Page 1

SB SERIES

FIBEROPTIC SWITCH

User’s Manual

Page 2

Page 3

Contents

Safety Information, Instructions, and Symbols.......................................................................1

Safety Information...........................................................................................................1

Classification .......................................................................................................1

Disconnecting from Line Power...........................................................................1

Line Power Requirements ...................................................................................1

Fuse Type............................................................................................................1

Safety Instructions...........................................................................................................2

Before Initializing and Operating the Unit............................................................2

Operating the Unit ...............................................................................................2

Safety Symbols...............................................................................................................4

Compliance.....................................................................................................................5

CE Compliance....................................................................................................5

General Information and Specifications..................................................................................6

General Information ........................................................................................................6

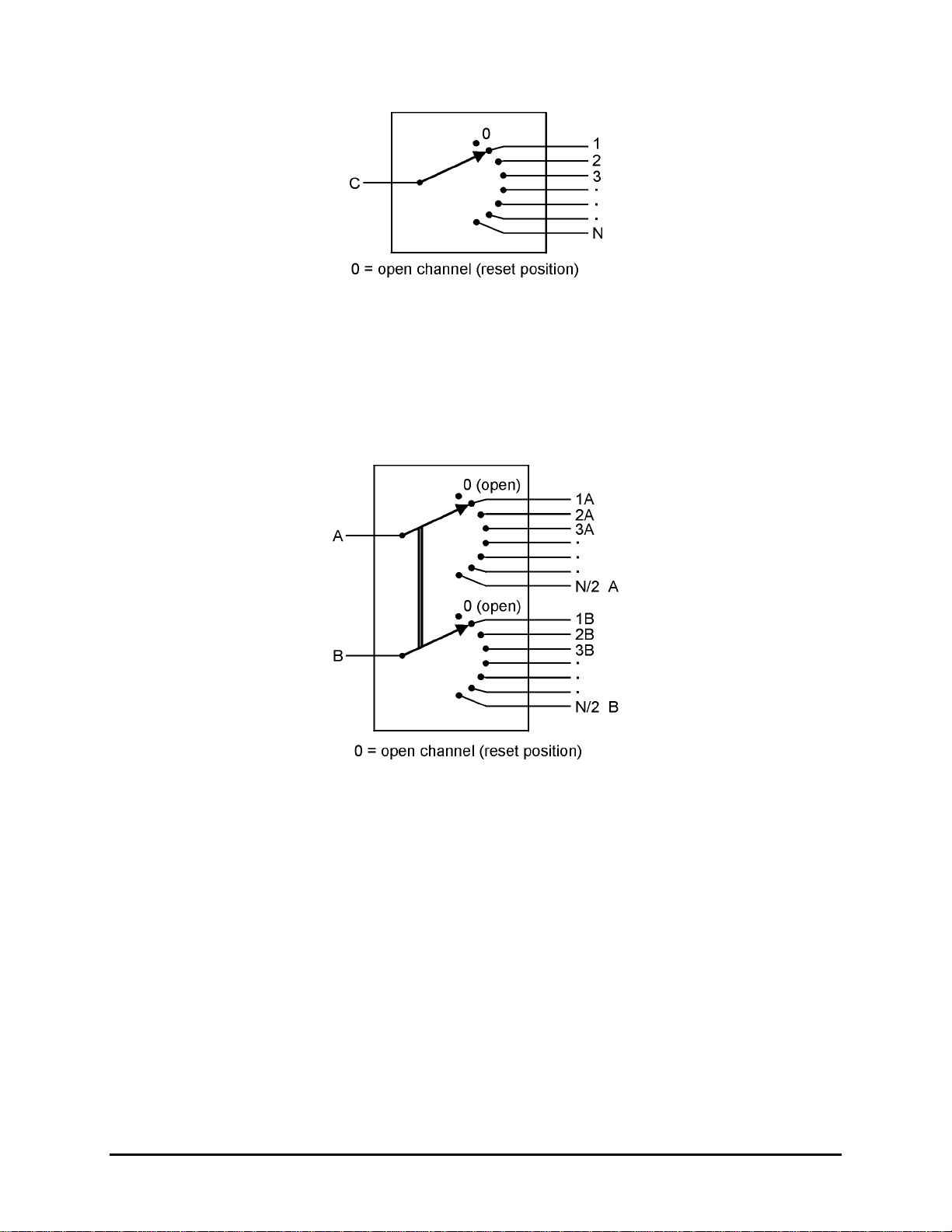

Single-Common (SB-C) Switch Configuration .....................................................6

Dual-Common (SB-D) Switch Configuration........................................................7

Single Step Dual Common (SB-E) Switch Configuration.....................................7

Dual-Common Blocking (SB-F) Switch Configuration..........................................8

Key Features.......................................................................................................8

Applications.........................................................................................................8

Standard Accessories ..........................................................................................8

Optional Accessories...........................................................................................8

Specifications..................................................................................................................9

Getting Started........................................................................................................................11

Before Initializing and Operating the Unit ......................................................................11

Initial I nspecti on.............................................................................................................11

Operating Environment.................................................................................................11

Temperature......................................................................................................12

Humidity.............................................................................................................12

Ventilation..........................................................................................................12

Storing and Shipping.....................................................................................................12

Claims and Repackaging...................................................................................12

Returning Shipments to JDS Uniphase.............................................................12

Cleaning Connectors.....................................................................................................13

Installing the Switch.......................................................................................................14

Operating and Maintenance Instructions..............................................................................15

Front Panel....................................................................................................................15

Operating Keys..................................................................................................15

Status LEDs.......................................................................................................15

Rear Panel....................................................................................................................16

External Swit ch Module Connections............................................................................16

External Switch Module without TTL Input Controls...........................................16

External Switch Module with TTL Input Controls................................................17

SD000153 Rev. J May 2000

Page 4

Sample Driver Application: Electrical Equival ent of Driver.............................................17

Powering Up the Switch................................................................................................18

Using and Selecting a Channel.....................................................................................18

Setting the GPIB Address.............................................................................................19

Setting the Interface Command Set for SC and SX Switches.......................................19

Controlling the Drivers...................................................................................................19

Controlling the Switch Locally.......................................................................................20

Controlling the Switch Remotely by GPIB Interface ......................................................20

Controlling the Switch Remotely by RS232 Interface....................................................20

Calibrating the Switch....................................................................................................21

Maintaining the Switch ..................................................................................................21

Programming Guid e................................................................................................................23

GPIB Pin Assignment....................................................................................................23

Setting the GPIB Address.............................................................................................23

GPIB Interface Functions..............................................................................................24

RS232

Pin Assignment.................................................................................................24

RS232 Interface Specifications.....................................................................................24

RS232 Driver

Pin Assignment.......................................................................................25

Operation and Query Commands .................................................................................25

Command Parser Rules.....................................................................................25

Operation Commands........................................................................................26

Query Commands..............................................................................................27

Status Reporting and Service Request Control.............................................................29

Condition Register.............................................................................................29

Status Register ..................................................................................................29

SRQ Mask Register ...........................................................................................30

GPIB Programming Examples.......................................................................................30

Sending Commands..........................................................................................31

Serial Polling the S t atus Register ......................................................................31

Generating a Service Request Interrupt ............................................................32

Learn Query (LRN?)..........................................................................................32

RS232 Programming Examples....................................................................................32

Sending Commands..........................................................................................33

Querying Status.................................................................................................33

Reading the Status Register..............................................................................33

Setting the Interface Command Set..............................................................................33

SC Series Switch Command Set (SCXXX-0XXX Models).................................34

SX Series Switch Command Set.......................................................................34

SD000153 Rev. J May 2000

Page 5

For sales and service information,

contact JDS Uniphase or your local representative.

