Page 1

User Guide

Ioline FlexJet E & StudioJet Printers

Page 2

User Notice

Trademarks

Ioline, StudioJet and FlexJet E printers are trademarks of Ioline Corporation. HP is a trademark of the

Hewlett-Packard Company. Other product names, logos, designs, titles, words or phrases mentioned

within this publication may be trademarks, service marks, or trade names of Ioline Corporation or other

entities and may be registered in certain jurisdictions including internationally.

Ioline Disclaimer

IOLINE CORPORATION PROVIDES THIS MANUAL “AS IS” WITHOUT WARRANTY OF ANY KIND,

EITHER EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES

OR CONDITIONS OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. IN NO

EVENT SHALL IOLINE, ITS DIRECTORS, OFFICERS, EMPLOYEES OR AGENTS BE LIABLE FOR ANY

INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES (INCLUDING DAMAGES

FOR LOSS OF PROFITS, LOSS OF BUSINESS, LOSS OF USE OR DATA, INTERRUPTION OF BUSINESS

AND THE LIKE), EVEN IF IOLINE HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES

ARISING FROM ANY DEFECT OR ERROR IN THIS MANUAL OR PRODUCT.

Limit of Liability Statement

It is the responsibility of the operator of the printer to monitor the performance of the printer and maintain it in proper working condition by following the instructions in this User Guide. It is the responsibility

of the operator of the printer to follow all safety precautions and warnings that are described in this User

Guide. Ioline Corporation is not responsible for injuries that may occur as a result of unsafe use. Ioline

Corporation is not responsible for substandard operational performance as a result of failure to maintain

the printer as described in this User Guide.

© 2003-2008 Ioline Corporation. All rights reserved. This manual may not be copied, photocopied, reproduced, translated, transmitted or converted to any electronic or machine-readable form in whole or in

part without prior written approval of Ioline Corporation.

Service and Support

If you require assistance with an Ioline product, your local Ioline dealer or authorized service center is

ready to help. Support information is also available 24/7 on the Ioline Web site—or you may contact Ioline

directly:

Ioline Corporation

14140 NE 200th Street

Woodinville, Washington 98072 U.S.A.

Ioline Customer Service Department

Monday through Friday

7:00 A.M. - 5:00 P.M. U.S. Pacic Time

Voice: 1.425.398.8282

Fax: 1.425.398.8383

support@ioline.com

www.ioline.com

Part Number 109619 Rev. 1

Page 3

Ioline FlexJet E

Printers

User Guide

Page 4

Table of Contents

Safety & Cautions

Visual Reference Guide

Chapter 1 Overview

Getting Started ................................................................................................. 15

How The Ioline FlexJet E and StudioJet printers Work ................................ 16

Chapter 2 Installation

Printer Assembly .............................................................................................. 17

Unpacking the Printer ......................................................................................................... 17

Assembling the Stand .......................................................................................................... 17

Attaching the Printer to the Stand ................................................................................... 17

Connect the printer to the Computer: Overview ....................................................... 17

Cable Connections .............................................................................................................. 18

Serial Conguration ............................................................................................................. 18

COM Port .............................................................................................................................. 18

Baud Rate ............................................................................................................................... 19

Other Serial Port Settings .................................................................................................. 19

Software Setup Options ..................................................................................................... 19

Power On ........................................................................................................... 21

Installing FlexPlot and the Control Center ................................................... 21

Chapter 3 Operation

Keypad Controls ............................................................................................... 23

Start/Stop ............................................................................................................................... 23

Clean ....................................................................................................................................... 24

Quality .................................................................................................................................... 24

Set Origin ............................................................................................................................... 24

Arrow Keys ............................................................................................................................ 25

Page Advance ......................................................................................................................... 25

Unroll (FlexJet E Only) ........................................................................................................ 25

Special Key Combinations .............................................................................. 25

Roll Up (FlexJet E Only) ..................................................................................................... 25

Reset Serial Port Baud Rate ............................................................................................... 25

Restore Factory Default Settings ...................................................................................... 25

The Control Center ......................................................................................... 26

Overview ................................................................................................................................ 26

Changing System Settings ................................................................................................... 26

Page 5

Control Center Menu Bar Features ............................................................... 27

File ........................................................................................................................................... 27

Communications .................................................................................................................. 27

Tools ........................................................................................................................................ 27

Help ......................................................................................................................................... 27

Control Center Menu Options ........................................................................ 28

Software Version ................................................................................................................... 28

Cartridge Count ................................................................................................................... 28

Get Plotter Data .................................................................................................................. 28

Plotter Data (check box) .................................................................................................... 28

Line Width .............................................................................................................................. 28

Scale ......................................................................................................................................... 28

Frame Size .............................................................................................................................. 28

Quality Setting ...................................................................................................................... 29

Measurement Units .............................................................................................................. 29

Consumables ..................................................................................................... 29

Paper ....................................................................................................................................... 29

Ink ............................................................................................................................................ 29

Guidelines for Installing a Cartridge

* ............................................................................................................................................... 29

Printing a Marker ............................................................................................. 30

Overview ................................................................................................................................ 30

General Guidelines .............................................................................................................. 30

Loading Paper on the StudioJet ...................................................................... 31

Loading Paper on the FlexJet E Printer ......................................................... 31

Installing the Take-up Shaft (FlexJet E Models only) ............................................ 32

Feeding Paper (FlexJet E Models only) ................................................................ 33

Tape Paper to the Take-up Shaft (FlexJet E Models only) .................................. 34

Positioning the Pinchwheels ............................................................................ 34

Insert Front Dancer Bar (FlexJet E Models only) ............................................... 35

Insert Read Dancer Bar (FlexJet E 2H+ Models only) ........................................ 36

Set an Origin ..................................................................................................... 36

Sending Plot Files ............................................................................................. 36

Pausing a Marker Plot ...................................................................................... 36

Canceling a Marker Plot .................................................................................. 37

Removing Markers from the Take-up Shaft (FlexJet E Models only) ................. 37

Manually Freeing the Take-up Shaft (FlexJet E Models only) ............................ 38

Automatically Freeing the Take-Up Shaft (FlexJet E Models only) .................. 39

Reattach Paper to the Take-up Shaft (FlexJet E Models only) .......................... 39

Printing to the Floor ........................................................................................ 40

Chapter 4 Routine Maintenance

Cleaning the Drive Shaft ................................................................................. 41

Cleaning the Platen and Traverse ................................................................... 41

Cleaning the Support Blocks (FlexJet E Models only) ....................................... 42

Size Calibration ................................................................................................ 42

Prepare the Printer (See the Operation chapter) ............................................................... 42

Use the Control Center to Gather the Calibration Data .......................................... 43

Enter the Calibration Data: ................................................................................................ 43

Cartridge Calibration ....................................................................................... 44

Prepare the Printer .............................................................................................................. 44

Motion Adjust (Carriage Scan Alignment) ..................................................................... 45

Frame Gap (Paper Scan Alignment) ................................................................................. 45

Page 6

Cartridge Maintenance and Handling ............................................................ 46

Check Cartridges ................................................................................................................. 46

Automatic Cleaning Procedure ......................................................................................... 46

Manual Cleaning Procedure ............................................................................................... 47

Print Cartridge Storage ................................................................................... 48

Short-term Storage (7 days or less) ................................................................................. 48

Long-term Storage (greater than 7 days) ........................................................................ 48

Updating Firmware using the Control Center .............................................. 48

Summary ................................................................................................................................. 48

Prepare the printer for a Firmware Update ................................................................... 48

Check the Current Firmware Version ............................................................................. 48

Update the Firmware .......................................................................................................... 49

Reset Calibration Values ..................................................................................................... 50

Chapter 5 Troubleshooting

General Troubleshooting .................................................................................. 51

Media Tracking .................................................................................................. 51

Printing Quality ................................................................................................ 52

Line Quality ....................................................................................................... 52

Serial Communication ..................................................................................... 52

Keypad Error Codes ......................................................................................... 53

Legend ..................................................................................................................................... 53

Common Issues ................................................................................................ 54

Common Issues (FlexJet E Models only) ............................................................. 57

Chapter 6 End Notes

Service & Support ............................................................................................ 59

Getting Help ..................................................................................................... 59

Customer Service ............................................................................................. 60

Your Comments Are Requested ..................................................................... 60

Before you contact Support… ........................................................................ 61

The FCC Wants You to Know... ........................................................................ 62

Glossary

Index

Page 7

NOTES

Page 8

NOTES

Page 9

The Ioline FlexJet E and StudioJet printers have many fast moving

components. Please read and follow these safety guidelines before

beginning operation of the printer:

n Do not try to repair the machine without factory authoriza-

tion. Only qualied service personnel should attempt any

disassembly or access to internal components. If external

mechanical adjustments are necessary, turn off the printer and

disconnect it from all power sources (both the computer and

the wall outlet).

Safety &

Cautions

n Be careful with hair, jewelry, or loose clothing near the printer.

They can become caught in the mechanical parts.

n Never attempt to move the carriage by hand when the power is

on. Always use the Arrow keys to move the carriage. To park

the carriage safely in

the Service Station

and protect the print

cartridges, press the

Clean button.

n Keep hands away

from the carriage

when the printer is in

operation. The car-

riage will automatically move to touch

the left end plate then

back to the right end

(the Service Station

position) when the

power is turned on.

n Never insert hands or other objects into the Service Station

area on the right side of the printer. The carriage occasionally

enters this area without warning and could collide with an

obstruction, potentially causing and injury.

