Page 1

User Service Guide

HP 9000 rp4410 and HP 9000 rp4440

Manufacturing Part Number: A9950-96011-ed4

Fourth Edition

Sept

ember 2008

© Co

pyright 2003-2008 Hewlett-Packard Development Company, L.P.

Page 2

Legal Notices

Copyright Notices. © Copyright 2003-2008 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products

and services are set forth in the express warranty statements accompanying such products and services.

Nothing herein should be construed as constituting an additional warranty. HP shall not be liable for

technical or editorial errors or omissions contained herein.

Printed in U.S.A.

Intel, Pentium, Intel Inside, Itanium, and the Intel Inside logo are trademarks or registered trademarks of

Intel Corporation or its subsidiaries in the United States and other countries.

Linux is a U.S. registered trademark of Linus Torvalds.

2

Page 3

1. Overview

HP 9000 rp4410 and rp4440 Server Views. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Detailed Server Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

I/O Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Processors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Cooling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Power Supply Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Front Display Panel, DVD, and Diagnostic Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Mass Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Dimensions and Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Controls, Ports, and LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Rear Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

USB Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

VGA Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Serial Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

iLO MP LAN Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Gigabit Ethernet LAN Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

SCSI Port, Ultra 3, 68-Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Additional Controls and LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Powering the Server On and Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Power States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Powering On the Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Powering Off the Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Contents

2. System Specifications

System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Dimensions and Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Grounding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Electrical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

AC Power Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

System Power Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Power and Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Operating Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Environmental Temperature Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Nonoperating Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Cooling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Acoustic Noise Specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Physical and Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

3. Installing the System

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

3

Page 4

Contents

Server Views. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Detailed Server Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

I/O Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Processors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Cooling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Power Supply Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Front Display Panel, DVD, and Diagnostic Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Mass Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Dimensions and Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Installation Sequence and Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Unpacking and Inspecting the Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Verifying Site Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Inspecting the Shipping Containers for Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Unpacking the Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Checking the Inventory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Returning Damaged Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Unloading the Server with a Lifter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Installing Additional Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Service Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Accessing a Rack-Mounted Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Accessing a Pedestal-Mounted Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Front Panel Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Additional Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Front Bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Front and Top Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Hot-Swappable Chassis Fan Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

I/O Baseboard Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

System Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Installing Power Supplies and Disk Drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Installing Processors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Installing Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Hot-Pluggable PCI/PCI-X . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Converting SCSI From Simplex to Duplex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Installing the Server Into a Rack, Non-HP rack, or Pedestal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

HP Rack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Non-HP Rack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Pedestal Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Connecting the Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

AC Input Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Core I/O Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Applying Standby Power to the Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Connecting to the LAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Console Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

4

Page 5

Contents

Setting Up the Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Setup Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Setup Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Configuring the iLO MP LAN Using DHCP and DNS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Configuring the iLO MP LAN Using ARP Ping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Configuring the iLO MP LAN Using the RS-232 Serial Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Logging In to the iLO MP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Additional Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Accessing the Host Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Accessing the Host Console With the TUI - CO Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Interacting with the iLO MP Using the Web GUI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Accessing the Graphic Console Using VGA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Powering the Server ON and Off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Power States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Powering On the Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Powering Off the Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Booting the Operating System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Supported Operating System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Booting and Shutting Down HP-UX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Verifying the Server Configuration Using Boot Console Handler . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Troubleshooting Methodology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Troubleshooting Using the Server Power Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Server Does Not Power On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

BCH Menu is Not Available . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Operating System Does Not Boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Operating System Boots with Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Intermittent Server Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

DVD Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Hard Drive Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Console Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Downloading and Installing the Latest Version of the Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Troubleshooting Using LED Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Information to Collect Before You Contact Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

4. Booting the Operating System

Supported Operating System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Booting and Shutting Down HP-UX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Standard HP-UX Booting Using Boot Console Handler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Booting HP-UX in Single-User Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Booting HP-UX in LVM Maintenance Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Shutting Down HP-UX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Verifying the Server Configuration Using Boot Console Handler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

5. Troubleshooting

5

Page 6

Contents

Troubleshooting Methodology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Troubleshooting System Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Using the Front Panel Power Button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

System Does Not Successfully Power On and Remain Powered On . . . . . . . . . . . . . . . . . . . . . . . . . 150

Operating System Boots. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Operating System Does Not Boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Troubleshooting Using Online Support Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Support Tools Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Event Monitoring Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

iLO MP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Troubleshooting Using Offline Support Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

ODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Troubleshooting PCI/PCI-X Hot-Pluggable Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Troubleshooting Using LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Front Control Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

QuickFind Diagnostic Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

I/O Baseboard LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Memory Extender Boards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Disk and I/O Path Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Core I/O Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

System I/O Board Switches and Jumpers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

6. Removing and Replacing Components

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Required Service Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Accessing a Rack-Mounted Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Extend the Server from the Rack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Inserting the Server Into the Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Accessing a Pedestal-Mounted Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Front Bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Removing the Front Bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Replacing the Front Bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Front and Top Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Removing the Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Replacing the Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Removing the Top Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Replacing the Top Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Memory Extender Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Removing a Memory Extender Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Replacing the Memory Extender Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

System Memory DIMMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Replacing Deallocated Memory Ranks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Removing Memory DIMMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Installing Memory DIMMs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Processor Extender Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Removing the Processor Extender Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

6

Page 7

Contents

Replacing the Processor Extender Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Replacing Dual Processor Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Dual Processor Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Processor Load Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Removing a Dual Processor Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Installing a Dual Processor Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Hot-Swappable Chassis Fan Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Removing a Hot-Swappable Chassis Fan Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Replacing a Hot-Swappable Chassis Fan Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

I/O Baseboard Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Removing the I/O Baseboard Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Replacing the I/O Baseboard Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Removing and Replacing the I/O Baseboard Locking Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

System Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Battery Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Replacing the System Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Removing and Replacing PCI/PCI-X Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

PCI/PCI-X Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

OLA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

OLR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Removing a PCI/PCI-X Card Offline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Installing a PCI Card Offline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

OLX Dividers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Removing an OLX Divider . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Replacing an OLX Divider . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

U320 SCSI Enablement and Conversion Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Time Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Upgrade Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Back Up Your System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Removing Server Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Removing the SCSI Duplex Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Removing the SCSI Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Replacing the SCSI Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Installing the SCSI Duplex Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Installing the Server Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Verify the Upgrade Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Converting SCSI From Duplex to Simplex Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Removing and Replacing Core I/O Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Required Service Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

PCI Slot Locations and Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Removing the LAN Core I/O Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Installing the LAN Core I/O Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Removing the SCSI Core I/O Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Hot-Pluggable Disk Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Removing a Hot-Pluggable Disk Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

7

Page 8

Contents

Replacing a Hot-Pluggable Disk Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

SCSI Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Removing the SCSI Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Replacing the SCSI Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Midplane Riser Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Removing the Midplane Riser Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Replacing the Midplane Riser Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Hot-Swappable Power Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Power Supply Load Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Removing a Hot-Swappable Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Replacing a Hot-Swappable Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Power Distribution Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Removing the Power Distribution Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Replacing the Power Distribution Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

DVD Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

Removing a DVD Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

Replacing a DVD Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

DVD I/O Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Removing a DVD I/O Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Replacing a DVD I/O Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

Display Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Removing the Display Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Replacing the Display Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

QuickFind Diagnostic Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

Removing the QuickFind Diagnostic Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

Replacing the QuickFind Diagnostic Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

A. Replacement Parts

Customer Self Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Replacement Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

B. Utilities

Boot Console Handler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

BCH Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

iLO MP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

C. Physical and Environmental Specifications

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

8

Page 9

Tables

Table 1. Publishing History Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 2. HP-UX 11i Releases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 1-1. Server Dimensions and Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 1-2. Control Panel LED Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 1-3. Switch and Button LED Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 1-4. Power Supply Status LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 1-5. iLO MP LED Status Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 1-6. iLO MP LED Status Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 1-7. Single-Port GigE LAN LED Status Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 1-8. Dual-Port GigE LAN Card LED Status Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 1-9. USB Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 1-10. Serial Port Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 1-11. iLO MP LAN Port Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 1-12. Gigabit Ethernet LAN Port Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 1-13. SCSI Port Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 1-14. Hot-Pluggable Disk Drive LED Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 1-15. DVD Drive LED Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 1-16. I/O Baseboard LEDs, Buttons, and Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 1-17. Power States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 2-1. Minimum and Maximum Server Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Table 2-2. Server Dimensions and Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 2-3. Power Cords. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 2-4. System Power Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 2-5. System Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 2-6. Typical Configuration Power Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 2-7. Physical and Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 3-1. Server Dimensions and Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Table 3-2. Installation Sequence Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Table 3-3. Control Panel LED Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Table 3-4. Switch and Button LED Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Table 3-5. Hot-Pluggable Disk Drive LED Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Table 3-6. DVD Drive LED Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Table 3-7. Dual Processor Module Load Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Table 3-8. DIMM Filler Requirements for 16-DIMM Extender Board . . . . . . . . . . . . . . . . . . . . . . . 95