JDS Uniph ase Cor poration

570 West Hunt Club Road

Nepean, Ontario, Canada

K2G 5W8

Phone: 613 727-1303

Fax: 613 727-8284

E-mail: sales@jdsunph.com

Website: http://www.jdsunph.com

SD000153 Rev. J May 2000

Page 6

Safety Information, Instructions, and Symbols

Safety I n for m ation

Classification

The unit consists of an exposed metal chassis that is connected directly to earth via a power

cord and, therefore, is classified as a Class 1 instrument. Class 1 refers to equipment relying

on ground protection as a means of shock protection.

The following symbol is used to indicate a protective conductor terminal in the unit.

Disconnecting from Line Power

Some of the circuits are powered whenever the unit is connected to the AC power source (line

power). To ensure that the unit is not connected to the line power, disconnect the power cord

from either the power inlet on the unit’s rear panel or from the AC line-power source

(receptacle). The power cord must always be accessible from one of these points. If the unit is

installed in a cabinet, the operator must be able to disconnect the unit from the line power by

the system’s line-power switch.

Line Power Require ments

The unit can operate from any single-phase AC power source that supplies between 100 and

240 V at a frequency range of 50 to 60 Hz. The maximum power consumption is 80 VA.

Fuse Type

The fuse type used by the unit is (5x20) mm, T1A / 250 V (slow).

Safety – 1

Page 7

Safety I n str u ction s

The following safety instructions must be observed whenever the unit is operated, serviced, or

repaired. Failure to comply with any of these instructions or with any precaution or warning

contained in the user’s manual is in direct violation of the standards of design, manufacture,

and intended use of the unit. JDS Uniphase assumes no liability for the cu stomer’s failure to

comply with any of these safety requirements.

Before Initializing and Operating the Unit

Inspect the unit for any signs of damage, and read the user’s manual thoroughly.

Install the unit as specified in the Getting Started section.

Ensure that the unit and any devices o r cords connected to it are properly grounded.

Operating t he Unit

Warning

To avoid the risk of injury or death, always observe the following precautions

before initializing the unit:

• If using a voltage-reducing autotransformer to power the unit, ensure that

the common terminal connects to the earthed pole of the power source.

• Use only the type of power cord supplied with the unit.

• Connect the power cord only to a power outlet equipped with a protective

earth contact. Never connect to an extension cord that is not equipped with

this feature.

• Willfully interrupting the protective earth connection is prohibited.

• Never look into the end of an optical cable connected to an optical output

device that is operating. Laser radiation is invisible, and direct exposure can

severely injure the human eye. For more information, see the user’s manual

of the laser source in use.

• Turning off the power to the device does not always block the externally

supplied radiation to the connector at the output of the unit.

• Do not use the unit outdoors.

• To prevent potential fire or shock hazard, do not expose the unit to any

source of excessive moisture.

• Do not operate the unit when its covers or panels have been removed.

• Do not interrupt the protective earth grounding. Any such action can lead to

a potential shock hazard that can result in serious personal injury.

• Do not operate the unit if an interruption to the protective grounding is

suspected. In this case, ensure that the unit remains inoperative.

• Use only the type of fuse specified by the manufacturer as appropriate for

this unit. Do not use repaired fuses, and avoid any situations that can short-

Safety – 2

Page 8

circuit the fuse.

• Unless absolutely necessary, do not attempt to adjust or perform any

maintenance or repair procedure when the unit is opened and connected to

a power source.

• Repairs are to be carried out only by a qualified professional.

• Do not attempt any adjustment, maintenance, or repair procedure to the

unit’s internal mechanism if immediate first aid is not accessible.

• Disconnect the power cord from the unit before adding or removing any

components.

• Operating the unit in the presence of flammable gases or fumes is

extremely hazardous.

• Do not perform any operating or maintenance procedure that is not

described in the user’s manual.

• Some of the unit’s capacitors can be charged even when the unit is not

connected to the power source.

Safety – 3

Page 9

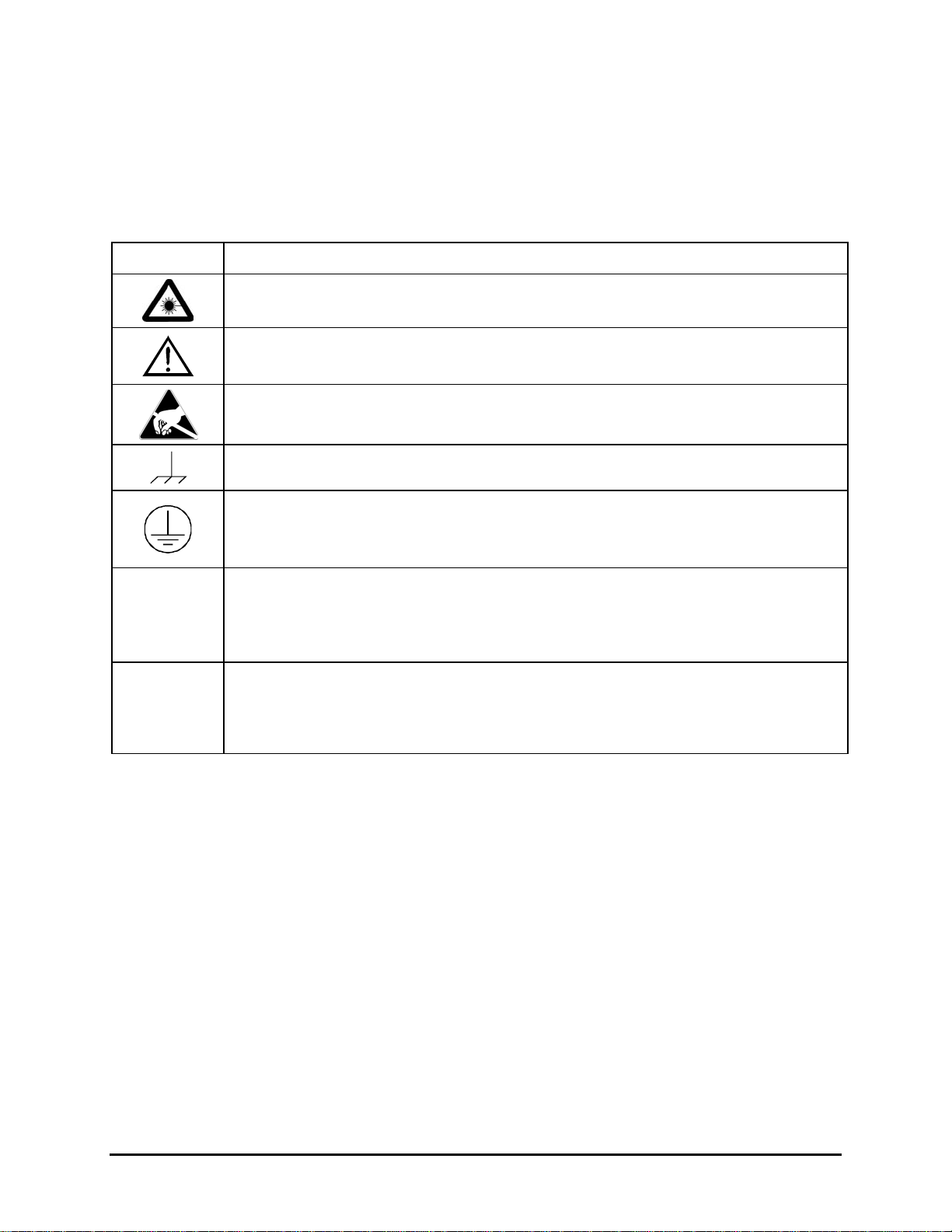

Safety Symbols

The following symbols and messages can be marked on the unit (Table 1). Observe all safety

instructions that are associated with a symbol.

