Page 1

HP StorageWorks 70 Modular Smart Array

Enclosure

user guide

Part number: 434893–002

irst edition: February 2007

F

Page 2

Legal and notice information

© Copyright 2007 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products and services are set forth

in the express warranty statements accompanying such products and services. Nothing herein should be construed as constituting

an additional warranty. H P shall not be liable for technical or editorial errors or omissions contained herein.

Microsoft and Windows are U.S. registered trademarks of Microsoft Corporation.

Page 3

Contents

Aboutthisguide .......................... 7

Intendedaudience...................................... 7

Documentconventionsandsymbols .............................. 7

HPtechnicalsupport..................................... 8

Customerselfrepair ..................................... 8

Productwarranties...................................... 8

Subscriptionservice ..................................... 8

HPwebsites......................................... 8

Documentationfeedback ................................... 9

1Identifyingthecomponents..................... 11

Frontpanelcomponents ................................... 11

FrontpanelLEDs....................................... 11

Rearpanelcomponents................................... 12

RearpanelLEDsandbuttons ................................ 13

Harddrivebaynumbers .................................. 14

HarddriveLEDs...................................... 14

HarddriveLEDcombinations ................................ 14

7-segmentdisplayboard .................................. 15

2Poweringupandpoweringdowntheenclosure ............ 17

Poweringup ....................................... 17

Poweringdown ...................................... 17

3Settinguptheenclosure ..................... 19

Environmentalrequirements ................................. 19

Space and airflowrequirements ............................. 19

Rackplanningresources ................................ 20

Temperaturerequirements................................ 20

Powerrequirements .................................. 20

Electricalgroundingrequirements ............................ 21

Rackwarnings ...................................... 21

Shippingcontents ..................................... 21

Rackmountinghardwarekitcontents............................. 22

Convertingrailsforround-holeracks ............................. 22

Installingtheenclosureintotherack ............................. 23

Installinghardwareoptions ................................. 24

Installingservers...................................... 24

Choosing a configuration.................................. 24

Single-enclosure configuration.............................. 25

Cascading (1+1) configuration.............................. 25

Cablingtheenclosure ................................... 26

SAScablingguidelines................................. 26

Supportedcables ................................... 26

Powercords...................................... 26

Updating firmware..................................... 27

4 Installing hard drives ....................... 29

user guide

3

Page 4

Harddriveoptions..................................... 29

Harddriveguidelines ................................. 29

Installingaharddrive ................................. 29

5Configuringtheenclosure ..................... 31

Configurationtools..................................... 31

Array ConfigurationUtility ............................... 31

Option ROM ConfigurationforArrays .......................... 31

SmartComponentsforROMFlash ............................ 31

Managementtools..................................... 32

HPSystemsInsightManager .............................. 32

ManagementAgents.................................. 32

Diagnostictools...................................... 32

IntegratedManagementLog............................... 32

ArrayDiagnosticUtility................................. 33

Remotesupportandanalysistools .............................. 33

OpenServicesEventManager.............................. 33

Keepingthesystemcurrent ................................. 33

Change control and proactive notification......................... 33

Naturallanguagesearchassistant ............................ 33

CarePack ...................................... 33

6 Troubleshooting . . ....................... 35

Whentheenclosuredoesnotstart .............................. 35

Diagnosticsteps...................................... 35

Arethepowersupply/fanmoduleLEDsgreen? ...................... 35

IsthesystempowerLEDgreen? ............................. 36

Recognizingharddrivefailure................................ 36

Effectsofaharddrivefailure .............................. 36

Compromisedfaulttolerance .............................. 37

Recoveringfromcompromisedfaulttolerance ....................... 37

Factorstoconsiderbeforereplacingharddrives ........................ 37

Automaticdatarecovery(rebuild) .............................. 38

Timerequiredforarebuild ............................... 38

Failureofanotherdriveduringrebuild .......................... 38

DrivefailureinaNetWareenvironment............................ 39

Faileddrivesorinterimrecoverymode .......................... 39

Handlingharddrivefailures............................... 39

ARegulatorycompliancenotices ................... 41

Regulatory compliance identificationnumbers ......................... 41

FederalCommunicationsCommissionnotice.......................... 41

FCCratinglabel.................................... 41

ClassAequipment................................... 41

ClassBequipment................................... 41

Declaration of conformity for products marked with the FCC logo, United States only . . . . . . . . . 42

Modifications....................................... 42

Cables.......................................... 42

Canadiannotice(AvisCanadien) .............................. 42

EuropeanUnionregulatorynotice .............................. 42

DisposalofwasteequipmentbyusersinprivatehouseholdsintheEuropeanUnion ......... 44

Japanesenotice...................................... 44

BSMInotice........................................ 44

Koreannotice....................................... 44

PowercordstatementforJapan ............................... 45

B Electrostatic discharge ...................... 47

4

Page 5

Preventingelectrostaticdischarge............................... 47

Groundingmethodstopreventelectrostaticdischarge...................... 47

CSpecifications ......................... 49

Environmental specifications................................. 49

Storage enclosure specifications ............................... 49

AcronymsandAbbreviations ..................... 51

Index .............................. 53

user guide

5

Page 6

Tables

1 ..Documentconventions............................... 7

2

..LEDFailure/FaultAlerts ............................. 15

6

Page 7

About this guide

This guide provides information about the HP StorageWorks 70 Modular Smart Array Enclosure.

Intended audi

This guide is intended for use by system administrators and technicians who are experienced with the

following:

• SAN management

• Network admin

• Network installation

ence

istration

Document conventions and symbols

Table 1 Document conventions

Convention

Blue text: Table 1

Blue, underlined text: http://www.hp.com

Bold text

Italic text Text emphasis

Monospa

Monospace, italic text

Monospace, bold text

ce text

Element

Cross-reference links and e-mail addresses

website add

• Keys that are pressed

• Text typed into a GUI element, such as a box

• GUI elements that are clicked or selected, such as

menu and list items, buttons, tabs, and check boxes

• File and

• System

• Code

• Comma

• Code variables

• Command variables

Emphasized monospace text

resses

directory names

output

nds, their arguments, and argument values

WARNIN G!

Indicates that failure to follow directions could result in bodily harm or death.

CAUTION:

Indicates that failure to follow directions could result in damage to equipment or data.

RTANT:

IMPO

ides clarifying information or specific instructions.

Prov

user guide

7

Page 8

NOTE:

Provides additional information.

TIP:

Provides helpful hints and shortcuts.

HP technical support

For worldwide technical support information, see the HP support website: http://www.hp.com/support.

Before contacting HP, collect the following information:

• Product model names and numbers

• Technical support registration number (if applicable)

• Product serial numbers

• Error messages

• Operating system type and revision level

• Detailed questions

Customer self repair

HP customer self repair (CSR) programs allow you to repair your StorageWorks product. If a CSR part

needs replac

parts do not

accomplished by CSR.

For more information about CSR, contact your local service provider. For North America, see the CSR

website: h

ing, HP ships the part directly to you so that you can install it at your convenience. Some

qualify for CSR. Your HP-authorized service provider will determine whether a repair can be

tp://www.hp.com/go/selfrepair.

t

Product warranties

For information about HP StorageWorks product warranties, see the warranty information website:

h

ttp://www.hp.com/go/storagewarranty.

Subscript

ion service

HP recomme

h

ttp://w

After reg

firmware u

ww.hp.com/go/e-updates.

istering, you will receive e-mail notification of product enhancements, new driver versions,

pdates, and other product resources.

nds that you register your product at the Subscriber’s Choice for Business website:

HP websites

For additional information, see the following HP websites:

ttp://www.hp.com

•h

•http://www.hp.com/go/storage

•http://www.hp.com/service_locator

•http://www.hp.com/support/manuals

•http://www.hp.com/support/downloads

8

About this guide

Page 9

Documentation feedback

HP welcomes your

To make comments and suggestions about product documentation, please send a message to

storagedocs.feedback@hp.com. All submissions become the property of HP.

feedback.

