Page 1

HP StorageWorks 6400/8400 Enterprise

Virtual Array user guide

Part number: 576284–001

Second edition: August 2009

Page 2

Legal and notice information

© Copyright 2009 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products and services are set

forth in the express warranty statements accompanying such products and services. Nothing herein should be construed as

constituting an additional warranty. HP shall not be liable for technical or editorial errors or omissions contained herein.

WARRANTY STATEMENT: To obtain a copy of the warranty for this product, see the warranty information website:

Microsoft and Windows are U.S. registered trademarks of Microsoft Corporation.

Java is a US trademark of Sun Microsystems, Inc.

UNIX is a registered trademark of The Open Group.

Page 3

Contents

About this guide ................................................................................. 13

Intended audience .................................................................................................................... 13

Related documentation .............................................................................................................. 13

Document conventions and symbols ............................................................................................. 13

Rack stability ............................................................................................................................ 14

HP technical support ................................................................................................................. 15

Customer self repair .................................................................................................................. 15

Subscription service .................................................................................................................. 15

HP websites ............................................................................................................................. 15

Documentation feedback ........................................................................................................... 15

1 EVA6400/8400 hardware ............................................................... 17

M6412A disk enclosures ........................................................................................................... 17

Enclosure layout ................................................................................................................. 17

I/O modules ..................................................................................................................... 18

I/O module status indicators ......................................................................................... 19

Fiber optic Fibre Channel cables .......................................................................................... 20

Copper Fibre Channel cables .............................................................................................. 20

Fibre Channel disk drives .................................................................................................... 20

Disk drive status indicators ............................................................................................ 21

Disk drive blank ........................................................................................................... 21

Controller enclosures ................................................................................................................. 21

Operator control panel ....................................................................................................... 23

Status indicators .......................................................................................................... 24

Navigation buttons ...................................................................................................... 25

Alphanumeric display ................................................................................................... 25

Power supplies ......................................................................................................................... 25

Blower module ......................................................................................................................... 26

Battery module ......................................................................................................................... 27

HSV controller cabling ............................................................................................................... 28

Storage system racks ................................................................................................................. 28

Rack configurations ............................................................................................................ 29

Power distribution ..................................................................................................................... 29

PDUs ................................................................................................................................ 30

PDU 1 ........................................................................................................................ 31

PDU 2 ........................................................................................................................ 31

PDMs ............................................................................................................................... 31

Rack AC power distribution ................................................................................................. 32

Rack System/E power distribution components ....................................................................... 33

Rack AC power distribution ........................................................................................... 34

Moving and stabilizing a rack .................................................................................................... 34

2 Enterprise Virtual Array startup .......................................................... 37

EVA8400 storage system connections .......................................................................................... 37

HP StorageWorks 6400/8400 Enterprise Virtual Array user guide 3

Page 4

EVA6400 storage system connections .......................................................................................... 38

Direct connect .......................................................................................................................... 39

iSCSI connection configurations .................................................................................................. 40

Fabric connect iSCSI ........................................................................................................... 40

Direct connect iSCSI ........................................................................................................... 40

Procedures for getting started ..................................................................................................... 41

Gathering information ......................................................................................................... 41

Host information .......................................................................................................... 41

Setting up a controller pair using the OCP ............................................................................. 42

Entering the WWN ...................................................................................................... 42

Entering the WWN checksum ....................................................................................... 43

Entering the storage system password ............................................................................. 44

Installing HP Command View EVA ........................................................................................ 44

Installing optional EVA software licenses ............................................................................... 44

3 EVA6400/8400 operation ............................................................... 45

Best practices ........................................................................................................................... 45

Operating tips and information .................................................................................................. 45

Reserving adequate free space ............................................................................................ 45

Using FATA disk drives ........................................................................................................ 45

Maximum LUN size ............................................................................................................ 45

Managing unused ports ...................................................................................................... 46

Failback preference setting for HSV controllers .............................................................................. 47

Changing virtual disk failover/failback setting ....................................................................... 49

Implicit LUN transition ......................................................................................................... 50

Storage system shutdown and startup .......................................................................................... 50

Shutting down the storage system ......................................................................................... 50

Starting the storage system .................................................................................................. 51

Saving storage system configuration data ..................................................................................... 52

Adding disk drives to the storage system ...................................................................................... 53

Creating disk groups .......................................................................................................... 53

Handling fiber optic cables ........................................................................................................ 53

Using the OCP ......................................................................................................................... 54

Displaying the OCP menu tree ............................................................................................. 54

Displaying system information .............................................................................................. 56

Displaying versions system information .................................................................................. 56

Shutting down the system .................................................................................................... 56

Shutting the controller down ................................................................................................ 57

Restarting the system ........................................................................................................... 57

Uninitializing the system ...................................................................................................... 58

Password options ............................................................................................................... 58

Changing a password ........................................................................................................ 59

Clearing a password .......................................................................................................... 59

4 Customer replaceable units ............................................................... 61

Customer self repair (CSR) ......................................................................................................... 61

Parts only warranty service .................................................................................................. 61

Best practices for replacing hardware components ........................................................................ 61

Component replacement videos ........................................................................................... 61

Verifying component failure ................................................................................................. 61

Identifying the spare part .................................................................................................... 62

Replaceable parts ..................................................................................................................... 62

Replacing the failed component .................................................................................................. 64

Replacement instructions ............................................................................................................ 64

4

Page 5

5 Error messages ................................................................................ 67

A Regulatory notices and specifications ................................................. 81

Regulatory notices .................................................................................................................... 81

Federal Communications Commission (FCC) notice ................................................................. 81

FCC Class A certification .............................................................................................. 81

Class A equipment ....................................................................................................... 82

Class B equipment ....................................................................................................... 82

Declaration of conformity for products marked with the FCC logo, United States only ............ 82

Modifications .............................................................................................................. 82

Cables ....................................................................................................................... 82

Laser device ...................................................................................................................... 83

Laser safety warnings ................................................................................................... 83

Compliance with CDRH regulations ................................................................................ 83

Certification and classification information ............................................................................. 83

Canadian notice (avis Canadian) ......................................................................................... 84

Class A equipment ....................................................................................................... 84

Class B equipment ....................................................................................................... 84

European union notice ........................................................................................................ 84

Notice for France ............................................................................................................... 84

WEEE Recycling Notices ..................................................................................................... 84

English notice .............................................................................................................. 84

Dutch notice ................................................................................................................ 85

Czechoslovakian notice ................................................................................................ 85

Estonian notice ............................................................................................................ 85

Finnish notice .............................................................................................................. 85

French notice ............................................................................................................... 86

German notice ............................................................................................................ 86

Greek notice ............................................................................................................... 86

Hungarian notice ........................................................................................................ 86

Italian notice ............................................................................................................... 87

Korean Communication Committee notice ....................................................................... 87

Latvian notice .............................................................................................................. 87

Lithuanian notice ......................................................................................................... 87

Polish notice ................................................................................................................ 88

Portuguese notice ......................................................................................................... 88

Slovakian notice .......................................................................................................... 88

Slovenian notice .......................................................................................................... 89

Spanish notice ............................................................................................................ 89

Swedish notice ............................................................................................................ 89

Germany noise declaration .................................................................................................. 89

Japanese notice ................................................................................................................. 90

Harmonics conformance (Japan) .................................................................................... 90

Taiwanese notice ................................................................................................................ 90

Japanese power cord notice ................................................................................................ 90

Country-specific certifications ............................................................................................... 90

B Controller fault management .............................................................. 93

Using HP Command View EVA ................................................................................................... 93

GUI termination event display ..................................................................................................... 93

GUI event display ............................................................................................................... 94

Fault management displays .................................................................................................. 94

Displaying Last Fault Information .................................................................................... 94

HP StorageWorks 6400/8400 Enterprise Virtual Array user guide 5

Page 6

Displaying Detailed Information ..................................................................................... 95

Interpreting fault management information ...................................................................... 95

C Non-standard rack specifications ....................................................... 97

Rack specifications .................................................................................................................... 97

Internal component envelope ............................................................................................... 97

EIA310-D standards ........................................................................................................... 97

EVA cabinet measures and tolerances ................................................................................... 98

Weights, dimensions and component CG measurements ......................................................... 98

Airflow and Recirculation .................................................................................................... 98

Component Airflow Requirements ................................................................................... 98

Rack Airflow Requirements ............................................................................................ 99

Configuration Standards ..................................................................................................... 99

Environmental and operating specifications .................................................................................. 99

UPS Selection .................................................................................................................... 99

Shock and vibration specifications ...................................................................................... 101

D Single Path Implementation ............................................................. 103

High-level solution overview ..................................................................................................... 103

Benefits at a glance ................................................................................................................ 104

Installation requirements .......................................................................................................... 104

Recommended mitigations ....................................................................................................... 104

Supported configurations ......................................................................................................... 104

General configuration components ..................................................................................... 105

Connecting a single path HBA server to a switch in a fabric zone ........................................... 105

HP-UX configuration .......................................................................................................... 107

Requirements ............................................................................................................. 107

HBA configuration ..................................................................................................... 107

Risks ........................................................................................................................ 108

Limitations ................................................................................................................. 108

Windows Server 2003 (32-bit) configuration ........................................................................ 109

Requirements ............................................................................................................. 109

HBA configuration ..................................................................................................... 109

Risks ........................................................................................................................ 109

Limitations ................................................................................................................. 109

Windows Server 2003 (64-bit) configuration ....................................................................... 110

Requirements ............................................................................................................. 110

HBA configuration ..................................................................................................... 110

Risks ........................................................................................................................ 111

Limitations ................................................................................................................. 111

SUN Solaris configuration ................................................................................................. 112

Requirements ............................................................................................................. 112

HBA configuration ..................................................................................................... 112

Risks ........................................................................................................................ 112

Limitations ................................................................................................................. 112

Tru64 UNIX configuration .................................................................................................. 113

Requirements ............................................................................................................. 113

HBA configuration ..................................................................................................... 113

Risks ........................................................................................................................ 114

OpenVMS configuration ................................................................................................... 115

Requirements ............................................................................................................. 115

HBA configuration ..................................................................................................... 115

Risks ........................................................................................................................ 115

Limitations ................................................................................................................. 115

6

Page 7

NetWare configuration ..................................................................................................... 116

Requirements ............................................................................................................. 116

HBA configuration ..................................................................................................... 116

Risks ........................................................................................................................ 116

Limitations ................................................................................................................. 117

Linux (32-bit) configuration ................................................................................................. 117

Requirements ............................................................................................................. 117

HBA configuration ..................................................................................................... 118

Risks ........................................................................................................................ 118

Limitations ................................................................................................................. 118

Linux (64-bit) configuration ................................................................................................ 119

Requirements ............................................................................................................. 119

HBA configuration ..................................................................................................... 119

Risks ........................................................................................................................ 119

Limitations ................................................................................................................. 119

IBM AIX configuration ....................................................................................................... 120

Requirements ............................................................................................................. 120