Table 3-9. DIMM Filler Requirements for 32-DIMM Memory Extender Board . . . . . . . . . . . . . . . . 95

Table 3-10. Hot-Pluggable Hardware and Software Interfaces and OS Availability . . . . . . . . . . . 100

Table 3-11. PCI/PCI-X Card Slot Frequency and Bus Mode Compatibility for Shared Slots . . . . 102

Table 3-12. Hot-Pluggable LED Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Table 3-13. Setup Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Table 3-14. Console Connection Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Table 3-15. LAN Configuration Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Table 3-16. ARP Ping Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Table 3-17. Power States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

9

Page 10

Tables

Table 3-18. Server Power Button Functions When Server is On and at BCH . . . . . . . . . . . . . . . . 137

Table 3-19. Server Power Button Functions When Server is On and OS is Running . . . . . . . . . . 137

Table 3-20. Server Power Button Functions When Server is Off . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Table 3-21. Front Control Panel LED Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Table 3-22. QuickFind Diagnostic Panel LED Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Table 5-1. Power Button Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Table 5-2. ODE Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Table 5-3. Front Control Panel LED Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Table 5-4. QuickFind Diagnostic Panel LED Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Table 5-5. I/O Baseboard LEDs, Buttons, and Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Table 5-6. 32-DIMM Memory Extender Board LED States. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Table 5-7. 16-DIMM Memory Extender Board LED States. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Table 5-8. Internal Disk and DVD Paths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Table 5-9. Extended Core I/O Paths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Table 5-10. PCI I/O Paths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Table 5-11. System I/O Board Indicators, Connectors, and Jumpers . . . . . . . . . . . . . . . . . . . . . . . 173

Table 6-1. DIMM Filler Requirements for 16-DIMM Memory Extender Board . . . . . . . . . . . . . . . 189

Table 6-2. DIMM Filler Requirements for 32-DIMM Memory Extender Board . . . . . . . . . . . . . . . 190

Table 6-3. Processor Load Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Table 6-4. PCI/PCI-X Card vs. Slot Frequency/Bus Mode Compatibility for Shared Slots . . . . . . 218

Table 6-5. PCI I/O Paths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Table 6-6. PCI I/O Hardware Paths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Table A-1. Customer Self Repair Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Table A-2. Replacement Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Table B-1. BCH Main Menu, Submenus, and Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Table B-2. Boot Paths. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

Table C-1. Physical and Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

10

Page 11

Figures

Figure 1-1. HP 9000 rp4410/rp4440 Server (Top View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 1-2. HP 9000 rp4410/rp4440 Server with Bezel Removed (Front View). . . . . . . . . . . . . . . . 21

Figure 1-3. HP 9000 rp4410/rp4440 Server (Rear View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 1-4. Control Panel - Front View of Server (with Bezel) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 1-5. Accessing the Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 1-6. Control Panel LEDs and Buttons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 1-7. Rear Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 1-8. Power Supply Status LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 1-9. iLO MP LAN LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 1-10. iLO MP LAN LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 1-11. Single-Port GigE LAN Connector and LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 1-12. Dual-Port GigE LAN Card LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 1-13. Server Rear View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 1-14. USB Port Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 1-15. Serial Port Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 1-16. iLO MP Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 1-17. Gigabit Ethernet LAN Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 1-18. SCSI Port, Ultra 3, 68-Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 1-19. Hot-Pluggable Disk Drive LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 1-20. DVD Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 1-21. QuickFind Diagnostic Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 1-22. I/O Baseboard LEDs, Buttons, and Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 2-1. Airflow Through HP 9000 rp4410 and rp4440 Servers . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 3-1. HP 9000 rp4410 and rp4440 Servers (Top View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 3-2. HP 9000 rp4410 and rp4440 Servers with Bezel Removed (Front View) . . . . . . . . . . . 57

Figure 3-3. HP 9000 rp4410 and rp4440 Servers (Rear View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 3-4. Accessing T-25 Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 3-5. Pedestal-Mounted Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Figure 3-6. Front View with Bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure 3-7. Accessing the Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure 3-8. Control Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 3-9. Hot-Pluggable Disk Drive LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Figure 3-10. DVD or CD-RW/DVD LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Figure 3-11. Removing and Replacing the Front Bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Figure 3-12. Removing and Replacing the Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Figure 3-13. Removing and Replacing the Top Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Figure 3-14. Hot-Swappable I/O Fans (Units 0 and 1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Figure 3-15. Hot-Swappable Power Supply Fan (Unit 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Figure 3-16. I/O Baseboard Locking Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Figure 3-17. I/O Baseboard Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Figure 3-18. System Battery Location on I/O Baseboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Figure 3-19. Metal Cover in Unused Slot P1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Figure 3-20. Volume Filler Installation in Slot 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

