Page 1

HP Scanjet Enterprise 8500 fn1

HP Digital Sender Flow 8500 fn1

Service Manual

Page 2

Page 3

8500 fn1

Service Manual

Page 4

Copyright and license

© 2013 Copyright Hewlett-Packard

Development Company, L.P.

Reproduction, adaptation, or translation

without prior written permission is

prohibited, except as allowed under the

copyright laws.

The information contained herein is subject

to change without notice.

The only warranties for HP products and

services are set forth in the express warranty

statements accompanying such products and

services. Nothing herein should be

construed as constituting an additional

warranty. HP shall not be liable for technical

or editorial errors or omissions contained

herein.

Part number: L2717-90014

Edition 2, 10/2013

Trademark credits

®

, Acrobat®, and PostScript® are

Adobe

trademarks of Adobe Systems Incorporated.

ENERGY STAR

®

and the ENERGY STAR

®

mark are registered U.S. marks.

Microsoft®, Windows®, Windows® XP,

and Windows Vista® are U.S. registered

trademarks of Microsoft Corporation.

Page 5

Table of contents

1 Theory of operation .......................................................................................................... 1

Flatbed scanner and ADF assembly ............................................................................................ 3

Network electronics assembly .................................................................................................... 4

User interface assembly ............................................................................................................ 6

2 Removal and replacement ................................................................................................ 7

Introduction ............................................................................................................................. 8

Removal and replacement strategy ............................................................................................. 9

Electrostatic discharge ............................................................................................................ 10

Required tools ........................................................................................................................ 11

Types of screws ..................................................................................................................... 12

Service approach ................................................................................................................... 15

Before performing service ........................................................................................ 15

Backup product data ................................................................................ 15

After performing service ........................................................................................... 15

Restore product data ................................................................................ 16

Save and repair process ........................................................................... 16

Post-service test ....................................................................................................... 16

Quality test .............................................................................................. 17

Customer self repair (CSR) assemblies ...................................................................................... 18

ADF rollers ............................................................................................................. 18

Remove the ADF rollers: ............................................................................ 18

Separation pad ........................................................................................ 21

Update the document feeder kit replacement history ..................................... 22

Set the Very Low Settings option from the control panel ................................. 22

Control-panel assembly ............................................................................................ 24

Reinstall the control-panel assembly ............................................................ 25

Hard disk drive ....................................................................................................... 26

Remove the hard disk drive ....................................................................... 26

Reinstall the hard disk drive ........................................................ 29

Reload the firmware .................................................................. 29

ENWW iii

Page 6

Formatter PCA ........................................................................................................ 31

Reinstall the formatter PCA ........................................................................ 36

Keyboard assembly ................................................................................................. 36

Internal assemblies ................................................................................................................. 39

Flatbed scanner and ADF assembly ........................................................................... 39

Remove the flatbed scanner and ADF assembly: ........................................... 39

Reinstall the flatbed scanner and ADF assembly ............................ 42

Power-button assembly ............................................................................................. 44

Remove the power-button assembly ............................................................ 44

Reinstall the power-button assembly ............................................................ 45

Interconnect cable, scanner cable, and control-panel cable .......................................... 46

Remove the scanner cable, control-panel cable, and interconnect cable .......... 46

Interconnect PCA, fan assembly, and DC controller PCA .............................................. 53

Remove the interconnect PCA, fan assembly, and DC controller PCA: ............. 53

3 Solve problems ............................................................................................................... 59

Solve problems checklist ......................................................................................................... 60

Administration Menu Map ....................................................................................................... 61

Preboot menu options ............................................................................................................. 62

Current settings page .............................................................................................................. 63

Troubleshooting process .......................................................................................................... 64

Determine the problem source ................................................................................... 64

Troubleshooting flowchart ......................................................................... 65

Power subsystem ..................................................................................................... 68

Power-on checks ...................................................................................... 68

Power-on troubleshooting overview .............................................. 68

Firmware startup steps ............................................................... 69

Control-panel checks ............................................................................................... 73

Control-panel checks from the control panel ................................................. 73

Control-panel checks from diagnostic mode ................................................. 73

Generate debug data .............................................................................................. 75

Check the maintenance history ................................................................................. 75

Check the number of scans ....................................................................................... 75

Tools for troubleshooting ......................................................................................................... 76

Component diagnostics ............................................................................................ 76

LED diagnostics ........................................................................................ 76

LED indicators on the formatter .................................................... 76

Interpret control-panel status lights ............................................... 77

Engine diagnostics ................................................................................... 77

Verify power to the flatbed scanner and ADF assembly .................. 77

Test simplex scanning ................................................................ 78

iv ENWW

Page 7

Test duplex scanning ................................................................. 78

Sensor test ............................................................................................... 78

Paper present sensor .................................................................. 78

ADF hatch sensor ...................................................................... 79

Flatbed cover sensor .................................................................. 79

Multi-Pick sensor ........................................................................ 79

Internal test pages ................................................................................................... 80

Configuration pages ................................................................................. 80

Configuration page ................................................................... 80

HP embedded Jetdirect page ...................................................... 82

Finding important information on the configuration pages .............. 83

Usage page ............................................................................................ 84

File Directory page ................................................................................... 85

Web Services Status Page ......................................................................... 86

Use HP Embedded Web Server features .................................................................... 86

Information tab ........................................................................................ 87

Control panel menus ................................................................................................ 87

Administration menu ................................................................................. 88

Reports menu ............................................................................ 88

General Settings menu ............................................................... 89

Scan/Digital Send Settings menu ................................................ 90

Fax Settings menu ..................................................................... 93

Display Settings menu ................................................................ 94

Manage Supplies menu ............................................................. 95

Network Settings menu .............................................................. 96

Troubleshooting menu ................................................................ 98

Device Maintenance menu ........................................................................ 99

Backup/Restore menu ................................................................ 99

Calibrate/Cleaning menu ........................................................ 100

USB Firmware Upgrade menu ................................................... 100

Service menu .......................................................................... 100

Interpret control-panel messages ............................................................................. 101

Control-panel message types ................................................................... 101

Control-panel messages .......................................................................... 101

20.00.00 Insufficient memory: <Device> To continue, touch “OK” 101

30.01.10 Scanner Failure ........................................................ 102

30.01.23 Scanner Calibration Failure ....................................... 102

30.01.36 Upgrade Error Try downloading upgrade again .......... 102

30.01.40 Scanner Communication Failure ................................. 102

30.01.47 Document Feeder Not Detected .................................. 103

30.01.YY Scanner Failure ........................................................ 103

ENWW v

Page 8

31.01.02 Jam in document feeder ............................................ 103

31.01.03 Document feeder pick error ....................................... 104

40.00.01 USB I/O buffer overflow To continue, touch “OK” ........ 104

40.00.02 Embedded I/O buffer overflow To continue, touch

“OK” ..................................................................................... 104

40.00.03 EIO <X> buffer overflow To continue, touch “OK” ........ 105

40.00.04 EIO <X> bad transmission To continue, touch “OK” ..... 105

40.00.05 Embedded I/O bad transmission To continue, touch

“OK” ..................................................................................... 105

49.XX.YY Error To continue turn off then on ................................ 105

57.10.01 The fan has failed Turn off and contact the administrator 106

62.00.00 No system To continue turn off then on ........................ 106

80.0X.YY Embedded JetDirect Error To continue turn off then on ... 106

98.00.0X Corrupt data in X volume ........................................... 107

Cleaning disk <X>% complete Do not power off ......................... 107

Digital send communication error .............................................. 107

Digital send communication error .............................................. 107

Disk full Delete stored jobs ........................................................ 108

Document feeder bin full .......................................................... 108

Document feeder is empty ........................................................ 108

Document feeder top cover open ............................................... 108

Event log is empty ................................................................... 108

Flatbed cover open .................................................................. 109

Initializing... ........................................................................... 109

Internal disk not found ............................................................. 109

Internal disk not functional ........................................................ 109

Internal disk not initialized ........................................................ 109

Moving solenoid To exit press ................................................... 110

Moving solenoid and motor To exit press ................................... 110

Performing Paper Path Test… .................................................... 110

Replace Document Feeder Kit ................................................... 110

Unable to cancel firmware update job ....................................... 110

Unable to Install ...................................................................... 111

Unable to install the firmware ................................................... 111

Unsupported USB accessory detected Remove USB accessory ....... 111

Upgrade complete To continue turn off then on ........................... 112

USB accessory needs too much power Remove USB Accessory

and Turn Off then On .............................................................. 112

USB needs too much power ...................................................... 112

USB storage accessory removed Clearing any associated data ..... 112

Event log messages ............................................................................................... 112

vi ENWW

Page 9

Show an event log ................................................................................. 113

Clear the event log ................................................................................. 113

Event log message table .......................................................................... 113

Clear jams .......................................................................................................................... 136

Clear jams from the paper path .............................................................................. 136

Solve paper-handling problems .............................................................................................. 138

Paper jamming, skewing, misfeeds, or multiple-page feeds ......................................... 138

Paper does not feed from the product ...................................................................... 138

Originals are curling up in the document output tray .................................................. 139

The bottom of the scanned image is cut off ............................................................... 139

The scanned images have streaks or scratches .......................................................... 139

An item loaded in the document input tray jams repeatedly ........................................ 139

The product has stopped working correctly ............................................................... 140

Clean the product ................................................................................................................ 141

Clean the touchscreen ........................................................................................... 141

Clean the scanning glass, scanning strip, and automatic document feeder (ADF) duplex

background .......................................................................................................... 141

Clean the rollers .................................................................................................... 144

Set the Very Low Settings option from the control panel ............................... 145

Solve connectivity problems ................................................................................................... 146

Check the Ethernet connection ................................................................................ 147

Service mode functions ......................................................................................................... 148

Service menu ........................................................................................................ 148

Product resets ....................................................................................................... 151

Restore factory settings ............................................................................ 151

Clean Disk and Partial Clean functions ..................................................... 151

Active and repository firmware locations .................................... 151

Partial Clean ........................................................................... 152

Clean Disk ............................................................................. 153

Preboot menu options ........................................................................................................... 155

Solve fax problems ............................................................................................................... 162

Internet Fax setup .................................................................................................. 162

