Page 1

RC3000 MOBILE ANTENNA CONTROLLER

USER’S MANUAL

Contents subject to change

1 December 2005

RESEARCH CONCEPTS INC.

5420 Martindale Road

Shawnee, Kansas 66218-9680 USA

VOICE: (913) 422-0210

FAX: (913) 422-0211

www.researchconcepts.com

support@researchconcepts.com

Serial No________

Page 2

Page 3

REVISION HISTORY

DATE MODIFICATION SOFTWARE VERSION

8 March 1999 Preliminary document 1.00

13 April 1999 Initial Release 1.04

1 June 1999 Update 1.07

13 March 2000 Software Update 1.16

15 November 2002 Chapter 2 Update 1.37

10 January 2003 Appendix E Update 1.38

3 January 2005 Manual Format Update 1.46

1 December 2005 Software Update 1.55

Page 4

WARRANTY INFORMATION

Research Concepts, Inc.(RCI) warrants to the original purchaser, this product shall be free from defects

in material and workmanship for one year, unless expressed otherwise, from the date of the original

purchase.

During the warranty period, RCI will provide, free of charge, both parts and labor necessary to correct

such defects.

To obtain such a warranty service, the original purchaser must:

(1) Notify RCI as soon as possible after discovery of a possible defect, of:

(a) the model and serial number

(b) identify of the seller and date of purchase

(c) detailed description of the problem, including details on the electrical connection to associated

equipment and list of such equipment, and circumstances when problem arose.

(2) Deliver the product to RCI, or ship the same in its original container or equivalent, fully insured

and shipping charges prepaid.

Correct maintenance, repair, and use are important to obtain proper performance from this product.

Therefore, read the instruction manual carefully and completely. This warranty does not apply to any

defect that RCI determines is due to:

- Improper maintenance or repair, including the installation of parts or accessories that do not

conform to the quality and specifications of the original parts.

- Misuse, abuse, neglect, or improper installation including disregard for installation of backup or

safety override equipment.

- Accidental or intentional damage.

- Lightning or acts of God.

There are no implied warranties.

The foregoing constitutes RCI's entire obligation with respect to this product, and the original purchaser

and any user or owner shall have no other remedy and no claim for incidental or consequential damages.

Some states do not allow limitations or exclusions of incidental or consequential damages, so the above

limitation and exclusion may not apply to you. This warranty gives you specific legal rights and you may

also have other rights which may vary from state to state.

RCI retains the right to make changes to these specifications any time, without notice.

Copyright – Research Concepts Inc., 2005

REPAIR RETURN INFORMATION

To help guarantee a fast and efficient repair, the user should request and receive a Return Merchandise

Authorization number (RMA#) from Research Concepts Inc. prior to shipping the unit.

In addition, international returns are required to complete the correct documents necessary for achieving

U.S. Customs clearance. In order to avoid duties and taxes, export documents must be accurately

completed to meet Export Administration Regulations. Contact RCI for guidance with respect to the

correct completion of shipping documents.

Page 5

TABLE OF CONTENTS

1.0 INTRODUCTION.................................................................................................................................................1

1.1 MANUAL ORGANIZATION.....................................................................................................................................1

1.2 RC3000 FEATURES ..............................................................................................................................................3

1.3 THEORY OF OPERATION .......................................................................................................................................5

1.3.1 Controller Description.................................................................................................................................5

1.3.2 System Interface Requirements ....................................................................................................................6

1.3.3 Operational Overview..................................................................................................................................7

1.3.4 Antenna Pointing Solution ...........................................................................................................................9

1.3.5 Timekeeping ...............................................................................................................................................11

1.3.6 Drive System...............................................................................................................................................11

1.3.7 Polarization Control ..................................................................................................................................13

1.3.8 Magnetic Variation ....................................................................................................................................14

1.3.9 System Performance...................................................................................................................................15

1.4 SPECIFICATIONS .................................................................................................................................................16

2.0 INSTALLATION................................................................................................................................................17

2.1 EQUIPMENT MOUNTING .....................................................................................................................................18

2.1.1 RC3000 Antenna Controller.......................................................................................................................18

2.1.2 GPS Receiver..............................................................................................................................................19

2.1.3 Fluxgate Compass......................................................................................................................................20

2.1.4 Electronic Clinometer ................................................................................................................................22

2.2 ELECTRICAL CONNECTIONS ...............................................................................................................................24

2.2.1 Power Entry................................................................................................................................................25

2.2.2 Motor Drive................................................................................................................................................26

2.2.3 Drive Sense.................................................................................................................................................27

2.2.4 Limit Switches ............................................................................................................................................28

2.2.5 Signal Strength...........................................................................................................................................29

2.2.6 Navigation Sensors.....................................................................................................................................30

2.2.7 Accessories.................................................................................................................................................31

2.2.8 RF Autopeak...............................................................................................................................................32

2.2.9 Hand Held Remote.....................................................................................................................................33

2.2.10 Pulse Sensors ...........................................................................................................................................35

2.2.11 Remote Control ........................................................................................................................................38

2.2.12 Waveguide Switch ....................................................................................................................................39

2.2.13 Resolver Inputs.........................................................................................................................................40

2.3 INITIAL CONFIGURATION....................................................................................................................................41

2.3.1 Software Initialization................................................................................................................................41

2.3.2 Elevation Calibration.................................................................................................................................43

2.3.3 Azimuth Calibration...................................................................................................................................47

2.3.4 Polarization Calibration ............................................................................................................................50

2.3.5 Fast/Slow Motor Speed ..............................................................................................................................53

2.3.6 Pulse Sensor Checkout...............................................................................................................................53

2.3.7 Drive System Checkout...............................................................................................................................53

2.3.8 Navigation Sensor Communication............................................................................................................53

2.4 FINAL CALIBRATION ..........................................................................................................................................54

2.4.1 Compass Calibration..................................................................................................................................54

2.4.2 Azimuth and Elevation Alignment..............................................................................................................55

2.4.3 Signal Strength Adjustment........................................................................................................................57

2.4.3.1 L-Band Power Detector .........................................................................................................................................57

2.4.3.2 Signal Strength Channel ........................................................................................................................................57

2.4.3.3 Signal Strength Channel Calibration......................................................................................................................58

2.4.3.4 Amplifier Gain vs. Frequency Characterization ....................................................................................................59

2.4.4 Pulse Scale Factors....................................................................................................................................60

2.4.5 Operational Presets....................................................................................................................................62

2.4.6 Miscellaneous Adjustments ........................................................................................................................62

2.4.7 Mechanizing Automatic Locates ................................................................................................................62

Page 6

3.0 DETAILED OPERATION ................................................................................................................................ 63

3.1 OPERATION OVERVIEW...................................................................................................................................... 63

3.1.1 Modes......................................................................................................................................................... 63

3.1.2 Keypad Usage............................................................................................................................................ 64

3.1.3 Data Entry ................................................................................................................................................. 66

3.1.4 Display Layout........................................................................................................................................... 67

3.2 OPERATING GROUP............................................................................................................................................ 68

3.2.1 Manual Mode............................................................................................................................................. 69

3.2.1.1 Heading Fix........................................................................................................................................................... 71

3.2.1.2 Waveguide Switch................................................................................................................................................. 72

3.2.2 Menu Mode................................................................................................................................................73

3.2.2.1 Deploy................................................................................................................................................................... 74

3.2.2.2 Stow....................................................................................................................................................................... 75

3.2.2.3 Locate.................................................................................................................................................................... 76

3.2.2.3.1 Satellite Selection........................................................................................................................................... 77