11

Page 12

Figures

Figure 3-21. Disk Drive Installation in Slot 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Figure 3-22. Disk Drive Installation in Slots 1 and 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Figure 3-23. Extender Board Latches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Figure 3-24. Removing the Processor Extender Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Figure 3-25. Processor Cable Placed Correctly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Figure 3-26. Processor Cable Placed Incorrectly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Figure 3-27. Installing the Processor on the Extender Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Figure 3-28. 16-DIMM Memory Extender Board Minimum Configuration . . . . . . . . . . . . . . . . . . . 95

Figure 3-29. 32-DIMM Memory Extender Board Minimum Configuration . . . . . . . . . . . . . . . . . . . 97

Figure 3-30. Removing the Memory Extender Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Figure 3-31. Inserting DIMM Into the Extender Board Connector . . . . . . . . . . . . . . . . . . . . . . . . . 99

Figure 3-32. Slot ID Numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Figure 3-33. PCI/PCI-X OLX Divider Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Figure 3-34. Inserting PCI/PCI-X Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Figure 3-35. Slider Gate Latch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Figure 3-36. Removing the SCSI Jumper Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Figure 3-37. Installing the Duplex Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Figure 3-38. Installing SCSI Cable B to the SCSI Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Figure 3-39. Installing SCSI Cable B to the SCSI Adapter Board. . . . . . . . . . . . . . . . . . . . . . . . . 114

Figure 3-40. Ports on Server Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Figure 3-41. iLO MP Setup Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Figure 3-42. Web Login Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Figure 3-43. Status Summary Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Figure 3-44. Front Control Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Figure 3-45. QuickFind Diagnostic Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Figure 5-1. PCI/PCI-X LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Figure 5-2. Front Control Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Figure 5-3. QuickFind Diagnostic Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Figure 5-4. I/O Baseboard LEDs, Buttons, and Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Figure 5-5. 32-DIMM Memory Extender Board LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Figure 5-6. 16-DIMM Memory Extender Board LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Figure 6-1. Accessing T-25 Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Figure 6-2. Pedestal-Mounted Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Figure 6-3. Removing and Replacing the Front Bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Figure 6-4. Removing and Replacing the Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Figure 6-5. Removing and Replacing the Top Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Figure 6-6. Memory Extender Board Latches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Figure 6-7. Memory Extender Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Figure 6-8. 16-DIMM Memory Extender Board Slot IDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Figure 6-9. 32-DIMM Memory Extender Board Slot IDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Figure 6-10. Inserting DIMM into the Extender Board Connector . . . . . . . . . . . . . . . . . . . . . . . . 191

Figure 6-11. Processor Extender Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Figure 6-12. Dipswitch Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

12

Page 13

Figures

Figure 6-13. Dipswitch Setting for S5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Figure 6-14. Removing the Dual Processor Module from the Processor Extender Board. . . . . . . 198

Figure 6-15. Locate the Socket in Processor Extender Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Figure 6-16. Processor Cable Placed Correctly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Figure 6-17. Processor Cable Placed Incorrectly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Figure 6-18. Installing Dual Processor Module on Processor Extender Board . . . . . . . . . . . . . . . 202

Figure 6-19. Hot-Swappable I/O Chassis Fans Removal and Replacement. . . . . . . . . . . . . . . . . . 204

Figure 6-20. Hot-Swappable Power Supply Chassis Fan Removal and Replacement . . . . . . . . . . 205

Figure 6-21. I/O Baseboard Locking Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Figure 6-22. I/O Baseboard Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Figure 6-23. S5102 Dipswitch Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Figure 6-24. Accessing the S5102 Dipswitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Figure 6-25. Battery Location on I/O Baseboard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Figure 6-26. Slot ID Numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Figure 6-27. PCI/PCI-X OLX Divider Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Figure 6-28. PCI-X Card Latch Opening Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Figure 6-29. Inserting PCI/PCI-X Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Figure 6-30. Slider Gate Latch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Figure 6-31. OLX Divider Removal and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Figure 6-32. OLX Slider Gate Bracket. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Figure 6-33. SCSI Cable B Connection to the SCSI Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Figure 6-34. Remove the SCSI Duplex Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Figure 6-35. Remove the SCSI Backplane Jumper Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Figure 6-36. Lift the SCSI Backplane Out of the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Figure 6-37. Aligning the Bracket Tabs on the SCSI Duplex Board . . . . . . . . . . . . . . . . . . . . . . . 238

