Page 1

SSL2000 Series Library

Maintenance and Service Guide

First Edition (May 2000)

Part Number 187195-001

Compaq Computer Corporation

Page 2

Notice

© 2000 Compaq Com puter Corporation.

Compaq, the Compaq lo go, and StorageWorks Registered in U. S. Patent and Trademark Office.

All other product na mes mentioned herein may be trademarks or registered trademarks of their res pective

companies.

Confidential comp uter software. Valid license from Compaq required for possession, use or copying.

Consistent with FAR 12.211 and 12.212, Commercial Computer Soft ware, Computer Software

Documentation, and Technical Data for Commercial It ems are licensed to the U.S. Government under

vendor's standard commercial license.

Compaq shall not be liable for t echnical or editorial errors or omissions contained herein. The information

in this document is subject to change without notice.

The information in this publication is subject to change without notice and is provided “AS IS” WITHOUT

WARRANTY OF ANY KIND. THE ENTIRE RISK ARISING OUT OF THE USE OF THIS

INFORMATION REMAINS WITH RECIPIENT. IN NO EVENT SHALL COMPAQ BE LIABLE FOR

ANY DIRECT, CONSEQUENTIAL, INCIDENTAL, SPECIAL, PUNITIVE OR OTHER DAMAGES

WHATSOEVER (INCLUDING WITHOUT LIMITATION, DAMAGES FOR LOSS OF BUSINESS

PROFITS, BUSINESS INTERRUPTION OR LOSS OF BUSINESS INFORMATION), EVEN IF

COMPAQ HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. THE FOREGOING

SHALL APPLY REGARDLESS OF THE NEGLIGENCE OR OTHER FAULT OF EITHER PARTY

AND REGARDLESS OF WHETHER SUCH LIABILITY SOUNDS IN CONTRACT, NEGLIGENCE,

TORT, OR ANY OTHER THEORY OF LEGAL LIABILITY, AND NOTWITHSTANDING ANY

FAILURE OF ESSENTIAL PURPOSE OF ANY LIMITED REMEDY.

The limited warranti es for Compaq products ar e exclusively set forth in t he documentation accompanying

such products. Nothing herein should be construed as constituting a further or additional warranty.

Printed in the U.S.A.

Compaq StorageWorks SSL2000 Series Library Maintenance and Service Guide

Maintenance and Service Guide

First Edition (April 2000)

Part Number 187195-001

Page 3

About This Guide

Symbols in Text..........................................................................................................xi

Compaq Technician Notes ........................................................................................xii

Where to Go for Additional Help..............................................................................xii

Integrated Management Display........................................................................xiii

Telephone Numbers ..........................................................................................xiii

Chapter 1

System Description

Introduction..............................................................................................................1-1

Library Models.........................................................................................................1-1

Multi-Unit Library Systems .....................................................................................1-2

Tape Cartridge Magazine Mail Slot .........................................................................1-2

SCSI Interface ..........................................................................................................1-2

Multi-Server Data Sharing ................................................................................1-3

SCSI Configuration...........................................................................................1-3

SCSI Bus Performance Considerations....................................................................1-3

Drives................................................................................................................1-3

Data Transfer Rate ............................................................................................1-3

Internal Cabling Configuration..........................................................................1-3

Bus Length Limitations.....................................................................................1-4

Independent SCSI Buses for SE........................................................................1-4

Physical Configuration............................................................................................. 1-4

Shuttle Lockdown Mechanism.................................................................................1-4

Library Features .......................................................................................................1-5

Control Panel.....................................................................................................1-6

Display ..............................................................................................................1-6

Power Supply....................................................................................................1-6

Tape Cartridge Magazine..................................................................................1-7

Integral Fan Cooling..........................................................................................1-8

Robotics.............................................................................................................1-8

Bar Code Reader...............................................................................................1-8

Advanced Design Features.......................................................................................1-8

Embedded Diagnostics......................................................................................1-8

Error Checking..................................................................................................1-8

Buffer................................................................................................................1-8

Compression......................................................................................................1-9

Capacity.............................................................................................................1-9

Media Life.........................................................................................................1-9

Contents

Page 4

iv Compaq StorageWorks SSL2000 Series Library Maintenance and Service Guide

Chapter 2

Operation

Introduction..............................................................................................................2-1

Front Panel ...............................................................................................................2-2

Power Switch.....................................................................................................2-2

Indicators and Buttons.......................................................................................2-3

LED Indicators.........................................................................................................2-4

Buttons .....................................................................................................................2-4

Using the Enter Button to Access Main Menu..................................................2-4

Using the Escape Button to Return to Default Screen.......................................2-4

Using the Escape Button to Access Status Mode..............................................2-5

Front Panel and Media Locks...................................................................................2-5

Startup Display Messages.........................................................................................2-6

Power-On Self Test Screen ...............................................................................2-6

Initialization Screens.........................................................................................2-6

Default Screen...................................................................................................2-7

Fault Screen.......................................................................................................2-7

Using the Library Menus..........................................................................................2-8

Using the Status Mode..............................................................................................2-9

Exiting the Status Mode....................................................................................2-9

Exploring the Status Mode................................................................................2-9

Library Status Submenu....................................................................................2-9

Drive Status Menu...........................................................................................2-10

Map Information Screen..................................................................................2-11

Using the Menu Mode............................................................................................2-11

Exiting the Menu Mode...................................................................................2-12

Navigating through the Menu Structure..........................................................2-12

Load/Unload Menu.................................................................................................2-12

Remove Magazine Menu........................................................................................ 2-12

Maintenance Menu.................................................................................................2-13

Configure Menu .....................................................................................................2-13

Security Menu ........................................................................................................2-13

Displaying Firmware Revisions.............................................................................2-14

Loading and Unloading..........................................................................................2-14

Inserting and Removing Cartridges........................................................................2-16

Removing the Magazine.........................................................................................2-17

Emergency Magazine Removal.......................................................................2-17

Inserting Cartridges into the Magazine...........................................................2-18

Inserting the Magazine....................................................................................2-18

Using the Mail Slot .........................................................................................2-19

Tape Cartridge Requirements.................................................................................2-19

Write Protecting Cartridges.............................................................................2-20

Bar Code Labels.....................................................................................................2-21

Multi-Unit Library System Operation....................................................................2-22

Powering Up....................................................................................................2-22

Connecting a Multi-Unit Library System........................................................2-22

Chapter 3

Maintenance

Introduction..............................................................................................................3-1

Running a Cleaning Cartridge..................................................................................3-1

Running a Cleaning Cartridge Automatically...................................................3-2

Running a Cleaning Cartridge Manually...........................................................3-2

Page 5

Removing the Cleaning Cartridge............................................................................3-3

Exercising the Library Robotics ...............................................................................3-3

Chapter 4

Troubleshooting

Introduction..............................................................................................................4-1

Platform Problems....................................................................................................4-1

General Drive Errors................................................................................................4-1

Error Recovery.........................................................................................................4-2

Error Recovery Procedures.......................................................................................4-3

Fault Symptom Codes (FSCs)..................................................................................4-3

Chapter 5

Parts Removal and Replacement

Introduction..............................................................................................................5-1

FRUs.........................................................................................................................5-1

Precaution.................................................................................................................5-2

Ferrites......................................................................................................................5-2

Using Loctite 222.....................................................................................................5-2

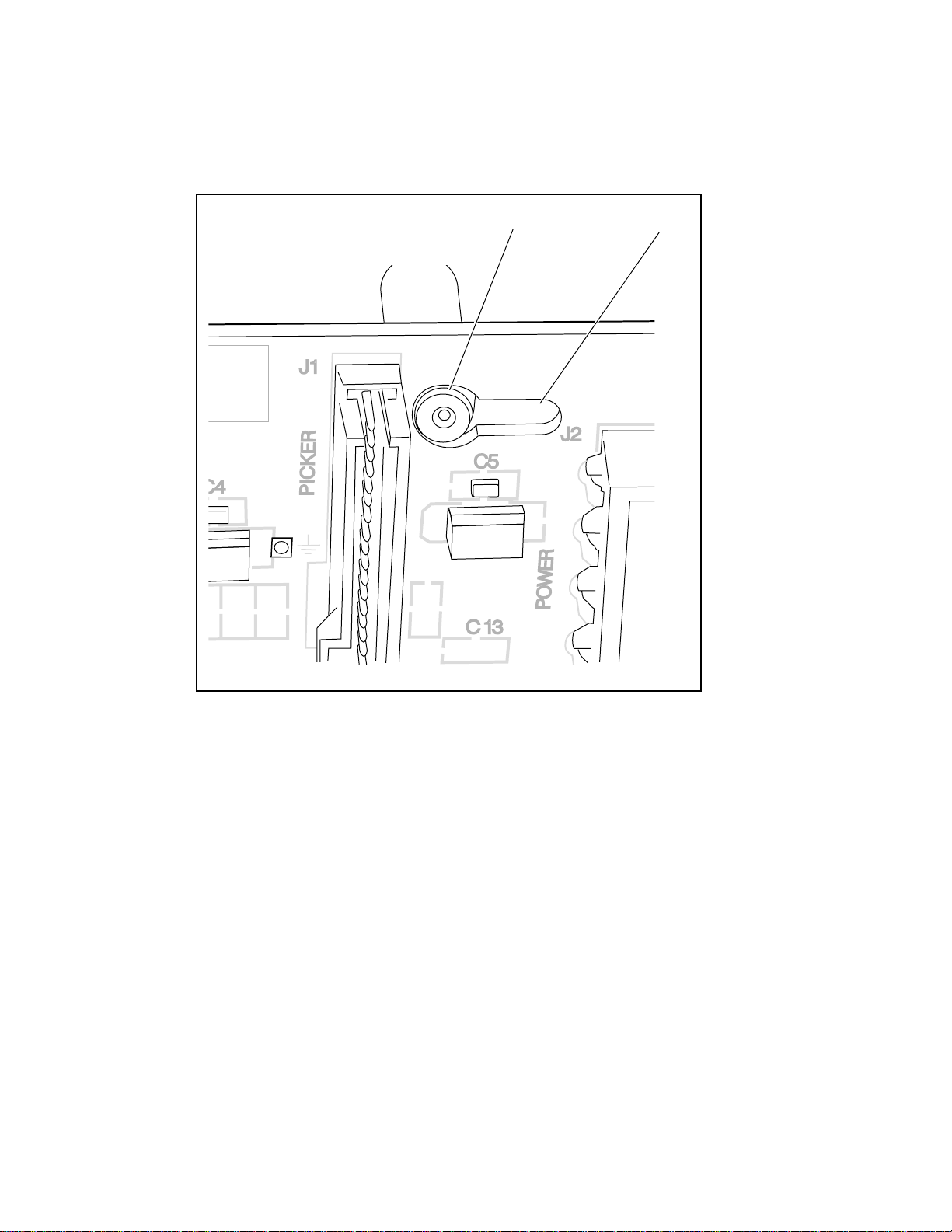

Removing and Replacing the Bar Code Reader .......................................................5-3

Removing and Replacing the Controller Board........................................................5-6

Removing and Replacing the Door Solenoid.........................................................5-10

