Page 1

HP R12000 and R18000 DirectFlow UPS

is document is for

Part Number: 709321-003

User Guide

Abstract

This document includes installation, configuration, and operation information for the HP R12000 and R18000 DirectFlow UPS. Th

the person who installs and maintains power products. HP assumes you are qualified in the servicing of high-voltage equipment and trained in

recognizing hazards in products with hazardous energy levels.

April 2015

Edition: 3

Page 2

© Copyright 2014, 2015 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products and services are set forth in the express

warranty statements accompanying such products and services. Nothing herein should be construed as constituting an additional warranty. HP shall

not be liable for technical or editorial errors or omissions contained herein.

Links to third-party websites take you outside the HP website. HP has no control over and is not responsible for information outside HP.com.

Confidential computer software. Valid license from HP required for possession, use or copying. Consistent with FAR 12.211 and 12.212,

Commercial Computer Software, Computer Software Documentation, and Technical Data for Commercial Items are licensed to the U.S. Government

under vendor’s standard commercial license.

Microsoft®, Windows®, and Windows Server® are trademarks of the Microsoft group of companies.

Page 3

Contents

Overview ..................................................................................................................................... 6

HP DirectFlow UPS overview ....................................................................................................................... 6

Power management options .............................................................................................................. 6

Advanced monitoring and management features ................................................................................. 7

Location Discovery Services for the UPS configuration .......................................................................... 7

REPO port ...................................................................................................................................... 8

Component identification ........................................................................................................................... 8

HP R12000 DirectFlow UPS .............................................................................................................. 8

HP R18000 DirectFlow UPS ............................................................................................................ 11

1U battery pack rear panel ............................................................................................................. 14

3U battery pack rear panel ............................................................................................................. 15

Power unit and battery pack configurations ................................................................................................ 15

Installation ................................................................................................................................. 18

Precautions ............................................................................................................................................. 18

Important device safety information .................................................................................................. 18

Preparing to install the hardware ............................................................................................................... 19

Tools and materials ........................................................................................................................ 19

Selecting a site .............................................................................................................................. 19

Readying the equipment ................................................................................................................. 20

Installing rack rails .................................................................................................................................. 20

Installing rack rails for the 1U power unit .......................................................................................... 20

Installing rack rails for the 2U power unit .......................................................................................... 23

Installing rack rails for the 1U battery pack ....................................................................................... 26

Installing rack rails for the 3U battery pack ....................................................................................... 29

Installing battery packs ............................................................................................................................. 33

Powering down the UPS ................................................................................................................. 33

Installing the 1U battery pack .......................................................................................................... 33

Installing the 3U battery pack .......................................................................................................... 39

Installing the power unit ........................................................................................................................... 47

Installing the R12000DF power unit ................................................................................................. 47

Installing the R18000DF power unit ................................................................................................. 52

Connecting the UPS to utility power ................................................................................................. 56

Connecting devices ....................................................................................................................... 57

Starting power to the load .............................................................................................................. 57

Continuing the installation of components ......................................................................................... 57

Installing the Management Module card ..................................................................................................... 57

Installing the Management Module card in the 1U power unit ............................................................. 58

Installing the Management Module card in the 2U power unit ............................................................. 60

Checking the Health/Alert LED ........................................................................................................ 62

Configuration ............................................................................................................................. 63

Accessing the Management Module .......................................................................................................... 63

Launching a terminal emulation program .......................................................................................... 63

Launching a telnet session ............................................................................................................... 64

Navigating the Service Menu .................................................................................................................... 64

Service Menu ................................................................................................................................ 65

Contents 3

Page 4

Module Configuration submenu ....................................................................................................... 65

Configuring the Management Module card for remote access ....................................................................... 70

Launching a web browser ............................................................................................................... 71

Signing into the Management Module web interface .......................................................................... 71

Configuring the power unit ....................................................................................................................... 72

UPS operations ........................................................................................................................... 73

Navigating UPS menu options .................................................................................................................. 73

UPS menu options.......................................................................................................................... 73

Configuring the battery charge power levels ..................................................................................... 75

Changing the language.................................................................................................................. 76

Working with UPS modes of operation ....................................................................................................... 76

AC mode ..................................................................................................................................... 76

Battery mode ................................................................................................................................ 77

Bypass mode ................................................................................................................................ 77

Maintenance .............................................................................................................................. 78

Updating the UPS firmware ...................................................................................................................... 78

Restoring power after a REPO activation .................................................................................................... 79

Verifying the REPO port connection ........................................................................................................... 79

Powering down the UPS and battery packs ................................................................................................. 80

Replacing the batteries ............................................................................................................................. 80

Important battery safety information ................................................................................................. 80

Battery care and storage guidelines ................................................................................................. 80

Battery replacement procedure ........................................................................................................ 81

Replacing the 1U battery pack .................................................................................................................. 83

Replacing the 3U battery pack .................................................................................................................. 84

Replacing the Management Module card ................................................................................................... 85

Replacing the power module .................................................................................................................... 85

Replacing the 1U power unit..................................................................................................................... 86

Replacing the 2U power unit..................................................................................................................... 87

Troubleshooting .......................................................................................................................... 89

LED and audible alarm troubleshooting ...................................................................................................... 89

Alarm descriptions and SNMP trap codes ......................................................................................... 90

General alarm condition .......................................................................................................................... 92

UPS does not start ................................................................................................................................... 93

Wiring condition ..................................................................................................................................... 93

Utility power condition ............................................................................................................................. 93

Battery connection condition ..................................................................................................................... 93

REPO condition ....................................................................................................................................... 94

UPS is in Bypass mode ............................................................................................................................. 94

Overload condition ................................................................................................................................. 94

UPS is in Battery mode ............................................................................................................................. 95

UPS frequently switches between utility and battery power ............................................................................ 95

Battery fault ............................................................................................................................................ 95

UPS backup time is short .......................................................................................................................... 95

Low battery shutdown .............................................................................................................................. 95

Deep Sleep mode .................................................................................................................................... 95

UPS alarm code decision flowcharts .......................................................................................................... 97

Specifications ........................................................................................................................... 112

Environmental specifications ................................................................................................................... 112

Power unit physical specifications ............................................................................................................ 112

REPO port specifications ............................................................................................................... 112

Contents 4

Page 5

Battery pack physical specifications ......................................................................................................... 112

1U battery pack specifications ...................................................................................................... 113

3U battery pack specifications ...................................................................................................... 113

Lead acid battery module specifications ......................................................................................... 113

Lithium-ion battery module specifications ......................................................................................... 113

Battery runtime ............................................................................................................................ 114

UPS input specifications ......................................................................................................................... 114

UPS output specifications ........................................................................................................................ 115

Voltage specifications .................................................................................................................. 115

Output tolerance specifications ...................................................................................................... 115

Output feature specifications ......................................................................................................... 115

Spares ..................................................................................................................................... 116

UPS spare parts list ................................................................................................................................ 116

R12000DF UPS spare parts list ..................................................................................................... 116

R18000DF UPS spare parts list ..................................................................................................... 116

Hardware options ................................................................................................................................. 117

Electrostatic discharge ............................................................................................................... 118

Preventing electrostatic discharge ............................................................................................................ 118

Grounding methods to prevent electrostatic discharge ................................................................................ 118

Regulatory information .............................................................................................................. 119

Safety and regulatory compliance ........................................................................................................... 119

Turkey RoHS material content declaration ................................................................................................. 119

Ukraine RoHS material content declaration ............................................................................................... 119

Warranty information ............................................................................................................................ 119

Support and other resources ...................................................................................................... 120

Before you contact HP ............................................................................................................................ 120

HP contact information ........................................................................................................................... 120

HP product QuickSpecs .......................................................................................................................... 120

Documentation feedback ........................................................................................................... 121

Acronyms and abbreviations ...................................................................................................... 122

Index ....................................................................................................................................... 124

Contents 5

Page 6

Overview

HP DirectFlow UPS overview

The HP DirectFlow UPS features a configurable rack-mount design that offers three-phase power protection

for loads up to a maximum of 20000 VA/18000 W (these numbers might vary by model). Features include:

• Configurations for extending runtime

o A configurable power unit with the following rack unit heights:

— R12000DF—1U

— R18000DF—2U

o Optional 3U lead acid or 1U lithium-ion battery packs

o A minimum of 60 seconds of backup power with one battery pack and 5 minutes of backup power

with two battery packs provided for the maximum load

• Advanced battery management to increase battery service life and optimize recharge time

o Warning before the end of the useful battery life

o Easily replaceable battery modules that simplify maintenance

• Configurable utility and generator battery charge power level switching

• Optional HP DirectFlow UPS Management Module network connectivity with advanced remote

monitoring, control, and management features

• Built-in location awareness of components

• Emergency shutdown control through a REPO port

• Firmware that is service upgradeable through a standard DB-9 serial communication port

• Backed by worldwide agency approvals

To benefit from product enhancements, update to the latest versions of UPS firmware and software. To

download the UPS firmware and software, see the HP website (http://www.hp.com/go/rackandpower).

Power management options

The DirectFlow UPS is comprised of an HP DirectFlow Power Unit configured with either HP DirectFlow VRLA

Battery Packs (3U) or an R12000DF (1U) or R18000DF (3U) HP DirectFlow Lithium-ion Battery Pack.

The DirectFlow UPS works within an overall power management plan that can include utility, generator, and

battery power.

The power unit includes front panel controls and an LCD screen for navigating UPS menu options (on page

73) to access system values. Certain values can be configured to accommodate your power management

plan.

Each battery pack provides a minimum of 60 seconds of backup power as a stopgap for a power supply lag

or outage. Depending upon configuration, including the number of battery packs and load requirements, the

Overview 6

Page 7

UPS can extend backup power for an increased amount of time. Distribute the load as evenly as possible

across the UPS configuration to most efficiently use the powerful three-phase UPS design.

The UPS modes of operation allow the UPS to transfer seamlessly between AC, Battery, and Bypass modes

to supply power to connected devices without interruption. For more information, see "Working with UPS

modes of operation (on page 76)." The power unit can use a built-in, time-based algorithm to switch between

utility and generator battery charging power levels when transferring operating modes. Using a lower

charge level while the UPS runs on generator power maximizes the output available to connected devices.

The Management Module provides additional features to receive generator commands. To set UPS battery

charge power levels, see "Configuring the battery charge power levels (on page 75)."

Advanced monitoring and management features

The Management Module card reports detailed information to the Management Module web interface

where the information is graphically displayed. Many commands and functions can be customized from the

interface. Customizable setup options in the UPS Service Menu can also be accessed using the Management

Module card. The Management Module is designed specifically for the DirectFlow UPS. It is not intended for

installation in other UPS devices.

To install and initially configure the Management Module in the DirectFlow UPS, see "Installing the

Management Module card (on page 57)" and "Accessing the Management Module (on page 63)." For

details about using the Management Module card and web interface, see the HP DirectFlow UPS

Management Module User Guide on the HP website (http://www.hp.com/support/DFUPS_MM_UG_en).

Location Discovery Services for the UPS configuration

HP provides built-in location awareness of rack components, a capability that works hand-in-hand with

technology in the new HP Intelligent Series racks. Together, the technologies provide the rack identification

number and precise U location of the components. This information is communicated through power

management software.

HP R12000DF

Overview 7

Page 8

HP R18000DF

When the power unit is fully seated within the rack, Discovery Services connectors meet with a rack-mounted

EEPROM strip. Discovery Services reports the specific location of the power unit and a calculated location of

any battery packs. The battery packs must be installed directly beneath the power unit in the rack, without a

U gap, for Discovery Services to locate them. Racks without pre-installed EEPROM strips may be upgraded

by ordering and installing the strips, available on the HP website

(http://www.hp.com/products/rackoptions).

REPO port

The power unit includes an isolated REPO port. When properly wired, the REPO feature enables the power

at the UPS output receptacles to be switched off from a remote location. To use this feature, the REPO port

must be connected to a remote, normally open switch (not supplied). The REPO switch is used in conjunction

with a main disconnect device that removes the AC source from the input of the power unit.

When the switch is closed:

• The REPO feature immediately powers down protected devices and does not utilize an orderly

shutdown procedure.

• The REPO feature shuts down power units operating under utility, generator, or battery power.

To connect a REPO port, see either "Connecting the R12000DF REPO port (on page 49)" or "Connecting the

R18000DF REPO port (on page 54)." To restore power to the load devices after the REPO feature has been

activated, see "Restoring power after a REPO activation (on page 79)."

Component identification

HP R12000 DirectFlow UPS

The components in the following sections are found in the HP R12000 DirectFlow UPS.

Overview 8

Page 9

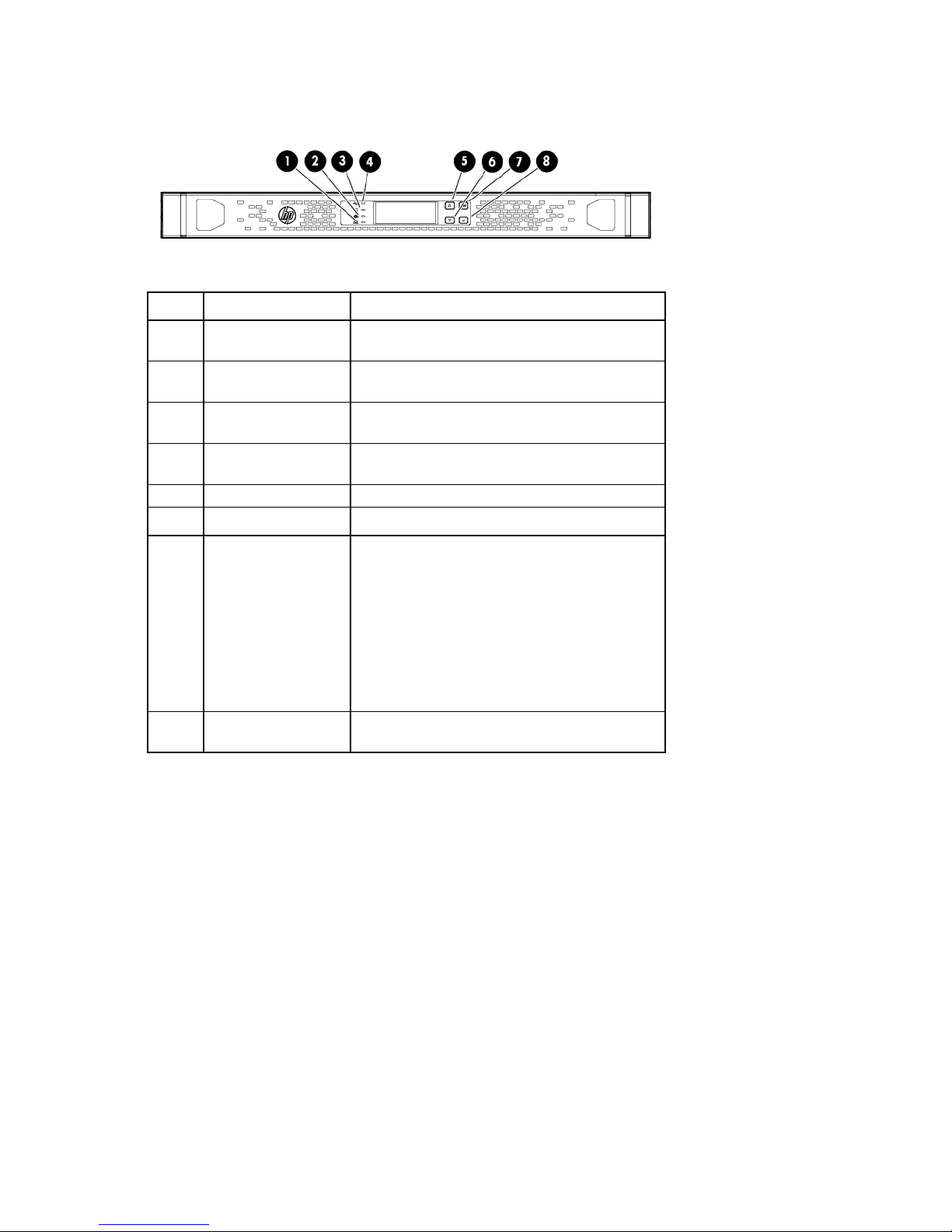

Power unit front panel controls

Up arrow

Press to scroll up through the menu structure.

