Page 1

getting started guide

hp StorageWorks

SDLT tape drive

internal model

SDLT 600i

Page 2

open this flap for quick

start installation poster

Page 3

1

4 5

Page 4

2 3

6

Page 5

Internal drives - contents

Pre-Installation

Before you start page 3

Backup software and drivers page 5

Using the CD-ROM page 7

Installing the tape drive

Step 1: Check the SCSI connection page 9

Step 2: Check the drive’s SCSI ID page 11

Step 3: Prepare the mounting bay page 13

Step 4: Attach mounting hardware page 15

Step 5: Install the drive page 17

Step 6: Attach power and SCSI cables page 19

Step 7: Secure the drive page 21

Step 8: Install drivers and verify installation page 23

Using the tape drive

Your HP StorageWorks SDLT 600 tape drive page 25

Use the correct media page 27

Register your tape drive page 29

Using HP OBDR page 31

Diagnostic tools page 33

Optimizing performance page 34

Troubleshooting page 36

Understanding the LEDs page 41

Problems with cartridges page 43

Other sources of information page 45

Replacing your tape drive page 46

1

Page 6

Copyright © 2004 by Hewlett-Packard Development Company, L.P.

January 2004

Part Number: AA984-90902

Hewlett-Packard Company makes no warranty of any kind with regard to this material,

including, but not limited to, the implied warranties of merchantability and fitness for a

particular purpose. Hewlett-Packard shall not be liable for errors contained herein or for

incidental or consequential damages in connection with the furnishing, performance, or use

of this material.

This document contains proprietary information, which is protected by copyright. No part of

this document may be photocopied, reproduced, or translated to another language without

the prior written consent of Hewlett-Packard. The information contained in this document is

subject to change without notice.

Microsoft

registered trademarks of Microsoft Corporation.

UNIX

DLTtape, the DLTtape logo, Super DLTtape and the Super DLTtape logo are trademarks of

Quantum Corporation registered in the U.S.A. and other countries.

Alpha and OpenVMS are registered trademarks of Hewlett-Packard Development Company,

L.P.

Hewlett-Packard Company shall not be liable for technical or editorial errors or omissions

contained herein. The information is provided ”as is” without warranty of any kind and is

subject to change without notice. The warranties for Hewlett-Packard Company products are

set forth in the express limited warranty statements for such products. Nothing herein should

be construed as constituting an additional warranty.

Printed in the U.K.

®, MS-DOS®, MS Windows®, Windows® and Windows NT® are U.S.

® is a registered trademark of The Open Group.

Product Details

Write your tape drive details here so you can find them easily if you need them. The model name is on the

front of the drive and the product and serial numbers are on a label on the bottom of the drive.

Model (type of drive):

Model (number):

Serial (number):

Date purchased/installed:

2

SCSI ID:

Page 7

Before you start

The HP StorageWorks SDLT 600 tape drive is a high-capacity, high-performance streaming

tape drive. It is installed into a spare drive bay in your server. Before starting to install your

tape drive, you should consider the following.

Which operating systems are supported?

HP StorageWorks SDLT 600 drives can be connected to servers running under Windows®,

NetWare, UNIX, Tru64, OpenVMS and Linux. Refer to the “HP StorageWorks Tape Software

Compatibility” topic on our World Wide Web site (

information about the operating system versions that are supported.

How do I the connect the tape drive to my server’s SCSI bus?

Your tape drive is attached to the SCSI bus of the host server via a spare connection on the

internal SCSI ribbon cable (supplied with the drive). The cable must be terminated, see

page 19.

You will need a properly installed and configured SCSI host bus adapter (HBA) or a built-in

SCSI controller on your server. For optimum performance your tape drive should be connected

to an Ultra 3 (160) or Ultra 4 (320) host bus adapter or SCSI controller using a correctly

terminated, LVDS-compatible ribbon cable with a spare 68-pin, high-density (HD), wide SCSI

connector. We strongly recommend that you use the SCSI ribbon cable supplied with the

drive, see page 19. We also recommend that the drive is the only device on the SCSI bus. Do

not connect more than two tape drives per SCSI controller. Do not attach the drive to the same

SCSI bus as your disk drive or to a RAID controller.

www.hp.com/go/connect) for more

Why is the SCSI bus type important?

The SCSI bus type determines the speed at which data can be transferred between devices on

the bus and the maximum length of cable that can be used. HP StorageWorks SDLT 600 tape

drives are high performance Ultra 3 SCSI devices with a maximum burst transfer speed of

160 MB/second. To benefit from this level of performance, it is important to ensure that the

drives are connected to a SCSI bus of a similar or higher specification. This means that you

need:

• An Ultra 3 (160) or Ultra 4 (320) SCSI bus. Ultra 160 SCSI supports the maximum bus speed

of 160 MB per second, Ultra 320 SCSI exceeds this.

• LVD-rated SCSI cabling and terminators. The LVD interface and cable supplied with the drive

enable the data to be transferred at the drive's maximum rate and provide a maximum cable

length of 12 meters.

If you attach the drive to a lower specification SCSI bus, it may still work, but data will not be

transferred as quickly. For example, on a single-ended (SE) Ultra 160 SCSI bus the maximum

burst transfer speed of the drive is 40 MB/second and the maximum cable length is restricted

to 3 meters. See also Table 1, “supported SCSI bus types,” on page 9.

Note The drives are not compatible with high voltage differential (HVD) SCSI devices.

How can I check the SCSI bus type?

For most operating systems you can install HP Library & Tape Tools, directly from the web site

at www.hp.com/support/tapetools or from the link on the HP StorageWorks Tape

3

Page 8

CD-ROM, and run the “Install Check” to check your server’s current SCSI configuration (see

page 33). This will provide information about the SCSI bus and the SCSI IDs in use.

What are the mounting requirements for the tape drive?

Mounting bay

You need one industry standard, 5¼-inch, full-height bay in which to install the

HP StorageWorks SDLT 600 tape drive. Power requirements are:

Voltage Typical Current Maximum Current

5 V 3.1 A (standby) to 5.5 A (write-streaming) 5.6 A

12 V 0.1 A (standby) to 0.7 A (media loading/unloading) 0.7 A

Mounting hardware

For many servers, no mounting tray or rails are required. Devices simply slide into the server’s

chassis and are fixed with screws. Other servers have built-in trays or rails.

Rail kits for a number of industry-standard servers may be available. For more details refer to:

www.hp.com/go/connect.

Some servers use non-standard mounting rails and do not include spares. If this is the case

with your system, you will have to order these accessories from the server manufacturer before

you can install the tape drive.

Air flow requirements

The internal tape drive requires adequate air flow to dissipate the heat resulting from

continuous drive operation. Specifically, the air flow must be sufficient to keep the tape path

temperature below 50

ambient air temperature of no more than 40

It is important to keep the cooling holes in the rear and the grill in the front of the tape drive

clear of any obstructions that may hinder the air flow and to ensure that all fans in your server

are in place and operational. Make sure that empty bays have the appropriate blanking

plates installed so that airflow is maintained.

o

C ambient operation. Always operate the tape drive within an

Do I need additional items for installation?

• You may need mounting hardware. See “What are the mounting requirements for the tape

drive?” above.

• If you do not have a spare, suitably rated SCSI connector on your server, a new HBA (also

known as a SCSI card) will be required. We recommend that a 64-bit Ultra 3 (160) HBA is

used. For specific details relevant to your server model please refer to

connect

expansion slot within your server before installing your tape drive. (The kit can also be

installed in a 32-bit PCI expansion slot, but performance may be degraded.)

. You will need to purchase and install the new HBA into an unused, 64-bit PCI

o

C.

www.hp.com/go/

Refer to our World Wide Web site for recommended products, configurations and ordering

information:

4

www.hp.com/go/connect or www.hp.com/support.

Page 9

Backup software and drivers

Backup software

For optimum performance it is important to use a backup application that is appropriate for

your system’s configuration. In a direct attach environment, where the tape drive is attached to

a standalone server, you can use backup software that is designed for a single server

environment. In network configurations you will need backup software that supports enterprise

environments. HP, Veritas, Legato, Yosemite and Computer Associates all provide suitable

products. Further details about these and other products that may be appropriate can be

found on our connectivity web site.

1 Go to our connectivity web site: www.hp.com/go/connect and select tape backup.

2 Select software compatibility.

3 Select your combination of operating system and tape drive model in the table. A list of

supported backup applications is displayed. This will also tell you whether your configuration

is compatible with HP One-Button Disaster Recovery, HP OBDR.

(All HP StorageWorks SDLT 600 tape drives support HP OBDR. However, you can only use this

feature. if your system configuration and backup application also support it. See “Using HP

OBDR” on page 31.)

4 Make sure you have a backup application that supports HP StorageWorks SDLT 600 tape

drives and download any upgrades or patches, if required.

Drivers

Windows users

After you install the tape drive, insert the HP StorageWorks Tape CD-ROM and follow the link

to download the HP driver from our web site:

accompanying README file for specific installation instructions for Windows NT, Windows

2000, Windows XP and Windows Server 2003 drivers.

Note: We recommend that you install drivers from the CD-ROM rather than the Windows

Hardware Installation Wizard, as you can also use software on the CD-ROM to verify that

your installation is correct (see “HP Library & Tape Tools” on page 33). If you do not have

internet access, you can also download drivers directly from the HP StorageWorks Tape

CD-ROM, but these may not be the latest versions available.

UNIX and OpenVMS users

The recommended backup applications use the operating system’s standard, built-in device

drivers. To upgrade drivers we recommend that you patch to the latest version of the operating

system, following the instructions in the patch documentation.You will also find information

about configuring device files in the Configuration Guides on the CD-ROM.

www.hp.com/support. Refer to the

IA64 users

If you are installing on IA64 system, such as an HP Integrity server, check www.hp.com/

go/connect

and drivers.

for the latest information on the availability of backup application upgrades

5

Page 10

HP Product

Registration

Drivers

User

Documentation

HP Library &

Tape Tools

Figure 1: the

6

HP StorageWorks Tape

CD-ROM Guide

CD-ROM

Page 11

Using the CD-ROM

The HP StorageWorks Tape CD-ROM contains drivers, useful utilities and information to help

you install and use your tape drive. Before installation, users of most operating systems can

use the link to HP Library & Tape Tools software to check SCSI ID information on the SCSI

bus. UNIX users may like to print off the UNIX configuration guide.