Removing and Replacing a Tape Drive..................................................................5-11

Removing and Replacing the Fan Assembly..........................................................5-14

Removing and Replacing the Front Panel..............................................................5-15

Removing and Replacing the Magazine Guide......................................................5-16

Removing and Replacing the Magazine Latch Solenoid........................................5-19

Removing and Replacing the Power Supply Assembly .........................................5-20

Removing and Replacing the Power Switch ..........................................................5-27

Removing and Replacing the Shuttle Mechanism..................................................5-28

Removing and Replacing a PTM............................................................................5-35

About This Guide v

Appendix A

Specifications

Introduction.............................................................................................................A-1

Safety.......................................................................................................................A-7

Electromagnetic Emission (EM) .............................................................................A-7

Notice...............................................................................................................A-7

Industry Canada................................................................................................A-7

Industrie Canada............................................................................................... A-7

FCC Notice.......................................................................................................A-8

FCC and VCCI Requirements.................................................................................A-9

Statement for Equipment Meeting FCC Class A Requirements.......................A-9

Equipment Meeting VDE Class B Requireme nt s (VFG 1046/84 and VFG

243/91 for Germany)......................................................................................A-10

VCCI Notice for Japan Class I Equipment.....................................................A-11

Appendix B

FRUs, Spares, and Accessories

Introduction............................................................................................................. B-1

Page 6

vi Compaq StorageWorks SSL2000 Series Library Maintenance and Service Guide

Appendix C

Installation

Introduction............................................................................................................. C-1

Unpacking ............................................................................................................... C-1

Releasing the Lockdown Mechanism...................................................................... C-2

Setting up the Desktop Model................................................................................. C-4

Setting up the Rackmount Model............................................................................ C-4

Precaution.........................................................................................................C-4

Removing the Desktop Outside Cover.............................................................C-5

Installing the Rackmount Top Cover ...............................................................C-6

Installing the Inner Slide Members..................................................................C-7

Installing the Panel Extensions.........................................................................C-9

Installing the Rackmount Model into a Storage Cabinet................................C-10

Installing and Removing the PTM.........................................................................C-10

Installing a Pre-Assembled PTM....................................................................C-10

Removing a PTM...........................................................................................C-15

Adding a PTM Extrusion ............................................................................... C-16

Setting up Interfaces and Cables ........................................................................... C-28

Power Cord Connector...................................................................................C-29

SCSI Interface Connectors............................................................................. C-30

Interface Cable Specifications........................................................................ C-30

Cabling the PTM and Multi-Unit Library System................................................. C-31

Connecting to the PTM Motor Housing Assembly........................................C-31

Connecting to Library Units...........................................................................C-33

Configuring the Library.........................................................................................C-35

Setting a SCSI ID........................................................................................... C-35

Configuring a Library System...............................................................................C-37

The Master Unit ............................................................................................. C-37

The Slave Unit................................................................................................C-38

Setting up Reserved Slots......................................................................................C-39

How Reserved Slots are Numbered................................................................C-39

To Reserve Slots.............................................................................................C-41

Configuration Options...........................................................................................C-41

SCSI Options.................................................................................................. C-41

Library Options.............................................................................................. C-43

Bar Code Options...........................................................................................C-43

Set Element Base............................................................................................C-44

Set Serial Number .......................................................................................... C-44

Set Default......................................................................................................C-44

Configuration Settings...........................................................................................C-45

Index

Page 7

List of Figures

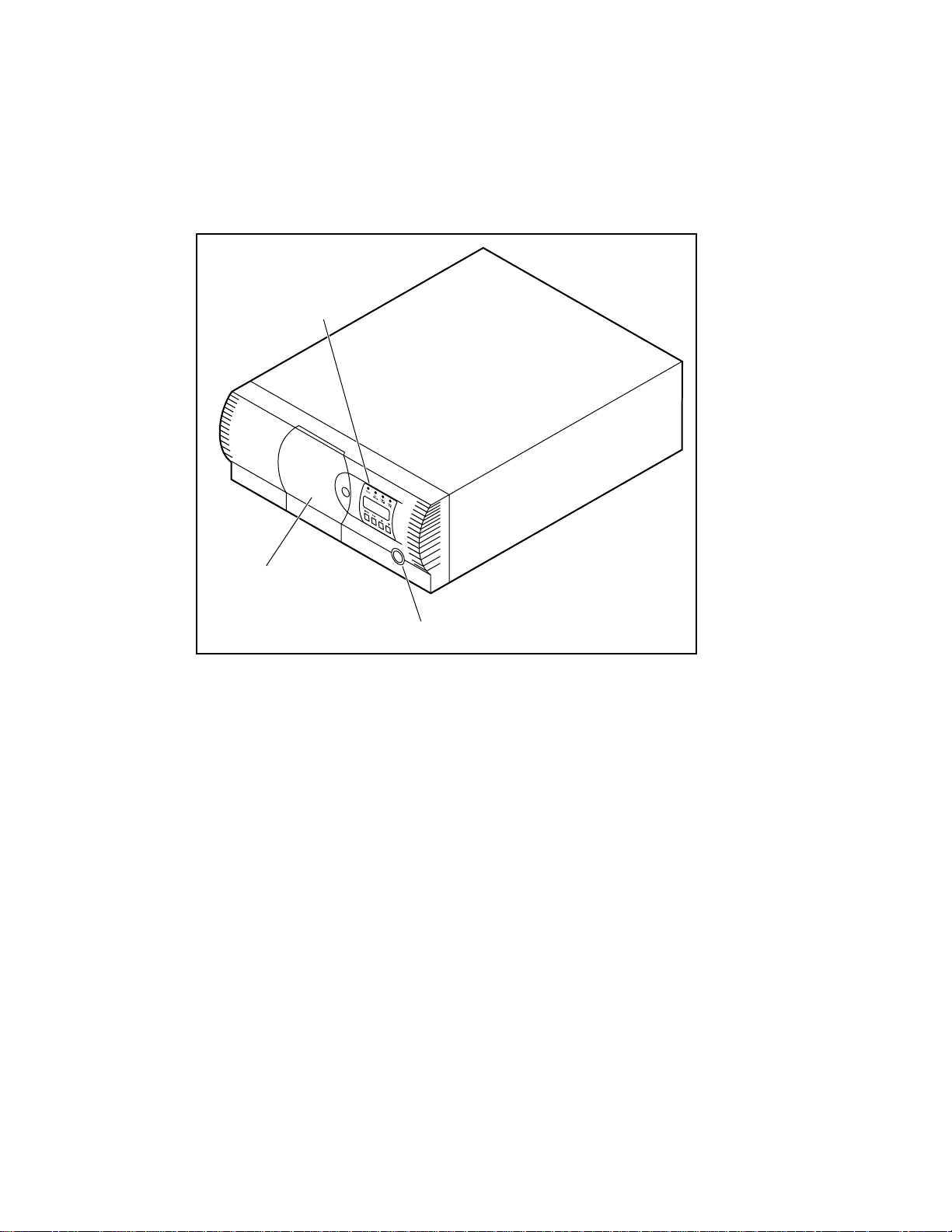

Figure 1-1. Library front view.................................................................................1-5

Figure 1-2. Library rear view ..................................................................................1-6

Figure 1-3. Tape cartridge magazine.......................................................................1-7

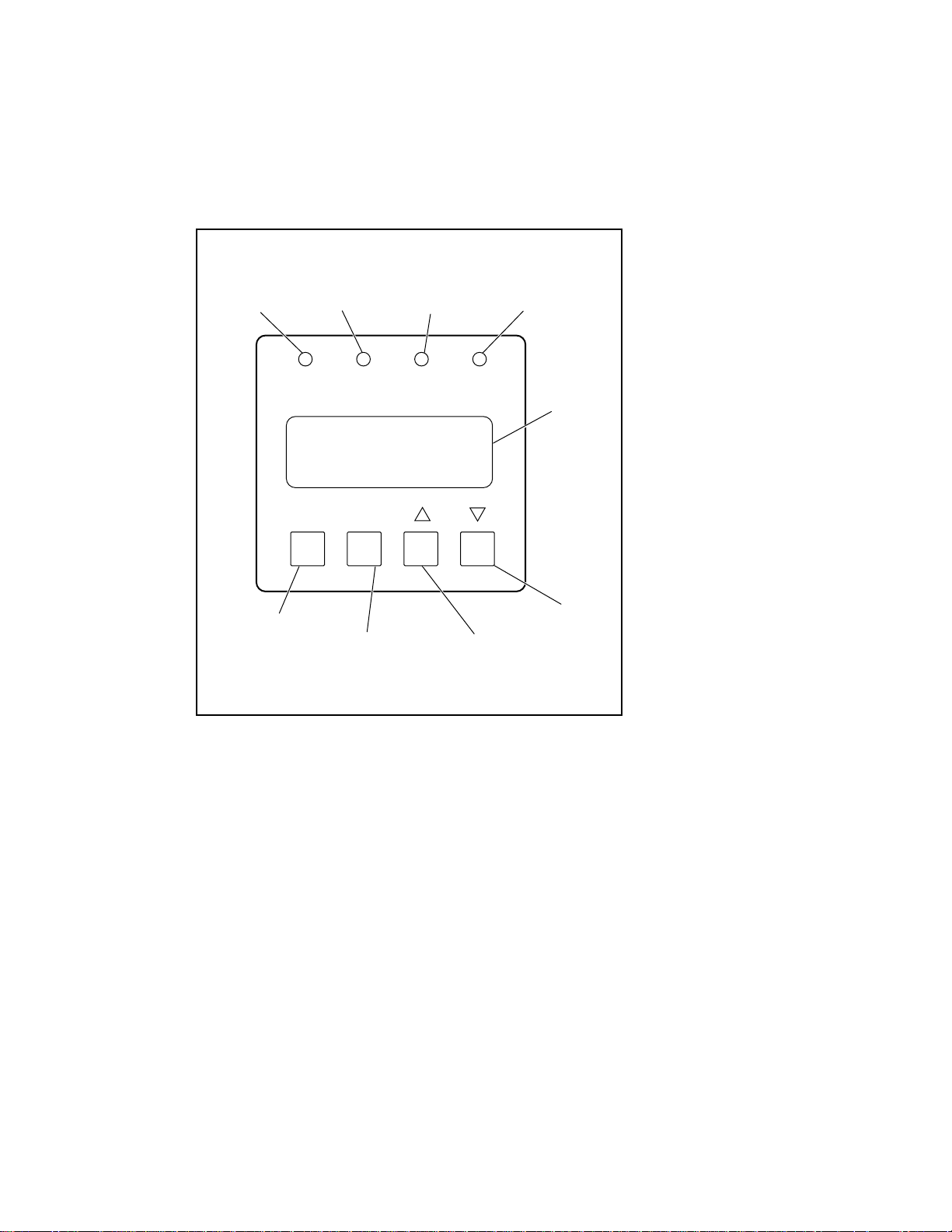

Figure 2-1. Library front panel................................................................................2-2

Figure 2-2. Library control panel ............................................................................2-3

Figure 2-3. Library menus.......................................................................................2-8

Figure 2-4. Magazine in place...............................................................................2-17

