Page 1

installation

guide

hp StorageWorks

SAN switch 2/32

Product Version: 4.0.x

Second Edition (February 2003)

Part Number: AA-RTQVB-TE

This installation guide provides basic procedures for setting up, configuring, and managing the

SAN Switch 2/32 and SAN Switch 2/32 Power Pak models.

Page 2

© Hewlett-Packard Company, 2003. All rights reserved.

Hewlett-Packard Company makes no warranty of any kind with regard to this material, including, but not limited to,

the implied warranties of merchantability and fitness for a particular purpose. Hewlett-Packard shall not be liable for

errors contained herein or for incidental or consequential damages in connection with the furnishing, performance,

or use of this material.

This document contains proprietary information, which is protected by copyright. No part of this document may be

photocopied, reproduced, or translated into another language without the prior written consent of Hewlett-Packard.

The information contained in this document is subject to change without notice.

Microsoft®, MS-DOS®, MS Windows®, Windows®, and Windows NT® are U.S. registered trademarks of

Microsoft Corporation.

UNIX® is a registered trademark of The Open Group.

BROCADE, the Brocade B weave logo, Brocade: the Intelligent Platform for Networking Storage, SilkWorm, and

SilkWorm Express, are trademarks or registered trademarks of Brocade Communications Systems, Inc. or its

subsidiaries in the United States and/or other countries.

Hewlett-Packard Company shall not be liable for technical or editorial errors or omissions contained herein. The

information is provided “as is” without warranty of any kind and is subject to change without notice. The warranties

for Hewlett-Packard Company products are set forth in the express limited warranty statements for such products.

Nothing herein should be construed as constituting an additional warranty.

Printed in the U.S.A.

SAN Switch 2/32 Installation Guide

Second Edition (February 2003)

Part Number: AA-RTQVB-TE

Page 3

3SAN Switch 2/32 Installation Guide

contents

Contents

About this Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Text Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Equipment Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Rack Stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Getting Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

HP Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

HP Storage Website . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

HP Authorized Reseller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

SAN Switch 2/32 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Port Side of the SAN Switch 2/32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Optical Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Fan Assembly Side of the SAN Switch 2/32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Optional Hardware Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2 Installing the SAN Switch 2/32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Unpack and Verify Carton Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Locating SAN Switch 2/32 Serial Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Installation and Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Selecting an Operating Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Cooling Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Page 4

Contents

4 SAN Switch 2/32 Installation Guide

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Setting Up the Switch as a Stand-alone Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Installing the SAN Switch 2/32 in an HP Series 9000 or EIA Cabinet . . . . . . . . . . . . . . . . . 31

Rack Mount Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Installing the Slide Rail Assemblies to the Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Separating the Inner Slide Rail Assembly from the

Outer Slide Rail Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Attaching the Inner Slide Rails to the Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Attaching the Rear or Front Rack Mount Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

For Rear Rack Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

For Front Rack Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Attaching the Outer Slide Rails to the HP 9000 Series Rack . . . . . . . . . . . . . . . . . . . . . 35

Finalizing the Rack Mounting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Positioning the Switch in the HP 9000 Series Rack . . . . . . . . . . . . . . . . . . . . . . . . . 38

Securing the Rack Mount Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Installing the Switch in the Optional HP System/e Rack. . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Connecting AC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Power On Self-Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Checking POST Results. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Configuring SAN Switch 2/32 Network Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Setting Network Addresses via a Serial Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Connecting the SAN Switch 2/32 to the LAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Core Switch PID Format Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Important Information on Checking the Core Switch PID Format . . . . . . . . . . . . . . . . . 52

Optional Configuration Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Modifying Domain IDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Specifying Custom Status Policies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Connecting the SAN Switch 2/32 to the Fabric . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Verifying Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Installing Multiple Switches into an Existing SAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Recommendations for Cable Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

3 Managing the SAN Switch 2/32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Interpreting LED Activity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

LEDs on the Port Side of the Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

LEDs on the Non-Port Side of the SAN Switch 2/32 . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Management Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Optional Management Feature – Fabric Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Page 5

Contents

5SAN Switch 2/32 Installation Guide

Displaying the Optional Feature Licenses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Running Basic Switch Operations Using Telnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Logging into the SAN Switch 2/32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Changing the Admin Password and User ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Configuring the IP and Fibre Channel Address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Displaying Devices within the Fabric . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Checking the Firmware Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Setting the Switch Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Displaying Switch Configuration Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

SAN Switch 2/32 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Interpreting POST Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Additional Diagnostic Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Field Replaceable Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Power Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Fan Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Motherboard Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

4 Backing Up the Configuration and Upgrading Firmware. . . . . . . . . . . . . . . . . . . . . .79

Backing Up System Configuration Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Restoring the System Configuration Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Upgrading or Restoring Switch Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Downloading Firmware from the HP Website. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

A Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Power Supply Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Memory Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Serial Port Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

B Updating the Core Switch PID Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

HP Recommendations on Changing the Core

Switch PID Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

How to Check the Current Core PID Setting for Switches Running Firmware Lower than

V4.0.0. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Updating the Core Switch PID Format Online . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Updating the Core Switch PID Format Offline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

HP/UX Procedure for Updating the Core Switch PID Format . . . . . . . . . . . . . . . . . 97

AIX Procedure for Updating the Core Switch PID Format. . . . . . . . . . . . . . . . . . . . 99

Page 6

Contents

6 SAN Switch 2/32 Installation Guide

C Regulatory Compliance Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

FCC EMC Statement (USA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

EMC Statement (Canada). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

EMC Statement (European Union). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Germany Noise Declaration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

VCCI EMC Statement (Japan) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

BSMI EMC Statement (Taiwan) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

RRL EMC Statement (Korea) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Laser Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

A. Certification and Classification Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

B. Product Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

C. Usage Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Battery Replacement Notice. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Glossary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

Figures

1 Port side of the SAN Switch 2/32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2 Fan assembly side of the SAN Switch 2/32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3 Shipping carton contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4 Securing the inner slide rails to the switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5 Attaching the rear rack mount brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6 Attaching the outer slide rails to the HP 9000 Series rack. . . . . . . . . . . . . . . . . . . . . . . . 37

7 Sliding the SAN Switch 2/32 into an HP 9000 Series rack . . . . . . . . . . . . . . . . . . . . . . . 39

8 Installing the mounting brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

9 Installing the Tinnerman clips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

10 Installing the rubber washers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

11 Assembling the inner rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

12 Connecting the power cords. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

13 Connecting the Serial cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

14 Connecting the Ethernet cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

15 Inserting a cable into an SFP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

16 LEDs on port side of SAN Switch 2/32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

17 LEDs on non-port side of SAN Switch 2/32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

18 Power supplies and fan assemblies locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

19 Power supplies and fan assemblies locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Page 7

Contents

7SAN Switch 2/32 Installation Guide

20 ioscan output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

21 ioscan -funC disk command output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Tables

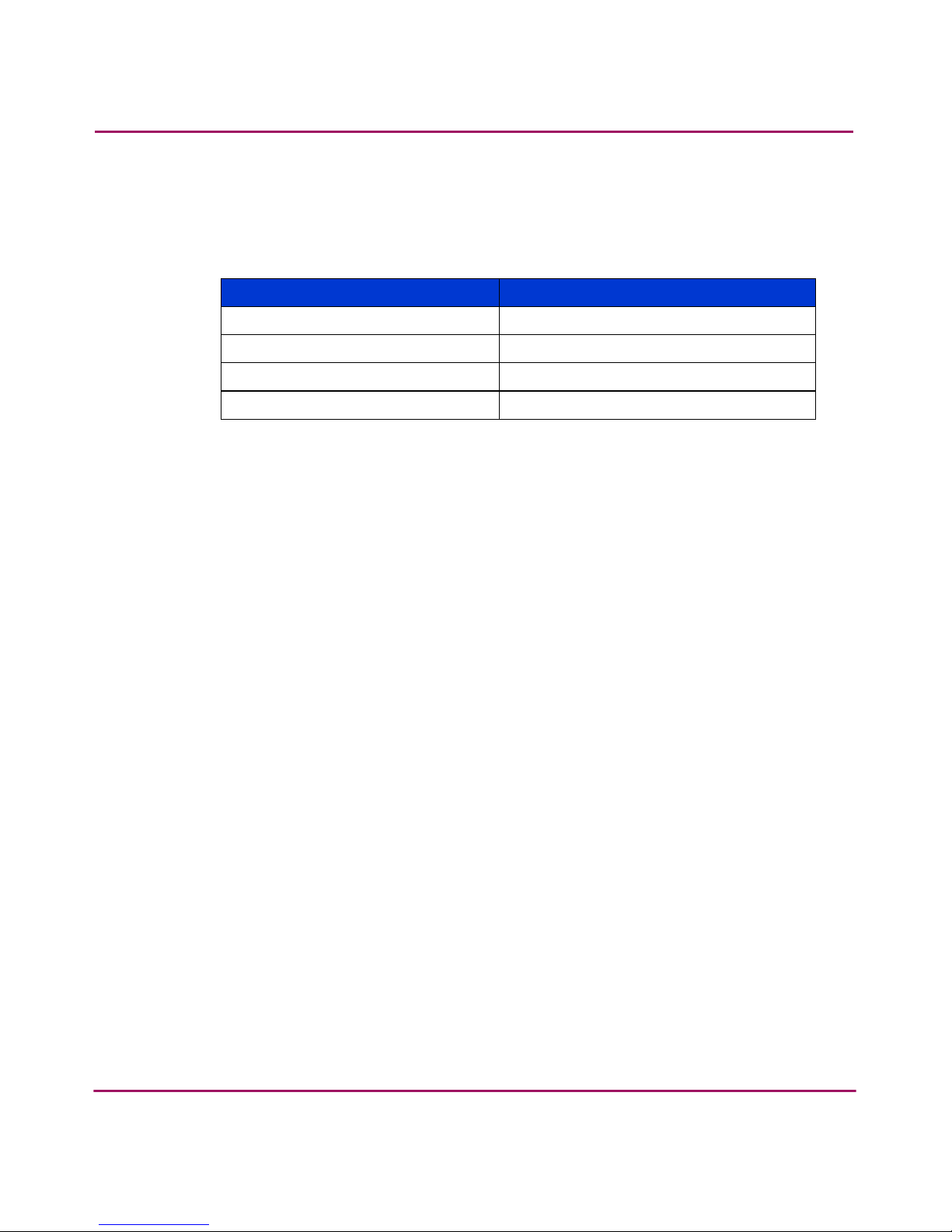

1 Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

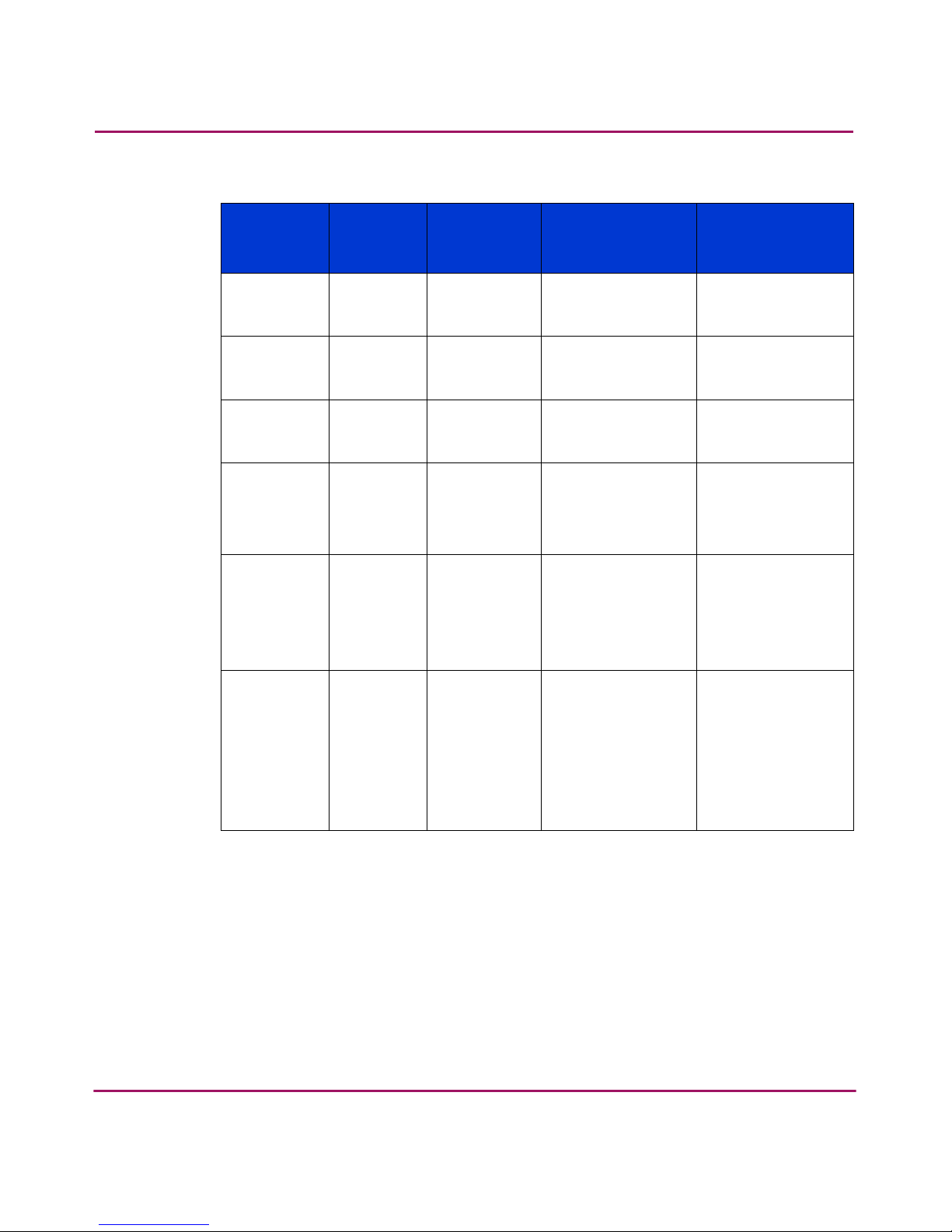

2 SAN Switch 2/32 Orderable Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3 Shipping Carton Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

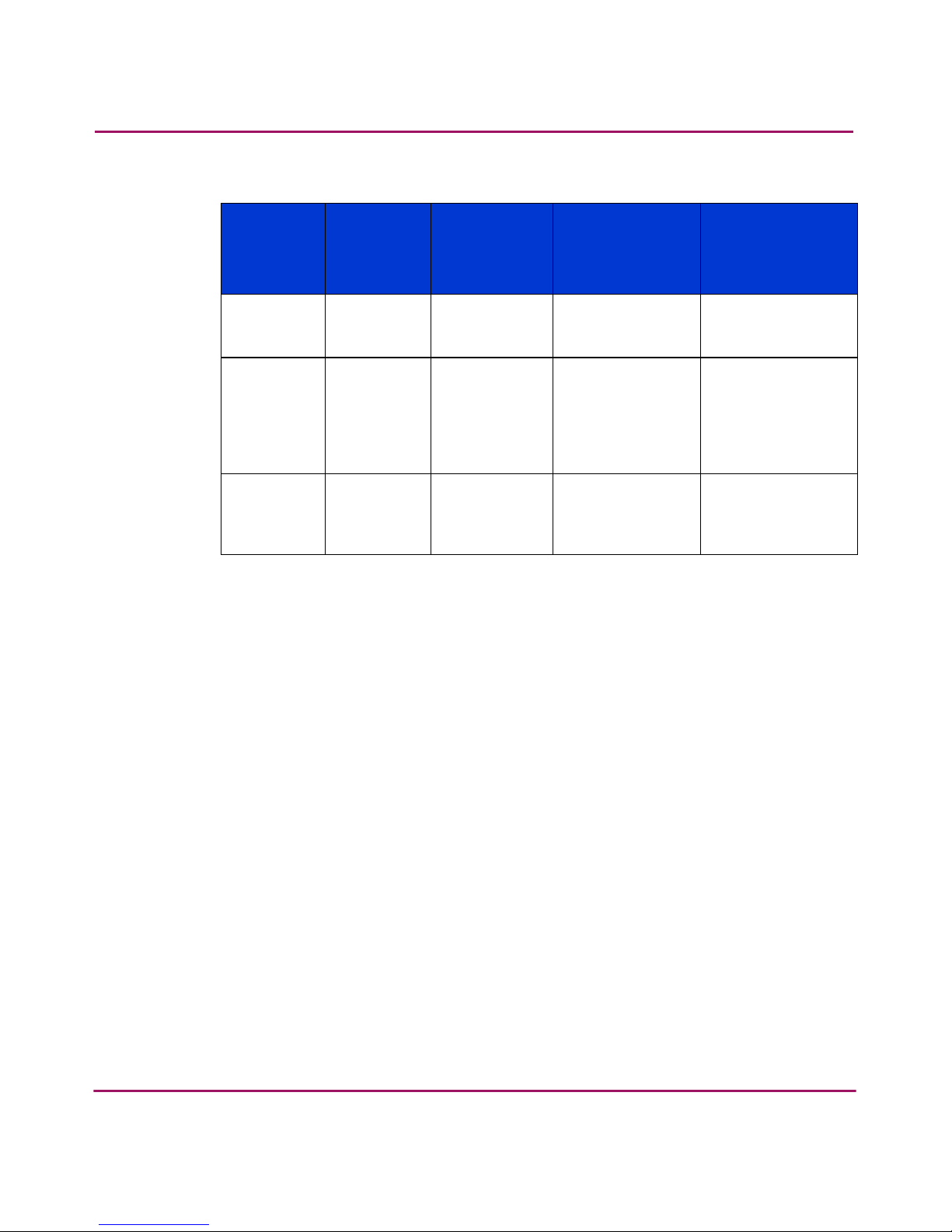

4 Front Panel LED Patterns During Normal Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5 Non-Port Side LED Patterns During Normal Operation . . . . . . . . . . . . . . . . . . . . . . . . . 66