Drivers

For detailed information about drivers, refer to the appropriate README file in the DRIVERS

directories on the HP StorageWorks Tape CD-ROM. There is a separate sub-directory for each

operating system.

HP Library & Tape Tools

HP Library & Tape Tools software provides diagnostic and troubleshooting utilities. It allows

you to identify your product correctly, check SCSI ID information on the SCSI bus, run tests,

carry out firmware upgrades and, if necessary, generate comprehensive troubleshooting

information for support calls. For further details see page 33.

User documentation

Refer to the “User Documentation” topic on the HP StorageWorks Tape CD-ROM for a UNIX

Configuration guide and an online User’s Guide that provides more detailed information

about using your HP StorageWorks SDLT 600 tape drive.

Refer to your backup application’s documentation for instructions on how to back up and

restore data.

CD-ROM guide

The CD-ROM guide provides an overview of the CD directory structure and information about

the languages in which the contents of the CD-ROM are available. It also contains a set of

URLs and links for further information.

HP product registration

To register your new tape drive electronically via the web, use the “Product Registration” link

on the HP StorageWorks Tape CD-ROM.

7

Page 12

SCSI ribbon

cable

68-pin internal

LVD/SE connector

(Use this connector)

68-pin internal

SE connector

(Do not use)

50-pin internal SE

connector

(Do not use)

The example shows an

Adaptec 29160 HBA

SCSI HBA

SCSI ribbon

cable

tape drive

Figure 2: checking the SCSI connection

8

Page 13

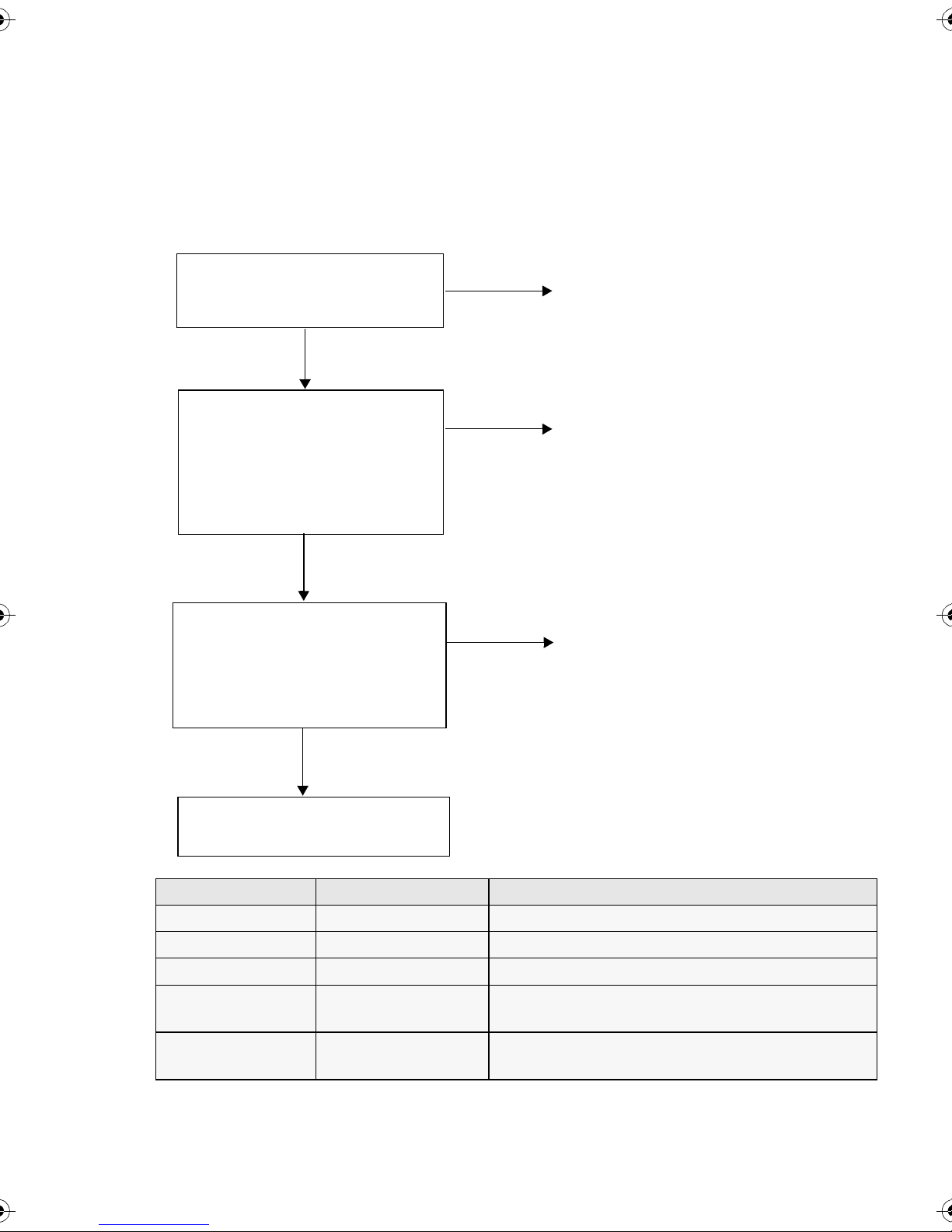

Step 1: Check the SCSI connection

Use the following questions to help you check your SCSI connection. As long as you have a

spare drive bay in your server you should have a spare connection on the internal SCSI bus.

You need to ensure it is the correct SCSI bus type. Most users can use HP Library & Tape Tools

to check the SCSI bus type, see page 33. If you answer ‘Yes’ to all these questions, you are

ready to install your tape drive. If you answer ‘No’, you will probably need to purchase and

install additional items. For product details, go to

1 Is there a spare SCSI port on

the server’s internal SCSI

bus?

Yes?

No?

www.hp.com/go/connect.

Purchase and install one of the

recommended HBAs into an unused

64-bit PCI expansion slot. (The HBA

can also be installed in a 32-bit PCI

expansion slot, but performance may

be degraded.)

2 Are the SCSI ribbon cable

and HBA card rated at Ultra

3 (160) or Ultra 4 (320)?

(Make sure the ribbon cable

is terminated. See page 19.)

Yes?

3 Will the drive be the only

device on the bus? This is the

recommended configuration.

Do not connect to a RAID

controller channel.

Yes

4 You are ready to install the

drive.

No?

No?

Performance may be impaired. See

table below. Consider replacing your

card with one of the recommended

HBAs. We recommend a 64-bit Ultra 3

(160) SCSI HBA kit.

Consider installing (if you have a spare

PCI slot) or replacing your card with an

Ultra 4 (320) HBA.

SCSI Bus Type Transfer Speed Supported

Ultra 3 (160) LVD Up to 160 MB/s Yes. This is a recommended configuration.

Ultra 4 (320) LVD Up to 320 MB/s Yes. This is a recommended configuration.

Ultra 2 LVD Up to 80 MB/s Yes, but this is not recommended

Ultra single-ended,

wide

High Voltage

Differential

Up to 40 MB/s Yes, but this is not recommended as it will restrict

Up to 40 MB/s No. The drive will not work and you may damage

table 1: supported SCSI bus types

performance. Do not connect to a narrow SCSI bus.