Figure 2-5. Tape magazine with cartridges installed.............................................2-18

Figure 2-6. Mail slot location................................................................................2-19

Figure 2-7. Tape cartridge write protection switch................................................2-20

Figure 2-8. Bar code label size..............................................................................2-21

Figure 4-1. Troubleshooting flowchart....................................................................4-2

Figure 5-1. Moving the shuttle assembly ................................................................5-3

Figure 5-2. Disconnecting the bar code reader cable...............................................5-4

Figure 5-3. Removing the bar code reader..............................................................5-5

Figure 5-4. Jack screw locations..............................................................................5-6

Figure 5-5. Top guide pin and keyhole....................................................................5-7

Figure 5-6. Bottom guide pin and keyhole..............................................................5-8

Figure 5-7. Removing the controller board.............................................................5-8

Figure 5-8. Replacing the controller board.............................................................. 5-9

Figure 5-9. Removing the door solenoid............................................................... 5-10

Figure 5-10. Removing the brace plate..................................................................5-11

Figure 5-11. Removing the upper drive mounting plate........................................5-11

Figure 5-12. Disconnecting the tape drive.............................................................5-12

Figure 5-13. Removing the tape drive...................................................................5-12

Figure 5-14. Removing the alignment pins...........................................................5-13

Figure 5-15. Replacing the fan assembly..............................................................5-14

Figure 5-16. Front panel attachment screw locations............................................5-15

Figure 5-17. Disconnecting the front panel cable..................................................5-16

Figure 5-18. Removing the bottom drive mounting plate......................................5-17

Figure 5-19. Magazine guide screw locations.......................................................5-17

Figure 5-20. Removing the magazine guide..........................................................5-18

Figure 5-21. Removing the magazine latch cover.................................................5-19

Figure 5-22. Magazine latch solenoid mounting bracket screw locations.............5-20

Figure 5-23. Disconnecting the picker ribbon cable ..............................................5-21

Figure 5-24. Picker ribbon cable tabs....................................................................5-21

Figure 5-25. Turning the base plate.......................................................................5-22

Figure 5-26. Unplugging the power supply...........................................................5-22

Figure 5-27. Power supply retaining screws..........................................................5-23

Figure 5-28. D isconnecting the controlle r board, fan, and drive power harness ...5-24

Figure 5-29. Disconnecting the power switch wires..............................................5-25

Figure 5-30. Removing the power supply.............................................................5-26

Figure 5-31. Connecting the power cable to the power supply .............................5-26

Figure 5-32. Power switch retaining screws..........................................................5-27

Figure 5-33. Cable clamp tab location...................................................................5-28

Figure 5-34. Cable release lever............................................................................5-29

Figure 5-35. Pushing the shuttle mechanism..........................................................5-30

Figure 5-36. Removing the guide bar screw..........................................................5-31

Figure 5-37. Accessing the guide bar screw..........................................................5-32

Figure 5-38. Lifting the shuttle mechanism...........................................................5-32

Figure 5-39. Anti-rotation bracket location........................................................... 5-33

Figure 5-40. Removing the shuttle mechanism.....................................................5-33

Figure 5-41. Unplugging the PTM motor housing assembly control cable...........5-35

About This Guide vii

Page 8

viii Compaq StorageWorks SSL2000 Series Library Maintenance and Service Guide

Figure 5-42. Removing the PTM...........................................................................5-36

Figure 5-43. Installing the PTM............................................................................5-37

Figure 5-44. Securing the PTM to the master unit................................................5-38

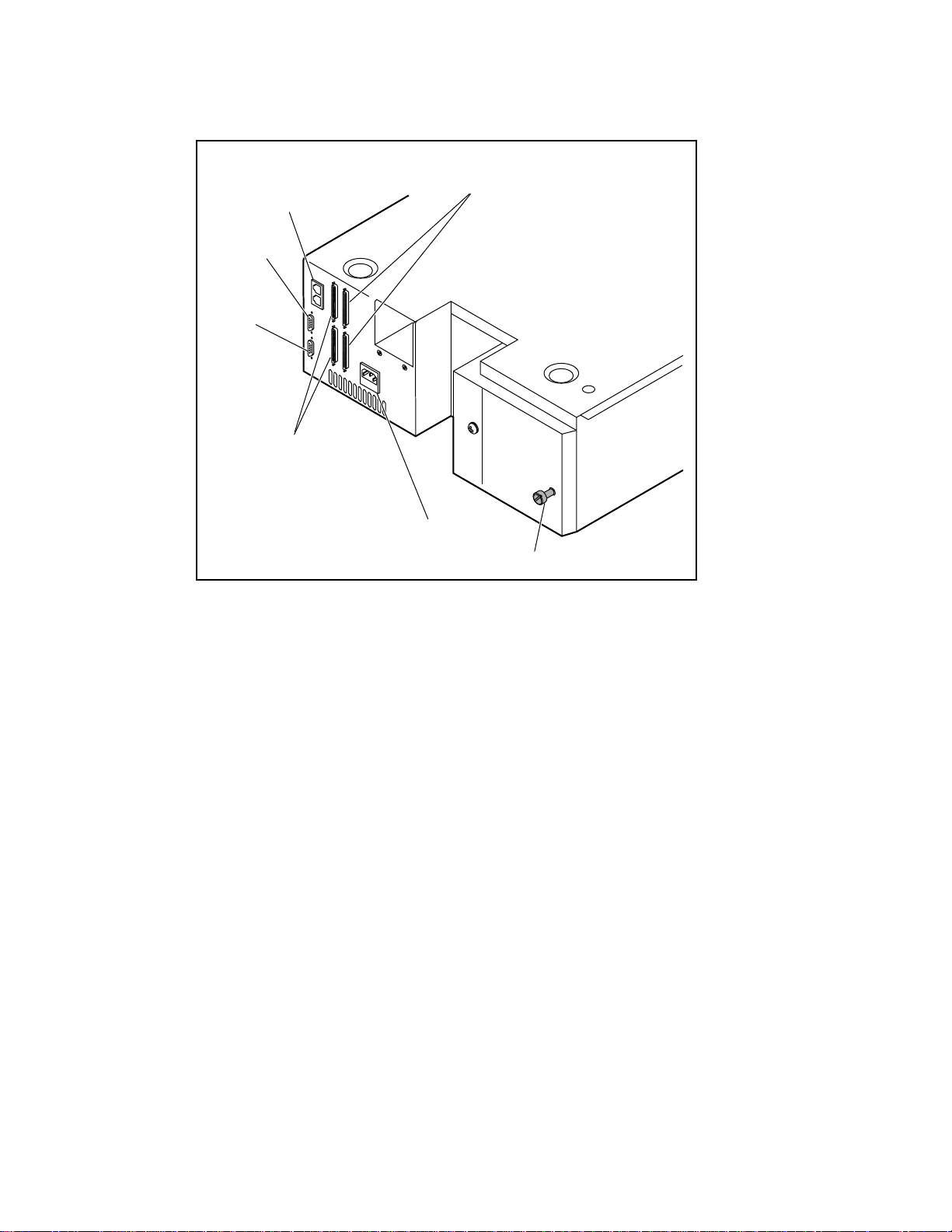

Figure C-1. Lockdown mechanism screw.............................................................. C-2

Figure C-2. Releasing the lockdown mechanism...................................................C-3

Figure C-3. Locking the lockdown mechanism......................................................C-4

Figure C-4. Removing the desktop outside cover...................................................C-5

Figure C-5. Installing the rackmount top cover......................................................C-6

Figure C-6. Rackmount slide parts.........................................................................C-7

Figure C-7. Installing the inner slides......................................................................C-8

Figure C-8. Installing the panel extension.............................................................. C-9

Figure C-9. Removing the PTM port cover..........................................................C-11

Figure C-10. Installing the PTM...........................................................................C-12

Figure C-11. Securing the PTM to the master unit...............................................C-13

Figure C-12. Securing the PTM to the slave unit................................................. C-14

Figure C-13. Unplugging the PTM motor housing assembly control cable......... C-15

Figure C-14. Location stop pin.............................................................................C-16

Figure C-15. Attaching tie bars............................................................................C-17

Figure C-16. Attaching PTM extrusions .............................................................. C-17

Figure C-17. Attaching tie bars to the PTM extension.........................................C-18

Figure C-18. Cutting the belt................................................................................C-19

Figure C-19. Threading the belt through the pulleys............................................C-20

Figure C-20. Attaching the belt clamp bracket.....................................................C-21

Figure C-21. Replacing the bottom pulley end cap..............................................C-21

Figure C-22. Snapping the spring over the tension post.......................................C-22

Figure C-23. PTM layout ..................................................................................... C-23

Figure C-24. Releasing the elevator car ...............................................................C-23

Figure C-25. Disengaging the wheels...................................................................C-24

Figure C-26. Removing the elevator car...............................................................C-25

Figure C-27. Aligning the belt tensioner ramp..................................................... C-26

Figure C-28. Removing tension from the belt...................................................... C-27

Figure C-29. Releasing the bottom pulley assembly............................................C-28

Figure C-30. Removing the bottom pulley assembly...........................................C-28

Figure C-31. Connectors, SCSI terminator, and cables........................................ C-29

Figure C-32. Connecting to the PTM motor housing assembly ........................... C-32

Figure C-33. Connecting a patch cable.................................................................C-33

Figure C-34. Connecting to Library units.............................................................C-34

Figure C-35. Reserved slot locations....................................................................C-40

Page 9

List of Tables

Table 1-1 Library Models.........................................................................................1-2

Table 1-2 Tape Capacities........................................................................................1-9

Table 2-1 Control Panel Button Functions...............................................................2-5

Table 4-1 Error Recovery Procedures......................................................................4-3

Table 4-2 Fault Symptom Codes..............................................................................4-3

Table A-1 Operational Performance Specifications................................................A-2

Table A-2 Reliability Specifications (Drives).........................................................A-3

Table A-3 Reliability Specifications (Library System Robotics)............................A-3

Table A-4 Power Specifications..............................................................................A-3

Table A-5 Mechanical Specifications (Tabletop Model).........................................A-4

Table A-6 Mechanical Specifications (Rackmount Model)....................................A-4

Table A-7 Environmental Specifications (Operating).............................................A-5

Table A-8 Environmental Specifications (Packed or Unpacked)............................A-5

Table A-9 Environmental Specifications (Storage/Transit) ....................................A-6

Table A-10 Acoustic Emission Level......................................................................A-6

Table A-11 Regulator Agency Product Safety Certifications..................................A-7

Table A-12 Acoustic Noise Declaration Declared per ISO 9296 and ISO 7779.....A-8

Table A-13 Schallemissionswerte - Werte angaben nach ISO 9296 und ISO 7779

/DIN EN27779..................................................................................................A-8

Table B-1 FRUs, Spares, and Accessories..............................................................B-1

Table C-1 Rackmount Slide Parts ........................................................................... C-8

Table C-2 Library Configuration Options.............................................................C-45

About This Guide ix

Page 10

This Maintenance and Service Guide is a troubleshooting guide that can be used for r eference

when servicing Compaq StorageW orks SSL2000 Series L ibraries.