user guide

9

Page 10

10

About this guide

Page 11

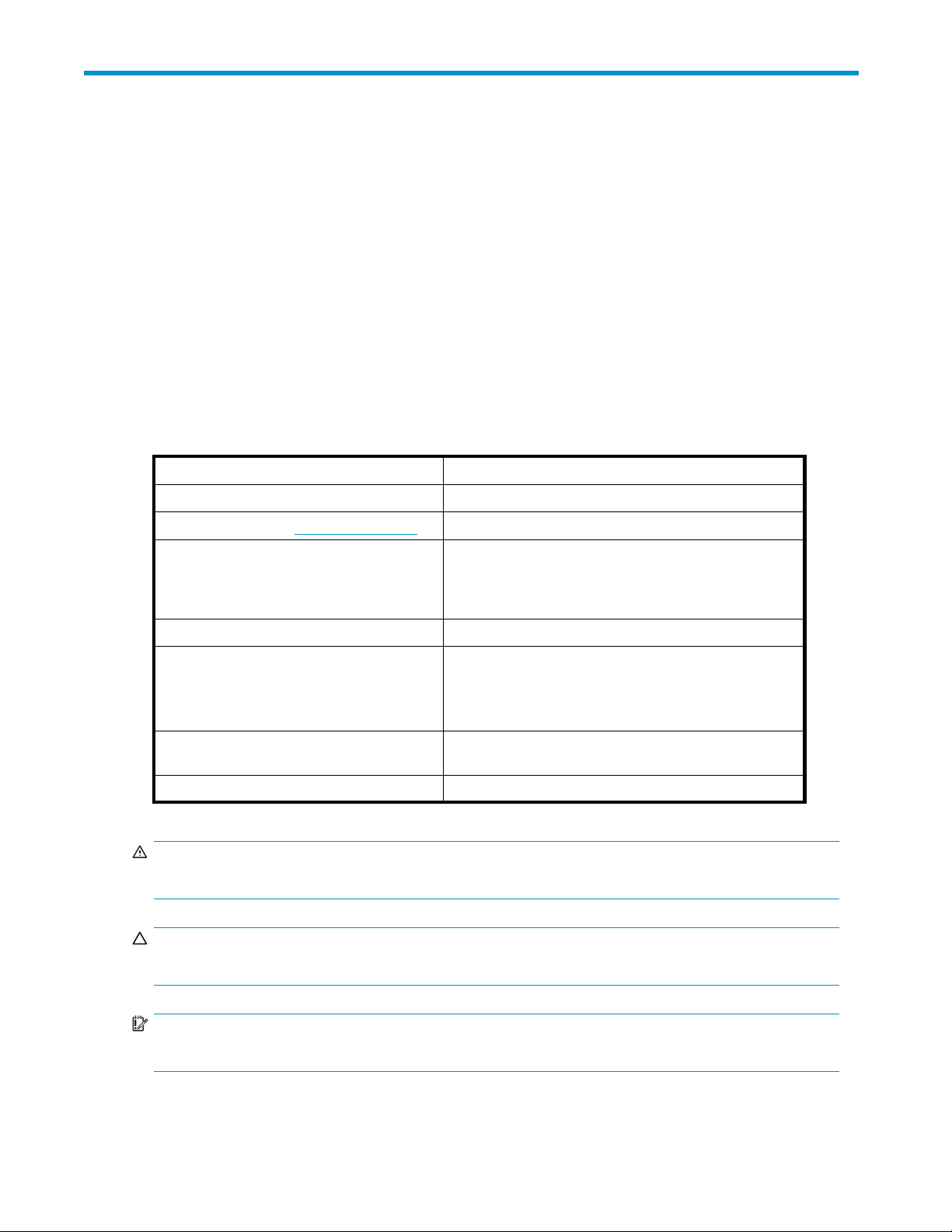

1 Identifying the components

Front panel components

Item

1

2

Description

Hard drive b

FrontunitID(UID)module

Front panel LEDs

1

ays

2

15486

Item

1

2

3

iption

Descr

Heartbeat LED

Fault LED Amber = Fault condition

tton/LED

UID bu

s

Statu

Green = System activity

Off=Nosystemactivity

Off=Nofaultcondition

Identified

Blue =

ashing = Active remote management

Blue fl

Off = No active remote management

15460

user guide

11

Page 12

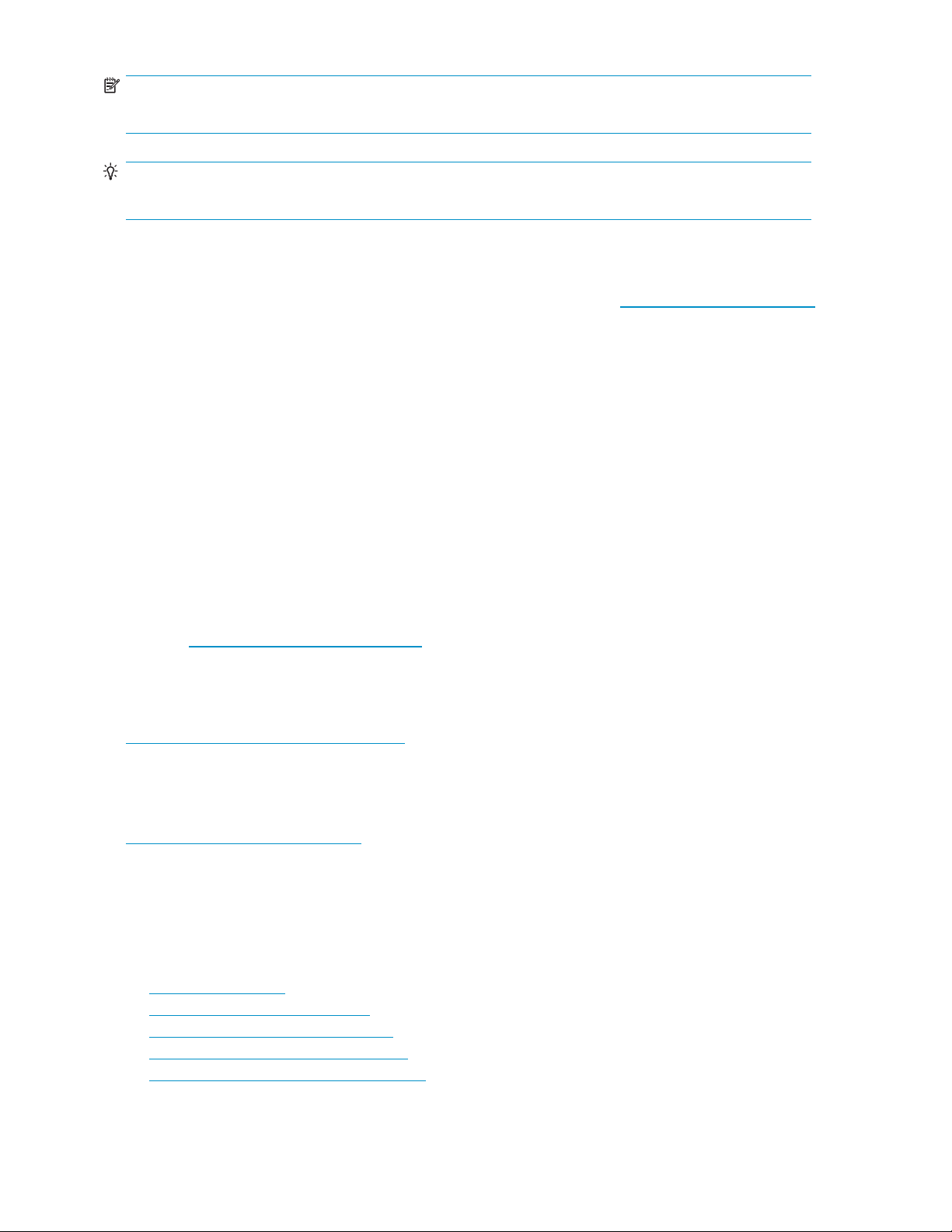

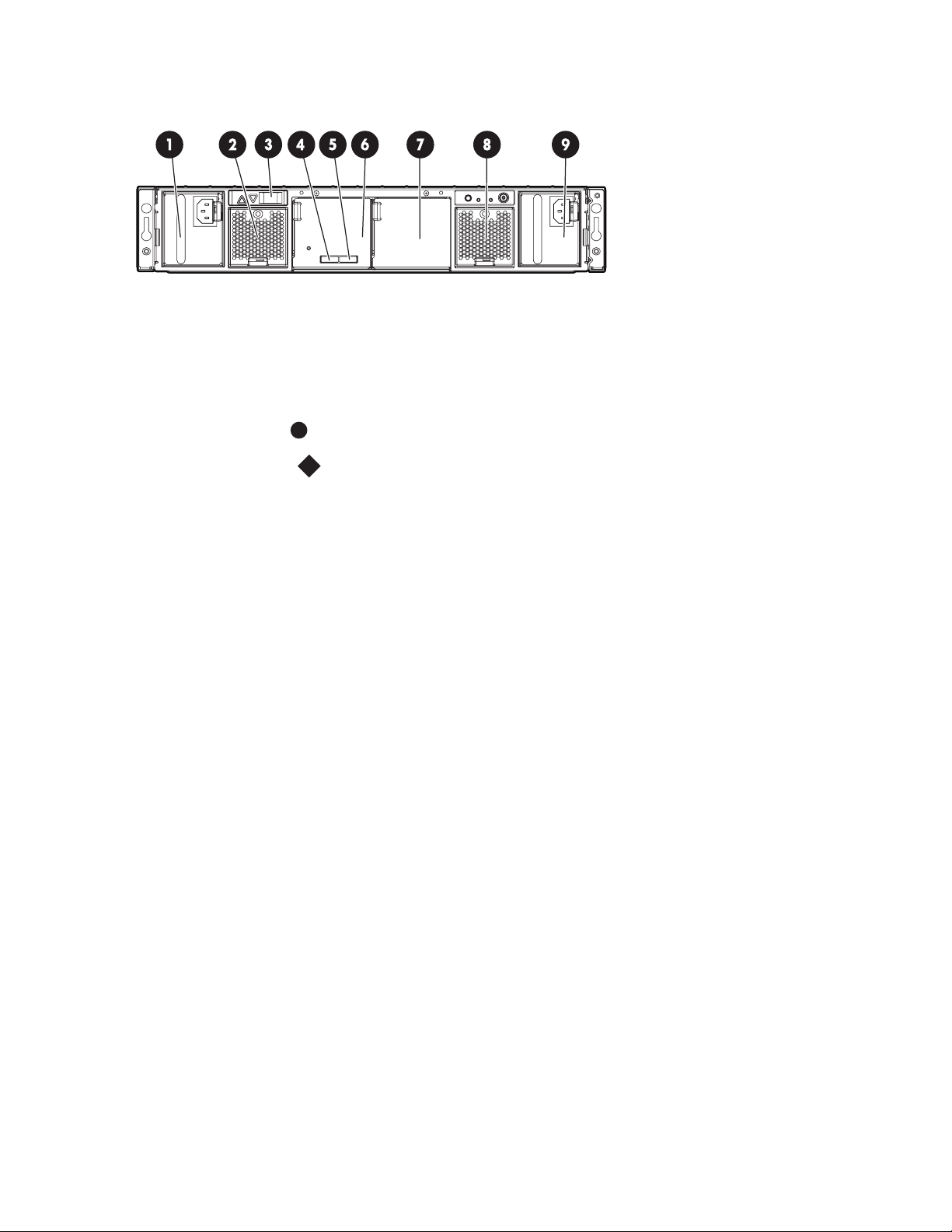

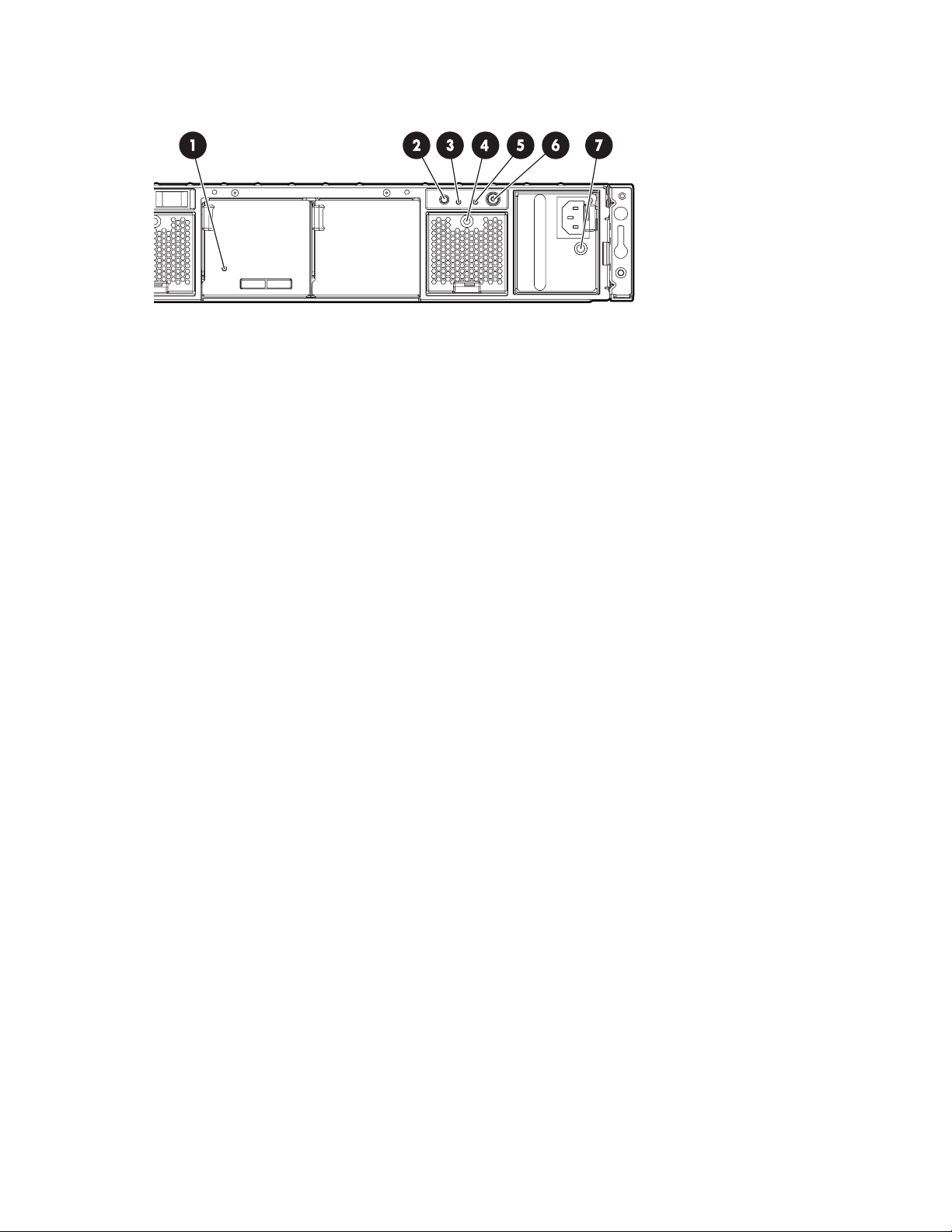

Rear panel comp

onents

15461

Item

1

2

3

4

5

6

7Futureuse

8

9

Description

Power supply 1

Fan module 1

7-segment display board

SAS in connector

SAS out connector

I/O module

Fan module 2

Power supp

ly 2

12

Identifying the components

Page 13

Rear panel LEDs

and buttons

15462

Item

1

2

3

4

5

6

7

Description Status

I/O module LED

UID button/LED Blue = Identified

Heartbeat LED

Fan module LED Green = Normal operation

System faul

Power On/Standby

button/system power

LED

Power supply LED

tLED

Green = System activity

Amber = Fault

Off=Nosystemactivity

Blue flashing = Active remote ma nagement

Off=Noacti

Green = System activity

Amber = Fault

Off=Nosystemactivity

Amber = Fault condition

Off=Fanunseatedformconnectororfailed

Amber = Fault condition

Off=Nofaultcondition

Green = On

Amber = Standby (power present)