3.2.2.3.2 LOCATE Automatic Movement............................................................................................ ........................ 79

3.2.2.3.3 Azimuth Scanning Autopeak ......................................................................................................................... 80

3.2.2.3.4 Spiral Search Autopeak.................................................................................................................................. 82

3.2.2.3.5 Terminal Peak Up.......................................................................................................................................... 83

3.2.2.3.6 Polarization Tilt Compensation...................................................................................................................... 83

3.2.2.4 Store ...................................................................................................................................................................... 84

3.2.2.5 Recall..................................................................................................................................................................... 85

3.2.2.6 Delete .................................................................................................................................................................... 85

3.2.2.7 Position.................................................................................................................................................................. 86

3.2.2.7.1 LAT/LON ...................................................................................................................................................... 86

3.2.2.7.2 HEADING ..................................................................................................................................................... 87

3.2.2.7.3 INIT ............................................................................................................................................................... 87

3.2.2.8 Settings.................................................................................................................................................................. 89

3.2.2.9 Track ..................................................................................................................................................................... 90

3.2.2.10 Remote ................................................................................................................................................................ 90

3.2.2.11 VSAT Mode........................................................................................................................................................91

3.3 PROGRAMMING GROUP...................................................................................................................................... 94

3.3.1 Configuration Mode................................................................................................................................... 94

3.3.1.1 NORMAL ACCESS ITEMS................................................................................................................................. 96

3.3.1.1.1 Expert Access Permission.............................................................................................................................. 96

3.3.1.1.2 Preset Locations............................................................................................................................................. 97

3.3.1.1.3 Preset Satellites.............................................................................................................................................. 98

3.3.1.2 INSTALLATION ACCESS ITEMS..................................................................................................................... 99

3.3.1.2.1 System Definition .......................................................................................................................................... 99

3.3.1.2.2 Elevation Calibration ................................................................................................................................... 100

3.3.1.2.3 Azimuth Calibration..................................................................................................................................... 102

3.3.1.2.4 Polarization Calibration ............................................................................................................................... 104

3.3.1.2.5 Signal Strength Factors................................................................................................................................ 105

3.3.1.2.6 Autopeak...................................................................................................................................................... 106

3.3.1.3 Super-User Access Items..................................................................................................................................... 108

3.3.1.3.1 Reset Defaults.............................................................................................................................................. 108

3.3.1.3.2 Azimuth Pot Drive.......................................................................................................................................109

3.3.1.3.3 Azimuth Pulse Drive ................................................................................................................................... 110

3.3.1.3.4 Azimuth Drive Monitoring .......................................................................................................................... 111

3.3.1.3.5 Elevation Pot Drive...................................................................................................................................... 113

3.3.1.3.6 Elevation Pulse Drive.................................................................................................................................. 114

3.3.1.3.7 Elevation Drive Monitoring........................................................................................................................ 114

3.3.1.3.8 Polarization Drive........................................................................................................................................115

3.3.1.3.9 Pol Drive Monitoring................................................................................................................................... 115

3.3.1.3.10 Stow & Deploy Positions........................................................................................................................... 116

3.3.1.3.11 SHAKE...................................................................................................................................................... 117

3.3.2 Maintenance Items................................................................................................................................... 118

3.3.2.1 Analog to Digital Voltage ................................................................................................................................... 119

3.3.2.2 Drive Error Resets............................................................................................................................................... 120

3.3.2.3 Time Maintenance............................................................................................................................................... 120

3.3.2.4 Signal Strength Offset Calculator........................................................................................................................ 122

Page 7

3.3.2.5 Limits Maintenance .............................................................................................................................................123

3.3.2.6 GPS Serial Port Diagnostics ................................................................................................................................124

3.3.2.7 Fluxgate Serial Port Diagnostics.......................................................................................................................... 124

3.3.2.8 MOVETO............................................................................................................................................................125

3.3.2.9 Fluxgate Calibration Procedure ...........................................................................................................................126

3.3.2.10 Shake .................................................................................................................................................................127

3.3.2.11 Configuration Item Record ................................................................................................................................128

3.4 ALARM DISPLAYS ............................................................................................................................................129

4.0 TROUBLESHOOTING....................................................................................................................................131

4.1 LIMIT SWITCHES...............................................................................................................................................131

4.2 MOTOR DRIVE..................................................................................................................................................132

4.3 AUTOMATIC MOVEMENTS................................................................................................................................133

4.4 GPS..................................................................................................................................................................133

4.5 FLUXGATE COMPASS........................................................................................................................................134

5.0 DRAWINGS & SCHEMATICS......................................................................................................................135

APPENDIX A - EXPERT ACCESS / RESET DEFAULTS CODE

APPENDIX B - MOUNT SPECIFIC DATA

APPENDIX C - DC MOTOR CONTROLLER

The following appendices describe optional features of the RC3000. These appendices will be

included in the manual if the option is present.

APPENDIX REM - REMOTE CONTROL

APPENDIX TRK - INCLINED ORBIT TRACKING

APPENDIX DVB - INTEGRATED DVB RECEIVER

APPENDIX DSI - ANTENNA DEPLOYMENT SAFETY INTERLOCK

APPENDIX TLE - TWO LINE ELEMENT TRACKING

Page 8

Page 9

RC3000 Antenna Controller Chapter 1 Introduction

1.0 INTRODUCTION

The RC3000 antenna controller is designed for use with elevation over azimuth antennas on mobile

satellite uplink vehicles. The RC3000 assists both the technically-oriented and the non-technical operator

of a mobile satellite antenna system by automating the process of locating and locking on to a particular

satellite. This process can be time-consuming due to several factors. For each shoot, the antenna may

be located in a different location, with its own local magnetic variation, and oriented in a different

direction. Since the beamwidth of the antenna is extremely narrow, the elevation and azimuth pointing

angles require a significant degree of accuracy to even be in the neighborhood of the satellite.

The design and function of the RC3000 is derived from two other proven antenna controllers from

Research Concepts Inc.: the RC8097 satellite locator and the RC2000C tracking antenna controller.

This pedigree allows the RC3000 to automate all operational steps within one piece of equipment. First,

a microcontroller based calculator function provides an accurate pointing solution through a collection of

sensor data. The RC3000 then uses the data from the sensors to accurately steer the antenna to the

calculated azimuth and elevation angles. The RC3000 also optionally automates the function of tracking

inclined orbit satellites.

PLEASE READ AND UNDERSTAND THE MANUAL. Due to the complexity of the functions performed

by the RC3000, time invested in understanding its installation and operation will be well spent.

1.1 Manual Organization

This manual contains five chapters and multiple appendices. Each chapter is divided into multiple

sections.

This section (1.1) summarizes the contents of the remainder of the manual and the conventions and

notations used throughout the manual. Section 1.2 highlights the functionality and features of the

RC3000. Section 1.3 reviews the theory of the RC3000’s operation and should be understood before

installation and initial use of the RC3000.

Chapter 2 describes the installation and configuration procedures for the RC3000. The rest of the

manual should be reviewed prior to installation in order to provide context for the installation procedures.

Chapter 3 provides detailed instructions on the operation of the RC3000. This chapter will describe the

data presented and user action required for every operational display screen.

Chapter 4 covers RC3000 error conditions and provides help for system troubleshooting.

Chapter 5 provides RC3000 schematics and drawings.

The appendices provide additional support for working with the RC3000:

Appendix A supplies the expert access codes on a single page, which at management’s discretion, may

be removed to eliminate the possibility of inexperienced users inadvertently corrupting configuration data.