IMPORTANT: The installation of options and servicing of this product shall be performed by individuals

who are knowledgeable of the procedures, precautions, and hazards associated with equipment

containing hazardous energy circuits.

Symbols in Text

These symbols may be foun d in the text of t his guide. They have the following meanin gs.

About This Guide

WARNING: To reduce the risk of personal injury from electrical shock and hazardous energy

levels, only authorized service technicians should attempt to repair this equipment. Improper

repairs could create conditions that are hazardous.

WARNING: Text set off in this manner indicates that failure to follow directions in the warning

could result in bodily harm or loss of life.

CAUTION: Text set off in this manner indicates that failure to follow directions could result in

damage to equipment or loss of information.

IMPORTANT: Text set off in this manner presents clarifying information or specific instructions.

NOTE: Text set off in this manner presents commentary, sidelights, or interesting points of information.

Page 11

xii Compaq StorageWorks SSL2000 Series Library Maintenance and Service Guide

Compaq Technician Notes

WARNING: Only authorized technicians trained by Compaq should attempt to repair this

equipment. All troubleshooting and repair procedures are detailed to allow only

subassembly/module level repair. Because of the complexity of the individual boards and

subassemblies, no one should attempt to make repairs at the component level or to make

modifications to any printed wiring board. Improper repairs can create a safety hazard. Any

indications of component replacement or printed wiring board modifications may void any

warranty.

WARNING: To reduce the risk of personal injury from electrical shock and hazardous energy

levels, do not exceed the level of repair specified in these procedures. Because of the

complexity of the individual boards and subassemblies, do not attempt to make repairs at the

component level or to make modifications to any printed wiring board. Improper repairs could

create conditions that are hazardous.

WARNING: To reduce the risk of electric shock or damage to the equipment:

■ If the system has multiple power supplies, disconnect power from the system by

unplugging all power cords from the power supplies.

■ Do not disable the power cord grounding plug. The grounding plug is an important safety

feature.

■ Plug the power cord into a grounded (earthed) electrical outlet that is easily accessible at

all times.

CAUTION: To properly ventilate your system, you must provide at least 12 inches (30.5 cm) of

clearance at the front and back of the computer.

CAUTION: The computer is designed to be electrically grounded. To ensure proper operation,

plug the AC power cord into a properly grounded AC outlet only.

Where to Go for Additional Help

In addition to this guide, the following information sources are available:

■ User Documentation

■

Compaq Service Quick Reference Guide

■ Service Training Guides

■ Compaq Service Advisories and Bulletins

■ Compaq QuickFind

■ Compaq Insight Manager

■ Compaq Download Facility: Call 1-28 1-518-1418

Page 12

About This Guide xiii

Integrated Management Display

Some Compaq server models include a Compa q Integrated Management Display (IMD), a n

integrated, 16x4 character display mounted on the front of the server. This display provides

easy-to-use menu-driven access to server information, including model number, LCD firmware

revision, and POST operations.

Telephone Numbers

For the name of your nearest Compaq Authori zed Reseller:

■ In the United States, call 1-800-345-1 518

■ In Canada, call 1-800-263-5868

For Compaq technical support:

■ In the Unit ed States and Canada, call 1-8 00-386-2172

For Compaq technical support phone numbers outside the United States an d Canada, visit the Compaq

website at http://www.compaq.com.

Page 13

Introduction

The

Intelligent Tape™ (AIT) drive technolog y with advanced robotics. Designed for high duty-cycle

online and near-online applications, such as hierarchical storage management, it is a superior

performer in high-volume backup and archival service.

A Compaq StorageWorks SSL2000 Series Library (AIT Libra ry) can be equi pped with one or

two tape dri ves and a 20-slo t tape cartridge magazine that includes one mail slot.

Compaq Stor ageWorks

Chapter 1

System Description

SSL2000 Series is a tape library system that combines Advanced

This chapter includes descriptions for:

■ Library models

■ Multi-unit Library systems

■ Tape cartridge mail slot

■ SCSI interface and bus performance considerations

■ Shuttle lockdown mechanism

■ Library features

■ Advanced design feat ures

Library Models

Libraries are currently available with:

■ A tabletop or rackmount version

■ One or two tape drives

■ An optional Pass-Through Mechanism (PTM) for conn ecting up to five library units

■ AIT 2 tec hnology

■ A Fast/Wide, Low Voltage Differential (LVD)/Single Ended (SE) SCSI-2 interface

Page 14

1-2 Compaq StorageWorks SSL2000 Series LIbrary Maintenance and Service Guide

The drives used in the Library read from and write to 8 mm A IT 2 data tape ca rtridges with a

native capac ity of 35 GB or 50 GB (see Table 1-1).

Table 1-1

Library Models

Model Number Configuration

175195-B21

175195-B22

175196-B21

175196-B22

Multi-Unit Library Systems

The Library features SmartScale Storage™ , an architecture that lets you combine multiple units

into an integrated library system. This architecture enables the robotics in each of the Library

units to exchange cartridges by means of a ve rtical PTM. Unde r the control of the unit you

configure to be the master unit, the PTM integrates the robotics in the indi vidual slave units into

a single high-performance library robotics system. For more information, see Appendix C,

“Installation.”

The SmartScale Storage architecture gives you a truly scaleable library that can smoothly

expand to mee t your growing storage needs. You can start with a system configured to your

present requirements, confident that as your storage needs evolve, adding units and extending

the PTM can easily modify the Library. Add drives for faster performance or magazine space

for greater capacity, as needed. Then just turn on the power, and immediately the system

updates the system map so the host is informed of the expanded capability. The SmartScale

Storage architecture has built-in redundancy so that if the master unit fails, a slave unit (slave 0)

can be configured to take over as the mas ter unit. This is done without having to make hardware

changes except moving the motor cable to the new master.

1 Drive, AIT 2 50 GB, tabletop, LVD/SE

2 Drive, AIT 2 50 GB, tabletop, LVD/SE

1 Drive, AIT 2 50 GB, rackmount, LVD/SE

2 Drive, AIT 2 50 GB, rackmount, LVD/SE

Tape Cartridge Magazine Mail Slot

If your host software permits, you can us e the front slot in the tape cartridge magaz ine (the first

slot you see when you open the door) as a mail slot for inserting or removing a single cartrid ge

without interrupting host operations in progress. The mail sl ot i s implemented as the SCSI

IMPORT/EXPORT commands.

SCSI Interface

The unit presents the following to the host:

■ A single SCSI medium changer device with a single SCSI medi um transport element

■ A number of SCSI storage el ements equal t o the total number of cartrid ge magazine slots

■ A single SCSI import/export element

■ A number of SCSI data tra nsfer elements equal to the total number of dr ives in the Libr ary

Page 15

Multi-Server Data Sharing

A host computer with a SCSI controller connected to a bus is a SCSI initiator. The Li brary is a

SCSI target. SCSI rules permit multiple initiators on a single bus. Therefore, with the proper

host software, it is possible to connect multiple hosts to a s ingle Library over a single SCSI bus.

This allows multiple hosts to operate the library robotic s, loading and unloading cartridges as

each host requires.

In a library syst em with many drives, it might be desirable to use multiple SCSI buses for the

drives so the data transfer rate of the drives is not limited by bus bandwidth. Individual drive s

can be connected to separate hosts. Using special software, one of the hosts can act as a master

server, processing all robotics commands and permitting several hosts to share a common

database.

SCSI Configuration

The Library standard SCSI interface is a Fast/Wide LVD/SE using high-density, 68-pin D-series

connectors. For more information, see Appendix C, “Installation.”

SCSI Bus Performance Considerations

System Description 1-3

Drives

With a standard Fast/Wide SCSI interface, each drive offers a sustained native data transfer rate

of 6 MB/s. In a two-drive unit, the total native rate is twice these rates. The rates for compressed

data are the native rates multiplied by the compression factor, whic h depends on file content, but

averages approximately 2:1.

Data Transfer Rate

The data tra nsfer rate of the Library depe nds on the type of the AIT drive, number of drives, and

the number of drives connected to the SCSI bus. The library robotics imposes minimal loading

on the bus.

AIT-2 Fast/Wide @ 40 MB/s (burst)

AIT-2 Sustained @ 6 MB/s (native)

Each drive has a maximum sust ained rate of 12 MB/s with compressed data. As a result, the

transfer rate of a two-drive unit occupies t he full bandwidth of the bus. Shar ing a SCSI bus

among more than two drives degrades the maximum performance of the library system.

Internal Cabling Configuration

Each SCSI bus i n t he Library is wired separately. The library ro botics and drive 1 share one bus;

add-on drives are connected to separate SCSI buses. SCSI jumper cables are available to allow

the drives and robotics of a uni t to be daisy-c hained to a single SCSI bus. For m ore detailed

information, see Appendi x C, “Installation.”

@ 12 MB/s (compressed)

Page 16

1-4 Compaq StorageWorks SSL2000 Series LIbrary Maintenance and Service Guide

Bus Length Limitations

A single-ended Fast/Wide SCSI bus is limited i n length to 10 ft (3 m), including cabling within

the units. A differential Fast/Wide SCSI bus can be up to 82 ft (25 m) in len gt h, inclu ding

cabling within the units. If all devices and host adapter are LVD, length is limite d t o

39 ft (12 m).

Independent SCSI Buses for SE

For those two-drive applications where both AIT drives run in SCSI SE mode (rather than LVD

mode), each drive must be connected to its own SCSI bus.

Physical Configuration

The Library is configured as a tabletop model. To convert a tabletop Library to a rackmounted

model, order the Compaq Conversion Kit Par t Number 175199-B21.

Shuttle Lockdown Mechanism

Compaq has installed a shuttle lockdown mechanism as a precautionary safety mechani s m to

prevent damage to the Libr ary during shi pment from the f actory. The mechanism is a springloaded screw in the back of the Library that secures the shuttle to a bracket.

NOTE: You must release the shuttle lockdown mechanism before powering up the unit or it will not operate.

See Appendix C, “Installation,” for more information.