HBA configuration ..................................................................................................... 120

Risks ........................................................................................................................ 121

Limitations ................................................................................................................. 121

VMware configuration ...................................................................................................... 122

Requirements ............................................................................................................. 122

HBA configuration ..................................................................................................... 122

Risks ........................................................................................................................ 122

Limitations ................................................................................................................. 122

Failure scenarios ..................................................................................................................... 123

HP-UX ............................................................................................................................. 123

Windows Server 2003 ..................................................................................................... 124

Sun Solaris ...................................................................................................................... 124

OpenVMS and Tru64 UNIX ............................................................................................... 125

NetWare ........................................................................................................................ 126

Linux ............................................................................................................................... 126

IBM AIX .......................................................................................................................... 127

VMware .......................................................................................................................... 128

Glossary .......................................................................................... 129

Index ............................................................................................... 147

HP StorageWorks 6400/8400 Enterprise Virtual Array user guide 7

Page 8

Figures

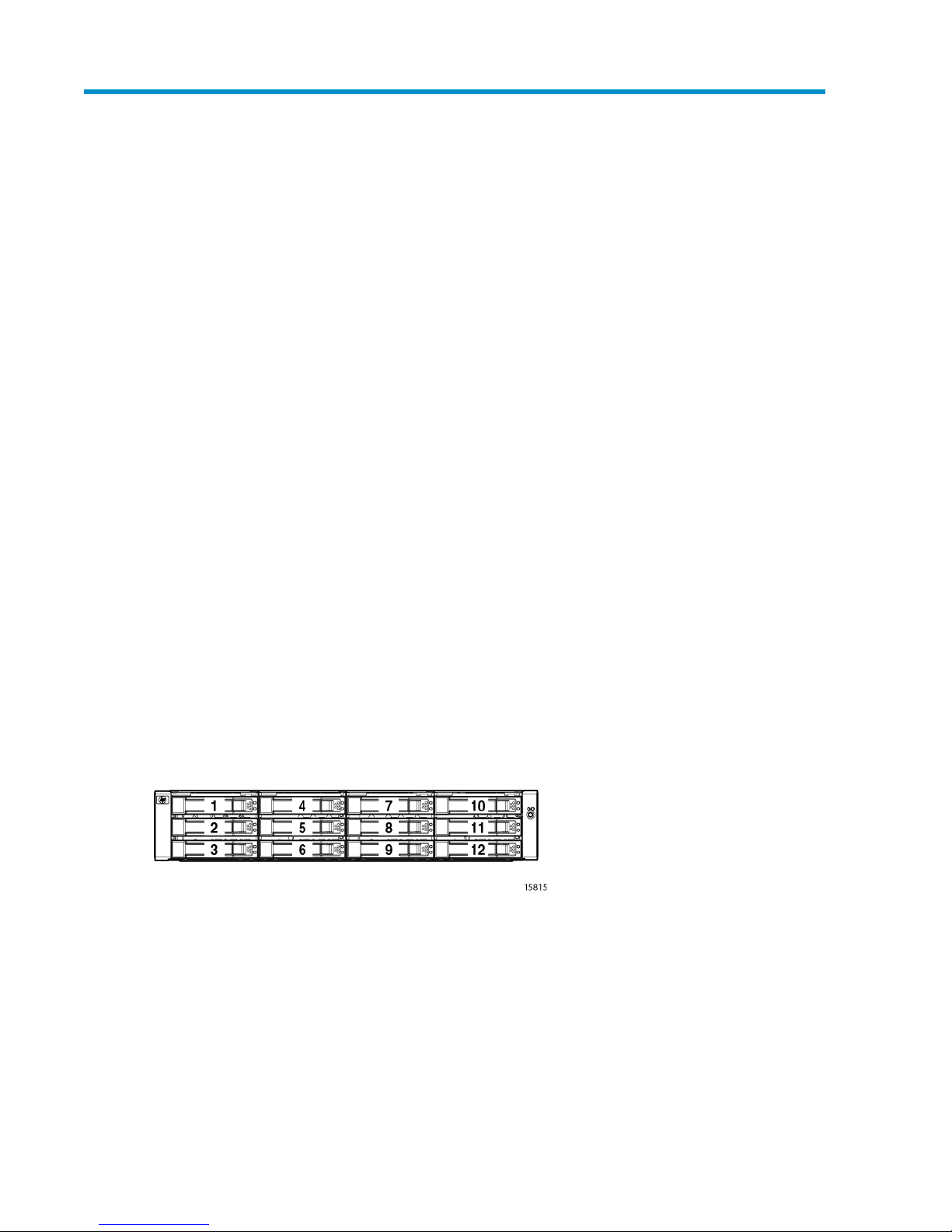

Disk drive bay numbering ........................................................................................ 171

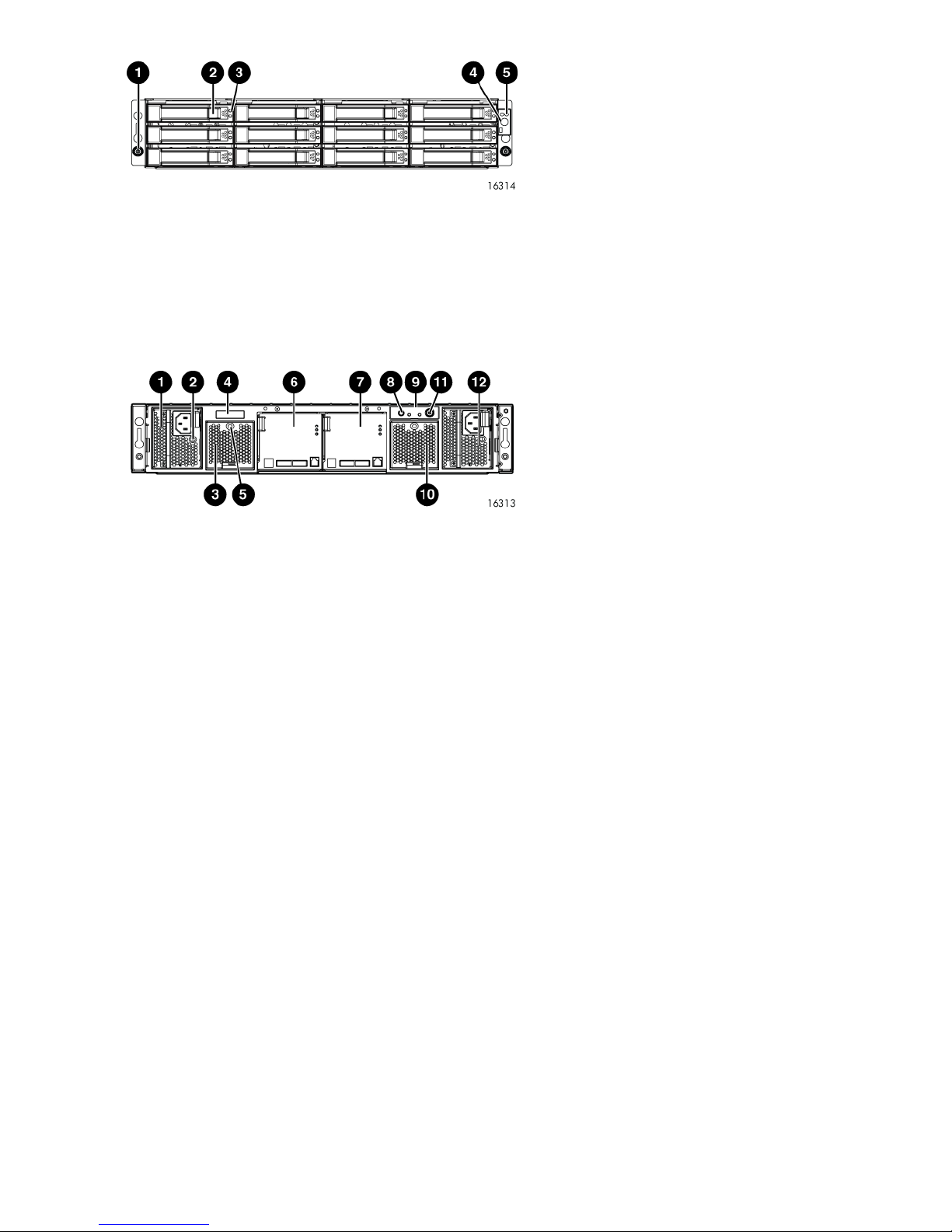

Disk enclosure front view without bezel ears ............................................................... 182

Disk enclosure rear view .......................................................................................... 183

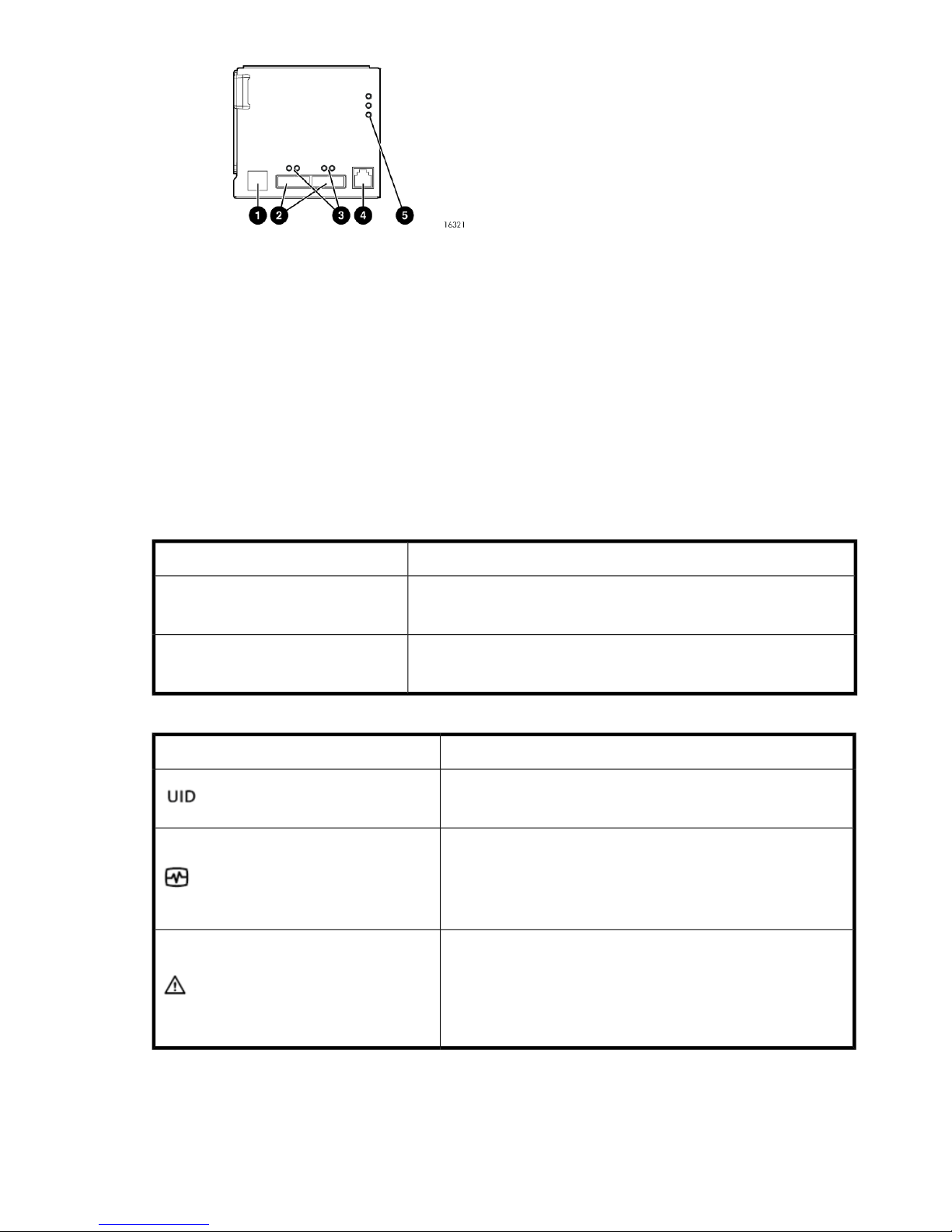

I/O module detail ................................................................................................... 194

