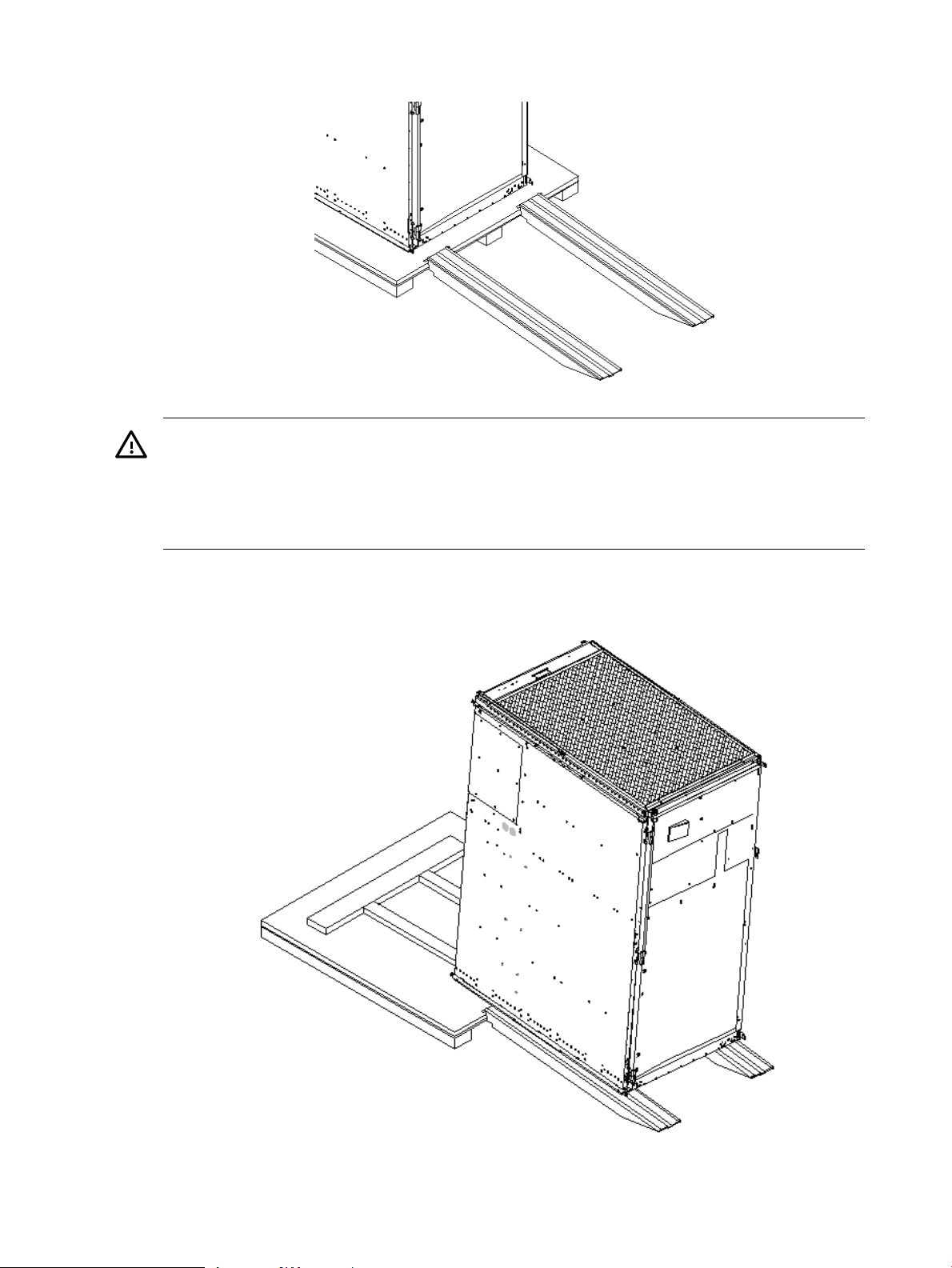

3-10 Positioning the Ramps...................................................................................................................70

3-11 Rolling the Cabinet Down the Ramp............................................................................................70

3-12 Blower Housing Frame..................................................................................................................72

3-13 Removing Protective Cardboard from the Housing.....................................................................73

3-14 Installing the Rear Blower Housing..............................................................................................73

3-15 Installing the Front Blower Housing.............................................................................................74

3-16 Installing the Blowers....................................................................................................................75

3-17 Attaching the Rear Side Skin.........................................................................................................76

3-18 Attaching the Front Side Skins......................................................................................................77

3-19 Attaching the Side Bezels..............................................................................................................78

3-20 Attaching the Leveling Feet...........................................................................................................79

3-21 Installing the Lower Front Door Assembly...................................................................................80