Appendix B provides unique information for a specific mount or family of mounts. Please refer to

appendix B now to note what paragraphs in the base manual are different for your mount.

Appendix C provides information on the applicable motor controller for your mount.

A test data sheet is included with the manual that accompanies a new RC3000 controller. The mount

configuration of a particular controller is noted on the test data sheet.

1

Page 10

RC3000 Antenna Controller Chapter 1 Introduction

MANUAL CONVENTIONS

Throughout the manual, representations of screens the user will see will be shown in the boxed format

that follows:

AZIM: 0.0 STOW SS1: 50 MANUAL

ELEV: -67.5 STOW SAT:TELSTAR 402

POL: 0.0 SPD:FAST CST

<0-9>JOG ANTENNA <MODE>MENU 14:25:47

The following table shows typical abbreviations used both on RC3000 screens and in the manual’s text.

ITEM ABREVIATION(S)

Azimuth AZ

AZIM, Azim

Elevation EL

ELEV, Elev

Polarization PL

POL, Pol

Clockwise CW

Counter-Clockwise (Anti-Clockwise) CCW

Down DN

Latitude LAT

Longitude LON

Satellite SAT

Global Positioning System GPS

Liquid Crystal Display LCD

Automatic Gain Control AGC

Satellite longitudes are presented in degree/decimal degree (79.0 W) format since that is the standard

representation of satellite position. Latitude and longitude of the mount are presented in degree/minute

(38°56 N) format.

When referring to a particular RC3000 mode of operation, that mode’s name will be capitalized – ex.

LOCATE.

Throughout the RC3000 manual and software, the latitude, longitude and true heading of the mount are

collectively referred to as the mount’s “position”.

Movements of the mount are represented by graphing the azimuth and elevation axes as shown below.

2

Page 11

RC3000 Antenna Controller Chapter 1 Introduction

1.2 RC3000 Features

The RC3000 antenna controller is designed to automate the operation of mobile (both vehicle mounted

and deployable) mounts. Features provided include:

- Automatic azimuth and elevation pointing solution calculation

- Optional GPS receiver for determination of antenna latitude and longitude

- Optional fluxgate compass for determination of antenna centerline heading

- Optional automatic tracking of inclined orbit satellites

- Automatic polarization control of rotating feeds

- Battery backed-up non-volatile memory for storing satellite locations and configuration data

- Automatic repositioning to stored satellites

- Slim 2U rack mounted unit

- Continuous monitoring of antenna drive status

- Optional RS-422/-232 remote control interface

- Support for C, Ku, Ka, L, X - band satellite operations

- 4 row x 40 column Liquid Crystal Display (LCD) for user interface

- 16 key keypad for data entry

The RC3000 supports mounts from multiple antenna manufacturers and provides optional software

configurations. When the RC3000 is powered on, the following identification screen appears for three

seconds.

RC3000A MOBILE ANTENNA CONTROLLER

(c) RESEARCH CONCEPTS INC. 2004

SHAWNEE, KANSAS (USA) 913-422-0210

SW:RC3K-P1-GTN version 1.44

Hardware Configuration. There are two basic versions of the RC3000 hardware. The “A” version is

configured with circuitry to support mounts with low voltage (12-36 VDC) DC motors. The “B” version

supports higher voltage (40-120 VDC) DC motors. Other hardware configurations provide customized

backpanel configurations, etc. Refer to the appendix B (mount specific data).

In late 2004, internal board configurations changed. These changes did not affect interface definitions or

software functionality. RC3000 units with serial numbers larger than 2000 contain the second generation

boards. Typically, low voltage drive units with second generation board configurations may be referred to

as "A2" units vs."A" which designates units with the original board configuration.

3

Page 12

RC3000 Antenna Controller Chapter 1 Introduction

Software Configuration. The software configuration (SW:) field is presented in the form RC3K-ab-xyz:

RC3K-(Mount Manufacturer/Model #)-(Nav Sensor Option)(Tracking Option)(Remote Option)

Descriptions of the software configuration designations are provided in the following tables:

Mount Manufacturer/Model #

The software within the RC3000 is customized to account for specifics of individual mounts. A particular

mount is referred to by a two character designation with the first character typically associated with the

mount manufacturer and the second character associated with a specific mount/antenna model from that

manufacturer.

CATEGORY DESIGNATION DESCRIPTION

Mount Manufacturer / Letter / # Example: V1 – Vertex 2.4m. DMK

Model Number S1 – SweDish 1.5m. DA

A3 - AVL 1.2m. USA

N1 - Andrew 4.5m. TriFold

As of December 2005, the RC3000 supported over 80 different mount models.

Navigation Sensor Options

The RC3000 may be provided with multiple navigation sensor options. Navigation sensors allow the

RC3000 to determine the mount's latitude, longitude and heading. If no navigation sensors are present,

estimates of this data may be entered manually.

CATEGORY DESIGNATOR DESCRIPTION

Navigation Sensors N No Navigation Sensors supported

G GPS & Fluxgate compass supported

A GPS, Fluxgate and integrated DVB

F GPS and DVB receiver (no compass)

C GPS Compass

receiver supported

Tracking Options

The RC3000 may provide optional support for tracking inclined orbit satellites.

CATEGORY DESIGNATOR DESCRIPTION

Inclined Orbit N Tracking not supported

Tracking T Step & Memory Track supported

E Step & Memory plus Two Line Element

set tracking supported

Remote Control Options

The RC3000 may provide optional support for controlling the mount from a remote (away from the front

panel) location.

CATEGORY DESIGNATOR DESCRIPTION

Remote Control N No Remote Control Supported

R Remote Monitor & Control Supported

O Antenna Deployment Safety Interlock

P Both Monitor & Control and

Deployment Safety Interlock

NOTE: Descriptions of the optional features are typically provided by separate appendices.

4

Page 13

RC3000 Antenna Controller Chapter 1 Introduction

1.3 Theory of Operation

The RC3000 performs its functions via digital and analog electronic equipment interfaced to the antenna’s

motor drive and position feedback systems. This equipment is controlled through embedded software

algorithms run by the RC3000’s microcontroller. This section provides an overview of the equipment,

interfaces and major software functions.

1.3.1 Controller Description

The following figure is a block diagram showing the major components of the RC3000 :

LIQUID CRYSTAL DISPLAY (LCD). The 4 row by 40 column LCD provides the user interface for

monitoring the status of the RC3000 and for entering data.

KEYPAD. The 4 row by 4 column keypad allows the user to enter data and commands to the RC3000.

DIGITAL BOARD. The digital board is essentially a small computer containing a microcontroller,

memory, real-time clock and circuitry to monitor and drive the keypad and LCD. The digital board

performs the following major functions:

- monitors user inputs from the keypad

- displays information on the LCD screen according to controller mode, antenna status and user input

- monitors antenna drive status

- battery backs up non-volatile memory (configuration data, etc.) and the real-time clock

5

Page 14

RC3000 Antenna Controller Chapter 1 Introduction

- performs communications between the microcontroller and the three (GPS, compass, remote control)

serial channels

- performs analog to digital conversion of drive position and signal strength inputs

- performs automatic antenna movement algorithms (locate, stow, recall, track, etc)

FEATURE BOARD. The feature board contains circuitry to implement many of the optional features of

the RC3000. The feature board provides the following major functions:

- signal drivers for PC remote control and navigation sensor serial communication

- circuitry for multiplexing signal strength indications from 1 of 3 sources

- circuitry for conditioning pulse based position feedback signals

- power transformation to supply required voltages to other modules

RF AUTOPEAK MODULE. This module accepts the output of an LNB (950-1450MHZ, -50 to –5dBm)

and generates a signal indicative of power across the band. This signal may be used for autopeak

operations.