Table 1: Safety Symbols

Symbol

WARNING

CAUTION

Description

Laser safety. See the user’s manual for instructions on handling and operating

the unit safely.

See the user’s manual for instructions on handling and operating the unit

safely.

Electrostatic discharge (ESD). See the user’s manual for instructions on

handling and operating the unit safely.

Frame or chassis terminal for electrical grounding within the unit.

Protective conductor terminal for electrical grounding to the earth.

The procedure can result in serious injury or loss of life if not carried out

in proper compliance with all safety instructions. Ensure that all

conditions necessary for safe handling and operation are met before

proceeding.

The procedure can result in serious damage to or destruction of the unit if not

carried out in compliance with all instructions for proper use. Ensure that all

conditions necessary for safe handling and operation are met before

proceeding.

Safety – 4

Page 10

Compliance

CE Compliance

The unit has been designed and tested to comply with directive 73/23/EEC and its subsequent

amendments by the European Community (EC or CE). The directive relates to electrical

equipment designed for use within certain voltage limits. It ensures that electrical equipment is

constructed with good engineering prac t ice in s a f ety matters.

The unit has been designed and tested to comply with directive 89/336/EEC, exclusive of the

1997 amendment. The directive relates to electromagnetic compatibility. It demands that

electromagnetic disturbance does not exceed a prescribed level; that the equipment be

immune to a prescribed level of ambient level of interference ; tha t the equipment be protected

against electrostatic discharges; and that the equipment be immune to all electrical shock

wave disturbances.

The requirements specified by directive 89/336/EEC are as follows. CE compliance requires

that the manufacturer or its authorized representative established within the Community affix

the EC conformity mark to the apparatus or else to the packaging, instructions for use, or

guarantee certificate. The EC conformity mark shall consist of the letters CE as specified and

the figures of the year in which the mark was affixed. This mark should, where appropriate, be

accompanied by the distinctive letters used by the notified body issuing the EC typeexamination certificate. Where the apparatus is the subject of other Directives providing for the

EC conformity mark, the affixin g of the EC mar k shall also indicate c onformity with the relevant

requirements of those other Directives.

Safety – 5

Page 11

General Information and Specifications

General Information

This user’s manual for the SB Series Fiberoptic Switch contains complete operating

instructions.

The SB Series 1xN programmable switches are designed to connect a single fiberoptic input

channel to any of N (up to 48) output channels (Figure 1). The performance, configuration,

flexibility, and portable enclosure are suitable for a wide range of applications, including

fiberoptic component testing systems, remote fiber test systems in telecommunications, and

research and development. Single-mode and multimode versions of the switches are available.

The SB Series switche s are bidire ctional.

Figure 1: S B Sw itch

The SB switch connects the input to a selected output channel. The terminations are precisely

aligned by a processor-controlled stepper motor. Collimating lenses terminate the fiberoptic

attachments, minimizing the insertion loss of the switch and improving the repeatability and

stability of its parameters.

The SB switch is equipped with IEEE 488.1 parallel and RS232 serial interfaces for remote

operation. The switch also is operated manually using the front-panel controls. The switch

status is displayed on the front-panel indicators.

The SB switch is available in single-common (SB-C) and dual-common (SB-D, SB-E, and SBF) configurations. The dual-common units support two (paired) fiberoptic input channels.

Single-Common (SB-C) Switch Configuration

The common input channel (C) is connected to the output channel (1). The reset position (0) of

the switch is an open circuit. This configuration is shown in Figure 2.

General Information and Specifications – 6

Page 12

Figure 2: Single-Common Configuration

Dual-Common (SB-D) Switch Configuration

The D configuration provides simultaneous connection of a bank of inputs to outputs (Figure

3). The input A can be connected to 1A of 1B or …(N/2)A. In this dual-common configuration,

channel connections are stepped in pairs. The channel displaye d is the current channel pair (A

and B). The number of channel pairs is equal to one-half o f the total number of channels (N).

Figure 3: Dual-Common Configuration

Single Step Dual Common (SB-E) Switch Configuration

This non-blocking configuration allows any input to be connected to any output, but at the

same time, adjacent inputs align with adjacent outputs (Figure 4). This configuration allows for

single-step movement of paired input channels (A and B). The channel connection displayed is

B path; A input channel is connected to B path minus one.

General Information and Specifications – 7

Page 13

Figure 4: Single-Step Dual-Common Configuration

Dual-Common Blocking (SB-F) Switch Configuration

This configuration allows one of the inputs to be aligned with an output in a blocking sense,

with reduced output channel counts available (Figure 5).

Figure 5: Dual-Common Blocking Configuration

Key Features

• Up to 48 channels

• Typical insertion loss 0.4 dB

• Typical repeatability 0.003 dB

• Typical return loss 65 dB

• Local control and rem ote control via IEEE 488 and RS232 interfaces

Applications

• Remote fiber test systems in telecommunication networks

• Fiberoptic component testing

• Transmitter/receiver measurement

• Research and development

Standard Accessories

• AC power cord

• User’s manual

Optional Accessories

• Rack-mount kit

General Information and Specifications – 8

Page 14

Specifications

The fo llo win g optical specific ations describe the warranted characteristics of the unit (Table 2).

Supplementary specifications describe the typical non-warranted performance of the unit

(Table 3 and Table 4).

Tabl e 2: Optical Specificati ons

Insertion loss

single-mode

multimode

1

Return lo ss

single-mode

multimode

3

Parameter

1

2

standard/analog

standard/analog

Typical

0.4 dB

0.3 dB

65 dB/>65 dB

25 dB/35 dB

0.7 dB

0.6 dB

60 dB/65 dB (minimum)

20 dB/30 dB (minimum)

Polarization dependent loss (s ingle-mode) 0.02 dB 0.05 dB

Insertion loss stability

Repeatability

sequential switching

5

random switching

4

±0.03 dB ±0.05 dB

±0.003 dB

±0.01 dB

±0.005 dB

±0.025 dB

Crosstalk (single-mode) -100 dB -80 dB

Input power (continuous wave) 300 mW —

Channel options

front-panel FC or ST connectors

front-panel SC connectors

5 m rear-panel pigtail

20 (maximum)

24 (maximum)

48 (maximum)

Maximum

Switching t ime

one channel

each additional channel

1

Insertion loss does not inclu de connectors. Include 0.2 dB (typical), 0.5 dB (maximum) for each connector.

2

Excluding co nnectors.

3

Values shown for 62.5 µm diameter maximum fiber core.

4

Drift of any channel relative to one assigned reference chann el at ±3 °C deviation of ambient temperature over

a seven-day period.

5

Optimum repeatability after one hour warm-up.

300 ms (typical)

+12 ms (typical)

General Information and Specifications – 9

Page 15

Tabl e 3: Operating S pecificati ons

Local control

• Step-up, step-down channel selection

• Control of one external relay driver

• IEEE 488.1 address selection

• Return-to-local function

• Language selection

Remote

control

• GPIB interface:

IEEE 488.1 1987 capability SH1, AH1, T6, L4, SR1, PP0, DC 1, C0 , E 1

• RS232 interface:

setting 8 bits, 1200 baud, 1 stop bit, no parity

Command set Revised command set. Capable of emulating command set of JDS

Uniphase SC-0 and SX-0 Series switch models.