Off=Off

Green = Power turned on and power supply functioning properly

Amber = Standby (auxiliary power present)

Blinking amber = Power to this power supply not present

Off = One or more of the following conditions exists:

• A/C power unavailable

• Power supply failed

• Power supply exceeded current limit

ve remote management

user guide

13

Page 14

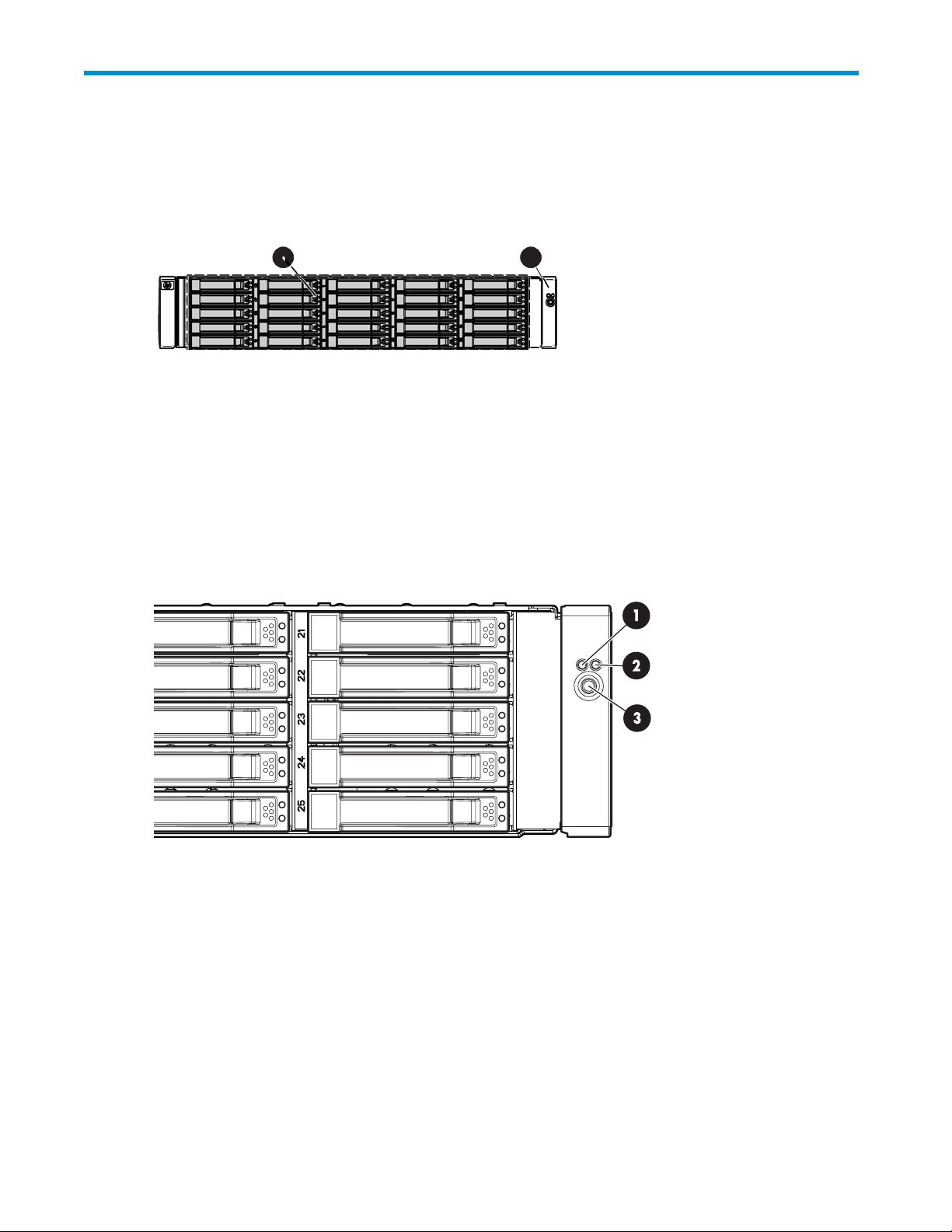

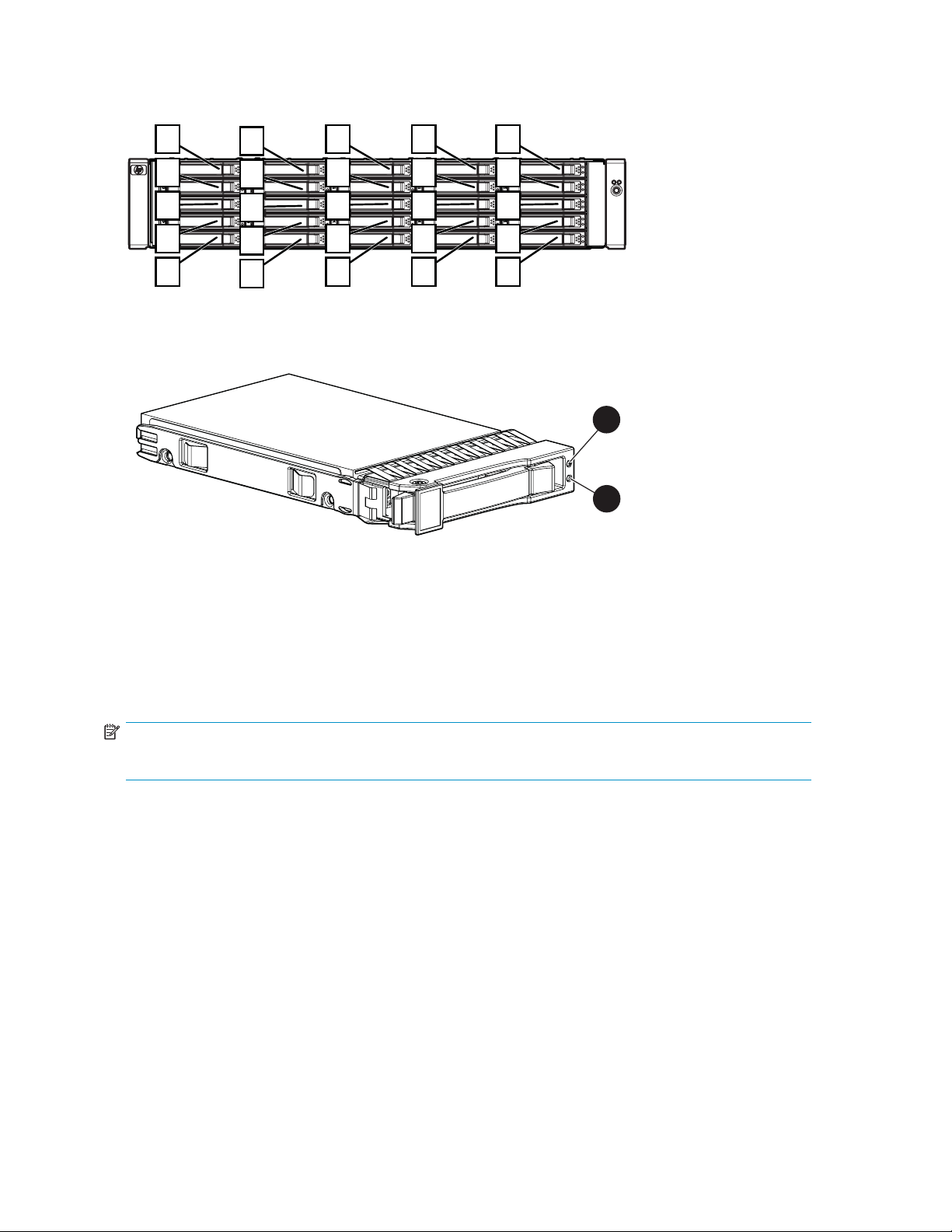

Hard drive bay n

umbers

1

2

3

4

5

Hard drive LEDs

Item

1

2

Description

Fault/UID LED (amber/blue)

Online/activity LED (green)

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

15463

1

2

15464

Hard dri

NOTE:

Predictive failure alerts can occur only when the enclosure is connected to a Smart Array controller.

ve LED combinations

14

Identifying the components

Page 15

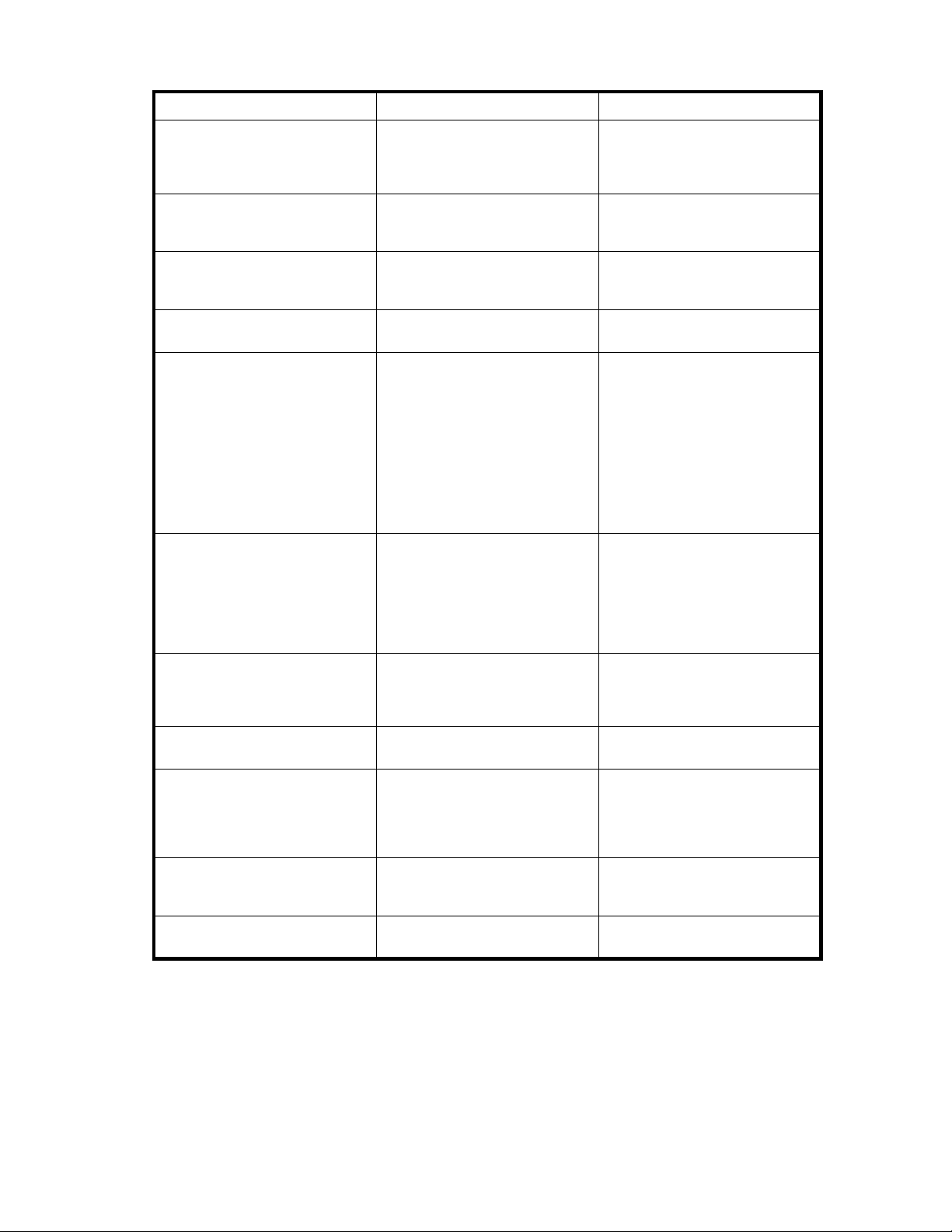

Table 2 LED Failure/Fault Alerts

Online/activity LED (green) Fault/UID LED (amber/blue)

On,off,orflashing

On,off,orflashing

On

On

Flashing regularly (1 Hz)

Flashing regularly (1 Hz)

Alternating amber and blue

Steadily blue The drive is operating normally,

er, flashing regularly (1 Hz)

Amb

Off

Amber, flashing regularly (1 Hz)

Off

Interpretation

The drive has failed, or a predictive

failure alert has been received for

this drive; it also has been selected

by a management application.

and it has been selected by a

management application.

edictive failure alert has been

Apr

ceived for this drive. Replace the

re

ive as soon as possible.

dr

The drive is online, but it is not

currently active.