•

•

•

Item Component Description

1

2

3

4

5

6

7

UPS fault LED Red light indicates a fault; no light indicates proper

function.

Bypass mode LED Green light indicates Bypass mode; no light

indicates AC mode.

Battery mode LED Yellow light indicates Battery mode; flashing

indicates low battery.

Input LED Green light indicates that the power input is

adequate.

Down arrow Press to scroll down through the menu structure.

Off/ESC/Clear fault

button

In AC mode, press the button for 3 seconds to

transfer the UPS to Bypass mode; in Battery

mode, press for 3 seconds to shut down the UPS

output.

During menu selection, press the button to go

back to the previous menu.

During a UPS fault, press the button for 3

seconds to clear the fault and transfer the UPS

to Bypass mode.

8

On/Enter button Press the button for 3 seconds to turn the UPS on;

press the button to confirm setup or menu entries.

Overview 9

Page 10

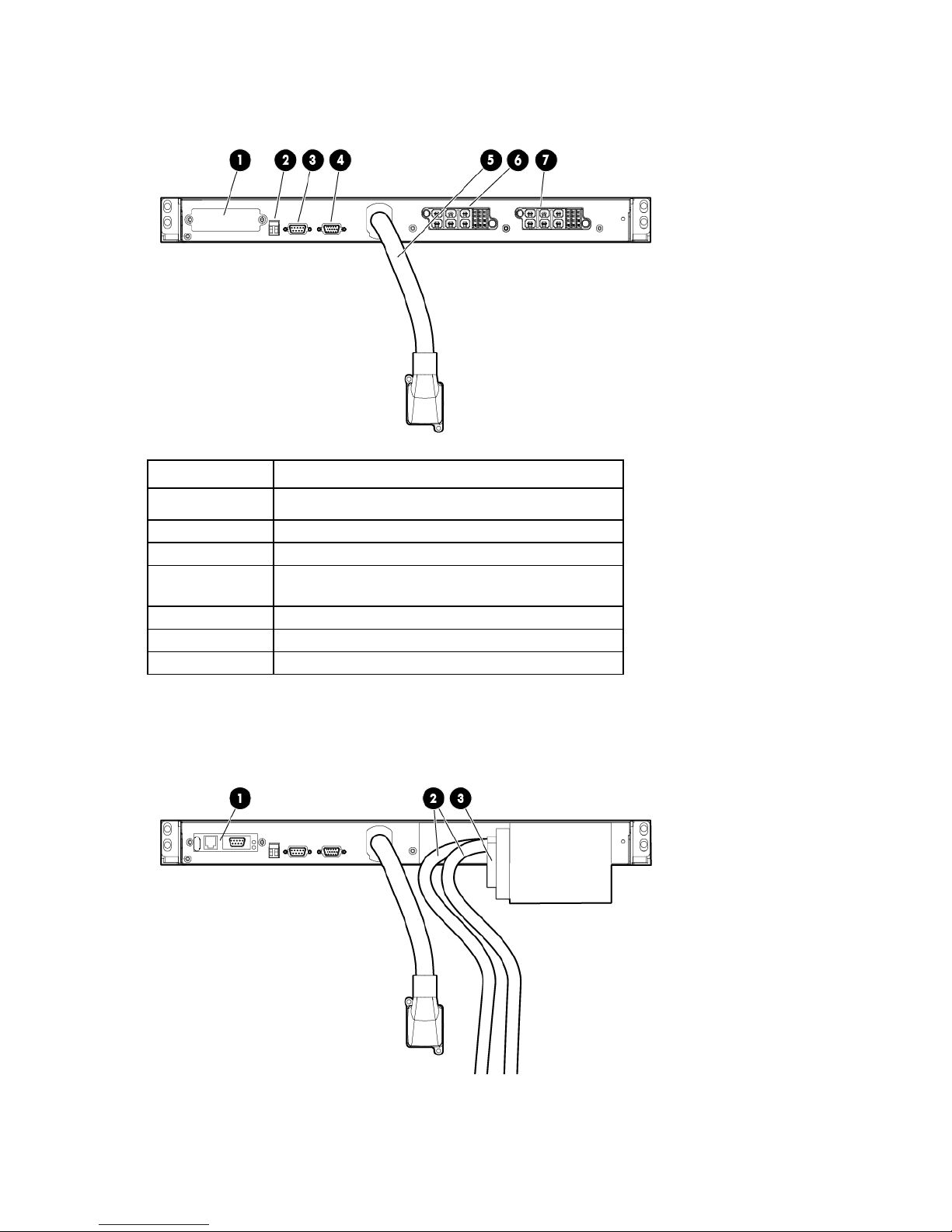

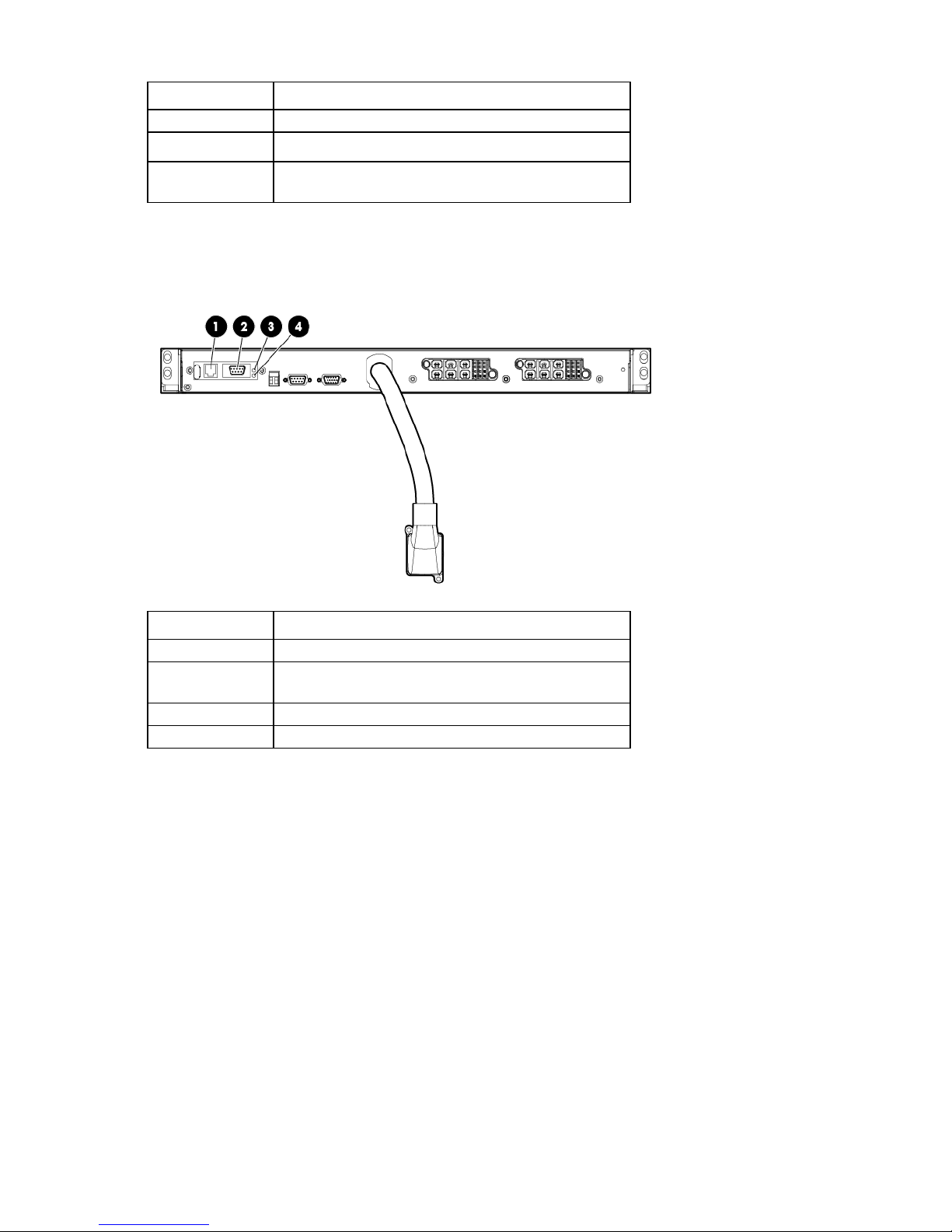

Power unit rear panel

DB-15 port for a CAN Bus cable for battery pack

Item Description

1

2

3

4

5

6

7

Cover plate for option slot

REPO port

DB-9 serial port for flashing UPS firmware

communication

Power cable for connection to the battery pack

Input/output power module connection

Input/output power module connection

Power unit rear panel with components

Overview 10

Page 11

Item Description

1

2

3

HP DirectFlow UPS Management Module card

HP DirectFlow Input/Output Power Module switch

HP DirectFlow Input/Output Power Module connection

and cables

Power unit rear panel with Management Module card

Item Description

1

2

3

4

RJ-45 for network or Ethernet communications

DB-9 serial port for configuration and flashing card

firmware

Power LED

Health/Alert LED

HP R18000 DirectFlow UPS

The components in the following sections are found in the HP R18000 DirectFlow UPS.

Overview 11

Page 12

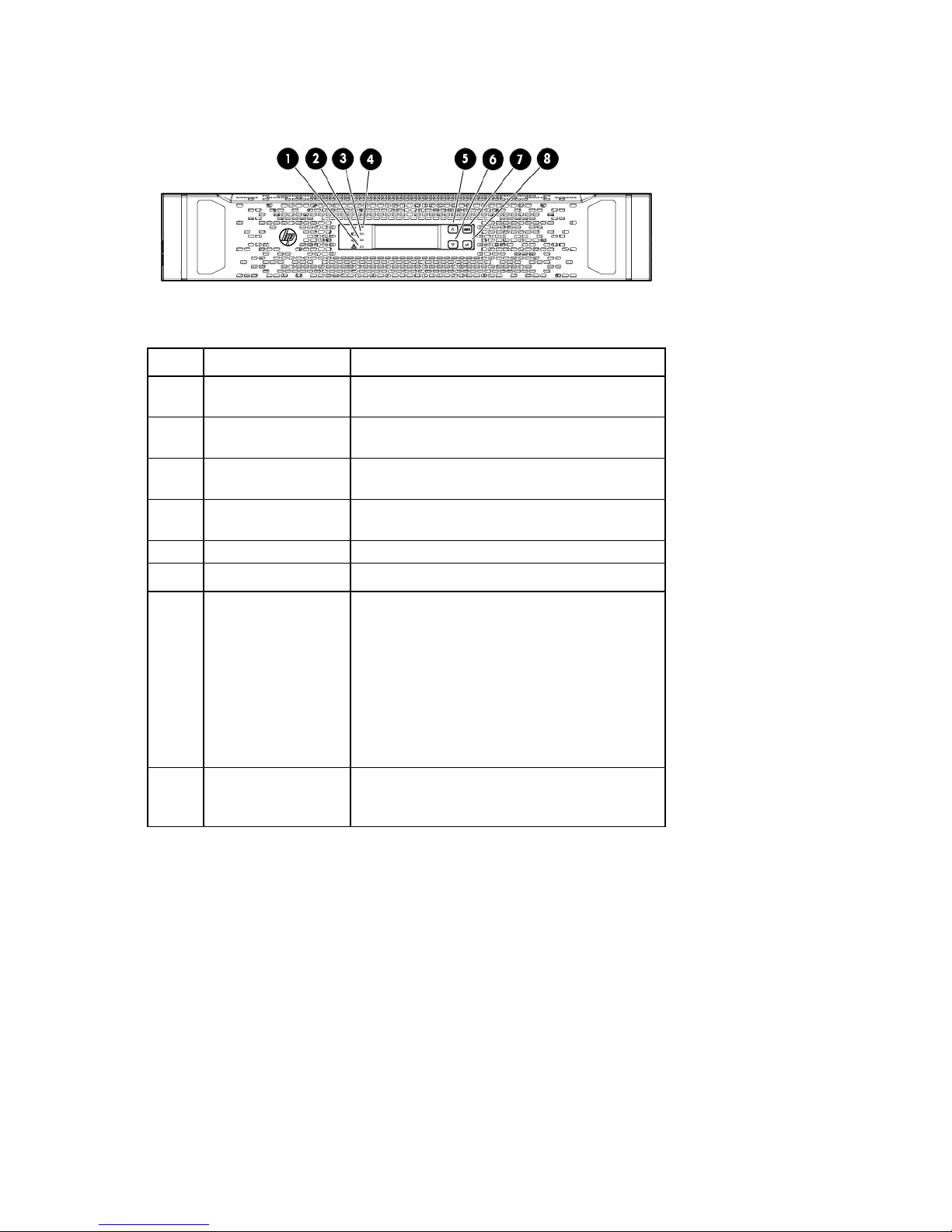

Power unit front panel controls

Up arrow

Press to scroll up through the menu structure.

•

•

•

Item Component Description

1

2

3

4

5

6

7

UPS fault LED Red light indicates a fault; no light indicates proper

function.

Bypass mode LED Green light indicates Bypass mode; no light

indicates AC mode.

Battery mode LED Yellow light indicates Battery mode; flashing

indicates low battery.

Input LED Green light indicates that the power input is

adequate.

Down arrow Press to scroll down through the menu structure.

Off/ESC/Clear fault

button

In AC mode, press the button for 3 seconds to

transfer the UPS to Bypass mode; in Battery

mode, press for 3 seconds to power down the

UPS output.

During menu selection, press the button to go

back to the previous menu.

During a UPS fault, press the button for 3

seconds to clear the fault and transfer the UPS

to Bypass mode.

8

On/Enter button Press the button for 3 seconds to power up the UPS

on; press the button to confirm setup or menu

entries.

