Page 1

HP ProLiant ML110 Generation 3 Server

Maintenance and Service Guide

Part number: 393172-003

Second edition: September 2007

Page 2

© Copyright 2007 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products and services are set forth in the

express warranty statements accompanying such products and services. Nothing herein should be construed as constituting an additional

warranty. HP shall not be liable for technical or editorial errors or omissions contained herein.

Intel, Pentium, and Celeron are trademarks or registered trademarks of Intel Corporation or its subsidiaries in the United States and other

countries.

Part number: 393172-003

Third edition: September 2007

Page 3

Contents

1 Illustrated parts catalog

Customer self repair ................................................................................................................................. 3

Mechanical parts exploded view ............................................................................................................... 4

System components exploded view ............................................................................................................ 5

HP contact information ............................................................................................................................. 6

Before you contact HP ..............................................................................................................................6

2 Removal and replacement procedures

Hardware configuration tools .................................................................................................................... 7

Hardware configuration information........................................................................................................... 7

Non-hot-plug device ............................................................................................................................ 7

Electrostatic discharge information ........................................................................................................ 7

Symbols on equipment......................................................................................................................... 8

Pre-installation instructions .................................................................................................................... 8

Post-installation instructions................................................................................................................... 9

Powering down the server......................................................................................................................... 9

System covers........................................................................................................................................ 10

Access panel.................................................................................................................................... 10

Front bezel....................................................................................................................................... 11

Drives................................................................................................................................................... 12

Cable management........................................................................................................................... 12

Cable connections ............................................................................................................................ 13

Drive bay configuration ..................................................................................................................... 14

Releasing drives................................................................................................................................ 14

Optical drive.................................................................................................................................... 15

Optional media device ...................................................................................................................... 16

Hard drives...................................................................................................................................... 17

Drive latch ....................................................................................................................................... 20

System board components ...................................................................................................................... 21

Processor ......................................................................................................................................... 21

Memory........................................................................................................................................... 24

Expansion cards ............................................................................................................................... 25

System battery .................................................................................................................................. 27

Power supply unit (PSU) .......................................................................................................................... 28

System fan ............................................................................................................................................ 30

HP Lights-Out 100 Remote Management Card........................................................................................... 31

3 Diagnostic tools

AMIBIOS software ................................................................................................................................. 32

Accessing the Setup Utility.................................................................................................................. 32

Navigating through the Setup Utility .................................................................................................... 33

Setup Utility primary menus ................................................................................................................ 34

System Summary Screen .................................................................................................................... 35

System passwords............................................................................................................................. 36

Loading system defaults ..................................................................................................................... 37

Clearing CMOS ............................................................................................................................... 38

Power-On Self Test (POST).................................................................................................................. 38

POST error indicators ........................................................................................................................ 39

POST-related troubleshooting.............................................................................................................. 40

4 Connectors, switches, and LEDs

Connectors and components ................................................................................................................... 41

Front panel components..................................................................................................................... 41

Rear panel components ..................................................................................................................... 42

System board components.................................................................................................................. 42

1

Page 4

Jumpers – Password and Boot Block .................................................................................................... 44

Clear CMOS button .......................................................................................................................... 44

Status LED indicators .............................................................................................................................. 44

Front panel LED indicators.................................................................................................................. 44

Rear panel LED indicators .................................................................................................................. 46

System board LED indicators .............................................................................................................. 46

5 Physical and operating specifications

System unit............................................................................................................................................ 47

Memory................................................................................................................................................ 49

Processor.............................................................................................................................................. 49

IDE CD-ROM drive ................................................................................................................................. 50

SCSI hard drive ..................................................................................................................................... 51

SATA hard drive.................................................................................................................................... 51

SCSI storage controller ........................................................................................................................... 52

Index

2

Page 5

1 Illustrated parts catalog

This chapter provides the illustrated parts breakdown and spare parts lists for the HP ProLiant ML110

Generation 3 server. Information for contacting HP is also provided.

Customer self repair

HP products are designed with many Customer Self Repair (CSR) parts to minimize repair time and allow for

greater flexibility in performing defective parts replacement. If during the diagnosis period, HP identifies that the

repair can be accomplished by the use of a CSR part, HP will ship that part directly to you for replacement. There

are two categories of CSR parts:

• Mandatory - Parts for which customer self repair is mandatory. If you request HP (including any of it's

partners or service providers) to replace these parts, you will be charged for the travel and labor costs of

this service.

• Recommended - Parts for which customer self repair is optional. These parts are also designed for customer

self repair. If, however, you require that HP replace them for you, this may be done at no additional charge

under the type of warranty service designated for your product.

Based on availability and where geography permits, CSR parts will be shipped for next business day delivery.

Same day or four-hour delivery may be offered where geography permits, for customers with those entitlements.

In cases where it is required to return the defective part to HP, you must ship the defective part back to HP within

a defined period of time, normally five (5) business days. The defective part must be returned with the associated

documentation in the provided shipping material. Failure to return the defective part may result in HP billing you

for the replacement. With a customer self repair, HP will pay all shipping and part return costs and determine the

courier/carrier to be used.

NOTE: Table items marked with an asterisk (*) are not shown in the figures.

3

Page 6

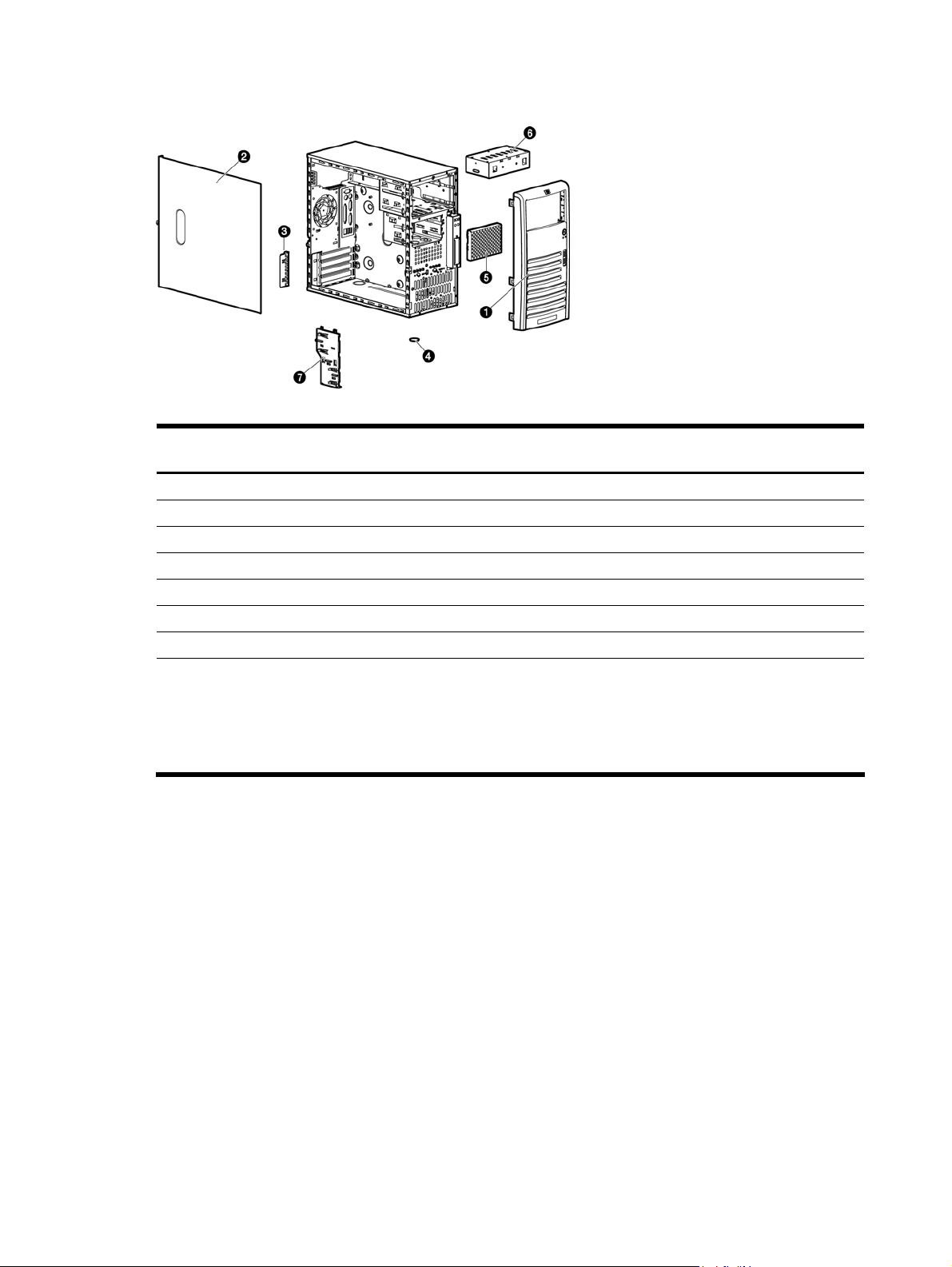

Mechanical parts exploded view

Figure -1 [Mechanical parts exploded view]

Table -1 Mechanical spare parts list

Item Description

1 Front bezel 391980-001 392174-001 Mandatory

2 Access panel 396648-001 397120-001 Mandatory

3 Expansion slot cover lock (included in Misc Hardware Kit) 397084-001 ---- Mandatory

4 Foot (included in Misc Hardware Kit) 166939-007 ---- Mandatory

5 Hard drive EMI shield 395015-001 395624-001 Mandatory

6 Optical drive shield 395019-001 395625-001 Mandatory

7 Drive release latch 395020-001 397122-001 Mandatory

8 Misc Plastics/Hardware Kit *, including:

Assembly

number

---- 397119-001 Mandatory

Spare part

number

Customer

self repair

• Screw, 6-32x.187,TF,HI/TP w/serr (10)

• Screw, M3,TT,HI/TP,S15IPX5mm (10)

• Feet (4)