Figure 6-38. Connecting SCSI Cable B to the SCSI Adapter Board . . . . . . . . . . . . . . . . . . . . . . . 239

Figure 6-39. Unplugging SCSI Cable B from the SCSI Backplane . . . . . . . . . . . . . . . . . . . . . . . . 241

Figure 6-40. Unplug SCSI Cable B from the SCSI Adapter Board . . . . . . . . . . . . . . . . . . . . . . . . 242

Figure 6-41. Removing the Duplex Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Figure 6-42. Installing the SCSI Jumper Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Figure 6-43. LAN I/O Card Latch Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Figure 6-44. Installing the LAN I/O Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Figure 6-45. SCSI I/O Card latch Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Figure 6-46. Install SCSI I/O Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Figure 6-47. Disk Drive Installation in Slots 1 and 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Figure 6-48. Disk Drive Installation in Slot 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Figure 6-49. Volume Filler Installation in Slot 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Figure 6-50. SCSI Backplane Removal and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Figure 6-51. Midplane Riser Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Figure 6-52. Hot-Swappable Power Supply Removal and Replacement . . . . . . . . . . . . . . . . . . . . 260

Figure 6-53. Power Distribution Board Removal and Replacement . . . . . . . . . . . . . . . . . . . . . . . . 262

Figure 6-54. DVD Drive Removal and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Figure 6-55. DVD I/O Board Removal and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

13

Page 14

Figures

Figure 6-56. Display Board Removal and Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

Figure 6-57. QuickFind Diagnostic Board Removal and Replacement . . . . . . . . . . . . . . . . . . . . . . 270

14

Page 15

About This Document

This document provides the information and instructions on servicing the HP 9000 rp4410 and rp4440

servers:

The document printing date and part number indicate the document’s current edition. The printing date

changes when a new edition is printed. Minor changes may be made at reprint without changing the printing

date. The document part number changes when extensive changes are made.

Document updates may be issued between editions to correct errors or document product changes. To ensure

you receive the updated or new editions, subscribe to the appropriate product support service. See your HP

sales representative for details.

The latest version of this document can be found on the web at:

http://www.docs.hp.com.

Intended Audience

This document is intended to provide technical product and support information for authorized service

providers, system administrators, and HP support personnel.

This document is not a tutorial.

New and Changed Information in This Edition

This following changes are included in this edition:

• The User Service Guide includes the contents of the Maintenance Guide and the Operations Guide.

• Server specification and installation information.

• I/O baseboard locking lever remove and replace procedures.

• Replacing deallocated memory ranks procedure.

• System power troubleshooting procedures.

• Physical and environmental specifications table.

Publishing History

Table 1 lists the publishing history details for this document.

Table 1 Publishing History Details

Document

Manufacturing

Part Number

A9950-96011-ed4 HP-UX 11i v1

Operating Systems

Supported

HP-UX 11i v2

HP-UX 11i v3

Supported Product Versions Publication Date

HP 9000 rp4410 and rp4440 September 2008

A9950-96011 HP-UX 11i v1

HP-UX 11i v2

HP-UX 11i v3

HP 9000 rp4410 and rp4440 April 2007

15

Page 16

Table 1 Publishing History Details (Continued)

Document

Manufacturing

Par t Number

A9950-96001

A9950-96002

N/A HP-UX 11i v1 HP 9000 rp4410 and rp4440 July 2003

Operating Systems

Supported

HP-UX 11i v1 HP 9000 rp4410 and rp4440 April 2005

Supported Product Versions Publication Date

Document Organization

This guide is divided into the following chapters:

Chapter 1 Overview: Provides views and descriptions of the server.

Chapter 2 System Specifications: Server details such as system configuration, physical

specifications, and requirements.

Chapter 3 Installing the System: Unpacking, installation, and preparation for booting the operating

system.

Chapter 4 Booting and Shutting Down the Operating System: Provides procedures to boot and

shut down the operating system.

Chapter 5 Troubleshooting: Provides diagnostics and basic troubleshooting methodology.

Chapter 6 Removing and Replacing Components: Provides instructions and procedures on how to

remove and replace server components.