3-22 Installing the Upper Front Door Assembly...................................................................................81

3-23 Installing the Rear Blower Bezel....................................................................................................82

3-24 Installing the Front Blower Bezel..................................................................................................83

3-25 PDCA Assembly for Options 6 and 7............................................................................................85

3-26 A 4-Wire Connector.......................................................................................................................85

3-27 A 5-Wire Connector.......................................................................................................................86

3-28 Installing the PDCA.......................................................................................................................86

3-29 Checking PDCA Test Points (5-Wire)............................................................................................87

3-30 Wall Receptacle Pinouts................................................................................................................88

3-31 Power Supply Indicator LED........................................................................................................89

3-32 Removing Front EMI Panel Screw................................................................................................90

3-33 Removing the Back EMI Panel......................................................................................................90

3-34 Cable Labeling...............................................................................................................................91

8 List of Figures

Page 9

3-35 Routing I/O Cables........................................................................................................................92

3-36 Front Panel with HKP and Present LEDs......................................................................................97

3-37 BPS LEDs.......................................................................................................................................98

3-38 MP LAN Connection Location......................................................................................................99

3-39 LAN Configuration Screen..........................................................................................................100

3-40 The ls Command Screen..............................................................................................................101

3-41 Logging In....................................................................................................................................102

3-42 Main MP Menu............................................................................................................................102

3-43 MP Command Option.................................................................................................................103

3-44 MP Virtual Front Panel................................................................................................................103

3-45 Example of Partition State—Cabinet Not Powered Up...............................................................103

3-46 MP Console Option.....................................................................................................................104

3-47 HP Integrity Superdome/sx2000 EFI Boot Manager...................................................................105

3-48 EFI Shell Prompt..........................................................................................................................105

3-49 HP Integrity Superdome/sx2000 Partitions at System Firmware Console..................................106

3-50 Power Status First Window.........................................................................................................107

3-51 Power Status Window.................................................................................................................107

3-52 Power Status Showing State of UGUY LEDs ..............................................................................108

3-53 Attaching Rear Kick Plates..........................................................................................................110

3-54 Cell Board Ejectors.......................................................................................................................111

3-55 Front EMI Panel Flange and Cabinet Holes................................................................................111

3-56 Reinstalling the Back EMI Panel..................................................................................................112

A-1 Utilities ........................................................................................................................................147

A-2 PDH Status..................................................................................................................................147

C-1 Connecting to the Host................................................................................................................173

C-2 Main MP Menu............................................................................................................................173

C-3 Checking for Other Users............................................................................................................174

C-4 Checking Current System Configuration....................................................................................174

C-5 MP Virtual Front Panel................................................................................................................174

C-6 Example of Partition State...........................................................................................................175

C-7 Partition Consoles Menu.............................................................................................................175

C-8 Entering the rr Command...........................................................................................................176

C-9 Using the de -s Command........................................................................................................177

C-10 Power Entity Command..............................................................................................................177

C-11 Power Status First Window.........................................................................................................178

C-12 Power Status Second Window.....................................................................................................178

C-13 Front Panel Display with Housekeeping (HKP) Power and Present LEDs On..........................179

C-14 BPS LEDs.....................................................................................................................................180

C-15 Power Entity Command..............................................................................................................181

C-16 Power Status First Window.........................................................................................................181

C-17 Power Status Window.................................................................................................................182

D-1 Cable Cutouts and Caster Locations...........................................................................................183

D-2 SD16 and SD32 Space Requirements...........................................................................................184

D-3 SD64 Space Requirements...........................................................................................................185

D-4 Computer Floor Template...........................................................................................................186

D-5 Computer Floor Template...........................................................................................................187

D-6 Computer Floor Template...........................................................................................................188

D-7 Computer Floor Template...........................................................................................................189

D-8 Computer Floor Template...........................................................................................................190

D-9 SD32, SD64, and IOX Cabinet Templates....................................................................................191

D-10 SD32, SD64, and IOX Cabinet Templates....................................................................................192

D-11 SD32, SD64, and IOX Cabinet Templates....................................................................................193

D-12 SD32, SD64, and IOX Cabinet Templates....................................................................................194

D-13 SD32, SD64, and IOX Cabinet Templates....................................................................................195

D-14 SD32, SD64, and IOX Cabinet Templates....................................................................................196

9

Page 10

List of Tables

1-1 HSO LED Status Indicator Meaning.............................................................................................28

1-2 Supported Processors and Minimum Firmware Versions............................................................32

1-3 SMS Lifecycles...............................................................................................................................42

2-1 Server Component Dimensions....................................................................................................49

2-2 I/O Expansion Cabinet Component Dimensions..........................................................................49

2-3 System Component Weights.........................................................................................................49

2-4 IOX Cabinet Weights.....................................................................................................................50