Page 17

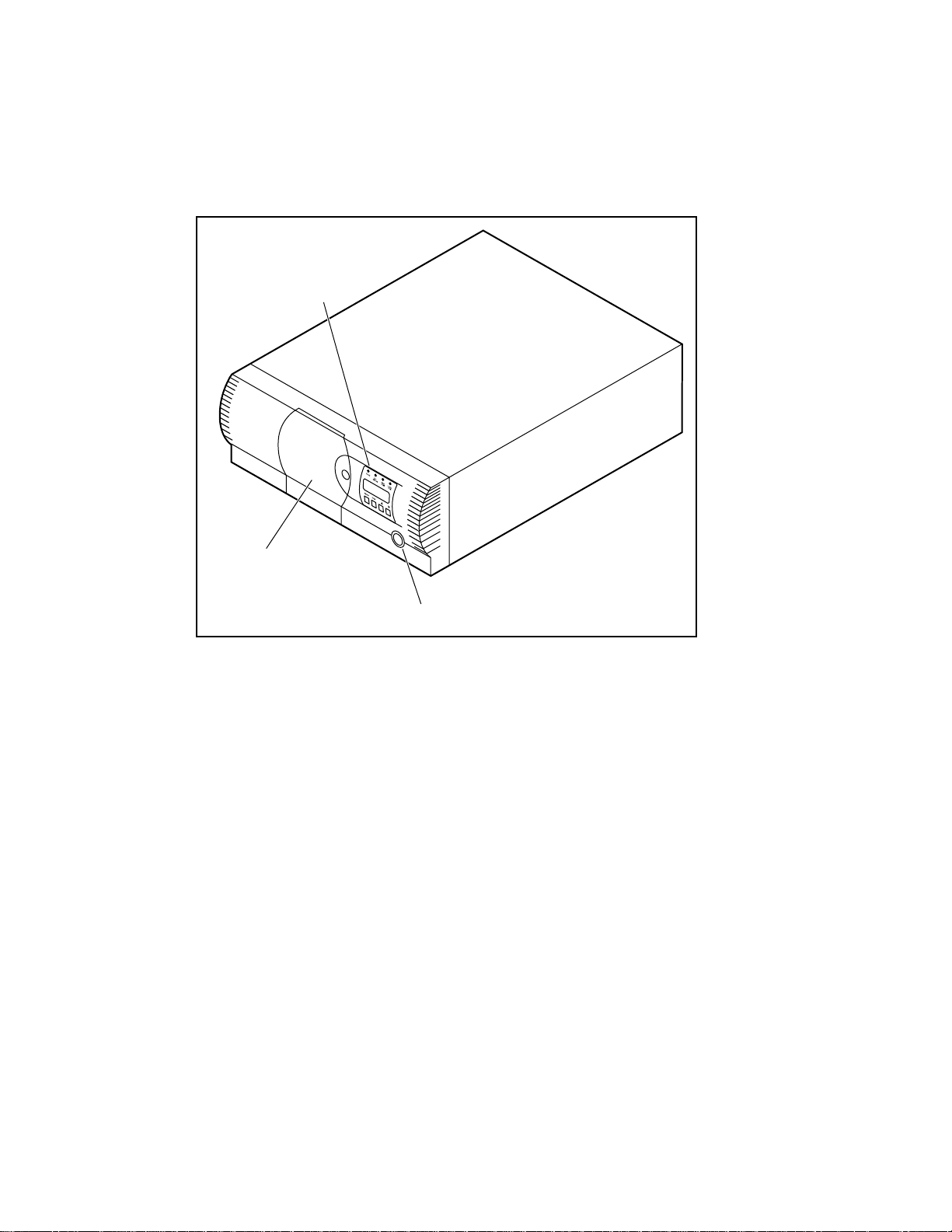

Library Features

Figures 1-1 through 1-3 shows some of the external features of the Library.

Control Panel

System Description 1-5

Magazine Door

Figure 1-1. Library front view

Power Switch

cc0052

Page 18

1-6 Compaq StorageWorks SSL2000 Series LIbrary Maintenance and Service Guide

1

2

Expansion Ports

Diagnostic

3

4

Motor

5

Drive 2

6

Power Cord Connector

Drv 1 + LIB

cc0053

Figure 1-2. Library rear view

Control Panel

The control panel features a 4-line by 20-character backlit liquid crystal display, four LED

indicators a nd four button s. The buttons let you navigate through the menu structure to select

and display operating modes, device sta t us, diagnostic and maintenance functions, device

history and e rror statistics, and library system configuration.

Display

The backlit, 4-line by 20-character control panel display provides a highly intell igi ble

presentation of drive and loader status, menu choices, and error messages. The scrolling feature

greatly expands the amount of information available to the operator.

Power Supply

The AC power switch is located on the front panel of the uni t . The autoranging power supply

adjusts automatically to either of two operating voltage ranges. The ranges are 100-120 VAC

and 220-240 VAC. The power supply is capable of operat ing at 47 or 63 Hz without any

adjustment or modification. AC power is supplied to the power supply by a single

IEC-compatible socket, which can be connected to any properly gro unded outlet.

Lockdown Mechanism

Page 19

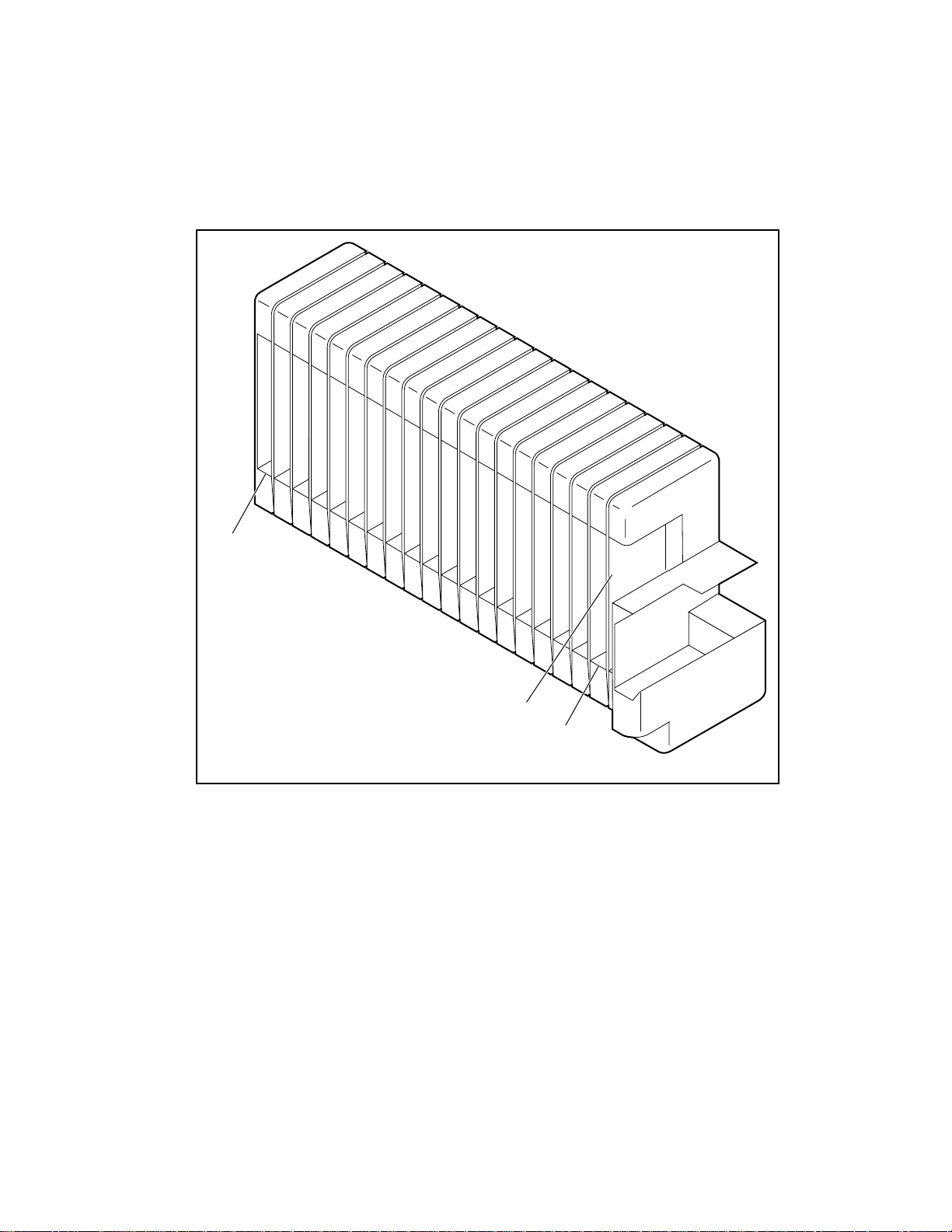

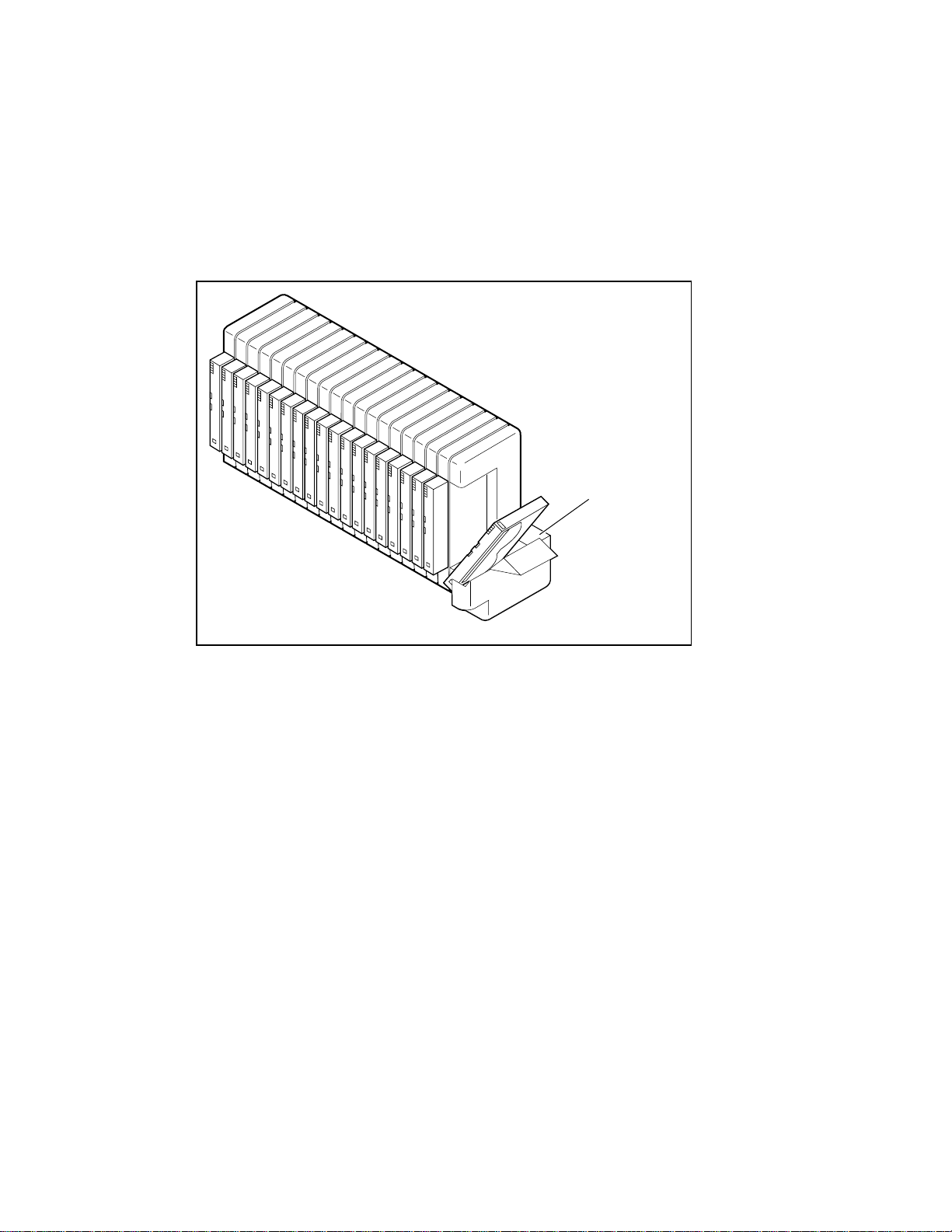

Tape Cartridge Magazine

The polymer magazine fits into an extruded track, which assures precise positioning for the

library robotics (see Figure 1-3).

