Page 1

User and

Service

Guide

HP StorageWorks

Virtual Arrays

VA 7000 Family

Edition January 2005

Part number A6183-96008

Printed in U.S.A.

Page 2

Notice

Trademark Information

© Copyright 2000-2005 Hewlett-Packard

Development Company, L.P.

Hewlett-Packard Company makes no warranty of

any kind with regard to this material, including,

but not limited to, the implied warranties of

merchantability and fitness for a particular

purpose. Hewlett-Packard shall not be liable for

errors contained herein or for incidental or

consequential damages in connection with the

furnishing, performance, or use of this material.

This document contains proprietary information,

which is protected by copyright. No part of this

document may be photocopied, reproduced, or

translated into another language without the prior

written consent of Hewlett-Packard. The

information contained in this document is subject

to change without notice.

Format Conventions

WARNING Identifies a hazard that can cause

personal injury

Red Hat is a registered trademark of Red Hat Co.

C.A. UniCenter TNG is a registered trademark of

Computer Associates International, Inc.

Microsoft, Windows NT, and Windows 2000 are

registered trademarks of Microsoft Corporation

HP, HP-UX are a registered trademarks of HewlettPackard Company. CommandView, Secure

Manager, Business Copy, Auto Path are

trademarks of Hewlett-Packard Company

Adobe and Acrobat are trademarks of Adobe

Systems Inc.

Java and Java Virtual Machine are trademarks of

Sun Microsystems Inc.

NetWare is a trademark of Novell, Inc.

AIX is a registered trademark of International

Business Machines, Inc.

Caution Identifies a hazard that can cause

hardware or software damage

Note Identifies significant concepts or

operating instructions

this font - used for all text to be typed

verbatim: all commands, path names, file names,

and directory names also, text displayed on the

screen

<

this font

commands

this font - used for GUI menu options and screen

controls

2

> - used for variables used in

Page 3

Revision History

January 2002

Change Page

Added new supported non-native operating systems. 16

Added Operating Tips section. 57

Clarified explanation of redundancy groups 39

Expanded the procedure for upgrading DIMMs. 135

Added procedure for reducing the amount of cache. 136

March 2002

Change Page

Updated warranty information 7

Added information on new power supply model 102

Added information on new disk filler panel. 100

Added a procedure for adding a disk enclosure to a VA 7400. 132

April 2002

Change Page

Added new warning LED status display for updating battery firmware. 82

Added processor model to array controller description 24

Changed part numbers of replacement array enclosure controllers. 93

Added support for DS 2405 Disk System Multiple

Added information for identifying type of disk enclosure 92

Added DS 2405 Disk System part numbers to disk enclosure

replaceable parts.

Added step for setting FC Loop Speed switch on DS 2405 LCCs. 127

Added note on ensuring controller firmware is HP14 or later when

adding a DS 2405 Disk System to the array.

95

132

3

Page 4

July 2002

Change Page

Updated product information to include VA 7410. 13

Added VA 7410 back-end cabling. 33

Added "Data I/O Architecture" information. 52

Updated replaceable parts to include VA 7410 components 93

Updated procedure for adding a disk enclosure to include VA 7410. 132

January 2003

Change Page

Updated capacity and performance tables for VA 7110. 17

Added 73 GB 15K disk module and 146 GB disk module for support

26

on VA 7110 and 7410.

Updated Data Storage Process information 38

Updated configuration drawings. 59

Added VA 7110 LED displays. 81

Added VA 7110 controller to replaceable parts. 93

September 2003

Change Page

Updated VA 7110 DIMM configuration information to indicate that

512 MB is not supported.

14, 136

4

Page 5

March 2004

Change Page

Added a step to the controller installation procedure for recognizing

110

the new controller on HP-UX.

Added note regarding installing multiple disks. 132

Added information on replacing a controller in a single-controller

112

array.

January 2005

Change Page

Added Japanese power cord statement. 148

5

Page 6

About This Guide

This guide is intended for use by information technology (IT), service, and other personnel involved in

managing, operating, servicing, and upgrading the HP StorageWorks Virtual Array products. It is

organized into the following chapters:

Chapter 1. Product Overview Describes the features, controls, and operation of the

disk array.

Chapter 2. System Configurations Guidelines for designing array configurations for

different system requirements.

Chapter 3. Troubleshooting Instructions for isolating and solving common problems

that may occur during array operation

Chapter 4. Servicing & Upgrading Instructions for removing and replacing all field

replaceable units.

Chapter 5. Specifications & Regulatory

Statements

Product dimensions, weight, temperature and humidity

limits, shock and vibration limits, electrical and power

specifications, regulatory and safety statements, and

Declaration of Conformity.

Related Documents and Information

The following items contain information related to the installation, configuration, and management and

of the HP StorageWorks Virtual Array products:

—

HP StorageWorks Virtual Array 7000 Family Installation Guide

for installing and configuring the hardware and software components of the HP StorageWorks

Virtual Array products.

—

HP StorageWorks Virtual Array Family Rack Installation Guide

for installing the HP StorageWorks Virtual Array products into HP Rack System/E, HP System

racks, and Compaq 9000 racks.

—

HP StorageWorks CommandView SDM Installation and User Guide

use the HP StorageWorks CommandView SDM software and its associated utilities to configure,

manage, and diagnose problems with the array.

- includes step-by-step instructions

- includes step-by-step instructions

- describes how to install and

6

Page 7

Warranty Information

Standard Limited

Warranty

Warranty Contacts

U.S. and Canada

Current Support

Information

Preparing for a

Support Call

The HP SureStore Virtual Array Family standard warranty includes the following:

Two-year, same-day on-site warranty (parts and labor). Same-day response

equates to:

4-hour response, available normal business days (Monday-Friday) 8 am - 5 pm.

See the "Hewlett-Packard Hardware Limited Warranty" on page 8 for a complete

description of the standard warranty.

For hardware service and telephone support, contact:

An HP-authorized reseller or

HP Customer Support Center at 970-635-1000, 24 hours a day, 7 days a week,

including holidays

For the latest support information, visit the following web site:

http://www.hp.com/support/va7100

http://www.hp.com/support/va7400

http://www.hp.com/support/va7410

http://www.hp.com/support/va7110

If you must call for assistance, gathering the following information before placing

the call will expedite the support process:

— Product model name and number

— Product serial number

— Applicable error messages from system or diagnostics

— Operating system type and revision

— Applicable hardware driver revision levels (for example, the host

adapter driver)

7

Page 8

Hewlett-Packard Hardware Limited Warranty

HP warrants to you, the end-user Customer, that HP SureStore Virtual Array Family hardware

components and supplies will be free from defects in material and workmanship under normal use after

the date of purchase for

warranty period, HP or Authorized Reseller will, at its option, either repair or replace products that prove

to be defective. Replacement parts may be new or equivalent in performance to new.

Should HP or Authorized Reseller be unable to repair or replace the hardware or accessory within a

reasonable amount of time, Customer's alternate remedy will be a refund of the purchase price upon

return of the HP SureStore Virtual Array Family.

two years

. If HP or Authorized Reseller receives notice of such defects during the

Replacement Parts

Warranty

Items Not Covered

HP replacement parts assume the remaining warranty of the parts they replace.

Warranty life of a part is not extended by means of replacement.

Your HP SureStore Virtual Array Family warranty does not cover the following:

— Products purchased from anyone other than HP or an authorized

HP reseller

— Non-HP products installed by unauthorized entities

— Customer-installed third-party software

— Routine cleaning, or normal cosmetic and mechanical wear

— Damage caused by misuse, abuse, or neglect

— Damage caused by parts that were not manufactured or sold by

HP

— Damage caused when warranted parts were repaired or replaced

by an organization other than HP or by a service provider not

authorized by HP

8

Page 9

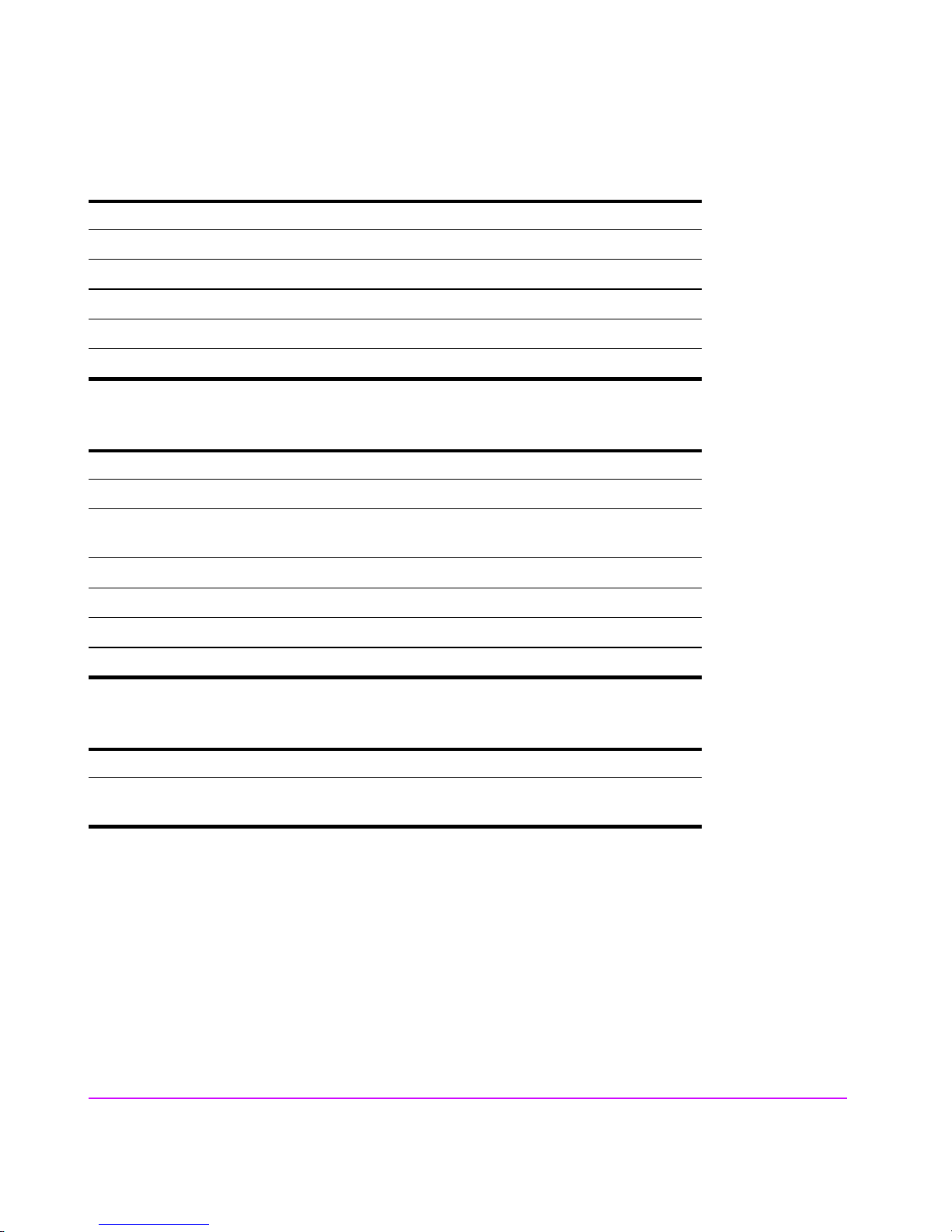

Warranty Information 6

Hewlett-Packard Hardware Limited Warranty 7

1 Product Overview 13

Supported Operating Systems 16

Array Management Software 16

Product Features 17

Controller Enclosure Components 19

Array Controller 24

Array Controller Filler Panel 26

Disk Drives 26

Disk Drive Filler Panels 28

Power Modules 28

Disk Enclosure Components 29

Link Controller Card (VA 7110/7400/7410 Only) 30

Disk Drives 30

Disk Drive Filler Panels 30

Power Modules 34

Operating the Power/Standby Switch 35

Power-On Self-Test 36

Shutdown 36

Data Storage Process 38

Virtual Array 38

Redundancy Groups 39

Performance Path 45

RAID Levels 47

Data I/O Architecture 52

Operating Tips 57

contents

9

Page 10

Automatic Hot Spare Setting Behavior 57

Install an Even Number of Disks in Each Redundancy Group 57

Auto Rebuild Behavior 58

2 System Configurations 59

Lowest Entry Point, Non-HA Minimum Configuration (VA 7100

only) 59

Lowest Entry Point, Non-HA Minimum Configuration (VA 7410) 60

Entry Level Non-Cluster With Path Redundancy (All VA arrays) 61

Entry Level Cluster with Path Redundancy High Availability (VA

7410) 62

Midrange Non-Cluster (All VA arrays) 63

Midrange Non-Cluster (VA 7410) 64

Midrange Non-Cluster with Full Storage Path Redundancy (All VA

Arrays) 65

Typical Non-Clustered with Path Redundancy (VA 7410) 66

Typical Clustered Configuration (All VA models) 67

Typical Clustered Configuration (VA 7410) 68

HP-UX MC Service Guard or Windows 2000 Cluster (All VA

arrays) 69

Highly Redundant Cluster (VA 7410) 70

Typical Highly Redundant Cluster (All VA models) 71

Typical Highly Redundant Cluster (VA 7410) 72

10 Contents

3 Troubleshooting 73

Troubleshooting Steps 74

Redundant FRUs 75

Array State & Status 76

Array Power-On Sequence 77

LED Status Indications 78

Tools for Checking Array State & Status 85

Array Controller Logs 86

Types of Array Controller Logs 86

Location of Array Controller Logs 86

Checking Array Controller Logs 87

EMS Hardware Monitors (HP-UX Only) 88

Page 11

4 Servicing & Upgrading 91

Field Replaceable Units (FRUs) 92

Identifying FRUs 92

Hot Swappable FRUs 97

Controller Enclosure Removal & Installation Procedures 98

Disk Drives 98

Disk Drive Filler Panels 100

Power Modules 102

Fiber Optic Cables 104

Gigabit Interface Converters 106

Array Controllers 107

Array Controller Filler Panels 115

Array Controller Batteries 117

Array Controller DIMMs 120

Midplane Assembly 122

Disk Enclosure Removal & Installation Procedures 125

Disk Drives 125

Disk Drive Filler Panels 125

Power Modules 125

Link Controller Cards (LCCs) 127

Midplane Assembly 131

Upgrading the Array 132

Increasing Storage Capacity 132

Upgrading Single to Dual Array Controllers 134

Upgrading Array Controller DIMMs 135

Upgrading Array Controller Firmware 137

Upgrading Link Controller Card Firmware 137

Upgrading Disk Firmware 138

5 Specifications & Regulatory Statements 139

Physical, Electrical & Environmental Specifications 140

Regulatory Statements 143

Contents 11

Page 12

12 Contents

Page 13

Product Overview

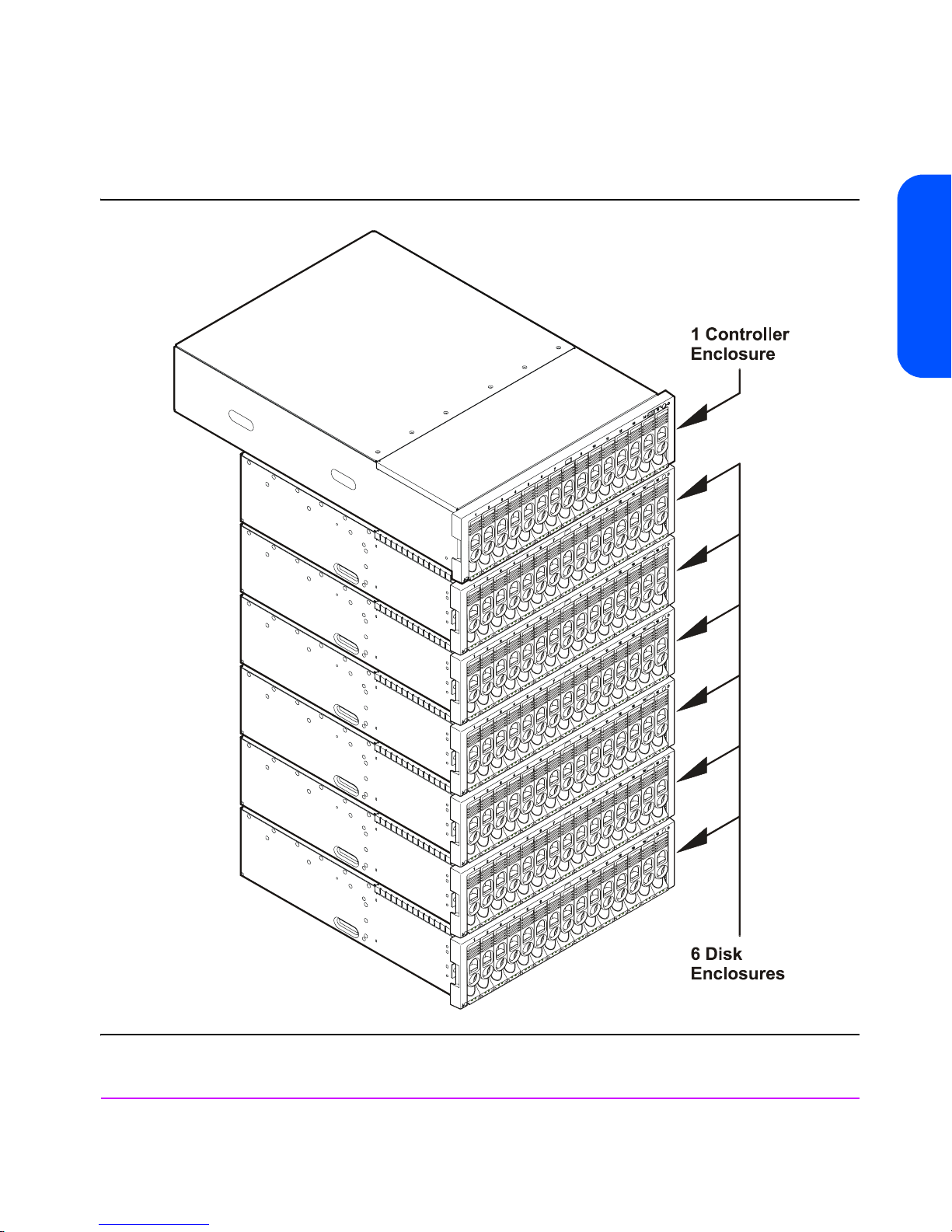

The HP StorageWorks Virtual Arrays are Fibre Channel disk arrays featuring

scalability, high performance, and advanced data protection. The VA 7000

Family includes the following models:

■ VA 7100 - an entry level array that includes a single controller enclosure

with up to 15 disks.

■ VA 7110 - a medium-capacity array that includes a controller enclosure

with up to 15 disks, and supports up to 2 additional external disk

enclosures each capable of housing 15 disks.

■ VA 7400 - a high-capacity array that includes a controller enclosure with

up to 15 disks, and supports up to 6 additional external disk enclosures

each capable of housing 15 disks.

■ VA 7410 - a higher-performance model of the VA 7400 that increases the

transfer speed between the array and disk enclosures to

2 Gbits/second, increases the amount of cache to 2 Gbytes, and adds

additional host and disk Fibre Channel ports.

1

Table 1 lists the VA 7000 Family configurations. Figure 1 illustrates the

enclosure configuration for the VA 7400/7410 products.

Both the controller enclosure and the disk enclosure can house up to 15 disk

modules in any combination of 18 GB, 36 GB, or 73 GB disk capacities. The

VA 7410 and VA 7110 also support 146 GB disk modules. The maximum

configuration for a VA 7400/7410 includes 105 disk drives with a total

capacity of 7.67 TB. The controller enclosure includes one or two array

controllers that use advanced storage technology to automatically select the

proper RAID level for storing data.

The array can be connected to one or more hosts, hubs, or switches via fiber

optic cables. Factory-racked products are shipped pre-configured in HP Rack

Product Overview 13

Page 14

System/E racks. Field-rackable products are supported in the racks listed in

Table 2.