ANALOG BOARD. The analog board contains circuitry to control the antenna motors and condition

antenna feedback signals. The analog board provides the following major functions:

- generation of azimuth and polarization limit indications based on sensed potentiometer feedback

- conditioning of elevation inclinometer input

- conditioning of azimuth stow and elevation up/down/stow limit switch inputs

- activation of relays (based on digital board control) to direct motor drive signals from the DC motor

control module.

DC MOTOR CONTROL MODULE. The solid state DC motor speed and reversing control module

contains circuitry for antenna motor regulation. This module provides:

- acceleration adjustment for smooth motor acceleration

- deceleration adjustment for ramp down time when motor speed lowered

- anti-plug instant reverse, solid state dynamic braking

- current limiting circuitry to protect the motor against overloads and demagnetization and to

limit inrush current during startup

- IR compensation to improve load regulation

POWER ENTRY MODULE. The power entry module allows the RC3000 to be configured for 115 or 230

VAC operation.

POWER TRANSFORMER. The power supply module transforms AC input voltage to a regulated DC

voltage for use by the digital and drive boards.

RESOLVER BOARD. To support mounts that use resolvers for position feedback, an optional resolver to

digital conversion board may be added to the baseline RC3000 hardware.

NOTE: Second Generation RC3000's (serial number > 2000) will have the circuitry of the analog board

and the feature board combined. Section 5.0 will contain the appropriate schematics for a particular

controller.

1.3.2 System Interface Requirements

The RC3000 is designed to interface with many different mobile antenna mounts. This manual attempts

to describe installation and operation in a manner applicable to most mounts.

The typical interfaces required for the RC3000 to perform all its automatic functions are described in

section 2.2 (Electrical Connections). Known differences to these interfaces and how they are

accommodated for a particular mount are described in appendix B (Mount Specific Data).

6

Page 15

RC3000 Antenna Controller Chapter 1 Introduction

1.3.3 Operational Overview

The RC3000 allows easy antenna operation via its menu based user interface. The screen displayed to

the user is based on the current controller mode. Controller modes are divided into two major groups:

operational and programming (see mode map in section 3.1.1). The operational modes provide for the

normal operation of the antenna. The programming group provides for initial configuration of the

controller and will typically not be used on a day by day basis. The following example highlights the basic

modes of operation provided by the RC3000.

Operational Group Functions

MANUAL. In MANUAL mode the user may jog the antenna in azimuth, elevation and polarization. Upon

power up, the fluxgate compass and GPS receiver initialize and begin providing data.

AZIM: 0.0 STOW SIG: 50 MANUAL

ELEV: -67.5 STOW SAT:TELSTAR 402

POL: 0.0 SPD:FAST CST

<0-9>JOG ANTENNA <MODE>MENU 14:25:47

AUTOMATIC LOCATION OF A SATELLITE. In LOCATE mode, azimuth and elevation pointing angles

are automatically calculated based on position (lat/lon), heading and the selected satellite. Position may

be obtained automatically from the optional GPS, selected from a preset list of user defined positions or

entered manually. Heading may be automatically obtained from the optional fluxgate compass or entered

manually. The user selects which satellite to locate from either a preset user defined list of commonly

used satellites, a provided extensive list of satellites or by manually entering satellite data. The RC3000

checks that the calculated pointing solution is within the mount’s range of movement and prompts the

user to automatically position the antenna.

POS: 38°56N 94°44W 180.0 LOCATE

SAT:GALAXY 6 74.0W AZ:-31.1

EL: 40.0

<1>SELECT NEW SAT READY TO LOCATE

STORING SATELLITE LOCATION. After verifying the antenna is precisely on the satellite, the user may

STORE the satellite’s azimuth and elevation angles along with horizontal and vertical polarization data. If

the satellite has been identified as having an inclined orbit, the TRACK mode will be automatically

entered as described below.

SAT LON INCLIN BAND STORE

BRASIL A1 79.0 2 C

VERIFY SATELLITE DATA OK FOR STORING

1-CORRECT, 2-INCORRECT

RECALLING STORED SATELLITES. The user may quickly and precisely move between previously

STOREd satellites via RECALL mode.

RECALL

STORED SATELLITE: BRASIL A1

SELECT SAT(SCROLL UP/DOWN) <ENTER>

AUTOMATIC ANTENNA STOWING. From STOW mode, the user may ask for the antenna to be

automatically moved to the stow position.

AZIM: -42.5 ( 0.0) STOW

ELEV: 23.4 (-67.5)

MOVING TO (TARGET),<STOP> TO HALT MOTION

7

Page 16

RC3000 Antenna Controller Chapter 1 Introduction

Programming Group Functions

The programming group modes provide for initial configuration of the controller and also provide screens

to aid in maintenance and troubleshooting of the controller.

Configuration mode screens allow the user to customize and calibrate the operation of the RC3000 for

use with a particular mount. Note that most configuration items will be factory set for correct operation

with a particular mount.

REF_VOLT:2.50 OFF: 0.0 CONFIG-AZIM

CCW:180 CW:180 SF:76.35

SET REFERENCE VOLTAGE <2.00 - 3.00>

Maintenance mode screens allow the user to monitor sensor inputs and perform periodic maintenance

actions such as setting time and resetting drive errors.

SYSTEM:11/10/97 22:26:40 TIME

GPS UTC:11/10/97 22:26:40 ZONE:CST

DISPLAY:11/10/97 16:26:40 OFFSET:- 6

1-DATE 2-TIME 3-SYNCH 4-ZONE 5-OFFSET

8

Page 17

RC3000 Antenna Controller Chapter 1 Introduction

1.3.4 Antenna Pointing Solution

The position (latitude and longitude) of the mount and the longitude of a selected satellite are required to

calculate a pointing vector from the mount to the selected satellite.

Given the mount’s latitude and longitude and the pointing vector to the satellite, the RC3000 calculates

the elevation (with respect to local horizontal) required. Feedback from the inclinometer on the elevation

axis will be used to move the mount to the required elevation.

9

Page 18

RC3000 Antenna Controller Chapter 1 Introduction

The azimuth portion of the pointing vector is calculated with respect to local true North. The fluxgate

compass is used to determine the heading of the centerline of azimuth travel and the required movement

in the azimuth axis is calculated.

In the above example a true heading of 135 degrees to the satellite has been calculated. Based on the

mount’s latitude, longitude and date, a local magnetic variation (see 1.3.8) of 10 degrees is calculated.

The compass senses a magnetic heading of 55 for the azimuth reference direction. Applying the

magnetic variation, this yields an apparent true heading of 45 degrees for the antenna reference

direction. An azimuth movement of 90 (135 – 45) degrees clockwise is therefore needed to point at the

satellite.

Since a position sensor on the azimuth axis is always active, the RC3000's default displayed azimuth

value is that of the antenna angle. Derived estimates of the magnetic and true heading of the mount may

be selected in the MANUAL (3.2.1) and LOCATE (3.2.2.3) modes.

10

Page 19

RC3000 Antenna Controller Chapter 1 Introduction

1.3.5 Timekeeping

There are several versions of time (system, sidereal, referenced and GPS) discussed within this manual.

System time is maintained by the RC3000’s real time clock. The real-time clock is backed up by battery

so that system time is available as soon as the RC3000 powers up. The system time is used to calculate

sidereal time for maintaining track tables. Since satellite’s do not experience time shifts (such as from

Standard Time to Daylight Savings Time or when moving from one time zone to another), it is

recommended that system time not be modified while active track tables are present. If system time is

changed, the information stored in track tables for inclined orbit satellites will no longer be valid.