Do not remove the drive. Removing

a drive may terminate the current

operation and cause data loss.

The drive is part of an array that

is undergoing capacity expansion

orastripesizemigration,buta

predictive failure alert has been

received for this drive. To minimize

the risk of data loss, do not replace

the drive until th e expansion or

migration is complete.

Do not remove the drive.

Removing a drive may terminate

the current operation and cause

data loss. The drive is rebuilding,

or it is part of an array that is

undergoing capacity expansion or

astripesizemigration.

Flashing irregularly

Flashing irregularly

Off

Off Amber, flashing regularly ( 1 Hz) A predictive failure alert has been

Off Off The drive is offline, a spare, or not

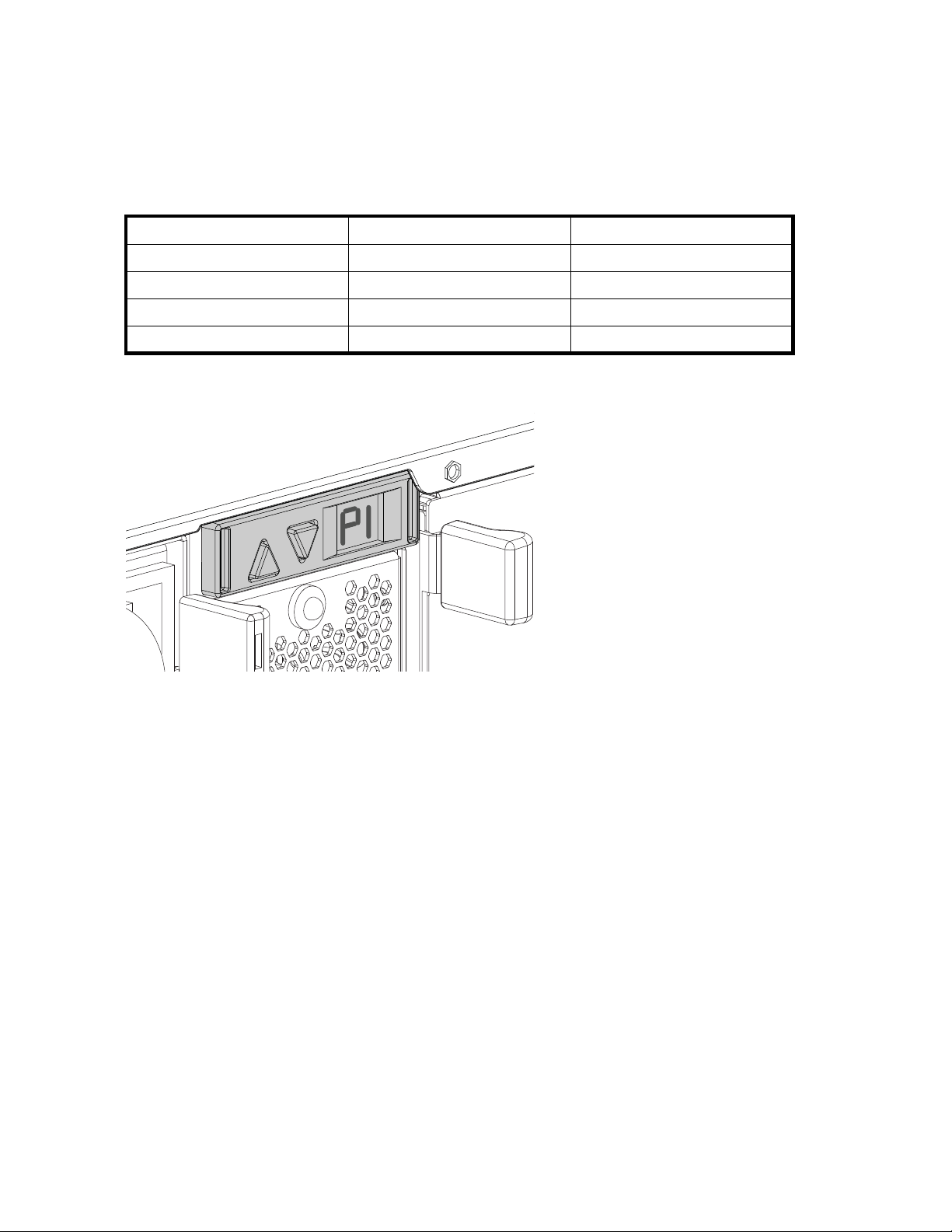

7-segment display board

The 7-segment display board allows you to identify the following:

• The port on the host controller to which the MSA70 is connected. There are two external ports on

the host controller; each port allows you to connect up to two MSA70s to the controller. Because

Amber, flashing regularly (1 Hz)

Off

Steadily amber

The drive is active, but a predictive

failure alert has been received for

this drive. Replace the drive as

soon as possible.

The drive is active, and it is

operating normally.

A critical fault condition has been

identified for this d rive, and the

controller has placed it offl ine.

Replace the drive as soon as

possible.

received for this drive. Replace the

drive as soon as possible.

configured as part of an array.

user guide

15

Page 16

one additional MSA70 can be attached to each of the MSA70s, a total of four MSA70s can be

connected to the host controller. See Cascading (1+1) configuration.

• The box ID number assigned to the MSA70 based on how it is connected to the host controller.

If there are multiple MSA70s attached to the controller, the box ID num ber identifies the order

in which they are attached.

When the MSA70 is connected to the host controller, the controller automatically assigns the port and

box ID numbers to the enclosure. The following table shows MSA70 enclosures and their associated

port and box ID assignments:

Storage Enclosure

MSA70 enclosure 1

MSA70 enclosure 2

MSA70 enclo

MSA70 enclosure 4

sure 3

Port Box ID

P1 B1

P1

P2 B3

P2

B2

B4

To view the port to which the MSA70 is connected, press the up arrow button on the 7-segment display

board. To view the box ID number, press the down button.

15487

You can also view the port and box ID numbers within Array Configuration Utility (ACU), HP Systems

Insight Manager (HP SIM), and Array Diagnostic Utility (ADU).

16

Identifying the components

Page 17

2 Powering up and powering down

the enclosure

IMPORTANT:

Before installing this product, read the

Powering up

Observe the following guidelines before p owering up the enclosure:

• Install all components of the enclosure.

• Install hard drives in the enclosure so the connected host controller can identify and configure

them at powerup.

• Always power up the enclosure first, and then the server. This ensures that the servers, during

their d iscovery, see the enclosure as an operational device. If you do not power up the enclosure

before powering up the servers, you will need to power down the servers, ensure that the

enclosure is powered up, and then power back up the servers.

To power up the enclosure:

1. Complete server hardware installation and cabling. See the server documentation.

2. Connect the SAS cables and power cords to the enclosure. See Choosing a configuration.

Important Safety Information

document provided.

3. Press and hold the Power On/Standby button. Wait and observe the system power LED and fan

modules. When the enclosure powers up, the system power LED illuminates solid green and the

fans spin to a high speed, and then spin down to a low speed.

4. Power up the servers. See the server documentation.

Powering down

CAUTION:

Be sure that the server is the first unit to be powered down and the last to be powered back up. Taking

this precaution ensures that the system does not erroneously mark the drives as failed when the server is

powered up.

IMPORTANT:

If installing a hot-plug device, it is not necessary to power down the enclosure.

To power down the enclosure:

1. Power down any attached servers. See the server documentation.

2. Press the Power On/Standby button on the enclosure. Wait for the system power LED to change

from green to amber.

3. Disconnect the power cords.

The system is now without power.

user guide

17

Page 18

18

Powering up and powering down the enclosure

Page 19

3 Setting up t he enclosure

Environmental requirements

When installing the enclosure in a rack, select a location that meets the environmental standards

described in this section.

Space and airflow requirements

To allow for s

when deciding where to install a rack:

• Leave minimum clearance of 63.5 cm (25 in) in front of the rack.

• Leave minim

• Leave minimum clearance of 121.9 cm (48 in) from the back of the rack to the back of another

rack or row of racks.

HP enclosur

Therefore,

enter the cabinet, and the rear door must be adequately ventilated to allow the warm air to escape

from the cabinet.

CAUTION:

To prevent

CAUTION:

When a vertical space in the rack is not filled by a server or rack component, the gaps bet ween the

components cause changes in airflow through the rack and across the servers. Always use blanking

panels to fill empty vertical spaces in the rack. This arrangement ensures proper airflow. Using a rack

without blanking panels results in improper cooling that can lead to thermal damage.

The 9000 and 10000 Series racks provide proper server cooling from flow-through perforations in the

front and rear doors that provide 64 percent open area for ventilation.

ervicing and adequate air flow, observe the following space and airflow requirements

um clearance of 76.2 cm (30 in) behind the rack.

es draw in cool air through the front door and expel warm air through the rear d oor.

the front and rear rack doors must be adequately ventilated to allow ambient room air to

improper cooling and damage to the equipm ent, do not block the ventilation openings.

CAUTION:

When using a Compaq-branded 7000 Series rack, you must install the high airflow rack door insert

[P/N 327281-B21 (42U) or P/N 157847-B21 (22U)] to provide proper front-to-back airflow and cooling.

CAUTION:

If a third-party rack is used, observe the following additional requirements to ensure ade quate airflow

and to prevent damage to the equipment:

• Front and rear doors—If the 42U rack includes closing front and rear doors, you must allow 5,350 sq

cm (830 sq in) of h oles evenly distributed from top to bottom to permit adequate air flow (equivalent

to the required 64 percent open area for ventilation).

• Side—Theclearancebetweentheinstalledrackcomponentandthesidepanelsoftherackmustbea

minimum of 7 cm (2.75 in).

user guide

19

Page 20

Rack planning r

The rack resource kit ships with all HP-branded or Compaq-branded 9000, 10000, and H9 Series racks.

For more information on the content of each resource, see the rack resource kit documentation.

If you intend to

deployment at

esources

deploy and configure multiple servers in a single rack, see the white paper on high-density

the HP website: h

Temperature requirements

To ensure continued safe and reliable equipment operation, install or position the enclosure in a

well-ventilated, climate-controlled environment.

The maximum recommended ambient operating temperature (TMRA) for most enclosure products is 35°C

(95°F). The temperature in the room where the rack is located must not exceed 35°C (95°F).

CAUTION:

To reduce the risk of damage to the equipment when installing third-party options:

• Donotpermitoptionalequipmenttoimpedeairflow around the enclosure or to increase the internal

rack temperature beyond the maximum allowable limits.

• Do not exceed the manufacturer’s TMRA.

Power requirements

Installation of this equipment must comply with local and regional electrical regulations governing the

installation of IT equipment by licensed electricians. This equipment is designed to operate in installations

covered by NFPA 70, 1999 Edition (National Electric Code) and NFPA-75, 1992 (code for Protection

of Electronic Computer/Data Processing Equipment). For electrical p ower ratings on options, see the

product rating label or the user documentation supplied with that option.

ttp://www.hp.com/products/servers/platforms.

WARNING!

To reduce the risk of personal injury, fire, or damage to the equipment, do not overload the AC supply

branch circuit that provides power to the rack. Consult the electrical authority having jurisdiction over

wiring and installation requirements of your facility.

CAUTION:

Protect the enclosure from power fluctuations and temporary interruptions with a regulating UPS. This

device protects the hardware from damage caused by power surges and voltage spikes and keeps the

enclosure in operation during a power failure.

When installing more than one enclosure, you may need to use additional power distribution devices to

safely provide power to all devices. Observe the following guidelines:

• Balance the enclosure power load between available AC supply branch circuits.