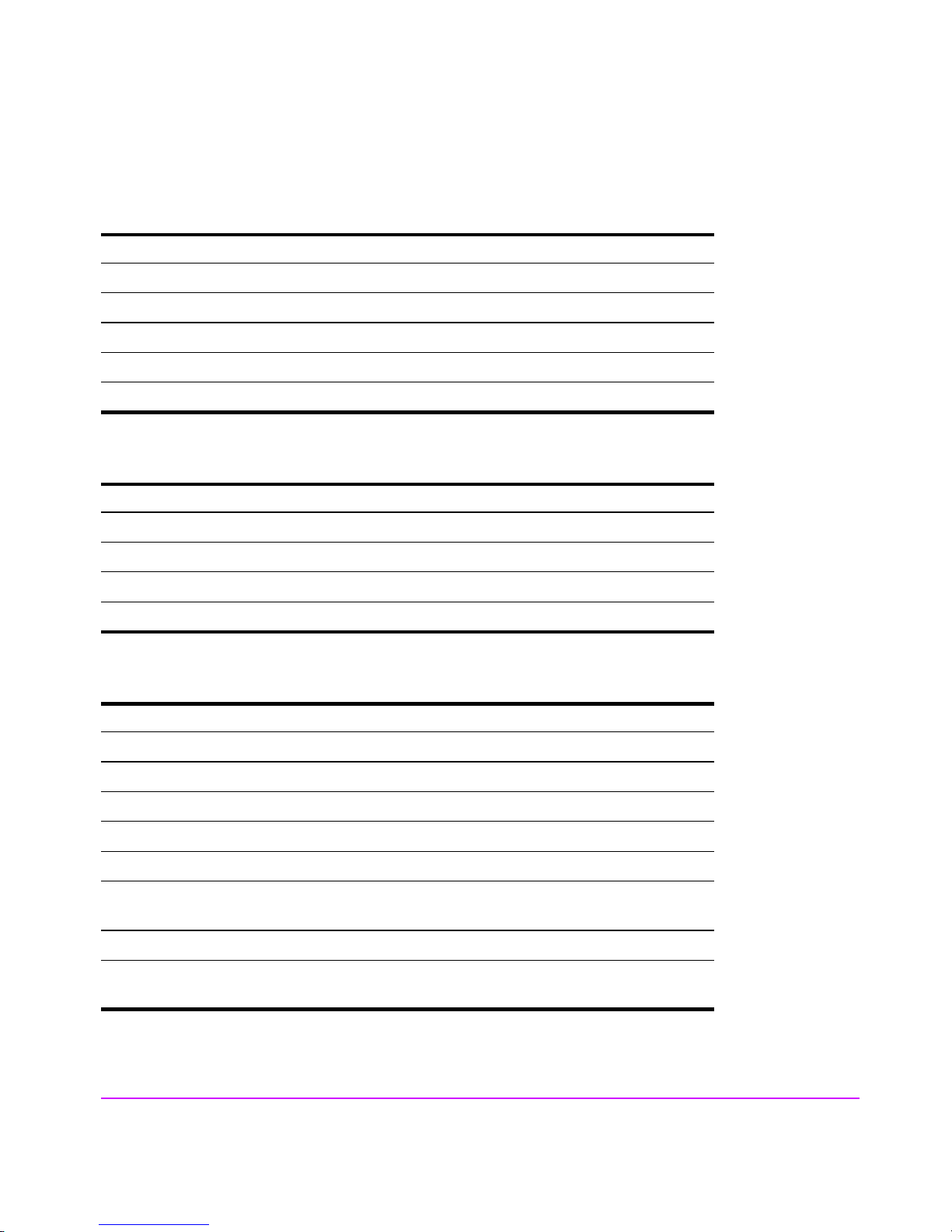

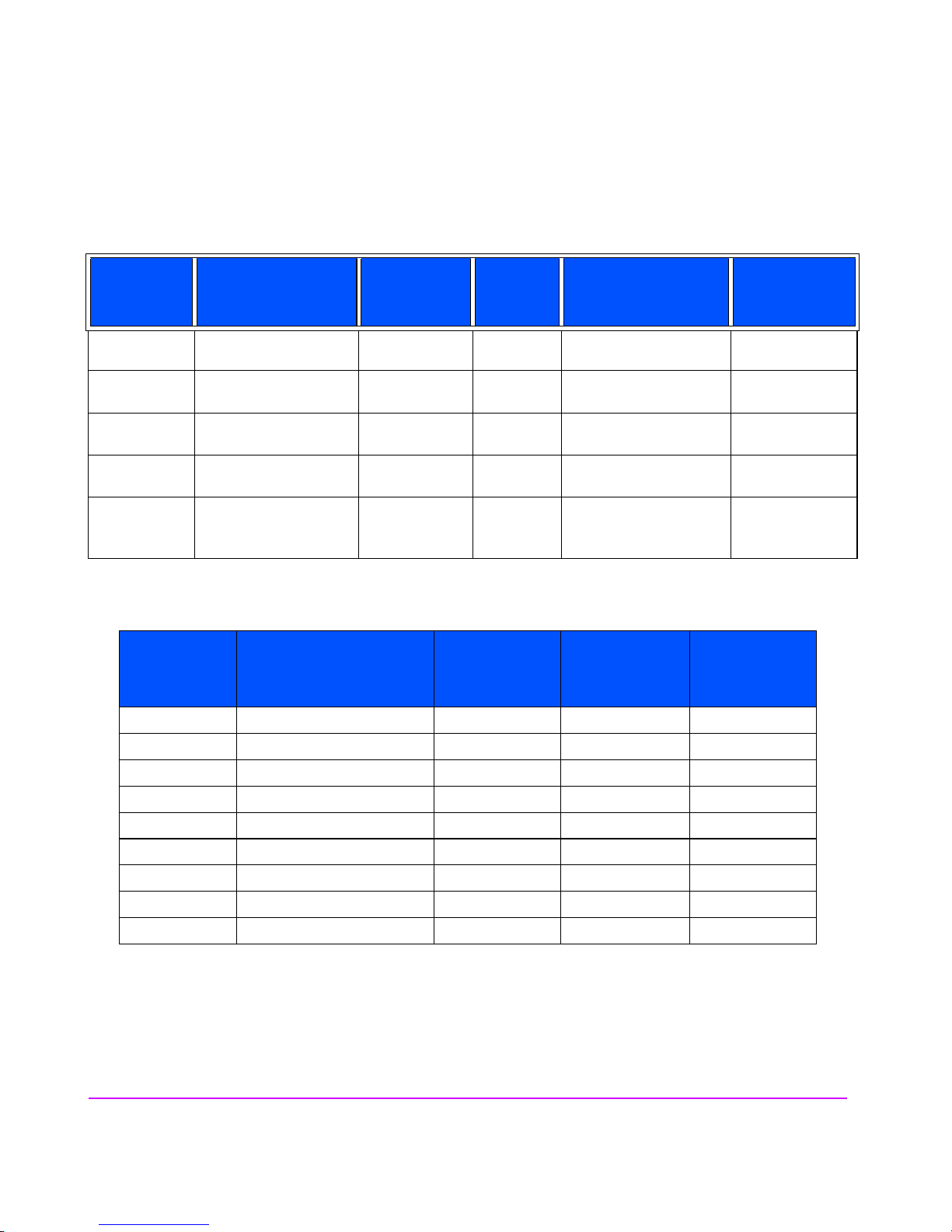

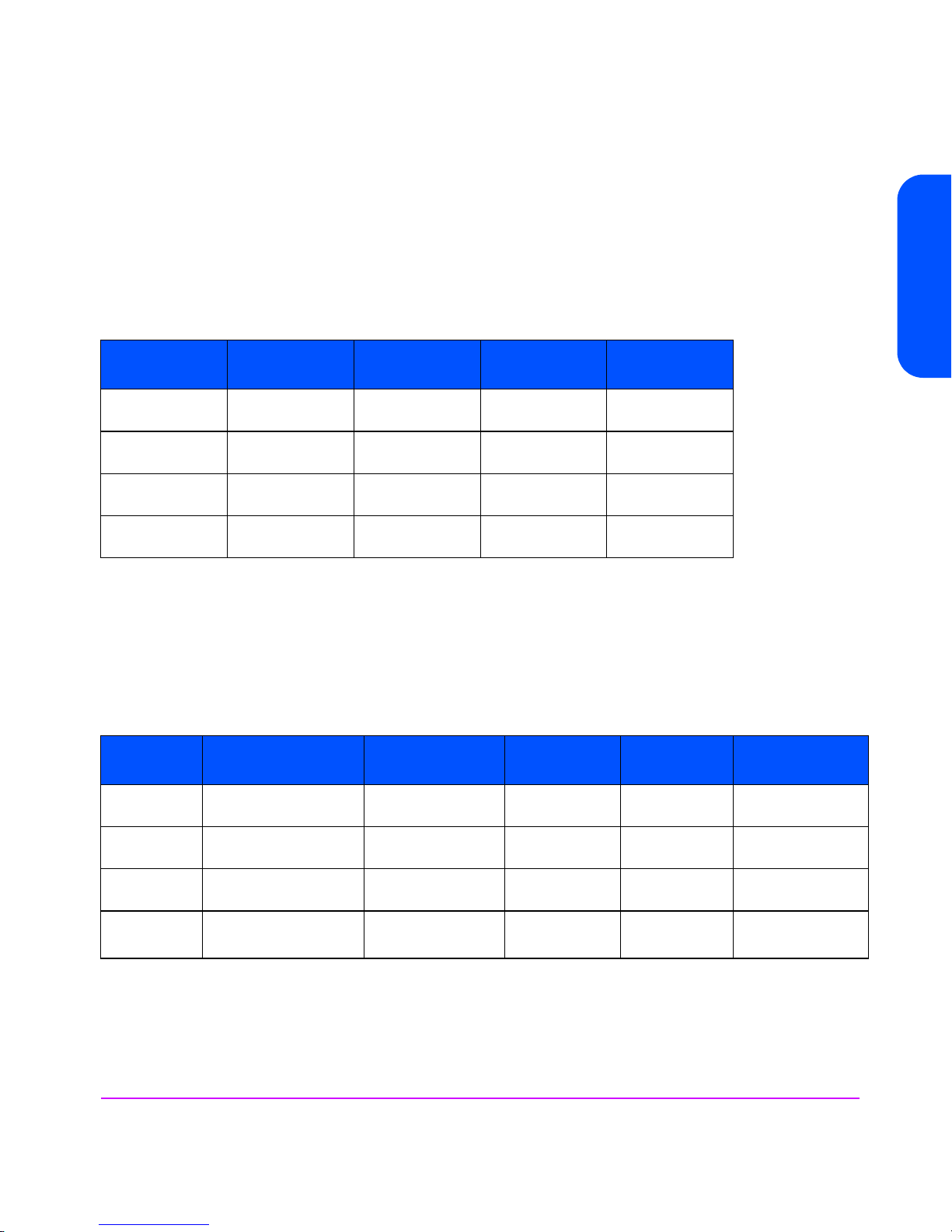

Table 1 Virtual Array Product Configurations

Model

Enclosure/

Configurations

VA 7100 Controller 1 4-15 1 or 2 array controllers

VA 7110 Controller 1 4-15 2 array controllers

VA 7400 Controller 1 10-15 2 array controllers

VA 7410 Controller 1 10-15 2 array controllers

VA 7110/

Disk 0-6 2-15 2 link controllers

7400/7410

a.See Table 25 on page 136 for valid DIMM configurations.

No. of

Enclosures

Disks

Per Encl.

Controller Cards

Per Encl.

1 Gbit/s

1 or 2 Gbit/s

1 or 2 Gbit/s

1 or 2 Gbit/s

7400: 1 Gbit/s

7410: 2 Gbit/s

Table 2 Virtual Array Supported Racks

Rack

Product No.

Rack Name

Height

meters/

EIA Units

No. of

EIA Units per

Array

1

Memory Per

Controller

(in MBytes)

256, 512,

or 1024

1024 or 2048

512 or 1024

1024 or 2048

No. of

Arrays

per Rack

a

N/A

2

J1500A HP Rack System/E41 1.96 m/ 41 U 3 13

J1501A HP Rack System/E33 1.60 m/ 33 U 3 11

J1502A HP Rack System/E25 1.25 m/ 25 U 3 8

E3660B HP System Rack 1.10 m/ 21 U 4 5

E3661B HP System Rack 1.60 m/ 32 U 4 8

E3662B HP System Rack 1.96 m/ 41 U 4 10

9142 Compaq 9000 Rack 2.0 m/ 42 U 3 14

9136 Compaq 9000 Rack 1.7 m/ 36 U 3 12

9122 Compaq 9000 Rack 1.1 m/ 22 U 3 7

1

HP Computer Cabinet requires a 1U filler panel to hide the mounting rails.

2

Does not include space that may be required for PDUs.

14 Product Overview

Page 15

Figure 1 VA 7400/7410 Maximum Configuration

Product Overview

(2 Enclosures Supported on VA 7110)

Product Overview 15

Page 16

Supported Operating Systems

Native Operating Systems

The arrays are supported on the following native operating systems running

CommandView SDM software:

— HP-UX 11.x

— Windows NT 4.0

— Windows 2000

— Red Hat Linux

Non-Native Operating Systems

The following non-native operating systems are only supported using a

dedicated management station running CommandView SDM on one of the

native operating systems listed above:

— Sun Solaris

— IBM AIX

— NetWare

— MPE/iX (VA 7100 only)

Array Management Software

HP StorageWorks CommandView SDM (Storage Device Manager)

shipped with the arrays, is used to configure, manage, diagnose, and monitor

the performance of the array. The software runs on the native operating

systems and includes the following interfaces:

— CommandView Graphical User Interface (GUI)

— Command Line User Interface (CLUI)

— CommandView User Interface (CVUI)

16 Product Overview

software,

Page 17

Product Features

The arrays include the following features:

■ Scalability

The capacities for the different products and disk modules are listed in Table 3.

Table 3 Data Storage Scalability

Product

No.

VA 7100 72 GB min

VA 7110 72 GB min

VA 7400 180 GB min

VA 7410 180 GB min

18 GB

Disk Module

270 GB max

810 GB max

1895 max

1895 max

■ High performance

— 10K rpm & 15K rpm disk drives

— 1 or 2 Gbit/s native Fibre Channel (host to controllers/controllers to

back-end)

— High performance read/write IOPS and cache hits. See Table 4

36 GB

Disk Module

144 GB min

540 GB max

144 GB min

1620 GB max

360 GB min

3780 GB max

360 GB min

3780 GB max

73 GB

Disk Module

292 GB min

1095 GB max

292 GB min

3285 GB max

730 GB min

7665 G B max

730 GB min

7665 G B max

Product Overview

146 GB

Disk Module

Not supported

584 GB min

6570 GB max

Not supported

1460 GB min

15,330 GB max

Table 4 Read/Write & Cache Performance

Product

No.