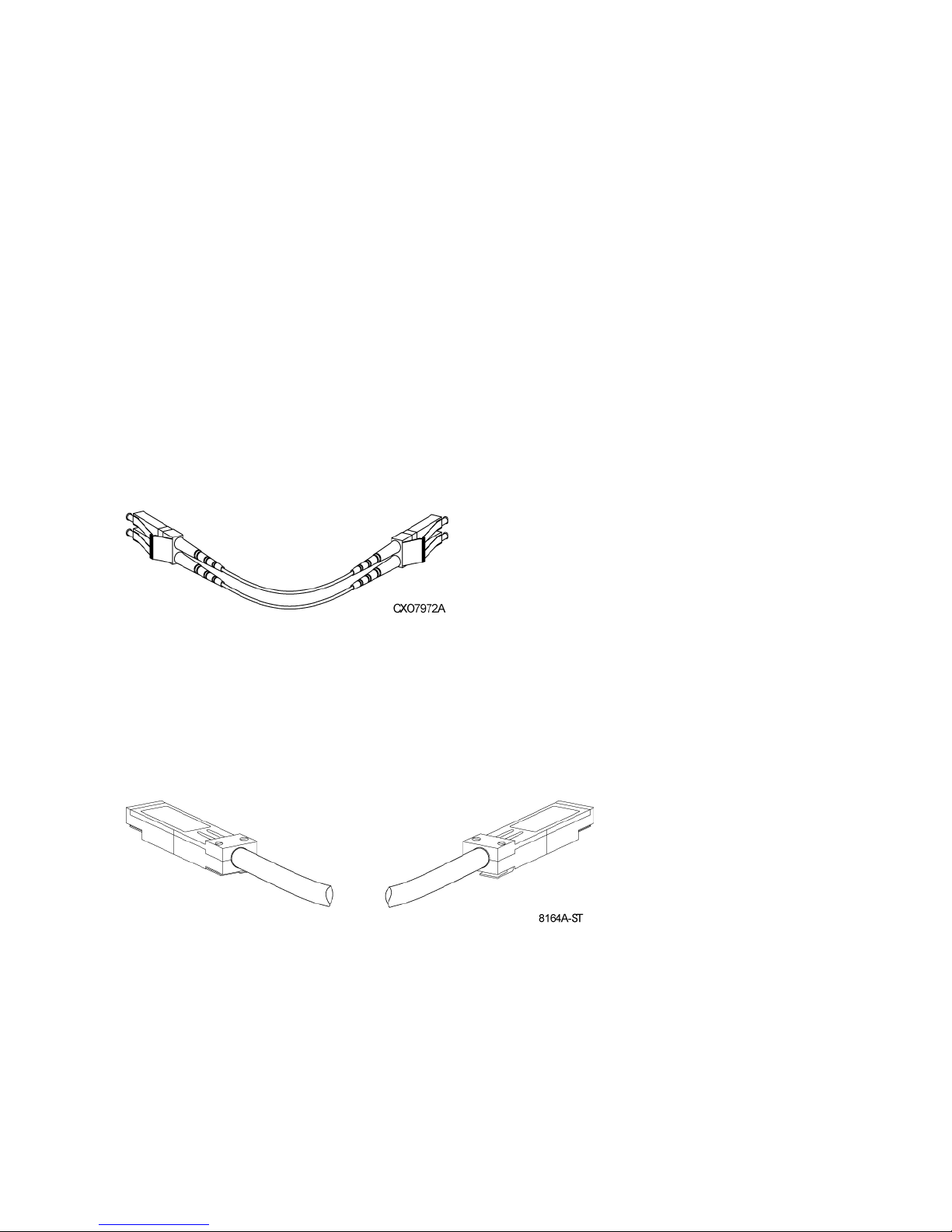

Fiber Optic Fibre Channel cable ............................................................................... 205

Copper Fibre Channel cable .................................................................................... 206

Disk status indicators ............................................................................................... 217

HSV400 controller rear view .................................................................................... 228

HSV450 controller rear view .................................................................................... 229

Controller front view ................................................................................................ 2310

Controller OCP ....................................................................................................... 2311

Power supply .......................................................................................................... 2612

Blower module pulled out ......................................................................................... 2613

Battery module ....................................................................................................... 2714

Storage system hardware components – back view ...................................................... 2915

60-Hz and 50-Hz wall receptacles ............................................................................ 2916

Dual PDU assembly ................................................................................................. 3117

Rack PDM .............................................................................................................. 3218

Rack AC power distribution ...................................................................................... 3319

Single rack configuration floor space requirements ...................................................... 3520

Raising a leveler foot ............................................................................................... 3521

EVA8400 configuration ........................................................................................... 3822

EVA6400 configuration ........................................................................................... 3923

Location of the World Wide Name labels .................................................................. 4324

Typical product label ............................................................................................... 6225

Typical enclosure certification label ........................................................................... 9126

GUI termination event display ................................................................................... 9327

Typical HP Command View EVA Event display ............................................................ 9428

Mounting space dimensions ..................................................................................... 9729

Single path HBA server without OpenVMS or Tru64 UNIX ......................................... 10630

Single path HBA server with OpenVMS or Tru64 UNIX .............................................. 10731

HP-UX configuration .............................................................................................. 10832

8

Page 9

Windows Server 2003 (32-bit) configuration ............................................................ 11033

Windows Server 2003 (64-bit) configuration ............................................................ 11134

SUN Solaris configuration ...................................................................................... 11335

Tru64 UNIX configuration ...................................................................................... 11436

OpenVMS configuration ........................................................................................ 11637

NetWare configuration .......................................................................................... 11738

Linux (32-bit) configuration ..................................................................................... 11839

Linux (64-bit) configuration ..................................................................................... 12040

IBM AIX Configuration ........................................................................................... 12141

VMware configuration ........................................................................................... 12342

HP StorageWorks 6400/8400 Enterprise Virtual Array user guide 9

Page 10

Tables

Document conventions ............................................................................................. 131

Port status LEDs ....................................................................................................... 192

I/O module status LEDs ........................................................................................... 193

Disk status indicator LED descriptions ......................................................................... 214

Controller status indicators ....................................................................................... 245

Controller port status indicators ................................................................................. 246

Navigation button functions ..................................................................................... 257

Fan status indicators ................................................................................................ 268

Battery status indicators ........................................................................................... 279

Push button functions ............................................................................................... 4210

Maximum LUN size ................................................................................................ 4511

Failback preference behavior .................................................................................... 4712

Failback settings by operating system ........................................................................ 4813

Impact on virtual disk presentation when changing failover/failback setting .................... 4914

Menu options within the OCP display ........................................................................ 5515

Shutdown methods .................................................................................................. 5716

Controller enclosure replacement parts ...................................................................... 6213

M6412-A disk enclosure replaceable parts ................................................................ 6318

Error Messages ....................................................................................................... 9519

Controller event text description file ........................................................................... 9520

Component data ..................................................................................................... 9821

HP UPS models and capacities ................................................................................. 9922

UPS operating time limits ....................................................................................... 10023

EVA8400 UPS loading .......................................................................................... 10024

EVA6400 UPS loading .......................................................................................... 10125

Operating Shock/Vibration .................................................................................... 10226

HP-UX failure scenarios. ......................................................................................... 12327

Windows Server 2003 failure scenarios .................................................................. 12428

Sun Solaris failure scenarios. .................................................................................. 12429

OpenVMS and Tru64 UNIX failure scenarios. ........................................................... 12530

NetWare failure scenarios. .................................................................................... 12631

Linux failure scenarios. ........................................................................................... 12632

10

Page 11

IBM AIX failure scenarios. ...................................................................................... 12733

VMware failure scenarios. ...................................................................................... 12834

HP StorageWorks 6400/8400 Enterprise Virtual Array user guide 11

Page 12

12

Page 13

About this guide

This user guide provides the following information:

• Description of the HP StorageWorks 6400/8400 Enterprise Virtual Array and its components

• Operating your storage system

• Regulations and specifications

• HSV fault management concepts

Intended audience

This book is intended for use by Enterprise Virtual Array customers involved in the operation and

management of EVA6400/8400 storage systems.

Related documentation

You can find the documents referenced in this guide on the Manuals page of the HP Business Support

Center website:

http://www.hp.com/support/manuals

Click Disk Storage Systems under Storage, and then select HP StorageWorks 6400/8400 Enterprise

Virtual Arrays under EVA Disk Arrays.

Document conventions and symbols

Table 1 Document conventions

ElementConvention

Cross-reference links and e-mail addressesBlue text: Table 1

website addressesBlue, underlined text: http://www.hp.com

• Keys that are pressed

Bold text

Monospace text

• Text typed into a GUI element, such as a box

• GUI elements that are clicked or selected, such as menu

and list items, buttons, tabs, and check boxes

Text emphasisItalic text

• File and directory names

• System output

• Code

• Commands, their arguments, and argument values

HP StorageWorks 6400/8400 Enterprise Virtual Array user guide 13

Page 14

ElementConvention

Monospace, italic text

Monospace, bold text

WARNING!

Indicates that failure to follow directions could result in bodily harm or death.

CAUTION:

Indicates that failure to follow directions could result in damage to equipment or data.

IMPORTANT:

Provides clarifying information or specific instructions.

NOTE:

Provides additional information.

• Code variables

• Command variables

Emphasized monospace text

TIP:

Provides helpful hints and shortcuts.

Rack stability

WARNING!

To reduce the risk of personal injury or damage to equipment:

• Extend leveling jacks to the floor.

• Ensure that the full weight of the rack rests on the leveling jacks.

• Install stabilizing feet on the rack.

• In multiple-rack installations, secure racks together.

• Extend only one rack component at a time. Racks may become unstable if more than one component

is extended.