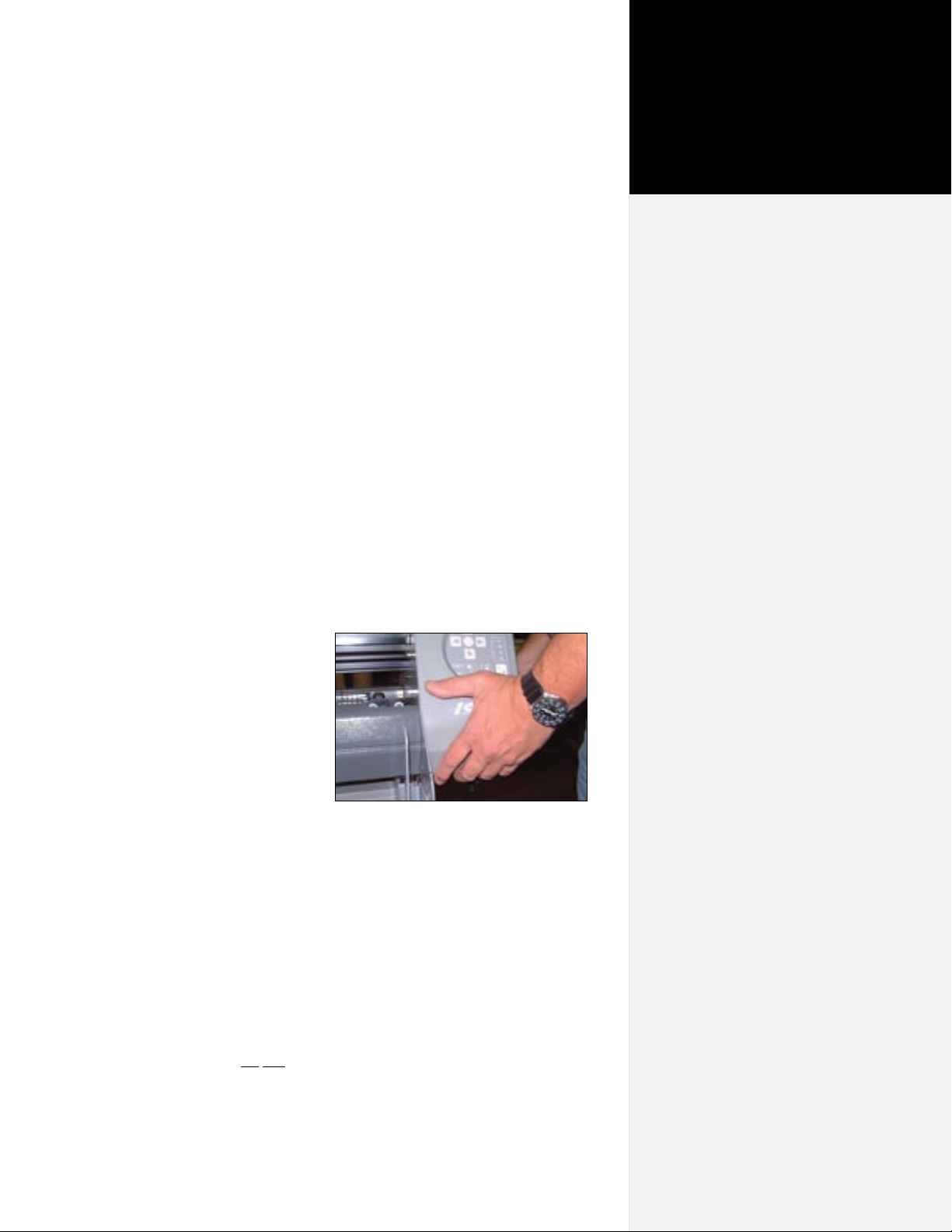

Figure 1. Hold the bottom surfaces of the

end covers to avoid injury to your ngers.

n Be careful when moving or lifting the printer. Moving the

FlexJet E printer requires at least 2 people. To avoid injury to

your ngers, do not lift either model by the end plates. Hold

the bottom surfaces of the end covers to lift or move them. See

Figure 1.

n Keep ngers away from the drive shaft when the printer is in

ix

Page 10

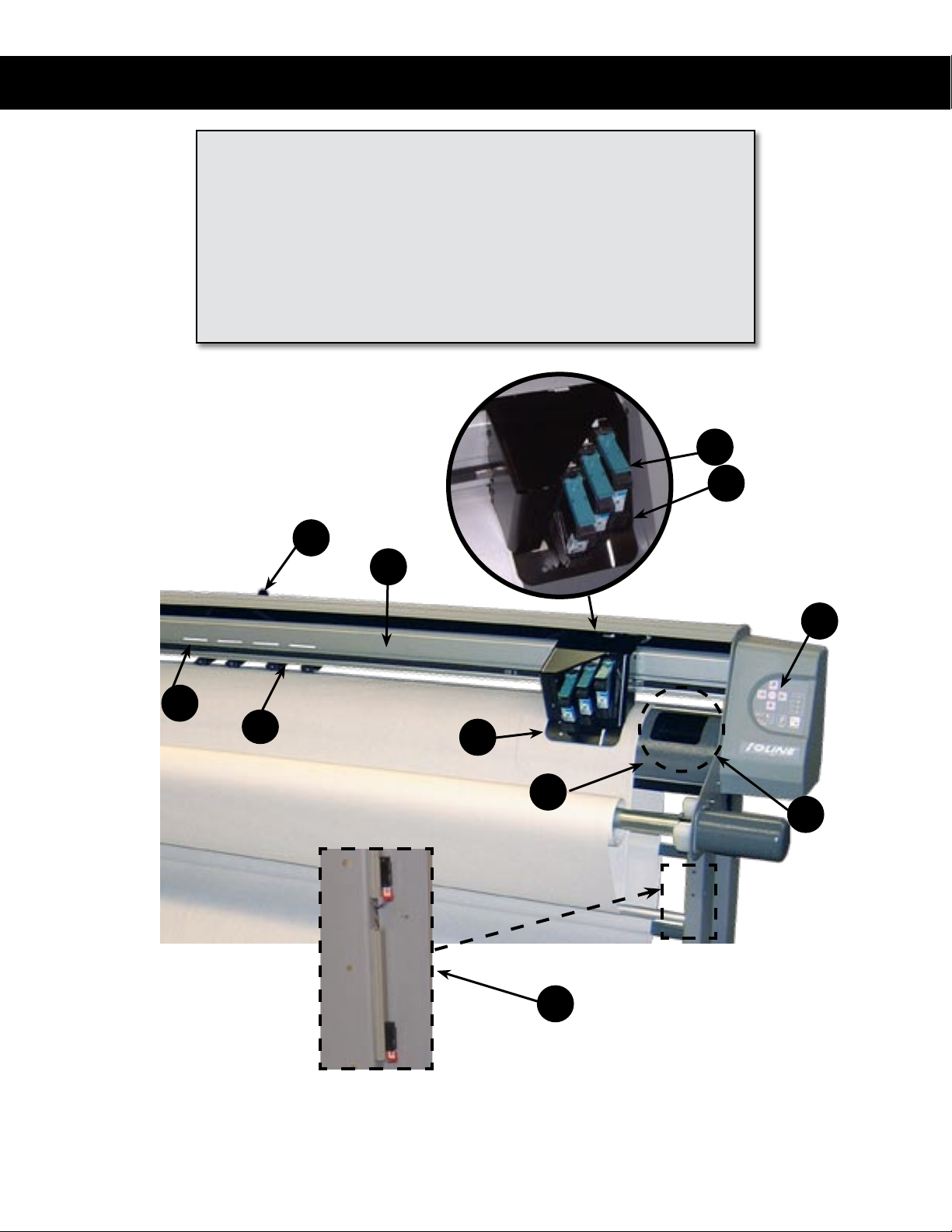

Visual Reference Guide

KEY

A

A. Left End Cover

B. Right End Cover

C. Take-up Motor

D. Stand Leveling Foot

E. Feed Roll

F. Take-up Shaft

Rear Panel Behind Right End Cover

G. Feed Shaft

H. Dancer Bar

I. Stand

AA. Power Switch

BB. Serial Port

CC. USB Port

AA BB

CC

B

F

H

I

C

G

E

D

x

The Ioline FlexJet E Printer Front View.

Page 11

Visual Reference Guide

KEY

J. Drive Shaft Marker

K. Pinchwheel

L. Traverse or Carriage Rail

M. Carriage Assembly

N. Platen

P. Ink Cartridge Latch

R

L

Q. Ink Cartridge Stall

R. Pinchwheel Lever

S. Keypad

T. Service Station

U. Take Up Sensors

P

Q

S

J

K

The Ioline FlexJet E Printer Front View Close-up

M

N

T

U

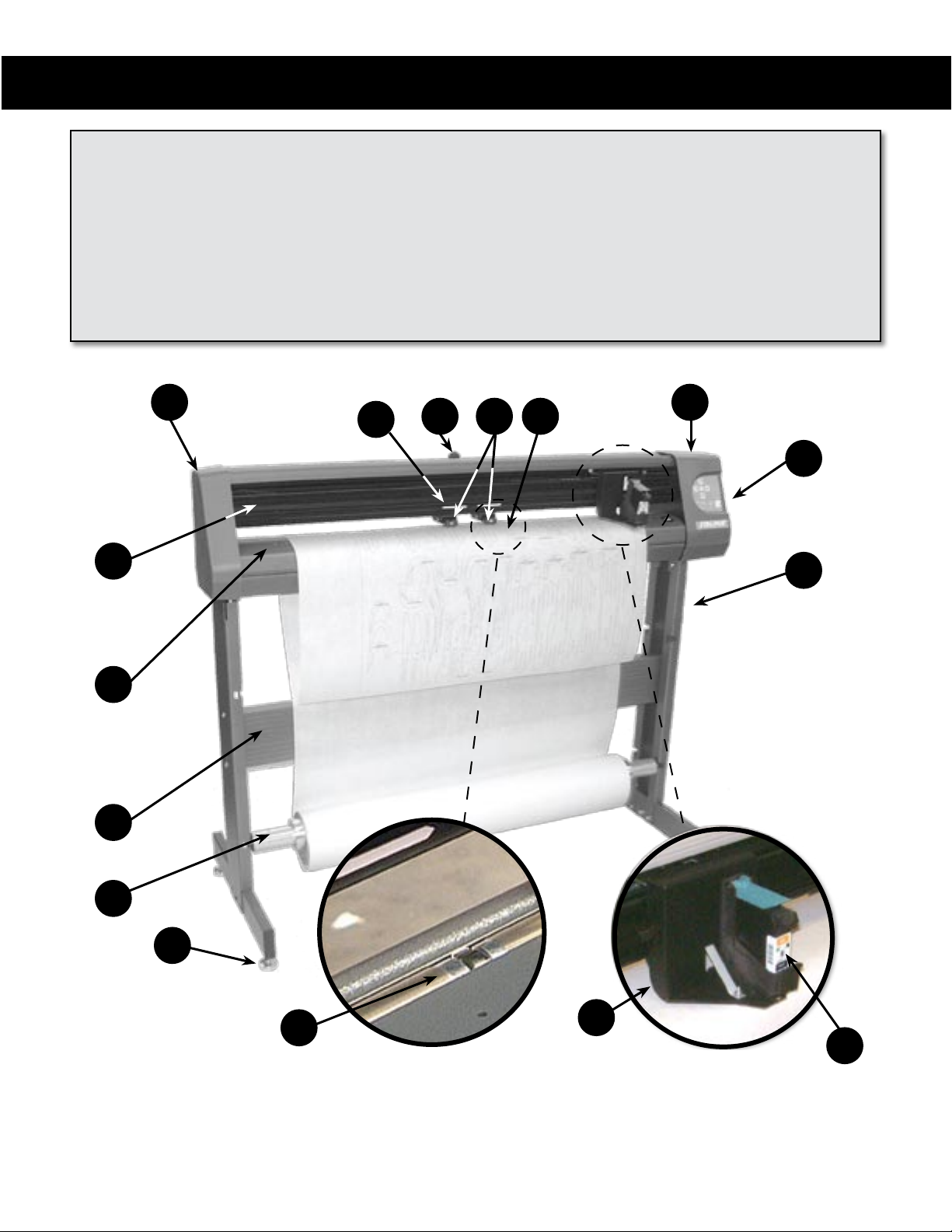

Page 12

Visual Reference Guide

KEY

A. Left End Cover

B. Drive Shaft Marker

C. Pinchwheel Lever

D. Pinchwheel

E. Drive Shaft

A

O

F. Right End Cover

G. Keypad

H. Stand Leg

I. Inkjet Cartridge

J. Carriage

B

C

D E

K. Stand Leveling Foot

L. Feed Shaft

M. Cross-member

N. Platen

O. Traverse

F

G

H

N

M

L

K

E

Figure 5. The Ioline StudioJet Front View.