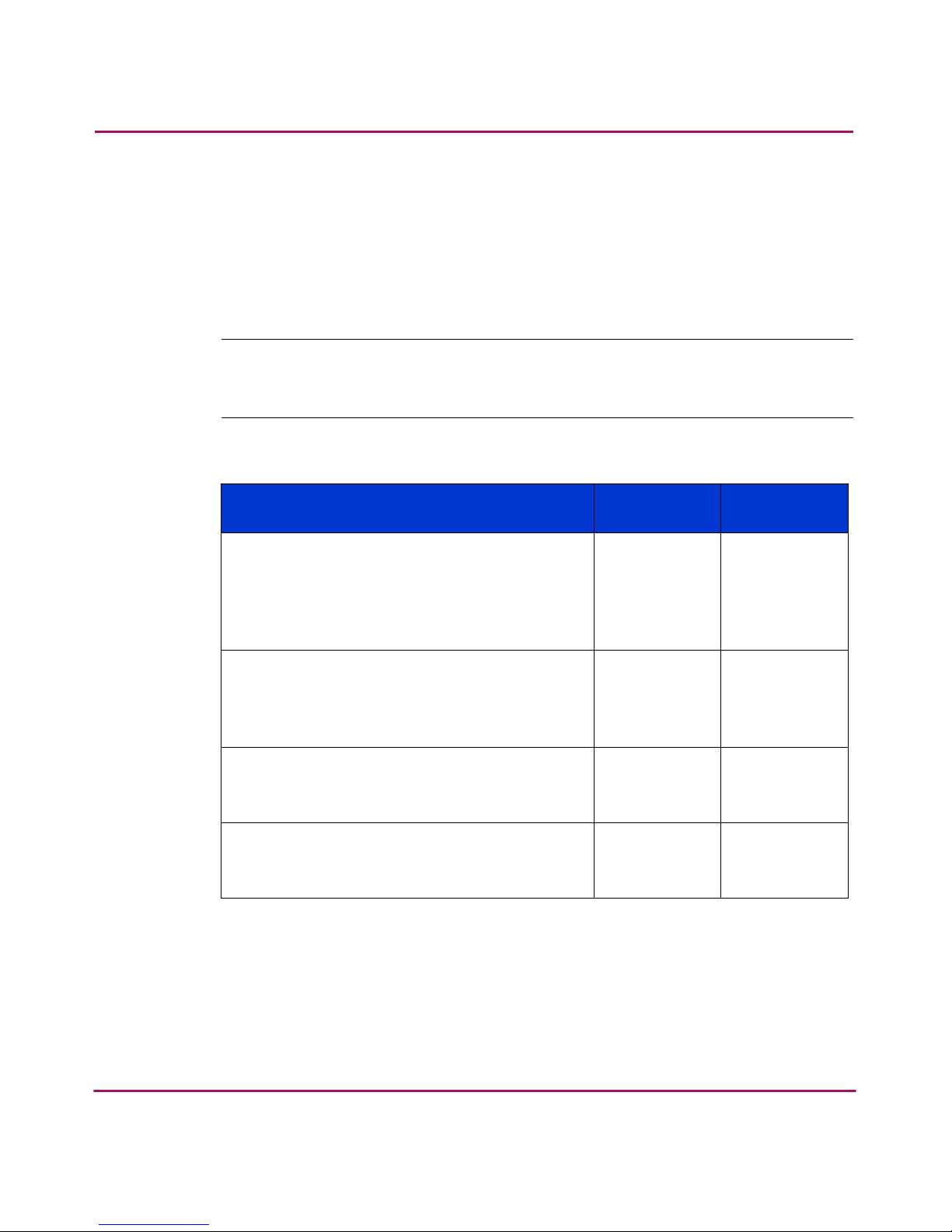

6 Management Options for the SAN Switch 2/32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

7 Physical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

8 Power Supply Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

9 Environmental Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

10 Cabling Pinouts if Pin 7 is Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Page 8

Contents

8 SAN Switch 2/32 Installation Guide

Page 9

9SAN Switch 2/32 Installation Guide

about this

guide

About this Guide

About this Guide

This installation guide provides information to help you:

■ Set up and configure the hp StorageWorks SAN Switch 2/32.

■ Maintain and operate the switch.

About this Guide topics include:

■ Overview, page 10

■ Conventions, page 11

■ Rack Stability, page 14

■ Getting Help, page 15

Page 10

About this Guide

10 SAN Switch 2/32 Installation Guide

Overview

This section covers the following topics:

■ Intended Audience

■ Prerequisites

■ Related Documentation

Intended Audience

This book is intended for use by customers who purchased the SAN Switch 2/32,

and for authorized service providers who are experienced with the following:

■ Configuration aspects of customer Storage Area Network (SAN) fabric

■ Customer host environments, such as Windows 2000, Windows NT, and IBM

AIX

■ Web Tools Graphical User Interface (GUI), for configuring the switch via a

supported Web browser

Prerequisites

Before you unpack the switch, make sure you consider the items below.

Related Documentation

For a list of related documents included with this product, see the Related

Documents section of the HP StorageWorks SAN Switch 2/32 Release Notes.

For the latest information, documentation and firmware releases, please visit the

following HP StorageWorks website:

http://www.q.c.com/storage/productindexdisk.html

For information about Fibre Channel standards, visit the Fibre Channel

Association website, located at

http://www.fibrechannel.com

.

Page 11

About this Guide

SAN Switch 2/32 Installation Guide

11

Conventions

Conventions consist of the following:

■ Document Conventions

■ Text Symbols

■ Equipment Symbols

Document Conventions

The document conventions included in Tabl e 1 apply in most cases.

Text Symbols

The following symbols may be found in the text of this guide. They have the

following meanings.

WARNING: Text set off in this manner indicates that failure to follow

directions in the warning could result in bodily harm or death.

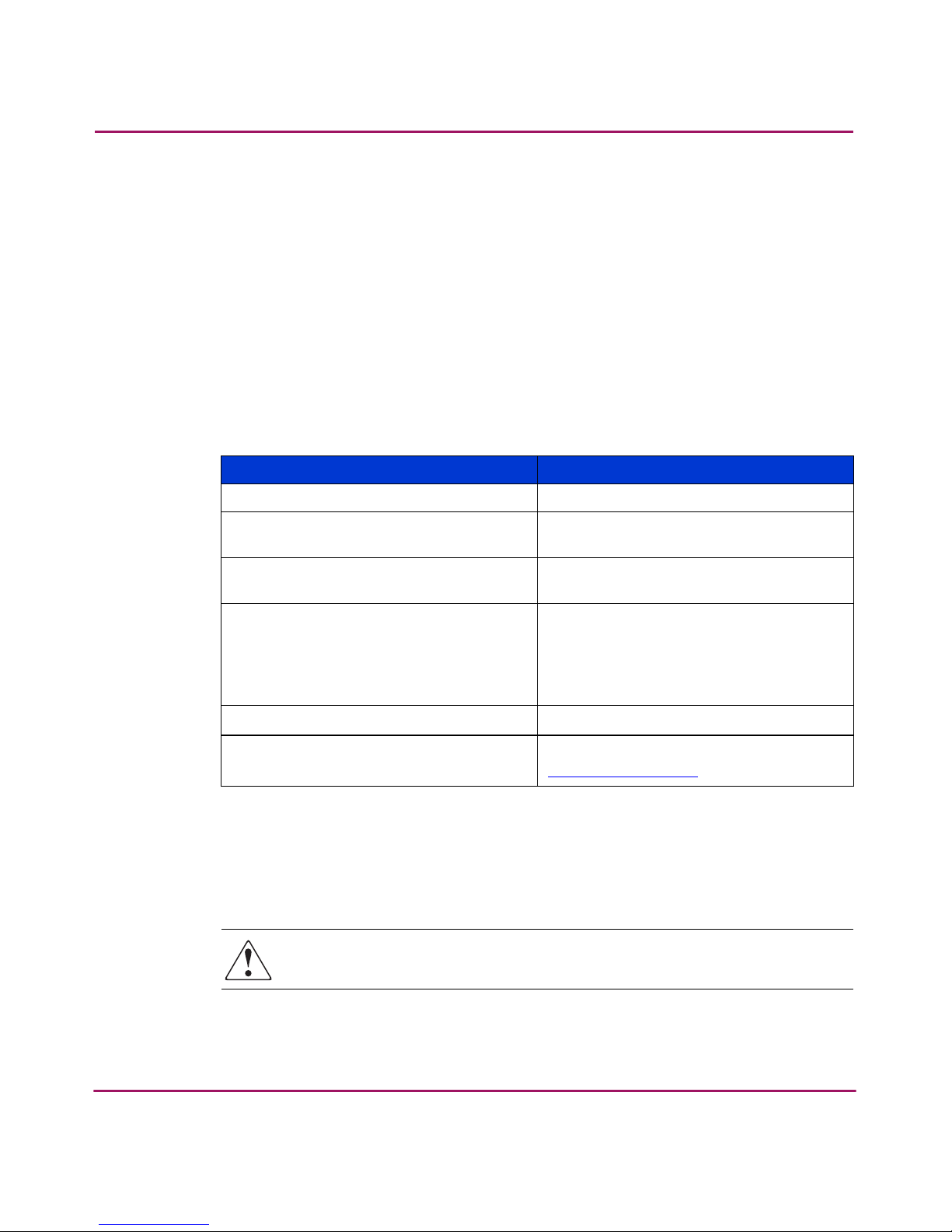

Table 1: Document Conventions

Element Convention

Cross-reference links Blue text: Figure 1

Key and field names, menu items,

buttons, and dialog box titles

Bold

File names, application names, and text

emphasis

Italics

User input, command and directory

names, and system responses (output

and messages)

Monospace font

COMMAND NAMES

are uppercase

monospace font unless they are case

sensitive

Variables

<monospace, italic font>

Website addresses

Blue, underlin

ed sans serif font text:

http://www.hp.com

Page 12

About this Guide

12 SAN Switch 2/32 Installation Guide

Caution: Text set off in this manner indicates that failure to follow directions

could result in damage to equipment or data.

Note: Text set off in this manner presents commentary, sidelights, or interesting points

of information.

Equipment Symbols

The following equipment symbols may be found on hardware for which this guide

pertains. They have the following meanings.

Any enclosed surface or area of the equipment marked with these

symbols indicates the presence of electrical shock hazards. Enclosed

area contains no operator serviceable parts.

WARNING: To reduce the risk to personal safety from electrical shock

hazards, do not open this enclosure.

Any RJ-45 receptacle marked with these symbols indicates a network

interface connection.

WARNING: To reduce the risk of electrical shock, fire, or damage to the

equipment, do not plug telephone or telecommunications connectors

into this receptacle.

Any surface or area of the equipment marked with these symbols

indicates the presence of a hot surface or hot component. Contact with

this surface could result in injury.

WARNING: To reduce the risk to personal safety from a hot

component, allow the surface to cool before touching.

Page 13

About this Guide

SAN Switch 2/32 Installation Guide

13

Power supplies or systems marked with these symbols indicate the

presence of multiple sources of power.

WARNING: To reduce the risk to personal safety from electrical

shock, remove all power cords to completely disconnect power

from the power supplies and systems.

Any product or assembly marked with these symbols indicates that the

component exceeds the recommended weight for one individual to

handle safely.

WARNING: To reduce the risk to personal safety or damage to the

equipment, observe local occupational health and safety requirements

and guidelines for manually handling material.

Page 14

About this Guide

14 SAN Switch 2/32 Installation Guide

Rack Stability

Rack stability protects personnel and equipment.

WARNING: To reduce the risk of personal safety or damage to the

equipment, be sure that:

■ The leveling jacks are extended to the floor.

■ The full weight of the rack rests on the leveling jacks.

■ In single rack installations, the stabilizing feet are attached to the rack.

■ In multiple rack installations, the racks are coupled.

■ Only one rack component is extended at any time. A rack may become

unstable if more than one rack component is extended for any reason.

Page 15

About this Guide

SAN Switch 2/32 Installation Guide

15

Getting Help

If you still have a question after reading this guide, contact an HP authorized

service provider or access our website:

http://www.hp.com

.

HP Technical Support

In North America, call technical support at 1-800-652-6672, available 24 hours a

day, 7 days a week.

Note: For continuous quality improvement, calls may be recorded or monitored.

Outside North America, call technical support at the nearest location. Telephone

numbers for worldwide technical support are listed on the HP website under

support:

http://thenew.hp.com/country/us/eng/support.html

.

Be sure to have the following information available before calling:

■ Technical support registration number (if applicable)

■ Product serial numbers

■ Product model names and numbers

■ Applicable error messages

■ Operating system type and revision level

■ Detailed, specific questions

HP Storage Website

The HP website has the latest information on this product. Access storage at

http://thenew.hp.com/country/us/eng/prodserv/storage.html

. From this website,

select the appropriate product or solution.

HP Authorized Reseller

For the name of your nearest HP authorized reseller:

■ In the United States, call 1-800-345-1518

■ In Canada, call 1-800-263-5868

Page 16

About this Guide

16 SAN Switch 2/32 Installation Guide

■ Elsewhere, see the HP website for locations and telephone numbers:

http://www.hp.com

.

Page 17

17SAN Switch 2/32 Installation Guide

1

Overview

The HP StorageWorks SAN Switch 2/32 is a high-performance, 32-port,

2 gigabit (Gb) Fibre Channel switch used to interconnect storage devices, hosts,

and servers in a Storage Area Network (SAN). It integrates Fabric Operating

System (FOS) firmware V4.0.2x or higher, and is compatible with the HP

StorageWorks switch product family. The SAN Switch 2/32 operates in a fabric

containing multiple switches, or as the only switch in the fabric.

This chapter provides the following information:

■ SAN Switch 2/32 Features, page 18

■ Optional Hardware Kits, page 21

Note: This guide refers to both models as the SAN Switch 2/32, unless otherwise

noted.

Page 18

Overview

18 SAN Switch 2/32 Installation Guide

SAN Switch 2/32 Features

Read the following sections for feature-specific information.