• Expansion slot cover lock

• Thumbscrew, 6-32 X .25, Cbn

4

Page 7

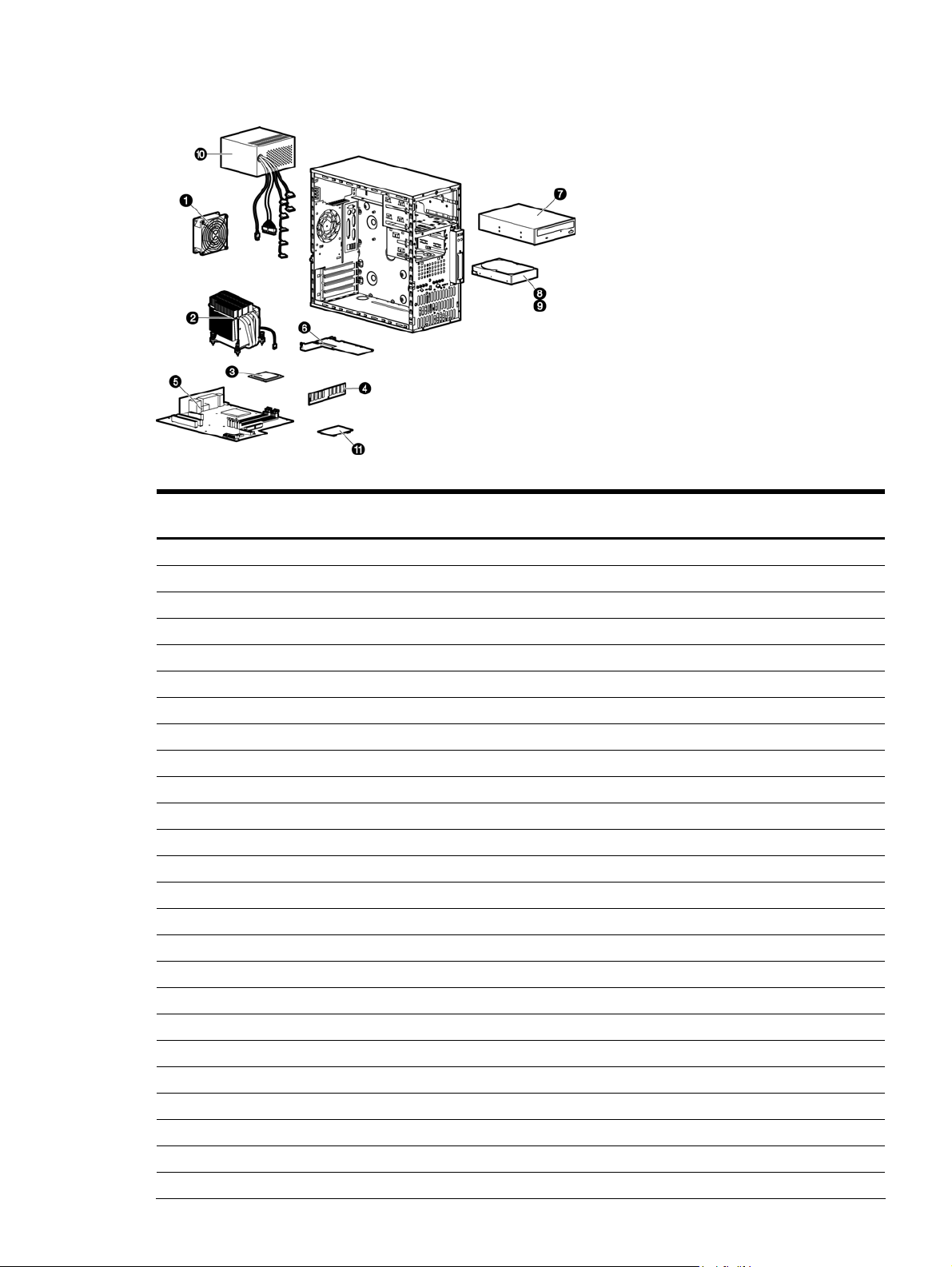

System components exploded view

Figure -2 [System components exploded view]

Table -2 System components spare parts list

Item Description

1 System fan 391976-001 392172-001 Mandatory

2 Processor heatsink-cooling fan (HSF) assembly 391818-001 392171-001 Recommended

3 Processors (include alcohol pad and thermal grease)

a) Intel Celeron D 2.53 GHz/533 MHz FSB with 256 KB L2 cache 367744-005 392167-001 Recommended

b) Intel Pentium 4 3.0 GHz/800 MHz FSB with 2 MB L2 cache 379289-001 392168-001 Recommended

c) Intel Pentium 4 3.2 GHz/800 MHz FSB with 2 MB L2 cache 379289-002 392169-001 Recommended

d) Intel Pentium 4 3.4-GHz/800 MHz FSB, with 2 MB L2 cache 379289-003 398388-001 Recommended

e) Intel Pentium 4 3.6-GHz/800 MHz FSB, with 2 MB L2 cache 379288-001 398389-001 Recommended

f) Intel Pentium 4 3.8-GHz/800 MHz FSB, with 2 MB L2 cache 379288-002 398390-001 Recommended

4 Memory boards (PC2-4200 unbuffered ECC DDR II DIMM )

a) 512 MB 384375-051 392176-001 Mandatory

b) 1 GB 384376-051 398955-001 Mandatory

c) 2 GB 384377-061 398956-001 Mandatory

5 System board 389504-001 392170-001 Recommended

6 SCSI controller card 332541-001 339051-001 Recommended

366651-001 Mandatory

Mass storage devices

7 48X CD-ROM drive 266072-001 288894-001 Mandatory

8 SCSI hard drive

a) 36GB 15K U320 357014-001 372659-001 Mandatory

b) 72GB 10K U320 332934-001 Mandatory

c) 146GB 10K U320 357915-001 Mandatory

9 SATA hard drive 332649-003 373311-001 Mandatory

Misc parts

10 350-W power supply unit with cable assembly 391977-001 392173-001 Mandatory

Assembly

number

Spare part

number

Customer self

repair

5

Page 8

Table -2 System components spare parts list

Item Description

11 HP Lights-Out 100 Remote Management Card * 389503-001 392175-001 Mandatory

12 Hard drive conversion bracket * 351795-001 397117-001 Mandatory

13 Return kit * ---- 394742-001 Mandatory

14 CD-ROM drive cable assembly, ATA100 * 395016-001 395620-001 Mandatory

15 SCSI hard drive cable * 391982-001 392178-001 Mandatory

16 SATA hard drive cable, 5.25-inch, ODD bay * 326965-002 346142-001 Mandatory

17 SATA hard drive cable * 381868-002 392179-001 Mandatory

18 USB/Power LED cable* 398417-001 398770-001 Mandatory

HP contact information

For the name of the nearest HP authorized reseller:

• In the United States, call 1-800-345-1518.

• In Canada, call 1-800-263-5868.

• In other locations, refer to the HP website at http://www.hp.com/.

For HP technical support:

• In North America:

• Call 1-800-HP-INVENT (1-800-474-6836). This service is available 24 hours a day, 7 days a week.

For continuous quality improvement, calls may be recorded or monitored.

• If you have purchased a Care Pack (service upgrade), call 1-800-633-3600. For more information

about Care Packs, refer to the HP website at http://www.hp.com/.

• Outside North America, call the nearest HP Technical Support Phone Center. For telephone numbers for

worldwide Technical Support Centers, refer to the HP website at http://www.hp.com/

Assembly

number

Spare part

number

.

Customer self

repair

Before you contact HP

Be sure to have the following information available before you call HP:

• Technical support registration number (if applicable)

• Product serial number

• Product model name and number

• Applicable error messages

• Add-on boards or hardware

• Third-party hardware or software

• Operating system type and revision level

6

Page 9

2 Removal and replacement procedures

This chapter provides subassembly/module-level removal and replacement procedures for the HP ProLiant ML110

Generation 3 server.

Review the specifications of a new component before installing it to make sure it is compatible with the server.

When you integrate new components into the system, record its model and serial number, and any other

pertinent information for future reference. After completing any removal or replacement procedure, run the

diagnostics program to verify that all components operate properly.

Hardware configuration tools

In performing any hardware configuration procedure you may need the following tools:

• T-15 Torx screwdriver

• Flat-blade screwdriver

NOTE: The figures used in this chapter to illustrate procedural steps are labeled numerically (i.e., 1, 2…).

When these figures are used in substep items, the alphabetically labeled instructions correspond to the

numbered labels on the related figure (i.e., Label 1 corresponds to step a, label 2 corresponds to step b, etc.).

Hardware configuration information

WARNING! Only authorized technicians trained by HP should attempt to repair this equipment. Because of the

complexity of the individual boards and subassemblies, no one should attempt to make repairs at the

component level or to make modifications to any printed wiring board. Improper repairs can create a safety

hazard.

CAUTION: Electrostatic discharge (ESD) can damage electronic components. Be sure that you are properly

grounded (earthed) before beginning any installation procedure. Refer to the “Electrostatic Discharge

Information” section for more information.

Before removing any serviceable parts, determine whether the part is hot-plug or non-hot-plug.

Non-hot-plug device

If the device is non-hot-plug, you must power down the server. Non-hot-plug devices in the server include the

processor, all boards, memory modules, fans, PCI option cards, and all hard drives.

Electrostatic discharge information

ESD can damage static-sensitive devices or microcircuitry. Proper packaging and grounding techniques are

necessary precautions to prevent damage. To prevent electrostatic damage, observe the following precautions:

• Transport products in static-safe containers such as conductive tubes, bags, or boxes.

• Keep electrostatic-sensitive parts in their containers until they arrive at static-free stations.

• Cover workstations with approved static-dissipating material. Use a wrist strap connected to the work

surface and properly grounded (earthed) tools and equipment.

• Keep work area free of nonconductive materials, such as ordinary plastic assembly aids and foam packing.

• Make sure that you are always properly grounded (earthed) when touching a static-sensitive component or

assembly.

• Avoid touching pins, leads, or circuitry.

• Always place drives with the Printed Circuit Board (PCB) assembly-side down.

• Use conductive field service tools.

7

Page 10

Symbols on equipment

These symbols may be located on equipment in areas where hazardous conditions may exist.

WARNING! This symbol, in conjunction with any of the following symbols, indicates the presence of a

potential hazard. The potential for injury exists if warnings are not observed. Consult your documentation for

specific details.

This symbol indicates the presence of hazardous energy circuits or electric shock hazards. Refer all

servicing to qualified personnel.

WARNING! To reduce the risk of injury from electric shock hazards, do not open this enclosure. Refer

all maintenance, upgrades, and servicing to qualified personnel.

This symbol indicates the presence of electric shock hazards. The area contains no user or field

serviceable parts. Do not open for any reason.

WARNING! To reduce the risk of injury from electric shock hazards, do not open this enclosure.

This symbol on an RJ-45 receptacle indicates a network interface connection.

WARNING! To reduce the risk of electric shock, fire, or damage to the equipment, do not plug

telephone or telecommunications connectors into this receptacle.

This symbol indicates the presence of a hot surface or hot component. If this surface is contacted, the

potential for injury exists.

WARNING! To reduce the risk of injury from a hot component, allow the surface to cool before

touching.

These symbols, on power supplies or systems, indicate that the equipment is supplied by

multiple sources of power.

WARNING! To reduce the risk of injury from electric shock, remove all power cords to

completely disconnect power from the system.

This symbol indicates that the component exceeds the recommended weight for one individual to

Weight in kg

Weight in lbs

handle safely.

WARNING! To reduce the risk of personal injury or damage to the equipment, observe local

occupational health and safety requirements and guidelines for manual material handling.

Pre-installation instructions

Perform the steps below before you open the server or before you remove or replace any component:

WARNING! Failure to properly turn off the server before you open it or before you start installing/removing

components may cause serious damage as well as bodily harm.

1. Turn off the server and all the peripherals connected to it.

Refer to the Powering down the server section in this chapter for detailed instructions on how to completely

power down the server.

2. Unplug all cables from power outlets to avoid exposure to high energy levels that may cause burns if parts

are short-circuited by metal objects such as tools or jewelry. If necessary, label each cable for reassembly.