About this guide14

Page 15

HP technical support

For worldwide technical support information, see the HP support website:

http://www.hp.com/support

Before contacting HP, collect the following information:

• Product model names and numbers

• Technical support registration number (if applicable)

• Product serial numbers

• Error messages

• Operating system type and revision level

• Detailed questions

Customer self repair

HP customer self repair (CSR) programs allow you to repair your StorageWorks product. If a CSR

part needs replacing, HP ships the part directly to you so that you can install it at your convenience.

Some parts do not qualify for CSR. Your HP-authorized service provider will determine whether a

repair can be accomplished by CSR.

For more information about CSR, contact your local service provider. For North America, see the CSR

website:

http://www.hp.com/go/selfrepair

Subscription service

HP recommends that you register your product at the Subscriber's Choice for Business website:

http://www.hp.com/go/wwalerts

After registering, you will receive e-mail notification of product enhancements, new driver versions,

firmware updates, and other product resources.

HP websites

For additional information, see the following HP websites:

• http://www.hp.com

• http://www.hp.com/go/storage

• http://www.hp.com/support/manuals

• http://h20293.www2.hp.com

Documentation feedback

HP welcomes your feedback.

To make comments and suggestions about product documentation, please send a message to

storagedocsfeedback@hp.com. All submissions become the property of HP.

HP StorageWorks 6400/8400 Enterprise Virtual Array user guide 15

Page 16

About this guide16

Page 17

1 EVA6400/8400 hardware

The EVA6400/8400 contains the following hardware components:

• HSV controllers — Contains power supplies, cache batteries, fans, and an operator control panel

(OCP)

• Fibre Channel disk enclosure — Contains disk drives, power supplies, fans, midplane, and I/O

modules

• Fibre Channel Arbitrated Loop cables — Provides connectivity to the HSV controllers and the Fibre

Channel disk enclosures

• Rack — Several free standing racks are available

M6412A disk enclosures

The M6412A disk enclosure contains the disk drives used for data storage; a storage system contains

multiple disk enclosures. The major components of the enclosure are:

• 12-bay enclosure

• Dual-loop, Fibre Channel drive enclosure I/O modules

• Copper Fibre Channel cables

• Fibre Channel disk drives and drive blanks

• Power supplies

• Fan modules

Enclosure layout

The disk drives mount in bays in the front of the enclosure. The bays are numbered sequentially from

top to bottom and left to right. A drive is referred to by its bay number (see Figure 1). Enclosure status

indicators are located at the right of each disk. Figure 2 shows the front and Figure 3 shows the rear

view of the disk enclosure.

Figure 1 Disk drive bay numbering

.

HP StorageWorks 6400/8400 Enterprise Virtual Array user guide 17

Page 18

5. Enclosure status LEDs

Figure 2 Disk enclosure front view without bezel ears

.

2. Disk drive release1. Rack-mounting thumbscrew

4. UID push button3. Drive LEDs

2. Power supply 1 status LED1. Power supply 1

4. Enclosure product number and serial number3. Fan 1

6. I/O module A5. Fan 1 status LED

8. Rear UID push button7. I/O module B

10. Fan 29. Enclosure status LEDs

Figure 3 Disk enclosure rear view

.

I/O modules

Two I/O modules provide the interface between the disk enclosure and the host controllers, (Figure

4). For redundancy, only dual-controller, dual-loop operation is supported. Each controller is connected

to both I/O modules in the disk enclosure.

Each I/O module has two ports that can transmit and receive data for bidirectional operation.

Activating a port requires connecting a Fibre Channel cable to the port. The port function depends

upon the loop.

12. Power supply 211. Power push button

EVA6400/8400 hardware18

Page 19

5. I/O module status LEDs

Figure 4 I/O module detail

.

I/O module status indicators

There are five status indicators on the I/O module. See Figure 4. The status indicator states for an

operational I/O module are shown in Table 2. Table 3 shows the status indicator states for a

non-operational I/O module.

Table 2 Port status LEDs

2. 4 Gb I/O ports1. Double 7–segment display: enclosure ID

4. Manufacturing diagnostic port3. Port 1 (P1), Port 2 (P2) status LEDs

DescriptionStatus LED

Green (left)

Amber (right)

Table 3 I/O module status LEDs

• Solid green — Active link.

• Flashing green — Locate: remotely asserted by application client.

• Solid amber — Module fault, no synchronization.

• Flashing amber — Module fault.

DescriptionStatus LED

• Locate.

• Flashing blue — Remotely asserted by application client.

• Module health indicator:

• Flashing green — I/O module powering up.

• Solid green — normal operation.

• Green off — firmware malfunction.

• Fault indicator:

• Flashing amber — Warning condition (not visible when solid

amber showing).

• Solid amber — Replace FRU.

• Amber off — Normal operation.

HP StorageWorks 6400/8400 Enterprise Virtual Array user guide 19

Page 20

Fiber optic Fibre Channel cables

The Enterprise Virtual Array uses orange, 50-µm, multi-mode, fiber optic cables for connection to the

SAN or the host, where there is a direct connection to the host. The fiber optic cable assembly consists

of two 2-m fiber optic strands and small form-factor connectors on each end. See Figure 5.

To ensure optimum operation, the fiber optic cable components require protection from contamination

and mechanical hazards. Failure to provide this protection can cause degraded operation. Observe

the following precautions when using fiber optic cables.

• To avoid breaking the fiber within the cable:

• Do not kink the cable

• Do not use a cable bend-radius of less than 30 mm (1.18 in)

• To avoid deforming, or possibly breaking the fiber within the cable, do not place heavy objects

on the cable.

• To avoid contaminating the optical connectors:

• Do not touch the connectors

• Never leave the connectors exposed to the air

• Install a dust cover on each transceiver and fiber cable connector when they are disconnected

If an open connector is exposed to dust, or if there is any doubt about the cleanliness of the connector,

clean the connector as described in Handling fiber optic cables.

Figure 5 Fiber Optic Fibre Channel cable

.

Copper Fibre Channel cables

The Enterprise Virtual Array uses copper Fibre Channel cables to interconnect disk shelves. The cables

are available in 0.6-meter (1.97 ft.) and 2.0-meter (6.56 ft.) lengths. Copper cables provide

performance comparable to fiber optic cables. Copper cable connectors differ from fiber optic small

form-factor connectors (see Figure 6).

Figure 6 Copper Fibre Channel cable

.

Fibre Channel disk drives

The Fibre Channel disk drives are hot-pluggable and include the following features:

• Dual-ported 4-Gbps Fibre Channel controller interface that allows up to 96 disk drives to be sup-

ported per array controller enclosure

EVA6400/8400 hardware20

Page 21

• Compact, direct-connect design for maximum storage density and increased reliability and signal

integrity

• Both online high-performance disk drives and FATA disk drives supported in a variety of capacities

and spindle speeds

• Better vibration damping for improved performance

Up to 12 disk drives can be installed in a drive enclosure.

Disk drive status indicators

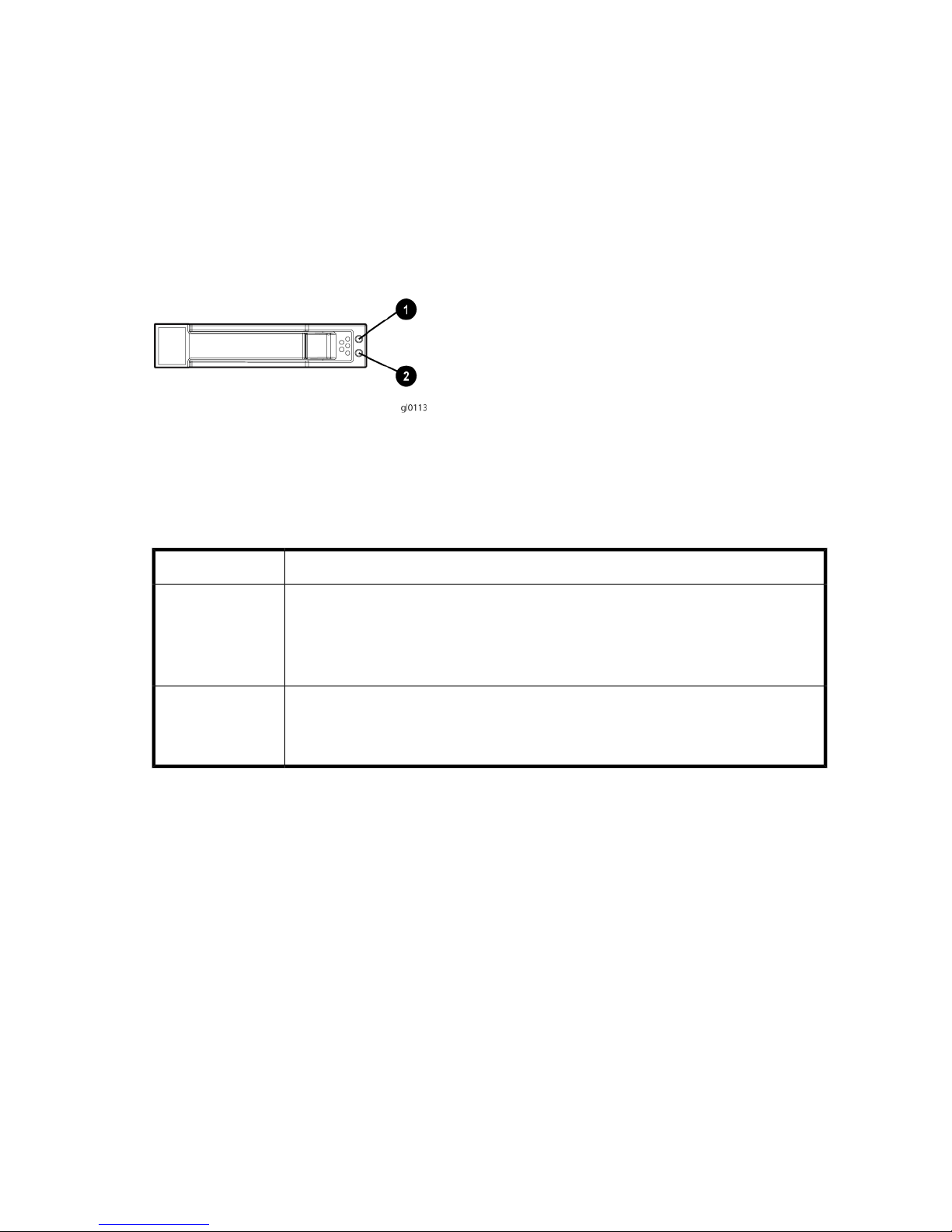

Two status indicators display drive operational status. Figure 7 identifies the disk drive status indicators.

Table 4 describes them.

Figure 7 Disk status indicators

.

Table 4 Disk status indicator LED descriptions

2. Green1. Bi-color (amber/blue)

DescriptionDrive LED

• Slow flashing blue (0.5 Hz) — Used to locate drive.