LAN Fax setup ...................................................................................................... 162

Solve e-mail problems ........................................................................................................... 164

Validate the SMTP gateway address ........................................................................ 164

Validate the LDAP gateway address ........................................................................ 164

Product updates ................................................................................................................... 165

Determine the installed revision of firmware .............................................................. 165

Perform a firmware upgrade ................................................................................... 165

HP Embedded Web Server ...................................................................... 165

USB storage device (Preboot menu) .......................................................... 166

ENWW vii

Page 10

USB storage device (control-panel menu) ................................................... 167

4 Parts ............................................................................................................................ 169

Order parts by authorized service providers ............................................................................ 170

Order parts, accessories, and supplies .................................................................... 170

Customer-self repair parts ....................................................................................... 170

Internal assemblies ................................................................................................ 171

Appendix A Service and support ..................................................................................... 173

Hewlett-Packard limited warranty statement ............................................................................. 174

End User License Agreement .................................................................................................. 176

Customer self-repair warranty service ..................................................................................... 179

Customer support ................................................................................................................. 180

Appendix B Product specifications ................................................................................... 181

Physical specifications .......................................................................................................... 182

Document feeder specifications .............................................................................................. 182

Power consumption .............................................................................................................. 182

Environmental specifications .................................................................................................. 183

Regulatory model number ..................................................................................................... 183

Appendix C Regulatory information ................................................................................. 185

Environmental product stewardship program ........................................................................... 186

Protecting the environment ...................................................................................... 186

Plastics ................................................................................................................. 186

Power consumption ............................................................................................... 186

Material restrictions ............................................................................................... 186

Disposal of waste equipment by users in private households in the European Union ...... 187

Chemical substances ............................................................................................. 187

For more information ............................................................................................. 187

Certificate of Volatility .......................................................................................................... 188

Volatile memory .................................................................................................... 188

Non-volatile memory ............................................................................................. 188

Hard disk drive memory ......................................................................................... 188

Index ............................................................................................................................... 189

viii ENWW

Page 11

1 Theory of operation

NOTE: The name for this product was changed to include the word “Flow”. There is no functional

difference between the HP Scanjet Enterprise 8500 fn1 (L2717A) and the HP Digital Sender Flow

8500 fn1 (L2719A). Service parts containing the product name have been updated to include the

words “Digital Sender” and “Flow”.

The 8500 fn1 is a fleet-compliant network scanner with an integrated legal-size flatbed scanner and

single-pass duplex automatic document feeder (ADF). The input tray for the ADF holds 100 pages of

standard size paper and can scan at 60 pages per minute (ppm) for simplex scanning and 120 ppm

for duplex scanning.

The product has three hardware subassemblies:

Flatbed scanner and ADF assembly

●

Network electronics assembly

●

User interface (control panel) assembly

●

ENWW 1

Page 12

Figure 1-1 Hardware subassemblies

2 Chapter 1 Theory of operation ENWW

Page 13

Flatbed scanner and ADF assembly

The scanner can scan paper up to 216 mm (8.5 in) x 863.6 mm (34 in) in size. Paper must be placed

in the ADF input tray or on the flatbed glass before the scanning can be initiated. Output from the

scanner is in .JPEG format and is transferred to a network using a Hi-Speed USB interface.

The major hardware components associated with this assembly are:

ADF with an integrated scan module

●

Flatbed scanner assembly

●

Scanner control-board assembly

●

ENWW

Flatbed scanner and ADF assembly

3

Page 14

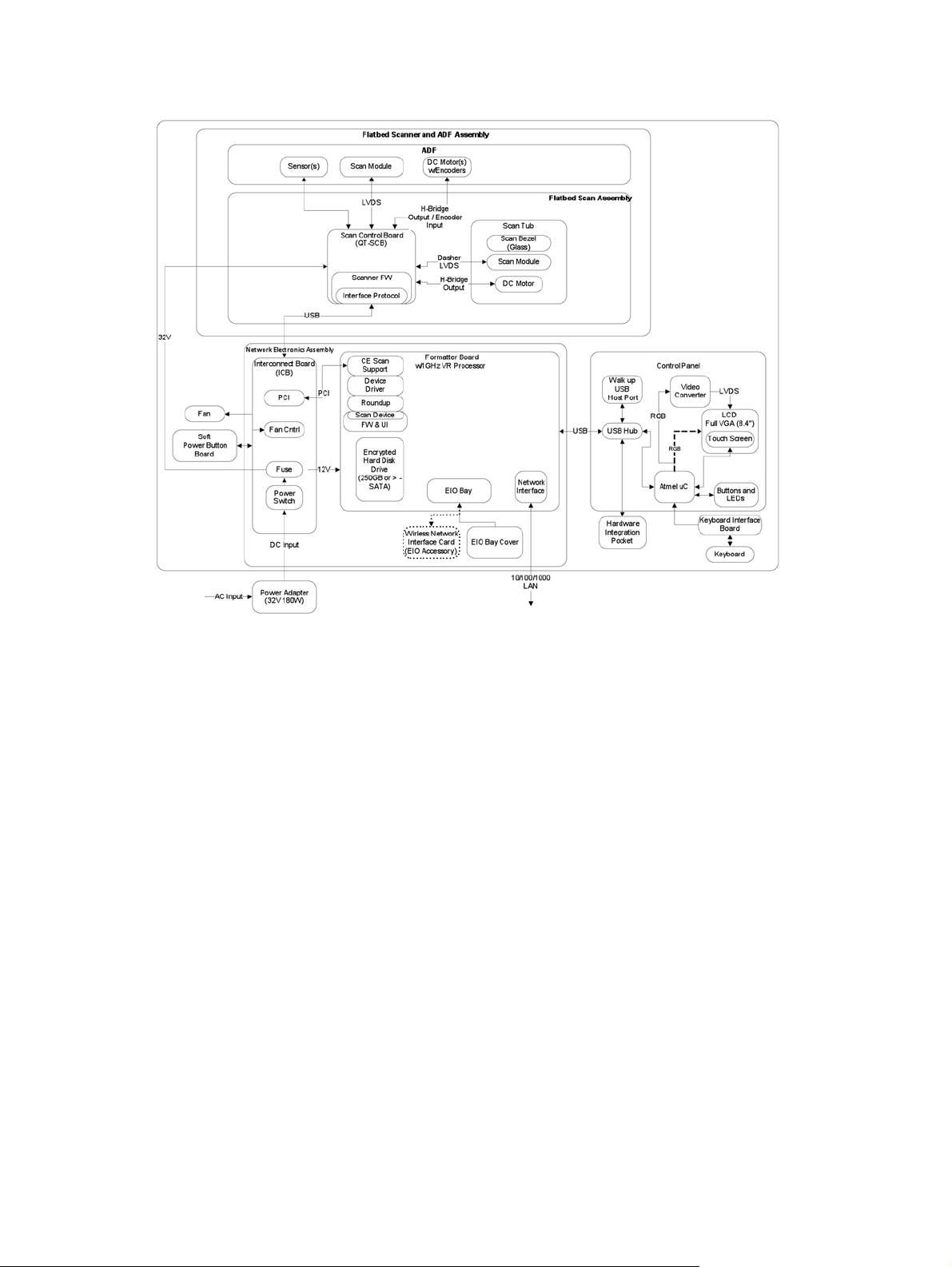

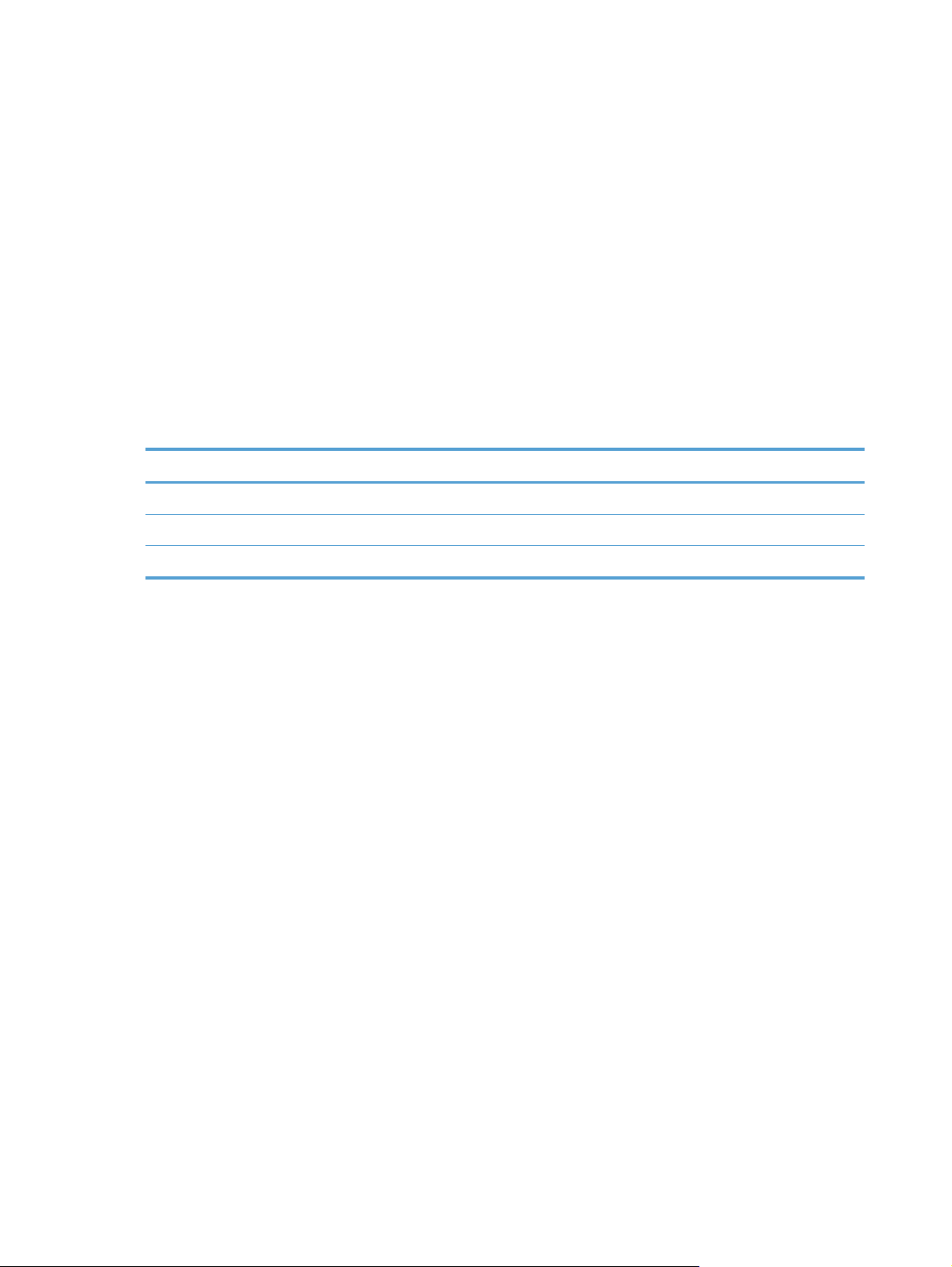

Network electronics assembly

The network electronics assembly controls all functions within the product and provides a connection to

the external gigabit network interface for the product. This assembly only accepts files from a USB

interface in .JPEG format from the flatbed scanner and ADF assembly. The assembly stores the files on

the encrypted hard disk drive for additional post-scan processing and routing based on the options

selected by the user.