2-5 Miscellaneous Dimensions and Weights.......................................................................................50

2-6 Available Power Options...............................................................................................................51

2-7 Option 6 and 7 Specifics................................................................................................................51

2-8 Power Requirements (Without SMS)............................................................................................52

2-9 Component Power Requirements (Without SMS)........................................................................53

2-10 I/O Expansion Cabinet Power Requirements (Without SMS).......................................................53

2-11 I/O Expansion Cabinet Component Power Requirements............................................................53

2-12 I/O Expansion Cabinet ac Power Cords........................................................................................54

2-13 Operational Physical Environment Requirements........................................................................54

2-14 Nonoperational Physical Environment Requirements.................................................................54

2-15 HP Integrity Superdome/sx2000 Dual-Core CPU Configurations...............................................55

2-16 HP Integrity Superdome/sx2000 Single-Core CPU Configurations.............................................55

2-17 Physical Environmental Specifications.........................................................................................57

3-1 Available Power Options...............................................................................................................71

3-2 Power Cord Option 6 and 7 Details...............................................................................................71

3-3 4- and 5-Wire Voltage Ranges.......................................................................................................87

A-1 Front Panel LEDs.........................................................................................................................145

A-2 Power and OL* LEDs...................................................................................................................146

A-3 OL* LED States............................................................................................................................147

A-4 PDH Status and Power Good LED States....................................................................................148

10 List of Tables

Page 11

List of Examples

3-1 Directory Example.........................................................................................................................95

3-2 Directory Example.........................................................................................................................95

4-1 Single-User HP-UX Boot..............................................................................................................124

B-1 BO command...............................................................................................................................149

B-2 CA Command..............................................................................................................................150

B-3 CC Command..............................................................................................................................151

B-4 CP Command..............................................................................................................................152

B-5 DATE Command.........................................................................................................................152

B-6 DC Command..............................................................................................................................153

B-7 DF Command..............................................................................................................................154

B-8 DI Command...............................................................................................................................155

B-9 DL Command..............................................................................................................................155

B-10 EL Command...............................................................................................................................156

B-11 HE Command..............................................................................................................................157

B-12 ID Command...............................................................................................................................158

B-13 Example: .....................................................................................................................................159

B-14 IT Command................................................................................................................................159

B-15 LC Command..............................................................................................................................160

B-16 LS Command...............................................................................................................................160

B-17 MP Main Menu............................................................................................................................161

B-18 ND Command.............................................................................................................................161

B-19 PD Command..............................................................................................................................162

B-20 PE Command for a Compute Cabinet.........................................................................................163

B-21 PS Command...............................................................................................................................164

B-22 Re-key lock for partition 3...........................................................................................................166

B-23 RR Command..............................................................................................................................166

B-24 RS Command...............................................................................................................................167

B-25 SA Command..............................................................................................................................167

B-26 SO Command..............................................................................................................................168

B-27 SYSREV Command......................................................................................................................169

B-28 TC Command..............................................................................................................................169

B-29 TE Command...............................................................................................................................170

B-30 VM Command.............................................................................................................................170

B-31 WHO Command..........................................................................................................................171

B-32 XD Command..............................................................................................................................172

11

Page 12

12

Page 13

About This Document

This document contains the system overview, system-specific parameters, installation procedures

of the system, operating system specifics, and procedures for components in the system.

Intended Audience

This document is intended for HP trained Customer Support Consultants.

Document Organization

This document is organized as follows:

Chapter 1 This chapter presents an historical view of the Superdome server family,

describes the various server components, and describes how the server

components function together.

Chapter 2 This chapter contains the dimensions and weights for the server and various

components. Electricalspecifications, environmental requirements, and templates

are also included.

Chapter 3 This chapter describes how to unpack and inspect the system, set up the system,

connect the MP to the customer LAN, and how to complete the installation.

Chapter 4 This chapter describes how to boot and shut down the server operating system

(OS) for each OS supported.

Appendix A This appendix contains tables that describe the various LED states for the front

panel, power and OL* states, and OL* states for I/O chassis cards.

Appendix B This appendix provides a summary for each management processor (MP)

command. Screen output is provided for each command so you can see the

results of the command.

Appendix C This appendix provides procedures to power off and power on the system when

the removal and replacement of a component requires it.

Appendix D This appendix contains templates for cable cutouts and caster locations; SD16,

SD32, SD64, and I/O expansion cabinets; and the computer room floor.

Typographic Conventions

The following typographic conventions are used in this document.

WARNING! Lists requirements that you must meet to avoid personal injury.

CAUTION: Provides information required to avoid losing data or to avoid losing system

functionality.

IMPORTANT: Provides essential information to explain a concept or to complete a task.