VA 7100 3,200 IOPS*

VA 7110 7150 IOPS*

VA 7400 8,000 IOPS*

VA 7410 11,000 IOPS*

Random

Reads

3,000 IOPS**

7100 IOPS**

7,500 IOPS**

11,000 IOPS**

Random

Writes

1,600 IOPS*

480 IOPS**

3500 IOPS*

1050 IOPS**

4,000 IOPS*

1,200 IOPS**

5,500 IOPS*

1,100 IOPS**

*RAID 1+0 only

**RAID 5DP only

Sequential

Reads

90 MB/s 45 MB/s 14,000 IOPS

160 MB/s 84 MB/s 15,500 IOPS

160 MB/s 80 MB/s 22,500 IOPS

330 MB/s 250 MB/s 30,000 IOPS

Sequential

Writes

Product Overview 17

Cache

Hits

Page 18

■ Advanced data protection

— RAID 5DP

— End-to-end data protection

— Mirrored ECC NV-SDRAM

1

— Dual battery cache backup

— Dual-ported native Fibre Channel disks

— Redundant, hot swappable field replaceable components – controllers,

power supplies, cooling, Fibre Channel components

1

Non-volatile synchronous dynamic random access memory/Error

Correction Code

18 Product Overview

Page 19

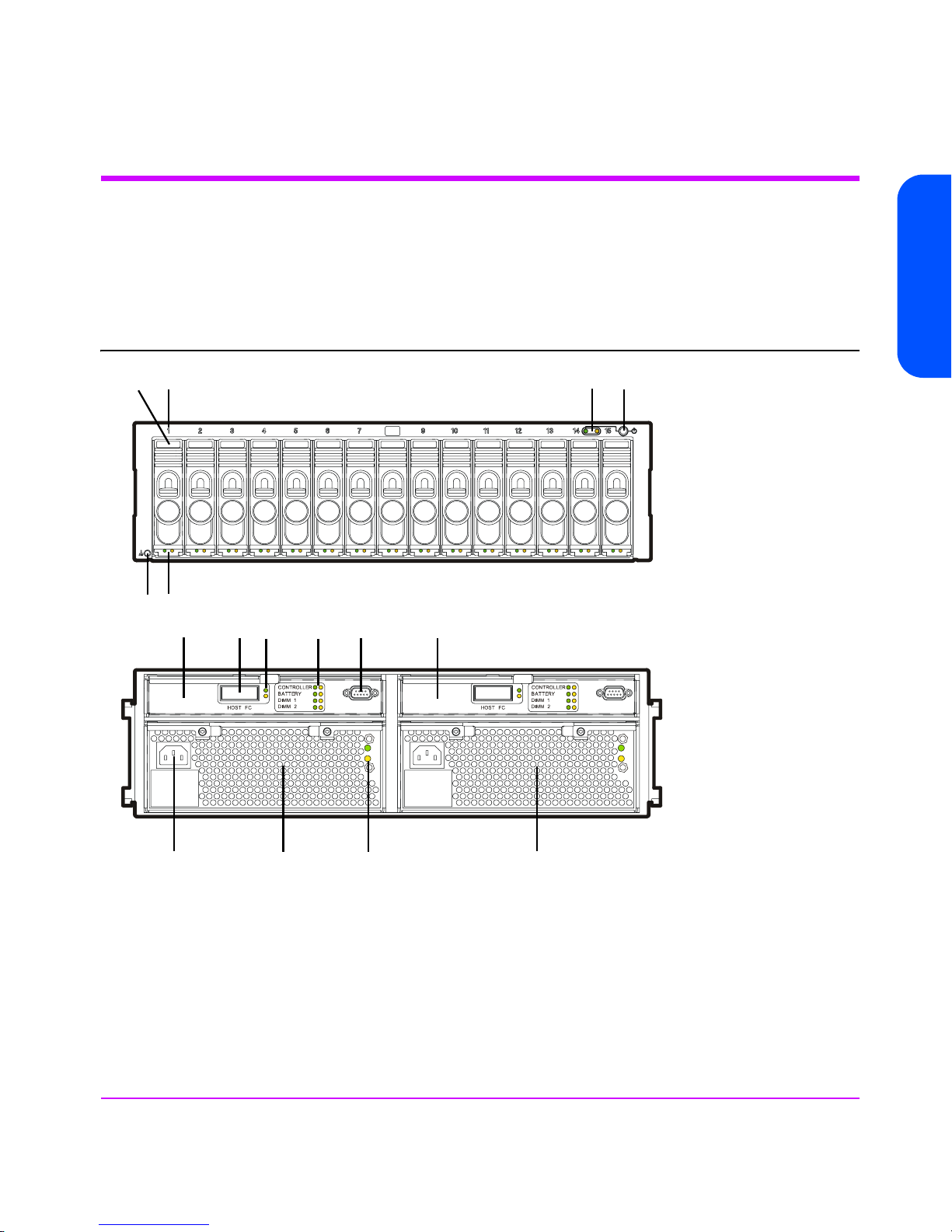

Controller Enclosure Components

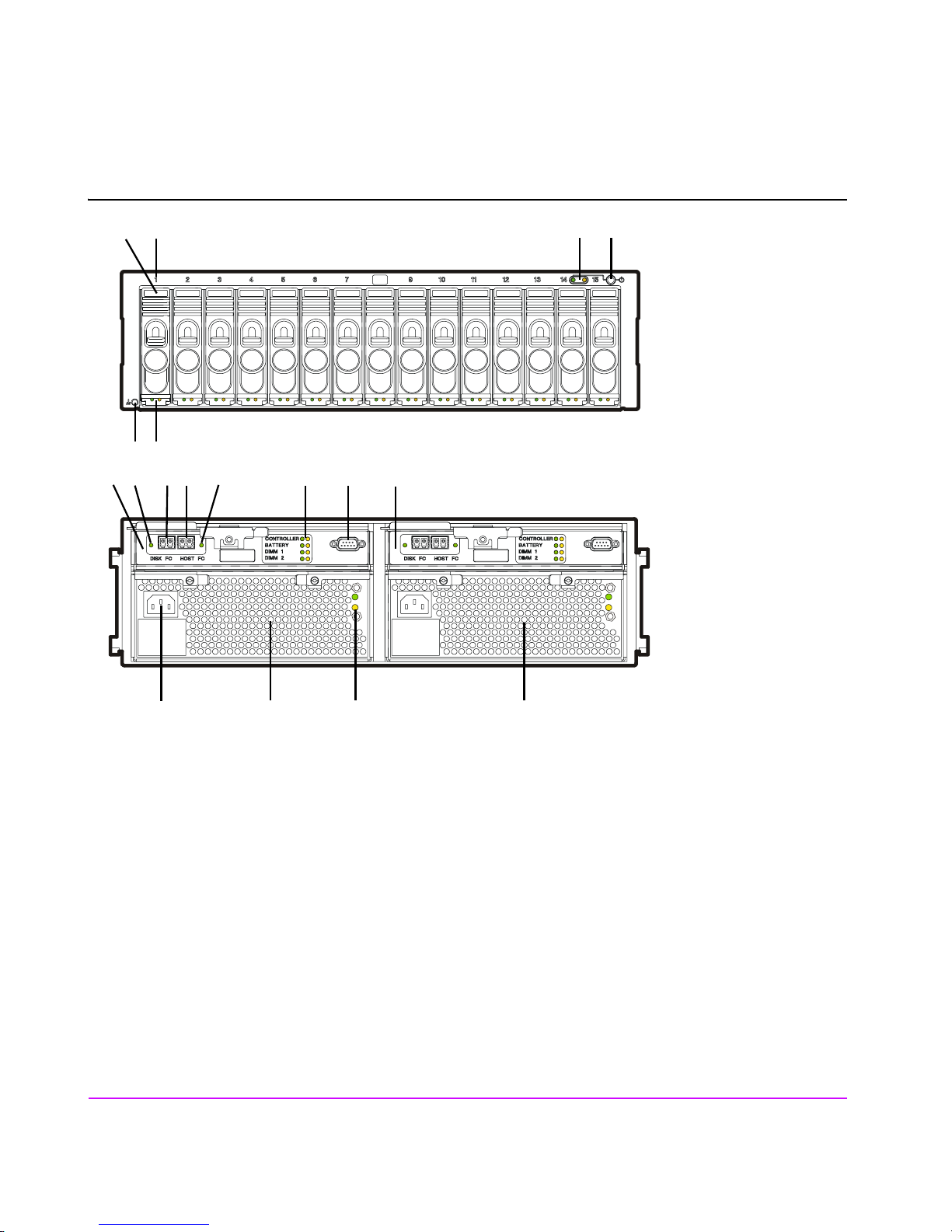

Figure 2 through Figure 6 show the front and rear panel components of the VA

7000 Family controller enclosures.

Figure 2 VA 7100 Factory-Racked & Field-Racked Controller Enclosure (A/AZ)

Product Overview

3

4

21

56

7

89

10 11

12

14 13 15

1 - Power/Standby Switch 9 - HOST FC LEDs

2 - System LEDs 10 - Array Controller LEDs

3 - Disk Drive Slot No. 1 (of 15) 11 - RS-232 Connector

4 - Disk Drive 1 (of 15) - M/D1* 12 - Array Controller 2 - M/C2*

5 - Disk Drive LEDs 13 - Power Module 1 - M/P1*

6 - ESD Ground Receptacle 14 - AC Power Connector

7 - Array Controller 1- M/C1* 15 - Power Module LEDs

8 - HOST FC Connector - M/C1.H1* 16 - Power Module 2 - M/P2*

*Reference designator used in CommandView SDM

16

Product Overview 19

Page 20

Figure 3 VA 7100 Controller Enclosure (D)

1

2

14

7

8

13

9

10

15

11

12

16

5

3

4

1 - Power/Standby Switch 10 - Array Controller LEDs

2 - System LEDs 11 - RS-232 Connector

3 - Disk Drive 1 (of 15) - M/D1* 12 - Array Controller 2 - M/C2*

4 - Disk Drive LEDs 13 - AC Power Connector

5 - Disk Drive Slot No. 1 (of 15) 14 - Power Module 1 - M/P1*

6 - Front ESD Ground Receptacle 15 - Power Module LEDs

7 - Array Controller 1 - M/C1* 16 - Power Module 2 - M/P2*

8 - HOST FC Connector - M/C1.H1* 17 - Rear ESD Ground Receptacle

9 - HOST FC LEDs

*Reference designator used in CommandView SDM

20 Product Overview

6 17

Page 21

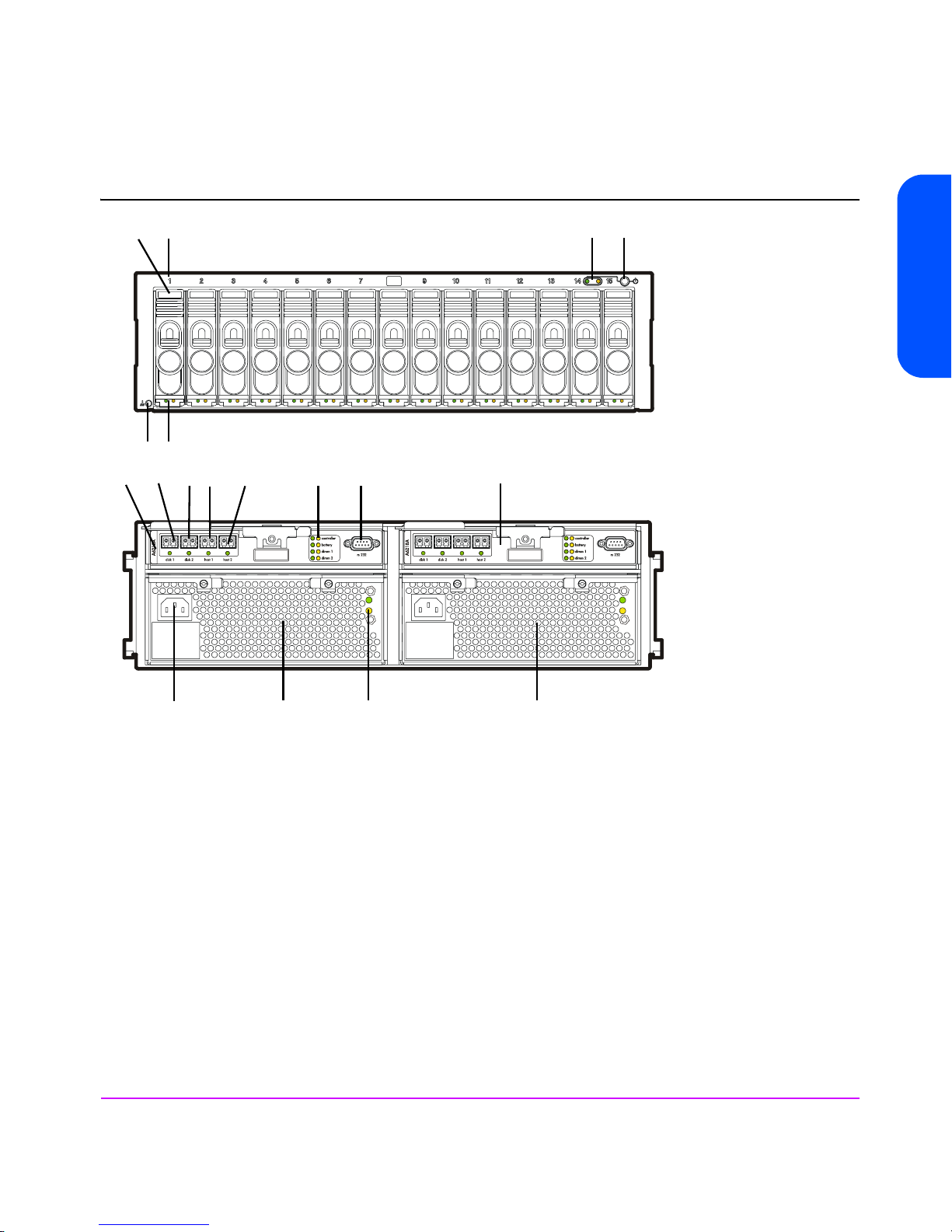

Figure 4 VA 7110 Controller Enclosure

3

4

65

789 1011

A

8

1

2

6

A

host 2disk 2

12

A

8

1

2

6

A

12

hostdisk

Product Overview

14

13

15

16

1 - Power/Standby Switch 9 - HOST FC Connector - M/C1.H1*

2 - System LEDs 10 - Array Controller LEDs

3 - Disk Drive Slot No. 1 (of 15) 11 - RS-232 Connector

4 - Disk Drive 1 (of 15) - M/D1* 12 - Array Controller 2 - M/C2*

5 - Disk Drive LEDs 13 - Power Module 1 - M/P1*

6 - ESD Ground Receptacle 14 - AC Power Connector

7 - Array Controller 1 - M/C1* 15 - Power Module LEDs

8 - DISK FC Connector and LED - M/C1.G1* 16 - Power Module 2 - M/P2*

*Reference designator used in CommandView SDM

Product Overview 21

Page 22

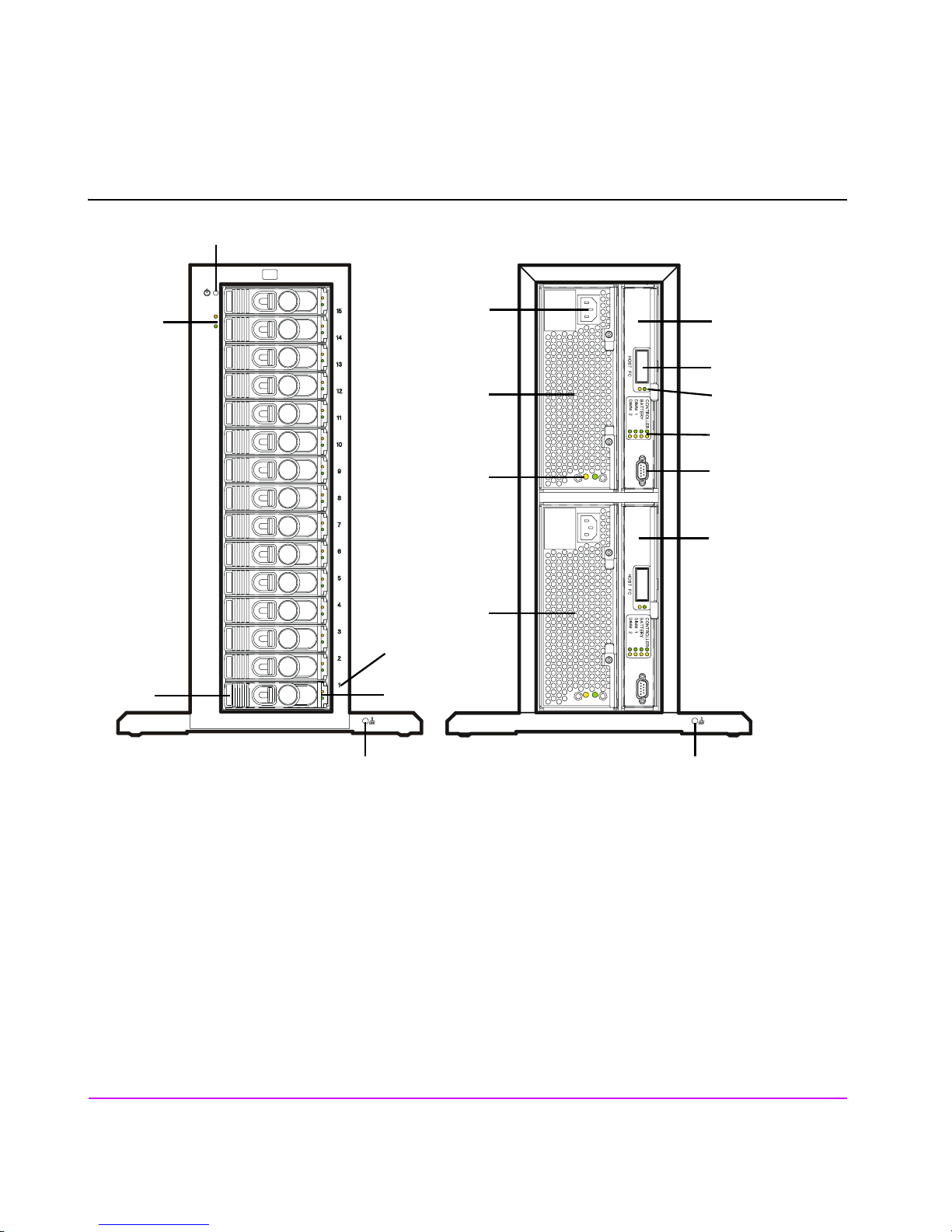

Figure 5 VA 7400 Controller Enclosure

4

65

8

3

9

1110

12 137

14

21

16 15 17 18

1 - Power/Standby Switch 10 - HOST FC Connector - M/C1.H1*

2 - System LEDs 11 - HOST FC LED

3 - Disk Drive Slot No. 1 (of 15) 12 - Array Controller LEDs

4 - Disk Drive 1 (of 15) - M/D1* 13 - RS-232 Connector

5 - Disk Drive LEDs 14 - Array Controller 2 - M/C2*

6 - ESD Ground Receptacle 15 - Power Module 1 - M/P1*

7 - Array Controller 1 - M/C1* 16 - AC Power Connector

8 - DISK FC LED 17 - Power Module LEDs

9 - DISK FC Connector - M/C1.G1* 18 - Power Module 2 - M/P2*

*Reference designator used in CommandView SDM

22 Product Overview

Page 23

Figure 6 VA 7410 Controller Enclosure (A/AZ)