• Do not allow the overall system AC current load to exceed 80 percent of the branch circuit

AC current rating.

• Do not use comm on power outlet strips for this equipment.

• Provide a separate electrical circuit for each power supply in the enclosure.

20

Setting up the enclosure

Page 21

Electrical grounding requirements

The enclosure must be grounded properly for proper operation and safety. In the United States, you must

install the equ

well as any local and regional building codes. In Canada, you must install the equipment in accordance

with Canadian Standards Association, CSA C22.1, Canadian Electrical Code. In all other countries,

you must instal

as the International Electrotechnical Commission (IEC) Code 364, parts 1 through 7. Furthermore, you

must be sure that all power distribution devices used in the installation, such as b ranch wiring and

receptacles, are listed or certified grounding-type devices.

Because of the high ground-leakage currents associated with multiple enclosures conne cted to the same

power source, HP recommends the use of a power distribution unit (PDU) that is either permanently wired

to the buildi

NEMA locking

Using commo

ipment in accordance with NFPA 70, 1999 Edition (National Electric Code), Article 250, as

ltheequipmentinaccordancewithanyregionalornationalelectricalwiringcodes,such

ng’s branch circuit or includes a nondetachable cord that is wired to an industrial-style plug.

-style plugs or those complying with IEC 60309 are considered suitable for this purpose.

n power outlet strips for the enclosure is not recommended.

Rack warnings

WARNIN G!

To reduce the risk of personal injury or damage to the equipment, be sure that:

• The leveling jacks are extended to the floor.

• The full weight of the rack rests on the leveling jacks.

• The stabilizing feet are attached to the rack if it is a single-rack installation.

• The racks are coupled together in multiple-rack installations.

• Only one component is extended at a time. A rack may become unstable if more than one

component is extended for any reason.

WARNIN G!

To reduce the risk of personal i njury or equipment damage when unloading a rack:

• At least two people are needed to safely unload the rack from the pallet. An empty 42U rack can

weighasmuchas115kg(253lb),canstandmorethan2.1m(7ft)tall,andmaybecomeunstable

when being moved on its casters.

• Never stand in front of the rack when it is rolling down the ramp from the pallet. Always handle the

rack from both sides.

Shipping contents

When unpacking the MSA70 enclosure, locate the following items:

• MSA70 enclosure

• Rack mounting hardware kit

• Power cords (2 )

• SAS cable

• Documentation kit

user guide

21

Page 22

Rack mounting hardware kit contents

The rack mounting hardware kit provides the required components for quick deployment in

Compaq-branded, HP-branded, and most square- and round-hole third-party racks. The adjustable

feature of the r

If you are installing the MSA70 enclosure in an M-Series rack, contact an authorized reseller to obtain an

M-Series Rack Rail option kit.

ack rails enables installation in racks with depths of 69.90 to 76.2 cm (27.52 to 30.00 in).

1

3

2

15601

Item

1

2

3

Description

Rack rail (left)

Rack rail (right)

Pins for round-hole rack conversion (8)

In addition to these supplied items, you may need a No. 2 Phillips screwdriver.

Converting rails for round-hole racks

The rack rails ship configured for square-hole racks. To convert the rack rails for use in a round-hole rack:

1. Locate the bag of miscellaneous hardware that ships with the rack rails.

2. Locate th

3. Use a No.

of the rail.

e eight round-hole pins.

2 Phillips screwdriver to remove the standard pins from the front and back ends

4. Install four round-hole pins into the rail.

22

Setting up the enclosure

15489

Page 23

5. Repeat steps 3 and 4 for the second rail.

Installing the enclosure into the rack

15600

To install t

he enclosure into a rack:

1. Secure the front end of the rails to the rack.

IMPORTANT:

Do not remove the pins from the ends of the rack rails unless you are c onverting the rails for use

in round-hole racks. These load-bearing pins are designed to fit through the holes without being

removed.

IMPORTANT:

Be sure that the scissor-type locking latches engage the rack fully when the pins extend through

the holes marked with the template.

NOTE:

Identify the left (L) and right (R) rack rails by markings stamped into the sheet metal.

2. Secure the back end of the rails to the rack.

15485

user guide

23

Page 24

IMPORTANT:

Be sure that the scissor-type locking latches engage the rack fully when the pins extend through

the holes marked with the template.

15488

3. Slide the chassis into the rack.

4. Use the thumbscrews on the front of the chassis to secure it to the rack.

5. Usetheshippingbrackettosecuretheenclosureforshipping:

IMPORTANT:

Use of the shipping bracket is required only when the rack is shipped with the MSA70 enclosure

installed.

a. Loosen the thumbscrew on the shipping bracket.

b. Slide the shipping bracket forward until it engages the chassis.

c. Tighten the thumbscrew .

If you are installing the enclosure into a telco rack, order the appropriate option kit at the RackSolutions

website: h

install t

ttp://www.racksolutions.com/hp. Follow the enclosure-specific instructions on the website to

he rack brackets.

Installing hardware options

Install any hardware options before initializing the enclosure. For options installation information, see the

option documentation. For enclosure-specific information, see Installing hardware drives.

Installing ser vers

l the servers in the rack directly above the enclosure. See the server documentation.

Instal

NOTE:

When installing servers and enclosures, HP recommends installing all enclosures at the bottom of the

rack. To optimize cabling access, avoid interleaving the enclosure and server products.

Choosing a configuration

Cable procedures vary, depending on the confi guration. Choose one of the following configurations.

24

Setting up the enclosure

Page 25

NOTE:

OUT

TheleftconnectoroftheI/Omoduleisforinputfromtheserver.TherightconnectoroftheI/Omoduleis

for output to another enclosure. See the icons on the cables and enclosure to assist in proper connection.

Single-enclosure configuration

S

A

S

OUT

1

3

Item

1

2

3

Description

Server

SAS cable

MSA70 enclosure

Cascading (1+1) configuration

5

IN

2

15465

1

S

A

S

IN

2

3

4

15466

user guide

25

Page 26

Item

1

2

3

4

5

Description

Server

SAS cable

SAS cable

MSA70 enclosure 1

MSA70 enclosure 2

Cabling the enclosure

After installing the enclosure in a rack, connect the SAS cables and power cords to the rear panel.

SAS cabling g

Observe the f

• Only use supported SAS cables with 3-GB connectors.

• Ensure that the servers at tached to the enclosure are powered down and power cords are

uidelines

disconnecte

Supported cables

A 0.5-m (1.64-ft) SAS cable ships standard with the enclosure. HP recommends using the shortest cable

possible, however, other supported cable lengths between SAS ports are 2 m (6.56 ft), 4 m (13.12 ft), and

6 m (19.69 ft). To acquire different lengths, contact the nearest authorized HP reseller.

Power cords

The power c

product and for the voltage and current marked on the electrical ratings label of the product. The voltage

and current rating for the cord should be greater than the voltage and current rating marked on the

product. In addition, the diameter of the wire must be a minimum of 1.00 mm

maximum length may be up to 3.66 m (12 ft).

WARNING

To reduc

• Do not disable the power cord grounding plug. The grounding plug is an important safety feature.

• Plug the power cord into a grounded (earthed) electrical outlet that is easily accessible at all times.

• Unplug t

• Do not route the power cord where it can be walked on or pinched by items placed against it. Pay

particular attention to the plug, electrical outlet, and the point where the cord extends from the

storage system.

!

e the risk of electric shock or damage to the equipment:

he power cord from the power supply to disconnect power to the equipment.

ollowing guidelines:

d before connecting SAS cables.

ord should be approved for use in your country. The power cord must be rated for the

2

or 18 AWG, your

To connect AC power cords:

1. Connect the power cords to the power supplies.

2. Connect the power cords to the AC power source.

26

Setting up the enclosure

Page 27

Updating firmware

After installing hardware and powering up the enclosure for the first time, be sure to verify that the host

controller, the enclosure, and hard drives have the latest firmware. You can identify which firmware

versions you ha

and ACU. ADU al

not the MSA70.

NOTE:

The firmware for both the SAS and SATA hard drives is upgradeable.

For firmware and software updates, see the HP website: http://h18004.www1.hp.com/support/files/

storage/us/index.html. You can also update the firmware on the server, controller, enclosure, and hard

drives using Smart Components. See Smart Components for ROM Flash.

You can receive proactive support alerts, such as Customer Advisories, as well as updates on drivers,

software, firmware, and customer replaceable components, via e-mail through HP Subscriber’s Choice.

Sign up for Subscriber’s Choice at the following HP website: h

select the appropriate product.

ve for the host controller, the MSA70, and the installed hard drives through HP SIM

lows you to view the firmware versions for the host controller and hard driv es, but

ttp://www.hp.com/go/myadvisory and

user guide

27

Page 28

28

Setting up the enclosure

Page 29

4 Installing hard drives

Hard drive options

The enclosure supports up to 25 SAS or SATA hard drives. Always populate hard drive bays starting with

thelowestdevicenumber(seeHard drive bay numbers).

Hard drive guidelines

When adding hard drives to the enclosure, observe the following general guidelines:

• The system automatically sets all device numbers.

• If only one h

• Drives must be the same capacity to provide the greatest storage space efficiency when drives are

grouped together into the same drive array.

NOTE:

ACU does not

Installingaharddrive

ard drive is used, install it in the bay with the lowest device number.

support mixing SAS and SATA drives in the same logical volume.

CAUTION:

To prevent improper cooling and thermal damage, do not operate the enclosure unless all bays are

populated with either a component or a blank.

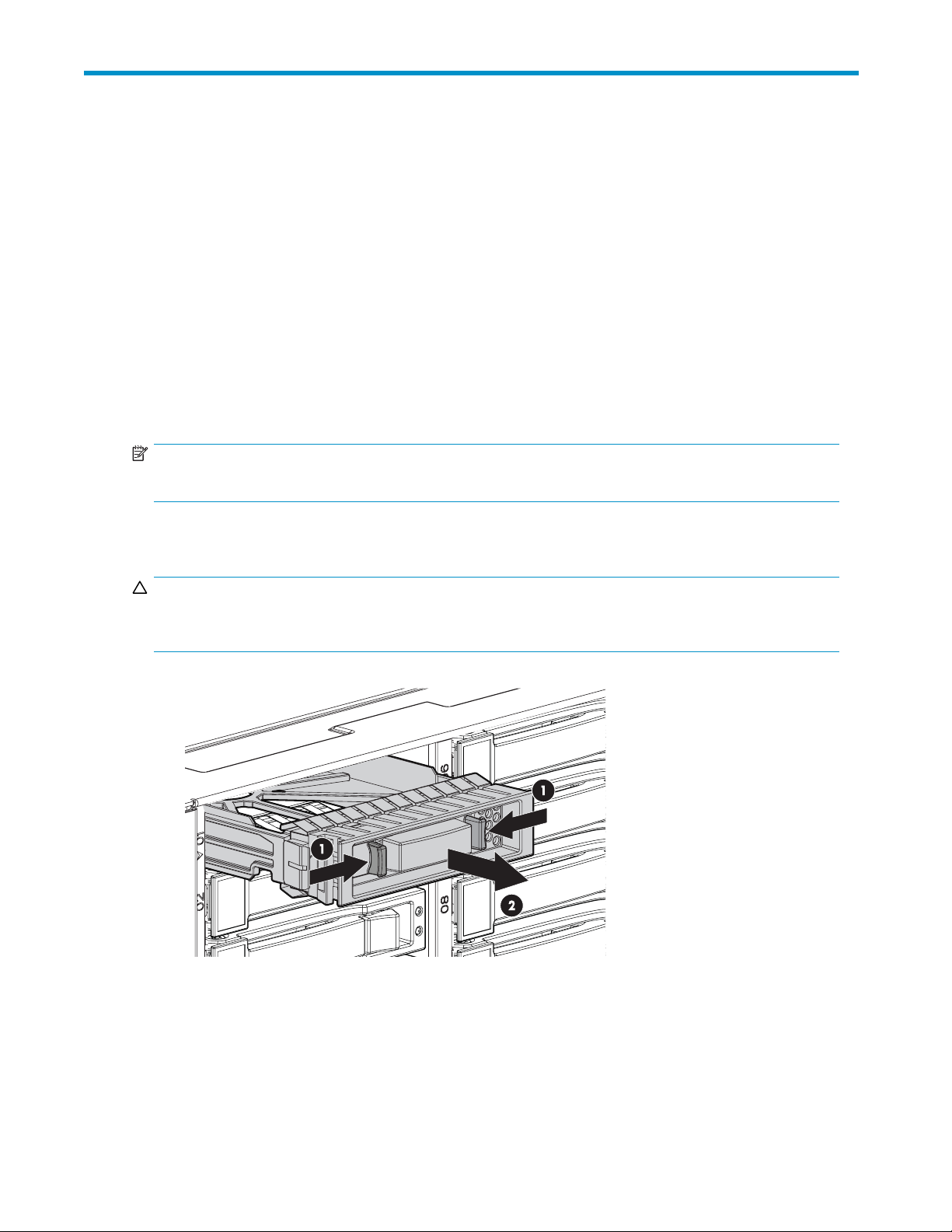

1. Remove the

hard drive b lank.