NOTE: Highlights useful information such as restrictions, recommendations, or important

details about HP product features.

• Commands and options are represented using this font.

• Text that you type exactly as shown is represented using this font.

Intended Audience 13

Page 14

• Text to be replaced with text that you supply is represented using this font.

Example: “Enter the ls -l filename command” means you must replace filename with your

own text.

• Keyboard keys and graphical interface items (such as buttons, tabs, and menu items)

are represented using this font.

Examples: The Control key, the OK button, the General tab, the Options menu.

• Menu —> Submenu represents a menu selection you can perform.

Example: “Select the Partition —> Create Partition action” means you must select the

Create Partition menu item from the Partition menu.

• Example screen output is represented using this font.

Related Information

Further informationon HP server hardware management, Microsoft® Windows®, and diagnostic

support tools are available through the following website links.

Website for HP Technical Documentation Thefollowing link is the main website for HP technical

documentation. This site offers comprehensive information about HP products available for free.

See http://docs.hp.com.

Server Hardware Information The following link is the systems hardware section of the

docs.hp.com website. It provides HP nPartition server hardware management information,

including information on site preparation, installation, and so on. See http://docs.hp.com/hpux/

hw/.

Diagnostics and Event Monitoring: Hardware Support Tools The following link contains

comprehensive information about HP hardware support tools, including online and offline

diagnostics and event monitoring tools. This website has manuals, tutorials, FAQs, and other

reference material. See http://docs.hp.com/hpux/diag.

Website for HP Technical Support The following link is the HP IT resource center website and

provides comprehensive support information for IT professionals on a wide variety of topics,

including software, hardware, and networking. See http://us-sup port2.external.hp.com.

Publishing History

The document printing date and edition number indicate the document’s current edition and

are included in the following table. The printing date will change when a new edition is produced.

Document updatesmay beissued between editions tocorrect errorsor documentproduct changes.

The latest version of this document is available on line at:

docs.hp.com.

March 2006. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .First Edition

September 2006. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Second Edition

February 2007. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Third Edition

November 2007. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Fourth Edition

March 2009. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Fifth Edition

September 2009. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Sixth Edition

14

Page 15

HP Encourages Your Comments

HP welcomes your feedback on this publication. Direct your comments to http://docs.hp.com/

en/feedback.html and note that you will not receive an immediate reply. All comments are

appreciated.