Firmware

The SAN Switch 2/32 operates using FOS firmware version 4.0.2x or higher. The

firmware supports:

■ High-speed data traffic using Interswitch Link (ISL) trunking technology

■ Automatic rerouting through the Fabric Shortest Path First (FSPF) algorithm

■ Application Programming Interface (API) which is a protocol that allows

applications to interface with switch services

■ Zoning functionality which provides a means to allocate storage controllers to

groups of computers. Allows you to create logical subsets of the fabric to

accommodate closed user groups or to create functional user groups within a

fabric

■ Per port statistics which help technicians diagnose and isolate problem ports

without disrupting switch operations

■ Error detections and fault isolation which automatically disables failing ports

and restarts when the problem is resolved

■ Industry standard Management Information Base (MIB) support

■ Automatic self-discovery which discovers and registers host server and

storage devices

■ Web Tools which provide a Graphical User Interface (GUI) to allow

management of a SAN from a browser, such as Internet Explorer or Netscape

Hardware

The SAN Switch 2/32 consists of the following components:

■ Air-cooled 1.5U chassis that can be set up as a stand-alone unit or mounted in

a standard Electronic Industries Association (EIA) 19-inch rack

■ 32 Fibre Channel ports

■ One RS-232 Serial port, designed to connect to a DTE port

■ One 10/100 Mb/s Ethernet port with an RJ-45 connector

■ Two redundant power supplies, with AC switches and built-in fans

Page 19

Overview

19SAN Switch 2/32 Installation Guide

■ Three redundant fan assemblies, hot-swappable if replaced one at a time

■ A field-replaceable motherboard assembly enclosed in a grounded EMI cage

■ Slide Rack Mount Kit

■ The following LED indicators:

— Switch Power/Status LED on the port side of the switch

— Port Readiness LED on the non-port side of the switch

— Port Status LED and Port Speed LED for each port

— Power LED on each power supply

— Fan Failure LED on each fan assembly

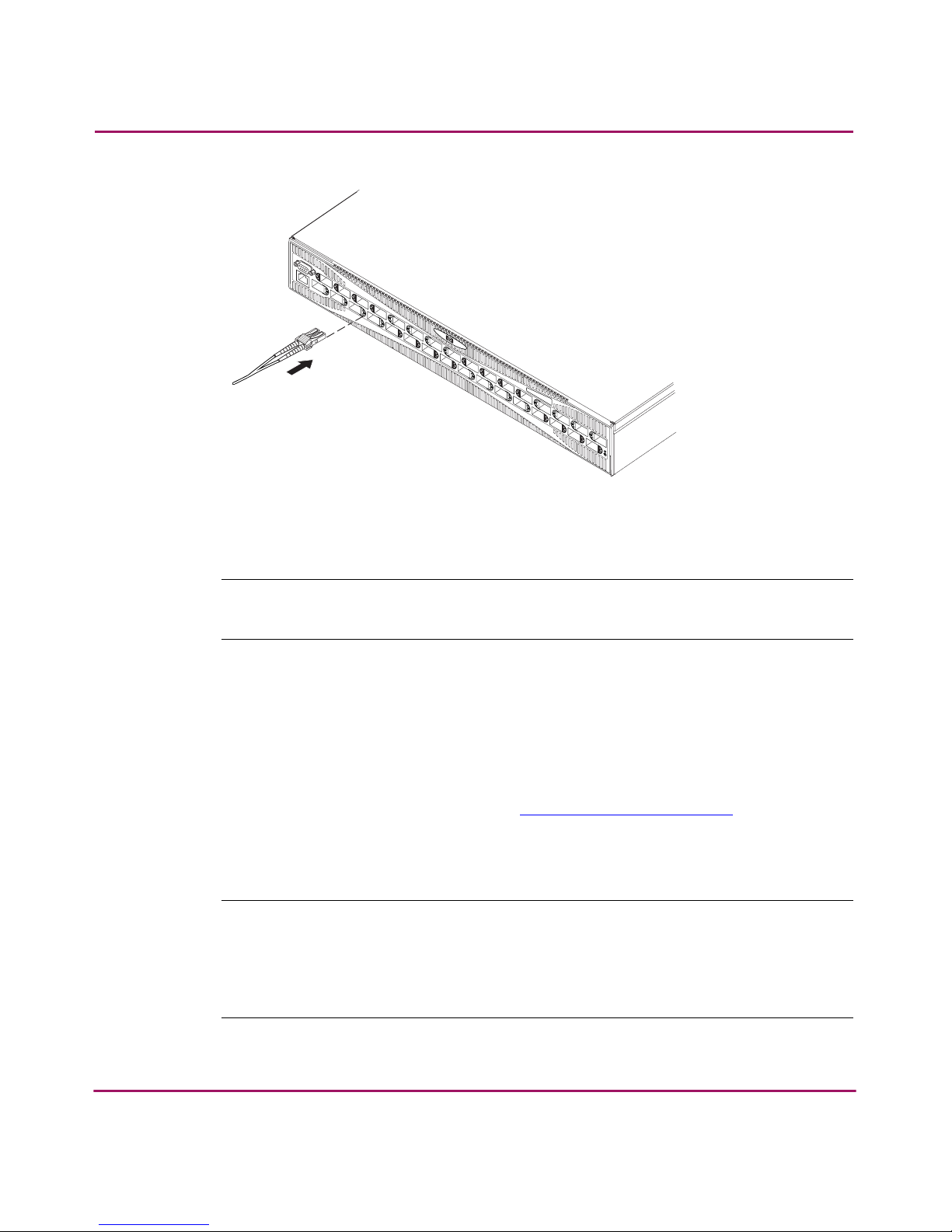

Port Side of the SAN Switch 2/32

Figure 1 shows the port side of the SAN Switch 2/32.

Figure 1: Port side of the SAN Switch 2/32

1 Serial port

2 Fibre Channel

port

3 IP address

label

4 Power switch

5 Ethernet port

SHR-2568A

1 3

5 4

2

Page 20

Overview

20 SAN Switch 2/32 Installation Guide

Optical Ports

The Fibre Channel ports are numbered from left to right, with ports 0–15 in the

lower row, and ports 16–31 in the upper row. The ports provide the following

functionality:

■ Automatic negotiation to highest common speed of all devices connected to

port

■ Port interfaces compatible with Small Form Factor Pluggable (SFP)

transceivers, both Short Wavelength (SWL) and Long Wavelength (LWL)

■ Universal and self-configuring: capable of becoming an F_Port (fabric

enabled), FL_Port (fabric loop enabled), or E_Port (expansion port).

The ports are color-coded into groups of four to indicate which ports can be used

in the same Interswitch Link (ISL) trunking group.

Note: ISL Trunking is an integrated software component that enables ISL trunking

groups between adjacent switches. For more information about trunking, refer to the

HP

StorageWorks ISL Trunking Version 3.0.x/4.0.x User Guide

.

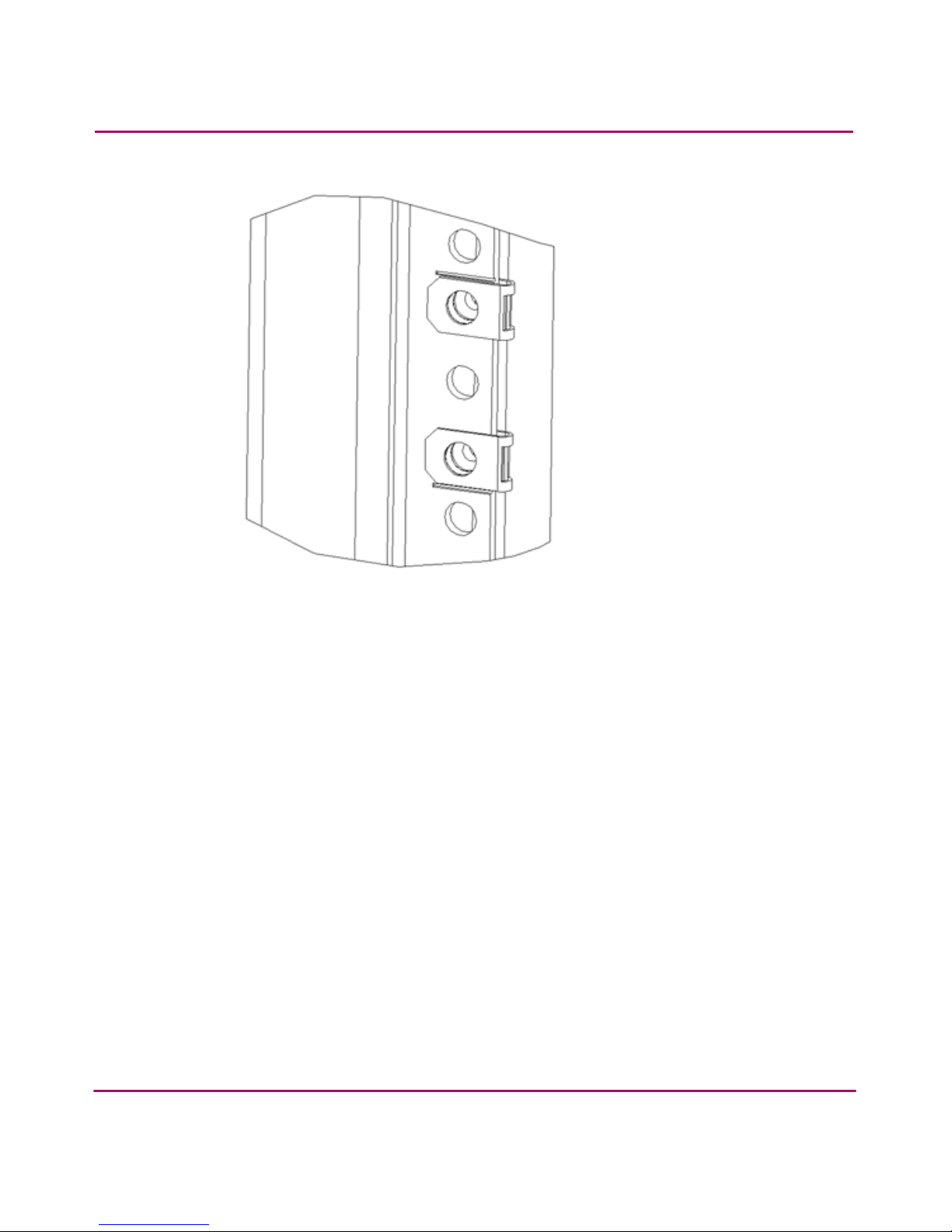

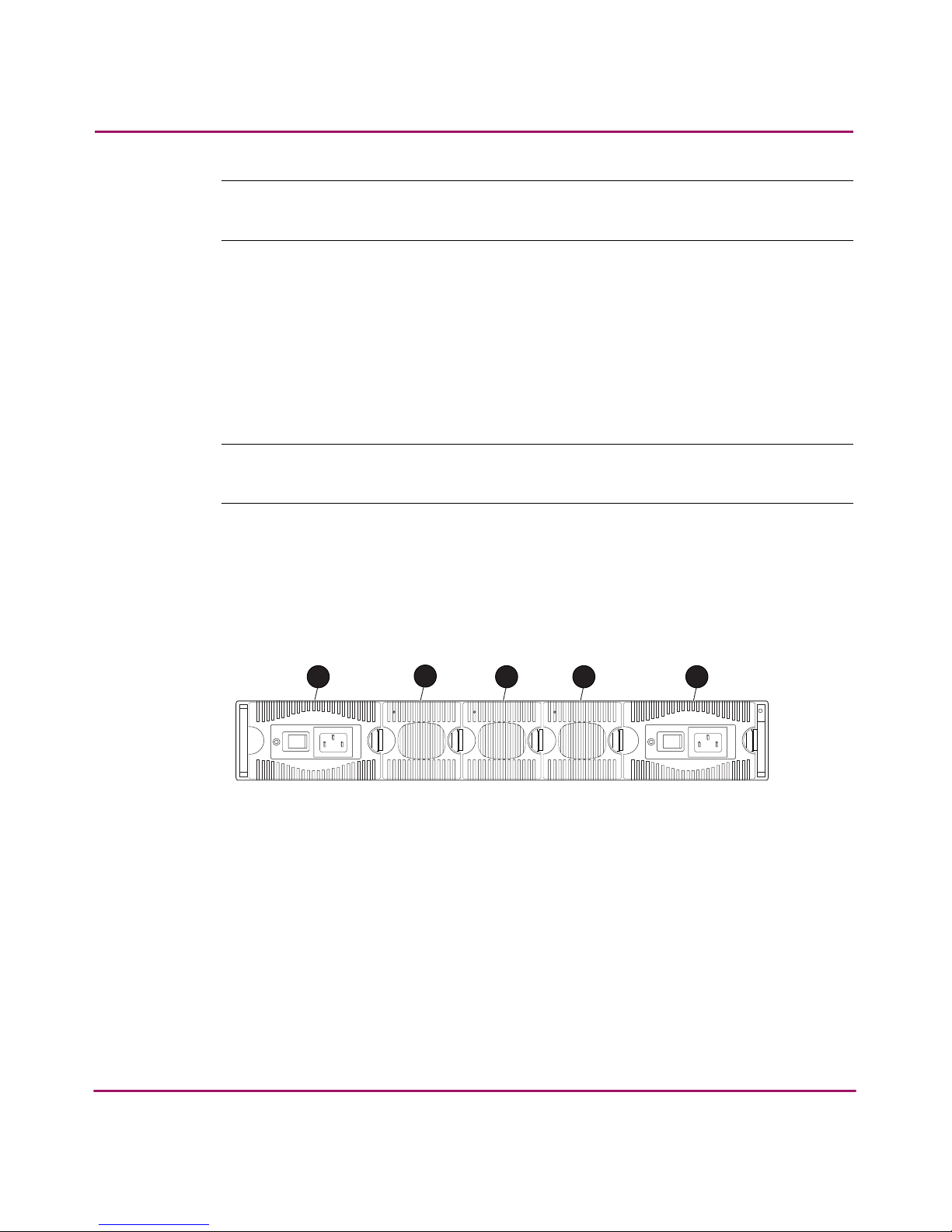

Fan Assembly Side of the SAN Switch 2/32

Figure 2 shows the fan assembly side of the SAN Switch 2/32. The fan assembly

side houses the fans with corresponding LEDs, power supplies, and the port

readiness LED.

Figure 2: Fan assembly side of the SAN Switch 2/32

1 Power supply

2 Fan assembly (1 0f 3)

3 Power supply

4 Port readiness LED

SHR-2569A

1 3

4

2

Page 21

Overview

21SAN Switch 2/32 Installation Guide

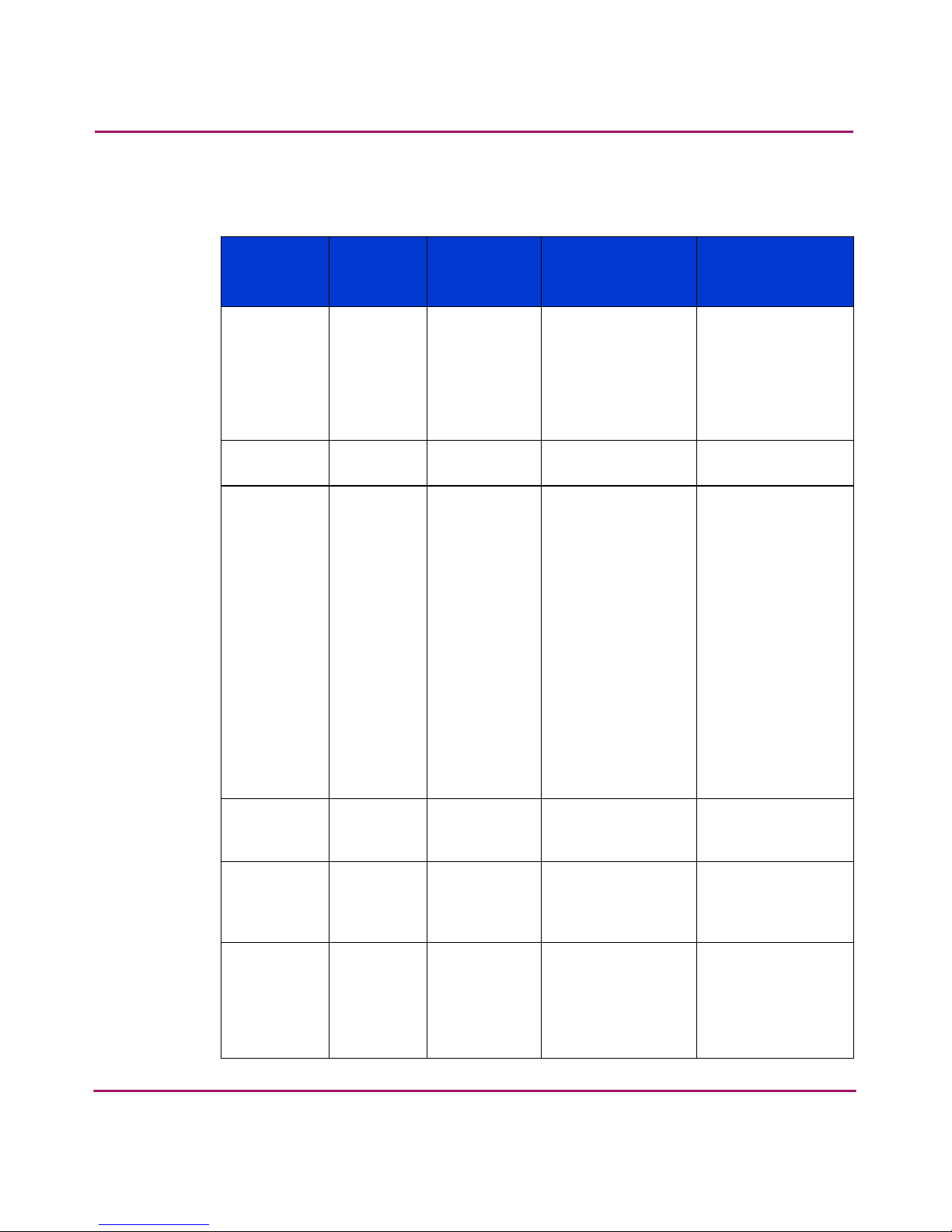

Optional Hardware Kits

HP provides the following optional hardware kits in support of the SAN Switch

2/32; see Tabl e 2.