3. Disconnect telecommunication cables to avoid exposure to shock hazard from ringing voltages.

4. Open the server according to the instructions described in the System covers section in this chapter.

8

Page 11

5. Follow the ESD precautions listed previously in this chapter when handling a server component.

Post-installation instructions

Observe the following items after installing or removing a server component:

1. Make sure that you install all components according to the described step-by-step instructions.

2. Make sure not to leave loose tools or parts inside the server.

3. Reinstall any expansion board(s), peripheral(s), and system cable(s) that have previously been removed.

4. Reinstall the system covers.

5. Connect all external cables and the AC power cord to the system.

6. Press the power button on the front panel to turn on the server.

CAUTION: Do not operate the server for more than 10 minutes with the access panel and drives removed.

Otherwise, improper cooling airflow may damage system components.

Powering down the server

To completely remove all power from the system, disconnect all power cords from the server.

WARNING! Hazardous voltages are present inside the server. Always disconnect AC power from the server

and other associated assemblies while working inside the unit. Serious injury may result if this warning is not

observed.

WARNING! To reduce the risk of injury from electric shock, disconnect all power cords to completely remove

power from the system.

WARNING! To reduce the risk of personal injury from hot surfaces, allow the internal system components to

cool before touching them.

CAUTION: Protect the server from power fluctuations and temporary interruptions with a regulating

uninterruptible power supply (UPS). This device protects the hardware from damage caused by power surges

and voltage spikes, and keeps the system in operation during a power failure.

CAUTION: The server must always be operated with the system covers on. Proper cooling is not achieved

when the system covers are removed.

To power down the server:

1. Shut down server as directed by the operating system documentation.

2. Disconnect the AC power cord from the AC outlet and then from the server.

3. Be sure that the power LED indicator is turned off and that the fan noise has stopped.

4. Disconnect all external peripheral devices from the server.

9

Page 12

System covers

The access panel and the front bezel are both detachable. You must remove these system covers before you can

remove or replace a server component.

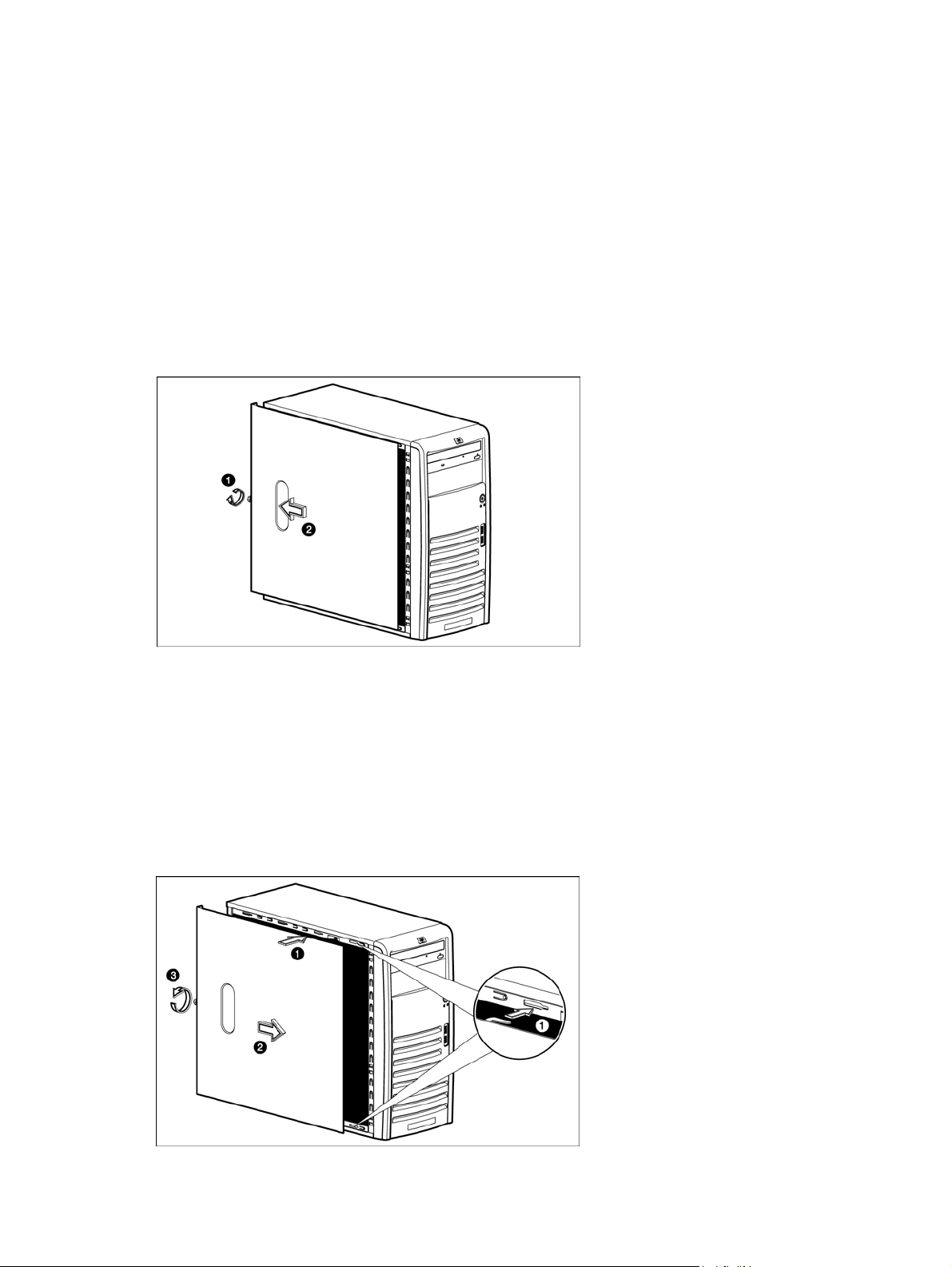

Access panel

You must remove the access panel to access internal components and mass storage devices.

To remove the access panel:

1. Perform steps 1 through 3 of the Pre-installation instructions.

2. Remove the access panel from the chassis:

a. Loosen the captive thumbscrew located on the rear edge of the access panel.

b. Slide the panel back about 2.5 cm (1.0 in).

c. Lift the panel from the chassis.

Figure -1 [Removing the access panel]

3. Place the access panel in a safe place for reinstallation later.

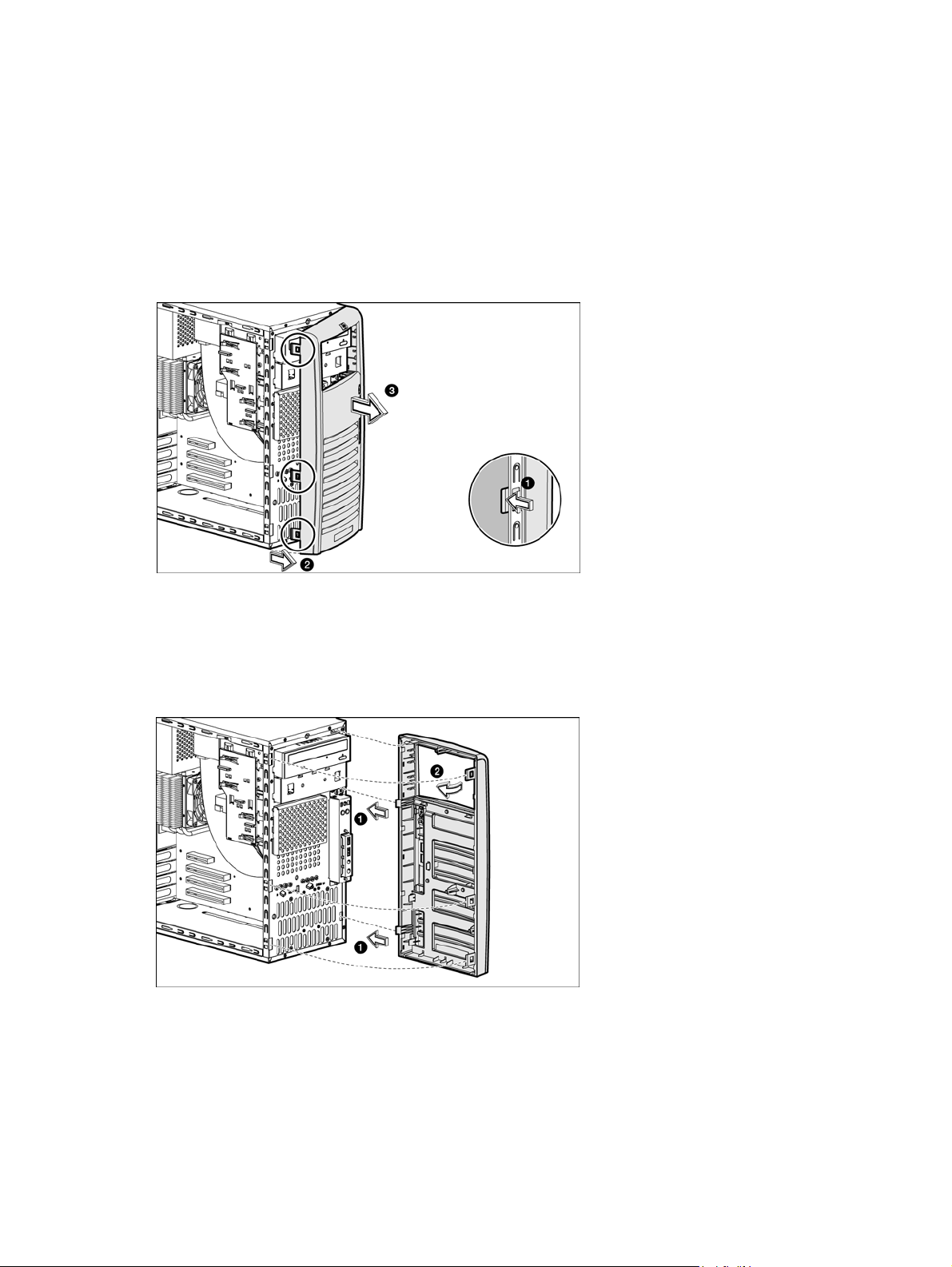

After completing any removal or replacement procedure, replace the access panel by following the steps below:

1. Perform steps 1 through 3 of the Post-installation instructions.

2. Reinstall the access panel:

a. Use two hands to place the access panel flat against the chassis, the back of the access panel

extending about 2.5 cm (1.0 in) behind the back of the server. Make sure the hooks on the access

panel align with the holes on the edges of the chassis.

b. Slide the access panel toward the front of the chassis to position it into place.

c. Tighten the captive thumbscrew to secure the access panel.