the drive or controller

9

Page 14

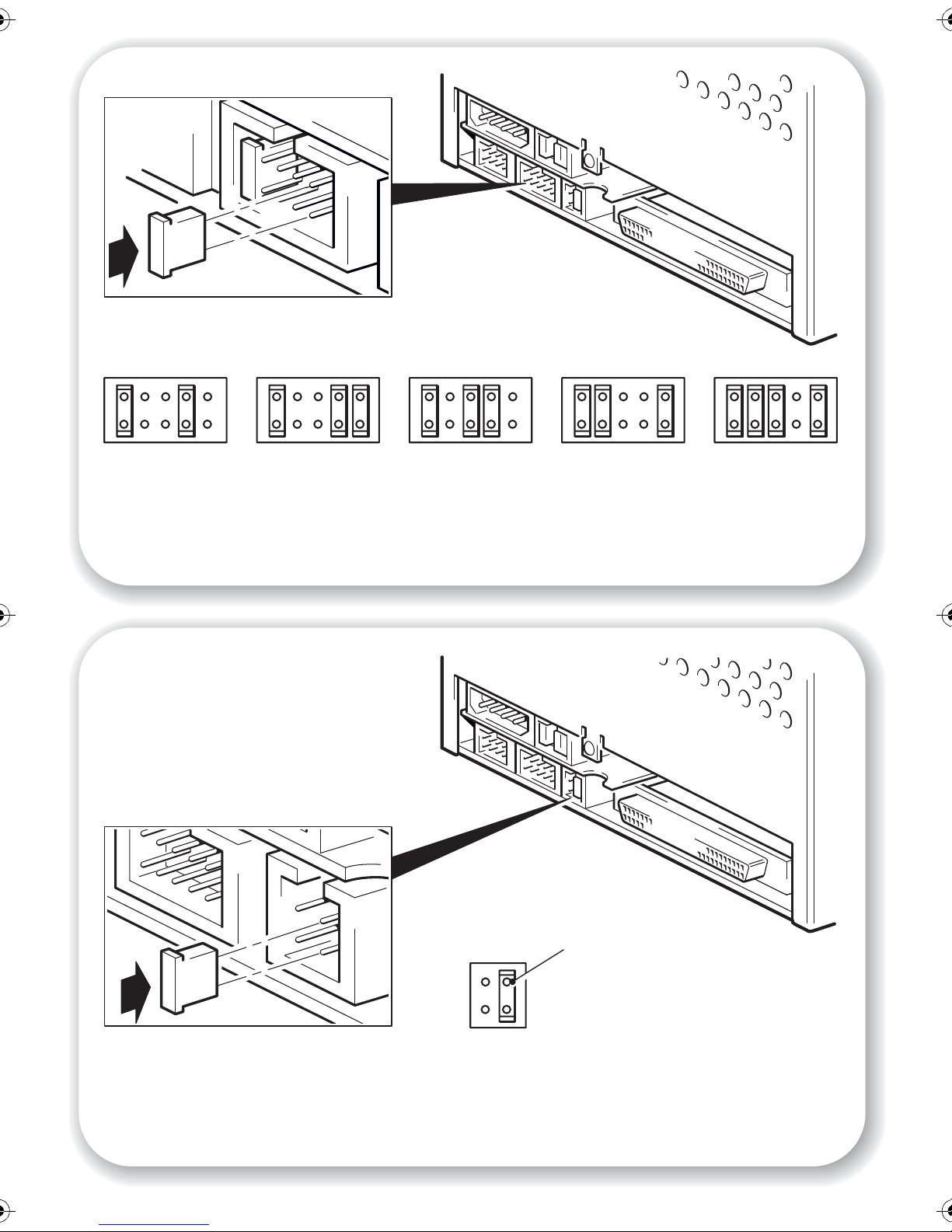

Example SCSI IDs

2

2418NC

22441188NC NC

36

9

2418NC

2418NC

13

DEFAULT

Figure 3a: checking the SCSI ID

10

TERM PWR jumper is fitted as

default

Simply remove jumper if you

need to disable termination

power

Figure 3b: checking TERM PWR

Page 15

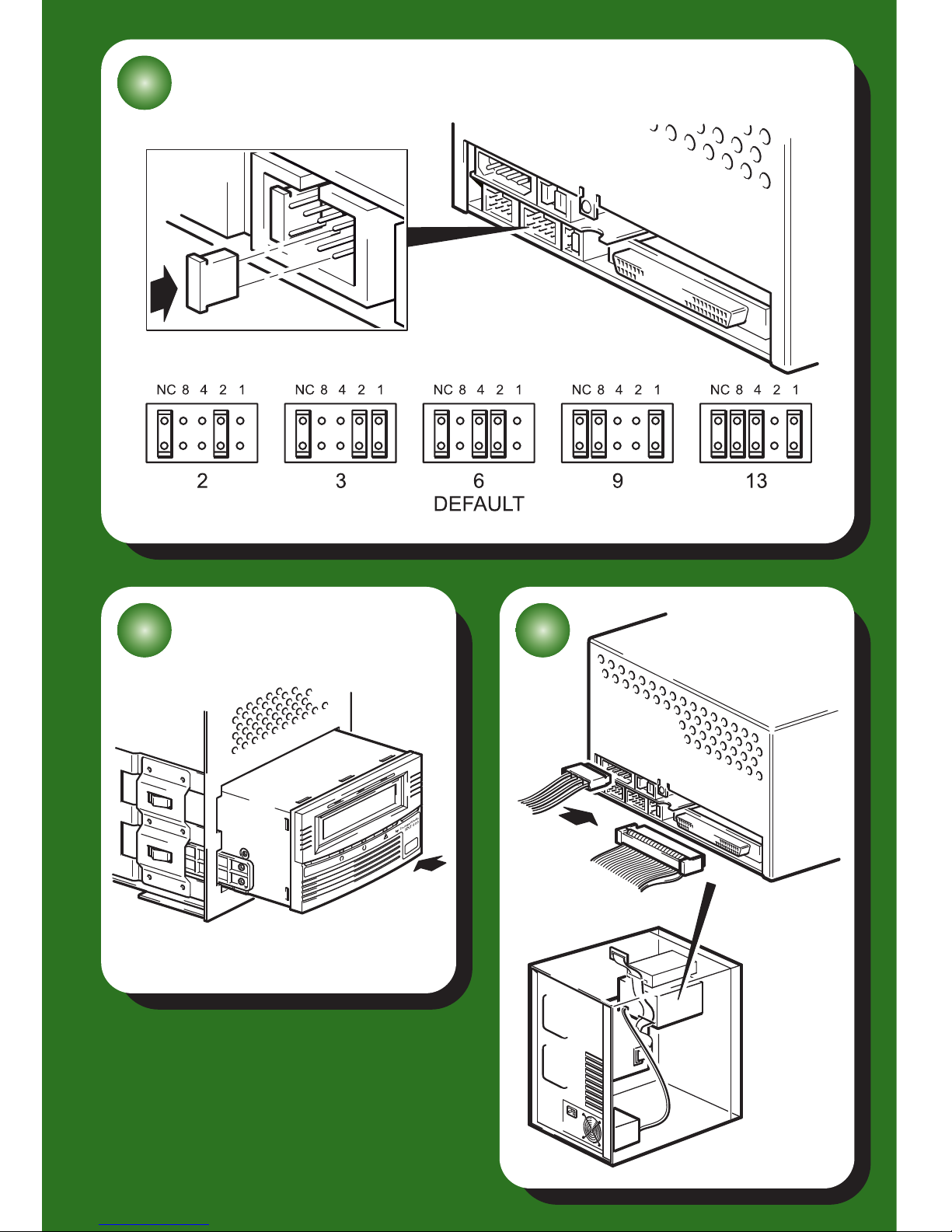

Step 2: Check the drive’s SCSI ID

Your HP StorageWorks SDLT 600 drive is shipped with a default SCSI ID of 6, but it can be

assigned any unused ID between 0 and 15. Do not use SCSI ID 7, which is reserved for the

SCSI controller.SCSI ID 0 is typically assigned to the boot disk and should also not be used

unless the tape drive is on a dedicated SCSI bus.

1 Determine whether you need to change the SCSI ID from the default of 6. For example, in multi-

initiator parallel SCSI environments (such as ProLiant clusters) it is possible that the initiator

devices will use IDs 6 and 7. In this case, you will need to change the tape drive’s SCSI ID.

For most operating systems you can install HP Library & Tape Tools from the link on the

HP StorageWorks Tape CD-ROM and run the “Install Check” to check your server’s current

SCSI configuration (see page 33). This will provide information about the SCSI bus and the

SCSI IDs in use.

For UNIX systems, check the UNIX Configuration Guide on the HP StorageWorks Tape

CD-ROM for instructions on how to determine the SCSI IDs of existing devices.

Caution Static electricity can damage electronic components. Always wear an antistatic wriststrap if

possible. If not, to equalize the electromagnetic charges, touch a bare metal part of the server

(such as the back plate) before you remove the tape drive from its bag.

2 Change the tape drive’s SCSI ID, if necessary.

The SCSI ID is set using jumpers on a set of pins at the rear of the drive. Use tweezers or small

pliers to move the jumpers to the pattern corresponding to the ID you want, see Figure 3a. If

you do not install any jumpers, the firmware makes the drive default to SCSI ID 6. If you do

install jumpers, the left-hand jumper (NC) should always be set.

Spare jumpers are provided with the drive.

Termination power

Your HP StorageWorks SDLT 600 drive is shipped with terminator power enabled, see Figure

3b. This allows the drive, in addition to the SCSI controller, to provide the termination power.

It is not normally disabled. Refer to the documentation that came with your SCSI adapter to

check that this is the correct configuration. If you need to disable it, simply remove the jumper.