Bi-color (top)

Green (bottom)

• Fast flashing blue (4 Hz) — Used for reserved locate.

• Medium flashing blue (1 Hz) — Used for critical locate.

• Solid amber — Drive fault.

• Flashing — Drive is spinning up or down and is not ready.

• Solid — Drive is ready to perform I/O operations.

• Flickering — Indicates drive activity.

Disk drive blank

To maintain the proper enclosure air flow, a disk drive or a disk drive blank must be installed in each

drive bay. The disk drive blank maintains proper airflow within the disk enclosure.

Controller enclosures

This section describes the major features, purpose, and function of the HSV400 and HSV450

controllers. Each Enterprise Virtual Array has a pair of these controllers. Figure 8 shows the HSV400

controller rear view and Figure 9 shows the HSV450 controller rear view. The front of the HSV400

and HSV450 is shown in Figure 10.

HP StorageWorks 6400/8400 Enterprise Virtual Array user guide 21

Page 22

NOTE:

Some controller enclosure modules have a cache battery located behind the OCP.

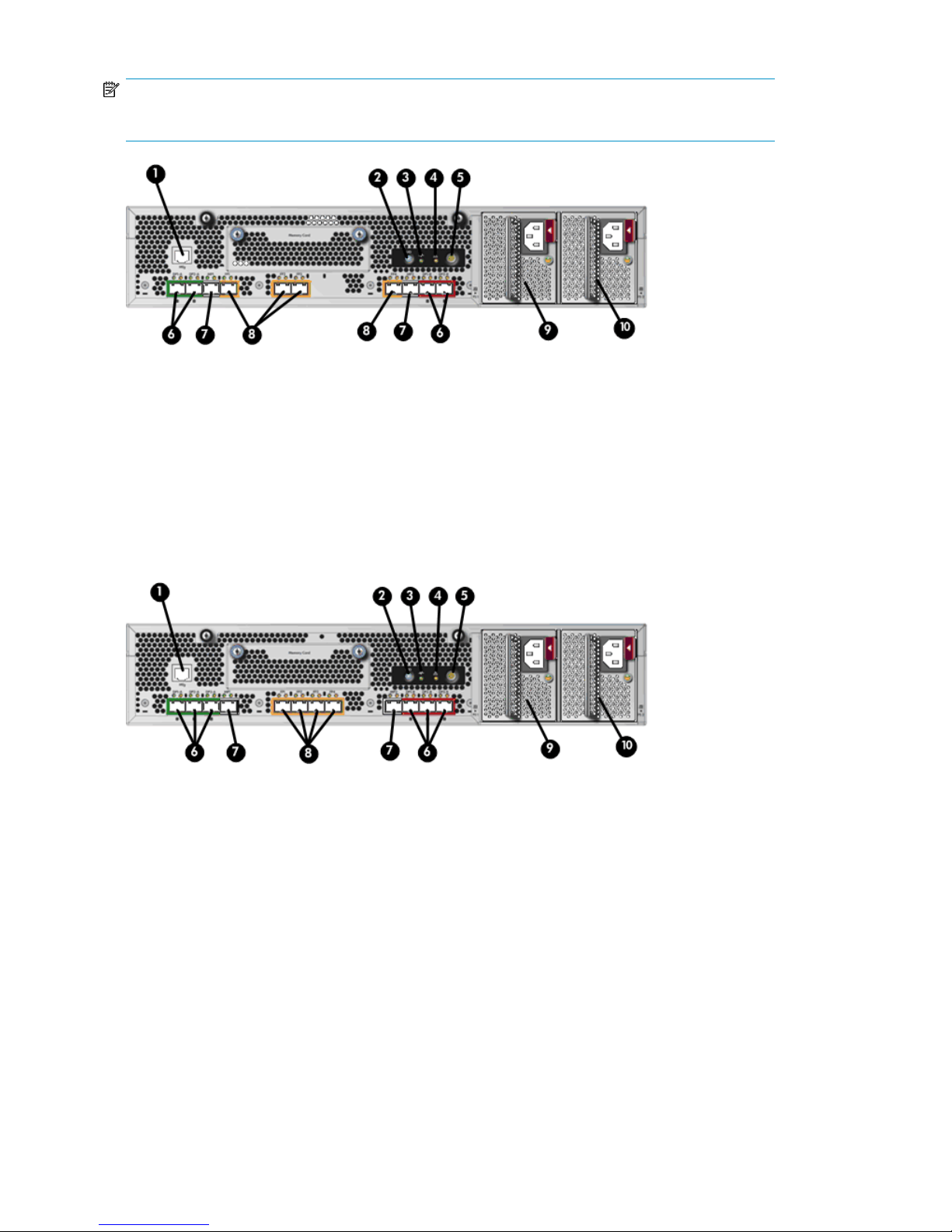

Figure 8 HSV400 controller rear view

.

2. Unit ID1. Serial port

4. Fault indicator3. Controller health

6. DPI ports5. Power

8. Fiber ports7. Mirror ports

Figure 9 HSV450 controller rear view

.

10. Power supply 29. Power supply 1

2. Unit ID1. Serial port

4. Fault indicator3. Controller health

6. DPI ports5. Power

8. Fiber ports7. Mirror ports

10. Power supply 29. Power supply 1

EVA6400/8400 hardware22

Page 23

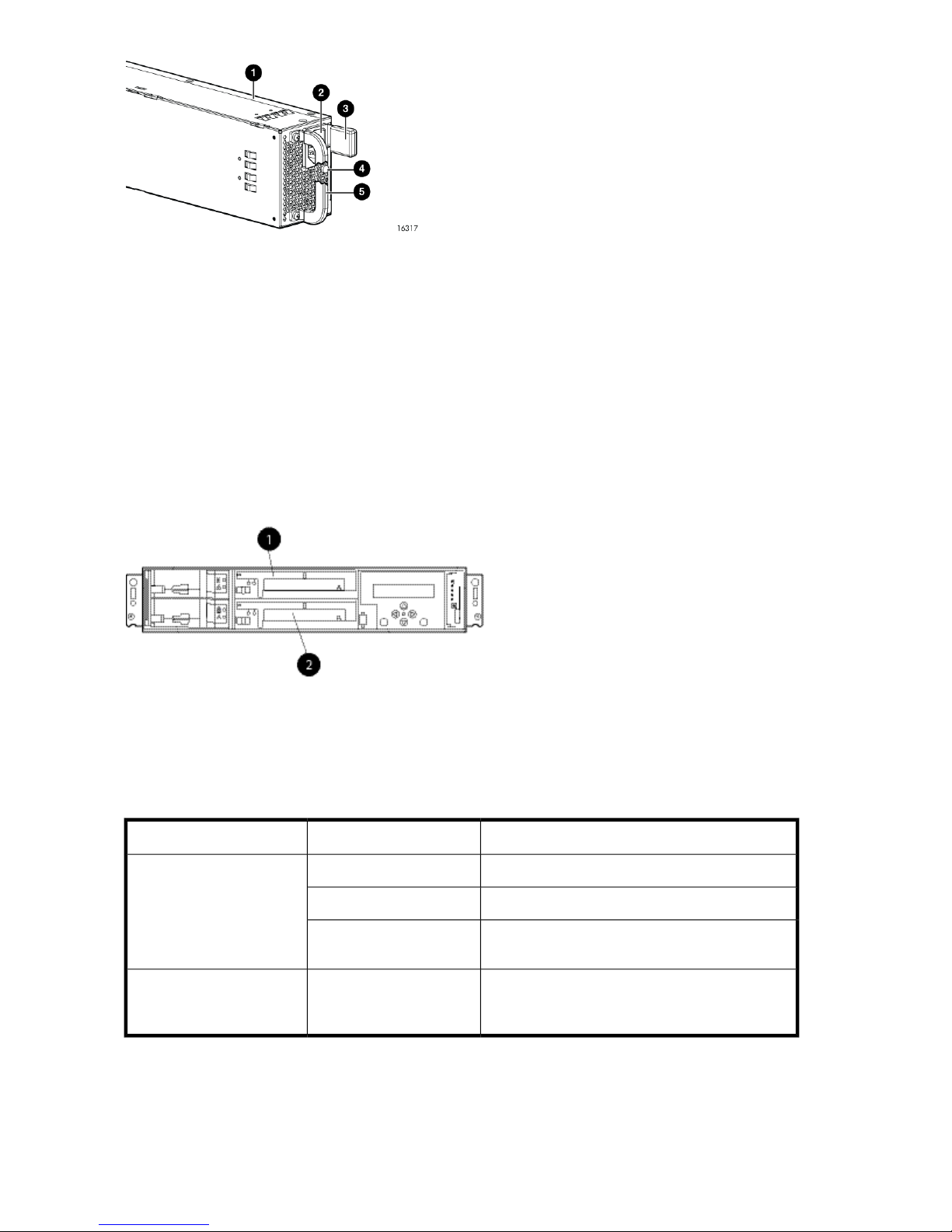

Figure 10 Controller front view

.