Drivers Eight open collector outputs, sink current 100 mA maximum per output

(driver):

• Drivers 1, 2, 3, 4, +5V, and GND (ground) are accessible from back

panel connector

• Drivers 5, 6, 7, and 8 are internal

• Driver 1 can also be controlled from the DRIVER1 key on the front panel

W arm-up time11 hour at 25 °C ambient temperature

1

Applicable for optimum repeatability performance.

Tabl e 4: Other Specifi cat ions

Electrical

Input voltage 100 to 240 V AC, 50 to 60 Hz

Power consumption 80 VA maximum

Physical

Dimensions (W x H x D)

standard

with rack-mount kit

Weight

Environmental

Operating temperature 0 to 55 °C

Storage temperature -40 to 70 °C

Humidity maximum 95% R H from 0 to 55 °C

1

Rack-mount kit is optional.

1

21.2 x 8.9 x 35.5 cm

48.3 x 8.9 x 35.5 cm

3.75 kg

General Information and Specifications – 10

Page 16

Getting Started

The SB Series Fiberoptic Switch consists of the switch unit and an AC power cord. The rackmount kit is optional.

Before Initializing and Operating the Unit

Inspect the unit for any signs of damage.

Read the user’s manual thoroughly, and become familiar with all safety symbols and

instructions to ensure that the unit is operated and maintained safely.

Initial Inspection

Warning

To avoid electrical shock, do not initialize or operate the unit if it bears any sign

Check that the unit and contents are complete:

1. Wear an anti-static wrist strap, and work in an electrostatic discharge (ESD) controlled

area.

2. Inspect the shipping container for any indication of excessive shock to the contents, and

inspect the contents to ensure that the shipment is complete.

3. Inspect the unit for structural damage that can have occurred during shipping.

4. Connect the unit to a power source, using the AC power cord provided.

5. Set the power switch to I (on) to initialize the SB switch. All key lamps and status LEDs

light. If no malfunction is detected during power-up, all lamps and LEDs turn off and the

display reads 0. If a malfunction is detected during the power-up sequence, an error

message is displayed.

of damage to any portion of its exterior surface, such as the outer cover or

panels.

6. Set the power switch to O (off), and disconnect the AC power cord from the power supply

and from the unit.

7. Keep the packaging.

Immediately inform JDS Uniphase and, if necessary, the carrier if th e contents of the shipment

are incomplete, if the unit or any of its components are damaged or defective, or if the unit

does not pass the initial inspection.

Operating Environment

In order for the unit to meet the warranted specifications, the operating environment must meet

the following conditions for temperature, humidity, and ventilation.

Getting Sta r ted – 11

Page 17

Temperature

The unit can be operated in the temperature range of 0 to 55 °C.

Humidity

The unit can be operated in environments with up to 95% humidity (0 to 55 °C). Do not expose

it to any environmental conditions or changes to environmental conditions that can cause

condensation to form inside the unit.

Ventilation

The unit contains a built-in cooling fan. Do not install it in any location where the ventilation is

blocked. For optimum performance, the unit must be operated from a location that provides at

least 75 mm (3 inches) of clearance at the rear and at least 25 mm (1 inch) of clearance at the

bottom. Blocking the air circulation around the unit can cause the unit to overheat,

compromising it s reliability.

Warning

• Do not use the unit outdoors.

• To prevent potential fire or shock hazard, do not expose the unit to any

source of excessive moisture.

Storing and Shipping

To maintain optimum operating reliability, do not store the unit in locations where the

temperature falls below -40 °C or rises above 70 °C. Avoid any environmental condition that

can result in internal condensation. Ensure that these temperature and humidity requirements

can also be met whenever the unit is shipped.

Claims an d R epackag in g

Immediately inform JDS Uniphase and, if necessary, the carrier, if

• The contents of the shipment are incomplete

• The unit or any of its components are damaged or defective

• The unit does not pass the initial inspection

In the event of carrier responsibility, JDS Uniphase will a llow for the repair or replacement of

the unit while a claim against the carrier is being processed.

Returning Shipments to JDS Uniphase

JDS Uniphase only accepts returns for which an approved Return Material Authorization

(RMA) has been issued by JDS Uniphase sales personnel. This number must be obtained prior

to shipping any material to JDS Uniphase. The owner’s name and address, the model number

and full serial number of the unit, the RMA number, and an itemized statement of claimed

defects must be included with the return material.

Getting Sta r ted – 12

Page 18

Ship return material in the original shipping container and packing material. If these are not

available, packaging guidelines are as follows:

1. Wear an anti-static wrist strap and work in an ESD controlled area.

2. Cover the front panel with a strip of cardboard.

3. Wrap the unit in anti-static packaging. Use anti-static connector covers, if applicable.

4. Pack the unit in a reliable shipping c ontainer.

5. Use enough shock-absorbing material (10 to 15 cm or 4 to 6 in on all sides) to cushion the

unit and prevent it from moving inside the container. Pink poly anti-static foam is the best

material.

6. Seal the shipping container securely.

7. Clearly mark FRAGILE on its surface.

8. Always provide the model and serial number of the unit and, if necessary, the RMA number

on any accompanying documentation.

9. Ship the unit only to the address given at the beginning of this document .

Cleaning Connectors

Caution

• Connecting damaged or dirty fibers to the unit can damage the connectors

on the unit.

• Never force an optical connector. Some connectors have a ceramic ferrule

that can easily be b ro ken.

Optical cable ends need to be cleaned before using them with the unit.

The following items are required for cleaning:

• Filtered compressed air or dusting gas (for example, Tech Spray Envi-Ro-Tech Duster

1671 gas, available from http://www.techspray.com/1671.htm)

• Lint-free pipe cleaners (for example, from 3M

• Li nt-f ree t owels (for examp le, 1 0 x 10 cm or 4 x 4 in Hy droS orb III wipe rs, a vaila ble from

http://www.focenter.com/acctech/hydrosobr_wipers.htm)

• Optical grade isopropyl alcohol or optical grade 200° ethanol (do not use rubbing alcohol,

which contains 30% water)

To clean the connectors:

1

) or lint-free swab

1

3M is a trademark of 3M.

Getting Sta r ted – 13

Page 19

1. Blow the sleeve with filtered compressed air (Figure 6).

Figure 6: Connector Cleaning (connector type can vary)

2. Apply optical grade isopropyl alcohol or optical grade ethanol (do not use rubbing alcohol)

to a small area of a lint-free towel and rub the end of the ferrule over the wet area.

3. Wipe th e ferrule on a dry area of the lint-free towel.

4. Using the dusting gas or compressed air, blow the end of the ferrule.

5. Apply the alcohol or ethanol to a lint-free pipe cleaner or swab and wipe off the remaining

parts of the connector.

6. With the other end of the pipe cleaner or swab, dry the areas cleaned.

7. Using the dusting gas or compressed air, blow the areas cleaned.

Installing the Switch

Warning

In sensitive applications, to avoid shock and vibration, do not mount the switch

in non-rigid racks or on top of raised floors or tables. Avoid use with highimpact doors that lack impact-reducing bumpers upon closing.

