Page 1

LFP Customer Assurance 1 HP Public

HP Stitch S300 and S500 Printers

TECHNICAL NEWSLETTERS FROM CUSTOMER ASSURANCE

Date: June 2020 Impact/Severity: Medium

Region: WW Category/Area: Applications

Audience: Support Confidentiality: HP Public

How to increase drying efficiency: Tips and tricks and external dryer recommendations

This document includes a list of recommendations for the proper printer settings to ensure that correct drying of

print jobs is achieved. After following all these recommendations, if ink drying and transfer issues are still present,

an alternative solution is presented that includes an external dryer.

Printer settings - tips and tricks

Before starting production, it is very important to find the optimal parameters for your paper/textile. Ensure that

the number of passes, density, and machine settings are appropriate for your substrate and your final

application.

If wrinkles occur when printing, this is an indication of excess ink; before you consider the purchase of an external

dryer, try to use the tips described below to solve the issue.

1.1 Optimize ink settings

The ink amount optimization is extremely important for several reasons. If we fire more ink than needed, we will

waste ink and also make the printer operation much more difficult, increasing the difficulties in drying, winding

the roll, etc.

Before starting production, most customers will print jobs at both 70% and 100% of ink (in the case of 1P, it will

be between 50% to 80%), and then build a profile using both of the densities printed, and compare color

saturation after calender:

• If the 30% ink step used shows the same step in saturation and there is a big visible difference, that

means that 100% should be closer to the optimum. In that case the remaining ink left on the paper

should not be much

• If, instead, there is no major visual difference between the two ink amounts printed, it means that the

optimum ink amount is around 70%. If, however, 70% is not enough, then select 100% and reduce the

global ink limit in the icc profile in steps big enough to see differences.

Page 2

LFP Customer Assurance 2 HP Public

Once saturation is matched with good transfer and little ink remaining on the paper, the optimum level is

reached.

NOTE: If you need a level in between two levels of ink density, please refer to the guide on how to do it from the

RIP.

IMPORTANT: Ensure that the heat fixation settings are the appropriate ones for your paper/fabric to give the

optimal saturation.

1.2 Optimize other printer settings

a. Drying temperature and airflow

Drying temperature and airflow are two parameters that have a direct impact on the drying

capabilities of the printer.

Increase them when:

• The paper/fabric is not dry enough at the take up reel.

b. Inter swath delay (ISD)

This parameter sets a delay of the carriage in milliseconds before starting the next swath,

increasing the drying time of the previous swath. It is also used to increase the drying

capabilities, but it has a negative impact on the total throughput.

Increase it when:

• Even with maximum temperature and airflow, the drying is not enough.

c. Input tension

This is a parameter involved in the substrate control on the Print Zone input. It solves issues

related with wrinkles or skew.

Increase it when:

• Having skew issues in the Print Zone.

d. Output tension (S500)

This parameter allows the adjustment of the Output Winding performance. It also helps to

control the flatness of fabrics in the Print Zone.

Decrease it when:

• Wrinkles are present in the Output Platen. This can also be solved by increasing the

drying settings.

Tip:

• Thicker substrates usually need more tension and thinner ones less tension.

Page 3

LFP Customer Assurance 3 HP Public

e. Vacuum

The vacuum setting plays an important role in the control of papers in the Print Zone.

Increase it when:

• There are smears due to substrate expansion caused by the ink, or there is curling of the

substrate.

Decrease it when:

• There are vertical marks on the substrate coming from the Print Zone.

If, after following all these steps, you still have ink drying issues then consider the purchase of an external dryer.