Figure -2 [Reinstalling the access panel]

3. Perform steps 5 through 6 of the Post-installation instructions.

10

Page 13

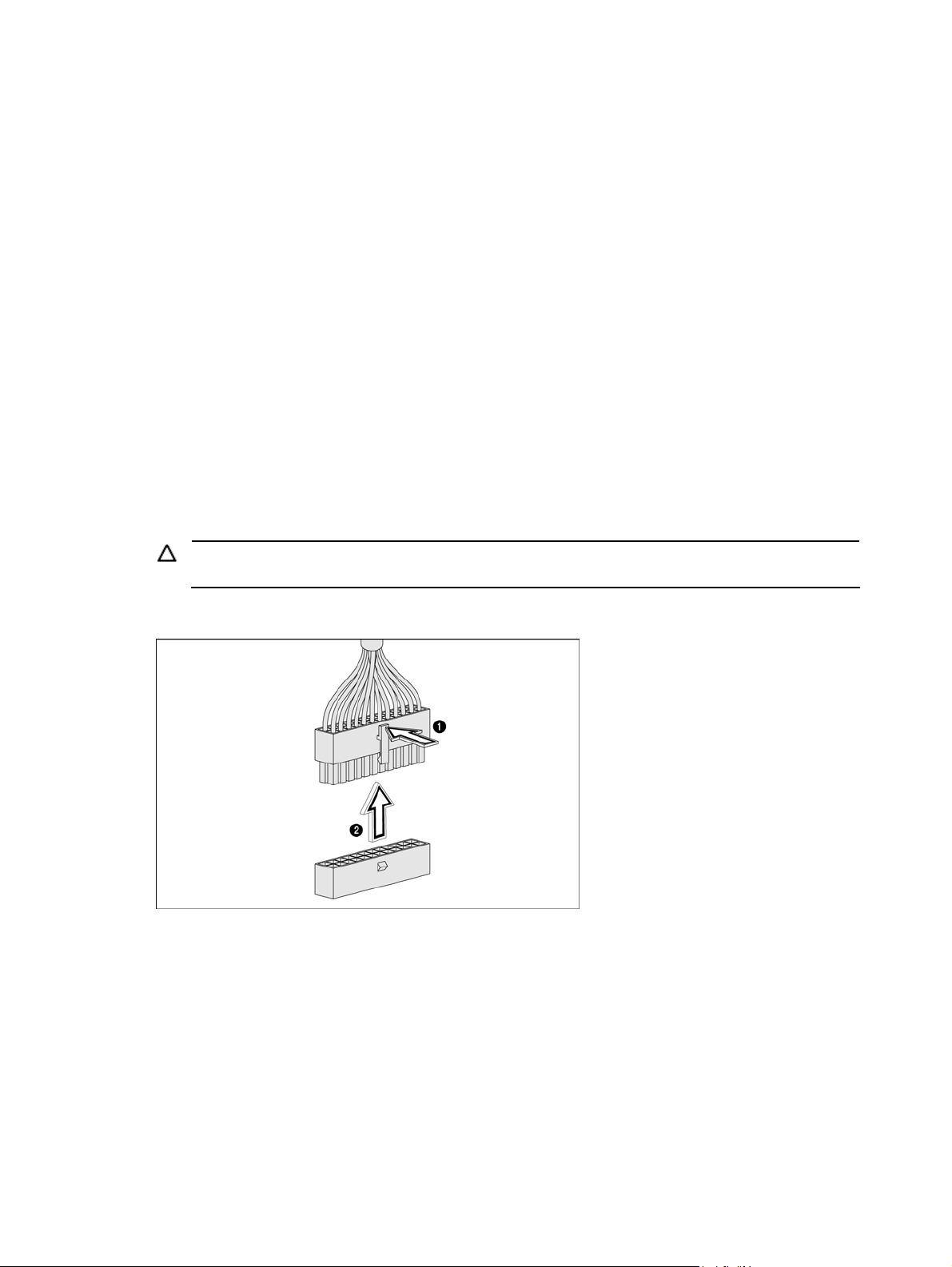

Front bezel

You must remove the front bezel to access the hard drives and optical drives.

To remove the front bezel:

1. Remove the access panel.

2. Remove the front bezel:

Figure -3 [Removing the front bezel]

a. Press in on the two bottom tabs on the side of the bezel so that they release from the chassis.

b. Press in on the upper tab on the side of the bezel so that it releases from the chassis. The bezel will

rotate out slightly.

c. Pull the bezel away from the front panel.

3. Place the front bezel in a safe place for reinstallation later.

To replace the front bezel, follow the steps below:

1. Position the chassis in the upright position.

2. Insert the two hooks on the right side of the bezel into the rectangular holes on the chassis, and then rotate

the bezel into place so that the three tabs on the left side of the bezel snap into the slots on the chassis.

Figure -4 [Reinstalling the front bezel]

11

Page 14

Drives

You can install up to two optical drives or up to three hard drives in the server. The second optical drive bay can

support a SATA or SCSI hard drive.

Cable management

Always follow good cable management practices when working inside the computer.

• Keep cables away from major heat sources like the heatsink.

• Do not jam cables on top of expansion cards or memory modules. Printed circuit cards are not designed to

withstand excessive pressure.

• Keep cables clear of sliding or moveable parts to prevent cutting or crimping.

• When folding a flat ribbon cable, never fold to a sharp crease. Sharp creases may damage the wires.

• Some flat ribbon cables come prefolded. Never change the folds on these cables.

• Do not sharply bend any cable. A sharp bend can break the internal wires.

• Never bend a SATA data cable tighter than a 30 mm (1.18 in) radius.

• Never crease a SATA data cable.

• Do not rely on components like the drive cage, power supply, or system cover to push cables down into the

chassis.

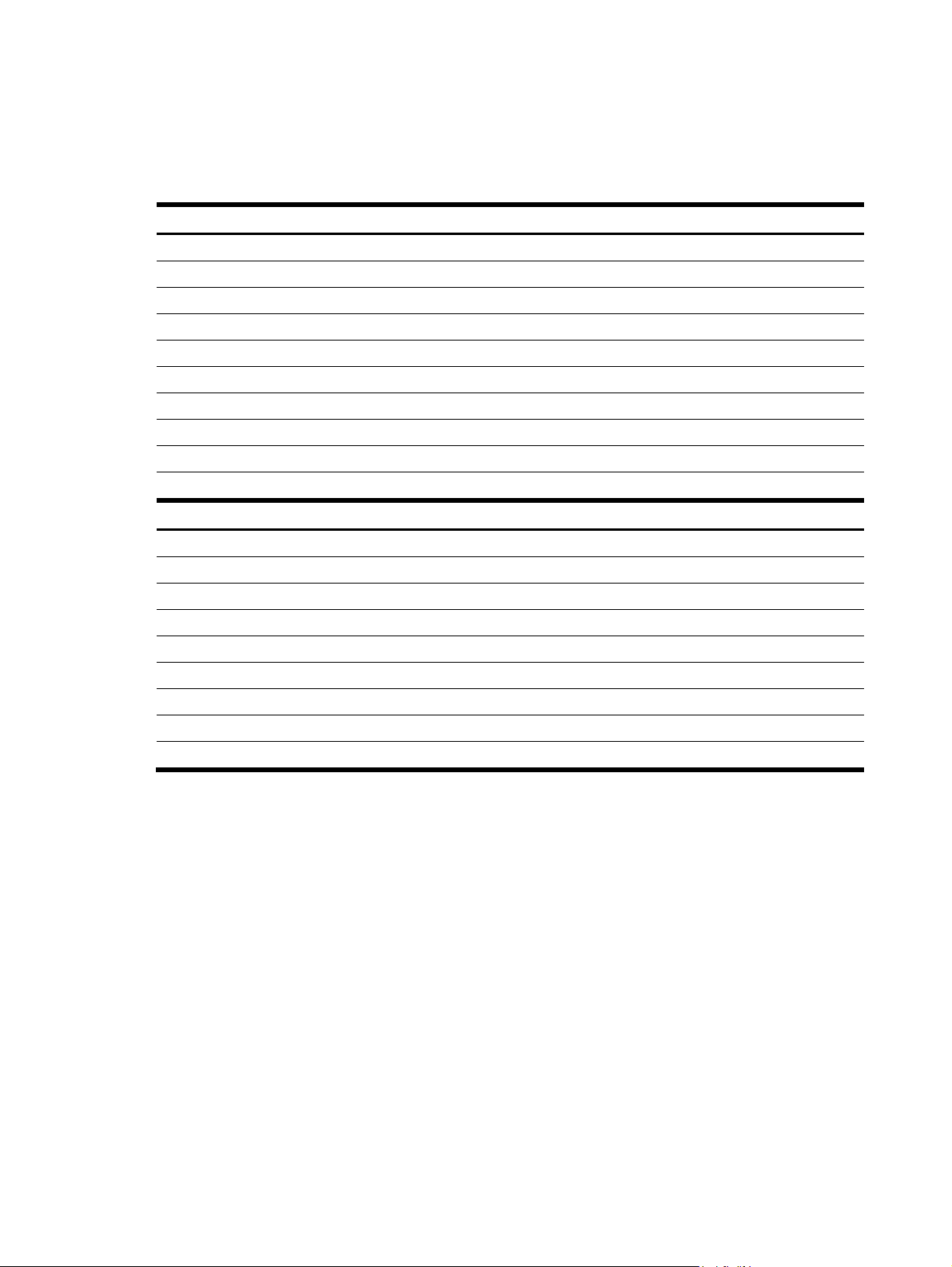

When removing the power supply power cables from the P2 or P3 connectors on the system board, always

follow these steps:

1. Squeeze on the top of the retaining latch attached to the cable end of the connector.

2. Grasp the cable end of the connector and pull it straight up.

CAUTION: Always pull the connector - NEVER pull on the cable. Pulling on the cable could damage the

cable and result in a failed power supply.

Figure -5 [Unplugging power cables]

12

Page 15

Cable connections

The following table provides information about power supply cable connector labels, as well as system board

connector designators. The top half of the table indicates the label on the power supply cable. The bottom half of

the table provides the system board designators that various cables plug into. For more detailed information

about system board components, see System board components in Chapter 4.

Table -1 Cable connections

Cable To Cable Designator

Power supply System board P1

Power supply System board CPU power P2

Power supply 1st SATA hard drive P9

Power supply 2nd SATA hard drive P8

Power supply 3rd SATA hard drive P7

Power supply 1st SCSI hard drive P6

Power supply 2nd SCSI hard drive P5

Power supply 3rd SCSI hard drive P4

Power supply 1st optical drive P3

Power supply 2nd optical drive P4

Cable To System board designator

CPU fan connector System board P70

Rear system fan System board P8

Serial port B System board P52

Front USB connector System board P24

Front I/O connector System board P5

1st SATA connector System board P60

2nd SATA connector System board P61

Internal USB tape drive System board J4

Internal USB port System board J3

13

Page 16

Drive bay configuration

The server supports a maximum of four internal drives. The two upper drive bays are primarily for removable

media devices, while the two lower drive bays are only for hard drives. The two upper bays are half height IDE

optical bays. The two lower drive bays can accommodate non-hot-plug hard drives.

NOTE: You can install a SATA or SCSI hard drive into the second half-height optical bay. This type of

installation requires use of a conversion kit.