7. Unit ID

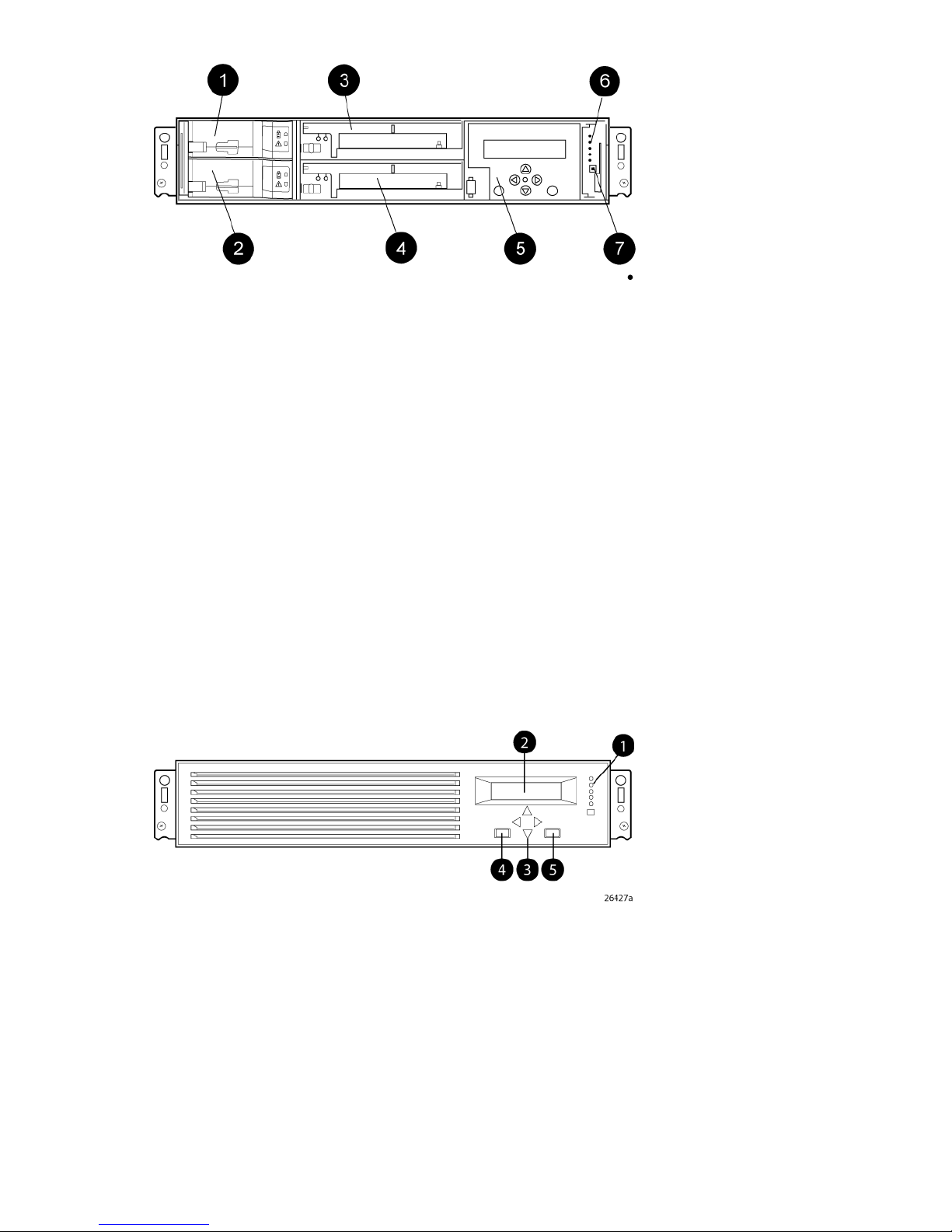

Operator control panel

The operator control panel (OCP) provides a direct interface to each controller. From the OCP you

can display storage system status and configuration information, shut down the storage system, and

manage the password.

The OCP includes a 40-character LCD alphanumeric display, six push-buttons, and five status indicators.

See Figure 11.

HP Command View EVA is the tool you will typically use to display storage system status and

configuration information or perform the tasks available from the OCP. However, if HP Command

View EVA is not available, the OCP can be used to perform these tasks.

2. Battery 21. Battery 1

4. Blower 23. Blower 1

6. Status indicators5. Operator Control Panel (OCP)

Figure 11 Controller OCP

.

1. Status indicators (see Table 5) and UID button

2. 40-character alphanumeric display

3. Left, right, top, and bottom push-buttons

4. Esc

HP StorageWorks 6400/8400 Enterprise Virtual Array user guide 23

Page 24

5. Enter

Status indicators

The status indicators display the operational status of the controller. The function of each indicator is

described in Table 5. During initial setup, the status indicators might not be fully operational.

The following sections define the alphanumeric display modes, including the possible displays, the

valid status indicator displays, and the pushbutton functions.

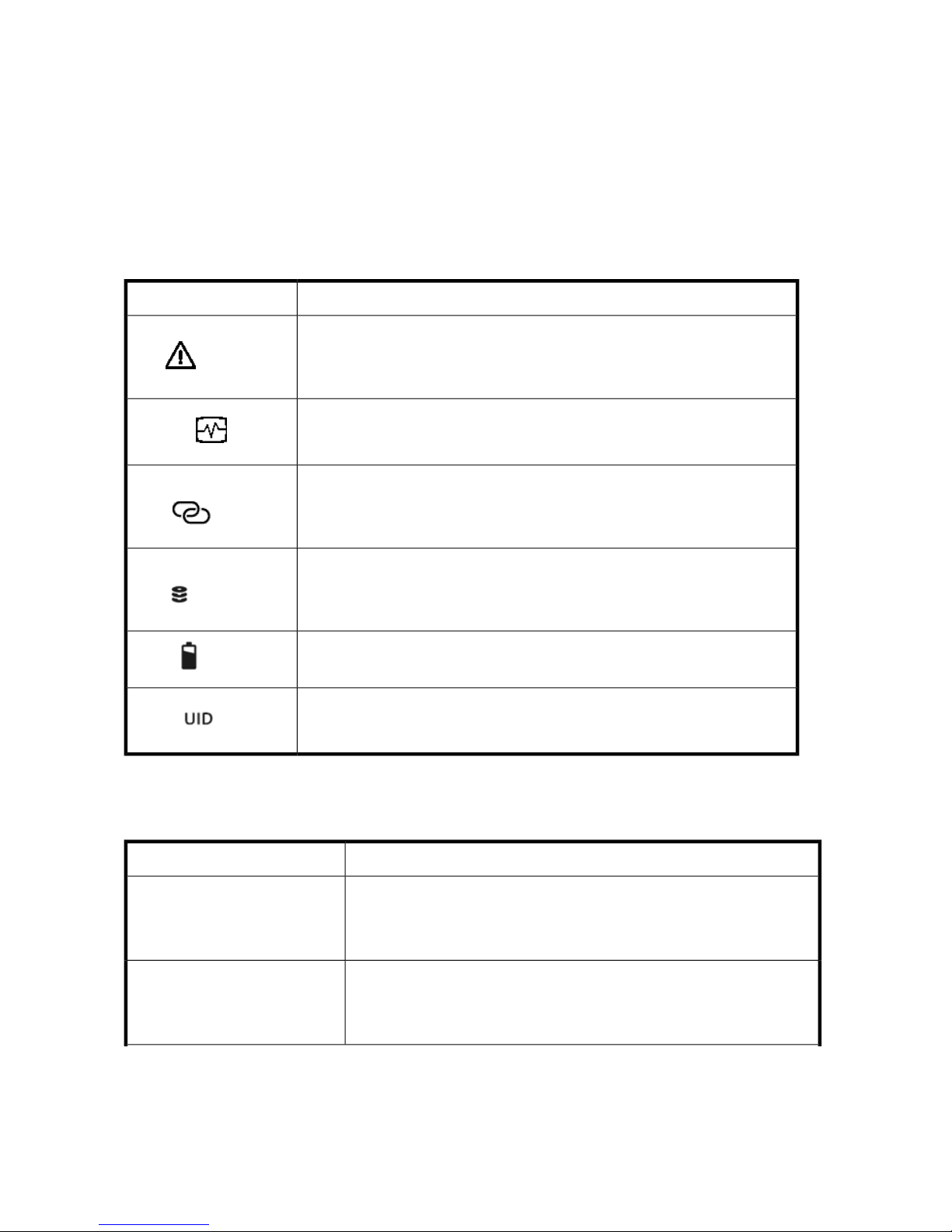

Table 5 Controller status indicators

Fault

Controller

DescriptionIndicator

When the indicator is a solid amber, it means there was a boot failure. When it

flashes, the controller is inoperative. Check either HP Command View EVA or the

LCD Fault Management displays for a definition of the problem and recommended

corrective action.

When the indicator is flashing green slowly, the controller is booting up. When

the indicator turns to solid green, boot is successful and the controller is operating

normally.

Physical link to hosts established

Virtual disks presented to

hosts

Battery

Unit ID

When this indicator is green, there is at least one physical link between the storage

system and hosts that is active and functioning normally. When this indicator is

amber, there are no links between the storage system and hosts that are active

and functioning normally.

When this indicator is green, all virtual disks that are presented to hosts are healthy

and functioning normally. When this indicator is amber, at least one virtual disk

is not functioning normally. When this indicator is off, there are no virtual disks

presented to hosts and this indicates a problem with the virtual disk on the array.

When this indicator is green, the battery is working properly. When this indicator

is amber, there is a battery failure.

Press to turn on (solid blue); press again to turn it off. This LED mimics the function

of the UID on the back of the controller.This indicator comes on in response to a

Locate command issued by HP Command View EVA.

Each port on the rear of the controller has an associated status indicator located directly above it.

Table 6 lists the port and its status description.

Table 6 Controller port status indicators

DescriptionPort

• Green—Normal operation

Fibre Channel host ports

• Amber—No signal detected

•

Off—No SFP1detected or the Direct Connect OCP setting is incorrect

Fibre Channel device ports

EVA6400/8400 hardware24

• Green—Normal operation

• Amber—No signal detected or the controller has failed the port

•

Off—No SFP 1 detected

Page 25

Fibre Channel cache mirror ports

1

On copper Fibre Channel cables, the SFP is integrated into the cable connector.

Navigation buttons

The operation of the navigation buttons is determined by the current display and location in the menu

structure. Table 7 defines the basic pushbutton functions when navigating the menus and options.

To simplify presentation and to avoid confusion, the pushbutton reference names, regardless of labels,

are left, right, top, and bottom.

Table 7 Navigation button functions

DescriptionPort

• Green—Normal operation

• Amber—No signal detected or the controller has failed the port

•

Off—No SFP1 detected

FunctionButton

Moves down through the available menus and options

Moves up through the available menus and options

Selects the displayed menu or option.

Alphanumeric display

The alphanumeric display uses two LCD rows, each capable of displaying up to 20 alphanumeric

characters. By default, the alphanumeric display alternates between displaying the Storage System

Name and the World Wide Name. An active (flashing) display, an error condition message, or a

user entry (pressing a push-button) overrides the default display. When none of these conditions exist,

the default display returns after approximately 10 seconds.

Power supplies

Two power supplies provide the necessary operating voltages to all controller enclosure components.

If one power supply fails, the remaining supply is capable of operating the enclosure.

Returns to the previous menu.

Used for “No” selections and to return to the default display.Esc

Used for “Yes” selections and to progress through menu items.Enter

HP StorageWorks 6400/8400 Enterprise Virtual Array user guide 25

Page 26

1. Power supply

3. Latch

Figure 12 Power supply

.

Blower module

Fan modules provide the cooling necessary to maintain the proper operating temperature within the

controller enclosure. If one fan fails, the remaining fan is capable of cooling the enclosure.

4. Status indicator (solid green on — normal operation; solid amber — failure or no power)

5. Handle2. AC input connector

2. Blower 21. Blower 1

Figure 13 Blower module pulled out

.

Table 8 Fan status indicators

On left — green

Off

OnOn right — amber

EVA6400/8400 hardware26

DescriptionFault indicatorStatus indicator

Normal operation.Solid green

Maintenance in progress.Blinking

Amber is on or blinking, or the enclosure is

powered down.

Fan failure. Green will be off. (Green and amber

are not on simultaneously except for a few seconds

after power-up.)