External dryer solution

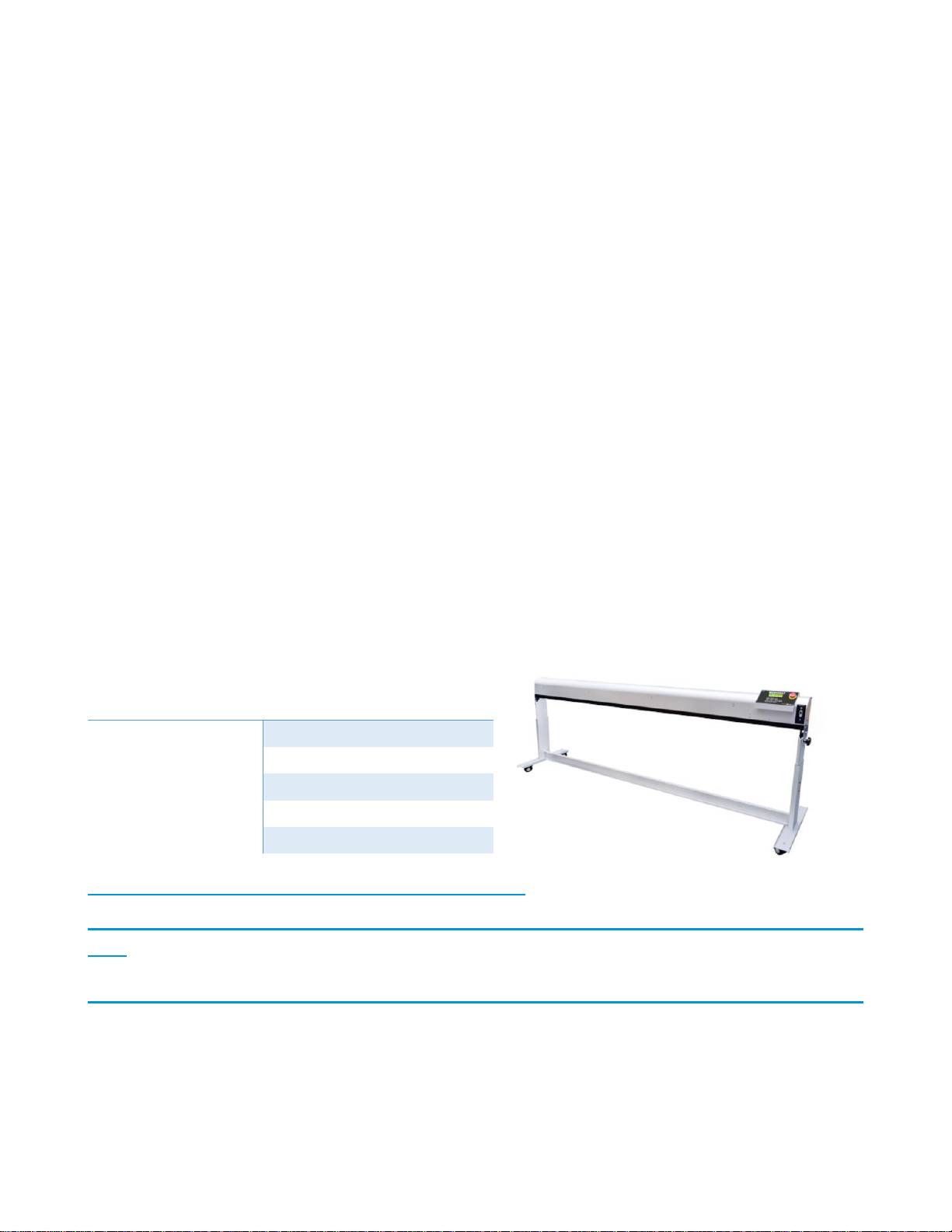

2.1 Models tested

In some cases, an external dryer should be used to ensure that we are able to dry the substrate completely at the

output area and, consequently, that a good-quality winding can be achieved.

The equipment tested is the external drying system for digital printing from NITE Industrial Co (KOREA).

Specifically, the Self Standing Type SDSWT-1600 64” external dryer.

This is a 2.0 kW external dryer mounted with an aluminum stand (“built-in type” version also available).

It combines radiation and convection with (x2) fast-response medium-wave lamps and (x6) air fans.

http://www.nitemall.net/home/bbs/board.php?bo_table=pro03

NOTE: Internal validations have been done using this specific external dryer. However, it is also possible to use any

other external dryer with similar or better characteristics.

The external dryer from FLEXA has also been tested. Specifically, the GHIBLI model. In this case, it is a 4.0 kW hotair dryer (convection) for 74” printers. It is known that hot-air technology (convection) is much less efficient than

the radiation alternative described above.