15467

2. Press the latch and slide it to the right to disengage the lever (1), and then open the lever (2). Make

sure that the lever is in the fully opened position before inserting the drive into the bay.

user guide

29

Page 30

1

2

15468

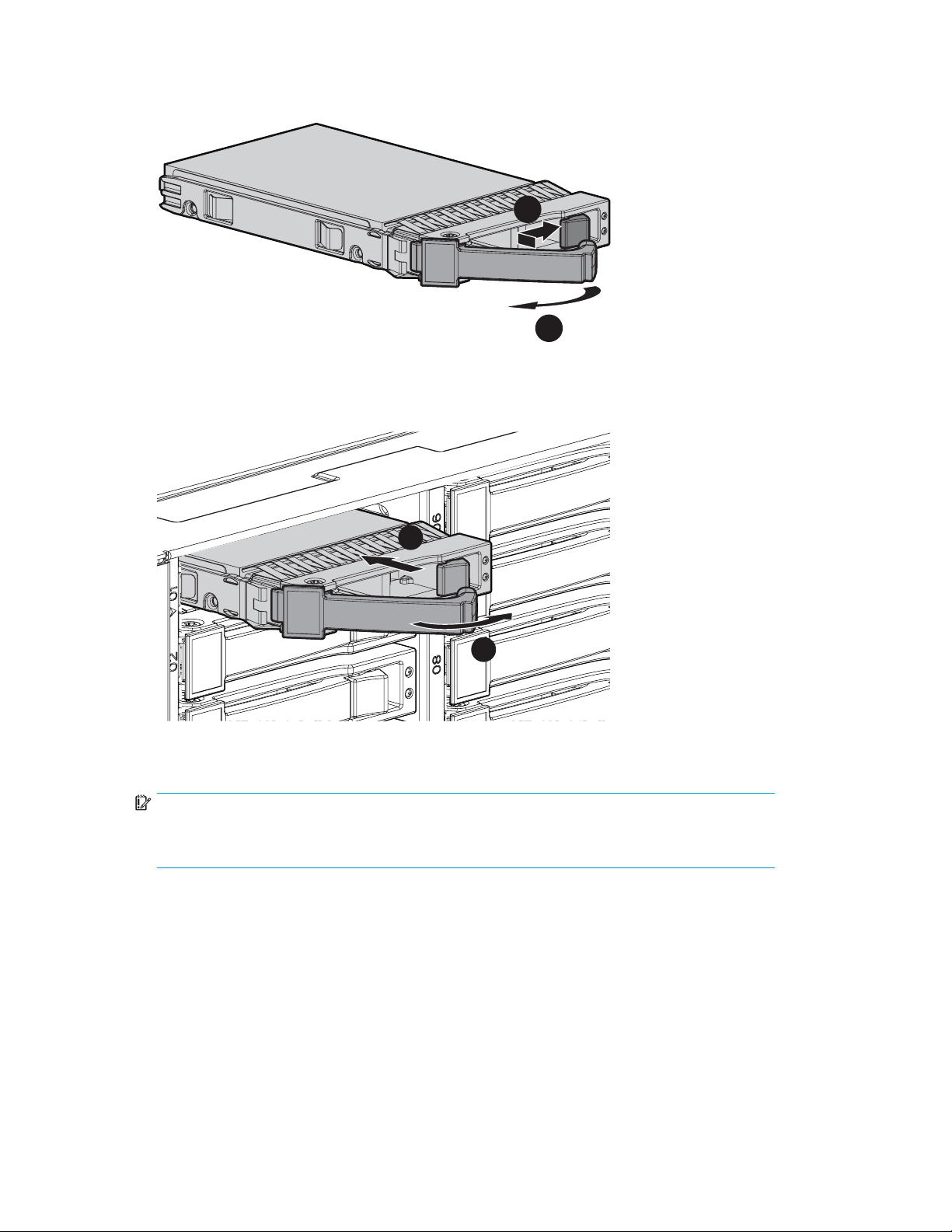

3. Slide the hard drive into the bay (1), pressing firmly on the drive to seat it. Close the lever (2), making

sure that it is flush with the front of the drive.

1

2

15469

IMPORTANT:

Whenthedriveisinserted,thedriveLEDsflash for 2 seconds to indicate that the drive is

dproperlyandreceivingpower.

seate

4. Determine the status of the hard drive (see Hard drive LED combinations).

30

Installing hard drives

Page 31

5Configuring the enclosure

Configuration tools

Array Configur

NOTE:

ACU does not support mixing SAS and SATA drives in the same logical volume.

ACU is a browser-based utility with the following features:

• Runs as a local application or remote service

• Supports online array capacity expansion, logical drive extension, assignment of online spares,

• Suggests the optimum configuration for an unconfigured system

• Provides different operating modes, enabling faster configu ration or greater control over the

• Remains available any time that the server is on

• Displays on-screen tips for individual steps of a configuration procedure

For optimum performance, the minimum display settings are 800 × 600 resolution and 256 colors.

Servers running Microsoft operating systems require Internet Exp lorer 5.5 (with Service Pack 1) or later.

For Linux servers, see the README.TXT file for additional browser and suppor t information.

For more information, see the ACU section of the array configuration reference guide on the

Documentation CD or the HP website: h

ation Utilit y

and RAID or stripe size migration

configuration options

ttp://www.hp.com.

Option ROM Configuration for Arrays

Before installing an operating system, you can use the ORCA utility to create the first logical drive, assign

RAID levels, and establish online spare configurations.

The utility also provides support for the following functions:

• Reconfiguring one or more logical drives

• Viewing the current logical drive configuration

• Deleting a logical drive configuration

• Setting the controller to be the boot controller

If you do not use the utility, ORCA defaults to the standard configuration.

For more information regarding array controller configuration, see the controller user guide.

For more information regarding the default configurations that ORCA uses, see the HP ROM-Based

Setup Utility user guide on the Documentation CD.

Smart Components for ROM Flash

To update the firmware on the server, controller, hard drives, or enclosure, use Smart Components. These

components are available on the Firmware Maintenance CD. A more recent version of a particular

component might be available on the support page of the HP website: h

Components for controller and hard drive firmware updates are also available from the software and

drivers page for storage products (h

ttp://www.hp.com/support.

ttp://www.hp.com/support/proliantstorage).

user guide

31

Page 32

1. Find the most recent version of the component that you require. Components for controller firmware

updates are available in offline and online formats.

2. Follow the instructions for installing the component on the server. These instructions are given with

the CD and are provided on the same Web page as the component.

3. Follow the additional instructions that describe how to use the component to flash the ROM. These

instructions are p rovided with each component.

Management tools

HP Systems Insight Manager

HP SIM is a web-based application that allows system administrators to accomplish normal administrative

tasks from any remote location, using a web browser. HP SIM provides device management capabilities

that consolidate a nd integrate management data from HP and third-party devices.

IMPORTANT:

You must install and use HP SIM to benefit from the Pre-Failure Warranty for processors, SAS and

SCSI hard drives, and memory modules.

For additional information, see the Management CD in the HP ProLiant Essentials Foundation Pack or the

HP SIM website: h

ttp://www.hp.com/go/hpsim.

Management Agents

Management Agents provide the information to enable fault, performance, and configuration

management. The agents allow e asy manageability of the server through HP SIM software, and third-party

SNMP management platforms. Management Agents are installed with every SmartStart-assisted

installation or can b e installed through the HP PSP. The Systems Management homepage provides status

and direct access to in-depth subsystem information by accessing data reported through the Management

Agents. For additional information, see the Management CD in the HP ProLiant Essentials Foundation

Pack or the HP website: h

ttp://www.hp.com/servers/manage.

Diagnostic tools

Integrated Management Log

The Integrated Management Log (IML) records events and stores them in an easy-to-view form. The IML

timestamps each event with 1-minute granularity.

You can view recorded events in the IML in several ways, including the following:

• From within HP SIM (see HP Systems Insight Manager)

• From within Survey Utility

• From within operating system-specificIMLviewers

• For NetWare: IML Viewer

•ForWindows:IMLViewer

• For Linux: IML Viewer Application

• From within the iLO user interface

• From within HP Insight Diagnostics

For more information, see the Ma nagem ent C D in the HP ProLiant Essentials Foundation Pack.

32

Configuring the enclosure

Page 33

Array Diagnosti

cUtility

ADU is a web—bas

report provide

ADU can be acce

ed application that creates a report of all HP storage controllers and hard drives. This

s vital information to assist in identifying faults or conditions that may require attention.

ssed from the SmartStart CD or downloaded from the HP website: h

Remote support and analysis tools

Open Services Event Manager

OSEM is a standalone tool that performs real-time reactive and proactive service event filtering, analysis,

and notification. The tool gathers event data from SNMP traps or information provided over an HTTP

interface and notifies an administrator or HP through SMTP and ISEE.

For more information, see the HP website: h

ttp://h18000.www1.hp.com/support/svctools/.

Keeping the system current

Change control and proactive notification

HP offers Change Control and Proactive Notification to notify customers 30 to 60 days in advance of

upcoming hardware and software changes on HP commercial products.

For more information, see the HP website: h

Natural language search assistant

ttp://h18023.www1.h p.com/solutions/pcsolutions/pcn.html.

ttp://www.hp.com.

The natural language search assistant, located at http://www.hp.com/support/natural_language_search,

is a search engine that finds information on HP products, including ProLiant servers. The search engine

responds to queries entered in question form.

Care Pack

HP Care Pack Services offer upgraded service levels to extend and expand standard product warranty

with easy-to-buy, easy-to-use support packages that help you make the most of your server investments.

See the Care Pack website: h

ttp://www.hp.com/hps/carepack/servers/cp_proliant.html.

user guide

33

Page 34

34

Configuring the enclosure

Page 35

6 Troubleshooting

When the enclosure does not start

If the enclosure does not power up:

1. Verify that the server, monitor, and enclosure are plugged in.

2. Verify that the server and monitor are working.

3. Verify that the power source is working:

a. Ensure that the Power On/Standby button was pressed firmly and held for approximately

three seconds.

b. View the system power LED on the back panel (see Rear panel LEDs and buttons).

4. Verify that the power supplies are working properly by viewing the power supply LEDs on the

back panel (see Rear panel LEDs and buttons).

5. Disconnect the AC power cords from both enclosure power supplies and reconnect them.

6. Restart the enclosure.

IMPORTANT:

If the system does not restart, proceed to Diagnostic steps.

7. Check the enclosure for the following normal power-up sequence to be sure that the system meets

the minimal hardware requirements a n d i s powered up during normal operations:

a. The front panel power LED turns from standby/off (am b er) to on (solid green).

b. Thefansspinuptoahighspeed,andthenspindowntoanormaloperatingspeed.

Diagnostic steps

Are the power supply/ fan module LEDs green?