Figure 1-2 Network electronics assembly overview

4 Chapter 1 Theory of operation ENWW

Page 15

Table 1-1 Network electronic assembly components

Subassembly Subassembly Subassembly Subassembly

Network electronics (formatter

board)

Interconnect circuit board

(ICB)

Power button board

Power input board

Interface cables From ICB USB cable to scanner

USB cable to control panel

ICB cable assembly DC power cable to scanner

Power/reset control to

System power button board

(non-standard voltages)

scanner

The interconnect circuit board (ICB) subassembly within the network electronics assembly is the main

communication interface for all system assemblies. This ICB controls the power sequencing of all

assemblies and the system fan. All communication interfaces are routed through this assembly.

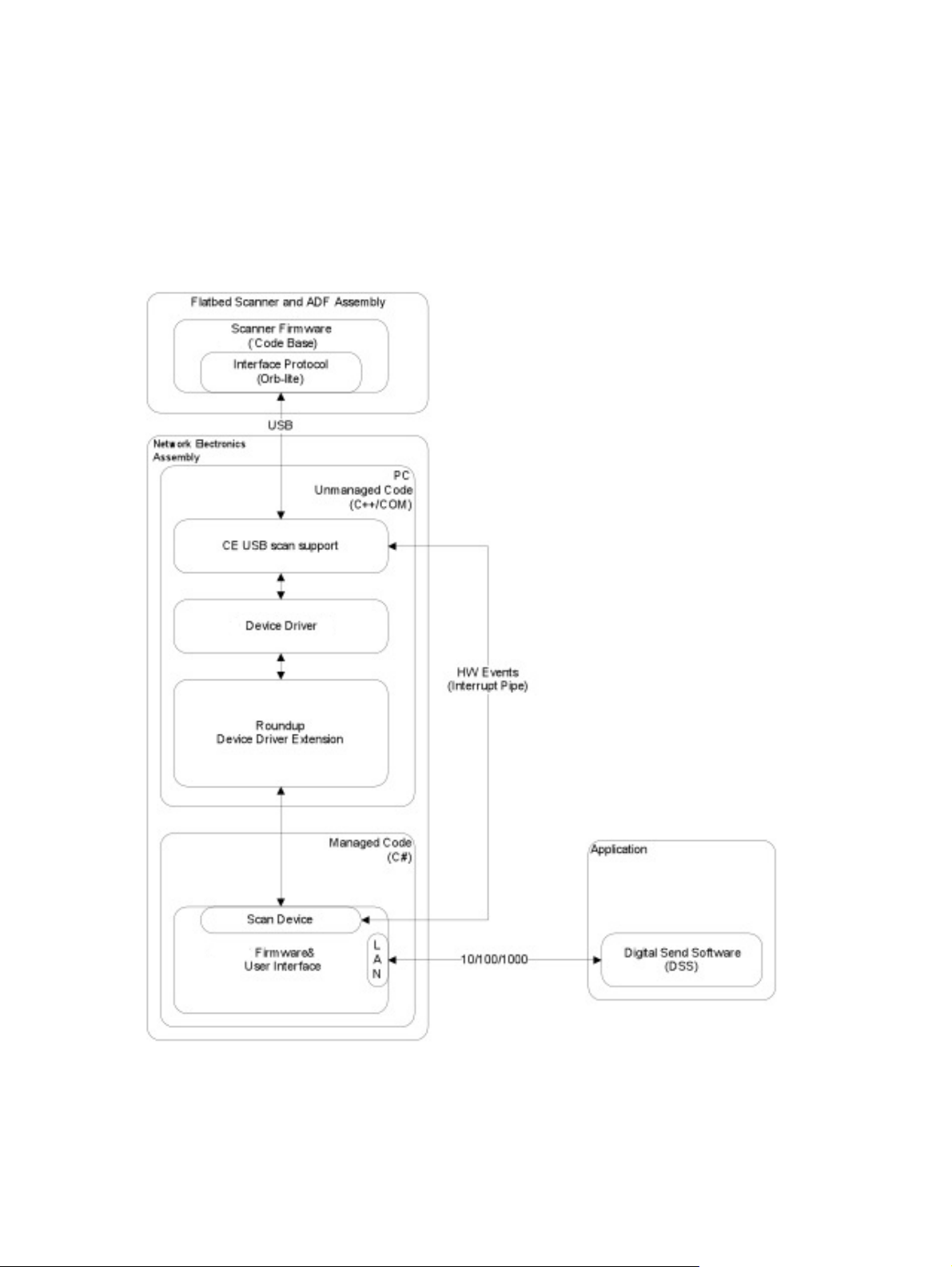

Figure 1-3 ICB connections

ENWW

Network electronics assembly

5

Page 16

User interface assembly

The user interface assembly has a 203.2 mm (8 in) color LCD display with and integrated touchscreen

and a full physical keyboard. The user interface assembly also includes:

A USB-host interface connection with an integrated cover for sending output files to a USB storage

●

accessory

A fleet-compliant hardware integration pocket (HIP)

●

Status LEDs

●

Physical buttons

●

The user interface assembly communicates with the network electronics assembly using a USB interface

through the ICB assembly.

Table 1-2 User interface assembly components

Subassembly Subassembly

Control-panel assembly

Physical keyboard Keyboard interface board

Cables 24-pin FFC from control panel to keyboard interface board

6 Chapter 1 Theory of operation ENWW

Page 17

2 Removal and replacement

Introduction

●

Removal and replacement strategy

●

Electrostatic discharge

●

Required tools

●

Types of screws

●

Service approach

●

Customer self repair (CSR) assemblies

●

Internal assemblies

●

NOTE: Your product might not appear exactly as the one shown in the photos in this chapter.

Although details such as the color of the external panels and covers might be different than your

product, the procedures in this chapter are appropriate for your product.

ENWW 7

Page 18

Introduction

This chapter describes the removal and replacement of field-replaceable units (FRUs) only.

Replacing FRUs is generally the reverse of removal. Occasionally, notes and tips are included to

provide directions for difficult or critical replacement procedures.

HP does

Note the length, diameter, color, type, and location of each screw. Be sure to return each screw to its

original location during reassembly.

Incorrectly routed or loose wire harnesses can interfere with other internal components and can become

damaged or broken. Frayed or pinched harness wires can be difficult to find. When replacing wire

harnesses, always use the provided wire loops, lance points, or wire-harness guides and retainers.

not

support repairing individual subassemblies or troubleshooting to the component level.

8 Chapter 2 Removal and replacement ENWW

Page 19

Removal and replacement strategy

WARNING! Turn the product off, wait 5 seconds, and then remove the power cord before

attempting to remove an assembly. If this warning is not followed, severe injury can result, in addition

to damage to the product. The power must be on for certain functional checks during troubleshooting.

However, disconnect the power supply during parts removal.

Never operate or service the product with the protective cover removed from the laser/scanner

assembly. The reflected beam, although invisible, can damage your eyes.

The sheet-metal parts can have sharp edges. Be careful when handling sheet-metal parts.

CAUTION: Do not bend or fold the flat flexible cables (FFCs) during removal or installation. Also, do

must

not straighten pre-folds in the FFCs. You

an FFC into a connector can cause a short circuit in a PCA.

NOTE: To install a self-tapping screw, first turn it counterclockwise to align it with the existing thread

pattern, and then carefully turn it clockwise to tighten. Do not overtighten. If a self-tapping screw-hole

becomes stripped, repair the screw-hole or replace the affected assembly.

TIP: For clarity, some photos in this chapter show components removed that would not be removed to

service the product. If necessary, remove the components listed at the beginning of a procedure before

proceeding to service the product.

fully seat all FFCs in their connectors. Failure to fully seat

ENWW

Removal and replacement strategy

9

Page 20

Electrostatic discharge

CAUTION: Some parts are sensitive to electrostatic discharge (ESD). Look for the ESD reminder

when removing product parts. Always perform service work at an ESD-protected workstation or mat, or

use an ESD strap. If an ESD workstation, mat, or strap is not available, ground yourself by touching the

before

sheet-metal chassis

Protect the ESD-sensitive parts by placing them in ESD pouches when they are out of the product.

touching an ESD-sensitive part.