J

I

Page 13

Unless otherwise noted, diagrams and descriptions depicting Ioline FlexJet E printer models also apply to the

Ioline StudioJet in this manual.

Getting Started

Chapter 1

Overview

Thank you for purchasing the Ioline FlexJet E or StudioJet printer.

This manual contains instructions and guidelines for setting up,

operating and maintaining your Ioline printer. The following components are needed to create markers:

n A FlexJet E printer assembled according to the directions out-

lined in the FlexJet E Printer or StudioJet Quick Start Guide.

n A computer system that is properly installed and has a func-

tioning serial or USB port.

n Apparel design software loaded into the computer according to

the installation instructions.

n Printing media and ink cartridges that are within the guidelines

stated under the Operation chapter.

n Depending on the communications setup, Ioline FlexPlot soft-

ware is required if your CAD software does not create compat-

ible les.

i

In order to output to the FlexJet

E or StudioJet printer, your

apparel design software must

create plot les in HPGL 7475

or DM/PL format. Alternatively,

you can output markers using the

FlexPlot software, included with

the printer. FlexPlot imports and

converts a variety of le formats

for output to your Ioline printer.

i

Note

Note

The Ioline Control Center

and FlexPlot will only run on

the Windows® 2000/XP/Vista

operating systems. Most design

software provides drivers for

Ioline printers. Contact Ioline

customer service if you need assistance with drivers.

Page 14

16

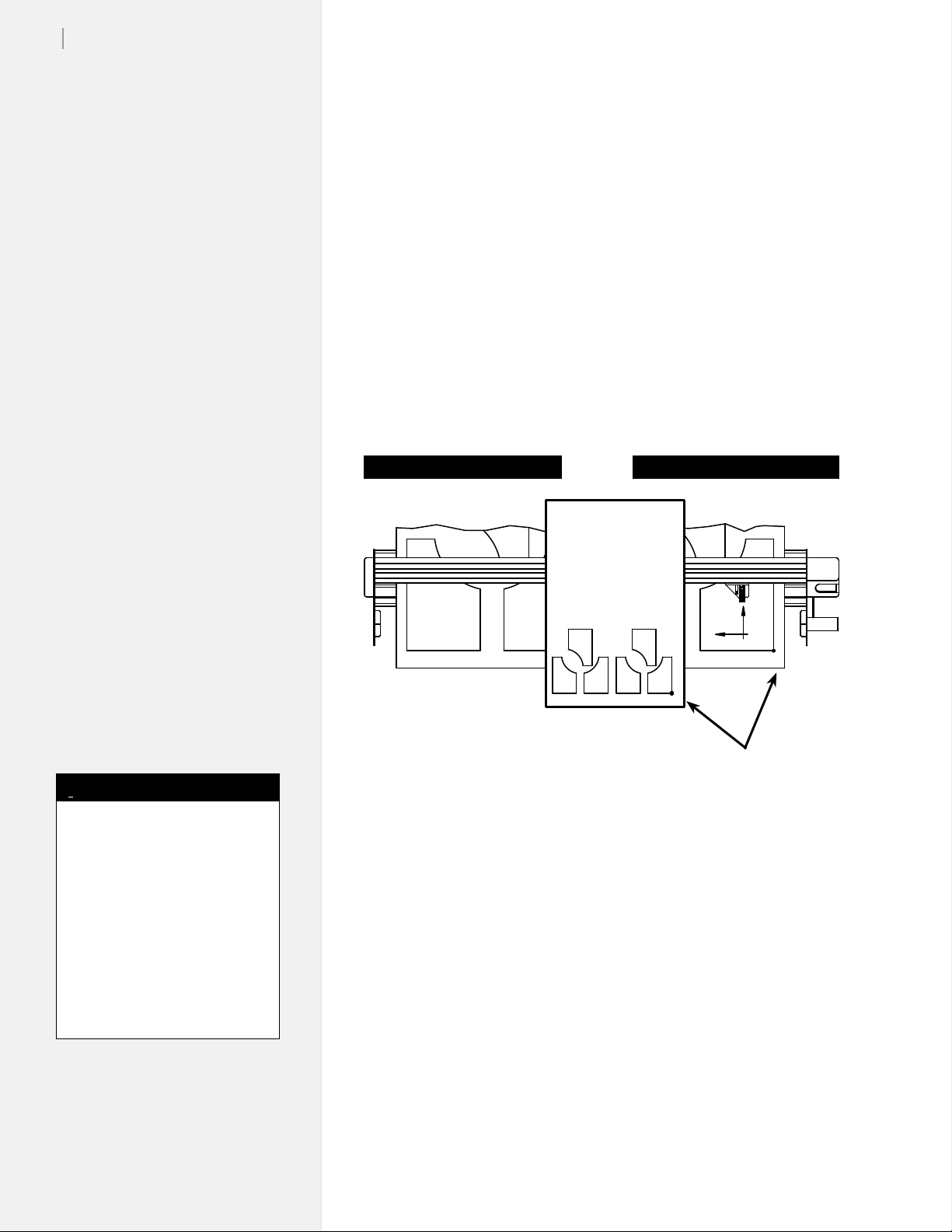

LEFT EDGE OF PLOT

LOWER EDGE OF PLOT

Y

Ioline FlexJet E User Guide

How The Ioline FlexJet E and

StudioJet printers Work

The FlexJet E and StudioJet printers create printed images through

synchronized media and carriage motion. Files are sent to the printer

from a computer or le server via a serial or USB* connection.

When the printer receives a le, the electronic logic system translates

the vector image into X-axis (paper motion) and Y-axis (carriage motion) instructions and uses digital feedback to ensure plot accuracy.

The FlexJet E and StudioJet printers break the plot le into frame

segments in order to plot long markers. The FlexJet E printer then

rolls the frame segments onto a take-up shaft. The FlexJet E printer

can roll up to 600 yards onto the take-up shaft at a time. The Studio-

Jet plots to the oor.

Left side of FlexJet E printer Right side of FlexJet E printer

i

In this manual the right and left

side refers to the right and left

side of the front of the printers.

Design software usually refers

to the Origin (or Start Point)

as “lower left” because it is the

lower left corner of a plot. The

plot is usually oriented in the

printer rotated 90 degrees counter clockwise as shown in Figure

5. The lower left corner of the

plot is physically on the right side

of the printer.

* Note: The StudioJet has a serial

port. The FlexJet E has both a se-

rial port and a USB port.

Note

Origin at right side of printer

and lower left on plot

Figure 7. The X- and Y-axes and origin (top view).

Page 15

An overview of the complete setup procedure is described

in detail in the FlexJet E Printer and StudioJet Quick

Start Guides (provided in the Accessory Kit).

Chapter 2

Installation

Printer Assembly

Unpacking the Printer

Carefully remove the printer from the box and place it on a at,

stable surface. This procedure requires two people. Check the packing list to ensure that all of the accessories are present. (See the FlexJet

E printer or StudioJet Quick Start Guide for more information.) Save all

packing materials and the box.

Assembling the Stand

Assemble and level the stand using the hardware included in the Accessory Kit and directions outlined in the See the FlexJet E printer or

StudioJet Quick Start Guide.

Attaching the Printer to the Stand

Attach the printer to the stand with the top bars resting in the

notches in the stand legs. Use the hardware as indicated in the See the

FlexJet E or StudioJet Quick Start Guide.

Connect the printer to the Computer: Overview

Connect the printer to your computer via serial cable (provided in the

Accessory Kit). The corresponding serial port on your computer may

be either a 9-pin or 25-pin male receptacle. If the computer has 25-pin

serial ports, a 25- to 9-pin adapter is necessary.

Once connected, select the correct port and data rate in your apparel

design software, FlexPlot and/or the Control Center. Consult the

design software manual or the dealer for further information. Information on conguring FlexPlot and the Control Center follows in

the Operation chapter.

Caution

Do not hold the printer

head by the bottom edge

of the end plates when

attaching it to the stand. Fingers

and hands might get pinched

between the end plates and stand

legs. Hold the bottom of the end

covers when handling the printer.

(See Figure 1.)

Caution

Before connecting the

printer to your PC, make

sure the computer and

the printer both have the power

turned off. Ioline recommends

using a surge protector power

strip for both the printer and the

computer.