11

Page 16

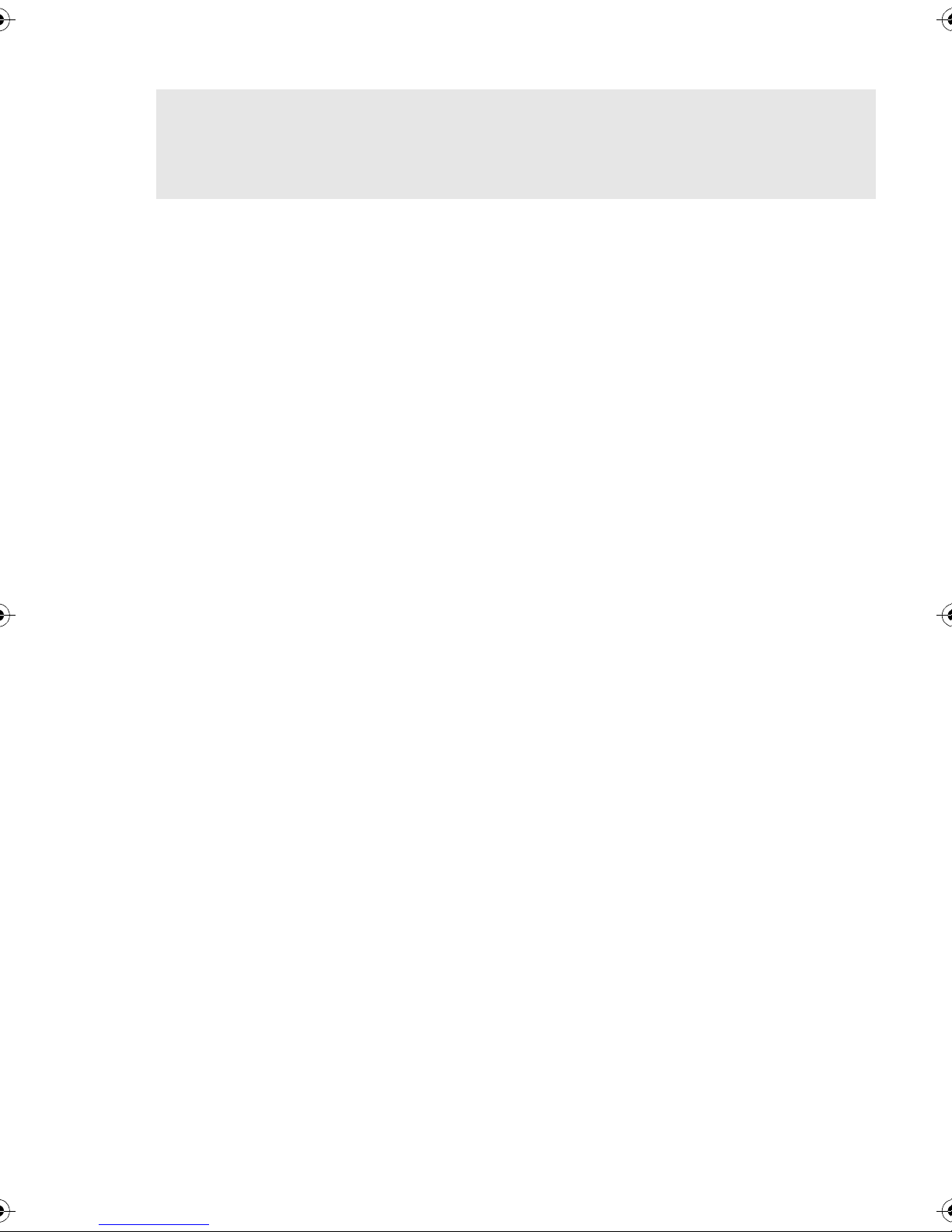

Figure 4a: preparing mounting bay in a typical HP AlphaServer

Figure 4b: preparing mounting bay in a typical HP Proliant server

12

Page 17

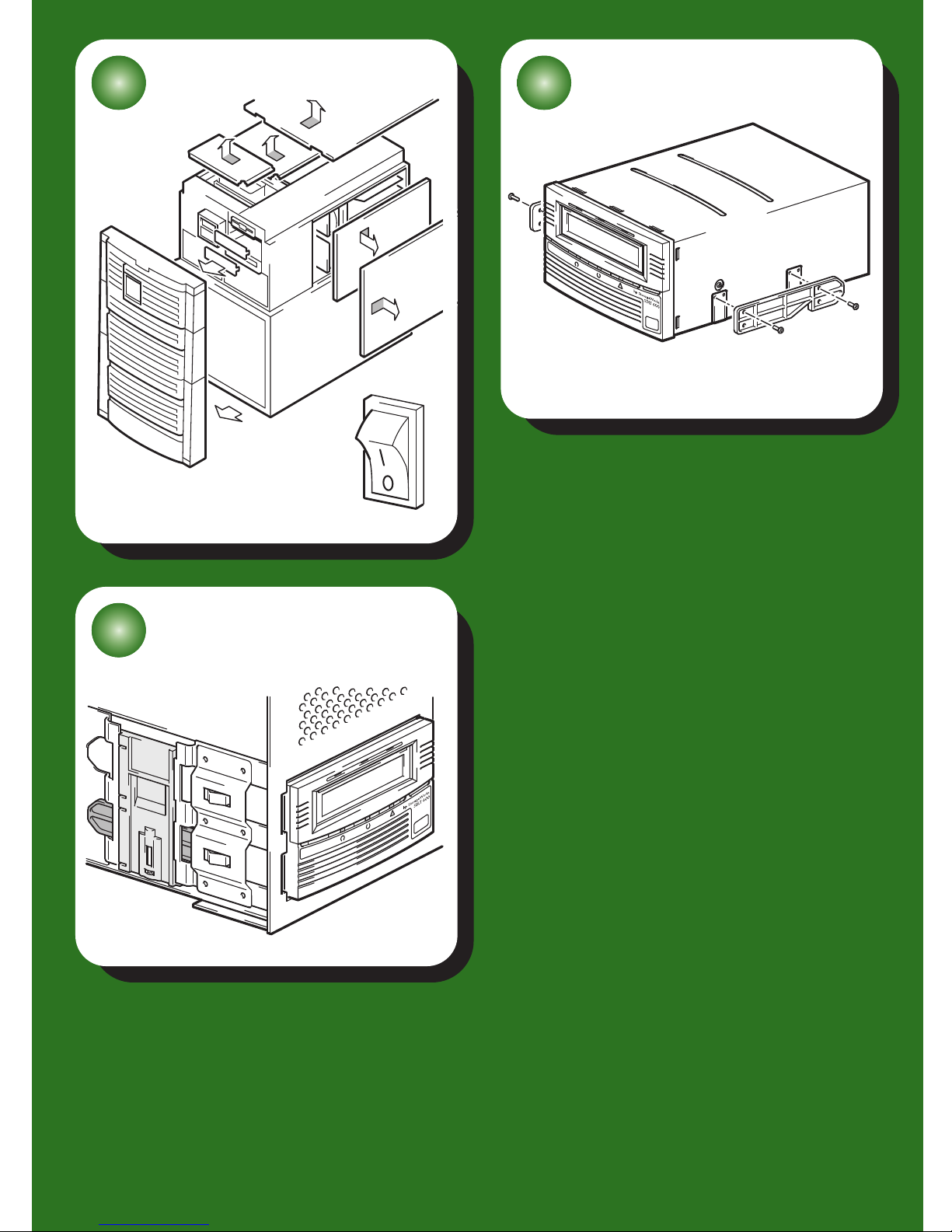

Step 3: Prepare the mounting bay

Warning To avoid personal injury or damage to the server or tape drive, ensure that the server is

disconnected from the mains power supply while you install the drive.

Caution Static electricity can damage electronic components. Always wear an antistatic wriststrap if

one is available. If not, after you have disconnected power from the server and removed the

cover, touch a bare metal part of the chassis. Similarly, touch a bare metal part of the drive

before installing it.

1 Assemble the necessary tools and materials:

• Phillips screwdriver

• Flat-bladed screwdriver (if your server uses slotted screws)

• Torx screwdriver (if your server uses torx screws)

• Your server manuals (for reference during installation)

2

Perform a normal system shutdown and turn off the server and any connected peripherals.

3 Remove the cover and front panel from the server, as detailed in your server’s documentation.

As you work inside the server, you may have to disconnect the SCSI cable or power cable

from other devices to maneuver the new drive into place. If you have to do this, make a note

of their position and connections so you can put them back correctly later.

4 Remove the front filler panel from a full-height, 5¼-inch bay of your server, as illustrated. With

some servers, such as the HP AlphaServer ES40, you must also remove the half-height device

divider.

The internal tape drive requires adequate air flow to dissipate the heat resulting from

continuous drive operation. It is important to keep the cooling holes in the rear and the grill

in the front of the tape drive clear of any obstructions that may hinder the air flow and to

ensure that all fans in your server are in place and operational. Make sure that empty bays

have the appropriate blanking plates installed so that airflow is maintained.

13

Page 18

hole 3

hole 1

hp

StorageWorks

SDLT 600

Figure 5a: preparing mounting bay in a typical HP Proliant ML530 server

hole 4

hole 2

hp

StorageWorks

SDLT 600

Figure 5b: preparing mounting bay in a typical HP Proliant ML570 server

hole 3

hole 1

hp

StorageWorks

SDLT 600

M3 mounting

screw (ML350)

M3 offset

mounting

screw

(ML370)

Figure 5c: attach mounting screws in a typical HP Proliant ML350 or 370 server

14

Page 19

Step 4: Attach mounting hardware

If your server requires special rails or other hardware to install the tape drive, mount them on

the tape drive in this step. If your server does not require special mounting hardware, proceed

to “Step 5: Install the drive” on page 17 now. For example, HP AlphaServers do not require

special mounting hardware.

HP ProLiant servers

Different models of server require different mounting methods. The server may also

incorporate a locking mechanism to hold the tape drive in place. See “Step 7: Secure the

drive” on page 21.

Please check your HP ProLiant server documentation to ascertain the correct method of

mounting, and to check whether mounting hardware is provided with the server.

Mounting rails

Some HP ProLiant servers, such as ML530 and ML570, require mounting rails. These may be

metal or plastic rails attached to the server's drive bay filler panel.

1 Use a regular Phillips screwdriver to attach the appropriate rails. Use the M3 screws provided

with the tape drive.

For ML530 servers position the screws in the right-hand holes on the tape drive (holes 1 and

3), as shown in Figure 5a. For ML570 servers position the screws in the left-hand holes on the

tape drive (holes 2 and 4), as shown in Figure 5b.

Ensure you do use the M3 screws provided - the rails may be attached to the filler panel by

screws of a different thread/size type and these should not be used. If in doubt, refer to your

HP ProLiant server documentation.

Mounting screws

Other HP ProLiant server models, such as ML350 and ML370, only require the use of special

locating screws with no mounting rail.

1 Use a T8 Torx screwdriver to attach the appropriate screws. You may need to purchase the

M3 screws separately. Position the screws in the right-hand holes on the tape drive (holes 1

and 3), as shown in Figure 5c.

• HP ProLiant ML350: Use M3 mounting screws. These have a thicker head than the standard

M3 screws.

• HP ProLiant ML370: Use M3 offset mounting screws. These have a thick offset piece and a

thicker head than the standard M3 screws.

Other servers

1 Attach the appropriate mounting hardware. Refer to the manufacturer’s documentation for

instructions.

15

Page 20

s

rk

o

W

e

g

ra

to

S

SDLT 600

hp

16

Figure 6: installing the drive

Page 21

Step 5: Install the drive

1 Slide the tape drive into the open bay, aligning the rails with the slots in the bay, as shown in

Figure 6.

If your server does not use mounting hardware, check that the holes in the chassis are aligned

with the holes in the side of the tape drive.

Do not secure the drive with screws at this point because you may have to move the drive to

get the cables into place.

Orientation

The internal tape drive may be installed top side up, left side down or right side down. Do

not install it upside down. Check your server documentation to check what orientations it

supports.

17

Page 22

1

power

cable

2

SCSI ribbon

cable

2

SCSI ribbon

cable (correctly

terminated)

SCSI controller

connection

18

tape drive

1

power cable

power

supply

Figure 7: attaching power and SCSI cables

Page 23

Step 6: Attach power and SCSI cables

To support the high performance of the tape drive it is important to use a suitably-rated SCSI

cable. We recommend that you use the ribbon cable supplied with the tape drive. This

supports up to Ultra 4 (320) bus speeds.

1 Attach a spare power cable from the server's internal power supply to the power connector,

as shown in Figure 7, item 1.

Attach the SCSI ribbon cable supplied with the tape drive to the SCSI host bus adapter or

controller.

2 Attach a spare connector on the server or HBA’s SCSI ribbon cable to the SCSI connector of

the drive, as shown in Figure 7, item 2.