HP Encourages Your Comments 15

Page 16

16

Page 17

1 Overview

Server History and Specifications

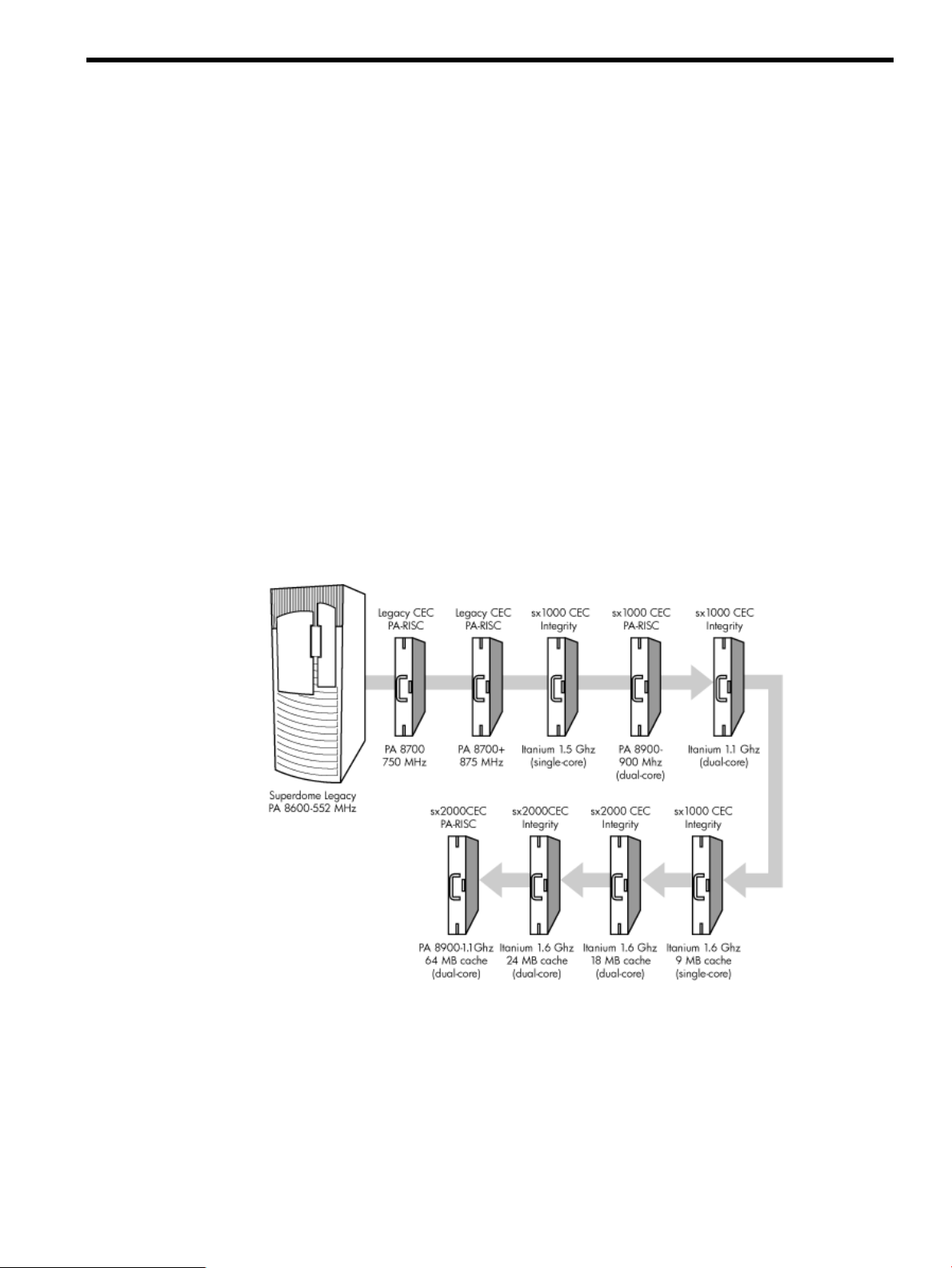

Superdome was introduced as the new platform architecture for high-end HP servers between

the years 2000 and 2004. Superdome represented the first collaborative hardware design effort

between traditional HP and Convex technologies. Superdome was designed to replace T- and

V-Class servers and to prepare for the transition from PA-RISC to Intel® Itanium® processors.

The new design enabled the ability of running different operating systems on the same server.

The design also included several new, high-availability features. Initially, Superdomewas released

with the legacy core electronics complex (CEC) and a 552 MHz PA-8600 processor. The Legacy

CEC supported two additional speeds; a 750 MHz PA-8700 followed by an 875 MHz PA-8700

processor.

The HP Integrity server project consisted of four projects based on the sx1000 CEC chipset and

the Integrity cell boards. The first release was the sx1000 chipset, Integrity cell boards, Itanium

firmware and a 1.2 MHz Intel® processor. This release included PCI-X and PCI I/O mixes. The

Integrity systems were compatible with the legacy Superdome IOX.

The second release, based on the sx1000 CEC, included Integrity cell boards, but used PA-RISC

firmware, and a dual-core PA-RISC processor. The release also included a 2 GB DIMM and a

new HP-UX version. Components such as processors, processor power pods, memory, firmware,

and operating system all changed for this release.

Figure 1-1 Superdome History

The third release, also based on the sx1000 chipset, included the Integrity cell boards, Itanium

firmware, and a 1.5 MHz Itanium CPU. The CPU module consisted of a dual-core processor with

a new cache controller. The firmware allowed for mixed cells within a system. All three DIMM

sizes were supported. Firmware and operating system changes were minor compared to their

earlier versions.

The fourth and final release is the HP super scalable sx2000 processor chipset. It is also based on

the new CEC that supports up to 128 PA-RISC or Itanium processors. It is the last generation of

Superdome servers to support the PA-RISC family of processors. Modifications to the server

components include:

Server History and Specifications 17

Page 18

• the new CEC chipset

• board changes including cell board

• system backplane

• I/O backplane

• associated power boards

• interconnect

• a redundant, hot-swappable clock source

Server Components

A Superdome system consists of the following types of cabinet assemblies:

• Minimum ofone Superdomeleft-side cabinet.The Superdomecabinet containsthe processors,

the memory, and the core devices of the system. They also house the system's PCI cards.

Systems can include both left and right cabinet assemblies containing a left or right backplane

(SD64) respectively.

• One or more HP Rack System/E cabinets. These rack cabinets are used to hold the system

peripheral devices such as disk drives.

• Optionally, one or more I/O expansion cabinets (Rack System/E). An I/O expansion cabinet

is required when a customer requires more PCI cards than can be accommodated in the

Superdome cabinets.

The width of the cabinet assemblies accommodates moving them through standard-sized

doorways. The intake air to the main (cell) card cage is filtered. This air filter is removable for

cleaning and replacement while the system is fully operational.

A status display is located on the outside of the front and rear doors of each cabinet. This feature

enables you to determine the basic status of each cabinet without opening any cabinet doors.