To install the switch:

1. Place the SB switch into its intended operating location.

2. Avoid blocking the ventilation holes at the back and at the bottom of the instrument.

3. Do not pull on the fibers exiting through the rear-panel strain relief. Excessive force can

damage the optics.

4. Route the fiber cables in such a way as to avoid creating bends that have a radius of less

than 1.5 cm; do not lay cables across sharp corners or tie bundles of cables together

tightly.

5. Reattach the AC power cord and reinitialize the switch.

Getting Sta r ted – 14

Page 20

Operating and Maintenance Instructions

Front Panel

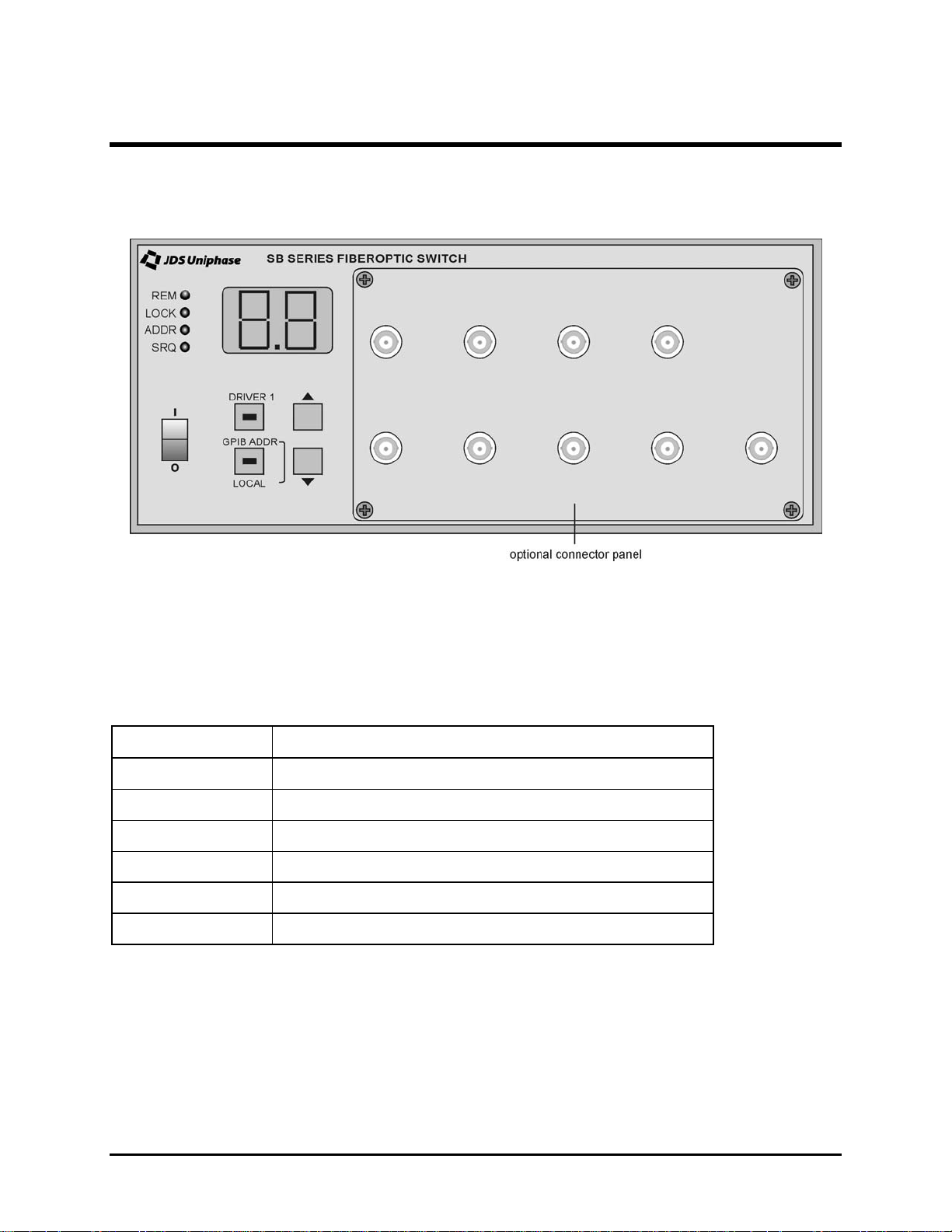

The front of the switch is shown in Figure 7.

Figure 7: Front of the Switch

Operating Keys

The operating keys are described in Table 5.

Tabl e 5: O perating Keys

Key Description

I / O

DRIVER 1 Toggles driver 1 on and off

GPIB ADDR Sets the swit ch t o G P IB Address (IEEE 488.1) mode

LOCAL Returns the switch to Local mode from Remote mode

▲

▼

Turns the power on (I) and off (O)

Channel increment key

Channel decrem ent key

Status LEDs

The status LEDs are described in Table 6.

Operating and Maintenance Instructions – 15

Page 21

Tabl e 6: Status LEDs

LED Description

REM Indicates that the GPIB or RS232 interface is in Remote mode. All front-panel

keys except Local are locked out.

LOCK Indicates that the SB switch is in Local Lockout mode. This mode prevents the

Local key from returning the SB switch to Local mode.

ADDR Indicates that the GPIB interface is in talk or listen state

SRQ Indicates that the interrupt logic of the SB switch has generated a service request

interrupt on the GPIB interface

Rear Panel

The back of the switch is shown in Figure 8.

Figure 8: Back of the Switch

External Switch Module Connections

External Switch Module without TTL Input Controls

The setup for a switch without transistor-to-transistor logic (TTL) is shown in Figure 9.

Operating and Maintenance Instructions – 16

Page 22

Figure 9: Switch Setup without TTL

External Switch Module with TTL Input Controls

The setup for a switch with TTL is shown in Figure 10.

Figure 10: Switch Setup with TTL

Sample Driver Application: Electrical Equivalent of Driver

A sample driver application is shown in Figure 1 1.

Operating and Maintenance Instructions – 17

Page 23

Figure 11: Sample Driver Application: Electrical Equivalent of Driver

Caution

Do not exceed 100 mA per driver.

Powering Up the Switch

To power up the switch:

1. Connect the switch to the AC power source with the AC power cord provided.

2. Set the power switch to I (on) to initialize the SB switch. All key lamps and status LEDs

light. If no malfunction is detected during power-up, all lamps and LEDs turn off, and the

display reads 0.

Using and Selecting a Channel

To use the switch:

1. Connect a channel to the front of the switch (Figure 12).

Figure 12: Using a Channel

Operating and Maintenance Instructions – 18

Page 24

To select a channel:

1. Press the ▲ or ▼ key to scroll to the channel number required. The switch mechanism

advances to the channel when the key is released.

In SB-C models (SB1CXXXXX+2XXXXXXXX), the channel number displayed is the current

channel number connected to the common fiber C (the switch has one common fiber).

In the SB-D models (SB2DXXXXX+2XXXXXXXX), the channel number displayed is the current

channel pair (the switch has two common fibers).

In the SB-E models (SB2EXXXXX+2XXXXXXXX), the channel number displayed is the

channel connected to the common fiber B. The channel connected to the common fiber A is B

- 1 (the switch has two common fibers).

In SB-F models (SB2FXXXXX+2XXXXXXXX), the channel number displayed is the channel

connected to the common fiber B. A blocked connection with B shows as an even-numbered

channel and the connected channels with B show as odd-numbered. The path connected to

common fiber A is B - 1.

In all configurations, channel 0 is an open circuit, that is, the switch is in an unconnected state.