4

65

3

9

8

10

11

12

137

14

21

Product Overview

16 15 17 18

1 - Power/Standby Switch 10 - HOST 1 FC Port and LED (M/C1.H1*)

2 - System LEDs 11 - HOST 2 FC Port and LED (M/C1.H2*)

3 - Disk Drive Slot No. 1 (of 15) 12 - Array Controller LEDs

4 - Disk Drive 1 (of 15) (M/D1*) 13 - RS-232 Connector

5 - Disk Drive LEDs 14 - Array Controller 2 (M/C2*)

6 - ESD Ground Receptacle 15 - Power Module 1 (M/P1*)

7 - Array Controller 1 (M/C1*) 16 - AC Power Connector

8 - DISK 1 FC Port and LED (M/C1.J1*) 17 - Power Module LEDs

9 - DISK 2 FC Port and LED (M/C1.J2*) 18 - Power Module 2 (M/P2*)

*Reference designator used in CommandView SDM

Product Overview 23

Page 24

Array Controller

The array controller contains the intelligence and functionality required to

manage the operation of the array. Its functions include:

■ Implementing HP

AutoRAID

™

technology to ensure optimum performance

and cost-efficient data storage.

■ Managing all communication between the host and the disk drives via one

(single array controller) or two (dual array controller) Fibre Channel

arbitrated loops.

■ Maintaining data integrity.

■ Rebuilding the array in the event of a disk failure.

■ Monitoring the operation of all hardware components, including the array

controller itself.

In a dual array controller configuration, two controllers provide redundant

paths to array data. Dual array controllers operate together in active-active

concurrent access mode, allowing a possible increase in I/O performance

while providing data redundancy. In active-active mode, memory maps on

both controllers are constantly and simultaneously updated. By maintaining a

mirror image of the maps, the second controller can take over immediately if

the first controller fails.

Each array controller card includes the following components:

— 1 or 2 Dual Inline Memory Modules (DIMMs)

— 1 Battery

— VA 7100 Only - 1 Gigabit Interface Converter (GBIC)

— Motorola 8240 PowerPC processor (VA 7100 and VA 7400)

— IBM 440 processor (VA 7410)

VA 7410 Fibre Channel Ports

The VA 7410 enhances flexibility, availability, and performance by adding an

additional host port to each controller. This increases the number of paths from

the host systems to the array. The VA 7410 also adds a second disk port to

each controller, resulting in four back-end ports. This creates two independent

Fibre Channel loops between the controller enclosure and the disk enclosures.

Back-end performance is enhanced by distributing the disks across both loops.

24 Product Overview

Page 25

DIMMs

Each array controller includes one or two ECC SDRAM DIMMs that are battery

backed up and mirrored with the dual controller. This memory is used for the

read and write cache, and for the virtualization data structures. These data

structures provide the logical-to-physical mapping required for virtualization

and are vital to the operation of the array. Without these data structures, all

data in the array is inaccessible.

Note The DIMMs are a critical component in maintaining correct

operation of the array. Use extreme caution when replacing or

modifying the DIMM configuration.

Table 25 on page 136 shows the valid configuration of DIMMs for each

controller cache size. In a dual controller configuration, both controllers must

have the same cache size.

Battery

Note The array controller battery is a critical component in

maintaining the virtualization data structures during a power

loss when the array has not successfully completed a shutdown.

Exhausting the battery power in this state may result in data loss.

Product Overview

Each array controller includes a Lithium Ion-type battery with a built-in

microprocessor. The battery provides backup power to the DIMMs in the event

of a power failure or if array power is switched off. The batteries provide

power for minimum of 84 hours. If line power is lost, the green BATTERY LED

will flash with a 5% duty cycle while powering the DIMMs. A fully charged

battery will maintain DIMM memory contents for a minimum of three days.

(The three-day specification includes derating for battery life, temperature, and

voltage.) If the battery loses its charge, or if it is removed from the controller,

the DIMMs will not be powered and memory maps will be lost.

Battery Status. The controller constantly interrogates the battery for its status. If

the battery cannot maintain memory contents for a minimum of three days, a

warning will notify the operator to replace the battery. Every six months, the

battery performs a self-test to determine its charge status. Then it is fully

discharged and fully recharged to optimize battery life. This action is not

indicated by software or LEDs. In a dual controller configuration, only one

battery at a time is discharged and recharged. If the battery becomes

discharged during normal operation, the green BATTERY LED will turn off and

the amber BATTERY LED will turn on. If the battery has low charge during a

Product Overview 25

Page 26

power-on self-test, the self-test will halt until the battery is charged to a

minimum operating level.

Battery Life. Many factors affect battery life, including length of storage time,

length of operating time, storage temperature, and operating temperature. A

battery should be replaced if the BATTERY LEDs or the software indicate a

battery has diminished storage capacity.

GBIC (VA 7100 Only)

A Gigabit Interface Converter (GBIC) is connected to the HOST FC connector

on the VA 7100 array controller card. It functions as a fiber optic transceiver,

converting data from an electrical to an optical signal in transmit mode, or

from an optical signal to an electrical signal in receive mode. On the

VA 7400/7410 array controller card, GBIC circuitry is integrated.

Array Controller Filler Panel

An array controller filler panel is used to fill an empty slot in place of an array

controller. A filler panel must be installed to maintain proper airflow in the

array enclosure.

Caution Do not operate the array for more than 5 minutes with an array

controller or filler panel removed. Either an array controller or a

filler panel must be installed in the slot to maintain proper

airflow in the array enclosure. If necessary, the foam in the

replacement array controller packaging can be used to

temporarily fill the array controller slot.

Disk Drives

Both the controller and disk enclosures contain disk drives. Disk drives, or

“disks”, provide the storage medium for the virtual array. Four types of native

Fibre Channel disk drives are supported in the array; disk capacities can be

homogeneous, or can be mixed within the array:

— 18 GB 15K rpm

— 36 GB 10K rpm

— 36 GB 15K rpm

— 73 GB 10K rpm

— 73 GB 15K rpm (VA 7110 and VA 7410 only)

— 146 GB 10K rpm (VA 7110 and VA 7410 only)

26 Product Overview

Page 27

A new disk can be added at any time, even while the array is operating.

When a disk is replaced, the array applies power to the disk in a controlled

manner to eliminate power stresses. The array controller will recognize that a

new disk has been added and, if the Auto Include feature is enabled, will

include the disk in the array configuration automatically. However, to make the

additional capacity available to the host, a new logical drive must be created

and configured into the operating system.

A label on the disk drive provides the following information:

— Capacity in gigabytes: 18G, 36G, 73G, or 146G

— Interface: FC (Fibre Channel)

— Rotational speed in revolutions per minute: 10K or 15K

Note A red zero (0) on the capacity label distinguishes a disk drive

filler panel from a disk drive.

Image Disks

When the array is formatted, the array controller selects two disks as image

disks. On the VA 7410 a third disk is identified as a backup in the event one of

the primary image disks fails. Because it is not possible to predict which disks

will be selected as the image disks, the management software must be used to

determine which disks have been selected.

Product Overview

The image disks serve two functions:

■ The image disks have space reserved for copies, or “images”, of the write

cache and virtualization data structures stored in the controller NVRAM.

During a shutdown, a complete copy of the NVRAM is stored on both

image disks. If the maps are lost, they can be restored from the image

disks.

■ When resiliency map settings are set to the factory default (Normal

Resiliency), changes to the maps, which have occurred since the last

shutdown, are updated every 4 seconds on the image disks.

Note A shutdown makes the disk set independent of its controller.

Because all of the necessary mapping information is on the

image disks, it is possible to install a new controller or move the

entire disk set to another controller. The new controller will

determine that it has a new disk set, and will logically attach

itself to those disks.

Product Overview 27

Page 28

If an image disk fails on the VA 7100 or VA 7400, the array will operate with

a single image disk until the failed disk is replaced. If an image disk fails on

the VA 7410, the backup image disk will be used, maintaining image disk

redundancy. When the original failed image disk is replaced, it will be

assigned the role of backup image disk.

Disk Drive Filler Panels

Disk drive filler panels are used in both the controller and disk enclosures to fill

empty slots in place of disk drives. A filler panel must be installed to maintain

proper cooling in the enclosure.

Caution Do not operate the array for more than 5 minutes with a disk

Power Modules

The controller enclosure is shipped with two fully redundant power modules.

Each power module contains:

■ An autoranging power supply that converts ac input power to dc output

power for use by the other array components. The power supplies share the

power load under non-fault conditions. If one power supply fails, the other

supply delivers the entire load to maintain power for the array. Each power

supply uses a separate power cord. Both power supplies can be plugged

into a common ac power source, or each supply can be plugged into a

separate ac circuit to provide power source redundancy.

drive or filler panel removed. Either a disk drive or filler panel

must be installed in the slot to maintain proper airflow and avoid

overheating.

■ Two internal blowers, which provide airflow and maintain the proper

operating temperature within the enclosure. If a blower fails, a fault will

occur. The other power module will continue to operate and its blowers will

continue to cool the enclosure. Even if a power supply fails, both of the

blowers within the power module will continue to operate; dc power for the

blowers is distributed from the midplane.