Answer

No

Yes

Possible Reasons Possible Solutions

• The power cords are not

connected or AC power is not

available.

• The power supp ly may not be

inserted properly, it may have

a damaged connector, or it

may have failed.

• The system midplane may need

to be replaced.

System is functioning properly.

• Be sure that the power cord is

connected to the power supply.

• Be sure that the p ower supply

is undamaged and is fully

seated.

• Be sure that all pins on

connectors and components

are straight.

• Contact an authorized service

provider for assistance.

If the system power LED is off, do

the following:

1. Press the Power On/Standby

buttonandholdfor

approximately three seconds.

2. See Is the system power LED

green?

No action required

user guide

35

Page 36

Is the system po

wer LED green?

Answer

No

Possible Reasons Possible Solutions

• The Power On/Standby button

has not been pressed firmly or

held long enough.

• The power supply may not be

inserted properly, it may have

a damaged connector, or it

may have failed.

• The system may have

experienced a short. Controller

firmware may be corrupted.

• The system midplane and/or

power button/LED assembly

may need to be replaced.

Recognizing hard drive failure

In an HP enclosure, a steadily glowing fault LED indicates that a drive has failed.

Other indications of failed hard drives a re as follows:

• ACU represents failed drives with a distinctive icon.

• HP SIM can detect failed drives remotely across a network. (For more information about HP SIM,

see the documentation on the Management CD.)

• ADU lists all failed drives.

• CPQONLIN identifies failed drives in a NetWare environment.

For additional information about diagnosing hard drive problems, see the HP ProLiant Servers

Troubleshooting G uide.

• Firmly press the Power

On/Standby button and

hold for approximately three

seconds.

• Be sure that the power supply

is undamaged and is fully

seated. Besurethatallpinson

connectors and components

are straight.

• Be sure that all components

are fully seated.

• Flash the controller firmware

(see Smart Components for

ROM Flash).

• Contact an authorized service

provider for assistance.

CAUTION:

Sometimes, a drive that has previously failed may seem to be operational after the system is power-cycled

or, for a hot-pluggable drive, after the drive has been removed and reinserted. However, continued use of

such marginal drives may eventually result in data loss. Replace the marginal drive as soon as possible.

Effects of a hard drive failure

When a hard drive fails, all logical drives that are in the same array are affected. Each logical drive in an

array may be using a different fault-tolerance method, so each logical drive can be affected differently.

• RAID 0 configurations cannot tolerate drive failure. If any physical drive in the array fails, all

non-fault-tolerant (RAID 0) logical drives in the same array also fail.

• RAID 1+0 configurations can tolerate multiple drive failures as long as no failed drives are

mirrored to one another (with no spares assigned).

• RAID 5 configurations can tolerate one drive failure (with no spares assigned).

• RAID 6 with ADG configurations can tolerate simultaneous failure of two drives (with no spares

assigned).

36

Troubleshooting

Page 37

Compromised fau

If more hard drives fail than the fault-tolerance method allows, fault tolerance is compromised, and the

logical drive f

errors. You are likely to lose data, although it can sometimes be recovered.

One example of a situation in which compromised fault tolerance m ay occur is when a drive in an array

fails while another drive in the array is b eing rebuilt. If the array has no online spare, any logical drives

in this array that are configured with RAID 5 fault tolerance will fail.

Compromised fault tolerance can also be caused by non-drive problems, such as a faulty cable or

temporary pow

drives. Howe

problem occurred.

lt tolerance

ails. In this case, all requests from the operating system are rejected with unrecoverable

er loss to a storage system. In such cases, you do not need to replace the physical

ver, you may still have lost data, especially if the system was busy at the time that the

Recovering from compromised fault tolerance

If fault tolerance is compromised, inserting replacement drives does not improve the condition of the

logical volume. Perform the following procedure to recover data:

1. Power down the enclosure (see Powering down).

2. Check for loose, dirty, broken, or bent cabling and c onnectors on all devices.

3. Power up the enclosure (see Powering up).

NOTE:

In some cases, a marginal drive is operational long enough to allow backups of important

files.

4. Make copies of important data, if possible.

5. Replace any failed drives. Read Factors to consider before replacing hard drives before replacing

thefailedharddrives.

Factors to consider before replacing hard drives

Insystemsthatuseexternaldatastorage,besurethattheserveristhefirstunittobepowereddownand

the last to be powered back up. Taking this precaution ensures that the system does not erroneously mark

the drives as failed when the server is powered up.

Before replacing a degraded drive:

• Open HP SIM and inspect the Error Counter window for each physical drive in the same array

to confirm that no other drives have any errors. For details, see the HP SIM documentation

on the Management CD.

• Be sure that the array has a current, valid backup.

• Use replacement drives that have a capacity at least as great as that of the smallest drive in the

array. The controller immediately fails drives that have insufficient capacity.

To minimize the likelihood of fatal system errors, take these precautions when removing failed drives:

• Donotremoveadegradeddriveifanyotherdriveinthearrayisoffline(theonlineLEDisoff).In

this situation, no other drive in the array can be removed without data loss.

Exceptions:

• When RAID 1+0 is used, drives are mirrored in pairs. Several drives can be in a failed

condition simultaneously (and they can all be replaced simultaneously) without data loss, as

long as no two failed drives belong to the same mirrored pair.

• When RAID 6 with ADG is used, two drives can fail simultaneously (and be replaced

simultaneously) without data loss.

user guide

37

Page 38

•Iftheoffline drive is a spare, the degraded drive can be replaced.

• Donotremoveaseconddrivefromanarrayuntilthefirst failed or missing drive has been

replaced and the rebuild process is complete. (The rebuild is complete when the Online LED on

the front of the drive stops blinking.)

Exceptions:

• In RAID 6 with ADG configurations, any two drives in the array can be replaced

simultaneously.

•InRAID1+0configurations, any drives that are not mirrored to other removed or failed drives

can be simultaneously replaced offline without data loss.

Automatic data recovery (rebuild)

When you replace a hard drive in an array, the controller uses the fault-tolerance information on the

remaining drives in the array to reconstruct the missing data (the d ata that was originally on the replaced

drive) and write it to the replacement drive. This process is called automatic data recovery, or rebuild. If

fault toler

If another drive in the array fails while fault tolerance is unavailable during rebuild, a fatal system error

may occur, and all data on the array is then lost. In exceptional cases, however, failure of another drive

need not lead to a fatal system error. These exceptions include:

• Failure af

• Failure of a drive that is not mirrored to any other failed drives (in a RAID 1+0 configuration).

• Failure of a second drive in a RAID 6 with A DG configuration.

ance is compromised, this data cannot be reconstructed and is likely to be permanently lost.

ter activation of a spare drive.

Time required for a rebuild

The time required for a rebuild varies considerably, depending on several factors:

• The priority that the rebuild is given over normal I/O operations (you can change the priority

setting by using ACU)

• The amount of I/O activity during the rebuild operation

• The rotational speed of the hard drives

• The availability of drive cache

• The brand, model, and age of the drives

• Theamountofunusedcapacityonthedrives

• The number of drives in the array (for RA I D 5 and RAID 6 with ADG)

Allow approximately 15 minutes per gigabyte for the rebuild process to be completed. This figure is

conservative, and newer drive models usually require less time to rebuild.

System performance is affected during the rebuild, and the system is unprotected against further drive

failure until the rebuild has finished. Therefore, replace drives during periods of low activity when possible.

CAUTION:

If the Online LED of the replacement drive stops blinking and the amber fault LED glows, or if other drive

LEDs in the array go out, the replacement drive has failed and is producing unrecoverable disk errors.

Remove and replace the failed replacement drive.

When automatic data recovery has finished, the online LED of the replacement drive stops blinking

and begins to glow steadily.

Failure of another drive during rebuild

If a non-correctable read error occurs on another physical drive in the array during the rebuild process,

the Online LED of the replacement drive stops blinking and the rebuild abnormally terminates.

38

Troubleshooting

Page 39

If this situation occurs, restart the server. The system may temporarily become operational long enough

to allow recovery of unsaved data. In any case, locate the faulty drive, replace it, and restore data

from backup.

Drive failure in a NetWare environment

Use CPQONLIN to identify and monitor drive failure status in a NetWare environment.

Failed drives or interim recovery mode

If a drive fails and hardware fault tolerance is enabled, operation continues. Do the following:

1. Replace the drive as soon as possible.

2. Select a logical drive.

3. Press the F3 key to monitor to the status of drive recovery.

Drive status messages include:

• Interim Recovery: The logical drive is operating, but a failed drive has not been replaced.

Replace the drive as soon as possible.

• Ready for Recovery: The logical drives are queued for recovery. This status is displayed when

another logical drive is a lready rebuilding or expanding.

• Rebuilding: The array is operating and rebuilding a replacement drive or an online spare, if

one was assigned.

• Logical Drive Failed: If you have one or more logical drives that are not protected by fault

tolerance in an a rray, the data on these logical drives will be lost. ACU shows the logical

drives as FAILED. After drive replacement, any fault-tolerant logical drives rebuild. The

logical drives that were not protected (FAILED) become available for data (the devices are

reactivated automatically). If you have a backup of the data, restore the data now.

If you do not replace the failed drive, the only option, using ACU, is to delete logical drives. Do

not delete logical drives that contain valid data. Doing so results in data loss.

NOTE:

A failed status can occur on drives protected by fault tolerance if two or more physical

drives fail concurrently.

Some status messages are available without pressing the F3 key. For example, on the Main menu,

the FAILED status appears next to the logical drive that has failed. EXPANDING and REBUILDING

appear next to the array in which the activity is occurring.

Handling hard drive failures

If the c ontroller was con figured with hardware fault tolerance, complete the following steps after a

hard drive failure:

1. Determine which physical drive failed. On hot-plug drives, an amber drive failure LED illuminates.

2. If the unit containing the failed drive does not support hot-plug drives, perform a normal shutdown.

3. Remove the failed drive and replace it with a drive that is of the same capacity. For hot-plug drives,

afteryousecurethedriveinthebay,theLEDsonthedriveeachflash once in an alternating pattern

to indicate a successful connection. The online LED flashes, indicating that the c ontroller recognized

the drive replacement and began the recovery process.

4. Power up the server, if applicable.

5. The controller reconstructs the information on the new drive, based on information from the remaining

physical drives in the logical drive. While reconstructing the data on hot-plug drives, the online LED

flashes. When the drive rebuild is complete, the online LED is illuminated.

user guide

39

Page 40

NOTE:

NetWare cannot detect a single physical drive failure when using hardware-based fault tolerance.

NetWare determines that the data is still valid and accessible during the rebuilding process. However,

the driver knows that a physical drive has failed. A message is printed on the console notifying the user

that a physical drive is in a degraded state. CPQONLIN also shows that the drive has failed.

40

Troubleshooting

Page 41

A Regulator y compliance n otices

Regulatory compliance identification numbers

For the purpose of regulatory compliance certifications and identification, this product has been

assigned a unique regulatory model number. The regulatory mod el number can be found on the

product nameplate label, along with all required approval markings and information. When requesting

compliance information for this product, always see this regulatory model number. The regulatory model

number is not the marketing name or model number of the product.

Federal Com

Part 15 of the Federal Communications Commission (FCC) Rules and Regulations has established Radio

Frequency (RF) emission limits to provide an interference-free radio frequency spectrum. Many electronic

devices, including computers, generate RF energy incidental to their intended function and are, therefore,

covered by t

and B, depending upon their intended installation. Class A devices are those that may reasonably be

expected to be installed in a business or commercial environment. Class B devices are those that may

reasonabl

The FCC requires devices in both classes to bear a label indicating the interference potential of the device

as well as additional operating instructions for the user.

munications Commission notice

hese rules. These rules place computers and related peripheral devices into two classes, A

y be expected to be installed in a residential environment (for example, personal computers).

FCC rating label

The FCC rating label on the device shows the classification (A or B) of the equipment. Class B devices

have an FCC logo or ID on the label. Class A devices do not have an FCC logo or ID on the label. After

you determine the class of the device, see the c orresponding statement.