Setting the GPIB Address

Set the SB switch to GPIB mode to display and edit the GPIB address:

1. Press the GPIB ADDR key. The current GPIB address is displayed.

2. To change the address, press the ▲ or ▼ key to scroll to the required address.

3. Press the GPIB ADDR key to store the new address. Or, to exit GPIB mode without

changing the address, press the DRIVER 1 key.

Setting the Interface Command Set for SC and SX Switches

The SB switch can be set to emulate the interface command sets of earlier models of JDS

Uniphase SC Series and SX Series switches.

To set the interface command set:

1. Press and hold the GPIB ADDR key while the SB switch powers u p. The active inte rface

command set is displayed.

2. Press the ▲ key to scroll to the required command set, for example, SB, SC, or SX.

3. Press the GPIB ADDR key to save the setting.

Controlling the Drivers

The SB switch has four drivers (drivers 1, 2, 3, and 4) for driving the external switch modules

and four drivers (drivers 5, 6, 7, and 8) for driving internal switch modules in custom

Operating and Maintenance Instructions – 19

Page 25

applications. All drivers are controlled by remote commands (use the Driver port at the back of

the switch). Driver 1 can also be controlled locally by the Driver 1 key.

To control driver 1 locally:

1. Press the Driver 1 key to toggle driver 1 on and off f or manual control. The status LED of

the key is lit when on.

Controlling the Switch Locally

To operate the switch using the front panel:

1. If the REM status LED is lit, press the Local key once to set the SB switch to Local mode.

2. Press the ▲ or ▼ key to select the switch position required. In SB-E configurations, the

display shows the common B switch position. Common A is set to the display reading

minus one.

3. To toggle external relay driver 1, press the Driver 1 key. This driver can be used to operate

a 1x2 source select switch. The status LED key is lit when on.

Controlling the Switch Remotely by GP I B In ter face

To control the switch by GPIB interface:

1. Connect a user-supplied GPIB cable to the controlling computer and to the IEEE 488

(GPIB) port at the back of the switch.

2. Verify that the interface command set is set to SB and that the GPIB address is set to 7. To

do this, turn the SB switch off and then on again. The display reads SB when set to SB

mode. See the Setting the Interface Command Set section for instructions on changing

the interface command set.

3. At the computer that controls the GPIB, set the message terminating character sequence

to carriage return and line feed (<CR><LF>), for example, ASCII character code 13, 10.

The <CR><LF> characters must be appended to the end of any messages sent to the SB

switch. Similarly, the switch appends these characters to all messages it returns.

4. Send a sample command to the SB switch; for example, use an OUTPUT statement (or

equivalent) to send the command CLOSE 10 at GPIB address 7. The channel setting

changes to 10. Most programming languages automatically append the terminating

sequence to the message.

5. Send a sample query command, for example, CLOSE?; then use an INPUT statement to

receive the message 10 from GPIB address 7.

Controlling the Switch Remotely by RS 232 In ter face

To control the switch by RS232 interface:

1. Connect an RS232 cable to the RS232C port of the SB switch and to a computer.

Operating and Maintenance Instructions – 20

Page 26

2. At the computer, initialize the serial port to 1200 baud, eight bit ASCII character code, one

stop bit, and no parity. Use the following MS-DOS

2

Qbasic program as an example:

OPEN "COM2;1200,N,8,1" FOR R ANDOM AS #1

PRINT #1, "CLOSE 5"

PRINT #1, "CLOSE? "

INPUT #1,A$

PRINT A$

END

Calibrating the Switch

No calibration is required.

Maintaining the Switch

Clean the connector ends with a lint-free tissue and alcohol before every mating. See the

Cleaning Connectors section.

Clean the internal connectors and the panel-mounted connector bulkheads periodically or

when high losses are suspected. The internal connectors can be accessed by removing the

connector panel:

1. Remove the retaining screws of the connector panel.

2. Slowly pull the panel out to the full extent of its guide rails (Figure 13).

Figure 13: Removing the Connector Panel

3. Remove the connectors from the connector bulkheads.

4. Clean the connector ends and the bulkhead mating sleeves with a lint-free tissue and

alcohol.

5. Reinstall the connectors into the bulkheads.

2

MS-DOS is a registered trademark of Microsoft Corporation.

Operating and Maintenance Instructions – 21

Page 27

6. Reinstall the connector panel, guiding the fibers back to ensure that they do not bend

sharply.

Operating and Maintenance Instructions – 22

Page 28

Programming Guide

The following programming instructions for the SB switch are intended for users who are

familiar with the GPIB interface and how to send or receive messages over a device. A

detailed description of the GPIB interface is contained in

Standard Digital Interface for Programmable Instrumentation

Electrical and Electronics Engi neers.

The SB switch is equipped with a GPIB parallel interface and an RS232C serial interface. The

switch accepts the same device dependent commands (commands that control the instrument)

over either i nterface.

The SB switch can be set to emulate the interface command sets, status reporting, and service

request control of the SC Series and SX Series switches. The active interface command set is

displayed when the switch is powered on. See the Setting the Interface Command Set

section for instructions on changing the interface command set.

GPIB Pin Assignment

The GPIB pin assignment is shown in Figure 14.

ANSI/IEEE Std. 488.1-1987 IEEE

, published by the Institute of

Figure 14: GPIB Pin Assignment

Caution

Tighten the connector lock screws by hand. Do not use a screwdriver.

Setting the GPIB Address

To display or edit the GPIB interface address:

1. Press t he GPIB ADDR key to set t he switch to GPIB mode. The current GPIB address is

displayed. (The factory-set GPIB address is 7.)

2. To change the address, press the ▲ or ▼ key to scroll to the required address.

Programming Guide – 23

Page 29

3. Press th e GPIB ADDR key. The ne w address is activated and stored. To leave the GPIB

address unchanged, press the Driver 1 key.

GPIB Interface Functions

The GPIB interface functions are listed in Table 7.

Tabl e 7: GPIB Interface Functions

Mnemonic Function

SH1 source handshake, complete capability

AH1 acceptor handshake, complete capability

T6 basic talker, serial poll, not addressed if MLA

L4 basic listener, not addressed if MTA

SR1 service request capability

RL1 remote/local, complete capability

PP0 parallel poll, no capability

DC1 device clear, complete capability

DT0 device trigger, no capability

C0 controller, no capability

E1 electrical interface, open collector drivers

RS232

The RS232 pin assignment is shown in Figure 15.

Pin Assignment

Figure 15: RS 232 Pi n Assignment

RS232 Interface Specifications

Table 8 lists the RS232 interface specifications.

Programming Guide – 24

Page 30

Table 8: RS232 Interface Specifications

Name Symbol Pin Number Signal Direction

transmitted data TxD 2 out

received data RxD 3 in

request to send RTS 8 out

clear to send CTS 7 in

data terminal ready DTR 6 out

signal ground SG 5 —

The data protocol is permanently set to 1200 baud ASCII character code, with eight bits per

character, one stop bit, and no parity bit. The serial port of the controlling computer must be

configured with the same settings.

RS232 Driver

Pin Assignment

The RS232 driver pin assignment is shown in Figure 16.

Figure 16: Driver Pin Assignment

Caution

Do not exceed 100 mA per driver.

Operation and Query Commands

Operation and query commands control instrument functions and are interface-independent.

Command Parser Rules

• A command consists of a mnemonic (for example, CLOSE) and, if required, a data

parameter. The mnemonic and the data parameter must be separated by at least one

space.