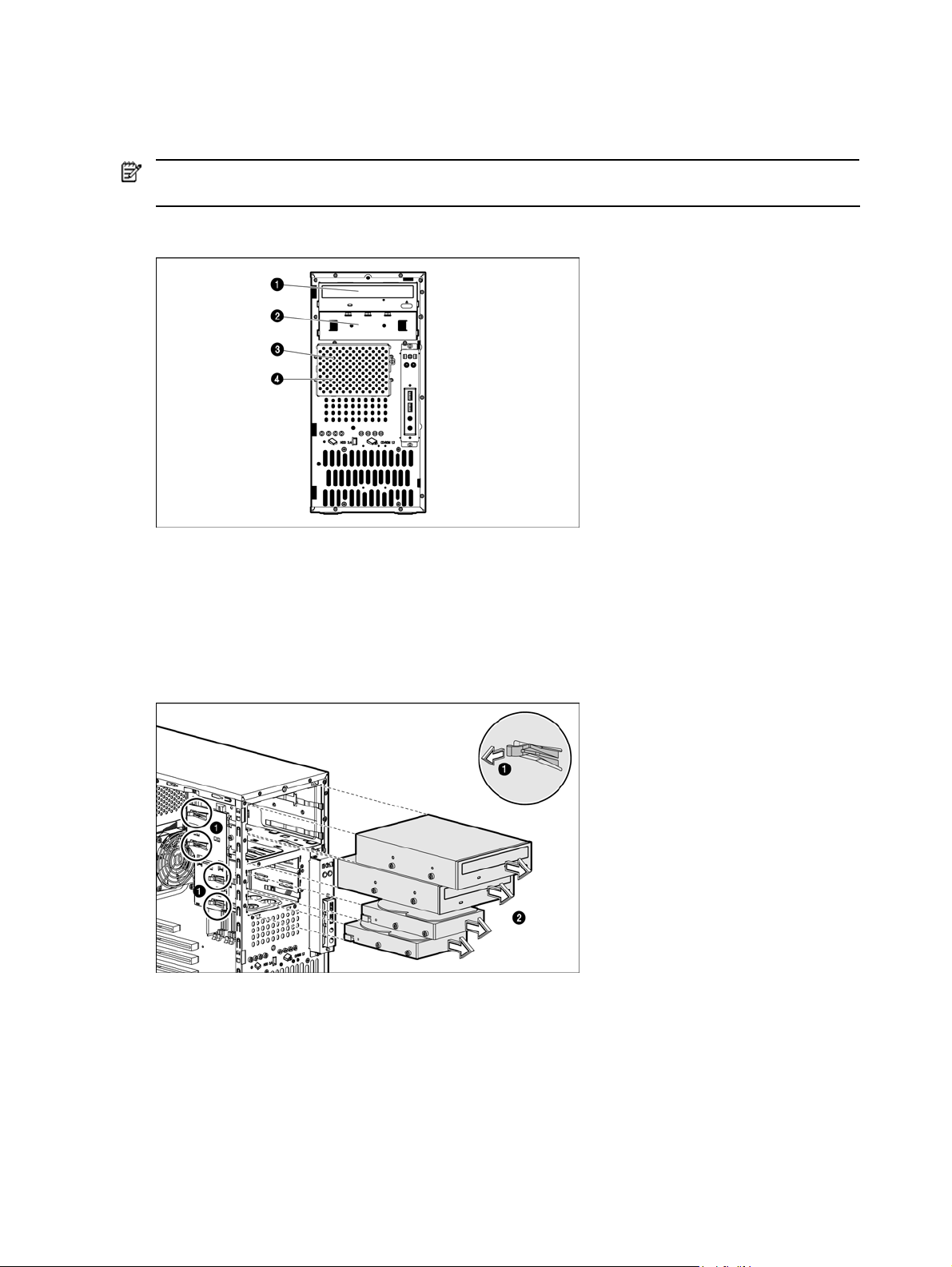

Figure -6 [Drive bay configuration]

1 Optical drive 3 2

nd

2 2

optical drive or 3rd SATA or SCSI hard drive 4 1st SATA or SCSI hard drive

Releasing drives

A drive latch with release tabs secures the drives in the drive bay. Lift the release tab on the drive latch for the

drive you want to remove, and then slide the drive from its drive bay.

Figure -7 [Releasing drives]

When replacing drives, remove the four guide screws (two on each side) from the old drive. You will need these

screws to install a new drive.

nd

SATA or SCSI hard drive

14

Page 17

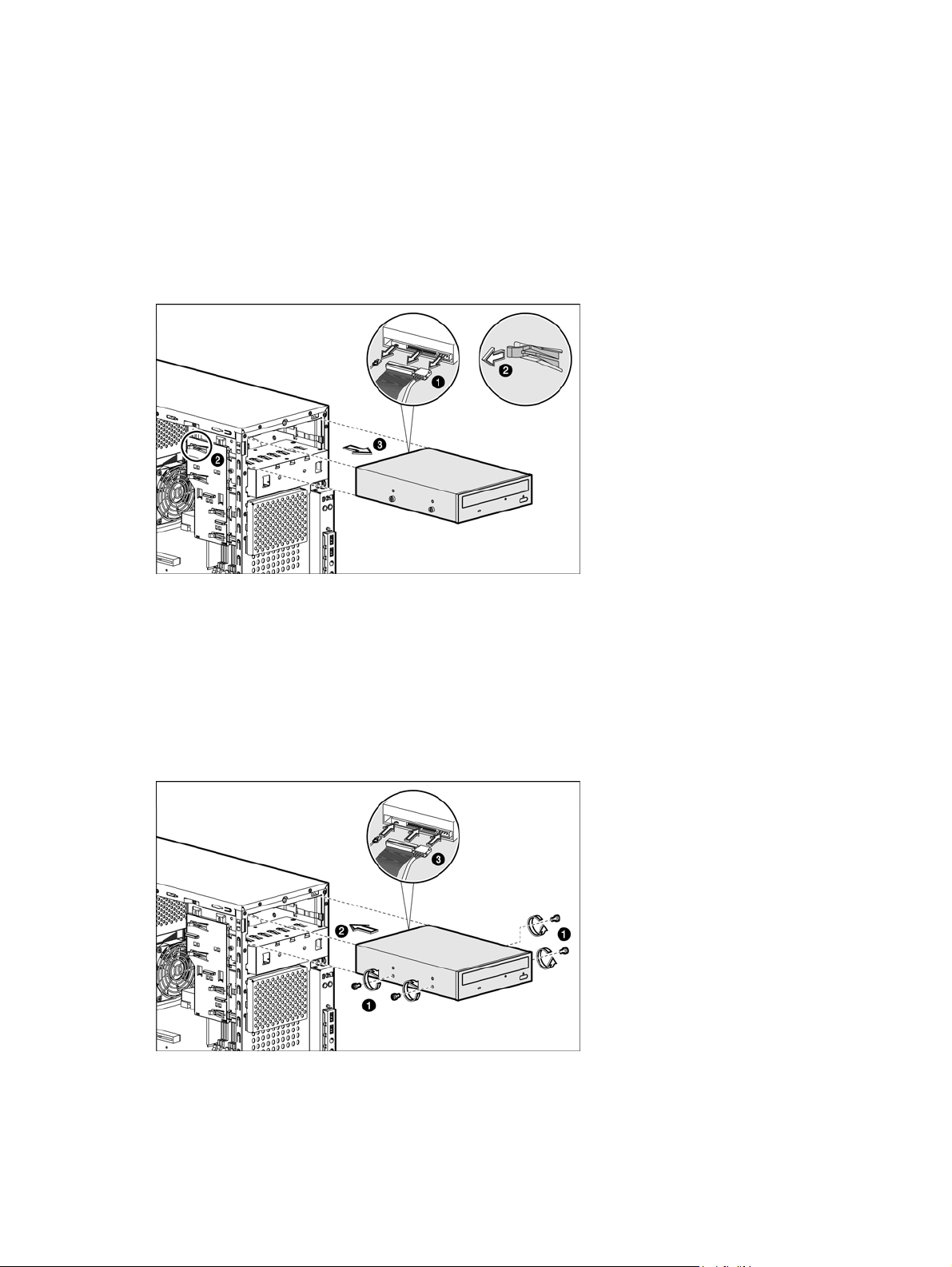

Optical drive

To replace an optical drive:

1. Perform steps 1 through 3 of the Pre-installation instructions.

2. Remove the access panel.

3. Remove the front bezel.

4. Remove the optical drive from the server:

a. Disconnect the power and data cables from the rear of the optical drive.

b. A drive latch with release tabs secures the drives in the drive bay. Lift the release tab on the drive latch.

c. Slide the drive from the drive bay.

Figure -8 [Removing an optical drive]

5. Place the old optical drive on a static-dissipating work surface or inside of an anti-static bag.

6. Remove the new optical drive from its protective packaging.

7. Check that the IDE jumper on the rear section of the optical drive is set to Cable-Select mode.

8. Install the new optical drive:

a. Insert four screws (two on each side) into the new optical drive.

b. Guide the new optical drive into the optical bay, with the cable connectors facing the rear of the

chassis, and then push the drive all the way into the drive bay until the drive clicks into place.

c. Connect the IDE power and data cables to their connectors on the rear of the drive.

Figure -9 [Installing an optical drive]

9. Observe the post-installation procedures.

15

Page 18

Optional media device

The lower half-height drive bay may be used for an optical drive or a non-hot-plug SATA or SCSI hard drive. For

more information about installing a hard drive in this bay, see Hard drive bracket later in this chapter.

To install an optional optical drive:

1. Perform steps 1 through 3 of the Pre-installation instructions.

2. Remove the access panel.

3. Remove the front bezel.

4. Remove the drive shield to prepare the bay for drive installation:

a. Remove the screw that secures the drive shield.

b. Pull the shield off of the chassis. Store it for later use.

CAUTION: Do not discard the shield. If the drive is removed in the future, you must reinstall the shield

to maintain proper system function.

Figure -10 [Removing the drive shield]

5. Prepare the new drive for installation. Refer to the documentation that came with the drive for related

installation procedures.

6. Install the new drive:

a. Insert four screws (two on each side) into the new optical drive.

b. Guide the new drive into the bay, with the cable connectors of the drive facing the rear of the chassis,

and then push the drive all the way into the chassis until the drive clicks into place.

c. Connect the power and data cables to the connectors on the rear of the drive.

Figure -11 [Installing an optional media drive]

7. Observe the post-installation procedures.

16

Page 19

Hard drives

You can install either SATA hard drives or SCSI hard drives in the server. The bottom two bays (bays 3 and 4)

are the hard drive bays. You can also install a SATA or SCSI hard drive into the second optical drive bay

(bay 2).

SCSI hard drives require that you also install a SCSI PCI expansion card. Connect the hard drive data cable from

the hard drive to the SCSI expansion card. Then connect power cable from the power supply to the back of hard

drive. For more information about installing PCI expansion cards, see Expansion cards.

To replace or install hard drives:

1. Perform steps 1 through 3 of the Pre-installation instructions.

2. Remove the access panel.

3. Remove the front bezel.

4. If you want to install the new hard drive in an occupied drive bay:

a. Disconnect the power and data cables from the back of the installed drive.

b. Remove the installed drive by lifting the drive latch and sliding the drive out of the bay.

c. Remove the four screws from the sides of the drive. You will reuse these screws when you install the

Figure -12 [Removing a hard drive]

new hard drive.