10 Chapter 2 Removal and replacement ENWW

Page 21

Required tools

Torx screwdrivers, size 10, 15, and 20

●

Small flat blade screwdriver

●

Needle-nose pliers

●

ESD mat or ESD strap (if one is available)

●

Penlight (optional)

●

USB thumbdrive

●

ENWW

Required tools

11

Page 22

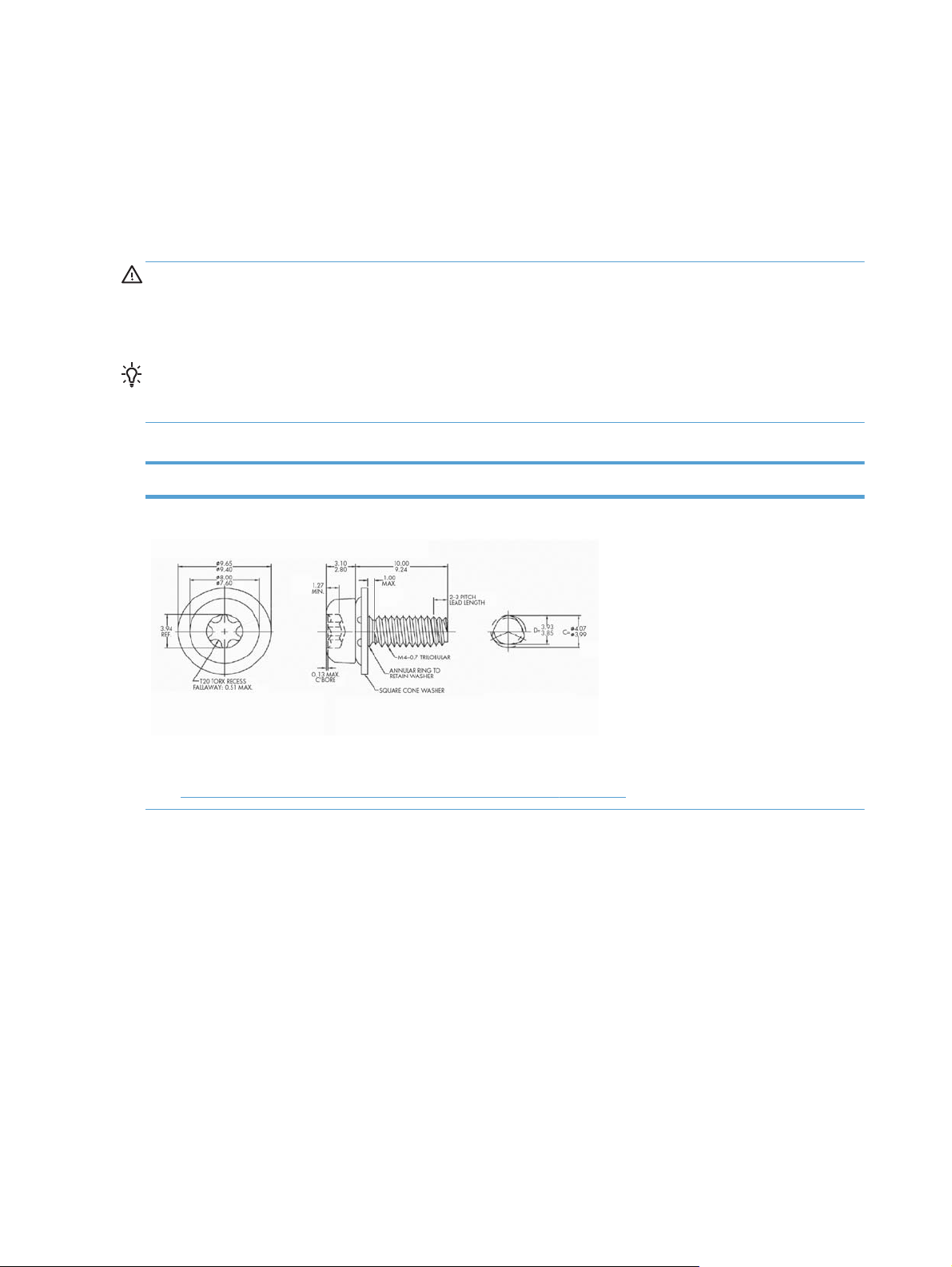

Types of screws

This table describes the screws that are used in the product and provides guidelines to help determine

where each type of screw is used. The screws can vary in length depending on the thickness of the

material that is being fastened.

Always note where each type of screw is located and replace each one in its original location.

WARNING! Make sure that components are replaced with the correct screw type. Using the

incorrect screw (for example, substituting a long screw for the correct shorter screw) can cause damage

to the product or interfere with product operation. Do not intermix screws that are removed with one

component with the screws that are removed from another component.

TIP: When you are disassembling the product, place the screws into the chassis holes from which

they were removed. This prevents their loss, and ensures that the proper type and length of screw for

each location is used when the product is reassembled.

Table 2-1 Common fasteners used in this product

Screw type

Silver Torx head 4 x 10 mm screw with cone washer

This screw type is shown in the following figure:

Figure 2-31 Remove the flatbed scanner and ADF assembly (1 of 7) on page 39

●

12 Chapter 2 Removal and replacement ENWW

Page 23

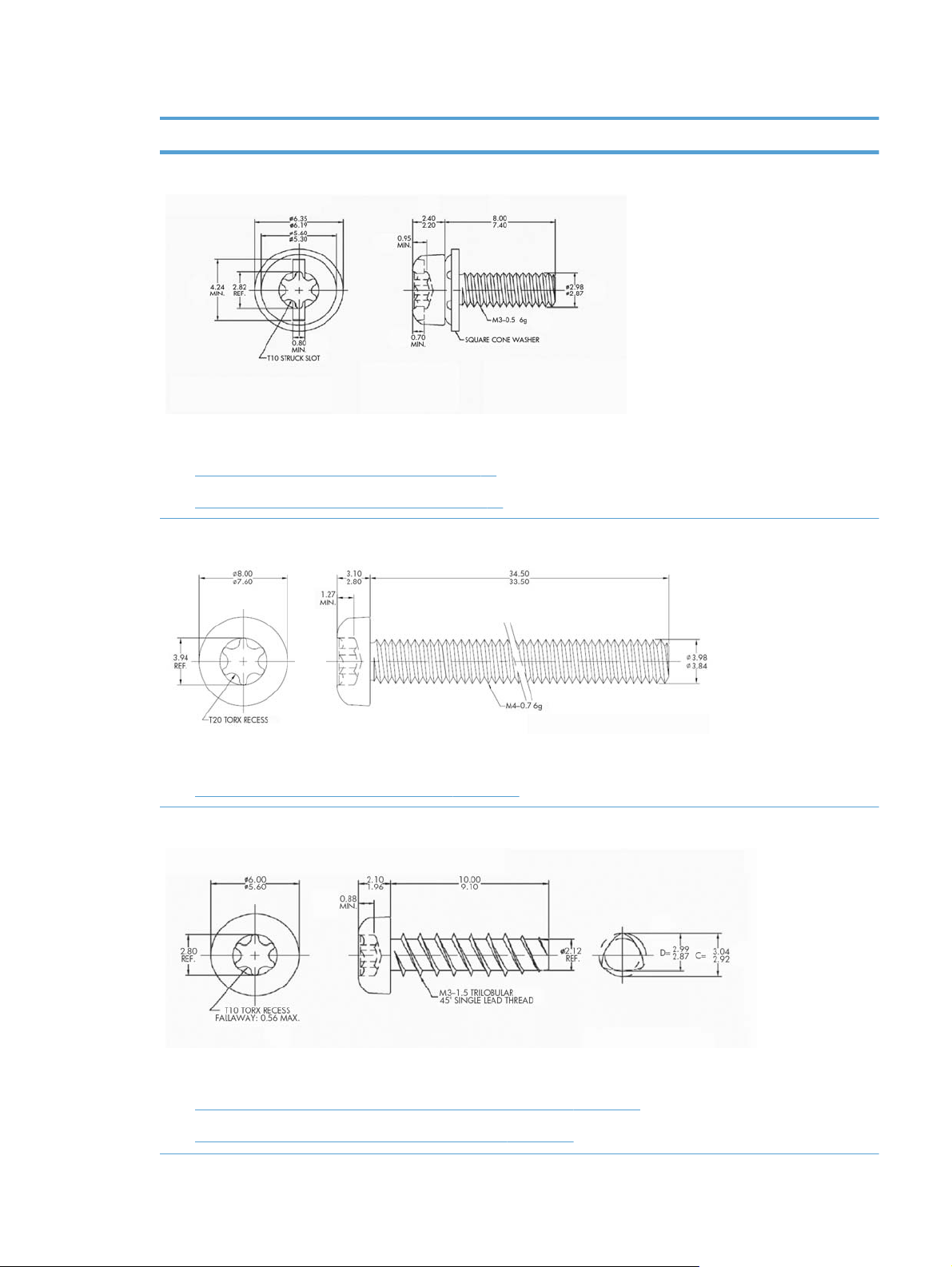

Table 2-1 Common fasteners used in this product (continued)

Screw type

Silver Torx head 3 x 8 mm screw with spring washer

This screw type is shown in the following figures:

Figure 2-61 Remove the interconnect PCA on page 56

●

Figure 2-65 Remove the DC controller PCA on page 58

●

Torx head 4 x 34 mm screw

ENWW

This screw type is shown in the following figure:

Figure 2-63 Remove the fan assembly (2 of 3) on page 57

●

Torx head 3 x 10 mm screw

This screw type is shown in the following figures:

Figure 2-32 Remove the flatbed scanner and ADF assembly (2 of 7) on page 40

●

Figure 2-38 Remove the power-button assembly (1 of 3) on page 44

●

Types of screws

13

Page 24

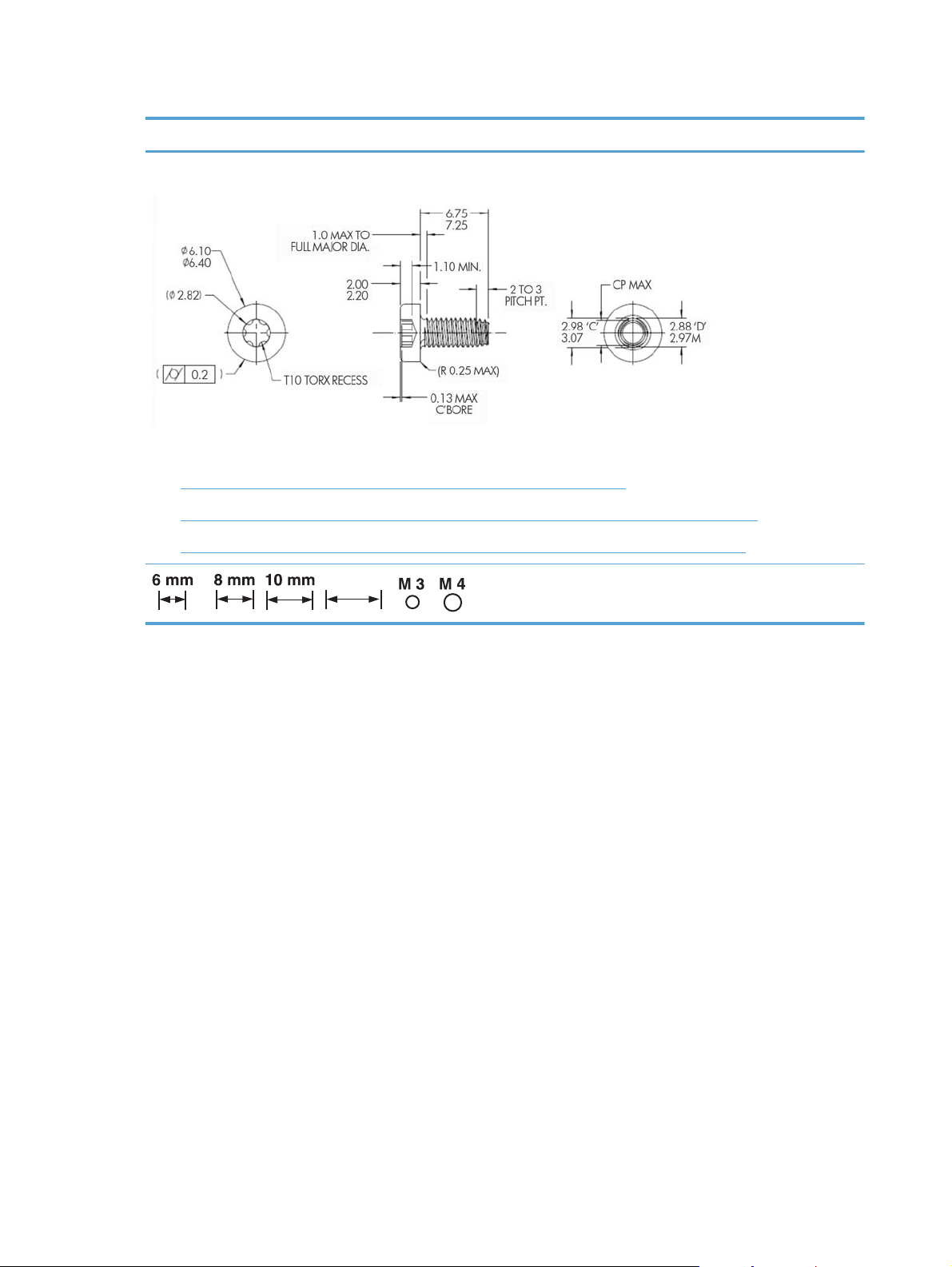

Table 2-1 Common fasteners used in this product (continued)

12 mm

Screw type

Torx head 3 x 7.25 mm screw

This screw type is shown in the following figures:

Figure 2-35 Remove the flatbed scanner and ADF assembly (5 of 7) on page 41

●

Figure 2-41 Remove the scanner cable, control-panel cable, and interconnect cable (1 of 4) on page 46

●

Figure 2-58 Remove the interconnect PCA, fan assembly, and DC connector PCA (4 of 6) on page 55

●

12 mm

Screw measurement guide

14 Chapter 2 Removal and replacement ENWW

Page 25

Service approach

Before performing service

Turn off the power using the power switch.

●

Unplug the power cable and network cable.

●

Place the product on an ESD workstation or mat, or use an ESD strap (if one is available). If an

●

ESD workstation, mat, or strap is not available, ground yourself by touching the sheet-metal

chassis

NOTE: Some procedures require that you backup product data prior to replacing the assembly.

Backup product data

To ensure that customer-specific configuration information and data are preserved, back up the product

data to a portable USB storage device prior to removing these assemblies. Restore the data after

replacing the assembly.

NOTE: You can also backup product data using the HP Embedded Web Server (EWS). The EWS

backs up product data to a customer specified network folder instead of the products hard drive. See

the product user guide for information.

before

touching an ESD-sensitive part.

1. From the Home screen on the product control panel, touch the Device Maintenance button.

2. Open the following menus:

Backup/Restore

●

Backup Data

●

Backup Now

●

NOTE: Backups are stored on the hard disk drive, including regularly scheduled backups. You

can export backups to a USB storage device from the hard disk drive.

3. Insert the portable USB storage device.

4. Touch Export Last Backup

5. Enter the password and confirm the password. Touch OK.

After performing service

Connect the network cable, and then plug in the power cable.

●

NOTE: Some procedures require that you perform a restore step after to replacing the assembly.

ENWW

Service approach

15

Page 26

Restore product data

To ensure that customer-specific configuration information and data are preserved, back up the product

data to a portable USB storage device prior to removing these assemblies. Restore the data after

replacing the assembly.

NOTE: You can also restore product data using the Embedded Web Server (EWS). See the product

user guide for information.

1. From the Home screen on the product control panel, touch the Device Maintenance button.

2. Open the following menus:

Backup/Restore

●

Restore Data

●

3. Insert the portable USB storage device.

4. Select the backup file, and then touch Restore.

5. Touch Restore.

Save and repair process

The save and repair process occurs automatically whenever the formatter PCA, interconnect PCA, or

encrypted hard disk drive (HDD) are replaced. This process is transparent to the user.

CAUTION: Replacing the formatter PCA and interconnect PCA at the same time or swapping these

assemblies between products can render the product unusable.

Formatter PCA: When a replacement formatter PCA is installed and the product is turned on,

●

NVRAM values from the interconnect PCA are transferred automatically to the replacement

formatter PCA. This process allows the product to return to normal operation with all of the

necessary product history.

Interconnect PCA: When a replacement interconnect PCA is installed, NVRAM values from the

●

formatter PCA are transferred automatically to the replacement interconnect PCA. This process

allows the product to return to normal operation with all of the necessary product history.

Hard disk drive (HDD): When a replacement hard disk drive is installed and product is turned on,

●

the replacement hard disk drive is locked to the formatter PCA of the product. The encryption key

is placed in the NVRAM of the formatter PCA and copied to the NVRAM of the interconnect PCA.

This allows the backed up NVRAM values from the interconnect PCA to be restored to a

replacement formatter PCA when either the formatter PCA or interconnect PCA are replaced. This

process also allows the hard disk drive to function when it is transferred from a defective formatter

PCA to a replacement formatter PCA. The hard disk drive cannot be used in another product or

accessed from outside the product.

Post-service test

Perform the following test to verify that the repair or replacement was successful.

16 Chapter 2 Removal and replacement ENWW

Page 27

Quality test

1. Verify that you have completed the necessary reassembly steps.

2. Verify that the power cord and network cable are correctly connected, and then turn on the

3. Verify that the control panel shows the product in Ready mode.

4. Perform the scanning features of the product to ensure the product is functioning correctly. See the

5. If necessary, restore any customer-specified settings.

6. Clean the outside of the product with a damp cloth.

product.

product user guide for information.

ENWW

Service approach

17

Page 28

Customer self repair (CSR) assemblies

ADF rollers

NOTE: Always replace the separation pad when replacing the ADF rollers. The ADF rollers and

separation pad are included in the ADF roller replacement kit.

The ADF roller replacement kit is a consumable and is not covered under warranty or standard service

agreements.

NOTE: HP recommends that you replace the rollers every 100,000 scans.

Remove the ADF rollers:

CAUTION: Do not touch the rollers. Oils from your fingers can impact performance.

NOTE: If the product is on and you open and close the ADF hatch, the attention message If

document feeder roller cleanup is complete, clear message displays. Touch Cancel to clear

the message.

1. Open the automatic document feeder (ADF) hatch.

Figure 2-1 Remove the ADF rollers (1 of 1)

18 Chapter 2 Removal and replacement ENWW

Page 29

2. Slide your fingertip behind the tab on the roller assembly door, and then pull gently forward and

down to open the door.

TIP: Lift the ADF input tray slightly to make it easier to reach the tab.

Figure 2-2 Remove the ADF rollers (1 of 2)