• Parameters can be entered in various formats; for example, 10, 10.0, and 1.0e1 are all

recognized as the same value.

• Commands can be sent in uppercase or lowercase characters.

Programming Guide – 25

Page 31

• A command is contained in a message, and messages can contain more than one

command, each one separated by a semicolon (;). For example, CLOSE 6;XDR 2 1 <CR>

<LF> contains two commands.

• All GPIB commands must end with the terminating sequence <CR> <LF>.

• All RS232 commands must be terminated with a single <CR> c haracter.

• The input buffer of the switch can hold as many as 100 characters. If the buffer becomes

full, the switch holds the handshaking line on the GPIB interface until space is available.

Similarly, over the RS232 interface, the switch sets the Clear To Send line low. Any

characters received after the line goes low are ignored.

• Commands are executed as they are parsed; consequently, a command can be executed

before the entire message in which it is contained is received.

• The switch delays accepting new characters sent over the GPIB interface while the switch

mechanism is moving, but no data are lost. The SB switch is always ready to accept

characters over the RS232 interface.

• A query command is used to extract status information from the switch. For example,

SRE? <CR> <LF> returns the contents of the status register.

• Multiple-command messages can contain only one query command. A query must be the

last command in the message, for example, CLOSE 20; XDRS? <CR> <LF>.

Operation Commands

RESET Reset

Returns the switch to the power-up state, for example, channel 0, relay drivers off.

CLOSE i Set Optical Channel

Closes the optical path represented by the integer i.

XDR i k Driver Control

Sets the specified external driver on or off.

• i = driver number (1 to 8)

• k = 1 (on)

• k = 0 (off)

Programming Guide – 26

Page 32

XDRS i Drivers Control

Sets all eight relay drivers according to the binary conversion of i. The binary weight of the

drivers is as follows:

• Driver 1 = 1

• Driver 2 = 2

• Driver 3 = 4

• Driver 4 = 8

• Driver 5 = 16

• Driver 6 = 32

• Driver 7 = 64

• Driver 8 = 128

Add together the weights of the drivers to be activated, and send the total. For example, when

i = 255, all eight rel ay drivers are turned on.

SRE i SQR Mask

Writes a decimal number to the SRQ mask register (see the Status Reporting and Service

Request Control section). Setting a bit to 1 generates an SRQ interrupt when the

corresponding bit in the status register changes from 0 to 1.

CSB Clear Status Byte

Resets the status byte.

CLR Clear Device

Clears the SRQ mask register and the status register.

Query Commands

CLOSE? Optical Swit ch Path

Returns the current optical path number. If the switch has two common input fibers (A and B),

CLOSE? returns the position of fiber B. CLOSE? MAX returns the maxi mum channel number.

XDR? i Driver

Returns the st a t e of an external rela y driver (i).

• 0 = relay driver is off

• 1 = relay driver is on

Programming Guide – 27

Page 33

XDRS? Drivers

Returns the states of all drivers in a binary-coded integer.

LRN? Learn

Returns a string containing three commands that, if sent, reset the switch to its current state,

for example, CLOSE i;XDRS k;SRE l, where i represents the current path number, k

represents the states of the external drivers, and l represents the value of the service request

enable register.

STB? Status Reg ister

Returns a three-digit integer and automatically clears the status register if the SRQ bit is set.

SRE? SRQ Mask

Returns the contents of the SRQ mask register.

CNB? Condition Register

Returns the contents of the condition register.

TST? Self-Test

Executes a self-test operation. An error code that can be queried with ERR? or LERR? is

placed in an error queue. The query TST? also sets bit 7 in the status register.

• 0 = self-test passed

• 1 = self-test failed

ERR? Error Number

Returns an error number if the self-test fails.

• 330 = self-test failed

• 0 = self-test did not fail

LERR? Last Number Error

Returns a three-digit error number from the error queue. The queue can contain as many as

five error numbers. The first error read is the last error that occurred. LERR? returns 000 if the

error queue is em pty .

Programming Guide – 28

Page 34

OPC? Operation Compl ete

Returns the status of the input buffer.

• 1 = the input buffer is empty, for example, all commands have been executed

• 0 = the input buffer is not empty, for example, commands are still pending

IDN? Identifier

Returns a string that identifies the manufacturer, the switch series, and the firmware level, for

example, JDS Uniphase, SB Switch, 2.00

Status Reporting and Service Request Control

The SB switch maintains three eight-bit registers that are used for status reporting and for

enabling the GPIB service request interrupt:

• Condition register

• Status register

• SRQ mask register

Condition Register

The condition register monitors the current state of the switch mechanism (Table 9). Bit 2, t he

settled condition bit, is 1 when the switch mechanism has stopped at the desired channel and

0 when the switch is moving to a new output channel. The CNB? query command returns the

value of the condition register. When the settled bit is true, CNB? query returns 4.

Table 9: Condition Register

Condition Register

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 0 0 0 0 settled 0 0

Status Register

The status register records errors and other events that have occurred in the switch (Table 10).

When an event occurs, the switch status logic sets the corresponding bit to 1. The status

register can be read at any time because the bits stay set until the register is read at least

once.

Tabl e 10: S t at us Register

Status Register

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

self-test service syntax message 0 settled 0 parameter

Programming Guide – 29

Page 35

error request error available error

• Bit 7 (self-test error) is set if a calibration error is detected after power-up or after the

self-test query (TST?) is executed. At all other times it is 0.

• Bit 6 (service request) is set when the interrupt request logic of the switch detects a reason

to generate a service request interrupt on the GPIB interface.

• Bit 5 (syntax error) is set when the parser det ects a sy ntax error i n a command mnemonic.

• Bit 4 (message available) is set when a message is available in the output buffer.

• Bit 2 (settled) is set when bit 2 in the condition register changes from 0 to 1.

• Bit 0 (parameter error) is set when a parameter value is out of the range of the SB switch.

The status register can be read with the status register query (STB?) or by serial polling the

GPIB interface. During power-up, the status register contains 0 and can only be read by serial

polling. After initial power-up, only the settled bit (bit 2) is set to 1. The clear status byte

command (CSB) and the clear device command (CLR) clear the status register. STB? also

clears the status register, but only if the service request bit (bit 6) is set to 1.

SRQ Mask Registe r

The SRQ mask register unmasks specific events in the status register that generate service

request interrupt on the GPIB interface (Table 11). The SRQ mask command (SRE) writes to

the SRQ mask register. When a bit in the SRQ mask register is set to 1, the interrupt logic of

the switch monitors the corresponding event bit in the status register. When a bit changes from

0 to 1, a service request interrupt is generated and bit 6 in the status register is set.

Tabl e 11: S RQ Mask Register

SRQ Mask Registe r

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

self-test

error

n/a syntax

error

message

available

n/a settled n/a parameter

error

The SRQ mask register can unmask more than one event at a time. The first unmasked event

to change from 0 to 1 causes an interrupt. To acknowledge this interrupt, the GPIB interface

can be serial polled or the status register can be read with STB?. The first time the SB switch

is serial polled after an SRQ is generated, bit 6 is on. Subsequent serial polling returns a va lu e

with bit 6 off. Similarly, STB? returns the status register with the SRQ bit set, but then the

switch logic automatically clears the register. As a result, subsequent STB? queries return 0.

The SRQ mask register is cleared by powering up the SB switch, by the clear device command

(CLR), or by the universal device clear command (DC1).