3 If the drive is the last device on the SCSI chain, make sure that the SCSI cable is terminated

correctly.

Where should the SCSI terminator be?

Termination must be present at two and ONLY two positions on the SCSI bus—at the

beginning of the SCSI bus and at the end of the SCSI bus. Termination is normally enabled

by default on the HBA and most internal SCSI cables have a terminator attached. This will

usually be a small, rectangular block of plastic attached to the cable end and marked ‘SCSI

Terminator’.

Therefore, assuming the HBA is the first device on the bus, you should check that the second

terminator is placed after the last device, as shown in Figure 7, item 2.

19

Page 24

plastic rail

server latch

Figure 8a: securing drive to mounting hardware

(example shows HP ProLiant ML530)

s

rk

o

W

e

g

ra

to

S

SDLT 600

hp

screws go through hole

position 1 and 3 of tape

drive (see page 14)

use M3 screws

Figure 8b: securing drive, no mounting hardware

20

(example shows HP AlphaServer ES40)

StorageWorks

hp

0

0

6

T

L

D

S

Page 25

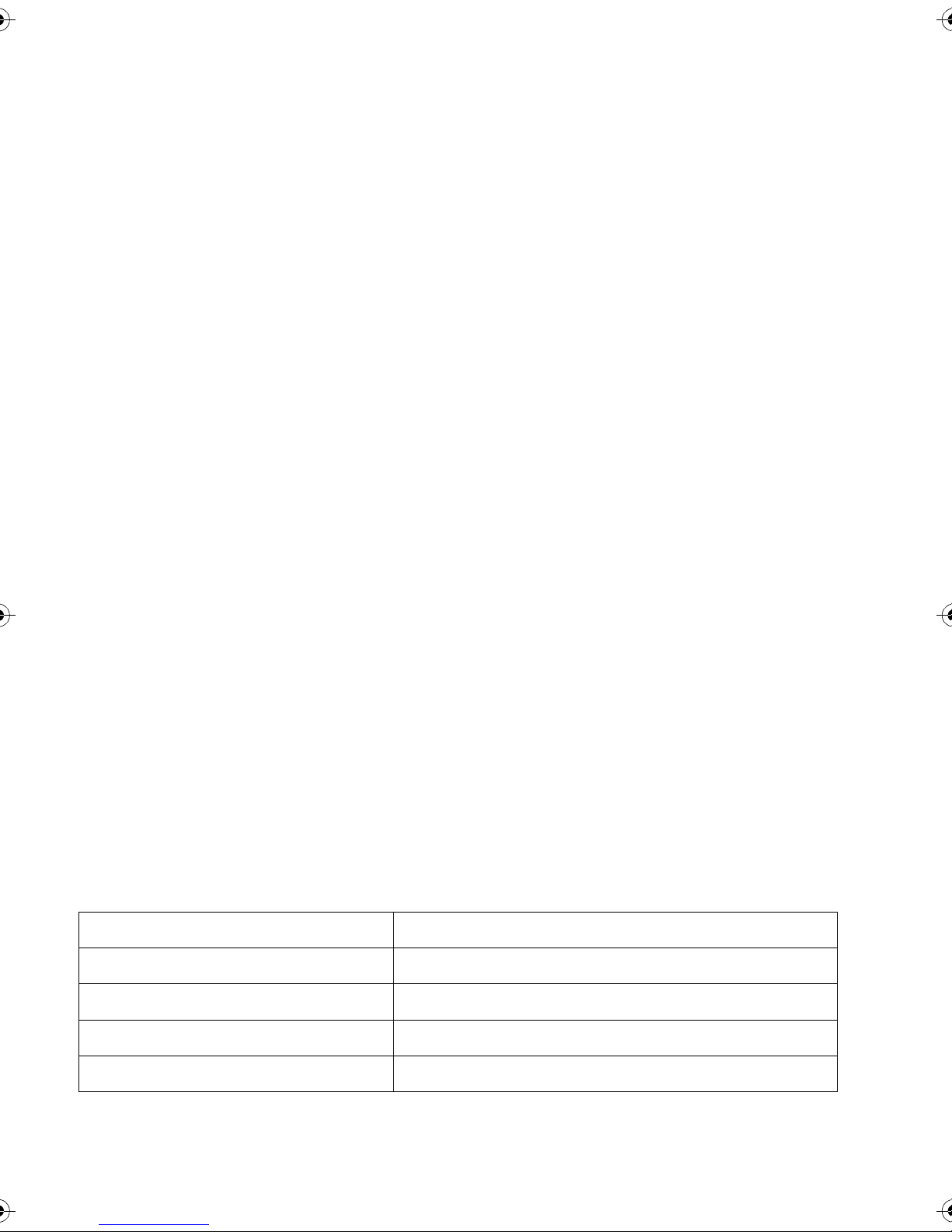

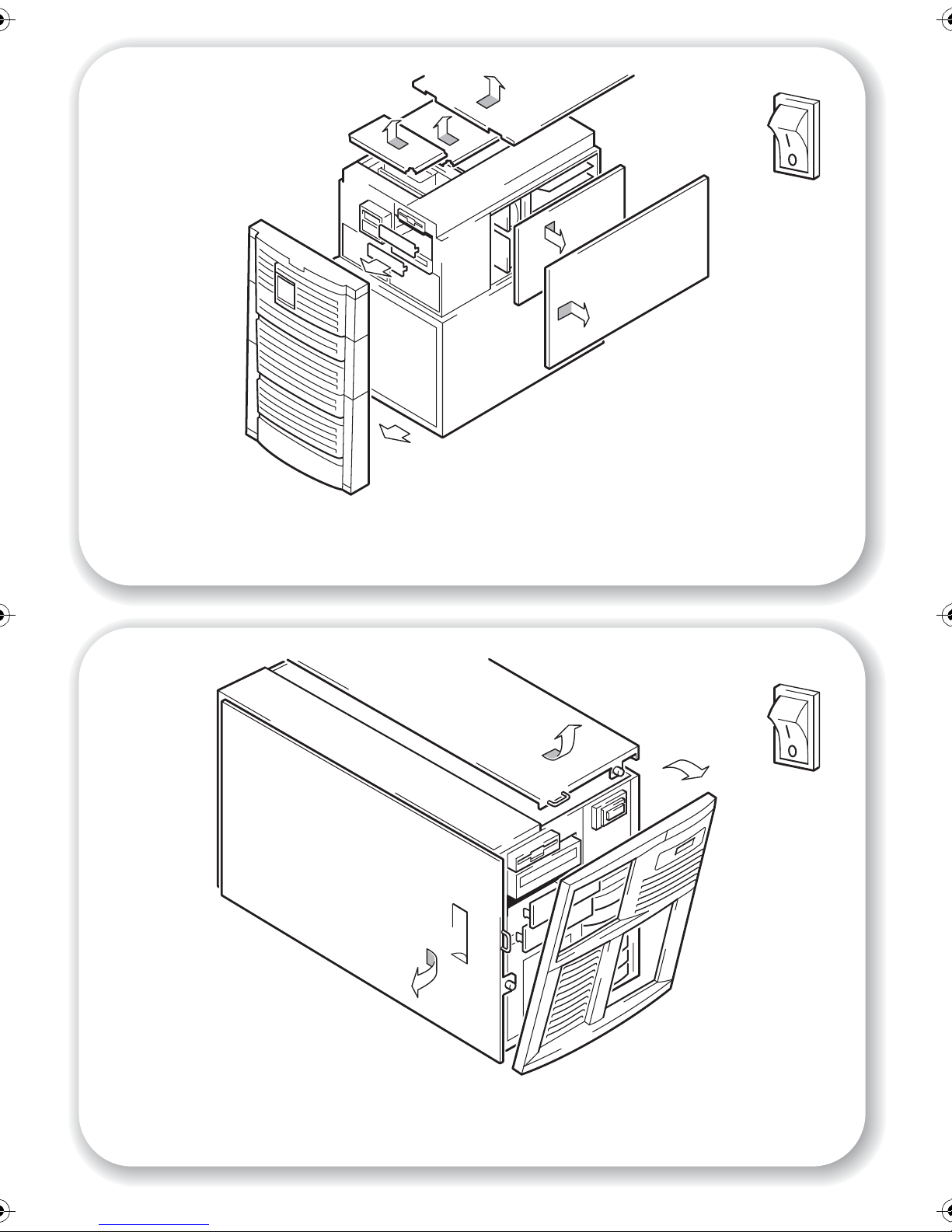

Step 7: Secure the drive

The server latches and side views of your server model may not be exactly the same as shown

in the illustrations. Please refer also to you server documentation.

Mounting hardware used (HP ProLiant)

Ensure that you use the correct mounting rails or locating screws, as described in “Step 4:

Attach mounting hardware” on page 15. The server also incorporates a locking mechanism

to hold the tape drive in place.

1 Push the tape drive firmly into the bay and make sure the server latch is locked in position, as

shown in Figure 8a.

2 Replace the cover on the server.

No mounting hardware used (HP AlphaServer)

1 Use the M3 screws provided with the tape drive to secure it in place. Check that the holes in

the chassis are aligned with the holes in the sides of the drive and use a regular Phillips

screwdriver to secure the M3 screws, as shown in Figure 8b. Position the screws so that they

sit in the right-hand holes on the tape drive (holes 1 and 3).

2 Replace the cover on the server.

21

Page 26

slide in

label here

indicates leading

direction

hp

Figure 9a: loading a cartridge

S

to

ra

g

e

W

o

SD

rks

L

T

6

0

0

22

Sto

ra

g

e

W

o

SD

rk

s

L

T

6

0

0

Figure 9b: unloading a cartridge

Eject button

Page 27

Step 8: Install drivers and verify installation

Check operation

1 Switch on the server. The tape drive will run its hardware self-test, which takes between 10 to

15 seconds. If self-test passes, the middle LED remains on and the other two LEDs are off. If

the test fails, the middle and right LEDs remain on and the left LED flashes. This continues until

the drive is reset. See “LEDs during self-test” on page 41 for more information about the LEDs.