ENWW

Customer self repair (CSR) assemblies

19

Page 30

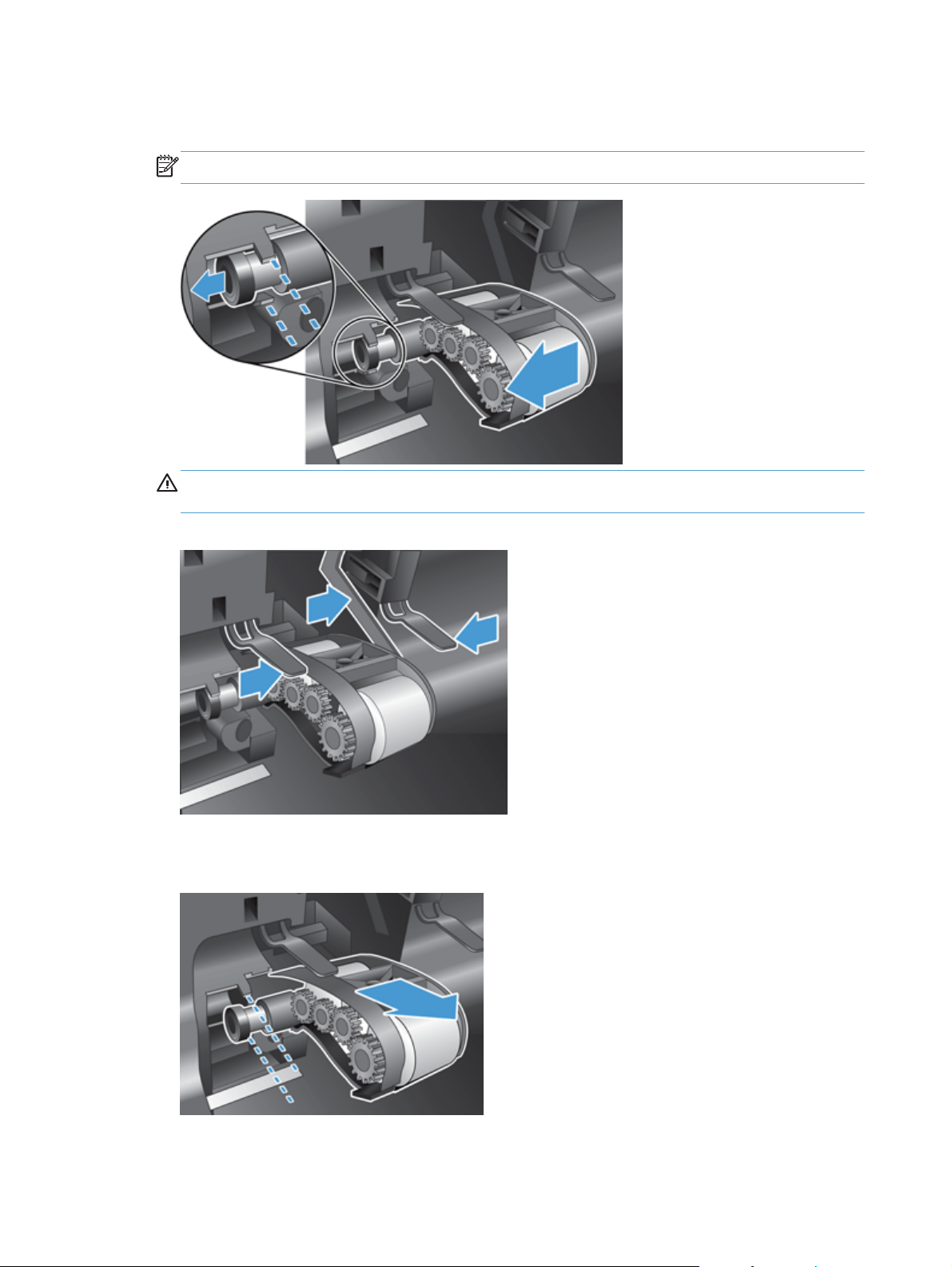

3. Holding the roller assembly door down and out of the way, grasp the roller assembly and slide it

to the left to release it from the enclosure.

NOTE: You might feel a slight resistance when sliding the roller assembly.

CAUTION: Take care not to press down on the alignment tabs or against the tab to the right of

the roller assembly.

Figure 2-3 Remove the ADF rollers (1 of 3)

4. Remove the roller assembly.

Figure 2-4 Remove the ADF rollers (1 of 4)

20 Chapter 2 Removal and replacement ENWW

Page 31

Separation pad

NOTE: Always replace the ADF rollers when replacing the separation pad. The ADF rollers and

separation pad are included in the ADF roller replacement kit.

CAUTION: Do not touch the pad. Oils from your fingers can impact performance.

1. Open the automatic document feeder (ADF) hatch.

Figure 2-5 Remove the separation pad (1 of 3)

2. Push the separation pad latch to release the separation pad.

TIP: Raise the ADF input tray slightly.

Figure 2-6 Remove the separation pad (2 of 3)

ENWW

Customer self repair (CSR) assemblies

21

Page 32

3. Lift the separation pad component to release it from its housing.

Reinstallation tip Make sure the spring seats properly on the new separation pad by pressing

down on the separation pad with a pencil or screwdriver after the pad is installed.

Figure 2-7 Remove the separation pad (3 of 3)

Update the document feeder kit replacement history

After installing new ADF rollers and a separation pad, update the product maintenance history:

1. From the Home screen on the product control panel, touch the Administration button.

2. Open the following menus:

Manage Supplies

●

Reset Supplies

●

New Document Feeder Kit

●

3. Touch Reset.

Set the Very Low Settings option from the control panel

1. From the Home screen on the product control panel, touch the Administration button.

2. Open the following menus:

Calibrate/Cleaning

●

Manage Supplies

●

Supply Settings

●

New Document Feeder Kit

●

22 Chapter 2 Removal and replacement ENWW

Page 33

3. In the Document feeder kit low box, enter a percentage of the total scans at which the

product displays a message to replace the document feeder kit.

4. Select one of the following options:

Select the Stop option to set the product to stop scanning until you replace the document

●

feeder kit.

Select the Prompt to continue option to set the product to stop scanning and prompt you to

●

replace the document feeder kit. You can acknowledge the prompt and continue scanning.

Select the Continue option to set the product to alert you that the document feeder kit needs

●

to be replaced, but to continue scanning.

ENWW

Customer self repair (CSR) assemblies

23

Page 34

Control-panel assembly

1. Raise the scanner lid.

2. Lift the left side of the control panel to release it from the product.

Figure 2-8 Remove the control-panel assembly (1 of 3)

3. Disconnect the FFC (callout 1), and then gently pull the FFC through the cable restraint (callout 2).

Figure 2-9 Remove the control-panel assembly (2 of 3)

24 Chapter 2 Removal and replacement ENWW

Page 35

4. Disconnect the control-panel cable and then remove the control panel.

Figure 2-10 Remove the control-panel assembly (3 of 3)

NOTE: If the firmware is in a compressed file, extract the file before saving it to the USB storage

device. Only files with a .bdl extension are valid firmware update files.

Reinstall the control-panel assembly

The replacement control-panel assembly ships with default calibration values. After installing a new

control-panel assembly, calibrate and test the control-panel. See

more information.

Control-panel checks on page 73 for

ENWW

Customer self repair (CSR) assemblies

25

Page 36

Hard disk drive

CAUTION: ESD sensitive component.

CAUTION: Replacing the hard disk drive and formatter PCA, hard disk drive and interconnect PCA,

or formatter PCA and interconnect PCA at the same time can render the product unusable. Swapping

these assemblies between products can also render the product unusable.

Remove the hard disk drive

1. If replacing the hard disk drive, back up the product data before removing. See Backup product

data on page 15.

2. Loosen two thumbscrews (callout 1), and then remove the formatter.

Figure 2-11 Remove the formatter

26 Chapter 2 Removal and replacement ENWW

Page 37

3. Disconnect the cable from the hard disk drive, gently lift the drive rail lever on the left leading

edge of the hard disk drive (1), and then slide the drive forward (2). Lift the hard disk drive out of

the drawer assembly.

Figure 2-12 Remove the hard disk drive (1 of 3)

ENWW

Customer self repair (CSR) assemblies

27

Page 38

4. Remove the black plastic mounting rails from the hard drive, and then install them on the new hard

drive.

Figure 2-13 Remove the hard disk drive (2 of 3)

Figure 2-14 Remove the hard disk drive (3 of 3)

28 Chapter 2 Removal and replacement ENWW

Page 39

Reinstall the hard disk drive

NOTE: The replacement hard disk drive is locked to the formatter PCA of the product the first time the

product is turned on after installation. The encryption key is placed in the NVRAM of the formatter PCA

and copied to the NVRAM of the interconnect PCA. This allows the backed up NVRAM values from the

interconnect PCA to be restored to a replacement formatter PCA when either the formatter PCA or

interconnect PCA are replaced. This process allows the hard disk drive to function when it is transferred

from a defective formatter PCA to a replacement formatter PCA. The hard disk drive cannot be used in

another product or accessed from outside the product.

1. Tuck the drive cable under the cable restraint.

Figure 2-15 Reinstall the hard disk drive

2. After installing a replacement hard disk drive, you must reload the firmware by performing a

firmware upgrade.

Reload the firmware

1. Go to

www.hp.com/support and select the country/region and language.

2. Select Drivers and Software and then search for the product. Select the product from search

results.

3. Select Cross operating system (BIOS, Firmware, Diagnostics, etc).

4. Select the appropriate firmware update file.

NOTE: If the firmware is in a compressed file, extract the .bdl file before saving it to a USB

thumbdrive. Only files with a .bdl extention are valid for firmware updates.

5. Download and copy the firmware upgrade file to the root directory of a USB storage accessory.

The firmware upgrade file has a .bdl extension.

6. Insert the USB storage accessory into the USB port on the bottom edge of the control panel.

7. Connect all cables and turn on the product. Error: 99.09.62 Not Bootable or a similar

message displays. Press the Start

button to continue.

ENWW

Customer self repair (CSR) assemblies

29

Page 40

8. Wait for the preboot menu to display on the control-panel display, and then press the up or down

navigation arrows on the keyboard to scroll to Administrator. Press the Start

button to select it.

9. Press the up or down keys on the keyboard to scroll to Administrator. Press the Start

button to

select it.

10. Press down arrow key on the keyboard to scroll to Download. Press the Start

11. Press the up or down keys on the keyboard to scroll to USB Thumbdrive. Press the Start

button to select it.

button

to select it.

12. Several .bdl files might be listed. Press the up or down keys on the keyboard to scroll to the

firmware upgrade file that you downloaded. Press the Start

button to select it. Wait while the

file transfers. When the transfer is complete, the message Complete displays on the control-panel

display.

13. Press and hold the power button to turn off the product (approximately 10 seconds). Remove the

USB storage accessory, and then turn the product on. Wait for several minutes while the product

initializes. If the upgrade is unsuccessful, try transferring the firmware upgrade file again.

14. If you created a backup of the product data prior to replacing the hard disk drive, restore the data

from the device or network location where the backup was saved. See

Restore product data

on page 16.

30 Chapter 2 Removal and replacement ENWW

Page 41

Formatter PCA

Remove the formatter PCA and transfer the hard drive

CAUTION: ESD sensitive component.

CAUTION: Replacing the hard disk drive and formatter PCA, hard disk drive and interconnect PCA,

or formatter PCA and interconnect PCA at the same time can render the product unusable. Swapping

these assemblies between products can also render the product unusable. This procedure specifies

replacing the formatter PCA and reinstalling the existing hard drive on the new formatter PCA.

NOTE: If replacing the hard disk drive, back up the product data before removing. See Backup

product data on page 15.

1. Loosen two thumbscrews (callout 1), and then remove the formatter.

Figure 2-16 Remove the formatter (1 of 11)

ENWW

Customer self repair (CSR) assemblies

31

Page 42

2. Slide the formatter PCA chassis out of the product.

Figure 2-17 Remove the formatter (2 of 11)

3. Disconnect the hard drive connector

Figure 2-18 Remove the formatter (3 of 11)

32 Chapter 2 Removal and replacement ENWW

Page 43

4. Release one tab (callout 1) and then slide the hard drive out of the carriage.

Figure 2-19 Remove the formatter (4 of 11)

1

Figure 2-20 Remove the formatter (5 of 11)

ENWW

Customer self repair (CSR) assemblies

33

Page 44

5. Remove the black plastic mounting rails from the old hard drive, and then install them on the new

hard drive.