The Superdome is a cell-based system. Cells communicate with others utilizing the crossbar on

the backplane. Every cell has its own I/O interface, which can be connected to one 12-slot I/O

card cage using two System Bus Adapter (SBA) link cables. Not all SBA links are connected by

default, due to a physical limitation of four I/O card cages per cabinet or node. In addition to

these components, each system consists of a power subsystem and a utility subsystem. Three

types of Superdome are available:

• SD16

• SD32

• SD64, a two-cabinet system with single-CPU cell board sockets

The SD## represents the maximum number of available CPU sockets.

An SD16 contains the following components:

• Up to four cell boards

• Four I/O card cages

• Five I/O fans

• Four system cooling fans

• Four bulk power supplies (BPS)

• Two power distribution control assemblies (PDCA)

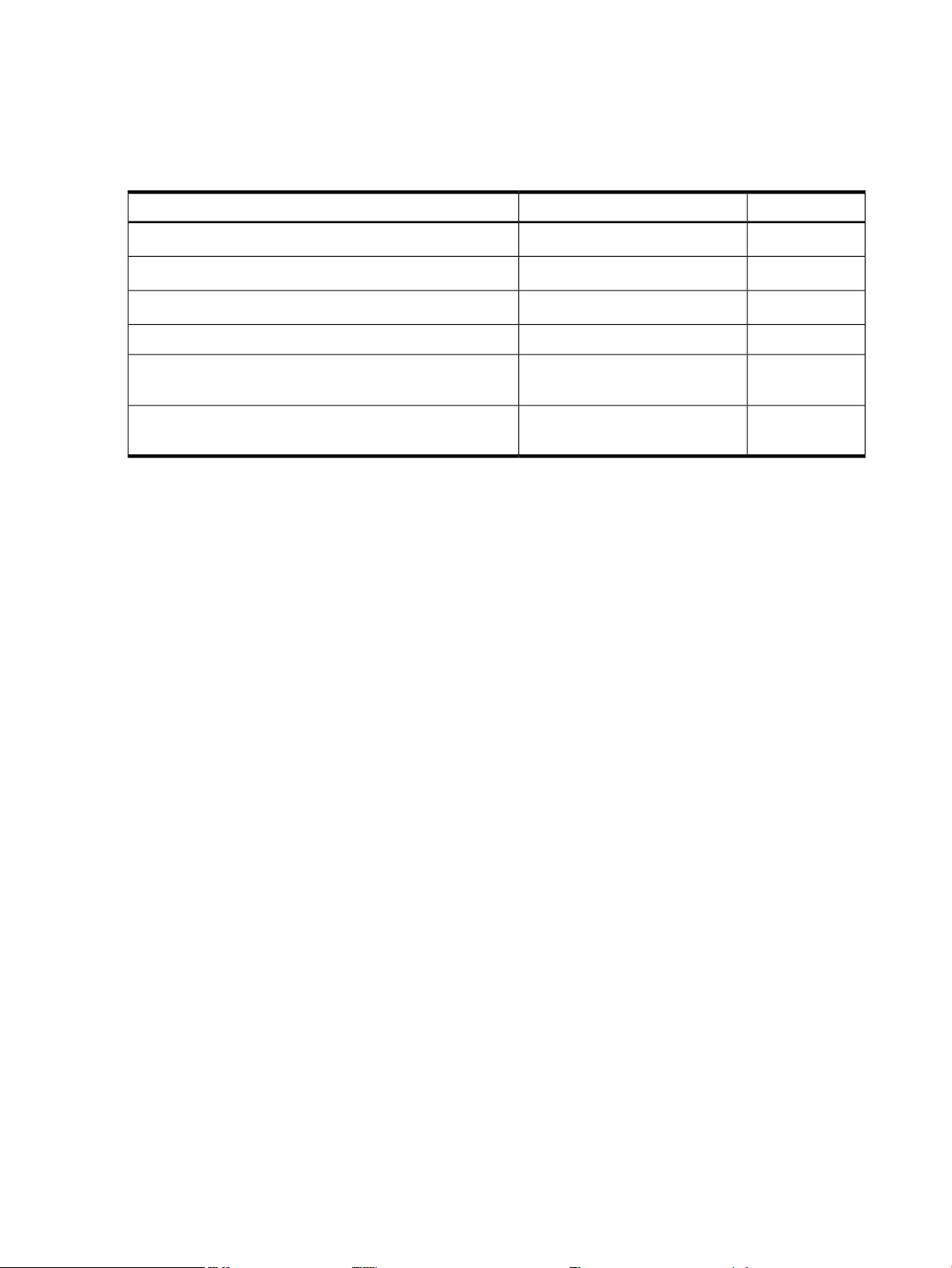

Two backplane N+1 power supplies provide power to the SD16. The four cell boards are connected

to one pair of crossbar chips (XBC). The backplane of an SD16 is the same as a backplane of an

SD32. On the HUCB utility PCB is a switch set to TYPE= 1.