Slot 18

System Description 1-7

Mail Slot

Slot 0

cc0054

Figure 1-3. Tape cartridge magazine

The front sl ot in the magazine is a Mail Slot, used to add or re move cartridges without

interrupting library operation. You can remove the magazine through the front door, but it is

protected from tampering in either of two ways:

■ An electronic combination lock, operated from the control panel

■ The host issuing a SCSI PREVENT/ALLOW MEDIUM REMOVAL command

For more information on inserting and removing the maga zine, see Cha pt er 2, “Operation.”

Page 20

1-8 Compaq StorageWorks SSL2000 Series LIbrary Maintenance and Service Guide

Integral Fan Cooling

Each AIT drive contains a ther mostat-controlled fan. I n addition, a fa n i s mounted inside the

Library to prevent critical parts from overheating.

Robotics

The Library features Compaq Mainframe-Class™ Library Robotics. These advanced robotics

can load any of the cartridges stored in the m agazine into any of the tape drives.

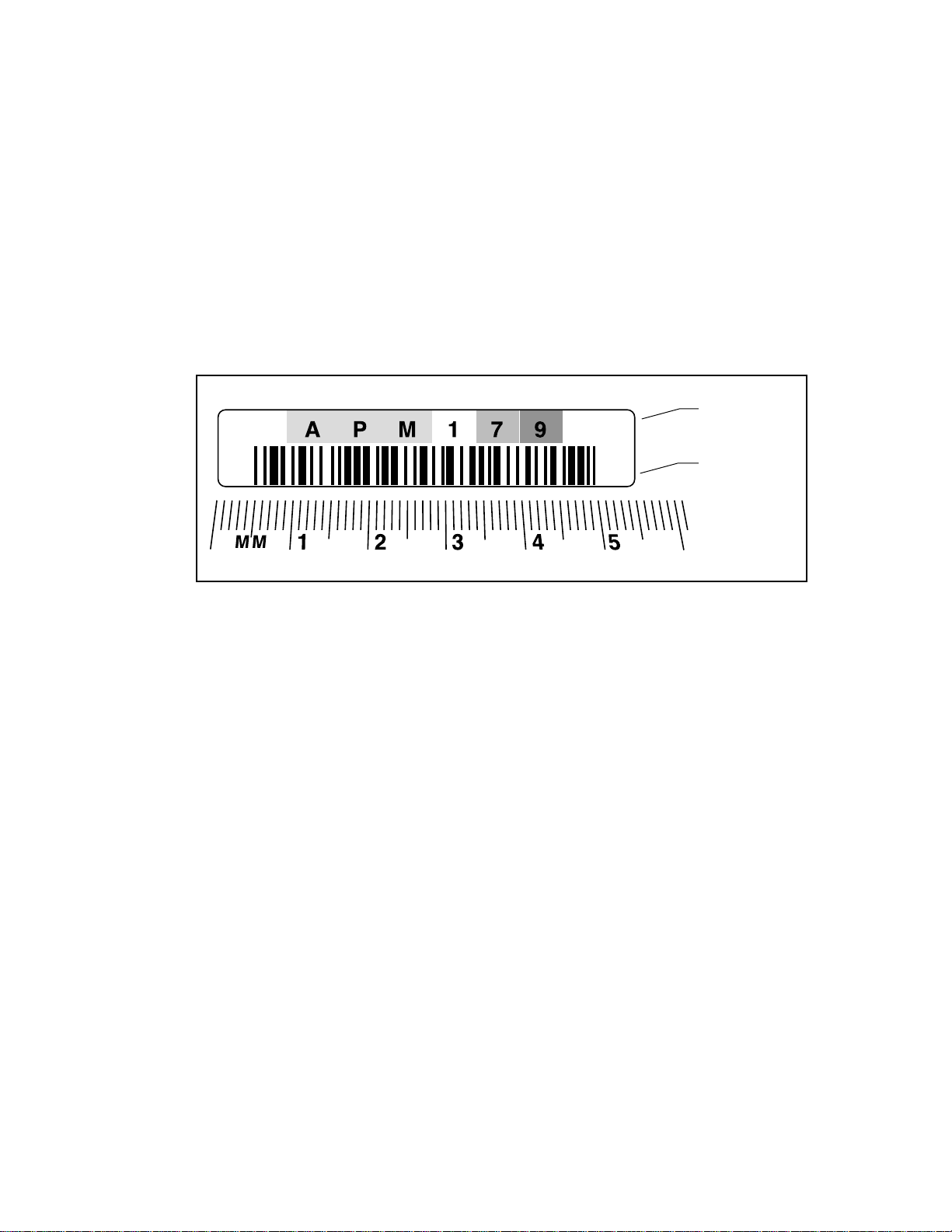

Bar Code Reader

A standard bar code reader is mounted on the cartridge shuttle. It reads bar code labels attached

to each cartridge, and maintains the bar code data in memory as part of the library system map.

Advanced Design Features

Embedded Diagnostics

The Library provides three levels of embedded diagnostics:

Power-On Self Test (POST )

configuration, host interface and device control functions, as well as memory tests when you

power on the unit.

User Diagnostics

panel.

CE Diagnostics

Library. Selected from front panel.

For more infor mation on user diagnostics, see Appendix C, “I nstallation.”

Error Checking

The drives used in the Library use read while write data checking and error-correction code

(ECC) technology such as is used in audio CD, DVD, and laser discs.

Buffer

Drives are equipped with an 8-MB buffer.

— Performs various verification tests on the system’s

— Lets you di splay and change configurati on options. Sel ected from fr ont

— Advance d di agnostics use d by Customer E ngineers (CEs) f or servicing the

Page 21

Compression

All drives used in the Library use the Adaptive Lossless Data Compression (ALDC data

compression algorithm developed by I B M).

Capacity

The Library with its 20-cartridge magazine offers the formatted capacities liste d in Table 1-5.

NOTE: Capacities are based on 19 storage slots.

System Description 1-9

Table 1-2

Tape Capacities

Media Life

Native Capacity Per Cartridge Per Cartridge Compressed

(2:1)

35 GB 70 GB 1,330 GB (665 native)

50 GB 100 GB 1,900 GB (950 native)

The media manufacturer r ates the media us ed in the Librar y at over 30,0 00 end-to-end passes

and specifies a shelf life of at least 30 years.

Full Magazine Compressed

(2:1)

Page 22

Introduction

This chapter describes operati ng the Compaq StorageWorks S S L2000 Series Library (AIT

Library) through the control panel at the front of the unit.

This chapter includes descriptions and or procedures for:

■ Front panel

■ LED indicators and buttons

Chapter 2

Operation

■ Front panel and media locks

■ Startup display message s

■ Using Library menus and modes

■ Displaying firmware revisions

■ Inserti ng and removing cartridges

■ Tape cartridge requirements

■ Bar code l abels

Page 23

2-2 Compaq StorageWorks SSL2000 Series Library Maintenance and Service Guide

Front Panel

The front panel of the Libra ry includes a power switch for the unit an d t he control panel, which

has buttons, a display, and i ndicators (see Figure 2-1).

Control Panel

Magazine Door

Figure 2-1. Library front panel

Power Switch

The power swit ch controls the supply of A C power to the L ibrary front panel. It is a push-on,

push-off swit ch. When the power is on, the backplane of t he control pane l display lights.

Power Switch

cc0052

Page 24

Indicators and Buttons

The control panel consists of four LED indicators, a four-line by 20-character backlit LCD

display, an d four buttons (s ee Figure 2-2).

Operation 2-3

234

Ready

(Green)

Use Cleaner

(Yellow)

Escape

(Navigate Menus)

Enter

(Select Menus)

Figure 2-2. Library control panel

Drive Fault

(Red)

Scroll Up

Loader Fault

(Red)

Display

Panel

Scroll Down

cc0055

Page 25

2-4 Compaq StorageWorks SSL2000 Series Library Maintenance and Service Guide

LED Indicators

There are four LED indicators on the control panel, labeled Ready (green), Use Cleaner

(yellow), Drive Fault (red), and Loader Fault (red).

The Ready LED (green) lights when the Library

computer. The Ready LED goes out when you enter the Menu mode, indicating that the Library

is offline.

The Use Cleaner LED (yellow) indicates that one or more of the drives in the Library

cleaning. Perform a cleaning operation as described in Chapter 5, “Maintenance.” When the Use

Cleaner LED lights, you can find out which drive needs cleaning by selecting Cleaning Needed

on the Drive Status submenu.

When either the Drive Fault or the Loader Fault LED (red) lights, a Fault screen appears on the

LCD display. The Fault screen is described later in this chapter.

See Chapter 4, “Troubleshooting,” for a list of Fault Symp tom Codes (FSC) and Error Recovery

Procedures (ERP).

Buttons

There are four buttons on the control panel: Escape

directly control specific functions or opt ions. Instead, you use the buttons to navigat e from the

Default screen through a multi-level menu structure, then select the desired option from the

appropriate menu using the Enter

under various conditions.

Using the Enter Button to Access Main Menu

Enter button. Table 2-1 lists the effect of each of the four buttons

EnterEnter

is ready to accept commands from the host

Escape, Enter

EscapeEscape

Enter, F

F, and GGGG. The buttons do not

EnterEnter

FF

needs

To enter the Menu mode and display the Main menu from the Default screen, press the Enter

button. When you enter the Menu mode, the Ready LED goes out. This means that the Library

is offline, and the Library

you exit the Menu mode and the Ready LED lights.

responds to all commands from the host with a SCSI Not Ready until

Using the Escape Button to Return to Default Screen

To return to the Main menu from a submenu, press the Escape

menu appears. Pressing the Escape

mode and returns you to the Default screen.

Escape button while the Main menu is displayed exi t s the Menu

EscapeEscape

Enter

EnterEnter

Escape button repeatedly until the Main

EscapeEscape

Page 26

Using the Escape Button to Access Status Mode

To enter the Status Mode, which displays all aspects of the Library’s operating and

configuration status, press the Escape

Escape button at the Default screen. The Library

EscapeEscape

Table 2-1

Control Panel Button Functions

Operation 2-5

remains online.

Display/Mode Escape Enter

At POST Screen N/A N/A N/A

At Default Screen Enters Status

Mode

In Status Mode

(while online)

In Menu Mode Rejects Currently

At Fault Screen N/A Clears Soft Errors N/A N/A

NOTE: There is an auto-repeat feature for the p and q buttons. When you press either button for

more than one-half second, the control panel behaves as if you were pressing and releasing the button

about four times per second. This effect stops when you release the button.