28 Product Overview

Page 29

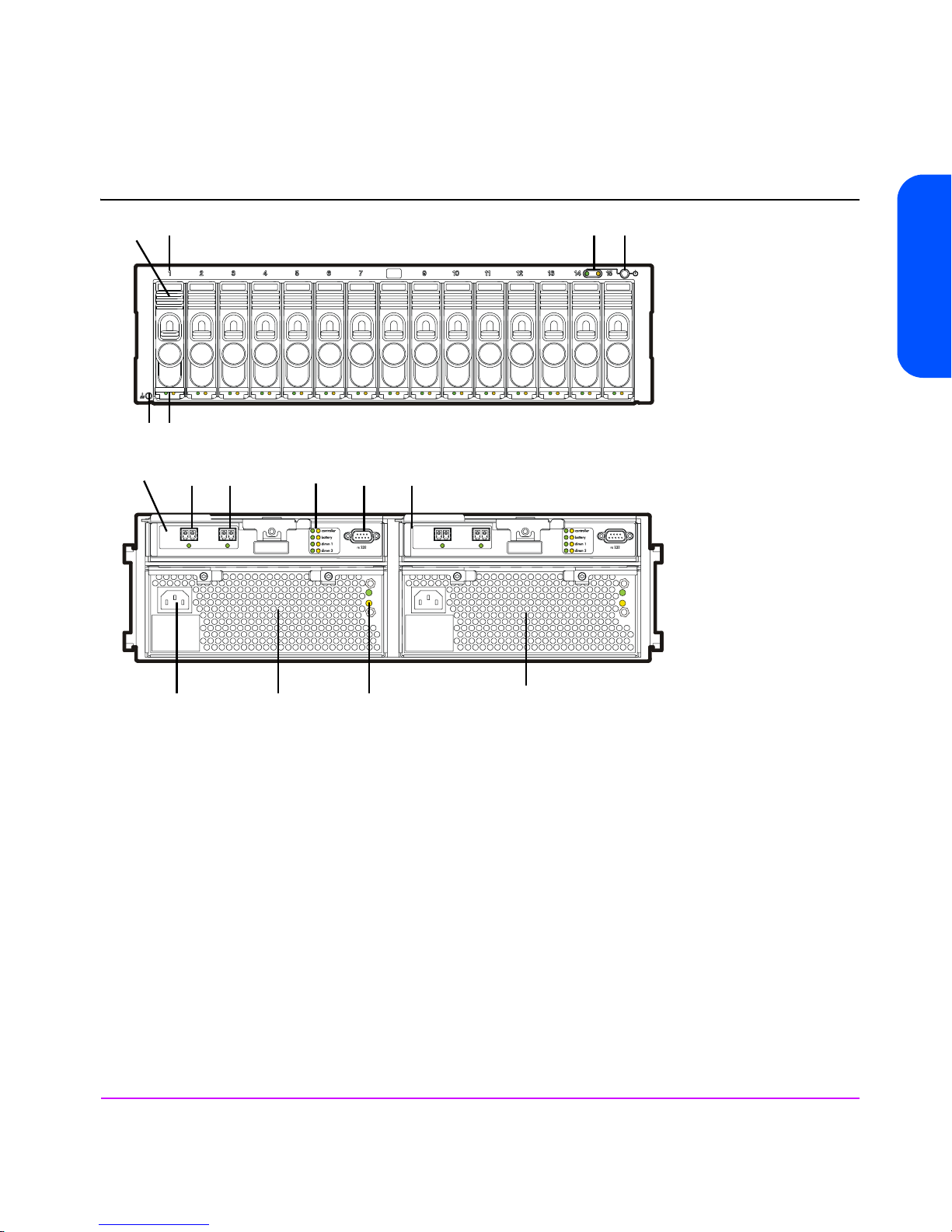

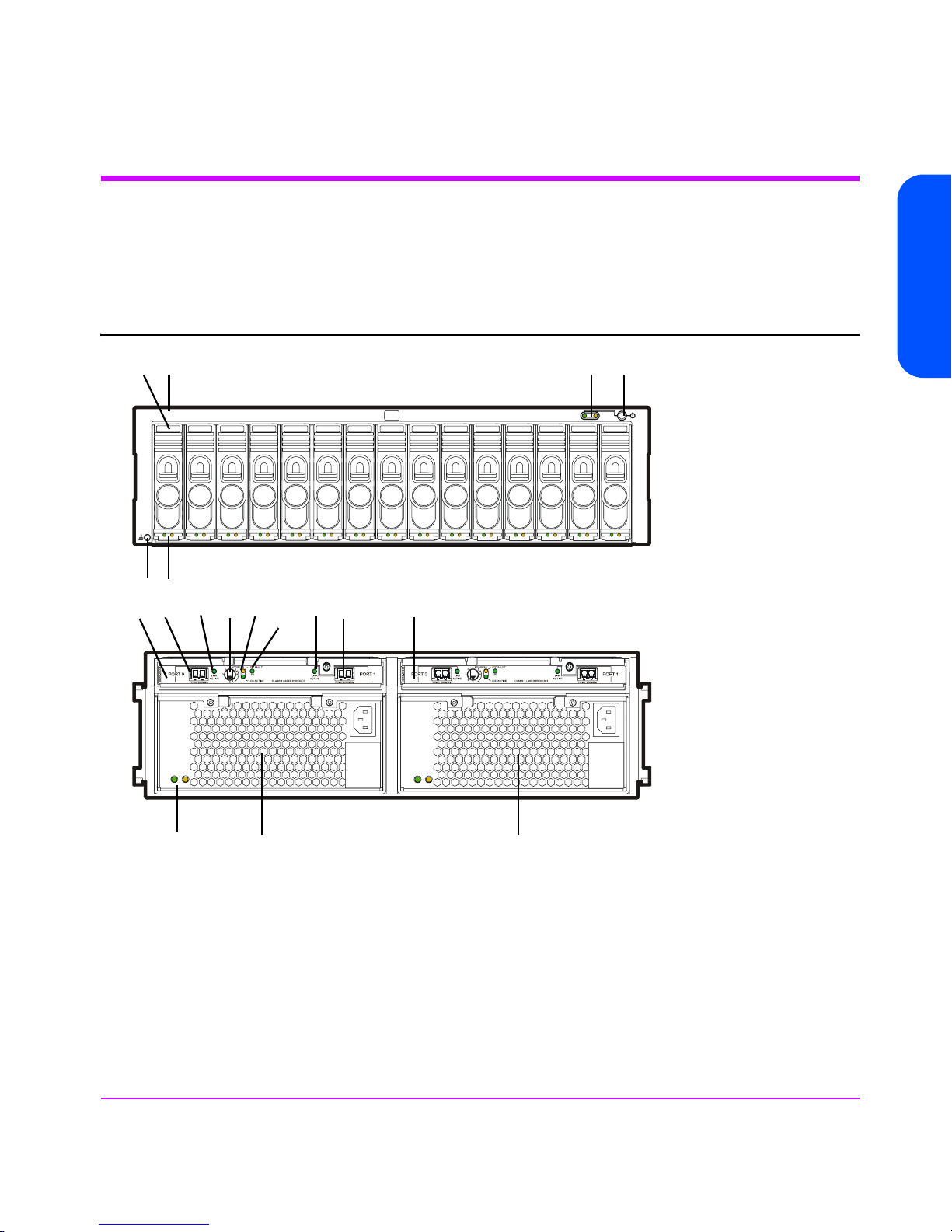

Disk Enclosure Components

Figure 7 shows the front and rear panel components of the disk enclosure

connected to the VA 7400/7410 controller enclosure. Both DS 2400 and

DS 2405 Disk Systems are used as disk enclosures on the VA 7400/7410.

Figure 7 VA 7110/7400/7410 Disk Enclosure (A/AZ)

Product Overview

4

123

56

10

11

9

8

7

17

12

13

14

16 15 18

1 - Power/Standby Switch 10 - ADDRESS Switch

2 - System LEDs 11 - LCC LEDs

3 - Disk Drive Slot No. 1 (of 15) 12 - PORT 1 LINK ACTIVE LED

4 - Disk Drive 1 (of 15) - JAn/D1* 13 - PORT 1 FC-AL Connector - JAn/C1.J2*

5 - Disk Drive LEDs 14 - Link Controller Card 2 - JAn/C2*

6 - ESD Ground Receptacle 15 - Power Module 1 - JAn/P1*

7 - Link Controller Card 1 - JAn/C1* 16 - Power Module LEDs

8 - PORT 0 FC-AL Connector - JAn/C1.J1* 17 - 2G LED (DS 2405 Disk System only)

9 - PORT 0 LINK ACTIVE LED 18 - Power Module 2 - JAn/P2*

*Reference designator used in CommandView SDM

Product Overview 29

Page 30

Link Controller Card (VA 7110/7400/7410 Only)

The link controller card (LCC) functions as a fiber optic transceiver for the disk

enclosure. It allows up to six disk enclosures to be connected to the controller

enclosure. Each LCC includes a Fibre Channel address switch, used to set the

Fibre Channel loop address of the card. Each disk enclosure must have a

unique address and both LCCs in a disk enclosure must be set to the same

address. For cabling connections and switch settings, see Figure 8 for the

VA 7110, Figure 9 for the VA 7400, and Figure 10 for the VA 7410.

The LCC also monitors the operation of the disk enclosure and provides status

information to the array controller. This includes what disks are present and

their status, power supply status, and notification if the enclosure operating

temperature has exceeded its limits.

Disk Drives

Up to 15 disks can be installed in each disk enclosure. The controller enclosure

and the disk enclosure both use the same disk drives. See "Disk Drives" on

page 26.

Image Disks

The image disks can be located in either the controller enclosure or the disk

enclosure. See "Image Disks" on page 27.

Disk Drive Filler Panels

The controller enclosure and the disk enclosure both use the same disk drive

filler panels. See "Disk Drive Filler Panels" on page 28.

30 Product Overview

Page 31

Figure 8 VA 7110 Back-End Fiber Optic Cabling & Addressing (2 Disk Enclosures)

CONTROLLER

Product Overview

ADDRESS4

3

LCC

5

ACTIVE

6

2

PORT 0 PORT 1

ADDRESS4

3

5

6

2

1

0

ADDRESS4

3

5

6

2

1

0

A6214-60001

PORT 0 PORT 1

A6214-60001

LCC

LINK

ACTIVE

1

0

FC-AL 100MB/s FC-AL 100MB/s

LINK

ACTIVE

FAULT

JBOD 1

ADDRESS4

3

5

LCC

ACTIVE

6

2

LCC

LINK

ACTIVE

1

0

FC-AL 100MB/s FC-AL 100MB/s

LINK

FAULT

ACTIVE

JBOD 2

ADDRESS4

3

LCC

5

ACTIVE

6

2

PORT 0 PORT 1

A6214-60001

PORT 0 PORT 1

A6214-60001

LCC

LINK

ACTIVE

1

0

FC-AL 100MB/s FC-AL 100MB/s

ADDRESS4

3

5

6

2

LINK

ACTIVE

1

0

FC-AL 100MB/s FC-AL 100MB/s

LINK

ACTIVE

FAULT

LCC

ACTIVE

LCC

LINK

FAULT

ACTIVE

ADDRESS4

3

5

6

2

1

0

4

ADDRESS

3

5

6

2

1

0

Product Overview 31

Page 32

Figure 9 VA 7400 Back-End Fiber Optic Cabling & Addressing (6 Disk Enclosures)

CONTROLLER

4

ADDRESS

3

LCC

5

ACTIVE

2

6

PORT 0 PORT 1

4

ADDRESS

3

5

6

2

1

0

ADDRESS4

3

5

6

2

1

0

4

ADDRESS

3

5

6

2

1

0

ADDRESS4

3

5

6

2

1

0

ADDRESS4

3

5

6

2

1

0

A6214-60001

PORT 0 PORT 1

A6214-60001

PORT 0 PORT 1

A6214-60001

PORT 0 PORT 1

A6214-60001

PORT 0 PORT 1

A6214-60001

LCC

LINK

ACTIVE

1

0

FC-AL 100MB/s FC-AL 100MB/s

LINK

ACTIVE

FAULT

JBOD 0

ADDRESS4

3

5

LCC

ACTIVE

6

2

LCC

LINK

ACTIVE

1

0

FC-AL 100MB/s FC-AL 100MB/s

LINK

FAULT

ACTIVE

JBOD 1

ADDRESS4

3

5

LCC

ACTIVE

2

6

LINK

ACTIVE

1

0

FC-AL 100MB/s FC-AL 100MB/s

LINK

LCC

FAULT

ACTIVE

JBOD 2

ADDRESS4

3

5

LCC

ACTIVE

6

2

LINK

ACTIVE

1

0

FC-AL 100MB/s FC-AL 100MB/s

LINK

LCC

FAULT

ACTIVE

JBOD 3

ADDRESS4

3

5

LCC

ACTIVE

2

6

LINK

ACTIVE

1

0

FC-AL 100MB/s FC-AL 100MB/s

LINK

LCC

ACTIVE

FAULT

JBOD 4

4

ADDRESS

3

LCC

5

ACTIVE

2

6

PORT 0 PORT 1

A6214-60001

PORT 0 PORT 1

A6214-60001

PORT 0 PORT 1

A6214-60001

PORT 0 PORT 1

A6214-60001

PORT 0 PORT 1

A6214-60001

LCC

LINK

ACTIVE

1

0

FC-AL 100MB/s FC-AL 100MB/s

ADDRESS4

3

5

6

2

LINK

ACTIVE

1

0

FC-AL 100MB/s FC-AL 100MB/s

ADDRESS4

3

5

2

6

LINK

ACTIVE

1

0

FC-AL 100MB/s FC-AL 100MB/s

ADDRESS4

3

5

6

2

LINK

ACTIVE

1

0

FC-AL 100MB/s FC-AL 100MB/s

ADDRESS4

3

5

2

6

LINK

ACTIVE

1

0

FC-AL 100MB/s FC-AL 100MB/s

LINK

ACTIVE

FAULT

LCC

ACTIVE

LCC

LINK

FAULT

ACTIVE

LCC

ACTIVE

LINK

LCC

FAULT

ACTIVE

LCC

ACTIVE

LINK

LCC

FAULT

ACTIVE

LCC

ACTIVE

LINK

LCC

ACTIVE

FAULT

ADDRESS4

3

5

6

2

1

0

4

ADDRESS

3

5

6

2

1

0

ADDRESS4

3

5

6

2

1

0

4

ADDRESS

3

5

6

2

1

0

ADDRESS4

3

5

6

2

1

0

ADDRESS4

3

LCC

5

ACTIVE

2

6

PORT 0 PORT 1

LINK

LCC

FAULT

ACTIVE

1

A6214-60001

0

ADDRESS4

3

5

6

2

1

0

FC-AL 100MB/s FC-AL 100MB/s

JBOD 5

32 Product Overview

ADDRESS4

3

LCC

5

ACTIVE

2

6

LINK

ACTIVE

PORT 0 PORT 1

LINK

ACTIVE

1

A6214-60001

0

FC-AL 100MB/s FC-AL 100MB/s

LINK

LCC

FAULT

ACTIVE

ADDRESS4

3

5

6

2

1

0

Page 33

Figure 10 VA 7410 Back-End Fiber Optic Cabling & Addressing (6 Disk Enclosures)

Product Overview

FC Loop 1

FC Loop 2

Product Overview 33

Page 34

Power Modules

The disk enclosure is shipped with two fully redundant power modules. Each

power module contains:

■ An autoranging power supply that converts ac input power to dc output

power for use by the other array components. The power supplies share the

power load under non-fault conditions. If one power supply fails, the other

supply delivers the entire load to maintain power for the array. Each power

supply uses a separate power cord. Both power supplies can be plugged

into a common power source, or each supply can be plugged into a

separate circuit to provide power source redundancy.