Page 16

18

Ioline FlexJet E User Guide

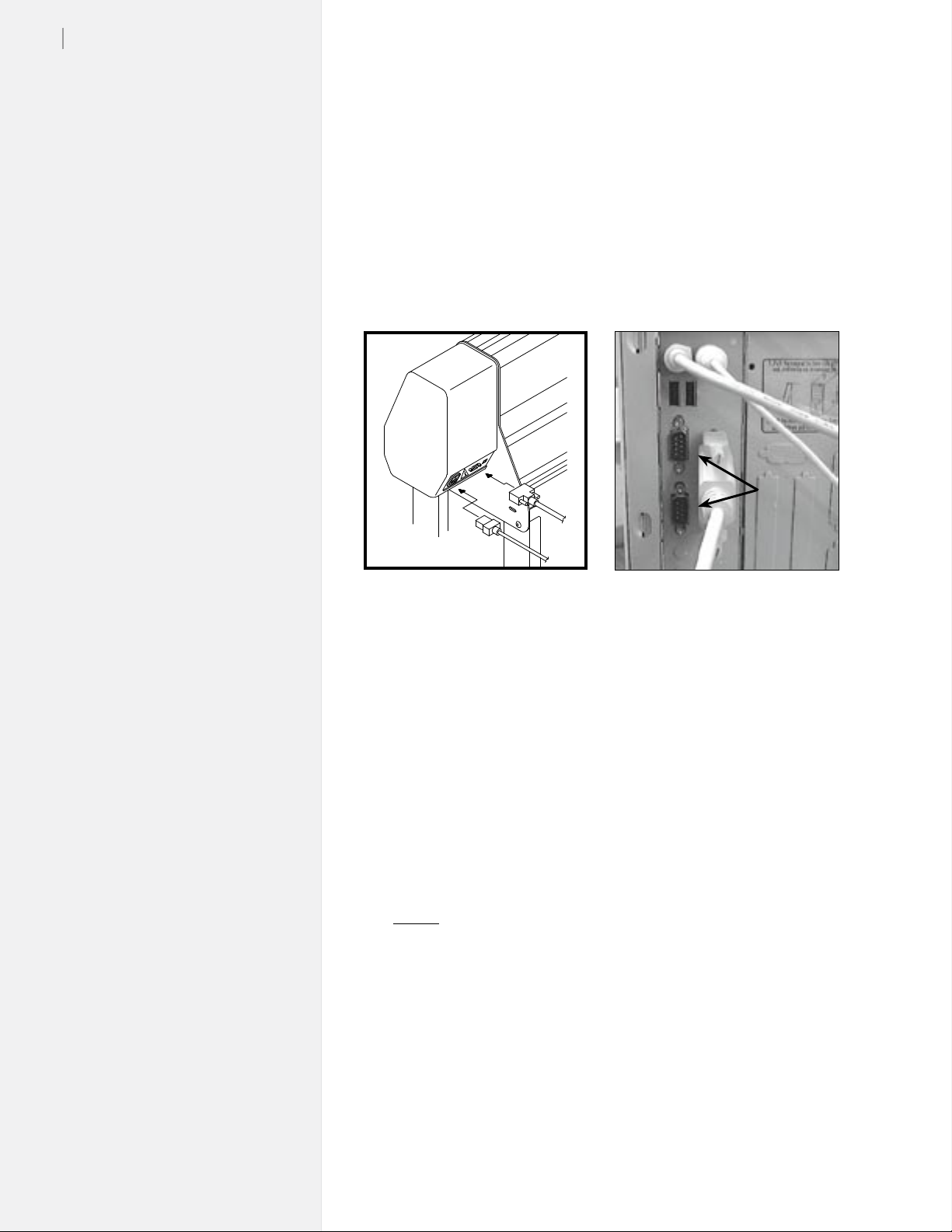

Cable Connections

When connecting the printer to the computer by serial cable:

1. Make sure that power to the printer is off. Power is off when

the switch is in the “0” position, and is turned on when placed

in the “1” position.

2. Connect the supplied serial cable and power cord to the panel

on the back right end cover of the printer. Lock the serial cable

to the port on the printer with the thumb screws.

COM

Ports

Figure 8. The serial cable and power

cord plug into the sockets in the back

of the right end cover.

3. Plug the printer power cable into a wall socket or a surge protector.

4. Make sure that power is off to the computer.

5. Connect the serial cable to a 9-pin male serial port on the back

of the computer. (If your computer has a 25-pin connector,

acquire a 25-pin to 9-pin serial adapter to make the connection.)

Tighten the thumbscrews.

Figure 9. PCs typically have two 9-pin

serial ports, COM 1 and COM 2.

Serial Conguration

It is critical that the Control Center, FlexPlot software, and any other

software that send data to the printer use the same COM port and

baud rate that the printer is using.

COM Port

A PC typically has two external 9-pin male serial connections.

These ports are often listed in the system settings as COM 1 and

COM 2. Determine which port is connected to the printer, then

select that port in all the software as instructed in the respective

software user guides. (See Figure 10.)

Page 17

Figure 10. FlexPlot Serial Port set-up window.

Baud Rate

The serial port on the printer has an adjustable baud rate. Available

speeds are 9600, 19200, 38400, 57600, and 115200. The default is set

at the factory to 38,400. The baud rate is adjustable in the Control

Center in the Communications>Settings window.

Chapter 2: Installation

19

Other Serial Port Settings

You may also need to set additional serial port settings, for instance,

when you use a terminal program. The recommended conguration

settings are:

Data Bits: 8

Parity: None

Stop Bits: 1

Flow Control: Software or Xon/Xoff

Software Setup Options

Ioline recommends using FlexPlot for marker making on the printer. FlexPlot offers the most robust and exible workow available

for creating output. It’s especially useful when many le formats are

used, a common situation for service bureaus. To set-up and learn

how to use the software, see the FlexPlot User Guide.

The printer is designed to work in many different production environments. The type of marker printing you do will often determine

your preferred communication method. Two typical methods for

sending markers are:

1. Plot directly from the marker or design software to the

printer. (See Figure 11.)

Unlike other marker printers, the FlexJet E and StudioJet print-

ers are capable of operating as stand-alone devices with no extra

software running on the computer. This method works if your

CAD software includes a driver for any Ioline product, such as

the Ioline 600Ae or the Summit 2200. It will also work if the CAD

software can create a compatible HPGL- or DM/PL-formatted le.

Page 18

20

Ioline FlexJet E User Guide

CAD

Software

HPGL

DM/PL

FlexJet E printer

Figure 11. Workow: output direct from CAD software (without FlexPlot).

2. Use FlexPlot software to convert les before sending them

to the printer for output.

The printer includes the FlexPlot software which will convert

many different les into a format that is compatible with the

printer. It also provides an advanced marker queue management system and other tools to optimize the performance of the

printer.

CAD

Software

[Network]

FlexPlot

HPGL

DM/PL

DXF

ASTM 6959

STD

(Alternate Conguration)

CAD

Software

+

FlexPlot

FlexJet E printer

Figure 12. Workow using FlexPlot for le conversion and output.

Page 19

Chapter 2: Installation

21

Power On

Turn on the computer and the printer to make sure they both work.

The printer power switch is located next to the power cord on the

back of the machine, behind the keypad. When the paper is properly

loaded and the printer is powered up, the carriage will move toward

the left side of the machine, then return to the opposite side to park

in the Service Station. The OK light will turn red and the Square

light will turn green on the front panel after the start-up process has

nished.

If no paper is loaded when the printer is powered up, the printer

displays an error message. The OK light will turn red and the Circle

light will turn orange. This combination of lights indicates a paper

out error. The keypad buttons do not work unless paper is properly

loaded—or a small piece of masking tape is placed over the Paper

Out sensor on the back of the printer. Once paper is loaded or the

sensor is taped over, press the Start/Stop button to clear the orange

circle and regain use of the keypad.

Installing FlexPlot and

the Control Center

The printer includes two software interfaces: FlexPlot and the

Control Center. FlexPlot will import and queue plot les from

many design programs to optimize production operations. The

Control Center is an interface for adjusting parameters to optimize

printer performance. The printer comes with a CD-ROM which has

Microsoft Windows® 2000/XP/Vista versions of the programs as

well as PDF user guides and the required Adobe® Acrobat® reader.

Caution

Keep hands and loose

clothing away from all

moving parts of the

printer. Make sure the Service

Station opening in the right end

plate is not obstructed and that

the stall latches are lowered.

i

In this manual the right and left

side refers to the right and left

side of the front of the printer.

Design software usually refers

to the Origin (or Start Point)

as “lower left” because it is the

lower left corner of a plot. The

plot is usually oriented in the

printer rotated 90 degrees counter clockwise as shown in Figure

5. The lower left corner of the

plot is physically on the right side

of the printer.

Note

1. Power on the computer and Windows®.

2. Insert the Ioline CD-ROM into the CD-ROM drive (usually D:).

3. The installation program should start automatically. If it does

not:

a. Select the Start button.

b. Choose Run.

c. Type D:\IOSETUP (substitute the correct letter if the CD-

ROM drive letter is not D:) and Click OK.

4. Follow the instructions that appear on the screen.

5. The FlexPlot User Guide has details on using the FlexPlot

software. In this manual, see the section The Control Center for

more details about the Control Center software.