Figure 2-21 Remove the formatter (6 of 11)

Figure 2-22 Remove the formatter (7 of 11)

6. Install the hard drive in the carriage on the new formatter.

Figure 2-23 Remove the formatter (8 of 11)

34 Chapter 2 Removal and replacement ENWW

Page 45

7. Reinstall the connector.

Figure 2-24 Remove the formatter (9 of 11)

8. Slide the formatter PCA chassis into the product.

Figure 2-25 Remove the formatter (10 of 11)

ENWW

Customer self repair (CSR) assemblies

35

Page 46

9. Tighten the two thumbscrews.

Figure 2-26 Remove the formatter (11 of 11)

Reinstall the formatter PCA

NVRAM values including the encryption key for the hard disk drive are restored to the replacement

formatter PCA from the NVRAM of the interconnect PCA when the product is turned on. The product

returns to normal operation with all of the product history loaded in the NVRAM of the formatter PCA.

Keyboard assembly

1. Slide the four tabs at the top of the keyboard toward the bottom of the keyboard.

Figure 2-27 Remove the keyboard assembly (1 of 4)

36 Chapter 2 Removal and replacement ENWW

Page 47

2. Release the four tabs at the bottom of the keyboard.

Figure 2-28 Remove the keyboard assembly (2 of 4)

3. Lift the keyboard from the product. Note the orientation of the flat flexible cable (FFC) for

reinstallation.

Figure 2-29 Remove the keyboard assembly (3 of 4)

ENWW

Customer self repair (CSR) assemblies

37

Page 48

4. Release the cable lock to release the FFC, and then remove the keyboard.

Figure 2-30 Remove the keyboard assembly (4 of 4)

38 Chapter 2 Removal and replacement ENWW

Page 49

Internal assemblies

Flatbed scanner and ADF assembly

Before proceeding, remove the following components:

Control-panel assembly. See

●

Control-panel assembly on page 24.

Remove the flatbed scanner and ADF assembly:

1. From the front of the scanner, remove four screws.

Figure 2-31 Remove the flatbed scanner and ADF assembly (1 of 7)

ENWW

Internal assemblies

39

Page 50

2. From the back of the scanner, remove five screws.

Figure 2-32 Remove the flatbed scanner and ADF assembly (2 of 7)

3. Carefully release the back cover.

NOTE: The serial number for the product is on the back cover. Do not lose or damage the cover.

Figure 2-33 Remove the flatbed scanner and ADF assembly (3 of 7)

40 Chapter 2 Removal and replacement ENWW

Page 51

4. Remove the back cover.

Figure 2-34 Remove the flatbed scanner and ADF assembly (4 of 7)

5. Remove two screws.

Figure 2-35 Remove the flatbed scanner and ADF assembly (5 of 7)

ENWW

Internal assemblies

41

Page 52

6. Lift the flatbed scanner and ADF assembly.

Figure 2-36 Remove the flatbed scanner and ADF assembly (6 of 7)

7. Disconnect three cables and then remove the flatbed scanner and ADF assembly.

Figure 2-37 Remove the flatbed scanner and ADF assembly (7 of 7)

Reinstall the flatbed scanner and ADF assembly

NOTE: After the flatbed scanner and ADF assembly is replaced, the product compares the firmware

version on the new assembly with the firmware on the product. If the firmware on the product is newer,

the firmware on the assembly is updated. The product will restart multiple times during the update

process.

After installing a new flatbed scanner and ADF assembly, reset the cycle counts.

42 Chapter 2 Removal and replacement ENWW

Page 53

Reset the cycle counts

1. From the Home screen on the product control panel, touch the Device Maintenance button.

2. Touch the Service button and log in.

3. Touch the Cycle Counts button.

4. Reset the following counts to 0:

Document Feeder Count

●

Clean Rollers Count

●

Flatbed Count

●

ADF Simplex Count

●

ADF Duplex Count

●

NOTE: Do not reset the Send Scan Count setting.

ENWW

Internal assemblies

43

Page 54

Power-button assembly

Before proceeding, remove the following components:

Control-panel assembly. See

●

Flatbed scanner and ADF assembly. See

●

Control-panel assembly on page 24.

Remove the power-button assembly

CAUTION: ESD sensitive component.

1. Disconnect one connector (callout 1), and remove two screws (callout 2).

Figure 2-38 Remove the power-button assembly (1 of 3)

1

Flatbed scanner and ADF assembly on page 39

2

44 Chapter 2 Removal and replacement ENWW

Page 55

2. Remove the power-button assembly.

Figure 2-39 Remove the power-button assembly (2 of 3)

Reinstall the power-button assembly

When installing the power-button assembly, install the button first and then install the PCA.

▲

Figure 2-40 Remove the power-button assembly (3 of 3)

ENWW

Internal assemblies

45

Page 56

Interconnect cable, scanner cable, and control-panel cable

Before proceeding, remove the following components:

Control-panel assembly. See

●

Flatbed scanner and ADF assembly. See

●

Control-panel assembly on page 24.

Flatbed scanner and ADF assembly on page 39.

Remove the scanner cable, control-panel cable, and interconnect cable

1. Remove four screws

Figure 2-41 Remove the scanner cable, control-panel cable, and interconnect cable (1 of 4)

2. Release two tabs and remove the sheet-metal plate.

Figure 2-42 Remove the scanner cable, control-panel cable, and interconnect cable (2 of 4)

46 Chapter 2 Removal and replacement ENWW

Page 57

3. Disconnect three cables (callout 1).

Figure 2-43 Remove the scanner cable, control-panel cable, and interconnect cable (3 of 4)

1

4. Identify the cable to be removed:

Scanner cable (callout 1). See

●

Control-panel cable (callout 2). See

●

Interconnect cable (callout 3). See

●

Figure 2-44 Remove the scanner cable, control-panel cable, and interconnect cable (4 of 4)

Remove the scanner cable on page 48.

Remove the control-panel cable on page 49.

Remove the interconnect cable on page 51.

2

1

3

ENWW

Internal assemblies

47

Page 58

Remove the scanner cable

1. If connected, disconnect the scanner cable from the interconnect PCA.

Figure 2-45 Remove the scanner cable (1 of 3)

2. Release the cable from one cable clamp.

Figure 2-46 Remove the scanner cable (2 of 3)

48 Chapter 2 Removal and replacement ENWW

Page 59

3. Remove the scanner cable.

Figure 2-47 Remove the scanner cable (3 of 3)

Remove the control-panel cable

1. If connected, disconnect the control-panel cable from the interconnect PCA.

Figure 2-48 Remove the control-panel cable (1 of 3)

ENWW

Internal assemblies

49

Page 60

2. Release the cable from one cable clamp.

Figure 2-49 Remove the control-panel cable (2 of 3)

3. Remove the control-panel cable.

Figure 2-50 Remove the control-panel cable (3 of 3)

50 Chapter 2 Removal and replacement ENWW

Page 61

Remove the interconnect cable

1. If connected, disconnect the interconnect cable from the interconnect PCA.

Figure 2-51 Remove the interconnect cable (1 of 4)

2. Release the cable from one cable clamp.

Figure 2-52 Remove the interconnect cable (2 of 4)

ENWW

Internal assemblies

51

Page 62

3. Release the cable from one cable clamp (callout 1) and disconnect one connector (callout 2).

Figure 2-53 Remove the interconnect cable (3 of 4)

1

2

4. Remove the interconnect cable.

Figure 2-54 Remove the interconnect cable (4 of 4)

52 Chapter 2 Removal and replacement ENWW

Page 63

Interconnect PCA, fan assembly, and DC controller PCA

NOTE: When a replacement interconnect PCA is installed and the product is turned on, it restores the

NVRAM values from the NVRAM of the formatter PCA. This process allows the product to return to

normal operation with all of the necessary product history.

CAUTION: Replacing the hard disk drive and formatter PCA, hard disk drive and interconnect PCA,

or formatter PCA and interconnect PCA at the same time can render the product unusable. Swapping

these assemblies between products can also render the product unusable.

Before proceeding, remove the following components:

Control-panel assembly. See

●

Flatbed scanner and ADF assembly. See

●

Control-panel assembly on page 24.

Flatbed scanner and ADF assembly on page 39.

Remove the interconnect PCA, fan assembly, and DC controller PCA:

CAUTION: ESD sensitive component.

1. Remove four screws.

Figure 2-55 Remove the interconnect PCA, fan assembly, and DC connector PCA (1 of 6)

ENWW

Internal assemblies

53

Page 64

2. Release two tabs and remove the sheet-metal plate.

Figure 2-56 Remove the interconnect PCA, fan assembly, and DC connector PCA (2 of 6)

3. Disconnect three cables (callout 1).

Figure 2-57 Remove the interconnect PCA, fan assembly, and DC connector PCA (3 of 6)

1

54 Chapter 2 Removal and replacement ENWW

Page 65

4. Remove nine screws.

Figure 2-58 Remove the interconnect PCA, fan assembly, and DC connector PCA (4 of 6)

5. Slide the sheet-metal drawer out of the product.

Figure 2-59 Remove the interconnect PCA, fan assembly, and DC connector PCA (5 of 6)

ENWW

Internal assemblies

55

Page 66

6. Identify the PCA or assembly to be removed:

Interconnect PCA (callout 1). See

●

Fan assembly (callout 2). See

●

DC controller PCA (callout 3). See

●

Figure 2-60 Remove the interconnect PCA, fan assembly, and DC connector PCA (6 of 6)

Remove the interconnect PCA on page 56.

Remove the fan assembly on page 57.

Remove the DC controller PCA on page 58.

31 2

Remove the interconnect PCA

Disconnect two connectors (callout 1), remove four screws (callout 2), and remove the interconnect

▲

PCA.

Figure 2-61 Remove the interconnect PCA

2

1

56 Chapter 2 Removal and replacement ENWW

Page 67

Remove the fan assembly

1. Release one cable retainer.

Figure 2-62 Remove the fan assembly (1 of 3)

2. Disconnect one connector (callout 1) and then remove four screws (callout 2).

Figure 2-63 Remove the fan assembly (2 of 3)

1

2

ENWW

Internal assemblies

57

Page 68

3. Remove the fan assembly.

Figure 2-64 Remove the fan assembly (3 of 3)

Remove the DC controller PCA

Disconnect one connector (callout 1), remove three screws (callout 2), and remove the DC

▲

controller PCA.