Overview 12

Page 13

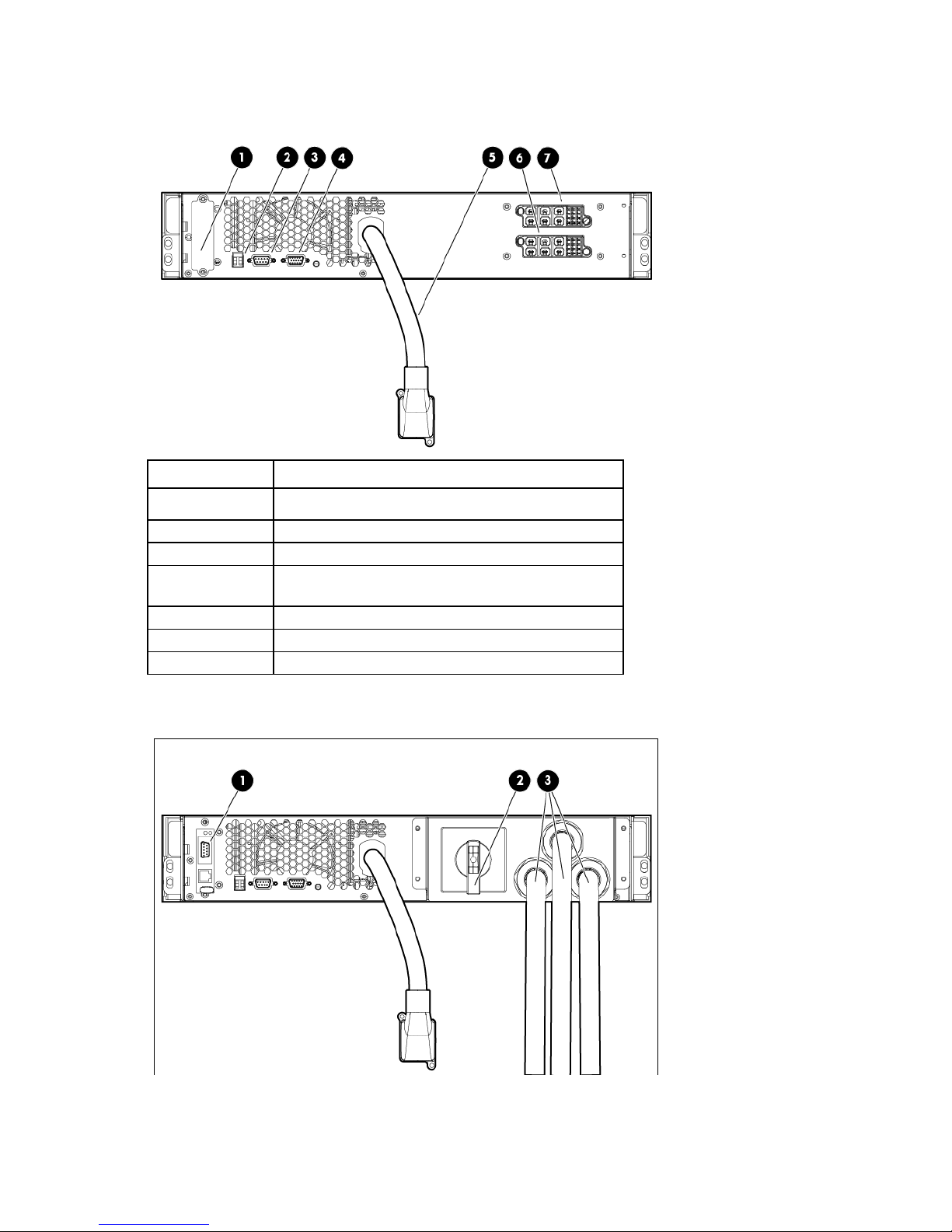

Power unit rear panel

DB-15 port for a CAN Bus cable for battery pack

Item Description

1

2

3

4

5

6

7

Cover plate for option slot

REPO port

DB-9 serial port for flashing UPS firmware

communication

Power cable for connection to the battery pack

Input/output power module connection

Input/output power module connection

Power unit rear panel with components

Overview 13

Page 14

Item Description

1

2

3

HP DirectFlow UPS Management Module card

HP DirectFlow Input/Output Power Module switch

HP DirectFlow Input/Output Power Module connection

and cables

Power unit rear panel with Management Module card

Item Description

1

2

3

4

Power LED

Health/Alert LED

DB-9 serial port for configuration and flashing card

firmware

RJ-45 for network or Ethernet communications

1U battery pack rear panel

Item Description

1

Connection for a DC to DC power cable to the power unit

2

Circuit breaker switch

Overview 14

Page 15

Item Description

3

4

Connection for a DC to DC power cable to the battery

pack

DB-15 ports for CAN Bus cables for battery pack

communication

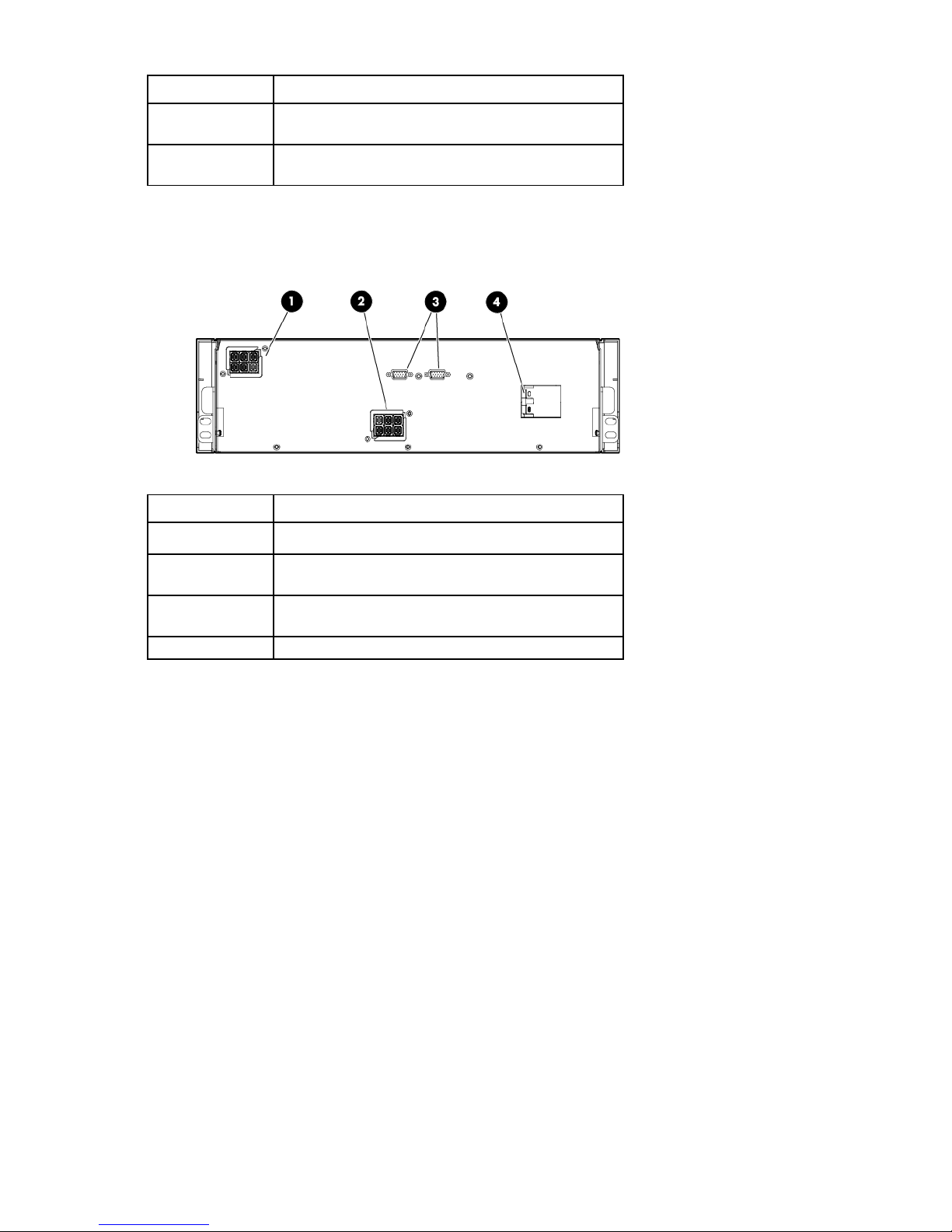

3U battery pack rear panel

Item Description

1

2

3

4

Connection for a DC to DC power cable to the power unit

Connection for a DC to DC power cable to the battery

pack

DB-15 ports for CAN Bus cables for battery pack

communication

Circuit breaker switch

Power unit and battery pack configurations

The DirectFlow UPS can be configured in the following ways:

• DirectFlow power unit without any battery packs

The power unit can work as a standalone line conditioner, or active filter, that mitigates harmonics and

power factor for the input AC line that supplies utility or generator power. To set the power unit active

current correction (ACC) options, see the "UPS menu options (on page 73)."

A configuration without battery packs does not supply power for extended runtime.

• DirectFlow power unit with one battery pack

Overview 15

Page 16

o 3U DirectFlow Battery Pack

o 1U DirectFlow Battery Pack

• DirectFlow power unit with two battery packs in series

The battery packs must be the same rack unit height and battery type; for instance, the power unit could

connect to a 3U lead acid battery pack connected in series to a 3U lead acid battery pack.

Overview 16

Page 17

o Two 3U DirectFlow Battery Packs

o Two 1U DirectFlow Battery Packs

Overview 17

Page 18

Installation

A risk of personal injury from electric shock and hazardous energy levels exists. The

Precautions

See the complete regulatory compliance notices in Safety and Compliance Information for Server, Storage,

Power, Networking, and Rack Products on the HP website

(http://www.hp.com/support/Safety-Compliance-EnterpriseProducts). In addition, follow the safety

precautions that are specific to this device.

Save these instructions. This document contains important safety instructions that should be followed during

installation, operation, and maintenance of the UPS and batteries.

100 kg

220 lb

12 kg

26.5 lb

WARNING: A risk of personal injury or damage to the equipment exists. Uneven loading of

equipment in the rack might cause the rack to become unstable. Install the heavier components

first, and then continue to populate the rack from the bottom to the top.

WARNING:

installation of options and routine maintenance and service of this product must be performed by

individuals who are knowledgeable about the procedures, precautions, and hazards associated

with AC power products.

WARNING: Contact with any part of a grounded battery can result in electrical shock. Shock risk

is reduced if grounds are removed during installation and maintenance.

This symbol indicates that the power unit exceeds the recommended weight for one

individual to handle safely. Weight for each power unit is:

• R12000DF—16 kg (35.2 lb)

• R18000DF—20.87 kg (46 lb)

WARNING: To reduce the risk of personal injury or damage to the equipment, observe

local occupational health and safety requirements and guidelines for manual material

handling.

This symbol indicates that the 3U DirectFlow Battery Pack exceeds the recommended

weight for one individual to handle safely.

WARNING: To reduce the risk of personal injury or damage to the equipment, observe

local occupational health and safety requirements and guidelines for manual material

handling.

This symbol indicates that the 1U DirectFlow Battery Pack exceeds the recommended

weight for one individual to handle safely.

WARNING: To reduce the risk of personal injury or damage to the equipment, observe

local occupational health and safety requirements and guidelines for manual material

handling.

Important device safety information

Installation 18

Page 19

WARNING: To reduce the risk of fire, only connect unit input to a circuit provided with branch

The rating label on the device provides the class (A or B) of the equipment. Class

B devices have a Federal Communications Commission (FCC) logo or FCC ID on the label. Class

circuit overcurrent protection for 30 A rating in accordance with the National Electric Code,

ANSI/NFPA 70.

Disconnect the charging source prior to connecting or disconnecting battery terminals.

Determine if the battery is inadvertently grounded. If inadvertently grounded, remove the source

from the ground.

CAUTION: The DirectFlow UPS is intended to supply three-phase linear/PFC loads only.

IMPORTANT:

A devices do not have an FCC logo or FCC ID on the label. After determining the class of the

device, see the complete regulatory compliance notices in Safety and Compliance Information for

Server, Storage, Power, Networking, and Rack Products on the HP website

(http://www.hp.com/support/Safety-Compliance-EnterpriseProducts).

Preparing to install the hardware

To prepare for the hardware installation:

1. Ensure the necessary tools and materials (on page 19) are available.

2. Select a site.

3. Ready the equipment for installation in the rack.

Tools and materials

The following tools are required for installation:

• Phillips screwdriver

• 10-mm hex-nut driver

The following items are supplied with the rack:

• Screws

• Hex nuts

• Cage nuts

• Cage nut-fitting tool

To download the latest software version, see the HP website (http://www.hp.com/go/rackandpower).

Additional materials might be supplied depending upon the optional devices included. For a specific list of

materials, see the install card for each device.

Selecting a site

WARNING: To prevent fire or electric shock, install the unit in a temperature- and

When selecting a site, consider the following factors:

humidity-controlled indoor environment, free of conductive contaminants.

Installation 19

Page 20

• Elevated operating ambient temperature—If the equipment is installed in a closed or multi-unit rack

assembly, the operating ambient temperature of the rack environment might be greater than room

ambient temperature. Install the equipment in an environment compatible with the operating

temperature.

• Reduced air flow—In the rack, the rate of air flow required for safe operation of the equipment must not

be compromised.

• Circuit overloading—Consideration should be given to the connection of the equipment to the supply

circuit and the effect that overloading of the circuits might have on overcurrent protection and supply

wiring. Appropriate consideration of equipment nameplate ratings should be used when addressing

this concern.

• Reliable earthing—Reliable earthing of rack-mounted equipment should be maintained. Particular

attention should be given to supply connections other than direct connections to the branch circuit, such

as the use of power strips.

• Electrical requirements—All models require a dedicated (unshared) branch circuit, including an

unshared grounding conductor, that is suitably rated for the specific UPS as stated in "UPS input

specifications (on page 114)."

Readying the equipment

1. Check the battery recharge date specified on the label that is affixed to the shipping carton.

IMPORTANT: Do not use the battery if the recharge date has passed. If the date on the battery

recharge date label has passed without the battery being recharged, contact an HP authorized

2. Transport the packaged unit to its installation location.

3. Unpack the equipment near the rack where the unit will be assembled.

service representative for directions.

CAUTION: Always plan the rack installation so that the heaviest item is on the bottom of the rack.

Install the heaviest item first, and continue to populate the rack from the bottom to the top.

Installing rack rails

IMPORTANT: For rack shipping or relocation of any of the components, ensure hex nuts and

shipping brackets are used with the rail supports. See the optional shipping steps in the rack rail

Reinforcement plates are required for rails that support the 2U power unit and 3U battery packs. Plates are

not needed for those rails that support the 1U power unit or 1U battery packs.

Installing rack rails for the 1U power unit

and component installation sections.

Installation 20

Page 21

WARNING: To reduce the risk of personal injury or damage to the equipment, be sure that:

• The leveling feet are extended to the floor.

• The full weight of the rack rests on the leveling feet.

• The stabilizing feet are attached to the rack if it is a single-rack installation.

• The racks are coupled together in multiple-rack installations.

• Only one component is extended at a time. A rack may become unstable if more than one

component is extended for any reason.

IMPORTANT: Mounting hardware for square- and round-holed racks is included in the battery

pack kit.