Appendix A Replacement Parts: Provides a list of available customer self-repair parts.

Appendix B Utilities: Provides information on the utilities on the server such as Boot Console Handler

(BCH) and Integrity iLO MP.

Appendix C Physical and Environmental Specifications: Provides temperature and airflow

information for minimum, typical, and maximum configurations for the server. It also lists

the server and rack weights and dimensions.

Typographic Conventions

This document uses the following conventions.

WARNING A warning lists requirements that you must meet to avoid personal injury.

CAUTION A caution provides information required to avoid losing data or avoid losing system

functionality.

IMPORTANT Important messages provide essential information to explain a concept or to complete a task.

16

Page 17

NOTE A note highlights useful information such as restrictions, recommendations, or important

details about HP product features.

TIP Tips provide you with helpful hints for completing a task. A tip is not used to give essential

information, but can be used, for example, to provide an alternate method for completing the

task that precedes it.

Book Title The title of a book. On the web and on the Instant Information CD, it can be a hot link to the

KeyCap The name of a keyboard key or graphical interface item (such as buttons, tabs, and menu

Emphasis Text that is emphasized.

Bold Text that is strongly emphasized.

Bold The defined use of an important word or phrase.

ComputerOut Text displayed by the computer.

UserInput Commands and other text that you type.

Command A command name or qualified command phrase.

Option An available option.

Screen Output Example of computer screen output.

[] The contents are optional in formats and command descriptions. If the contents are a list

{} The contents are required in formats and command descriptions. If the contents are a list

... The preceding element can be repeated an arbitrary number of times.

| Separates items in a list of choices.

book itself.

items).

separated by |, you must select one of the items.

separated by |, you must select one of the items.

Return and Enter both refer to the same key.

HP-UX Release Name and Release Identifier

Each HP-UX 11i release has an associated release name and release identifier. The uname (1) command with

the -r option returns the release identifier.

Table 2 shows the releases available for HP-UX 11i operating system.

Table 2 HP-UX 11i Releases

Release Identifier Release Name Supported Processor Architecture

B.11.20 HP-UX 11i v1.5 PA-RISC

B.11.22 HP-UX 11i v1.6 PA-RISC

B.11.23 HP-UX 11i v2 PA-RISC, Intel® , Itanium

B.11.31 HP-UX 11i v3 PA-RISC, Intel, Itanium

17

Page 18

Related Documents

You can find other information on HP server hardware management and diagnostic support tools in the

following publications.

Website for HP Technical Documentation:

http://docs.hp.com

Server Hardware Information:

http://docs.hp.com/en/hw.html

Diagnostics and Event Monitoring: Hardware Support Tools

Complete information about HP’s hardware support tools, including online and offline diagnostics and event

monitoring tools, is available at:

http://docs.hp.com/hpux/diag/

This site has manuals, tutorials, FAQs, and other reference material.

Website for HP Technical Support:

http://us-support2.external.hp.com/

Books about HP-UX Published by Prentice Hall

The http://www.hp.com/hpbooks/ website lists the HP books that Prentice Hall currently publishes,

including the following:

• HP-UX 11i System Administration Handbook

http://www.hp.com/hpbooks/prentice/ptr_0130600814.html

• HP-UX Virtual Partitions

http://www.hp.com/hpbooks/prentice/ptr_0130352128.html

HP Books are available worldwide through bookstores, online booksellers, and office and computer stores.

HP Encourages Your Comments

HP encourages your comments concerning this document. We are truly committed to providing

documentation that meets your needs.

Send comments to:

netinfo_feedback@cup.hp.com

Include title, manufacturing part number, and any comments, errors found, or suggestions for improvement

you have concerning this document. Also, please include what we did right so we can incorporate it into other

documents.

18

Page 19

1 Overview

The HP 9000 rp4410 and the HP 9000 rp4440 servers are designed to be easy to install, service, and

maintain. They deliver performance, reliability, and availability in a compact, rack-dense design to meet the

most demanding enterprise-level computing requirements.

A rack-dense 4U form-factor maximizes the number of servers for each rack, up to 10 systems for each HP

10000 G2 series rack (42U). They fit easily into the HP 10000 G2 series rack and into many third-party racks

using side-mounted slides and a cable management arm that you can install quickly without tools.