The RC3000’s system time is set to approximately Universal Coordinated Time (UTC) at the factory. It

will vary from UTC due to the tolerance of the real-time clock.

If the optional GPS receiver is installed, the RC3000 parses UTC from the data sent by the GPS receiver.

This data is only available when the GPS receiver is sufficiently locked on to GPS satellites to determine

UTC. The RC3000 allows the user to synchronize system time to the UTC reported by the GPS receiver.

The period of a satellite’s motion is one sidereal day (approximately 23 hours 56 minutes 4 seconds).

Entries in the track table for an inclined orbit satellite are stored at intervals of 1/48th of a sidereal day.

The RC3000 determines at what point in a sidereal day (with respect to the RC3000 reference) it is by

calculating how many sidereal days have passed from January 1, 1992 until the present system time.

In several screens the RC3000 displays a reference time. The user may designate a three letter

timezone designation and an hourly offset from system time. This allows the user to display local time or

some other reference time without modifying system time. If system time is maintained close to UTC, the

reference time displayed may be of use to operators for coordinating events.

See section 3.3.2.3 for details on time maintenance.

1.3.6 Drive System

The RC3000 implements several mechanisms for the driving and monitoring of the azimuth, elevation

and polarization axis.

Position Sensing and Limits

The RC3000 senses absolute axis position using feedback from various sensors (potentiometers,

resolvers, inclinometer for elevation, etc). The sensed voltage is scaled appropriately for the particular

mount. This sensed position is displayed in angular format.

For systems requiring very small movements for inclined orbit tracking, the RC3000 also supports pulse

feedback from the azimuth and elevation axis. Sensed pulses from the axis motor don’t provide an

absolute indication of position but allow for very precise relative movements.

The boresight of the antenna is displayed for the azimuth and elevation axis. In elevation, this angle is

with respect to the local horizontal. In azimuth, this angle is with respect to the centerline of azimuth

travel.

The following diagram shows a typical range of movement for mobile satellite antennas. Note that

elevation movement to the stow position is limited about a small range of azimuth movement in order to

ensure safe stowing of the antenna.

11

Page 20

RC3000 Antenna Controller Chapter 1 Introduction

In the azimuth axis, movement in one direction is disabled when clockwise and counterclockwise limit

switches are activated. There is also typically a region in the center of azimuth travel indicating that the

azimuth axis is in a position that will allow for moving the elevation axis down to the stow position.

In the elevation axis, there are typically three limit switches. The UP switch prevents further movement

up. The “DOWN” switch delimits the elevation the mount may not move further downward unless it has

been placed in the azimuth stow region. The STOW switch indicates when the mount has reached its

furthest down position which is typically where the dish is stowed for travel.

Jam and Runaway Sensing

The RC3000 continuously monitors the axis positions to detect incorrect movement of the mount. If an

axis has been commanded to move and the RC3000 does not detect movement within a prescribed time,

the controller will declare a “JAM” condition and not allow further movement in that axis until the condition

has been reset.

Similarly if the RC3000 senses movement in an axis when no movement should be occurring, the

RC3000 will declare a “RUNAWAY” condition. Like JAM, the RUNAWAY condition must be reset before

further movement in the axis may occur.

Anti-Reversal

In order to save wear on the drive motors, the RC3000 limits how fast an axis may reverse its direction.

This mechanism prevents a motor from instantly changing direction before coasting to a stop in the

original direction. This mechanism is also useful for correct counting of pulses. Since the RC3000

counts a pulse as being in the direction that the controller thinks the axis should be going, it is imperative

to stop the motor completely before moving in the opposite direction.

Automatic Movements

In order to provide smooth automatic movement to target positions, the RC3000 utilizes several

parameters to account for different mount characteristics.

12

Page 21

RC3000 Antenna Controller Chapter 1 Introduction

The Fast/Slow Transition parameter defines how far away from a target position the RC3000 will switch

from fast to slow motor speed. The Coast Range defines where the RC3000 will de-energize the motor

drive to allow the mount’s inertia to coast into the target position. The Max Error parameter defines how

close to the target position will be considered good enough.

Note that the DC motor control module in the RC3000 provides for smooth acceleration/deceleration, load

regulation and dynamic braking of the motors.

1.3.7 Polarization Control

The RC3000 calculates the required position and automatically moves the polarization axis as part of the

satellite LOCATE function. The following diagram shows the polarization axis sign convention used. The

diagram depicts looking at the arc of satellites from behind the antenna.

The RC3000 allows the user to specify the type of polarization axis mechanism present. If a circular

polarization scheme is present, no automatic movement of the polarization axis is performed. If a linear

polarization scheme is present, the RC3000 will calculate the theoretical position as a function of mount

latitude, mount longitude and satellite longitude.

13

Page 22

RC3000 Antenna Controller Chapter 1 Introduction

1.3.8 Magnetic Variation

In order to calculate satellite pointing solutions, the mount’s orientation with respect to true North must be

known. The RC3000 uses the fluxgate compass to measure the local horizontal component of the earth’s

magnetic field. The earth’s magnetic field is very irregular as shown in the following diagram from the

National Geophysical Data Center.

The magnetic field also changes slowly over time. The following table shows how the magnetic variation

for Washington D.C. has changed over the last 250 years.

YEAR MAGNETIC VARIATION

1750 -3.3

1800 -1.0

1850 -2.5

1900 -5.5

1950 -7.5

2000 -10.6

To calculate the local magnetic variation (difference between magnetic North and true North), the

RC3000 uses the International Geomagnetic Reference Field (IGRF) model. The IGRF is a mathematical

model of the earth’s magnetic field and how it is changing. The IGRF is based on world wide

observations and is updated every five years. The IGRF model cannot account for short term effects

such as magnetic storms, etc.

Local magnetic variation is calculated given the mount’s latitude, longitude and the current date. The

magnetic variation calculation cannot account for isolated local anomalies (typically less then a few

degrees). It also cannot account for local external effects (power lines, train tracks, etc). The autopeak

scan functions (3.2.2.3.2.3) used by the RC3000 attempt to compensate for the small heading calculation

errors that may occur at any particular location.

14

Page 23

RC3000 Antenna Controller Chapter 1 Introduction

1.3.9 System Performance

The performance achieved by the RC3000 in locating and tracking satellites is dependent on the

mechanical tolerances of the mount, the correctness of the installation and the accuracy of the various

sensors.

The largest source of error for the system is due to errors in determining the truck's magnetic heading.

Errors in heading primarily affect the accuracy of the antenna's calculated azimuth position. The flux gate

determines the magnetic heading by measuring the direction of the magnetic field at the sensor tower.

Problems arise because the earth's magnetic field can be distorted by ferrous metals (such as steel and

iron; aluminum is a non-ferrous metal) and man-made magnetic fields. These man-made fields can be

generated by electric motors, generators, and transformers, as well as those "worked into" the coach

body during manufacturing.

For the flux gate sensor, there are two unique categories of objects that distort the magnetic field in the

vicinity of the truck. Some of the distortion is due to objects and electrical devices on the truck itself. This

component of the distortion can be largely compensated for during system calibration.

The other component of the distortion is due to large metal objects and man-made magnetic fields around

the site where the truck is being operated. This component of the distortion varies as the truck moves

from one location to another, and it affects the accuracy of the calculated azimuth position. Environments

which typically produce the largest errors include railroad yards, areas around electrical substations, and

sites near structures containing large amounts of steel or iron, such as bridges or large buildings.