2 Install drivers and backup software.

For all operating systems ensure that you have downloaded drivers and any upgrades

necessary for your backup application (see page 5). On Windows systems the Windows

Hardware Installation wizard is displayed automatically. We recommend that you close the

wizard and install the drivers from the link on the HP StorageWorks Tape CD-ROM.

3 Verify that the tape drive installation was successful.

For most operating systems use HP Library & Tape Tools on the HP StorageWorks Tape

CD-ROM, as described on page 33. For UNIX systems, the UNIX Configuration Guide on the

HP StorageWorks Tape CD-ROM includes a verification procedure.

If you encounter a problem during this verification procedure, turn to “Troubleshooting” on

page 36 for help in diagnosing and fixing the problem.

4 You are now ready to carry out a backup and restore test to check that the drive can write data

to tape. Refer to your backup application documentation for specific instructions. Use the blank

cartridge supplied with the tape drive. See “Use the correct media” on page 27 for more

information about recommended cartridges.

To load a cartridge

1 Insert the cartridge into the slot in front of the drive with the markings uppermost and facing

the drive door. Apply gentle pressure until the drive takes the cartridge and loads it. (See

Figure 9a.)

2 The Drive Status LED flashes green while the drive performs its load sequence. When the

cartridge is ready for use, the Drive Status LED shows steady green.

To unload a cartridge

Caution Never try to remove a cartridge before it is fully ejected or power off the tape drive while a

cartridge is still loaded. Failure to remove a data cartridge may result in cartridge or tape

drive damage.

1 Press the Eject button on the front panel. (See Figure 9b.)

2 The drive will complete its current task, rewind the tape to the beginning, and eject the

cartridge. The Drive Status LED will flash to indicate that the unload is still in progress and will

show steady green, when the cartridge is ready for removal. This may take a maximum of 10

minutes, if the drive has to rewind from the end of the tape.

23

Page 28

hp

StorageWorks

SDLT 600

Eject button

Drive

Density

24

Drive

Status

Figure 10: tape drive controls and indicators

Cleaning

Required

Page 29

Your HP StorageWorks SDLT 600 tape drive

Your HP StorageWorks SDLT 600 tape drive has three LEDs (light emitting diodes) on the front

panel, which indicate drive status, and an eject button. The LEDs provide useful

troubleshooting information. See also “Understanding the LEDs” on page 41. See page 23

for more information about using the eject button in normal operation.

Front panel LEDs

There are three LEDs as illustrated in the diagram. (See Figure 10.)

Drive Density - left, green/red

• On, green: blank or SDLT 600 formatted Super DLTtape II inserted

• On, red: blank or SDLT 220/320 formatted Super DLTtape I cartridge inserted

• Off: no cartridge inserted

• Flashing-off repeated pattern: the drive is in OBDR mode

Drive Status - middle. green

• On: the drive is ready for use

• Off: the drive power is off or there was a failure during self-test

• Flashing: the drive is busy

Cleaning Required - right, yellow

• On: cleaning is required

• Off: the drive does not require cleaning

• Flashing-off repeated pattern: the drive is in OBDR mode

Eject button

Use the eject button to eject the tape cartridge from the drive. When you press the button, the

drive completes any active writing of data to the tape, then ejects the cartridge.

An overtemp condition exists when the measured tape path temperature reaches 50o C.

When this condition is detected, the tape cartridge is rewound, unloaded, and ejected from

the drive. SCSI status will indicate the drive is in the over temperature condition.

25

Page 30

SDLT

uper

tape

TM

II

Q2020A

orange rectangle

indicates cartridge

is protected

600GB

T

DL

uper tape II

S

Q2020A

M

T

26

Figure 11: write-protecting cartridges

Page 31

Use the correct media

For best performance we recommend HP branded media. Order online at:

www.hp.com/go/storagemedia

Guide on the HP StorageWorks Tape

and cleaning cartridges.

Data cartridges

Note * All values assume 2:1 compression.

We recommend HP Super DLTtape II 600 GB* tape cartridges for use with your tape drive.

These are single-reel cartridges that match your drive's format and are optimized for high

capacity, throughput and reliability.

HP StorageWorks SDLT 600 tape drives are also backward-read compatible with some

earlier formats, as shown in the following table.

Type of cartridge Capacity Compatibility

Super DLTtape II

Super DLTtape I 320 GB* Read Only

. If you do not have internet access, refer to the User’s

CD-ROM for ordering information for tape cartridges

600 GB* Read/Write

Super DLTtape I 220 GB* Read Only

DLT formats Various None

table 2: SDLT 600 data cartridge compatibility

Note SDLT 600 tape drives will eject a data cartridge written in DLT formats.

Write-protecting cartridges

If you want to protect the data on a cartridge from being altered or overwritten, you can writeprotect the cartridge.

If you move the write-protect switch during operation, the write-protect feature does not take

effect until after the current write operation completes.

• To write-protect a cartridge, slide the switch to the left; a small orange rectangle is visible.

• To write-enable a cartridge, slide the switch to the right; the orange rectangle is no longer

visible.

Figure 11 illustrates the location of the write-protect tab.

Write-protection will not prevent a cartridge being erased by bulk-erasure or degaussing.

Cleaning cartridges

You must use the SDLT CleaningTape with HP StorageWorks SDLT 600 tape drives, as other

cleaning cartridges, such as CleaningTape III or DLT VS CleaningTape will not load and run.

Caution Do not use other format cartridges in your tape drive and do not use SDLT CleaningTape

cartridges in other format tape drives.

To clean the tape drive:

An SDLT CleaningTape cartridge should only be used when the yellow Cleaning Required

LED is constantly lit or when your backup software notifies you that the tape drive needs

27

Page 32

cleaning. Do not clean the tape drive unless the tape drive specifically indicates cleaning is

necessary.

For ordering information see www.hp.com/go/storagemedia.

1 Insert the SDLT CleaningTape cartridge, with the Front Slide Label Slot facing outward.

2 The drive will carry out its cleaning cycle and eject the cartridge on completion, which can take

th

between 1 (the first time that the cartridge is used) and 4 minutes (the 20

time that the

cartridge is used). During the cleaning cycle the yellow Cleaning Required LED will be on

solidly and the green Drive Status LED will flash.

Each SDLT CleaningTape cartridge can be used up to 20 times. If the cartridge has expired, it

will not clean and the yellow Cleaning Required LED will remain on.

Looking after cartridges

Caution You may damage the tape drive if you try to insert and load a damaged cartridge. If you

have dropped the cartridge or suspect it may be damaged, please refer to the “Cartridges”

topic in the online User’s Guide on the HP StorageWorks Tape CD-ROM for more detailed

information about how to inspect it. This topic also contains comprehensive information about

looking after and handling cartridges.

• Do not touch the tape media.

• Do not attempt to clean the tape path or tape guides inside the cartridge.

• Do not leave cartridges in excessively dry or humid conditions. Do not leave cartridges in

direct sunlight or in places where magnetic fields are present (for example, under

telephones, next to monitors or near transformers).

• Do not drop cartridges or handle them roughly.

• Insert labels into the label area only.

• See the insert included with the tape cartridge for storage conditions.

28

Page 33

Register your tape drive

Once you have installed and tested your HP StorageWorks SDLT 600 tape drive, please take

a few minutes to register your product. You can register via the web at

www.register.hp.com.

To ensure your registration is complete, there are a number of questions on the electronic form

that are mandatory. Other questions are optional. However, the more you feel able to

complete, the better we can meet your needs.

Note HP and its subsidiaries are committed to respecting and protecting your privacy. For further

information, please visit our World Wide Web site (

Statement.

www.hp.com) and click on Privacy

29

Page 34

Figure 12a: using HP OBDR, step 1

Figure 12b: using HP OBDR, step 2

Figure 12c: using HP OBDR, step 3

30

Page 35

Using HP OBDR

Compatibility

HP One-Button Disaster Recovery is a standard feature on all HP StorageWorks SDLT 600

tape drives. However, it can only be used with specific configurations and will only recover

the server to which the tape drive is directly connected.

To check whether your system (hardware, operating system and backup software) is OBDRcompatible, please refer to our World Wide Web site

For more specific information concerning the benefits of OBDR and the latest new features

please refer to our World Wide Web site

www.hp.com/go/obdr.

Note HP OBDR is not applicable to HP-UX and other non-Intel UNIX operating systems, and it is not

compatible with Intel-based Solaris systems. HP OBDR is supported on a server with a RAID

controller if the tape drive is connected directly to a host bus adapter (HBA).

If your system does not support HP One-Button Disaster Recovery, you can still use your tape

drive normally to back up and restore data. However, you must remember to create a

separate set of emergency recovery disks for your operating system whenever you change

your system configuration.

www.hp.com/go/connect.

What does HP OBDR do?

Using just the tape drive and the most recent backup cartridge HP OBDR allows you to

recover from the following types of system disaster:

• Hard disk failures, as long as the replacement hard disk is the same size or larger than the

original and uses the same interface (for example, replace a SCSI hard disk with another

SCSI disk)

• Hardware failures where the server is replaced by an identical component

• File corruption because of an operating system error

• File corruption because of an application software error

• Viruses that prevent you from booting your system correctly

• User errors that stop you from booting your system correctly

When you run HP One-Button Disaster Recovery, your tape drive goes through the following

sequence:

1 It goes into a special disaster recovery mode that enables it to restore your operating system

and reboot. It acts like a bootable CD-ROM. (Your system’s ability to boot from CD-ROM is

normally enabled by default. If you have changed this setting, you will need to enable it

again. Refer to your system BIOS manual for further details.)

2 It returns to normal tape drive mode and restores the data.

Remote disaster recovery (ProLiant servers only)

The HP Remote Insight Lights-Out Edition (RILOE) on ProLiant servers gives the IT Administrator

the ability to completely recover a failed server at a remote location without physically

traveling to where the server resides. The on-site non-technical person need only insert the

bootable cartridge into the tape drive when asked to do so by the administrator.