5. If you want to install a new hard drive in an empty drive bay, remove four screws from the front of the

chassis labeled ‘HDD SCREWS’. See Figure -13 for the location of these spare screws.

Figure -13 [Drive screw location]

17

Page 20

6. Install the new hard drive into the bay:

a. Insert the four drive screws (two on each side) into the hard drive.

b. Slide the new hard drive into the selected bay until it clicks into place.

c. If you are installing a SATA hard drive, connect the data and power cables from the system board to

the back of the hard drive and connect the power cable from the power supply to the back of the hard

drive.

d. If you are installing a SCSI hard drive, connect the data cable from the SCSI PCI expansion card to the

back of the hard drive, and then connect the power cable from the power supply to the back of the

hard drive.

Figure -14 [Installing a hard drive]

7. Observe the post-installation procedures.

Hard drive bracket - second optical drive bay

You can install a hard drive in the second optical drive bay. To install a hard drive into this bay, you first must

insert the hard drive to the hard drive conversion kit. After installing the hard drive into the conversion kit, you

can install it into the second optical bay.

To insert a hard drive into the hard drive conversion kit:

1. Insert the hard drive into the conversion kit bracket, making sure the screw holes in the bracket align with

the holes in the hard drive.

2. Insert four screws (two on each side) into the hard drive assembly, making sure the screws secure the hard

drive to the bracket.

Figure -15 [Installing a hard drive into the half-height bay bracket]

18

Page 21

To install the hard drive assembly into the second optical drive bay:

1. Remove the drive shield from the front of the second optical drive bay to prepare the bay for drive

installation:

a. Remove the screw that secures the drive shield.

b. Pull the shield off of the chassis. Store it for later use.

NOTE: Do not discard the shield. If the drive is removed in the future, you must reinstall the shield to

maintain proper system function.

Figure -16 [Removing the optical drive shield]

2. Insert four screws (two on each side) into the hard drive bracket. These screws secure the hard drive

assembly in the server after you install the drive assembly.

3. Slide the hard drive assembly into the bay until it clicks into place.

4. Connect the data and power cables to the back of the hard drive.

NOTE: If you are installing a SCSI hard drive, use the cable that comes with the server.

Figure -17 [Installing the hard drive assembly into the second optical drive bay]

5. Replace the front bezel.

6. Replace the access panel.

7. Observe the post-installation procedures.

19

Page 22

Drive latch

You can remove the latch that secures and allows removal of the drives.

To replace the drive latch:

1. Perform steps 1 through 3 of the Pre-installation instructions.

2. Remove the access panel.

3. Remove the front bezel.

4. Remove the drive latch:

Figure -18 [Removing the drive latch]

a. Pull the latch to loosen the two tabs that secure the latch to the chassis.

b. Slide the latch straight down and remove it from the chassis.

NOTE: To loosen the latch, you may also have to pull the tabs that secure inserted drives. Drive latch

tabs may break during removal.

5. Install a new drive latch:

a. Insert the two tabs on the top of the latch into their holders near the top of the chassis.

b. Slide the latch upward until the two tabs in the middle of the latch click into place.

Figure -19 [Installing a drive latch]

6. Observe the post-installation procedures.

20

Page 23

System board components

Refer to the following sections for instructions about how to remove or replace the processor, the memory

modules, the expansion cards, and the system battery.

Processor

The LGA775 processor socket supports Intel Pentium 4, Pentium D, and Celeron D processors.

Figure -20 [LGA775 processor socket]

WARNING! To reduce the risk of injury from a hot component, allow the surface to cool before touching.

To replace the processor:

1. Perform steps 1 through 3 of the Pre-installation instructions.

2. Remove the access panel.

3. Lay the server on its side with the open side facing up.

4. If necessary, remove any accessory boards or cables that prevent access to the processor socket.

5. Remove the heatsink-cooling fan (HSF) assembly:

a. Disconnect the processor fan cable from the connector on the system board (P70).

b. Twist the mounting pins counterclockwise to loosen them.

c. After you loosen all four mounting pins, lift the HSF away from the system board.

Place the HSF down in an upright position with the thermal patch facing upward. Do not let the thermal

patch touch the work surface.

Figure -21 [Removing the heatsink-cooling fan assembly]

21

Page 24

6. Remove the processor:

a. Disengage the load lever.

b. Lift the retention plate to expose the socket body.

c. Grasp the processor by its edges and lift it out of the socket.

Figure -22 [Removing the processor]

7. Place the processor on a static-dissipating work surface or in an anti-static bag.

To allow the heatsink to draw as much heat as possible from the processor base, there must be good

contact between the heatsink base and the top of the processor. To ensure good contact, you must apply

thermal grease compound.

8. Apply the thermal grease compound:

a. Use a clean cloth dipped in rubbing alcohol to clean the contact surface on the HSF and on the new

processor. Wipe the contact surfaces several times to make sure they are free of particles or dust

contaminants.

CAUTION: Never touch the bottom size of the processor; any contaminant could prevent the

processor contact pads from making contact with the socket.

b. Apply the thermal grease compound to both contact surfaces.

c. Use a proper tool to spread the grease throughout the entire contact surface and lightly scrape off any

excess grease.

CAUTION: Applying too much grease creates a gap between the contact surfaces, significantly

reducing the ability of the heatsink to draw out heat. Installing the heatsink with excessive grease can

also cause the grease to spread over the processor pins or the system board base, which can cause

electrical shorts that damage the system.

9. Install the new processor:

a. With the load lever and the retention plate disengaged, hold the processor by its edges and align it

over the empty processor socket. Make sure that you properly align the processor with the orientation

notch on the socket.

b. Insert the processor into the socket.

c. Engage the retention plate and the load lever.

22

Page 25

Figure -23 [Installing a processor]

After you install the processor, you must reinstall the HSF on top of the processor socket. The thermal grease you

applied on the contact surfaces of the HSF and the processor provides the necessary thermal bonding to allow

the heatsink to draw heat from the processor.

CAUTION: To prevent processor overheating or system instability, use only an HSF assembly specified for the

HP ProLiant ML110 Generation 3 server.

10. Replace the heatsink-cooling fan assembly:

a. Properly align the HSF mounting pins to the system board mounting holes and press down until you

hear a click.

b. Twist the mounting pins clockwise to secure the HSF connection to the system board.

c. Connect the processor fan cable to the connector on the system board (P70).

CAUTION: Failure to connect the processor fan cable to the system board may result in damage to the

processor and could cause the server to shut down without displaying messages.

Figure -24 [Installing the heatsink-cooling fan assembly]

11. Observe the post-installation procedures.

23

Page 26

Memory

The HP ProLiant ML110 Generation 3 server has four DIMM slots that support up to 8 GB maximum system

memory (2 GB in each of the four DIMM slots).

Figure -25 [DIMM slots]

Guidelines for installing memory modules

You must adhere to the following guidelines when adding or replacing memory modules:

• Use PC2-4200 unbuffered ECC DDRII DIMMs.

• DIMM sizes supported are 512 MB, 1 GB, and 2 GB, allowing up to a total of 8 GB maximum system

memory capacity.

• Supported DIMM configurations are single DIMM, one pair (two DIMMs), or two pairs (4 DIMMs).

• For optimal two-DIMM configuration, populate slot 1 and slot 3. Identical DIMMs are recommended.

To remove a memory module:

1. Perform steps 1 through 3 of the Pre-installation instructions.

2. Remove the access panel.

3. Lay the server on its side with the open side facing up.

4. If necessary, remove any accessory boards or cables that prevent access to the memory slots.

5. Locate and remove the memory module:

a. Disengage the latch socket at both ends of the DIMM sockets.

b. Gently pull the memory module upward to remove it from the socket.

Figure -26 [Removing a memory module]

6. Place the memory module on a static-dissipating work surface or inside of an anti-static bag.

To install a memory module:

a. Locate an empty memory socket on the system board.

b. Remove the memory module from its protective packaging, handling only the edges of the module.

24

Page 27

7. Install the memory module:

a. Orient the module so that the notch on the bottom edge of the module aligns with the keyed surface of

the DIMM socket, and then press it fully into the socket.

The memory sockets are structured to ensure proper installation. If you insert a memory module but it

does not fit easily into the socket, you may have inserted it incorrectly. Double-check the orientation of

the module and reinsert.

b. Firmly press the latches inward to secure the memory module in place.

If the latches do not close, the module is not inserted correctly.

Figure -27 [Installing a memory module]

8. Observe the post-installation procedures.

Expansion cards

You must remove the PCI expansion slot cover lock before installing or removing expansion cards.

The server supports the following:

• Two 32-bit/33-MHz 3.3V PCI slots (J20 to J21)

• One PCI-Express x4 link with x4 slot (J33)

• One PCI Express x8 link with x16 slot (J32)

Figure -28 [PCI slot location]

To install an expansion card:

1. Perform steps 1 through 3 of the Pre-installation instructions.

2. Remove the access panel.

3. If necessary, remove any accessory boards or cables that prevent access to the PCI slots.

4. Remove the PCI slot cover lock from the rear of the server to gain access to the expansion slots:

a. Remove the retaining screw that secures the lock to the chassis.

b. Remove the slot cover lock from the chassis.

25

Page 28

Figure -29 [Removing the PCI slot cover lock]

5. Lay the server on its side with the open side facing up.

If replacing a PCI expansion card go to step 6.

If installing a PCI expansion card for the first time, skip to step 8.

6. When removing an expansion card from an expansion slot, hold the card at both ends, and then carefully

rock the card back and forth until the expansion cards pull free from the slot.

7. Remove the card from the chassis. Store the old card in the anti-static packaging.

8. If a PCI expansion slot has a slot cover, remove it prior to installation the card.

CAUTION: Do not discard the slot cover. If the PCI expansion card is removed in the future, the slot

cover must be reinstalled to maintain proper cooling.

9. When installing an expansion card, hold the card just above the expansion slot on the system board, and

then move the card toward the rear of the chassis so that the bracket on the card is aligned with the open

slot on the rear of the chassis.

10. Press the card straight down into the expansion slot on the system board.

Figure -30 [Installing a PCI card]

11. Replace the slot cover lock by sliding it onto the rails toward the server.

12. Replace the slot cover lock retaining screw.

26

Page 29

Figure -31 [Replacing the PCI slot cover]

13. Connect any necessary cables to the card.

14. Observe the post-installation procedures.

System battery

The server uses volatile memory that requires a battery to retain system information when power is removed. This

3-volt lithium coin cell battery is located on the system board.

Figure -32 [System battery location]

If the server no longer automatically displays the correct date and time, you may need to replace the system

battery. Under normal use, battery life is five to ten years.

WARNING! Note the following reminders when replacing the system battery:

•

Replace the battery with the same type as the battery recommended by HP. Use of another battery may present a risk of

fire or explosion.

• A risk of fire and chemical burn exists if the battery is not handled properly. Do not disassemble, crush, puncture, or

short external contacts, or expose the battery to temperatures higher than 60°C (140°F).

• Do not dispose of used battery in water or fire. Dispose of used batteries according to the manufacturer's instructions.

CAUTION: Loss of BIOS settings occurs when the battery is removed. You must reconfigure BIOS settings

whenever you replace the battery.