To date, the largest known azimuth error due to these interactions is less than 10 degrees. To help

alleviate this azimuth error, the Auto Peak feature scans an azimuth range about the target azimuth and

seeks the strongest signal. This feature is explained in full in section 3.2.2.3.

The RC3000 uses a 10 bit analog to digital converter for measuring voltages from azimuth, elevation and

polarization potentiometers as well as measuring signal strength inputs. In most cases this provides

adequate resolution but should be considered. For example, if the azimuth axis has 360 degrees of

travel, the resolution achieved is 360 / 1024 (approximately 0.35 degrees). This example highlights why

pulse or resolver sensors are used to make precise movements for inclined orbit tracking. The optional

resolver interface uses a 16 bit resolver to digital converter. This allows resolution of 0.0055 ( 360 /

65536) degrees.

15

Page 24

RC3000 Antenna Controller Chapter 1 Introduction

1.4 Specifications

Physical

Size 19.0 inches x 3.5 inches x 17.5 inches

Weight 19 lbs 13 lbs

Input Power

Fusing

Temperature -20C to +50C 0C to +50C

Humidity 35% to 85% (optional special-environmental kit available)

Antenna Drive

Azimuth/Elevation 12-36 VDC, 10 Amps max

Polarization 12-36 VDC, 10 Amps max 12 VDC, 1 Amp max

Electromechanical

Brakes (optional)

Waveguide/Switch

(optional) 24VDC 2Amps max or 115VAC 1 Amp max (specify on order)

Position Sense

Azimuth

Elevation

Polarization Potentiometer, 10-bit resolution standard; optional resolver, 16-bit resolution

Limit Switch Inputs

Locate Mode

Elevation Accuracy +0.2 degrees (typical)

Azimuth Accuracy +1.5 degrees (typical)

Polarization Accuracy +3 degrees (typical)

GPS Lockup Time 0 seconds (when configured for accessory powered GPS receiver)

VSAT Mode Single key-press-to-locate-operation for untrained operators

Autopeak Input

Modem Receive-Lock

Input TTL or contact closure, (optional non-invasive modem lock detector available)

Track Mode

Antenna Size 0.4 – 12.0 meters

Tracking Accuracy 0.1 to 3.0 dB selectable; mount dependent

Maximum Inclination 16 deg., standard

Tacking Modes

Signal-Strength Input -15VDC to +15VDC; 2Mohm input impedance, two channels

Non-volatile Memory

Backup Duracell DL2450

RC3000A RC3000B

115/230 VAC switchable 50/60Hz; 50W max

Idle;850W max Antenna Moving; optional

universal input

115 VAC, 8Amp Slow-Blow; 230 VAC,4

AMP Slow-Blow

115 OR 230 VAC 50/60Hz; 50W

max Idle;850W max Antenna

Moving

115VAC and 230VAC, 12 AMP Fast

Blow

90VDC (3/4 HP max) for 115VAC,90

or 180 VDC (1.5 HP max) for

230VAC input

28 VDC 300mA, or 115 VAC 1Amp

max(specify on order)

115 VAC 1Amp max (specify on

order)

Potentiometer, 10-bit resolution standard; optional single phase pulse sensors

(Reed, Hall-Effect, Optical); optional resolver, 16-bit resolution

Inclinometer, 10-bit resolution standard; optional single phase pulse sensors (Reed,

Hall-Effect, Optical); optional resolver, 16-bit resolution

Five- 12 VDC inputs, standard: EL Up, EL Down, EL Stow, AZ Stow, Pol Stow.Four

additional inputs optional, mount dependent

full L-Band power detection to find strongest signal.(configurable to AGC voltage or

Beacon receiver output -15VDC to +15VDC; 2Mohm input impedance, two

channels)

Step-Track, Memory-Track, Intelli-Searchtm , Program Track, optional Ephemeris

Track

16

Page 25

RC3000 Antenna Controller Chapter 2 Installation

2.0 INSTALLATION

Proper installation is important if the full capability and accuracy of the RC3000 is to be realized. The

procedures that follow will insure the optimum level of performance from all sensors and the system in

general.

Installation will be more efficient if each step in the physical installation and calibration be performed in

the order in which it appears in the following schedule. Each step is referenced to a particular section of

this manual, and should be checked off as it is completed. Coordination between the mount

manufacturer, vehicle integrator and end user is required. Some steps are applicable only if the tracking

or remote control options were purchased with the unit. The installation procedures are written to cover

the most common mount installations. Some steps are slightly different according to the type of mount

the RC3000 is interfacing to (see appendix B). Installation requires basic operational knowledge of the

RC3000. Please review chapter 3 for information on how to navigate the RC3000’s screens and how to

enter data.

SECTION ACTION COMPLETE

2.1 Equipment Mounting

2.1.1 RC3000 Antenna Controller

2.1.2 GPS Receiver

2.1.3 Fluxgate Compass

2.1.4 Inclinometer

2.2 Electrical Connections

2.2.1 Power Entry

2.2.2 Motor Drive

2.2.3 Drive Sense

2.2.4 Limit Switches

2.2.5 Signal Strength

2.2.6 Navigation Sensors

2.2.7 Accessories

2.2.8 RF Autopeak

2.2.9 Hand Held Remote

2.2.10 Pulse Sensors

2.2.11 PC Remote Control

2.2.12 Waveguide Switch

2.2.13 Resolver Inputs

2.3 Initial Configuration

2.3.1 Software Initialization

2.3.2 Elevation Calibration

2.3.3 Azimuth Calibration

2.3.4 Polarization Calibration

2.3.5 Fast/Slow Motor Speed

2.3.6 Pulse Sensor Checkout

2.3.7 Drive System Checkout

2.3.8 Navigation Sensor Communication

2.4 Final Calibration

2.4.1 Compass Calibration

2.4.2 Azimuth and Elevation Alignment

2.4.3 Signal Strength Adjustment

2.4.4 Pulse Scale Factors

2.4.5 Miscellaneous Adjustments

2.4.6 Mechanizing Automatic Locate

17

Page 26

RC3000 Antenna Controller Chapter 2 Installation

2.1 Equipment Mounting

This section describes the physical mounting requirements for the RC3000 and optional sensor units.

Wiring requirements are discussed in section 2.2.

2.1.1 RC3000 Antenna Controller

NOTE: The RC3000 unit should not be installed in the rack until the final step of the Initial

Configuration (section 2.3) because access to the interior of the unit may be necessary prior to

that procedure. The cables may be run through the chosen location in the rack and connected to

their respective components.

The RC3000 enclosure is a standard rack mount chassis that occupies two rack units (2U). The front

panel is mounted via four (4) 10-32 screws. Due to the length and weight of the RC3000, much strain

can be put on the faceplate, particularly in a mobile unit. To help alleviate stress on the front panel

mounting, additional mounting points accepting 10-32 and M4 screws are provided on each side, back

and bottom of the unit. The user may use any of these additional mounting points to provide support for

the RC3000 via strapping, shelving, etc. The additional mounting screws on the back of the unit may be

also used to provide strain relief for cabling.

CAUTION: support of the back of the RC3000 is a requirement. RCI’s warranty does not cover

repair to units with ripped faceplates.

The RC3000’s LCD is optimized for viewing from a 6 o’clock position. The optimum position to mount the

unit would therefore be above the operator’s eye level.

The following diagram shows the typical dimensions (in inches) of the RC3000. See appendix B for exact

dimensions of your controller. See section 5 for a detailed depiction of the side mounting holes.