To install the mounting rails for the 1U DirectFlow Battery Pack:

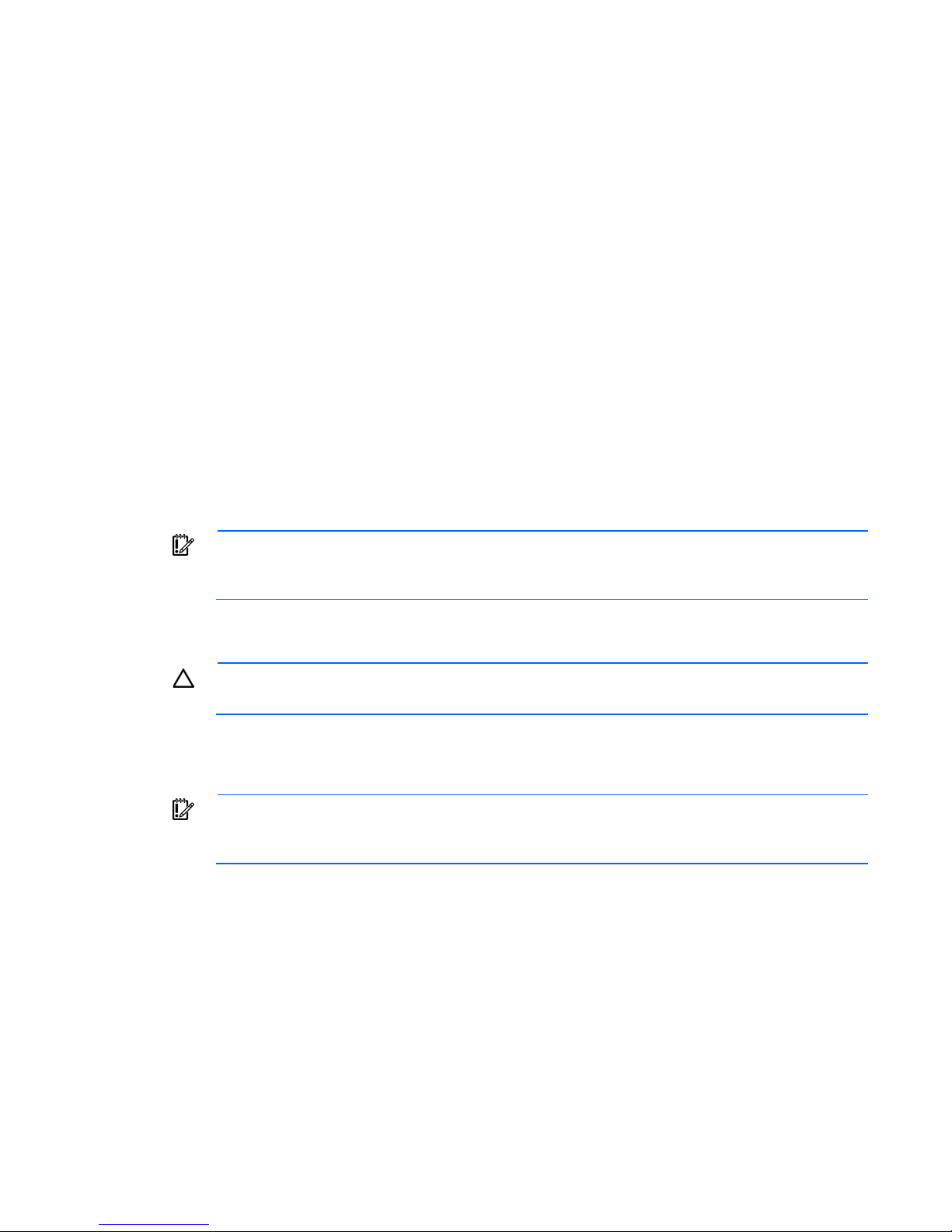

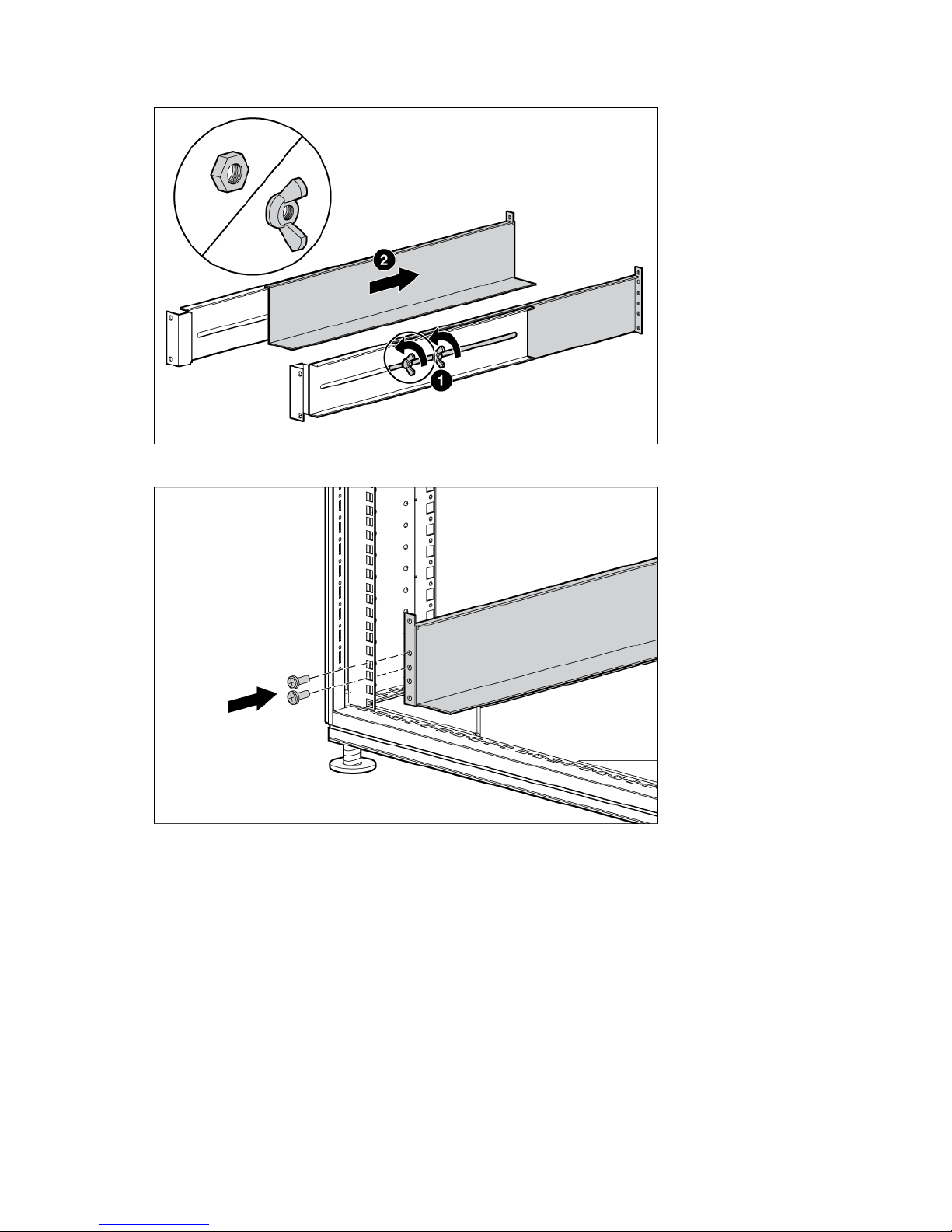

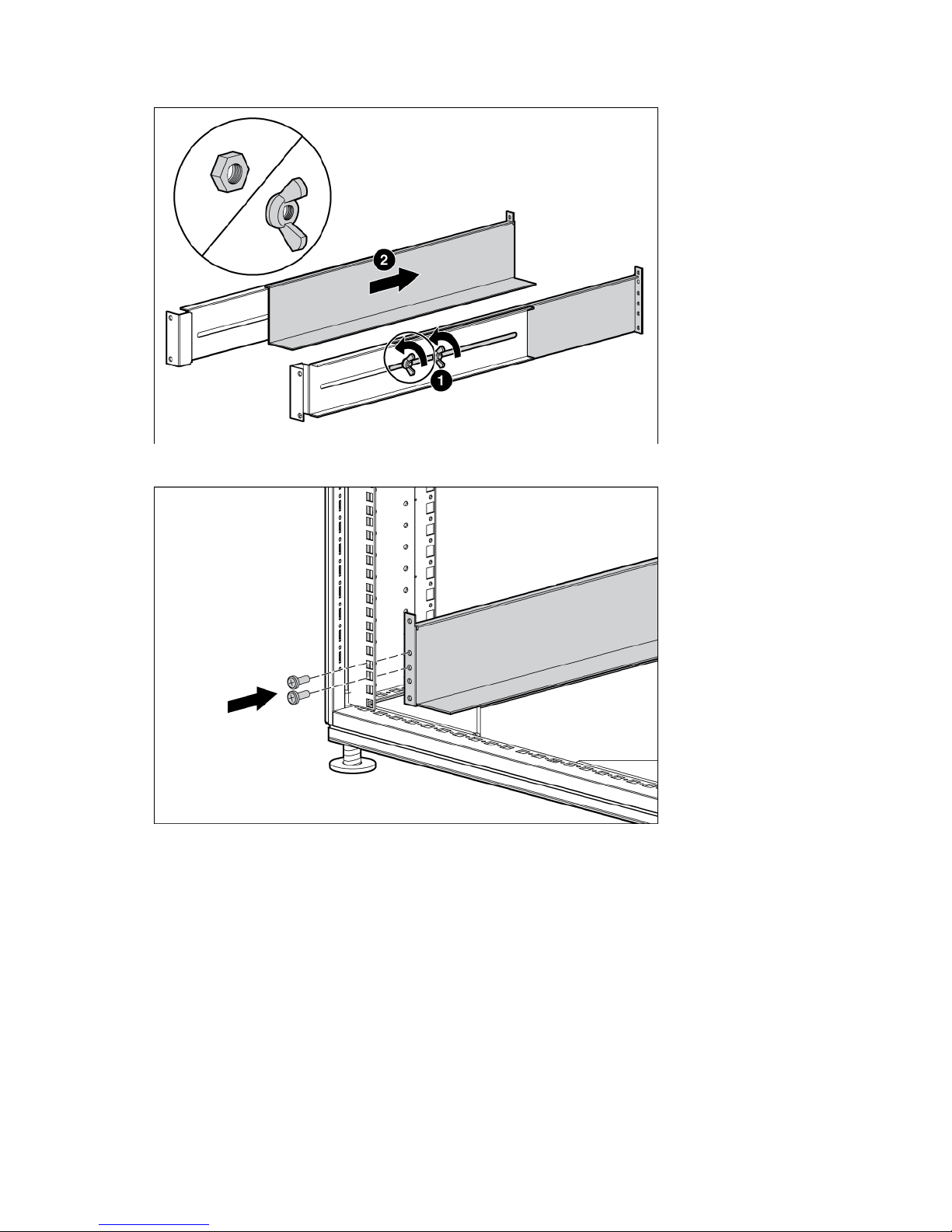

1. Loosen the wing nuts or hex nuts, and then extend the brackets to the desired length.

For rack shipping or relocation, ensure hex nuts are used in the rail supports.