Page 20

22

Ioline FlexJet E User Guide

This page intentionally left blank

Page 21

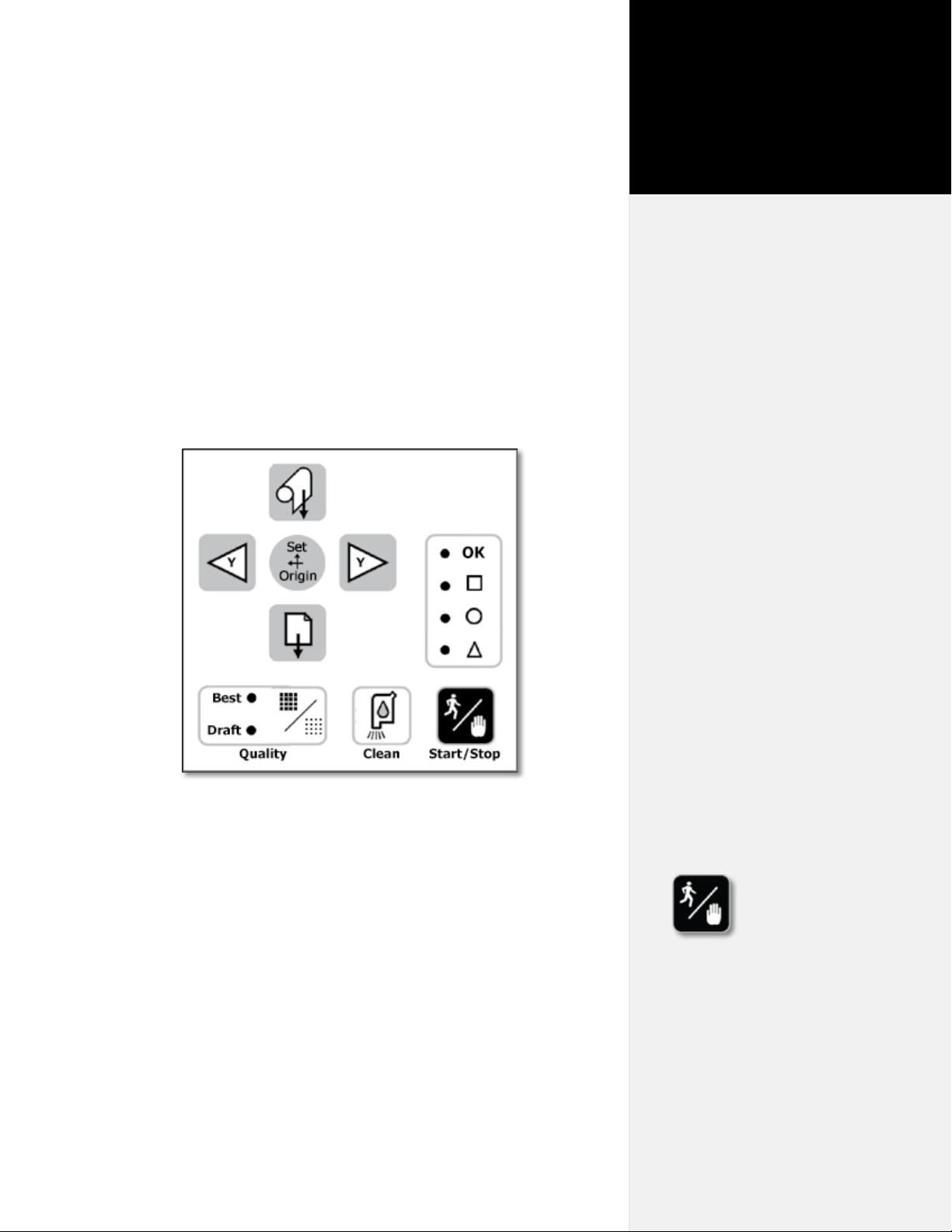

Keypad Controls

The keypad provides access to the main functions of the printer.

Chapter 3

Operation

Figure 13. The Printer Keypad.

Start/Stop

The Start/Stop key toggles the printer online and ofine. If the Start/

Stop key is pressed during printing, the OK light turns red and

the machine will stop after it nishes printing the current scan. The

Arrow, Unroll and Paper Advance keys are active when in STOP

mode. When the Start/Stop key is pressed again, the printer enters

START mode, the OK light turns green and printing resumes exactly where it stopped.

START mode OK = green Arrow keys inoperable,

printer online (ready to receive instructions).

STOP mode OK = red Arrow keys operable,

printer ofine (not ready to

receive instructions).

Page 22

24

Ioline FlexJet E User Guide

Clean

Runs the print heads through a cleaning cycle in the Service Station.

Put the printer in STOP mode and wait until the OK light turns red.

Then press the Clean button. If the carriage is not already parked,

it will return to the Service Station. After auto cleaning, the printer

will react differently when you put it in green light (START) mode,

depending on what it was doing just prior to the cleaning:

Printer state before auto cleaning—e.g.

what the printer is doing just before it is put

in STOP (red light) mode

Printing in START mode (OK light is green) Resumes printing

Idle in START mode (OK light is green) Stays parked and capped.

Idle, in STOP mode (OK light is red) Stays parked and capped.

Printer reaction when put in

START mode after auto cleaning

Quality

Switches between the Best—or dark (600 dpi)—line mode and Draft

mode (300 dpi), which prints lighter and consumes less ink. You can

change line quality while the printer is printing.

Set Origin

The Set Origin key sets the initial origin or starting position for the

marker. It’s best to always set a new origin point after cycling power.

To set a new origin, press Start/Stop until the OK light turns red

(STOP mode). Use the Arrow keys to move the carriage so that the

white marker is positioned over the desired starting point. Press the

Set Origin key. The OK light will turn green, indicating the printer

is ready to accept plot les. (See Figure 14.)

i

Apparel design software usually

refers to the origin as “lower

left” because it is the lower left

corner of a marker. Because the

plot is usually oriented as shown

in Figure 5, it is physically on the

right side of the printer.

Note

Origin Marker

Figure 14. The Set Origin key sets the marker origin point directly below the

top of the white origin marker on the carriage base—located on the right side.

Page 23

Arrow Keys

Pressing the Arrow keys moves the carriage left or right. The Arrow

keys are only active in STOP mode (see Start/Stop), when the OK

light is red.

Page Advance

Pressing this button advances the paper in small increments. This is

useful if a plot was removed from the printer and you need a paper

leader to tape to the take-up shaft. The Page Advance key is only active in STOP mode (when the OK light is red).

Unroll (FlexJet E Only)

Unroll Material – Press the Start/Stop button until the OK light turns

red. Press and release the Unroll button. The printer will unroll a

short segment of paper from the take-up shaft.

Automatic Unroll – Press the Start/Stop button until the keypad

light turns red. Press and hold the Unroll button. The printer will

automatically unroll paper. To cancel Automatic mode, press the

Start/Stop key again.

Chapter 3: Operation

i

For more details on removing

plotted markers from the take-up

shaft see Removing Markers

from the Take-Up Shaft later in

this chapter.

Note

25

Special Key Combinations

Roll Up (FlexJet E Only)

Use this function to roll material back onto the take-up shaft. Press

and hold the Unroll and Right Arrow buttons at the same time. The

rolling will continue until the dancer bar reaches the optical sensor.

The Roll Up key is only active in STOP mode (when the OK light is

red).

Reset Serial Port Baud Rate

This key combination will restore the serial port baud rate to the

default speed of 38,400. This is useful for diagnostic testing of the

communication system. Turn power off. Press and hold the Page

Advance key as you turn power on again. Continue holding the key

down until the OK light turns red and the Square light turns green.

Restore Factory Default Settings

This function replaces settings that are not working properly and can

be used when manual calibration is unsuccessful. This key combination will restore all calibration values to the factory defaults. Turn

power off. Press and hold the Unroll key as you power up again.

Continue holding the key down until the OK light turns red and the

Square light turns green.

+

+

+

1

0

1

0

Page 24

26

Ioline FlexJet E User Guide

i

To avoid communication port

conicts, do not simultaneously

run more than one application

that communicates with the

printer.

Note

The Control Center

Overview

The Control Center is a utility program that does two things:

n Allows you to adjust settings to tailor output (e.g. scale, line

width) from the computer.

n Provides an interface to send completed les to the printer.

Figure 15. Control Center Main Menu.

Changing System Settings

A variety of settings are adjustable to t specic needs:

n Make sure the printer power is on and that the initialization

process is complete. The carriage will park, the keypad OK

light will turn red and the Square light will turn green.

n The Screen Menu displays the primary settings that are adjust-

able. The Menu Bar contains utilities for setting up the Control

Center and calibrating the printer.

n Changes only take effect after one of the Send buttons is

pushed.

Page 25

Control Center Menu Bar Features

File

Send Plot File Print a PLT or PLX le.

Download Firmware Allows the user to download the lat-

est rmware version for the printer.

See the section Downloading Firmware in the Routine Maintenance

chapter for more information.

Exit Exit the Control Center.

Communications

Settings Select the COM port and baud rate

to match the printer.

Send Command Permits advanced users to manually

enter commands.

Chapter 3: Operation

27

Automatic Buffer Creates an End of Frame command

Closing after a long communications delay.

By default this is set to On. Turn off

for MAC computers.

USB Info USB Info displays hardware and

driver information about the direct

USB connection.

Tools

Aux Sensor When checked, disables the Paper

Out sensor. The default is On. (The

Paper Out sensor is an option on the

printer.)

Cartridge Calibration Displays tools to adjust print

cartridge alignment. See Routine

Maintenance for more details.

Size Calibration Allows adjustment of the size cali-

bration settings. See Routine Main-

tenance for more details.

About Your FlexJet Displays the licensing status of the

machine.

FlexJet Licensing Displays the licensing status and

licensing updates.

Help

Contents Displays the Help le.

About Displays Control Center version

information.

Page 26

28

Ioline FlexJet E User Guide

Control Center Menu Options

Firmware Version and Base

Displays the current rmware version installed in the printer.

Enabled Heads

Displays how many cartridges are in active use by the printer.

Get Plotter Data

Reads and displays the current settings stored in the printer.

Plotter Data (check box)

Indicates when the displayed settings were successfully downloaded

from the printer. If this box is unchecked, the Control Center was

unable to connect with the printer Check the connections, baud rate

and COM port . Press the Get Plotter Data button to attempt to

download settings if the process failed during startup.

Loop Length

Controls the length of the take-up paper loop in the front of the

machine. Shorter loops can help reduce paper jams when using challenging material like heat seal or very thin paper.

Line Width

Controls the weight of the plotted line using line width. Three levels

are available; Thin, Normal, and Thick. Thin lines use less ink and

make ne details like Asian text and small pieces easier to see. Thick

lines use more ink to produce higher contrast lines. Used in conjunction with the Quality Setting (see below), the printer provides six options to produce visible lines using the least possible amount of ink.

Scale

The printer scale ranges from 1% to 999%. The factory default Scale

is 100%. A scale set to 50% prints at half size. Changes do not take

effect until the Set Scale button is pressed. Note: Both X- and Y-axes

are set independently.

Frame Size

Most design software sends long plots to printers by breaking them

into smaller pieces called frames. In general, design software does this

automatically and adjusts the Frame Size in the printer to match.

The Frame Size setting establishes clipping limits for each data

frame. If the printed size of a plot frame exceeds the frame size set

in the printer, the excess is clipped or thrown away. (If the plot is

clipped, try increasing the Frame Size manually.) The factory-set

Page 27

X-axis (paper direction) frame size is 46-in (116.8-cm), maximum is

21600-in (54,864-cm). Default and maximum Y-axis (carriage direction) frame size is 72-in (182.9-cm).

Quality Setting

Choose Draft or Best to control line density. Draft mode uses 300 DPI.

Best mode uses 600 DPI. A lower DPI setting uses less ink by creating

a fainter line. Higher DPI uses more ink but makes a darker line. Use

this setting in conjunction with the Line Width (see above) to nd a balance between saving ink and making clearly visible lines.

Measurement Units

Choose between English or Metric units for settings display.