18

Page 27

RC3000 Antenna Controller Chapter 2 Installation

2.1.2 GPS Receiver

The optional GPS receiver (RC3000GPS) should be mounted in a position (such as the truck’s roof)

where it has an unobstructed view of the horizon and sky. It should be mounted outside of the reflector

when in a stowed position, with the connector (on the underside) towards the cable’s entry point into the

truck. Care should be taken in the routing of the cable to avoid any problems.

The GPS receiver should be mounted at least three feet from other antennas and electrical generating

equipment. Strong RF interference from other sources may disrupt the GPS receiver’s signal reception.

Wiring of the GPS connector is discussed in section 2.2.6.

Recent RC3000s have been supplied with the GPS17 receiver model. The following diagram shows its

dimensions.

Earlier RC3000s were supplied with the GPS35 receiver model. The following diagram shows its

dimensions.

The GPS35 unit is supplied with 25 feet of cable. The GPS35 unit is supplied with a flange mounting

bracket as shown above. An optional marine mounting bracket is also provided.

19

Page 28

RC3000 Antenna Controller Chapter 2 Installation

2.1.3 Fluxgate Compass

The optional fluxgate compass unit (RC3000FG) should be placed on the roof of the vehicle away from

ferrous metals, electric motors, and any equipment that generates magnetic fields such as air

conditioners, generators, and traveling wave tube (TWT) amplifiers. Experience has shown that the

fluxgate performs best when mounted as high as possible on the vehicle. The fluxgate compass must be

mounted in an upright position.

Some mounts position the compass on the mount so that the compass may be lifted well above the top of

the vehicle. If the compass is attached to the mount, the compass configuration item (3.3.1.2.1) must be

set to the “antenna mounted” value.

The RC3000 uses the fluxgate to determine the true heading of the mount’s azimuth centerline (0.0

degrees azimuth). If the compass is not aligned in the direction of the azimuth centerline, that difference

must be described in the azimuth offset configuration item (3.3.1.2.3). Some operators prefer to mount

the compass pointing forward on the vehicle. If the mount faced rearward, an azimuth offset of 180

degrees would need to be input.

Refer to the drawing of the fluxgate enclosure to verify the proper orientation of the fluxgate. NOTE: An

unhoused version of the compass is available for use in a user-designed enclosure.

The Fluxgate Compass box may be either bracket mounted or flush mounted. Without the bracket it may

be attached to a flat surface by four 10-32 screws from inside or outside the box through the four corner

holes shown in the FRONT view diagram above. When using the bracket mount, it may be mounted with

four 1/4 inch bolts using the holes shown in the bottom view of the bracket in the above diagram. The

cable may be routed through either hole in the bracket. The circuit board may also be removed from the

housing or an unhoused model is available on order for custom installations.

The following method may be used to determine the best location for the compass.

Park the vehicle in a location that is away from large metal objects or sources of magnetic fields. NOTE:

for best results, the vehicle should be parked facing in an easterly or westerly direction. The

vehicle's generator should be running, as well as all electrical equipment on the vehicle that generates

magnetic fields.

20

Page 29

RC3000 Antenna Controller Chapter 2 Installation

Stand on the roof of the vehicle with a standard magnetic compass. Slowly lower the compass to the

proposed fluxgate mounting location on the vehicle without changing the orientation (or heading) of the

compass body. If the needle of the compass swings as the compass is lowered to the mounting location,

it is due to distortion of the earth's magnetic field by ferrous metals on the vehicle, or magnetic fields

generated by the vehicle.

The fluxgate should be mounted in the location where the needle of the compass experiences the

minimum amount of swing as the compass is lowered to the proposed mounting location.

21

Page 30

RC3000 Antenna Controller Chapter 2 Installation

2.1.4 Electronic Clinometer

The electronic clinometer (also referred to as the inclinometer) should be positioned on the mount

structure in an orientation that allows the inclinometer’s linear range of movement to rotate through the

antenna’s RF boresight operational range.

Determining the correct orientation of the inclinometer requires knowledge of the mount’s mechanical

structure and the antenna’s RF offset. Typically the mount manufacturer will place the inclinometer in the

correct position on the mount. See appendix B for the correct orientation for a particular mount.

The elevation position sense circuit of the RC3000 is designed to interface to the Lucas/Schaevitz

AccuStar model 0211 1002-000 or 0211 1102-000 inclinometers. The inclinometer’s position reference is

marked on the body of the inclinometer. The inclinometer should be mounted such that the body of the

inclinometer is rotated CW (as viewed by an observer looking at the front of the inclinometer) as the

antenna’s elevation angle increases. The inclinometer must also be oriented properly on the antenna

mount.

To describe the orientation of the inclinometer, the term ‘elevation offset angle’ needs to be defined.

Elevation offset angle is defined as the antenna’s RF elevation pointing angle (relative to horizontal) when

a straight edge oriented vertically across the face of the antenna reflector (reflector top to bottom) is

plumb. The inclinometer should be oriented so that, when the antenna reflector is plumb, the reference

mark is deflected CCW (from the vertical position) by an amount equal to the 35 degrees minus the

‘elevation offset angle’. If the inclinometer is attached as described the sensor will operate in its most

accurate region for elevation look angles up to 80 degrees.

The inclinometer mounting flange allows for some adjustment of the device’s rotational orientation. The

mounting position selected for the inclinometer should allow for adjustment of the inclinometer’s

orientation. The inclinometer should be mounted in a location such that it is protected somewhat from

blowing rain.

See section 2.2.3 for wiring of the inclinometer.

22

Page 31

RC3000 Antenna Controller Chapter 2 Installation

23

Page 32

RC3000 Antenna Controller Chapter 2 Installation

2.2 Electrical Connections

This section provides cabling requirements for interfacing to the RC3000. Note that cables should be

made long enough to allow the unit to be open while still connected to the system.

The following sections supply a schedule of connection requirements. Note that the pinout requirements

for J1, J3, J6, J7 and J10 are the same as required for RC8097 installations and therefore should not

require rework of those cables for retrofitting to the RC3000. The following diagram shows the typical

location of the backpanel connectors on original (serial # < 2000) controllers.

Second Generation RC3000s (serial # > 2000) have a slightly different connector arrangement. For

example, rather than having a single DB-37 for navigation sensors, the second generation controllers

have individual DB-9s for each sensor. Any differences between original and second generation

connectors will be described in the following paragraphs.

Also, some versions of the RC3000 have customized backpanels to accommodate existing antenna

connector schemes.

See appendix B for your exact backpanel configuration.

24

Page 33

RC3000 Antenna Controller Chapter 2 Installation

2.2.1 Power Entry

J6 is an IEC male power connector on the backpanel for supplying AC power to the RC3000.

The RC3000 is shipped from the factory with a line cord appropriate for the line voltage selected. If the

line cord received with the unit is not appropriate for the power available at the installation site, the

installer should check the controller to ensure that the proper line voltage has been selected.

The RC3000A can be configured to operate on either 115 VAC or 230 VAC. The AC input voltage the

unit is currently configured for is displayed in a window located in the fuse holder. To change the AC

input voltage selection, remove the fuse holder and reverse the jumper assembly (on which the ‘115’ and

‘230’ labels are located).

To convert AC Voltage. Switch the power off at the front panel. Remove the IEC power cord from the

back panel power entry module. With a small straight-blade screwdriver, remove the fuse drawer from

the power entry module. With the same tool, remove the small plastic circuit card. Rotate the card so

that the desired operating voltage will be displayed through the front of the fuse drawer and reinsert the

card so that it firmly seats into the power entry module.

NOTE: The RC3000B can only be configured for 115 or 230 VAC since the internal DC motor

controller module is different for each voltage. The fuse holder is glued into the correct voltage

position and cannot be modified as in the RC3000A case.