To replace the system battery:

1. Perform steps 1 through 3 of the Pre-installation instructions.

2. Remove the access panel.

3. Lay the server on its side for better access to the battery holder (XBT2).

4. If necessary, remove any accessory boards or cables that prevent access to the battery holder.

27

Page 30

5. Replace the battery:

a. To release the battery from its holder, squeeze the metal clamp that extends above one edge of the

battery. When the battery pops up, lift it out.

b. To insert the new battery, slide one edge of the replacement battery under the holder’s lip with the

positive side up. Push the other edge down until the clamp snaps over the other edge of the battery.

Figure -33 [Replacing the battery]

6. Replace the access panel.

7. Observe the post-installation procedures.

Power supply unit (PSU)

Located on the rear panel of the server power supply is a single standard autoranging 350-watt PSU with PFC

(power factor correction) function.

WARNING! Note the following reminders are to reduce the risk of personal injury from electric shock hazards

and/or damage to the equipment.

• Installation of power supply units should be referred to individuals who are qualified to service server

systems and are trained to deal with equipment capable of generating hazardous energy levels.

• DO NOT open the power supply unit. There are no serviceable parts inside it.

To replace the power supply:

1. Perform steps 1 through 3 of the Pre-installation instructions.

2. Remove the access panel.

3. Lay the server on its side with the open side facing up.

4. Remove the power supply:

a. Disconnect the processor and system board power cables from the system board connectors

(P1 and P2).

b. Disconnect the power cables of all installed drives from the PSU.

c. Remove the four screws that secure the PSU to the chassis.

d. Lift the power supply out of the chassis.

28

Page 31

Figure -34 [Removing the PSU]

5. Install a new PSU:

a. Align the new PSU to the support edges inside of the chassis.

b. Secure the PSU to the chassis using four screws.

c. Reconnect the processor and system board power cables to the system board connectors (P1 and P2),

and then connect the power cables to all installed drives.

Figure -35 [Installing a PSU]

6. Observe the post-installation procedures.

29

Page 32

System fan

A new system fan can be installed to allow the server to operate properly in case the default system fan becomes

defective.

To replace the system fan:

1. Perform steps 1 through 3 of the Pre-installation instructions.

2. Remove the access panel.

3. Remove the system fan:

WARNING! Be sure to support the system fan with your hand when removing screws from the chassis.

The fan could fall onto the system board or an accessory board causing damage if not supported.

a. Disconnect the system fan cable from its connector (P8) on the system board.

b. Remove the four screws from the rear of the chassis that secure the fan.

c. Remove the fan from the chassis.

Figure -36 [Removing the system fan]

4. Install a new system fan:

a. Align the new fan to the screw holes inside of the chassis

b. While holding the new fan against the chassis, secure the fan to the chassis with four screws.

c. Connect the system fan cable to its connector (P8) on the system board.

Figure -37 [Installing a system fan]

5. Observe the post-installation procedures.

30

Page 33

HP Lights-Out 100 Remote Management Card

Lights-Out 100 Remote Management is a suite of products that enable remote management of ProLiant 100

Series servers. HP Lights-Out 100 allows customers or their service providers to remotely manage ProLiant ML110

G3 servers over a LAN or the Internet. With HP Lights-Out 100, users can access a system's text console, control

system power, and monitor system environmental conditions from a browser or command line.

To install the remote management card:

1. Perform steps 1 through 3 of the Pre-installation instructions.

2. Remove the access panel.

3. Lay the server on its side with the open side facing up.

4. Locate the remote management card connector on the system board.

Figure -38 [Remote management card connector location]

5. Install the remote management card in the connectors located in J110 and J111 on the system board. The

connectors are angled so that you can only install the card in one at the correct position.

Figure -39 [Installing the remote management card]

6. Observe the post-installation procedures.

31

Page 34

3 Diagnostic tools

This chapter describes the system diagnostic tools available for the HP ProLiant ML110 Generation 3 server. It

also provides a comprehensive list of POST-related messages and their meanings.

AMIBIOS software

The G3 server uses AMIBIOS to boot up the system. AMIBIOS software is a ROM BIOS-based firmware that

allows reliability, manageability, and connectivity for server platforms. This software contains a set of programs

permanently stored in an EEPROM chipset located on the system board. These programs assist in managing,

initializing, and testing the hardware devices installed on the computer.

AMIBIOS software allows you to:

• Perform configuration from the AMIBIOS Setup Utility

Using the Setup Utility, you can install, configure, and optimize the hardware devices on the system board.

In addition, you can enable various features such serial console redirection, hyper-threading, PXE boot,

IPMI Virtual Floppy support, and much more.

• Initialize hardware at bootup using POST routines

During power-on or warm reset, the BIOS performs Power-On Self Test (POST) routines to test system

components, to allocate resource for various hardware devices, and to the prepare the system to boot to

various operating systems.

Accessing the Setup Utility

1. Turn on the monitor and server. If the server is already turned on, save your data and exit all open

applications, then restart the server.

2. When the HP logo is displayed during POST, press F10. If you fail to press F10 before POST is completed,

you will need to restart the server.

The first page displayed is the Main menu showing the Setup Utility menu bar. Use the left (←) and right

(→) arrow keys to move between selections on the menu bar. Use the up (↑) and down (↓) arrow keys to

select items within a menu.

Figure -1 [Setup Utility Main menu]

32

Page 35

Navigating through the Setup Utility

Use the keys listed in the legend bar on the right of the Setup screen to navigate through the various menu and

submenu screens of the Setup Utility. Table -1 lists these legend keys and their respective functions.

Table -1 Setup Utility Navigation Keys

Key Function

← and → To move between selections on the menu bar.

↑ and ↓ To move the cursor to the field you want.

The currently selected field is highlighted. The right side of each menu screen displays a field help

panel—Item Specific Help panel. This panel displays the help text for the currently selected field. It

updates as you move the cursor to each field.

+ and - To select a value for the currently selected field (only if it is user-configurable).

Press the (+) or (-) keys repeatedly to display each possible entry, or the Enter key to choose from a

pop-up menu.

A parameter that is enclosed in square brackets [ ] is user-configurable.

Grayed-out parameters are not user-configurable for one of the following reasons:

• The field value is auto-configured or auto-detected.

• The field value is informational only.

• The field is password-protected.

Enter, Tab, ShiftTab

Esc If you press this key:

F1 To bring up the General Help window.

F9 To load default system values.

F10 To save changes and close the Setup Utility.

Figure -2 [Setup Utility General Help screen]

To select a field value or display a submenu screen.

• On one of the primary menu screens, the Exit menu displays.

• On a submenu screen, the previous screen displays.

• When you are making selections from a pop-up menu, the pop-up closes without making a selection.

The General Help window describes other Setup navigation keys that are not displayed on the legend

bar.

33

Page 36

Setup Utility primary menus

The Setup Utility menu bar displays the five primary menu selections. Table -2 lists these menus and their

corresponding functions.

Table -2 Setup Utility Primary Menus

Menu Function

Main Use this menu to:

• Set system time and date

• View BIOS version

• View BIOS build date

• View processor type

• View processor speed

• View system memory size

• View system serial number

• View MAC address for the embedded NIC

Advanced Use this menu to:

• Enable or disable hardware prefetcher.

• Enable or disable Cache Line prefetch.

• Enable or disable the support of hyper-threading technology.

• Disable SATA/IDE configuration or configure IDE/SATA to Compatible or Enhanced mode. When the

system is in Enhanced mode, you can configure the SATA as IDE, RAID, or AHCI. When the system is in

compatible mode, you can configure the IDE channels as SATA only, PATA as primary and SATA

secondary, SATA as primary and PATA as secondary, or PATA only.

NOTE: When the SATA/IDE configuration is set to Compatible mode (4 drive mode), only one SATA

drive, which acts as the Primary master, appears in the system. For example, if you set the legacy IDE

channels to SATA PRI, PATA Sec in the IDE configuration of the Setup Utility, and install two SATA drives,

one IDE hard drive, and one CD ROM drive, you will see the following:

• Primary IDE Master: [Hard Disk]

• Primary IDE Slave: [Not Detected]

• SEC IDE Master: [Hard Disk]

• SEC IDE Slave: [ATAPI CDROM]

The secondary IDE master has the IDE hard drive. There is no Primary IDE slave.

• Configure a superior device such as serial com1, serial com2, or parallel port.

• View CPU and ambient temperature.

• View CPU and chassis fan speed (RPMs).

• Enable or disable temperature display via BMC.

• View IPMI system event logging.

• Clear IPMI system event logging.

• Set IP address and subnet mask for remote access.

• Enable or disable COM1 port muxed to the remote management card.

• Enable or disable the remote management card virtual floppy,

• Enable or disable Serial over LAN (SOL) support.

NOTE: When COM1 is selected, the mux to the remote management card, you cannot use COM1 as the

BIOS serial console redirection. Use COM2 as the serial console redirection if COM1 is enabled for

remote management card muxing.

NOTE: When Serial Over LAN (SOL) is enabled, it uses virtual com3 to send data.

NOTE: All the functions above are applicable if a remote management card is installed in the server.

NOTE: The IPMI configuration menu item is not displayed on the Advanced screen if no remote

management card is inserted in the server. Configure console redirection settings to allow the system to be

displayed on a remote terminal for online server management. You can configure the baud rate from

9600 to 115200.

• Enable/disable USB legacy support. When legacy USB support is enabled, you can select either Hispeed

or Fullspeed under USB 2.0 Controller Mode if the USB 2.0 Controller is enabled.

34

Page 37

Table -2 Setup Utility Primary Menus

Menu Function

Boot Use this menu to:

• Enable or disable the BIOS summary display.

• Enable or disable the HP splash display.

• Turn on or off bootup NumLock.

• Set restore on AC power loss options, such as last state, power off, and power on.

• Set boot device priority. By default, the server searches for boot devices in the following order:

a. Removable device

b. IDE CD-ROM drive

c. Hard disk drive

d. PXE (Preboot Execution Environment, remote boot)

• View hard disk drive information.

• View network drive information.

Security Use this menu to:

• Prevent unauthorized users from accessing the system.

• Configure user access levels.

• Input asset tag ID.

For more information about this menu, please refer to the System Passwords section in this chapter.

Exit Use this menu to select an exit option from the Setup Utility. Options include:

1 Save changes and exit out of the Setup Utility

2 Discard any changes made and exit out of the Setup Utility

3 Discard any changes made and remain in the Setup Utility

4 Load optimal default CMOS configuration for the system

System Summary Screen

Figure -3 [System Summary screen]

To enable display of the System Summary Screen during bootup:

1. From the Main menu screen, select Boot.

2. Select Boot Settings Configuration.

3. Select the BIOS Summary Display field.

4. Press the plus (+) or minus (-) key to set the field to Enabled.

35

Page 38

5. Press F10 to save the changes you made and close the Setup Utility.

6. Reboot the server.

7. Press Pause/Break to freeze the screen until another key is pressed.

8. Press ESC to continue booting the system.

System passwords

The Security menu allows you to set system passwords that provide different levels of protection for the server.