An SD32 has up to eight cell boards. All eight cell boards are connected to two pairs of XBCs.

The SD32 backplane is designed for a system upgrade to an SD64. On an SD32, four of the eight

connectors use U-Turn cables. The U-Turn cables double the number of links and the bandwidth

between the XBCs and are recommended to achieve best performance. An SD64 has up to 16 cell

boards and requires two cabinets. All 16 cell boards are connected to four pairs of XBCs. The

18 Overview

Page 19

SD64 consists of left backplane and right backplane cabinets, which are connected using 12

m-Link cables.

When the PA-RISC dual-core or the Itanium dual-core processors are used, the CPU counts are

doubled by the use of the dual-die processors, as supported on the Intel® Itanium® cell boards.

Up to 128 processors can be supported.

Figure 1-2 Superdome Cabinet Components

Power Subsystem

The power subsystem consists of the following components:

• One or two PDCAs

• One Front End Power Supply (FEPS)

• Up to six BPS

• One power board per cell

• An HIOB power system

• Backplane power bricks

• Power monitor (PM) on the Universal Glob of Utilities (UGUY)

• Local power monitors (LPM) on the cell, the HIOB, and the backplanes

Power Subsystem 19

Page 20

AC Power

The ac power system includes the PDCA, one FEPS, and up to six BPS.

The FEPS is a modular, 2n+2 shelf assembly power system that can consume up to 17 KVA of

power from ac sources. The purpose of the FEPS chassis is to provide interconnect, signal and

voltage busing between the PDCAs and BPSs, between the BPSs and utility subsystem, and

between the BPS and the system power architecture. The FEPS subsystem comprisesthree distinct

modular assemblies: six BPS, two PDCAs, and one FEPS chassis.

At least one 3-phase PDCA per Superdome cabinet is required. For redundancy, you can use a

second PDCA. The purpose of the PDCA is to receive a single 3-phase input and output three

1-phase outputs with a voltage range of 200 to 240 volts regardless of the ac source type. The

PDCA also provides a convenience disconnect switch/circuit breaker for service, test points, and

voltage present LED indicators. The PDCA is offered as a 4-wire or a 5-wire PDCA device.

Separate PDCAs (PDCA-0 and PDCA-1) can be connected to 4-wire and 5-wire input source

simultaneously as long as the PDCA internal wiring matches the wiring configuration of the ac

source.

The 4-wire PDCA is used in a phase to phase voltage range of 200 to 240 volts at 50/60 Hz. This

PDCA is rated for a maximum input current of 44 Amps per phase. The ac input power line to

the PDCA is connected with power plugs or is hardwired. When using power plugs, use a power

cord [OLFLEX 190 (PN 6008044) four conductor 6-AWG (16 mm), 600 V, 60 Amp, 90˚C, UL and

CSA approved, conforms to CE directives GN/YW ground wire].

When installing cables in locations that have been designated as “air handling spaces” (under

raised flooring or overhead space used for air supply and air return), advise the customer to

specify the use of data cables that contain a plenum rating. Data cables with this rating have been

certified for FLAMESPREAD and TOXICITY (low smoke emissions). Power cables do not carry

a plenum rating, they carry a data processing (DP) rating. Power cables installed in air handling

spaces should be specified with a DP rating. Details on the various levels of the DP rating system

are found in the National Electric Code (NEC) under Article 645.

The following recommend plugs for the 4-wire PDCA:

• In-line connector: Mennekes ME 460C9, 3-phase, 4-wire, 60 Amp, 250 V, UL approved, color

• Panel-mount receptacle: Mennekes ME 460R9, 3-phase, 4-wire, 60 Amp, 250 V, UL approved,

The 5 wire PDCA is used in a phase-to-neutral voltage range of 200 to 240 V ac 50/60Hz. This

PDCA is rated for a maximum input current of 24 Amps per phase. The ac input power line to

the PDCA is connected with power plugs or is hardwired. When using power plugs, a power

cord [five conductors, 10-AWG (6 mm), 450/475 V, 32 Amps, <HAR< European wire cordage,

GN/YW ground wire]. Alternatively the customer can provide the power plug including the

power cord and the receptacle. Recommended plugs are as follows:

• Inline connector: Mennekes ME532C6-16, 3-phase, 5-wire, 32 Amps, 450/475 V, VDE certified,

• Panel-mount receptacle: Mennekes ME532R6-1276, 3-phase, 5-wire, 32 Amp, 450/475 V, VDE

• FUSE per phase: 25 Amp (valid for Germany).

blue, IEC309-1 grounded at 9:00 o'clock.

color blue, IEC309-1 grounded at 9:00 o'clock.

color red, IEC309-1, IEC309-2, grounded at 6:00 o'clock.

certified, color red, IEC309-1, IEC309-2, grounded at 6:00 o'clock.