Consumables

Chapter 3: Operation

29

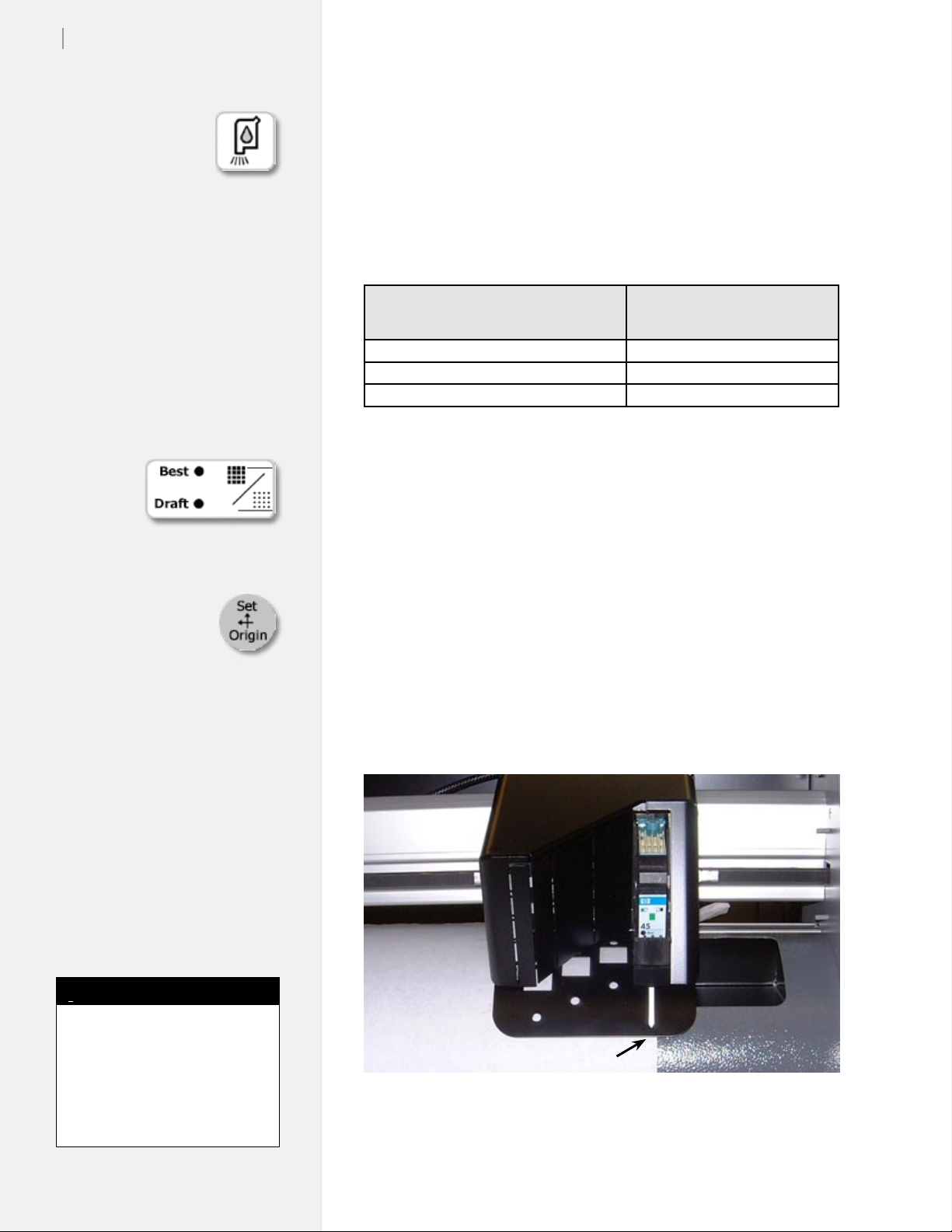

Figure 16. The Hewlett-Packard 51645A (‘45’ cartridges)

are widely available.

Paper

Ioline recommends 27 to 35 pound recycled or bond paper, 36- to 74-in

(91- to 188-cm) wide. The feed system supports rolls up to 600 yds long.

Ink

The Ioline FlexJet E and StudioJet printers require Hewlett-Packard

51645A or ‘45’ cartridges.

Guidelines for Installing a Cartridge

1. With the printer in STOP mode (red OK light), press the left

arrow key to move the carriage out onto the platen away from

the right end plate.

2. Open the blue stall latch and remove the old cartridge if one is

present. Squeeze the handle between your ngers and pull forward, then up.

*

Page 28

30

Ioline FlexJet E User Guide

Figure 17. Insert ink cartridge at an angle into the cartridge bay. Lock in place with

the stall latch.

3. Insert the new cartridge with the print head pointing down

toward the rear of the stall and at a slight outward angle. Press

rmly while rotating the top of cartridge toward the back of the

stall until it stops in an upright position. (See Figure 17.)

4. Close the stall latch. If the cartridge is inserted properly, the

latch will snap shut and securely hold the cartridge. Do not

force the latch. If the latch does not close properly, remove and

reinsert the cartridge.

Printing a Marker

Overview

The basic steps required to print a marker on the printer are:

1. Turn the printer and computer power on.

2. Load paper.

3. Install cartridge in the stall.

4. Set an origin.

5. Start FlexPlot or your design application.*

6. Send marker/plot les.

These steps are outlined in the next several sections. In most cases

the design les are sent to the printer from FlexPlot or the design ap-

plication. If necessary, use the Ioline Control Center to send design

les or adjust settings.

* Refer to the FlexPlot User Guide

for information on set-up and

conguration.

General Guidelines

1. Good paper loading makes good plots. Follow loading instructions carefully.

2. Ensure that the paper roll is properly loaded on the feed shaft.

Paper width determines the roll’s position on the shaft.

3. Keep the plastic feed shaft block clean and well lubricated.

4. Use the FlexPlot software for optimal le management and

printing throughput.

Page 29

Chapter 3: Operation

31

Loading Paper on the StudioJet

See the StudioJet Quick Start Guide.

Loading Paper on the FlexJet E

1. Before loading a new paper roll always make sure the drive shaft

is clean. See the Routine Maintenance section for more details.

2. Place a paper hub in each end of the paper roll using a rubber

mallet.

3. Slide the feed shaft through the paper hubs and the paper roll.

If a paper hub falls out, press it rmly back into the end of the

paper roll and re-seat it with a rubber mallet.

4. For paper narrower than 70-in, center the paper roll on the feed

shaft. Make sure the hubs remain securely in place. For paper

greater than 70-in in width, offset the paper to the left slightly

to avoid covering the Service Station area. Also leave a minimum 1/4 inch gap between the paper edge and the edge of the

fan on the left side of the rear cover of the machine.

5. Use the supplied hex wrench to tighten both screws on each

paper hub.

6. Check that the right support block is clear of debris and apply a

light coating of white lithium grease (found in the Accessory Kit.)

Caution

Keep hands and loose

clothing away from all

moving parts.

7. Lift the feed shaft ends, one at a time, into the support blocks.

Support

Block w/

Bearings

Feed

Shaft

Paper Roll

(Unrolls from behind)

Support Block

(apply grease)

Hint

The FlexJet Set-up, Operating and

Maintenance Video, provided on

CD-ROM in the Accessory Kit,

provides a helpful visual overview.

i

Note

Paper Hub (2)

Figure 18. Installing the feed shaft. (As shown on the FlexJet E model.)

Flanged Coupling

Make sure the paper unrolls from

behind and towards the printer.

Page 30

32

Ioline FlexJet E User Guide

Caution

Never touch the take-up

key or anged coupling

while they are rotating.

Serious

personal

injury

could re-

sult. Turn

power off

rst.

Installing the Take-up Shaft

(FlexJet E only)

The Paper Out sensor on the back of the printer detects when the

paper runs out. If paper isn’t loaded or if the take-up key is not positioned properly, place a small piece of masking tape over the Paper

Out sensor before following the steps below. Remove the tape after

the take-up key is properly positioned before installing paper.

1. If the take-up shaft has plotted markers on it, remove them. See

Removing Markers from the Take-up Shaft later in this chapter.

2. Turn the printer on (the switch is on the back of the left cover.)

3. Use the keypad Unroll key to rotate the take-up key until it is

oriented perpendicular to the support block opening as shown

in Figure 19.

4. Put the take-up shaft into the front support blocks with the

anged coupling at the right (keypad) end. Rotate the shaft

until the slot in the anged coupling is aligned with the take-

up key. When the shaft slot and the key are aligned, push the

Rectangular

slot

Take-up

Shaft

Figure 19. Installing the take-up shaft in the support blocks.

Flanged

Coupling

Position take-up

key as shown

Support Block

Page 31

take-up shaft into place until it is seated in the support block.

Feeding Paper

(FlexJet E only)

Figure 20 represents the proper paper path. The left side of the diagram shows the paper path for a 1H FlexJet E. The right side shows

the proper path for a FlexJet E with 2 or more heads.

1. Remove any printed markers from the take-up shaft and make

sure the carriage is parked in the Service Station before feeding

the paper. (To park the carriage, press Start/Stop. Wait for the

OK light to turn red and press the Clean button.)

2. If the pinchwheels are lowered, raise them by pushing the

pinchwheel lever away from the machine.

3. Pull a long leader of paper off of the paper roll and insert it

through the stand, behind the plotting head between the platen

and pinchwheels.

Chapter 3: Operation

33

4. Temporarily lock the paper in place by pulling the pinchwheel

lever toward the machine to lower the pinchwheels.

Front

Dancer Bar

Take-up

Shaft

Feed Roll

Proper Paper Path

1H FlexJet E

Figure 20. The correct paper feeding path on the Ioline FlexJet E printers. (See the

StudioJet Quick Start Guide for paper path instructions for the StudioJet.)

Proper Paper Path

2H+ FlexJet E

Page 32

34

Ioline FlexJet E User Guide

i

When installing or retaping paper,

remove the front dancer bar and

set it aside.

Note

Tape Paper to the Take-up Shaft

1. Stand in front of the machine.

2. Place 3 short pieces of masking tape within easy reach on the top

cover. (See Figure 21.)

3. Holding the edge of the paper with one hand, use your free

hand to lower the pinchwheel lever to raise the pinchwheels.

4. Grasp the front edge of the paper with both hands and pull

20-in (51-cm) of paper over the platen and gray top bar and

under the take-up shaft. (See Figure 20 for the proper paper path.)

5. Add tension to the feed roll by applying gentle pressure using

the bottom of your foot.

6. To align the paper, gently pull it forward and side to side until

the tension feels even.

7. Press and hold the paper on the center of the platen with your left

hand, then lower the pinchwheels to lock the paper in place.

8. Attach the paper to the take-up shaft in the center and 2-in (5-cm)

from each end with the tape.

Do not cover the hole in

the platen with paper.