There are two types of passwords:

• Supervisor password

Allows you to access and change all settings in the Setup Utility. The supervisor password allows you to

configure access for system users. The following list provides different user access levels:

• No Access – Prevents access to the Setup Utility.

• View Only – Allows access to the Setup Utility without change capability.

• Limited – Allows limited capability to change field values, such as date and time.

• Full Access – Allows capability to modify any value in the Setup Utility.

In addition, supervisor password access can protect users from booting to the operating system by setting

the Password check field to “Always”. Figure -4 shows the Security Settings screen, and that supervisor

password access allows the ability to clear user passwords and to configure so that users do not have to

enter a password to access the operating system.

• User password

Entering this password will restrict a user’s access to the Setup menus. A user can only access and modify

fields depending on the user access level set using supervisor password access.

Figure -4 [System passwords screen]

To set a system password:

NOTE: You must set a Supervisor password before defining a User password.

1. In the Security screen, select a set password field—Set User Password or Set Supervisor

Password, and then press Enter.

2. Type a new password in the Enter New Password box.

The password may consist of up to eight alphanumeric characters (A-Z, a-z, 0-9).

36

Page 39

Figure -5 [Enter New Password dialog box]

3. Retype the password to verify the first entry, and then press Enter.

4. Press F10 to save the password and close the Setup Utility.

After setting the password, Setup automatically sets the selected password field to Enabled.

To reset a system password:

• If you forget the user password or the supervisor password, the server functions normally, but you cannot

access the Setup Utility.

• If you do not know the user password but do know the supervisor password, you can use the Clear User

Password menu to clear the user password.

• If “Always” is selected in the Password check field and you do not know either the user or the supervisor

password, you cannot boot to the operating system or access the Setup Utility.

1. Perform the Pre-installation instructions listed in Chapter 2.

2. If necessary, remove any accessory boards or cables that prevent access to the CMOS button.

3. Locate the Password jumper (P137) on the system board.

4. Remove the jumper from pins 1 and 2 and power on the server.

5. Power down the server.

6. Place the jumper back on pins 1 and 2.

7. Reinstall the access panel as described in Chapter 2.

Loading system defaults

To load system default settings:

1. Reboot the server.

2. During POST, press F10 to access the Setup Utility.

3. Press F9 to load the default values.

4. Press F10 to save the changes and close the Setup Utility.

37

Page 40

Figure -6 [Load defaults screen]

Clearing CMOS

You may need to clear the Setup configuration values (CMOS) if the configuration has been corrupted, or if

incorrect settings made in the Setup Utility have caused error messages to be unreadable.

To clear CMOS:

1. Perform the pre-installation instructions listed in Chapter 2.

2. If necessary, remove any accessory boards or cables that prevent access to the system configuration switch.

3. Locate the system configuration switch (SW50) on the system board.

4. Press the switch. AC power must not be connected.

5. Perform the post-installation instructions listed in Chapter 2.

6. During POST, press F10 to access the Setup Utility.

7. Set time, date, and other system values.

8. Press F10 to save the changes you made and close the Setup Utility.

NOTE: Clearing CMOS deletes all system configurations and password settings.

Power-On Self Test (POST)

Before you can use a server, all devices must be tested and initialized, and the operating system must be

bootstrapped to the memory. This is referred to as Power–On Self–Test or POST. POST is a series of diagnostic

tests that checks firmware and hardware components on the system to ensure that the server is properly

functioning. This diagnostic function automatically runs each time the server is powered on.

These diagnostics, which reside in the BIOS ROM, isolate server-related logic failures and indicate the board or

component that you need to replace, as indicated by the error messages. Most server hardware failures will be

accurately isolated during POST. The number of tests displayed depends on the configuration of the server.

During POST you can:

• Press ESC to skip the HP logo and go to POST boot progress display system summary screen.

• Press F8 to display the Boot menu.

• Press F10 to access the Setup Utility.

• Press F12 to request a network boot (PXE).

38

Page 41

POST error indicators

When POST detects a system failure, it displays a POST error message.

Recoverable POST errors

Whenever a non-fatal error occurs during POST, an error message describing the problem appears onscreen.

These error messages are displayed in normal video (white text on black background), and show the details of

the error. The following is an example of a POST error message:

018 – CMOS Date/Time not set

Table -3 lists the most common POST error messages with corresponding troubleshooting recommendation. HP

recommends that you correct the error, even if the server appears to boot successfully.

Table -3 POST Error Messages

Error code Error Message Description/Corrective Action

000 Timer Error Indicates an error while programming the count register of

003 CMOS Battery Low CMOS Battery is low. This message usually indicates that the

004 CMOS setting Wrong CMOS settings are invalid. This error can be resolved by using

005 CMOS Checksum Bad CMOS contents failed the Checksum check. Indicates that the

008 Unlock keyboard PS2 keyboard is locked. Users need to unlock the keyboard to

009 PS2 Keyboard not found Keyboard not working. Verify that the keyboard cable is securely

018 CMOS Date/Time not Set The CMOS Date and/or Time are invalid. This error can be

019 Ps2 mouse not found Mouse not working. Verify the mouse cable is securely connected

048 Password check failed Password is incorrect after retried a few times. Users might need

04c Keyboard/Interface Error Keyboard controller failed test. This may indicate a problem with

04D Primary Master Hard Disk Error The IDE/ATAPI device configured as Primary Master could not

04E Primary Slave Hard Disk Error The IDE/ATAPI device configured as Primary Slave could not be

4F Secondary Master Hard Disk Error The IDE/ATAPI device configured as Secondary Master could not

channel 2 of the 8254 timer. This may indicate a problem with

system hardware. Requires repair of the system board.

CMOS battery needs to be replaced. It could also appear when

the users intentionally discharge the CMOS battery.

F9 to load optimal default in the Setup Utility.

CMOS data has been changed by a program other than the

BIOS or that the CMOS is not retaining its data due to

malfunction. This error can be resolved by using F9 to load

optimal default in the Setup Utility.

continue the BIOS POST.

connected to the keyboard port (not the mouse port) on the rear

panel of the server. If the problem persists, replace the keyboard

or contact your HP Customer Support provider.

resolved by readjusting the system time in the Setup Utility.

to the mouse port (not the keyboard port) on the rear panel of the

server. If the problem persists, replace the mouse or contact your

HP Customer Support provider.

to reset the password.

system hardware.

be properly initialized by the BIOS. This message is typically

displayed when the BIOS is trying to detect and configure

IDE/ATAPI devices in POST

properly initialized by the BIOS. This message is typically

displayed when the BIOS is trying to detect and configure

IDE/ATAPI devices in POST.

be properly initialized by the BIOS. This message is typically

displayed when the BIOS is trying to detect and configure

IDE/ATAPI devices in POST.

39

Page 42

Table -3 POST Error Messages

Error code Error Message Description/Corrective Action

50 Secondary Slave Hard Disk Error The IDE/ATAPI device configured as Secondary Slave could not

be properly initialized by the BIOS. This message is typically

displayed when the BIOS is trying to detect and configure

IDE/ATAPI devices in POST.

51 Master Hard Disk Error The IDE/ATAPI device configured as Master in the 3rd IDE

controller could not be properly initialized by the BIOS. This

message is typically displayed when the BIOS is trying to detect

and configure IDE/ATAPI devices in POST.

52 Master Slave Disk Error The IDE/ATAPI device configured as Slave in the 3rd IDE

controller could not be properly initialized by the BIOS. This

message is typically displayed when the BIOS is trying to detect

and configure IDE/ATAPI devices in POST.

0641 BMC card not responding. System does not see the remote management card. Verify the

remote management card is connected to the system board.

Uncorrectable memory error System halts after displaying this message. If the problem

persists, contact HP Customer Support.

Microcode Error BIOS could not find or load the CPU Microcode Update to the

CPU. The message is most likely to appear when a new CPU is

installed in a system board with an outdated BIOS. In this

situation, you must update the BIOS to include the Microcode

Update for the new CPU.

Checking NVRAM..Update Failed BIOS could not write to the NVRAM block. This message

appears when the FLASH part is malfunctioning.

Operating system not found Operating system cannot be located on any of the boot drives.

• Verify that the priority boot drive has power and that the IDE

or SCSI cable is connected properly.

• Verify that the desired boot drive has power and the SCSI

cable is connected.

• Verify that the IDE or SCSI cable is securely plugged into the

respective system board connectors.

• Verify that the boot device is enabled in the Setup Utility.

• Verify that the boot device has an operating system

installed.

If the problem persists, contact your HP Customer Support

provider.

POST-related troubleshooting

Perform the following procedures when POST fails to run, displays error messages, or emits beep codes.

If the POST failure is during a routine bootup, check the following:

• All external cables and power cables should be firmly plugged in.

• The power outlet to which the server is connected and is working.

• The server and monitor are both turned on. The bicolor status LED indicator on the front panel must be lit up

green.

• The monitor's contrast and brightness settings are correct.

• All internal cables are properly connected and all boards firmly seated.

• The processor is fully seated in its socket on the system board.

• The HSF assembly is properly installed on top of the processor.

• All memory modules are properly installed.

• If you have installed a PCI accessory board, verify that the board is firmly seated and any switches or

jumpers on the board are properly set. Refer to the documentation provided with the accessory board.

• All internal cabling and connections are in their proper order.

• If you have changed any switches on the system board, verify that each is properly set.

40

Page 43

4 Connectors, switches, and LEDs

This chapter contains illustrations and tables identifying and describing the connectors, switches, buttons, and

LED indicators located on the front panel, rear panel, system board and hard drives of the HP ProLiant ML110

Generation 3 server.

Connectors and components

This section contains illustrations and tables identifying connectors and components on the front and rear panels

of the server, as well as those located on the system board.

Front panel components

Figure -1 and the following table show and describe the components on the front panel of the server.

Figure -1 [Front panel components]

1 Optical drive 8 Drive activity indicator

2 Optical drive manual eject hole 9 Front USB 2.0 ports

3 Optical drive eject button 10 Hard drive EMI shield

4 Optical drive activity indicator 11 Hard drive EMI shield screw

5 Half-height common bay 12 Optical drive spare screws

6 Power button 13 Hard drive spare screws

7 Power LED indicator

41

Page 44

Rear panel components

Figure -2 and the following table show and describe the components on the rear panel of the server.

Figure -2 [Rear panel components]

1 PSU fan 9 LAN port (RJ - 45)

2 Serial port B 10 PCI slot covers

3 PS/2 mouse port 11 Kensington lock notch

4 PS/2 keyboard port 12 Power supply outlet

5 Serial port A 13 Rear system fan

6 Parallel port 14 Thumbscrew for access panel

7 Monitor port 15 Cable lock provision tab

8 Rear USB 2.0 ports 16 PCI expansion slot cover lock

System board components

Figure -3 and Table -1 show and describe the components on the system board.

Figure -3 [System board components]

Table -1 System board components

Item Component Code Description

1 U19 Super I/O

2 XMM1 - 4 DDRII slots

3 P70 CPU fan connector

4 U3 Intel E7230

5 XU1 Intel LGA775 CPU socket

6 P3 4-pin ATX CPU power connection

42

Page 45

Table -1 System board components