* premerger HP part number

** premerger Compaq part number

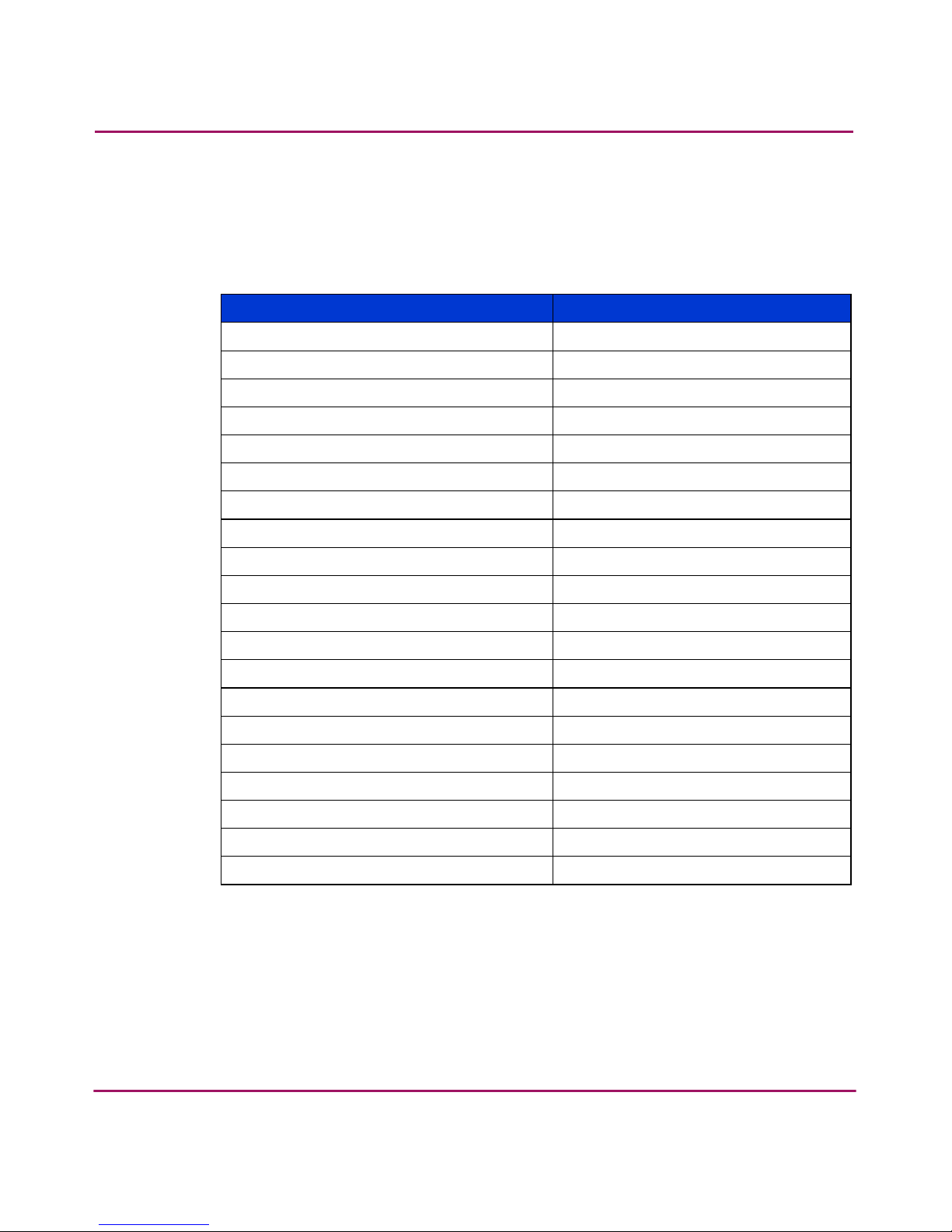

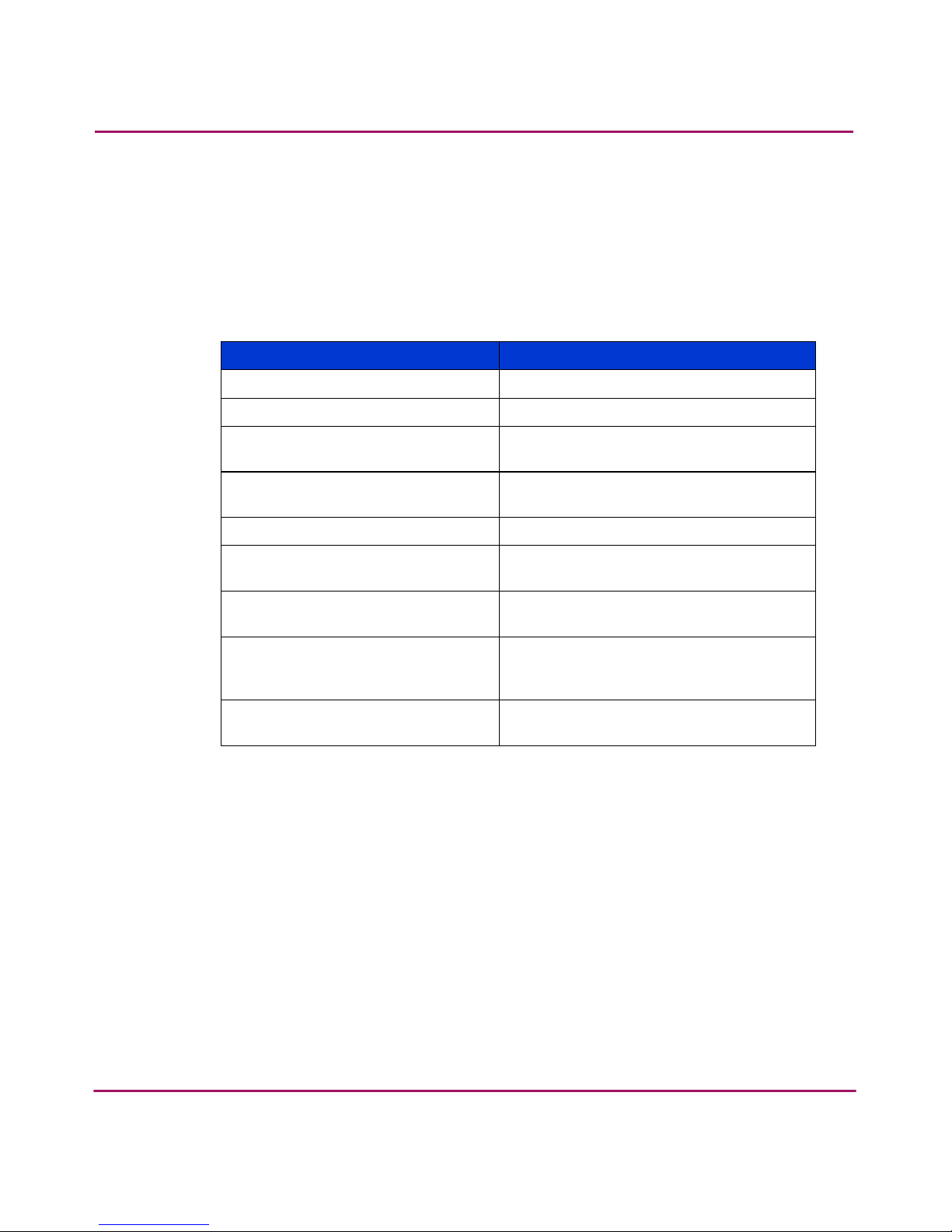

Table 2: SAN Switch 2/32 Orderable Hardware

Accessory Part Number

Short wavelength SFP A6515A* or 300834-B21**

Long wavelength SFP, 10 km A6516A* or 300835-B21**

2m LC-to-LC Fibre Channel (fc) cable C7524A*

2m LC-to-LC multimode fc cable 221692-B21**

16m LC-to-LC fc cable C7525A*

5m LC-to-LC multimode fc cable 221692-B22**

50m LC-to-LC fc cable C7526A*

15m LC-to-LC multimode fc cable 221692-B23**

200m LC-to-LC fc cable C7527A*

30m LC-to-LC multimode fc cable 221692-B26**

50m LC-to-LC multimode fc cable 221692-B27**

2m LC-to-SC fc cable C7529A*

2m LC-to-SC multimode fc cable 221691-B21**

16m LC-to-SC fc cable C7530A*

5m LC-to-SC multimode fc cable 221691-B21**

15m LC-to-SC multimode fc cable 221691-B23**

30m LC-to-SC multimode fc cable 221691-B26**

50m LC-to-SC multimode fc cable 221691-B27**

SC female to SC female adapter C7534A*

2m LC male to SC male adapter kit C7534A*

Page 22

Overview

22 SAN Switch 2/32 Installation Guide

Page 23

23SAN Switch 2/32 Installation Guide

2

Installing the

SAN Switch 2/32

This chapter covers the following topics:

■ Unpack and Verify Carton Contents, page 24

■ Locating SAN Switch 2/32 Serial Numbers, page 27

■ Installation and Safety Guidelines, page 28

■ Setting Up the Switch as a Stand-alone Unit, page 30

■ Installing the SAN Switch 2/32 in an HP Series 9000 or EIA Cabinet, page 31

■ Installing the Switch in the Optional HP System/e Rack, page 40

■ Connecting AC Power. page 45

■ Power On Self-Test, page 46

■ Configuring SAN Switch 2/32 Network Addressing, page 47

■ Connecting the SAN Switch 2/32 to the LAN, page 51

■ Core Switch PID Format Summary, page 52

■ Optional Configuration Settings, page 54

■ Connecting the SAN Switch 2/32 to the Fabric, page 56

■ Installing Multiple Switches into an Existing SAN. page 58

■ Recommendations for Cable Management, page 59

Page 24

Installing the SAN Switch 2/32

24 SAN Switch 2/32 Installation Guide

Unpack and Verify Carton Contents

Unpack and inspect the SAN Switch 2/32 carton contents as follows:

1. Inspect the shipping container for possible damage caused during transit.

2. Unpack the shipping cartons.

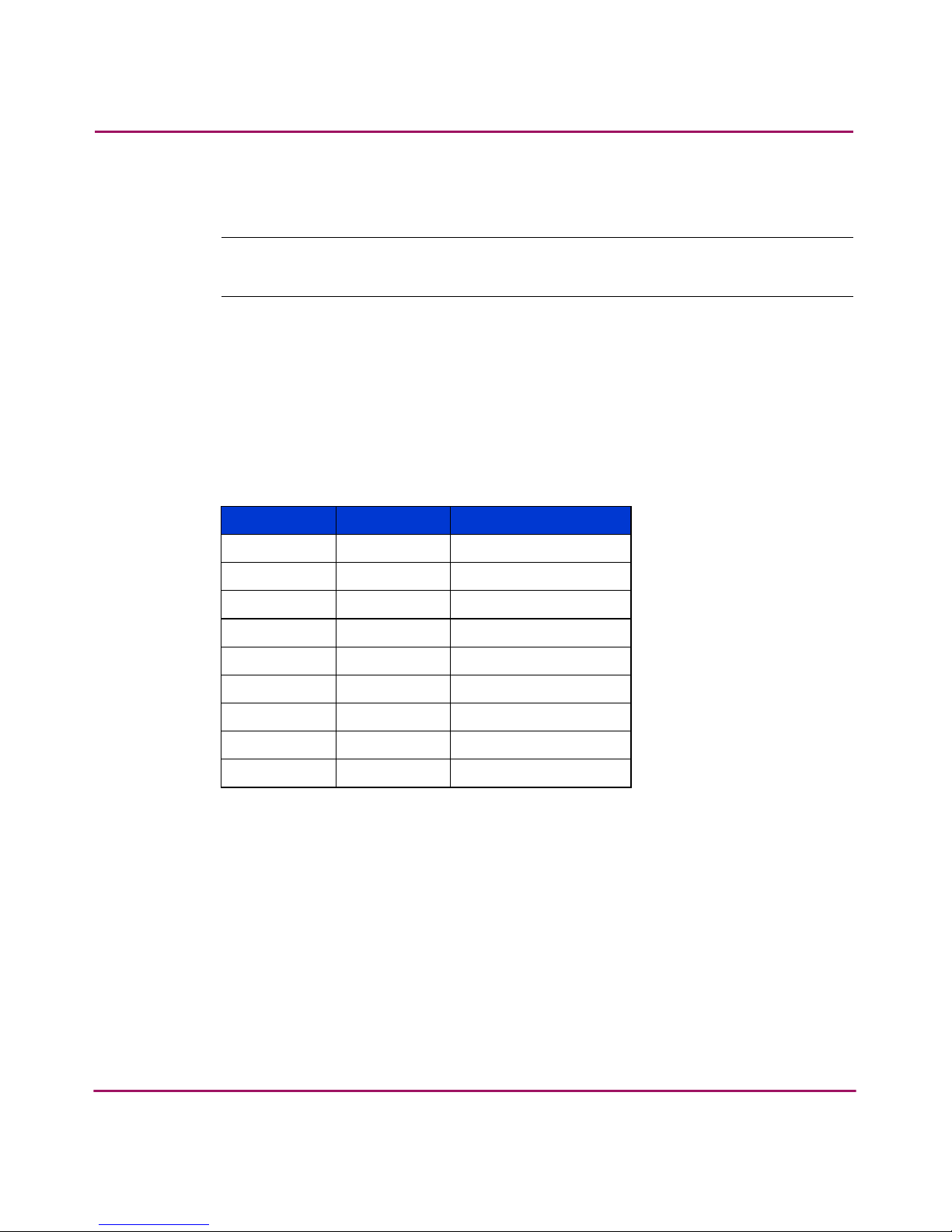

Note: The Rack Mount Kit shown in Figure 3 may not represent the kit that shipped

with your switch. HP reserves the right to substitute Rack Mount Kits, providing

applicable instructions with each switch.

3. Verify that the carton contains the items shown in Figure 3 and Tab le 3.

Page 25

Installing the SAN Switch 2/32

25SAN Switch 2/32 Installation Guide

Note: If any items are damaged or missing, please contact HP or an HP authorized

reseller.