Tape the paper

in 3 places

Figure 21. Taping the paper to the take-up shaft.

Positioning the Pinchwheels

Pinchwheel position does not correspond to paper size. Always place

all pinchwheels at the machine center.

1. Ensure that the paper is loaded as described in the previous steps

and is taped to the take-up shaft.

2. Raise the pinchwheels by pushing the pinchwheel lever away

from the machine.

Page 33

Chapter 3: Operation

35

Pinchwheel

White Driveshaft Markers

Drive Shaft

Segment

3. Make sure that the paper roll is tight on the feed shaft.

4. Move the pinchwheels into their proper positions over a tread and

under the white markers on the traverse rail. (See Figure 22.) Do

not place pinchwheels over drive shaft bearings.)

5. Lower the pinchwheels.

Drive Shaft

Bearing

Figure 22. Positioning the pinchwheels.

i

Ensure that the paper roll is centered on the feed shaft.

Note

Insert Front Dancer Bar

(FlexJet E only)

1. With the pinchwheels lowered, hold the paper in place over the

rear top bar.

2. Insert the front dancer bar into the dancer bar channel.

Front Dancer

Bar (Silver

light rod)

Figure 24. Inserting the dancer bar.

Page 34

36

Ioline FlexJet E User Guide

Insert Rear Dancer Bar (2H+ FJE Models Only)

1. FJE models with two or more printheads and the high speed

printing kit require that a heavy dancer bar is inserted in the

rear dancer bar channel (see paper path in Feeding Paper).

2. Take the heavy dancer bar (painted black on some models) and

insert the ends into the notches in the stand legs on the back of

the machine as shown in the image below.

3. Use a hand on the rear rolling bar to slow rotation as the dancer

bar slides into the channel and forms a rear paper loop.

Notch in Stand Leg

* See the FlexPlot User Guide or

your design application user guide

for information on how to send

les to the printer.

Set an Origin

1. Ensure that cartridges are installed in the carriage stall(s). (See

Guidelines for Installing a Cartridge earlier in this chapter.)

2. Turn on the power. After a brief pause, the carriage will glide to

the left end plate, then return to the Service Station. When nished, the OK light turns red and the Square light turns green.

3. Press the Left Arrow key to position the carriage so that the tip of

the white marker is over the desired starting point of the plot.

4. Press the Set Origin key. The OK light will turn green. The

printer is ready to plot.

Sending Plot Files

Send plot les to the printer using FlexPlot or design software. Make

sure the power is on and paper is loaded as described above. Also,

be sure that a new origin is set with the Set Origin keypad button

and that the printer is in Start mode (green light). From FlexPlot*:

1. Choose input le type and location then double click on the le.

2. Conversion will occur and the Send to Queue button is acti-

vated. Press this button to add the le to the queue.

3. Repeat steps 1 to 2 until the all les are queued then press Send.

Caution

Do not pull paper tight

between the drive shaft

and the take-up shaft while

printing is paused. Do not turn the

feed roll or take-up roll by hand

while printing is paused.

Pausing a Marker Plot

1. Pause a plot by pressing the Start/Stop key.

2. The OK light will change from green to red. The printer will nish

printing the current scan, then pause.

3. Once printing stops, use the keypad keys to move the carriage,

paper, and take-up shaft. When Start/Stop is pressed again (OK

light turns green) printing will start again where it left off.

Page 35

Canceling a Marker Plot

1. Press the Start/Stop key to place the printer in STOP mode (red

light). The printer will nish printing the current scan and pause.

2. To stop the computer from sending plot les to the printer,

click the Abort button in FlexPlot.

3. Use the keypad Arrow keys to position the carriage for the start of

a new plot le as described earlier.

4. Press the Set Origin key to ready the printer for the next plot le.

Removing Markers from the

Take-up Shaft

(FlexJet E Only)

1. Press Start/Stop until the OK light changes to red (STOP mode).

2. Wait for the plotting to halt.

3. Remove the dancer bar. Rest it on the top of the cover for storage.

4. Cut the paper with the supplied cutting tool, using the groove

in the front of the platen as a guide.

5. Use one of the following methods to remove completed markers:

Chapter 3: Operation

i

Except when the feed roll is

changed, it is best to leave the

pinchwheels down when removing

completed markers from the takeup roll. Leaving the pinchwheels

down will help keep the paper

aligned with the feed roll and

reduce the time between printing

operations.

Note

37

Method 1: Unroll with the take-up shaft in place

a. With the power off, rotate the take-up shaft by hand until

the rectangular opening in the anged coupling is perpendicular to the opening in the support block (see Figure 19).

b. Remove the shaft from the support blocks.

c. When unwound, the plotted image faces up, permitting

markers to be unrolled onto the cutting table with the

take-up shaft in place.

Method 2: Manual unroll with the Unroll key

a. Press the Unroll key to unroll full markers in short steps.

b. Cut the marker free from the take-up shaft. Reattach the

paper to the take-up shaft with masking tape following the

steps outlined under the section Reattach Paper to the Take-

up Shaft later in this chapter before continuing printing.

Method 3: Automatic Unroll with the Unroll Key

a. Press and hold the Unroll key for 3 seconds; The take-up

shaft will automatically unroll.

b. Cancel automatic unroll at any time by pressing Start/Stop.

Method 4: Remove the shaft and unroll away from the machine

a. Cut the marker free, wind it manually or automatically with

the take-up motor, and remove the take-up shaft from the

support blocks.

Caution

The take-up shaft is very

heavy when many plots

have been rolled up. It is

recommended that two or more

people remove a full take-up roll

from the machine.

Hint

An alternate method to ease

removal of markers is to slide

a 3-in cardboard core over the

take-up shaft then tape paper to

it. The cardboard core will rotate

slowly at rst—and may not raise

the front dancer bar—but will still

roll up completed markers. Simply

slide the core off the take up shaft

when plotting is complete.

Page 36

38

Ioline FlexJet E User Guide

Manually Freeing

the Take-up Shaft

(FlexJet E Only)

Use this method to remove the take-up shaft from the completed roll

without having to unroll the markers.

1. Tape the loose end of the roll down so that it cannot ap freely.

2. Rotate the take-up shaft by hand until the rectangular opening in

the anged coupling is perpendicular to the opening in the support block (see Figure 19). Remove the shaft.

3. Stand the roll on end with the anged coupling pointing up. Rotate the take-up shaft counter clockwise (opposite to the direction

that the paper was rolled on the machine. (See Figure 25.)

4. The larger the roll, the more rotations are required to free the shaft.

When the shaft freely rotates, lay the roll on the ground.

5. Continue to twist the shaft counter clockwise while pulling it out

of the paper roll until it is free.

Figure 25. Manually freeing the take-up shaft.

Page 37

Chapter 3: Operation

39

Automatically Freeing

the Take-Up Shaft

(FlexJet E Only)

Like the manual method, this method removes the take-up shaft

from the completed roll without having to unroll the markers. The

only difference is the use of the take-up motor.

1. Tape the loose end of the roll down so that it cannot ap free.

2. While one person lifts from the bottom and holds the paper roll

still, press the Unroll key to rotate the take-up shaft opposite to

the direction that the paper was rolled on the machine.

3. The larger the roll, the more rotations are required to free the

shaft. When the shaft freely rotates in the roll, stop turning the

take-up shaft. If the printer jams and the motor does not turn

then do not unwind the roll with the motor. (See Manually

Freeing the Take-Up Shaft above.)

4. Rotate the take-up shaft by hand until the rectangular opening

in the anged coupling is perpendicular to the opening in the

support block (see Figure 19). Remove the shaft and lay it on the

ground.

Caution

The take-up shaft is very

heavy when many plots

have been rolled up. It is

recommended that two or more

people remove the plotted paper

roll from the machine.

5. Continue to twist the shaft counter clockwise while pulling it

out of the paper roll until it is free.

Reattach Paper

to the Take-up Shaft

(FlexJet E Only)

1. Use the Page Advance key to drive enough paper forward to

wrap under and around the take-up shaft.

2. Make sure the paper wraps under the take-up shaft.

3. Follow the guidelines described in Taping Paper to the Take-

Up Shaft.

i

Except when the feed roll is

changed, it is best to leave the

pinchwheels down when removing

completed markers from the takeup roll. Leaving the pinchwheels

down will help keep the paper

aligned with the feed roll and

reduce the time between printing

operations.

Note

Page 38

40

Ioline FlexJet E User Guide

Caution

If the paper bubbles or

wrinkles while it ows

over the platen surface,

the carriage might catch the edge

of the paper and tear it, causing

a paper jam. Make sure that the

paper is smoothly collecting on

the oor to avoid paper jams.

i

The front dancer bar should not be

used when plotting to the oor.

Note

Printing to the Floor

With careful setup and constant supervision, the printer will print

markers directly onto the oor. This method is NOT intended for

printing long markers or unattended printing.

1. Thread the paper on the front of the machine. It should drape

off the platen, over the feed roll, and onto the oor.

2. Set an origin normally and begin plotting. Make sure that the

paper piles smoothly onto the oor. If it bunches up, it may

catch on the moving carriage and tear.

Page 39

Chapter 4

Routine Maintenance

Cleaning the Drive Shaft

Clean the drive shaft

regularly to assure accurate plotting:

1. Turn off the printer and disconnect

the power cord.

2. Gently remove

any accumulated

dust and residue

with the stiff nonmetal bristle brush

provided in the

Accessory Kit.

Figure 27. Cleaning the Drive Shaft.

Cleaning the Platen and Traverse

Dust and paper residue accumulate on the platen and traverse. Under regular use, clean every two weeks:

1. Turn off power to the printer.

2. Dampen a lint-free cloth with isopropyl (pharmacy) alcohol

and gently wipe

traverse rails until

accumulated residue is removed.

Caution

Do not pray the printer

with water, solvents or

other liquids. Use a nonmetal bristle brush or a cloth

dampened with water or isopropyl alcohol. Keep the drive shaft

bearings free of all liquids.

3. Use a lint-free

cloth dampened

with de-ionized

water to clean ink

splatters off the

platen and excess

ink out of the Ser-

vice Station waste

well.

Figure 28. The Service Station

Hint

Use antistatic spray to clean

platen and traverse, if desired.

Page 40

42

Ioline FlexJet E User Guide

Caution

Never touch the take-up

key or anged coupling

while they are rotating.

Serious personal injury could

result. Turn power off rst.