DC Power

Each power supply output provides 48 V dc up to 60 A (2.88 kVA) and 5.3 V dc housekeeping.

Normally an SD32 Superdome cabinet contains six BPS independent from the installed number

of cells and I/O. An SD16 normally has four BPS installed.

20 Overview

Page 21

Power Sequencing

The power on sequence is as follows:

1. When the main power circuit breaker is turned on, the housekeeping (HKP) voltage turns

on first and provides 5.3 V dc tothe UGUY, ManagementProcessor (MP), system backplane,

cells, and all HIOB. Each BPS provides 5.3 V.

2. When HKP voltage is on the MP performs the following steps:

a. De-asserts the Reset and begins to boot SBC.

b. Loads VxWorks from flash (can be viewed from the local port).

c. Completes the SBC, single board computer hub (SBCH) power-on self-test (POST)

begins, and LED start activity appears.

d. Loads firmware from Compact Flash to RAM.

e. SBCH POST completes. The heartbeat light blinks. USB LEDs turn on later.

f. CLU POST and PM POST immediately after power on.

3. After MP POST completes, the MP configures the system.

4. The CLU POST completes.

5. When PM POST completes, the system takes several steps.

6. When the MP finishes the system configuration, it becomes operational and completes

several tasks.

7. When the PDHC POST completes, it becomes operational and completes its tasks.

When the MP, CLU, and PM PDHC POST completes, utilities entities run their main loops.

Enabling 48 Volts

The PM must enable +48 V first , but it must obtain permission from the MP. To enable 48 V, the

transition cabinet power switch must be moved from OFF to ON. Alternatively you can use the

MP Command pe if the power switch is already ON. If the switch is ON, the cabinet wakes up

from Power on Reset).

If the PM has permission, it sends a PS_CTL_L signal to the FEPS. Then the BPS enables +48 V

converters, which send +48 V to the backplane, I/O chassis, HUCB, cells, fans, and blowers. Once

the +48 V is enabled, it is cabled to the backplane, cells, and I/O chassis.

Cooling System

The Superdome has four blowers and five I/O fans per cabinet. These components are all

hot-swappable. All have LEDs indicating their current status. Temperature monitoring occurs

for the following:

• Inlet air for temperature increases above normal

• BPS for temperature increases above normal

• The I/O power board over temperature signal is monitored

The inlet air sensor is on the main cabinet, located near the bottom of cell 1 front. The inlet air

sensor and the BPS sensors are monitored by the power monitor 3 (PM3) on the UGUY, and the

I/O power board sensors are monitored by the CLU on the UGUY.

The PM controls and monitors the speed of groups of N+1 redundant fans. In a CPU cabinet, fan

group 0 consists of the four main blowers and fan group 1 consists of the five I/O fans. In an I/O

Expansion (IOX) cabinet, fan groups 0–3 consist of four I/O fans and fan group 4 consists of two

management subsystem fans. All fans are expected to be populated at all times with the exception

of the OLR of a failed fan.

The main blowers feature a variable speed control. The blowers operate at full speed; available

circuitry can reduce the normal operating speed. All of the I/O fans and managed fans run at

one speed.

Cooling System 21

Page 22

One minute after setting the main blower fan Reference to the desired speed or powering on the

cabinet, the PM uses the tach select register to cycle through each fan and measure its speed.

When a fan is selected, Timer 1 is used in counter mode to count the pulses on port T1 over a

period of one second. If the frequency does not equal the expected frequency plus some margin

of error, the fan is considered to have failed and is subtracted from the working fan count.

If the failure causes a transition to N- I/O or main fans in a CPU cabinet, the cabinet is immediately

powered off. If the failure causes a transition to N- I/O fans in an IOX cabinet, the I/O backplanes

contained in the I/O Chassis Enclosure (ICE) containing that fan groupare immediately powered

off.

Only inlet temperature increases are monitored by HP-UX; all other high temperature increase

chassis codes do not activate the envd daemon to act as configured in the /etc/envd.conf

file. The PM monitors ambient inlet temperature. The PM polls an analog-to-digital converter to

read the current ambient temperature. The temperature falls into one of four ranges: Normal,

OverTempLow, OverTempMid, or OverTempHigh. The following state codes describe the actions

taken based on the various temperature state transitions:

OTL_THRESHOLD = 32C -----> Send error code PDC_IPR_OLT

OTM_THRESHOLD = 38C ----> Send error code PDC_INT_OTM

OTH_THRESHOLD = 40C -----> Shut down 48 V