Refer to the HP OBDR web site at

this feature and compatibility.

www.hp.com/go/obdr for more information about using

31

Page 36

Testing for compatibility

We recommend that you perform a full disaster recovery immediately after installation—if

possible, onto a blank hard disk. If you do not have a blank hard disk and do not want to

overwrite your system, you can safely cancel the disaster recovery process at step 3 in the

following procedure.

Refer to our connectivity web site (

suitable backup applications.

www.hp.com/go/connect) for more information about

Running HP OBDR

HP OBDR can only be used with backup applications that support one-button disaster

recovery and methods of operating OBDR will vary between different software companies.

Check our World Wide Web site (

firmware upgrades and troubleshooting before you use HP OBDR.

1 Insert the latest bootable cartridge in the tape drive (see figure 12a). The cartridge must be

written by a backup application that writes data to tape in CD-ROM format.

2 Hold down the eject button. Keeping the eject button pressed down, power on your server (see

Figure 12b). This puts the device into HP One-Button Disaster Recovery mode when you power

on. Release the button as soon as the Drive Density (left) and Cleaning Required (right) LEDs

on the front panel flash in the OBDR sequence. This is a repeated pattern of: flash-flash-off. (The

Drive Status LED functions as normal; flashing when moving tape and solid when in the ready

state.)

Keyboard shortcut for HP ProLiant servers

www.hp.com/go/obdr) for the latest information about

There is no need to press the Eject button. Just power on your server and press the [F8]

function key during the Power On Self Test (POST). This invokes OBDR to restore your system.

For more information and specific instructions please refer to our World Wide Web site at

www.hp.com/go/obdr.

3 Follow the on-screen instructions to set up the operating system (see Figure 12c). (These will

vary depending upon the backup software.) Normally, you can accept the default response to

all the prompts, for example just press <Enter>.

4 The LEDs will flash in OBDR mode (as described in step 2) while the tape drive restores your

operating system to a state where it can run a normal data restore.

5 Once the operating system has been set up and rebooted, the Drive Status (middle) LED display

on the tape drive changes to constant green and you can remove the backup cartridge, if you

wish. You are now ready to run a normal data restore. Follow the normal process for your

restore application.

If restore fails

If the restore fails for any reason, refer to our World Wide Web site (www.hp.com/go/

) for detailed troubleshooting information.

obdr

32

Page 37

Diagnostic tools

HP Library & Tape Tools

HP Library & Tape Tools works on most operating systems, but not all. Compatibility

information, updates, and latest version of this software can be found at

support

HP Library & Tape Tools software provides free diagnostic and troubleshooting utilities. It

allows you to:

• Quickly identify, diagnose and troubleshoot drive and media problems.

• Verify that the drive is installed correctly and check drive health.

• Upgrade to the latest drive firmware (you will need internet connection to do this)

You can also install HP Library & Tape Tools from the link on the HP StorageWorks Tape

CD-ROM.

Performance Assessment Tool

For optimum performance your disk sub-system needs to be able to supply data at 36 MB/

second (native). You can use our free Performance Assessment Toolkit, PAT, to check tape

performance and test whether your disk sub-system can supply data at the optimum transfer

rate.

.

www.hp.com/

PAT does not work on all operating systems. Compatibility information, updates and the latest

version of this software can be found at

www.hp.com/support/pat.

33

Page 38

Optimizing performance

Various factors can affect tape drive performance, particularly in a network environment or if

the drive is not on a dedicated SCSI bus. If your tape drive is not performing as well as

expected, consider the following points before contacting HP Support at

support

Is the tape drive on a dedicated SCSI bus?

For optimum performance, we recommend that the tape drive is the only device on the SCSI

bus. If it is not, ensure other devices are LVD-compliant. If they are single-ended, the bus will

switch to single-ended mode with a lower transfer speed. There will also be restrictions on

cable length.

Can your system deliver the required performance?

The HP StorageWorks SDLT 600 tape drive can write data at 36 MB/s (native) or 72 MB/s

(compressed, assuming 2:1 compression). However, to get this performance it is essential that

your whole system can deliver this performance.

Typical areas where bottlenecks can occur are:

.

www.hp.com/

• Disk system (a single hard disk drive will not be able to deliver a transfer rate of 72 MB/s).

• Some file systems are able to transfer data faster than others.

• The type of data being backed up can affect backup performance (for example, file sizes

and compressibility).

• Some backup software performs better than others.

To improve performance we strongly recommend a RAIDed disk solution with a large number

of physical hard disks.

Some enterprise class backup applications can be made to interleave data from multiple

sources, such as clients or disks, to keep the tape drive working at optimum performance.

Performance checklist

The following list summarizes factors that can affect performance. They provide a guideline

only of areas that may need further investigation. They do not attempt to explain how to

configure individual systems. For a more detailed discussion, including information about tools

that allow you to test performance, refer to our white papers on

product first and look at the Information Library.)

• Is the tape drive reading and writing data at the correct speed?

www.hp.com. (Select the

• Is the source system (hard disk) transferring data at the correct speed?

• Is the backup application writing buffers at the correct speed? You may need to tune the

transfer, buffer and block size settings to optimize the speed that the application writes data

to the tape drive. HP StorageWorks SDLT 600 tape drives have an internal buffer of 64 MB.

34

Page 39

• Is the operating system tuned for performance? You may need to adjust the data transfer

packet size.

• Are user applications, such as Exchange or database servers, optimized for backup

performance?

• Are there other factors that could be affecting performance, such as interference?

35

Page 40

Troubleshooting

The first step in problem-solving is establishing whether the problem lies with the cartridge, the

drive, the host server and its connections, or with the way the system is being operated.

Most modern SCSI host bus adapters locate and display attached devices when the system is

booting up. On Windows systems, if you swap or connect a product when your system is

running, you will need to reboot the system. IA32 systems also usually need to be rebooted.

UNIX systems may have pluggable drivers, which allow drives to be attached to a running

system and detected without rebooting.

If the device is not detected on boot up, there is probably a problem with the physical

hardware: cables, termination, connections, power or the host bus adapter itself. If the device

is displayed during boot up but cannot be found in the operating system, this is more likely to

be a software problem.

• If you encounter a problem during installation and need further clarification, refer to the

“Problems encountered during installation” on page 37.

• If a problem arises during testing after you have installed the drive, refer to the symptom-

based section “Testing after installation” on page 39.

• For more information about LED sequences, refer to “Understanding the LEDs” on page 41.

• For information about cartridges, refer to “Problems with cartridges” on page 43.

Users of most operating systems can use HP Library & Tape Tools to help them diagnose

problems.

36

Page 41

Problems encountered during installation

Unpacking

Description Further information

Some parts appear to be missing or

damaged.

Contact your vendor if any parts need replacing.

The SCSI cable shipped with the drive is not correct

Description Further information

The SCSI cable shipped with the drive does

not plug into the SCSI host adapter of the

server.

The cable provided will connect to the majority of

systems. if a different cable is required, refer to the

www.hp.com/go/connect web site.

The screws or mounting hardware are not suitable for the server

Description Further information

Additional parts may be required for fitting

the tape drive into the server.

The HP StorageWorks SDLT 600 internal tape drive

will fit into most servers without the need for

additional hardware other than that originally

shipped with your system. If additional parts are

required, or the original parts have been lost, contact

your server vendor. See “Step 4: Attach mounting

hardware” on page 15.

It is unclear which SCSI ID to use

Description Further information

It is uncertain which ID numbers are

available.

Use HP Library & Tape Tools (see page 33) to provide

information on your current SCSI settings. You can

also normally check the SCSI configuration from the

boot-up screen or from the Windows Control Panel

The HP StorageWorks SDLT 600 drive has its SCSI ID

set to 6 by default. This should be left unchanged

unless this number is already in use. Full instructions

on how to change the SCSI ID are given on

page 11page 11.

How should the SCSI bus be configured?

Description Further information

Correct configuration of the SCSI bus with

multiple drives can be a complex area and

more help may be required.

Refer to the “SCSI Configuration” section in the online

User’s Guide on the HP StorageWorks Tape

CD-ROM.

37

Page 42

How should the SCSI bus be terminated?

Description Further information

It is unclear if the bus is already terminated

or where an additional terminator should

be placed.

Both ends of a SCSI bus must be terminated.

Typically, when connecting an internal drive to the

ribbon cable already inside your server then both the

host bus adapter and the end of the ribbon cable will

already be terminated and no further action is

required.

Refer also to the “SCSI Configuration” section in the

online User’s Guide on the HP StorageWorks Tape

CD-ROM.

Is the correct SCSI host bus adapter installed?

Description Further information

The server already has a SCSI host bus

adapter but it is difficult to determine what

type it is.

The server may not have a SCSI host bus

adapter installed.

If your server is in its original configuration (no SCSI

adapters have been added or removed) then use

www.hp.com/go/connect to check the

compatibility of your system. You can also check the

SCSI configuration from the boot-up screen or from

the Windows Control Panel, or by using HP Library &

Tape Tools (see page 33).

Use HP Library & Tape Tools (see page 33) to check

whether you have a SCSI host adapter on your

system. If not, you will need to purchase one. Refer to

the ordering supplies section in the online User’s

Guide on the HP StorageWorks Tape CD-ROM.

38

Page 43

Do drivers need to be installed and, if so, which ones

Description Further information

It is unclear whether there is a need to

install drivers onto the system and more

help is required.

The required drivers do not appear to be

available.

Detailed information specific to your system can be

found on the www.hp.com/go/connect web site.

For support on Windows operating systems, drivers

can be obtained from the HP StorageWorks Tape

CD-ROM or from www.hp.com/support. For

support on UNIX systems, see the UNIX Configuration

Guide on the HP StorageWorks Tape CD-ROM.

(Backup software that states support for

HP StorageWorks SDLT 600 tape drives also provides

the required drivers.)

Future drivers will be provided via the support web

site when they become available.

Testing after installation

Remember that the system recognizes devices during boot-up. If you swap or connect a

product when your system is running, you will need to reboot the system. Rebooting the system

will reset devices and will often resolve problems. It is good practice to reboot every time you

add a driver or install firmware.