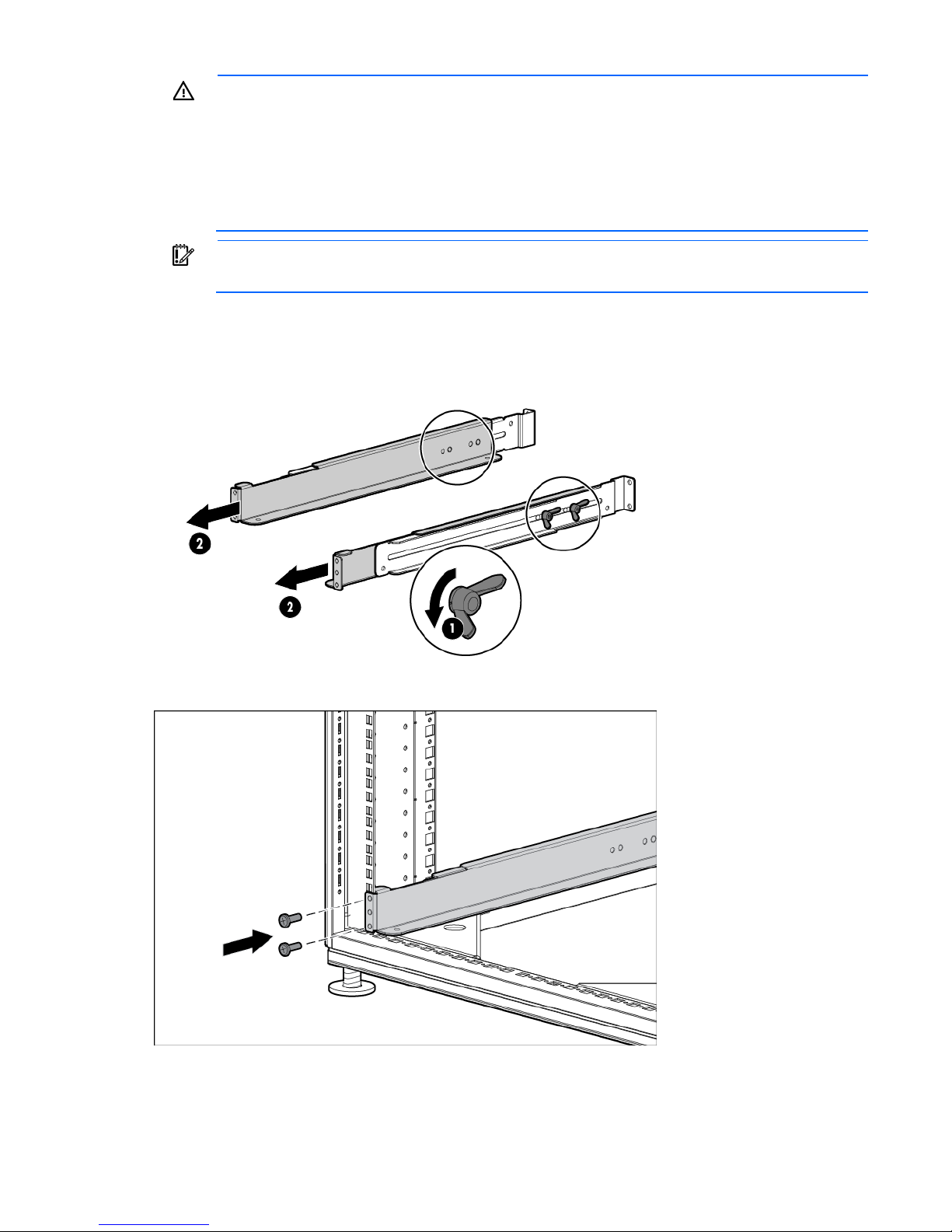

2. Install the screws through the rack into the mounting rail and the front of each mounting bracket.

Installation 21

Page 22

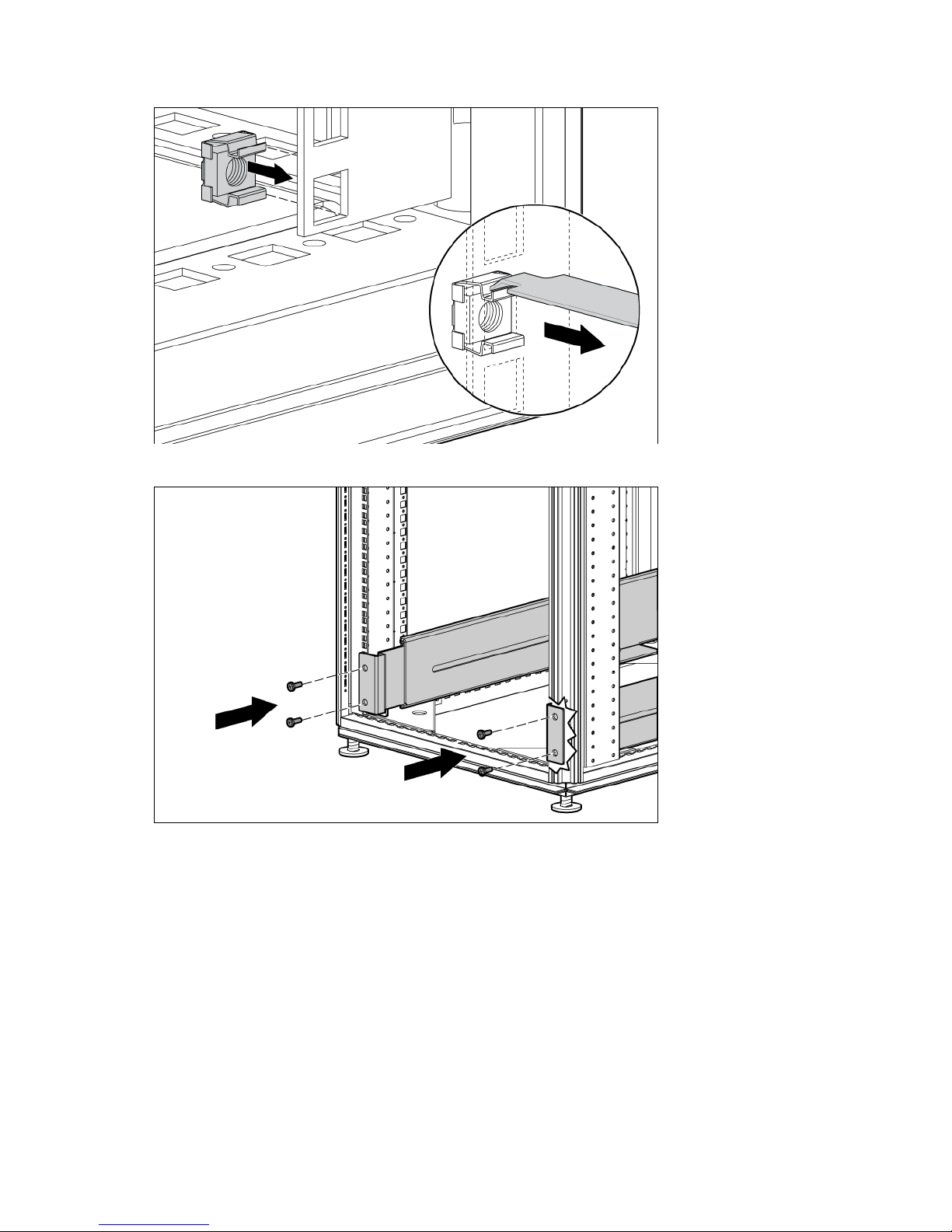

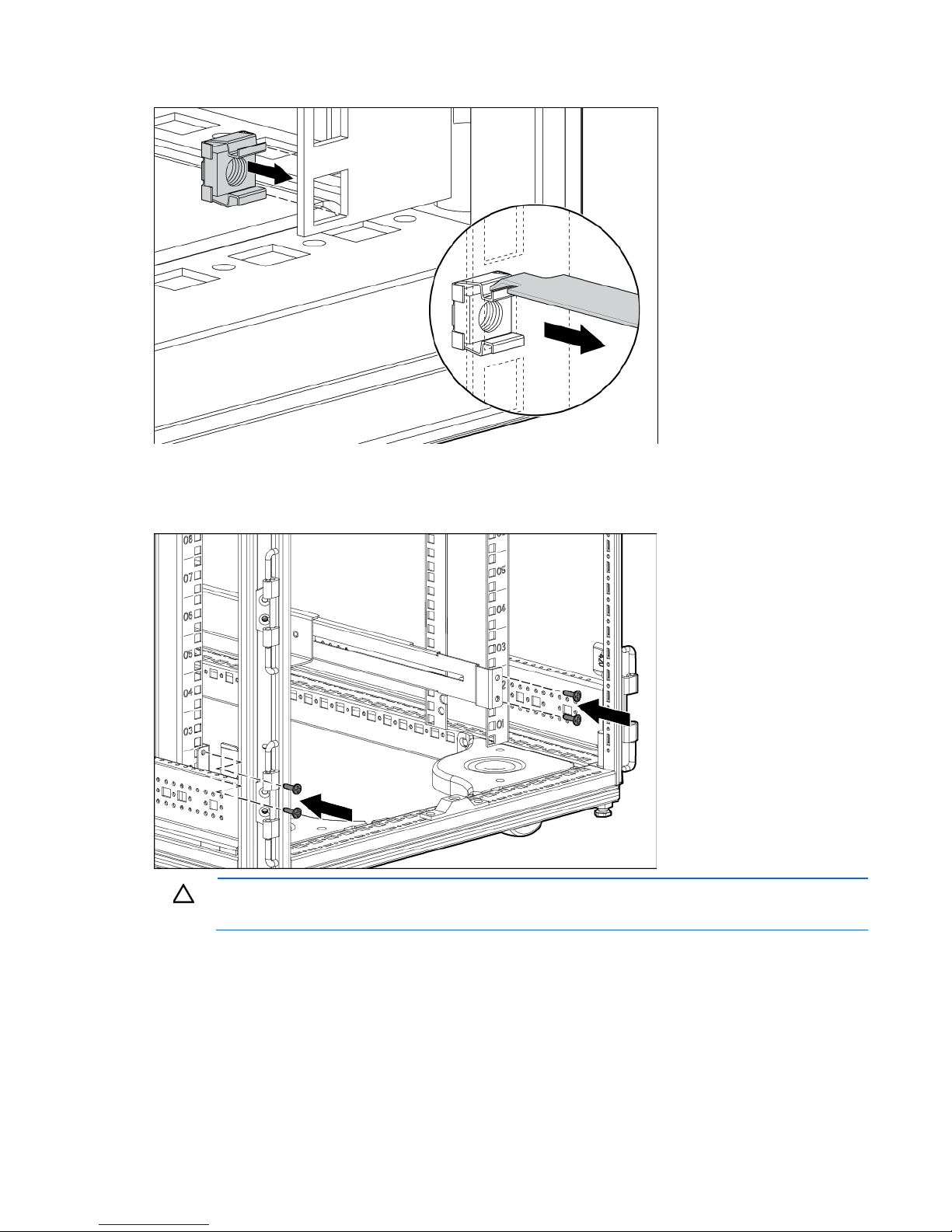

3. Install cage nuts or clip nuts into the rear of the rack.

4. Do one of the following:

o For a stationary rack installation, install the screws through the mounting rail into the cage nuts or

clip nuts.

CAUTION: When shipping or relocating a rack with installed components, always use the

shipping bracket to secure the unit.

Installation 22

Page 23

o For rack shipping or relocation, install the shipping brackets at the rear of each rail.

5. Tighten the wing nuts or hex nuts.

Installing rack rails for the 2U power unit

WARNING: To reduce the risk of personal injury or damage to the equipment, be sure that:

• The leveling feet are extended to the floor.

• The full weight of the rack rests on the leveling feet.

• The stabilizing feet are attached to the rack if it is a single-rack installation.

• The racks are coupled together in multiple-rack installations.

• Only one component is extended at a time. A rack may become unstable if more than one

component is extended for any reason.

IMPORTANT: If preparing the rails for integrated shipping, follow the same instructions as in

Installing the power unit (on page 47).

IMPORTANT: Mounting hardware for square- and round-holed racks is included in the UPS kit.