SDSWT-1600

Electrical power

2.0 kW

Drying technology

Radiation + Convection

Number of lamps

2 (covering the whole width)

Number of fans

6

Width

64”

Page 4

LFP Customer Assurance 4 HP Public

https://www.flexa.it/en/products/more/ink-dryer/ghibli

2.2 Test conditions and results

The substrates used for the internal validation are the following:

Papers:

- Harsh paper (sublimation) 70 g/m² (INDIA)

- Moorim paper NeoStar quick dry 58 g/m² (KOREA)

- Hansol Sublimation paper 50 g/m² Economic - [Eco] (KOREA)

- SAPI Fashion 45 g/m²

- KASPAR Superlite 45 g/m²

Textile to be transferred: Anibal (Sportswear Lycra)

The job type used for the internal validation consists of a high-density plot at a high speed (Black 100% area fill

(C100, M100; Y100, K100), 2 pass – 100%, no icc profile).

NOTE: HP Stitch S500 maximum drying capabilities (built-in “Drop and Dry” PZ dryer) has been used in all the cases

evaluated. PZ temperature 60°C, and air pressure 390 mm H2O.

IMPORTANT: All tests have been carried out only 1 minute after switching on the dryer. 80% of the final

temperature on the substrate is achieved after 1 minute. A quick warm-up can be ensured and the stop-start

operations (e.g. pauses between jobs, maintenance) do not compromise dryer capabilities.

In the case of IR dryers, the performance of the dryer is highly dependent on the distance between the dryer and

the paper (exponential dependence).

GHIBLI-1800

Electrical Power

4.0 kW

Drying technology

Convection (hot air)

Number of lamps

Heaters

Number of fans

9

Width

74”

Page 5

LFP Customer Assurance 5 HP Public

NOTE: For hot-air dryers (convection dryers), the airflow stream is an important variable for dryer performance.

Thus, the greater the airflow velocity, the more heat can be extracted from the substrate, and higher dryer

capabilities can be obtained.

In ambient conditions (21°C / 40% RH) all tests with an external dryer show successful results. Some substrates

need more dryer power but all of them are completely dry at the take-up-reel area.

Some substrates had wrinkles due to paper expansion (wet) / contraction (dry). However, these wrinkles become

completely dry at the take-up-reel area and consequently there is no ink transfer / ink removal from the layers.

In worst-case climatic conditions (35°C / 80% RH) performance between substrates showed some variation in

behaviors. Moorim Paper had the wrinkles controlled but still suffered some ink transfer and IQ defects after

sublimation. The rest of the substrates showed good results.

2.3 External dryer minimum specifications required

For this assessment some samples of transfer papers from a selected list of countries (Turkey, MEMA, Latin

America, and APJ excluding Japan and Australia) have been tested in the worst climatic conditions (35°C / 80% RH)

with the HP Stitch S500 Printer. These kind of substrates, mainly used in vertical fashion (due to their low cost),

tend to be low-cost, poor-quality, low-grammage (45–70 g/m²) substrates. Consequently, they are more difficult

to dry.

Moreover, all substrates have been validated using the HP Stitch worst conditions in terms of ink usage (100%)

and printing speed (2-pass print mode).

Successful results have been achieved in all cases tested in this study.

The minimum recommended specs for a 3rd party external dryer are:

IR lamp dryer

(radiation & convection)

Hot-air dryer

(convection)

Electrical power

>2.0 kW

>3.0 kW

Air flow

N/A

8 m/s

Air temperature

N/A

>40°C at max. airflow

Wavelength

Fast response mid-wavelength

N/A

Page 6

LFP Customer Assurance 6 HP Public

NOTE: For IR dryers (radiation) the airflow stream does not require high-velocity or high heat content. In some

cases, there may not be a need for any airflow at all (because of a reduced requirement for air, a radiant system

might use smaller blowers). Moreover, in some conditions, reducing airflow velocity can achieve higher drying

efficiency (see normal conditions vs. climatic conditions airflow settings in section 4.3).

2.4 Dryer optimal position (HP Stitch S500)

The optimal position for an external dryer to be installed in an HP Stitch S300/S500 printer is on top of the output

sheet metal of the printer, perpendicular to the substrate and before the substrate changes direction. See the

following picture.

In this position, the distance between the dryer and the substrate is constant during the whole printing process

(independent of output roll diameter). Moreover, in this position the ink starts to dry before the substrate changes

direction, so wrinkle marks due to substrate expansion/contraction are minimized.