Cleaning the Support Blocks

(FlexJet E Only)

When dust and paper residue will accumulate on the take-up and

feed shaft support blocks, frequent feed shaft jams can occur. Perform this procedure when debris inhibits easy rotation of the shaft.

1. Turn off power to the printer.

2. Remove the feed shaft and the take-up shaft.

3. Dampen a lint-free cloth with isopropyl (pharmacy) alcohol

and gently wipe the plastic support blocks until accumulated

residue is removed.

4. Apply a light coating of grease to the plastic feed shaft support block. White Lithium grease is supplied with the printer.

3-in-1™ brand oil is also a very good lubricant for the feed

block.

5. Wipe down both ends of the feed and take-up shafts before

reinstalling them.

Size Calibration

Over time, the printer may require calibration to account for normal

wear. Calibration adjusts the output to match design intent.

Prepare the Printer (See the Operation chapter)

1. Load the printer with, at minimum, 46-in wide paper.

2. Install ink cartridges.

3. Using the Arrow keys, move the carriage so that the carriage

notch is positioned about 1 inch from the right edge of the paper.

4. Press the Set Origin key to put the printer in START (green

light) mode.

i

The Scale command does not

effect calibration values.

Note

Figure 29. Calibration screen in Control Center.

Page 41

Chapter 4: Routine Maintenance

43

Use the Control Center to Gather the Calibration Data

1. Open the Control Center program.

2. Select Tools>Size Calibration from the Menu Bar. The window in Figure 30 will appear:

3. Press the Send Size Plot button to print the factory stored

calibration box. The printer will print a box that is 40” (102-cm)

long on the X-axis and 30-in (76-cm) wide on the Y-axis.

Y1

X1 X2

~40 in.

Y2

Figure 30. The Calibration box and measurements.

i

Only use Reset Calibration to

restore original factory calibration

settings.

Note

4. Precisely measure both sides (X) and the top and bottom (Y) of

the box and record the results. Better accuracy in measurement

equals better calibration.

5. Take the average of the horizontal (Y) values by adding them

together and dividing by 2. Repeat this procedure for the vertical (X) values.

Example:

If X1 = 39.750-in and X2 = 39.700-in

The sum is 79.450-in (39.750-in + 39.700-in = 79.450-in)

The average is 39.725-in (79.450-in / 2 = 39.725-in)

The X calibration value is the average, 39.725-in

Enter the Calibration Data:

1. Enter the measured values in the boxes in the Calibration window. Make sure the printer is in START (green light) mode.

Select the Set Calibration button.

2. The Control Center will send the calibration values to the

printer and the new Calibration Setting will be displayed in

the boxes in the window pictured in Figure 31.

3. Click on Done when nished.

Hint

The Get Plotter Data button

will read the stored calibration

settings from the printer and display them in the Factor windows.

Hint

The factory-set calibration values

are written on a small sticker on

the under side of the right end

cover. (See Figure 33.)

Page 42

44

Ioline FlexJet E User Guide

i

Cartridge alignment is not necessary for models with a single

activated cartridge stall.

Note

i

Cartridge Calibration

There are three types of adjustments associated with the ink cartridges.

Most line quality issues are resolved by adjusting these values.

n Cartridge Alignment is not necessary on the FlexJet E and Stu-

dioJet printers.

n Motion Adjustment aligns scans in the direction of carriage travel.

n Frame Gap aligns scans in the direction of paper movement.

Figure 31. Cartridge calibration window.

Prepare the Printer

1. Load the printer with paper. (Follow the loading instructions

under the Operation chapter.) Install cartridges.

2. Move the carriage using the Arrow keys so that the carriage

notch is over the paper and roughly one inch from the right

paper edge.

3. Put the printer in START (green light) mode by pressing the

Set Origin key. (See the Operation chapter for more details on

preparing to plot.)

4. Start the Control Center software. Ensure that there are no errors when the program tries to communicate with the printer.

If errors occur, check the cables and ensure that the correct port

number and baud rate are selected. (See Connect the printer to

the Computer: Overview in the Installation chapter for information on serial port connections.)

Page 43

Chapter 4: Routine Maintenance

45

Motion Adjust (Carriage Scan

Alignment)

1. Press Select Alignment Plot.

2. Browse to the c:\Ioline\Calibration

folder. Select the 40X8.plt test le.

3. The Motion Adjust box has one number

for adjustment. The default value is 0.

4. Changing the values affects the next scan,

created when moving from left to right.

5. Press the Set Motion button after

making adjustments to the values.

Example:

a. Lines from the second scan shift left to align with the rst scan.

b. Decrease the Motion Adjust value by 1.

c. Press the Set Motion button.

d. Repeat the test until alignment is correct.

6. Click on Done when nished.

Figure 32. The Motion

Adjust Box.

Frame Gap (Paper Scan

i

Adding (+) numbers moves the

second scan left.

Subtracting (-) moves the second

scan right.

Note

Alignment)

1. Press Select Alignment Plot.

2. Browse to the c:\Ioline\Calibration

folder. Select the 40X8.plt test le.

3. The Frame Gap box has one number

for adjustment. The default value is 0.

4. Changing the values affects the next

scan, created when moving paper

forward through the printer.

5. Press the Set Gap button after making adjustments to the values.

Example:

a. Lines from the next scan have a small space gap between the previous

scan.

b. Decrease the Frame Gap value by 1.

c. Press the Set Gap button.

d. Repeat the test until alignment is correct.

6. Click on Done when nished.

Figure 33. The Frame

Gap Box.

i

Note

Adding (+) numbers moves the

scans further apart.

Subtracting (-) moves the scans

closer together.

Page 44

46

Ioline FlexJet E User Guide

Hint

Use Best Mode when testing print

quality as the higher resolution

(600 dpi) setting exercises more

nozzles and pushes more ink out

of the cartridge.

Cartridge Maintenance and

Handling

A key to maintaining good print quality is proper print cartridge

maintenance. During printing, ink-spray, paper bers and dust can

build up on the print cartridge and eventually will degrade plot

quality. In addition, when print cartridges sit inactive for a period of

time, ink may dry in the nozzles and create an ink plug. This results

in the appearance of white streaks in the printed text or graphic.

Check Cartridges

If you experience print quality problems, rst verify that the ink

cartridge is undamaged and is not out of ink:

1. Press the Start/Stop key.

2. If the carriage is parked in the Service Station, use the Left Ar-

row key to move it out over the platen.

3. Open a blue stall latch and remove the cartridge.

4. Inspect the cartridge for damage and check the ink level indicator. If it is green, the cartridge still contains ink. If it is black, the

cartridge is empty and needs replacing. (See Figure 36.)

i

Use only berless cloth as bers

will block the nozzles of the print

cartridge.

The cloth must be moistened

with deionized water so it does

not scratch the print cartridge.

Scratches can blur line quality.

Note

6. If the cartridge is undamaged and still contains ink, move on to

the Automatic Cleaning Procedure.

Automatic Cleaning Procedure

1. Press the Start/Stop key and wait until the OK light turns red.

2. Press the Clean key; The carriage will park in the Service Sta-

tion and automatically clean the print heads.

3. When the cleaning process nishes, test the print quality again

in Best Mode (activated with the Quality key.) Press the Start/

Stop key. The OK light will turn green. If the printer was active

when you initiated Step 1, it will resume printing. If it was idle,

send a marker to the print queue.

4. If print quality remains poor, the paper ber build-up may be

such that auto cleaning alone is insufcient for removing ink

plugs from the nozzles. You may need to manually clean the

print head.

Page 45

Manual Cleaning Procedure

To maintain optimal print quality, manually clean cartridges after

they sit idle for longer than two days—or are placed in storage. Wip-

ing the print head will clean out the nozzles and ring chambers.

A Cloth Should Be:

n Soft, berless, and moistened with deionized water.

Should NOT Be:

n Abrasive, made of small bers, dry nor contain chemical additives.

1. Press the Start/Stop key.

2. Using the Left Arrow key, reposition the carriage over the

platen.

3. Open the latch for the rst cartridge and remove it.

Chapter 4: Routine Maintenance

47

4. Inspect the ink level indicator on the cartridge to verify the

cartridge is not empty.

5. Dampen the cloth with de-ionized water.

6. Drag the surface of the cartridge print head over the surface of

the cloth. Wipe slowly across the long-axis with the print cartridge facing down. Do not apply excessive force, as this could

scratch the nozzle area.

7. Repeat until the print head leaves an evenly dark line of ink on

the cloth.

8. When the cleaning process nishes, test the print quality again

in Best Mode (activated with the Quality key.) Press the Start/

Stop key. The OK light will turn green. If the printer was active

when you initiated Step 1, it will resume printing. If it was idle,

send another marker to the print queue.

Page 46

48

Ioline FlexJet E User Guide

Print Cartridge Storage

Short-term Storage (7 days or less)

n Simply leave the print cartridge in the machine, capped in the

Service Station.

n If the cartridge was not in the Ser-

vice Station, it may require manual

cleaning.

Long-term Storage (greater

than 7 days)

n lace the print cartridge upside-

down in an air-tight container. Lay

a sponge or cloth dampened with

de-ionized water next to it to help

prevent the cartridge from drying

out.

Figure 34. Ink cartridges

should be stored in an airtight container.

i

If the rmware le is a ZIP

archive, make sure it is decompressed before sending it to the

printer. You can download a ZIP

decompression utility at

http://www.winzip.com if

necessary.

Note

n To return the cartridge to service, follow the manual cleaning

procedure above.

Updating Firmware

using the Control Center

Summary

1. Prepare the printer.

2. Check the Current Version.

3. Update the rmware.

Prepare the printer for a Firmware Update

1. Power on the PC and printer.

2. Ensure that the serial cable is connected between the PC and

the printer.

3. Copy the rmware le to the folder c:\Ioline\Firmware (or

another location that is easy to remember.)

Check the Current Firmware Version

1. Start the Control Center.

2. The main screen shows the current rmware version in the upper right corner.

Page 47

Chapter 4: Routine Maintenance

49

3. If you do not see a rmware version displayed, please check

connections to the printer. Call Ioline Customer Service for help

resolving communication issues.

Update the Firmware

1. Choose File>Download Firmware from the menu bar.

2. Press the Select Firmware button.

3. Follow the on-screen directions for restarting the printer so

that it will accept new rmware. Press OK when the printer is

ready (three yellow lights on the keypad.)

4. Use the le window to browse to the location where you stored

the rmware le (e.g. c:\Ioline\Firmware.)

5. A download progress window will appear.

6. When the download nishes, the printer will go through the