Installation 23

Page 24

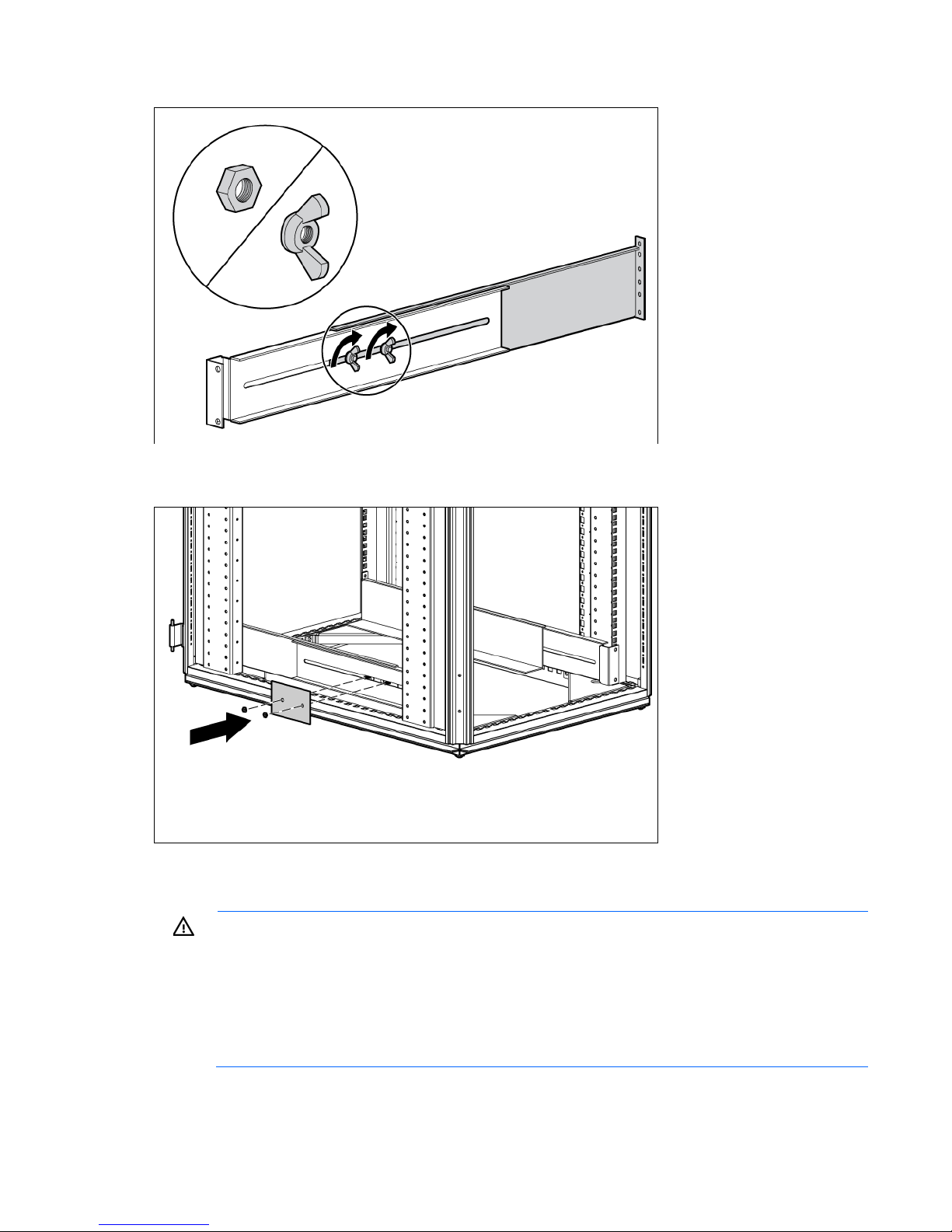

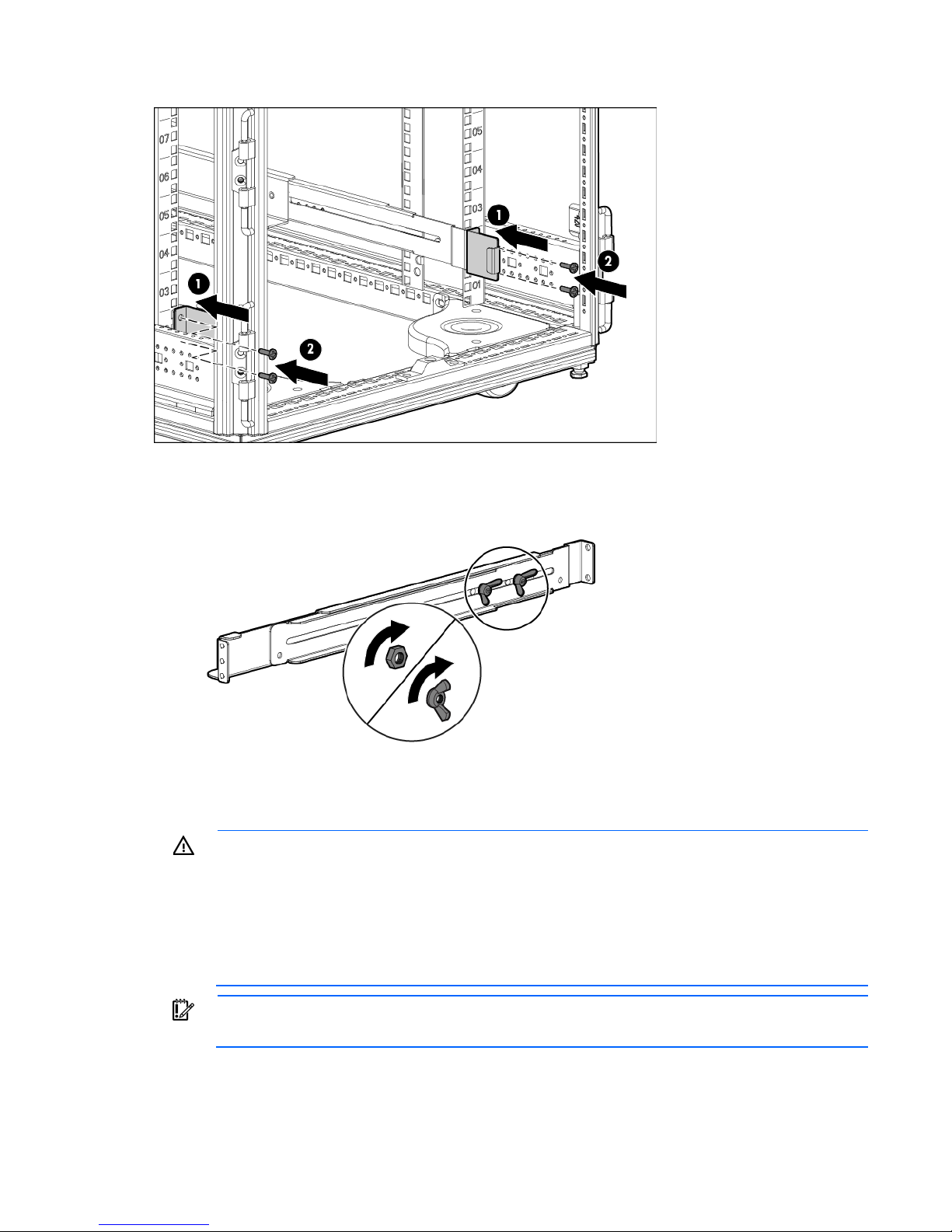

1. Loosen the wing nuts or hex nuts, and then extend the brackets to the desired length.

2. Insert screws through the rack into the mounting rail and the front of each mounting bracket.

Installation 24

Page 25

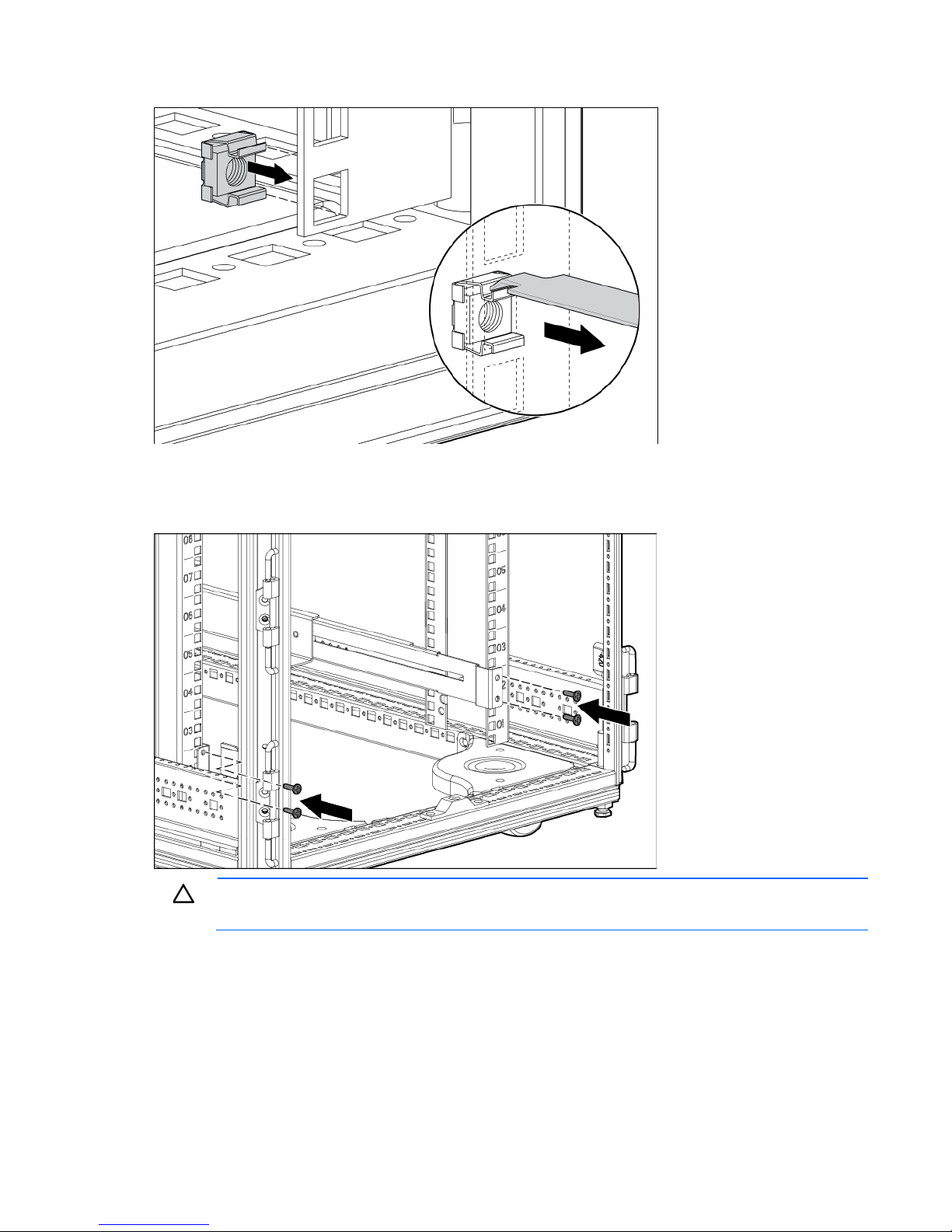

3. Install cage nuts or clip nuts into the rear of the rack.

4. Insert screws through the mounting rail into the cage nuts or clip nuts.

Installation 25

Page 26

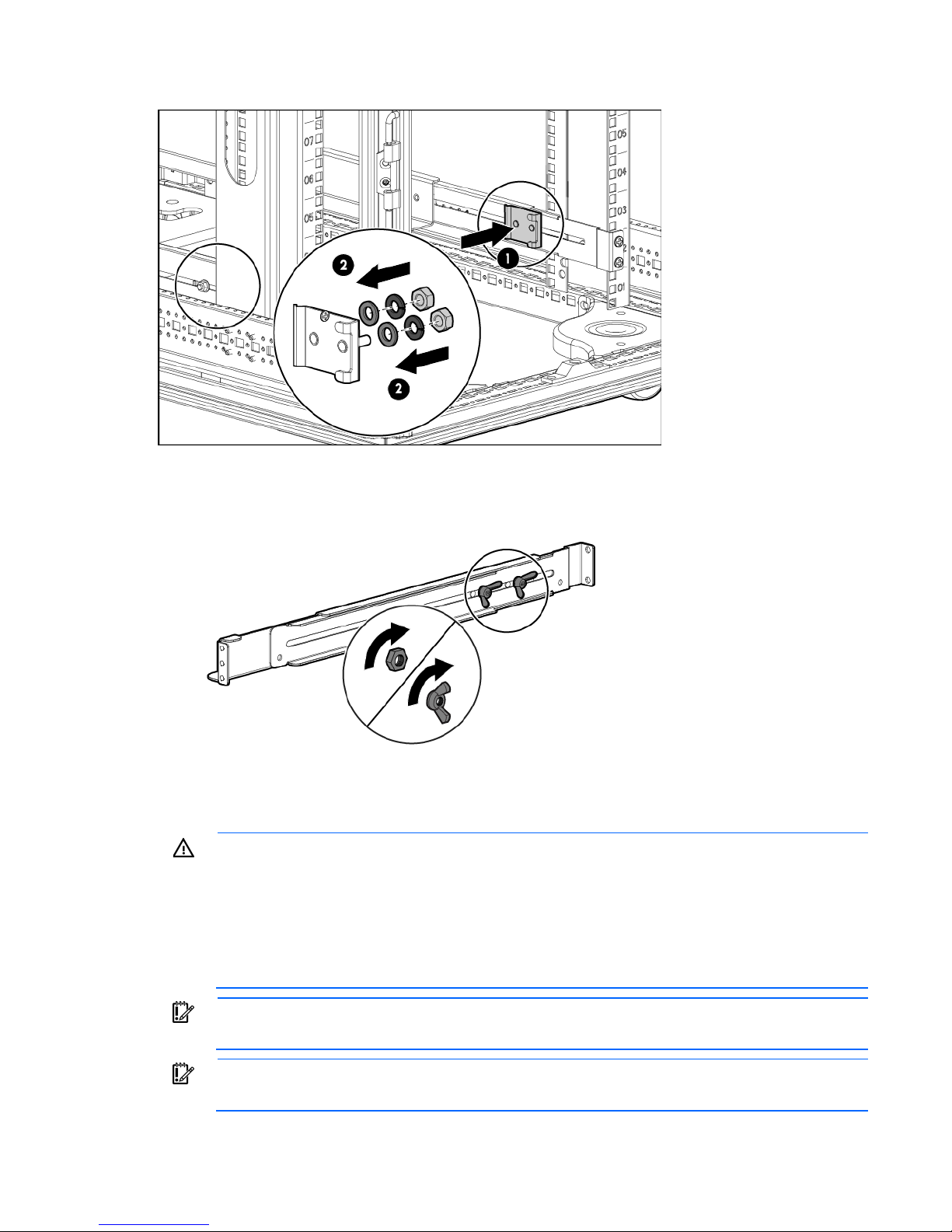

5. Tighten the wing nuts or hex nuts.

6. Install the reinforcement plates using hex nuts. Wait until the unit is installed and the brackets are

adjusted before tightening the nuts.

Installing rack rails for the 1U battery pack

WARNING: To reduce the risk of personal injury or damage to the equipment, be sure that:

• The leveling feet are extended to the floor.

• The full weight of the rack rests on the leveling feet.

• The stabilizing feet are attached to the rack if it is a single-rack installation.

• The racks are coupled together in multiple-rack installations.

• Only one component is extended at a time. A rack may become unstable if more than one

component is extended for any reason.

Installation 26

Page 27

IMPORTANT: Mounting hardware for square- and round-holed racks is included in the battery

pack kit.

To install the mounting rails for the 1U DirectFlow Battery Pack:

1. Loosen the wing nuts or hex nuts, and then extend the brackets to the desired length.

For rack shipping or relocation, ensure hex nuts are used in the rail supports.

2. Install the screws through the rack into the mounting rail and the front of each mounting bracket.

Installation 27

Page 28

3. Install cage nuts or clip nuts into the rear of the rack.

4. Do one of the following:

o For a stationary rack installation, install the screws through the mounting rail into the cage nuts or

clip nuts.

CAUTION: When shipping or relocating a rack with installed components, always use the

shipping bracket to secure the unit.

Installation 28

Page 29

o For rack shipping or relocation, install the shipping brackets at the rear of each rail.

5. Tighten the wing nuts or hex nuts.

Installing rack rails for the 3U battery pack

WARNING: To reduce the risk of personal injury or damage to the equipment, be sure that:

• The leveling feet are extended to the floor.

• The full weight of the rack rests on the leveling feet.

• The stabilizing feet are attached to the rack if it is a single-rack installation.

• The racks are coupled together in multiple-rack installations.

• Only one component is extended at a time. A rack may become unstable if more than one

component is extended for any reason.

To install the mounting rails for the 3U DirectFlow Battery Pack:

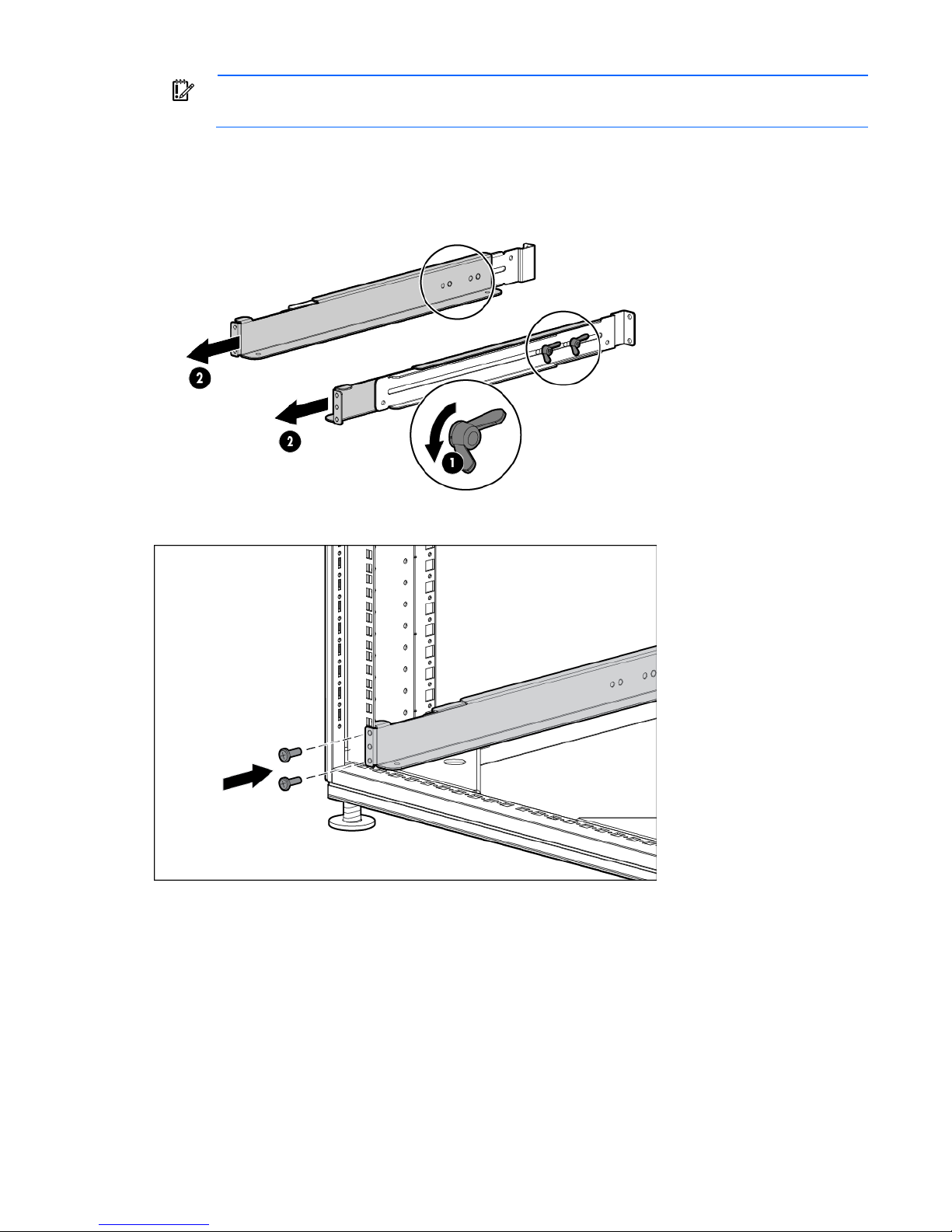

1. Loosen the wing nuts or hex nuts, and then extend the brackets to the desired length.

IMPORTANT: Mounting hardware for square- and round-holed racks is included in the battery

pack kit.

Installation 29

Page 30

For rack shipping or relocation, ensure hex nuts are used in the rail supports.

2. Install screws through the rack into the mounting rail and the front of each mounting bracket.

Installation 30

Page 31

3. Install cage nuts or clip nuts into the rear of the rack.

4. Do one of the following:

o For stationary rack installation, install the screws through the mounting rail into the cage nuts or clip

nuts.

CAUTION: When shipping or relocating a rack with installed components, always use the

shipping bracket to secure the unit.

Installation 31

Page 32

o For rack relocation or shipping, install the shipping brackets at the rear of each rail.

5. Tighten the wing nuts or hex nuts.

Installation 32

Page 33

6. Install the reinforcement plates using hex nuts. Wait until the unit is installed and the brackets are

adjusted before tightening the nuts.

Installing battery packs

The HP DirectFlow Battery Pack can be installed to provide extended run-time. The HP DirectFlow VRLA

Battery Pack (3U) consists of a four-battery string in a 3U chassis. The HP R12000 and R18000 DirectFlow

1U Lithium-ion Battery Packs consist of an eight lithium-ion battery string in a 1U chassis. Each battery pack

can connect directly to a power unit and optionally to another battery pack that is the same battery type and

rack unit (U) height. Up to two battery packs can be connected in series.

Powering down the UPS

Before installing any battery packs, see "Powering down the UPS (on page 33)."

To power down an existing UPS configuration that includes battery packs, see "Powering down the UPS and

battery packs (on page 80)."

To power down the UPS:

1. Power down all load devices.

2. Press the ESC button for 3 seconds, and then press the Enter button to place the UPS in Bypass mode.

3. Disconnect the power unit from utility power.

4. Wait at least 5 minutes for the UPS internal circuitry to discharge and power down.

Installing the 1U battery pack

Before installing the unit, review and adhere to all warnings provided in "Precautions (on page 18)."