Returns to

Default Screen

Displayed Choice,

or

Aborts Control

Panel Operation

In Progress, or

Exits to Next

Higher Menu

Level, or

Exits Menu Mode

to Default Screen

Enters Menu

Mode

Same as in Menu

Mode

Accepts Currently

Displayed Choice

pq

Toggles between Page 1

and Page 2

Same as in Menu Mode

Moves u 1 Line

Upward Through

List of Options, or

Scrolls Part of

Display 1 Line

Toward Top of

List of Options

Moves u 1 Line

Downward

Through List of

Options, or

Scrolls Part of

Display 1 Line

Toward Bottom of

List of Options

Front Panel and Media Locks

A security feature is available to avoid accidental interruption of Library operation by entering

the Menu mode or removing cartridges while the host is accessing the Library. The front panel

and the media can be electronically locked. When the front panel is locked, you can only enter

the Menu mode after entering a 4-digit code. That is, when the Default screen appears, pressing

the Enter

Enter button does not invoke the Menu mode until you enter the code. The front panel

EnterEnter

cannot be unlocked without using the Security submenu to un lock it.

The media can also be locked by software running on the host, using the SCSI

ALLOW/PREVENT MEDIUM REMOVAL command. The Library

override for this command. Usually, exiting the host software restores media access. In the event

of host failure, you can restore media access by cycling the Library

Procedures for locking and unlocking front panels and media are described later i n this chapter.

provides no c o ntr ol pa ne l

power.

Page 27

2-6 Compaq StorageWorks SSL2000 Series Library Maintenance and Service Guide

Startup Display Messages

The display on the control panel is capable of displaying four lines of 20 characters ea ch, to

allow the use of easy-to-understand messages. Many of these messages and their functions are

described in this chapter. Those displays t hat are described in other chapt ers are crossreferenced here as well.

Power-On Self Test Screen

When power is first applied to the module, a series of Power-On Self Test (POST) diagnostics

are performed. During POST execution, the model number of the module, the firmware

revision, and the status or result of the test in progres s are displayed on the control panel as

shown:

Compaq SSL2020TL

Firmware Level 0X.XX

Checking Hardware

Initialization Screens

After the POST completes, the library robotics are initialized. A series of screens similar to the

one shown is displa yed d ur in g this pr oc e ss.

Compaq SSL2020TL

Firmware Level 0X.XX

Initializing Loader

Page 28

Default Screen

After the POST diagnostics have concluded successfully and initialization is complete, the

following Default screen appears. Note that the Default screen consists of two pages.

Page 1 Default screen:

Page 2 Default screen:

Page 1 displays the library and drive status. Page 2 displays the library sta tus (Line 1) an d

magazine slo t status (Lines 3 and 4).

The library status lines show each slot as a rectangle. A solid block indicates that a cartridge is

present. A h ollow block indicates that a slot is empty.

Loader Idle

Drv0: Ready or No Tape

Drv1: Idle

Loader Idle

0 _ _ _ _ _ _ _ 9

10

_ _ _ _ _ _ _ 18

Operation 2-7

Line 4 also shows the status of the mail slot. A

slot. A

The

Fault Screen

When a fault is detected, a screen similar to the one shown appears. In addition, either the Drive

Fault or the Loader Fault LED on the control panel lights.

The first line shows a numeric al FSC. The seco nd l ine shows a bri ef description of the error.

The third and fourth lines contain a one- or t wo-line message describing t he initial ERP.

For a list of FSCs and ERPs, see Chapter 4, “Troubleshooting.”

symbol indicates that a cartridge is in the mail

symbol indicates that the mail slot is empty.

F

F, and GGGGbuttons cont rol which Default page is displayed.

FF

Fault Code: 3004

Elevator Jammed

Power Down to Clear

Page 29

2-8 Compaq StorageWorks SSL2000 Series Library Maintenance and Service Guide

Using the Library Menus

Use the Library menus (Fig ure 2-3) to dis pl ay status information and to operate and co nfigure

the Library.

Power-Up Displays

Default Display

Fault Display

Status Mode

Access Mail Slot

Library Status

Model Number

Firmware Revision

SCSI Bus ID

SCSI Bus Parity

Boot Version

Flash T ype

Library T ype

Library Mode

Library Config

Vendor ID

Product ID

Baud Rate

Transport Addr

Storage Addr

Transfer Addr

Import/Export

Serial Number

Negotiation Mode

Transfer Rate

Unload Mode

Auto Clean Mode

Reserved Slots

Mode Page 1F Length

TUR Reporting

Init Elem Status

Bar Code Reader

Label Size

Label Alignment

Loader Status

SCSI Mode

Post Recv'd Error

Tape Alert Mode

Drive n Status

Tape Motion

SCSI Bus ID

Firmware Revision

Cartridge Preset

Hardware Error

Cleaning Needed

Write Protected

Map Info

Escape Button

Load/Unload

From/To

Remove

Magazine

Enter Button

Panel Lock

Main Menu

Maintenance

Menu

Clean Drive

Cleaning

Using

Diagnostic Menu

Cartridge Cycle

Friction Test

Tach Feedback

Scanner Feedback

Scan Labels

Demo Menu

Demo 1

Demo 2

Flash Update

NOVRAM Update

Park

Reboot Module

Configuration

Menu

SCSI Options

Library Parity

Library Bus ID

Drive 0/1 Bus ID

Vendor ID

Product ID

Negotiation Mode

Transfer Rate

Mode Pg 1F Length

Init Elem Status

Unit Attn Report

SCSI Mode

Post Recv'd Error

Tape Alert Mode

Library Options

Configuration

Unload Mode

Numbering

Element Base

Auto Clean

Library Mode

Baud Rate

Reserved Slots

Model Number

Bar Code Options

Label Size

Label Alignment

Check Digit

Set Element Base

Transport

Storage

Transfer

Import/Export

Set Serial Number

Set Default

Compaq Defaults

Security Menu

Set Unlock Code

Figure 2-3. Library menus

Page 30

Using the Status Mode

Operation 2-9

You can enter the Status Mode by pressing the Escape

appears. Entering the Status Mode does not affect operation of the Library. When you enter the

Status Mode, the following appears:

u Access Mail Slot

Library Status

Drive 0 Status

Map Info ¤

Exiting the Status Mode

To exit the Status Mode, press the Escape

Escape

Escape button again to display the Defa ult screen.

EscapeEscape

Exploring the Status Mode

The functions available in the Status Mode are:

■ Access Mail Slot

■ Library Sta tus

■ Drive

■ Map Info

Scroll up or down with the

n

Status

Escape button whenever the Default screen

EscapeEscape

Escape button until the Status menu appears. Press the

EscapeEscape

p and q buttons and press the Enter

Enter button to select the item.

EnterEnter

Library Status Submenu

When you selec t Library Sta t us, the following menu appears:

Model Number:

Compaq SSL2020TL

Firmware Revision:

03.03 ¤

Page 31

2-10 Compaq StorageWorks SSL2000 Series Library Maintenance and Service Guide

Scroll through this screen to view the list of available options:

■ Model Number ■ Negotiation Mode

■ Firmware Revision ■ Transfer Rate

■ SCSI Bus ID ■ Unload Mode

■ SCSI Bus Parity ■ Auto Clean Mode

■ Boot Version ■ Reserved Slots

■ Flash Type ■ Mode Page 1F Length

■ Library Mode ■ TUR Reporting

■ Library Config ■ Initialize Element Status

■ Vendor Iden ■ Barcode Reader

■ Product Iden ■ Label Size

■ Baud Rate ■ Label Alignment

■ Transport Address ■ Loader Status

■ Storage Address ■ SCSI Mode

■ Transfer Address ■ Post Recv’d Error

■ Import/Export Addr ■ Tape Alert Mode

■ Serial Number

Drive Status Menu

When you select either of the drives, the following menu appears:

u Tape Motion:

Idle

SCSI Bus ID:

4 ¤

Scroll through this screen to view the list of available options:

■ Tape Motion

■ SCSI Bus ID

■ Firmware Revision

■ Cartridge Present

■ Hardware Error

■ Cleaning Needed

■ Write Protected

Page 32

Map Information Screen

When you select Map Info, the following screen appears. The location being reported appears

on Line 1. The content of the bar code on the l abel, up to 6 characters, ap pears on Line 4.

Drv 0

Occupied

Label Valid

XXXXXXXX ¤

The list of locations available for display on line 1 is as follows. If yo u do not designat e any

mail slots, those lines are omitted from the list.

■ Drive0

■ Drive1

■ Slot0

■ Slot1

■ . . .

■ Slot18

■ Mail Slot

Operation 2-11

Depending on the report for each location, Line 2 might display either Empty or Occupied, or, if

a magazine is absent, Not Installed. Depending on the report for each location, Line 3 might

display either Label Valid, or Label Not

For each location reported, Line 4 displays the actual bar code on the label, up to 6 characters.

Using the Menu Mode

NOTE: When the Library enters the Menu mode, the Ready LED goes out. This means that the module is

offline, and responds to all commands from the host with a SCSI Not Ready until you exit the Menu Mode

and the Ready LED comes on.

To prevent int erruption of host operations, you can lock out the Menu Mode using the Security

menu. See “Security Menu” later in this chapter. When all control panels are locked, you must

enter your unlock code to display the Main menu.

When the Default screen appears, you can enter the Menu Mode by pressing the Enter

The followi ng Main menu appears:

u Load/Unload

Remove Magazine

Maintenance Menu

Configure Menu ¤

NOTE: If the control panel has been locked, the following screen appears instead of the one shown

above. You must know the unlock code for the Library before you can continue.

Present.

Enter button.

EnterEnter

Front Panel Locked

ENTER to Unlock

ESCAPE to Exit

Page 33

2-12 Compaq StorageWorks SSL2000 Series Library Maintenance and Service Guide

When you pre ss the Enter

Unlock Code £

“

¤

Using the p and the q b utt on, set the first digit of the unlock code. Press the Enter

move the cursor to the second digit and repeat the process. Press the Escape

Enter

Enter button to confirm your entry. If the code is correct, the Main menu appears. If the code is

EnterEnter

incorrect, an error screen appears.

Enter button, the following screen appears:

EnterEnter

Exiting the Menu Mode

To exit the Menu Mode and return to the Default screen, press the Escape

Each time you press the Escape

Main menu appears, pressing the Escape

the Ready LED lights.

Escape button, the display moves to a hi gher menu level. When the

EscapeEscape

Escape button once returns to the Default screen. At this point,

EscapeEscape

Navigating through the Menu Structure

To select a submenu, move the u on the display to the desired line using the pand q buttons.

Press the Enter

fourth line means you can scroll to additional configuration option s with the

Enter button to select your choice and display the submenu. The

EnterEnter

Enter button to

EnterEnter

Escape button, then the

EscapeEscape

Escape button repeatedly.

EscapeEscape

¤ at the end of the

q button.

The options available on the Main Menu are:

■ Load/Unload

■ Remove Magazine

■ Maintenance Menu

■ Configur ation Menu

■ Security Menu

Load/Unload Menu

See “Loading and Unloading Tapes,” later in this chapter.

Remove Magazine Menu

When you scroll to Remove Magazine and press the Enter

open.

NOTE: If the message Magazine Locked appears on the screen, the host software has locked the

magazine. Exiting your backup or host management software usually releases the lock. (The host

management software should have a way to release the magazine without shutting down.) If the host

fails, you can cycle power to the Library to release the lock.