Figure 3: Shipping carton contents

SHR-2570A

1

3

2

Page 26

Installing the SAN Switch 2/32

26 SAN Switch 2/32 Installation Guide

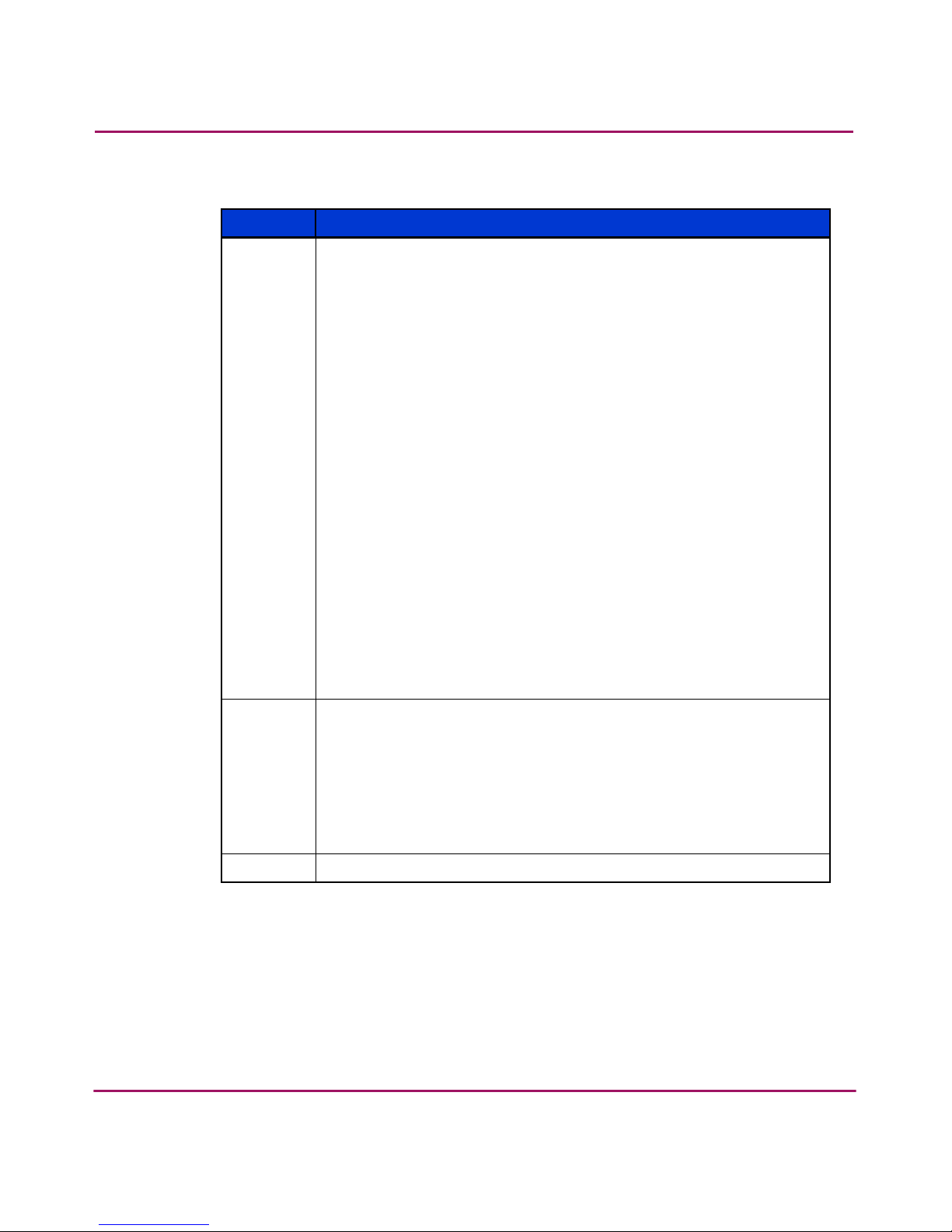

Table 3: Shipping Carton Contents

Number Item

1

One HP StorageWorks SAN Switch 2/32 product accessories box

containing:

■ One RS-232 Serial cable (convertible to an RJ-45 connector, by

removing the adapter on the end of the cable)

■ Rack Mount hardware pouch:

—Power cord clips (6)

—3-hole bar nuts (4)

— 10-32 x 3/8 inch Black Phillips head screws (12)

— 8-32 x 3/16 inch Phillips head screws (10)

— Square alignment washers (8)

— Right and left rear rack mount brackets (2); use if installing

so that port side slides from the rear of the rack

— Right and left front mount brackets (2); use if installing so

that power supply end slides out from the front of the rack

■ Documentation, release notes, license, warranty, and CD

■ Two country-specific AC power cords

■ Two Power Distribution Unit (PDU) power cords (not shown in

Figure 3)

■ Four rubber mounting feet for stand-alone installations on a

table or lab bench

2 Slide assembly; includes one inner and one outer slide rail, with the

following items preinstalled:

■ L-bracket, slide mount, 3-hole (4)

■ Nut, Hex, Locking, 8-32 (4 nuts in each slide assembly, for a

total of 8)

■ 8-32 x 3/8 inch, zinc slotted screw (requiring a torque of 15

inch-pounds) (8)

3 HP StorageWorks SAN Switch 2/32

Page 27

Installing the SAN Switch 2/32

27SAN Switch 2/32 Installation Guide

Locating SAN Switch 2/32 Serial Numbers

Before contacting HP for technical support or service, obtain the three serial

numbers located on the switch. Each serial number provides specific logistical

information, identifying the device’s manufacturing location.

Page 28

Installing the SAN Switch 2/32

28 SAN Switch 2/32 Installation Guide

Installation and Safety Guidelines

Read the following sections for installation guidelines. Install the SAN Switch

2/32 in one of the following ways:

■ As a stand-alone unit on a flat surface.

■ In an Electronics Industries Association (EIA) cabinet (like the HP 9000

Series Rack), using the Slide Rack Mount Kit provided with the switch. See

Slide Rack Mount Kit contents outlined in Tab le 3.

■ In an HP System/e rack.

Selecting an Operating Location

To ensure correct operation of the switch, the location where the switch is in use

must meet the following requirements:

■ Adequate supply circuit, line fusing, and wire size, as specified by the

electrical rating on the switch nameplate.

■ An air flow of at least 300 cubic feet per minute, available in the immediate

vicinity of the switch.

■ If installing the switch in the HP 9000 Series, or comparable EIA rack:

— All equipment installed in the rack should have a reliable branch circuit

ground connection, and should not rely on a connection to a branch

circuit, such as a power strip.

— The rack should be balanced and the installed equipment should be within

the rack’s weight limits. Ensure the rack is mechanically secured to insure

stability in the event of an earthquake.

Cooling Requirements

Cooling air is drawn into the switch chassis by the fans mounted on the rear of the

chassis. The air is expelled through vents in the front (port side) of the chassis,

next to the HP logo. HP recommends installing the switch so that air intake and

exhaust for all components in the rack is flowing in the same front-to-back

direction.

Note: HP highly recommends mounting the switch in a cabinet or rack so that the fans

reside in the front of the cabinet, and the ports (cables) reside in the rear of the cabinet.

Page 29

Installing the SAN Switch 2/32

29SAN Switch 2/32 Installation Guide

Follow these guidelines to ensure proper air flow, and prevent component

overheating:

■ To ensure adequate cooling, install the switch with the non-port side, which

contains the air intake vents, facing the cool-air aisle.

■ Verify a minimum of 47 cubic feet/minute (79.8 cubic meters/hour) of air

flow is available to the air intake vents on the non-port side of the switch.

■ Verify that the ambient air temperature does not exceed 40° Celsius (104°

Fahrenheit) while the switch is operating.

Caution: Do not block air vents. The switch uses ambient air for cooling.

Power Requirements

Two AC power cords connect to the switch on either side of the rear panel. The

AC power source must meet these requirements:

■ Primary AC Input 100–240 VAC (switch auto-senses input voltage) 47–63 Hz

■ Correctly wired primary outlet, with circuit protected by a circuit breaker and

grounded in accordance with local electrical codes

■ Adequate supply circuit, line fusing, and wire size, as specified by the

electrical rating on the switch nameplate

■ Voltage capability of 85–264 VAC

■ Input voltage frequency of 47–63 Hz

■ Power capability of 75 W maximum

The switch has a universal power supply capable of functioning worldwide

without voltage jumpers or switches. The power supply is auto ranging in terms of

accommodating input voltages and line frequencies.

Page 30

Installing the SAN Switch 2/32

30 SAN Switch 2/32 Installation Guide

Setting Up the Switch as a Stand-alone Unit

Use these procedures for setting up the switch as a stand-alone unit. The following

items are required for this setup:

■ SAN Switch 2/32

■ AC power cords and cables supplied with the switch

■ Rubber mounting feet supplied with the switch

1. Place the SAN Switch 2/32 on a flat, sturdy surface like a table or lab bench.

2. Apply the rubber feet as follows:

a. Clean the four depressions that are at each corner of the bottom of the

switch to ensure they are free of dust.

b. Place a rubber foot in each depression, with the adhesive side against the

chassis, and press into place.

Caution: Installing the rubber feet on the switch is recommended to help

prevent the switch from accidentally sliding off the table or bench.

3. Connect the power cables to the SAN Switch 2/32 power connectors and to a

power outlet. Ensure the power cable is routed so that it is not exposed to

stress.

4. Turn on the power to the switch (flip the AC switch to “1”). The switch

automatically runs a Power On Self-Test (POST).

Caution: Do not connect the switch to the network until the IP address is

correctly set. For instructions on how to set the IP address, see “Configuring

SAN Switch 2/32 Network Addressing,” later in this chapter.

Page 31

Installing the SAN Switch 2/32

31SAN Switch 2/32 Installation Guide

Installing the SAN Switch 2/32 in an HP Series 9000

or EIA Cabinet

Read the following sections for complete installation instructions. Before you

begin, obtain the following tools:

■ #2 Phillips screwdriver, with torque capability

■ Torx screwdriver

■ Slotted blade screwdriver, 1/4 inch, with torque capability

Rack Mount Checklist

Verify that the rack and the area around the rack meets the following

requirements:

■ The cabinet must be a standard EIA cabinet.

■ Plan a cabinet space that is 1.5 rack units high (2.6 inches; 6.7 cm), 19 inches

(48.3 cm) wide, and at least 23 inches (68.6 cm) deep.

■ Ground all equipment in the cabinet through a reliable branch circuit

connection, and maintain ground at all times. Do not rely on a secondary

connection to a branch circuit, such as a power strip.

■ Ensure that airflow and temperature requirements are met on an ongoing

basis, particularly if the switch is installed in a closed or multi-rack assembly.

■ Verify that the additional weight of the switch does not exceed the cabinet’s

weight limits or unbalance the cabinet in any way.

■ Secure the cabinet to insure stability in case of unexpected movement.

Note: This procedure is written with the assumption that the non-port side of the switch,

which contains the air intake vents, is installed facing the cool-air aisle.

Page 32

Installing the SAN Switch 2/32

32 SAN Switch 2/32 Installation Guide

Installing the Slide Rail Assemblies to the Switch

The SAN Switch 2/32 Rack Mount Kit consists of two slide rail assemblies

consisting of an inner slide rail attached to an outer slide rail. Read the following

sections for complete instructions on first separating, then installing the Slide Rail

Assemblies.

Separating the Inner Slide Rail Assembly from the

Outer Slide Rail Assembly

Separate the two inner (smaller) slide rails from the two outer (larger) slide rails as

follows.

1. Holding one slide rail assembly horizontally, pull the inner slide rails out of

the outer slide rail until the lock release lever engages.

2. Press the lock release lever located on the inner slide rails. The inner slide rail

separates from the outer slide rail.

3. Repeat steps 1 and 2 to separate the second slide rail assembly.

4. Put the outer slide rails aside. Follow the steps in the next section, “Attaching

the Inner Slide Rails to the Switch.”

Attaching the Inner Slide Rails to the Switch

Use the following steps to secure each inner slide rail to the switch chassis.

Caution: It is important to install the inner slide rails using the Phillips head,

8-32 x 3/16 inch screws supplied in the Rack Mount Kit. Installing screws

longer than 3/16 inch can damage the switch.

1. Position the inner slide rails with the flat side against the switch, oriented in

one of the following two ways:

Page 33

Installing the SAN Switch 2/32

33SAN Switch 2/32 Installation Guide

Caution: HP recommends installing the SAN Switch 2/32 so that the port side

of the switch slides out the rear of the rack (as described in step 1a below). In

this way, the switch faces the aisle where exhaust air is released. Air intake

and exhaust for all components in the rack should flow in the same direction.

a. To allow the port side of the switch to slide out the rear of the rack:

Orient the inner slide rail with the end containing the lock release lever

towards the power supply end of the switch.

b. To allow the power supply side of the switch to slide out the front of the

rack:

Orient the inner slide rail with the end containing the lock release lever

towards the port end of the switch.