Caution Never power off the drive while a cartridge is still loaded or during a firmware upgrade.

The server does not reboot after installation

Possible reason Recommended action

You have installed an additional SCSI host

bus adapter and its resources are clashing

with an existing adapter.

You have disconnected the power or SCSI

cable from the server’s boot disk during the

drive installation process.

Remove the new host bus adapter and check the

server documentation.

Check that the cables to all devices are firmly

connected.

39

Page 44

The server boots but does not recognize the tape drive

Possible reason Recommended action

The power or SCSI cable is not connected

properly.

The SCSI bus is not terminated correctly. Check that the SCSI bus is actively terminated. (Refer

The tape drive’s SCSI ID address is not

unique.

Check that the cables to the tape drive are firmly

connected. Ensure that the SCSI cable is LVDScompliant and does not have any bent pins.

Replace, if necessary. (See the “ordering supplies”

topic on the HP StorageWorks Tape CD-ROM.)

also to the documentation for your SCSI controller

and any other SCSI devices you may have.)

Make sure that each device on the SCSI bus has a

unique ID.

We recommend that the tape drive is connected to a

dedicated host bus adapter. Do not attach the drive

to the same SCSI bus as your disk drive, or to a RAID

controller.

The application does not recognize the tape drive

Possible reason Recommended action

The application does not support the tape

drive.

Use HP Library & Tape Tools to check that the drive

is installed properly. Refer to our World Wide Web

site (www.hp.com/go/connect) for details of

backup applications that support the

HP StorageWorks SDLT 600 tape drive. Load any

service packs as necessary.

Some applications require drivers to be

loaded.

Check that the correct SCSI and tape drive drivers

are installed. Consult the backup application’s

installation notes for details.

The drive does not work

Possible reason Recommended action

If the drive does not power up (all LEDs are

off), the power cable may not be connected

to the drive properly.

If the self-test fails (see “LEDs during self-test”

on page 41), there may be a hardware or

firmware failure.

Make sure that the power cable is firmly connected.

If it is, try another power connector. If the drive still

does not power up, call for assistance.

If there is a cartridge in the drive, remove it. Power

down the drive and power it up again. Try another

power connector. If the self-test still fails, call for

assistance.

40

Page 45

Understanding the LEDs

LEDs during self-test

hp

StorageWorks

SDLT 600

Eject button

Drive

Density

Drive

Status

Cleaning

Required

Your HP StorageWorks SDLT 600 tape drive has three LEDs (light emitting diodes) on the front

panel, which indicate drive status. These LEDs provide useful troubleshooting information.

The tape drive performs a power on self-test whenever power is applied. The test takes

between 10 and 15 seconds.

• At power on, all three LEDs are on solid for approximately 1 second and then flash for one

iteration.

• During the self-test the Drive Status (middle) LED flashes and the other two LEDs are off.

• If self-test passes, the Drive Status (middle) LED is on solid and the other two LEDs are off.

• If the test fails, the middle and right LEDs remain on and the left LED flashes. This continues

until the drive is reset.

41

Page 46

Using the LEDs for troubleshooting

If you cannot resolve a problem, contact customer service at www.hp.com/support.

Use the following table to interpret the front panel LED sequences and the appropriate action

to take, if any.

LED Sequence Cause Action required

All LEDs OFF.

Left LED blinks RED;

middle LED solid

GREEN; right LED

solid YELLOW.

Middle LED solid

GREEN.

Drive may not have

power, may be faulty or

may have been power

cycled or reset during a

firmware upgrade.

The drive has failed to

execute power-on self

test (POST).

The drive is ready for

operation.

Make sure the server is switched on.

Check the internal power cable connection

and replace the cable if necessary.

If the power supply is present and all LEDs

remain off, power cycle the server. If it still

fails, call for service.

Power cycle or reset the server.

If the error condition reappears, call for

service.

None. This is normal.

Middle LED blinks

GREEN.

Left LED blinks RED;

middle LED solid

GREEN; right LED

blinks YELLOW.

Left LED blinks RED;

middle LED blinks

GREEN

Right LED solid

YELLOW

Middle LED blinks

GREEN; right LED

solid YELLOW.

Left LED blinks or is

solid RED; middle LED

blinks or is solid

GREEN; right LED

blinks or is solid

YELLOW.

.

The drive is carrying out

a normal activity (read,

write).

The drive is in OBDR

mode.

The drive is

downloading firmware.

The drive requires

cleaning.

None.

If the drive is upgrading firmware, do not reset

or power cycle it.

See “Running HP OBDR” on page 32 for

further details.

None.

Do not reset or power cycle the drive.

Load the cleaning cartridge. See page 27 for

supported cartridges and instructions.

If the Cleaning Required LED is still

illuminated when you load a new or known

data cartridge after cleaning, call for service.

Cleaning is in progress. None. The cleaning cartridge will eject on

completion.

The cleaning cycle can take up to 5 minutes to

complete.

The drive mechanism

has detected an error or

Power cycle or reset the drive.

Load the latest firmware.

the drive has a firmware

error.

Load a new cartridge.

If the problem persists, call for service.

42

Page 47

Problems with cartridges

For detailed information about handling and inspecting cartridges for damage, please refer

to the online User’s Guide on the HP StorageWorks Tape

If you experience any problems using HP branded cartridges, check:

• The cartridge case is intact and that it contains no splits, cracks or damage.

• The cartridge has been stored at the correct temperature and humidity. This prevents

condensation. See the insert included with the tape cartridge for storage conditions.

• The write-protect switch is fully operational. It should move from side to side with a positive

click.

CD-ROM.

• The World Wide Web site for more detailed troubleshooting information:

www.hp.com/support

.

Cartridge is jammed

If the cartridge is jammed or the backup application is unable to eject it, you can force eject

the cartridge. Once the cartridge is successfully ejected, it is good practice to upgrade the

firmware. If the failure occurs regularly, contact customer service at

www.hp.com/support.

1 Press and hold the Eject button on the front of the tape drive for 10 seconds.

2 Wait for the cartridge to be ejected. This process may take up to 15 minutes (the maximum

rewind time). It is important that you allow sufficient time for the drive to complete this process.

If you interrupt it, you may damage the media or the tape drive.

3 If the cartridge is still jammed, see the “Removing a jammed cartridge” topic in the online

User’s Guide on the HP StorageWorks Tape CD-ROM.

4 Wait for the drive to reset and get back to the loaded position. This process may take up to 15

minutes (the maximum rewind time) to complete.

5 Press and hold the Eject button for 10 seconds.

If the cartridge is still jammed, the tape drive has failed. Contact customer service at

www.hp.com/support.

The drive will not accept cartridge (or ejects it immediately)

The cartridge may have been damaged, for example dropped, or the drive may have a fault.

Caution You may damage the tape drive if you try to insert and load a damaged cartridge. If you

have dropped the cartridge or suspect it may be damaged, please refer to the cartridge care

section of the User’s Guide on the HP StorageWorks Tape CD-ROM for more detailed

information about how to inspect it.

1 Check that the drive has power (the power cable is properly connected and the Drive Status

LED is on).

43

Page 48

2 Check that you are using the correct media. Only use Super DLTtape media, we recommend

Super DLTtape II cartridges (see page 27).

3 Make sure that you have loaded the cartridge with the correct orientation (see “To load a

cartridge” on page 23).

4 Check for damage to your media (to the cartridge case, leader pin or cartridge teeth) and

discard it if it is damaged. See the cartridge care section of the User’s Guide on the

HP StorageWorks Tape CD-ROM for more information about checking the leader pin and

cartridge teeth.

5 Use a new or known, good piece of media and see if it loads. If it does, the original cartridge

is faulty and should be discarded.

6 If you are confident that the cartridge is not damaged, check if another SDLT 600 drive will

accept the cartridge. If it does, the original drive may be faulty. Before calling customer service,

please check that the tape drive is responding and that it can be seen on the SCSI bus. Users

of most operating systems can use HP Library & Tape Tools to do this, see page 33.

44

Page 49

Other sources of information

You will also find troubleshooting information and contact details on the HP StorageWorks

Tape CD-ROM and the HP web site. In particular:

• The online User’s Guide on the HP StorageWorks Tape CD-ROM contains an extensive

troubleshooting topic.

• The HP support web site contains a link to

Customer Care web site for a wide range of up-to-date information about your product.

• The HP web site at

products and configurations.

• The HP web site at

HP One-Button Disaster Recovery.

How to contact HP

You can also use the HP Customer Call Centers for specialist technical help. Contact details

can be found at

To make the best use of this service, we ask that you work with our Support Specialists to

resolve any issues with your drive. This may include downloading diagnostic software, that

will assist in the rapid resolution of your problems. If you do not have web access, a full listing

of HP Customer Call Centers, correct at time of printing, is given in the online User’s Guide on

the HP StorageWorks Tape CD-ROM.

www.hp.com/support that takes you to HP’s

www.hp.com/go/connect provides details of recommended

www.hp.com/go/obdr provides detailed information about

www.hp.com. Click on the link to “contact HP”.

45

Page 50

Replacing your tape drive

If your tape drive proves to be faulty and cannot be repaired and it is still covered by the

original warranty, it will be replaced.

To disconnect your drive

1 Unpack your replacement drive, and retain the packaging.

2 Power off your server and any other devices that are on the same SCSI bus.

3 Remove the cover from the server, see page 13.

4 Observing normal anti-static precautions (see page 13) remove any screws that are holding

the tape drive in place.

5 Disconnect the drive from the server’s power and SCSI cables and slide it carefully out of the

mounting bay.

6 Put the drive into the packaging that contained the replacement drive.

7 Return the faulty drive to your local HP Service Center. Instructions on where to return faulty

drives will be shipped with the replacement drive.

Note If you are not replacing the drive immediately, you should insert a blanking plate into the

empty bay. Replace the cover on the server and secure with screws, as appropriate.

To reconnect your tape drive

Follow the step-by-step instructions in this Getting Started guide.

46

Page 51

Page 52

http://www.hp.com/go/storagemedia

http://www.hp.com/support/tape

AA984-90902

Loading...

Loading...