■ One internal blower, which provides airflow and maintains the proper

operating temperature within the array enclosure. If the blower fails, a fault

will occur. The other power module will continue to operate and its blower

will continue to cool the enclosure. Even if a power supply fails, the blower

within the power module will continue to operate; dc power for the blower

is distributed from the midplane.

34 Product Overview

Page 35

Operating the Power/Standby Switch

When the power/standby switch is in the “power” position, ac power is

applied to the primary and secondary sides of the power supplies in the power

module and all of the dc circuits in the array are active. When the power/

standby switch is in the “standby” position, ac power is only applied to the

primary side of the power supplies; all of the dc circuits in the array are

disabled.

To switch power on, push in the power/standby switch to the “power” position.

See Figure 11.To switch power to standby, push in the power/standby switch

then release it to the “standby” position.

Caution If it is necessary to completely remove power from the array, you

must unplug both power cords from the ac power connectors on

the array rear panel.

Figure 11 Operating the Power/Standby Switch

Product Overview

Product Overview 35

Page 36

Power-On Self-Test

Shutdown

Immediately after the array is powered on, the controller enclosure and disk

enclosures (VA 7400/7410 only) perform a power-on self-test.

During a power-on self-test, you will see the following front panel activity:

■ The system power/activity LED turns on solid green.

■ The disk drive activity LEDs flash while the controller establishes

communication with the drives, then two LEDs at a time turn on solid green,

one from the lower disk drive slots (1-8) and one from the upper disk drive

slots (9-15), while the associated drives spin up.

When the power-on self-test completes successfully:

■ All LEDs on the front panel should be solid green.

The coordinated shutdown process is used to take the array offline. The

primary function of shutdown is to copy the contents of the NVRAM to the

image disks. This protects the array against data loss if a battery fails in the

absence of ac power. In the shutdown state, the array can still respond to

management commands from the host, but the host cannot access any of the

data in the array.

36 Product Overview

During shutdown, the array will use the contents of the controller NVRAM if

valid. For a dual controller configuration only a single NVRAM image is

required to be valid.

Note If the NVRAM image is not valid the array will enter an error

state. The configuration information and the write cache have

been lost. Access to the data requires a Recover process.

Recovery will attempt to recover the configuration information

from the data disks. The contents of the write cache are not

recoverable.

A shutdown is automatically initiated in two ways:

■ By moving the power/standby switch to the standby position.

■ Using the array management software.

Page 37

Note Using software to perform a shutdown is the preferred method

because confirmation of a successful shutdown is reported to the

operator.

If the power fails or if you unplug the power cords without performing a

shutdown, the following sequence will occur when the array is powered on

again:

1 The array will attempt to retrieve the maps from cache and determine if they

are valid.

2 If the maps are not valid, the array will retrieve the maps from the image

disks.

Note If power to the array is lost by any means other than by moving

the power/standby switch to the standby position, the array will

not have time to perform a successful shutdown. In this case, a

fully charged battery can sustain NVSDRAM contents for 3

days.

Product Overview

Product Overview 37

Page 38

Data Storage Process

Virtual Array

The term “Virtual Array” refers to the way the array manages the disks as a

pool of data storage blocks instead of whole physical disks. Like other

virtualization within computer systems, this virtualization greatly simplifies the

management of the array. Internally, the array uses sophisticated data

structures to manage the logical-to-physical address translation. These data

structures, often referred to as the “maps”, are key to the operation of the array.

See Figure 12.

Administrators’ manage the capacity of the array using Redundancy Groups

and LUNs. Each disk belongs to a predefined Redundancy Group, and a LUN

is created from the capacity of a Redundancy Group. This is similar to

traditional arrays. The virtualization eliminates the need to manage the lower

level details. Redundancy Groups can be constructed from any number or

capacity of supported disks. Any number of disks can be added to a

Redundancy Group at any time. LUNs can be of any size up to the available

capacity of a RAID Group, or created and deleted without the knowledge of

the underlying physical disk layout. The VA 7100 supports up to 128 LUNs;

the VA 7400/7410 support up to 1024 LUNs.

38 Product Overview

Page 39

Figure 12 Virtual Data Storage

Product Overview

Host

LUN 1

LUN 2

Cache

Maps

Storage

Pool

Redundancy Groups

Array physical capacity is divided into Redundancy Groups. A Redundancy

Group (RG) can be thought of as an independent array. Each RG has its own

set of disks, active hot spare, and controller. LUNs are created from capacity

within a single RG. LUNs can be accessed simultaneously through either

controller.

Multiple redundancy groups provide the following benefits:

■ Fault isolation. Because each redundancy group has its own resources, a

■ Performance management. Applications can be assigned to different RGs,

■ Greater configurability. Each RG can be constructed from different classes

disk failure in one RG will not impact the other RG. This effectively

increases the data availability of the array.

thus isolating their performance impact on each other.

of disks. As an example, one RG could be constructed from a few, small,

Product Overview 39

Page 40

high-performance disks, and the other RG from large, slower, highcapacity disks.

The VA 7100 and VA 7400/7410 differ in their implementation of

redundancy groups.

VA 7100/7110 Redundancy Group

The VA 7100 and VA 7110 each have one redundancy group (RG1). See

Figure 13 and Figure 14. All the disks in the array belong to RG1. LUNs

created from RG1 are available through both controllers (in a dual controller

configuration).

There are two internal fibre channel loops, one from each controller. The Fibre

channel disks are dual ported; each fibre channel port is connected to a

different controller. The controllers are connected via an internal highperformance bus, which allows the LUNs to be accessed through both

controllers, and for loop or disk failover communication.

Figure 13 VA 7100 Redundancy Group

Host

Controller 1

RG1

D1

RG1

N-Way Bus

...

D2

RG1

D15

RG1

Host

Controller 2

RG1

40 Product Overview

Page 41

Figure 14 VA 7110 Redundancy Group

Product Overview

Host

Controller 1

Disk

L

C

C

1

RG1

RG1

D1

RG1

D1

N-Way Bus

D2

RG1

...

D2

RG1

...

RG1

D15

RG1

D15

Host

Controller 2

RG1

Disk

L

C

C

2

L

C

C

1

D1

RG1

RG1

D2

...

D15

RG1

L

C

C

2

Product Overview 41

Page 42

VA 7400/7410 Redundancy Groups

The VA 7400 and VA 7410 have two redundancy groups (RG1 and RG2). See

Figure 15 and Figure 16.

■ Controller 1 manages Redundancy Group 1 (RG1), which consists of all

disks in odd numbered slots (D1, D3, D5, D7, D9, D11, D13, D15) in the

controller enclosure, and in all disk enclosures (JA0-JA5).

■ Controller 2 manages Redundancy Group 2 (RG2), which consists of all

disks in even numbered slots (D2, D4, D6, D8, D10, D12, D14) in the

controller enclosure, and in all disk enclosures (JA0-JA5).

On the VA 7410, Redundancy Group are independent of both back-end FC

loops. Management of the redundancy group disks is independent of which

disk enclosure LCC the array controller is connected to. For example, array

controller 1 can be connected to LCC 1 or LCC 2 and it will still manage the

disks in the odd numbered slots.

The array controllers are connected via an internal N-Way bus, which used for

controller-to-controller communication and loop failover.

42 Product Overview

Page 43

Figure 15 VA 7400 Redundancy Groups

Product Overview

Host

Controller 1

Disk

L

C

C

1

RG1

RG1

D1

RG1

D1

N-Way Bus

D2

RG2

...

D2

RG2

...

RG1

D15

RG1

D15

Host

Controller 2

RG2

Disk

L

C

C

2

L

C

C

1

D1

RG1

D2

RG2

...

D15

RG1

L

C

C

2

. . .

L

C

C

1

D1

RG1

D2

RG2

...

D15

RG1

L

C

C

2

Product Overview 43

Page 44

Figure 16 VA 7410 Redundancy Groups

D1

N-Way Bus

RG2

L

C

C

2

D2

...

L

C

C

1

D15

RG1

D1

RG1

Host 2Host 1

Controller 2

RG2

Disk 1 Disk 2

...

D2

RG2

D15

RG1

L

C

C

2

Host 2Host 1

Controller 1

RG1

Disk 1 Disk 2

L

C

C

1

D1

RG1

D2

RG2

...

RG1

D15

RG1

L

C

C

1

D1

RG1

D2

RG2

FC Loop 1 Disk Enclosures FC Loop 2 Disk Enclosures

44 Product Overview

...

D15

RG1

L

C

C

2

L

C

C

1

D1

RG1

D2

RG2

...

D15

RG1

L

C

C

2

Page 45

Performance Path

The performance path is the most direct path from the host to the data in the

array. It is specified by two separate device files that direct the data either

through Controller 1 or through Controller 2. The performance path is always

the faster path in terms of data transfer rate.

Because the array has two active controllers, the host will typically have two

paths to data, as shown in Figure 17.

■ The primary path is through the controller which owns the LUN being

accessed. That is, the controller that manages the RG the LUN belongs to.

On the VA 7400 and 7410 each LUN is assigned to RG1 or RG2,

managed by controller 1 and controller 2 respectively. When accessing

data on a LUN, the host should send I/Os to the controller which owns the

LUN.

■ The secondary path is through the controller which does not own the LUN

being accessed. In this situation, the non-owning controller must use the

internal N-Way bus to send the I/O to the controller that owns the LUN.

Whenever the secondary path is used, I/O performance is impacted due

to the inter-controller communication required.

System and SAN configuration with the knowledge of the performance path is

a technique to maximize the array performance. For normal workloads this

provides very little performance improvements, but for benchmarking and

highly utilized arrays, this can provide modest performance gains. The biggest

gains can be found with the VA 7100/7400, improvements with the

VA 7110/7410 have reduced the performance gained through performance

path management.

Product Overview

The use of load balancing software in normal workloads, such as HP AutoPath,

can, in many cases, offset any gains in performance by managing the

configuration of the performance path.

VA 7100/7110 Performance Path

In the VA 7100, the performance path is always specified by the device file for

Controller 1. Because the VA 7100 has only one redundancy group, and the

secondary controller is recommended only for failover, the primary controller

is always the most direct path to the data. If Controller 1 fails, the host should

use the secondary path to Controller 2.

Product Overview 45

Page 46

VA 7400/7410 Performance Path

The following example illustrates how the performance path is used in a

VA 7400/7410:

Assume LUN 4 is part of Redundancy Group 2 under Controller 2. An HP-UX

host has two device files that have two separate paths to LUN 4: The primary

device file that addresses Controller 2, and the secondary device file that

addresses Controller 1. The performance path uses the primary device file,

because Controller 2 owns LUN 2. The non-performance path uses the

secondary device file. If the secondary device file is used, data flows through

Controller 1, across the N-way bus to Controller 2, and then to LUN 2 and its

associated disk drives.

Figure 17 Data Paths on the VA 7400/7410

VA 7400/7410

Controller 1

m

i

a

r

P

Secondary path

h

p

t

y

a

r

LUN 4 on

RG 1

46 Product Overview

Host

Controller 2

Page 47

RAID Levels

Redundant Array of Inexpensive Disks (RAID) technology uses different

industry-standard techniques for storing data and maintaining data

redundancy. These techniques, called “RAID levels”, define the method used

for distributing data on the disks in a logical unit (LUN). LUNs that use different

RAID levels can be created in the same array.

The virtual array can be operated in RAID 1+0 level or AutoRAID level, which

is a combination of RAID 1+0 and RAID 5DP. The RAID level selected is

influenced by factors such as capacity demands and performance

requirements. Once a RAID level is selected, it is used for the entire array.

Changing the RAID Level of the Array

The RAID level for the array is established during installation. It is possible to

change the RAID level after installation. The steps involved in changing the

RAID level depend on which mode you are changing to.

■ Changing from RAID 1+0 to AutoRAID. The RAID level can be changed

from RAID 1+0 to AutoRAID on-line. However, it is recommended that you

backup all data on the array before changing the RAID level.

■ Changing from AutoRAID to RAID 1+0. The RAID level cannot be

changed from AutoRAID to RAID 1+0 on-line. This change requires a

complete reformat of the entire array, which will destroy all data on the

array. Before changing from AutoRAID to RAID 1+0, backup all data on

the array for restoration after the format and RAID change are complete.

Product Overview

RAID 1+0

RAID 1+0 provides data redundancy and good performance. However, the

performance is achieved by using a less efficient technique of storing

redundant data called “mirroring”. Mirroring maintains two copies of the data

on separate disks. Therefore, half of the disk space is consumed by redundant

data — the “mirror”. RAID 1+0 also stripes the mirrored data segments across

all the disks in a RAID Group. A read can use either copy of the data; a write

operation must update both copies of the data.