2. Locate three Phillips head, 8-32 x 3/16 inch screws provided in the Rack

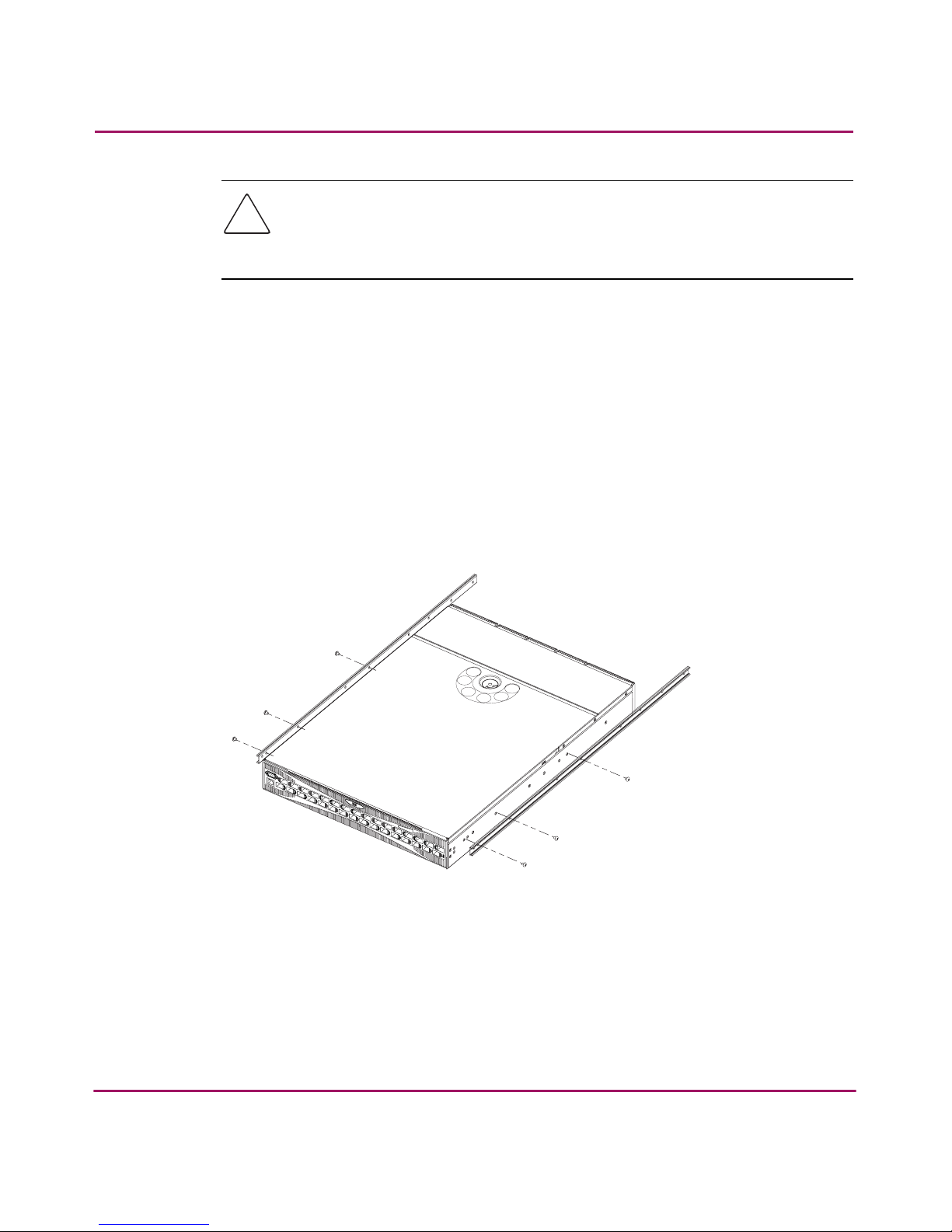

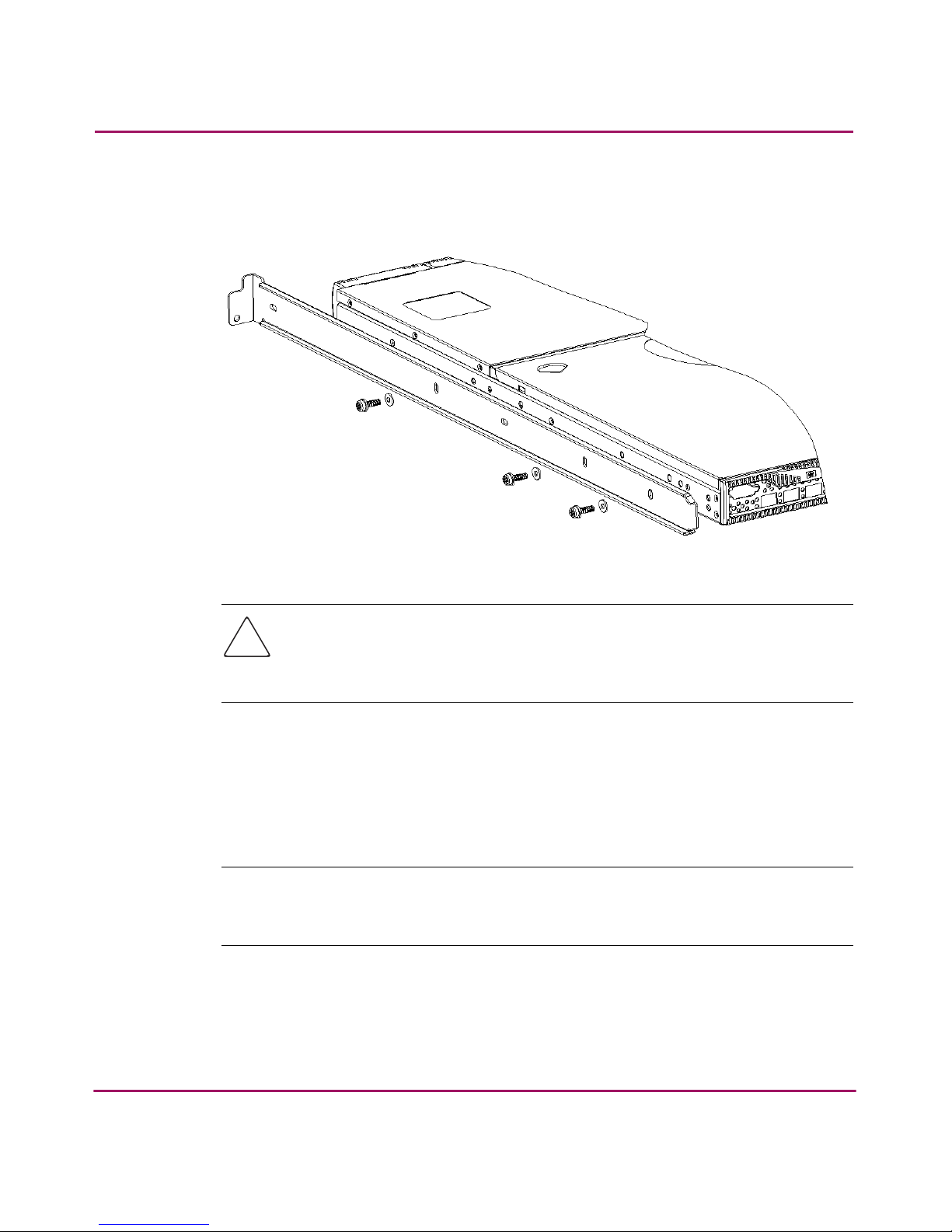

Mount Kit. Secure the inner slide rail to the switch, see Figure 4.

3. Tighten the screws and torque to 15 inch-pounds.

Figure 4: Securing the inner slide rails to the switch

4. Repeat steps 1 and 2 to attach the second inner slide rail to the switch. Make

sure to orient the second inner slide rail in the same way you positioned the

first (based on 1a or 1b above).

SHR-2575A

Page 34

Installing the SAN Switch 2/32

34 SAN Switch 2/32 Installation Guide

Attaching the Rear or Front Rack Mount Brackets

The Rack Mount Kit supplied with the SAN Switch 2/32 contains two rear rack

mount brackets and two front rack mount brackets. Install these rack mount

brackets to prevent the switch from accidentally sliding out of the rack, as follows.

Caution: HP recommends installing the SAN Switch 2/32 so that the port side

of the switch slides out the rear of the rack. (For example, the switch should

face the aisle where exhaust air is released. Air intake and exhaust for all

components in the rack should flow in the same direction.)

For Rear Rack Access

Use these steps to attach the rear rack mount brackets to the switch. The rear rack

mount brackets act as “stops” to prevent the switch from sliding out the rear of the

rack. Use these steps if you installed the inner slide rails to the switch using the

procedure outlined in “Attaching the Inner Slide Rails to the Switch,” step 1a.

1. Align the right rack mount bracket with the two screw holes at the port end of

the switch.

2. Locate two Phillips head 8-32 x 3/16 inch screws, contained in the Rack

Mount Kit. Secure the right mount bracket to the switch; see Figure 5.

Figure 5: Attaching the rear rack mount brackets

SHR-2576A

Page 35

Installing the SAN Switch 2/32

35SAN Switch 2/32 Installation Guide

3. Tighten the screws and torque to 15 inch-pounds.

4. Repeat steps 1 through 3 to install the left mount bracket on the left side of the

switch; see Figure 5.

For Front Rack Access

Use these steps to attach the front rack mount brackets to the switch. The front

rack mount brackets act as “stops” to prevent the switch from sliding out the front

of the rack. Use these steps if you installed the inner slide rails to the switch using

the procedure outlined in “Attaching the Inner Slide Rails to the Switch,” step 1b.

1. Align the right rack mount bracket with the two screw holes at the end of the

inner rails on the right, power supply end of the switch.

2. Locate two slotted head Phillips head 8-32 x 3/8 inch screws and two lock

nuts contained in the Rack Mount Kit accessory pouch.

3. Secure the right mount bracket to the end of the inner slide rail using the

screws and lock nuts.

4. Tighten the screws and torque to 15 inch-pounds.

5. Repeat steps 1 through 4 to install the left mount bracket onto the second

inner slide rail.

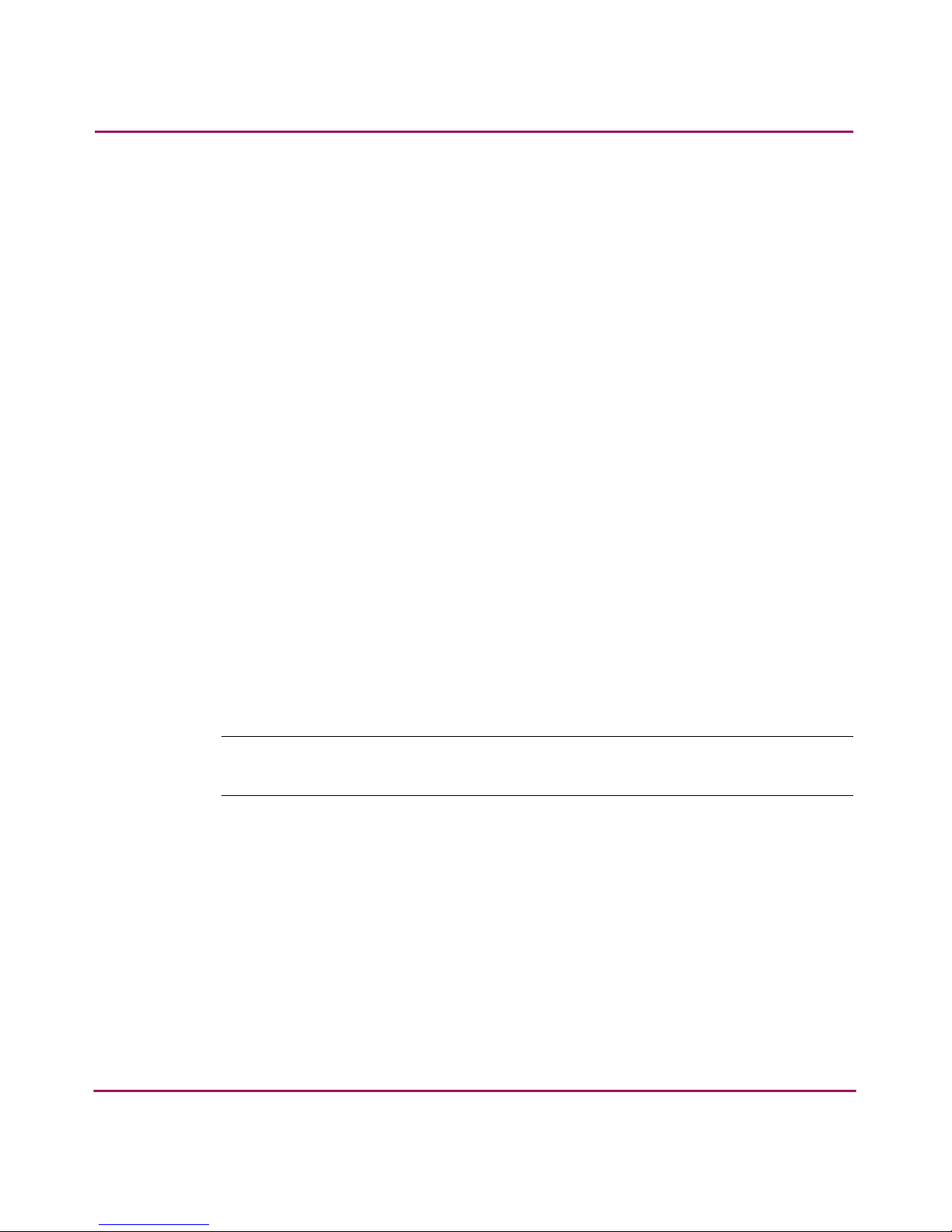

Attaching the Outer Slide Rails to the HP 9000 Series Rack

Use the following steps to install the outer slide rails in the HP 9000 Series Rack.

Note: This procedure requires two technicians to properly align the outer slide rails in

the HP 9000 Series Rack.

Obtain the following items, located in the Rack Mount Kit:

■ Four 3-hole bar nuts

■ Eight Phillips head 8-32 x 3/8 inch screws

■ Eight square alignment washers

■ # 2 Phillips screwdriver with torque capability

Page 36

Installing the SAN Switch 2/32

36 SAN Switch 2/32 Installation Guide

Note: Before starting this procedure, verify that two of the slide mount L-brackets are

preinstalled at the end of each outer slide rail; see Figure 6. The L-brackets are

necessary to attach the outer rails to the rack.

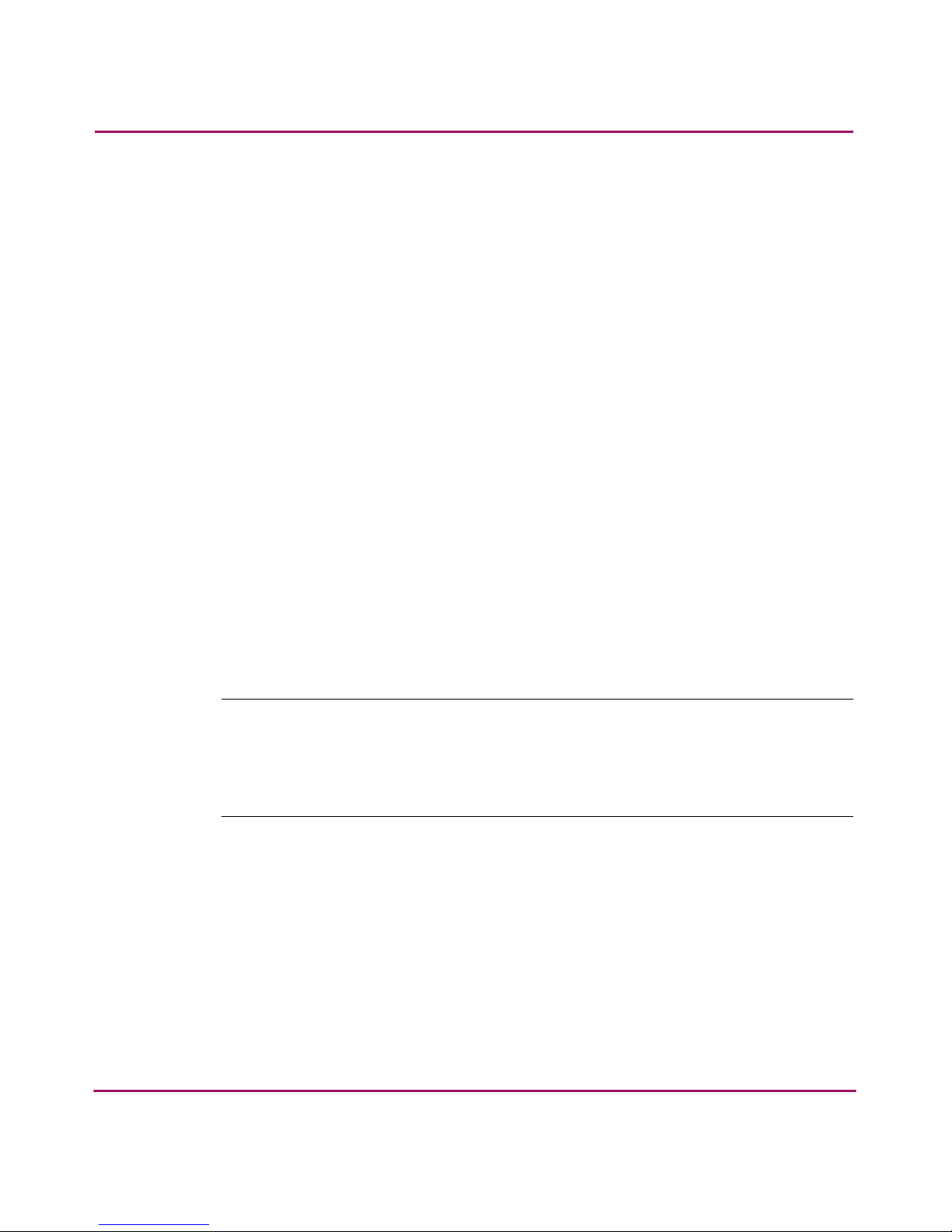

1. Determine the appropriate placement for the switch inside the rack. The HP

9000 Series Rack’s rails are divided into Units (Us). Each U is marked with a

small, round hole and three square openings for mounting equipment.

Note: The SAN Switch 2/32 requires 1.5 Units of rack space.

2. Locate the small, round marker hole on the rack’s rails, which coincides with

the location selected in step 1. Each marker hole delineates the beginning of

one U.

3. Insert one square alignment washer on each of the

eight 10-32 x 3/8 inch Phillips

head screws.

Note: The square alignment washers are mandatory for proper switch alignment.

4. Adjust the outer slide rail’s length to fit the length of the rack.

5. Position one of the outer slide rails in the rack, as described below:

a. To allow the switch’s port end to slide out the back of the rack, orient with

the closed end of the outer slide rail towards the front of the rack.

b. To allow the power supply end to slide out the front of the rack, orient the

closed end of the outer slide rail towards the back of the rack.

6. Holding the outer slide rail in place, insert one 3-hole bar nut in between the

rack’s rail and the L-bracket at the end of the outer slide rail, Figure 6.

Note: Position the square alignment washers onto the Phillips head 10-32 x 3/8 inch

screws, as described in step 3. The square alignment washers are mandatory for

proper switch alignment.

Page 37

Installing the SAN Switch 2/32

37SAN Switch 2/32 Installation Guide

7. Secure each L-bracket and 3-hole bar nut to the rack’s rails with two Phillips

head 10-32 x 3/8 inch screws (and attached square alignment washers); see

Figure 6.