Page 27

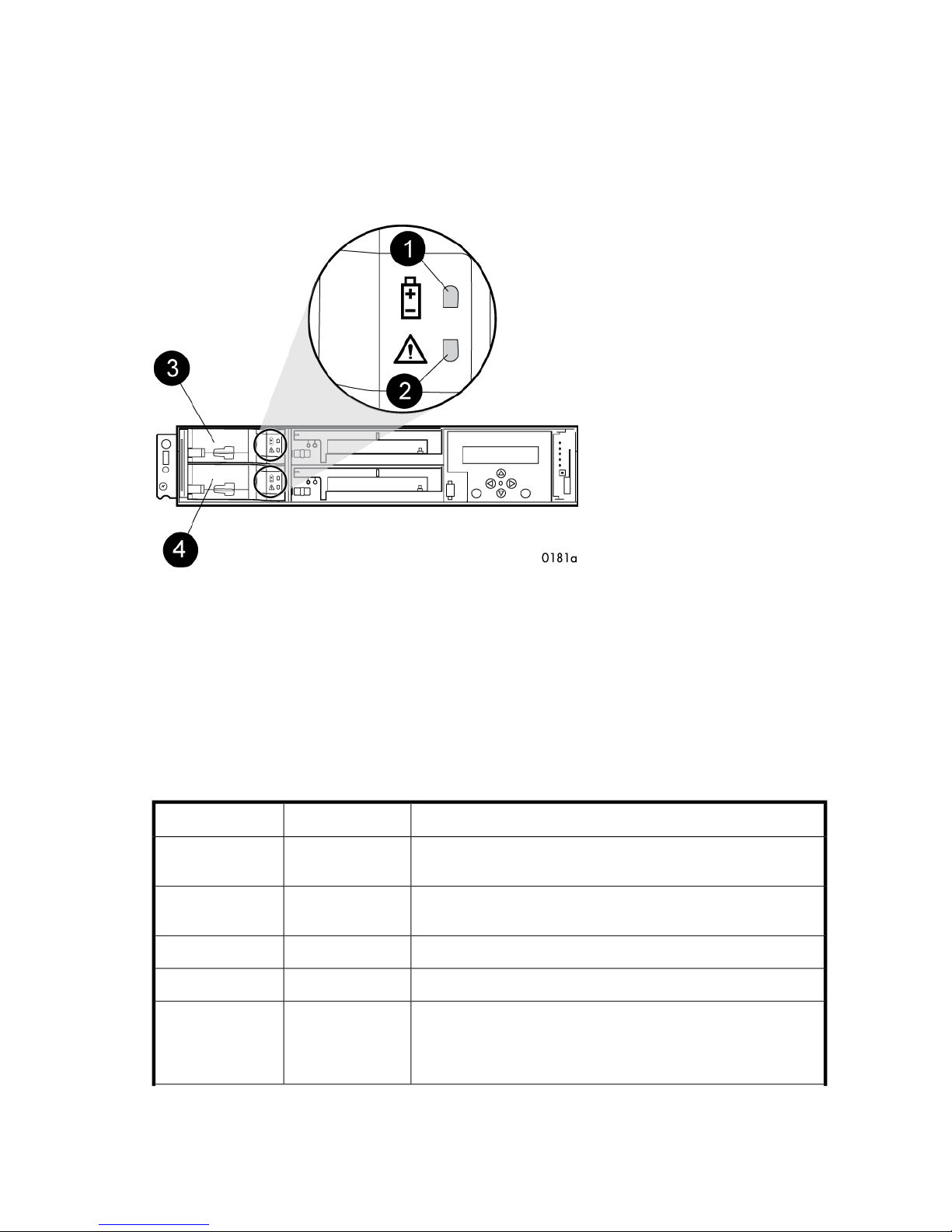

Battery module

Batteries provide backup power to maintain the contents of the controller cache when AC power is

lost and the storage system has not been shutdown properly. When fully charged the batteries can

sustain the cache contents for to 96 hours. Three batteries are used on the EVA8400 and two batteries

are used on the EVA6400. Figure 14 illustrates the location of the cache batteries and the battery

status indicators. See Table 9 for additional information on the status indicators.

Figure 14 Battery module

.

2. Fault indicator1. Status indicator

4. Battery 13. Battery 0

The table below describes the battery status indicators. When a battery is first installed, the fault

indicator goes on (solid) for approximately 30 seconds while the system discovers the new battery.

Then, the battery status indicators display the battery status as described in the table below.

Table 9 Battery status indicators

DescriptionFault indicatorStatus indicator

OffOn

OffFlashing

Flashing (fast)Flashing (fast)

Normal operation. A maintenance charge process keeps the battery

fully charged.

Battery is undergoing a full charging process. This is the indication

you typically see after installing a new battery.

Battery fault. The battery has failed and should be replaced.OnOff

The battery has experienced an over temperature fault.FlashingOff

Battery code is being updated. When a new battery is installed, it

may be necessary for the controllers to update the code on the

battery to the correct version. Both indicators flash rapidly for approximately 30 seconds.

HP StorageWorks 6400/8400 Enterprise Virtual Array user guide 27

Page 28

FlashingFlashing

HSV controller cabling

All data cables and power cables attach to the rear of the controller. Adjacent to each data connector

is a two-colored link status indicator. Table 6 identifies the status conditions presented by these

indicators.

NOTE:

These indicators do not indicate whether there is communication on the link, only whether the link

can transmit and receive data.

The data connections are the interfaces to the disk drive enclosures or loop switches (depending on

your configuration), the other controller, and the fabric. Fiber optic cables link the controllers to the

fabric, and, if an expansion cabinet is part of the configuration, link the expansion cabinet drive

enclosures to the loop is in the main cabinet. Copper cables are used between the controllers (mirror

port) and between the controllers and the drive enclosures or loop switches.

DescriptionFault indicatorStatus indicator

Battery is undergoing a scheduled battery load test, during which

the battery is discharged and then recharged to ensure it is working

properly. During the discharge cycle, you will see this display. The

load test occurs infrequently and takes several hours.

Storage system racks

All storage system components are mounted in a rack. Each configuration includes one enclosure

holding both controllers (the controller pair), FC cables the controller and the disk enclosures. Each

controller pair and all the associated drive enclosures form a single storage system.

The rack provides the capability for mounting 483 mm (19 in) wide controller and drive enclosures.

NOTE:

Racks and rack-mountable components are typically described using “U” measurements. “U”

measurements are used to designate panel or enclosure heights. The “U” measurement is a standard

of 41 mm (1.6 in).

The racks provide the following:

• Unique frame and rail design — Allows fast assembly, easy mounting, and outstanding structural

integrity.

• Thermal integrity — Front-to-back natural convection cooling is greatly enhanced by the innovative

multi-angled design of the front door.

• Security provisions — The front and rear door are lockable, which prevents unauthorized entry.

• Flexibility — Provides easy access to hardware components for operation monitoring.

• Custom expandability — Several options allow for quick and easy expansion of the racks to create

a custom solution.

EVA6400/8400 hardware28

Page 29

Rack configurations

Each system configuration contains several disk enclosures included in the storage system. See Figure

15 for a typical EVA6400/8400 rack configuration. The standard rack is the 42U HP 10000 G2

Series rack. The EVA6400/8400 is also supported with 22U, 36U, 42U 5642, and 47U racks. The

42U 5643 is a field-installed option and the 47U rack must be assembled onsite because the cabinet

height creates shipping difficulties.

For more information on HP rack offerings for the EVA6400/8400, see http://h18004.www1.hp.com/

products/servers/proliantstorage/racks/index.html.

Figure 15 Storage system hardware components – back view

.

Power distribution

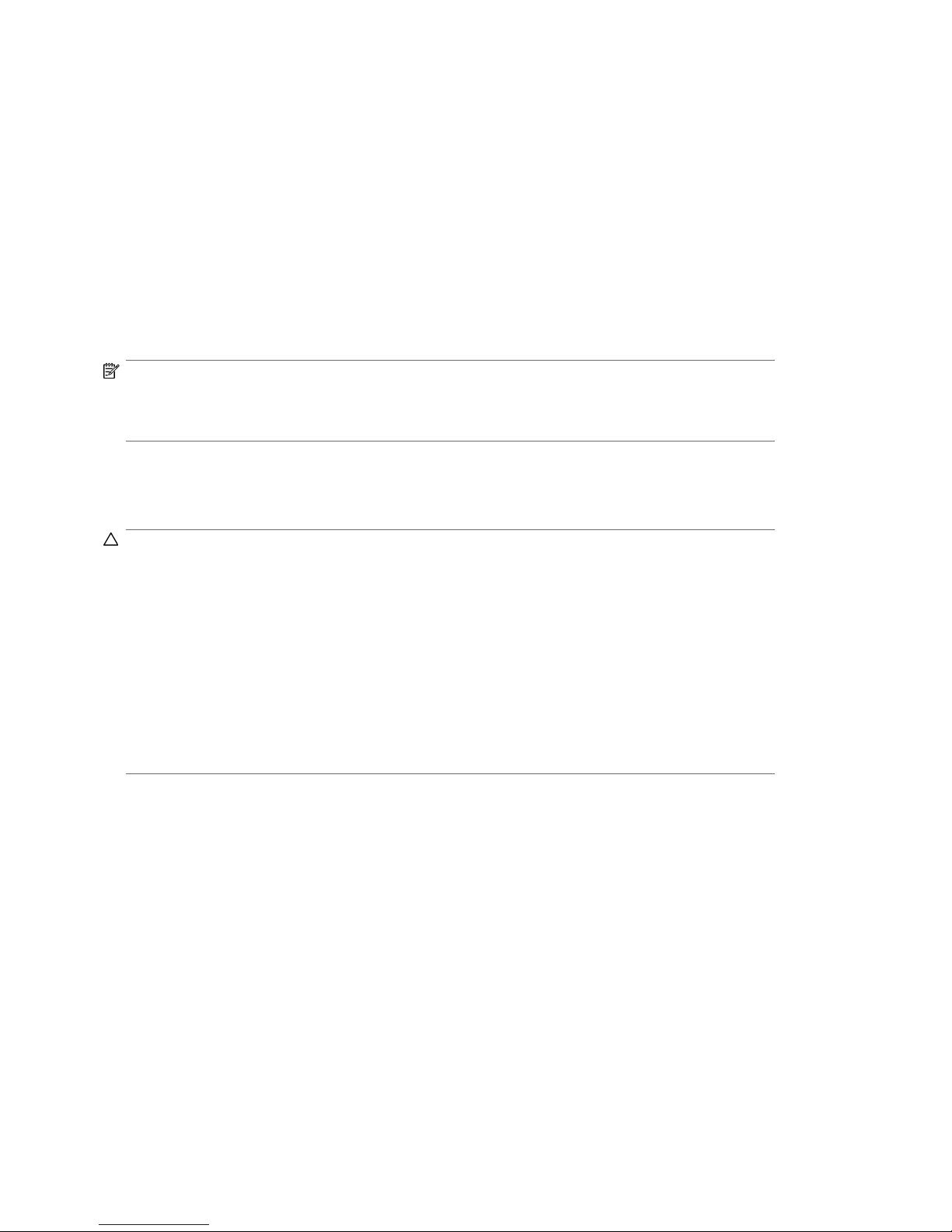

AC power is distributed to the rack through a dual Power Distribution Unit (PDU) assembly mounted

at the bottom rear of the rack. The characteristics of the fully-redundant rack power configuration are

as follows:

• Each PDU is connected to a separate circuit breaker-protected, 30-A AC site power source

(220–240 VAC ±10%, 50 or 60-Hz, ±5%). Figure 16 illustrates the compatible 60-Hz and 50-

Hz wall receptacles.