WARNING: To reduce the risk of personal injury or equipment damage due to weight

considerations, first load the empty battery pack chassis into the rack, and then install the battery

Mount the battery pack directly below the UPS without a U gap.

modules in the chassis.

Installation 33

Page 34

To install the battery pack:

1. Power down the UPS before installing the battery packs. For more information, see "Powering down the

UPS (on page 33)."

2. Install the mounting rails.

3. With one person on each side of the carton, lift the chassis and lower it to the floor in front of the rack.

4. With one person on each side, lift the chassis to rail level and slide the chassis on the mounting rails.

For shipping or relocating a populated rack, secure the rear of the chassis to the rails by mating the

chassis slots to the shipping bracket tabs.

5. Attach the chassis to the rack using the supplied screws.

To complete the installation, see the following instructions:

1. Installing the lithium-ion batteries (on page 35)

2. Attaching the 1U battery pack front bezel (on page 35)

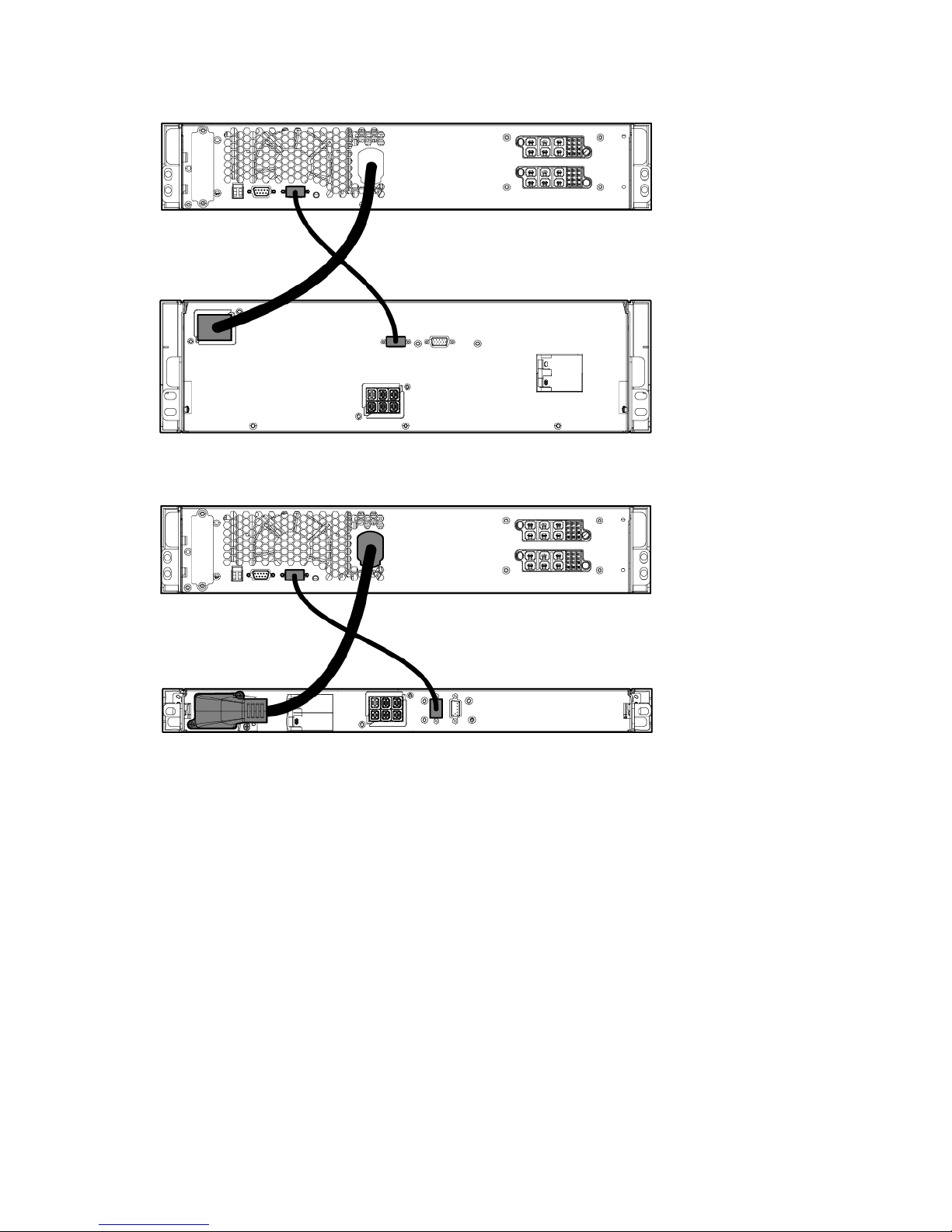

3. Connecting the 1U battery pack to the 1U power unit (on page 35)

4. Connecting the 1U battery pack to the 2U power unit (on page 37)

5. Charging lithium-ion batteries (on page 39)

Installation 34

Page 35

Installing the lithium-ion batteries

Attaching the 1U battery pack front bezel

Connecting the 1U battery pack to the 1U power unit

IMPORTANT: Use only the Phillips 6-32, .375 screws provided in the kit to secure the

connection. The UPS does not recognize the battery pack if the screws are not tightened.

Installation 35

Page 36

To connect the battery pack to the power unit from the rear panels:

1. Switch the circuit breaker on the battery pack left to the Off position.

2. Connect the power cable on the power unit to the power connector on the battery pack, and then secure

the cable with the Phillips 6-32, .375 screws.

3. Connect the CAN bus communication cable from the DB-15 connector on the power unit to the DB-15

connector on the battery pack.

4. Switch the circuit breaker on the battery pack right to the On position.

To install a second battery pack that is the same battery type and rack U height:

1. Verify that the circuit breaker on the battery pack is in the left, Off position.

Installation 36

Page 37

2. Connect the DC to DC power cable from the first battery pack connector to the second battery pack

connector.

Up to two packs can be connected to the power unit.

3. Connect the CAN bus communication cable from the first battery pack to the second battery pack.

4. Switch the circuit breaker on the battery pack right to the On position.

The DC to DC power cable is a UPS option required for connecting battery packs; the cable can be ordered

Connecting the 1U battery pack to the 2U power unit

on the HP website (http://www.hp.com/go/rackandpower) (HP part number AF497A).

IMPORTANT: Use only the Phillips 6-32, .375 screws provided in the kit to secure the

connection. The UPS does not recognize the battery pack if the screws are not tightened.

To connect the battery pack to the power unit from the rear panels:

1. Switch the circuit breaker on the battery pack left to the Off position.

2. Connect the power cable on the power unit to the power connector on the battery pack.

Installation 37

Page 38

Pull back the retaining clip next to the power connector on the battery back in order to connect or

disconnect the power cable.

3. Connect the CAN bus communication cable from the DB-15 connector on the power unit to the DB-15

connector on the battery pack.

4. Switch the circuit breaker on the battery pack right to the On position.

To install a second battery pack that is the same battery type and rack U height:

1. Verify that the circuit breaker on the battery pack is in the left, Off position.

2. Connect the DC to DC power cable from the first battery pack connector to the second battery pack

connector.

Up to two packs can be connected to the power unit.

Installation 38

Page 39

3. Connect the CAN bus communication cable from the first battery pack to the second battery pack.

4. Switch the circuit breaker on the battery pack right to the On position.

The DC to DC power cable is a UPS option required for connecting battery packs; the cable can be ordered

on the HP website (http://www.hp.com/go/rackandpower) (HP part number AF497A).

Charging lithium-ion batteries

To connect the power unit to a grounded utility power outlet, see "Installing the R12000DF power module (on

page 50)." When the UPS is in AC mode, the power unit automatically begins charging the batteries. Allow

the batteries to charge for at least 5 hours.

To extend the useful life of the batteries through good maintenance practices, see "Battery care and storage

guidelines (on page 80)."

Installing the 3U battery pack

Before installing the unit, review and adhere to all warnings provided in "Precautions (on page 18)."

WARNING: To reduce the risk of personal injury or equipment damage due to weight

considerations, first load the empty battery pack chassis into the rack, and then install the battery

Mount the battery pack directly below the UPS without a U gap.

To install the battery pack:

1. Install the mounting rails including any reinforcement plates to support the battery packs. For more

2. Power down the power unit before installing the battery packs. For more information, see "Powering

modules in the chassis.

information, see "Installing rack rails (on page 20)."

down the UPS (on page 33).

3. With one person on each side of the carton, lift the chassis and lower it to the floor in front of the rack.

Installation 39

Page 40

4. Install the mounting ears on the chassis using the screws provided.

5. With one person on each side, lift the chassis to rail level and slide the chassis on the mounting rails.

For shipping or relocating a populated rack, secure the rear of the chassis to the rails by mating the

chassis slots to the shipping bracket tabs.

6. Attach the chassis to the rack using the supplied screws.

To complete the installation, see the following instructions:

1. Removing the 3U battery bracket (on page 41)

2. Installing the lead acid batteries (on page 41)

3. Replacing the 3U battery bracket (on page 42)

4. Attaching the 3U front bezel (on page 42)

5. Connecting the 3U battery pack to the 1U power unit (on page 42)

6. Connecting the 3U battery pack to the 2U power unit (on page 45)

7. Charging lead acid batteries

Installation 40

Page 41

Removing the 3U battery bracket

Installing the lead acid batteries

WARNING: To prevent personal injury, prepare the area and observe all materials-handling

procedures when transporting a battery module. Battery modules weigh 20 kg (44 lb).

Installation 41

Page 42

Replacing the 3U battery bracket

Attaching the 3U front bezel

Connecting the 3U battery pack to the 1U power unit

IMPORTANT: Use only the Phillips 6-32, .375 screws provided in the kit to secure the

connection. The UPS does not recognize the battery pack if the screws are not tightened.

Installation 42

Page 43

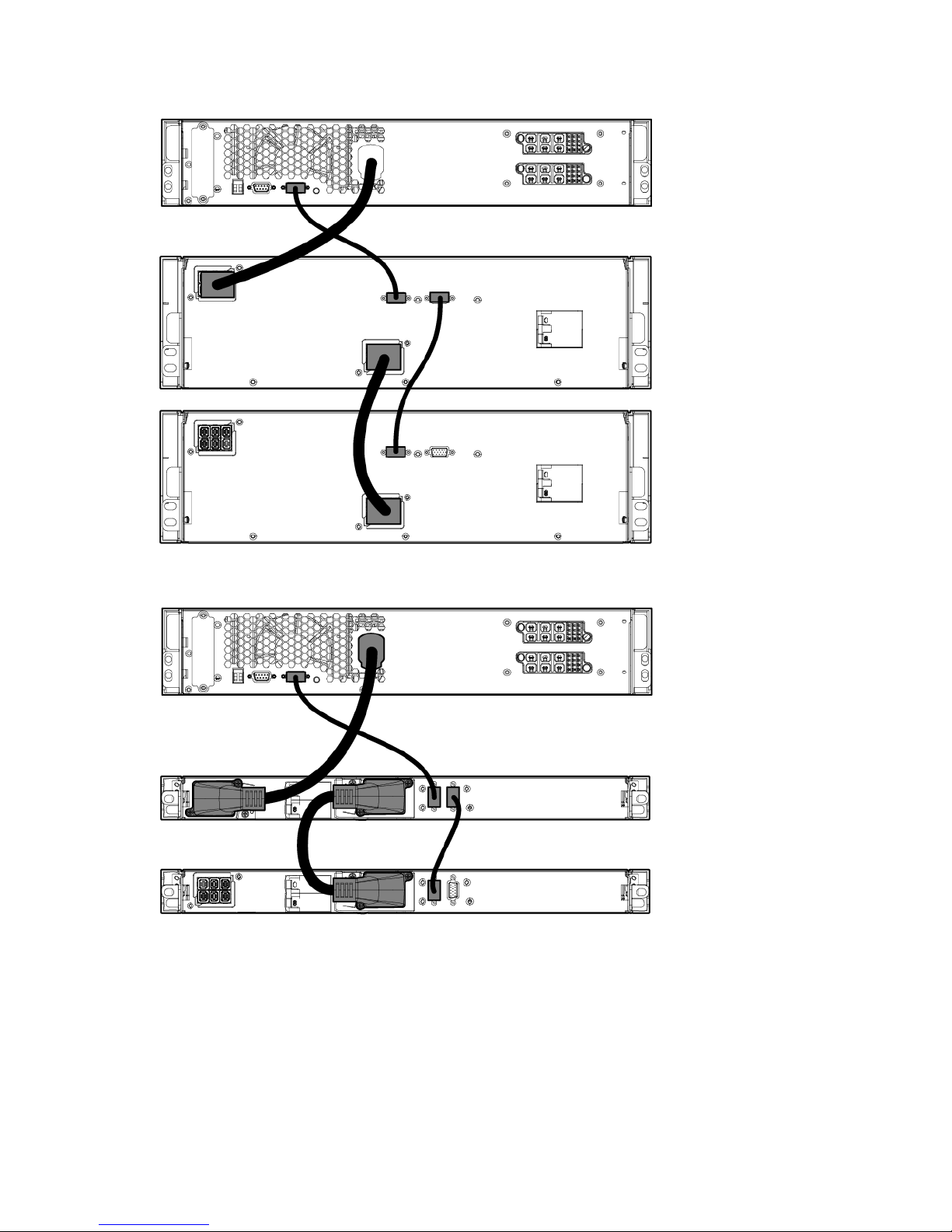

To connect the battery pack to the UPS from the rear panels:

1. Switch the circuit breaker on the battery pack left to the Off position.

2. Connect the power cable on the UPS to the power connector on the battery pack.

Installation 43

Page 44

3. Connect the CAN bus communication cable from the DB-15 connector on the UPS to the DB-15

connector on the battery pack.

4. Switch the circuit breaker on the battery pack right to the On position.

To install a second battery pack that is the same battery type and rack U height:

1. Verify that the circuit breaker on the battery pack is in the left, Off position.

2. Connect the DC to DC power cable from the first battery pack connector to the second battery pack

connector.

Up to two packs can be connected to the UPS.

3. Connect the CAN bus communication cable from the first battery pack to the second battery pack.

Installation 44

Page 45

4. Switch the circuit breaker on the battery pack right to the On position.

The DC to DC power cable is a UPS option required for connecting battery packs. The cable can be ordered

on the HP website (http://www.hp.com/go/rackandpower) (HP part number AF497A).

Connecting the 3U battery pack to the 2U power unit

IMPORTANT: Use only the Phillips 6-32, .375 screws provided in the kit to secure the

connection. The UPS does not recognize the battery pack if the screws are not tightened.

To connect the battery pack to the UPS from the rear panels:

1. Switch the circuit breaker on the battery pack left to the Off position.

2. Connect the power cable on the UPS to the power connector on the battery pack.

Installation 45

Page 46

3. Connect the CAN bus communication cable from the DB-15 connector on the UPS to the DB-15

connector on the battery pack.

4. Switch the circuit breaker on the battery pack right to the On position.

To install a second battery pack that is the same battery type and rack U height:

1. Verify that the circuit breaker on the battery pack is in the left, Off position.

2. Connect the DC to DC power cable from the first battery pack connector to the second battery pack

connector.

Up to two packs can be connected to the UPS.

3. Connect the CAN bus communication cable from the first battery pack to the second battery pack.

Installation 46

Page 47

4. Switch the circuit breaker on the battery pack right to the On position.

The DC to DC power cable is a UPS option required for connecting battery packs. The cable can be ordered

on the HP website (http://www.hp.com/go/rackandpower) (HP part number AF497A).