.

Figure 6: Attaching the outer slide rails to the HP 9000 Series rack

Note: Remember to position the 3-hole bar nut behind the L-bracket.

8. Tighten the screws, and torque to 25 inch-pounds.

1 Phillips head 10-32 x 3/8 in screw

2 3-hole bar nut

3 Outer slide rail

4 L-Brackets

5 Power cord clip (1 of 6)

[1] Select this graphic frame.

[2] Select File.

[3] Select Import.

[4] Select File.

[5] Choose the appropriate graphic file name.

[6] Make sure you’ve checked the Copy Into Document.

[7] Select Import. Position the illustration as required.

Delete this set of instructions

[8] Adjust the size of the outer graphic frame as required.

SHR-2478A

1

3

4

5

2

Page 38

Installing the SAN Switch 2/32

38 SAN Switch 2/32 Installation Guide

9. Repeat steps 5 through 7 to secure the other end of the outer slide rail.

10. Repeat steps 3 through 7 to install the second outer slide rail.

Finalizing the Rack Mounting Procedure

Read this section to finalize the rack mount procedure.

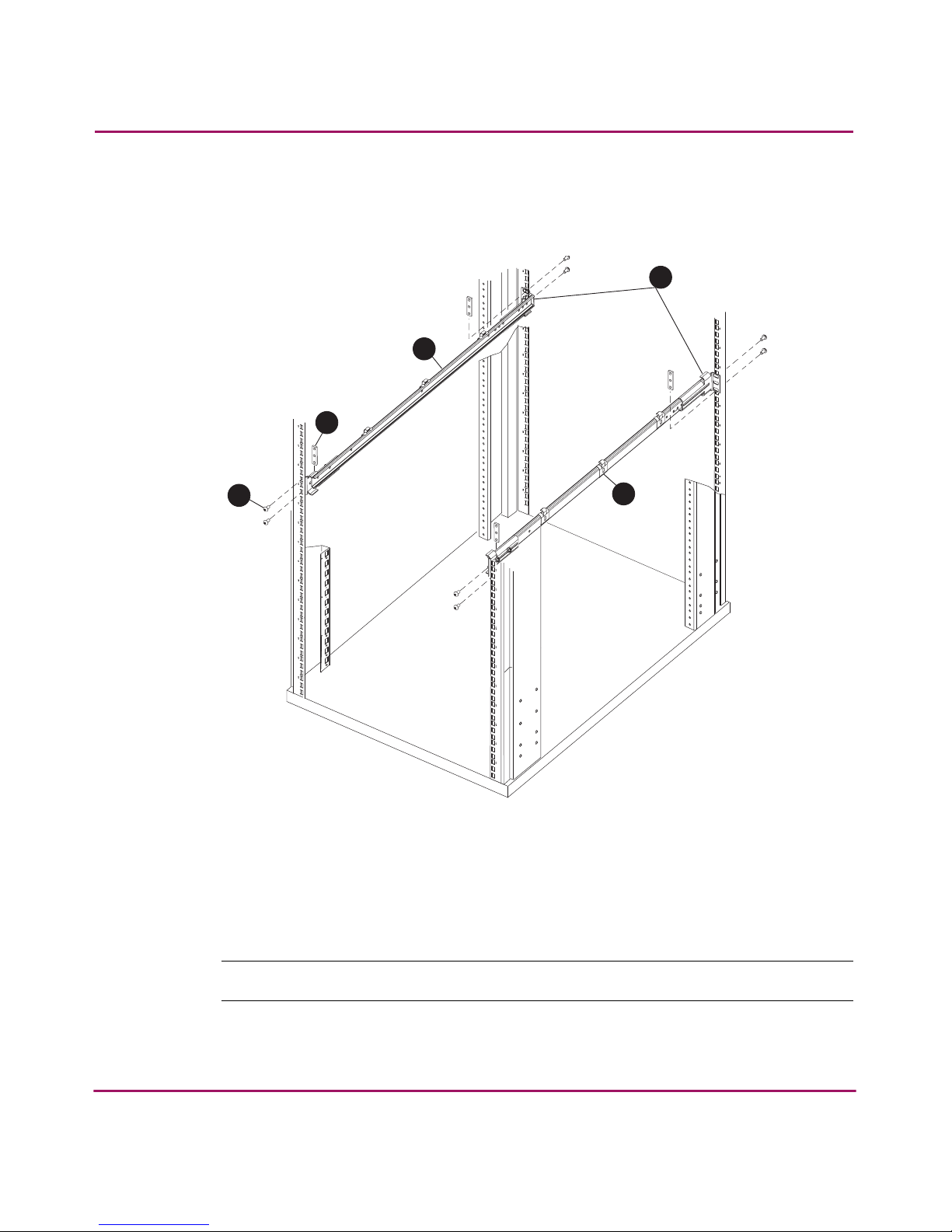

Positioning the Switch in the HP 9000 Series Rack

Follow these steps to install the switch in the rack.

Note: If installing more than one SAN Switch 2/32 directly on top of one another (in a

3U space), you must mount the slide rails attached to the switch using the set of holes

on the top of the switch, and the bottom using the set of holes on the bottom of the

switch.

1. Depending on the type of install (front or rear access), slide the outer slide

rails all the way toward the front or back of the rack.

2. Carefully lift the switch into the rear of the rack, inserting the inner slide rails

(attached to the switch) into the outer slide rails (attached to the rack).

3. Slide the switch into the rack; see Figure 7.

Page 39

Installing the SAN Switch 2/32

39SAN Switch 2/32 Installation Guide

.

Figure 7: Sliding the SAN Switch 2/32 into an HP 9000 Series rack

4. To verify proper alignment, slide the switch in and out of the rack.

Securing the Rack Mount Brackets

Secure the Rack Mount Brackets (installed earlier; see “Attaching the Rear or

Front Rack Mount Brackets”) to the rack rails, as follows:

1. Locate two Phillips head 10-32 x 3/8 inch screws in the Rack Mount Kit

accessory pouch.

2. Secure each rack mount bracket to the rack rails.

3. Tighten the screws, and torque to 25 inch-pounds.

SHR-2577A

Page 40

Installing the SAN Switch 2/32

40 SAN Switch 2/32 Installation Guide

Installing the Switch in the Optional HP System/e Rack

This section provides instructions for installing the SAN Switch 2/32 in the

optional HP System/e rack. The HP System/e Rack Kit consists of the following

items:

■ HP System/e Rack Rail Kit - pre-merger HP part number A7340-87901;

pre-merger Compaq part number QA-71AAA-GZ

■ HP System/e Rack Rail Kit Hardware - part number A7340-87902

The following hardware is required to install the HP System/e Rack Mount Kit:

■ Rails rear mounting brackets

■ Rail mounting hardware, shown next

:

Caution: For proper airflow, the SFP media side of the SAN Switch 2/32

faces the rear of the rack. This mounting allows air to enter from the front of the

rack and to exhaust at the rear of the rack, similar to other rack-mounted

equipment. This prevents switch overheating, which may cause it to fail.

Use these steps to install the switch in the HP System/e rack.

1. Verify that all required hardware is available.

(6) #8-32 x 5/16 inch Phillips pan-head screw with captive star

lock washer

(6) #8 Flat washer

(6) M5 Torx head screw with captive lock washer

(2) Rubber washer

(4) M5 U-type Tinnerman clip

Page 41

Installing the SAN Switch 2/32

41SAN Switch 2/32 Installation Guide

2. Choose a mounting location in the rack for the switch.

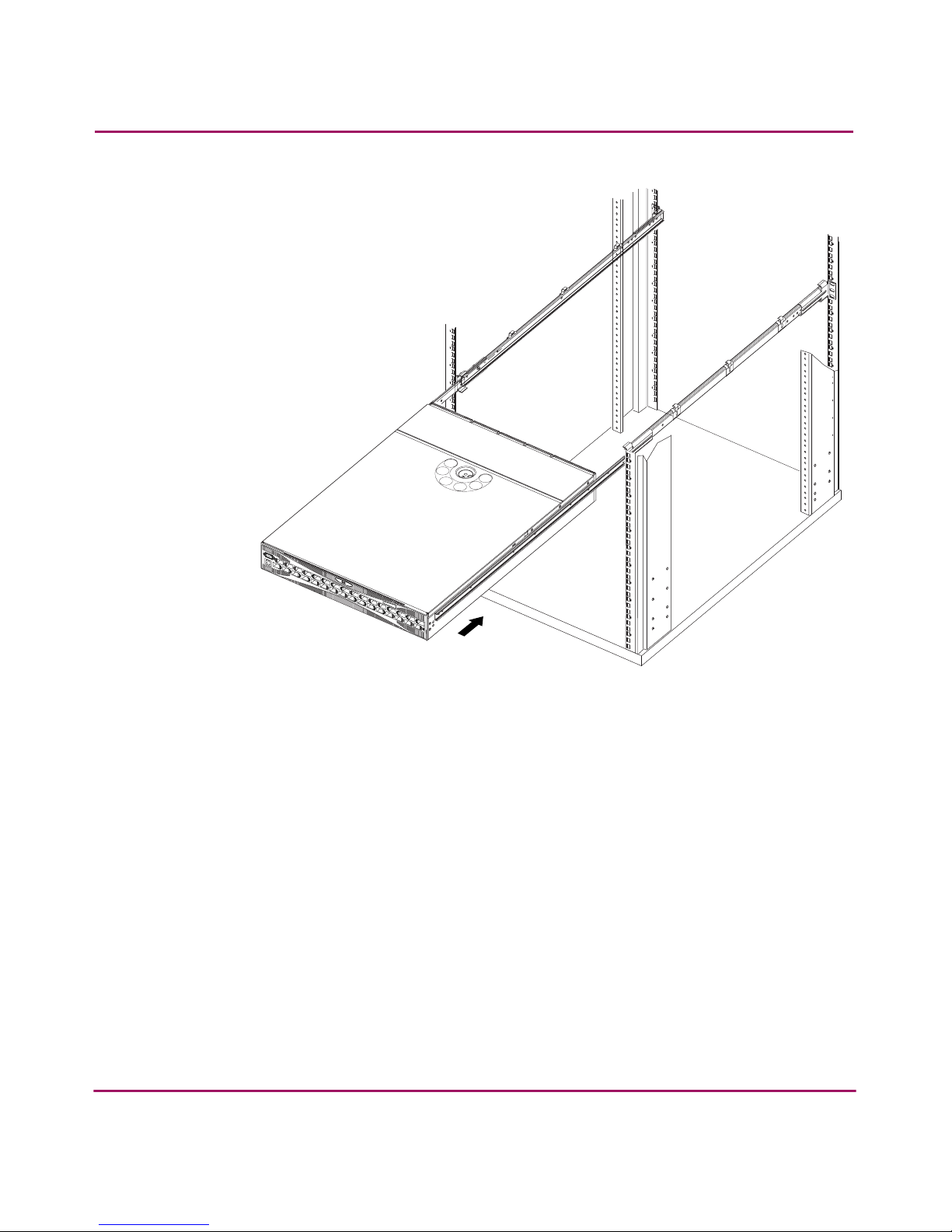

3. Install each of the two mounting brackets with (1) M5 Torx head screw with

captive lock washers as shown in Figure 8.

Figure 8: Installing the mounting brackets

4. Install (2) M5 U-type Tinnerman clips for each of the front columns of the

rack in the top and bottom positions of the three-hole EIA pattern as shown in

Figure 9.

SHR-2581A

Page 42

Installing the SAN Switch 2/32

42 SAN Switch 2/32 Installation Guide

Figure 9: Installing the Tinnerman clips

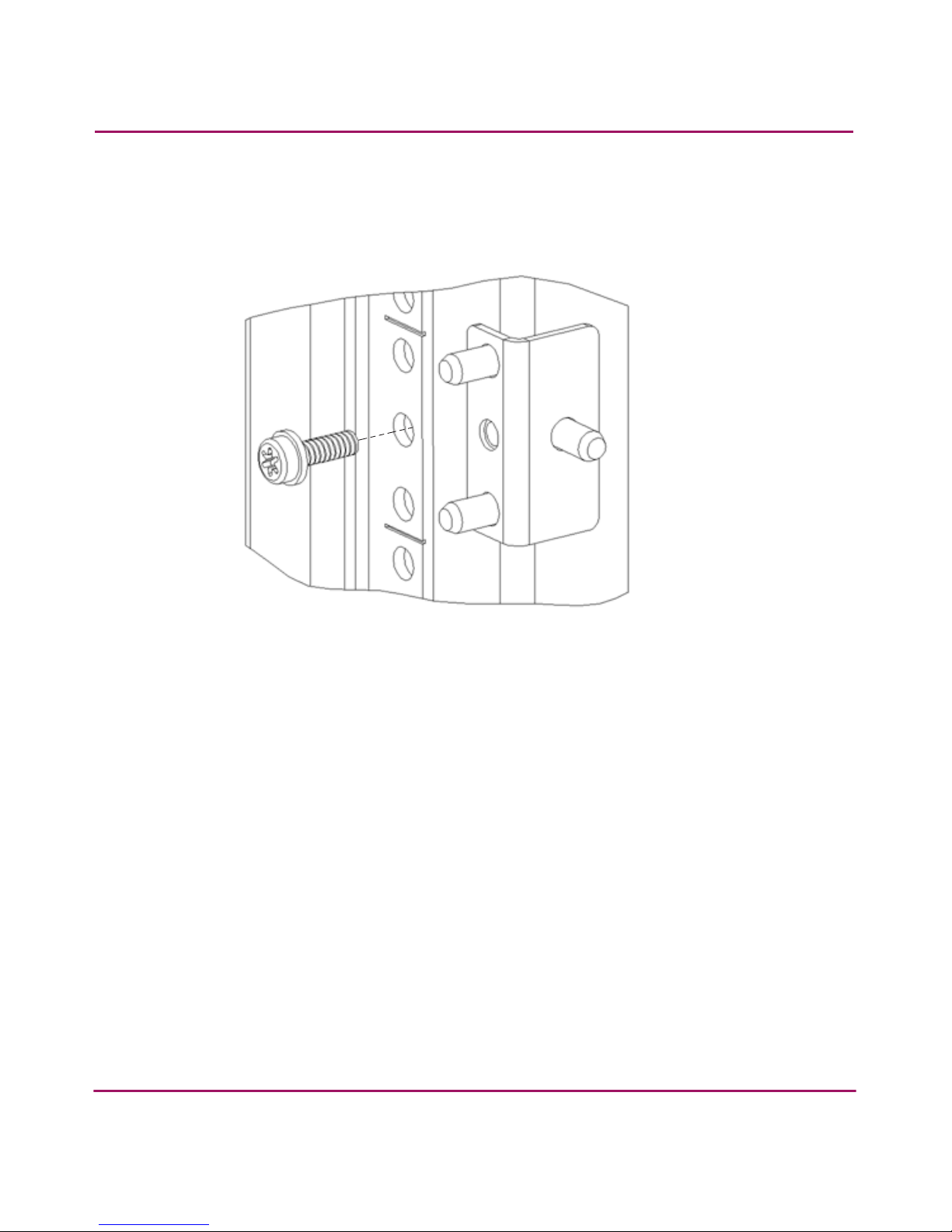

5. Assemble the outer rails by completing the following steps:

a. As an aid in assembly, two rubber washers have been included to help

keep the rear slotted portion of the outer rail flush against the rear rail-tray

brackets. Install them as shown in Figure 10.

b. Insert the alignment pins attached to the outer rail front flange into the

center opening in the rack.

SHR-2582A

Page 43

Installing the SAN Switch 2/32

43SAN Switch 2/32 Installation Guide

I

Figure 10: Installing the rubber washers

6. Install(1) M5 Torx screw in the upper hole location of the right rail. Then,

install (1) M5 Torx screw in the lower location of the left rail. See Figure 11.

Note: Do not install the upper left and the lower right screws until step 9.

1 Rubber washer (1 of 2) 2 Rear rail tray bracket (1 of 2)

[1] Select this graphic frame.

[2] Select File.