Class A equipment

uipment has been tested and found to comply with the limits for a Class A digital device, pursuant

This eq

15oftheFCCRules.Theselimitsaredesignedtoprovidereasonableprotectionagainstharmful

to Part

erence when the equipment is operated in a commercial environment. This equipment generates,

interf

and can radiate radio frequency energy and, if not installed and used in accordance with the

uses,

uctions, may cause harmful interference to radio communications. Operation of this e quipment in a

instr

residential area is likely to cause harmful interference, in which case the user will be required to correct

the interference at personal expense.

Class B equipment

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant

toPart15oftheFCCRules.Theselimitsaredesignedtoprovidereasonableprotectionagainstharmful

interference in a residential installation. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this e quipm ent does cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipm ent into an outlet on a circuit that is different from that to which the receiver is

connected.

user guide

41

Page 42

• Consult the dealer or an experienced radio or television technician for help.

Declaration of

logo, United St

This device com

(1) t h i s d evi c

received, including interference that may cause undesired operation.

For questions regarding this product, contact us by mail or telephone:

• Hewlett-Pack

• 1-800-HP-INVENT (1-800-474-6836). (For continuous quality improvement, calls may be recorded

or monitored.)

For question

• Hewlett-Packard Company P. O. Box 692000, Mail Stop 510101 Houston, Texas 77269-2000

• 1 281 - 514 - 33 33

To identify t

e may not cause harmful interference, and (2) this device must accept any interference

s regarding this FCC declaration, contact us by mail or telephone:

his product, see the part, series, or model number found on the product.

Modifications

TheFCCrequirestheusertobenotified that any changes or modifications made to this device that are not

expressly approved by Hewlett-Packard Company may void the user’s authority to o perate the equipment.

Cables

Connections to this device must be made with shielded cables with metallic RFI/EMI connector hoods

in order to m

aintain compliance with FCC Rules and Regulations.

conformity for products marked with the FCC

ates only

plies with Part 15 of the FCC Rules. Operation is subject to the following t wo conditions:

ard Company P . O. Box 692000, Mail Stop 530113 Houston, Texas 77269-2000

Canadian notice (Avis Canadien)

Class A equipment

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment

Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel

brouilleur du Canada.

Class B eq uipment

This Class B digital apparatus meets all requirements of the Canadian Interference-Causing Equipment

Regulations.

Cet appareil numérique de la classe B respecte toutes les exigences du Règlement sur le matériel

brouilleur du Canada.

European U

This product complies with the following EU Directives:

• Low Voltage Directive 7 3/23/EEC

• EMC Directive 89/336/EEC

nion regulatory notice

42

Regulatory compliance notices

Page 43

CE Compliance of this product is valid only if powered with the correct HP-provided and CE m a rked

AC adapter.

If this product has telecommunication functionality, it also complies with the essential requirements of:

• R&TTE Directive 1999/5/EC

Compliance with these directives implies conformity to harmonized European standards (European

Norms) which are listed on the EU Declaration of Conformity issued by Hewlett-Packard for this product

or product family.

The telecommunications functionality of this product may be used in the following EU and EFTA countries:

Austria,Belgium,Cyprus,CzechRepublic,Denmark,Estonia,Finland,France,Germany,Greece,

Hungary, Iceland, Ireland, Italy, Latvia, Liechtenstein, Lithuania, Luxembourg, Malta, Netherlands,

Norway,Poland,Portugal,SlovakRepublic,Slovenia,Spain,Sweden,Switzerland,andUnitedKingdom.

Notice for use in France and Italy

Italy:

Per l’uso del prodotto, è necessaria una concessione ministeriale. Si consiglia di verificare con il

distributore di fiducia o direttamente presso la Direzione Generale Pianificazione e Gestione Frequenze.

License required for use. Verify with your dealer or directly with General Direction for Frequency Planning

and Management (Direzione Generale Pianificazione e Gestione Frequenze).

France:

L’utilisation de cet equipement (2.4GHz Wireless L AN) est soumise a certaines restrictions: Cet

equipement peut etre utilise a l’interieur d’un batiment en utilisant toutes les frequences de 2400 a

2483.5MHz (Chaine 1-13). Pour une utilisation en environement exterieur, vous devez utiliser les

frequences comprises entre 2454-2483.5MHz (Chaine 10-13). Pour les dernieres restrictions, voir

http://www.art-telecom.fr.

For 2.4 GHz Wireless LAN operation of this product certain restrictions apply: This product may be

used indoor for the entire 2400-2483.5 MHz frequency band (channels 1-13). For outdoor use, only

2454-2483.5 MHz frequency band (channels 10-13) may be used. For the latest requirements, see

http://www.art-telecom.fr.

Notice for products incorporating 5GHz Wireless LAN devices

Frequency availability for 802.11a or 802.11h Wireless LAN is not currently harmonized throughout the

European Union. For compliance requirements, users should verify with their supplier, local HP office or

Telecommunications authority.

user guide

43

Page 44

Disposal of waste equipment by users in private households

in the European Union

Japanese notice

This symbol on the product or on its packaging

indicates tha

with your othe

responsibili

by handing it

for the recycling of waste electrical and electronic

equipment.

your waste equipment at the time of disposal will

help to conserve natural resources and ensure that it

is recycled in a manner that protects human health

and the environment. For more information about

where you can drop off your waste equipment for

recycling, please contact your local city office, your

household waste disposal service or the shop where

you purchased the product.

t this product must not be disposed of

r household waste. Instead, it is your

ty to dispose of your waste equipment

over to a designated collection point

The separate collection and recycling of

BSM

Inotice

Korean notice

Class A equipment

44

Regulatory compliance notices

Page 45

Class B equipment

PowercordstatementforJapan

user guide

45

Page 46

46

Regulatory compliance notices

Page 47

B Electrostatic discharge

Preventing electrostatic discharge

To prevent damaging the system, be aware of the precautions you ne ed to follow when setting up the

system or handling parts. A discharge of static electricity from a finger or other conductor may damage

system boards or other static-sensitive devices. This type of damage may reduce the life expectancy of

the device.

To prevent electrostatic damage:

• Avoid hand contact by transporting and storing products in static-safe containers.

• Keep electrostatic-sensitive parts in their containers until they arrive at static-free workstations.

• Place parts on a grounded surface before removing them from their containers.

• Avoid touching pins, lea ds, or circuitry.

• Always be properly grounded when touching a static-sensitive component or assembly.

Grounding methods to prevent electrostatic discharge

Several methods are used for grounding. Use one or more of the following methods when handling or

installing electrostatic-sensitive parts:

• Use a wrist

Wrist stra

±10 percent resistance in the ground cords. To provide proper ground, wear the strap snug against

the skin.

• Use heel s

when stan

• Use conductive field service tools.

• Use a portable field service kit with a folding static-dissipating work mat.

strap c onnected by a ground cord to a grounded workstation or computer chassis.

ps are flexible straps with a minimum of 1 megohm.

traps, toe straps, or boot straps at standing workstations. Wear the straps on both feet

ding on conductive floors or dissipating floor mats.

If you do not have any of the suggested equipment for proper grounding, have an authorized reseller

the part.

install

For more information on static electricity or assistance with product installation, contact an authorized

reseller.

user guide

47

Page 48

48

Electrostatic discharge

Page 49

CSpecifications

Environmental specifications

Specification

Temperature range

Operating

Storage

Relative humidity

Operating

Storage

Altitude

Operating

Non-operating

1

Temperature ratings shown are for sea level. An altitude rating of 1°C per 300 m (1.8°F per 1,000 ft) to 3048 m (10,000 ft)

is applicable. No direct sunlight allowed. The upper limit may be limited by the type and number of options installed.

2

Storage maximum humidity of 95% is based on a maximum temperature of 45°C (113°F). Altitude maximum for storage

corresponds to a pressure minimum of 70 KPa.

3

Maximum allowable altitude change rate is 457 m/min (1500 ft/min)

1

2

3

Value

10°C to 35°C (50°F to 95°F)

Maximumrateofchangeis10ºC/Hr(50ºF/Hr)

-30°C to 60°C (-22°F to 140°F)

Maximumrateofchangeis20ºC/Hr(68ºF/Hr)

10% to 90 % re lat ive hum i d ity (Rh )

28º C (82.4º F) maximum wet bulb temperature

non-condensing

5% to 95% relative humidity (Rh)

38.7º C (101.66º F) maximum wet bulb temperature

non-condensing

3048 m (10,000 ft)

This value may be limited by the type and number of options

installed.

9144 m (30, 000 ft)

Storage enclosure specifications

Specificati

Height

Depth

Width

Weight (maximum) 2 1.77 kg (48 lb)

Weight (no drives installed) 15.88 kg (35 lb)

on

Value

8.8 cm (3.47 in)

59 cm (23.25 in)

44.80 cm (1

7. 6 4 i n )

user guide

49

Page 50

50

Specifications

Page 51

Acronyms and Abbreviations

ACU Array Configuration Utility

ADG Advanced Data Gua rding (also known as RAID 6)

ADU Array Diagnostics Utility

CSA Canadian Standards Association

HBA host bus adapter

IEC International Electrotechnical Commission

IEEE Institute of Electrical and Electronics Engineers

IML Integrated Management Log

MSA Modular Smart Array

MSA70 HP Storage Works 70 Modular Smart Array Enclosure

NECA National Electrical Code

NEMA National Electrical Manufacturers Association

NFPA National Fire Protection Association

ORCA Option ROM Configuration for Arrays

OSEM Open Services Event Manager

PSP ProLiant Support Pack

RAID redundant array of inexpensive (or independent) disks

RBSU ROM-Based Setup U tility

SAS serial attached SCSI

SAT A serial ATA

SCSI small computer system interface

SFF small form-factor

SIM Systems Insight Manager

TMRA recommended ambient operating temperature

UID unit identification

user guide

51

Page 52

52

Acronyms and Abbreviations

Page 53

Index

A

ACU

See Array Configuration Utility

ADU

See Array Diagnostic Utility

airflow requirements,19

Array Configuration Utility,31

Array Diagnostic Utility,33

audience,7

automatic data recovery (rebuild),38,38

B

BSMI notice,44

C

cables,42

cables, supported,26

cabling guidelines,26

Canadian notice,42

Class A equipment,42

Class B equipment,42

Care Pack,33

Change Control,33

Class A equipment

Canadian n notice,42

Federal Communications Commission notice,

41

Class B equipment

Canadian notice,42

Federal Communications Commission notice,

41

component identification,11

components,11

front panel,11

rear panel,12

compromised fault tolerance,37

recovering from,37

configuration

cascading (1+),25

choosing,24

single-enclosure,25

configuration tools,31

conventions

document,7

text symbols,7

customer self repair,8

D

data recovery,38,38

Declaration of Conformity,42

diagnostic steps,35

diagnostic tools,32

document conventions,7

documentation, providing feedback,9

drive LEDs,14

E

electrical grounding requirements,21

electrostatic discharge,47

grounding methods,47

preventing,47

enclosure

cabling,26

configuring,31

installing into rack,23

environmental requirements,19

European Union regulatory notice,42

F

failureofharddriveduringrebuild,38

fault tolerance, compromised,37

FCC

See Federal Communications Commission

notice

Federal Communications Commission notice,

41

Class A e quipment,41

Class B equipment,41

FCC rating label,41

Modifications,42

firmware, updating,27

front panel

components,11

LEDs,11

G

grounding methods,47

grounding requirements,21

guidelines

cabling,26

hard drive,29

user guide

53

Page 54

H

hard drive

bay numbers,14

failure during rebuild,38

failureinaNetWareenvironment,39

failure, effects of,36

failure, handling,39

failure, recognizing,36

guidelines,29

installation,29

installing,29

LED combinations,14

LEDs,14

options,29

hard drives

installing,29

replacing,37

hardware options, installing,24

help, obtaining,8

HP ProLiant Essentials Foundation Pack,32

HP Systems Insight Manager,32

HP technical support,8

I

IML

See Integrated Management Log