Enter button, the magazine door swings

EnterEnter

Page 34

Maintenance Menu

The Maintenance menu options, intended for operator use, are described in Chapter 3,

“Maintenance.”

Configure Menu

The Config ure menu, how to use it, and the options available under it are describe d i n Appendix

C, “Installat ion.”

Security Menu

Use the Securi ty menu to lock the control panel. This pre vents inadvertent or unauthorized

access to the Menu Mode, which takes the Library offline.

NOTE: You can display the Show Status menu without unlocking the panel (and without taking the

Library offline) by pressing the Escape button at the Default screen.

When you select the Security menu, the following screen appears:

u Set Unlock Code

Set Mail Slot Code

Operation 2-13

The Security Menu includes the following options:

■ Set Unlock Code

■ Set Mail Slot Code

To change the unlock code, or to enable or disable the panel locking function, scroll downward

to Set Unlock Code. Press the Enter

Unlock Code £

*“0000”

0000 Disables Lock ¤

An underline cursor displays under the first digit. To set the first digit, press the p but ton or the

q button until the number you want appears. To move the cursor to the second digit, press the

Enter

Enter button. Repeat the process for each of the four digits. Be sure to remember the 4-digit

EnterEnter

number; yo u use it to enter the Menu Mode. Use an unlock code of 0000 to disable control panel

locking.

When you have finished entering four dig its, press the Escape

appears. Your code appears instead of XXXX.

Unlock Code £

*“XXXX”

ENTER to Accept

ESCAPE to Exit ¤

Enter button. The following screen appears:

EnterEnter

Escape button. The follow ing screen

EscapeEscape

Page 35

2-14 Compaq StorageWorks SSL2000 Series Library Maintenance and Service Guide

Press the Enter

Enter button to accept the displayed unlock code or Escape

EnterEnter

Escape to return to the Main

EscapeEscape

menu.

The next time you try to enter the Menu Mode , the followin g screen appear s. You can still

display the St atus menu without using the security code by pressing the Escape

Escape button at the

EscapeEscape

Default screen.

Front Panel Locked

ENTER to Unlock

ESCAPE to Exit

When you pre ss the Enter

Unlock Code £

“ “

¤

Using the p and q buttons, set the first digit of the unlock code. Press the Enter

Enter button, the following screen appears:

EnterEnter

Enter button to

EnterEnter

move the cur s or to the secon d digit and repea t the process. W hen you have finished, press the

Escape

Escape button. The following screen appears:

EscapeEscape

Unlock Code

*“XXXX”

ENTER to Validate

ESCAPE to Exit

Press the Enter

Enter button to validate your choice. If the code is correct, the Main menu appears. If

EnterEnter

the code is incorrect, an error screen appears. If you forgot your unlock code, contact your

Technical Support representative for assistance.

Displaying Firmware Revisions

You can display the library robotics firmware revision a t any time by pressing the Escape

at the Default screen to enter the Status Mode. It displays as one of the options on the Library

Status subme nu of the Status menu. It is also displ ayed on line 2 of the POST Screen a nd the

Initialization Screens.

Loading and Unloading

The Load/Unload menus let you specify a s ource and a dest ination for a ca rtridge movem ent, so

you use exact ly the same procedure to load and unload. To load or unloa d a tape from the front

panel, use the Load/Unloa d menus as follows:

Ready

0

_ _ _ _ _ _ _ 9

10

_ _ _ _ _ _ _ 18

Escape button

EscapeEscape

Page 36

Operation 2-15

From the Default screen, enter the Menu Mode by pressing the Enter

Main menu appears with the

u next to Load/Unload.

Enter button. The following

EnterEnter

u Load/Unload

Remove Magazine

Maintenance Menu

Configure Menu ¤

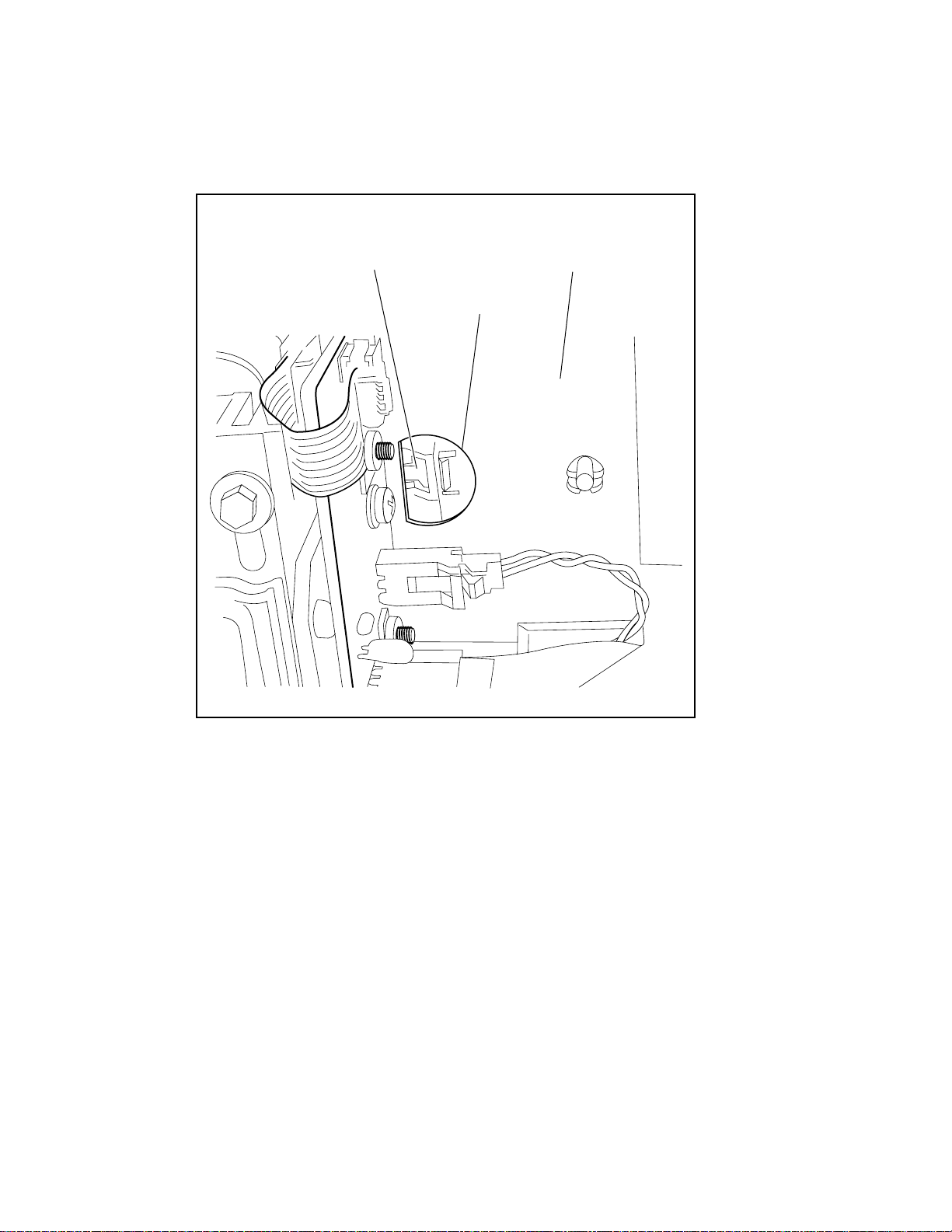

Press Enter

Enter to di splay the first Load/Unload submenu, as shown.

EnterEnter

From:

u *Slot 1

To

*Drv0 ¤

The u is next to line 2 of the displa y. Line 2 shows the top item in a sc rollable list of sources.

Note that a

¤ has appeared on the right of the bottom line. This indicates that the q button can

now be used to scroll through the list, and that the top item on the list is displ ayed. As soon as

you press the

q button, the following three things happen:

1. The list scrolls down one item (only line 2 scroll s) .

2. An £ displays on the right of line 1, meaning there are more options above the item

displayed on line 2.

3. The * at the left of line 2 (the c urrent selection) disappear s, meaning you have not selected

an item from the list.

NOTE: The contents of the lists on line 2 and line 4 vary as follows.

Initial Screen – From Line

The list on line 2 (the From line) includes every drive and magazine sl ot (including mail slots)

with cartridges. (You cannot retrieve a cartridge from an empty slot or drive.)

Initial Screen – To Line

The list on line 4 (the To line) includes all the valid destina tion choices, that is, drives and slots

that are empty. (You can’t put a cartridge into a full slot or drive.)

Scroll List – To Line

There is another limitation on the To list. If you select a drive on the From screen, the To list

can include only slots. If you select a slot on the From screen, the To list can contain only

drives.

For example, load the cartridge that is in Slot 11 into any available drive. Use the

scroll line two to Slot 11. The following screen appears:

From: £

u Slot 11

To:

Drv 0

q button to

Page 37

2-16 Compaq StorageWorks SSL2000 Series Library Maintenance and Service Guide

When you scroll to your desired source, press the Enter

Enter button to select it. Two changes occur in

EnterEnter

the display as shown belo w:

■ The * reappears at the beginning of line 2, indicati ng that you have made a select i on.

■ The u moves to line 4, indicating that you can select a desti nation.

From:

*Slot 11

To:

u *Drv 0

Press the Enter

Enter button to select Drive 1 as the destination. The following Confirmation Screen

EnterEnter

appears:

From: Slot 11 To: Drv 0

ENTER to Execute

ESCAPE to Cancel

Press the Enter

Enter butt on to execute the load or unload or the E s cape

EnterEnter

Escape button to cancel or return to

EscapeEscape

the From entry screen.

When you pre ss the

Enter

Enter button, the following screen appears: If the source is a drive, the word

EnterEnter

Unload appears in place of the word Load on line 4.

From: Slot 11 To: Drv 0

Load In Progress

When the load or unload operation completes, the Default screen reappears.

Inserting and Removing Cartridges

The tape magazine must be r emoved from the Library in order to remove or insert cartridges

(see Figure 2-4). Make sure t he slot you want t o use is not already reserved for a cartridge that is

now in a drive. The safest way to do this is to unload all drives before removing the magazine.

You can unload all the drives either through your host computer software or by using the

LOAD/UNLOAD command on the Main menu.

Make sure the control panel is unlocked. When the control panel is locked, it is impossible to

enter the Menu Mode. The host computer must allow removal of the magazine. The host

software can enable or disable the door unloc k function using the SCSI PREVENT/ALLOW

MEDIUM REMOVAL command. If the host is preventing removal, when you select Unlock

Door on the Main menu and pr ess the Enter

Enter button, the message Magazine Locked appears.

EnterEnter

Page 38

The host software should be able to release the magazine without shutting down. If ho st

computer failure prevents the host from releasing the lock, cycle power to the Library.

IMPORTANT: If you are still unable to open the magazine door, see “Emergency Magazine Removal,”

later in this chapter.

Magazine In

1

Place

R

e

a

d

y

U

s

C

e

l

e

a

n

e

r

D

r

i

v

e

F

a

u

l

t

L

o

a

d

e

F

r

a

u

l

t

E

s

c

a