[3] Select Import.

[4] Select File.

[5] Choose the appropriate graphic file name.

[6] Make sure you’ve checked the Copy Into Document.

[7] Select Import. Position the illustration as required.

Delete this set of instructions

[8] Adjust the size of the outer graphic frame as required.

1

2

SHR-2559A

Page 44

Installing the SAN Switch 2/32

44 SAN Switch 2/32 Installation Guide

7. Assemble the two inner rails (one on each side) to the switch using (6) #8-32

x 5/16 inch Phillips pan-head screws, and #8 flat washer as shown in

Figure 11.

Figure 11: Assembling the inner rails

Caution: Do not use any screws other than the six that are provided. Use of

any longer lengths can cause damage to internal components of the switch.

Before tightening screws, make sure that the rails are centered to the overall

height of the switch.

8. Insert the switch with the attached inner rails into the outer rails.

9. Install the (2) remaining M5 Torx screws to complete the installation.

10. Go to the next section, “Connecting AC Power” for steps on applying power

to the switch.

Caution: Do not connect the switch to the network until the IP address is

correctly set. For instructions on how to set the IP address, see “Configuring

SAN Switch 2/32 Network Addressing,” later in this chapter.

Page 45

Installing the SAN Switch 2/32

45SAN Switch 2/32 Installation Guide

Connecting AC Power

Use these steps to power on the SAN Switch 2/32.

Caution: Do not plug the power cords into the power source until the switch is

completely installed in the rack.

1. Connect the SAN Switch 2/32 power cords to the power connectors on the

switch, see Figure 12.

Figure 12: Connecting the power cords

2. Attach the remaining ends of the power cords to power outlets.

3. Turn on the power switch (the 1 position indicates power on, the O position

indicates power off). The switch automatically runs POST.

WARNING: Do not connect the switch to the network until the IP address is

correctly set. For instructions on setting the IP address, see “Configuring SAN

Switch 2/32 Network Addressing,” later in this chapter.

SHR-2571A

Page 46

Installing the SAN Switch 2/32

46 SAN Switch 2/32 Installation Guide

Power On Self-Test

Each time the switch is powered on, rebooted, or reset, the switch automatically

runs POST. During POST, the port status LEDs flash, verifying that the switch is

operating properly. POST completes in approximately six minutes, with total boot

time approximately seven minutes.

POST runs through the following test cycles:

■ Preliminary POST diagnostics

■ Initialization of operating system

■ Initialization of hardware

■ Diagnostic tests are run on a number of functions, including circuitry, port

functionality, memory, parity, statistics counters, and serialization

If the switch prompt does not display when POST completes, POST was

unsuccessful. Contact your authorized HP switch supplier for more information.

To determine whether POST completed without errors, verify that all LEDs return

to a normal state after POST is complete. If one or more LEDs do not return to a

normal state (and this is not due to the switch being set to beacon), see

“Interpreting LED Activity,” in Chapter 3.

Note: For more information about beaconing, refer to the

HP StorageWorks Fabric

OS Procedures Version 3.0.x/4.0.x User Guide

.

Checking POST Results

Check the success/fail results of the diagnostic tests run during POST via LED

activity, the error log, or CLI using the errShow command. For more

information about error messages, refer to the HP StorageWorks

Fabric OS

Version 3.0.x/4.0.x Reference Guide.

Page 47

Installing the SAN Switch 2/32

47SAN Switch 2/32 Installation Guide

Configuring SAN Switch 2/32 Network Addressing

Read the following sections for information on how to configure the SAN Switch

2/32 addressing scheme.

For instructions about configuring the switch to operate in a fabric containing

switches from other vendors, refer to the HP StorageWorks Fabric OS Procedures

Version 3.0.x/4.0.x User Guide.

For detailed information about the commands used in this procedure, refer to the HP

StorageWorks

Fabric OS Version 3.0.x/4.0.x Reference Guide.

Requirements

The following items are required for configuring and connecting the SAN Switch

2/32 in a network and fabric:

■ An unused IP address and corresponding subnetmask and gateway address

from your Network Administrator

■ SAN Switch 2/32 installed and connected to a power source

■ A local workstation (desktop or notebook computer) with:

— Microsoft Windows 98, Windows 2000, Windows Millennium Edition, or

Windows NT 4.0 operating system

— RS-232 Serial communication software (for example, ProComm Plus or

HyperTerminal)

■ Serial cable provided with the switch

■ Ethernet cable

■ SFP transceivers and compatible cables, as required

■ Access to an FTP server for backing up the switch configuration

Setting Network Addresses via a Serial Connection

Use the following steps to verify or change the SAN Switch 2/32 IP address,

subnetmask, or gateway address.

Page 48

Installing the SAN Switch 2/32

48 SAN Switch 2/32 Installation Guide

Note: During first time setup, you must replace the factory IP, subnetmask and gateway

addresses with addresses provided by your Network Administrator.

1. Remove the shipping plug from the SAN Switch 2/32 Serial port.

2. Connect the Serial cable to the SAN Switch 2/32 Serial port; see Figure 13.

Figure 13: Connecting the Serial cable

3. Connect the other end of the Serial cable to an RS-232 Serial port on the

workstation. If no RS-232 Serial port is available on the workstation, the

adapter on the end of the Serial cable can be removed to use the RJ-45

connector to create a Serial connection.

4. Verify that the switch power is on and POST is completed. See the “Power On

Self-Test” section, earlier in this chapter.

5. Power on the workstation and establish a connection to the switch using a

terminal emulator application (such as Hyperterminal).

Note: These steps show instructions specific to Hyperterminal. If using a different

application, consult the specific application’s documentation.

SHR-2572A

Page 49

Installing the SAN Switch 2/32

49SAN Switch 2/32 Installation Guide

6. Using Hyperterminal (or similar application), configure the port settings as

follows:

■ Bits per second: 9600

■ Databits: 8

■ Parity: None

■ Stop bits: 1

■ Flow control: None

To configure port settings in a UNIX environment, type:

tip /dev/ttyb -9600

7. Login to the switch (with administrative privileges). The default

administrative logon is admin and the default password is password.

a. Enter the following at the prompt:

ipAddrSet

b. Enter the following information at the corresponding prompts, as in the

example below:

Example

c. To verify that the IP address was entered correctly, type:

ipAddrShow

d. Once the IP address is verified as correct, remove the Serial cable, and

replace the shipping plug in the Serial port.

switch:admin> ipaddrset

Ethernet IP Address [10.77.77.77]:10.32.53.47

Ethernet Subnetmask [255.0.0.0]:255.255.240.0

Fibre Channel IP Address [0.0.0.0]:

Fibre Channel Subnetmask [0.0.0.0]:

Gateway IP Address [0.0.0.0]:10.32.48.1

Set IP address now? [y = set now, n = next

reboot]:y

IP address being changed...

Committing configuration...Done.

switch:admin>

Page 50

Installing the SAN Switch 2/32

50 SAN Switch 2/32 Installation Guide

Caution: The Serial port is intended only for use during the initial setting of

the IP address and for service purposes. Using the Serial port during normal

switch operation or for regular maintenance is not recommended.

8. Record the IP address on the label affixed to the SAN Switch 2/32.

Page 51

Installing the SAN Switch 2/32

51SAN Switch 2/32 Installation Guide

Connecting the SAN Switch 2/32 to the LAN

Use the following steps to connect the SAN Switch 2/32 to the Ethernet Local

Area Network (LAN) segment.

1. Remove the shipping plug from the SAN Switch 2/32 Ethernet port.

2. Connect one end of an Ethernet cable to the SAN Switch 2/32 Ethernet port;

see Figure 14.

Figure 14: Connecting the Ethernet cable

3. Connect the other end of the Ethernet cable to the workstation or to an

Ethernet network containing the workstation.

Note: You can now access the switch remotely (and from multiple connections), using

telnet or the Web Tools application. Verify that the switch is not accessed from any other

connections during the remaining steps.

4. Login to the switch with administrative privileges by telnet. The default

administrative logon is admin and the default password is password.

SHR-2573A

Page 52

Installing the SAN Switch 2/32

52 SAN Switch 2/32 Installation Guide

Core Switch PID Format Summary

A Core PID format is one of several addressing formats used in Fibre Channel.

The parameter is used by the routing and zoning services in Fibre Channel fabrics

to identify ports in the network.

The PID format is analogous to specifying the physical switch and port that a

device is attached to in data networks. It is not analogous to an IP address. PIDs

are assigned by a Fibre Channel switch when a device logs into the fabric. An

example PID might look like this: 011F00.

Many scenarios cause a device to receive a new PID. For example, unplugging the

device from one port and plugging it into a different port will cause this. (This

might happen when cabling around a bad port, or when moving equipment

around.) Another example is changing the domain ID of a switch, which might be

necessary when merging fabrics, or changing compatibility mode settings.

Note: All switches running Fabric OS version 4.0.x or higher are shipped with the

Core Switch PID Format enabled, so it is not necessary to change the Core Switch PID

format on these switches. For example, the HP StorageWorks SAN Switch 2/32 and HP

StorageWorks Core Switch 2/64 always use Core Switch PID format 1. This parameter

is always 1 and cannot be changed.

Important Information on Checking the Core Switch PID Format

Updating the Core Switch PID Format is necessary when upgrading an existing

SAN to support larger port-count switches. When a switch with more than 16

ports is introduced into an existing fabric, this parameter needs to be set on all

switches in the fabric.

For example, all SAN Switch 2/32 units ship with the Core Switch PID format set

to 1. Before connecting to the SAN, you must verify that the Core Switch PID

formats of all switches already running in the SAN are also set to 1.

Note: If the Core PID format is set to 0 in switches already running in the SAN, you

must follow the procedures in Appendix B, “Updating the Core Switch PID Format” to

change the parameter to 1. If the Core Switch PID format is not changed to 1 to match

the SAN Switch 2/32’s value, then the switches residing in the SAN will fail to

communicate with one another.

Page 53

Installing the SAN Switch 2/32

53SAN Switch 2/32 Installation Guide

For detailed recommendations and instructions on updating the Core Switch PID,

please refer to Appendix B in this guide, “Updating the Core Switch PID Format.”

Page 54

Installing the SAN Switch 2/32

54 SAN Switch 2/32 Installation Guide

Optional Configuration Settings

The following sections describe how to modify domain IDs and status policies.

Modifying Domain IDs

Optional. Modify the domain IDs, if desired, as follows.

Note: The default domain ID is 1. If the default domain ID is already in use when the

switch is connected to the fabric, the domain ID for the new switch is automatically reset

to a unique value. The domain IDs that are currently in use can be determined using the

telnet command fabricShow.

1. Disable the switch by entering the following:

switchDisable

2. Enter the following:

configure

3. Enter y after the Fabric parameters prompt.

Fabric parameters (y, n)

4. Enter a unique domain ID (such as the domain ID used by the previous

switch, if still available).

Domain: (1..239) [1] 3

5. Complete the remaining prompts (or press CTRL+D to accept the remaining

settings without completing all the prompts).

6. Re-enable the switch by entering the following:

switchEnable

Specifying Custom Status Policies

Optional If desired, specify any custom status policies for the fabric as follows.

1. Enter the following at the prompt.

switchStatusPolicySet

2. Specify the desired status policies. To completely deactivate the alarm for a

particular condition, enter 0 at the prompt for that condition.

Page 55

Installing the SAN Switch 2/32

55SAN Switch 2/32 Installation Guide

Note: Configure each port to match the topology of each host or target before

connecting to the device. The default port configuration is fabric, not private loop. The

switch does not auto-sense topology.

Page 56

Installing the SAN Switch 2/32

56 SAN Switch 2/32 Installation Guide

Connecting the SAN Switch 2/32 to the Fabric

Use these steps to connect the SFPs and cables to SAN Switch 2/32 ports as

required.

Note: The ports and cables used in trunking groups must meet specific requirements.

For a list of these requirements, refer to the

HP StorageWorks ISL Trunking Version

3.0.x/4.0.x User Guide

.

1. Remove the shipping plug from the appropriate ports.

2. Position the SFP so that the key (the tab near the cable-end of the SFP) is on

top.

3. Insert the SFP into the port until it is firmly seated and the latching

mechanism clicks.

Note: The SFP is keyed so that it can only be inserted with the correct orientation into

the port. If the SFP does not slide in easily, check the orientation.

4. Connect the cables to the SFPs as appropriate to the fabric topology, by

positioning each cable so that the key (the ridge on one side of the cable

connector) is aligned with the slot in the SFP; see Figure 15.

Page 57

Installing the SAN Switch 2/32

57SAN Switch 2/32 Installation Guide

Figure 15: Inserting a cable into an SFP

Note: The cable is keyed so that it can only be inserted correctly into the SFP. If the

cable does not slide in easily, check the orientation.

Verifying Operation

After making the appropriate connections, as outlined in this chapter, use these

steps to verify that the switch is running properly.

1. Access your browser.

2. At the URL address window, type

http://your switch IP address.

3. If connected properly, the name of your switch appears (in green) at the

prompt, indicating Healthy/OK.

Note: Backing up the configuration is strongly recommended. This ensures that a

complete configuration is available if required for a replacement switch. For instructions

on how to back up the configuration, refer to Chapter 4, “Backing Up Configuration

Data and Upgrading Firmware.” Or, for more detailed information and commands,

refer to the

HP StorageWorks Fabric OS Procedures Version 3.0.x/4.0.x User Guide.

SHR-2574A

Page 58

Installing the SAN Switch 2/32

58 SAN Switch 2/32 Installation Guide

Installing Multiple Switches into an Existing SAN

Use these steps to set up more than one SAN Switch 2/32 in an existing SAN.

1. Connect the appropriate components as outlined in the installation section of

this chapter.

2. Connect the power cord to the AC connector on the switch. The switch

performs POST.

If a malfunction occurs during POST, error messages are written to the switch

error log and can be viewed by a telnet or terminal session when the POST

session completes.

If the malfunction prohibits the switch from completing the boot process (fatal

error), the switch stops the boot process. If the switch does not fully boot, the

switch prompt will not be displayed when the Serial port is connected.

3. Connect the Serial cable, provided in the package contents, between a host

computer and the Serial port of the switch. See “Setting Network Addresses

via a Serial Connection,” earlier in this chapter, to make a Serial connection

through a workstation and to set the IP address.

4. Set the switch Domain Address using the configure command to the next

unused domain in the SAN. The default domain setting is 1.

Note: If a switch boot failure occurs, the switch must be taken offline for repair or

replacement. Contact your HP Technical Support for assistance.

5. Power off the new switch and connect one Fibre Channel cable from the SAN

to the new switch.

Page 59

Installing the SAN Switch 2/32

59SAN Switch 2/32 Installation Guide

Recommendations for Cable Management

HP recommends following these cable management guidelines:

■ Plan cable management before installing the switch in a rack.

■ Leave at least one meter of slack for each port cable (this provides room to

remove and replace the switch).

■ If using ISL Trunking:

— Group cables by trunking groups.

— The cables used in trunking groups must meet specific requirements. For

a list of these requirements, refer to the HP StorageWorks ISL Trunking

Version 3.0.x/4.0.x User Guide.

■ Label the fiber optic cables and record the devices to which they are

connected.

■ Keep LEDs visible by routing port cables and other cables directly

downwards or otherwise away from the LEDs.

■ Do not use tie wraps on fiber optic cables, because they are easily

overtightened and can damage the optic fibers.

Note: The minimum bend radius for a 50-micron cable is 2 inches under full tensile

load, and 1.2 inches with no tensile load.

Page 60

Installing the SAN Switch 2/32

60 SAN Switch 2/32 Installation Guide

Page 61

61SAN Switch 2/32 Installation Guide

3

Managing the

SAN Switch 2/32

This chapter covers the following topics:

■ Interpreting LED Activity, page 62

■ Management Overview, page 68

■ Running Basic Switch Operations Using Telnet, page 70

■ SAN Switch 2/32 Diagnostics, page 74

■ Field Replaceable Units, page 75

Page 62

Managing the SAN Switch 2/32

62 SAN Switch 2/32 Installation Guide

Interpreting LED Activity

SAN Switch 2/32 status is determined through the LED activity on the switch.