Charging lead acid batteries

To connect the power unit to a grounded utility power outlet, see "Installing the R18000DF power module (on

page 56)." When the UPS is in AC mode, the power unit automatically begins charging the batteries. Allow

the UPS batteries to charge for 24 hours.

For more information on extending the useful life of the batteries through good maintenance practices, see

"Battery care and storage guidelines (on page 80)."

Installing the power unit

The power unit can be installed with either an R12000DF or an R18000DF configuration.

Installing the R12000DF power unit

Before installing the unit, review and adhere to all warnings provided in "Precautions (on page 18)."

To install the power unit in the rack:

1. Install the mounting rails.

CAUTION: When shipping or relocating a rack with installed components, always use the

shipping bracket to secure the unit.

For shipping or relocation, secure the rear of the power unit to the rails using the shipping brackets. Be

sure that each shipping bracket overlaps the corresponding tab on the power unit chassis.

2. With one person on each side of the carton, lift the chassis and lower it to the floor in front of the rack.

Installation 47

Page 48

3. Install the mounting ears on the chassis using the screws provided.

4. With one person on each side, lift the chassis to rail level and slide the chassis on the mounting rails.

5. Attach the chassis to the rack using the supplied screws.

Installation 48

Page 49

Attaching the power unit front bezel

Connecting the R12000DF REPO port

WARNING: To meet the requirements stated in NEC (NFPA 70) Articles 645-10 and 645-11, a

UPS installed in a computer equipment room must be connected to a REPO circuit.

IMPORTANT: The remote switch must be in the Off (open) position to enable power to the output

receptacles.

Separate wire pairs should be attached to a single, normally open contact in a parallel connection. HP

recommends these practices:

• Choose different colors for the positive and negative wires.

• Use stranded, non-shielded wire (AWG #22 - #18, or the equivalent).

• Wire the connector block before powering up the power unit to avoid unintentionally tripping the power

unit.

Installation 49

Page 50

• Secure the REPO wires tightly to the rack and the rear of the power unit with tie wraps and tie wrap

blocks after installing the power unit in the rack.

Connecting the R12000DF serial communications port

To flash the UPS firmware, or to communicate with another device, connect a computer interface cable

between the power unit serial communications port and the serial port on a host computer or device.

Installing the R12000DF power module

When configuring a 1U power unit and the HP DirectFlow Input/Output Power Module with a 1U battery

pack, install the power unit and the power module above the battery pack.

Installation 50

Page 51

To install the power module in the power unit:

1. Connect the power module, and then tighten the screws.

2. Install the hold down bracket, and then tighten the screws.

Installation 51

Page 52

3. Ensure that the switch is in the normal, down position.

Before connecting any devices to the UPS, see "Connecting devices (on page 57)."

Installing the R18000DF power unit

Before installing the unit, review and adhere to all warnings provided in "Precautions (on page 18)."

To install the power unit in the rack:

1. Install the mounting rails.

CAUTION: When shipping or relocating a rack with installed components, always use the

shipping bracket to secure the unit.

For shipping or relocation, attach the shipping brackets at the rear of each rail.

2. With one person on each side of the carton, lift the chassis and lower it to the floor in front of the rack.

Installation 52

Page 53

3. Install the mounting ears on the chassis using the screws provided.

4. With one person on each side, lift the chassis to rail level and slide the chassis on the mounting rails.

For shipping or relocation, secure the rear of the power unit to the rails using the shipping brackets. Be

sure that each shipping bracket overlaps the corresponding tab on the power unit chassis.

5. Attach the chassis to the rack using the supplied screws.

Installation 53

Page 54

Attaching the power unit front bezel

Connecting the R18000DF REPO port

WARNING: To meet the requirements stated in NEC (NFPA 70) Articles 645-10 and 645-11, a

UPS installed in a computer equipment room must be connected to a REPO circuit.

IMPORTANT: The remote switch must be in the Off (open) position to enable power to the output

receptacles.

Separate wire pairs should be attached to a single, normally open contact in a parallel connection. HP

recommends these practices:

• Choose different colors for the positive and negative wires.

• Use stranded, non-shielded wire (AWG #22 - #18, or the equivalent).

• Wire the connector block before powering up the power unit to avoid unintentionally tripping the power

unit.

Installation 54

Page 55

• Secure the REPO wires tightly to the rack and the rear of the power unit with tie wraps and tie wrap

blocks after installing the power unit in the rack.

Connecting the R18000DF serial communications port

To flash the UPS firmware, or to communicate with another device, connect a computer interface cable

between the power unit serial communications port and the serial port on a host computer or device.

Installation 55

Page 56

Installing the R18000DF power module

To install the HP DirectFlow Input/Output Power Module in the power unit:

1. Connect the power module, and then tighten the screws.

2. Ensure that the switch is in the normal, down position.

Before connecting any devices to the UPS, see "Connecting devices (on page 57)."

Connecting the UPS to utility power

Installation 56

Page 57

WARNING: To prevent injury from electric shock or damage to the equipment:

• Plug the input line cord into a grounded (earthed) electrical outlet that is installed near the

equipment and is easily accessible.

• Do not disable the grounding plug on the input line cord. The grounding plug is an important

safety feature.

Connect the power unit to a grounded utility power outlet.

• Do not use extension cords.

Connecting devices

CAUTION: Do not plug laser printers into the UPS output receptacles. The instantaneous current

drawn by this type of printer can overload the UPS.

CAUTION: The DirectFlow UPS is intended to supply three-phase linear/PFC loads only.

Before connecting load devices to the UPS, verify the following:

• The ratings of the devices that will be connected do not exceed the UPS capacity, which will overload

the UPS

If the equipment rating is listed in amps, multiply the number of amps by the selected output voltage to

determine the VA.

• The load devices are linear/PFC loads

After verification, connect the device power cords to the UPS output receptacles.

Starting power to the load

Start power to the load by placing the UPS in AC mode.

IMPORTANT: AC power must be available the first time the UPS is started.

Continuing the installation of components

HP DirectFlow Battery Packs and the HP DirectFlow UPS Management Module card can be installed for

extended run-time and advanced battery management. To install these components, see the following

instructions:

• Installing battery packs (on page 33)

• Installing the Management Module card (on page 57)

For instructions about testing the REPO port function, see "Verifying the REPO port connection (on page 79)."

Installing the Management Module card

The HP DirectFlow UPS Management Module web interface allows remote monitoring and control of the HP

DirectFlow Power Unit, HP DirectFlow UPS Management Module card, and any HP DirectFlow Battery Packs

installed in the configuration. Power usage information is accessed through the network connector located on

Installation 57

Page 58

the front of the HP DirectFlow UPS Management Module card. Multiple devices can monitor the UPS over the

network connection. The Management Module card is designed specifically for the power unit. It is not

intended for installation in other UPS devices.

For information about configuring access from the HP DirectFlow UPS Management Module card to the web

interface, see "Accessing the Management Module (on page 63)."

For more information about accessing, signing in, and configuring the web interface software, see the HP

DirectFlow UPS Management Module User Guide on the HP website

(http://www.hp.com/support/DFUPS_MM_UG_en).

Installing the Management Module card in the 1U power unit

IMPORTANT: It is not necessary to power down the UPS before installing the Management

To install the card in the UPS:

1. Remove the two screws securing the cover plate on the power unit, and then slide the plate out.

Module card.

Installation 58

Page 59

2. Install the Management Module card along the alignment channels in the option slot.

3. If the UPS is powered up, check that the Management Module card is seated properly and receiving

power by verifying that the card's Power LED light is illuminated solid green.

Connecting the serial communications cable in the 1U power unit

Connect the serial port to configure or flash Management Module card firmware or to communicate to

another local device.

For the initial setup of the HP UPS DirectFlow Management Module web interface access to the management

module card, use a local host computer or device connected to the serial communication port. For details, see

"Accessing the Management Module (on page 63)."

Installation 59

Page 60

Connecting the network cable to the 1U power unit

Connect the Management Module card to a network or Internet connection with an RJ-45 Ethernet cable.

A network-connected computer can be used to login to the Management Module web interface for remote

access to the Management Module card and to view information about the DirectFlow UPS. To access the

Management Module web interface, see "Accessing the Management Module (on page 63)."

Installing the Management Module card in the 2U power unit

IMPORTANT: It is not necessary to power down the UPS before installing the Management

To install the card in the UPS:

1. Remove the two screws securing the cover plate on the power unit, and then slide the plate out.

Module card.

Installation 60

Page 61

2. Install the Management Module card along the alignment channels in the option slot.

3. If the UPS is powered up, check that the Management Module card is seated properly and receiving

power by verifying that the card's Power LED light is illuminated solid green.

Connecting the serial communications cable in the 2U power unit

Connect the serial port to configure or flash Management Module card firmware or to communicate to

another local device.

For the initial setup of the HP UPS DirectFlow Management Module web interface access to the management

module card, use a local host computer or device connected to the serial communication port. For details, see

"Accessing the Management Module (on page 63)."

Installation 61

Page 62

Connecting the network cable to the 2U power unit

Connect the Management Module card to a network or Internet connection with an RJ-45 Ethernet cable.

A network-connected computer can be used to log in to the Management Module web interface for remote

access to the Management Module card and to view information about the DirectFlow UPS. To access the

Management Module web interface, see "Accessing the Management Module (on page 63)."

Checking the Health/Alert LED

If the Health/Alert LED illuminates red or flashes red, see "Troubleshooting (on page 89)" for more

information.

Installation 62

Page 63

Configuration

Accessing the Management Module

A local connection to the HP DirectFlow UPS Management Module card is required the first time for initial

configuration.

To access the HP DirectFlow UPS Management Module locally:

1. Install the Management Module card in the power unit.

a. Connect the serial communications cable to a local host computer or device. For more information,

see "Connecting the serial communications cable in the 1U power unit (on page 59)" or

"Connecting the serial communications cable in the 2U power unit (on page 61)."

b. Connect the network cable to the Internet or network. For more information, see "Connecting the

network cable to the 1U power unit (on page 60)" or "Connecting the network cable to the 2U

power unit (on page 62)."

2. Launch a terminal emulation program. For more information, see "Launching a terminal emulation

program (on page 63)."

The POST executes on the session screen. For details about the information output by POST, see "POST

(on page 64)."

3. Record the IPv4 or IPv6 address for the Management Module card from the POST.

4. At the prompt, press any key within 5 seconds to access and configure the Management Module

Service Menu (on page 65).

-or-

Launch a telnet session to access and configure the Service Menu. For more information, see "Launching

a telnet session (on page 64)."

To prepare for remote access:

1. Access the Service Menu to configure the Management Module card for remote access.

2. Launch a web browser on a network-connected computer or device and sign into the Management

Module web interface. For more information, see "Launching a web browser (on page 71)" and

"Signing into the Management Module web interface (on page 71)."

Launching a terminal emulation program

HyperTerminal is the serial communication program provided with Microsoft Windows and is used in this

section as an example for setting up a terminal emulation session. If you are using another utility, the steps

might be different.

To launch a terminal emulation program:

1. On the host computer or device, click Start, and select

Programs>Accessories>Communications>HyperTerminal.

The Connection Description window appears.

Configuration 63

Page 64

2. Enter a description, select an icon for the connection, and then click OK. The Connect To window

appears.

3. Select the serial connector on the host computer to which the DB-9 cable is attached, and then click OK.

The COM Properties window appears.

4. Select the following parameter values, and then click OK.

o Bits per second—115,200

o Data bits—8

o Parity—None

o Stop bits—1

POST

o Flow control—None

When the card is powered up or reset, the boot loader performs a POST and outputs the following text.

IRQ test: PASS

Serial loopback test: PASS

HP DirectFlow UPS Management Module

NETWORK INTERFACE PARAMETERS:

IP address: 16.83.130.246

Subnet mask: 255.255.255.0

Default gateway: 16.83.130.1

HARDWARE PARAMETERS:

Module Serial number: 1US2010015

MAC address: 44:1E:A1:D1:02:14

Press any key in 5 seconds to enter the Service menu.

If an error is detected in the boot process, the Health/Alert LED illuminates or flashes. To correct the error, see

"Updating the UPS firmware (on page 78)" or "Troubleshooting (on page 89)."

To access a list of commands, open Help. Enter info or vers to display information such as IP address,

model and serial number, and version numbers for specific firmware.

Launching a telnet session

To launch a telnet session to access the Management Module Service Menu (on page 65):

1. Enter the following command at a DOS prompt or the command line:

Telnet xxx.xxx.xxx.xxx

where xxx.xxx.xxx.xxx is the IP address of the management module.

2. At the prompt, enter the user name and password.

The default user name is admin, and the default password is admin.

Navigating the Service Menu

The Management Module Service Menu provides an alternative, limited interface to the Management

Module card during initial setup and when the web interface is disabled or not preferred. The menu structure

textually displays measurements, warnings, and alarm messages from the Management Module card. Some

Configuration 64

Page 65

setup options and system values can be configured through the Service Menu and sent to the Management

Save New Changes and

Saves changes and resets the Management

Module web interface.

All status information included in the Management Module Service Menu is also available by signing into the

Management Module web interface (on page 71).

To navigate the Service Menu:

1. Enter the corresponding option number at the prompt to open a submenu.

2. Follow the on-screen prompts to enter or change configuration information.

3. Enter 0 at the submenu prompt to go to the previous menu.

Or, enter 0 at the main menu prompt to exit the utility.

4. Press the Enter key to refresh the screen.

The Management Module card resets automatically to allow configuration changes to take effect.

Service Menu

This menu only appears when accessing the Management Module card using a terminal emulation program.

Option number Submenu Description

1

2

Module Configuration Opens the Module Configuration submenu (on

Exit Exits the Service Menu and resets the

Module Configuration submenu

The Module Configuration submenu opens when Module Configuration is selected from the terminal

emulation Service Menu or when the telnet session is launched to access the Management Module card.

Option number Submenu Description

1

2

x

s

d

System Information Displays information about the power unit,

System Setup Sets the date, time, and daylight saving time

Exit Without Saving Exits a menu without saving the changes

Restart

Restore Configuration to

Factory Defaults

page 65)

Management Module card

battery packs, and Input/Output Power Module

parameters

Module card

Restores all parameters to default settings

System Information submenu

Option number Submenu Description

1

2

UPS Information Displays identification information and

firmware version for the power unit and

Input/Output Power Module

Battery Information Displays identification information and

firmware version for the battery packs

Configuration 65

Page 66

Option number Submenu Description

Static Subnet Mask

Sets the Management Module card subnet mask

3

4

5

0

UPS Status Displays power status for the power unit and

Input/Output Power Module

Battery Status Displays status of the battery capacity,

remaining run-time, test status and schedule,

delay times, and voltage

Additional Information Displays additional operating information

related to the UPS such as temperature, delay

time, operating mode, frequency, and

limitations

Previous Menu Returns to the previous menu

System Setup submenu

Each System Information submenu has the Refresh Data option to obtain the current status of the unit.

Option number Submenu Description

1

2

3

4

0

User Accounts submenu

Option number Submenu Description

(1-5)

0

User Accounts Enters or changes user account parameters