You can equip the servers with up to eight 800 MHz or 1.0 GHz PA-8900 processors with 1.5 MB of on-chip L1

cache for each processor and 64 MB of shared L2 cache for each processor module, up to 128 GB RAM, and six

PCI-X I/O expansion slots.

The blue server identification LED can be activated locally or remotely for easy physical identification of

problem hardware, and the QuickFind diagnostic LED panel speeds problem diagnosis by identifying

defective or mismatched hardware components.

HP 9000 rp4410 Server

The HP 9000 rp4410 server is a PA-8900-based server in a 4U form factor. It is based on the same hardware

as the HP 9000 rp4440 server, but in the rp4410 server, two of the four processor sockets are disabled using

firmware, limiting it to a 2P/2C. Like the HP 9000 rp4440 server, the HP 9000 rp4410 server has full access to

all 16 or 32 memory slots (for a total of up to 128 GB of memory) and full access to all six PCI-X I/O slots.

Because it has a maximum of four processors, the HP 9000 rp4410 server qualifies for Oracle Standard

Edition licensing. The HP 9000 rp4410 server is available in 1P/1C, 1P/2C, and 2P/2C configurations and can

be easily upgraded to an HP 9000 rp4440 server using a firmware upgrade kit.

This chapter addresses the following topics:

• “HP 9000 rp4410 and rp4440 Server Views” on page 20

• “Detailed Server Description” on page 21

• “Controls, Ports, and LEDs” on page 24

• “Powering the Server On and Off” on page 42

Chapter 1

19

Page 20

Overview

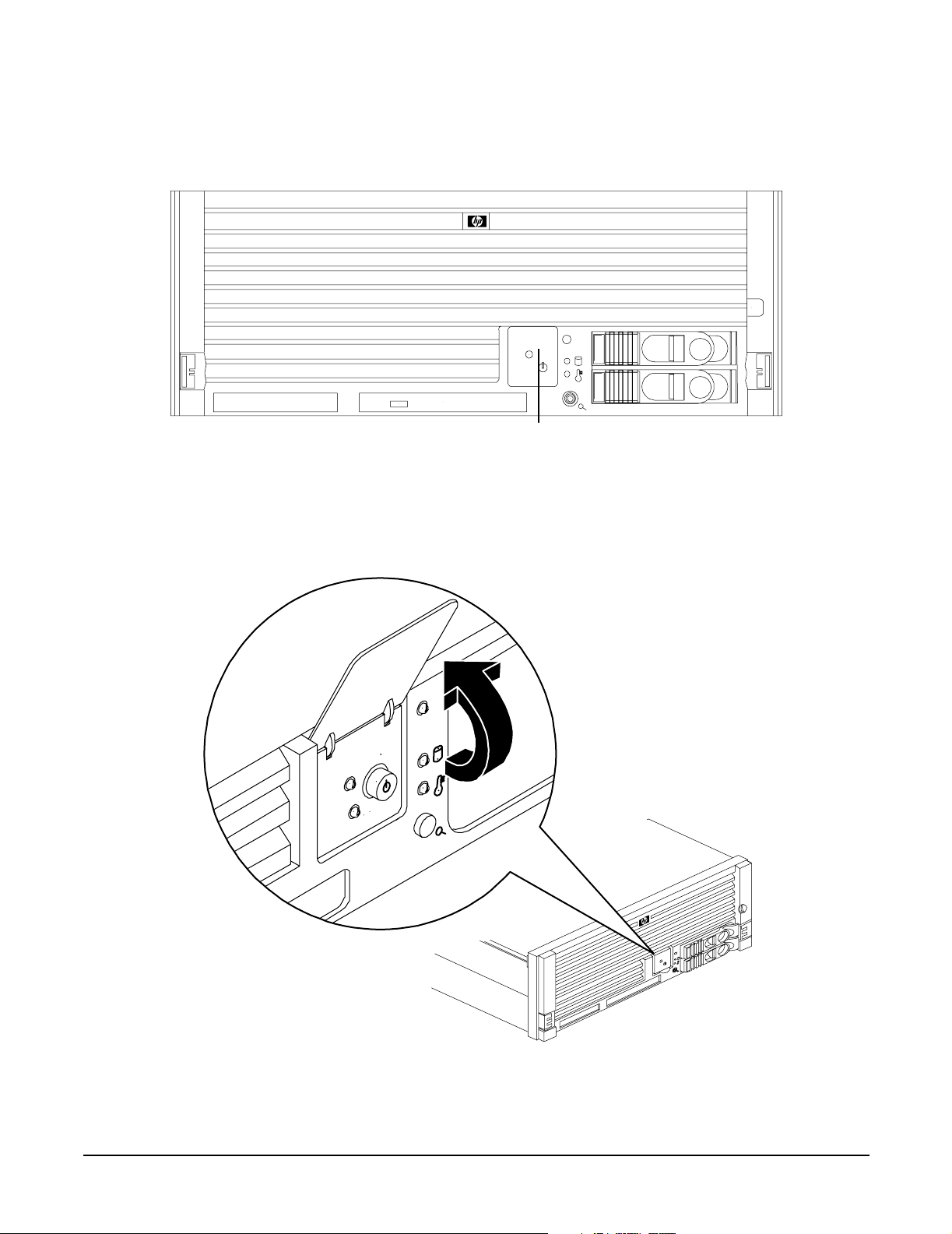

HP 9000 rp4410 and rp4440 Server Views

HP 9000 rp4410 and rp4440 Server Views

Figure 1-1, Figure 1-2, and Figure 1-3 show the top, front, and rear views of the HP 9000 rp4410 and rp4440

servers.

Figure 1-1 HP 9000 rp4410/rp4440 Server (Top View)

20

Chapter 1

Page 21

Detailed Server Description

Figure 1-2 HP 9000 rp4410/rp4440 Server with Bezel Removed (Front View)

Figure 1-3 HP 9000 rp4410/rp4440 Server (Rear View)

Overview

Detailed Server Description

The following sections list information on the main subsystems within the HP 9000 rp4410 and rp4440

servers.

I/O Subsystem

The following is supported on the HP 9000 rp4410 and rp4440 servers:

• PCI-X slots available - 8.

— Two dedicated PCI slots: Slot 1 is for SCSI; slot 2 is for LAN.

— Four hot-pluggable PCI-X 66 MHz 64-bit 3.3V 25W slots with shared busses and I/O. Slots 3 and 4

share capabilities and slots 5 and 6 share capabilities.

— Two hot-pluggable PCI-X 133 MHz 64-bit 3.3V 15W slots dedicated for core I/O.

Chapter 1

21

Page 22

Overview

Detailed Server Description

• I/O bandwidth - 4 GBs.

• Pinnacle FXe PCI video card.

• PCI Gigabit, Fast Ethernet Controller with Wake-on-LAN enabled/disabled with BIOS setup.

Internal Core I/O

The following is supported on the HP 9000 rp4410 and rp4440 servers:

• Dual channel SCSI U320 or U160 (PA8800 only) interface or RAID, two internal 68-pin connectors, two

68-pin external connectors.

• SCSI backplane configured as either one or two channels.

• One internal Integrated Drive Electronics (IDE) connector for a slimline optical device (CD and DVD).

• No floppy connector.

• Optional dual channel U320 RAID controller, two internal 68-pin connectors, two 68-pin external

connectors (replaces SCSI interface).

External Core I/O

The following is supported on the HP 9000 rp4410 and rp4440 servers:

• Three external serial ports.

• Two external USB ports.

• Two SCSI U320 or U160 68-pin connectors (U160 for PA8800 only).

• One or two 10/100/1000Base-T ethernet LAN connectors for copper cable.

• Two USB 2.0 ports.

• Three DB-9 ports (console, UPS, and modem).

• Optional dual channel U320 RAID controller, two 68-pin external connectors (replaces SCSI interface).

Processors

The following is supported on the HP 9000 rp4410 and rp4440 servers:

• 800 MHz/1.5 GB cache or 1 GHz/1.5 GB cache per CPU.

• Both processors are available with 32 MB or 64 MB L2 cache per dual processor module.

• HP 9000 rp4410 server can have one processor or both processors of a single dual processor module

enabled, or two processors enabled in each of two dual processor modules.

• HP 9000 rp4440 server can be 1P/2C, 2P/2C, 3P/2C, or 4P/2C.

Memory

The following is supported on the HP 9000 rp4410 and rp4440 servers:

• 16 DIMM slots on standard memory extender board.

• 32 DIMM slots on optional memory extender board.

• Maximum memory size of 128 GB (4 GB DIMMs on 32-slot memory extender board).

• Supports up to 32 Double Data Rate (DDR) registered ECC memory, in PC2100 DIMMs.

22

Chapter 1

Page 23