NEMA L6-30R receptacle, 3-wire, 30-A, 60-Hz

IEC 309 receptacle, 3-wire, 30-A, 50-Hz

Figure 16 60-Hz and 50-Hz wall receptacles

.

HP StorageWorks 6400/8400 Enterprise Virtual Array user guide 29

Page 30

• The standard power configuration for any Enterprise Virtual Array rack is the fully redundant

configuration. Implementing this configuration requires:

• Two separate circuit breaker-protected, 30-A site power sources with a compatible wall receptacle (see Figure 16).

• One dual PDU assembly. Each PDU connects to a different wall receptacle.

• Eight Power Distribution Modules (PDM) per rack. Four PDMs mount vertically on each side of

the rack. Each set of PDMs connects to a different PDU.

• The drive enclosure power supplies on the left (PS 1) connect to the PDMs on the left with a

gray, 66 cm (26 in) power cord.

• The drive enclosure power supplies on the right (PS 2) connect to the PDMs on the right with

a black, 66 cm (26 in) power cord.

• Each controller has a left and right power supply. The left power supplies of each should be

connected to the left PDMs and the right power supplies should be connected to the right PDMs.

NOTE:

Drive enclosures, when purchased separately, include one 50 cm black cable and one 50 cm gray

cable.

The configuration provides complete power redundancy and eliminates all single points of failure for

both the AC and DC power distribution.

PDUs

CAUTION:

Operating the array with a single PDU will result in the following conditions:

• No redundancy

• Louder controllers and disk enclosures due to increased fan speed

• HP Command View EVA will continuously display a warning condition, making issue monitoring

a labor-intensive task

Although the array is capable of doing so, HP strongly recommends that an array operating with a

single PDU should not:

• Be put into production

• Remain in this state for more than 24 hours

Each Enterprise Virtual Array rack has either a 50- or 60-Hz, dual PDU mounted at the bottom rear

of the rack. The 228481-002/228481-003 PDU placement is back-to-back, plugs facing down, with

switches on top.

• The standard 50-Hz PDU cable has an IEC 309, 3-wire, 30-A, 50-Hz connector.

• The standard 60-Hz PDU cable has a NEMA L6-30P, 3-wire, 30-A, 60-Hz connector.

If these connectors are not compatible with the site power distribution, you must replace the PDU

power cord cable connector.

Each of the two PDU power cables has an AC power source specific connector. The circuit

breaker-controlled PDU outputs are routed to a group of four AC receptacles (see Figure 17). The

voltages are then routed to PDMs, sometimes referred to as AC power strips, mounted on the two

vertical rails in the rear of the rack.

EVA6400/8400 hardware30

Page 31

NOTE:

The dual PDU assembly shown in Figure 17 typically lays flat in a rack, but is shown raised to illustrate

the AC receptacles and mounting hardware.

Figure 17 Dual PDU assembly

.

2. PDU 21. PDU 1

PDU 1

PDU 2

4. AC receptacles3. Circuit breakers

5. Mounting hardware

PDU 1 connects to AC power distribution source 1. A PDU 1 failure:

• Disables the power distribution circuit.

• Removes power from PDMs 1, 2, and 3.

• Disables PS 1 in the drive enclosures.

• Disables the upper controller power supply.

PDU 2 connects to AC power distribution source 2. A PDU 2 failure:

• Disables the power distribution circuit.

• Removes power from PDMs 4, 5, and 6.

• Disables PS 2 in the drive enclosures.

• Disables the lower controller power supply.

PDMs

There are six PDMs mounted in the rear of each rack:

• Three mounted on the left vertical rail connect to PDU 1.

HP StorageWorks 6400/8400 Enterprise Virtual Array user guide 31

Page 32

• Three mounted on the right vertical rail connect to PDU 2.

Each PDM has eight AC receptacles and one thermal circuit breaker. The PDMs distribute the AC

power from the PDUs to the enclosures. Two power sources exist for each controller pair and drive

enclosure. If a PDU fails, the system will remain operational.

CAUTION:

The AC power distribution within a rack ensures a balanced load to each PDU and reduces the

possibility of an overload condition. Changing the cabling to or from a PDM could cause an overload

condition. HP supports only the AC power distributions defined in this user guide.

Figure 18 Rack PDM

.

3. AC power connector

Rack AC power distribution

The power distribution in an Enterprise Virtual Array rack is the same for all variants. The site AC

input voltage is routed to the dual PDU assembly mounted in the rack lower rear. Each PDU distributes

AC to a maximum of four PDMs mounted on the left and right vertical rails (see Figure 19).

• PDMs 1 through 4 connect to receptacles A through D on PDU 1. Power cords connect these PDMs

to the number 1 drive enclosure power supplies and to the upper controller enclosure.

• PDMs 5 through 8 connect to receptacles A through D on PDU 2. Power cords connect these PDMs

to the number 2 drive enclosure power supplies and to the lower controller enclosure.

NOTE:

The locations of the PDUs and the PDMs are the same in all racks.

2. Thermal circuit breakers1. Power receptacles

EVA6400/8400 hardware32

Page 33

Figure 19 Rack AC power distribution

.

2. PDM 21. PDM 1

4. PDM 43. PDM 3

6. PDM 55. PDU 1

8. PDM 77. PDM 6

10. PDU 29. PDM 8

Rack System/E power distribution components

AC power is distributed to the Rack System/E rack through Power Distribution Units (PDU) mounted

on the two vertical rails in the rear of the rack. Up to four PDUs can be mounted in the rack—two

mounted on the right side of the cabinet and two mounted on the left side.

Each of the PDU power cables has an AC power source specific connector. The circuit

breaker-controlled PDU outputs are routed to a group of ten AC receptacles. The storage system

components plug directly into the PDUs.

HP StorageWorks 6400/8400 Enterprise Virtual Array user guide 33

Page 34

Rack AC power distribution

The power distribution configuration in a Rack System/E rack depends on the number of storage

systems installed in the rack. If one storage system is installed, only two PDUs are required. If multiple

storage systems are installed, four PDUs are required.

The site AC input voltage is routed to each PDU mounted in the rack. Each PDU distributes AC through

ten receptacles directly to the storage system components.

• PDUs 1 and 3 (optional) are mounted on the left side of the cabinet. Power cords connect these

PDUs to the number 1 drive enclosure power supplies and to the controller enclosures.

• PDUs 2 and 4 (optional) are mounted on the right side of the cabinet. Power cords connect these

PDUs to the number 2 drive enclosure power supplies and to the controller enclosures.

Moving and stabilizing a rack

WARNING!

The physical size and weight of the rack requires a minimum of two people to move. If one person

tries to move the rack, injury may occur.

To ensure stability of the rack, always push on the lower half of the rack. Be especially careful when

moving the rack over any bump (e.g., door sills, ramp edges, carpet edges, or elevator openings).

When the rack is moved over a bump, there is a potential for it to tip over.

Moving the rack requires a clear, uncarpeted pathway that is at least 80 cm (31.5 in) wide for the

60.3 cm (23.7 in) wide, 42U rack. A vertical clearance of 203.2 cm (80 in) should ensure sufficient

clearance for the 200 cm (78.7 in) high, 42U rack.

CAUTION:

Ensure that no vertical or horizontal restrictions exist that would prevent rack movement without

damaging the rack.

Make sure that all four leveler feet are in the fully raised position. This process will ensure that the

casters support the rack weight and the feet do not impede movement.

Each rack requires an area 600 mm (23.62 in) wide and 1000 mm (39.37 in) deep (see Figure 20).

EVA6400/8400 hardware34

Page 35

Figure 20 Single rack configuration floor space requirements

.

2. Rear door1. Front door

4. Service area width 813 mm3. Rack width 600 mm

6. Rack depth 1000 mm5. Rear service area depth 300 mm

8. Total rack depth 1706 mm7. Front service area depth 406 mm

If the feet are not fully raised, complete the following procedure:

1. Raise one foot by turning the leveler foot hex nut counterclockwise until the weight of the rack is

fully on the caster (see Figure 21).

2. Repeat Step 1 for the other feet.

Figure 21 Raising a leveler foot

.

3. Carefully move the rack to the installation area and position it to provide the necessary service

areas (see Figure 20).

2. Leveler foot1. Hex nut

HP StorageWorks 6400/8400 Enterprise Virtual Array user guide 35

Page 36

To stabilize the rack when it is in the final installation location:

1. Use a wrench to lower the foot by turning the leveler foot hex nut clockwise until the caster does

not touch the floor. Repeat for the other feet.

2. After lowering the feet, check the rack to ensure it is stable and level.

3. Adjust the feet as necessary to ensure the rack is stable and level.

EVA6400/8400 hardware36

Page 37

2 Enterprise Virtual Array startup

This chapter describes the procedures to install and configure the Enterprise Virtual Array. When

these procedures are complete, you can begin using your storage system.

NOTE:

Installation of the Enterprise Virtual Array should be done only by an HP authorized service

representative. The information in this chapter provides an overview of the steps involved in the

installation and configuration of the storage system.

EVA8400 storage system connections

Figure 22 shows how the storage system is connected to other components of the storage solution.

• The HSV450 controllers connect via four host ports (FP1, FP2, FP3, and FP4) to the Fibre Channel

fabrics. The hosts that will access the storage system are connected to the same fabrics.

• The HP Command View EVA management server also connects to the fabric.

• The controllers connect through two loop pairs to the drive enclosures. Each loop pair consists of

two independent loops, each capable of managing all the disks should one loop fail.

HP StorageWorks 6400/8400 Enterprise Virtual Array user guide 37

Page 38

Figure 22 EVA8400 configuration

.

8 Controller A1 Network interconnection

9 Controller B2 Management server

10 Cache mirror ports3 Non-host

11 Drive enclosure 14 Host A

12 Drive enclosure 25 Host B

13 Drive enclosure 36 Fabric 1

7 Fabric 2

EVA6400 storage system connections

Figure 23 shows a typical EVA6400 SAN topology:

• The HSV400 controllers connect via four host ports (FP1, FP2, FP3, and FP4) to the Fibre Channel

fabrics. The hosts that will access the storage system are connected to the same fabrics.

• The HP Command View EVA management server also connects to both fabrics.

• The controllers connect through one loop pair to the drive enclosures. The loop pair consists of

two independent loops, each capable of managing all the disks should one loop fail.

Enterprise Virtual Array startup38

Page 39

Figure 23 EVA6400 configuration

.

Direct connect

NOTE:

Direct connect is currently supported on Microsoft Windows only.

Direct connect provides a lower cost solution for smaller configurations. When using direct connect,

the storage system controllers are connected directly to the host(s), not to SAN Fibre Channel switches.

Make sure the following requirements are met when configuring your environment for direct connect:

7 Fabric 21 Network interconnection

8 Controller A2 Management server

9 Controller B3 Non-host