The fuse holder is designed to accommodate 1/4” by 1 1/4” fuses. “Slow Blow” type fuses should be

used. The following table shows the appropriate fuse for each model and line voltage combination.

LINE VOLTAGE

MODEL 115 VAC 230 VAC

RC3000A 8 Amp 4 Amp

RC3000B 12 Amp 6 Amp

Some RC3000 units may be fitted with an optional card that automatically senses 115 or 230 VAC input.

25

Page 34

RC3000 Antenna Controller Chapter 2 Installation

2.2.2 Motor Drive

J7 is an MS3102A22-20S (Female on backpanel) connector, which terminates three motor cables. The

minimum wire size for these cables is 16AWG.

The RC3000A is designed to drive 12 to 36 volt DC azimuth, elevation, and polarization motors. The

absolute maximum allowed motor current is 12 Amps. The RC3000A employs a built-in, solid-state motor

controller (model 25A8 from Advanced Motion Controls). The motor drive module supports IR

compensation, current limiting, dual speed operation, and dynamic braking. The drive train is also

protected with resettable fuses.

The RC3000B is designed to drive 90 volt (3/4 horsepower max) or 180 volt (1.5 horsepower max) DC

azimuth and elevation motors. Ideally, 90 volt DC motors would be specified with 115 VAC input power

and 180 volt DC motors with 230 VAC input power. 180 volt motors cannot be used with 115 VAC input

power. The motor drive in the RC3000B is the model KBPB by KB Electronics . This motor drive

supports IR compensation, current limiting, dual speed operation, and dynamic braking.

The polarization drive of the RC3000B is designed to power a 12 volt DC motor which draws less than

400 ma.

The following table describes the polarity of the RC3000’s motor drive output signals.

Axis RC3000 Connector

J7 Terminals

Azimuth G, F Azimuth CW – G has higher potential

Elevation H, J Elevation UP – H has higher potential

Polarization A, B RC3000A:Polarization CW – B has higher potential

Polarity

RC3000B:Polarization CW – A has higher potential

26

Page 35

RC3000 Antenna Controller Chapter 2 Installation

2.2.3 Drive Sense

J1 (DB-15 Female on backpanel) receives position sense from the azimuth and polarization

potentiometers and the elevation inclinometer.

Normally, it is not necessary to modify the sensors on the antenna. The antenna manufacturer should

insure that the antenna is compatible with the RC3000. This information is provided for informational

purposes only.

The directional sense of azimuth movement is defined as clockwise (CW) or counter-clockwise (CCW),

as viewed by an observer located above the antenna. On the controller, CW movement results in a

greater sensed azimuth position.

The directional sense of elevation movement is defined as UP when the RF look angle of the antenna is

increasing.

The directional sense of polarization movement is defined as CW or CCW, as seen by an observer

standing behind the antenna reflector looking ‘through’ the reflector at the satellite. See diagram in

section 1.3.7 – Polarization Control. The reference position for the polarization position angle is

vertical polarization for a satellite located at the same longitude as the antenna. In the northern

hemisphere, for vertically polarized satellites to the west of the antenna, the polarization deflection is

defined as CW relative to the reference position. In the northern hemisphere, the polarization angle

increases for satellites farther to the west. In some modes of operation the controller predicts the

polarization value required to align the antenna with a given satellite’s horizontal or vertical polarization

position. For this feature to function properly the antenna’s polarization directional sense characteristics

(defined by the polarization motor and position sensor) must be consistent with that of the controller.

27

Page 36

RC3000 Antenna Controller Chapter 2 Installation

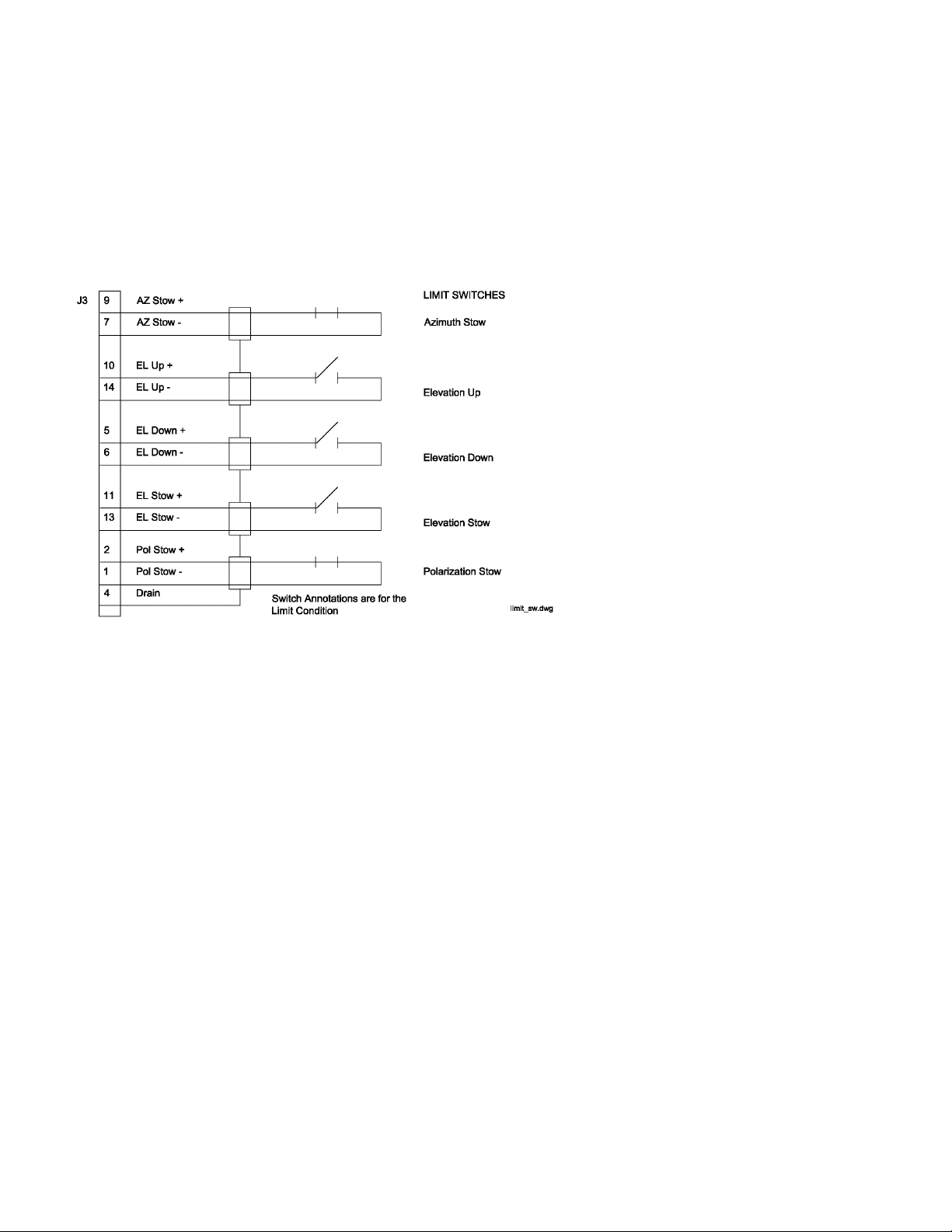

2.2.4 Limit Switches

J3 (DB-15 Female on backpanel) connects to the azimuth stow, elevation stow, elevation up and

elevation down limit switches.

The + side of each limit switch circuit supplies 12 VDC. This 12 VDC supply is protected by a resettable

fuse rated at 250 mA.