In the case of IR dryers, the performance of the dryer is highly dependent on the distance between the dryer and

the paper. The optimal dryer distance is as close as possible without compromising safety, between 20 mm and

70 mm.

It is highly recommended that the dryer is not placed closer than 20 mm in order to avoid undesired paper jams or

printer overheating.

NOTE: All dryer manufacturer safety instructions must be followed and are additional to the recommendations of

this document.

Another possible position (not optimal)

Another possible position for the external dryer is just after the printer output, just between the output sheet metal

and the output roll.

This position is not the most suitable because the distance from the substrate is not constant during printing; it

depends on the radius of the output roll. Thus, drying settings may change during the roll and different consistency

issues may be seen.

Page 7

LFP Customer Assurance 7 HP Public

Limitations

3.1 Extreme climatic conditions

Environmental specifications for HP Stitch S300/S500 printers are provided in the User Guide. These specifications

detail the temperature and humidity ranges within which the printer can operate.

As far as the drying process is concerned, if the environmental conditions are outside these ranges (e.g.

temperatures are too cold or humidity is too high), the drying performance of the internal dryer of the printer is

likely not to be enough.

In addition, if the climatic conditions are too far outside the ranges specified in the User Guide, then the minimum

specifications for an external dryer validated in this document might also be insufficient.

For this reason, in order to get the best print quality and drying performance, it is highly recommended to install

the printer in a room with controlled environmental conditions according to the specifications below.

Page 8

LFP Customer Assurance 8 HP Public

3.2 Extreme poor-quality substrates

Despite the use of an external dryer, in some cases, mainly when poor-quality substrates are used, some drying

issues may still occur. These drying issues may be linked with substrate management problems such as wrinkles,

smears, etc. These may be addressed as follows:

▪ Optimize ink consumption in the ICC profile (ink limits).

▪ Reduce the amount of ink using lower ink densities (e.g. 90%, 85%) if possible.

▪ Increase printer inter-swath delays.

▪ Reduce printing speed by using higher-pass print modes (e.g. 3 pass).

▪ Change substrate.

External dryer – tips & tricks

4.1 Stand

The standard stand that comes with the external dryer is too short for an optimal dryer position in HP Stitch

S300/S500 printers (min. height: 650 mm; max. height: 850 mm). In order to place the external dryer in its optimal

position (see section 2.4), a specific higher stand has been built with standard aluminum profiles.

NITE Industrial Co (KOREA) also provides the same external dryer tested in a “built-in type” version that can be

hung from the printer without a stand (see picture below).

Page 9

LFP Customer Assurance 9 HP Public

“Built-in type” NITE external Dryer SDSWT-1600-BI (source: http://www.nitemall.net/home/bbs/board.php?bo_table=pro03)

4.2 Use of printhead/carriage detection sensor (optional)

For safety reasons and to improve remote operation of the printer and the external dryer, it is recommended to

add an optical detection sensor near the Print Zone.

This feature detects if the printhead/carriage does not move for a certain period of time. If this is the case, the dryer

will be in waiting mode. If the printer begins working again, the dryer will turn on automatically.

As seen in section 2.3, the quick warm-up times offered by this technology (fast-response mid-wavelength IR

lamps) ensure the right drying settings a few seconds after the printing process starts again.

4.3 Cold environments

In hot-air drying (convective), the temperature has the most significant effect on drying kinetics. Airflow velocity

has the second most significant effect.

Thus, in cold environments where the internal dryer of the HP printer could struggle to reach the maximum PZ

temperature (with the maximum air pressure): 60°C at 390 mm H2O, it could be useful to slightly reduce the air

pressure to be able to reach 60°C.

Page 10

LFP Customer Assurance 10 HP Public

Other alternatives

Other external dryers available in the market tend to extend the printer substrate path including hot surfaces that

the substrate is in contact with. These dryers are usually more efficient and with greater drying capabilities because

the heat is applied directly to the substrate by conduction.

These kind of dryers are much more expensive, and they usually include a take-up-reel unit.

NITE Drying System TRDS-1600 (source: http://www.nitemall.net/home/bbs/board.php?bo_table=pro03)

Loading...

Loading...