Figure 2-65 Remove the DC controller PCA

2

1

58 Chapter 2 Removal and replacement ENWW

Page 69

3 Solve problems

Solve problems checklist

●

Administration Menu Map

●

Preboot menu options

●

Current settings page

●

Troubleshooting process

●

Tools for troubleshooting

●

Clear jams

●

Solve paper-handling problems

●

Clean the product

●

Solve connectivity problems

●

Service mode functions

●

Preboot menu options

●

Solve fax problems

●

Solve e-mail problems

●

Product updates

●

ENWW 59

Page 70

Solve problems checklist

Simple issues such as smudges on the scanning glass or loose cables can cause your product to

produce fuzzy scans, operate in an unexpected manner, or fail to operate. Always check the following

items when you encounter scanning problems.

If scans are fuzzy, check to see if the scanning strip to the left of the scanning glass is dirty or

●

smudged. If so, clean the scanning strip.

If you are scanning a document that will be analyzed using Optical Character Recognition (OCR),

make sure that the original document is clear enough to be analyzed.

Make sure that the Ethernet and power cables are firmly seated in their respective connectors on

●

the back of the product, and that the power cord is plugged into a working electrical outlet or

surge protector.

Ensure that the product is receiving power.

●

Check that the green LED on the power supply case is on.

◦

If the green LED is not on, ensure that power is available to the power outlet or surge

◦

protector that the power supply is plugged into.

If power is available to the power outlet or surge protector but the green LED is still not on,

◦

the power supply might be defective.

Make sure that the power LED and heartbeat LED on the formatter are functioning correctly.

●

Make sure that the product buttons are enabled.

●

Press and hold the power button for 10 seconds to turn off the product, wait 30 seconds, and then

●

press the Power button again to turn on the product.

Make sure the automatic document feeder (ADF) hatch is closed.

●

Verify that the product is connected to the LAN, and that the product is correctly configured to use

●

the network.

If you continue to have problems, it is possible that the firmware or associated drivers are out of date or

have become corrupted. Go to

product.

www.hp.com/support to locate firmware and driver updates for the

60 Chapter 3 Solve problems ENWW

Page 71

Administration Menu Map

The Administration Menu Map report presents the entire structure of the Administration menu so you

can identify how to navigate to any option.

1. From the Home screen on the product control panel, touch the Administration button.

2. Open the following menus:

Reports

●

Configuration/Status Pages

●

Administration Menu Map

●

3. Touch the View button to view the report.

ENWW

Administration Menu Map

61

Page 72

Preboot menu options

If an error occurs while the product is booting, an error message appears on the control-panel display.

The user can access the Preboot menus. The Error menu item will not be seen if an error did not occur.

CAUTION: The Clean Disk, or Format Disk (in newer firmware versions), option performs a disk

initialization for the entire disk. The operating system, firmware files, and third party files (among other

files) will be completely lost. HP does not recommend this action unless upgrading firmware from the

preboot menu.

Access the Preboot menu

1. Turn the product on.

2. Press and hold the Stop

3. Use the keyboard to navigate the menu.

Cold reset using the Preboot menu

1. Turn the product on.

2. Press the Stop

3. On the product keyboard press the down arrow to highlight Administrator, and then press the

enter key.

4. On the product keyboard press the down arrow to highlight Startup Options, and then press the

enter key.

5. On the product keyboard press the down arrow to highlight Cold Reset, and then press the enter

key.

6. On the product control panel press the back arrow

option, and then press the enter key on the keyboard.

NOTE: The product will initialize.

button when the Ready, Data, and Attention LEDs are illuminated solid.

button when the LED lights are illuminated solid.

button twice to highlight the Continue

62 Chapter 3 Solve problems ENWW

Page 73

Current settings page

The current settings pages provides a map of the user configurable settings that might be helpful in the

troubleshooting process.

1. From the Home screen on the product control panel, touch the Administration button.

2. Open the following menus:

Reports

●

Configuration/Status Pages

●

Current Settings Page

●

3. Touch the View button to view the report.

ENWW

Current settings page

63

Page 74

Troubleshooting process

Determine the problem source

When the product malfunctions or encounters an unexpected situation, the product control panel alerts

you to the situation. A troubleshooting flowchart helps you diagnose the root cause of the problem. The

remainder of this chapter provides steps for correcting problems.

Use the troubleshooting flowchart to pinpoint the root cause of hardware malfunctions. The

●

flowchart guides you to the section of this chapter that contains steps for correcting the

malfunction.

Before beginning any troubleshooting procedure, check the following issues:

Are supply items within their rated life?

●

Does the configuration page reveal any configuration errors?

●

NOTE: The customer is responsible for checking supplies and for using supplies that are in good

condition.

64 Chapter 3 Solve problems ENWW

Page 75

Troubleshooting flowchart

Symptom Check Possible causes Possible solutions

The control-panel display is

blank, no lights are lit, and the

product makes no sounds from

the motors.

The power outlet is not

The external power supply has

Is the power on? The power cable is

disconnected.

functioning.

failed.

1. Make sure that the power

cable is connected to the

power supply and a power

outlet or power strip. Make

sure the power supply is

connected to the product.

2. If power cable is connected

to a power strip, make sure

that power strip is

connected to the power

outlet and the power strip is

turned on. If the power strip

has a circuit breaker, reset

the circuit breaker.

See

Power-on checks

on page 68.

Test the outlet by connecting the

product to an outlet that is known

to work.

See

Power-on checks

on page 68.

If the problem persists, replace

the external power supply.

Are the subassemblies receiving

power?

See

Power-on checks

on page 68.

Bad connection to the

Bad connection to the DC

controller PCA

interconnect PCA

See

Power-on checks

on page 68.

1. Turn the power off.

2. Check all connections to the

DC controller PCA.

3. Turn the power on.

See the replacement procedure

for the DC controller PCA in the

service manual.

1. Turn the power off.

2. Check all connections to the

interconnect PCA.

3. Turn the power on.

See the replacement procedure

for the interconnect PCA in the

service manual.

ENWW

Troubleshooting process

65

Page 76

Symptom Check Possible causes Possible solutions

DC controller PCA is defective. Replace the DC controller PCA.

See the replacement procedure

for the DC controller PCA in the

service manual.

interconnect PCA is defective. Replace the interconnect PCA.

See the replacement procedure

for the interconnect PCA in the

service manual.

The control-panel display is

blank, no LED's are lit, but the

other subassemblies have power.

Is the brightness of the

Are the cables to the control

The control-panel display is

The product stops during the

startup process.

The formatter, interconnect PCA,

The firmware is corrupt. See

The firmware on an assembly is

Is the device in sleep mode? The product is in sleep mode. Touch the touchscreen display.

touchscreen display turned off?

panel connected?

What state is the touchscreen

showing?

The touchscreen display

brightness is off.

The cables are not connected. Check the cable connections.

defective.

The firmware was recently

updated.

or another assembly was recently

replaced.

not updating.

Press the + sign on the brightness

adjustment button until the

control-panel display shows.

See the replacement procedure

for the control panel in the

service manual.

Replace the control-panel

display.

See the replacement procedure

for the control-panel display in

the service manual.

Wait 5 minutes and then restart

the product.

on page 69.

Firmware startup steps

The hard drive, formatter, or

other assembly is defective.

An error or warning message

displays on the control-panel

display.

Does message display as a full

Does the message display on the

status line?

screen?

A supply limit is approaching. Follow the instructions to resolve

the warning message.

An error condition exists within

the product.

Follow the instructions to resolve

the error message.

66 Chapter 3 Solve problems ENWW

Page 77

Symptom Check Possible causes Possible solutions

The product cannot connect to

the network.

The product was reset to factory

Are network cables connected? The network cables are

Can you ping the product using

Has an IP address been assigned

to the product?

its IP address?

The product was not configured. Touch the Network Address

default settings.

disconnected.

No network connection Use the command prompt to

button on the control panel to

display the IP address.

Check the configuration from the

control-panel display or HP

Embedded Web Server.

Check each cable connection. If

the problem persists, try a

different cable or port on the hub

or transceiver.

ping the product from your

computer. For example: ping

192.168.45.39 Ensure that the

ping displays round-trip times. If

you are able to ping the product,

verify that the IP address

configuration for the product is

correct on the computer. If it is

correct, delete and then add the

product again. If the ping

command failed, verify that the

network hubs are on, and then

verify that the network settings,

the product, and the computer

are all configured for the same

network.

Is the HP Jetdirect embedded

print server functioning?

The formatter is defective. See the replacement procedure

Are the link speed and duplex

settings correct?

Is the protocol enabled? The product is not configured

The HP Jetdirect embedded print

server is not configured correctly.

The product is not configured

correctly.

correctly.

Check the HP Jetdirect LEDs on

the formatter. The top-left LED is

green and indicates the link

status. If it is off, a link has

failed. The top-right LED is

yellow. It blinks on and off to

indicate network activity.

for the formatter PCA in the

service manual.

The link speed and

communication mode of the

Jetdirect server must match the

network settings. The available

settings depend on the product

and installed Jetdirect server.

Leave the setting in automatic

mode (the default setting).

Check the protocol status using

the HP Embedded Web Server.

See the features of the HP

Embedded Web server in the

service manual.

ENWW

Troubleshooting process

67

Page 78

Symptom Check Possible causes Possible solutions

The product will not scan. Do the flatbed scanner and

document feeder start up

correctly?

The flatbed scanner and ADF

The firmware for the flatbed

scanner and ADF assembly is

corrupted.

assembly is defective.

1. Verify that the flatbed

scanner and ADF assembly

is receiving power and the

firmware is functioning by

loading a sheet of paper in

the input tray and verifying

that the Document load/

detect LED turns on.

2. Turn the product off and

then on.

3. Upgrade the product

firmware. See the firmware

upgrade process in the

service manual.

4. Restart the product.

Replace the flatbed scanner and

ADF assembly.

See the replacement procedure

for the flatbed scanner and ADF

assembly in the service manual.