GPIB Programm ing Examples

This section provides programming samples for controlling the SB switch over the GPIB

interface. The samples were written in MS-DOS Qbasic and run on a personal computer

Programming Guide – 30

Page 36

equipped with a National Instruments3 GPIB interface board, with National Instruments

Universal Language Interface drivers loaded. The commands that control the GPIB are similar

to Hewlett Packard

4

HP Basic commands. Most other controller board manufacturers provide

basic output and input statements for communicating messages to a GPIB instrument.

Before using any of these samples, ensure that the GPIB address is set to 7, the interface

command set is SB, the ULI.EXE driver is loaded, and the switch is connected to the computer

via a GPIB cable.

The GPIB commands provided in this section do not always show the terminating sequence

<CR><LF>; however, it is implied.

Sending Commands

This example sets the SB switch to channel 6 and turns on all the external relay drivers.

' set up t h e interf ace card and drivers

OPEN "GPIB0" FOR OUTPUT AS #1

OPEN "GPIB0" FOR INPUT AS #2

PRINT #1, " ABORT"

' set terminating character to CR LF sequence

PRINT #1, " G PIBEOS OUT CR LF"

PRINT #1, "GPIBEOS IN CR LF"

' sample commands"close 6; xdrs 255"

PRINT #1, "OUTPUT 07;CLOSE 6;XDRS 255"

' sample queries

PRINT #1, "OUTPUT 07;CLOSE?"

PRINT #1, "ENTER 07"

INPUT #2, a

PRINT "channel ",a

PRINT #1, "OUTPUT 07;XDRS ?"

PRINT #1, "ENTER 07"

INPUT #2, a

PRINT "driver state ",a

END

Serial Polling the Status Register

This example changes the channel setting and reads the status register continuously until the

output has settled.

PRINT #1, "OUTPUT 07;csb" ' clearing the status byte clears the settling

bit

PRINT #1, "OUTPUT 07;CLOSE 12" ' change channel

sr = 0 ' initialize sr variable to enter the while loop

WHILE ((sr AND 4 ) =0) ' loop until settled bit is true

PRINT #1, "SPOLL 07" ' serial poll SB switch

INPUT #2, sr

3

National Instruments is a trademark of National Instruments.

4

Hewlett Packard is a registered trademark of Hewlett-Packard Co.

Programming Guide – 31

Page 37

WEND

PRINT sr ' print final value of sr

END

Generating a Service Reque st Interrupt

This example tests the service request interrupt function. It unmasks the settled bit in the

SRQ mask register and selects a channel. An interrupt is generated when the switch reaches

the channel.

ON PEN GOSUB SPOLL ' enable SRQ interrupt

PEN ON

PRINT #1, "OUTPUT 07;CSB;SR E 4" ' clear status register and unmask

' settled bit in SRQ mask register

PRINT #1 "OUTPUT 07;CLOSE 6" ' change channel

' More code executed while switch channel set

'

'

WHILE (INKEY$ = "") ' endless loop to simulate bigger program

WEND ' ends when any key is pressed

PEN OFF

END

SPOLL:

PRINT #1, "SPOLL 07" ' serial poll the switch

INPUT #2, sr ' read status register

PRINT sr ' verif y SRQ bit is set

PRINT #1, "SPOLL 07" ' serial poll again to verify SRQ bit is now cleared

INPUT #2, sr ' read status register

PRINT sr

RETURN

Learn Query (LRN?)

This example demonstrates the use of the learn query.

DIM LEARN$[100]

PRINT #1, "OUTPUT 07;LRN?" ' send the learn query command

PRINT #1, "ENTER 07"

LINE INPUT #2, LEARN$

' The above variables can be saved in a data file before quitting the program and

' then later read back and used to restore the switch to a same state.

' Like this...

PRINT#1, "OUTPUT 07;"LEARN$

' SB settings are now restored

END

RS232 Programming Examples

This section provides programming examples for controlling the SB switch over the RS232

interface. The examples were written in MS-DOS Qbasic and run on a personal computer

Programming Guide – 32

Page 38

equipped with a serial port. COM port 2 of the computer is designated as the serial port and is

connected to the switch.

Before using any of these examples, ensure that the active interface command set is SB.

The RS232 interface cannot receive an SRQ interrupt.

The RS232C commands that appear in this section do not always show the terminating

character <CR>; however, it is implied.

Sending Commands

OPEN "COM2:1200,N,8,1" FOR R ANDOM AS #3

A = 10

PRINT#3, "CLOSE ";A

PRINT#3, "XDRS 255"

END

Querying Status

This example queries and displays the current channel setting.

PRINT#3, "CLOSE?"

INPUT#3, A

PRINT A

END

Reading t he Status Register

The serial polling function is not supported on any RS232 interface, but STB? can be used to

query the status register since the query command performs the same function as serial

polling.

This example changes the channel setting and reads the status register continuously until the

output has settled.

OPEN "COM2:1200,N,8,1" FOR R ANDOM AS #3

PRINT#3, "CSB" ' clear status register

PRINT#3, "CLOSE 5"

DO ' loop until motor settles

PRINT#3, "STB?"

INPUT#3, SR1

LOOP UNTIL (SR1 AND 4)

PRINT SR1

END

Setting the Interface Command Set

The SB switch can be set to emulate the interface command sets of earlier models of JDS

Uniphase SC Series and SX Series switches.

Programming Guide – 33

Page 39

To change the command set:

1. Press and hold the GPIB ADDR key while the SB switch powers u p. The active inte rface

setting is displayed.

2. Press the ▲ key to scroll to the required command set, for example, SB, SC, or SX.

3. Press the GPIB ADDR key to save the setting.

SC Series Switch Command Set (SCXXX-0XXX Models)

The syntax and functions for the SC series switch commands are provided in Table 12.

Tabl e 12: SC Sw itch Command Set

Syntax Function

AnE switch to channel n

FE verify channel

XE turn external driver on

YE turn external driver off

Response messages (Table 13) are formatted as qn, where q is the switch status (A = normal,

I = syntax error, C = calibration error), and n is the channel number.

Table 13: Response Messages for SC Switch Commands

Status Byte Register

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Message

0000 0 0 0BUSY

0000 0 0 1NORMAL

0 RQS 0 0 0 0 1 CAL ERROR

0 RQS 0 0 1 0 1 BAD DATA

0 RQS 0 0 1 1 1 UNIT FAILURE

SX Series Switch Command Set

The syntax and functions for the SX Series switch commands are provided in Table 14.

Programming Guide – 34

Page 40

Table 14: SX Switch Command Set

Syntax Function

An switch to channel n

Sn set driver n

Cn clear driver n

Bk conf igure drivers with binary code k

E enable unit to assert SRQ interrupt after completing each command

D disable SRQ interrupt except when an error occurs

R remote mode: lock out front panel keys;

not implemented in SB switch (RS232 only)

L local mode: enable front panel keys;

not implemented in SB switch (RS232 only)

Response messages (Table 15) are formatted as qn Rm, where q is the unit status (A =

normal, C = command error, S = system error); n is the channel number (0 to N); R is the letter

R; and m is the state of the external relay drivers (0 to 255).

Table 15: Response Messages for SX Switch Commands

Status Byte Register

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Message

0RQS0 00000 BUSY

0RQS0 00001 NORMAL

0 RQS 1 0 0 0 0 1 BAD DATA

0 RQS 1 0 0 0 1 0 UNIT FAILURE

These bits are usually set to 0. Bit 6 (RQS) is set to 1 when the SB switch generates a service

request interrupt.

Programming Guide – 35

Loading...

Loading...