Figure 18 is an example showing the distribution of the two copies of data in a

RAID 1+0 configuration. This example shows one RAID Group with 10 data

segments, each data segment has an associated mirror segment. After a

single disk failure, the copy of a segment is always is available on another disk

— this disk(s) is referred to as the “adjacent disk(s)”. The array will continue

operation without data loss in the event of any non-adjacent disk failure.

Product Overview 47

Page 48

Upon completion of the rebuild of a failed disk, the array is once again

protected against any single disk failure.

Note RAID groups with an even number of disks will always have a

single adjacent disk after a disk failure, and RAID groups with

an odd number of disks will always have two adjacent disks

after a disks failure.

The segment size for a Virtual Array is always 256 Kbytes.

The Virtual Array technology and RAID 1+0 stripes distribute data to all the

disks in an RG, thus effectively eliminating ‘hot spots’ — disks that are

accessed so frequently that they impede the performance of the array.

Figure 18 RAID 1+0 Data Storage Example

RAID 5DP

RAID 5DP provides data redundancy and improves cost-efficiency by using a

more efficient method of storing the redundancy data. Although virtual array

technology attempts to minimize any performance impact, there can be a

performance penalty associated with write operations. This can impact system

performance when using applications that frequently update large quantities of

data (greater than 10% of a fully allocated array), or performs predominantly

small (<256 Kbytes) random write operations.

RAID 5DP uses two algorithms to create two independent sets of redundancy

data. This allows the array to reconstruct RAID 5DP data in the event of two

48 Product Overview

Page 49

simultaneous disk failures. The two redundancy segments are referred to as

“P” and “Q” parity. P, like traditional RAID 5 arrays, uses an XOR (parity)

algorithm. P parity is based on Reed-Solomon ECC technology, similar to

error detection and correction found in ECC DRAM.

Application data, and the P and Q parity data, rotate to different disks for

each stripe in a RAID Group. Like RAID 1+0, this effectively eliminates hot

spots.

A read operation only requires a single access to the disk(s) containing the

data, a small (<256 Kbytes) write operation requires that the data, and the P

and Q parity data be updated – this is the source of the small random write

performance impact. For larger (>256 Kbytes) write operations, the Virtual

Array implements a log-structured RAID 5DP write. Log-structured writes

effectively eliminate the read-modify-write associated with small block writes to

RAID 5DP by redirected the write operation to a new RAID 5DP stripe. The P

and Q parity data is held in non-volatile write cache until the whole stripe is

written, then the P and Q are written. Thus the P and the Q are written only

once for each stripe.

Note Until a rebuild is complete, the array is operating in a degraded

mode. In degraded mode, the array will use P and/or Q parity

to reconstruct data that resided on the failed disk.

Product Overview

Figure 19 is an example showing the distribution of user data and parity data

in a RAID 5DP configuration. The example shows one RAID group with five

stripes: three data segments and two parity segments (P and Q). The

segments are striped across the disks in a rotating fashion. Note that any two

disks can fail, but the data, P, or the Q parity is always available to complete a

read operation.

Product Overview 49

Page 50

Figure 19 RAID 5DP Data Storage Example

Data Availability and AutoRAID

When configured in the AutoRAID mode, the Virtual Array uses a combination

of RAID 1+0 and RAID 5DP. As a result, the disks within a single RG can have

a portion of its data capacity used as RAID 1+0, while the other portion is

used as RAID 5DP.

50 Product Overview

During disk failures, rebuild is directed to rebuild the most statistically

vulnerable data first. After the first disk failure in an RG, the rebuild process

prioritizes RAID 1+0 data first. If a second disk fails before the rebuild

completes, then RAID 5DP is prioritized first. This logic represents the statistical

availability model for the two failure states. Once the RAID 1+0 data has

been rebuilt, the RAID group is protected against any two simultaneous disk

failures. The status of a RAID 1+0 data rebuild can be displayed using

Command View.

AutoRAID and Dynamic Data Migration

Unlike conventional disk array, the virtual array has the option to self manage

the RAID level selection based on the workload characteristics. In this mode,

the array controller attempts to place data in the RAID level that provides the

best performance based on how the host accesses that data. This RAID level

selection is both automatic and dynamic. Dynamic Data Migration is a

background operation, and gives priority to host operations. It is possible that

Page 51

continuous high demand from the host will preempt all data migration

activities.

AutoRAID manages the data placement to the individual 256 K-block. Each

LUN is divided into 256 K-blocks call clusters. A cluster can be stored in either

RAID 1+0 or RAID 5DP format. The virtualization data structures manage the

translation of the logical address (LUN) and the physical location.

The controller is programmed to manage cluster placement. It uses well-known

logic, or rules, about RAID level performance characteristics and storage

efficiency. This logic directs data that is frequently modified by small

transactions to RAID 1+0 storage. Data that is infrequently written, or data

that is written sequentially, is directed to RAID 5DP storage.

The behavior is similar to other hierarchical memory systems, such as data

caches or Hierarchical Storage Mangers. AutoRAID, like these other systems,

provide the performance approaching the highest level of the memory

hierarchy, at the cost of the lowest level in the hierarchy.

The controller provides information about data placement and data migration

through the Command View performance log. These logs provide details

about the storage level for each LUN, and any active migration the array has

performed.

Product Overview

End-to-End Data Protection

End-to-end data protection is a process within the array controller to validate

the integrity of the data stored on the array. This process is in addition to the

normal data checking provided by the disk drives. During a write operation,

as data enters the array controller from the host, the controller appends 8 bytes

of additional information to each 512-sector. This additional information

includes both a checksum and the logical address of the data. To

accommodate this additional information, the disks have been reformatted to

520-byte sectors.

During a read operation, as the data is returned to the host, the check

information is verified for correctness. An error in the check information will

cause the controller to recover the data using the RAID redundancy

information. If the recovery is unsuccessful, the transaction is marked

unrecoverable, and the array continues to process other host request.

Product Overview 51

Page 52

Data I/O Architecture

The internal architecture of the array controllers is designed to optimize the

speed of data transfer between the array and the host. The internal

architecture for each product is illustrated in Figures 20, 22, and 23.

The following major components are involved in the flow of data through the

array:

■ Data flow processor - manages movement of data over the internal high-

speed busses. The processor also manages the flow of data into and out of

the ECC cache.

■ ECC cache - provides temporary storage of data for high-speed access.

■ High-speed busses - provide the data path from the host to the disk media.

The N-Way bus provides the communication link between controllers for

management and redundancy.

■ FC ports - provide the interface to the host and the back-end disk

enclosures. The VA 7410 includes additional FC ports for added flexibility

and performance.

52 Product Overview

Page 53

Figure 20 VA 7100 I/O Architecture

VA 7100 Controller 1

Product Overview

Host FC Port 1

(H1)

Mirrored

ECC Cache

Battery

Mirrored

ECC Cache

Battery

800MB/s

N-WAY Bus

800MB/s

528 MB/s

Data Flow

Processor

Motorola 8240

PowerPC

800MB/s

Data Flow

Processor

Motorola 8240

PowerPC

Internal

Disks

Host FC Port 1

(H1)

VA 7100 Controller 2

528 MB/s

Product Overview 53

Page 54

Figure 21 VA 7110 I/O Architecture

54 Product Overview

Page 55

Figure 22 VA 7400 I/O Architecture

VA 7400 Controller 1

Product Overview

Host FC Port 1

(H1)

Mirrored

ECC Cache

Battery

Mirrored

ECC Cache

Battery

800MB/s

N-WAY Bus

800MB/s

528 MB/s

Data Flow

Processor

Motorola 8240

PowerPC

800MB/s

Data Flow

Processor

Motorola 8240

PowerPC

Disk FC Port 1

(J1)

External

Disks

1234567 9101112131415

1234567 9101112131415

Internal

Disks

Host FC Port 1

(H1)

VA 7400 Controller 2

528 MB/s

Disk FC Port 1

(J1)

Product Overview 55

Page 56

Figure 23 VA 7410 I/O Architecture

V A 7 4 1 0 C o ntro lle r 1

Host FC Port 1

(H 1)

Host FC Port 2

(H 2)

M irro red

ECC Cache

Battery

M irro red

ECC Cache

Battery

800MB/s

N-WAY Bus

800MB/s

528 MB/s

D a ta F lo w

Processor

IB M 44 0

800MB/s

D a ta F lo w

Processor

IB M 44 0

Disk FC Port 2

(J2)

Disk FC Port 1

(J1)

Internal

Disks

External

Loop 1

Disks

1234567 9101112131415

1234567 9101112131415

External

Loop 2

Disks

1234567 9101112131415

1234567 9101112131415

Host FC Port 1

(H 1)

Host FC Port 2

(H 2)

V A 7 4 1 0 C o ntro lle r 2

56 Product Overview

Disk FC Port 1

(J1)

528 MB/s

Disk FC Port 2

(J2)

Page 57

Operating Tips

The following information will help you understand some of the operating

features of the array and may help you manage the array efficiently.

Automatic Hot Spare Setting Behavior

The following behavior only occurs on a VA 7400/7410 operating in

AutoRAID mode, and with the hot spare mode set to Automatic. To avoid this

behavior, you may want to set the hot spare mode to a setting other than

Automatic.

The Automatic hot spare setting exhibits some unique behavior that you should

be aware of. If there are 15 or fewer disks in a redundancy group (RG), the

automatic hot spare setting reserves enough capacity to rebuild the largest disk

in the RG. When the number of disks increases to 16 or more, the array

increases the amount of capacity reserved to rebuild the two largest disks in

the array. This feature can result in the following behaviors:

■ When the 16

be used to meet the increased hot spare capacity requirements. As a result,

you will not see any increase in the amount of capacity available on the

array.

■ If the 16

provide enough capacity to create the required hot spare capability. For

example, if most of the disks in the RG are 73 GB, the array will need 146

GB of capacity for hot sparing (2 X 73). If the 16

necessary capacity may not be available. In this case, a Capacity

Depletion error and a Hot Spare Unavailable error may occur.

th

disk is added to an RG, the entire capacity of the disk will

th

disk is of lower capacity than other disks in the RG, it may not

th

disk is a 36 GB disk, the

Product Overview

■ If a failed disk is replaced with a disk of lower capacity, there may no

longer be enough capacity to meet the hot spare requirements. This

situation will generate a Capacity Depletion warning, indicating that there

is not enough hot spare capacity. For example replacing a failed 73 GB

disk with a 36 GB disk may cause this problem. To avoid this situation,

always replace a failed disk with a disk of the same capacity.

Install an Even Number of Disks in Each Redundancy Group

A slight increase in data availability can be achieved by managing the

number of disks in each redundancy group. Because of the manner in which

disk arrays stripe data in RAID 1+0, an even number of disks will reduce the

Product Overview 57

Page 58

possibility of data loss in the event of multiple disk failures. Although the

statistical advantage of this minimal but measurable, HP advises when ever

possible to keep an even number of disks in each redundancy group.

For optimum availability, it is recommended that you have an even number of

disks in each redundancy group. Because of the manner in which the array

stores data, an even number of disks reduces the possibility of data loss in the

event of multiple disk failures. Although the possibility of this is extremely low,

using an even number of disk reduces the risk even further.

Auto Rebuild Behavior

(Firmware version HP14 and greater)

When a disk fails and Auto Rebuild is enabled, the array always attempts to

rebuild the data on the failed disk. This will occur even if the array may not

have enough capacity to complete the rebuild. For example, if hot sparing has

been disabled, there may not be enough capacity available to complete a

rebuild.

The array first makes an attempt to rebuild any data that was stored in

RAID1+0. This data is more vulnerable to another disk failure than data stored

in RAID 5DP. The array will continue to perform the rebuild until there is no

longer any capacity available to continue. This situation may result in

diminished performance when new data is written to the array in this

condition. The performance impact increases with the number of disks in the

redundancy group.

58 Product Overview

To avoid this situation, it is recommended that in configurations with 15 or

more disks per redundancy group, that Auto Rebuild is disabled whenever hot

spare is disabled.

Page 59

System Configurations

2

This chapter illustrates some of the typical system configurations which can be

built using the VA arrays.

Note These are representative configurations. For more detailed

information on VA array system configurations, contact your HP

Sales Representative.

Lowest Entry Point, Non-HA Minimum Configuration (VA 7100 only)

Single HBA (two hosts)

Dual controller

No Multi-Path driver required

No hub or switch required

Windows/HP-UX/Linux supported

Command View SDM required

System Configurations 59

Page 60

Lowest Entry Point, Non-HA Minimum Configuration (VA 7410)

Single HBA per host

Dual controllers

Windows 2000/HP-UX/Linux

Host

Host

Host

Host

supported

Command View SDM required

required on one of the hosts

HBA

HBA

Controller 1

Array

HBA

Controller 2

HBA

Up to 4 host optional

60 System Configurations

Page 61

Entry Level Non-Cluster With Path Redundancy (All VA arrays)

Dual HBA

Requires multi-path driver with dual HBAs

Command View SDM required

System Configurations

System Configurations 61

Page 62

Entry Level Cluster with Path Redundancy High Availability (VA 7410)

Requires LUN Security support

Dual HBA

Two controllers setup with both

personalities

Requires multi-path driver with dual HBAs

Command View SDM required on one of

the hosts

62 System Configurations

Page 63

Midrange Non-Cluster (All VA arrays)

Dual controllers

Dual HBAs

Requires multi-path driver